Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "High abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

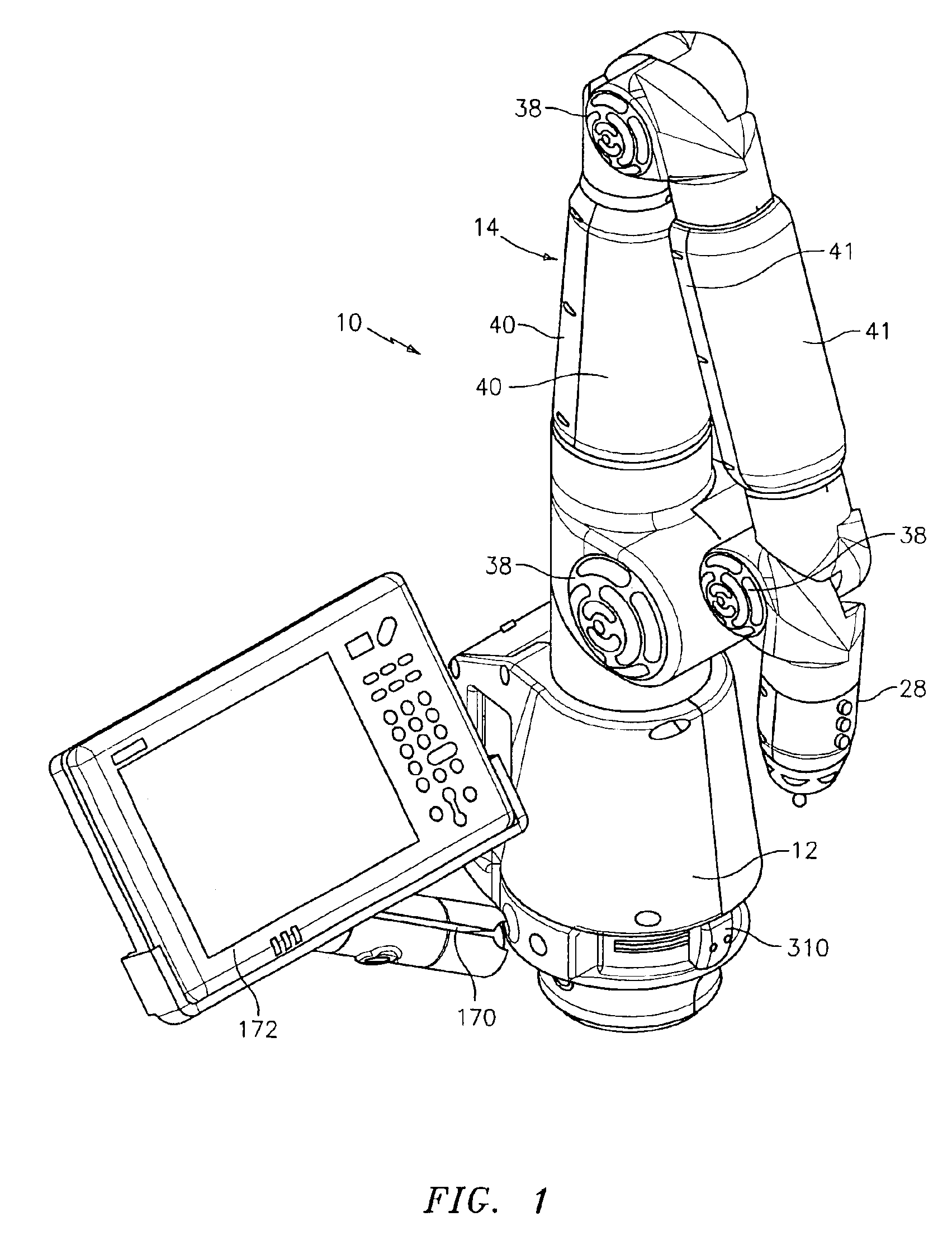

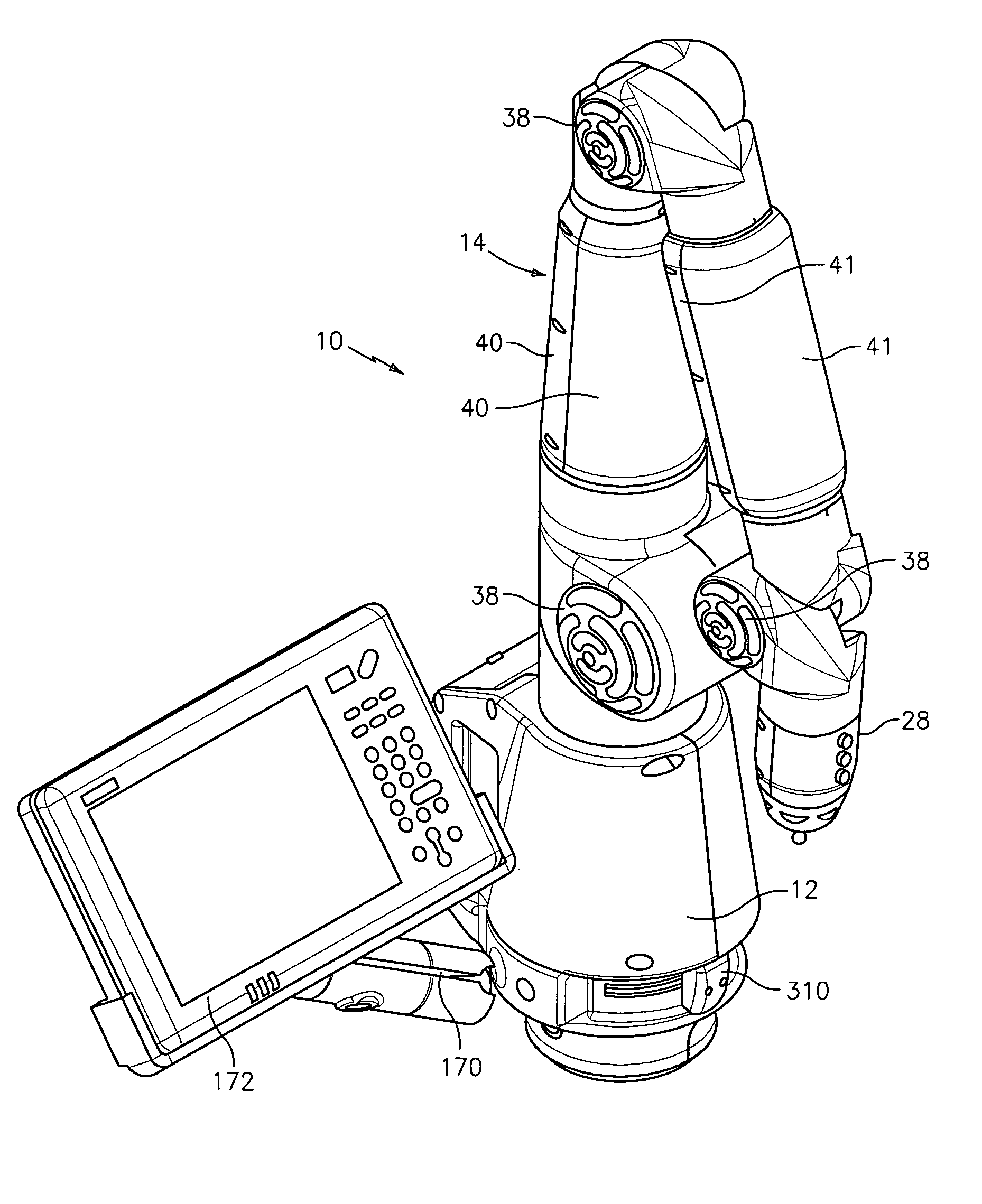

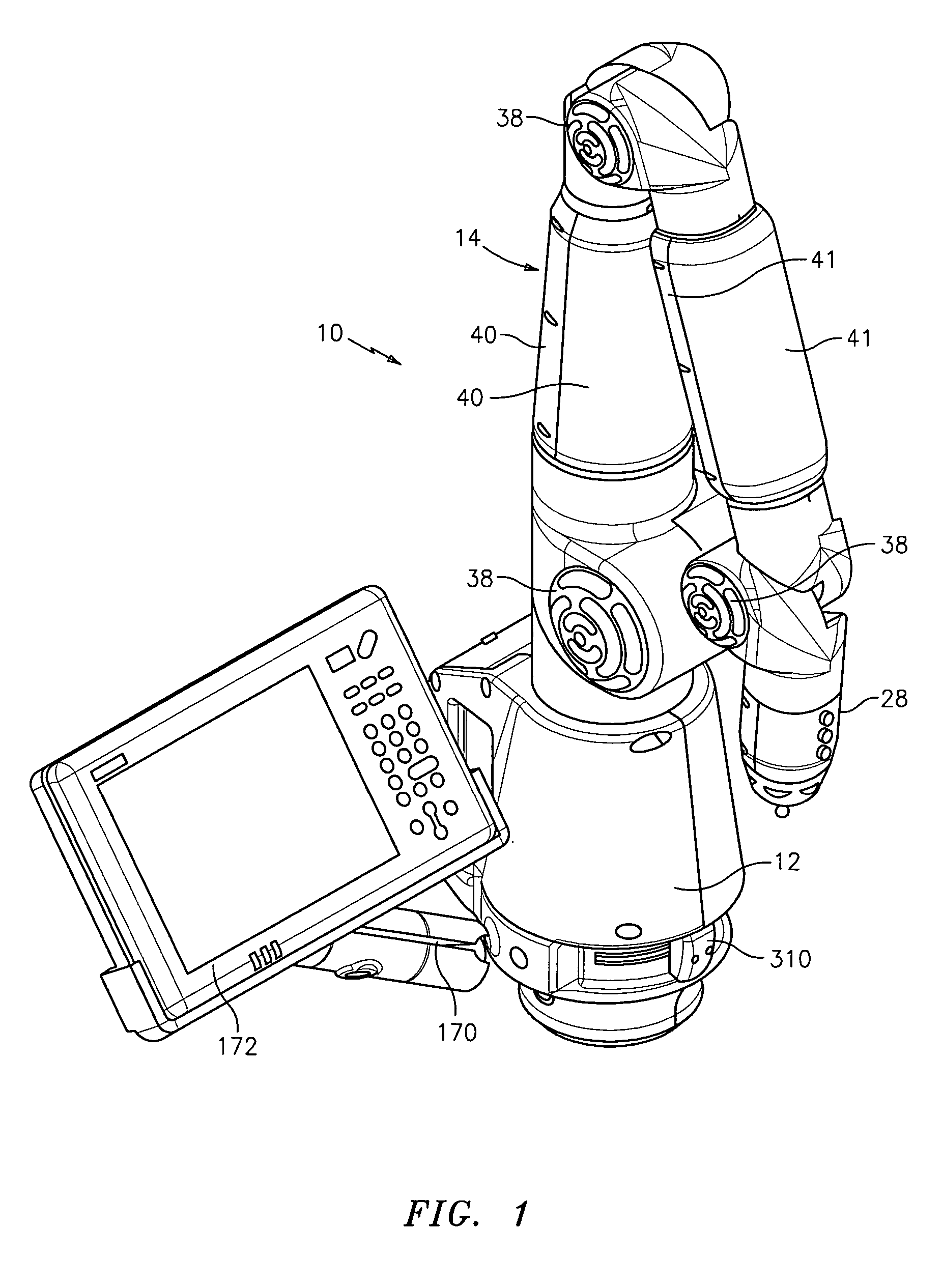

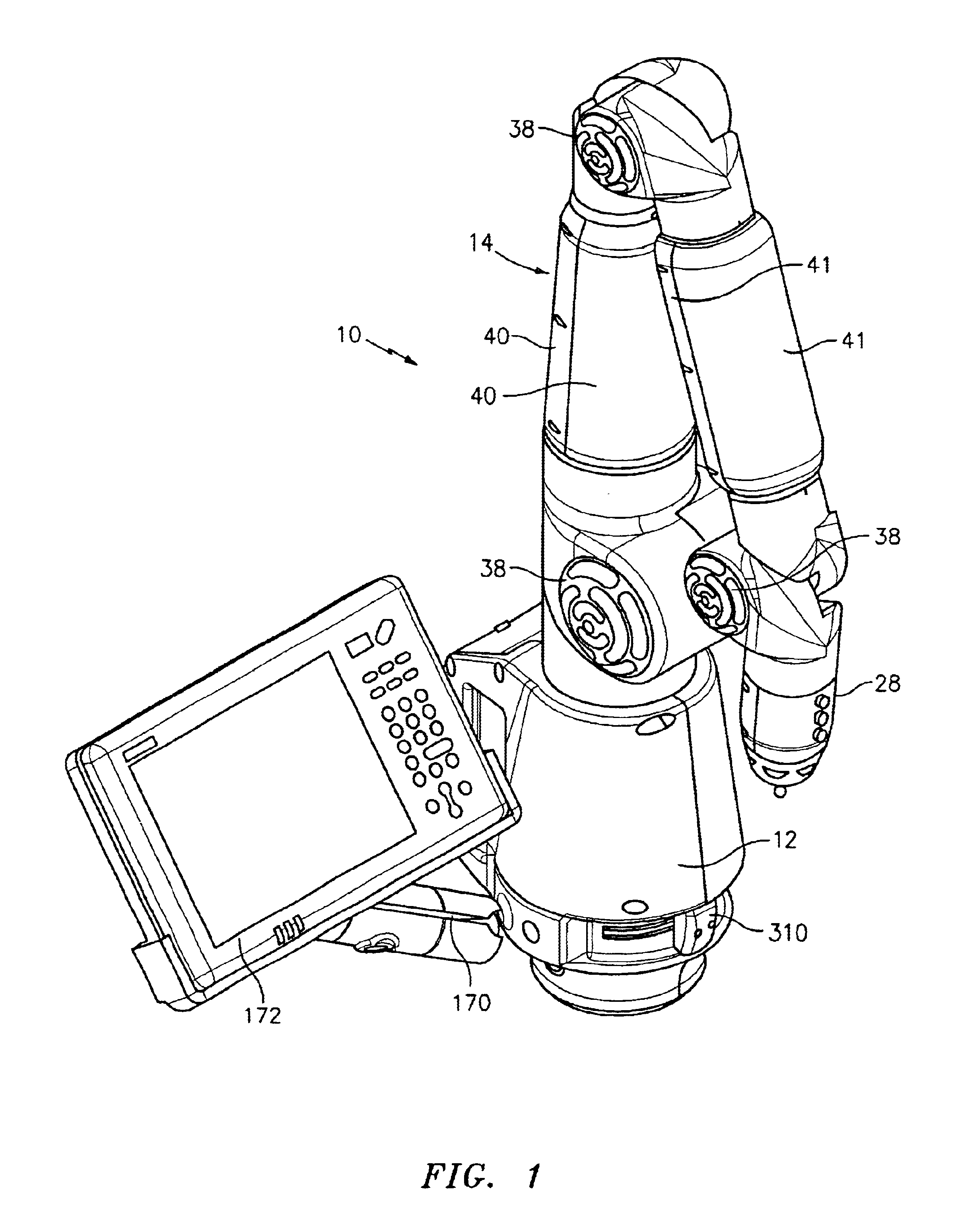

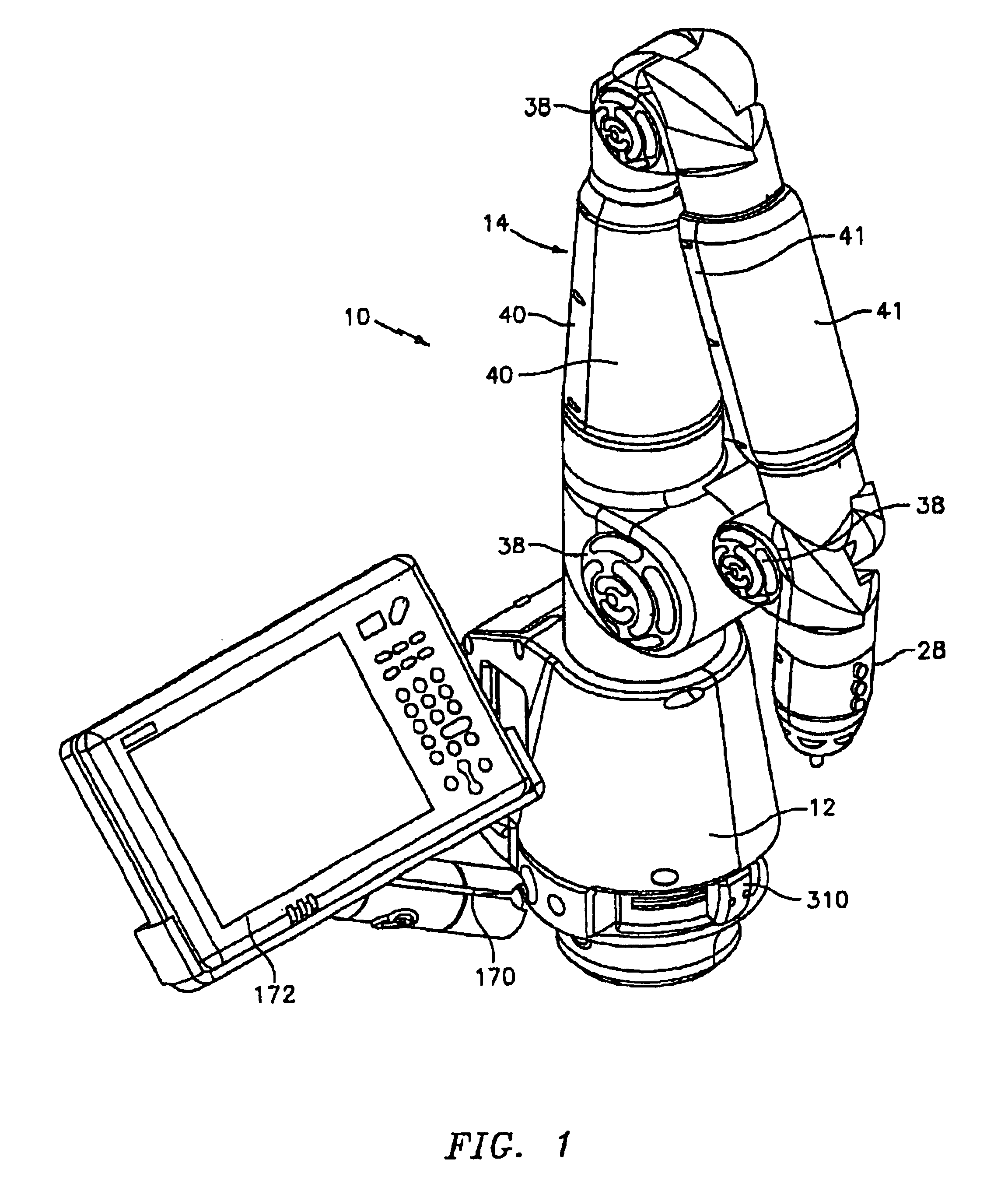

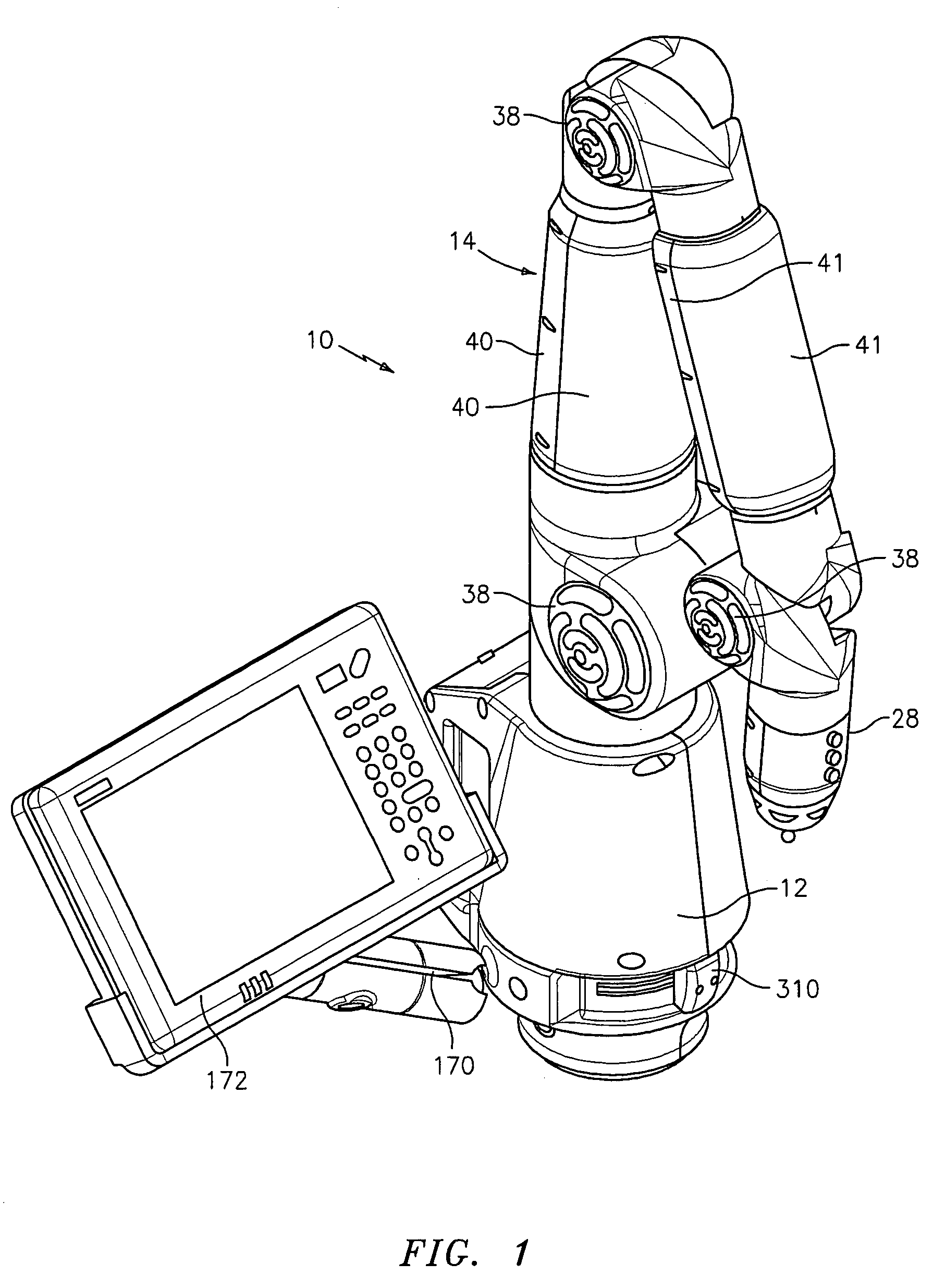

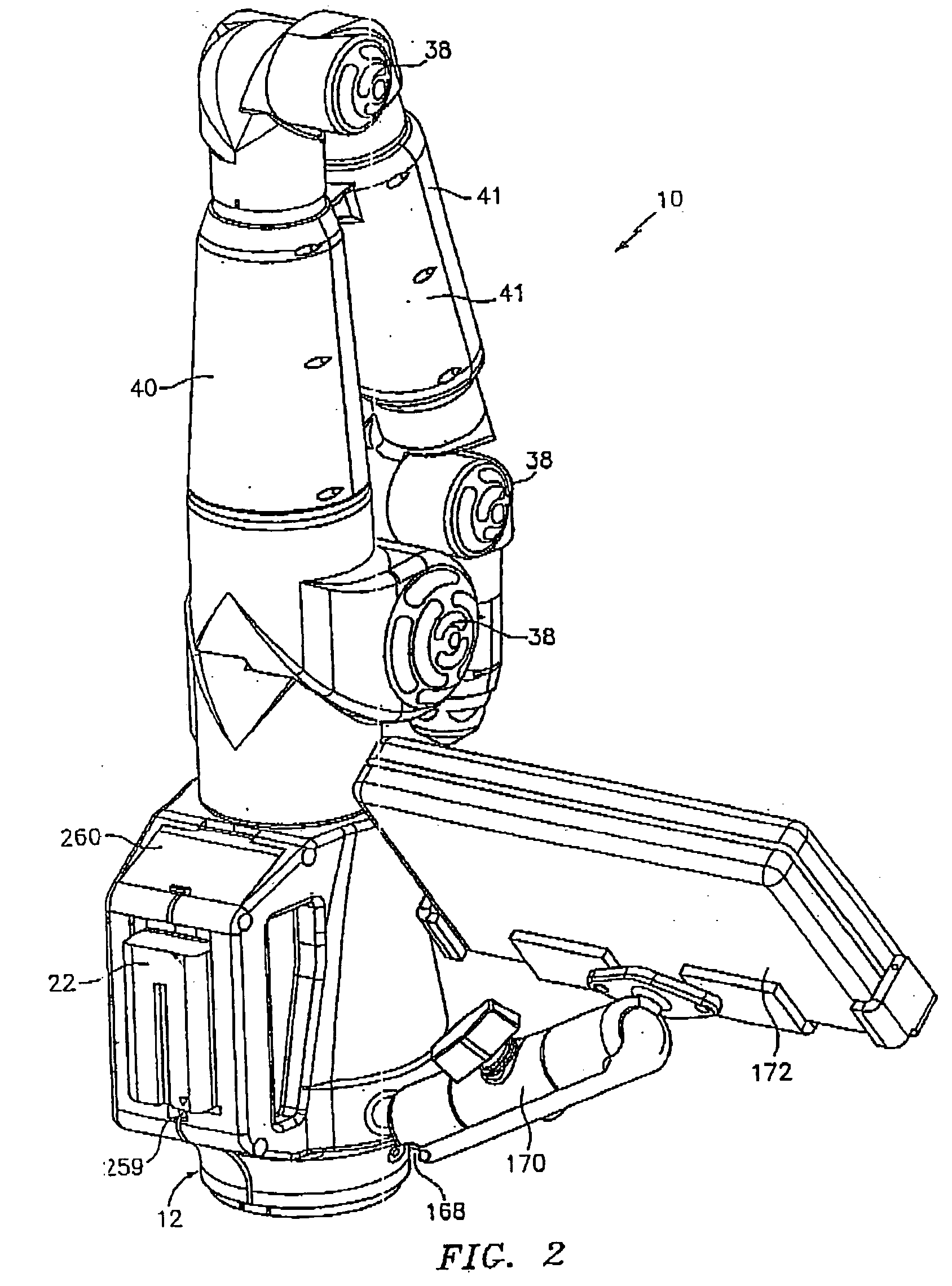

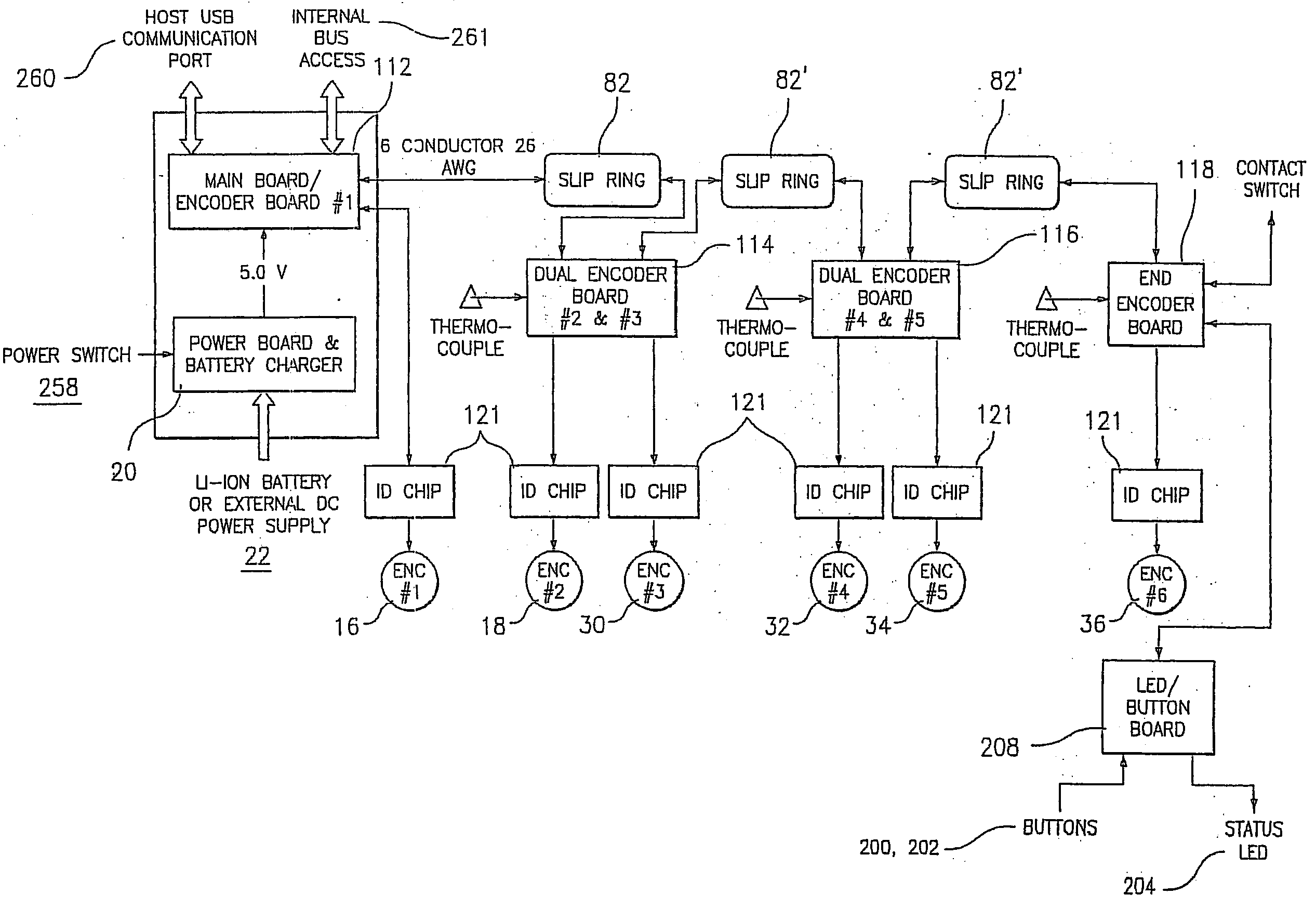

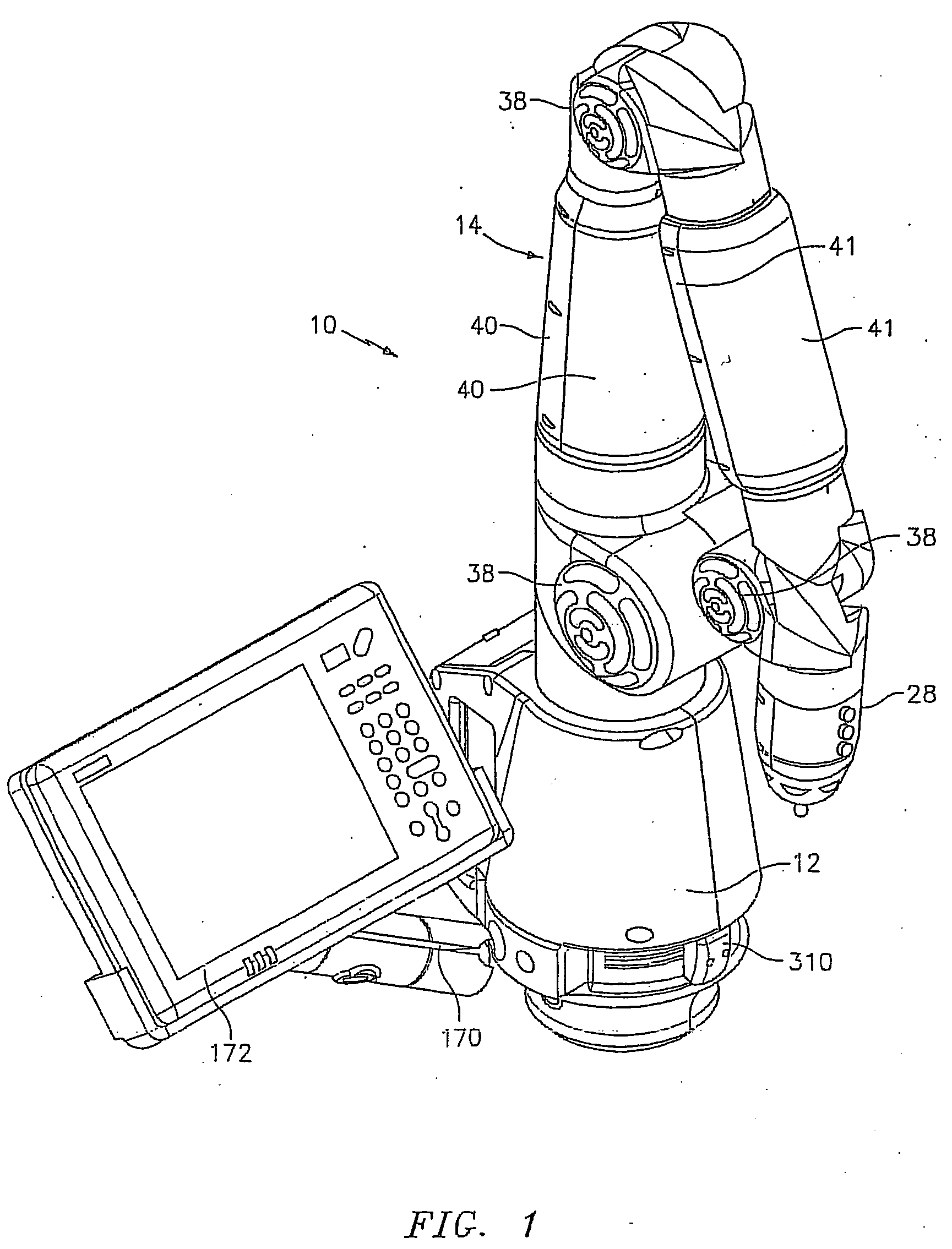

Portable coordinate measurement machine with integrated magnetic mount

InactiveUS6892465B2Easy to convertEasy to distinguishProgramme-controlled manipulatorImage analysisEngineeringMagnet

