Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Reduce dust generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

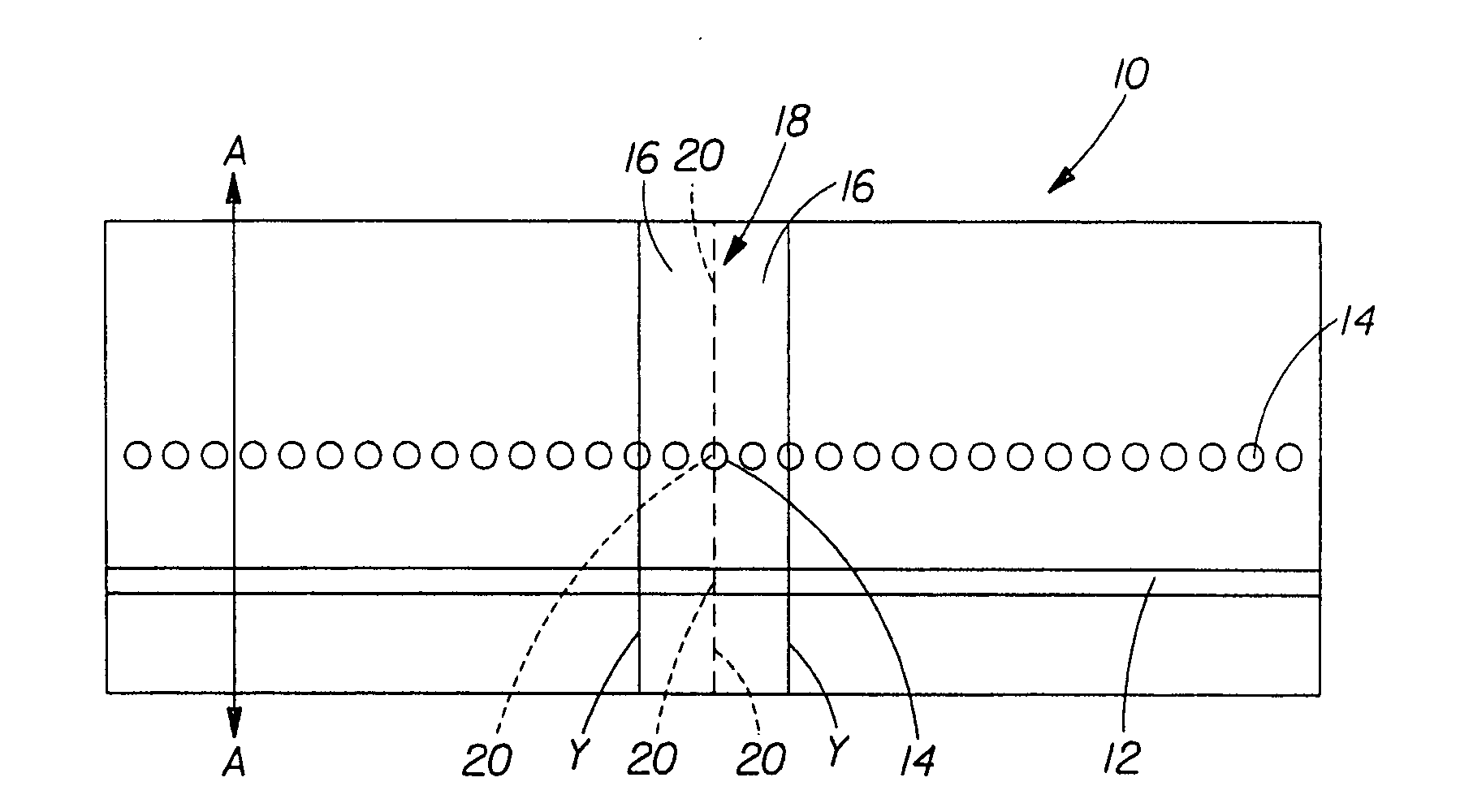

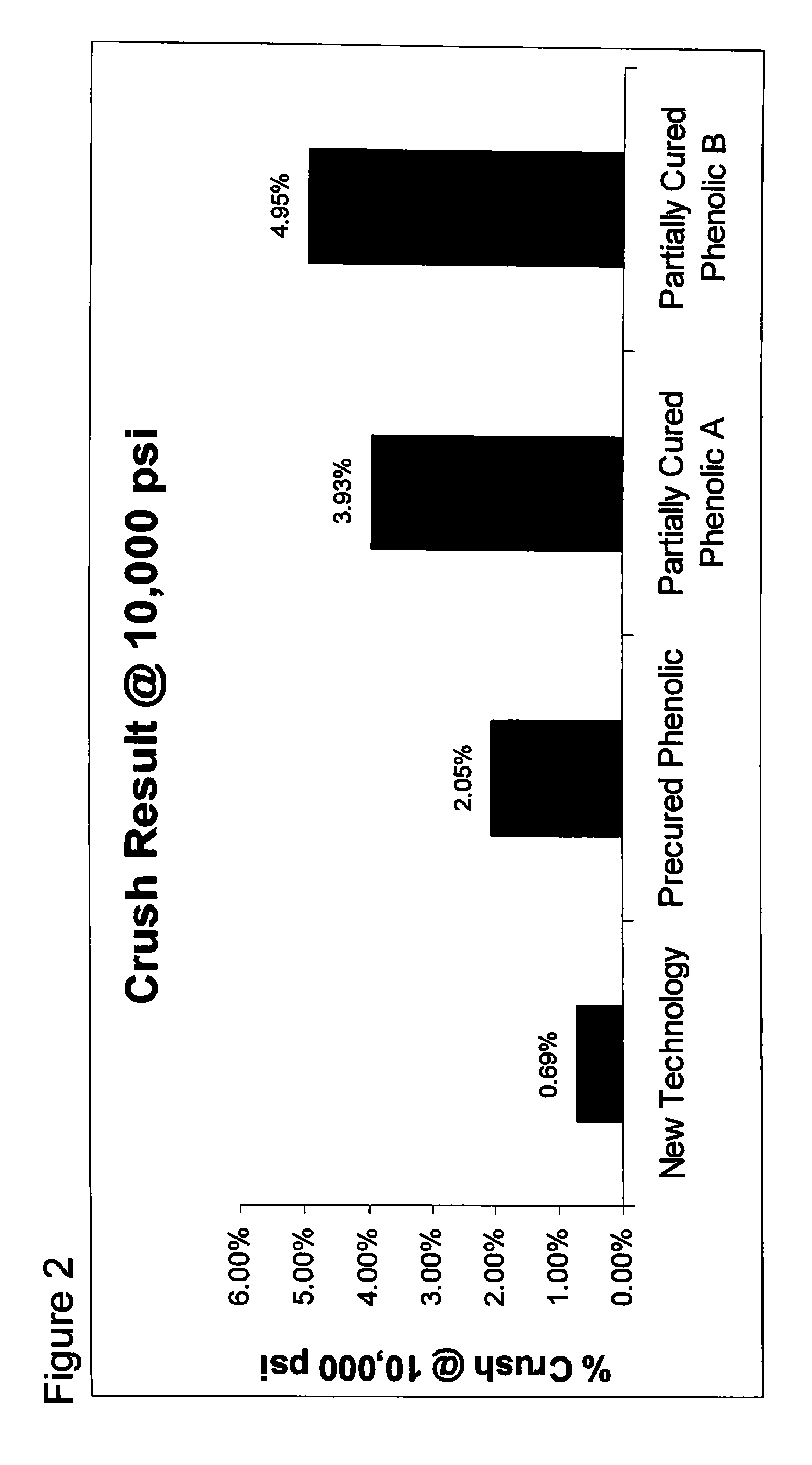

Coated and cured proppants

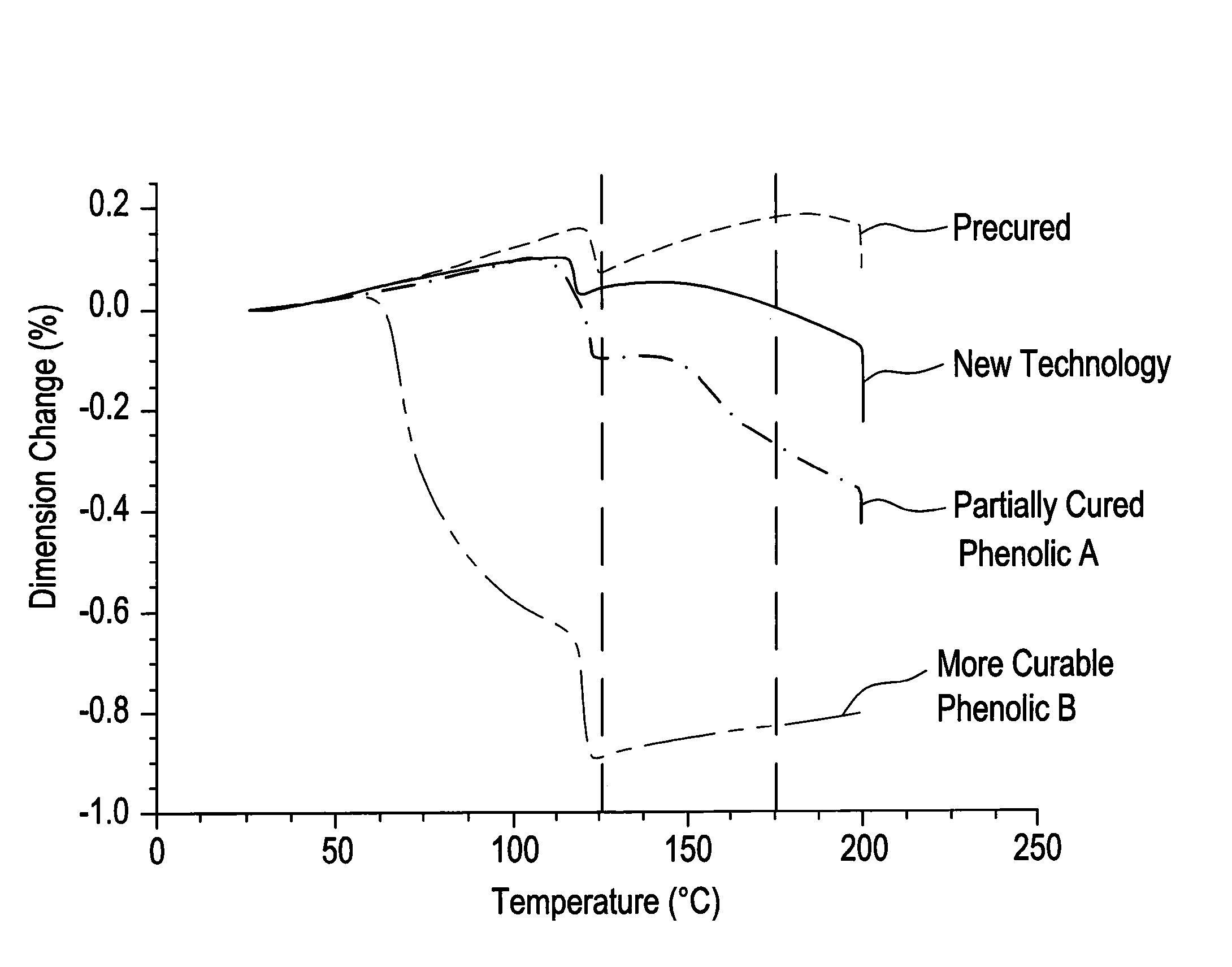

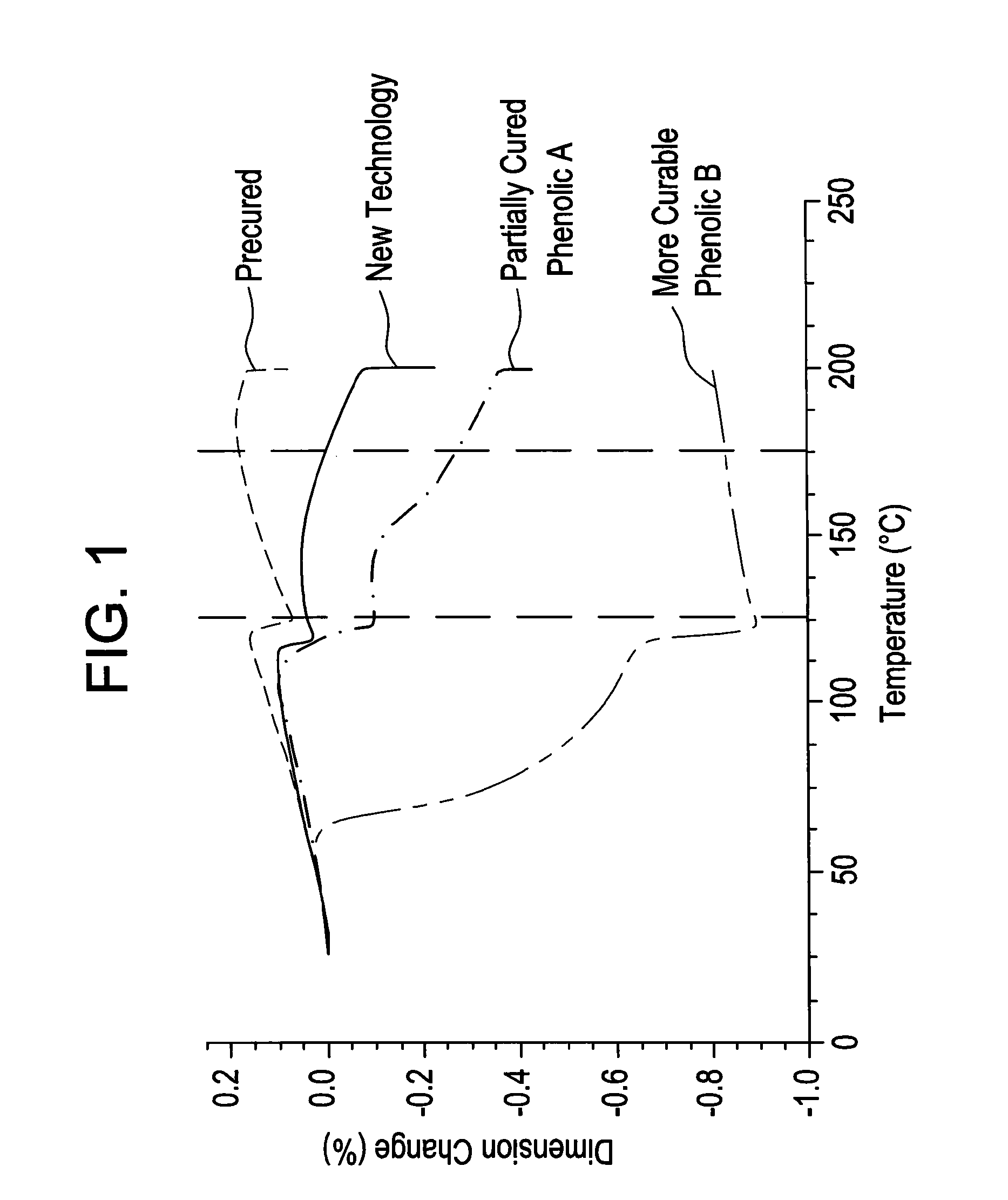

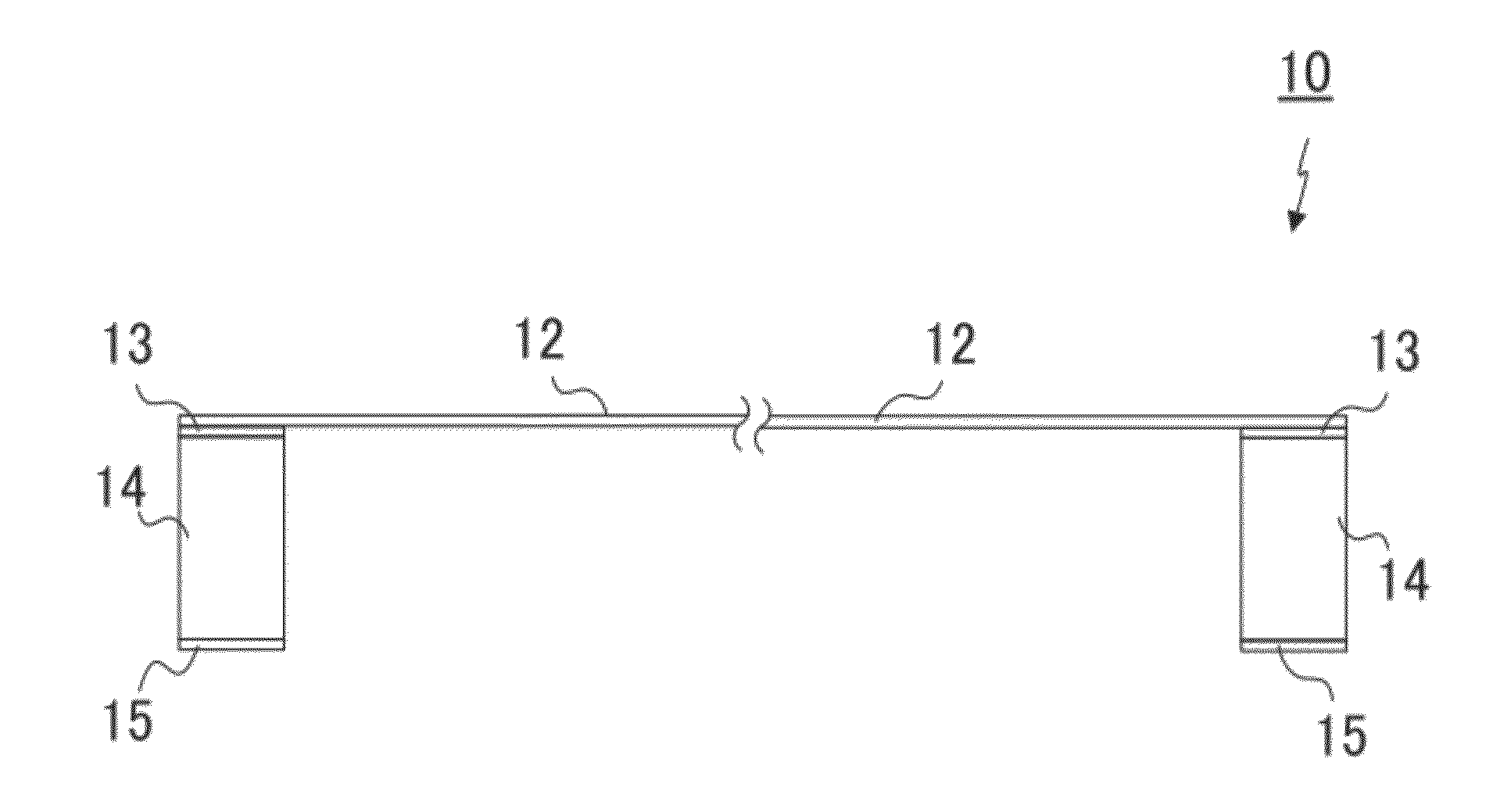

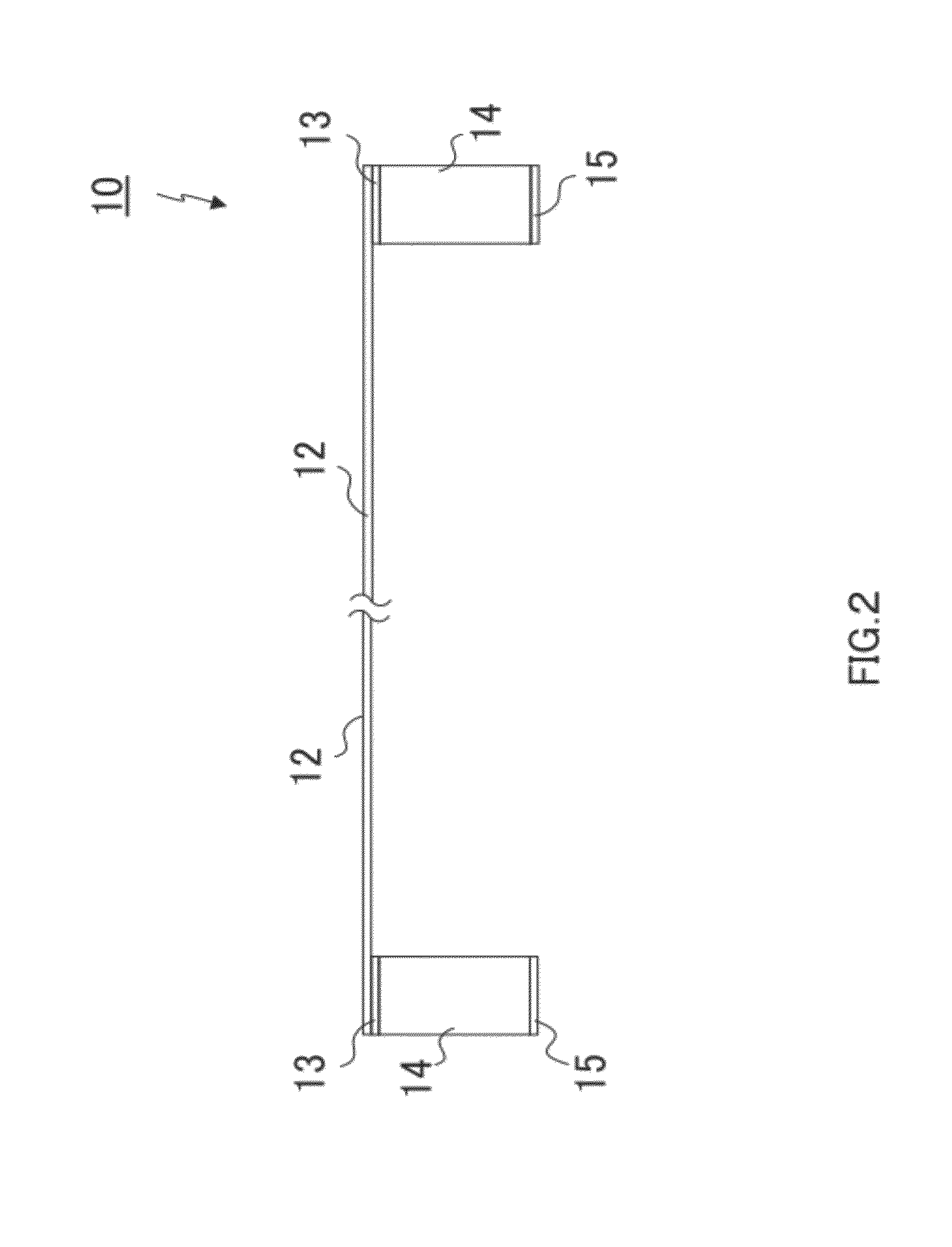

