Lower bainite wear-resisting steel tube for slurry transport and production method of steel tube

A technology for wear-resistant steel pipes and manufacturing methods, which is applied in the field of wear-resistant steel pipes, and can solve problems such as toughness deterioration, unsatisfactory strength-toughness coordination, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

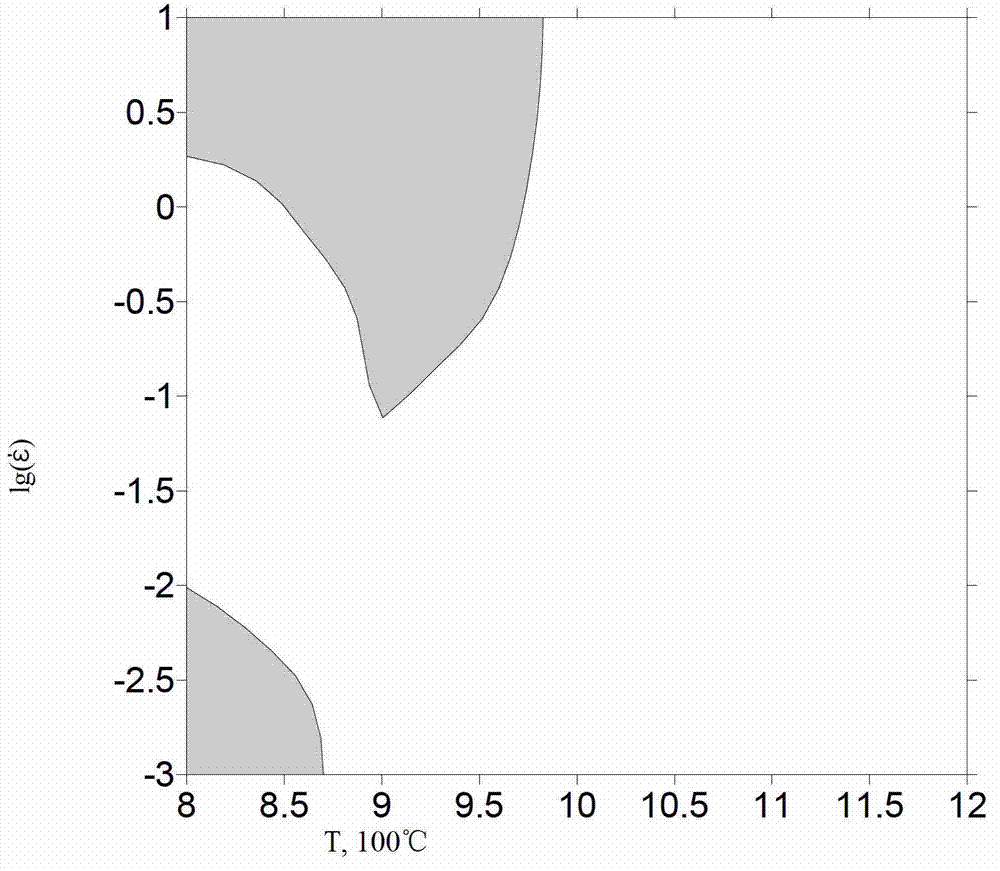

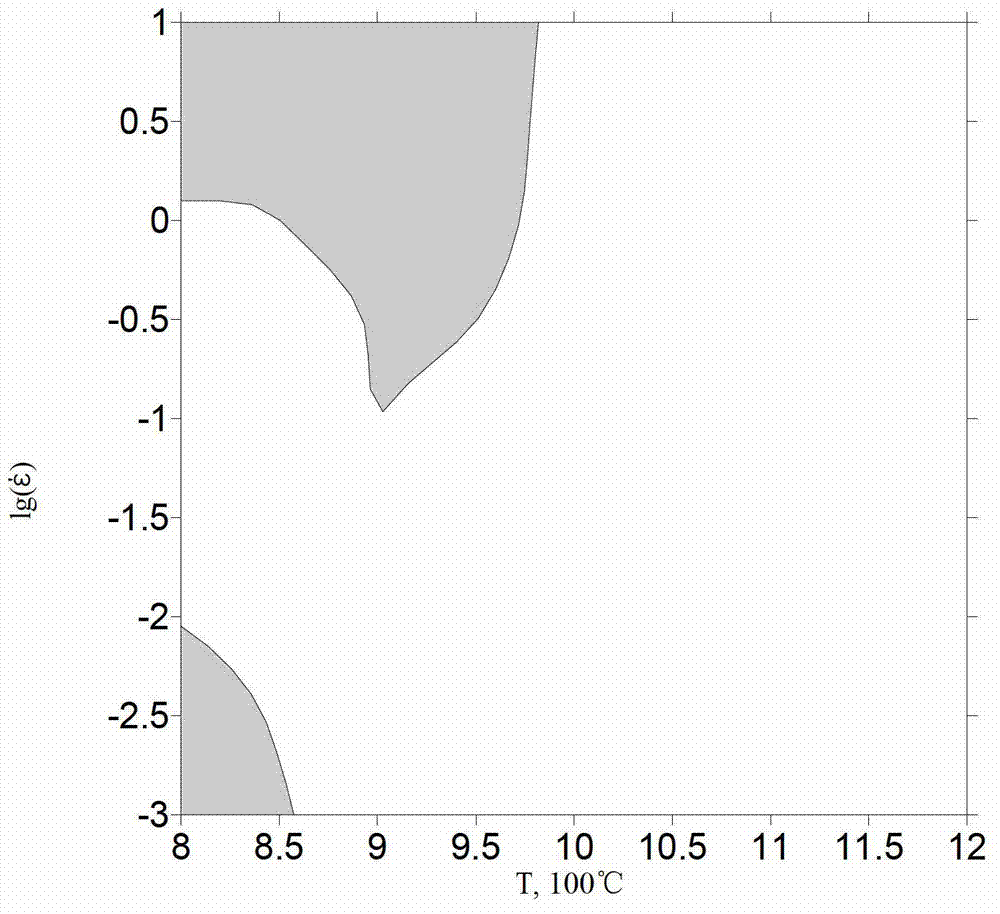

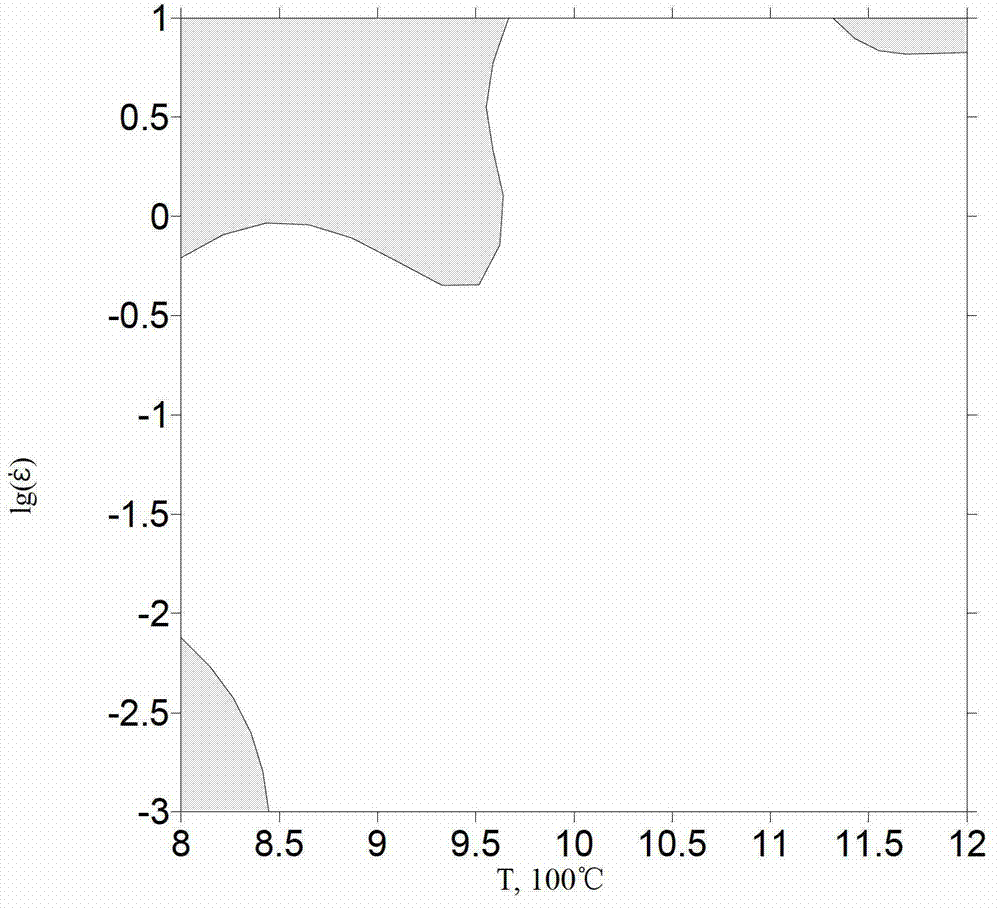

Image

Examples

Embodiment 1

[0033] The lower bainite wear-resistant steel pipe for slurry transportation described in this embodiment mainly consists of C, Mn, Cr and Fe. In terms of mass percentage: C: 0.01wt%, Mn: 1.2wt%, Cr: 0.5wt%, and the balance is Fe. It should be noted that some impurities will inevitably be mixed in the production process. The lower bainite wear-resistant steel pipe for slurry transportation has a performance hardness of HRC22.5, and an impact toughness of V-notch greater than 100J / cm 2 , Tensile strength 850MPa, yield strength 550MPa.

Embodiment 2

[0035] The lower bainite wear-resistant steel pipe for slurry transportation described in this embodiment mainly consists of C, Mn, Cr and Fe. In terms of mass percentage: C: 0.50wt%, Mn: 5.0wt%, Cr: 1.8wt%, and the balance is Fe. It should be noted that some impurities will inevitably be mixed in the production process. The lower bainite wear-resistant steel pipe for slurry transportation has a performance hardness of HRC70 and an impact toughness of V-notch greater than 30J / cm 2 , tensile strength 2500MPa, yield strength 2000MPa.

Embodiment 3

[0037] The lower bainite wear-resistant steel pipe for slurry transportation described in this embodiment mainly consists of C, Mn, Cr and Fe. In terms of mass percentage: C: 0.05wt%, Mn: 3wt%, Cr: 1wt%, P: 0.001wt%, and the balance is Fe. It should be noted that some impurities will inevitably be mixed in the production process. The lower bainite wear-resistant steel pipe for slurry transportation has a performance hardness of HRC25 and an impact toughness of V-notch greater than 50J / cm 2, tensile strength 900MPa, yield strength 450MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com