Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Avoid environmental impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

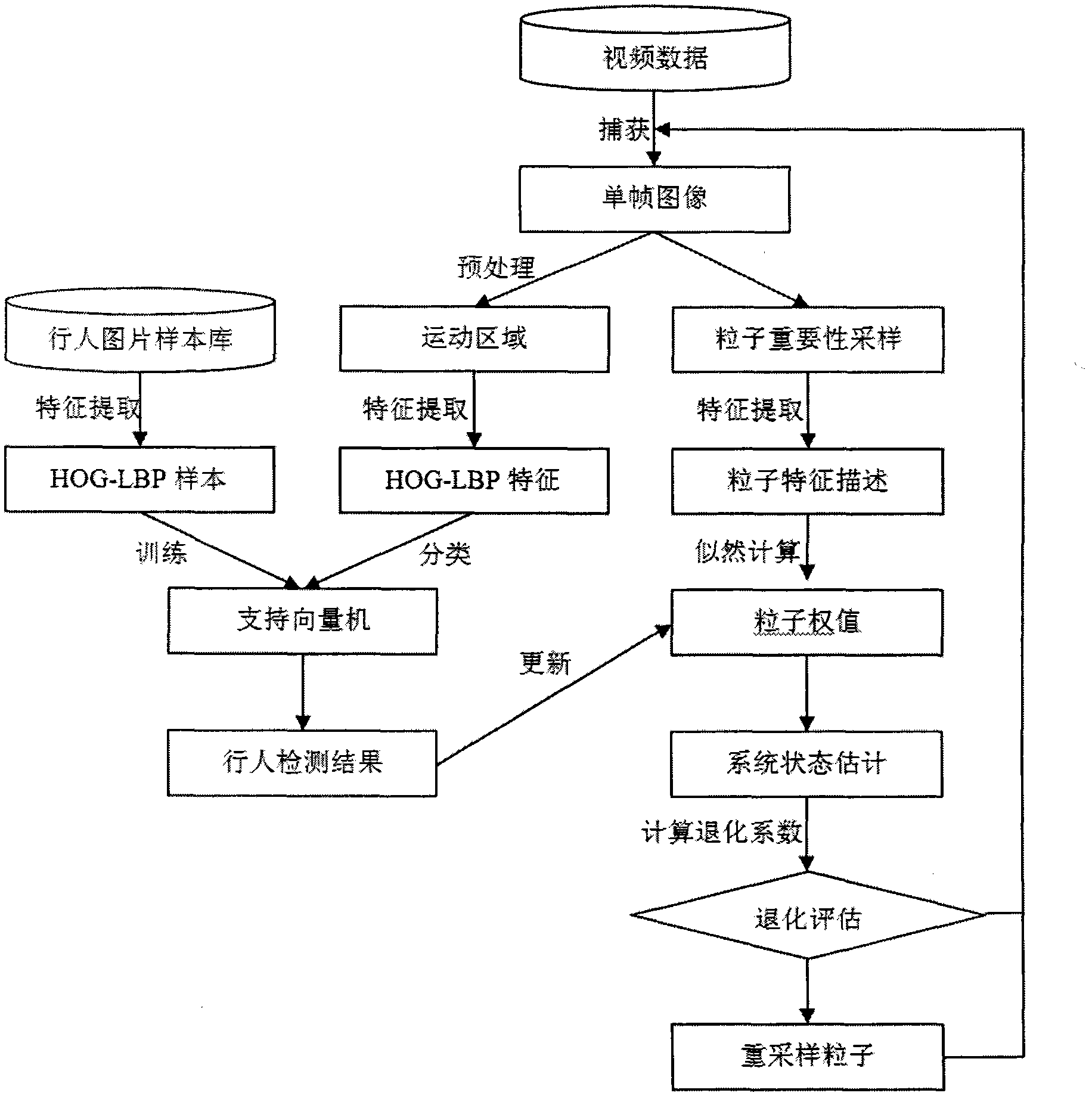

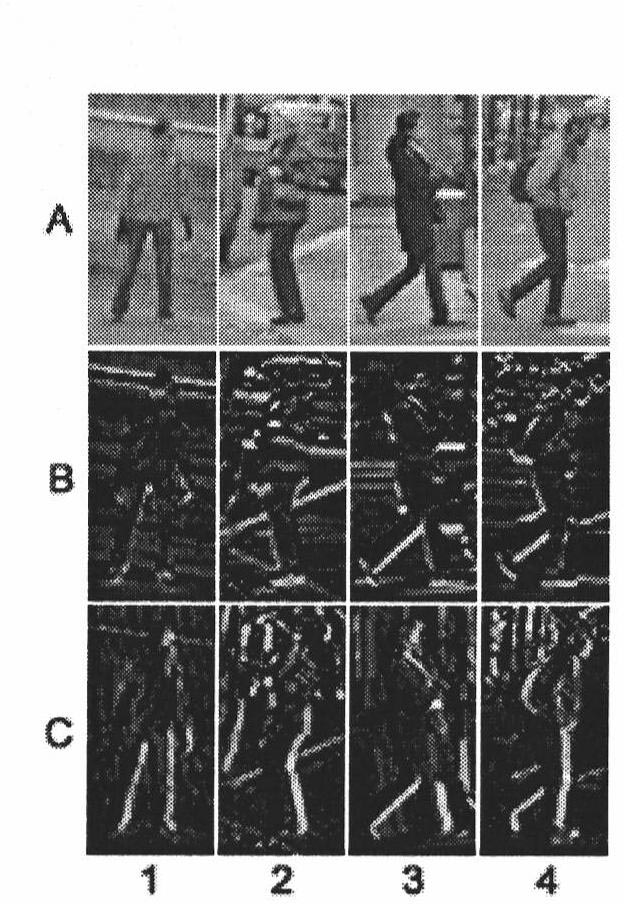

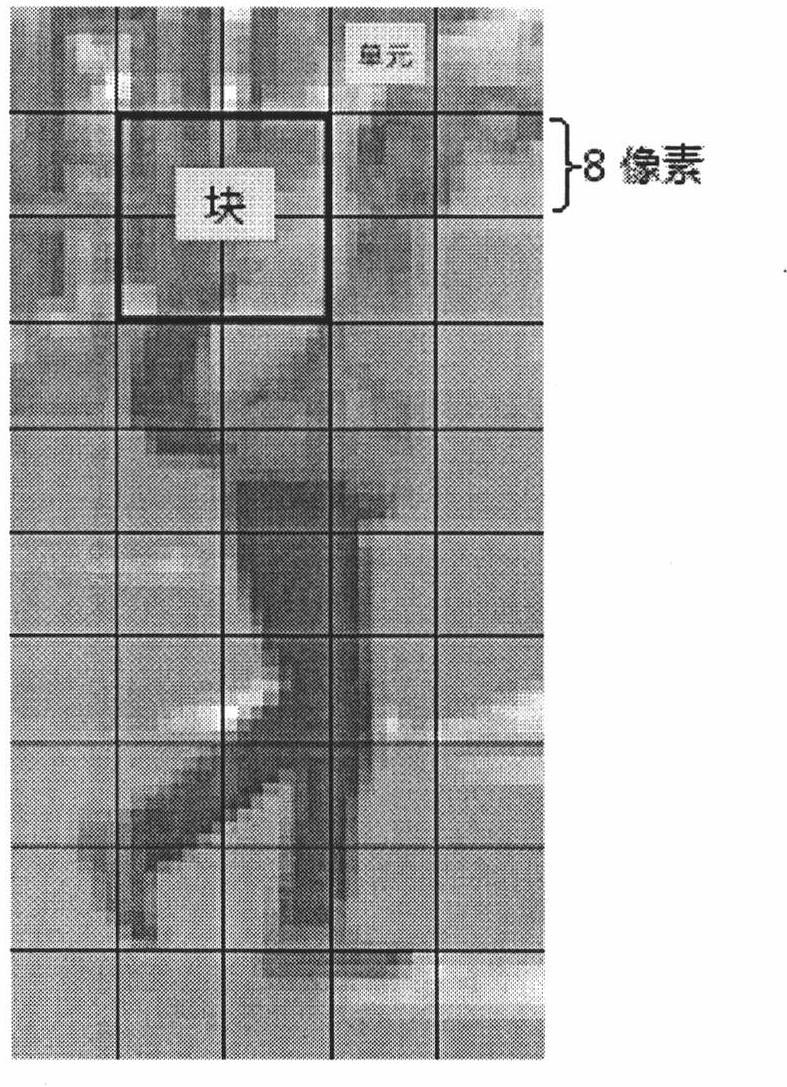

Pedestrian tracking method based on HOG-LBP

InactiveCN102663409AAvoid environmental impactOvercome occlusionImage analysisCharacter and pattern recognitionSupport vector machineFeature extraction

The invention discloses a pedestrian tracking method based on HOG-LBP, comprising the following steps of, A1, sample establishment; A2, feature extraction; A3, SVM model establishment; A4, classifier training; A5, video capture and pretreatment; A6, video pedestrian examination; A7, video pedestrian tracking: applying a particle filtering tracking method based on an HOG-LBP feature to track the pedestrian examined in step A6. The method firstly learns an image pedestrian mode through a support vector machine, and then classifies a moving area in a video sequence and inputs the result to a particle filtering machine to update the particle status, and finally realizes continuous tracking to pedestrian movement in the scene. Because the method collects pedestrian feature by adopting HOG-LBP and uses the particle filtering to track movement, it has good adaptability and stability to movement interleave and sheltering phenomenon in a scene and non-linear feature presented by the movement.