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

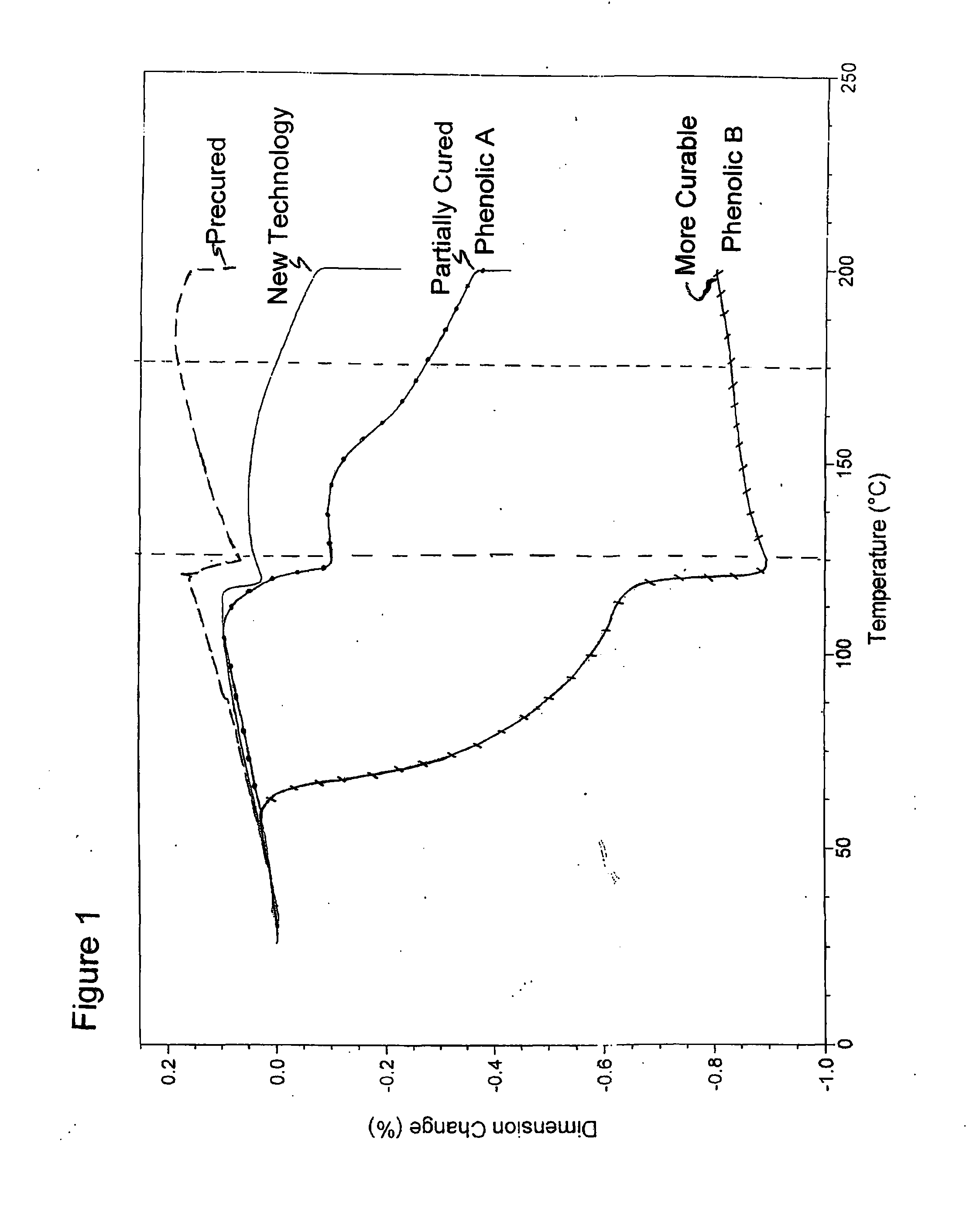

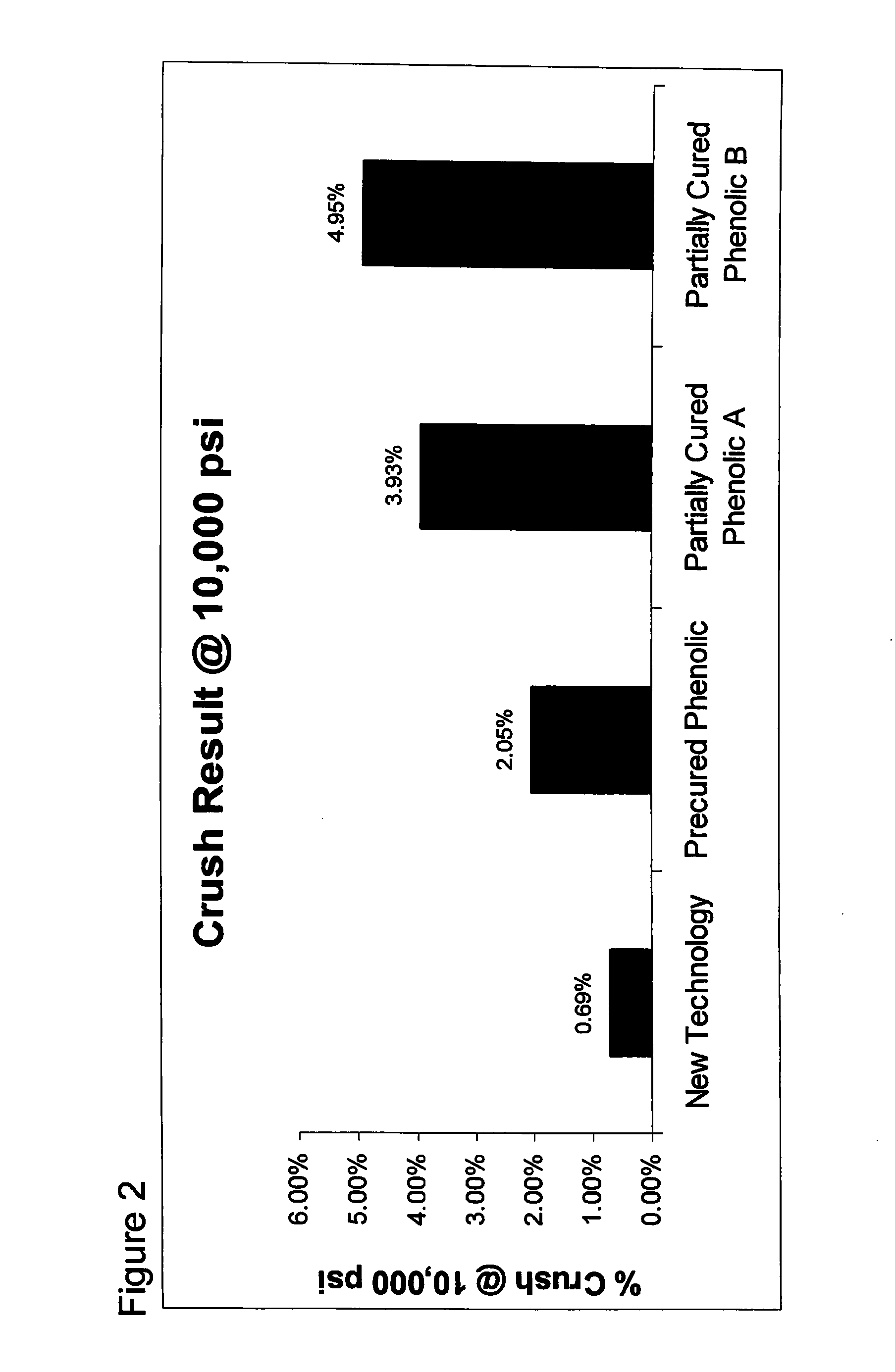

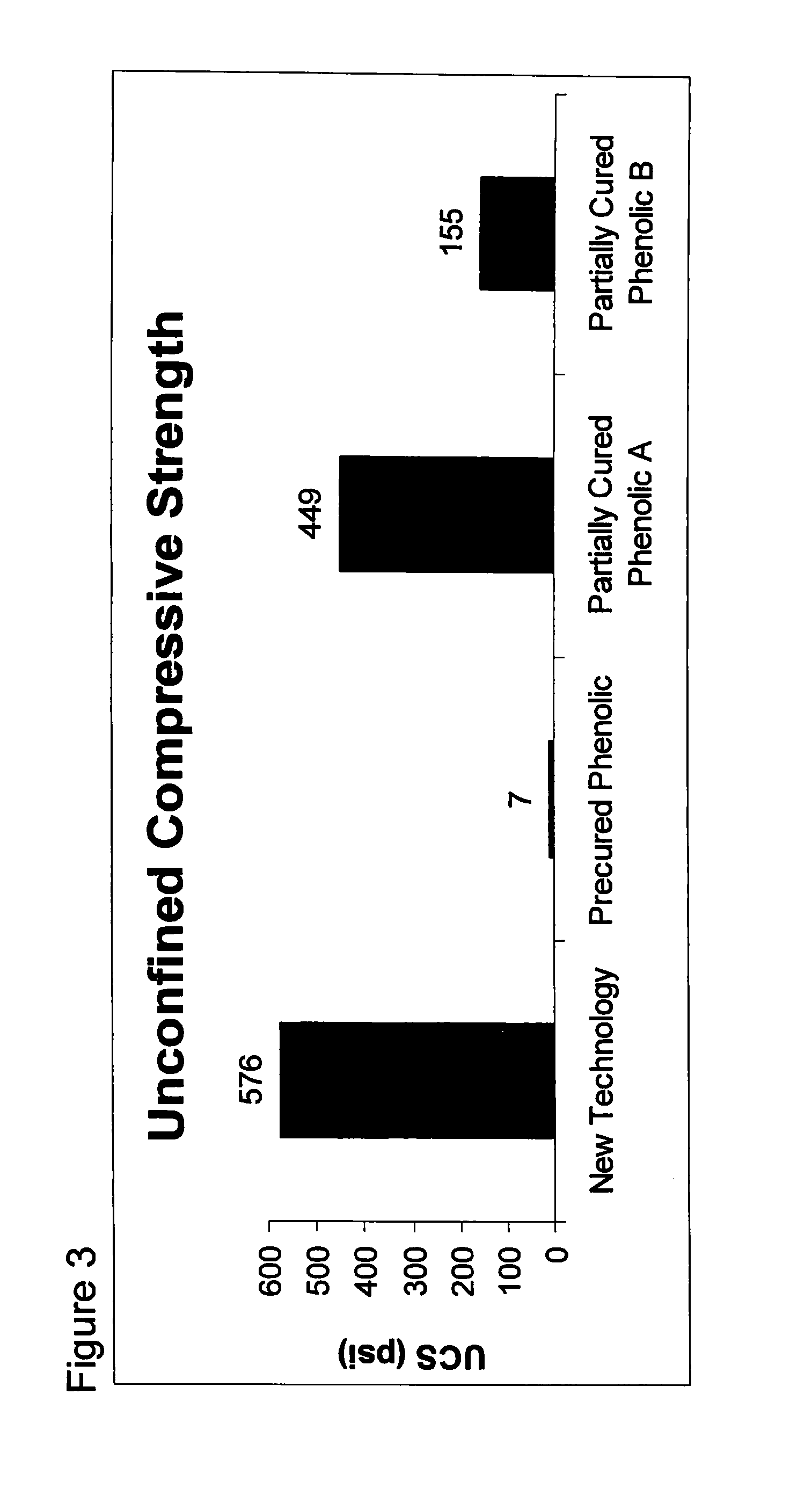

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

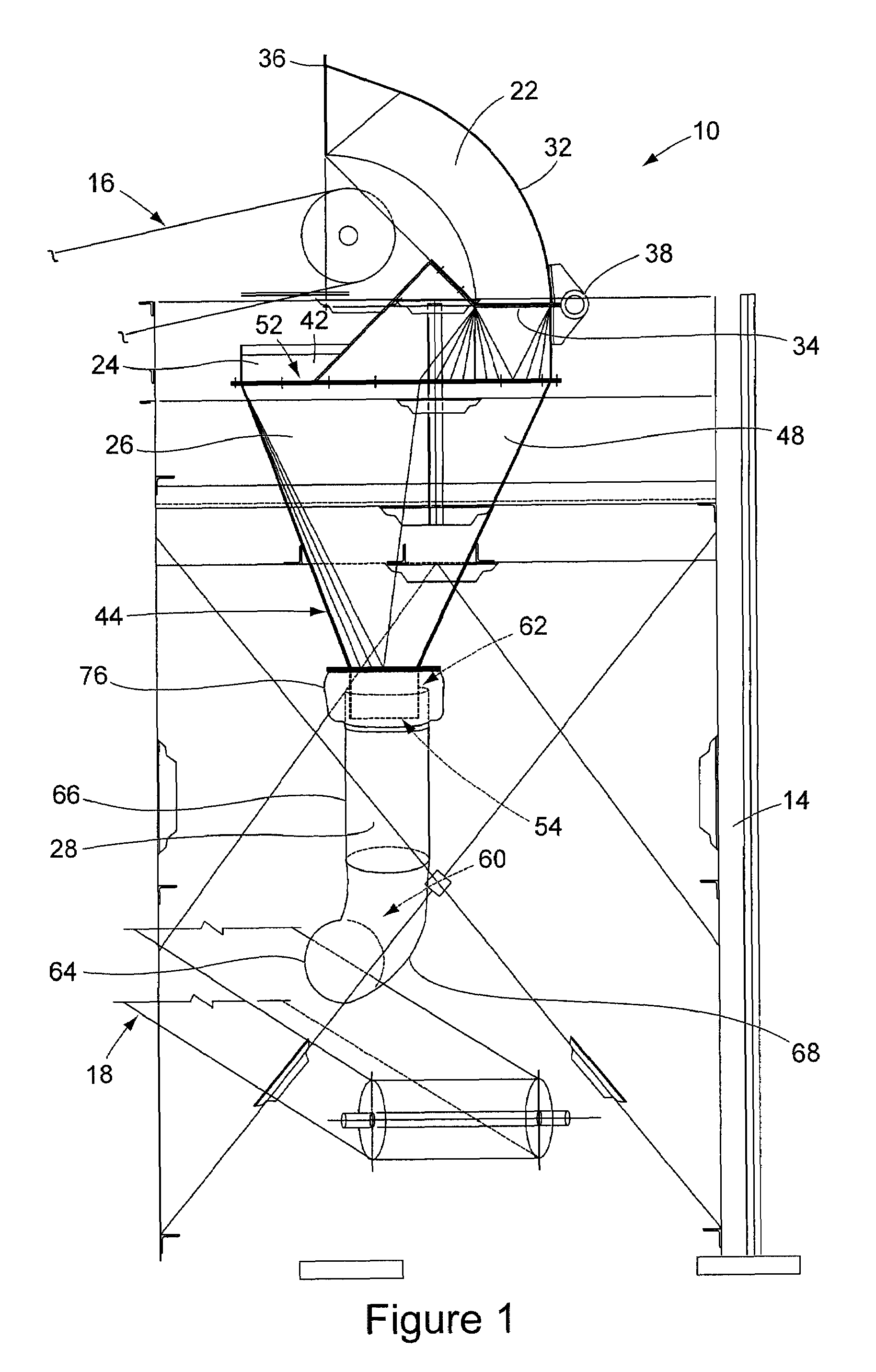

Bulk material precision transfer chute apparatus

ActiveUS20060151280A1Avoid cloggingMinimize spillagePackagingLoading/unloadingEngineeringMechanical engineering