Owner:FARO TECH INC

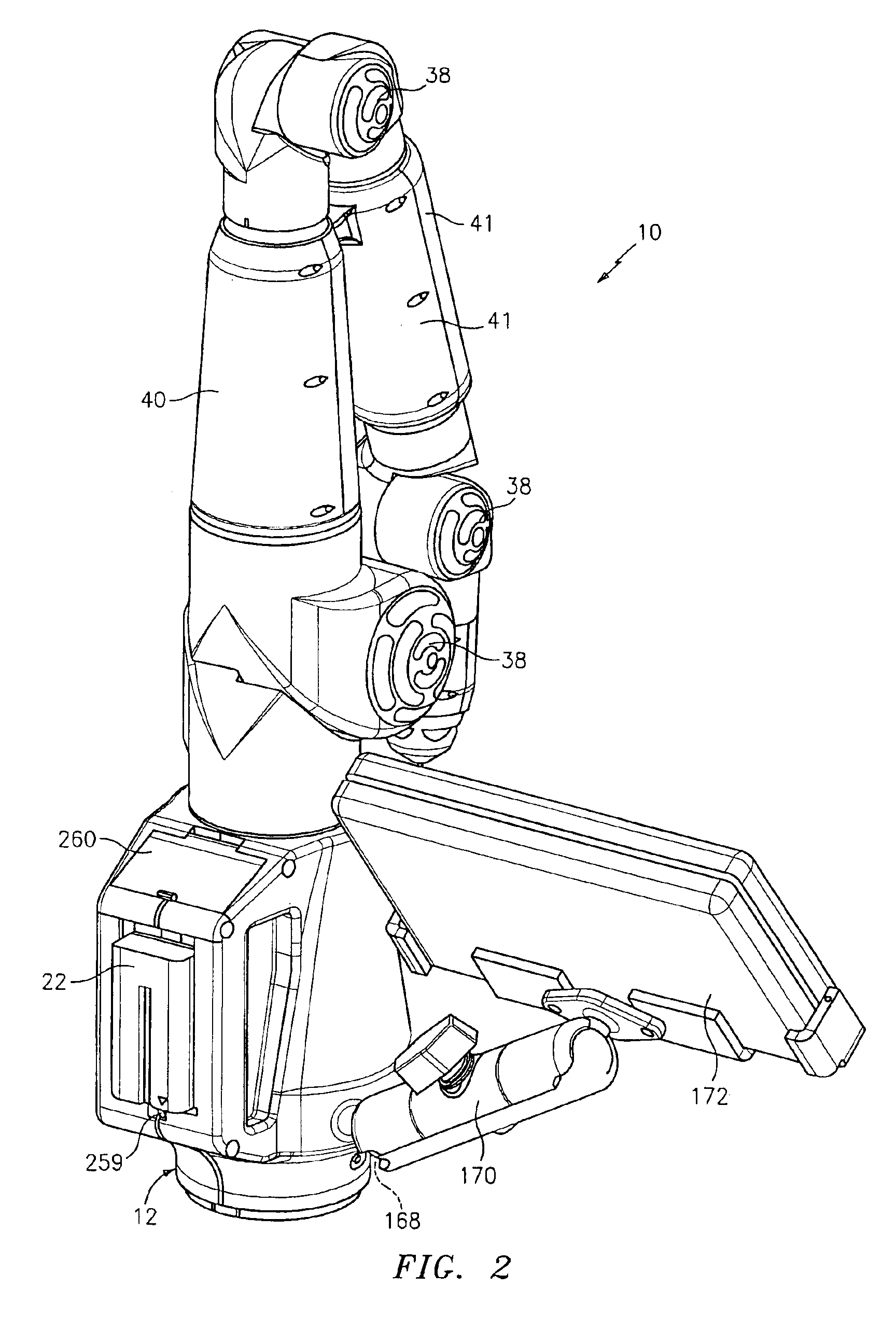

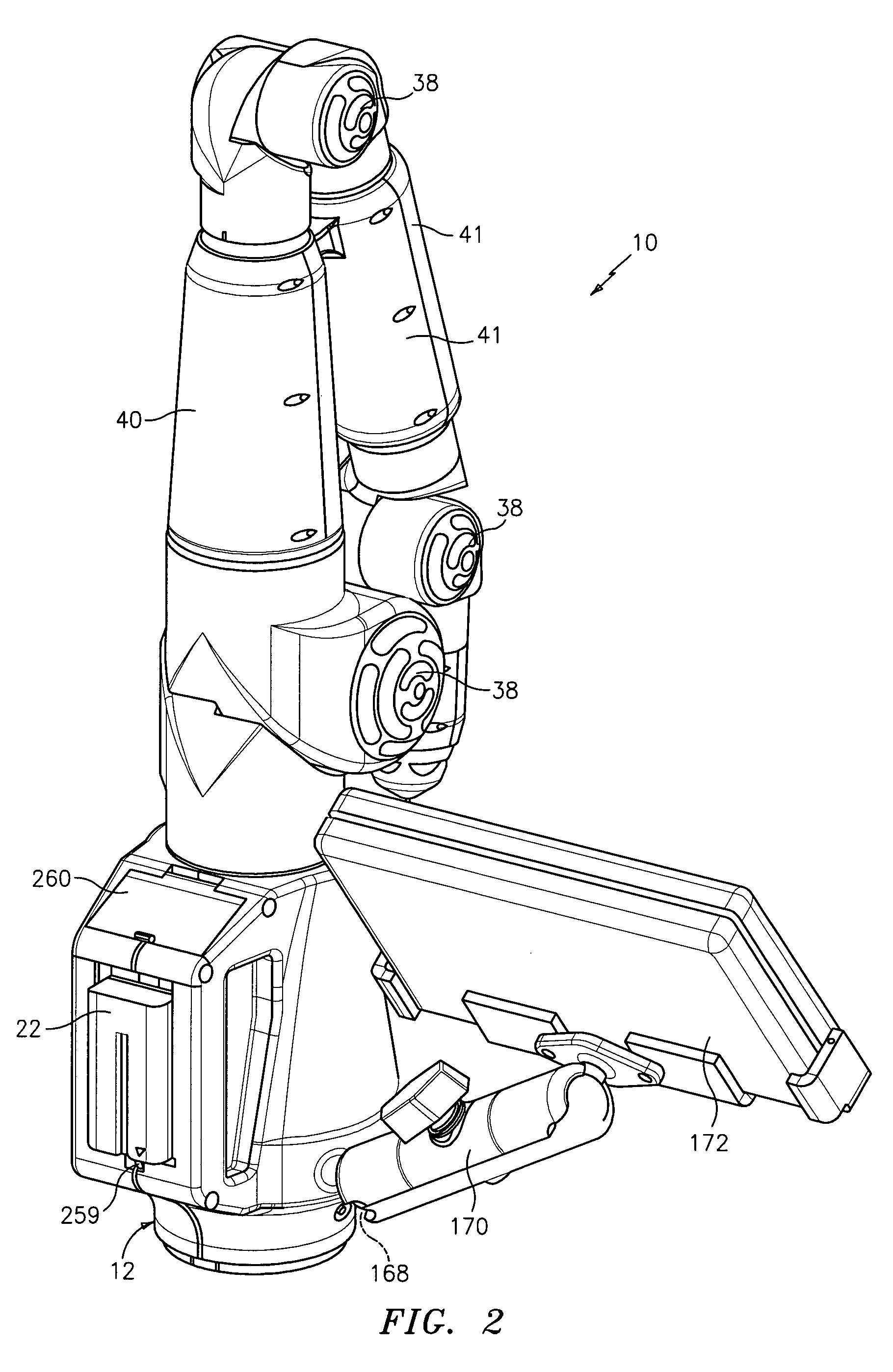

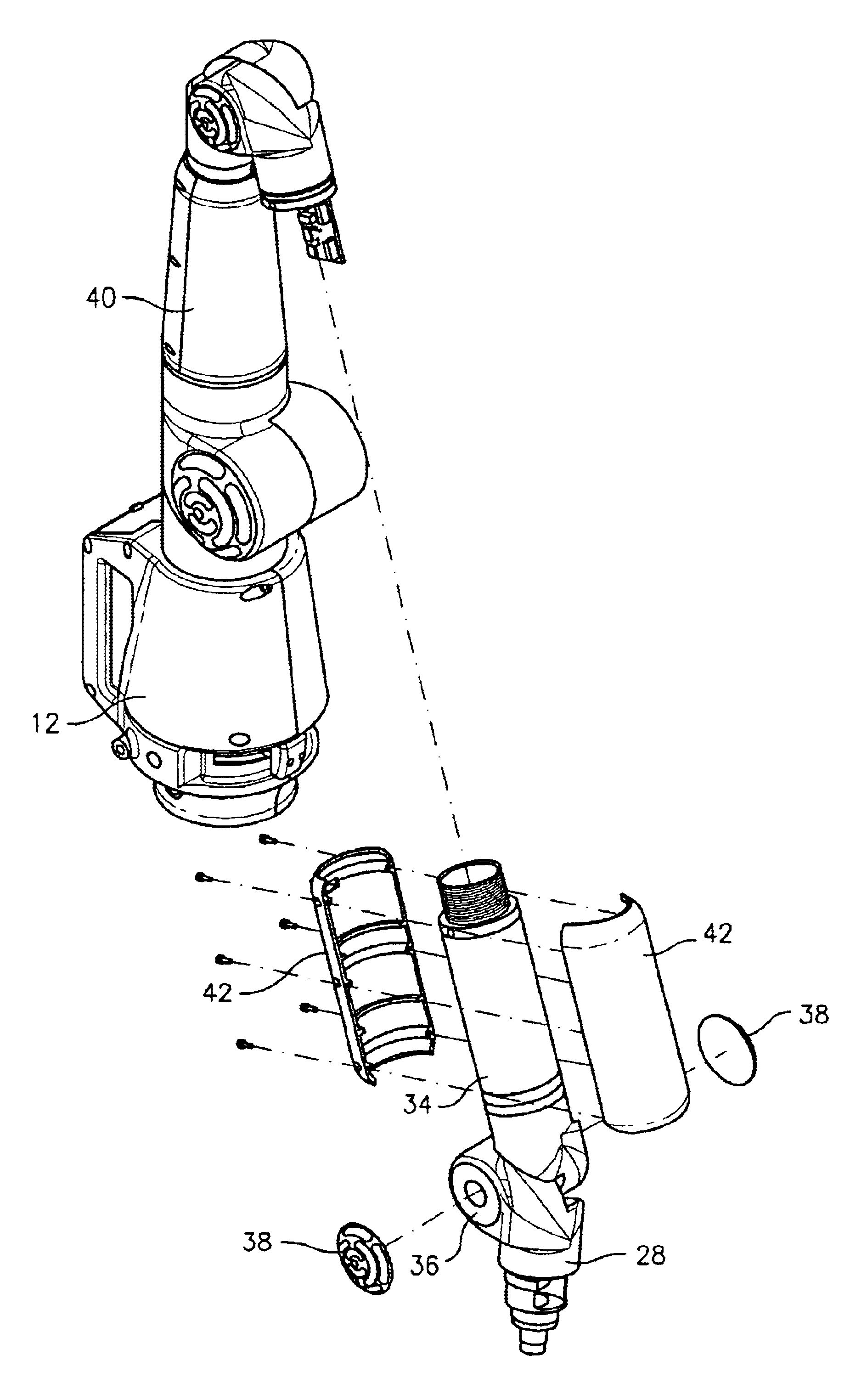

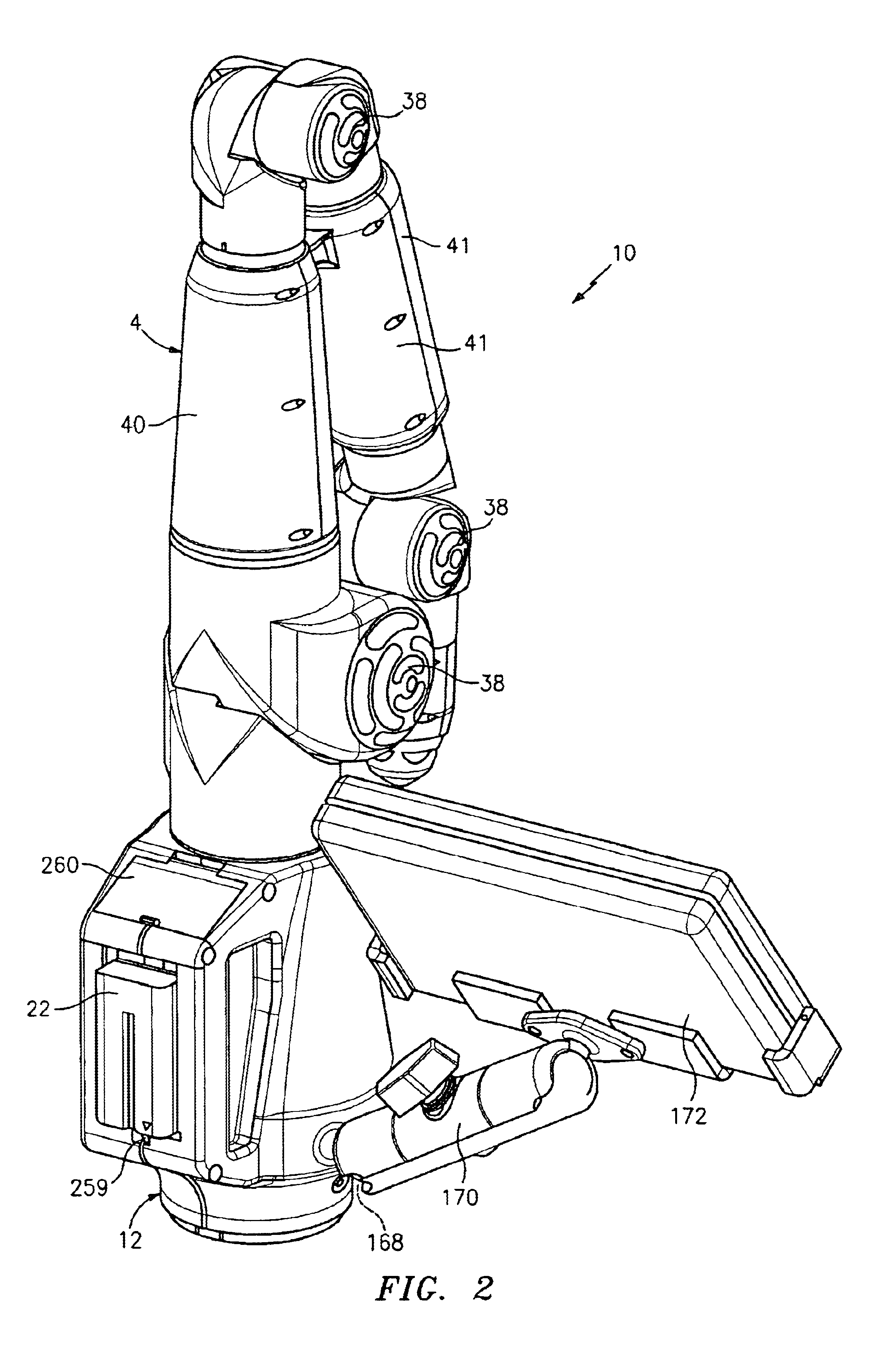

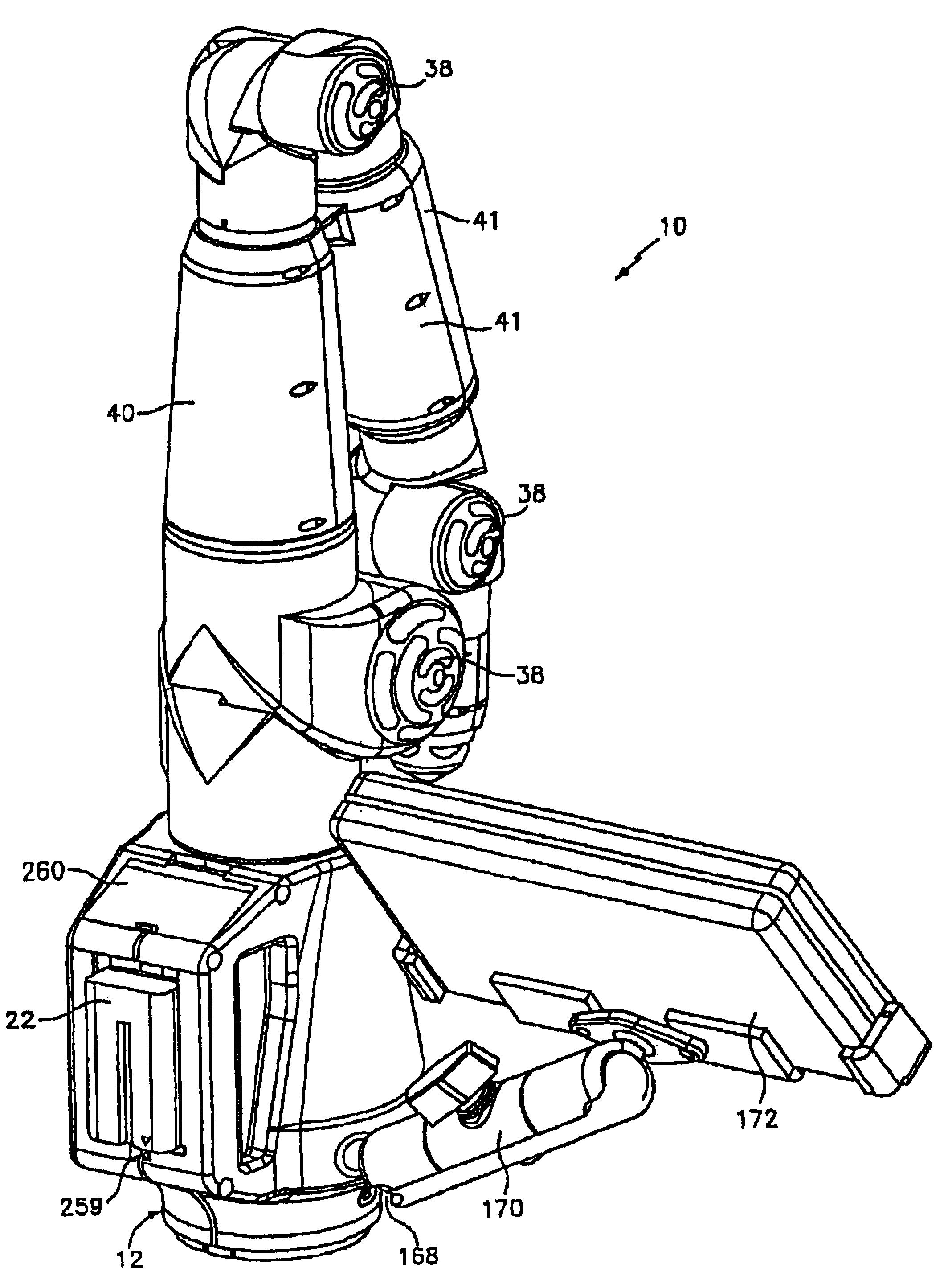

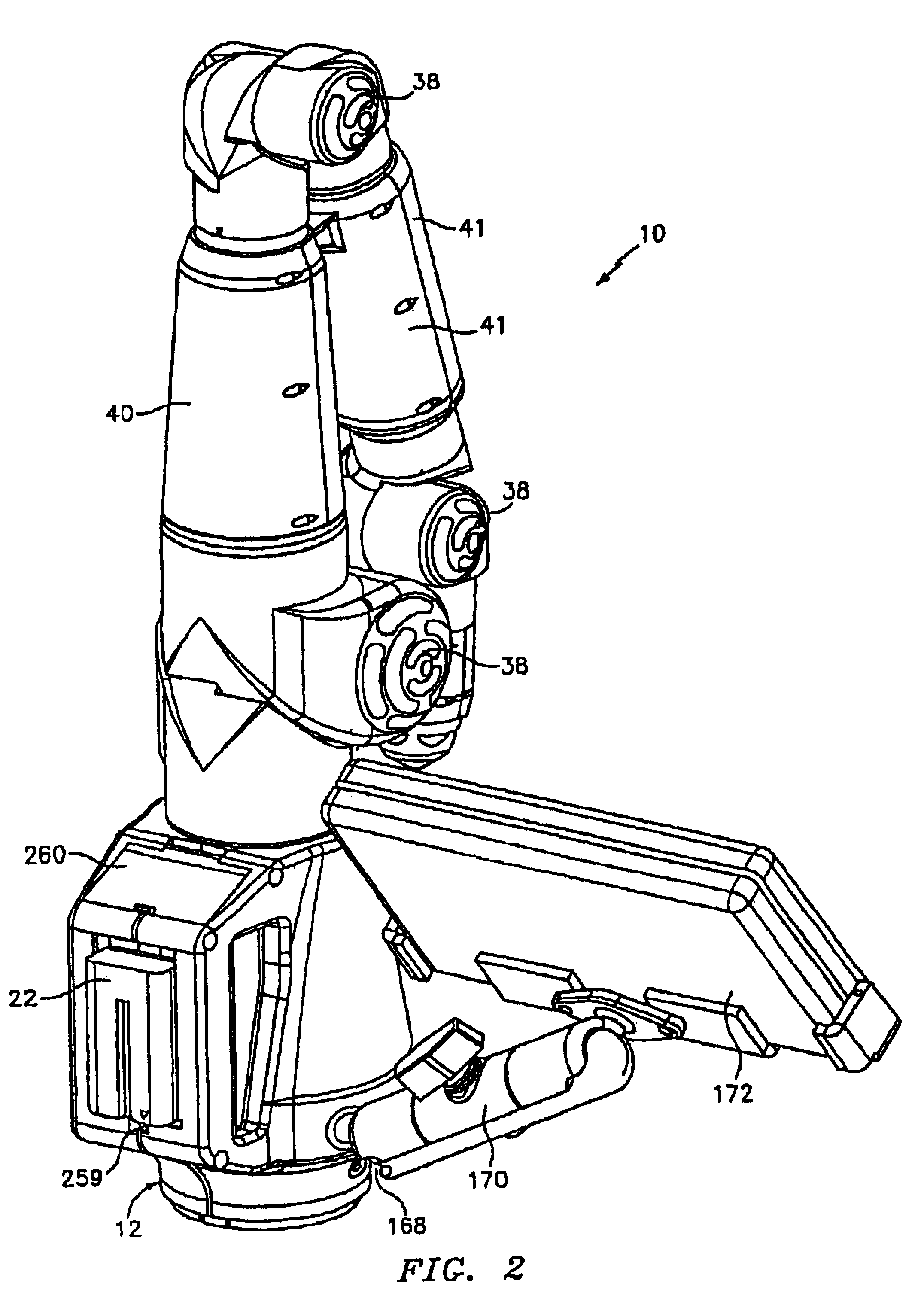

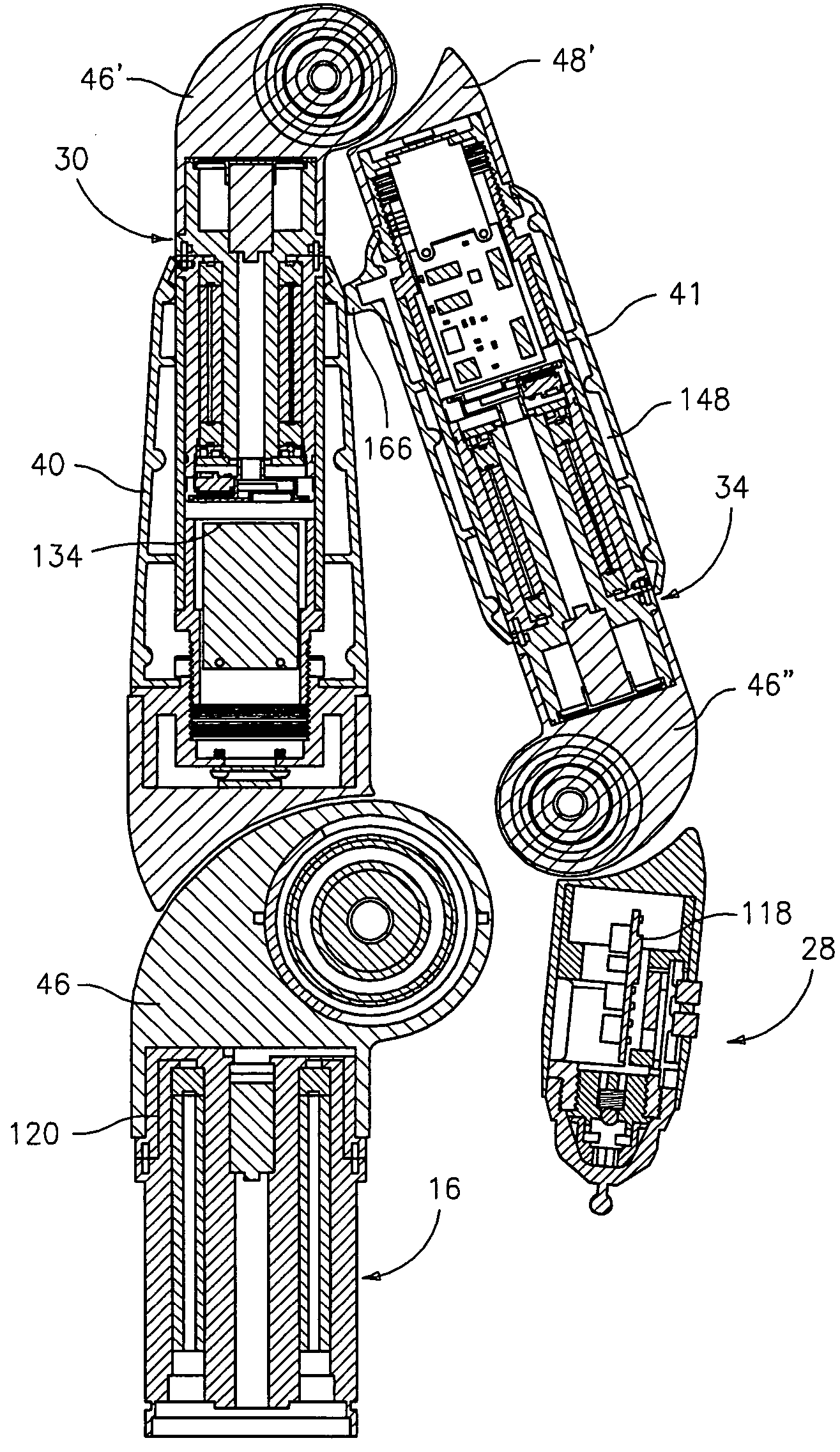

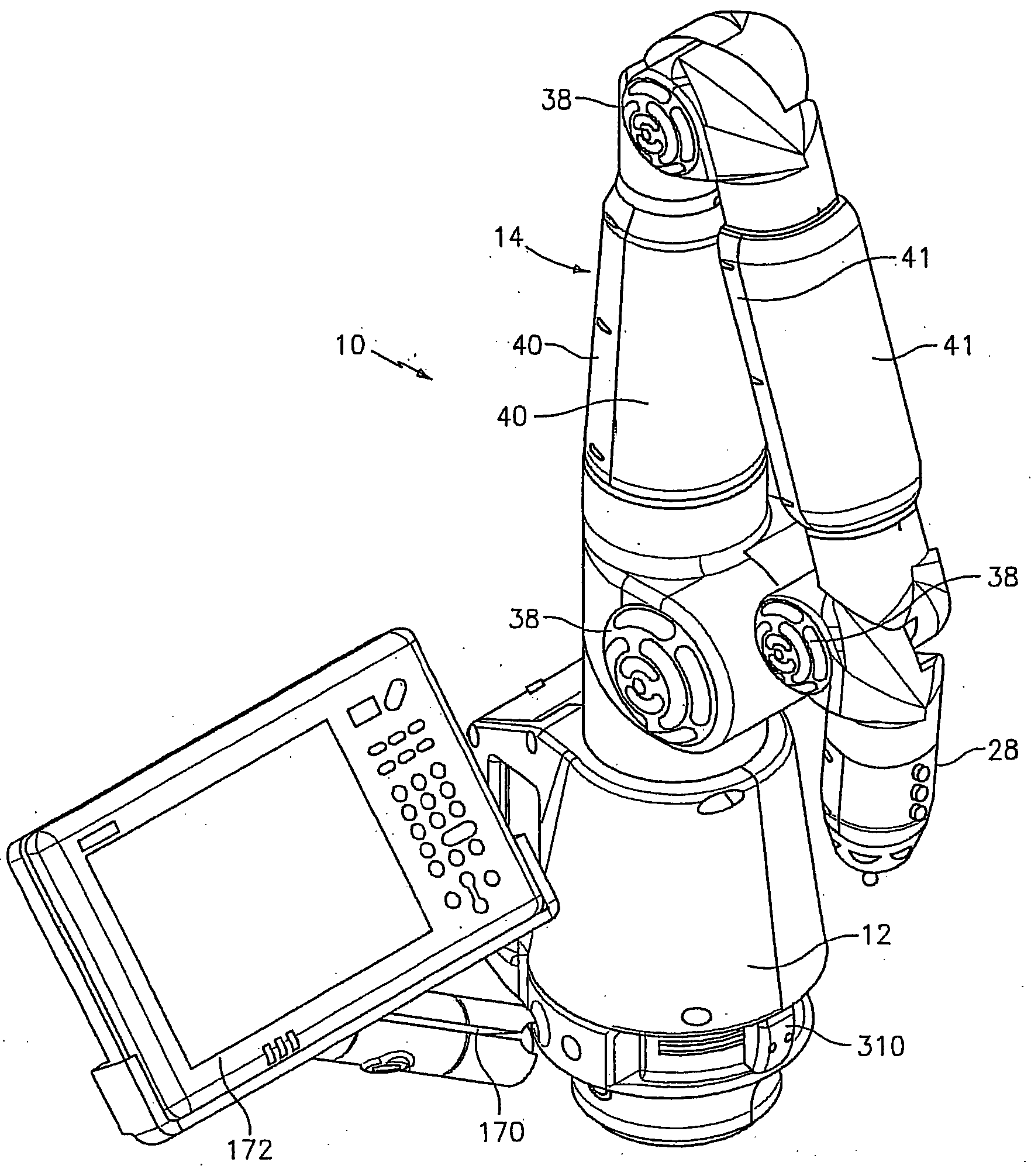

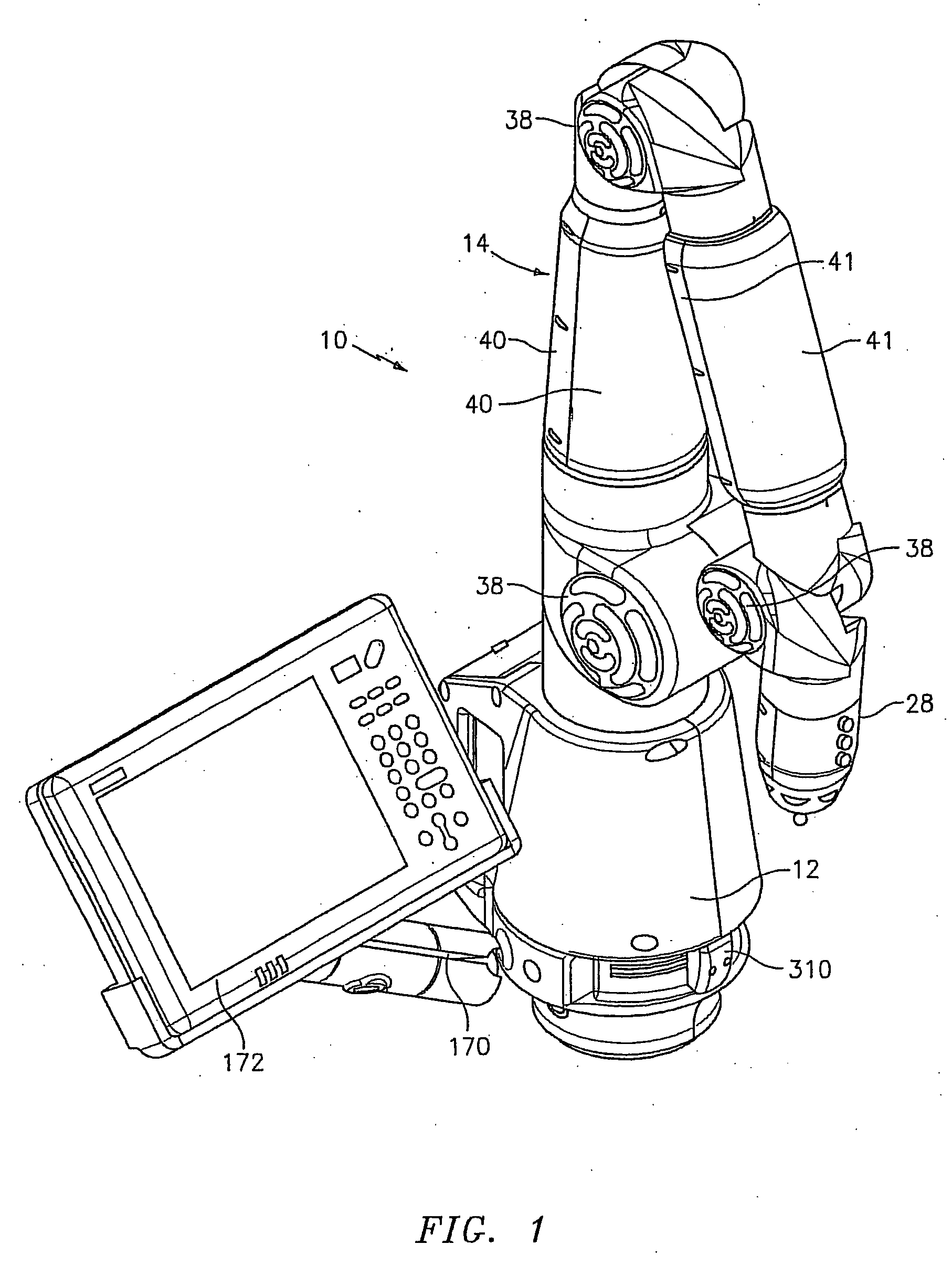

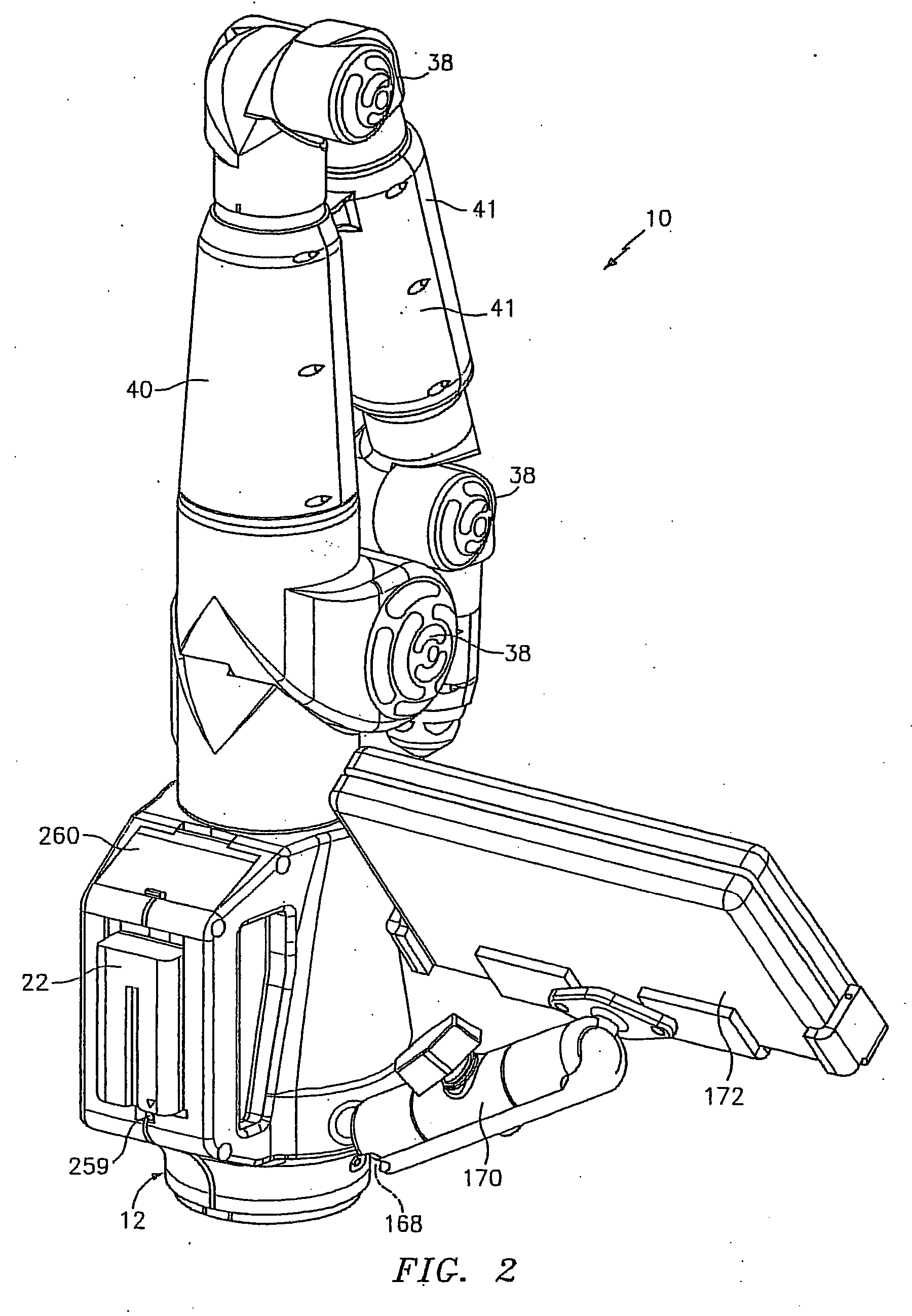

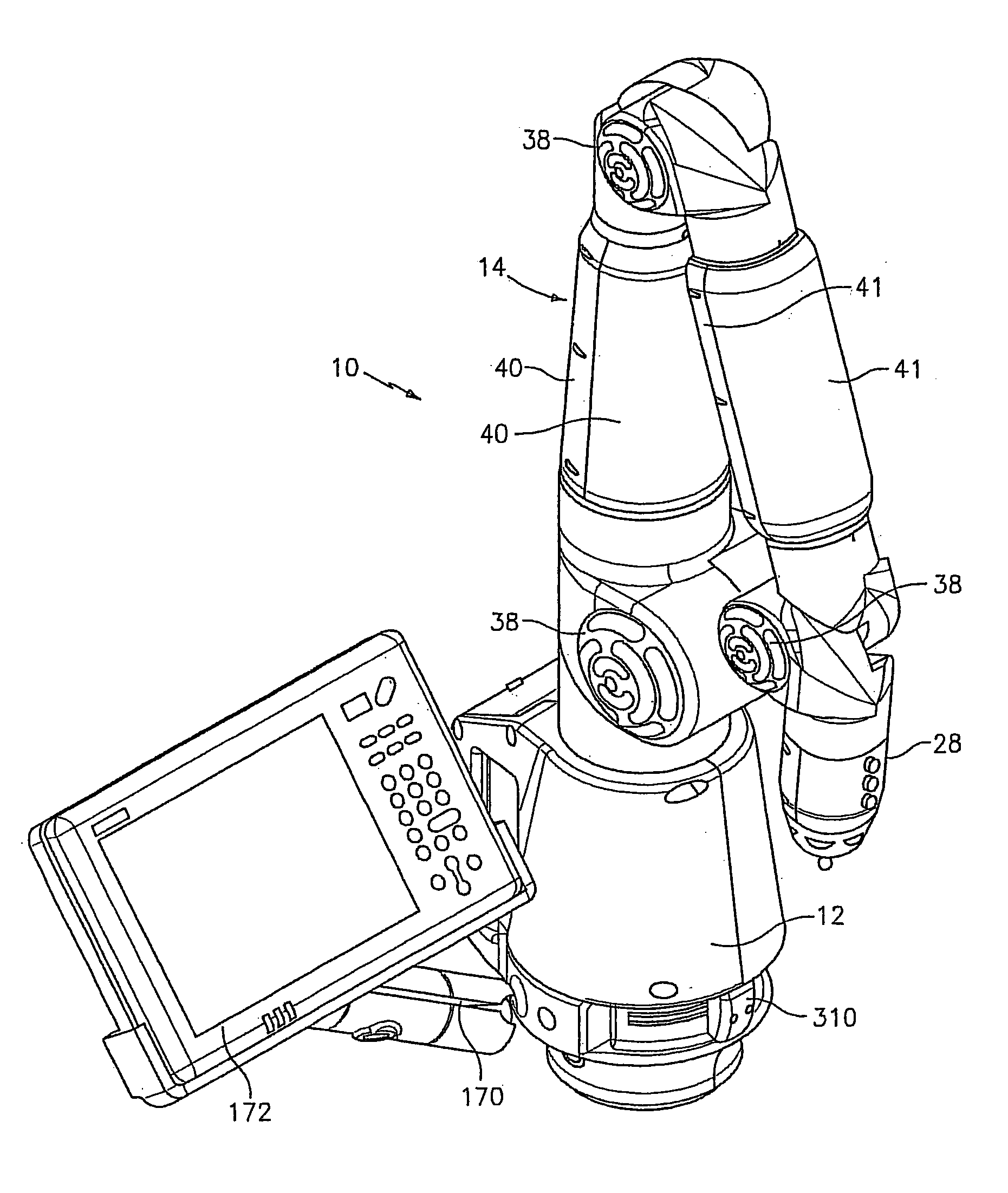

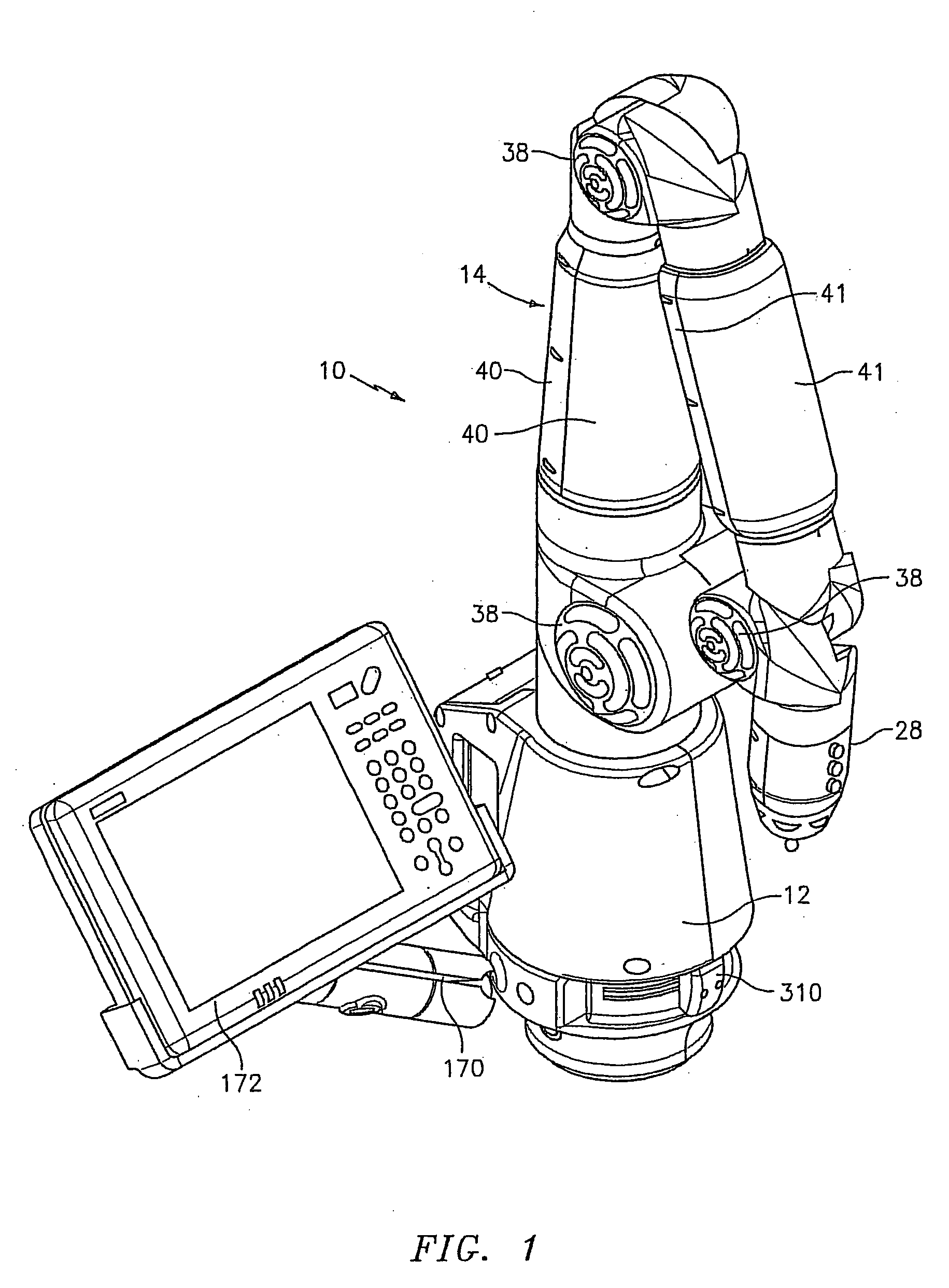

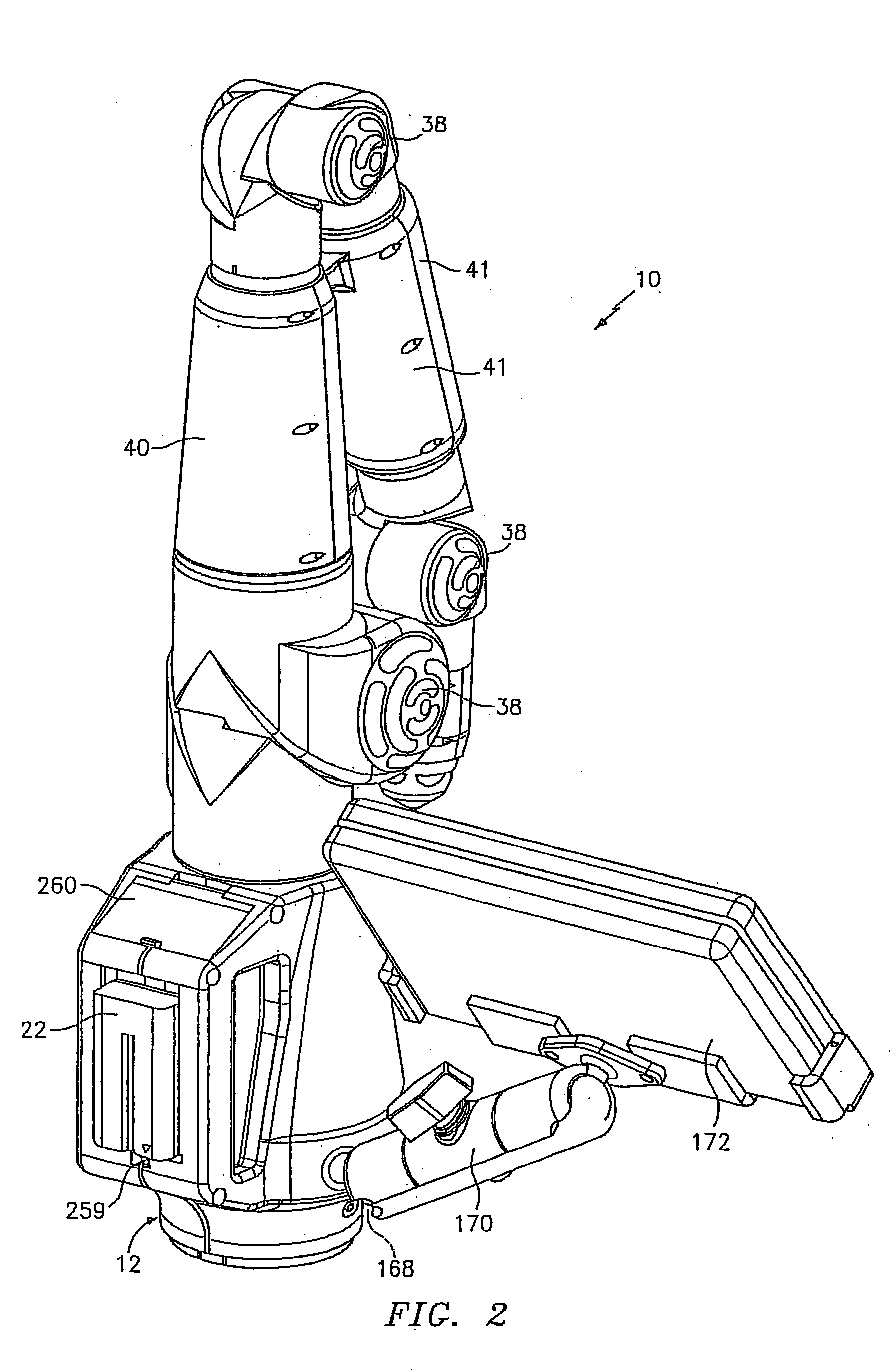

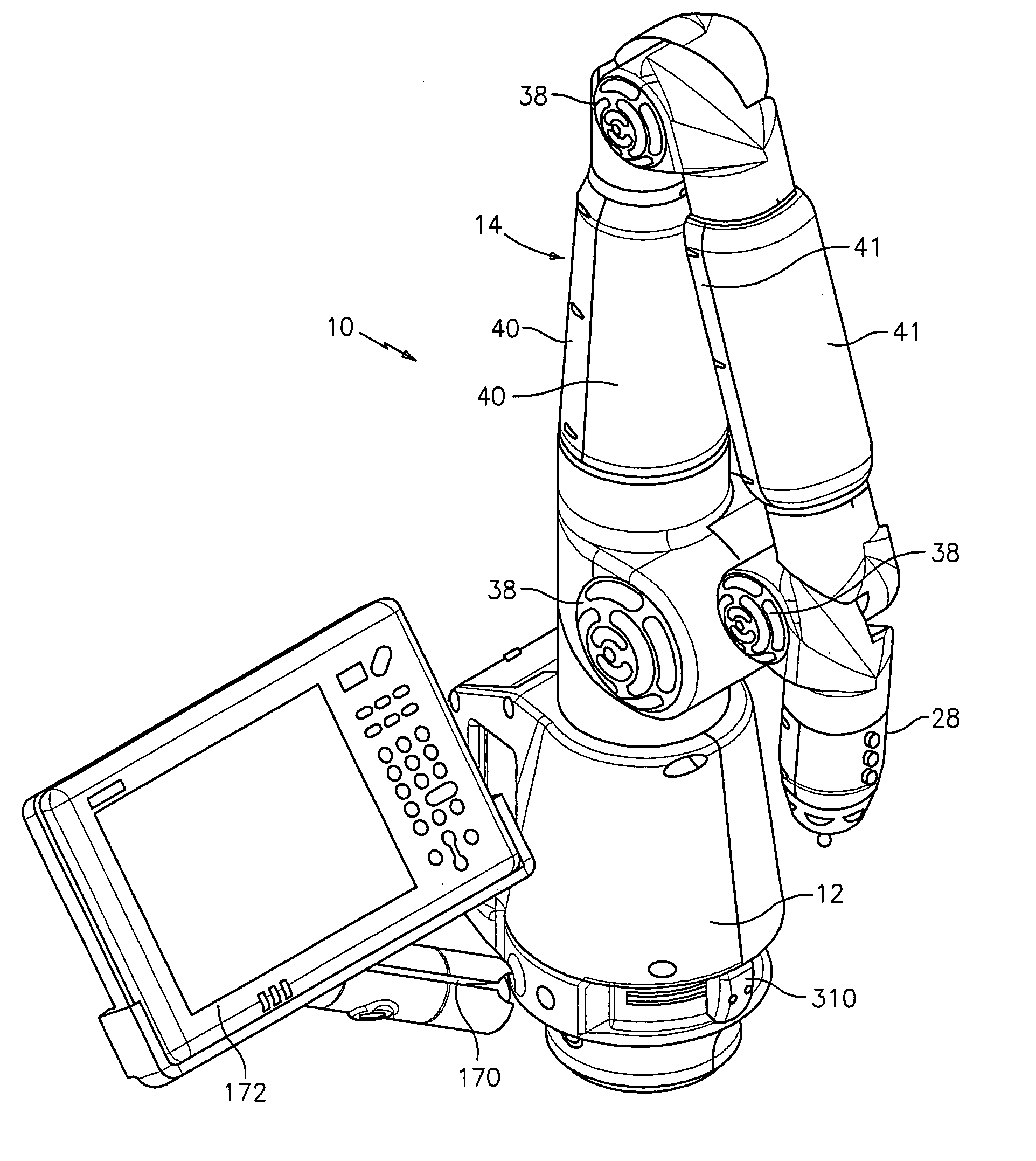

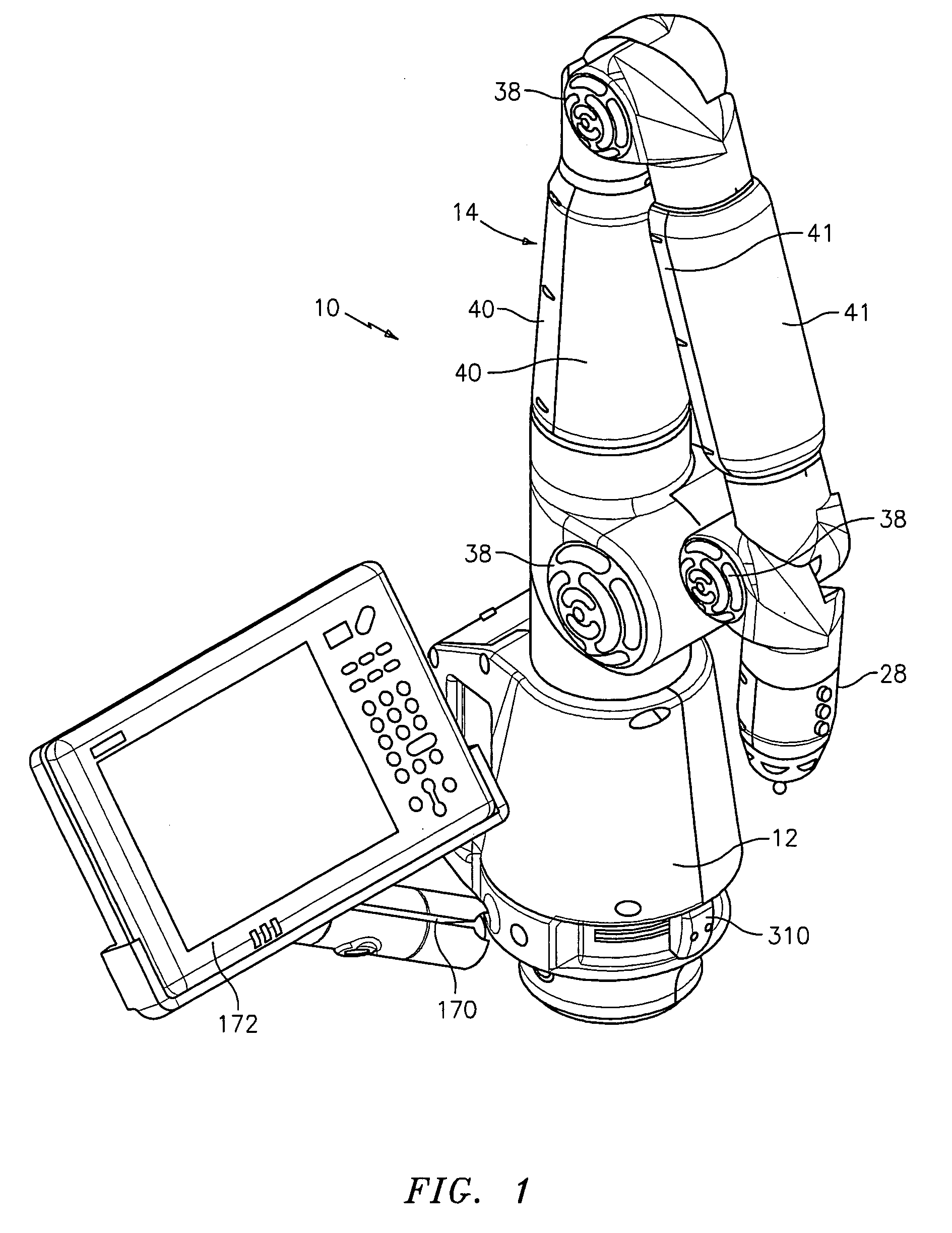

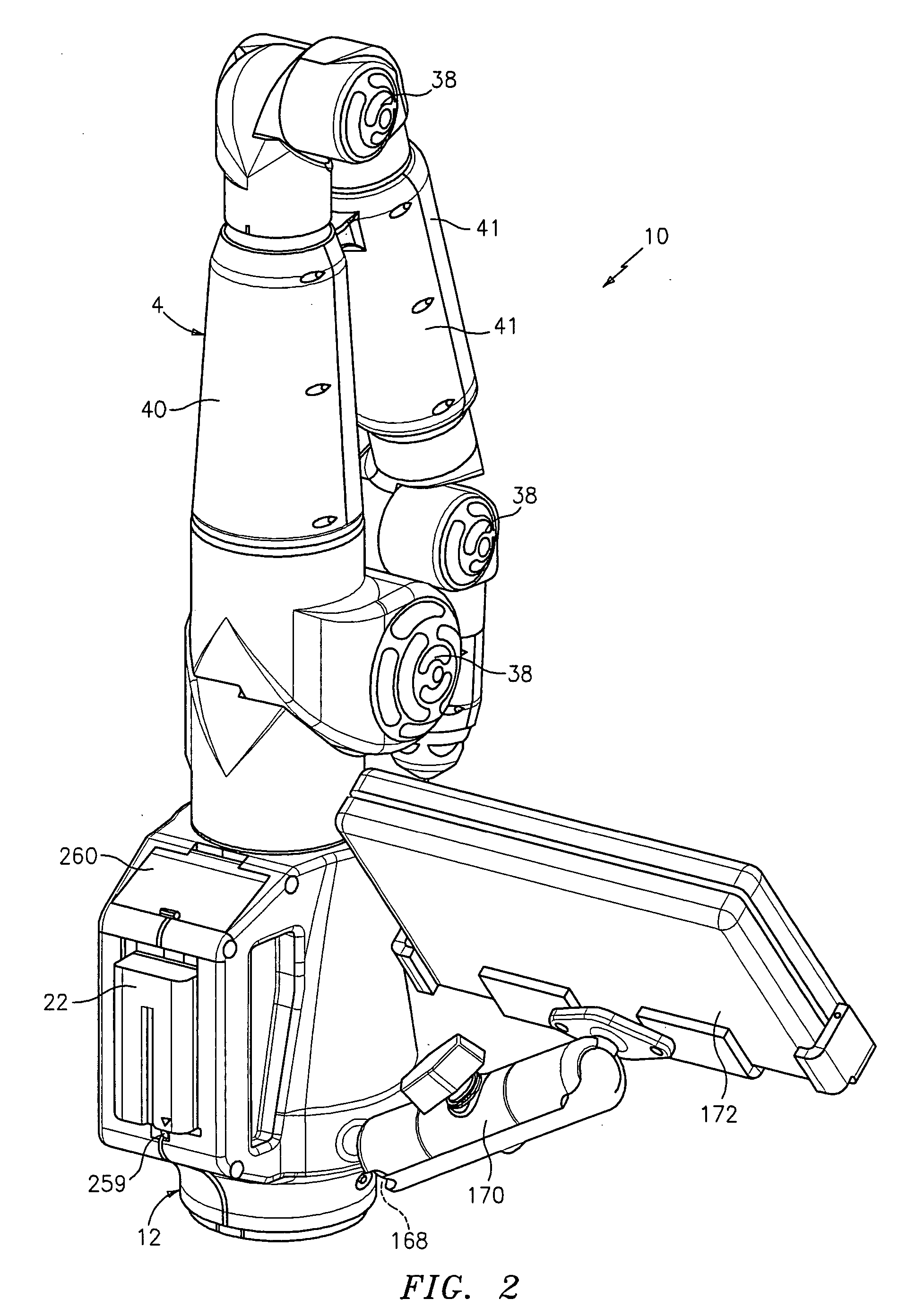

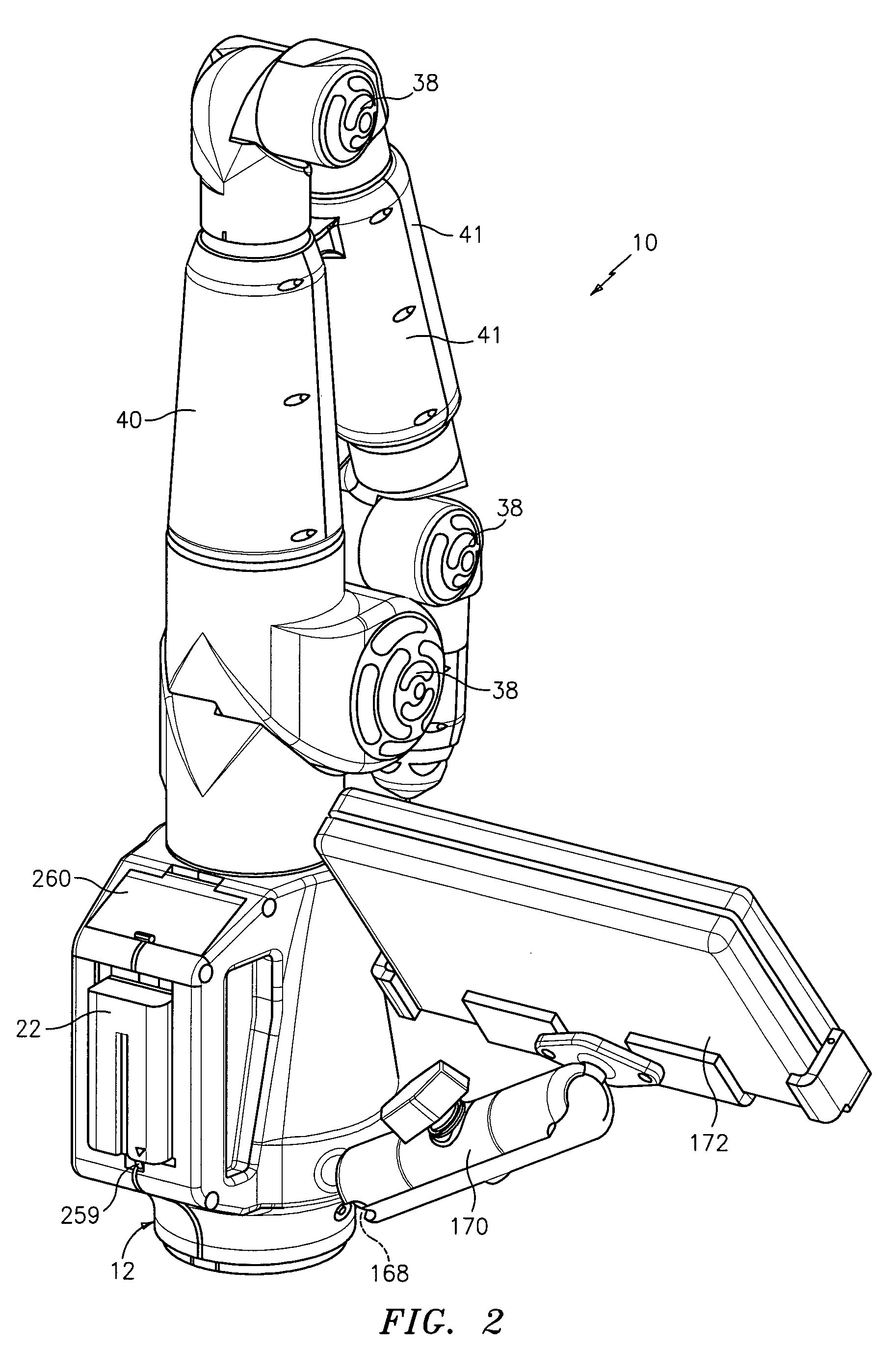

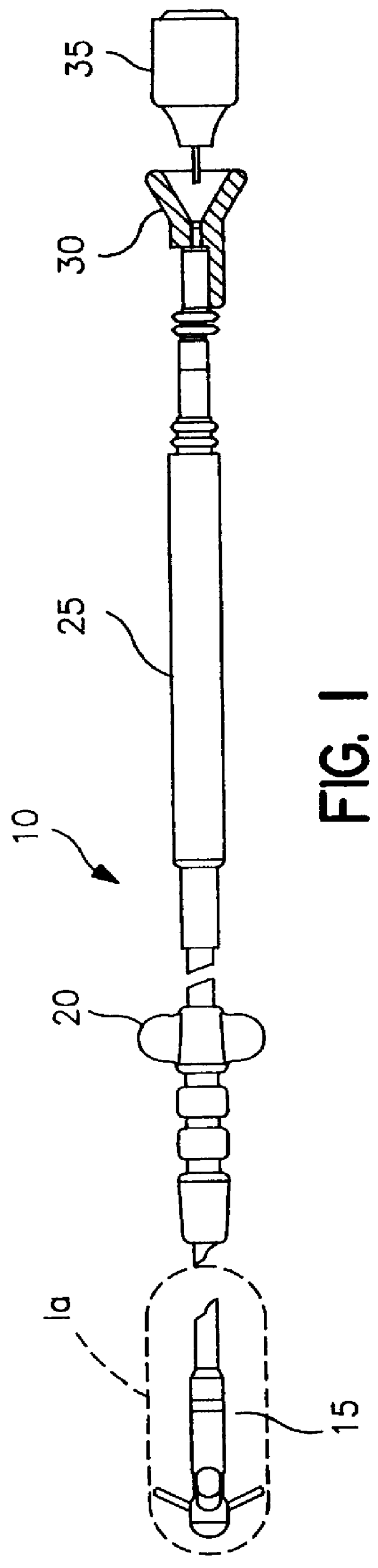

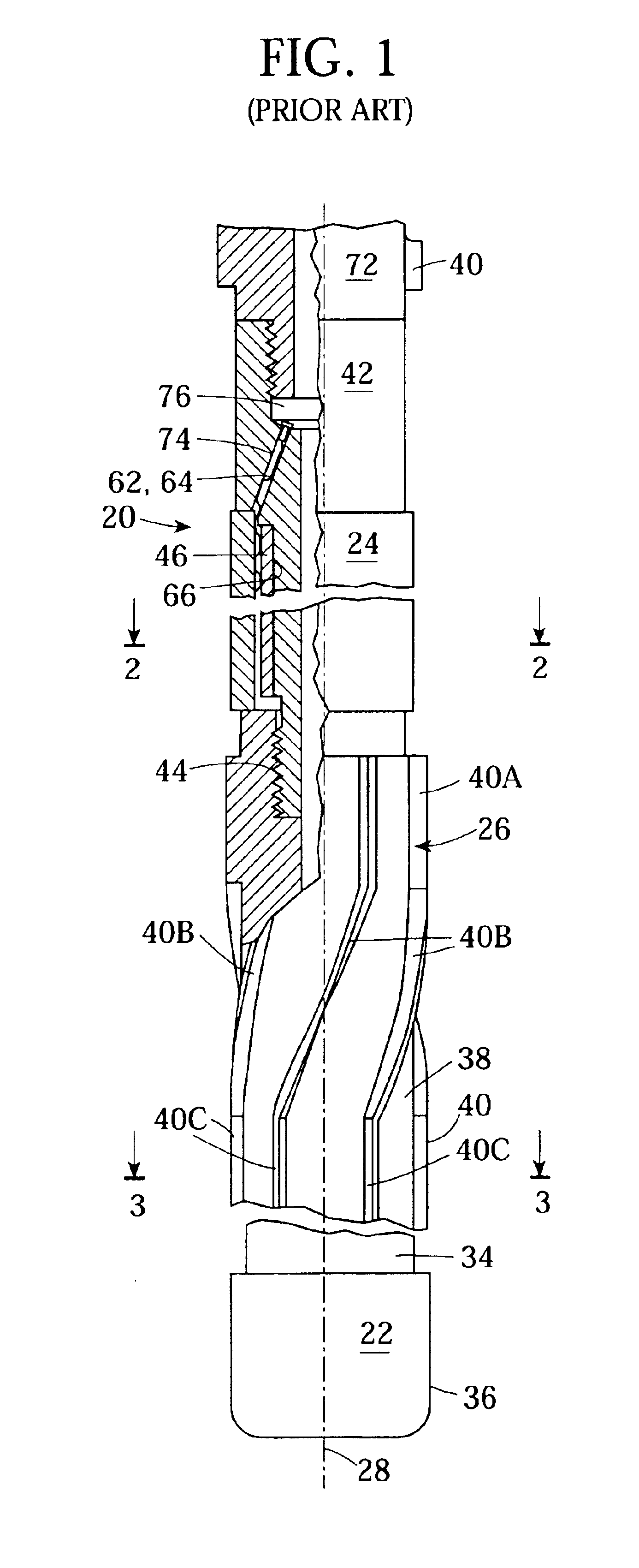

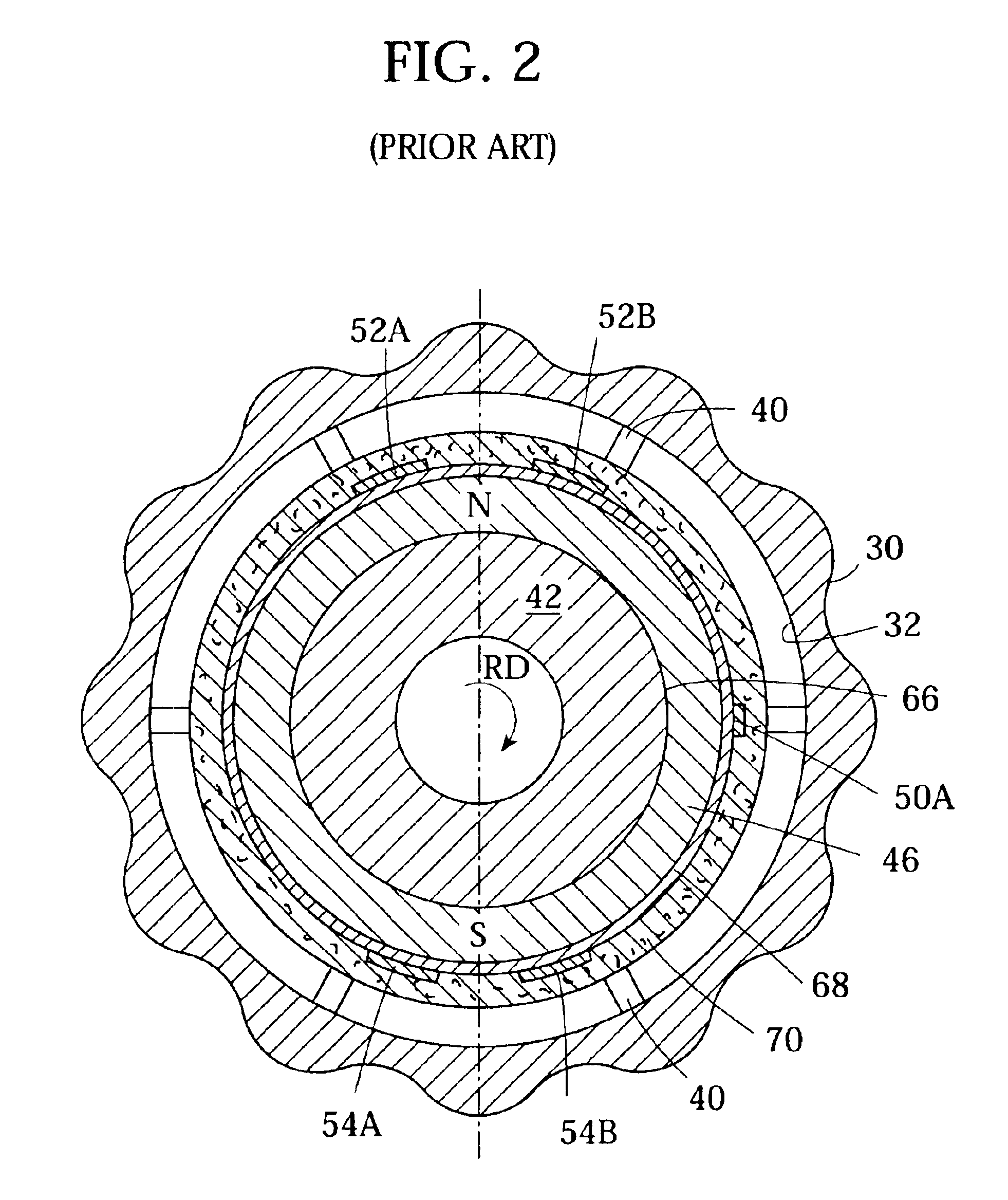

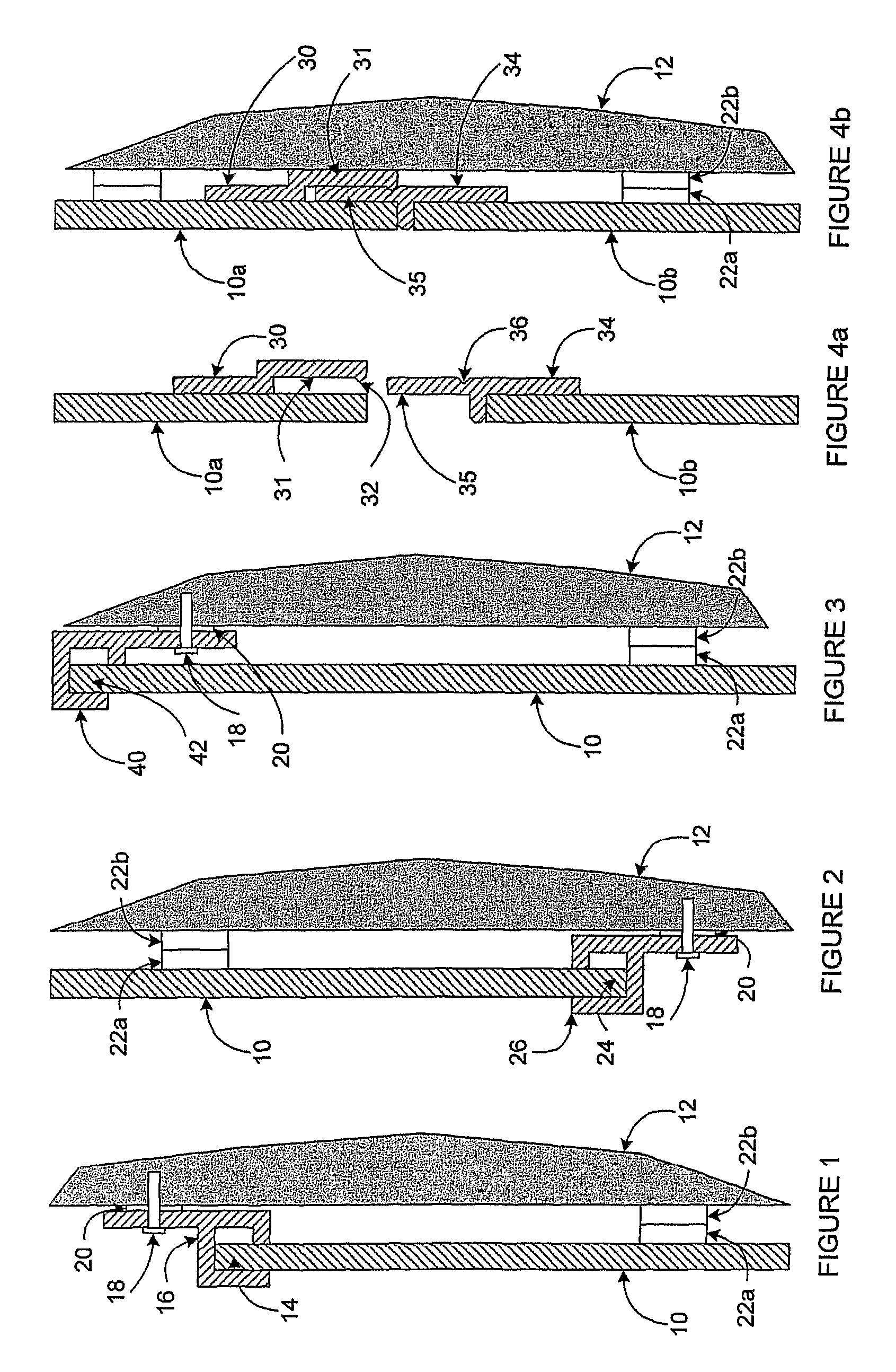

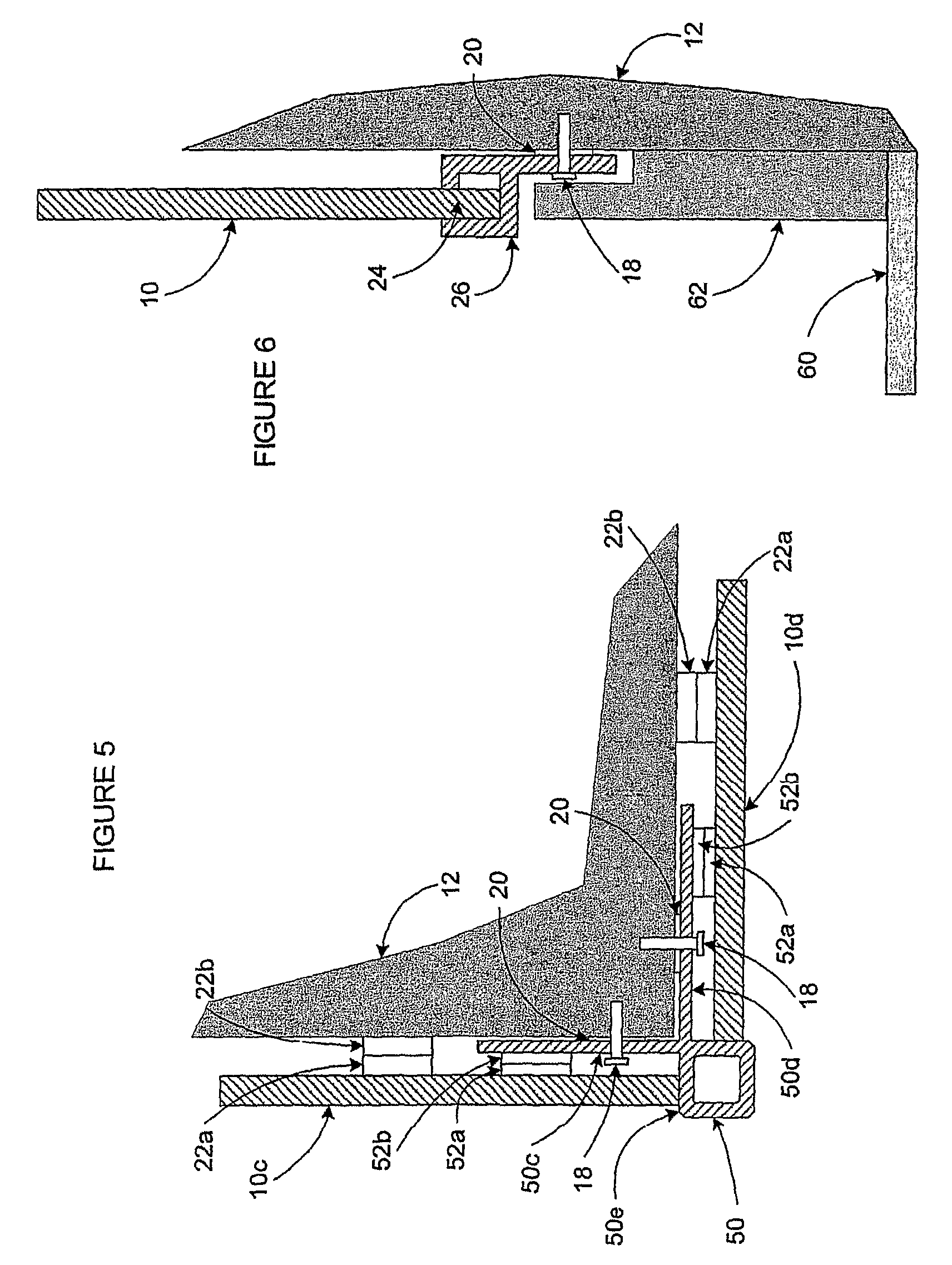

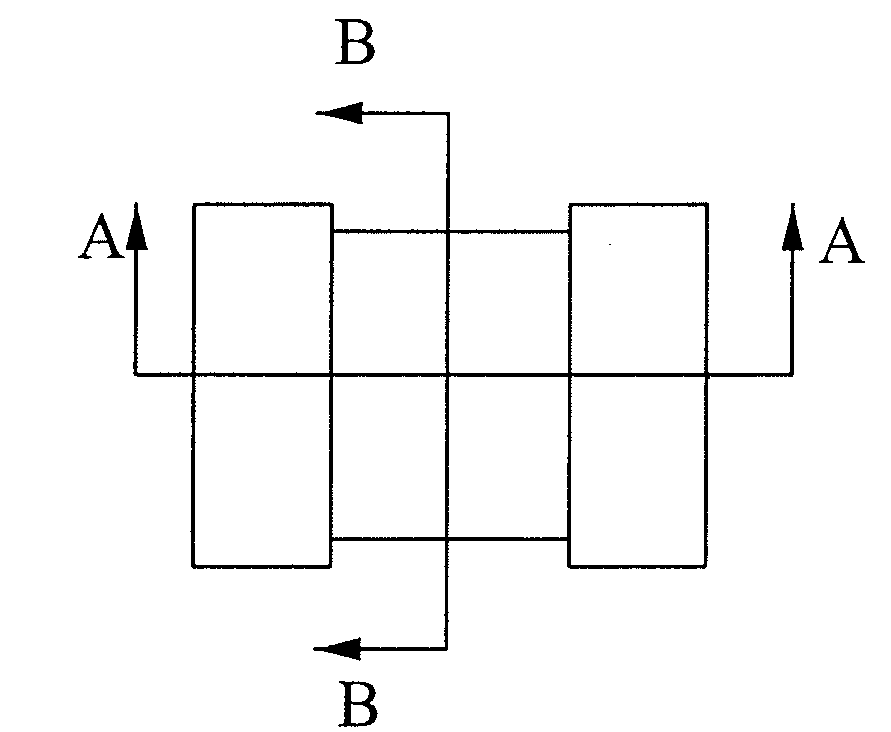

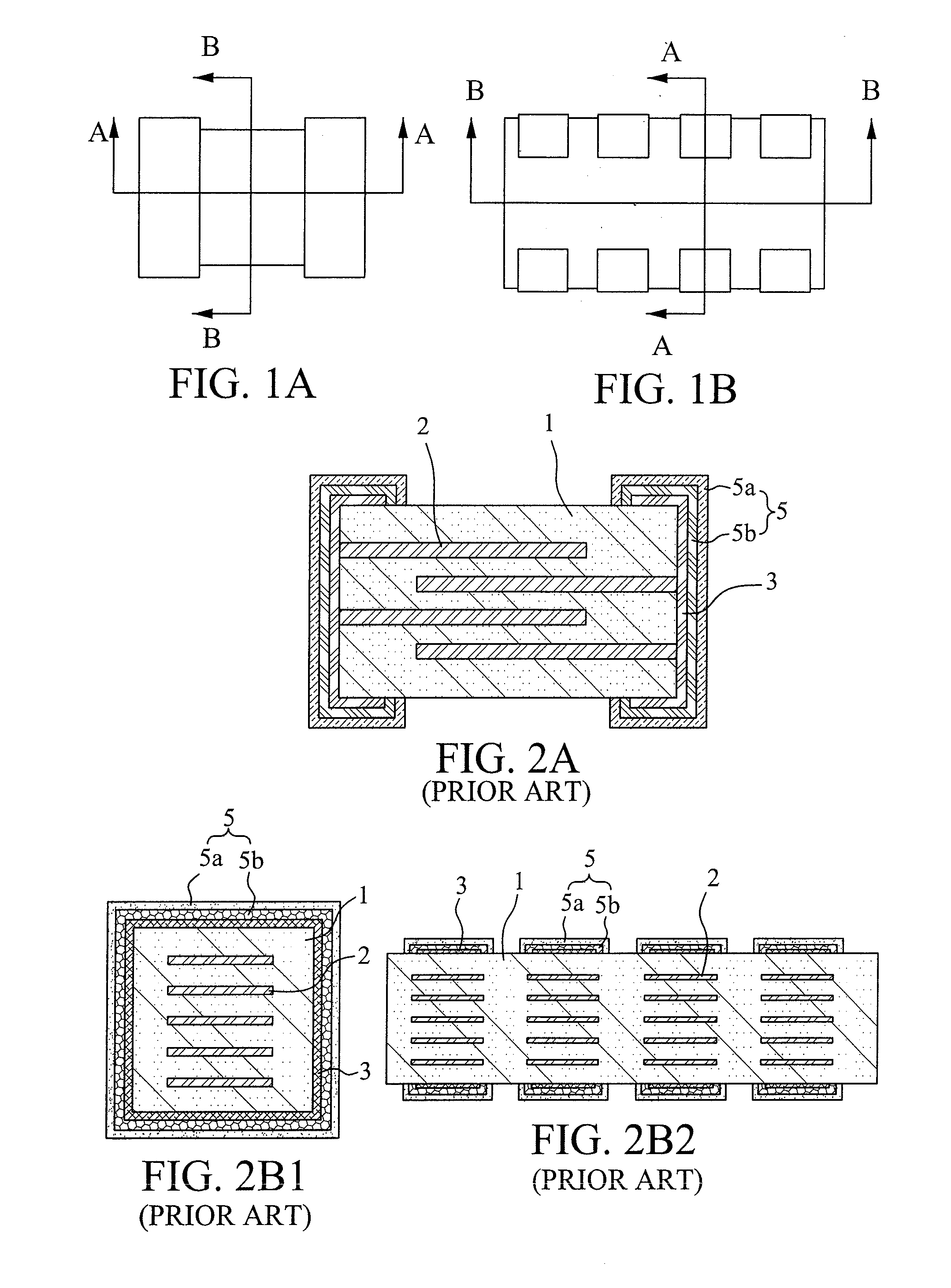

Portable coordinate measurement machine

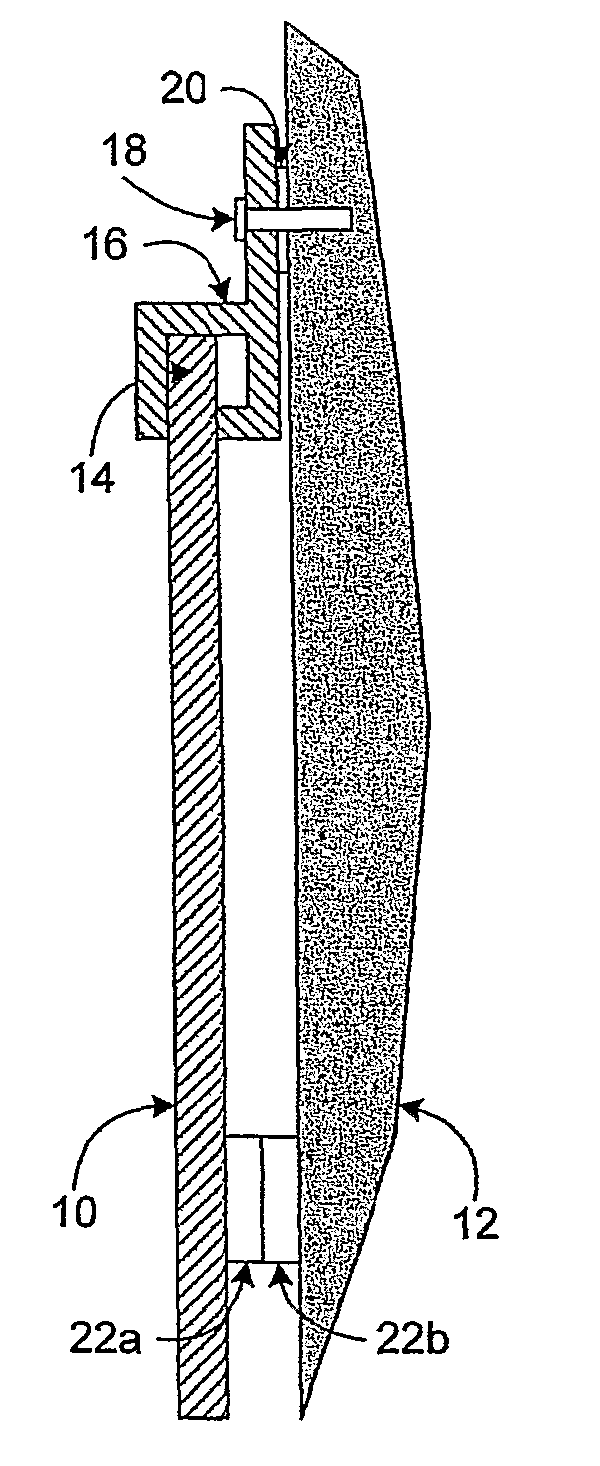

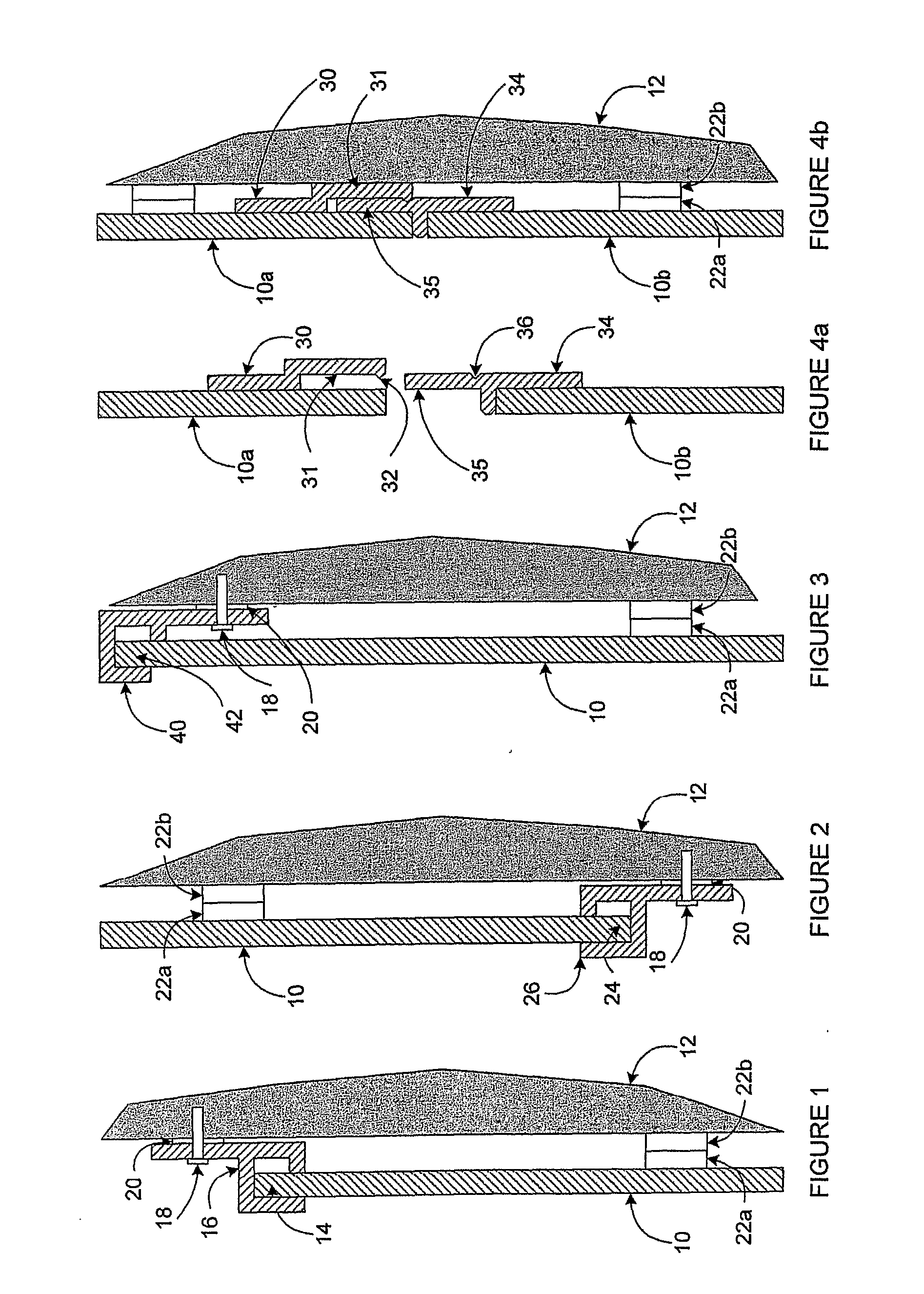

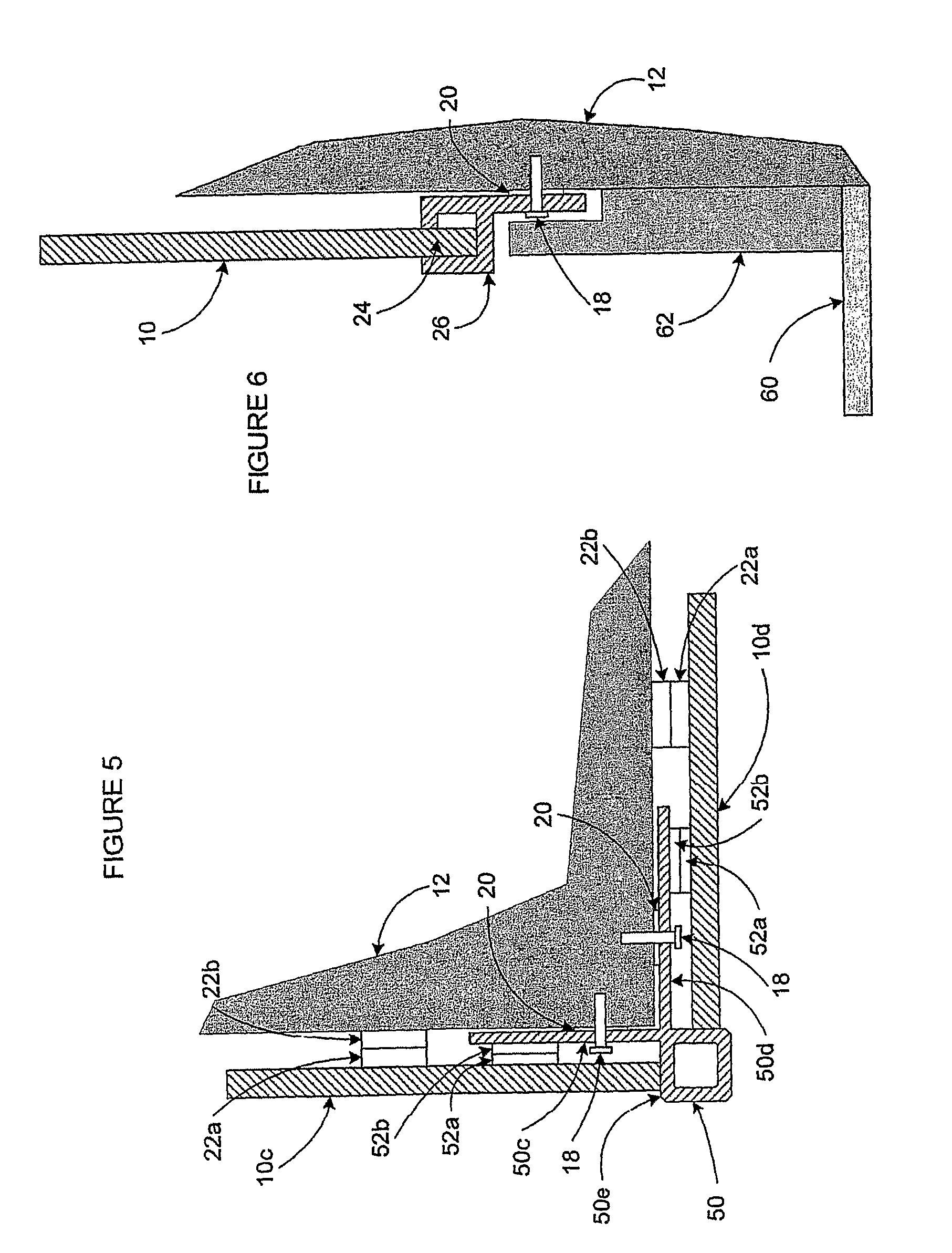