Owner:XIDIAN UNIV

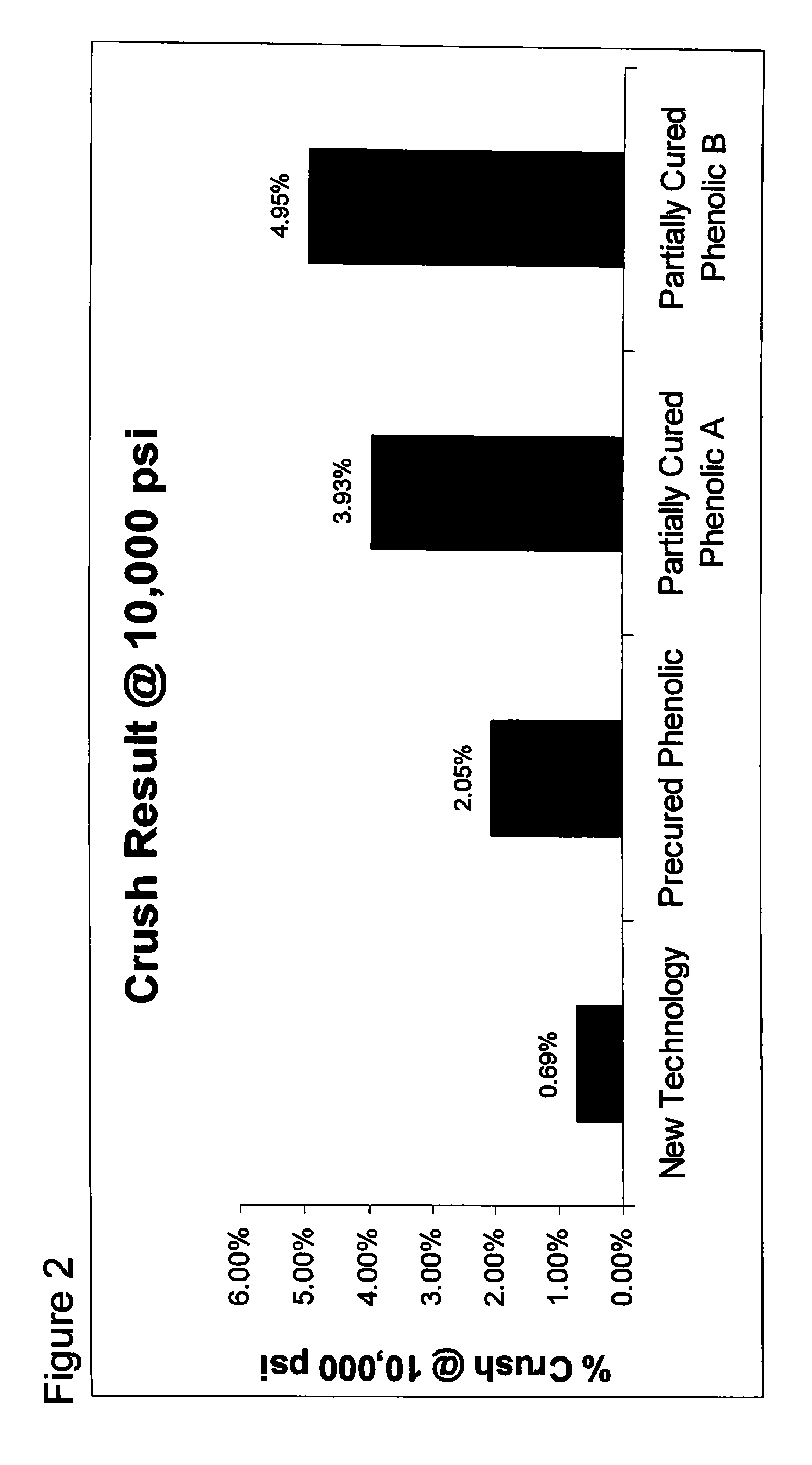

Coated and cured proppants

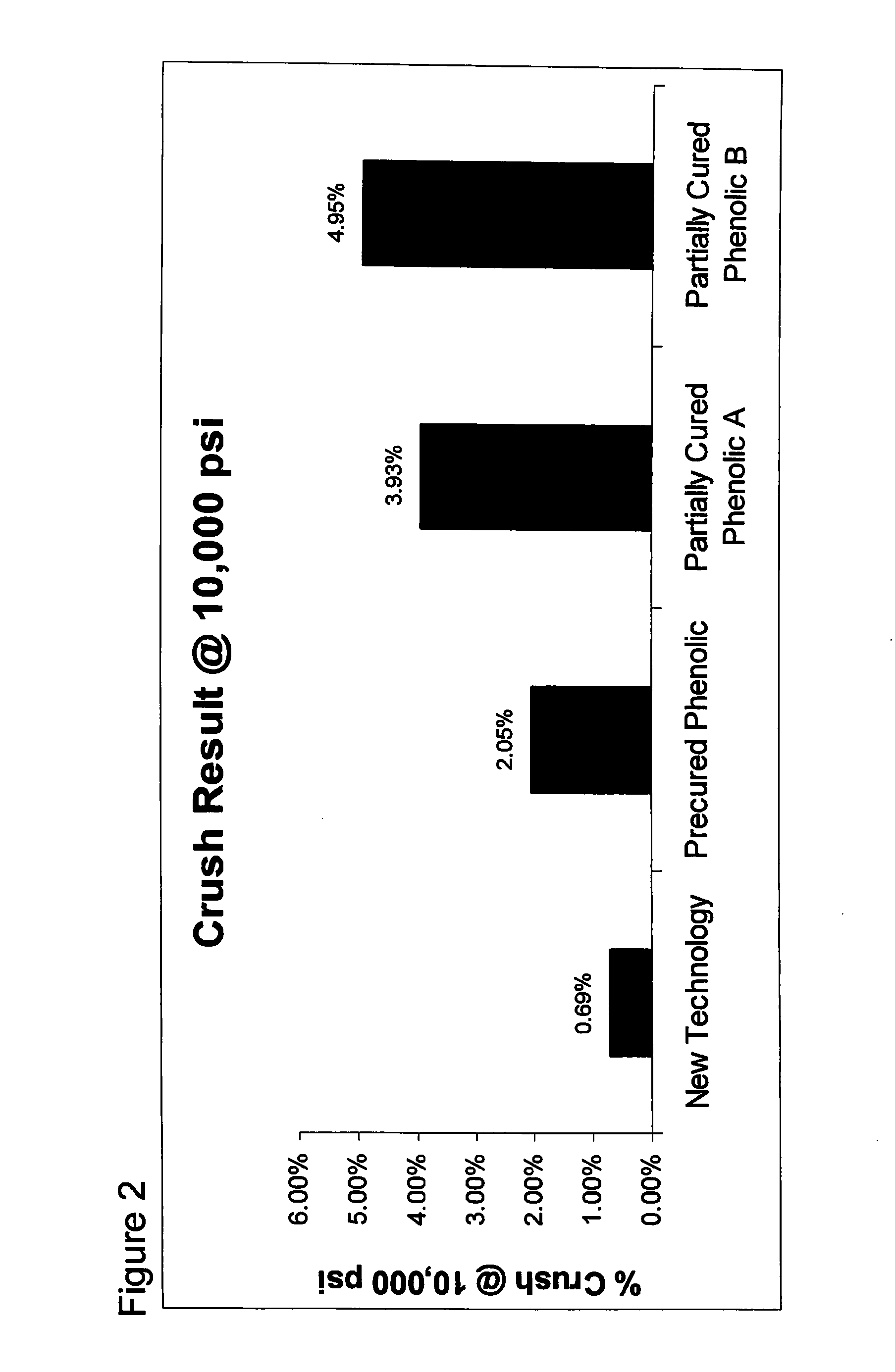

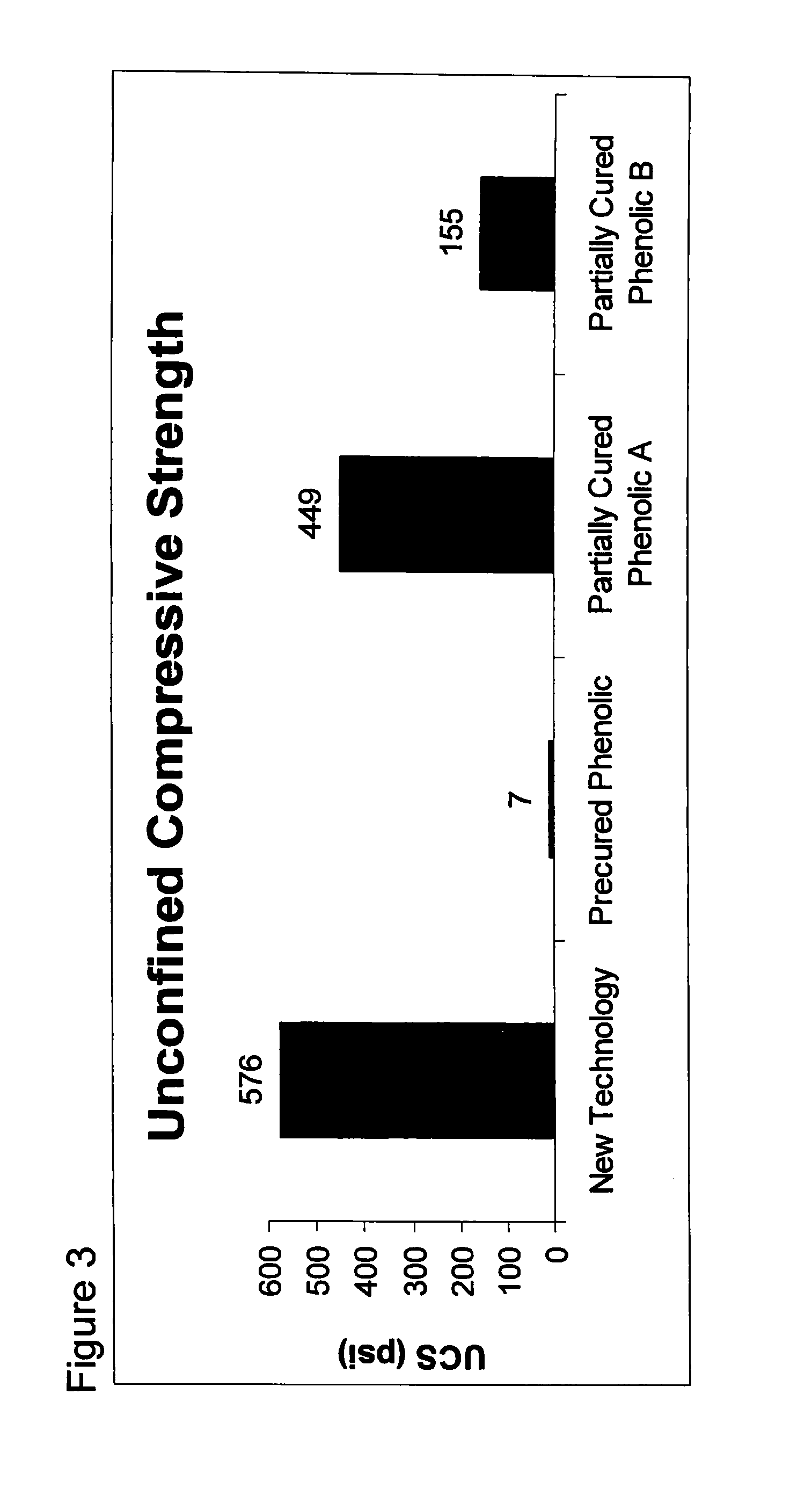

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

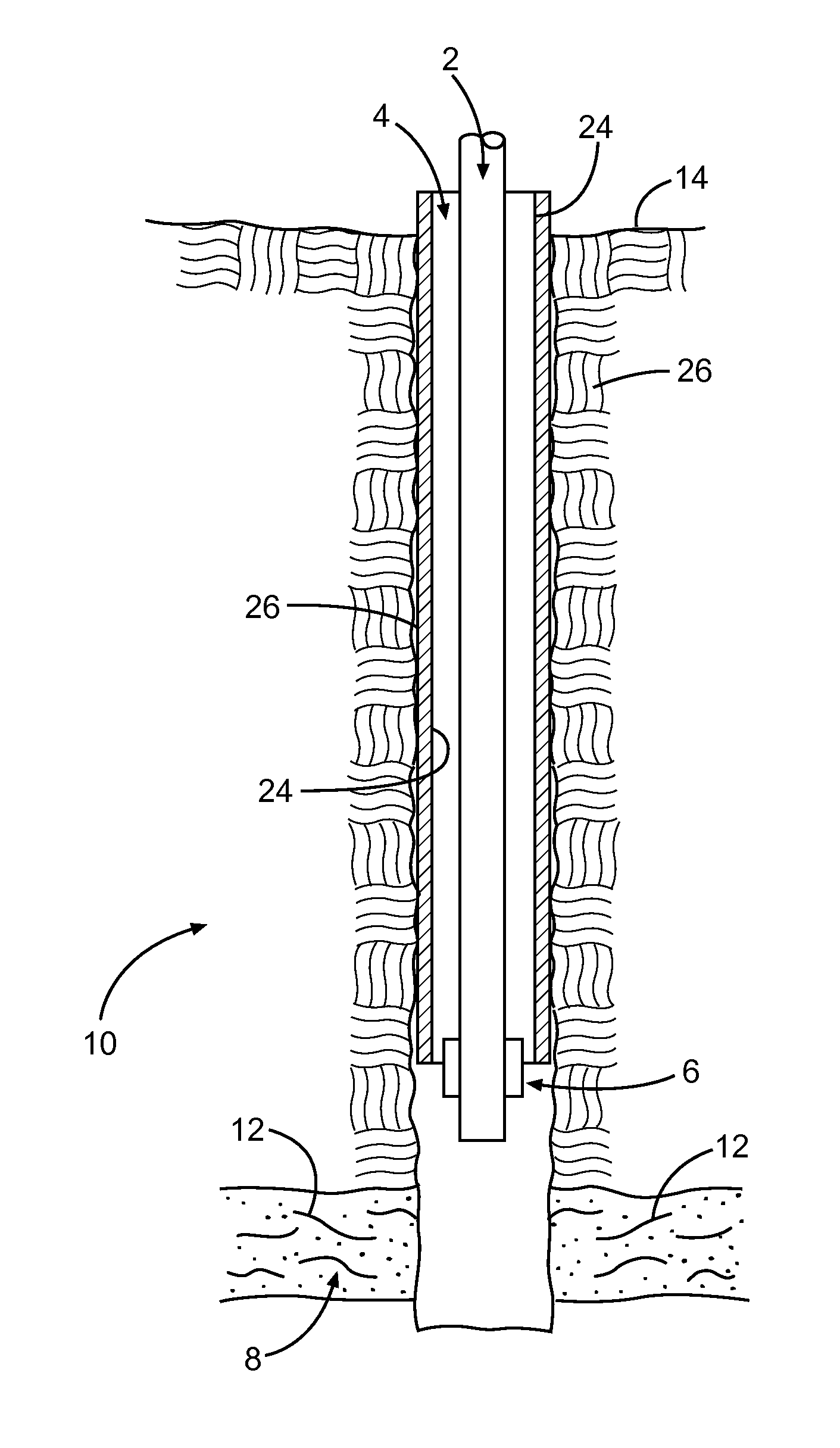

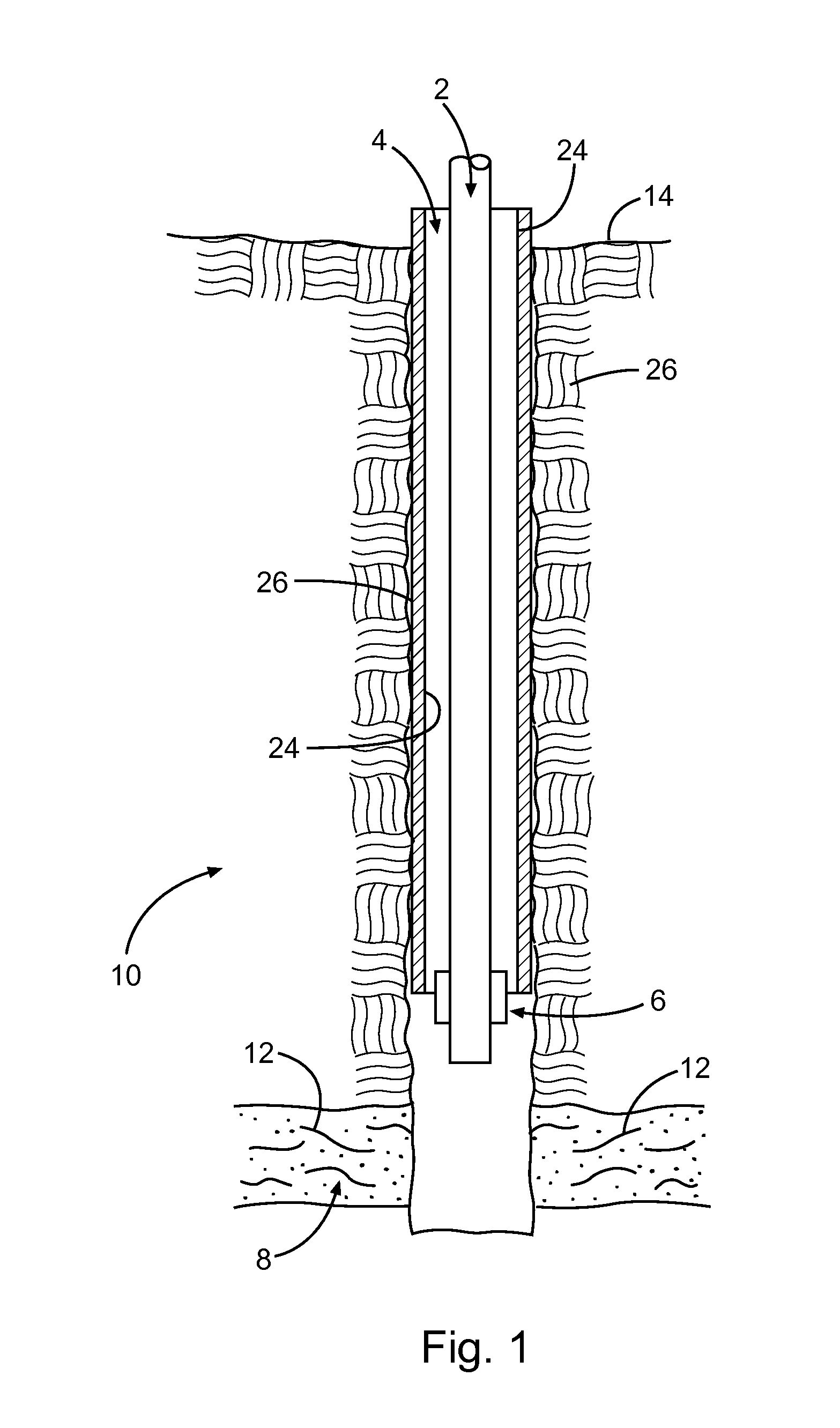

Methods for treatment of a subterranean formation

The present invention relates to methods of treating subterranean formations. In various embodiments, the present invention provides a method of treating a subterranean formation including placing a first aqueous composition and a second aqueous composition in a subterranean formation. The placing includes injecting the first aqueous composition through a tubular passage in a wellbore. The placing also includes injecting the second aqueous composition through an annular passage in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