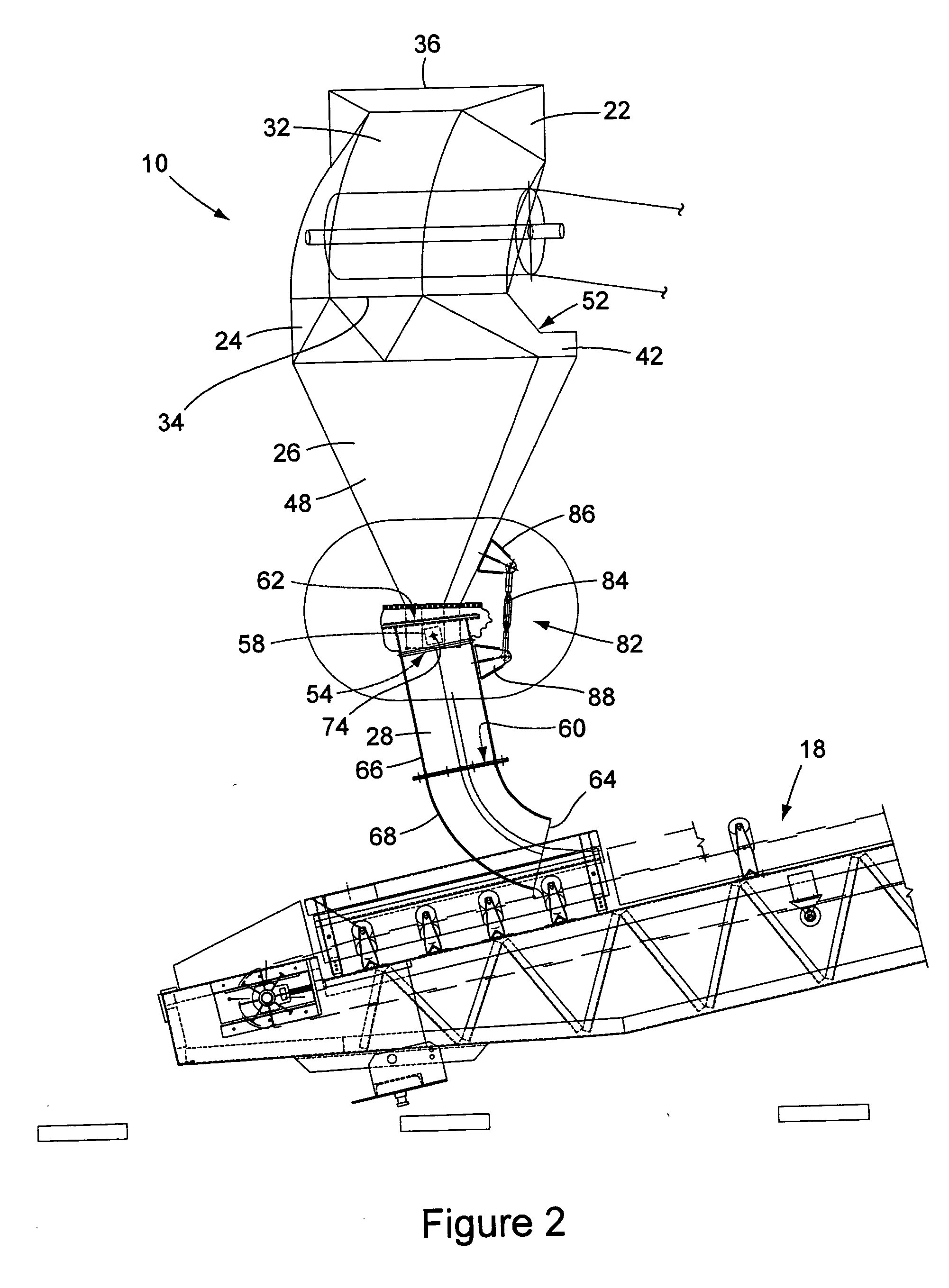

A bulk material precision transfer chute apparatus transfers a flow of material from a discharge conveyor to a separate receiving conveyor. The apparatus receives a flow of material from the discharge conveyor and transfers that material to a receiving conveyor depositing the material in a precise manner that avoids spillage of the material from the receiving conveyor, avoids wear to the receiving conveyor, and avoids excess dust generation from the transfer of the material.

Owner:BENETECH INC

Lint-free wiper

InactiveUS6739160B1Performance requirementReduce dust generationOrnamental textile articlesCarpet cleanersYarnFiber

A lint-free wiper of the present invention is formed of a fabric containing no cut face in the structure thereof which may cause the generation of lint and fiber fall-off. Accordingly, the wiper can be used in a high-grade clean room of at least Class 100 without fear of dust generation. Since the dust-generation suppressing function is based on the fabric end structure formed of yarn loops, the wiper can be produced while eliminating fusion-bonding or an adhesion treatment of the cut face of the fabric. Therefore, the lint-free wiper can be composed of any materials including non-thermoplastic cellulosic fibers or others.

Owner:ASAHI KASEI KK

Coated and cured proppants

ActiveUS9040467B2Solve the lack of resistanceResistant to leachingLiquid surface applicatorsFluid removalThermodynamicsEngineering

Solid proppants are coated with a coating that exhibits the handling characteristics of a precured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity.

Owner:PREFERRED TECH

Granulate or powder for producing coating or binding agents for medicaments

InactiveUS7175857B2Reduce dust generationLow water vapor permeabilityPowder deliveryFibre treatmentFood supplementMeth-

The invention relates to a process for the production of granules or powders, suitable as coating agents and binders for oral or dermal pharmaceutical forms, for cosmetics or food supplements, consisting essentially of (a) a copolymer, consisting of free radical-polymerized C1- to C4-esters of acrylic or methacrylic acid and further (meth)acrylate monomers which contain functional tertiary amino groups, (b) 3 to 25% by weight, based on (a), of an emulsifier having an HLB of at least 14, (c) 5 to 50% by weight, based on (a), of a C12- to C18-monocarboxylic acid or of a C12- to C18-hydroxyl compound, where the components (a), (b) and (c) are simultaneously or successively blended or mixed with one another, optionally with addition of a pharmaceutical active compound and / or further customary additives, fused in a heatable mixer, mixed, the melt is cooled and comminuted to give granules or powders.

Owner:EVONIK OPERATIONS GMBH

Pellicle frame and pellicle containing same

ActiveUS20120122025A1Moderate film strengthGood chemical resistanceSynthetic resin layered productsRecord information storageEpoxyHigh resistance

Provided is a pellicle that has appropriate membrane strength, high resistance to chemicals, and a low degree of sulfate ion generation and outgassing. A provided pellicle frame supports the outer rim of a pellicle membrane, and an epoxy resin coating is formed on the surface of the pellicle frame. In the infrared absorption spectrum of said epoxy resin coating, the ratio of the absorbance of a peak in the range between 1450 cm−1 and 1550 cm−1 to the absorbance of a peak in the range between 1200 cm−1 and 1275 cm−1 is at least 0.5 and at most 3; also, the ratio of the absorbance of a peak in the range between 1450 cm−1 and 1550 cm−1 to the absorbance of a peak in the range between 905 cm−1 and 930 cm−1 is at least 1 and less than 7.

Owner:MITSUI CHEM INC

Bulk material precision transfer chute apparatus

ActiveUS7228956B2Reduce dust generationAvoid material degradationPackagingLoading/unloadingMechanical engineeringSpillage

A bulk material precision transfer chute apparatus transfers a flow of material from a discharge conveyor to a separate receiving conveyor. The apparatus receives a flow of material from the discharge conveyor and transfers that material to a receiving conveyor depositing the material in a precise manner that avoids spillage of the material from the receiving conveyor, avoids wear to the receiving conveyor, and avoids excess dust generation from the transfer of the material.

Owner:BENETECH INC

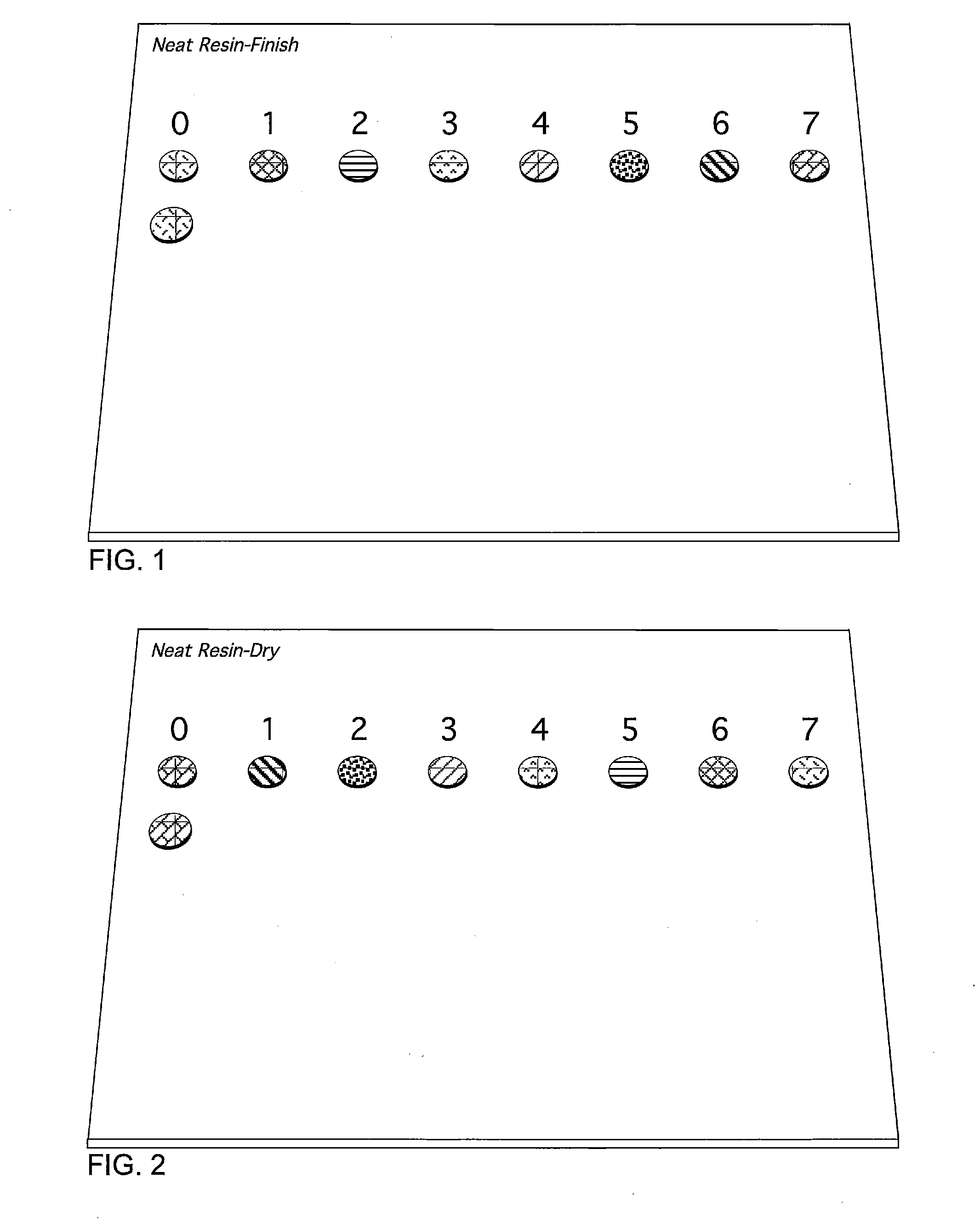

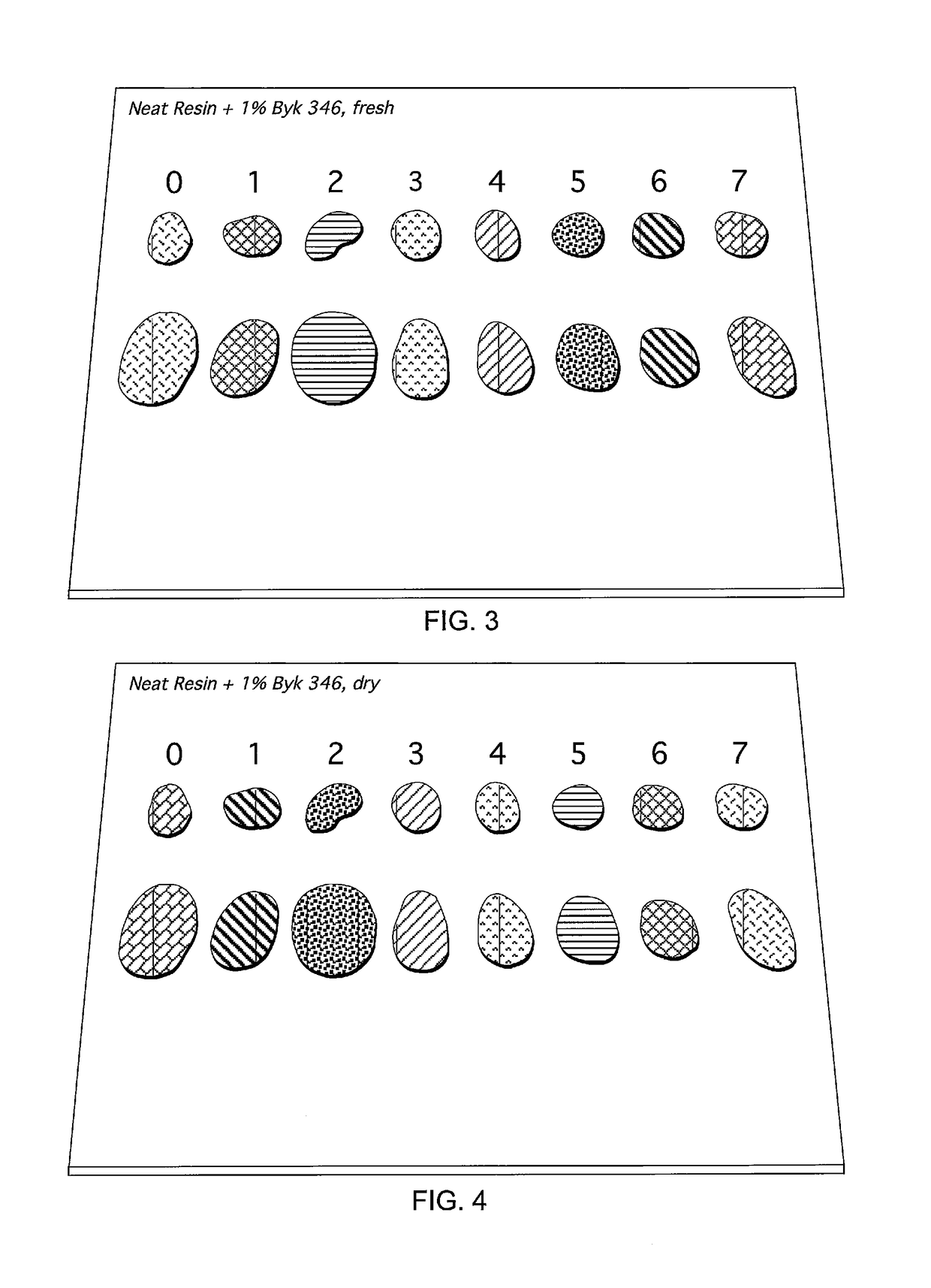

Proppant sand coating for dust reduction

InactiveUS20160257876A1Reduce dustReduce metal partLiquid surface applicatorsFluid removalHydraulic fracturingMetal

The present invention provides for coating proppants, such as sand, with a resin-containing dispersion which dramatically reduces the dust generated during handling, for example in hydraulic fracturing, by protecting the surface of the particle from abrasion and degradation. Such resin-containing dispersion coated-sand may also reduce the wear on metal parts used in transporting such proppants.

Owner:COVESTRO LLC

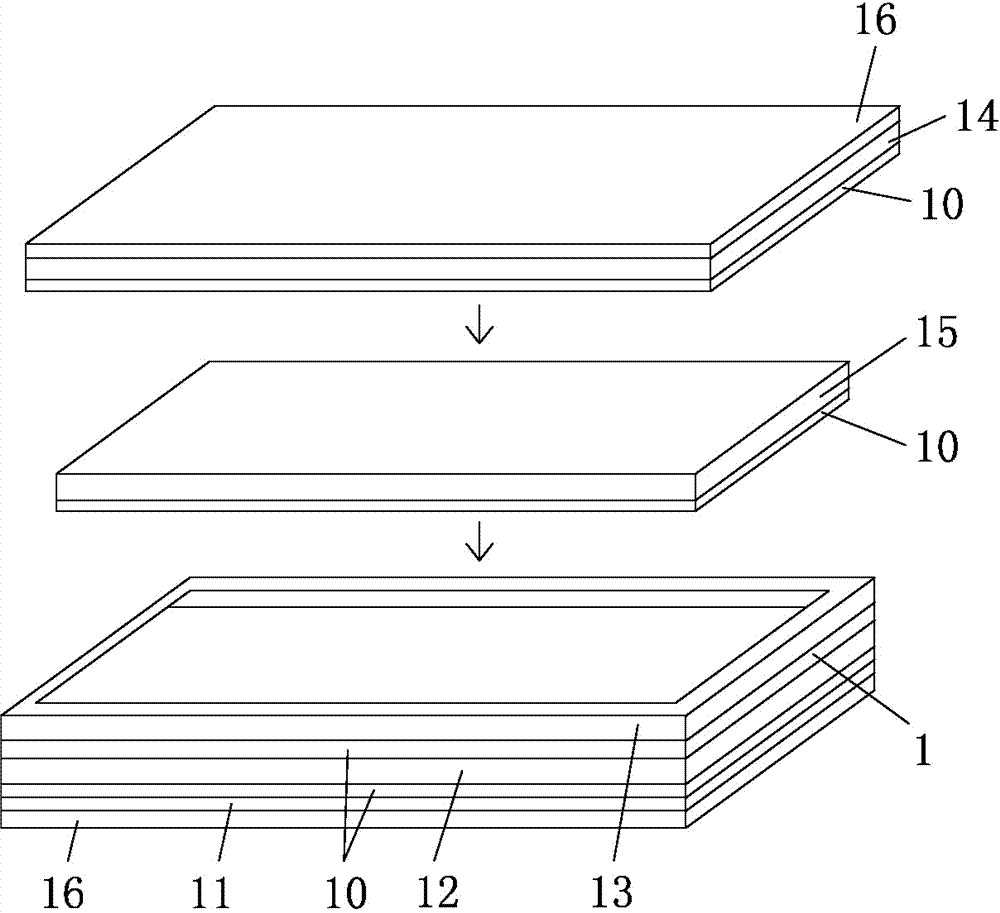

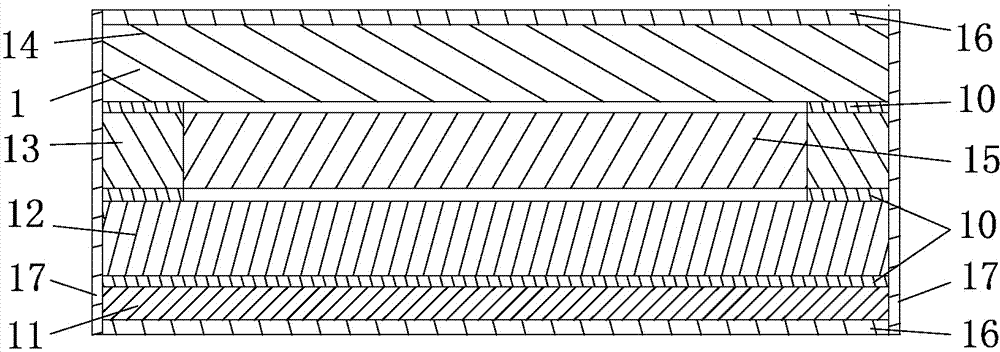

Fully-sealed touch control integrated liquid crystal screen and manufacturing process thereof

