Auxiliary selection device for fluidized bed jet mill

A jet mill and fluidized bed technology, which is applied in the field of auxiliary selection devices for fluidized bed jet mills, can solve the problems of reducing the pulverization efficiency of the pulverizer, endangering the health of operators, and generating more dust, so as to ensure work safety. The effect of reducing dust generation and improving pulverization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

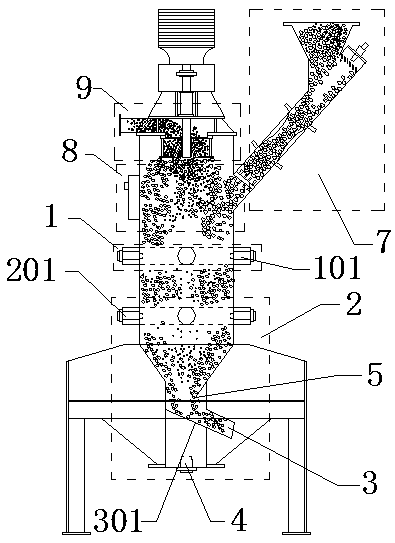

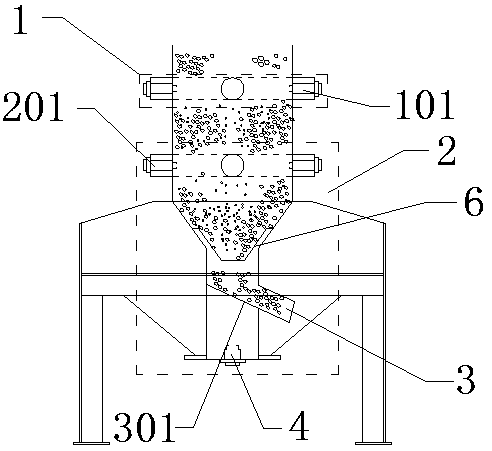

[0026] Auxiliary equipment for fluidized bed jet mill, which includes:

[0027] Air intake chamber 1, a number of scrap nozzles 101 are arranged on the side wall of the inlet chamber 1, and a slag discharge chamber 2 is provided at the lower part of the inlet chamber 1. The input end of the scrap nozzle 101 is connected with an air compressor, and the air is compressed The air flow medium in the machine is not limited to air, depending on the nature of the material, you can also choose CO 2 , N 2 , He, Ar, etc. For example, when the pulverized material is a sensitive, flammable and explosive object, the air flow medium in the air compressor is CO 2 , N 2 etc. to prevent O 2 Entering and causing safety hazards;

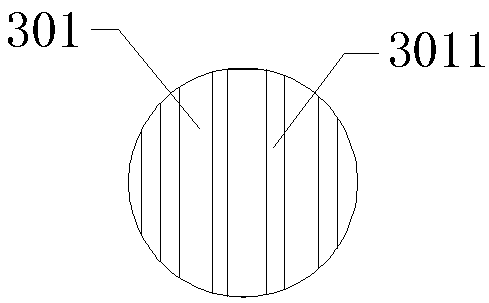

[0028] Slag discharge chamber 2, a number of patching nozzles 201 are provided on the side wall of the slag discharge chamber 2, a slag discharge port 3 is provided at the lower part of the slag discharge chamber 2, and an air distribution plate 301 is provided at ...

Embodiment 2

[0045] Embodiment 2 is the same as Embodiment 1, except that the polyurethane composite material is composed of the following raw materials in parts by weight: 96 parts of polyurethane prepolymer, 3 parts of polyurethane toughening agent, and 6 parts of modified rare earth oxide powder , 4 parts of superfine vanadium oxide powder, 9 parts of carbon fiber, 3 parts of silane coupling agent, 37 parts of curing agent, 2 parts of defoamer, 170 parts of silica particles, 2 parts of rare earth dithiocarbamate accelerator and Anti-aging agent 4 parts. Among them, the silica particles are composed of a mixture of two specifications with a particle size of 0.1-0.3mm and a particle size of 0.5-0.7mm. The mass ratio of silicon oxide particles to 0.5-0.7mm (the particle size is not specifically limited, but within 0.5-0.7mm) particle size silicon dioxide particles is 1:2; the anti-aging agent is lanthanum p-aminobenzenesulfonate anti-aging agent , the toughening agent is polyurethane, the...

Embodiment 3

[0048] Embodiment 3 is the same as Embodiment 1 and Embodiment 2, except that the polyurethane composite material is composed of the following raw materials in parts by weight: 90 parts of polyurethane prepolymer, 2 parts of polyurethane toughening agent, modified rare earth oxidation 5 parts of powder, 3 parts of superfine vanadium oxide powder, 8 parts of carbon fiber, 1 part of silane coupling agent, 30 parts of curing agent, 1 part of defoamer, 150 parts of silica particles, rare earth dithiocarbamate accelerator 1 part of anti-aging agent and 1 part of anti-aging agent. Among them, the silica particles are composed of a mixture of two specifications with a particle size of 0.1-0.3mm and a particle size of 0.5-0.7mm. The mass ratio of silicon oxide particles to 0.5-0.7mm (the particle size is not specifically limited, but within 0.5-0.7mm) particle size silicon dioxide particles is 1:2; the anti-aging agent is lanthanum p-aminobenzenesulfonate anti-aging agent , the tough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com