InactiveUS7073271B2High abrasionHigh impactAngles/taper measurementsUsing electrical meansStructural engineeringCoordinate-measuring machine

Owner:FARO TECH INC

Portable coordinate measurement machine

InactiveUS6952882B2Easy to convertEasy to distinguishProgramme-controlled manipulatorAngles/taper measurementsProximity sensorEngineering

A portable coordinate measurement machine comprises an articulated arm having jointed arm segments. The arm includes joint assemblies which include at least one read head together with one or more (preferably five) sensors (preferably proximity sensors) in communication with a periodic pattern of a measurable characteristic, the pattern and read heads being positioned within the joint so as to be rotatable with respect to each other.

Owner:FARO TECH INC

Method and apparatus for improving measurement accuracy of a portable coordinate measurement machine

InactiveUSRE42082E1Easy to convertEasy to distinguishProgramme-controlled manipulatorAngles/taper measurementsEngineeringMeasurement precision

A method for improving the measurement accuracy of a portable coordinate measurement machine which comprises an articulated arm having jointed arm segments is presented. This method includes sensing deformation of a portion of the articulated arm when the arm is placed under a load, this deformation causing an error in the measurement made by the CMM, and correcting such error in response to the sensed deformation.

Owner:FARO TECH INC

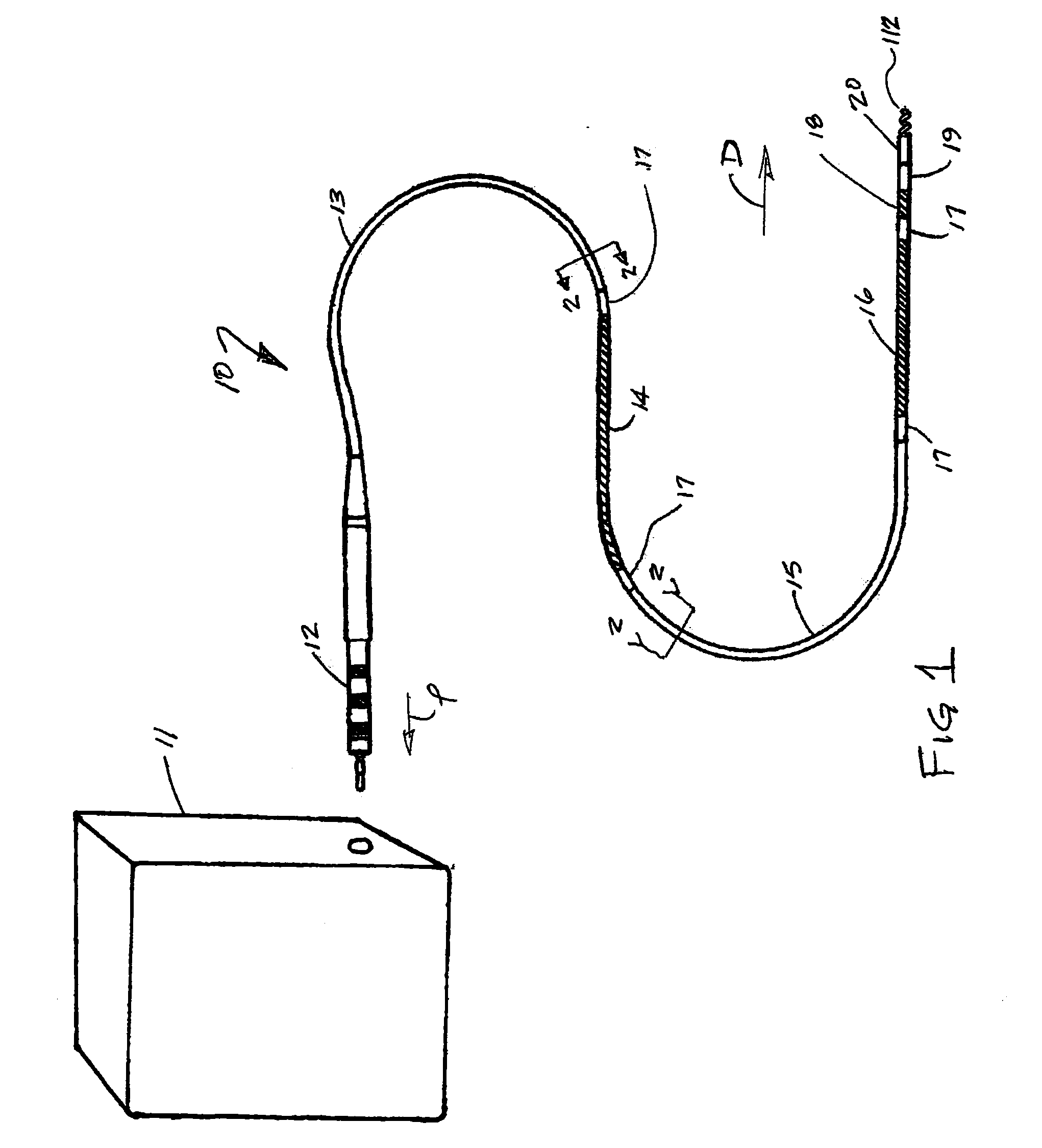

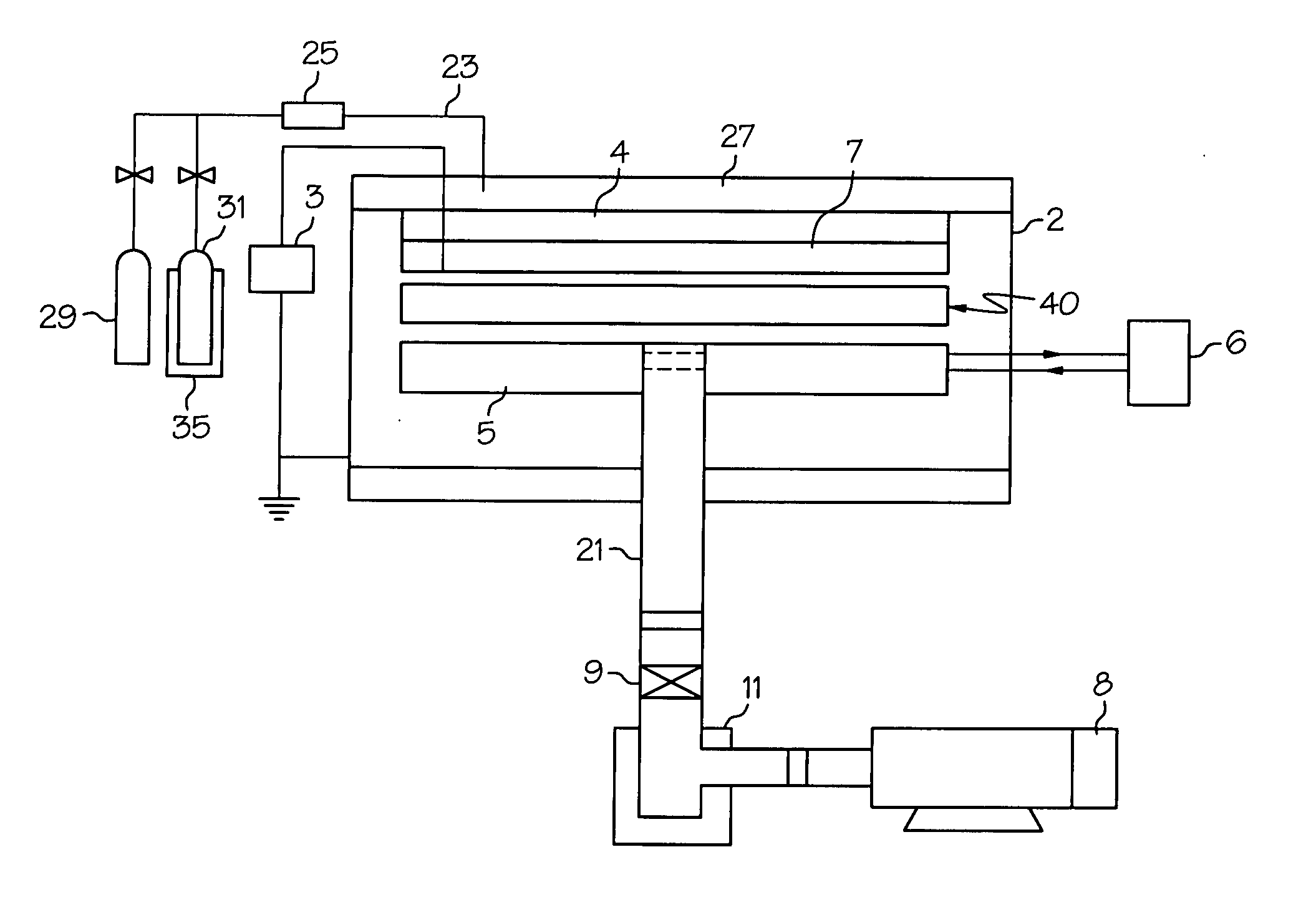

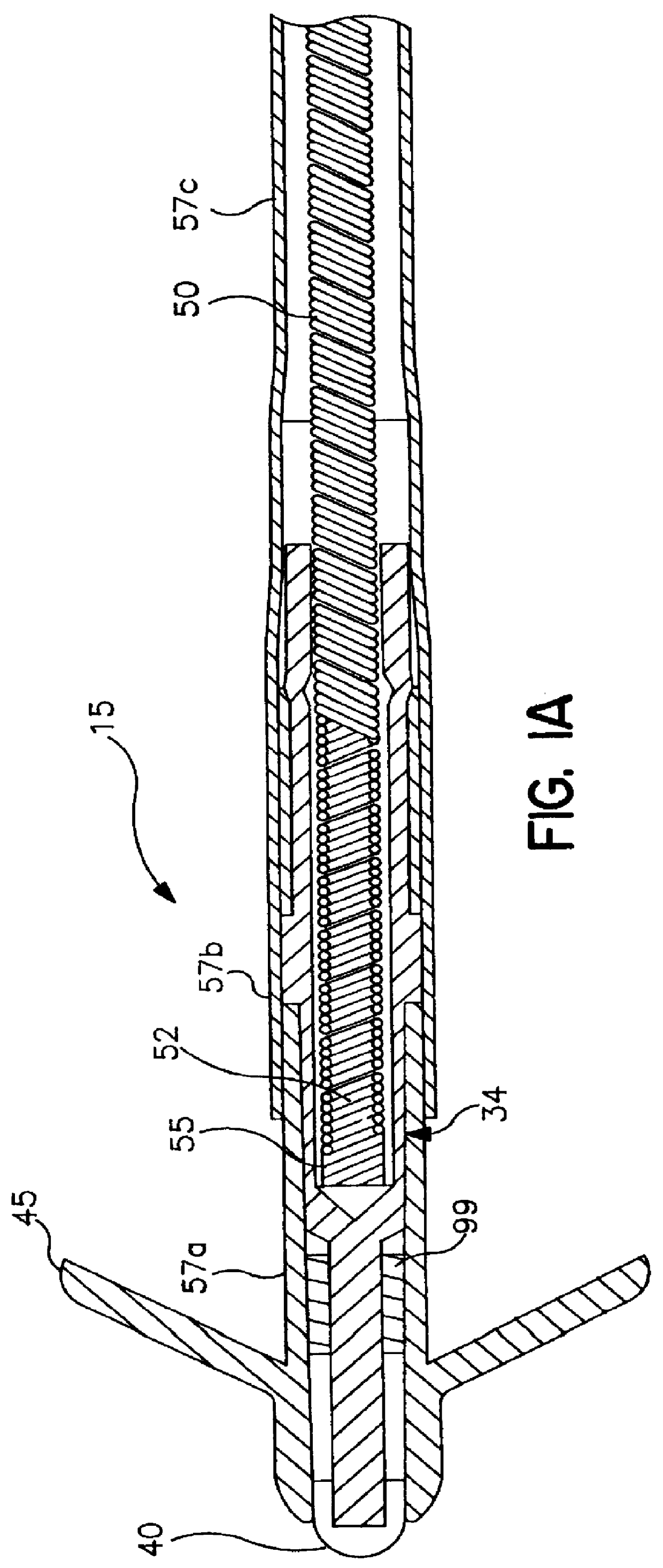

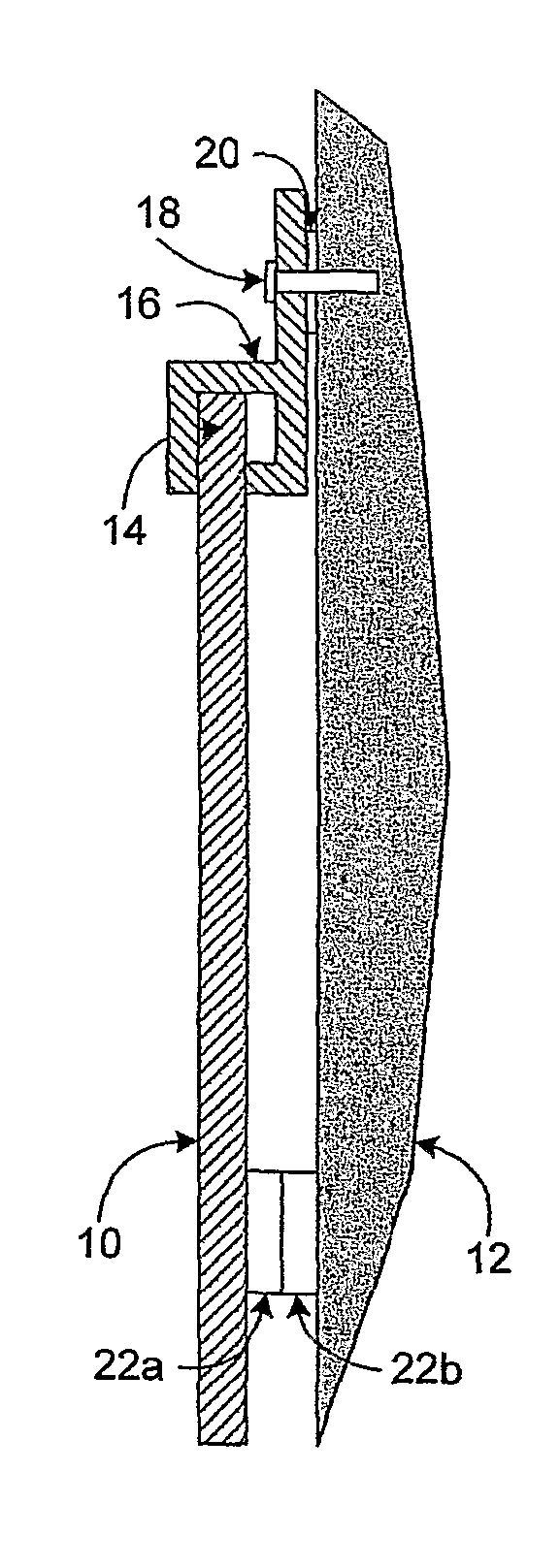

Implantable lead

ActiveUS20100137928A1Good flexibility , fatigue resistance and flex lifeImprove reliabilityContact member manufacturingInternal electrodesTissue damageDefibrillation

Owner:WL GORE & ASSOC INC

Method for providing sensory feedback to the operator of a portable measurement machine

InactiveUS20050016008A1High abrasionHigh impactProgramme-controlled manipulatorJointsSensory FeedbacksEngineering

A method for providing feedback to the operator of a portable coordinate measurement machine which comprises an articulated arm having jointed arm segments is presented. The method includes sensing deformation of a portion of the articulated arm when the arm is placed under a load, the deformation being an indication of the magnitude of the external force being applied to the arm, and providing feedback to the operator of the CMM in response to the sensed external forces.