InactiveCN104503630AGood solid fluidityAchieve extrusionNon-linear opticsInput/output processes for data processingGlass coverUltraviolet

The invention discloses a manufacturing process of a fully-sealed touch control integrated liquid crystal screen. According to the manufacturing process, components which are arranged in sequence are glued to each other to form the fully-sealed touch control integrated liquid crystal screen through solid ultraviolet flexible glue; the components include a touch screen set, a liquid crystal screen set, an organic glass frame and a glass cover plate, wherein a backlight module is embedded among the liquid crystal screen set, the organic glass frame and the glass cover plate. According to transparent gluing bodies produced through the novel technology, bubbles cannot be easily generated, and the novel glued touch control display backlight integrated screen with features that the distances between every two adjacent gluing bodies are equal, the thickness difference and the unevenness difference do not exist, no stiffness phenomenon exists, and glue overflowing cannot easily happen can be manufactured.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

Fibrous structures comprising a region of auxiliary bonding and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

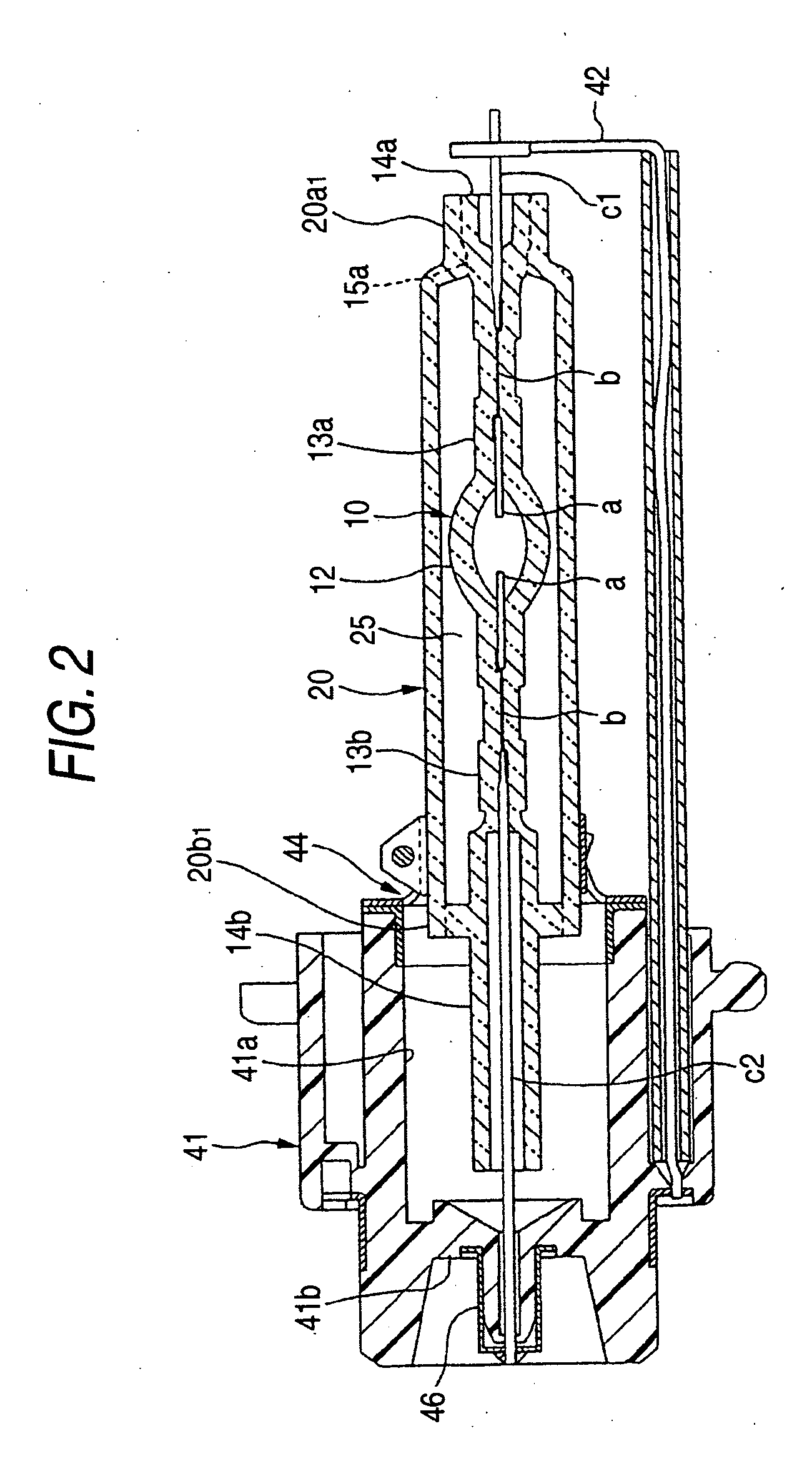

Shutter device and image pickup apparatus

A shutter device makes it possible to restrict bounding of a shutter blade using a shock-absorbing member when movement of the shutter blade is completed. In addition, the shutter device makes it possible to reduce production of dust that is produced when the shock-absorbing member and the shutter blade collide with each other. Examples of dust are wear powder and flake.

Owner:CANON KK

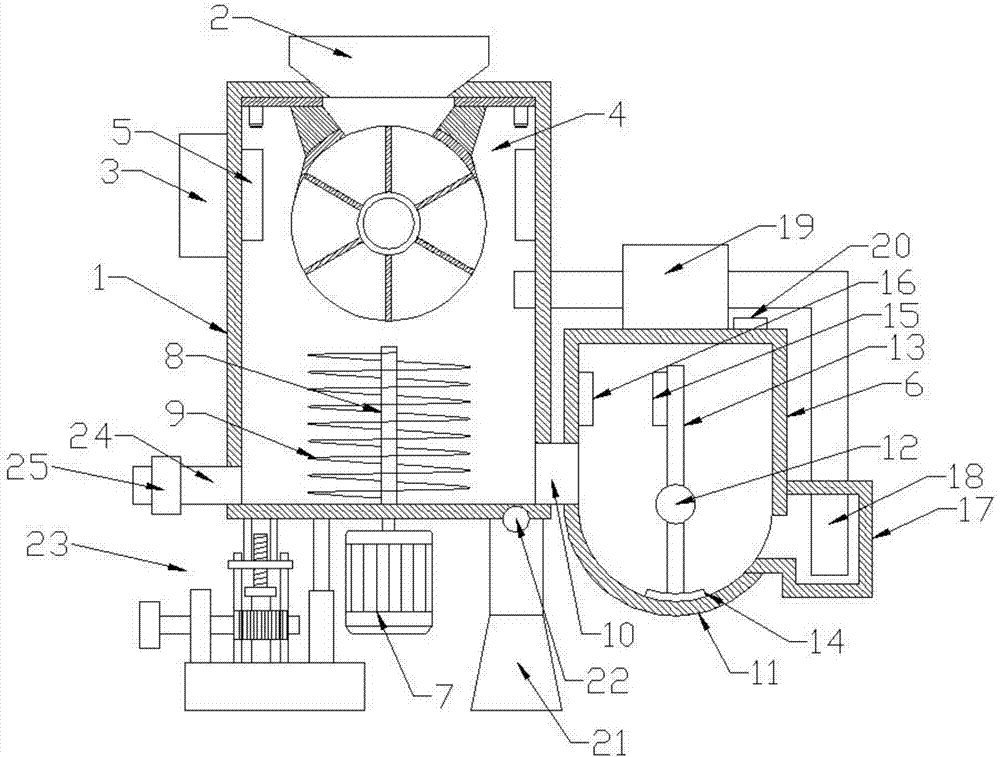

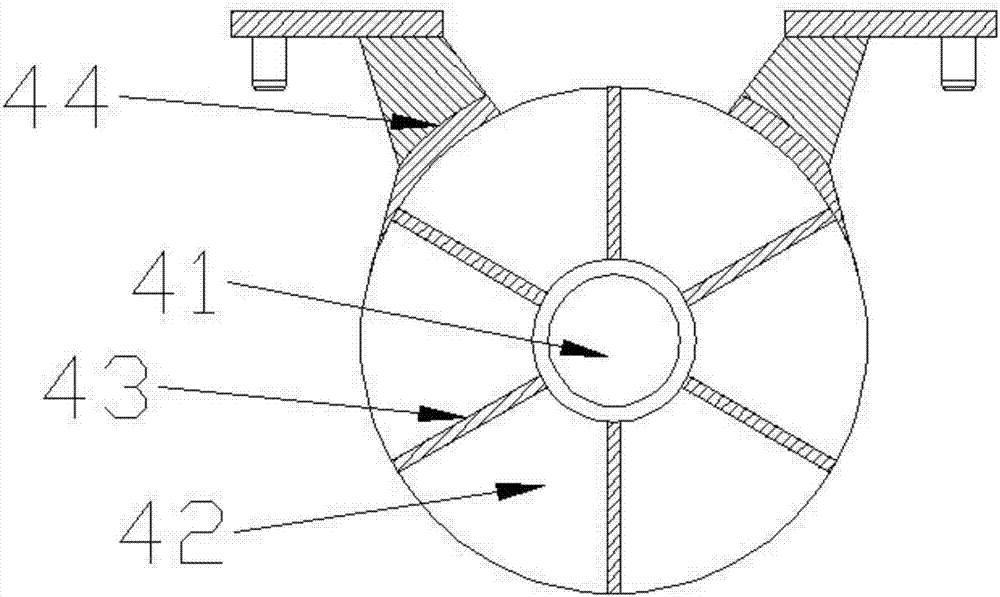

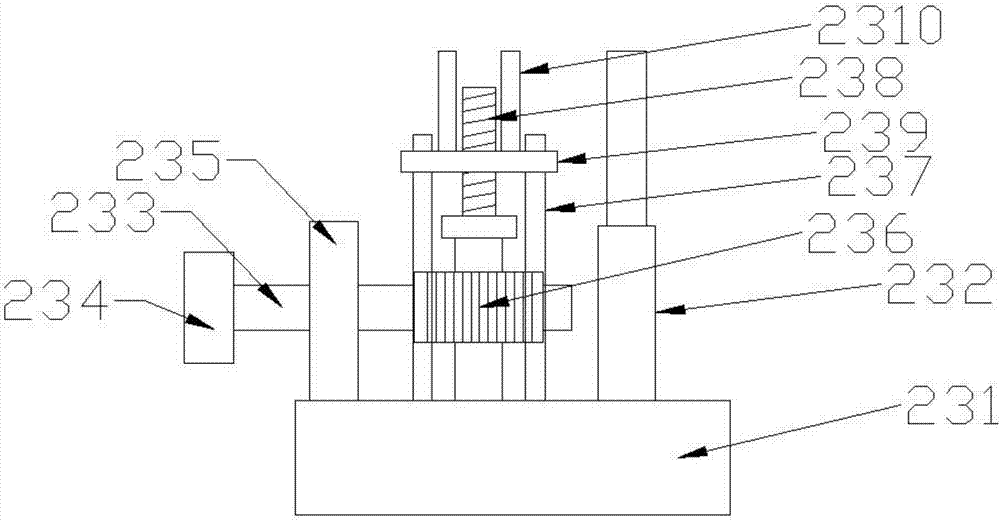

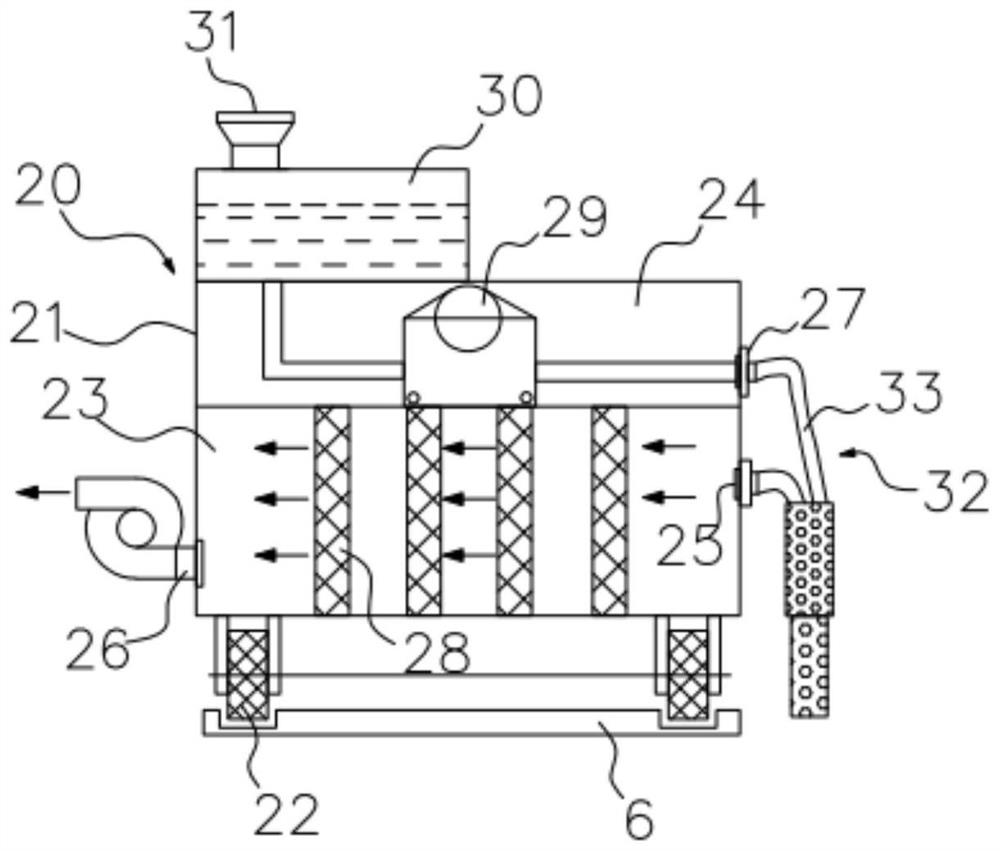

Angle-adjustable concrete mixer for building

InactiveCN107322799APrevent splashReduce dust generationDischarging apparatusCement mixing apparatusMotor loadRaw material

The invention discloses a concrete mixer with an adjustable angle for construction, which includes a cylinder body, a feeding hopper, a fan and a motor; a sealed feeding device is installed in the corresponding cylinder directly below the feeding hopper, and the sealed feeding device includes There is a central rotating shaft, a feeding cavity, a partition and a sealing arc plate. The bottom of the mixing box is provided with an arc cavity, and a connecting rod is installed on the support shaft. The lower end of the connecting rod is fixed with a feeding scraper that matches the arc cavity; the adjustment mechanism It includes a fixed seat, a telescopic rod, a worm, a handle, a support bearing, a worm wheel, a guide rod, a screw rod, a lifting plate and a push rod. In the present invention, the raw materials are evenly fed into the interior through the sealed feeding device, which avoids the increase of the motor load and affects the service life of the motor. It is concrete dust, reduce the generation of dust, and protect the surrounding environment.

Owner:阮霞伟

High-powered dustproof fabric

The invention discloses a high performance dustproof fabric, which is characterized in that the fabric consists of non-dust generating polyester long staple and non-dust generating electrically conductive fiber, wherein, the electrically conductive fiber is distributed inside the fabric in the shape of strips or lattices; the tightness of the fabric is between 2,000 and 4,000. The dustproof fabric has excellent dustproof performance, better antistatic property and air permeability and simplifies the manufacture process of the prior dustproof fabric; moreover, the dustproof fabric which is light, air permeable, comfortable during wearing and convenient for a wearer to work flexibly can be used as dustproof garment fabrics used in industries such as semiconductor, foodstuff and medicine.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

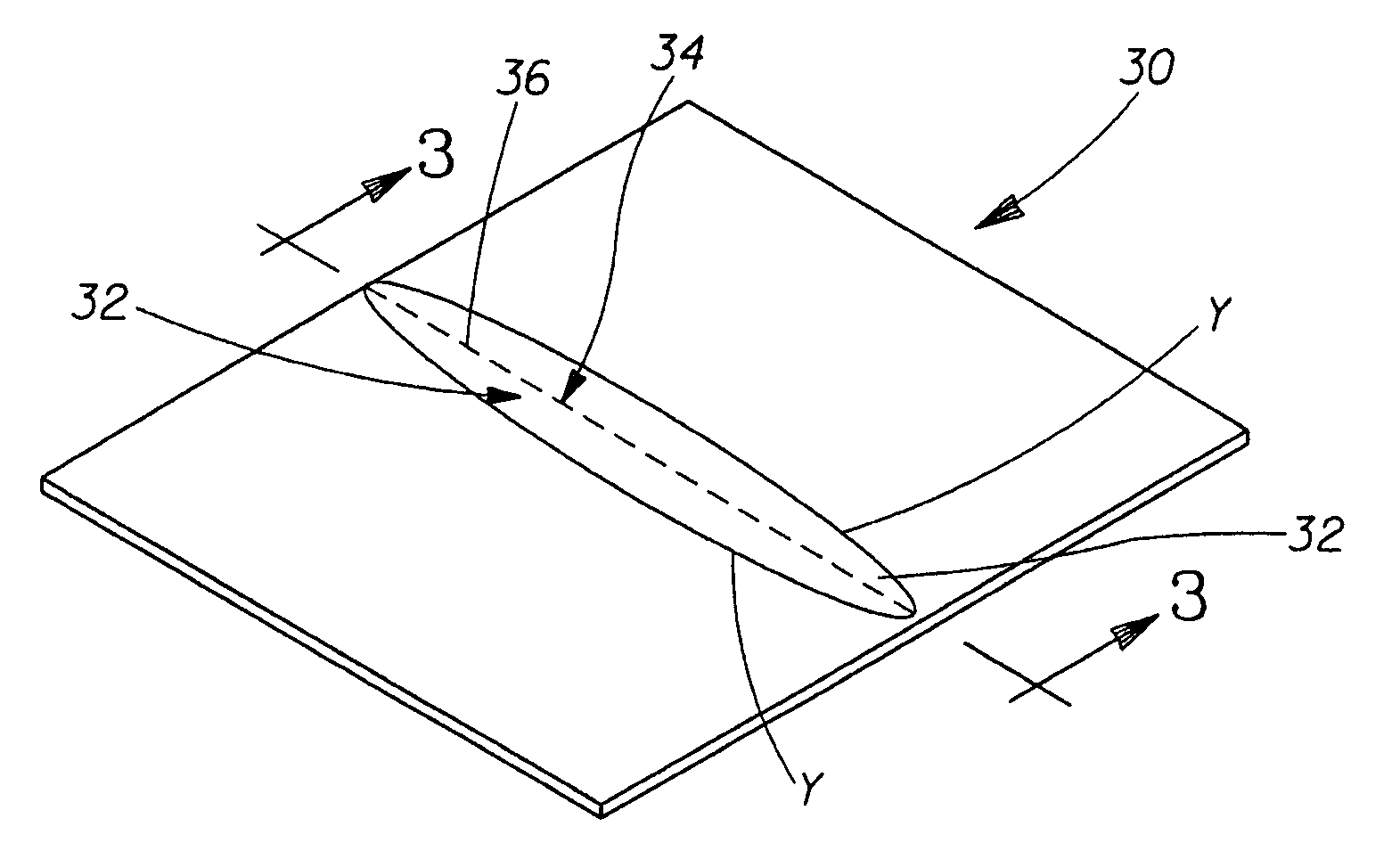

Pellicle

ActiveUS20100323281A1Reduce dust generationAvoid dustPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringAtmospheric pressure

