Follow-up supporting device and method

A support device and a support method technology, applied in the direction of lifting devices, etc., can solve problems such as bridge jacking safety threats, safety accidents, oil pipe bursts, etc., and achieve the effects of overcoming uneven load stress, safety, reliability, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

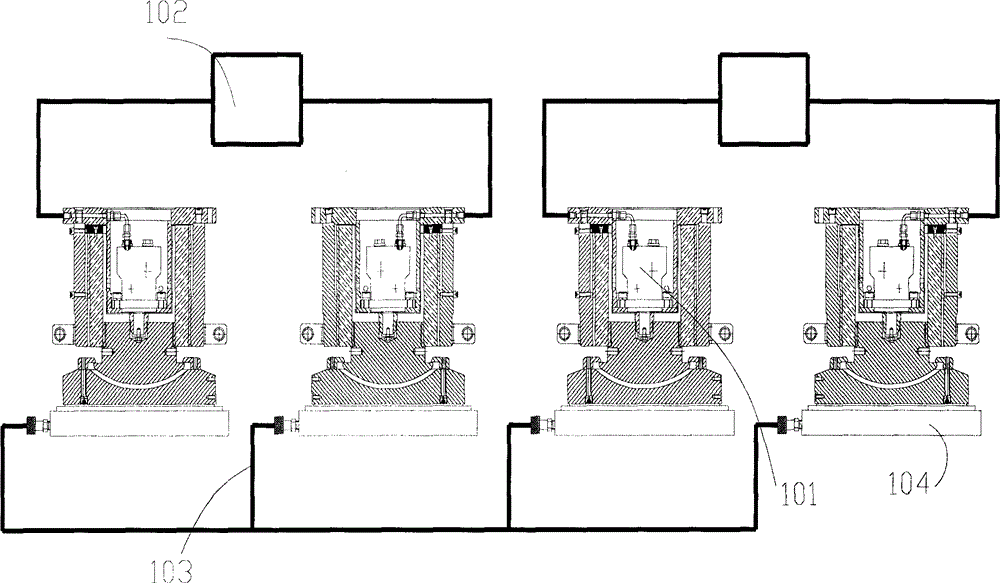

[0029] The invention is a support system applied to building (structure) jacking engineering, especially a supporting system of bridge jacking engineering. It is a major improvement made on the basis of the existing follow-up support system, including the shortcomings of the support device and the support method, and has very important practical significance.

[0030] Below in conjunction with accompanying drawing and embodiment the invention will be further described:

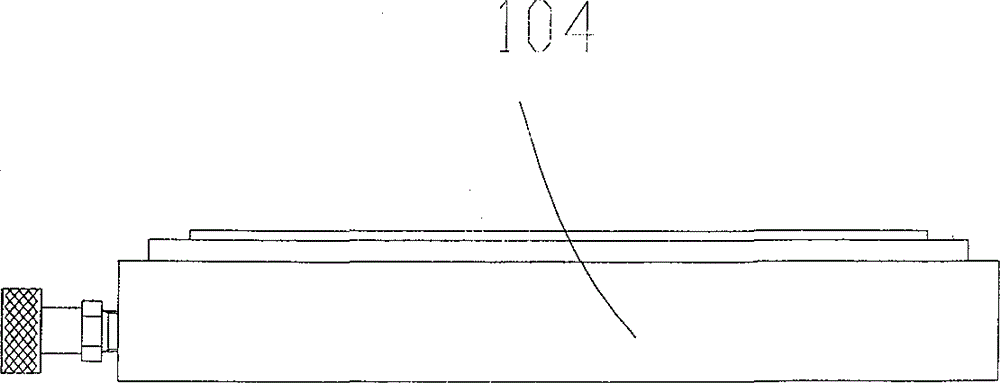

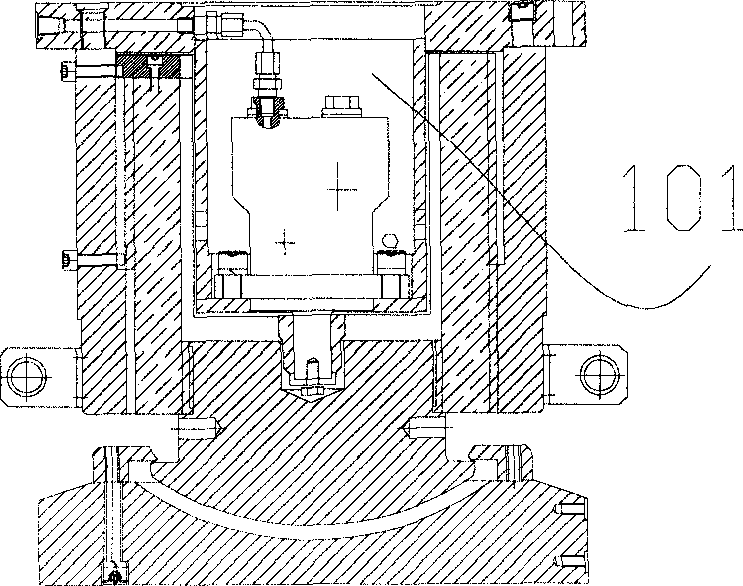

[0031] The invention discloses a follow-up support system, which includes a follow-up support device and a follow-up support method. The system is composed of several follow-up jacks, hydraulic pump stations, oil pipes and balance oil cylinders.

[0032] The follower jack or follower jack is driven by hydraulic pressure, and the internal mechanical thread is used to carry the upper load; the present invention presses part of the hydraulic oil from the larger load to the smaller load balance cylinder through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com