Aluminized film with wire drawing effects and film-coated colored steel plate

A wire drawing effect, aluminized film technology, applied in the field of decorative film and coated color steel plate, can solve the problem of increasing the cost of decorative film, and achieve the effect of good appearance and decorative beauty, soft luster and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

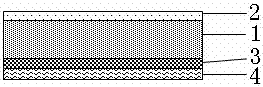

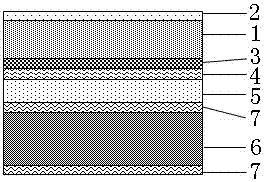

[0024] Such as figure 1 As shown, the aluminum-plated film with drawing effect includes vacuum plating aluminum on the surface of a PET drawing film to form the aluminum-plated film. The upper surface of the PET drawing film is provided with a scratch-resistant coating, and the lower surface is provided with a vacuum aluminum plating layer; the surface of the vacuum aluminum plating layer is provided with an adhesion enhancing resin coating.

[0025] Such as figure 2 As shown, the coated color steel plate is a color steel plate made by coating an aluminum-plated film with a wire drawing effect on the surface of a cold-rolled steel plate by using a composite adhesive layer.

[0026] In this embodiment, the PET drawn film uses a longitudinal heat shrinkage rate of 1.5% and a transverse heat shrinkage rate of 0.5%; a precision coating machine is used to coat a layer of scratch-resistant coating with a semi-matte effect on the upper surface of the PET drawn film, with a 60º angle The...

Embodiment 2

[0029] In this example, the PET drawn film adopts a longitudinal heat shrinkage rate of 1.2% and a transverse heat shrinkage rate of 0.3%; a precision coating machine is used to coat a layer of scratch-resistant coating with a semi-matte effect on the upper surface of the PET drawn film, with an angle of 60º The surface gloss is 70 Gs. The vacuum aluminum coating is a metal coating with a tungsten steel color appearance, and the unit of optical density is 0.75. Use a precision coating machine to coat a layer of adhesion-enhancing resin on the surface of the vacuum aluminized layer. The adhesion-enhancing resin coating selects a polyurethane resin containing a coupling agent. The coupling agent is composed of a silane coupling agent (KH560) and Monoalkoxy pyrophosphate titanate coupling agent (HY311W) is compounded according to the mass ratio of 30:70wt%. Adhesion enhancement resin coating thickness is 1.5μm. The composite adhesive layer is made of a high temperature resistant...

Embodiment 3

[0032] In this example, the PET drawing film uses a longitudinal thermal shrinkage rate of 1.0% and a transverse thermal shrinkage rate of 0.3%; a precision coating machine is used to coat a layer of scratch-resistant coating with a semi-matte effect on the upper surface of the PET drawing film, with an angle of 60º The surface gloss is 55 Gs. The vacuum aluminum coating is a metal coating with a tungsten steel color appearance, and the unit of optical density is 0.90. Use a precision coating machine to coat a layer of adhesion-enhancing resin on the surface of the vacuum aluminum coating. The adhesion-enhancing resin coating selects a polyurethane resin containing a coupling agent. The coupling agent is composed of a silane coupling agent (KH570) and Chelate type titanate coupling agent (LD-311) is compounded according to the mass ratio of 40:60wt%. Adhesion enhancement resin coating thickness 1μm. The composite adhesive layer is made of a high temperature resistant polyeste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com