There is provided a pellicle which has a ventilation hole made through at least one frame bar for adjusting the pressure inside the frame to the atmospheric pressure, and a filter to cover up the external opening of the ventilation hole for preventing entrance of a foreign substance, and at least one of two openings of the ventilation hole is chamfered to a degree selected from a group consisting of

Owner:SHIN ETSU CHEM IND CO LTD

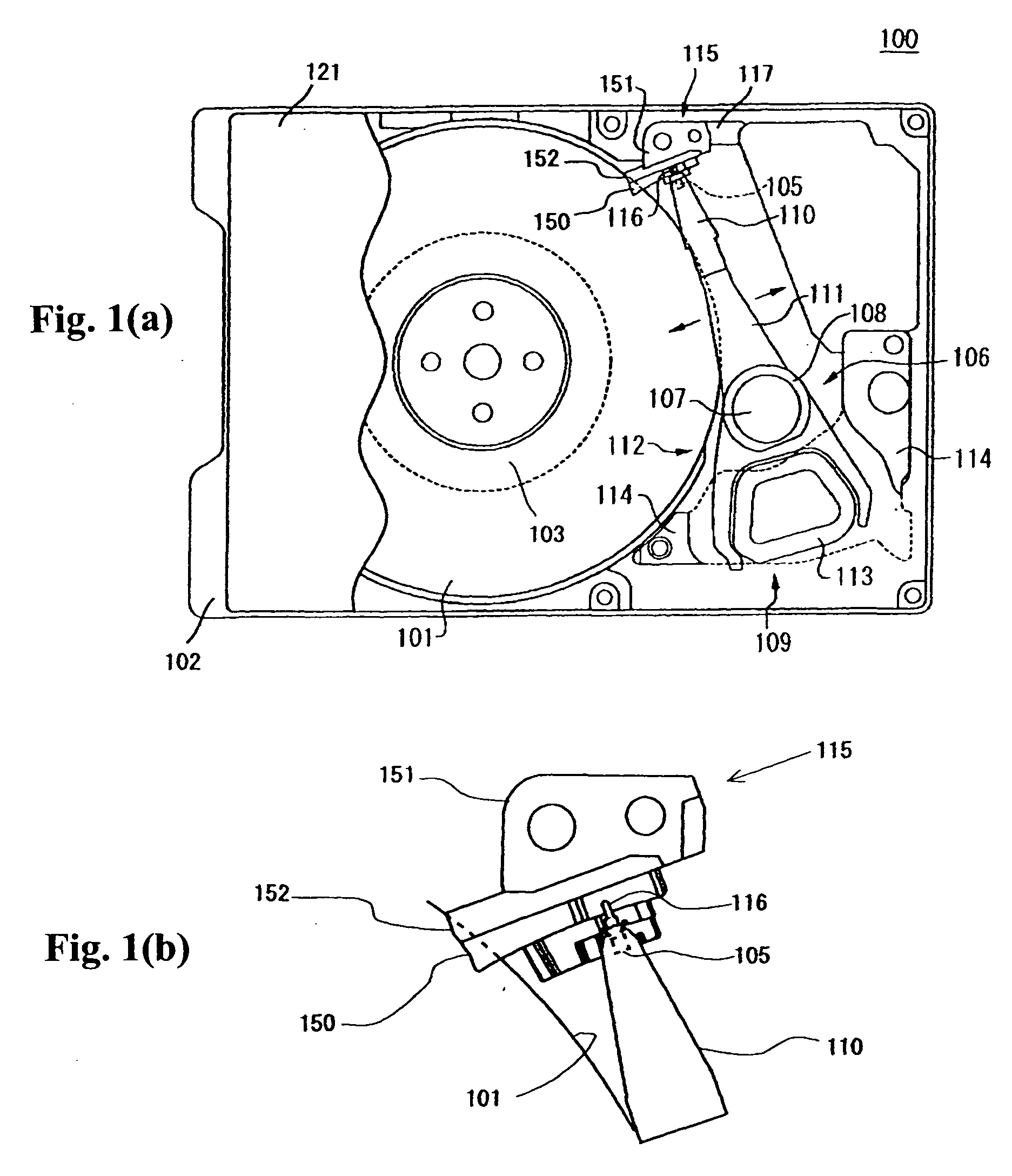

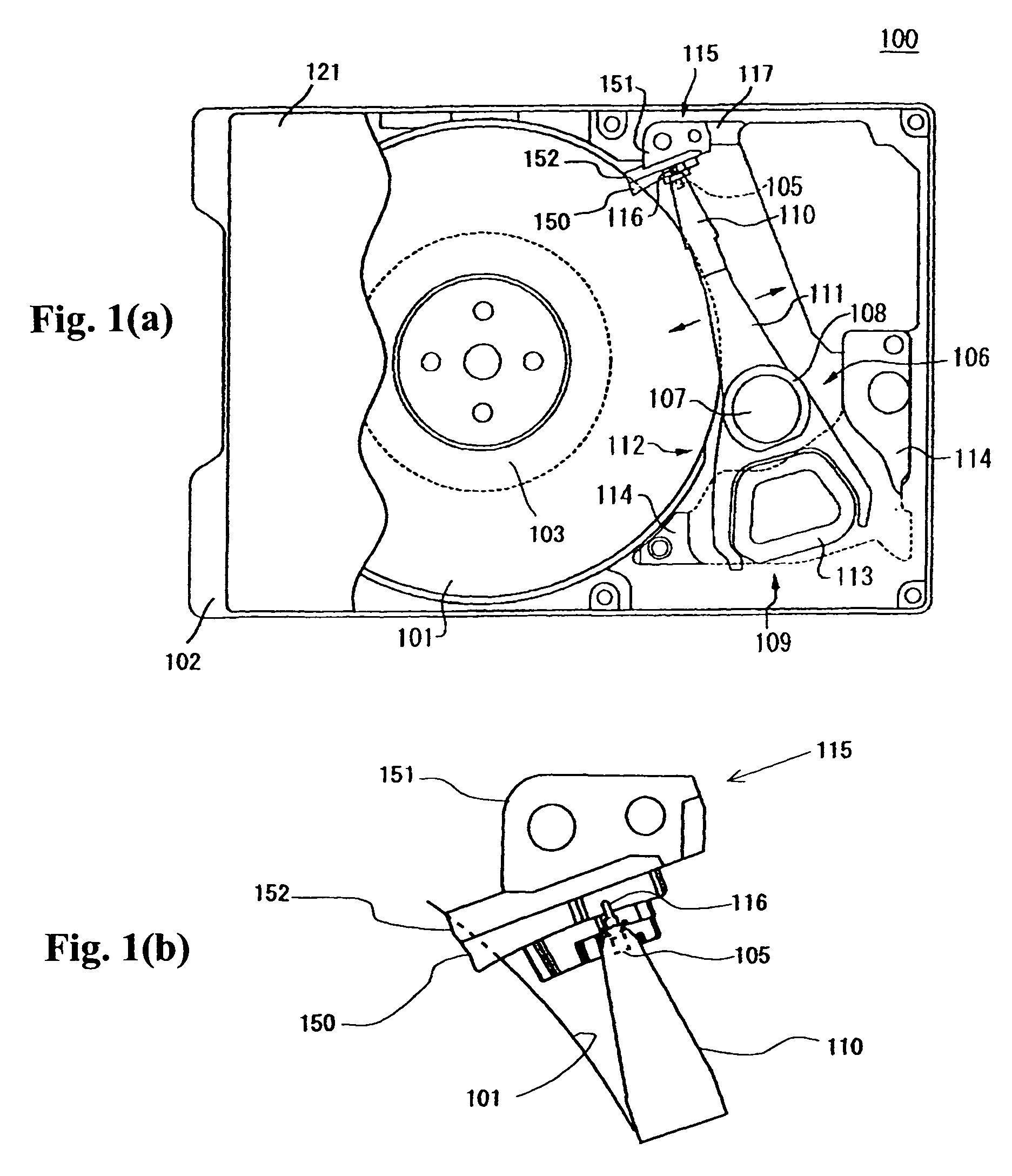

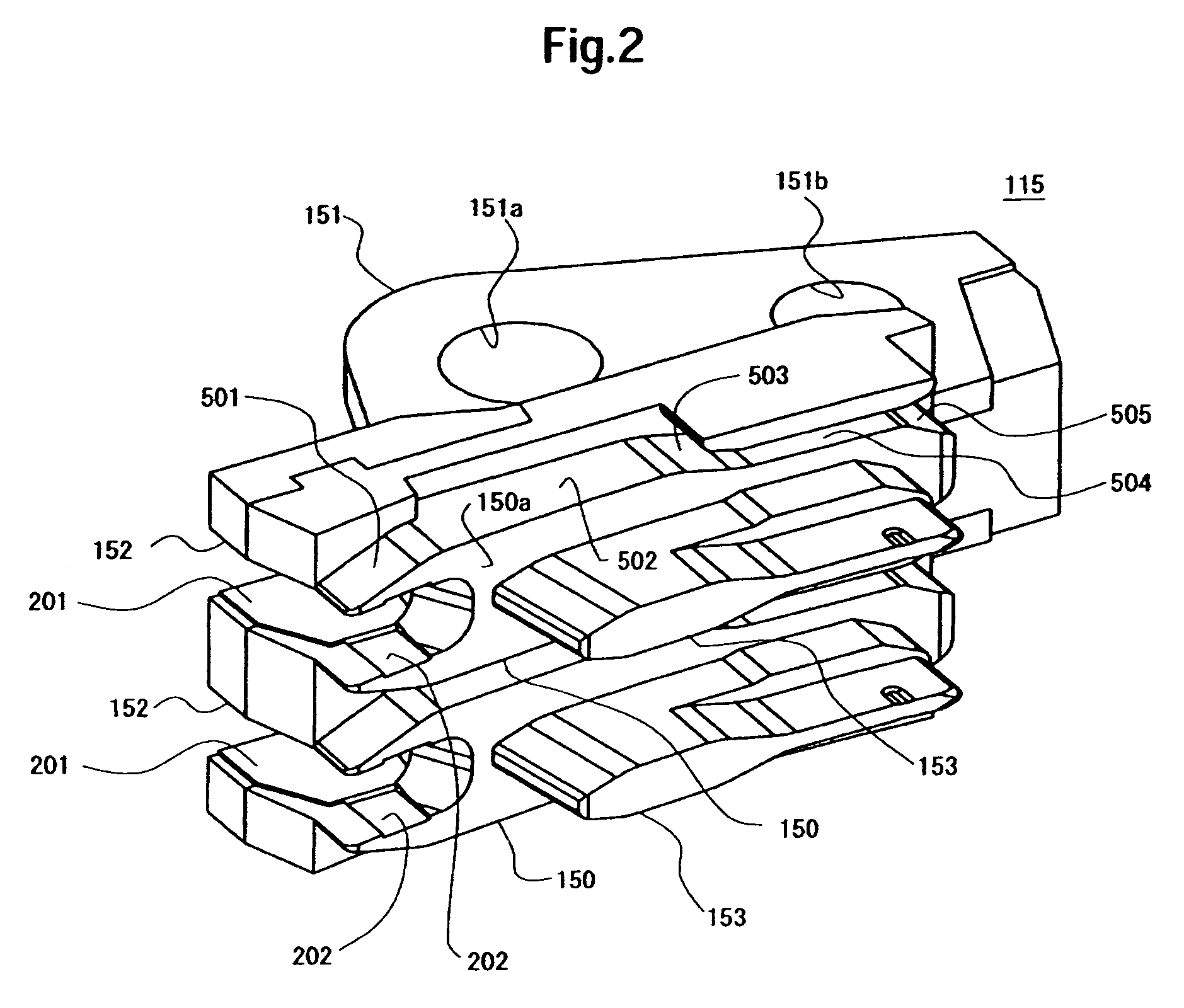

Disk drive device and ramp used therefor

InactiveUS20080204925A1Avoid it happening againHigh mechanical strengthDisposition/mounting of recording headsDriving/moving recording headsHard disc driveData error

Embodiments of the present invention help to prevent data error occurrence in a hard disk drive by reducing the generation of dust caused by friction between a magnetic disk and a ramp. According to one embodiment, a hard disk drive comprises an enclosure, a motor for rotating a magnetic disk, an actuator for supporting a head slider for accessing the disk, and a ramp for loading / unloading the head slider disposed in the enclosure. The ramp comprises a tab slide formed of a resin material having a sliding characteristic to slide a tab at a tip end of the actuator at a specific velocity, and a slit on which a reinforcement made of a resin material with higher mechanical strength than the tab slide is formed.

Owner:WESTERN DIGITAL TECH INC

Dust fall system for urban long and narrow type support-free deep foundation pit excavation construction

PendingCN111705807AReduce dust generationFlexible layoutUsing liquid separation agentDirt cleaningStructural engineeringArchitectural engineering

The invention discloses a dust fall system for urban long and narrow type support-free deep foundation pit excavation construction. A foundation pit body is included. At least one of the two sides ofthe outer edge of an opening of the foundation pit body is provided with a shielding mechanism for pavement of dustproof net cloth towards the other side of the outer edge of the opening in the lengthdirection of the foundation pit body, a negative-pressure area for improving flow of air in the foundation pit body is formed between the dustproof net cloth and the outer edge of the opening of thefoundation pit body, guide rail assemblies which are in moving fit connection with the shielding mechanism are laid on the two sides of the foundation pit body in the length direction of the foundation pit body, and after the dustproof net cloth is laid and shielded, the two sides of the foundation pit body in the length direction of the foundation pit body are provided with a plurality of dust fall mechanisms for adsorbing and settling of raise dust in the foundation pit body, wherein the dust fall mechanisms are adaptive to the guide rail assemblies. According to the dust fall system, through the comprehensive means of shielding, adsorbing and settling, generation of raise dust is reduced to the maximum degree.

Owner:QINGDAO NO 1 CONSTR GRP

Dustproof fabric capable of being dyed at normal pressure

InactiveCN102102258AReduce dust generationImprove antistatic performanceWoven fabricsMonocomponent polyesters artificial filamentFiberEngineering

The invention discloses a dustproof fabric capable of being dyed at normal pressure, which comprises non-fume-diffusion copolyester fibers containing a 2-methyl-1,3-propylene glycol structure and non-fume-diffusion conductive fibers, wherein the conductive fibers are distributed in a strip shape or a grid shape in the fabric, and the compactness of the fabric is 2000 to 4000. The dustproof fabric has excellent dustproof performance, better antistatic property and higher air permeability. The manufacturing process of the traditional dustproof fabric is simplified, the fabric can be dyed at normal pressure, and the production cost is reduced. The obtained dustproof fabric is light, thin and permeable, is comfortable to wear, is convenient for wearers to work flexibly, and is applicable to dustproof clothing of industries of semiconductors, foods, medicines and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Proppant sand coating for dust reduction

InactiveUS9896620B2Reduce wearReduce dust generationLiquid surface applicatorsFluid removalPrillHydraulic fracturing

The present invention provides for coating proppants, such as sand, with a resin-containing dispersion which dramatically reduces the dust generated during handling, for example in hydraulic fracturing, by protecting the surface of the particle from abrasion and degradation. Such resin-containing dispersion coated-sand may also reduce the wear on metal parts used in transporting such proppants.

