Pile-forming equipment and method of control modulus pile

A technology of modulus pile and pile formation, which is used in the test of foundation structure, construction, foundation structure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

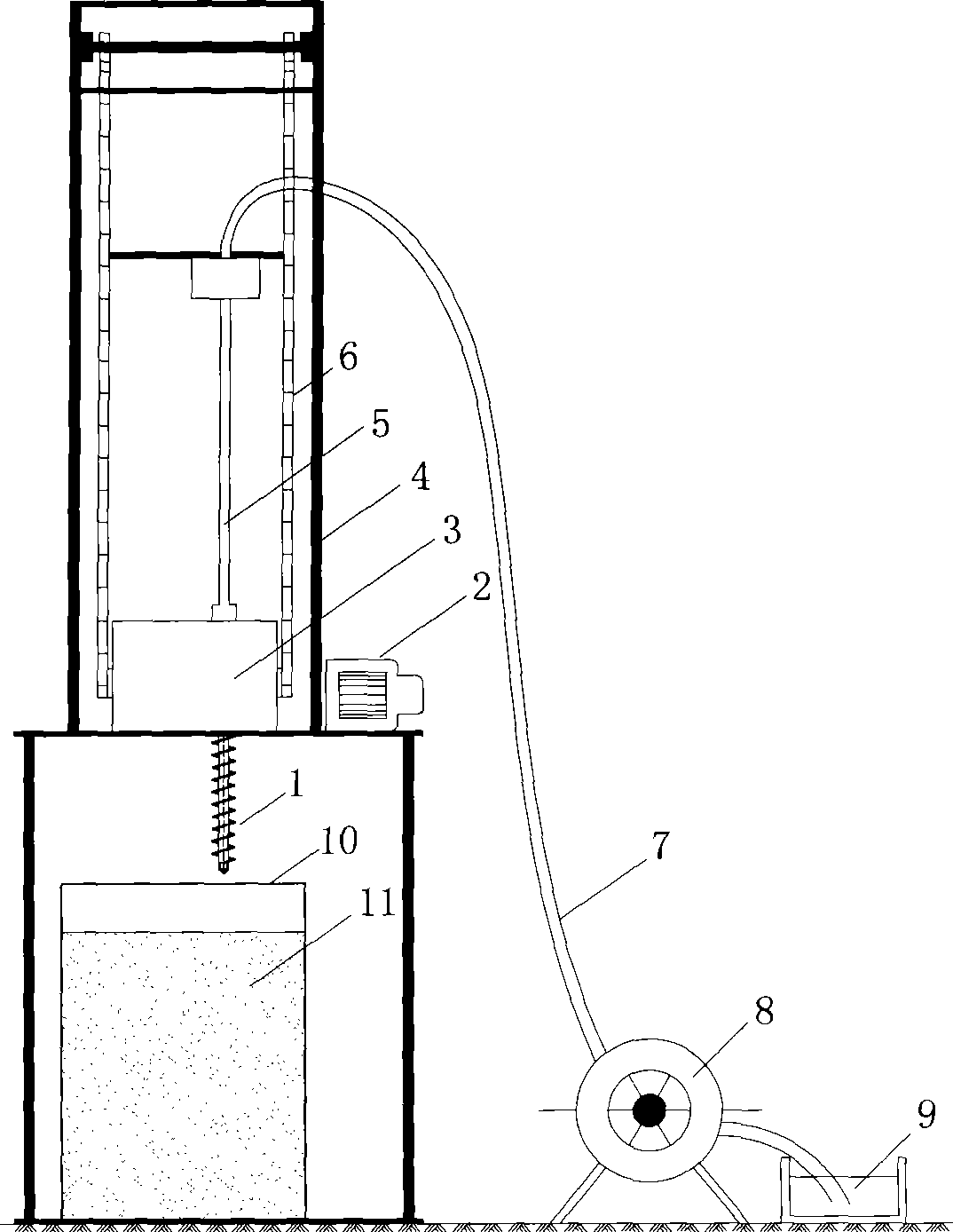

[0014] like figure 1 shown. A control modulus pile forming equipment, which consists of a drill bit 1, a motor 2, a control platform 3, a drill frame 4, a drill pipe 5, a transmission chain 6, a slurry delivery pipe 7, a pressurizing pump 8, and a model box 10, wherein the drill bit 1 and the drill pipe 5 are provided with longitudinal through holes, the output port of the booster pump 8 communicates with the upper through hole of the drill pipe 5 through the slurry delivery pipe 7, the lower part of the drill pipe 5 is set opposite to the upper part of the control platform 3, and the control platform 3 is fixed to the upper part of the drill frame 4, the upper part of the transmission chain 6 is respectively set opposite to the cross bar on the upper part of the drill frame 4, the lower part of the transmission chain 6 is respectively set opposite to the left and right ends of the control platform 3, and the motor 2 is fixed on the drill The upper part of the frame 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com