High-efficiency and environment-friendly continuous roller kiln

An environment-friendly, kiln technology, applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of high energy consumption, environmental pollution, etc., and achieve the effect of preventing falling and fast fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

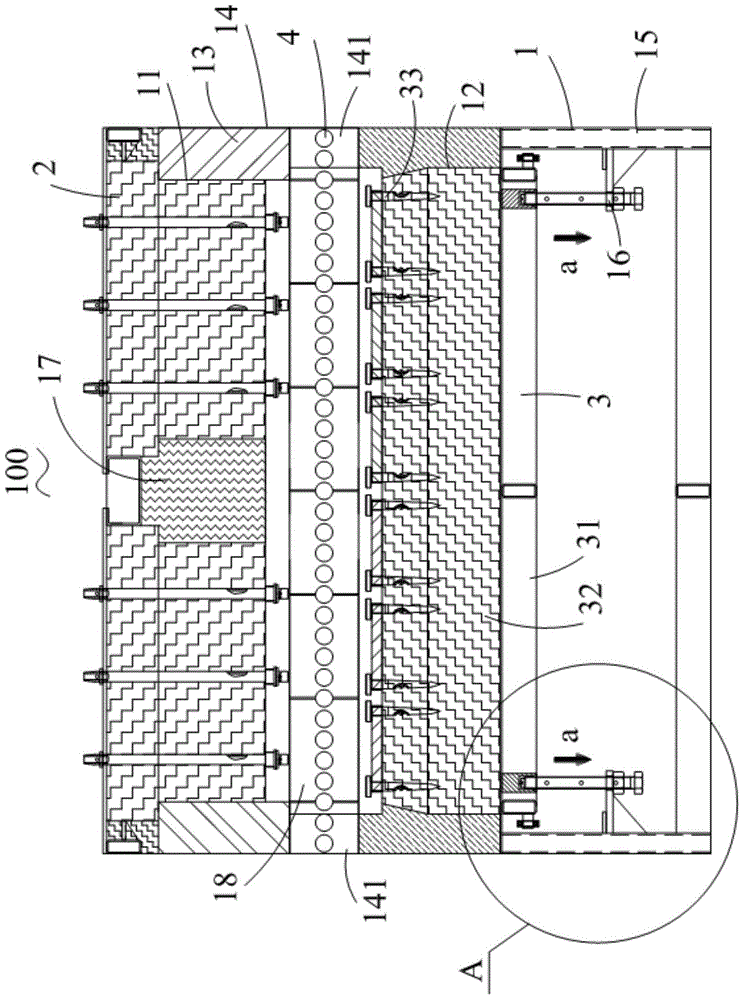

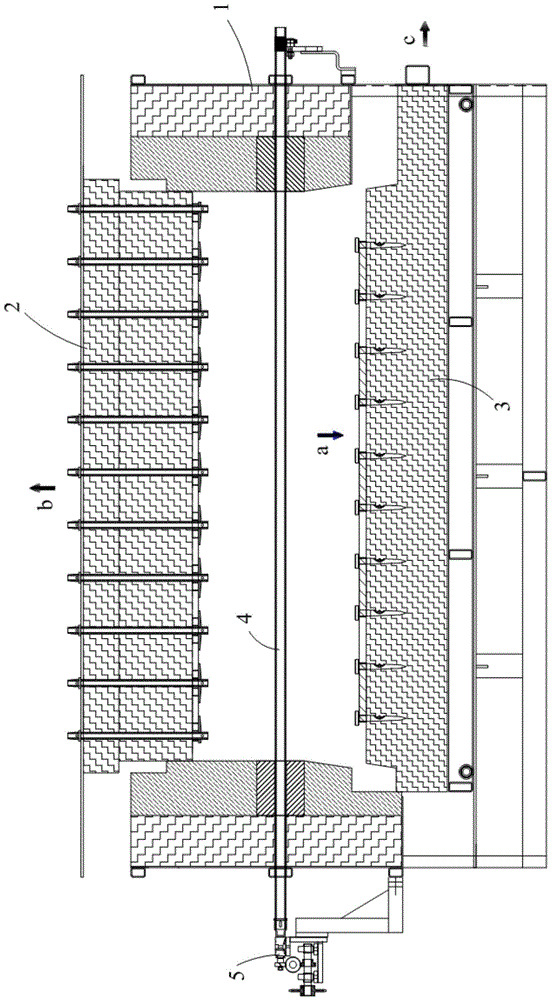

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] see Figure 1 to Figure 7 , a high-efficiency environment-friendly continuous roller kiln described in a preferred embodiment of the present invention is used for firing ceramic products (not shown), which includes at least one kiln module 100, the high-efficiency environment-friendly continuous roller kiln The number of kiln modules 100 used in a kiln is determined according to the length of the actual production line. When the number of kiln modules 100 is equal to or greater than two, two or more kiln modules 100 are in turn left and right Arranged in a row.

[0022] Each kiln module 100 includes a furnace frame 1 with an upper opening 11 and a lower opening 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com