Owner:COVESTRO LLC

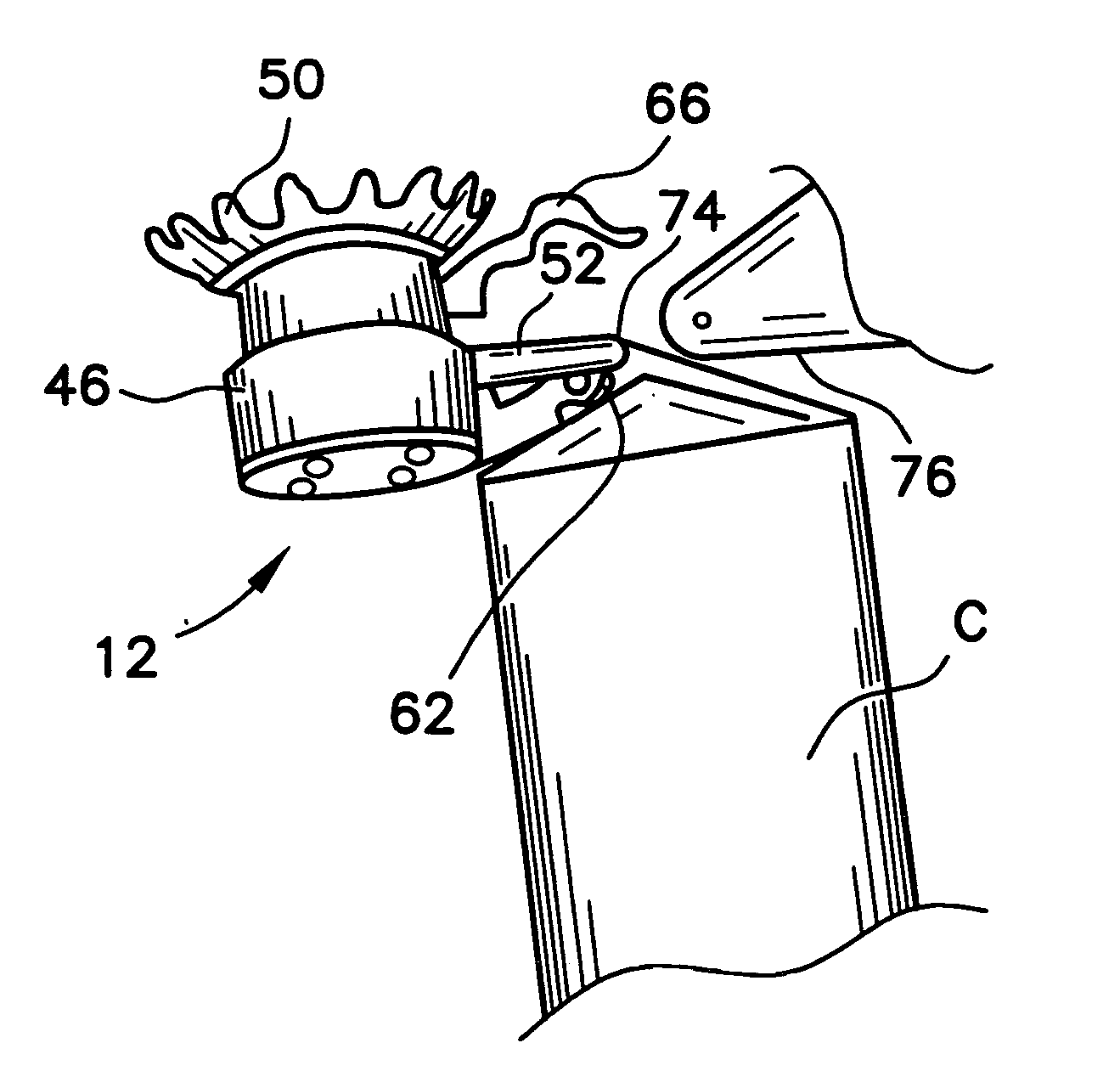

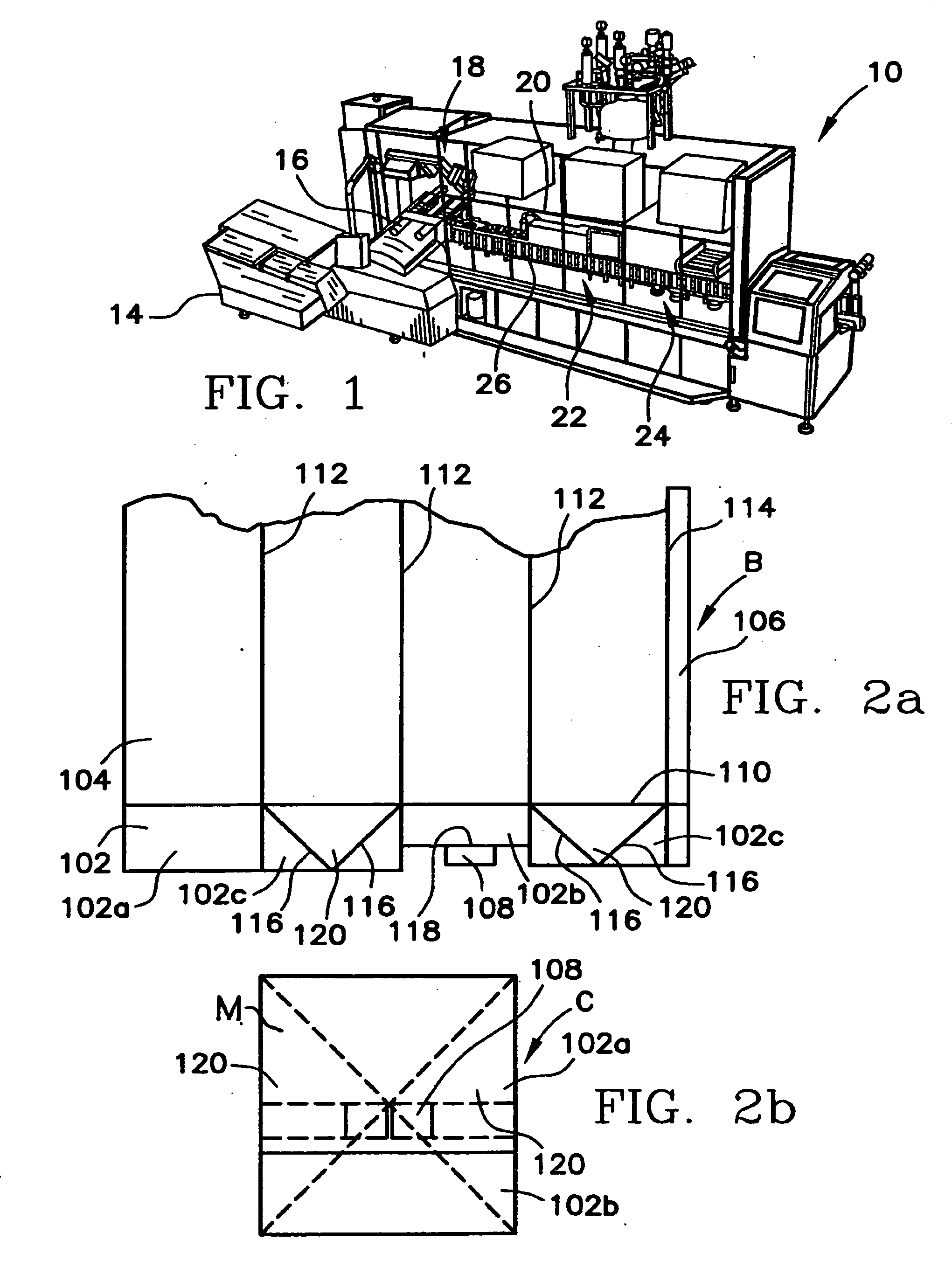

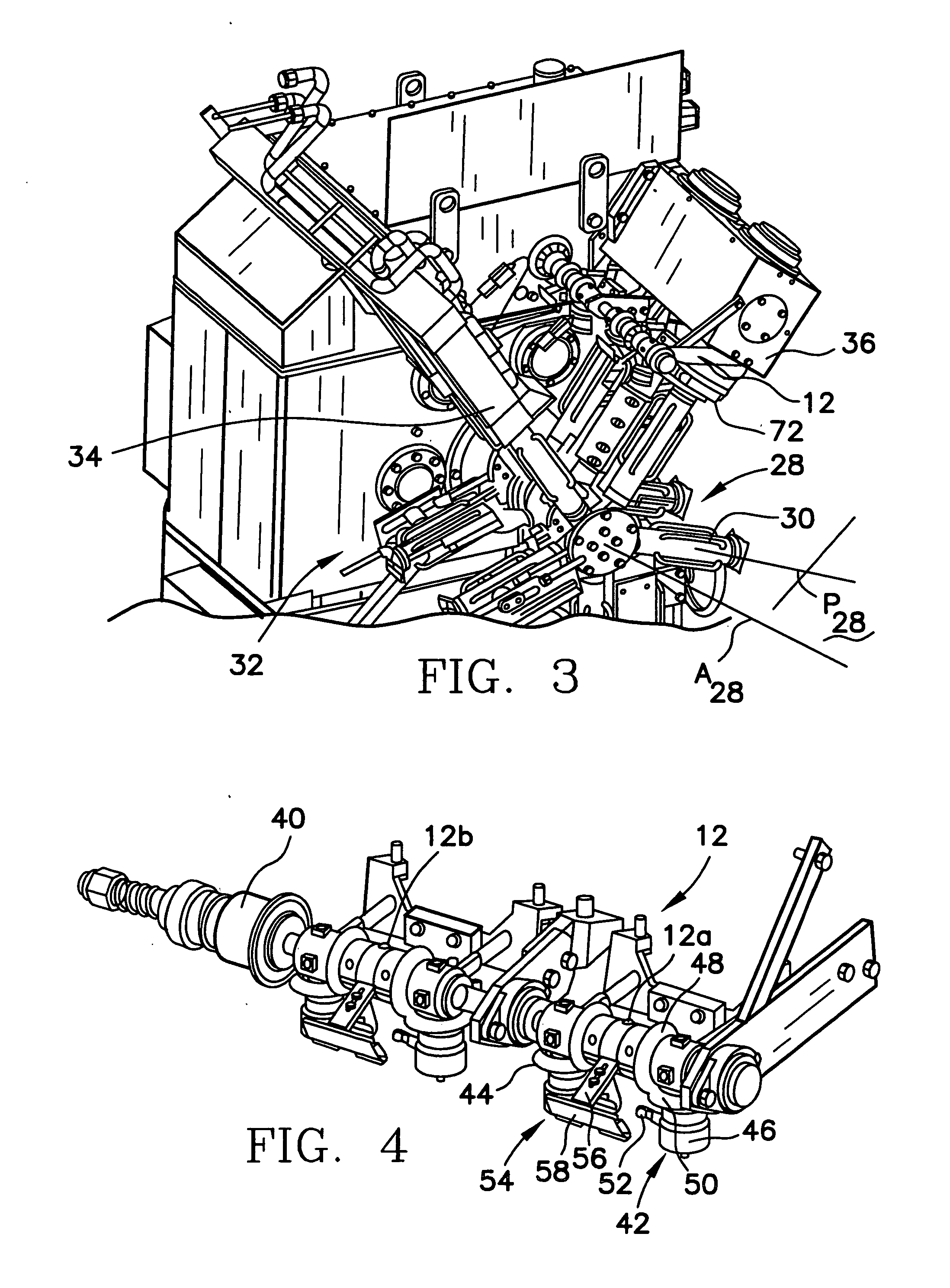

Carton bottom folding assembly

InactiveUS20050060965A1Reduce exposureReduce dust generationBoxes/cartons making machineryWrapper twisting/gatheringDrive shaftTurret

A bottom folding assembly for a packaging machine is configured to infold the bottom side panels, leading panel and trailing panel of a carton for forming a sealed carton bottom in such a manner as to reduce the contact of rotating elements with the carton material to reduce the generation of dust. The bottom folding assembly is positioned about a rotating turret that defines a turret plane. The mandrels are configured to receive a carton in the tubular form and to carry the carton with the carton positioned such that a bottom of the carton is positioned at a free end of the mandrel. The bottom folding apparatus, located between a carton bottom heater and a carton bottom sealer includes a rotating drive shaft mounted transverse to the turret plane and a pair of opposing rotating members are operably mounted to the drive shaft and are disposed on either side of the turret rotational path. The rotating member rotate in a plane transverse to the turret plane. A tucking assembly is disposed between the opposing rotating members and is mounted to the drive shaft for rotating in a plane transverse to the rotating members and parallel to the turret plane. When a carton is positioned on the mandrel and passes the folding assembly, the opposing rotating members contact the bottom side wall flaps, urging the bottom side wall flaps inwardly, and the tucking assembly contacts the bottom trailing flap, urging the bottom trailing flap inwardly, over the bottom side wall flaps. A form, fill and seal machine having the bottom folding assembly is also disclosed.

Owner:TETRA LAVAL HLDG & FINANCE SA

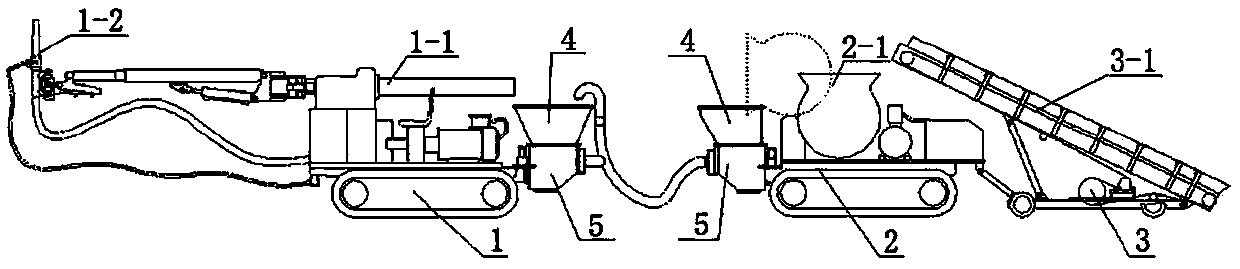

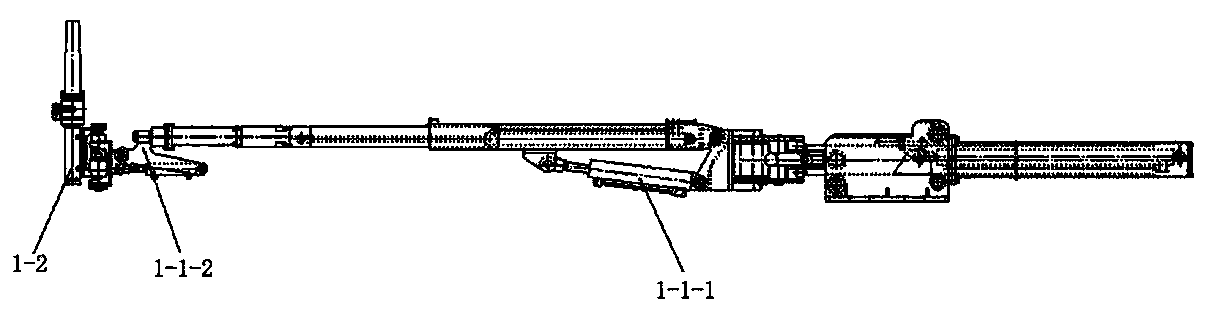

Wet concrete spouting process for use under coal mine

ActiveCN103775104AGood environmental effectReduce dust generationUnderground chambersTunnel liningTunnel constructionCoal

The invention discloses a wet concrete spouting process for use under a coal mine. A mechanical grouting production line is adopted, and comprises a crawler-type movable wet concrete sprayer, a crawler-type movable mixing station and a rubber-wheel movable belt feeder. The process comprises the following steps: feeding a mixed dry material into a stirring hopper of a stirring station by using a belt feeder; adding water into the stirring hopper; conveying wet concrete into a hopper of the concrete sprayer; pushing to a spray gun through a pumping system; spraying the concrete onto a tunnel construction surface in a circle-drawing manner by using compressed air containing a liquid setting accelerator; performing overall grouting on the roof and sides of a tunnel through the mechanical actions such as forward / backward extension and contraction, upward / downward pitching and leftward / rightward swing of a manipulator in the tunnel. By adopting the wet concrete spouting process, a dry (damp) spraying process adopted in the conventional grouting of tunnels under coal mines in China is eliminated, the hidden danger of dust endangering the health of workers is eliminated greatly, and the grouting mechanization level is raised.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Coated and cured proppants

ActiveUS9290690B2Solve the lack of resistanceResistant to leachingPretreated surfacesFluid removalWashoutHigh pressure