Owner:FARO TECH INC

Method for improving measurement accuracy of a portable coordinate measurement machine

InactiveUS20050028393A1High abrasionHigh impactProgramme-controlled manipulatorJointsEngineeringCoordinate-measuring machine

A method for improving the measurement accuracy of a portable coordinate measurement machine which comprises an articulated arm having jointed arm segments is presented. This method includes sensing deformation of a portion of the articulated arm when the arm is placed under a load, this deformation causing an error in the measurement made by the CMM, and correcting such error in response to the sensed deformation.

Owner:FARO TECH INC

Apparatus for providing sensory feedback to the operator of a portable measurement machine

InactiveUS20050188557A1High abrasionHigh impactProgramme-controlled manipulatorJointsSensory FeedbacksEngineering

An apparatus for providing feedback to the operator of a portable coordinate measurement machine which comprises an articulated arm having jointed arm segments is presented. The apparatus includes sensing deformation of a portion of the articulated arm when the arm is placed under a load, the deformation being an indication of the magnitude of the external force being applied to the arm, and providing feedback to the operator of the CMM in response to the sensed external forces.

Owner:FARO TECH INC

Method for improving measurement accuracy of a protable coordinate measurement machine

InactiveUS20040111908A1Easy to convertEasy to distinguishProgramme-controlled manipulatorJointsEngineeringAccuracy and precision

A method for improving the measurement accuracy of a portable coordinate measurement machine which comprises an articulated arm having jointed arm segments is presented. This method includes sensing deformation of a portion of the articulated arm when the arm is placed under a load, this deformation causing an error in the measurement made by the CMM, and correcting such error in response to the sensed deformation.

Owner:FARO TECH INC

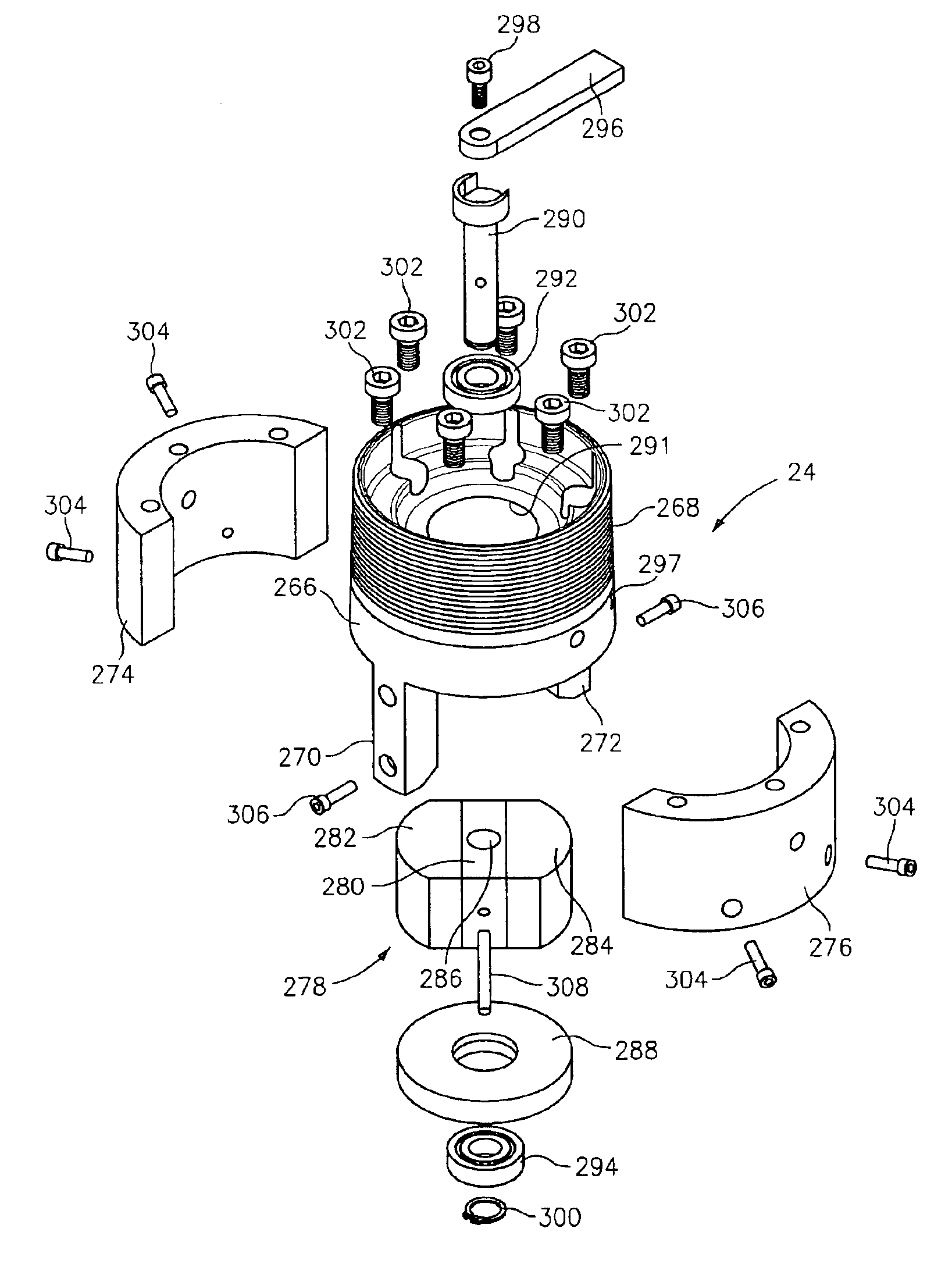

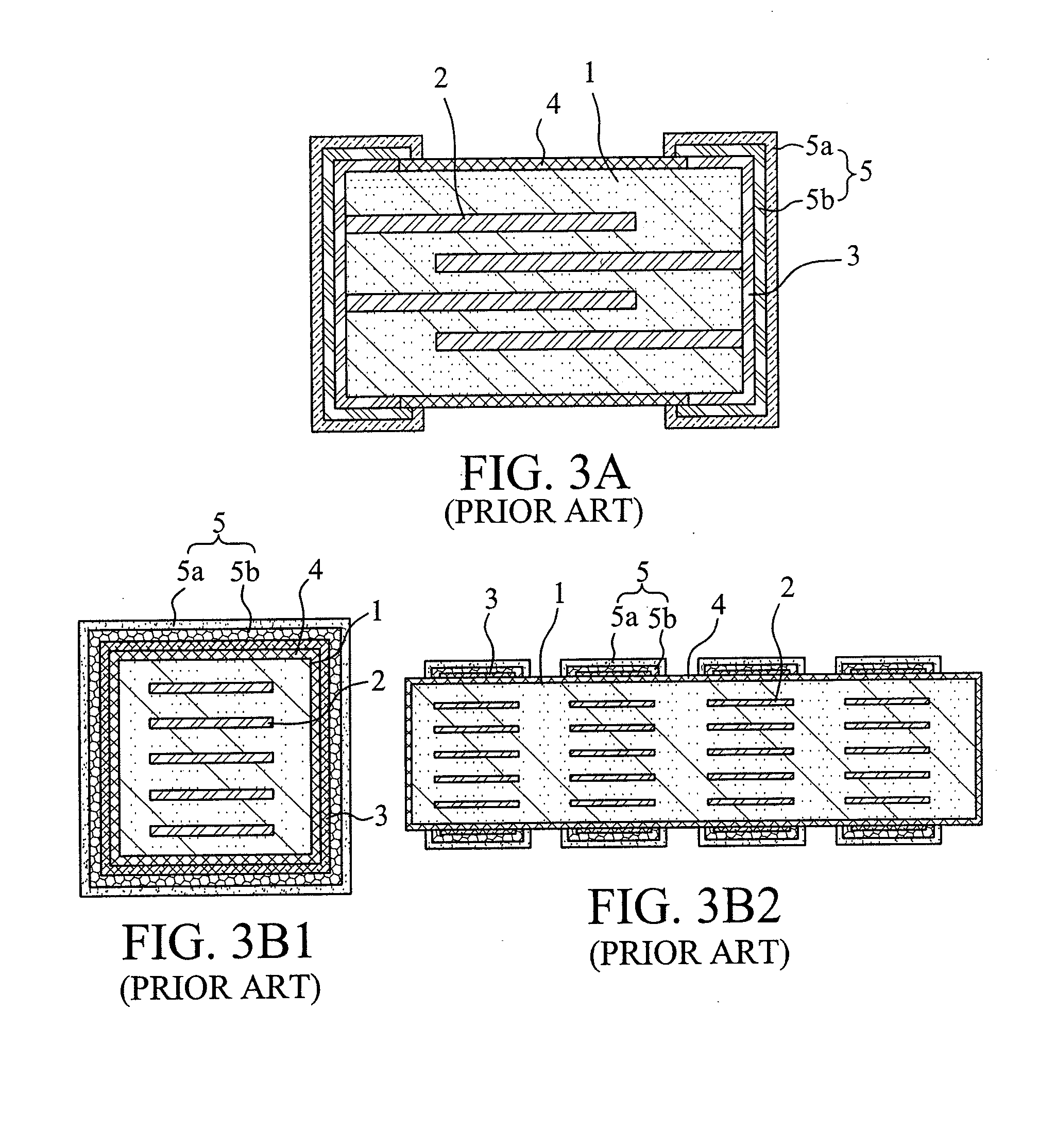

Portable coordinate measurement machine

InactiveUS20060016086A1High abrasionHigh impactMechanical measuring arrangementsEngineeringCoordinate-measuring machine

A portable coordinate measurement machine comprises an articulated arm having jointed arm segments. The jointed arm segments include a rotatable shaft, at least two spaced bearings and a housing surrounding the bearings and shaft wherein races for the bearings are formed by at least one of the following: (1) the shaft constitutes the inner race of at least one of the two bearings and (2) the housing constitutes the outer race of at least one of the two bearings.