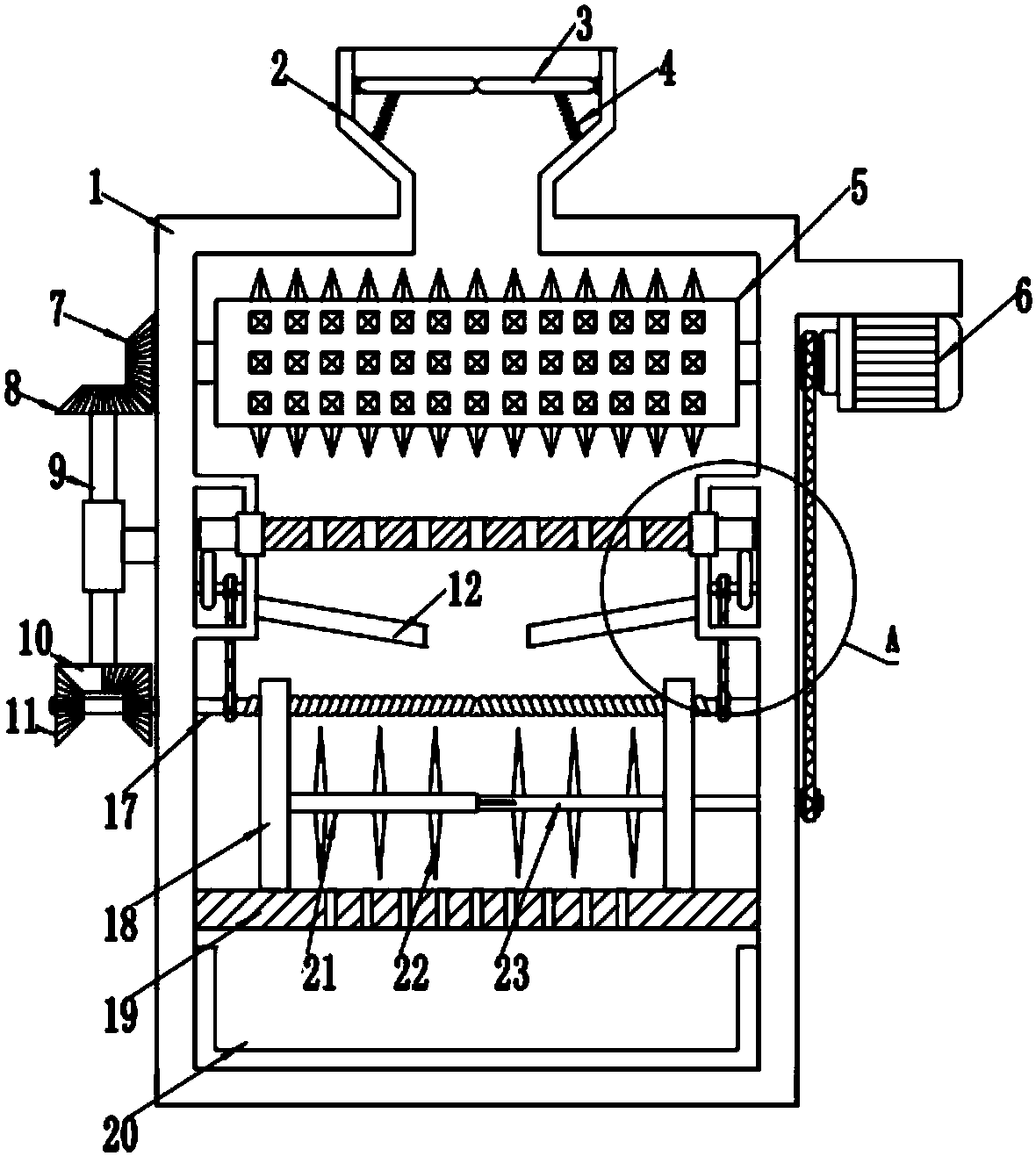

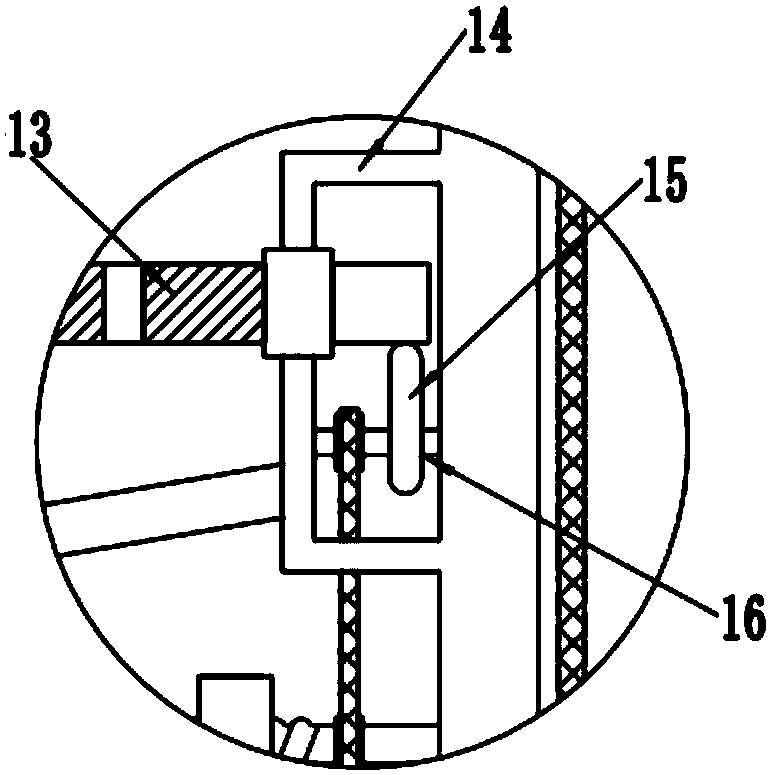

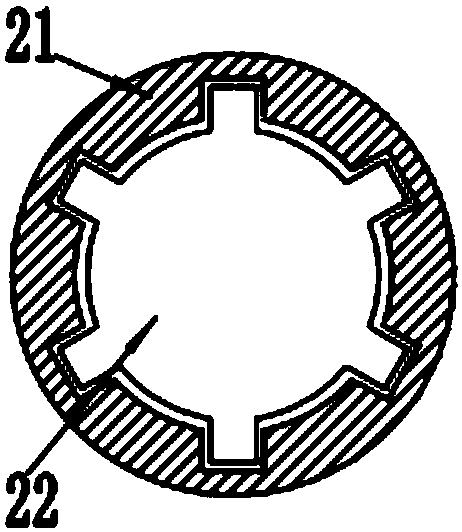

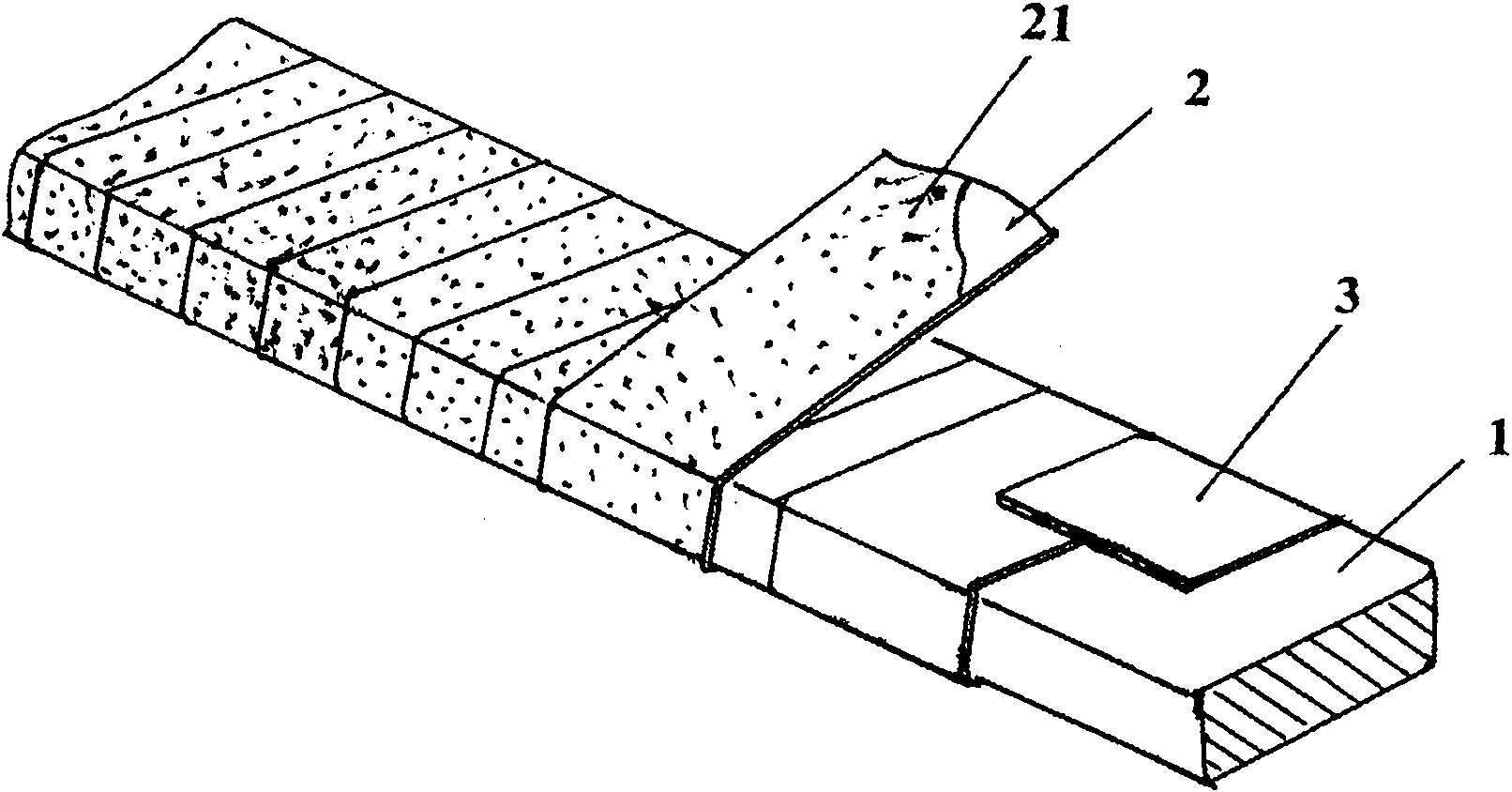

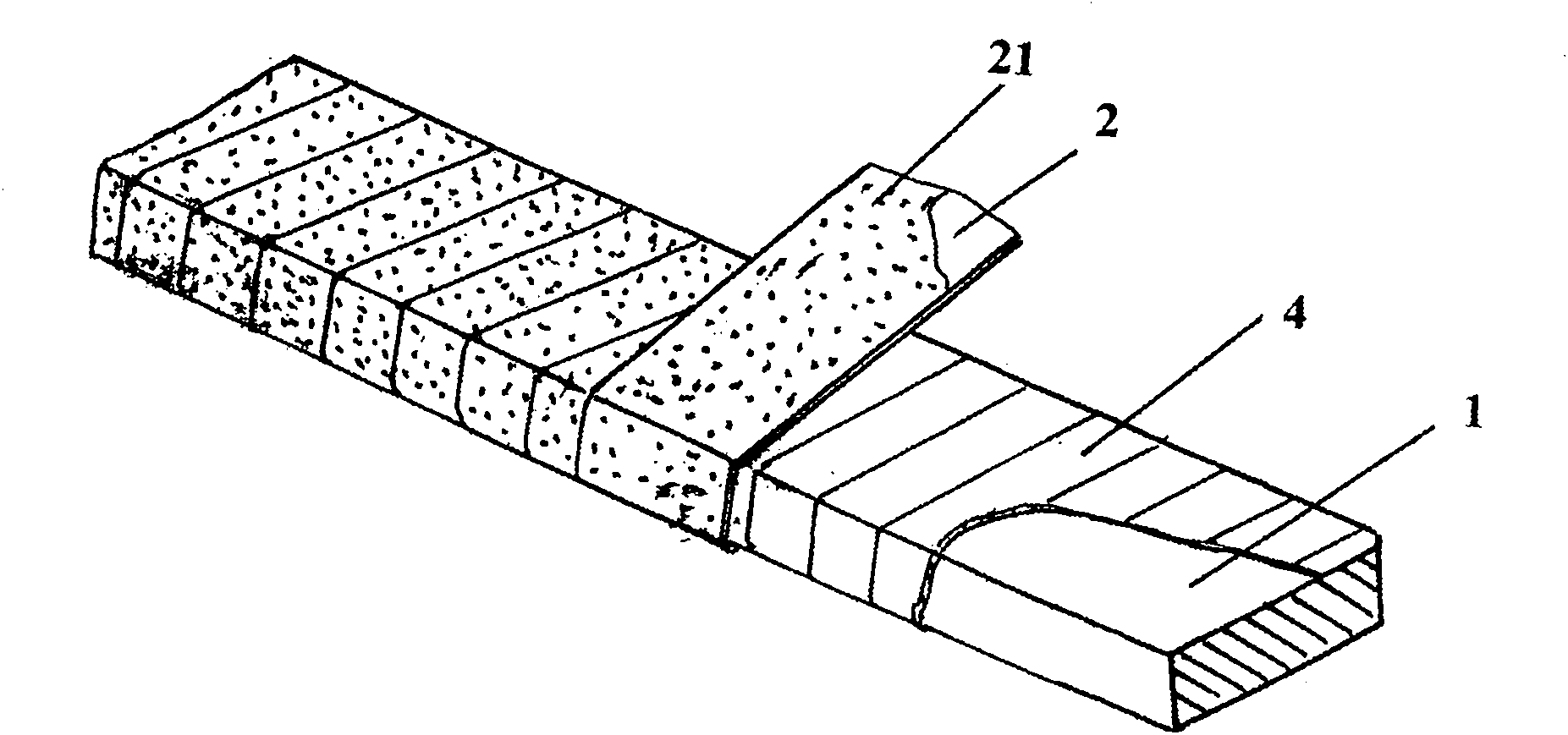

Wood crushing device for papermaking

InactiveCN108525752AAvoid environmental impactImprove screening efficiencySievingScreeningPapermakingEngineering

The invention discloses a wood crushing device for papermaking. The wood crushing device comprises a shell, a feeding hopper, a dustproof mechanism, a primary crushing mechanism, an extruding and crushing mechanism and a collection groove, wherein the primary crushing mechanism is arranged at the upper end of the inner side of the shell; the primary crushing mechanism comprises a crushing roller,a motor, a first sieving plate, a sliding rail, an eccentric wheel and a second rotating rod; the extruding and crushing mechanism is arranged below the primary crushing mechanism; the extruding and crushing mechanism comprises a bidirectional thread rod, side plates, a second sieving plate, a sleeve, a crushing blade and a rotating shaft. The wood crushing device disclosed by the invention is novel in design; the dustproof mechanism can be used for effectively preventing wood dust generated in a wood crushing process from flying out to lead the environment influence; when the bidirectional thread rod rotates, the two side plates are driven to do face-to-face movement or opposite-direction movement; when the side plates do face-to-face movement, wood blocks at the inner sides of the side plates can be pressurized and gathered toward the middle, so that the crushing effect of the wood blocks is improved.

Owner:苏加强

Low emission, non-oxygenated fuel composition

InactiveUSH2182H1Good performanceGood emissionSolid fuelsLiquid carbonaceous fuelsChemistryReid vapor pressure

Provided is an unleaded gasoline fuel which is substantially free of oxygenates, and most preferably contains substantially zero oxygenates. The gasoline fuel also has a Reid vapor pressure less then 7.5 psi, a sulfur content less than 30 ppmw, an aromatic hydrocarbon content between 25 and 30 volume percent, and / or a 50% D-86 Distillation Temperature between 210 and 220.degree. F., and / or a 90% D-86 Distillation Temperature between 300 and 330.degree. F., and the fuel composition fails the California Predictive Model requirements for emissions. Preferably, the olefin content of the fuel is also 8 volume percent or less. Such a gasoline fuel offers a substantially oxygenate free gasoline which avoids the environmental impact of oxygenates, yet when combusted in an internal combustion automobile provides good performance and good emissions, despite failing the California Predictive Model. The gasoline fuel in particular can provide surprisingly lower NO.sub.x emissions than that predicted by the California Predictive Model.

Owner:CHEVROU USA INC

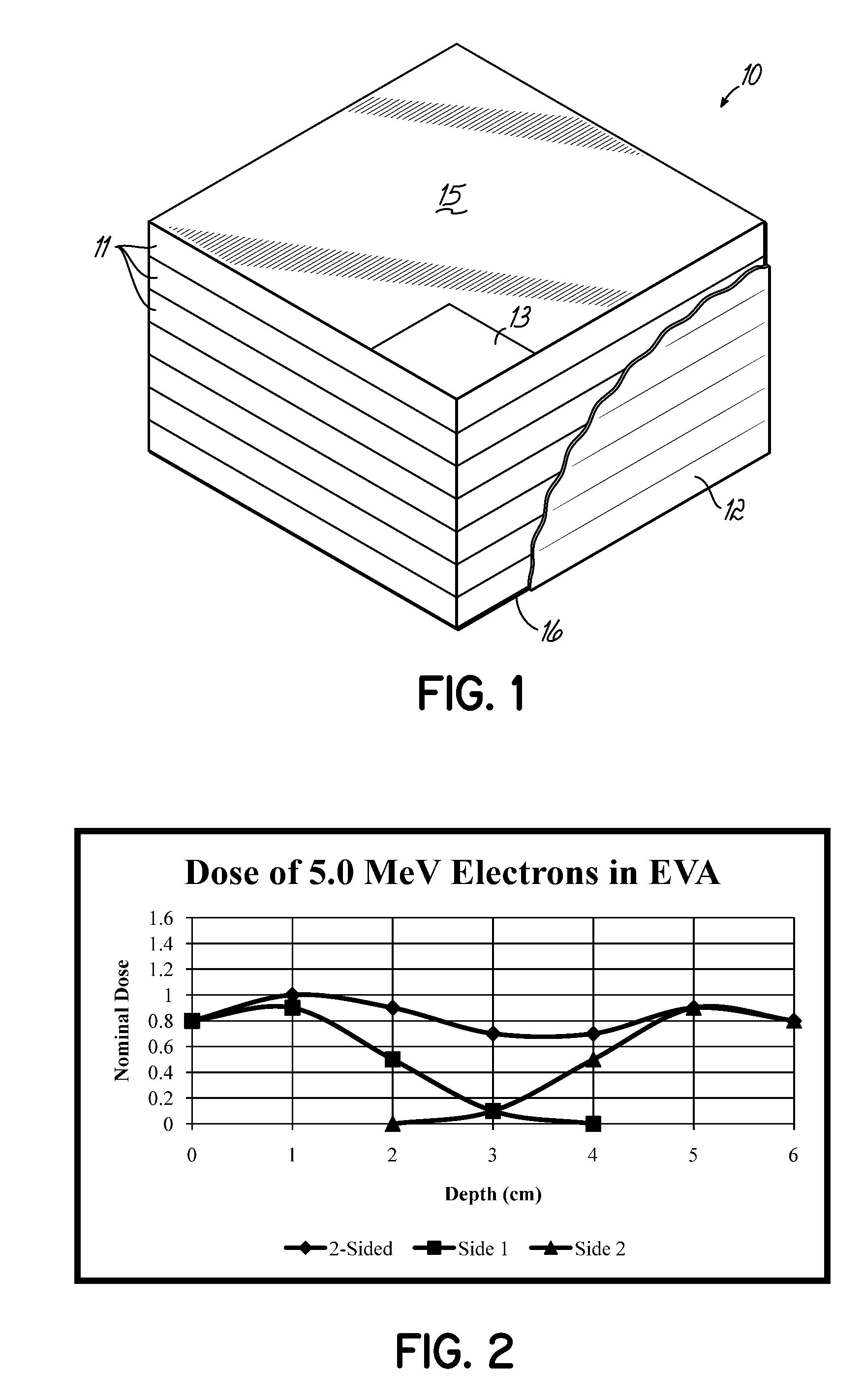

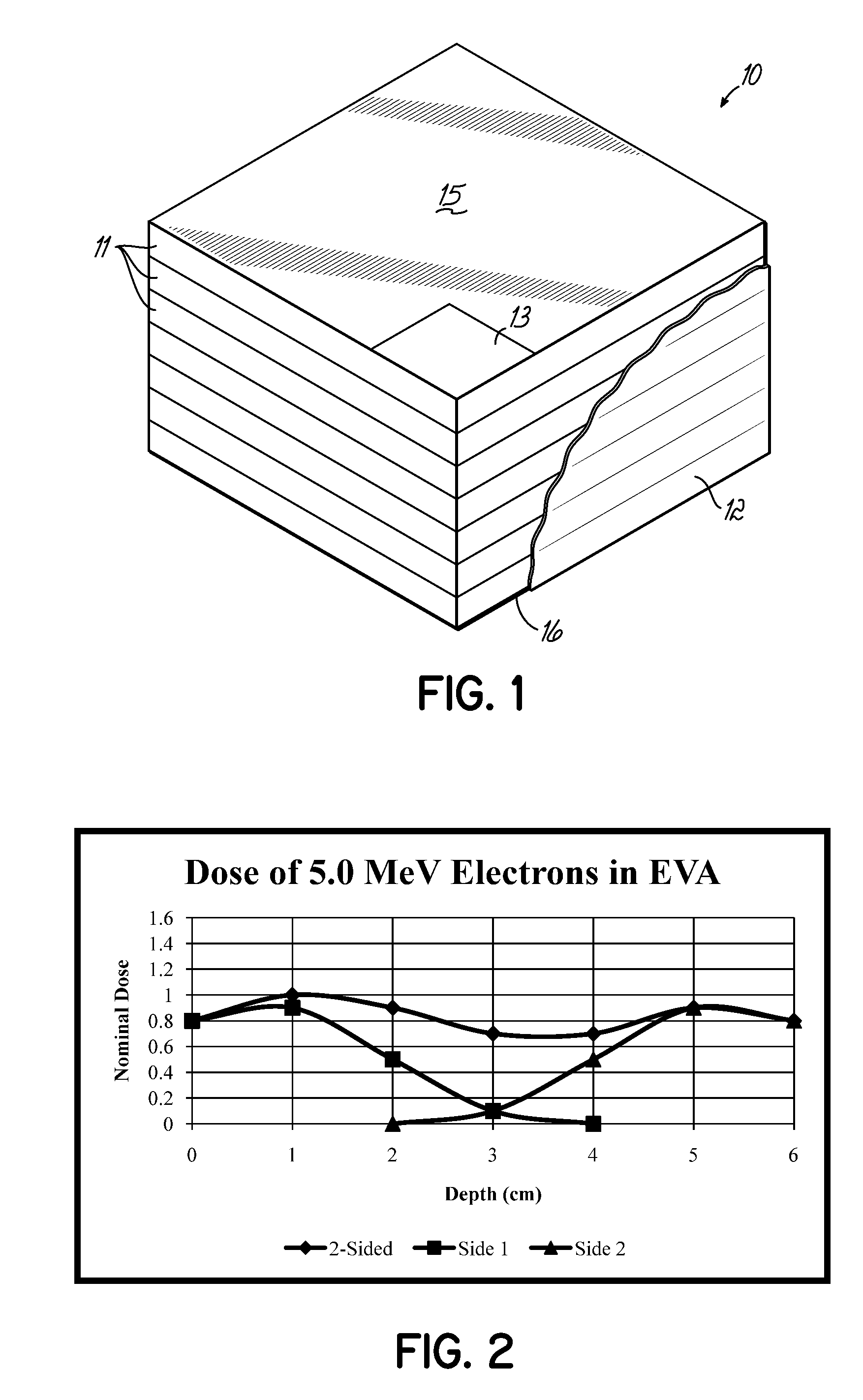

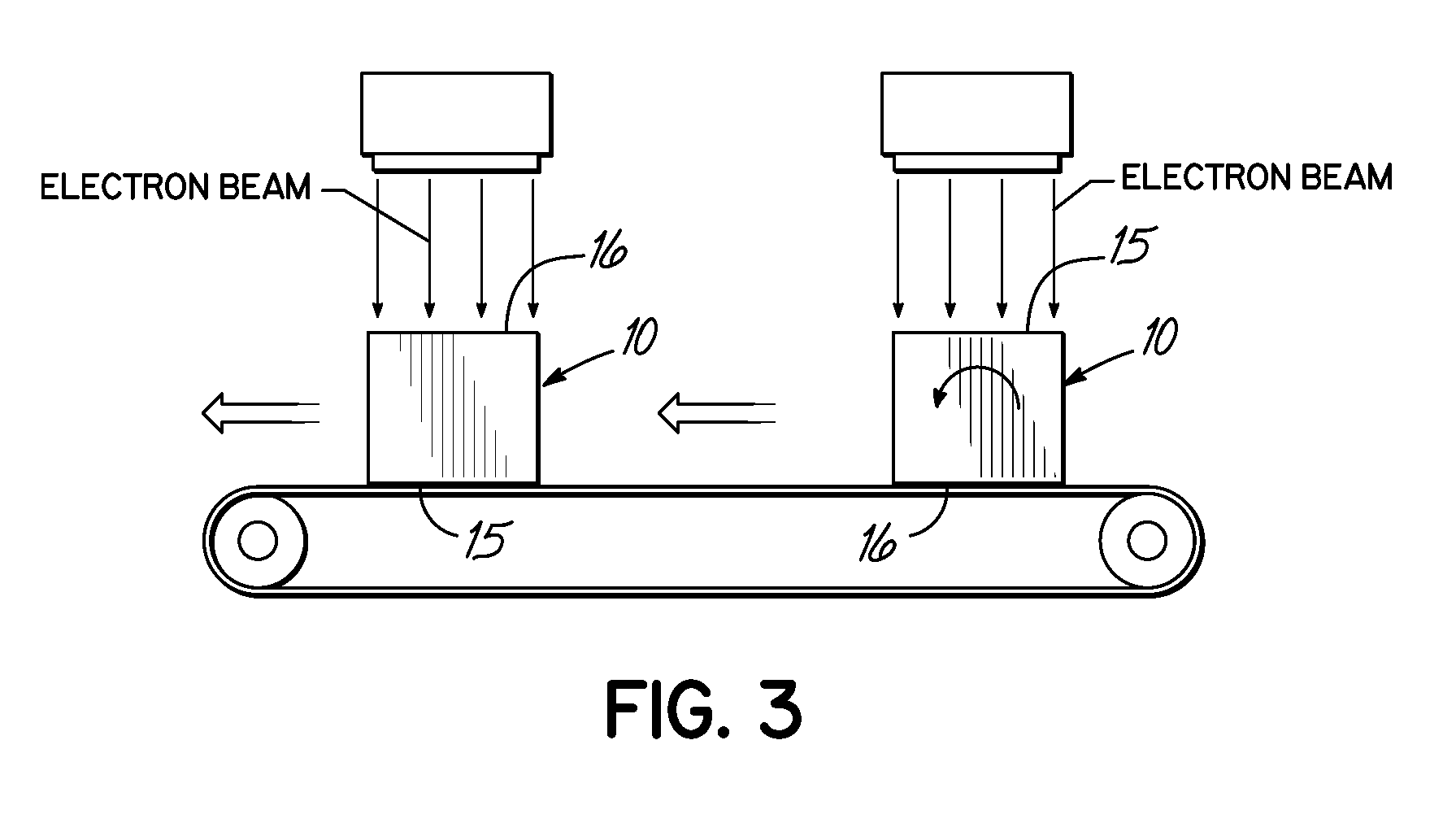

Electron Beam Irradiation of Bulk Material Solids

ActiveUS20110031657A1Easy to handleEasy disposalElectric discharge tubesSolid materialHigh energy electron beamElectron

Owner:E BEAM SERVICES

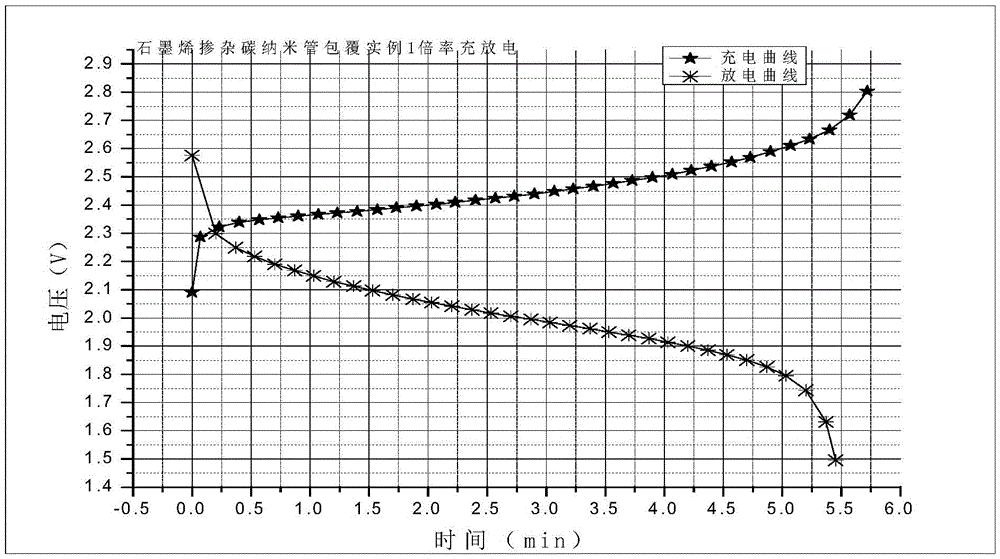

Lithium titanate electrode material and preparation method thereof

ActiveCN105552357AImprove conductivityIncrease capacitySecondary cellsNegative electrodesHigh rateCarbon nanotube

The invention relates to a lithium titanate electrode material and a preparation method thereof. The preparation method of the lithium titanate electrode material comprises the following steps: (1) mixing water, saccharose and triton X-100, and adding graphene and a carbon nanotube for stirring to obtain slurry A; (2) feeding the slurry A to a grinder, adding zirconia particles for grinding at the rotating speed of 150-250r / min for 60-300 minutes, adding lithium titanate to the ground slurry A for mixing and stirring to obtain slurry B; and (3) carrying out drying treatment on the slurry B to obtain the lithium titanate electrode material. Compared with the prior art, by the lithium titanate electrode material, the battery capacity can be improved by 1%-8%; the discharge rate is improved by 1%-5%; rapid charging is achieved; and meanwhile, the problem of heating of the battery in the high-rate charge-discharge process can be reduced.