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

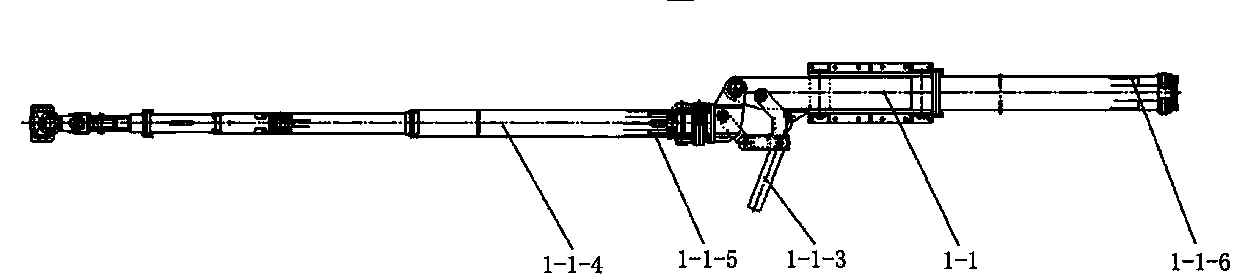

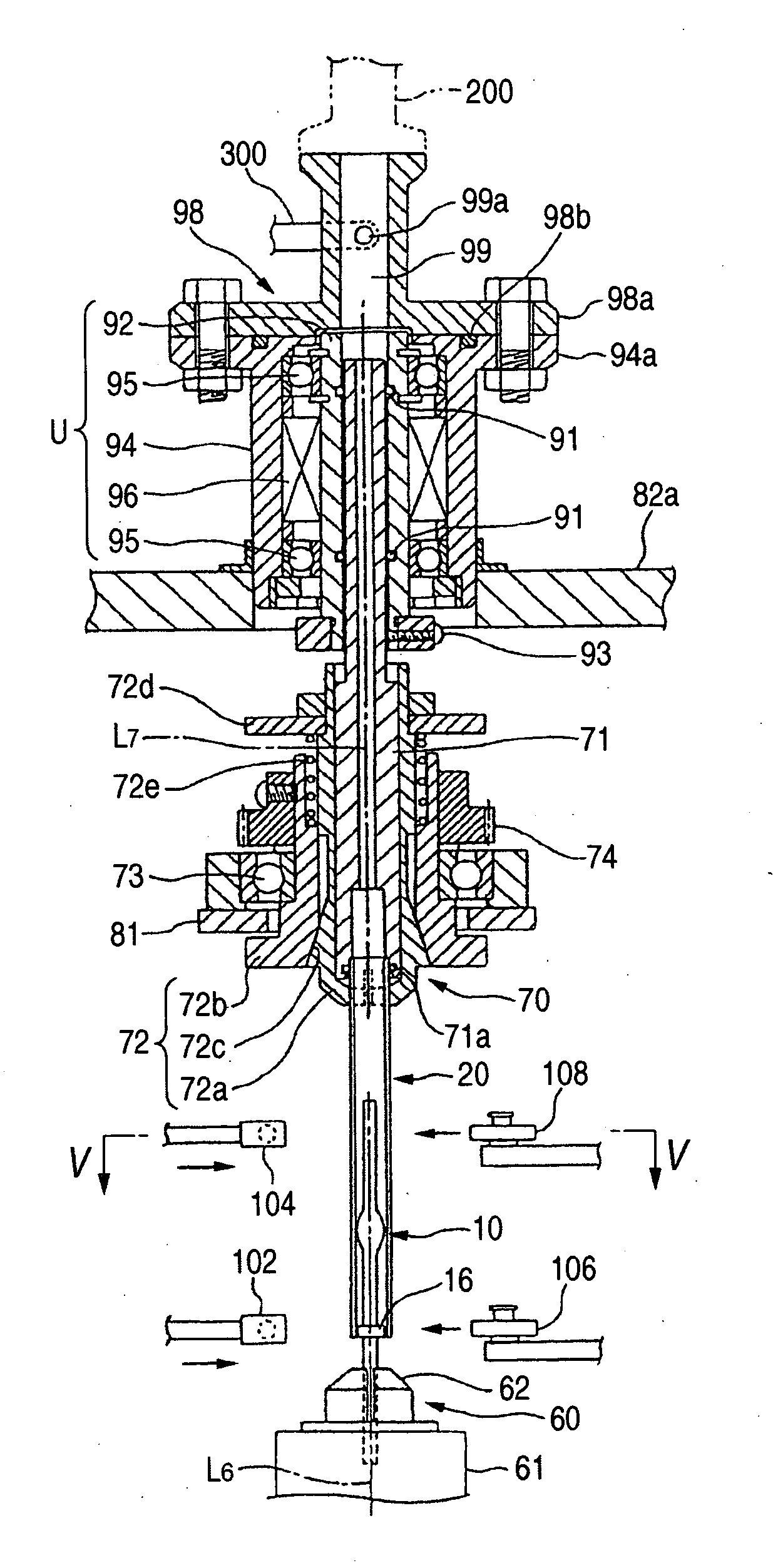

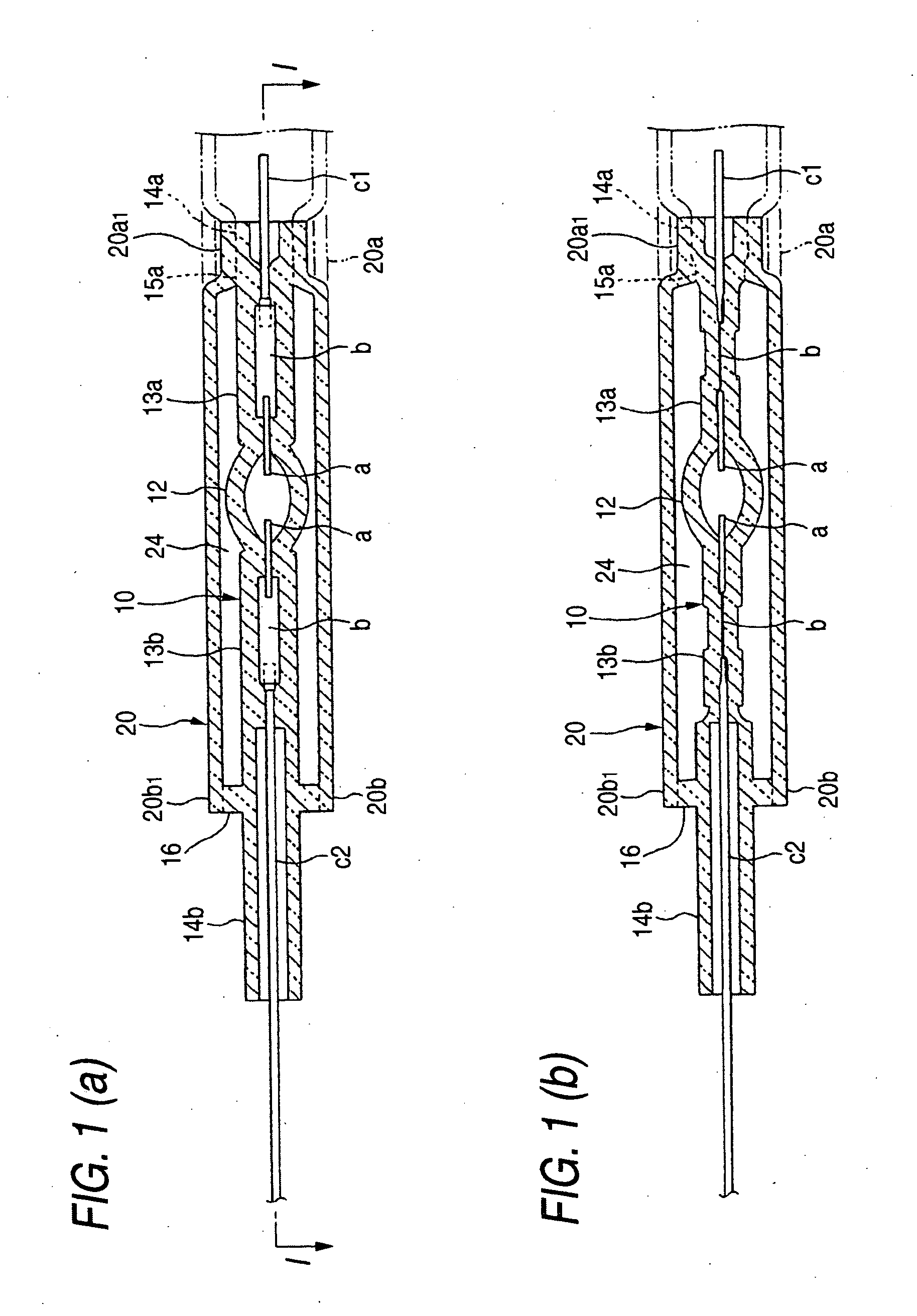

Method and apparatus for welding shroud glass tube in arc tube for discharge lamp

InactiveUS20050255783A1Reliable shieldingCarry-out quicklyTube/lamp screens manufactureElectroluminescent light sourcesSecondary sideInert gas

A method of secondarily welding one end of a shroud glass tube covering an arc tube body having a discharge emitting portion, having the other end welded primarily to one of the arc tube body ends, to the other end side of the arc tube body, while discharging air from, and introducing an inactive gas into, the tube through the opening end of the glass tube to hold a negative pressure. Heating and melting from a side is carried out. The opening end of the glass tube is connected to a piping passage component for discharging air and introducing an inactive gas through a rotatable magnetic fluid seal unit. Secondary welding is carried out with the rotation of the glass tube around an axis. The glass tube rotated with respect to secondary side heater is uniformly heated, molten and softened circumferentially, and welded along the arc tube body outer periphery.

Owner:KOITO MFG CO LTD

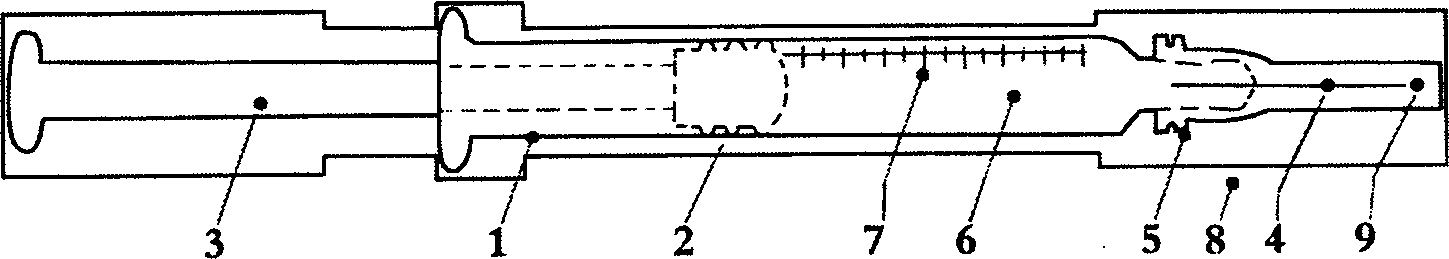

Antineoplastic precharging preparation

InactiveCN1836650AConvenient for clinical operationEasy to useAmpoule syringesPharmaceutical containersDocetaxelPre-charge

The present invention is pre-charged antitumor medicine preparation and relates to medicine preparation form. Pre-charged syringe, which has the structure comprising outer sleeve, protecting cap, needle, piston, mandrel and needle sealing rubber plug, is used as the inner package of water soluble antitumor injection. The outer sleeve has inner wall of polypropylene material with less adsorption of medicine, and the needle has diameter of 0.2-0.5 mm. The antitumor medicine may be vinorelbine, taxol, docetaxel, etc. The present invention has less medicine residue, accurate dosage, less pollution risk, convenient packing, lowered medical cost and other advantages.

Owner:SINOPHARM A THINK PHARMA

Fibrous structures comprising a region of auxiliary bonding and methods for making same

Owner:PROCTER & GAMBLE CO

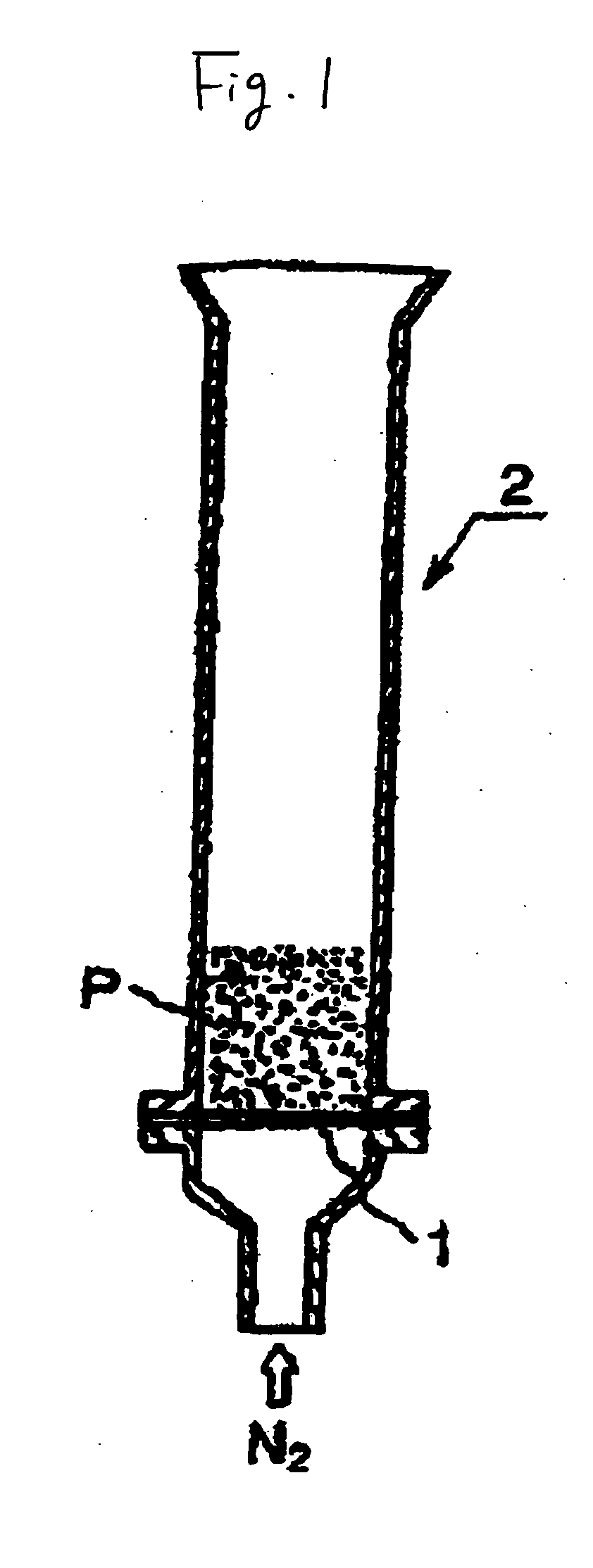

Spherical active carbon and process for producing the same

InactiveCN1956919AReduce dust generationDustyCarbon compoundsOther chemical processesActivated carbonSolid carbon

Owner:KURARAY CO LTD

Disk drive device and ramp used therefor

InactiveUS7986496B2Avoid it happening againHigh mechanical strengthDisposition/mounting of recording headsDriving/moving recording headsHard disc driveData error

Embodiments of the present invention help to prevent data error occurrence in a hard disk drive by reducing the generation of dust caused by friction between a magnetic disk and a ramp. According to one embodiment, a hard disk drive comprises an enclosure, a motor for rotating a magnetic disk, an actuator for supporting a head slider for accessing the disk, and a ramp for loading / unloading the head slider disposed in the enclosure. The ramp comprises a tab slide formed of a resin material having a sliding characteristic to slide a tab at a tip end of the actuator at a specific velocity, and a slit on which a reinforcement made of a resin material with higher mechanical strength than the tab slide is formed.