Owner:FARO TECH INC

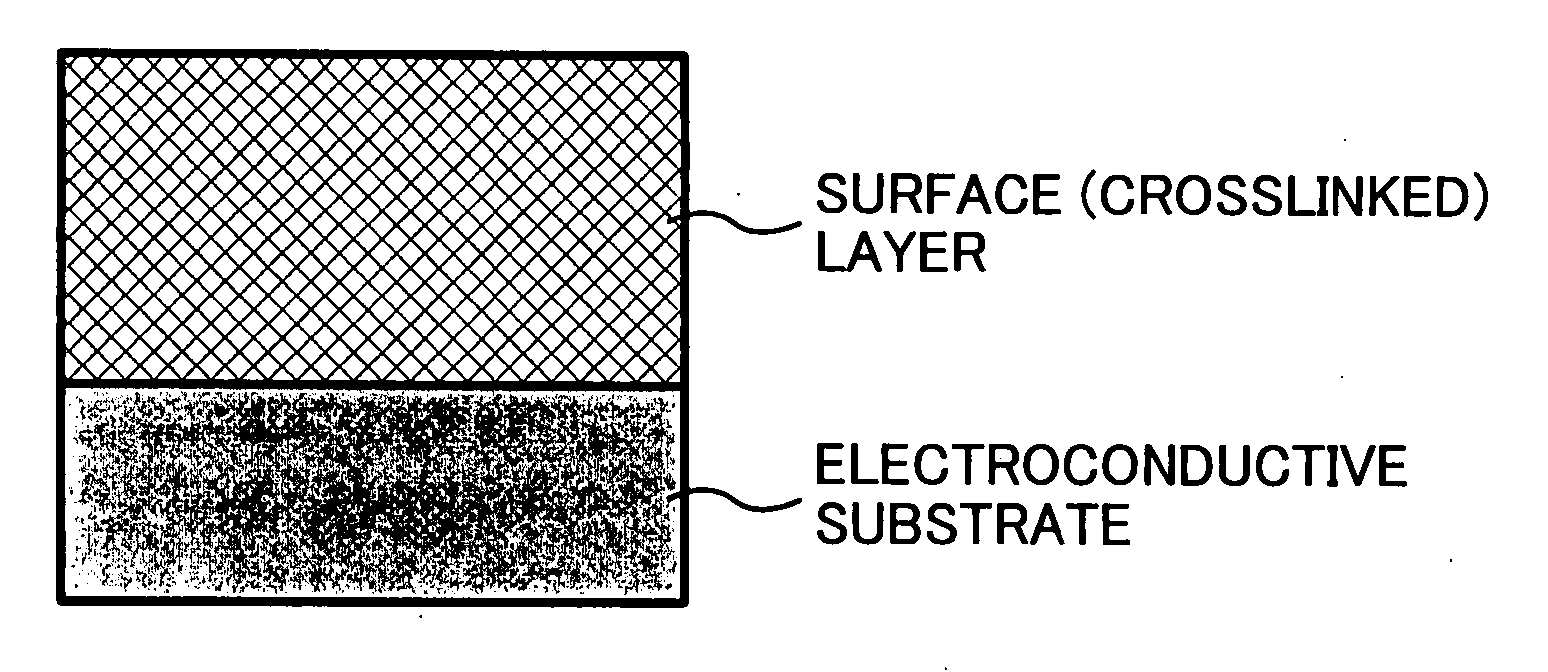

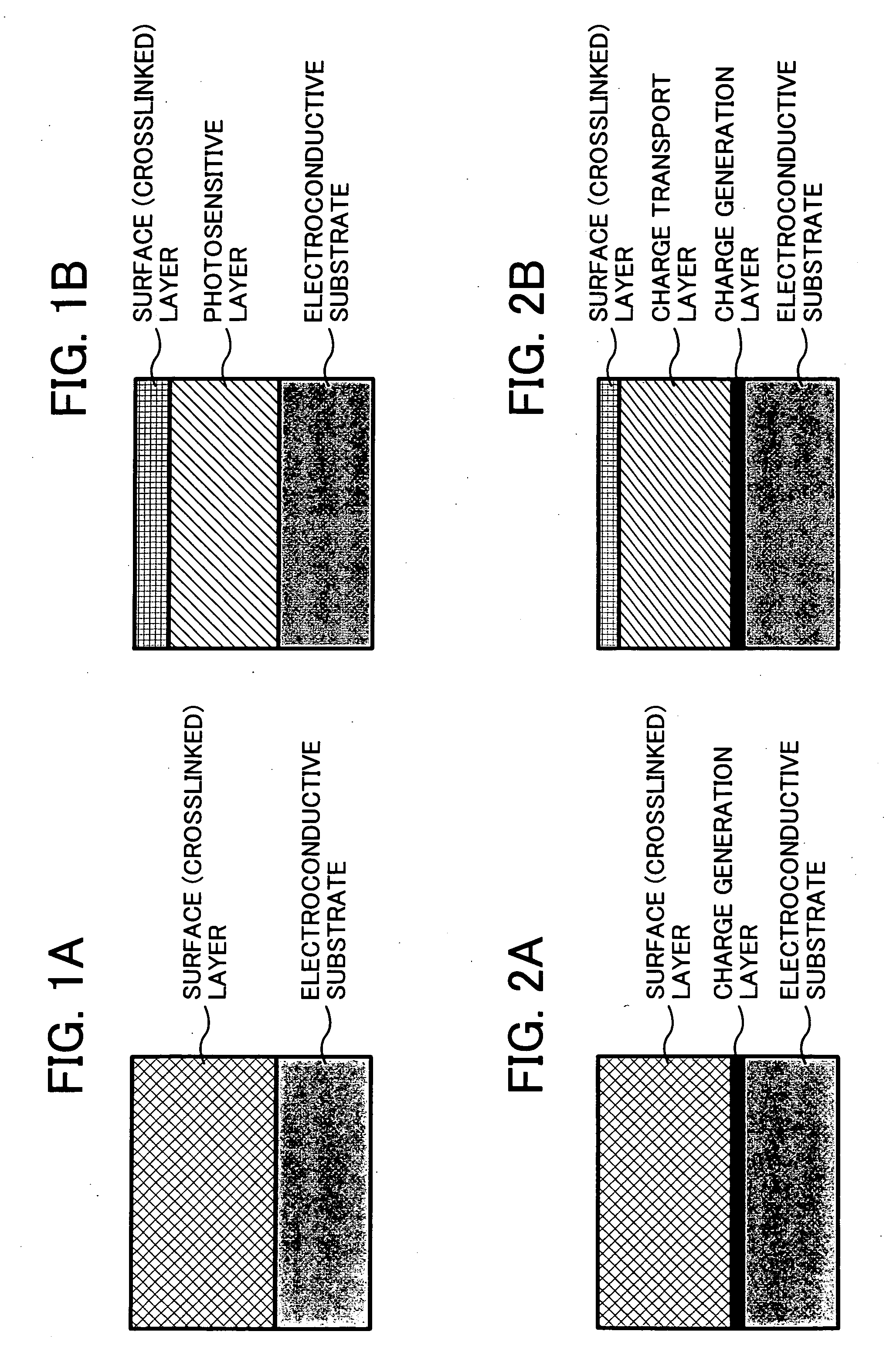

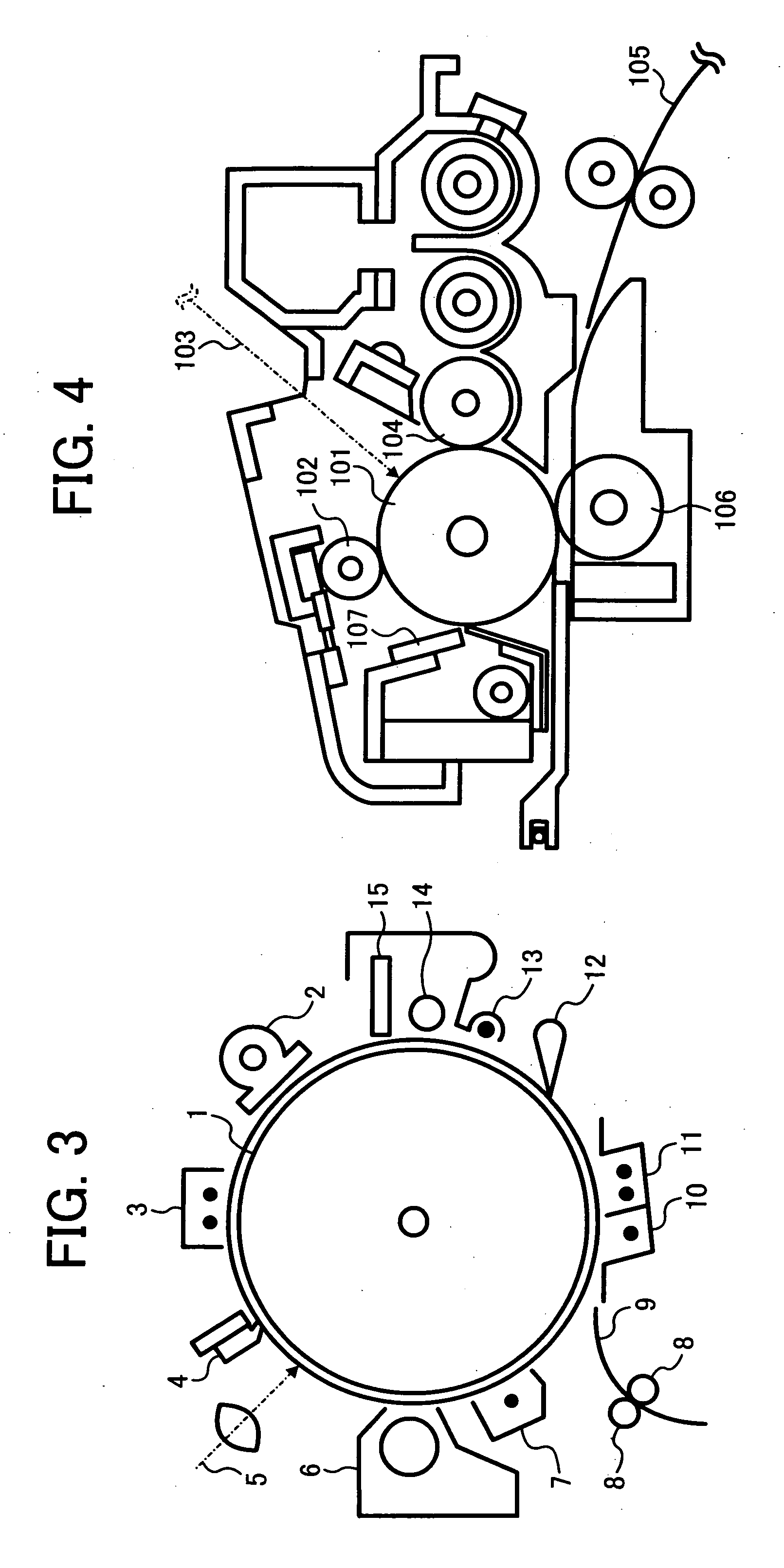

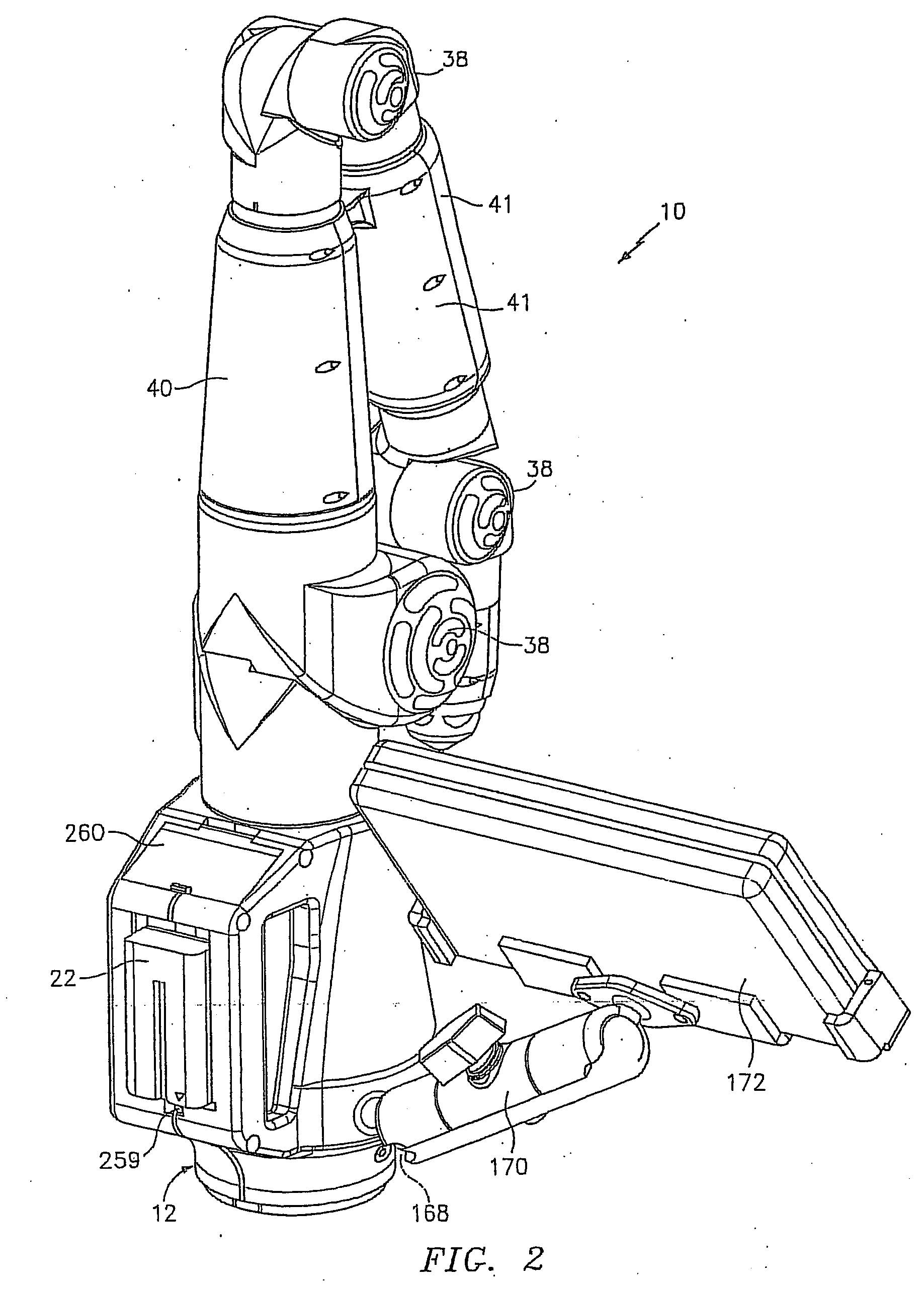

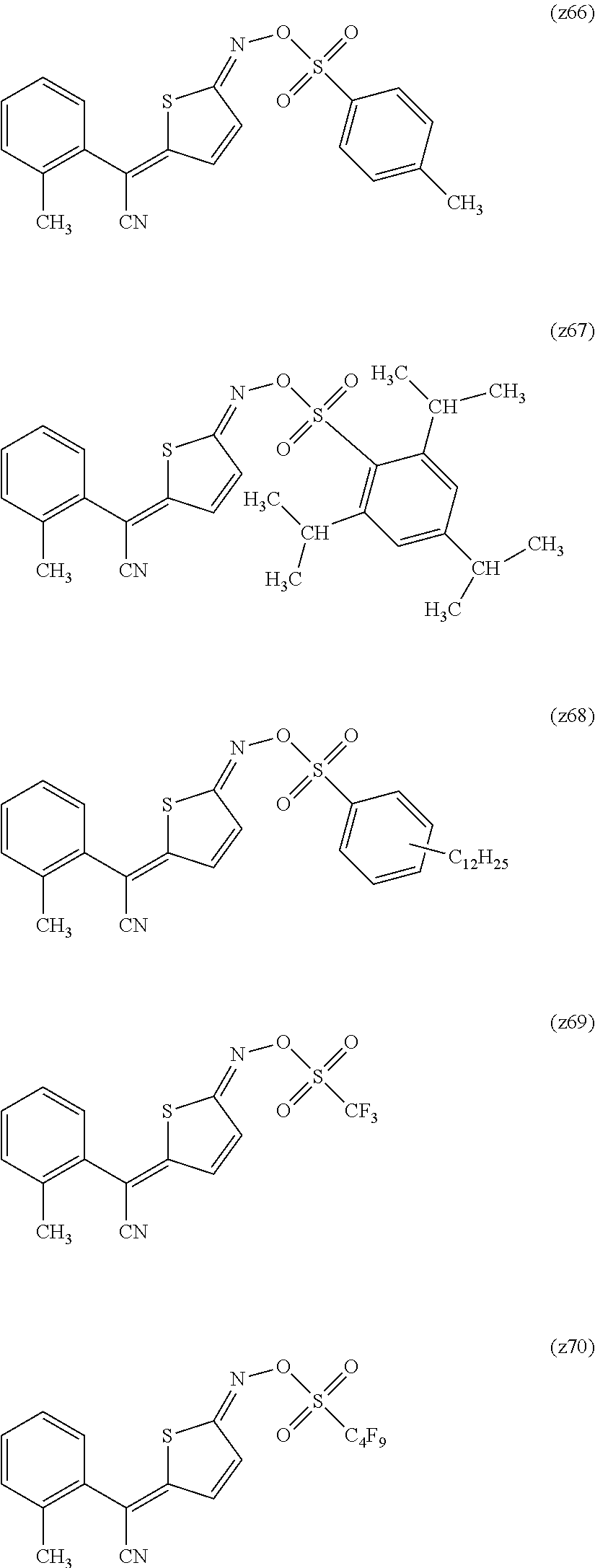

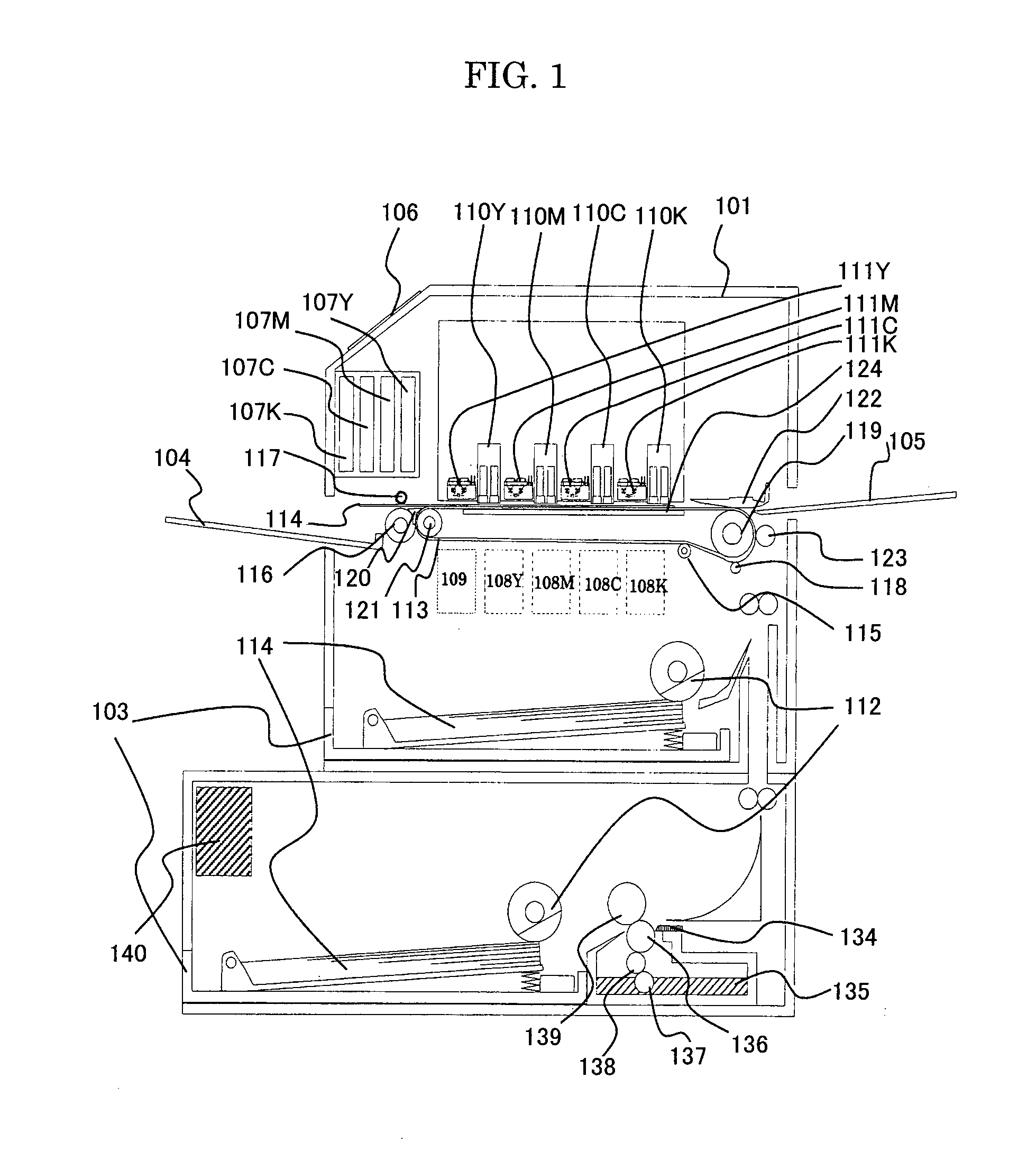

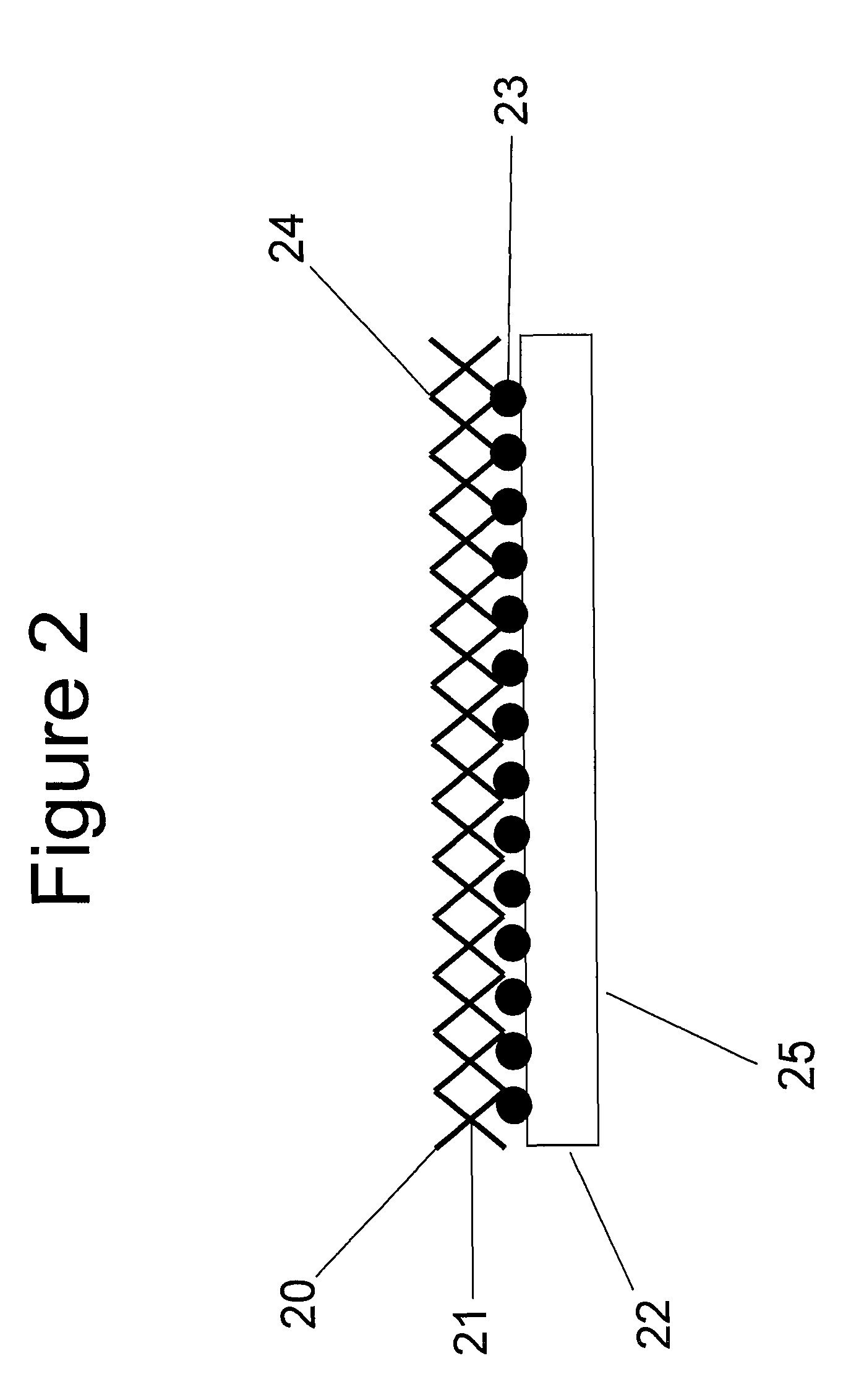

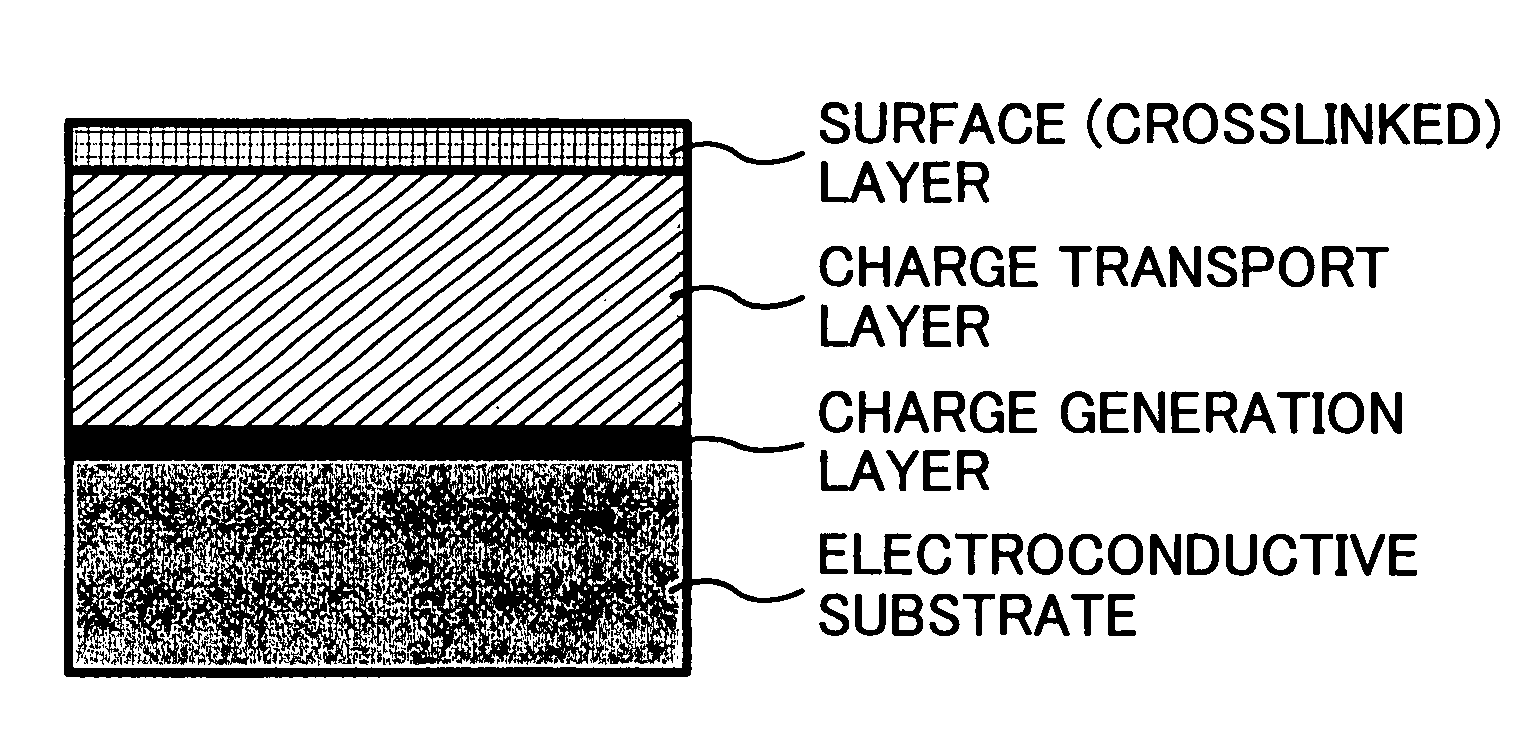

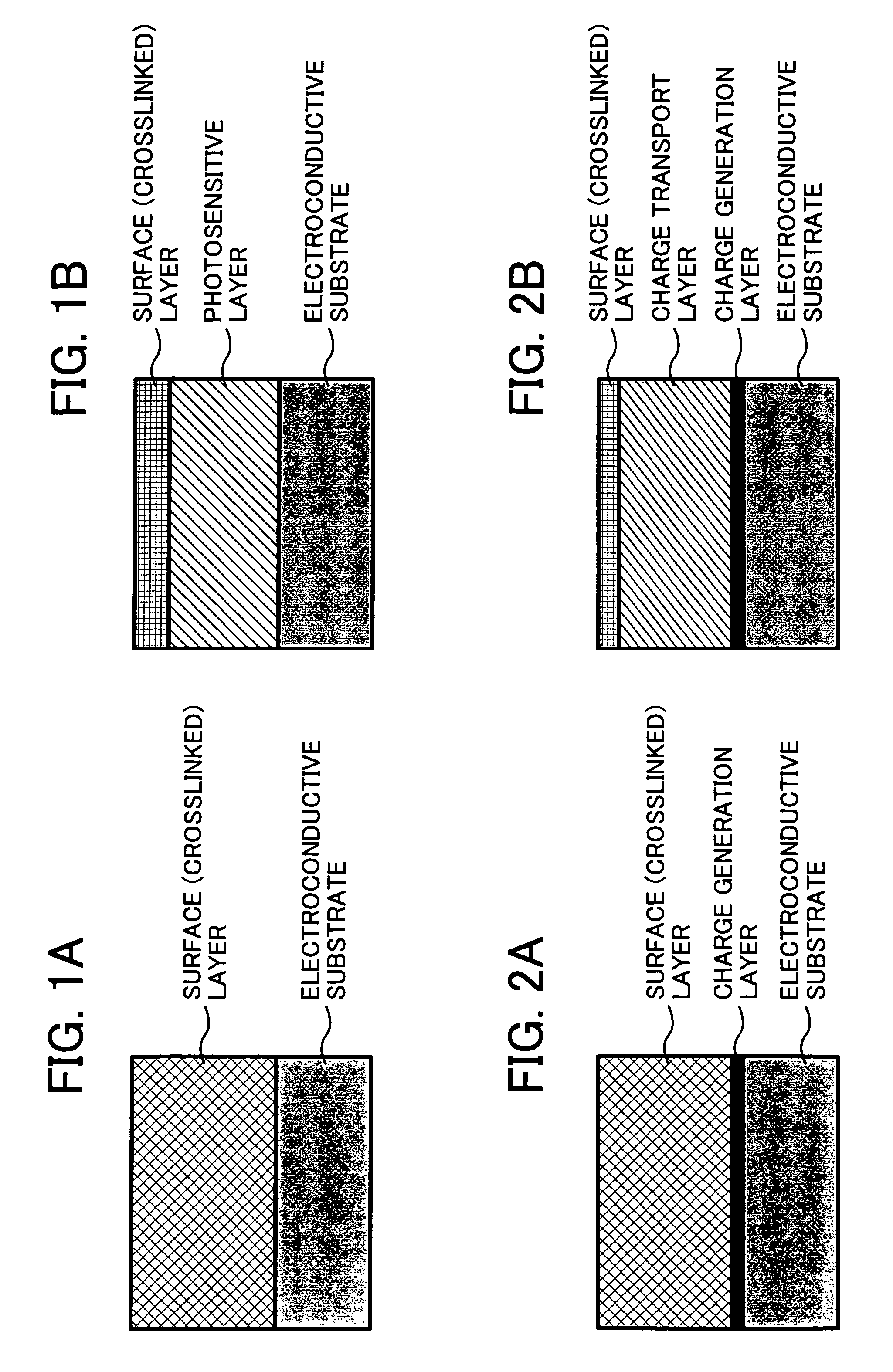

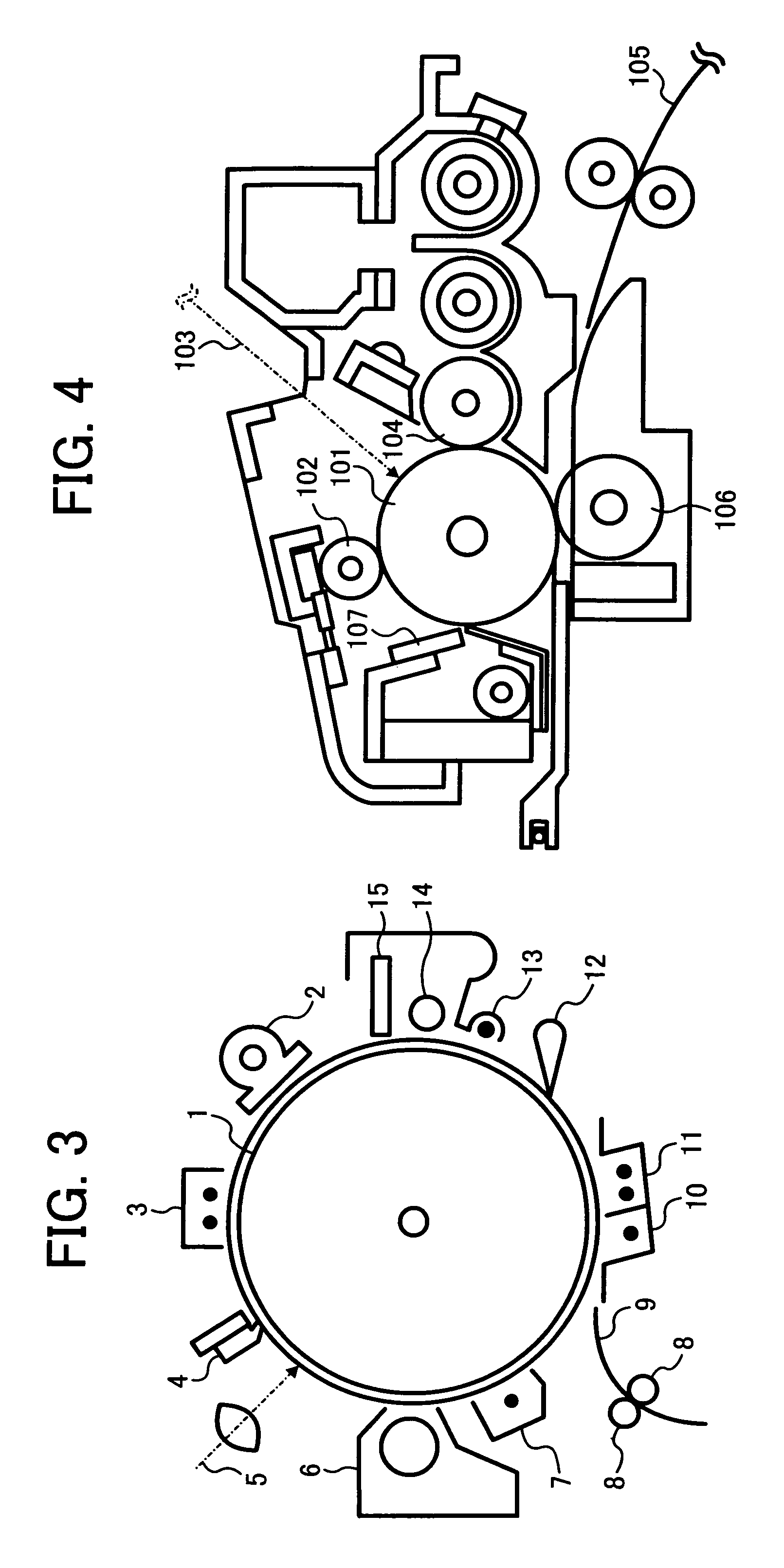

Electrophotographic photoreceptor and method of preparing the photoreceptor, and image forming method, image forming apparatus and process cartridge therefor using the photoreceptor

InactiveUS20060110668A1Improve electrical performanceHigh abrasionElectrographic process apparatusCorona dischargeOrganic chemistryPolymer chemistry

An electrophotographic photoreceptor, including an electroconductive substrate; and a photosensitive layer overlying the electroconductive substrate, which includes a crosslinked layer at the surface thereof, wherein the crosslinked layer is formed by a method including: coating a coating liquid, which includes a solvent; a radical polymerizing monomer having three or more functional groups and no charge transportable structure; and a radical polymerizing compound having a charge transportable structure on the photosensitive layer; and irradiating the coating liquid to be hardened while the surface of the photosensitive layer is controlled to have a temperature not higher than a boiling point of the solvent.

Owner:RICOH KK

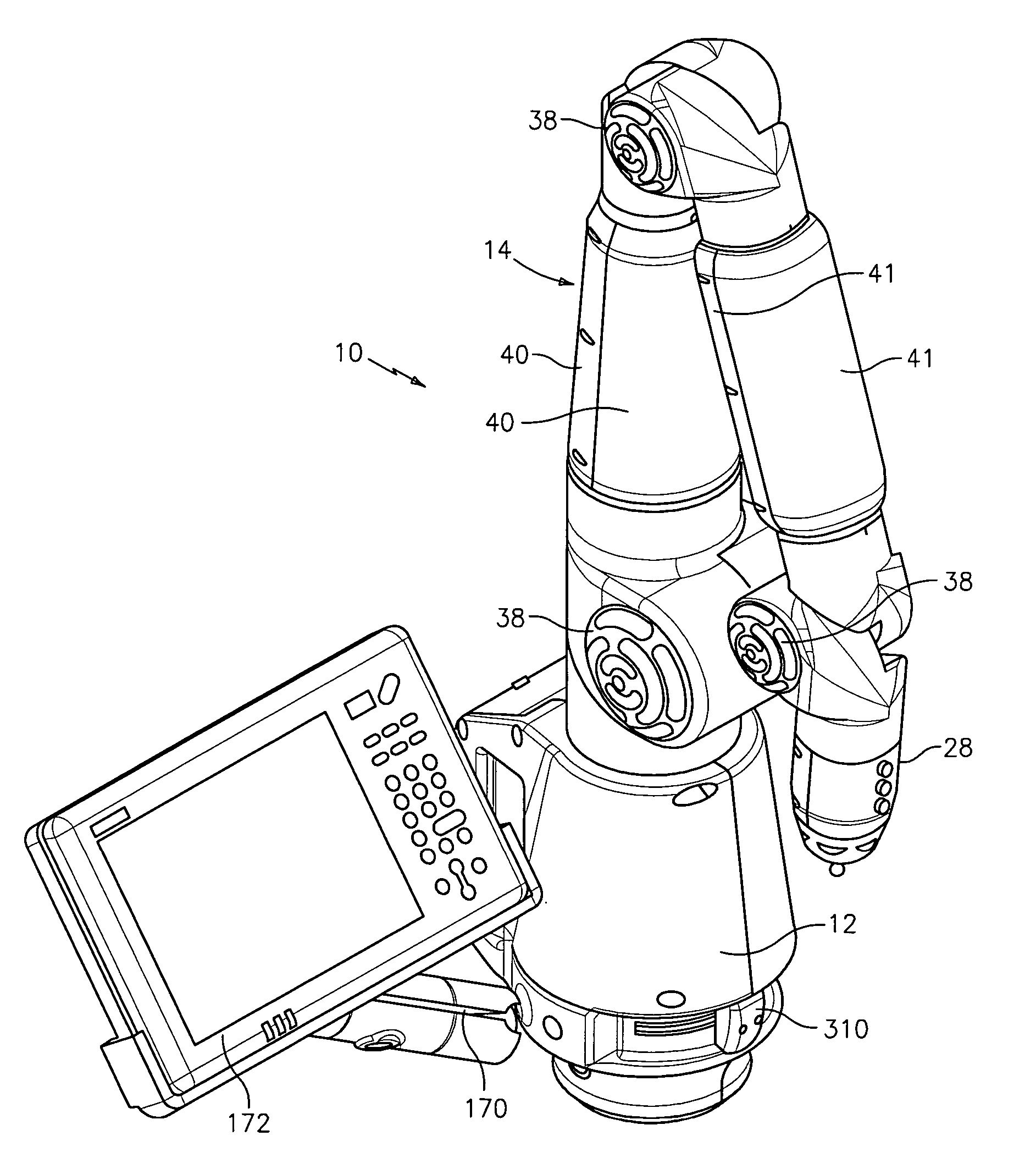

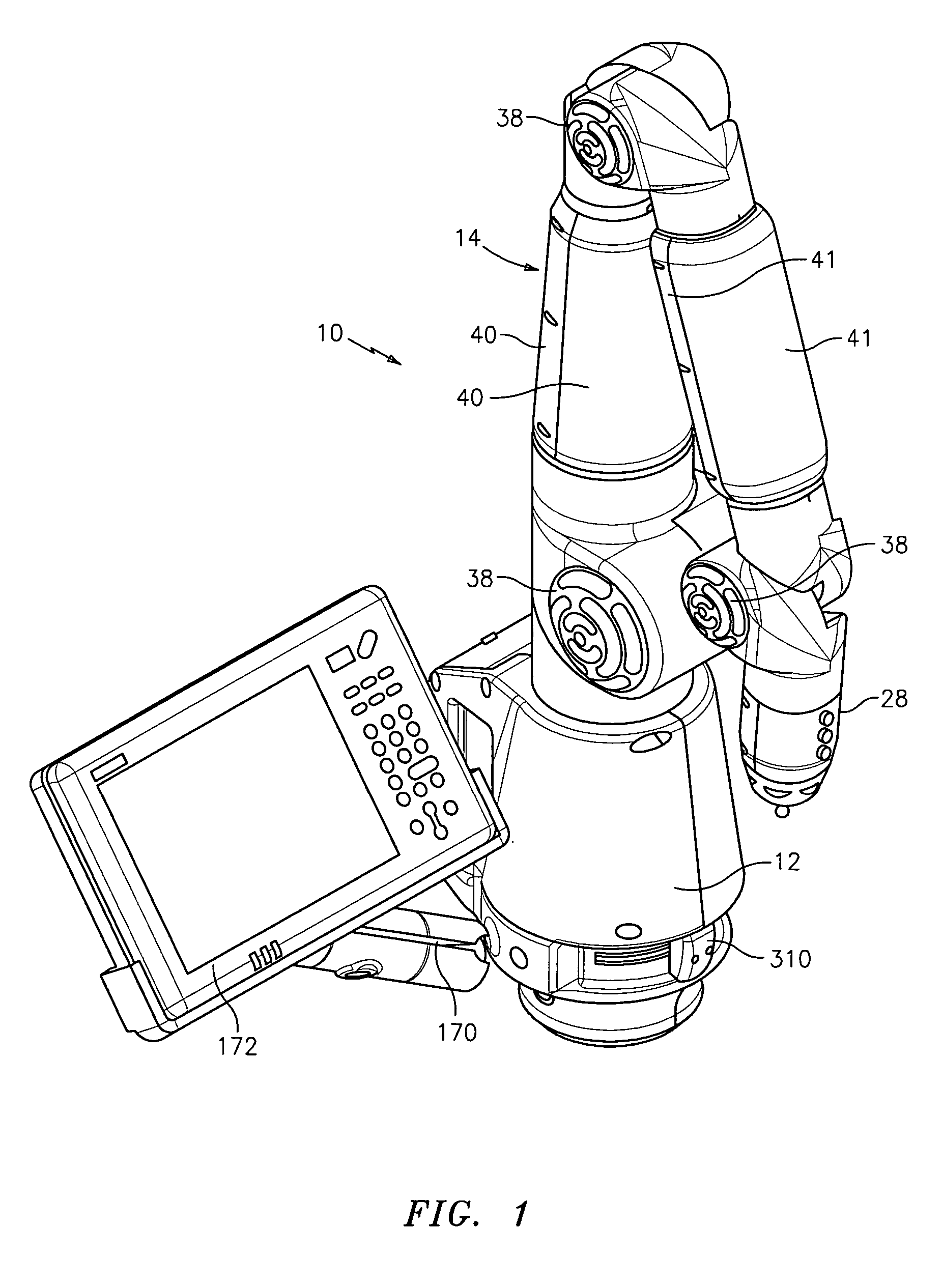

Portable coordinate measurement machine with improved handle assembly

InactiveUS20050115092A1High abrasionHigh impactProgramme-controlled manipulatorImage analysisCoordinate-measuring machineBiomedical engineering

A portable coordinate measurement machine comprises an articulated arm having jointed arm segments. The arm includes a probe at one end thereof. The probe also includes improved switches and a measurement indicator light.

Owner:FARO TECH INC

Medical devices and processes for preparing same

InactiveUS20060122560A1Reduce frictional resistanceReduce resistanceSurgeryPharmaceutical containersMedical deviceMedical treatment

A medical device formed at least in part of a polymeric composition, and having a surface modified with covalently bonded fluorine, and a process for modifying the surface including the step of exposing the surface of the medical device to gaseous plasma sufficient to covalently bond fluorine to the surface.

Owner:BOSTON SCI SCIMED INC

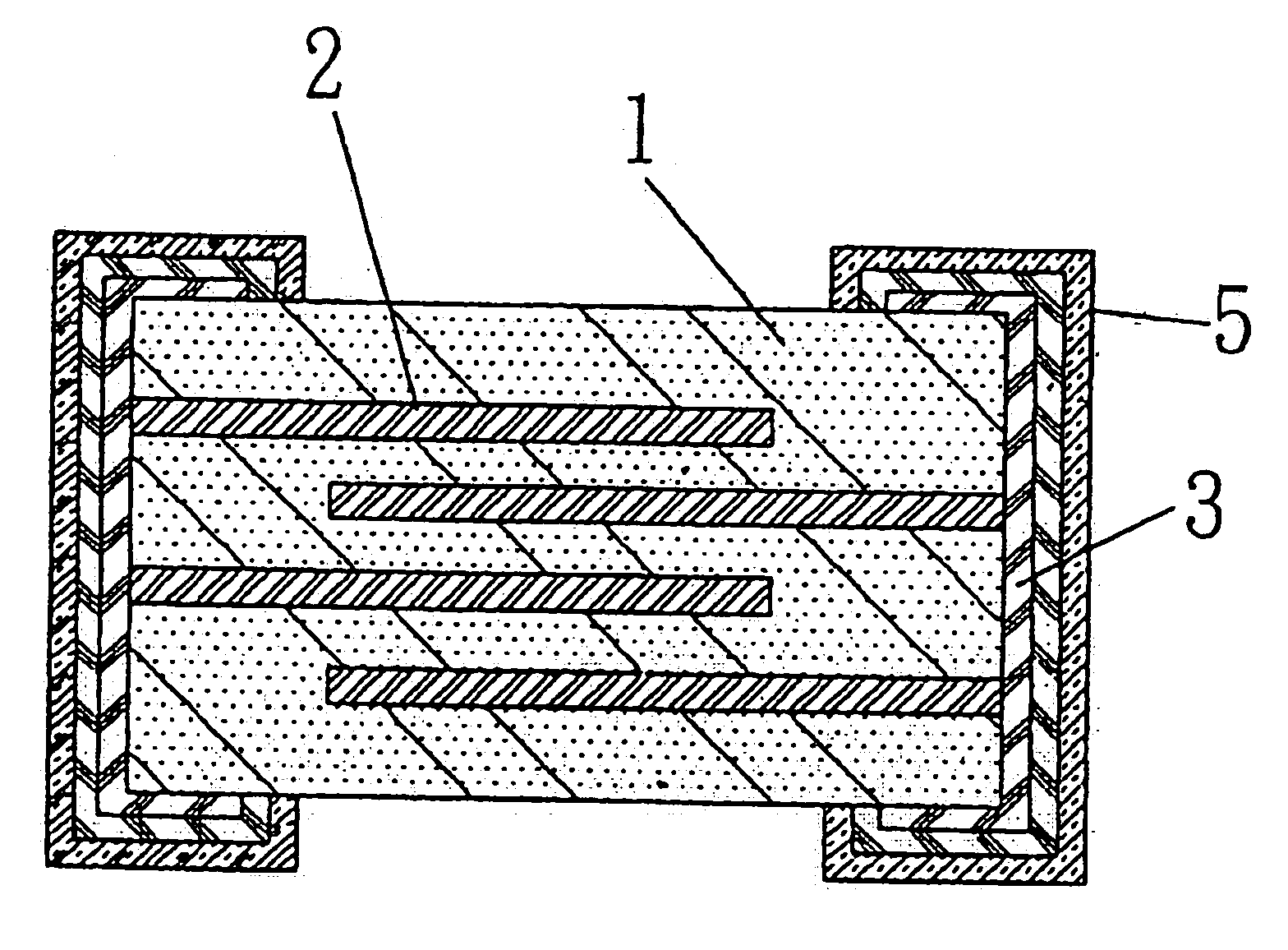

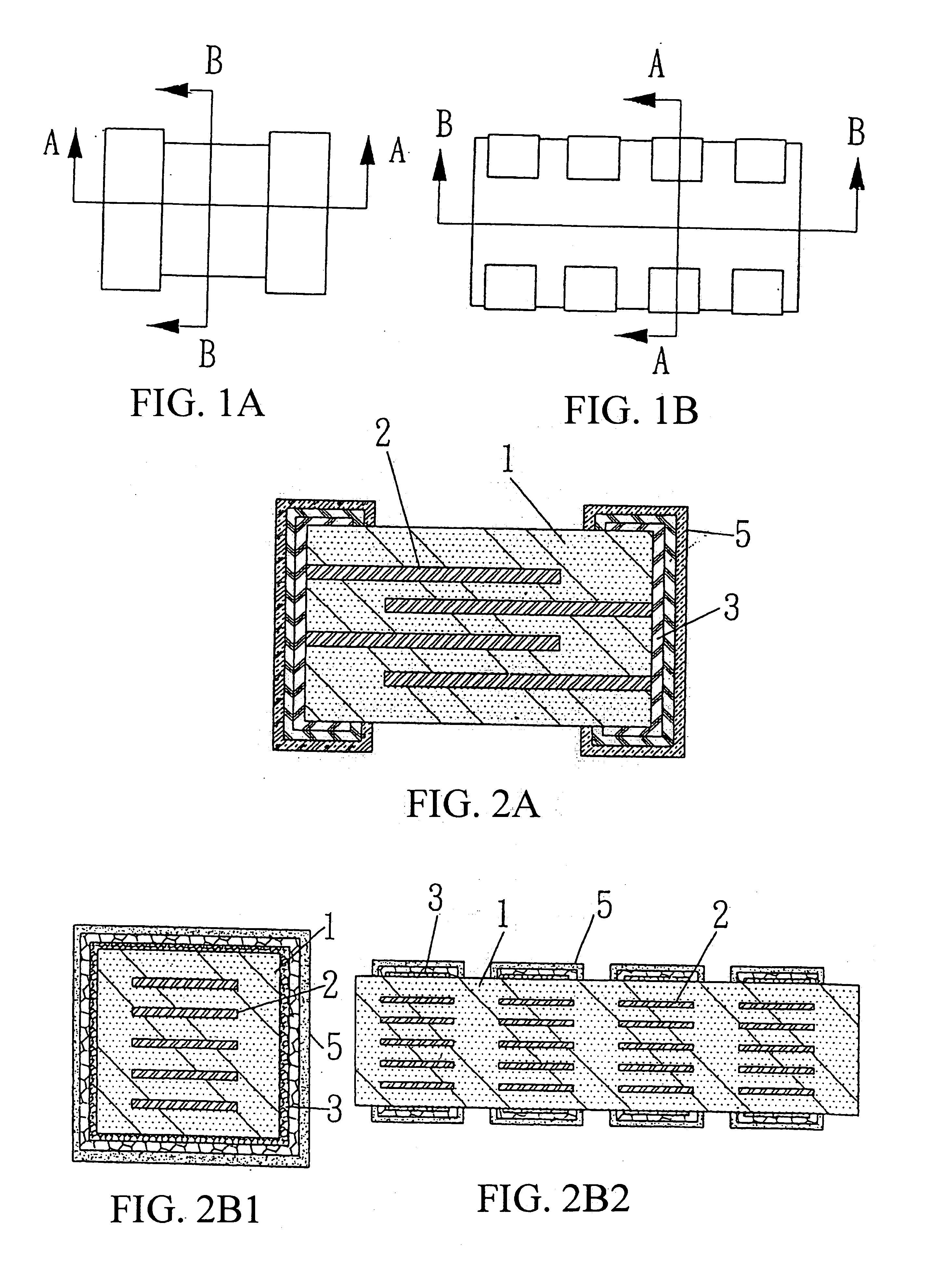

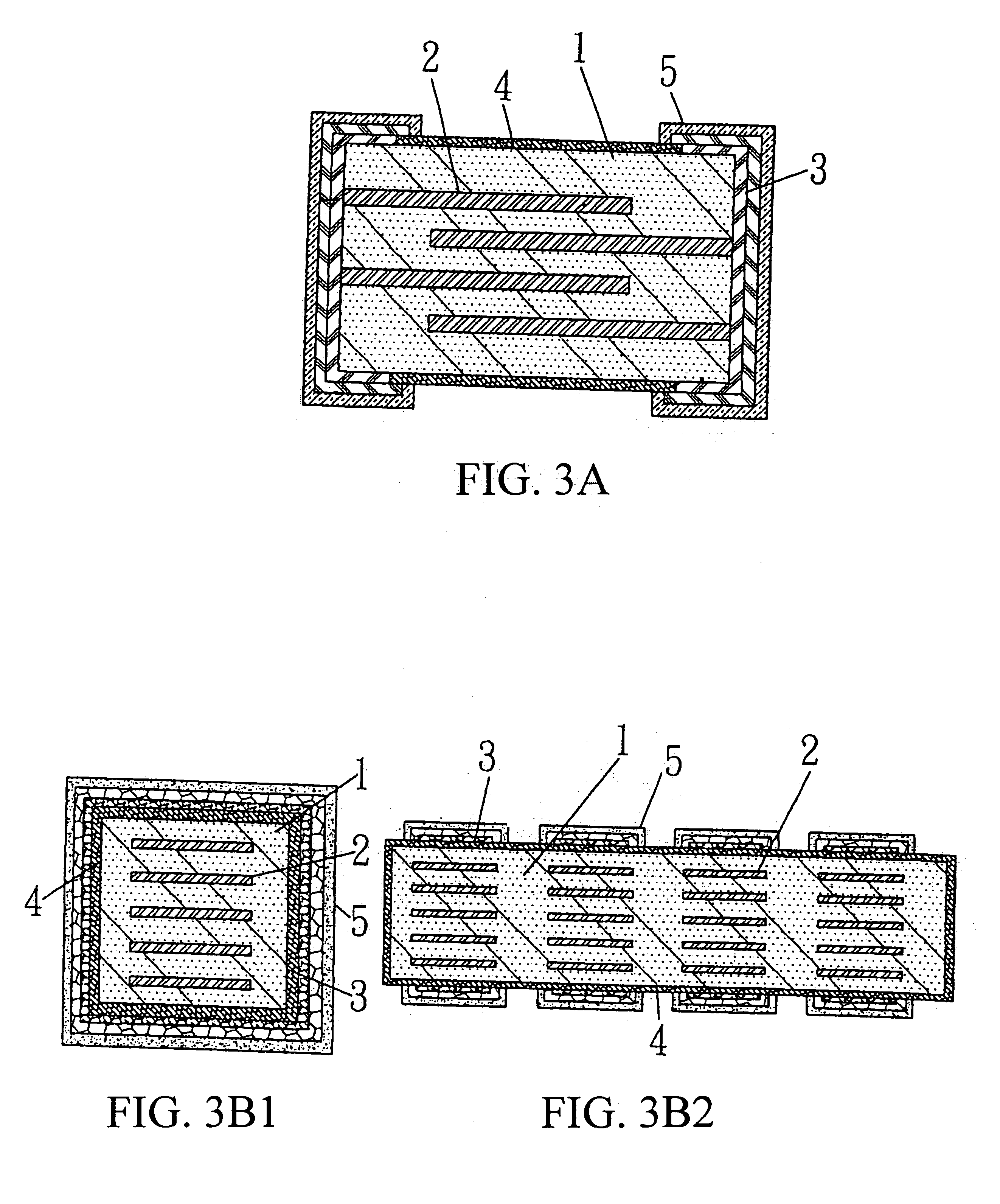

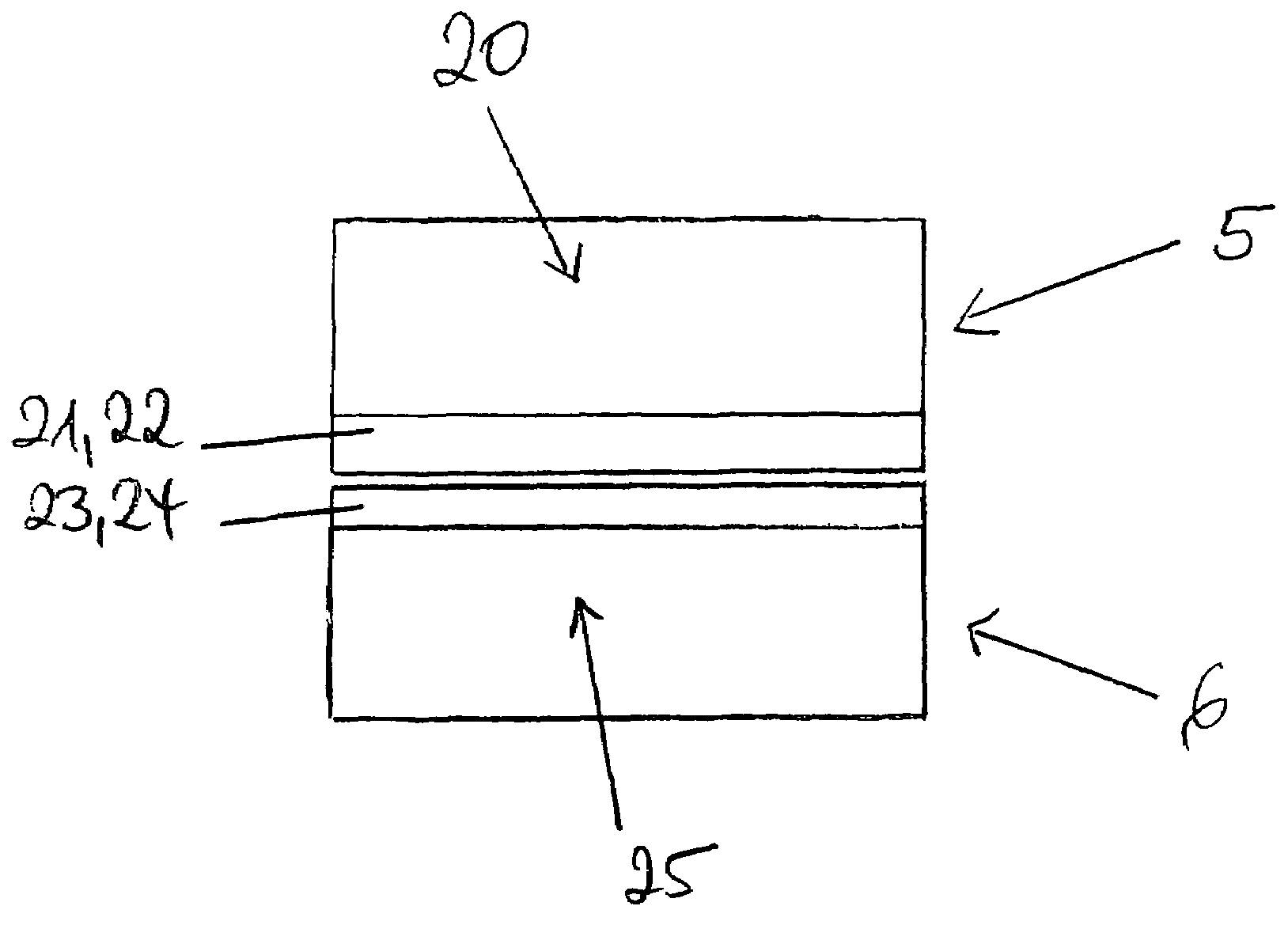

Ceramic glaze coating structure of a chip element and method of forming the same

InactiveUS20060234022A1Increase in costEnhance concentrationFixed capacitor dielectricStacked capacitorsCeramic glazeHigh impedance

A ceramic glaze-coating structure of a chip element and a method of forming the same are provided. In the ceramic glaze-coating structure, a high-density, smooth, and high-impedance ceramic glaze is coated on the body of an element. As for the terminal electrode part, the unique firing characteristics between the material of the terminal electrode (e.g., conductive compositions) and the ceramic glaze are utilized, such that the ceramic glaze layer between the surface of the terminal electrode or the terminal electrode and the ceramic body is absorbed and then removed by sintering; thus, the ceramic glaze coating structure of a chip element with only the element body being coated is formed.