Owner:YINLONG ENERGY CO LTD

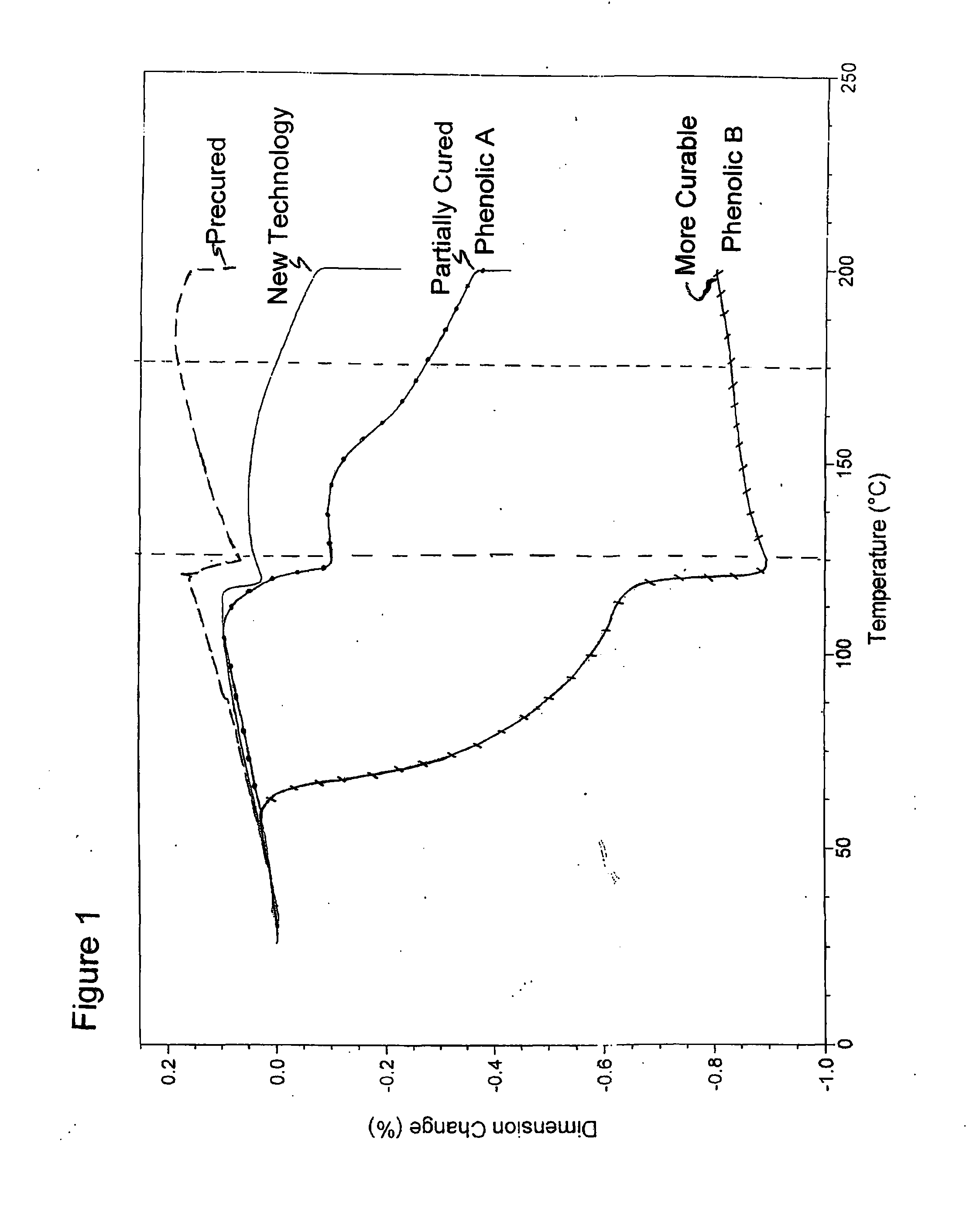

Coated and cured proppants

ActiveUS9290690B2Solve the lack of resistanceResistant to leachingPretreated surfacesFluid removalWashoutHigh pressure

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

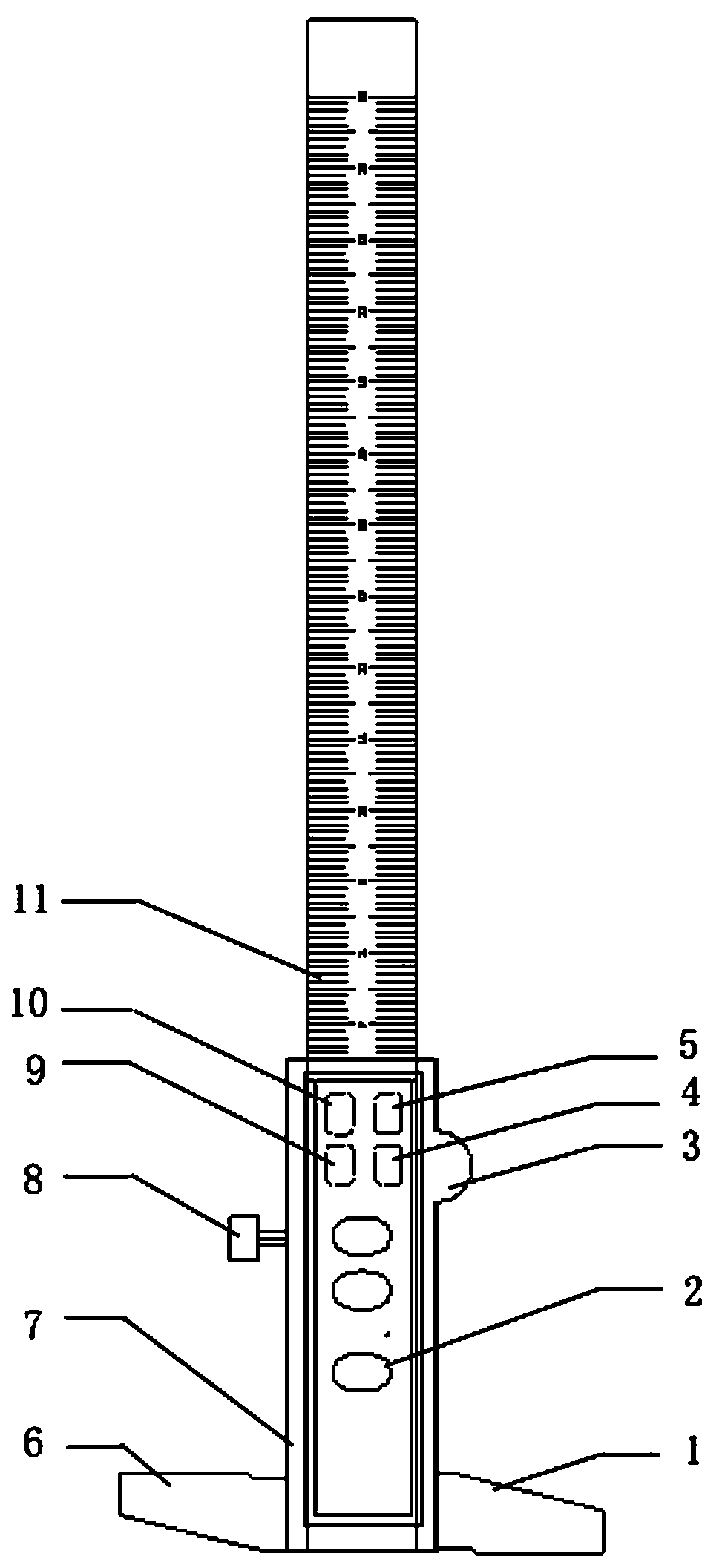

Digital display type multifunctional measuring ruler for shield TBM tunnel

PendingCN109186405AImprove construction qualityAvoid environmental impactMechanical clearance measurementsDisplay deviceMeasuring ruler

The invention relates to a digital display type multifunctional measuring ruler for a shield TBM tunnel. The measuring ruler comprises a measuring ruler body, a digital display device, an upper shiftclaw (6) and a lower shift claw (1), wherein the measuring ruler body comprises a measuring main ruler (11) and a measuring base (12); the digital display device (7) comprises a result digital displayscreen (2), a pulley (3), a switch checker (4), a zero setting button (5), a fixing bolt (8), a shield tail gap measurement mode button (9) and a duct piece dislocation measurement mode button (10);the digital display device (7) sleeves the measuring main ruler (11), and the digital display device (7) and the measuring main ruler (11) can move relatively. The upper shift claw (6) and the lower shift claw (1) are fixed on the digital display device (7); and the lower end surfaces of the upper shift claw (6) and the lower shift claw (1) are flush with the lower end surfaces of the digital display device (7) and the measuring base (12). According to the digital display type multifunctional measuring ruler, a shield tail gap and duct piece dislocation can be more conveniently and accuratelymeasured in a tunnel construction environment; the operation is simple; the numerical value is accurate; and a result is convenient to read.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +3

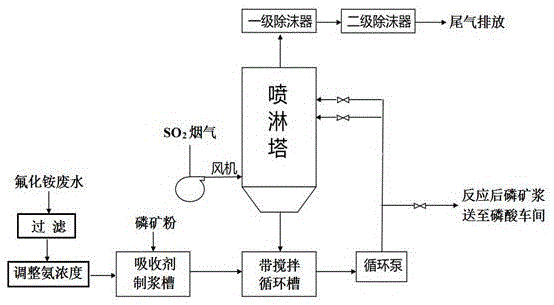

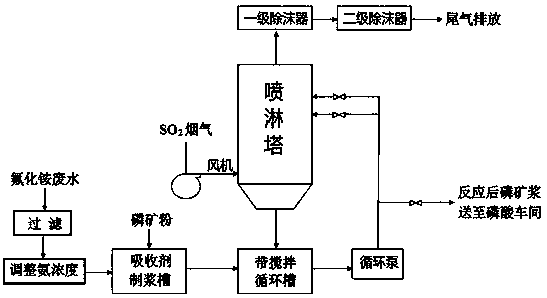

Method for preparing phosphoric ore slurry desulfurizer by ammonium fluoride wastewater

ActiveCN105536492AAvoid environmental impactImprove desulfurization efficiencyGas treatmentDispersed particle separationFlue gasPhysical chemistry

Large volume of flue gas containing sulfur dioxide with low concentration is generated in an industrial process, phosphoric ore slurry desulfurization has obvious technical advantages in phosphorus chemical production enterprises, so the popularization and application are achieved. The absorption efficiency of phosphoric ore slurry to sulfur dioxide is not stable due to the influence of fluctuation of flue gas volume and change of the sulfur dioxide concentration in the flue gas. The method provided by the invention adopts ammonium fluoride wastewater and phosphate rock powder discharged in the phosphorus chemical enterprises to prepare a desulfurization absorber, so that the sulfur dioxide with low concentration in the flue gas can be absorbed. The method comprises the steps of uniformly mixing the pretreated ammonium fluoride wastewater and fine-grained phosphoric ore to obtain the desulfurization absorber with 15 to 50 percent of solid content, and the pH value is 8.0 to 9.0, the liquid-gas ratio is controlled to be 4-12 L / m<3> in an absorption process; when the pH value of circulating slurry is less than 4.0, discarding 50 percent of absorption slurry, and adding the same amount of newly prepared phosphoric ore slurry absorption liquid into a circulating tank. The prepared absorbent has stable desulphurization efficiency, and the obvious influences of the sulfur dioxide concentration and of the fluctuation of the flus gas volume to the absorption efficiency of the sulfur dioxide do not exist. According to the method, waste control by waste is realized, and the method has the characteristics of being simple in process facility, low in cost of operation, cheap and easily obtained materials.