Owner:WESTERN DIGITAL TECH INC

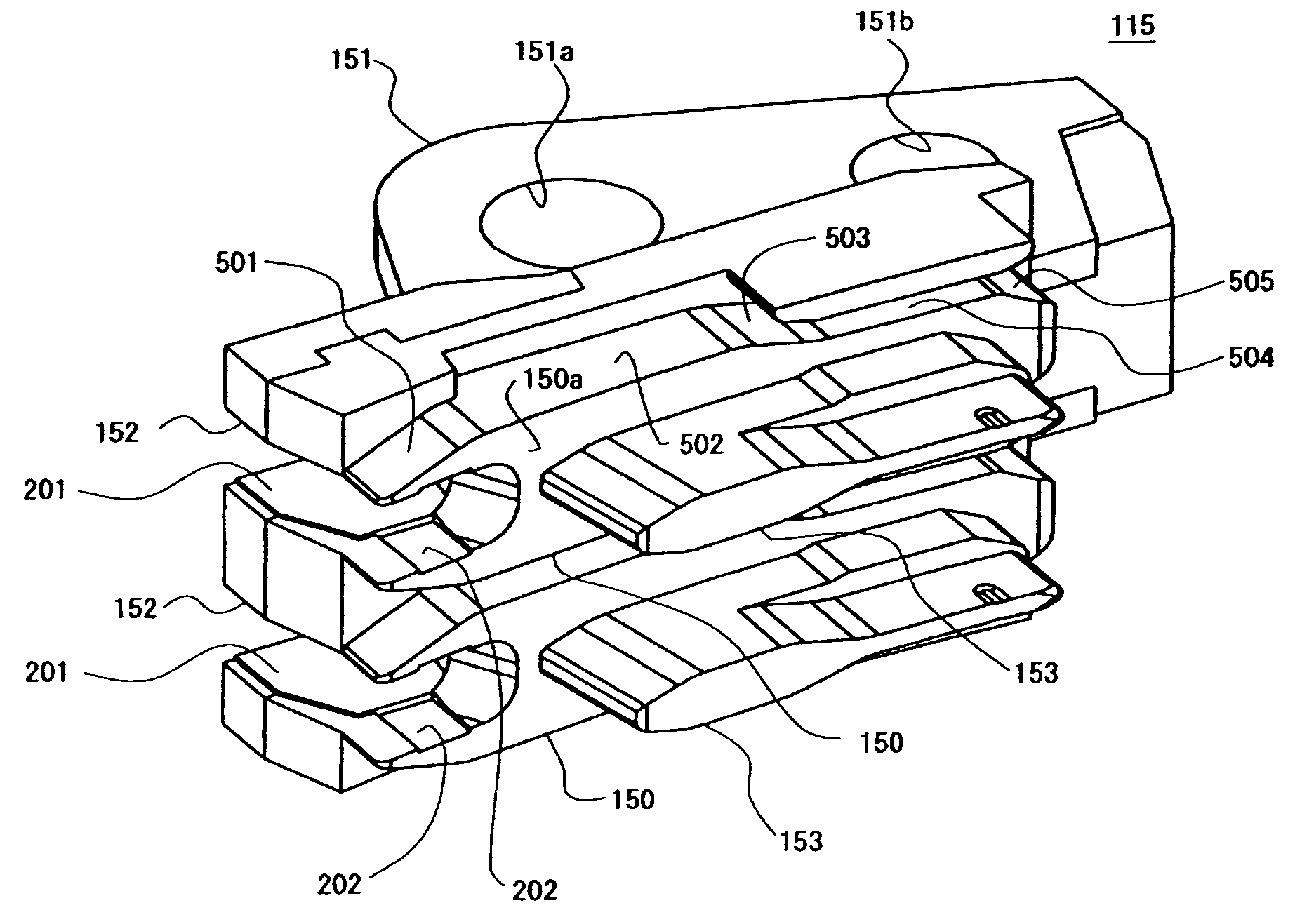

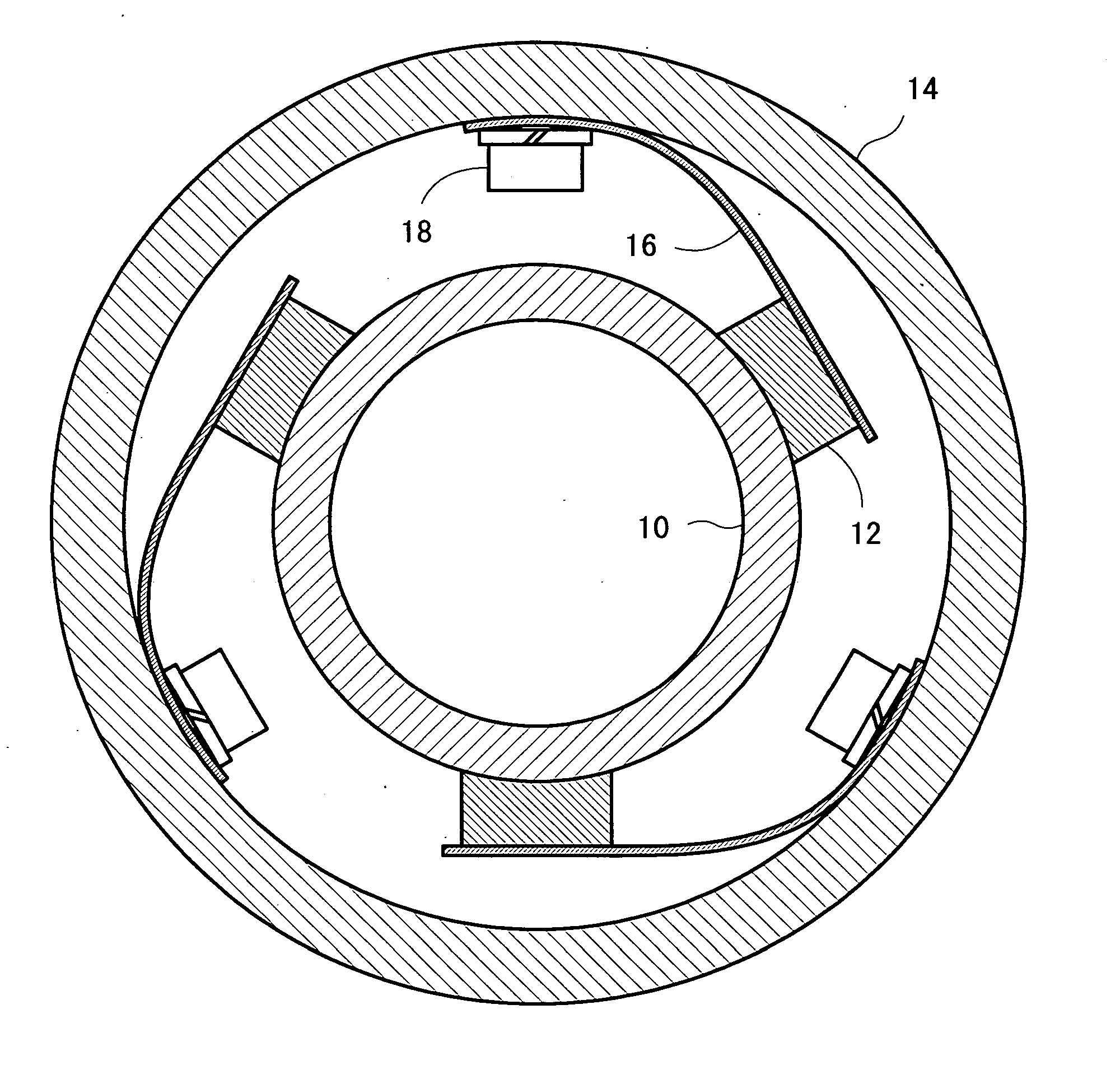

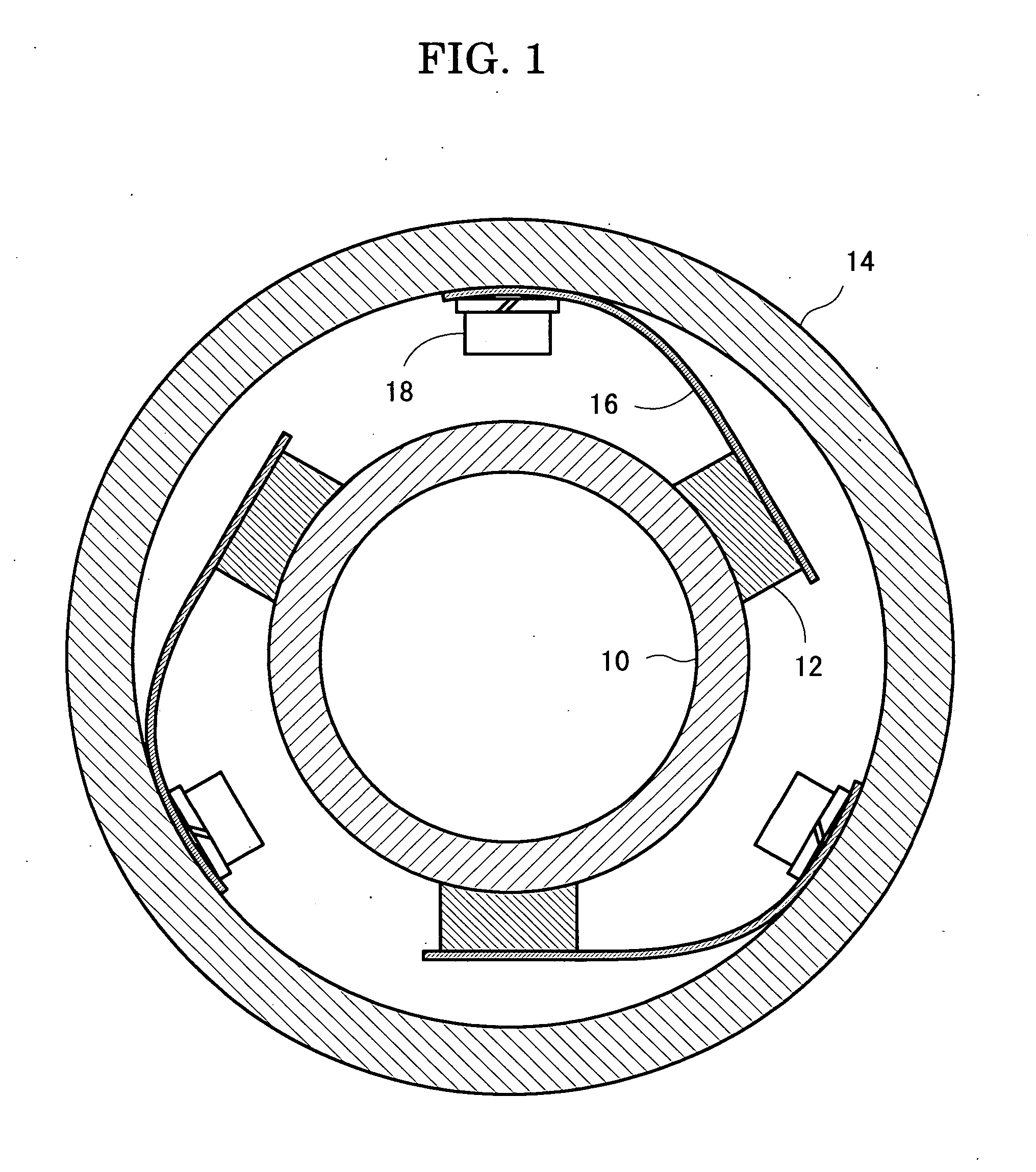

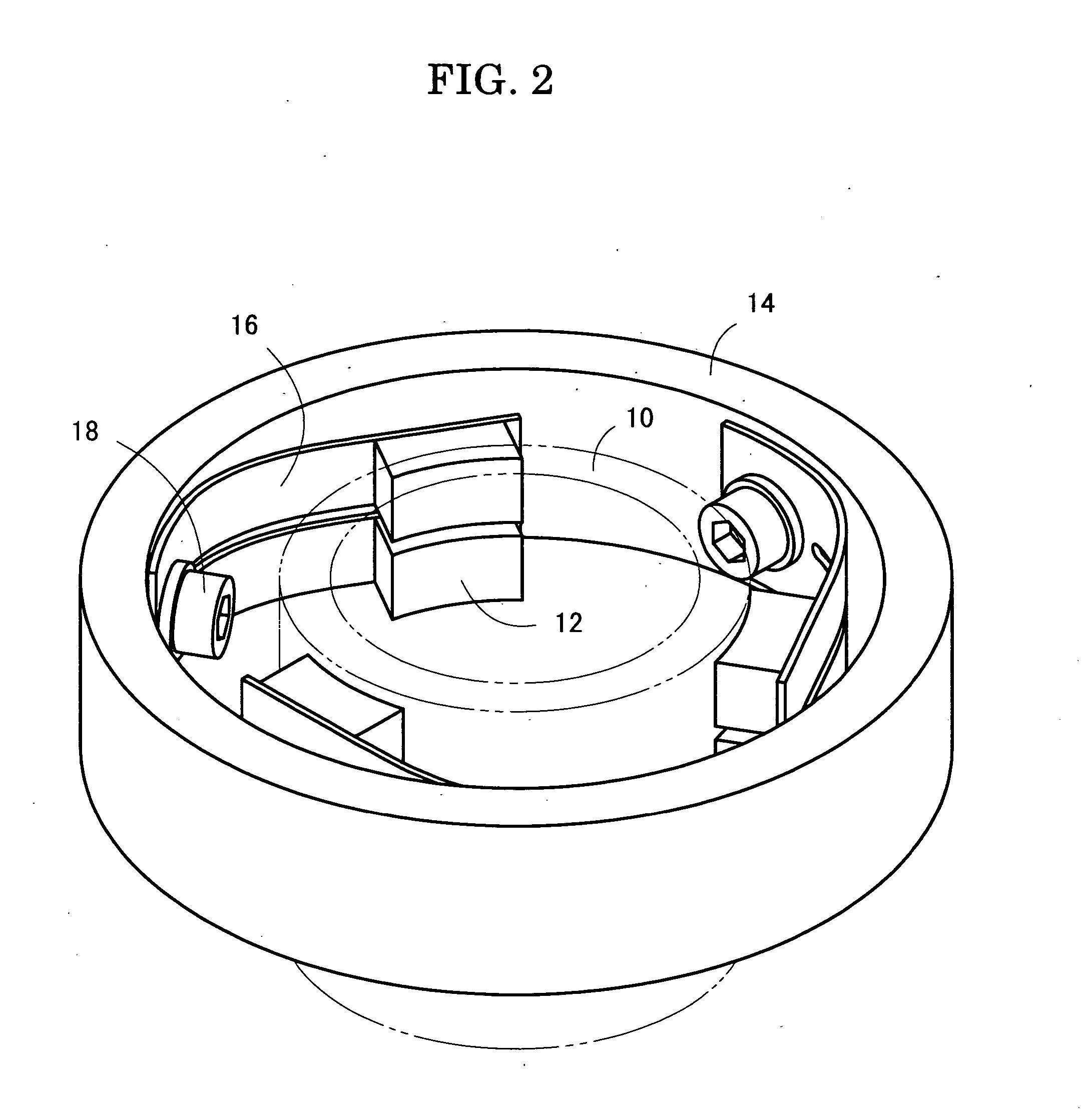

Rotary current-collecting device and rotating anode X-ray tube

ActiveUS20050082936A1Reduce coefficient of frictionLess dust generationRotary current collectorX-ray tube electrodesEngineeringGraphite

A rotary current-collecting device includes a rotary slip ring and brushes coming into sliding contact with the outer peripheral surface of the slip ring. The brush-holding ring has an inner surface to which three brush-holding springs are fixed by screws. Each of the brushes is fixed to the tip end of the brush-holding spring and is pushed against the outer surface of the slip ring under the resilient restoration force of the brush-holding spring. When the slip ring revolves, the brushes come into sliding contact with the outer peripheral surface of the slip ring. The brush is made of a metal-graphite compound consisting of 70 weight percent copper and 30 weight percent graphite. The slip ring is entirely made of glassy carbon, so that the brush abrasion can be reduced.

Owner:RIGAKU CORP

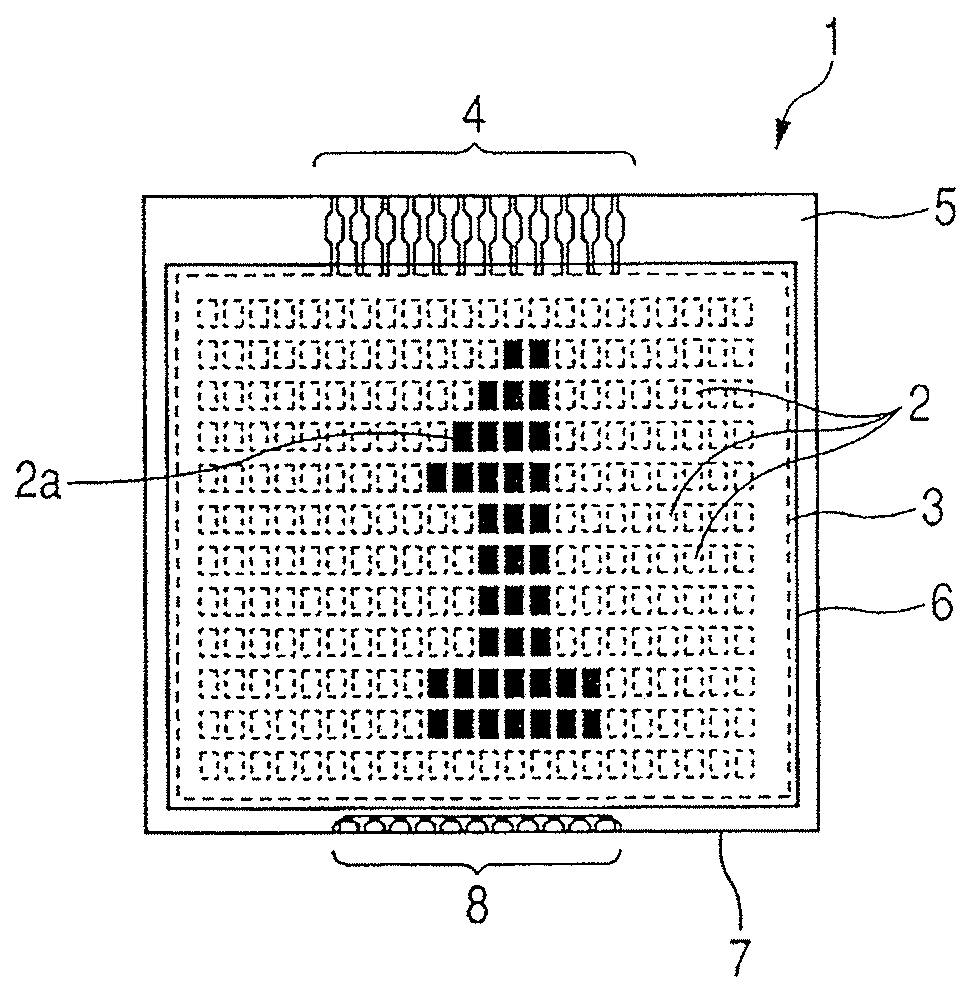

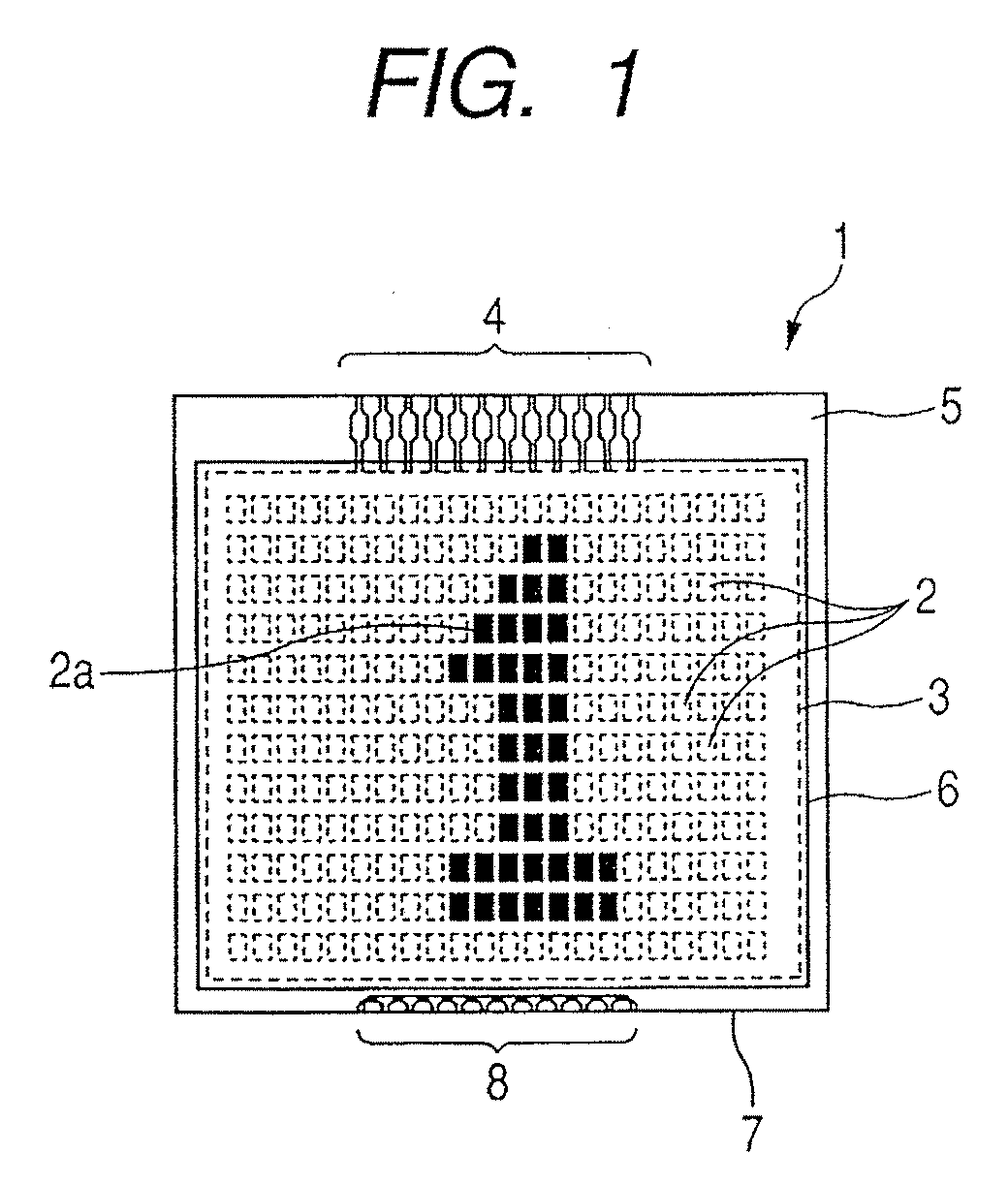

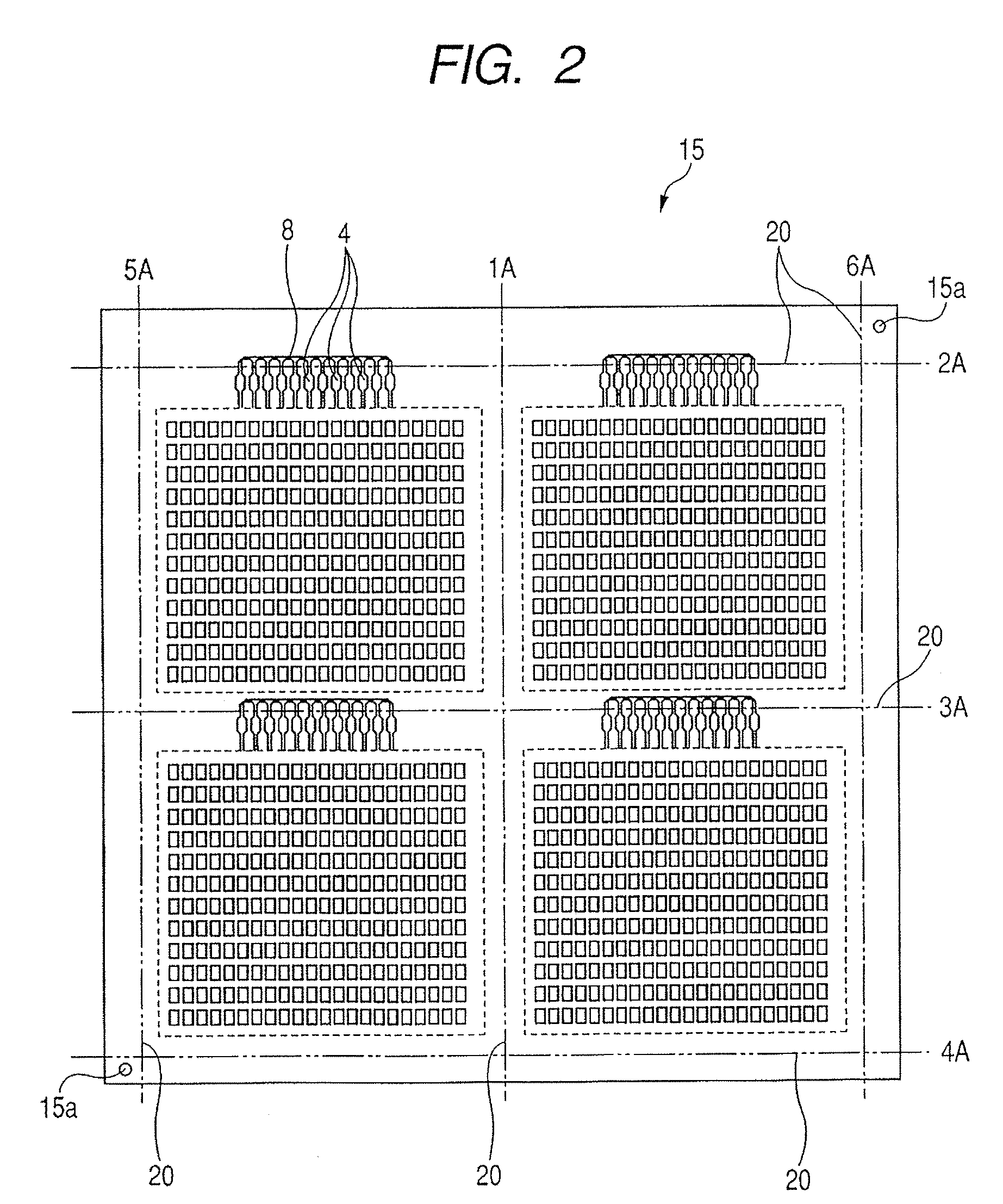

Electronic component and method of producing same

InactiveUS20080220684A1Reduce the numberImprove productivitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectronic component

There are provided an electronic component production method and an electronic component by which the number of scribing processes can be reduced and the productivity can be made higher while surely preventing short circuiting during the production. An electronic component including a short ring residue portion and a method of producing the electronic component are provided.

Owner:CANON KK

Mixed Powder For Powder Metallurgy, Green Compact Thereof, and Sintered Body

ActiveUS20090007725A1Reduce dust generationReduce segregationTransportation and packagingMetal-working apparatusGraphiteMechanical property

The present invention relates to a mixed powder for powder metallurgy containing an iron-base powder and a carbon supply component, in which the carbon supply component contains a graphite powder and a carbon black, and in which a mixing ratio of the graphite powder to the carbon black is in the range of 25 to 85 parts by weight to 75 to 15 parts by weight; and a mixed powder for powder metallurgy containing an iron-base powder and a carbon supply component, in which the carbon supply component contains, as a main component, a carbon black having a dibutyl phthalate absorption of 60 mL / 100 g or less and a nitrogen absorption specific surface area of 50 m2 / g or less.The mixed powder for powder metallurgy of the invention is less in the dust generation and segregation of the carbon supply component. Additionally, when the mixed powder for powder metallurgy of the invention is used, a green compact and a sintered body excellent in the mechanical property can be produced.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com