Owner:INPAQ TECH

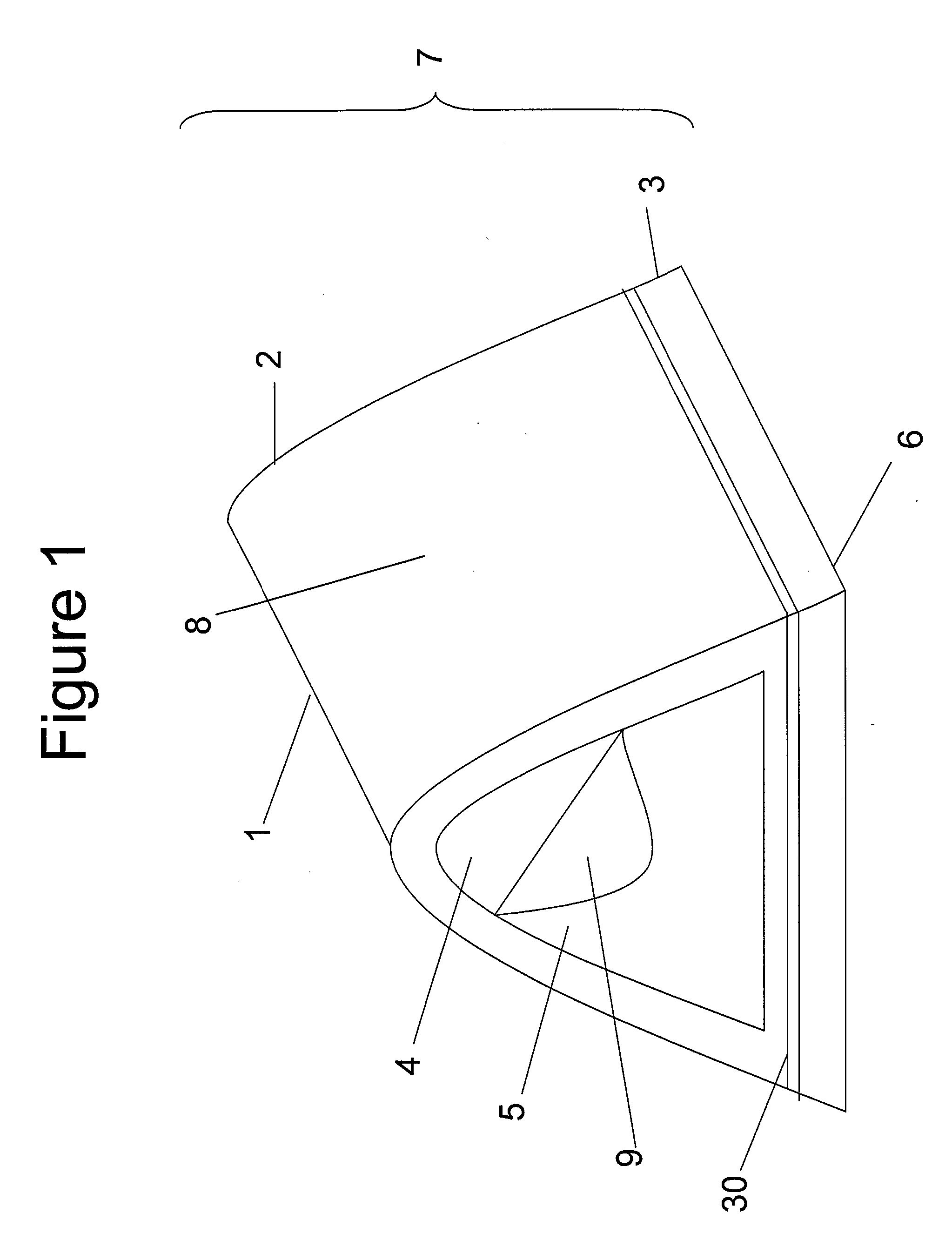

Cladding

InactiveUS20080010927A1Improve securityImprove fire resistanceCovering/liningsPublic buildingsSurface finishPanelling

There can be provided a method of cladding a surface with panelling. The method can comprise: attaching a first panel support member to the surface, the first panel support member being configured to receive at least a part of a first edge of a panel comprising a core of woven and non-woven glass impregnated with resin and a surface finish of paper and melamine resin; placing the first edge in a position of co-operative reception with the first panel support member; and placing a second edge of the panel substantially opposite the first edge in a position of co-operative reception with a second panel support member, the second panel support member being configured to be attached to the surface.

Owner:BAA IP HOLDCO

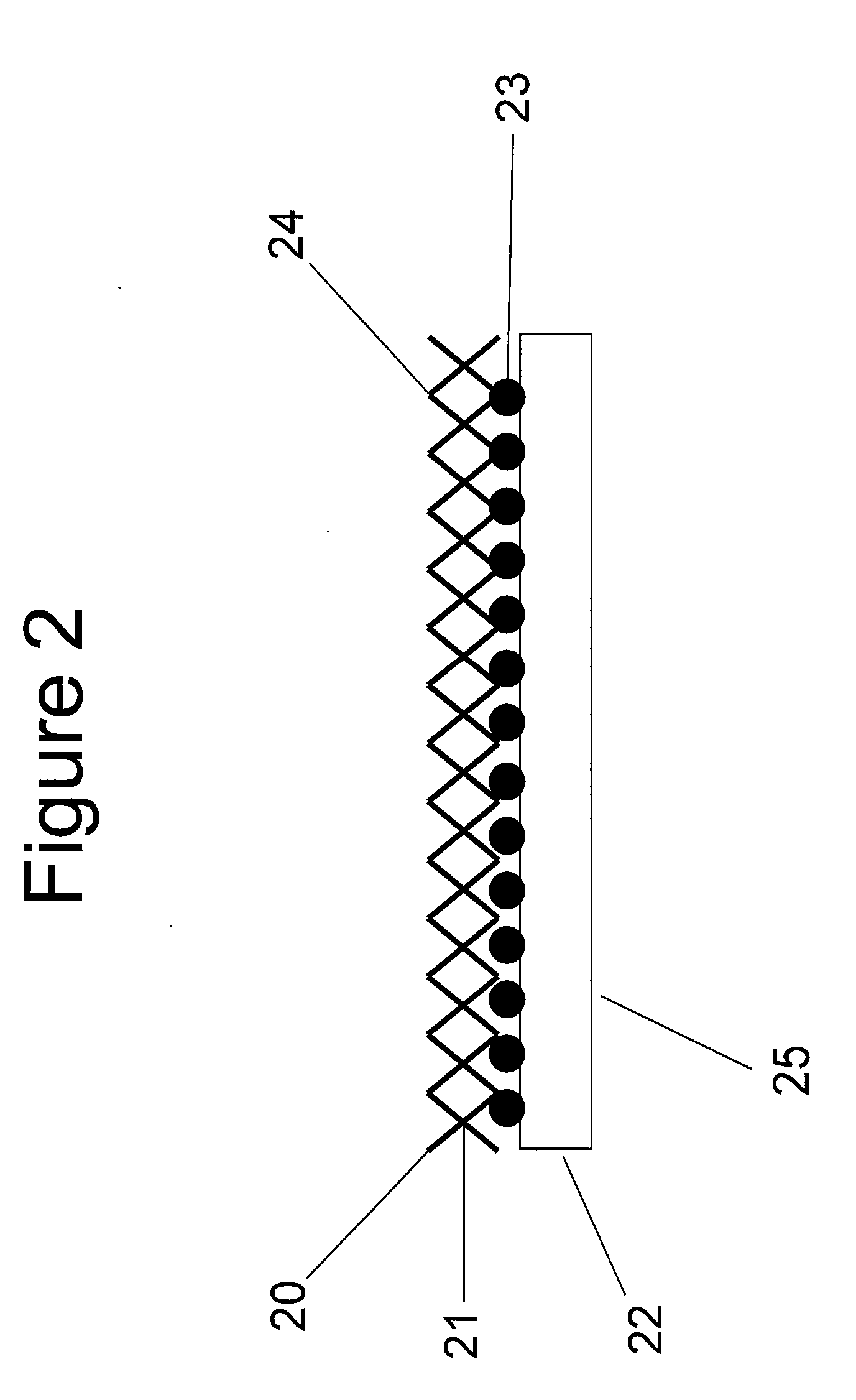

Conductive member, production method of the same, touch panel, and solar cell

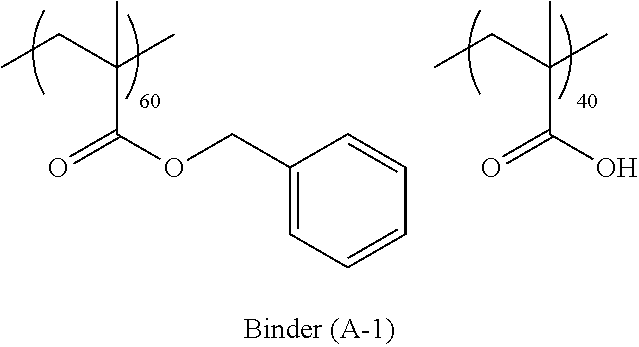

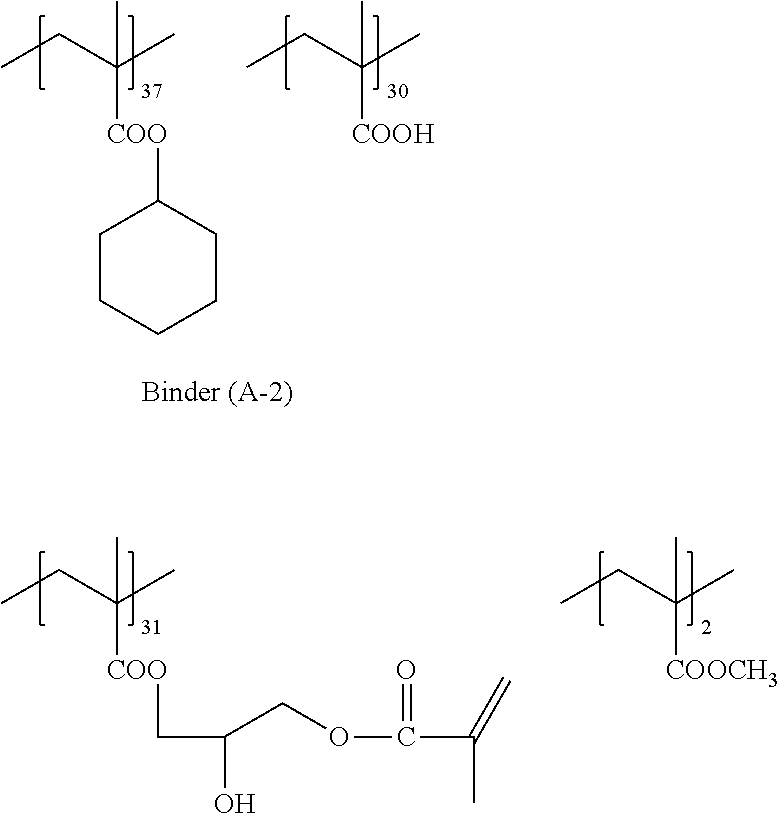

InactiveUS20140034360A1High resistance against scratchHigh abrasionConductive materialNon-conductive material with dispersed conductive materialSurface resistivityTouch panel

A conductive member containing: a base material; a conductive layer provided on the base material, wherein the conductive layer includes a metallic nanowire having an average short axis length of 150 nm or less and a matrix; and a protective layer including a three-dimensional crosslinked structure represented by the following Formula (I), sequentially in this order, and which has a surface resistivity measured at a surface of the protective layer of 1,000 Ω / □ or less, a production method of the conductive member, and a touch panel and a solar cell, each of which uses the conductive member. The conductive member may provide high resistance against scratches and abrasion, excellent conductivity, excellent transparency, excellent heat resistance, excellent moisture and heat resistance, and excellent bendability.-M1-O-M1- Formula (I):In the Formula (I), M1 represents an element selected from the group consisting of Si, Ti Zr and Al.

Owner:FUJIFILM CORP

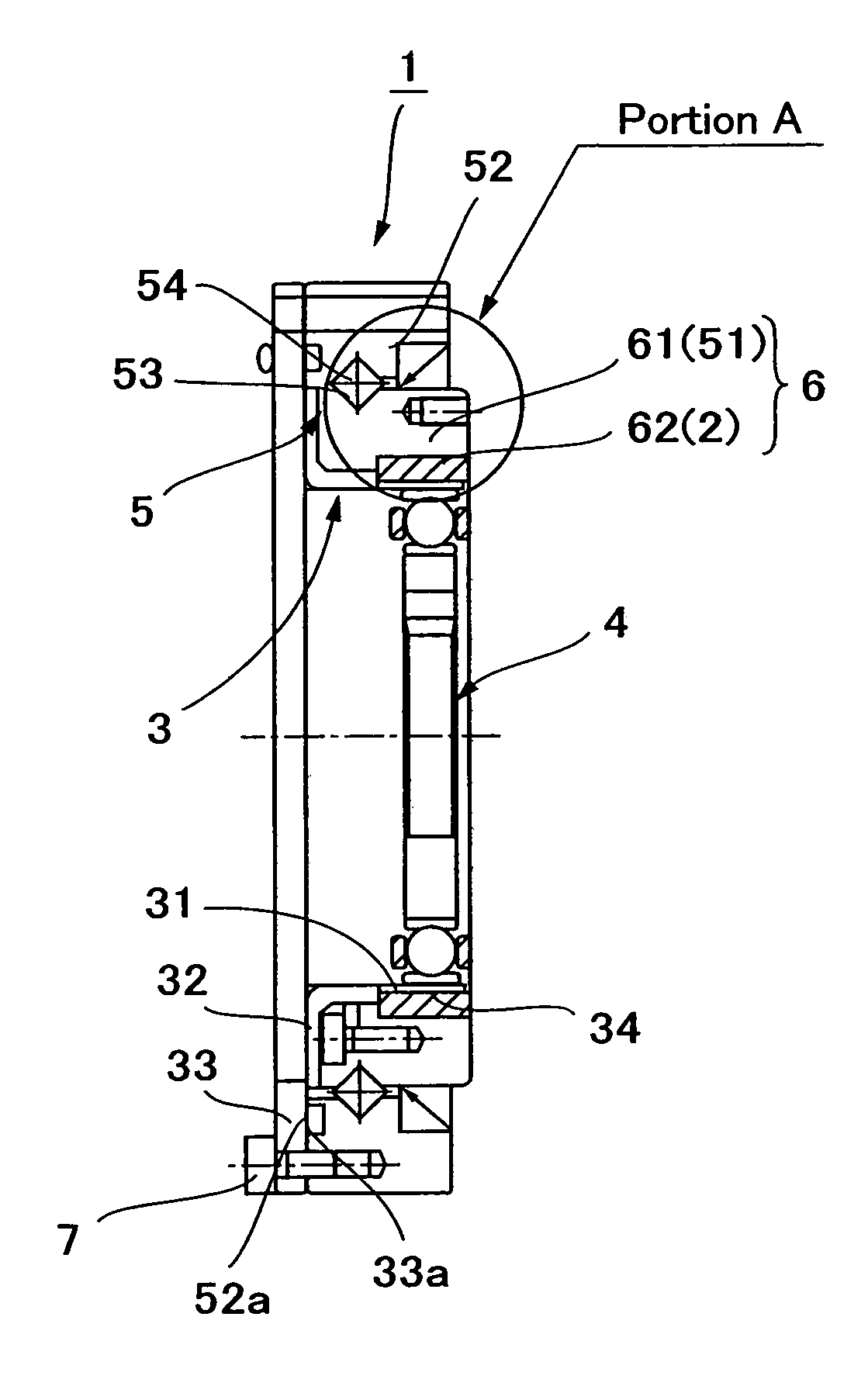

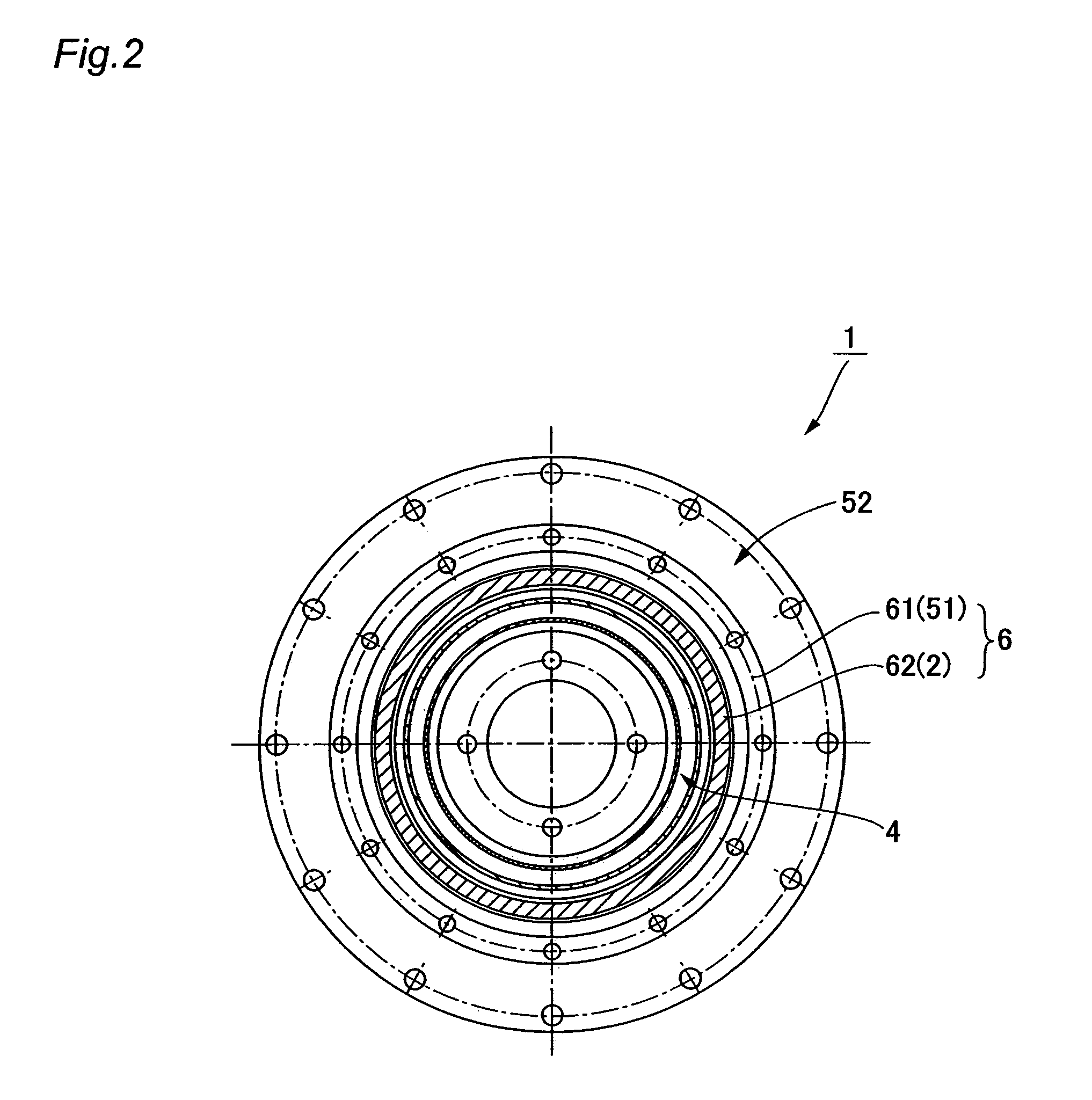

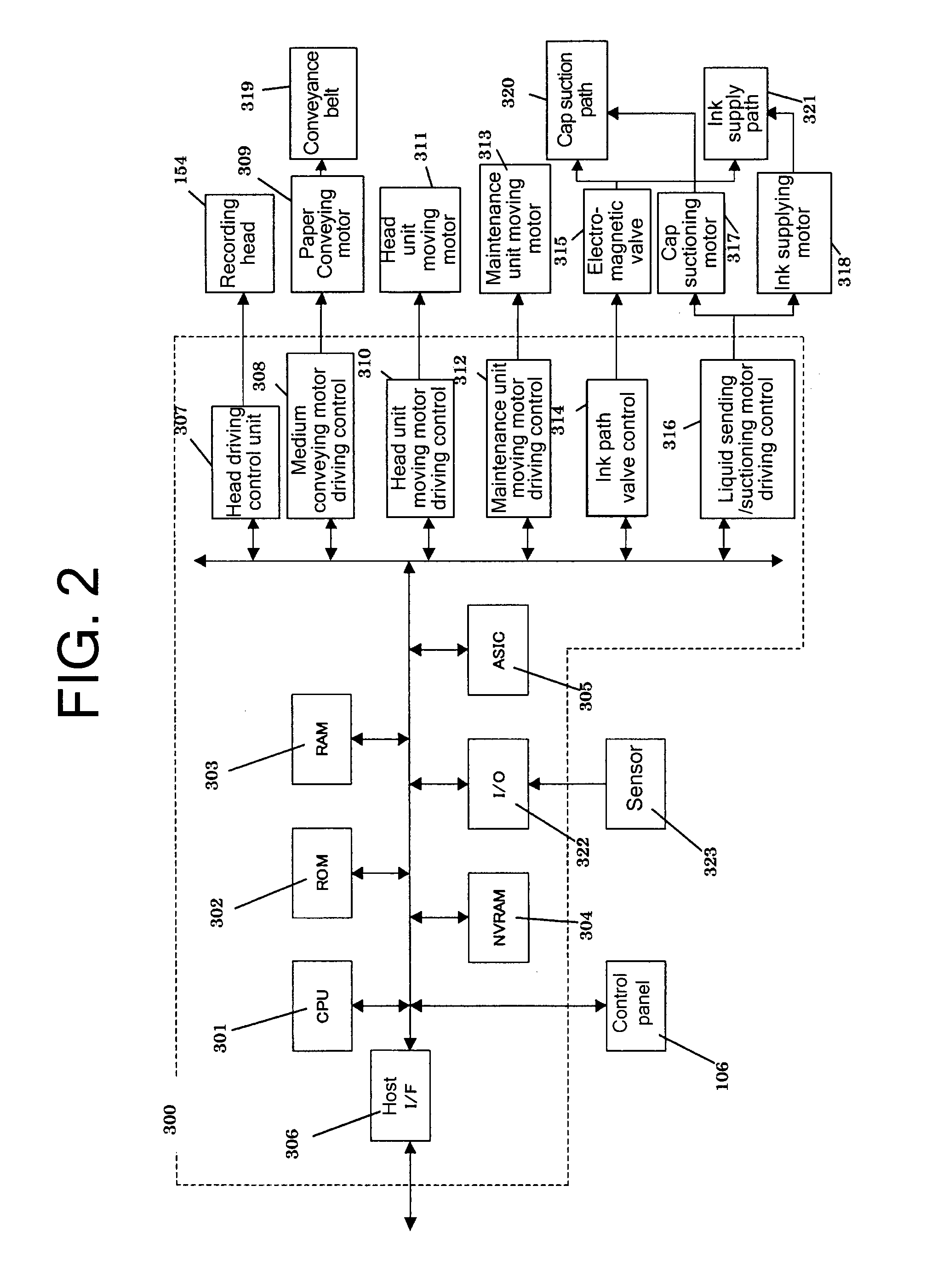

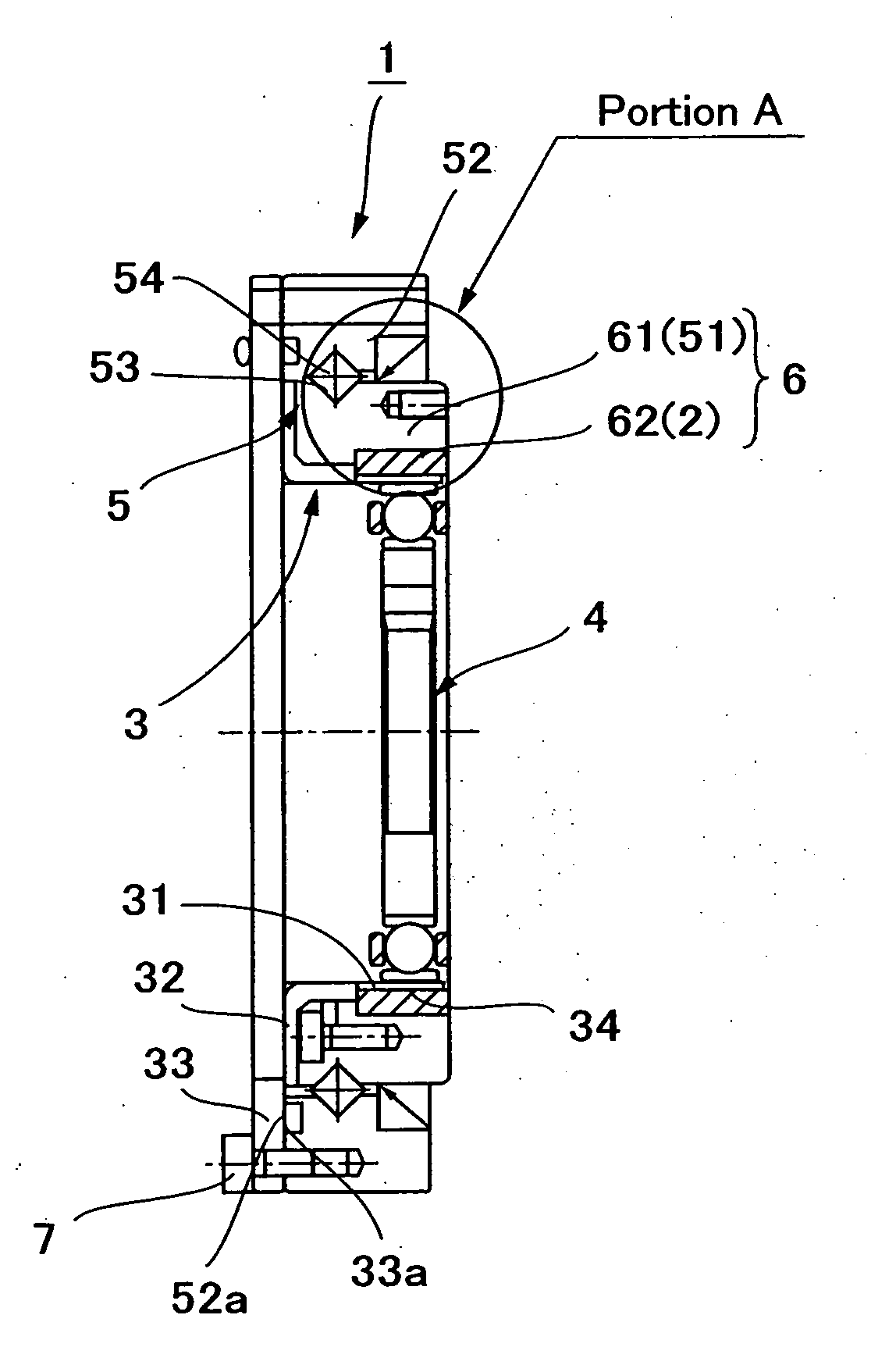

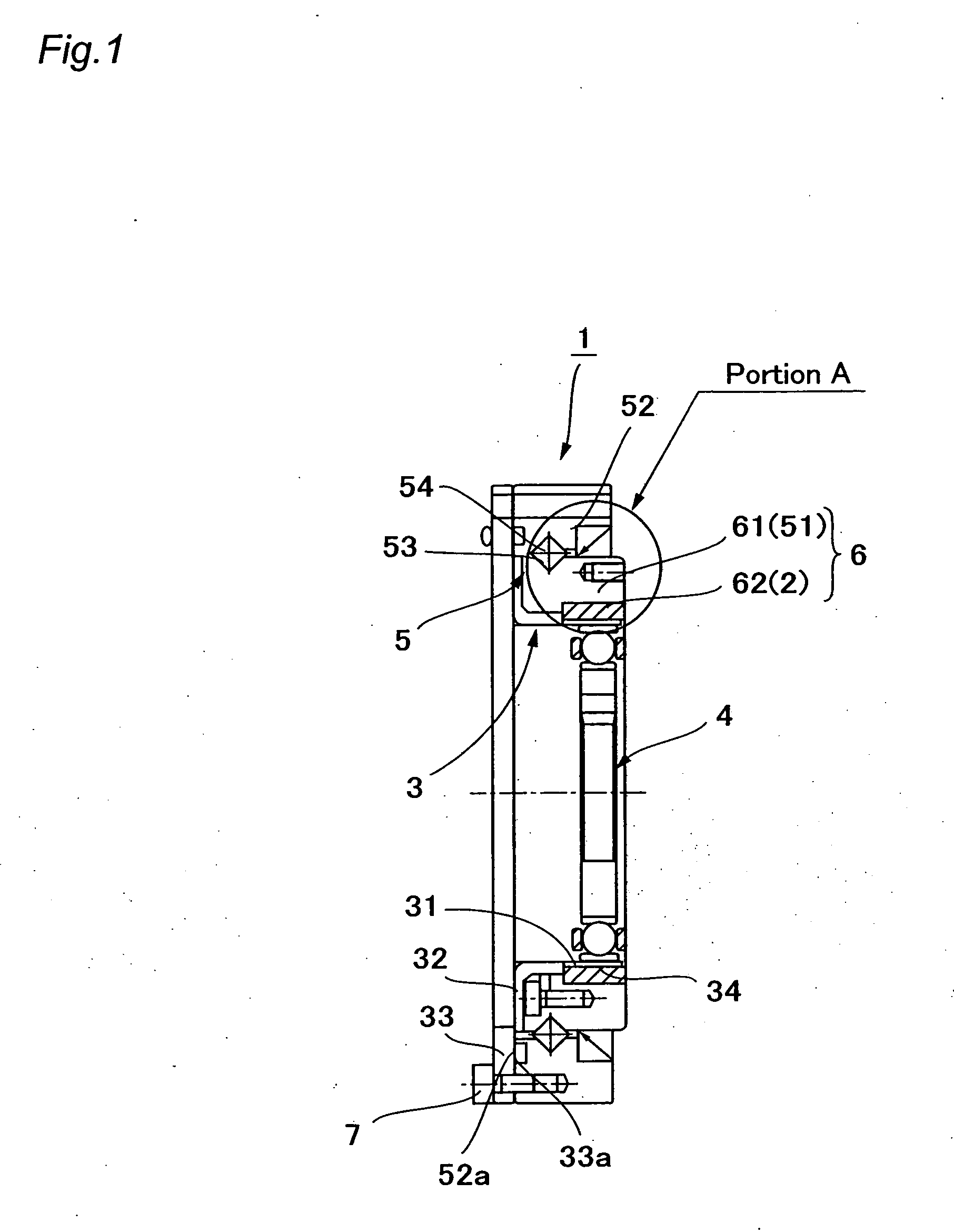

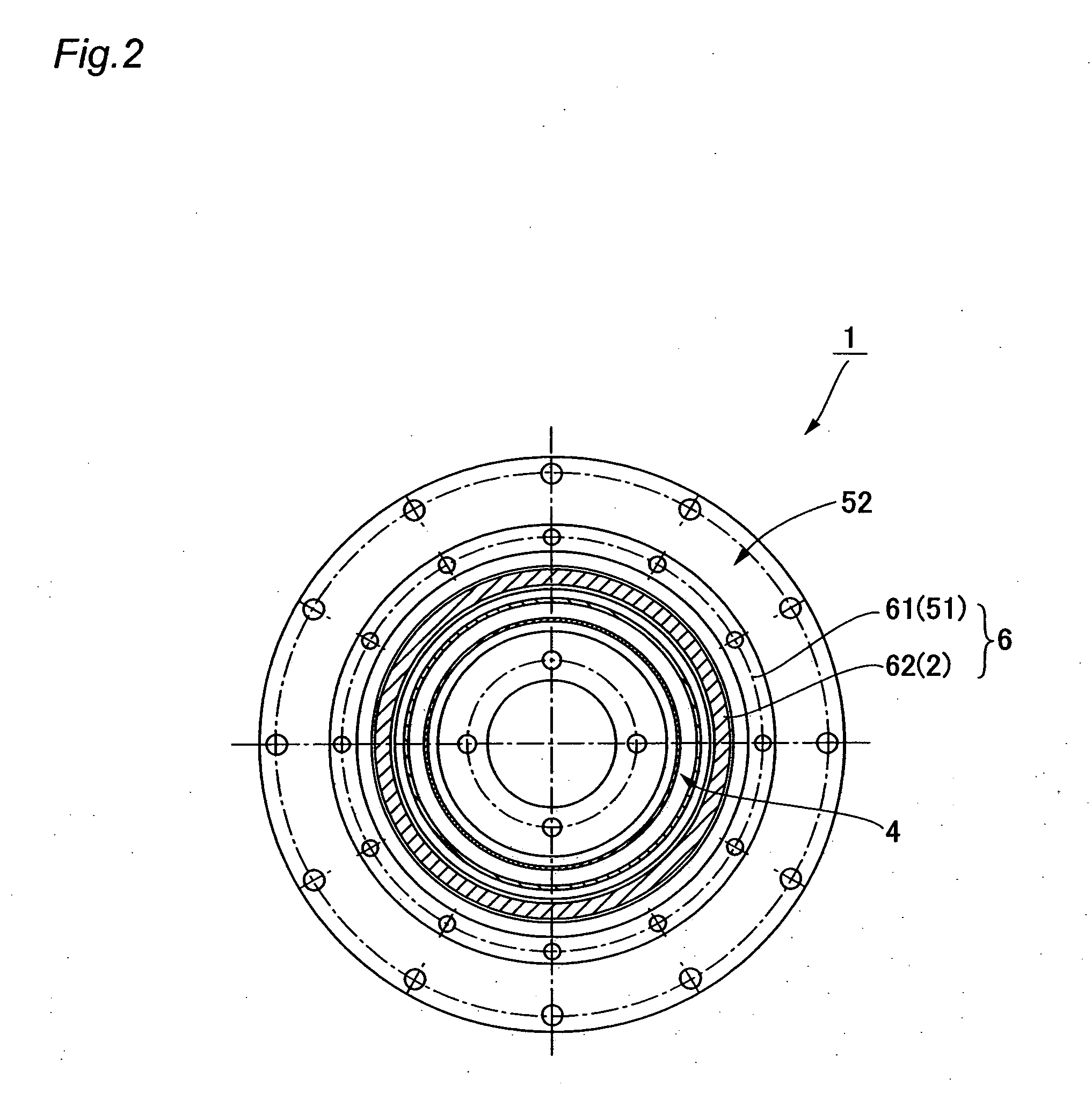

Wave gear device having internal gear integrally formed with inner ring of bearing

A wave gear device has a rigid internal gear, a flexible external gear, a wave generator, and a cross roller bearing for supporting the gears in a relatively rotatable manner. A toroidal composite member that functions as the rigid internal gear and an inner ring of the cross roller bearing has an inner ring-forming member that functions as the inner ring, and an internal teeth-forming member that functions as the rigid internal gear, and the internal teeth-forming member composed of a ductile casting is integrated by diffusion bonding with the inner ring-forming member composed of bearing steel.

Owner:HARMONIC DRIVE SYST IND CO LTD

Medical electrical lead and reinforced silicone elastomer compositions used therein

InactiveUS6040369AImprove mechanical propertiesImproved compression setRubber insulatorsPlastic/resin/waxes insulatorsVulcanizationElectrical conductor

A medical electrical lead and a reinforced silicone elastomer used therein. The silicone elastomer used therein is preferably made from a novel silica reinforced polysiloxane material, which after vulcanization by cross-linking exhibits improved mechanical properties. The medical electrical lead features a an electrode at a distal end thereof, a connector at a proximal end thereof and an elongated electrical conductor extending between the electrode and the connector, the conductor in electrical contact with the electrode at a distal end and in electrical contact with the connector at a proximal end, the conductor comprised of a plurality of wires or wire bundles wound in a multifilar coil configuration.