Owner:KUNMING ECON TECH CO LTD

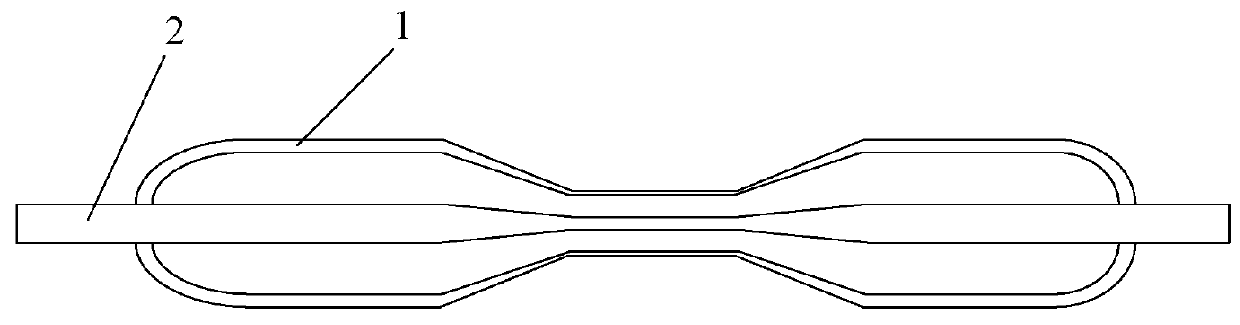

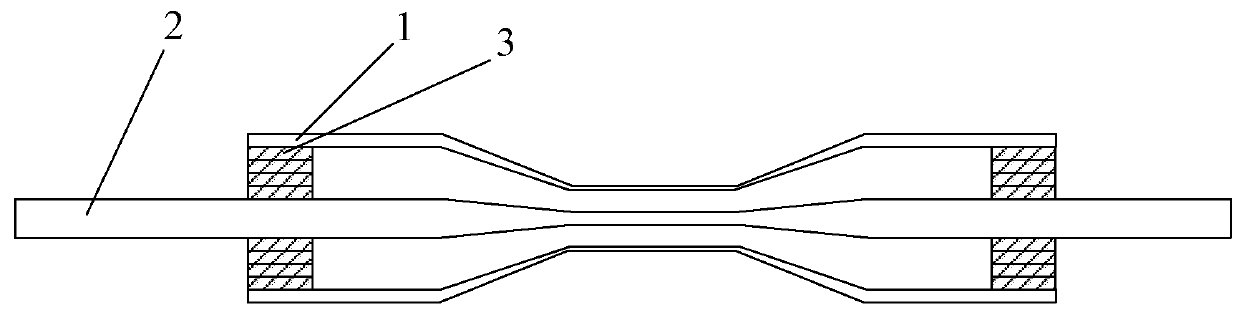

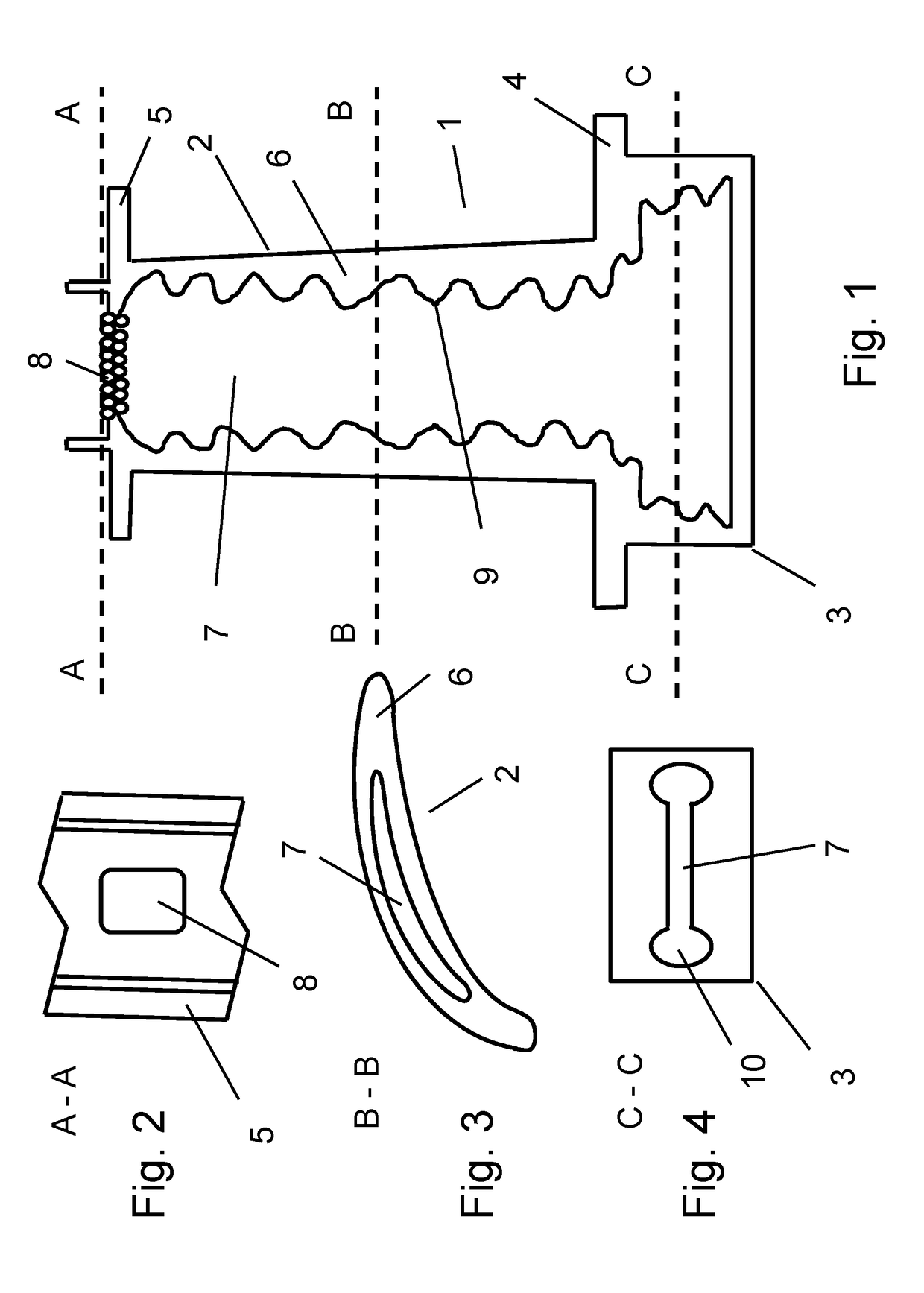

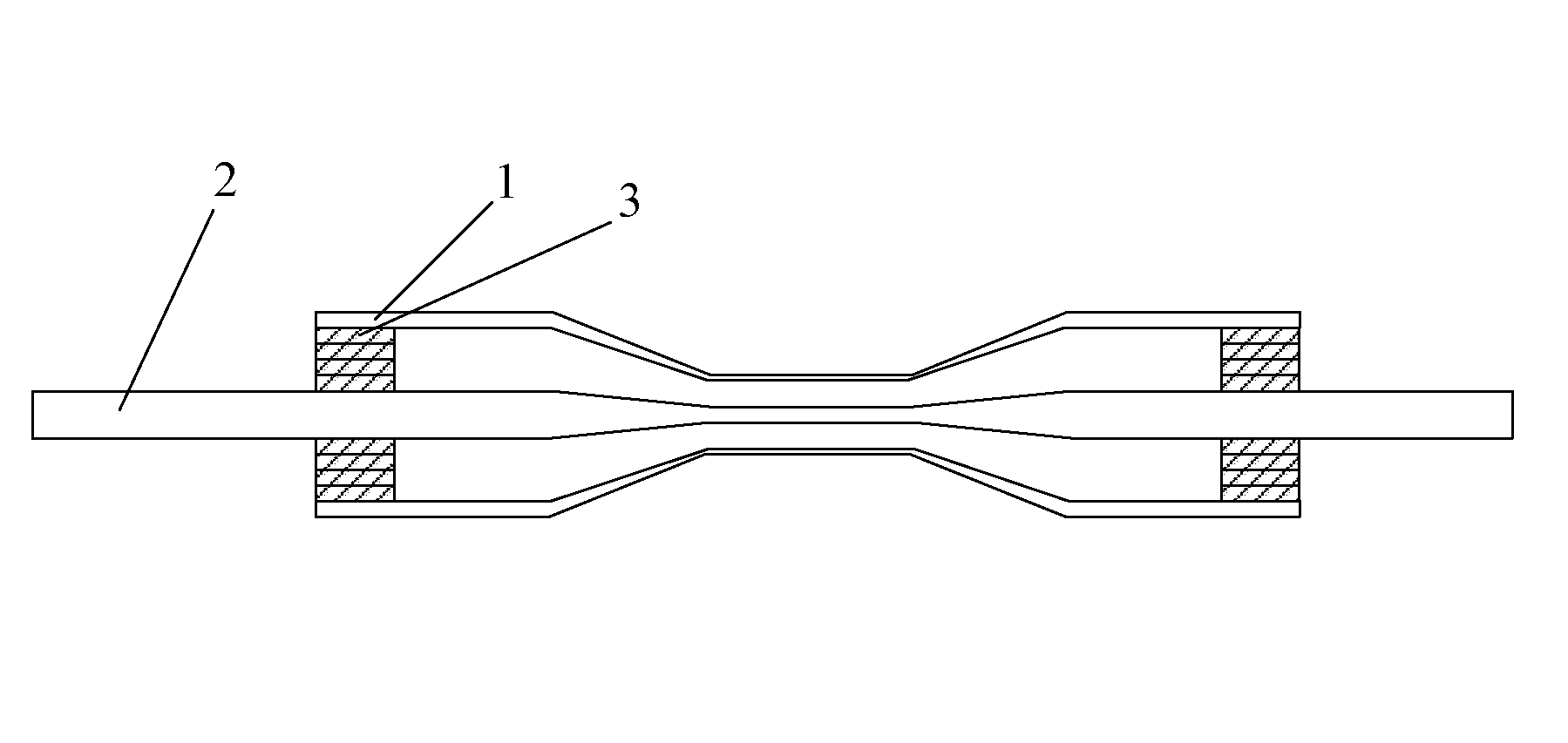

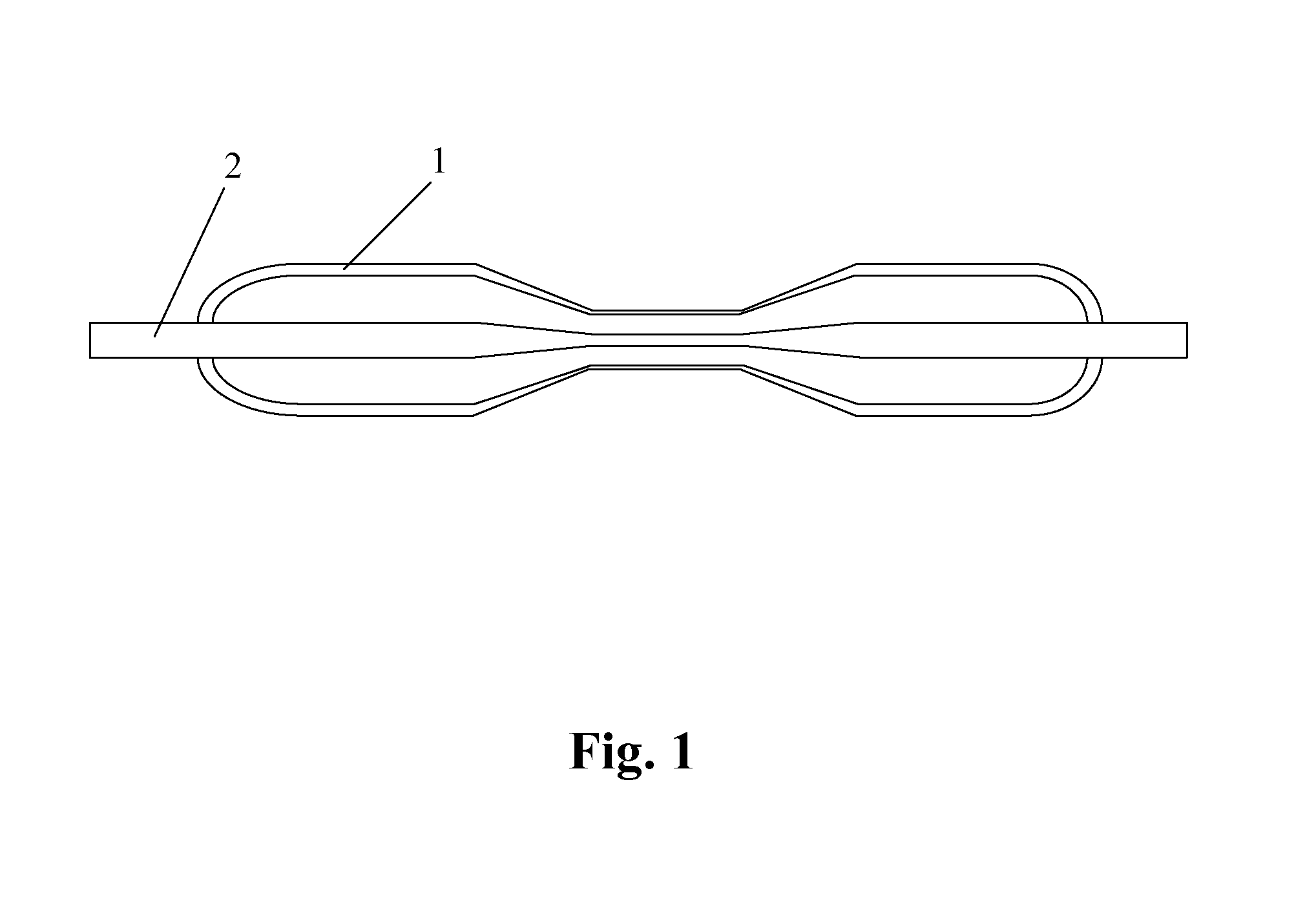

Optical fiber microwire devices and manufacture method thereof

ActiveUS20160033721A1Simple configurationSuitable for manufactureGlass making apparatusMaterial analysis using wave/particle radiationSolid structureOptical fiber cable

Herein presents an optical fiber microwire device, wherein the device comprising a silica tube, an optical fiber (2) inserted into the silica tube (1) and pigtailed at two sides, wherein the two ends of the silica tube (1) are fused with the optical fiber (2) to form a solid structure, or the two ends of the silica tube (2) are filled with silica rods (3), silica capillaries (4) or segments of optical fibers and fused to form a solid structure. The silica tube (1) together with the optical fiber (2) inside is then tapered to form a micro structure region. Therefore, the micro structure region is consisted of the tapered optical fiber as the microstructure core, tapered silica tube, and the air in between. This invention combine the manufacture of optical fiber microwire and the sealing process, avoiding the disadvantages of the conventional tapered optical fiber microwire, such as fragile mechanical structure, and sensitive to the outer environment variations.

Owner:JIANGSU UNIV

Production of biochar absorbent from anaerobic digestate

ActiveUS9381493B2Avoid environmental impactHigh activityBio-organic fraction processingMethane captureActivated carbonSource material

A novel carbon absorption material is described which is formed from anaerobic digestate. The material has a hollow tubular structure and is particularly advantageous in converting hydrogen sulfide in biogas and in absorbing the converted sulfur and sulfur compounds from biogas into its structure. The material after use as a hydrogen sulfide absorbent has value as a horticultural or agricultural product or as a sulfur impregnated activated carbon. The process for producing this novel carbon absorption material is described. In an embodiment, the process described uses in particular, a humidified inert gas over a temperature range of between about 500° C. to 900° C. to convert anaerobic digestate to an active carbon absorbent. The thermal treatment is relatively mild and retains the fibrous structure of the source material while removing cellulosic and hemicellulosic components from the anaerobic digestate.

Owner:CHAR TECH INC

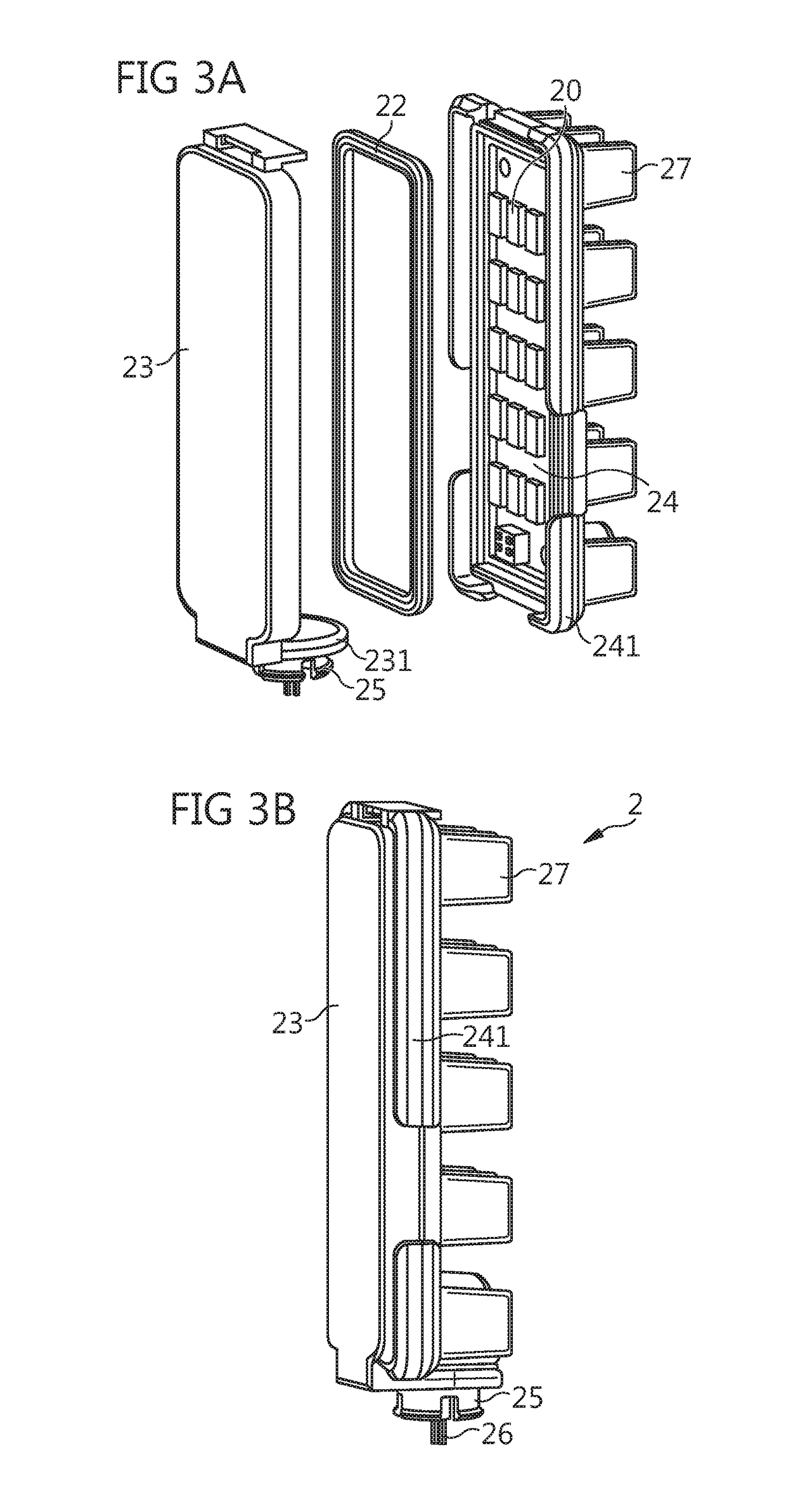

Fixed electronic transmission control module

InactiveCN102537305AAvoid environmental impactAvoid short circuitCasings with connectors and PCBFinal product manufacturePrinted circuit boardElectricity

The present invention provides an electronic control module (1) for controlling a transmission and a corresponding method for manufacturing the electronic control module (1), wherein, the control module (1) is provided with the following components: a controller (3) which is used for controlling the transmission, a printed circuit board (5) and a supporting plate (7), wherein, the printed circuit board (5) is electrically connected with the controller (3). Furthermore, the printed circuit board (5) and the controller (3) are connected through hollow rivets (9) for becoming a first unit (11). The first unit (11) is fixed on the supporting plate (7) by means of fixing components (15), wherein, the fixing components (15) are equipped in hollow gasp (49) of the hollow rivets (9).

Owner:ROBERT BOSCH GMBH

Electron beam irradiation of bulk material solids

ActiveUS8220226B2Easy to handleEasy disposalSolid materialRotary pressesHigh energy electron beamElectron bunches

Owner:E BEAM SERVICES

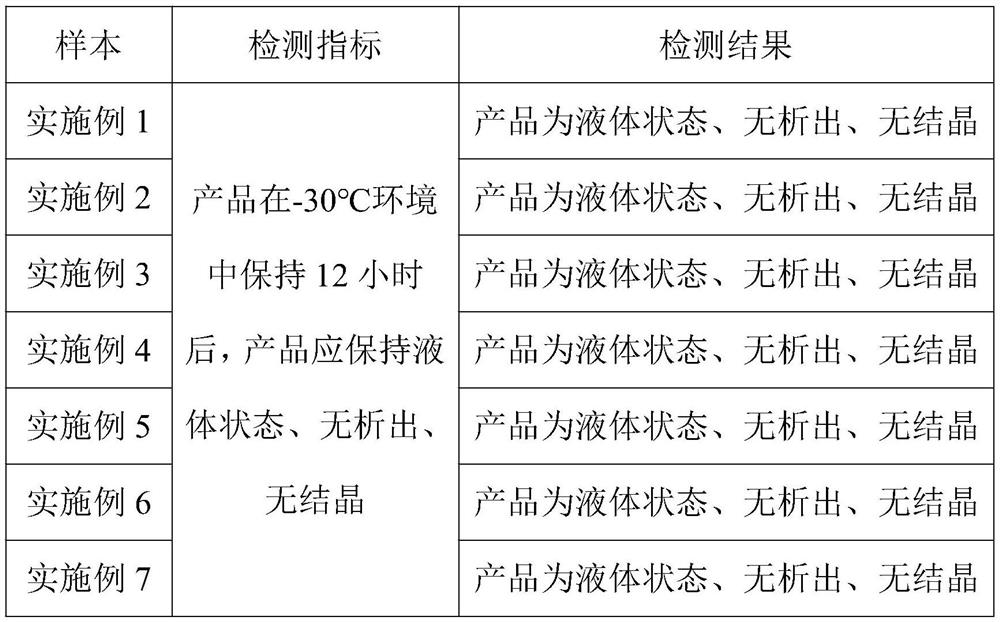

Low-temperature disinfectant and preparation method thereof

PendingCN113854309AMeet the needs of disinfection and sterilizationImprove stabilityBiocideFungicidesMeth-Disinfectant

The invention relates to the technical field of disinfectants, in particular to a low-temperature disinfectant and a preparation method thereof. The low-temperature disinfectant is prepared from components in percentage by mass as follows: 0.1%-1% of polyhexamethylene biguanide, 0.05%-0.1% of composite quaternary ammonium salt, 25%-35% of a synergist, 15%-25% of an anti-freezing agent, 0.1%-1.5% of a pH regulator and the balance of deionized water. The preparation method comprises the following steps: adding the deionized water, the polyhexamethylene biguanide and the synergist into a beaker, uniformly stirring and mixing the mixture, respectively adding the compound quaternary ammonium salt and the anti-freezing agent, stirring and dissolving the components, adding the pH regulator, and regulating the pH value of the mixed solution to 7.5-8.0 to prepare the low-temperature disinfectant. The low-temperature disinfectant is suitable for being used in a low-temperature environment at the lowest temperature of -30 DEG C, wherein the sterilization rate can reach 99.99% after acting on the surface of an object for 10 minutes, and a layer of sterilization protective film is formed on the surface of the object after 45 minutes, and the sterilization time is as long as 15 days. By means of the product, the labor cost and the sterilizing agent cost are saved, and the environmental influence caused by excessive spraying of the disinfectant is completely avoided.

