Low-temperature disinfectant and preparation method thereof

A disinfectant and low-temperature technology, applied in the direction of disinfectants, botany equipment and methods, bactericides, etc., can solve the problems of reduced sterilizing effect, failure, and freezing of disinfectants, and achieve improved sterilizing effect, low use concentration, Fast bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

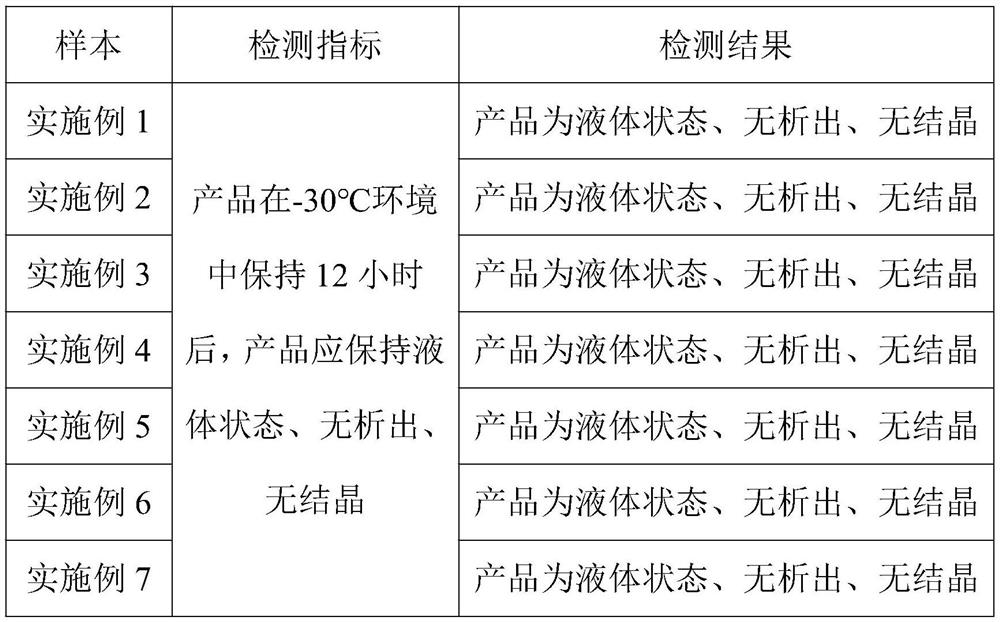

Examples

Embodiment 1

[0021] Add 549.35g deionized water, 4g polyhexamethylene biguanide with a mass concentration of 25% and 260g ethanol into a beaker, stir and mix evenly, add 0.3g benzalkonium chloride, 0.35g bisdecyldimethylammonium chloride and 180 g of sodium chloride, after stirring and dissolving, adding a mixed solution of 6 g of citric acid and sodium citrate to adjust the pH value of the mixed solution to 7.6 to prepare a finished product.

Embodiment 2

[0023] Add 549.7g deionized water, 3.5g polyhexamethylene biguanide with a mass concentration of 25% and 280g ethanol into a beaker, stir and mix evenly, add 0.5g benzalkonium chloride, 0.3g bisdecyldimethylammonium formate and 160 g of sodium chloride, after stirring and dissolving, adding a mixed solution of 6 g of citric acid and sodium citrate to adjust the pH value of the mixed solution to 7.6 to prepare a finished product.

Embodiment 3

[0025] Add 536.25g deionized water, 5g polyhexamethylene biguanide with a mass concentration of 25% and 300g ethanol into a beaker, stir and mix evenly, add 0.5g benzalkonium bromide, 0.25g bisdecyldimethylammonium bromide and 150 g of sodium chloride, after stirring and dissolving, adding a mixed solution of 8 g of citric acid and sodium citrate to adjust the pH value of the mixed solution to 7.8 to prepare a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com