Owner:NUSIL TECH

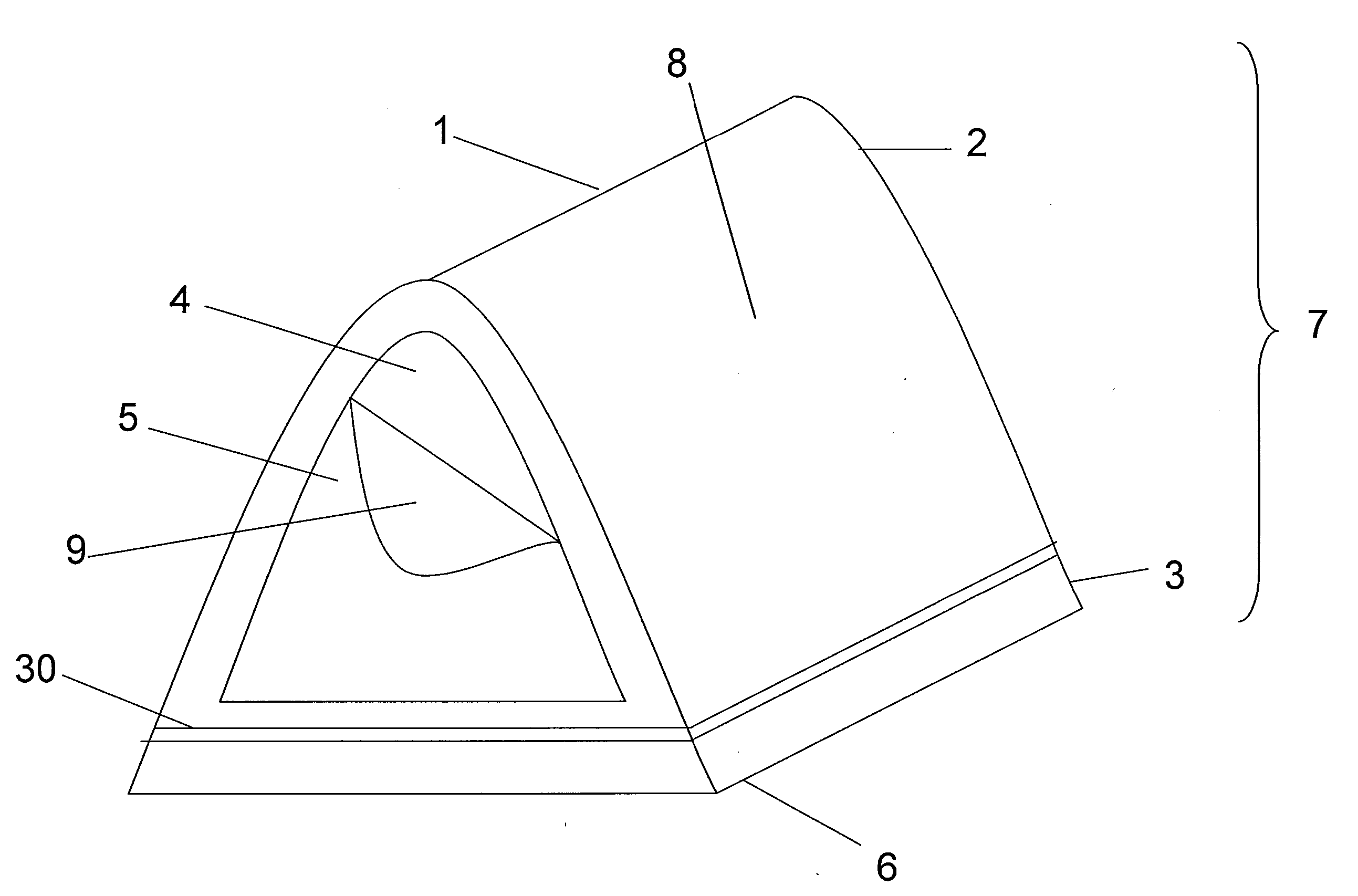

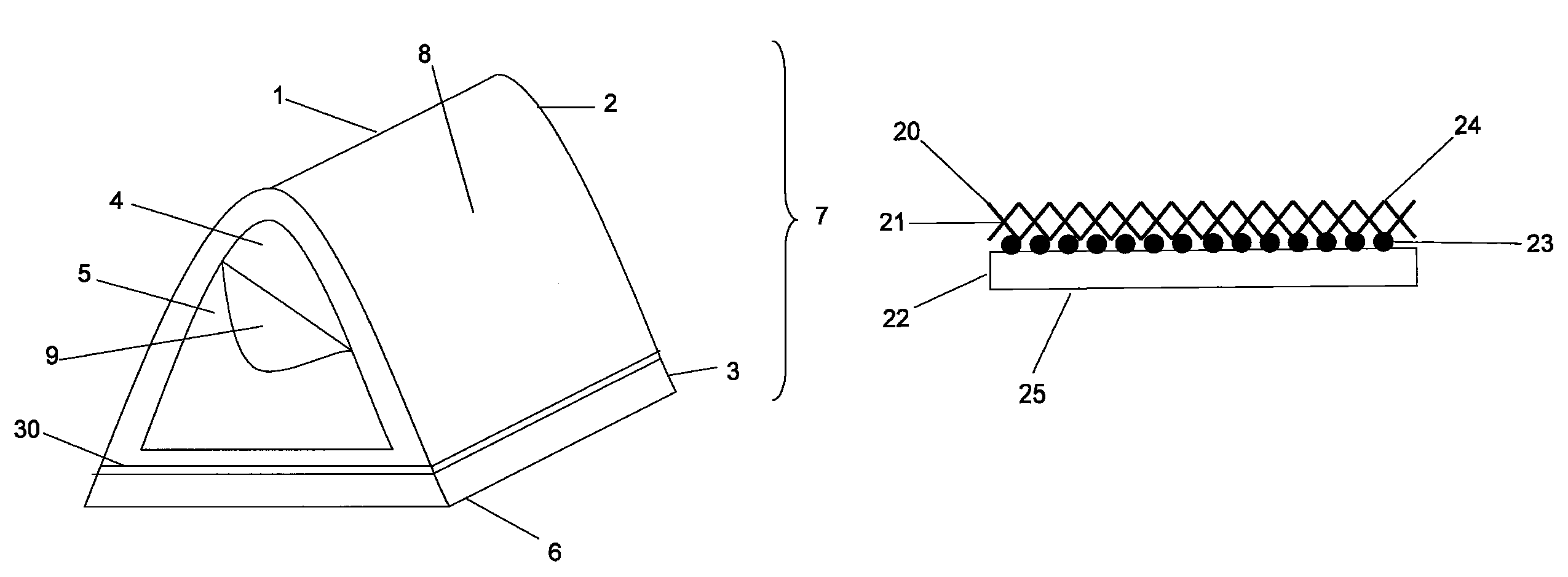

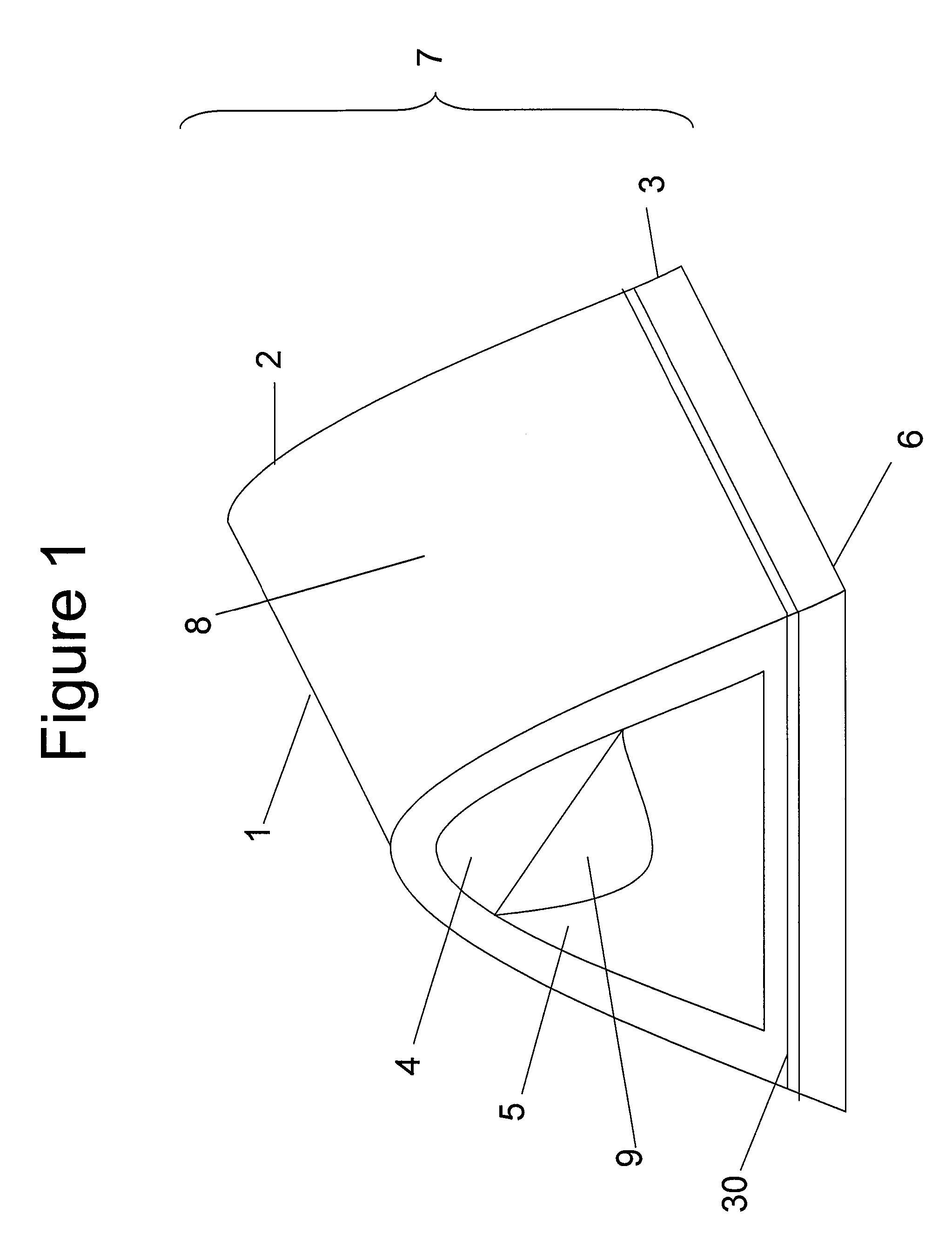

Lightweight, durable enclosures and laminates for making the same

ActiveUS20100288321A1Sufficient oxygen permeabilityRemaining durably liquidproofNatural cellulose pulp/paperProtective equipmentFlame resistanceEngineering

A lightweight enclosure is described that has an exterior film surface. The lightweight enclosure comprises a laminate having a porous outer film. The laminate is moisture vapor transmissive and flame resistance (passing CPAI-84), and abrasion resistance on the outer film surface thereby remaining durably liquidproof. The lightweight enclosure may be a single wall tent and is formed from a laminate having sufficient oxygen permeability to sustain life while enclosure openings are closed.

Owner:WL GORE & ASSOC INC

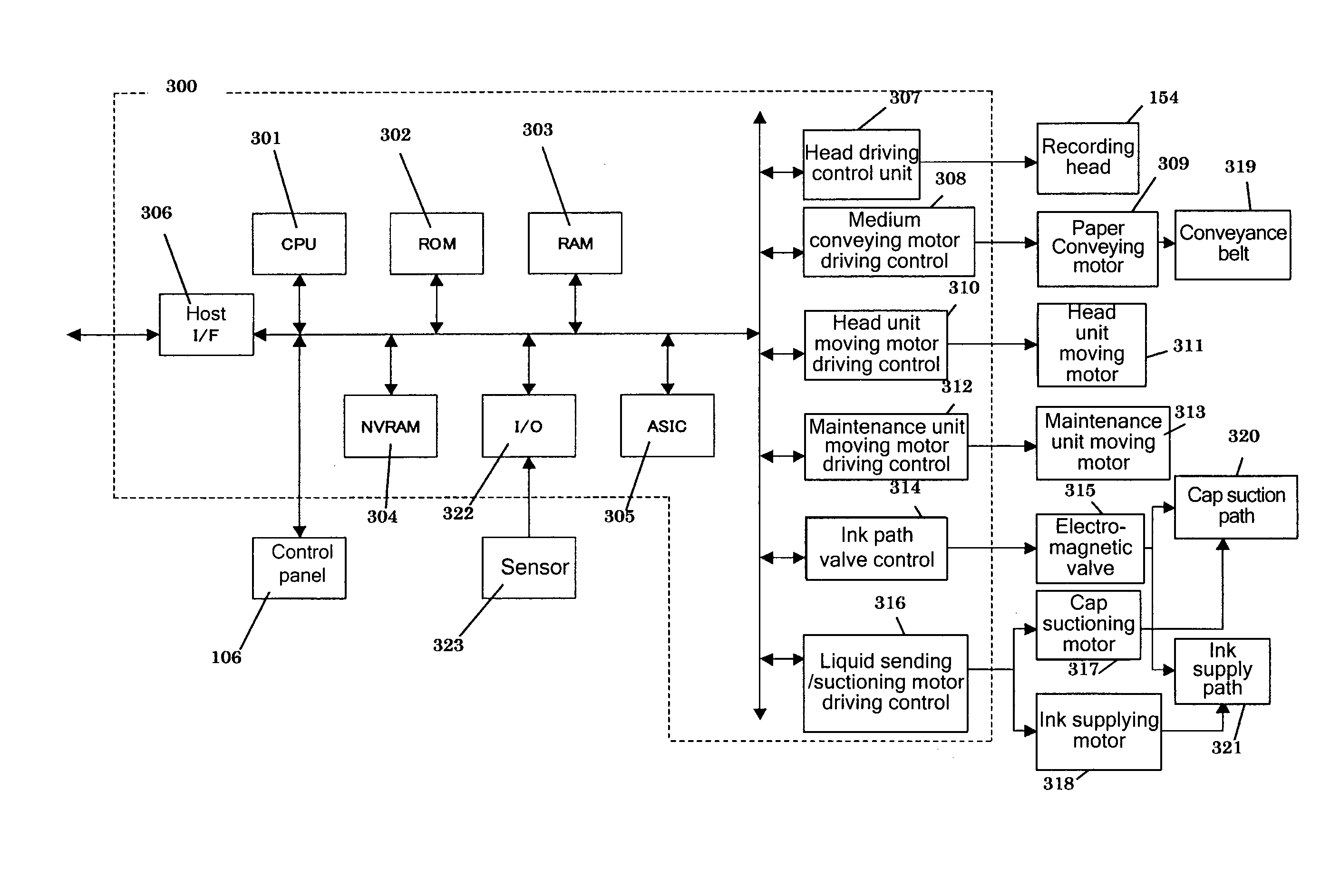

Ink set, cartridge, inkjet recording method, and inkjet recording device

InactiveUS20130321524A1Improve fixing abilityHigh image quality and fixing abilityDuplicating/marking methodsInksOrganic acidWater soluble

To provide an ink set, which contains: a treatment liquid containing at least an organic acid, a surfactant and water; and an ink containing at least a colorant, a water-soluble organic solvent, a carboxyl group-containing resin, a surfactant, and water, wherein the treatment liquid, or the ink, or both the treatment liquid and the ink further contain an epoxy resin.

Owner:RICOH KK

Wave gear device having internal gear integrally formed with inner ring of bearing

ActiveUS20050217420A1High abrasionHigh precisionRoller bearingsEngine of arcuate-engagement typeGear wheelEngineering

A wave gear device has a rigid internal gear, a flexible external gear, a wave generator, and a cross roller bearing for supporting the gears in a relatively rotatable manner. A toroidal composite member that functions as the rigid internal gear and an inner ring of the cross roller bearing has an inner ring-forming member that functions as the inner ring, and an internal teeth-forming member that functions as the rigid internal gear, and the internal teeth-forming member composed of a ductile casting is integrated by diffusion bonding with the inner ring-forming member composed of bearing steel.

Owner:HARMONIC DRIVE SYST IND CO LTD

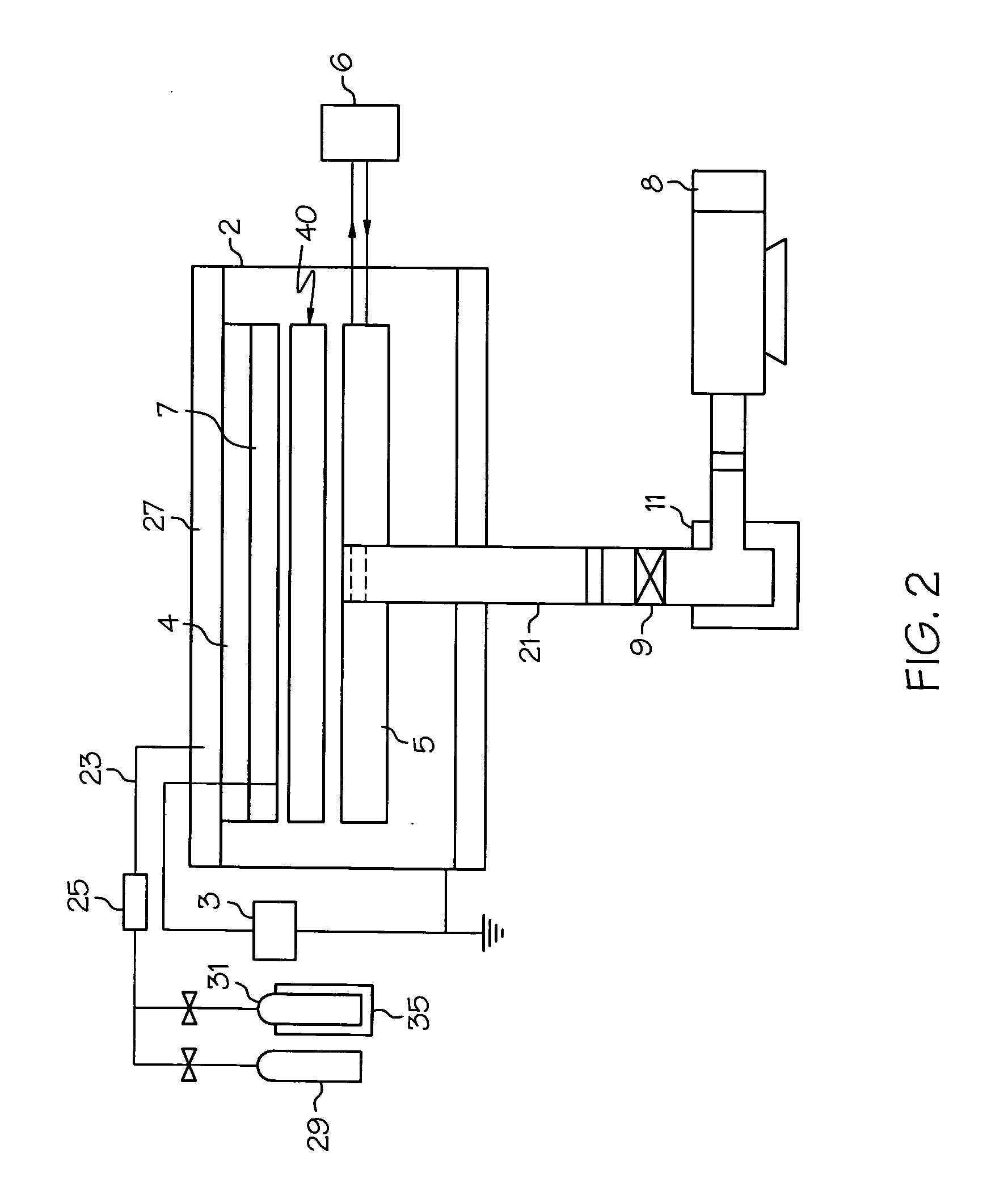

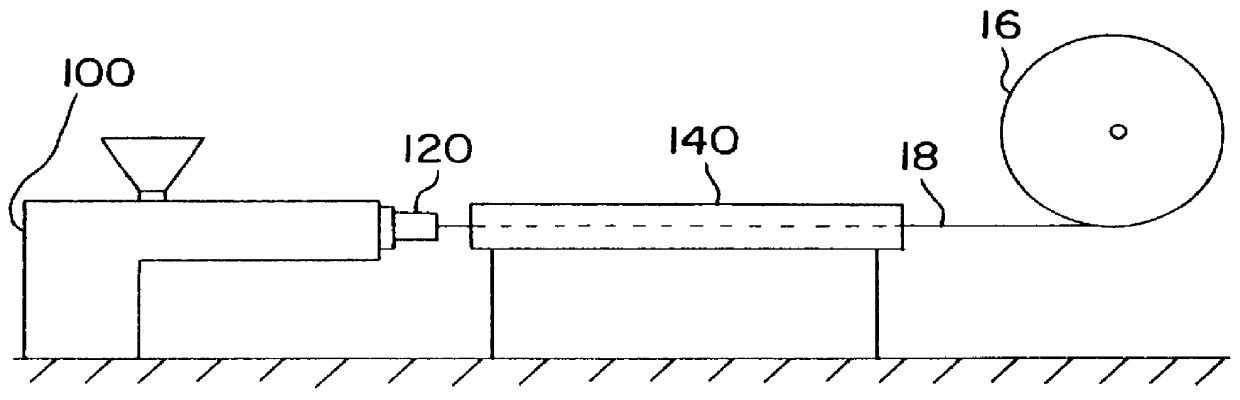

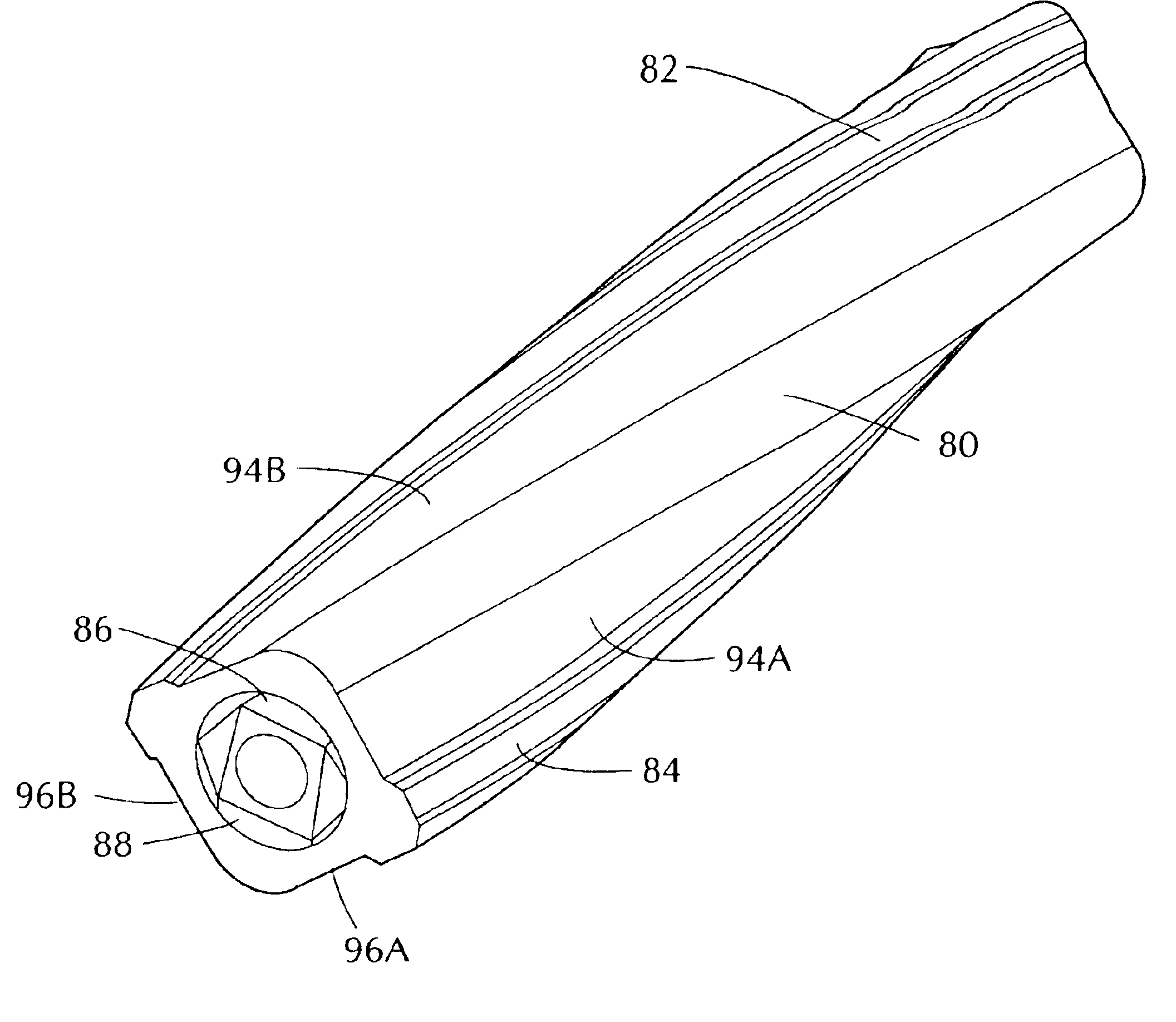

System and method for NMR logging with helical polarization

InactiveUS6956372B2High strength and abrasion resistanceMinimize interferenceElectric/magnetic detection for well-loggingMaterial analysis by using resonanceNMR - Nuclear magnetic resonanceRadio frequency

Nuclear magnetic resonance well logging apparatus and method of use for geophysical examination of a borehole as the borehole is drilled. The apparatus is connected to the drill bit to follow it through the borehole as the borehole is formed. The apparatus comprises a non-magnetic protective collar with lateral protrusions or wings, which provide enhanced abrasion resistance, strength, and rigidity to the probe section. This collar is twisted about its longitudinal axis. The apparatus also comprises one or more permanent magnets within the metal collar and an antenna mounted outside of the collar. Both the magnet and the antenna are twisted about the longitudinal axis of the probe section to produce a generally helical static magnetic field and a radio frequency magnetic field that is substantially orthogonal to the static magnetic field.

Owner:HALLIBURTON ENERGY SERVICES INC

Cladding

InactiveUS7966783B2Improve fire resistanceEmission reductionCovering/liningsPublic buildingsSurface finishPanelling

There can be provided a method of cladding a surface with panelling. The method can comprise: attaching a first panel support member to the surface, the first panel support member being configured to receive at least a part of a first edge of a panel comprising a core of woven and non-woven glass impregnated with resin and a surface finish of paper and melamine resin; placing the first edge in a position of co-operative reception with the first panel support member; and placing a second edge of the panel substantially opposite the first edge in a position of co-operative reception with a second panel support member, the second panel support member being configured to be attached to the surface.

Owner:BAA IP HOLDCO

Lightweight, durable enclosures and laminates for making the same

ActiveUS8163662B2Remaining durably liquidproofSufficient oxygen permeabilityProtective equipmentSynthetic resin layered productsEngineeringMoisture

A lightweight enclosure is described that has an exterior film surface. The lightweight enclosure comprises a laminate having a porous outer film. The laminate is moisture vapor transmissive and flame resistance (passing CPAI-84), and abrasion resistance on the outer film surface thereby remaining durably liquidproof. The lightweight enclosure may be a single wall tent and is formed from a laminate having sufficient oxygen permeability to sustain life while enclosure openings are closed.

Owner:WL GORE & ASSOC INC

Electrophotographic photoreceptor and method of preparing the photoreceptor, and image forming method, image forming apparatus and process cartridge therefor using the photoreceptor

InactiveUS7449272B2Improve electrical performanceHigh abrasionElectrographic process apparatusCorona dischargeBoiling pointImage formation

An electrophotographic photoreceptor, including an electroconductive substrate; and a photosensitive layer overlying the electroconductive substrate, which includes a crosslinked layer at the surface thereof, wherein the crosslinked layer is formed by a method including:coating a coating liquid, which includes a solvent; a radical polymerizing monomer having three or more functional groups and no charge transportable structure; and a radical polymerizing compound having a charge transportable structure on the photosensitive layer; andirradiating the coating liquid to be hardened while the surface of the photosensitive layer is controlled to have a temperature not higher than a boiling point of the solvent.

Owner:RICOH KK

Substrate covered with an intermediate coating and a hard carbon coating

InactiveUS7927700B2High hardnessReduce coefficient of frictionLayered productsBearing componentsCarbon coatingCarbide

The invention relates to a substrate covered at least partially with a layered coating. The layered coating comprises an intermediate coating and a hard carbon coating. The intermediate coating comprises a first metal layer deposited on the substrate, the first metal layer comprising at least one element of group IVB, group VB or group VIB; a nitride layer deposited on the first metal layer, the nitride layer comprising at least one nitride of an element of group IVB, group VB or group VIB; a second metal layer deposited on the nitride layer, the second metal layer comprising at least one element of group IVB, group VB or group VIB; a transition layer deposited on the second metal layer, the transition layer comprising at least one carbide of an element of group IVB, group VB or group VIB.

Owner:SULZER METAPLAS

Coating composition to obtain surface effects

InactiveUS20110160379A1Improve the immunityReduce dry-film thicknessPolyurea/polyurethane coatingsCross-linkOrganic solvent

This invention provides a coating composition providing a soft-feel effect and enhanced suntan cream resistance, the composition comprisingA) 5 to 50 wt %, preferably 20 to 40 wt %, of an dispersion and / or solution of at least one hydroxyl functional polyurethane, the dispersion and / or solution having a solids content in a range of 25 to 90 wt %, the wt % being based on the weight of the dispersion and / or solution,B) 0 to 35 wt %, preferably 5 to 20 wt %, of at least one polyisocyanate as cross-linking agent,C) 0.1 to 20 wt %, preferably 4 to 15 wt %, of at least one aqueous hydroxyl functional crosslinked (meth) acrylic latex,D) 0 to 20 wt %, preferably 4 to 15 wt %, of organic solvent, andE) 0.1 to 10 wt %, preferably 4 to 10 wt %, of at least one pigment, extender and / or coating additive,the wt % being based on the total weight of the composition of A) to E).

Owner:BUETTNER GABRIELE +2

Ceramic glaze coating structure of a chip element and method of forming the same

InactiveUS20090004367A1High yieldLow equipment costStacked capacitorsSemiconductor/solid-state device manufacturingHigh densityMetallurgy

A ceramic glaze-coating structure of a chip element and a method of forming the same are provided. In the ceramic glaze-coating structure, a high-density, smooth, and high-impedance ceramic glaze is coated on the body of an element. As for the terminal electrode part, the unique firing characteristics between the material of the terminal electrode (e.g., conductive compositions) and the ceramic glaze are utilized, such that the ceramic glaze layer between the surface of the terminal electrode or the terminal electrode and the ceramic body is absorbed and then removed by sintering; thus, the ceramic glaze coating structure of a chip element with only the element body being coated is formed.

Owner:INPAQ TECH

Tribologically loaded component and accompanying gas engine or internal combustion engine

ActiveUS7455906B2Excellent abrasion resistanceHigh wear resistanceRecord information storageMachines/enginesDiamond-like carbonExternal combustion engine

A tribologically loaded component, in particular an injection needle, an injection valve, or a component of a combustion-engine injection system. This component has a surface region, which moves in relation to a counterbody during operation, is tribologically loaded in the process, and is provided with a first coating. This first coating has a first layer of diamond-like carbon having a hydrogen level of at least 30 atom %. Additionally provided is a gas engine or an internal combustion engine, which is driven by a dry gas, such as natural gas or hydrogen, as a fuel, or is driven under oil-free and / or water-free combustion conditions, and has such a tribologically loaded component.

Owner:ROBERT BOSCH GMBH

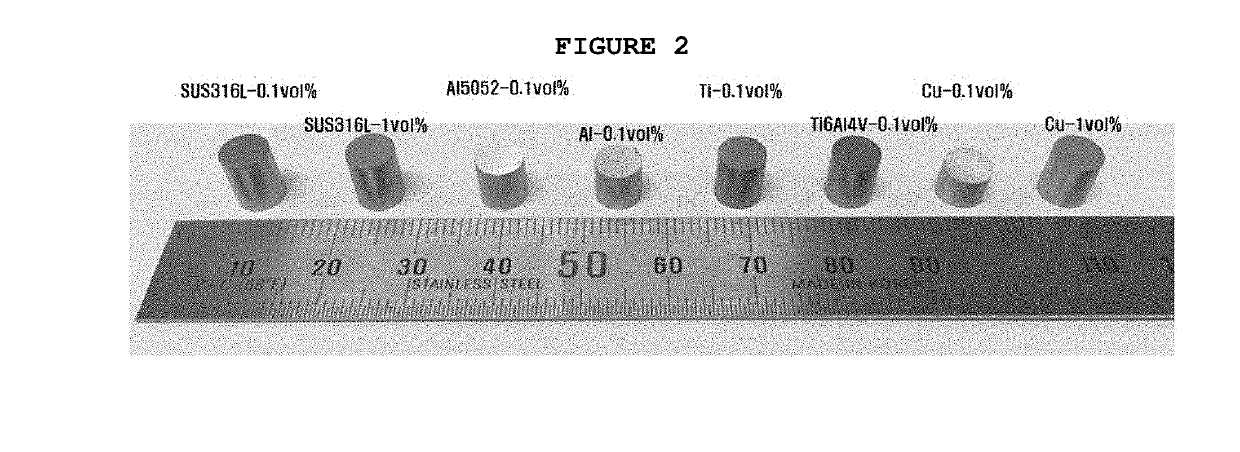

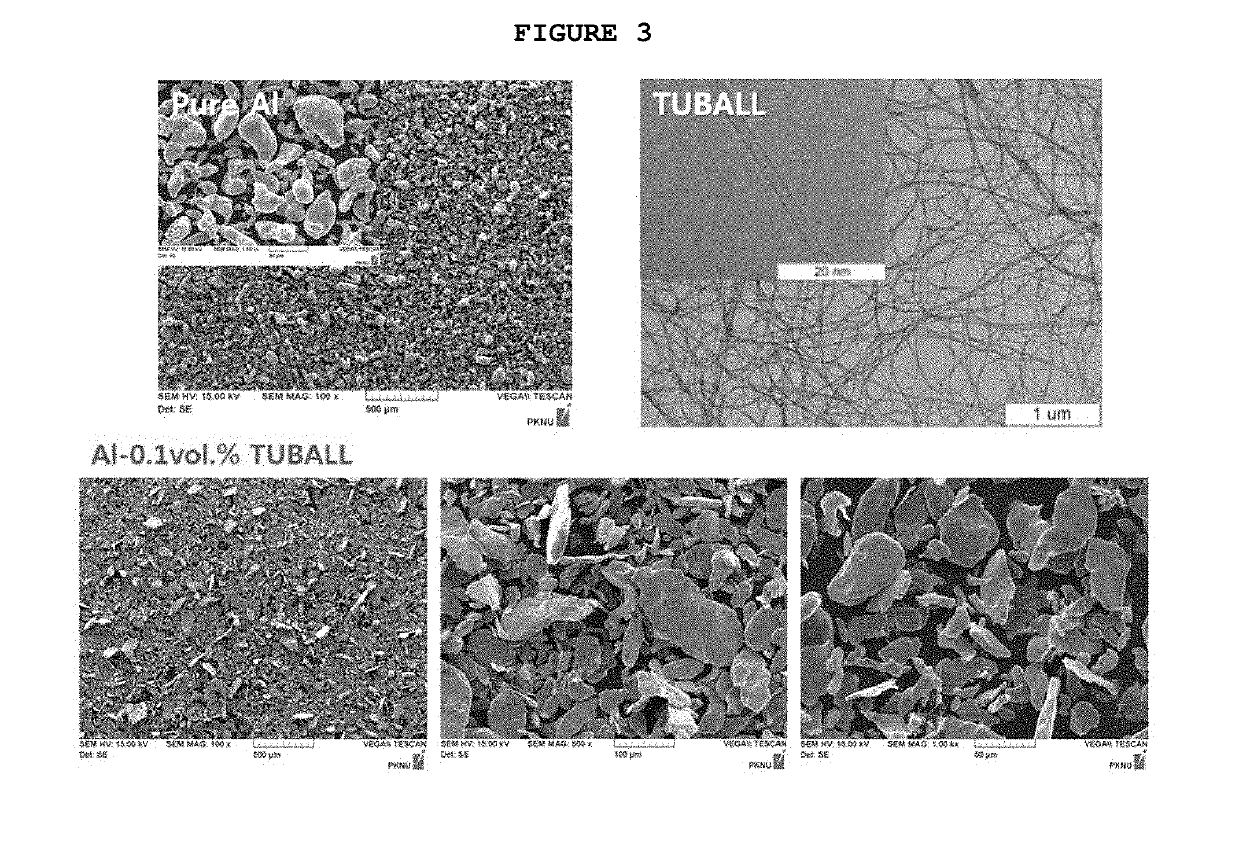

Discharge plasma sintering method for manufacturing single-walled carbon nanotube reinforced metal matrix composite and composite material produced thereby

ActiveUS20190276915A1Good physical propertiesExcellent abrasion resistanceSingle-walled nanotubesFilled nanotubesDispersityCarbon nanotube

The present invention provides a method of manufacturing a single-walled-carbon-nanotube-reinforced metal matrix complex material. The method includes (a) manufacturing a complex powder by performing ball milling of a metal powder and a single-walled carbon nanotube powder, and (b) manufacturing a metal-carbon-nanotube complex material by spark-plasma-sintering (SPS) the complex powder manufactured during step (a). According to the method of manufacturing the single-walled-carbon-nanotube-reinforced metal matrix complex material according to the present invention, in order to manufacture material parts requiring high strength and abrasion resistance, the single-walled carbon nanotube powder is added to various metal matrixes and ball milling is performed, thus manufacturing a complex powder having uniform dispersity. The manufactured complex powder is subjected to complexation in a short period of time using a spark-plasma-sintering (SPS) process, thereby easily manufacturing a bulk-type single-walled-carbon-nanotube-reinforced metal matrix complex material having excellent physical properties.

Owner:PUKYONG NAT UNIV IND ACADEMIC COOPERATION FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com