Owner:重明鸟新材料盐城有限公司

New Use Of An Extract Of Plant Origin Of Globularia And Method For Obtaining Said Extract By In Vitro Plant Culture

ActiveUS20130309332A1Improve securitySupply rapidityBiocideCosmetic preparationsFine lineWrinkle skin

According to the present invention the extract of plant origin of the Globularia genus is used for a non-therapeutic cosmetic treatment of the skin and / or appendages. Preferably the species is Globularia cordifolia and the extract is obtained by in vitro plant culture. The extract can be used in particular for preventing and / or treating skin ageing by stimulating the 10 reactions of detoxification and cellular regeneration through a hormetic type response, for improving the transparency and radiance of complexion, for preventing or treating sensitive and reactive skins, for preventing or treating rednesses, for preventing protein glycation, for increasing and / or maintaining the number of dermal stem cells, for increasing and / or maintaining the dermal macromolecules, in particular collagen and elastin, for increasing the volume of the dermis, for 15 preventing and / or treating fines lines and wrinkles, for firming skin, for preventing hair loss and / or stimulating hair regrowth. The invention also proposes an original method of obtaining the extract by in vitro plant culture of undifferenciated cells of Globularia and an extract of plant origin that can be obtained by such method.

Owner:SEDERMA SA

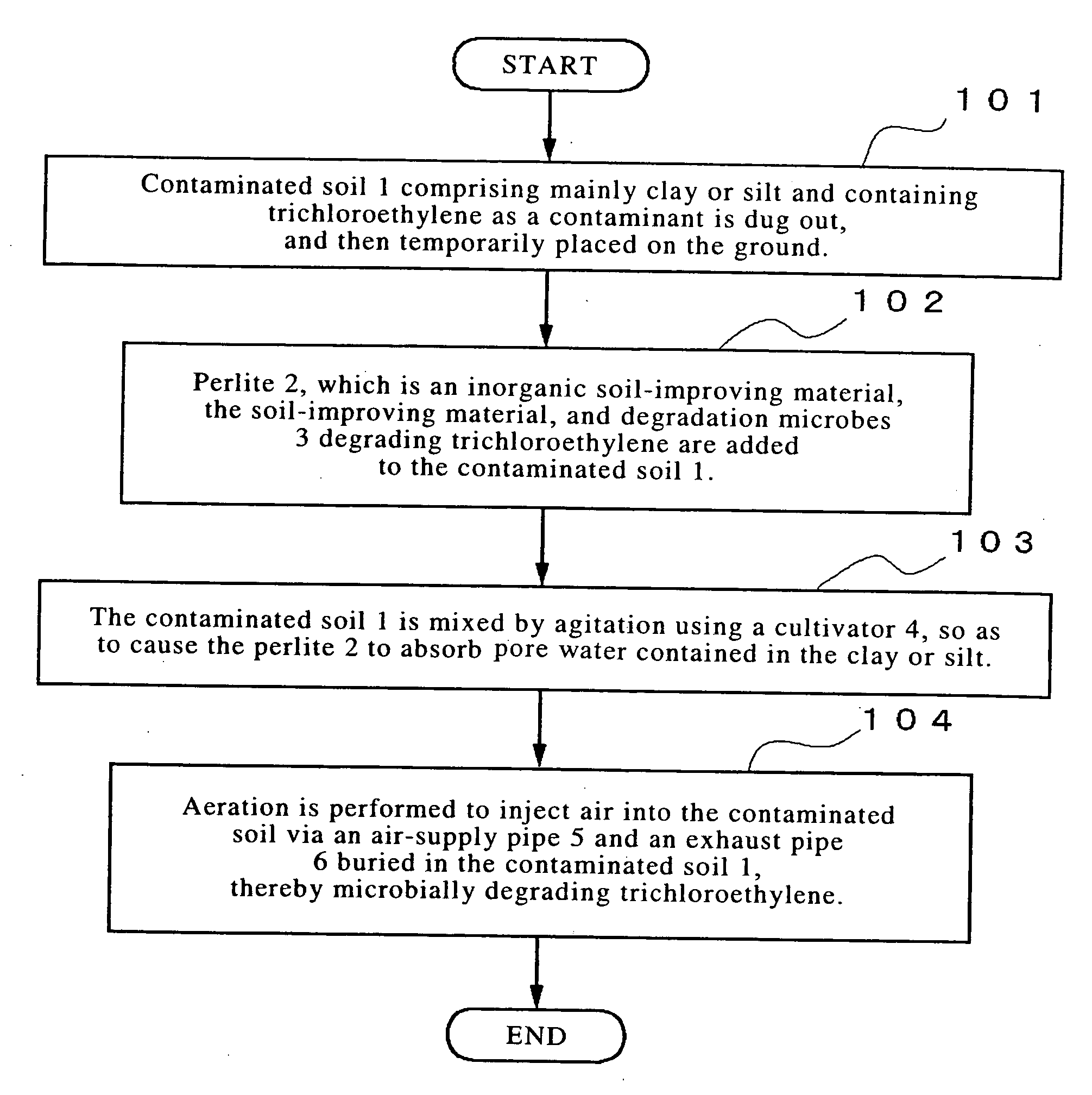

Method of purifying contaminated soil using microorganism

InactiveUS20050152746A1Avoid placingImprove degradation efficiencyAgriculture tools and machinesBacteriaMicroorganismTrichloroethylene

Contaminants are efficiently purified without affecting the environment or necessitating the performance of any post-treatments such as pH adjustment that would be used to prevent environmental impact, even when the contaminated soil is highly viscous. In the method of purifying contaminated soil by microorganisms according to the present invention, contaminated soil mainly comprising clay or silt and containing trichloroethylene as a contaminant is dug out, and then temporarily placed on the ground (step 101). Next, perlite 2, which is an inorganic soil-improving material, the soil-improving material, and degradation microbes 3 degrading trichloroethylene are added to the contaminated soil 1 (step 102). The contaminated soil is subsequently mixed by agitation, so as to cause the perlite 2 to absorb pore water contained in the clay or silt (step 103). Next, aeration is performed to inject air into the contaminated soil 1, thereby microbially degrading trichloroethylene (step 104).

Owner:TOYOTA JIDOSHA KK

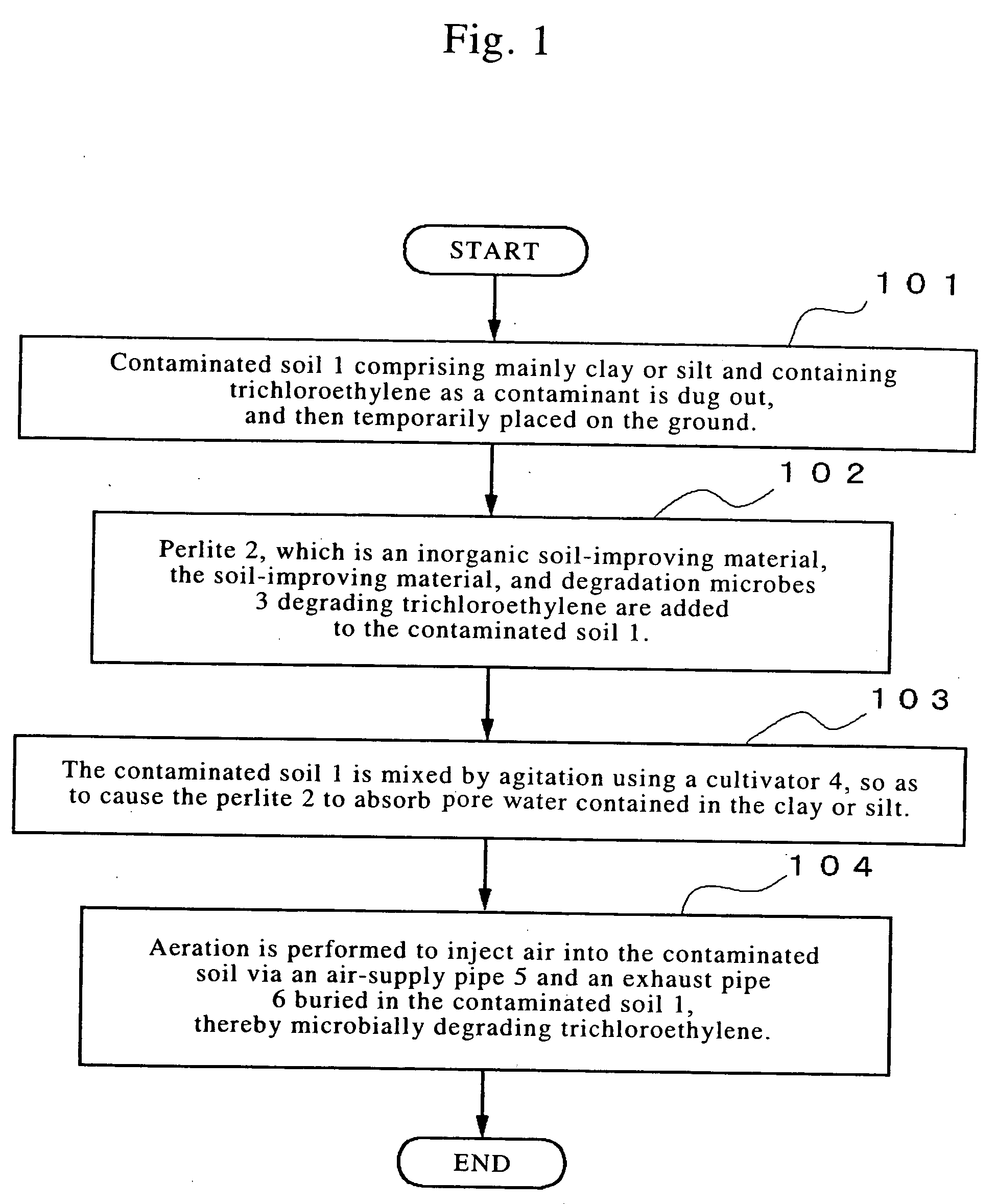

Garbage collection method, garbage collection system and arm-hook garbage can

PendingCN106742977AAvoid environmental impactReasonable mode of operationRefuse vehiclesTruckExperience base

The invention relates to a garbage collection method, a garbage collection system and an arm-hook garbage can. The garbage collection method comprises the following steps: a preset warning message for prompting of arm-hook garbage can cleaning is received, and a location of the arm-hook garbage can is determined according to the preset warning message; and the arm-hook garbage truck carries out garbage collection according to the location of the arm-hook garbage can. The arm-hook garbage truck can can carry out the garbage collection according to the location of the arm-hook garbage can determined by the warning message for the prompting of the arm-hook garbage can cleaning. Compared with the experience-based cleaning mode of the existing arm-hook garbage truck, when the cleaning requirement of the arm-hook garbage can is definite, location information of the corresponding arm-hook garbage can can be provided to the arm-hook garbage truck, so that the arm-hook garbage truck can accurately find the arm-hook garbage can to be cleaned and timely clean the arm-hook garbage can, environmental influence due to the fact that the arm-hook garbage can is not cleaned timely can be avoided to the greatest extent, the arm-hook garbage truck has a more reasonable operation mode, and the garbage collection cost is reduced.

Owner:XCMG CONSTR MACHINERY +1

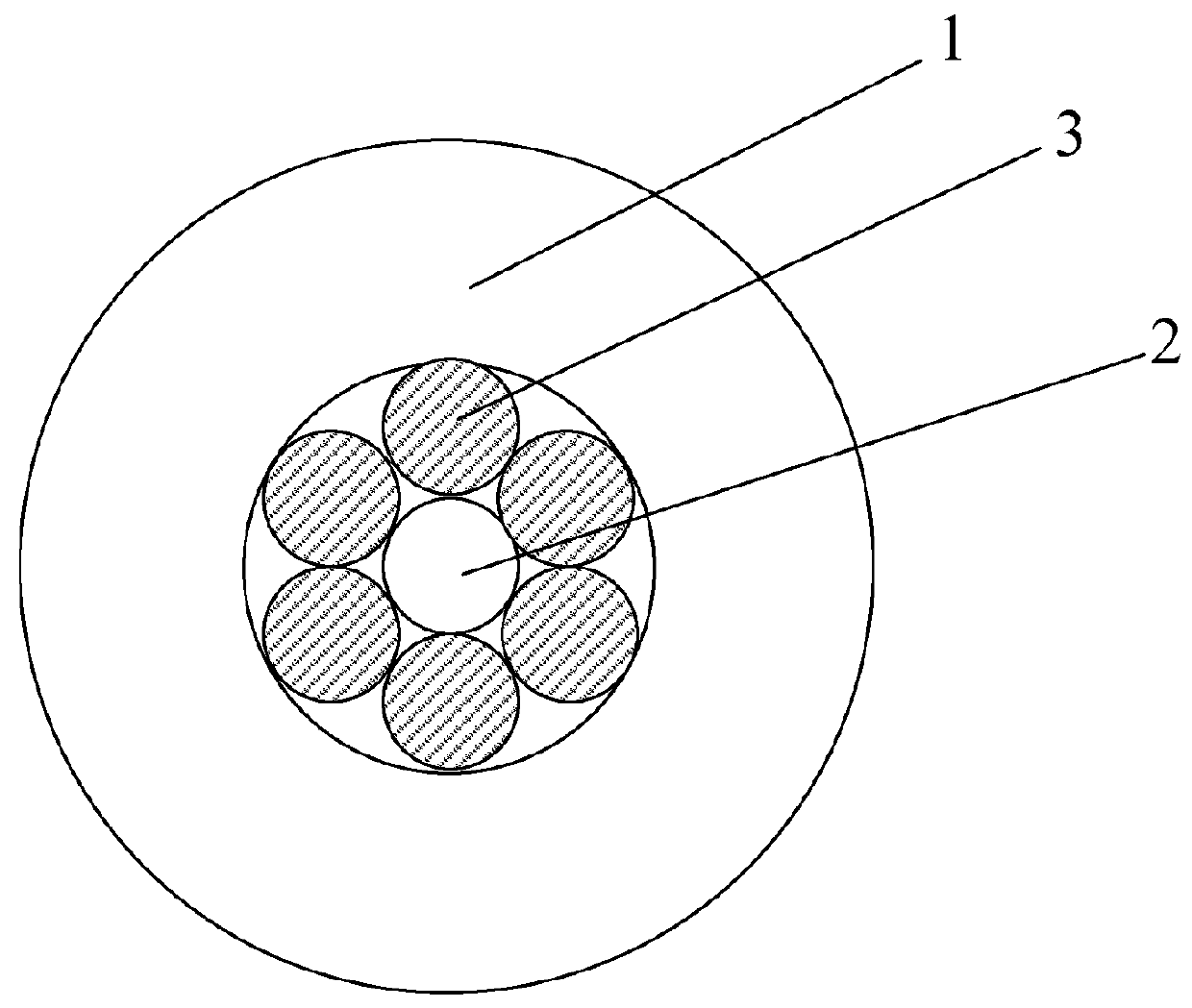

High density anti-compression optical fiber bundle optical cable for data center

PendingCN107884891AMeet the anti-lateral pressureSatisfy bending resistanceFibre mechanical structuresClimate change adaptationHigh densityPhosphate

The invention discloses a high density anti-compression optical fiber bundle optical cable for a data center. The optical fiber herein includes a micro-beam optical fiber, an aramid fiber layer whichcoats outside the micro-beam optical fiber, and a sheath layer which coats outside the aramid fiber layer. The sheath layer is embedded with three non-metal reinforcing members therein. The three non-metal reinforcing members constitute a triangle. The material of the sheath layer is composed of the following components by weight: polyurethane of 20-40 parts, polyvinyl choride of 25-45 parts, polyoxyalkylene modified polymethyl siloxane of 5-15 parts, chemigum of 20-30 parts, dibutoxyethyl adipate of 0.5-2 parts, trioctyl phosphate of 0.4-1 parts, modified filling material of 0.5-2 parts, a fire retardant of 2-4 parts, an activator of 0.2-0.6 parts, and a promoter of 0.5-1 parts. According to the invention, the optical fiber uses a center tubular structure, can ensure the moulding processof the optical fiber free from impact, and can also meet higher mechanical and environmental performances of the optical fiber.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

