Spherical flue element equivalent model thermotechnical waterpower experimental apparatus

A spherical fuel element and equivalent model technology, applied in teaching models, educational appliances, instruments, etc., can solve the problem that the spherical fuel element cannot be used as an equivalent model structure, the spherical fuel element has no similarity, and cannot simulate spherical fuel elements, etc. problems, to achieve the effect of reducing the difficulty of assembly, facilitating replacement, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

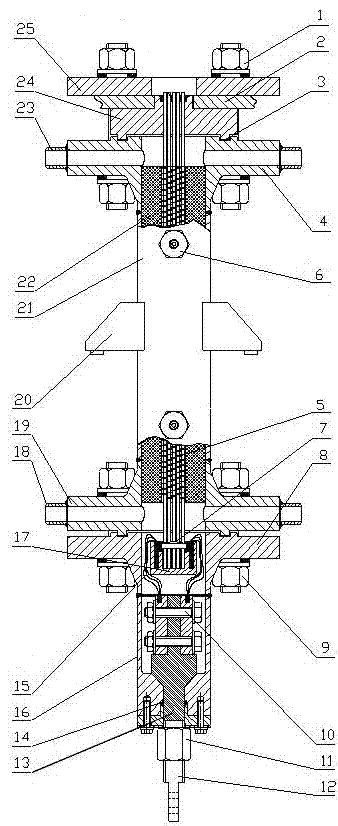

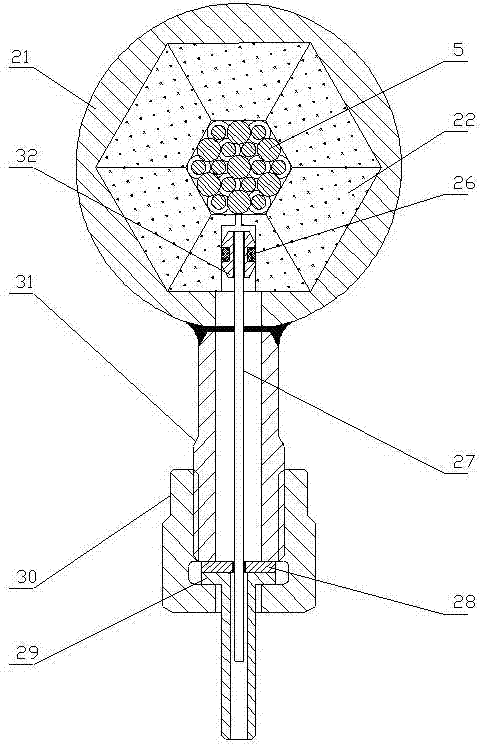

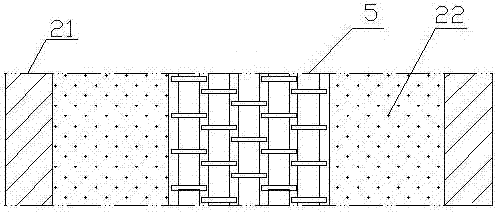

[0029] Such as Figures 1 to 4As shown, the spherical fuel element equivalent model thermal-hydraulic experiment device of the present invention includes an upper cylinder 21, the upper cylinder 21 is a cavity structure with upper and lower opening ends, and its internal cavity forms a cylindrical structure. The upper opening end of the cylinder body 21 is provided with an upper groove surface flange 4, and the upper cylinder body 21 is welded with the upper groove surface flange 4, and an upper conductive copper plate 24 is arranged on the end surface of the upper groove surface flange 4, and the upper groove surface The flange 4 and the upper conductive copper plate 24 are provided with an insulating gasket 3, and an outlet connecting pipe 23 is provided on the side of the flange on the upper groove surface, and an upper conductive plate 2 is installed on the upper conductive copper plate 24, and an upper end of the upper conductive plate 2 is placed. The upper flange cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com