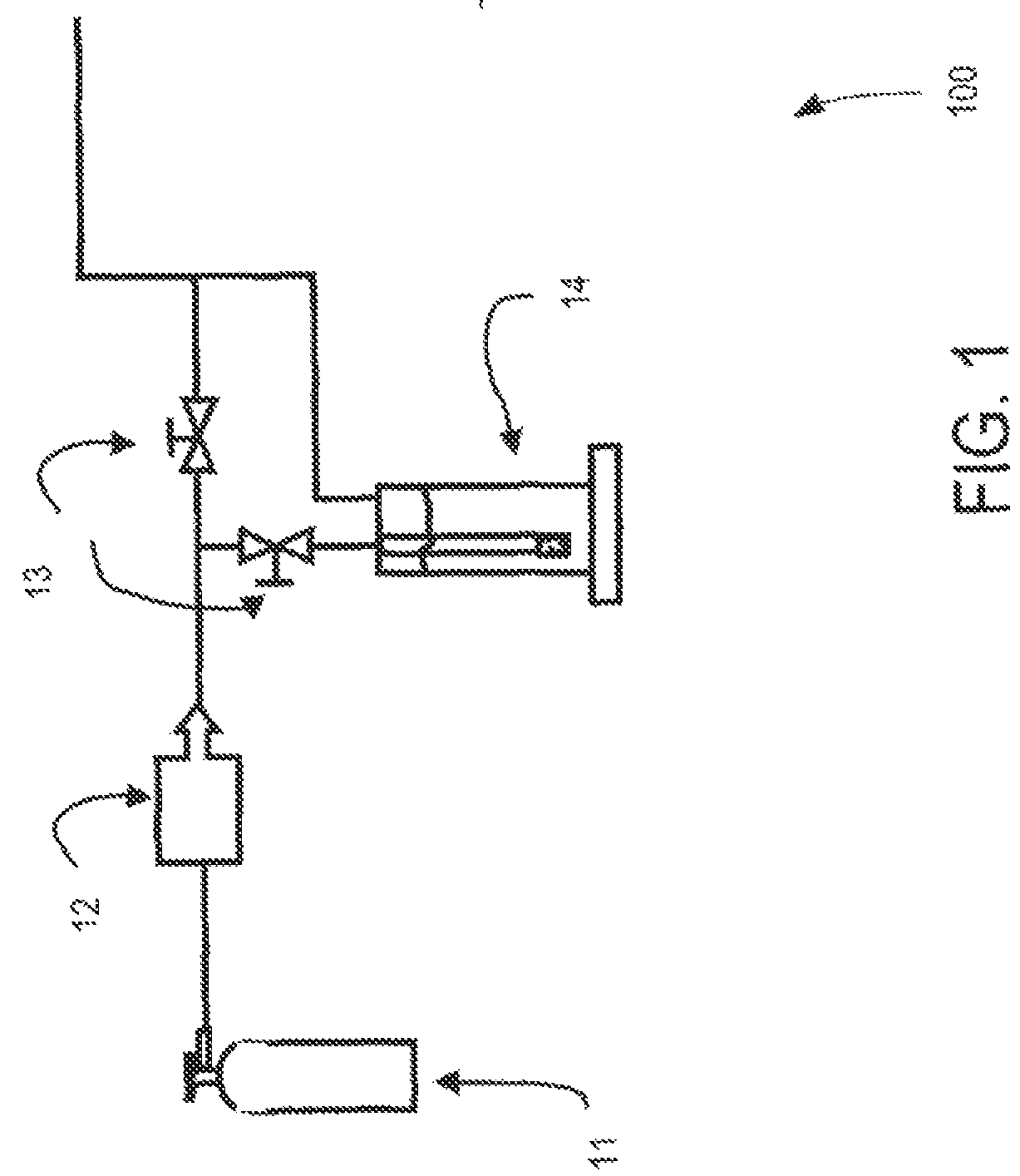

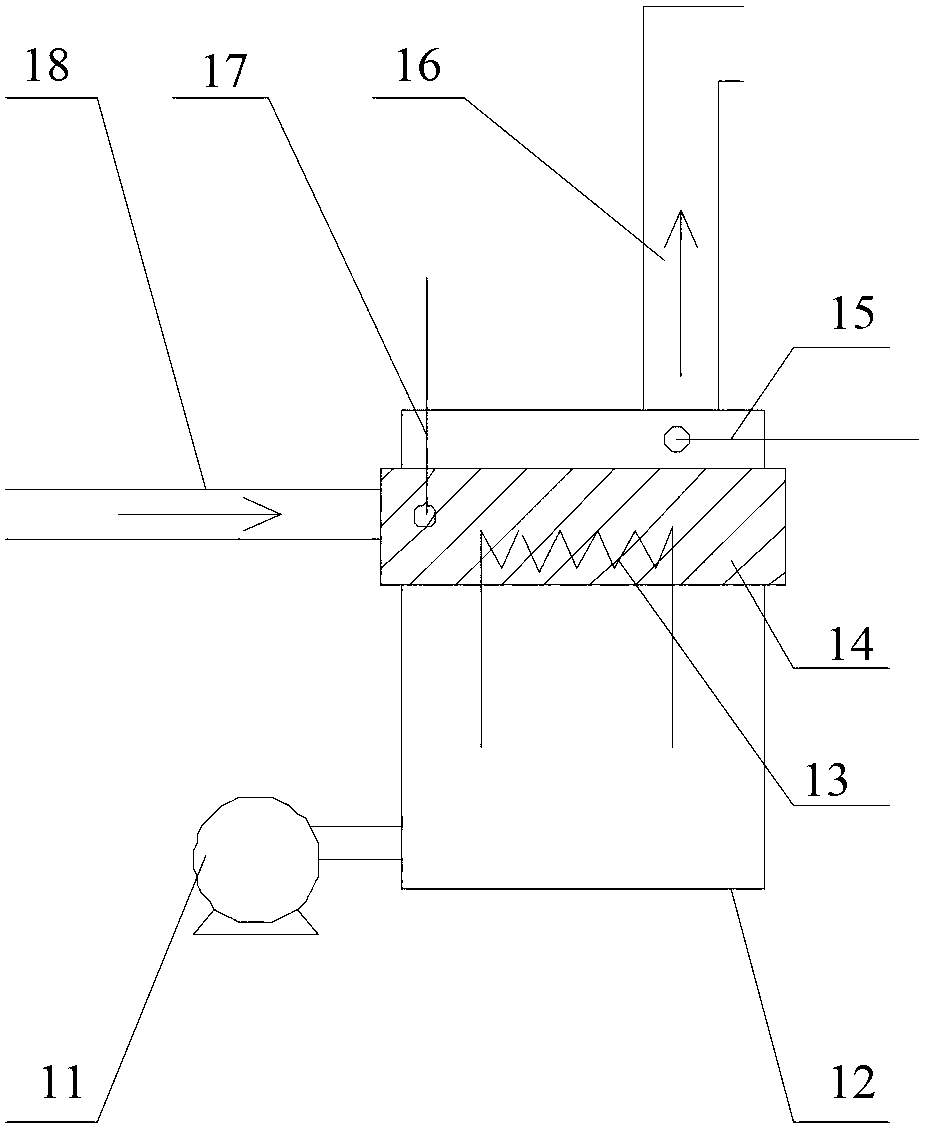

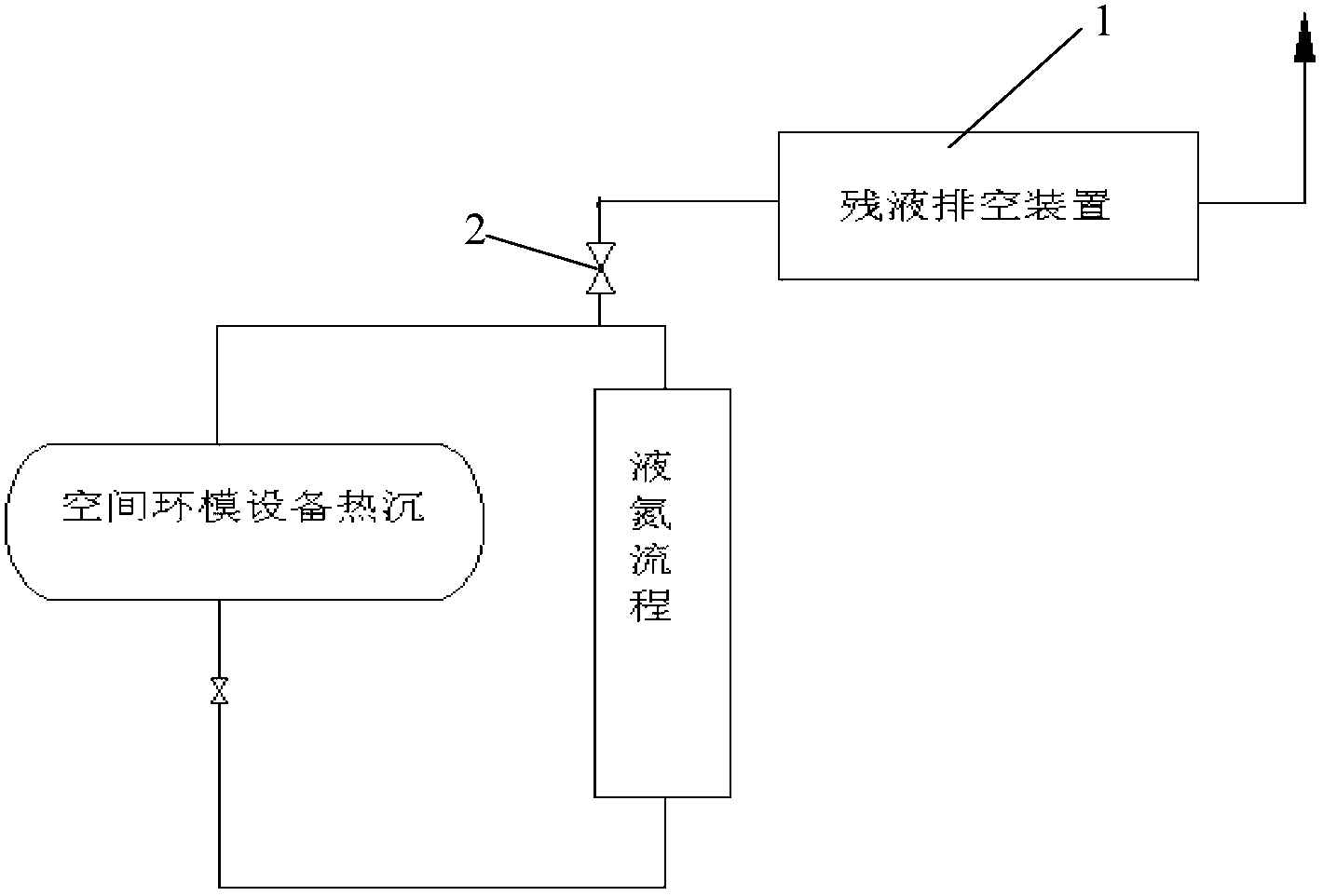

Residual liquid emptier

ActiveCN103016951ASolve the problem of direct discharge to the outsideGuaranteed full gasificationContainer discharging methodsContainer filling under pressureProcess engineeringAir blower

The invention provides a residual liquid emptier. The residual liquid emptier comprises an air blower, a residual liquid vaporizing chamber, a heater, a residual liquid collector, an outlet temperature measuring device, an emptying tube, an inlet temperature measuring device and a residual liquid inlet tube, wherein the residual liquid collector is arranged on the upper part of the residual liquid vaporizing chamber; the air blower is connected to the bottom of the residual liquid vaporizing chamber; the heater is arranged in the residual liquid vaporizing chamber and is connected with the residual liquid collector; the residual liquid inlet tube is connected with the residual liquid collector; the emptying tube is connected with the residual liquid vaporizing chamber; the inlet temperature measuring device is arranged at the connected part of the residual liquid inlet tube and the residual liquid collector; and the outlet temperature measuring device is arranged at the connected part of the emptying tube and the residual liquid vaporizing chamber. The residual liquid emptier can be used for vaporizing liquid nitrogen within a short time for effectively avoiding influence on environmental and personal injury or device damage caused by direct emission of the liquid nitrogen, and has the beneficial effects of high vaporizing efficiency, energy conservation and an extensive applicable range.

Owner:SHANGHAI YUDA IND

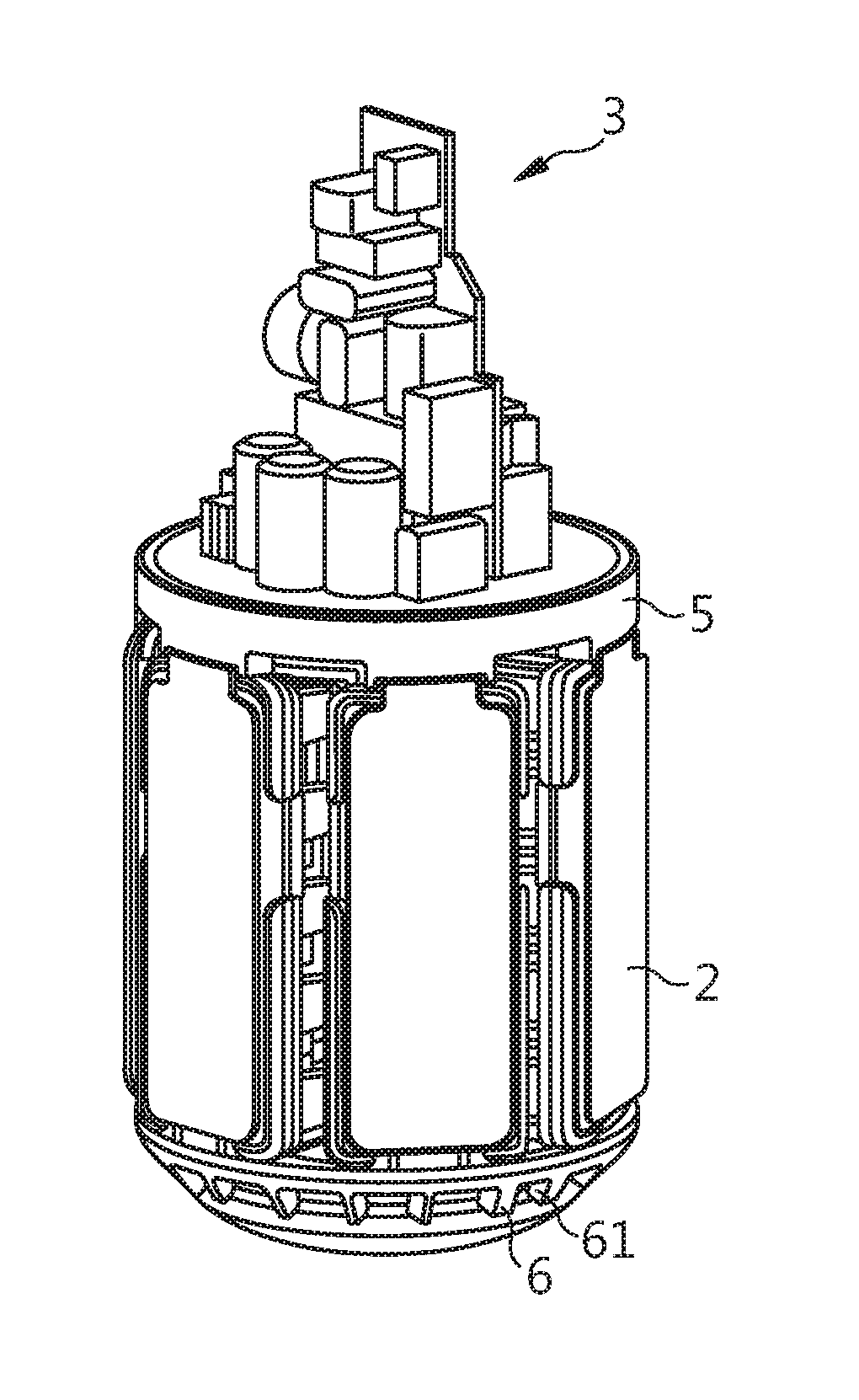

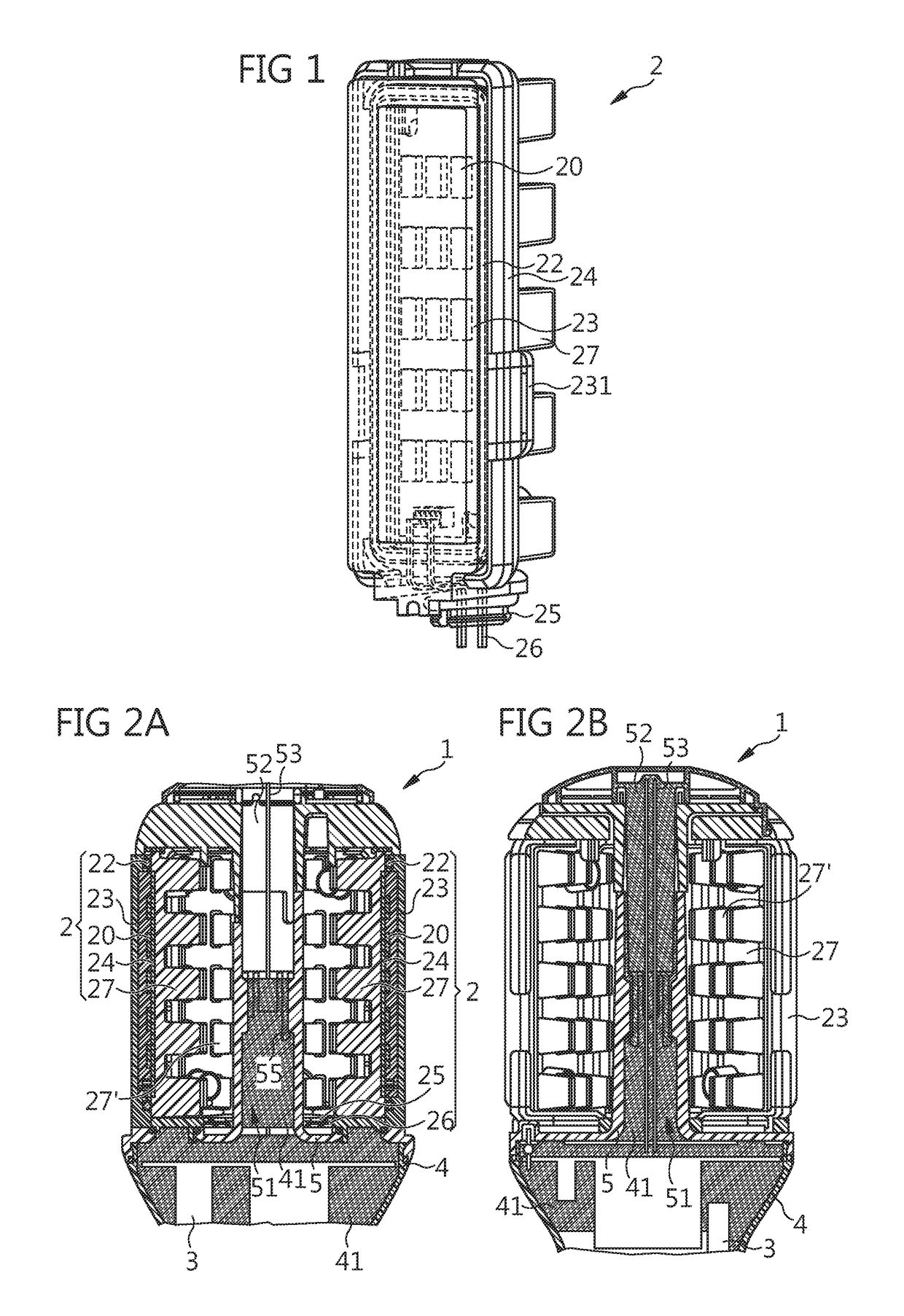

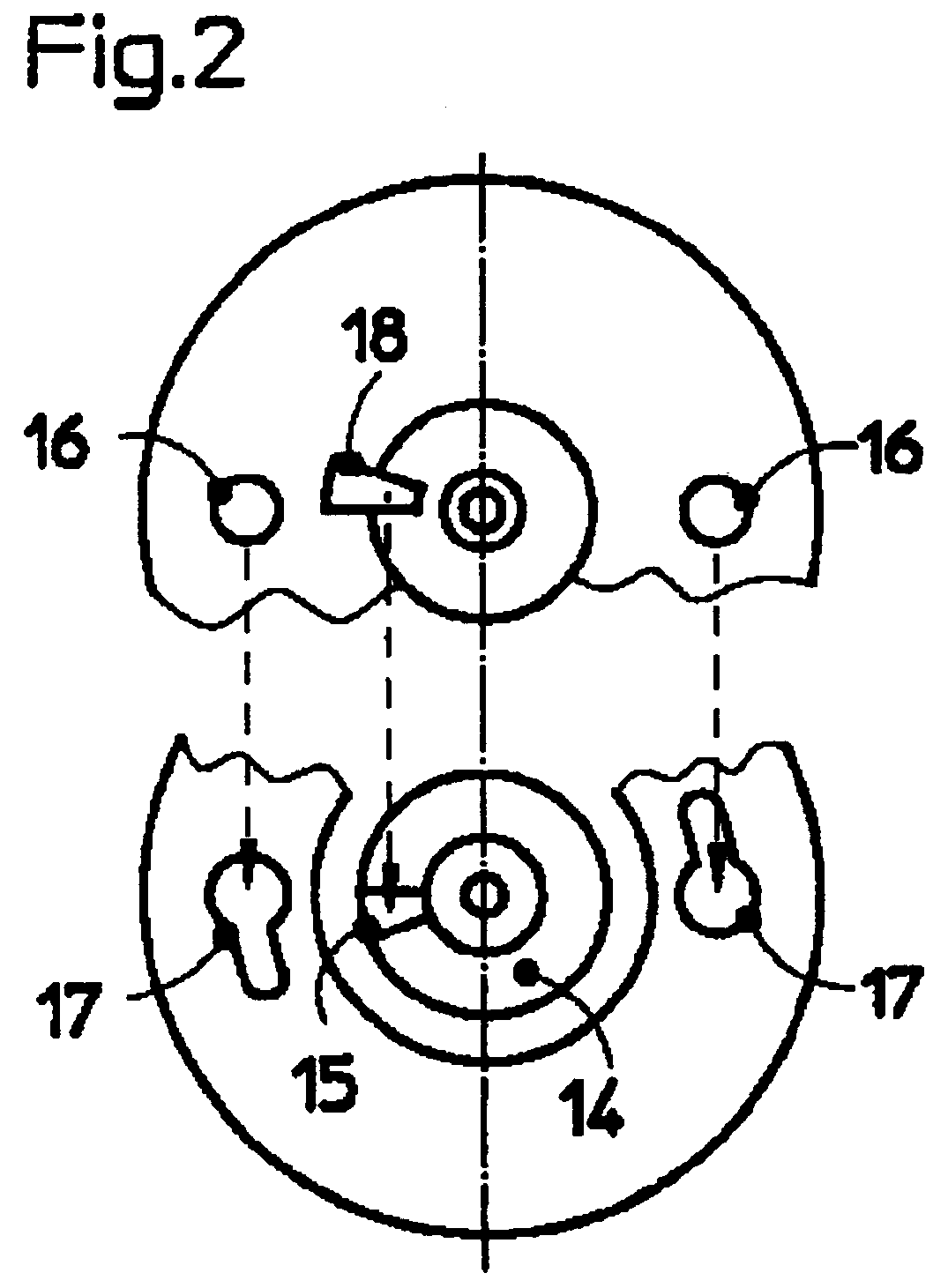

Lamp and method for assembling a lamp

ActiveUS20180187880A1Improve protectionImproved protection against environmental influenceElectric circuit arrangementsLighting heating/cooling arrangementsEngineering

Owner:LEDVANCE GMBH

Ardealite harmlessly treated as ecological restoration material and method

InactiveCN114180918AAvoid natural disastersImprove liquiditySolid waste managementChemical reactionChemical compound

The invention discloses an ecological restoration material prepared from phosphogypsum through innocent treatment and a method. The ecological restoration material is prepared from the following raw materials in parts by weight: 5-10 parts of lime milk, 0.01-0.05 part of a water reducing agent and 0.01-0.05 part of a dispersing agent. The method is realized through chemical reaction, even if soluble phosphorus and fluorine in the phosphogypsum form insoluble compounds to passivate the phosphogypsum, the phosphogypsum can be used for ecological restoration if miscellaneous fill is needed for leveling terraces of concave terrains in building construction and earth surface backfill lamps are needed for open-cast mining, so that the phosphogypsum is harmless to the environment and has no pollution to the environment. The added water reducer can enhance the fluidity and play a role in lubrication, the dispersant can enhance the capacity of the particles and reduce the time and energy required for completing the dispersion process, and after the phosphogypsum is modified, the phosphogypsum is harmless and can be used as a filling material for ecological restoration; the problems of environmental influence caused by no repair after mining of various mines and natural disasters of landslide are solved.

Owner:YUNNAN COPPER IND SUNWARD CHEM

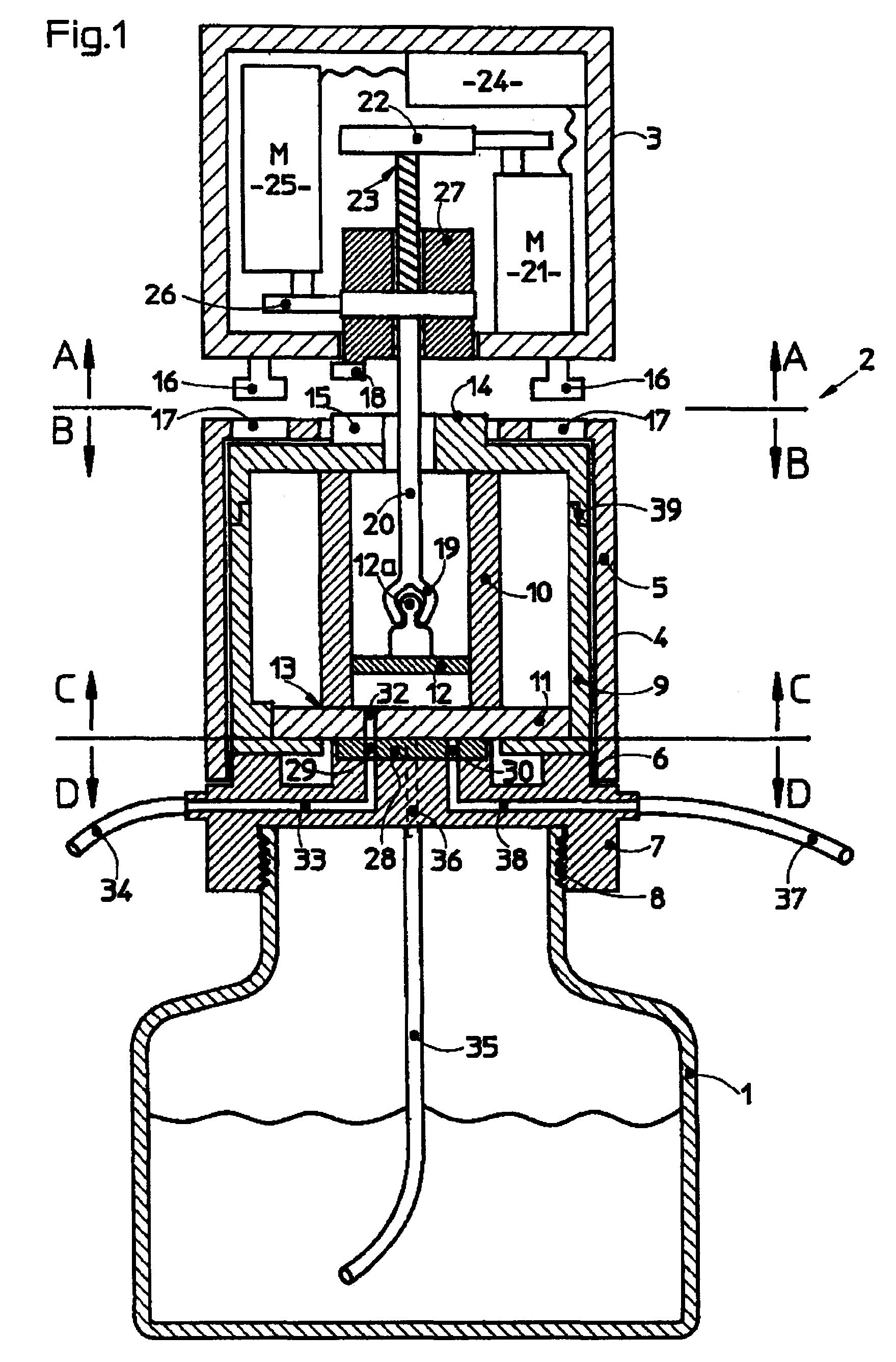

Volume measurement and/or metering device and method for operating a volume measurement and/or metering device

ActiveUS7753238B2Free from pollutionMaterial is limitedOpening closed containersBottle/container closureEngineeringPiston

A volume measurement and / or metering device includes a cylinder / piston and cock system for sucking in and / or discharging liquids in a defined way, the piston being movable in relation to the cylinder for sucking in or discharging the liquid. The cylinder is mounted, together with the cylinder bottom, rotatably with respect to the cock system about an axis of rotation parallel to the cylinder longitudinal axis. The cylinder bottom bears with a sealing seat against a cock element of the cock system, the cock element having at least one duct orifice. These orifices are arranged in such a way that the at least one orifice in the cylinder bottom can be brought into congruence with the orifices of the cock element when the cylinder and the cylinder bottom are rotated. Further, the cock element is brought into a sealing closing position for simultaneously closing of all the orifices of the cylinder bottom are provided.

Owner:METROHM AG

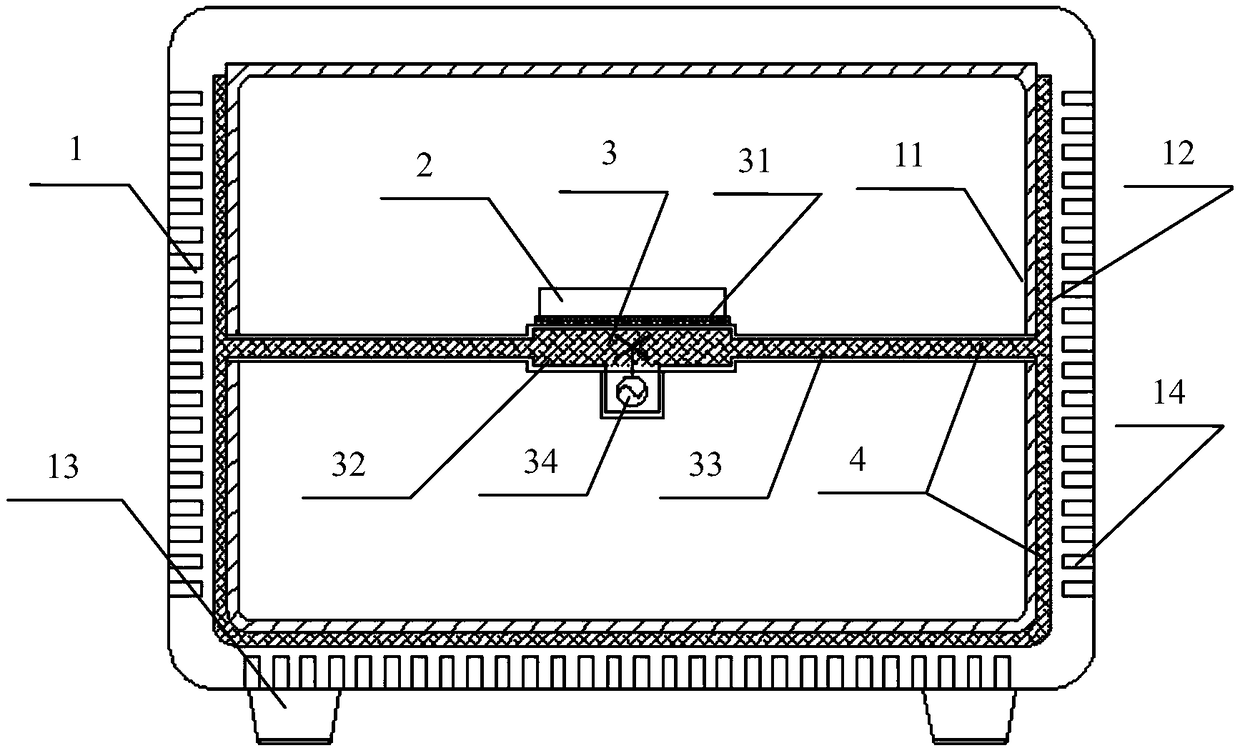

A heat dissipation device for a temperature control system of a PCR detector

PendingCN109168298ASave instrument spaceImprove cooling efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringInstrumentation

The invention relates to a heat dissipation device for a temperature control system of a PCR detector, which comprises a temperature control system, a heat conduction mechanism and a heat dissipationchassis. Temperature control system refers to the system and structure of temperature control required by PCR detector when it is running. The heat conduction mechanism comprises a heat conduction metal layer, a heat conduction pipe and a heat conduction liquid; The heat-conducting metal layer is closely connected with the heating and refrigerating devices in the temperature control system which need to dissipate heat through the heat-conducting medium. The heat-conducting metal layer contains a cavity filled with a heat-conducting liquid, and the cavity is connected with a heat-conducting pipe, the cavity of the heat-conducting metal layer is communicated with the cavity of the heat-conducting pipe, and the heat of the heating refrigeration device in the temperature control system needingheat dissipation is transferred to the heat-conducting liquid in the cavity of the heat-conducting metal layer through the heat-conducting metal layer. The invention is particularly suitable for miniaturization and portable PCR detector, so that the heat dissipation part occupies much less instrument space, and the heat dissipation efficiency can be improved, and the cost can be reduced at the same time.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

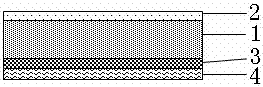

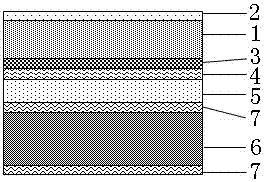

Self-adhesive mica tape winding wire

InactiveCN101894618AAvoid environmental impactReduce process stepsManufacturing dynamo-electric machinesFlat/ribbon cablesMicaSurface binding

The invention discloses a self-adhesive mica tape winding wire, which belongs to the technical field of motor accessories. The winding wire comprises a conductor and an insulator combined outside the conductor. The insulator comprises a first mica tape wound outside the conductor; a film and the first mica tape which are wound outside the conductor in turn; a packaging layer combined outside the conductor by sintering or hot sealing and the first mica tape wound outside the packaging layer; a second mica tape and the first mica tape which are wound outside the conductor in turn; the second mica tape, a third mica tape and the first mica tape which are wound outside the conductor in turn; the film, the second mica tape and the first mica tape which are wound outside the conductor in turn; or the packaging layer combined outside the conductor by sintering or hot sealing and the second mica tape and the first mica tape which are wound outside the packaging layer in turn. The winding wire is characterized in that the outside lateral surface of the first mica tape is combined with a self-adhesive layer. Most ideally, the self-adhesive property is favorable for the shaping of a coil; and environmental influences are avoided and process steps in a manufacturing process are reduced.

Owner:江苏豪威富电气股份有限公司

A kind of method that ammonium fluoride waste water prepares phosphate pulp desulfurizer

ActiveCN105536492BAvoid environmental impactImprove desulfurization efficiencyGas treatmentDispersed particle separationFlue gasPhysical chemistry

Owner:KUNMING ECON TECH CO LTD

Method for manufacturing a titanium aluminide component with a ductile core and correspondingly manufactured component

InactiveUS20190070665A1High strengthImprove reinforcementTurbinesAdditive manufacturing apparatusTitanium alloyAluminide

A method is provided, for manufacturing a component of a turbomachine, in particular a blade, in which initially a shell (6) including an interior cavity (7) corresponding to the outer contour of the component is manufactured from an intermetallic TiAl material, and subsequently a Ti alloy in powder form is filled into the cavity, and the cavity with the filled-in Ti alloy powder is tightly sealed, the tightly sealed shell (6) including the enclosed titanium alloy powder being subsequently processed into a component of the turbomachine using hot isostatic pressing. Alternatively, the invention relates to a method for generatively manufacturing a component including a shell made from a TiAl alloy and a core made from a Ti alloy. In addition, the invention relates to a correspondingly manufactured component.

Owner:MTU AERO ENGINES GMBH

Aluminized film with wire drawing effects and film-coated colored steel plate

ActiveCN107538864AAvoid coolingAvoid relaxation creep deformationVacuum evaporation coatingSputtering coatingSheet steelResin coating

The invention provides an aluminized film with wire drawing effects and a film-coated colored steel plate. The aluminized film comprises a PET wire drawing film, the upper surface of the PET wire drawing film is provided with a scratch-resistant coating, the lower surface of the PET wire drawing film is provided with a vacuum aluminized layer and the surface of the vacuum aluminized layer is provided with an adhesion-enhanced resin coating. The aluminized film has metal wire drawing effects, production processes are simplified, economy and practicability are obtained and environmental influence caused by a PVC film is avoided. The film-coated colored steel plate comprises a cold-roll steel sheet and the aluminized film which has wire drawing effects and is bonded to the cold-roll steel sheet through a composite adhesive layer. The composite adhesive layer provides good high temperature resistance and water boiling resistance to the film-coated colored steel plate and satisfies processing and use requirements of the film-coated colored steel plate. Through change of the anti-rust paint color of the surface of the cold-roll steel sheet and combination with the tungsten steel color ofthe aluminized film with wire drawing effects, the appearance of different colors is realized through color superposition.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Optical fiber microwire devices and manufacture method thereof

ActiveUS9529149B2Simple configurationSuitable for manufactureGlass making apparatusCoupling light guidesSolid structureEngineering

Herein presents an optical fiber microwire device, wherein the device comprising a silica tube, an optical fiber (2) inserted into the silica tube (1) and pigtailed at two sides, wherein the two ends of the silica tube (1) are fused with the optical fiber (2) to form a solid structure, or the two ends of the silica tube (2) are filled with silica rods (3), silica capillaries (4) or segments of optical fibers and fused to form a solid structure. The silica tube (1) together with the optical fiber (2) inside is then tapered to form a micro structure region. Therefore, the micro structure region is consisted of the tapered optical fiber as the microstructure core, tapered silica tube, and the air in between. This invention combine the manufacture of optical fiber microwire and the sealing process, avoiding the disadvantages of the conventional tapered optical fiber microwire, such as fragile mechanical structure, and sensitive to the outer environment variations.

Owner:JIANGSU UNIV

Artificial stone artware prepared from agglomerated stone waste residues and preparation method of artificial stone artware

InactiveCN113277811AReduce dosageReduce generationSolid waste managementPhysical chemistryEnvironmental engineering

The invention discloses artificial stone artware prepared from agglomerated stone waste residues and a preparation method of the artificial stone artware. The artificial stone artware comprises the following raw materials by weight: 50%-70% of agglomerated stone waste residue powder, 10%-15% of calcium carbonate powder, 0.1%-2% of an auxiliary agent, 10%-16% of a binder and 5%-7% of water. The artificial stone artware prepared from the agglomerated stone waste residues is prepared through the steps of treatment of the agglomerated stone waste residues, mixing, vacuum treatment, curing and the like. The artware is made of the agglomerated stone waste residues, so the stone can be turned into the valuable, the influence of the waste residues on the environment is reduced, manufacturing cost is reduced, and the performance of the artware is improved.

Owner:GUANGXI LISHENG STONE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com