Method and apparatus for improving measurement accuracy of a portable coordinate measurement machine

a coordinate measurement machine and measurement accuracy technology, applied in mechanical measuring arrangements, instruments, manufacturing tools, etc., can solve the problems of not being able to create executable programs or modify executable programs, and achieve the effects of easy conversion to, easy arctuatation by the operator, and easy distinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

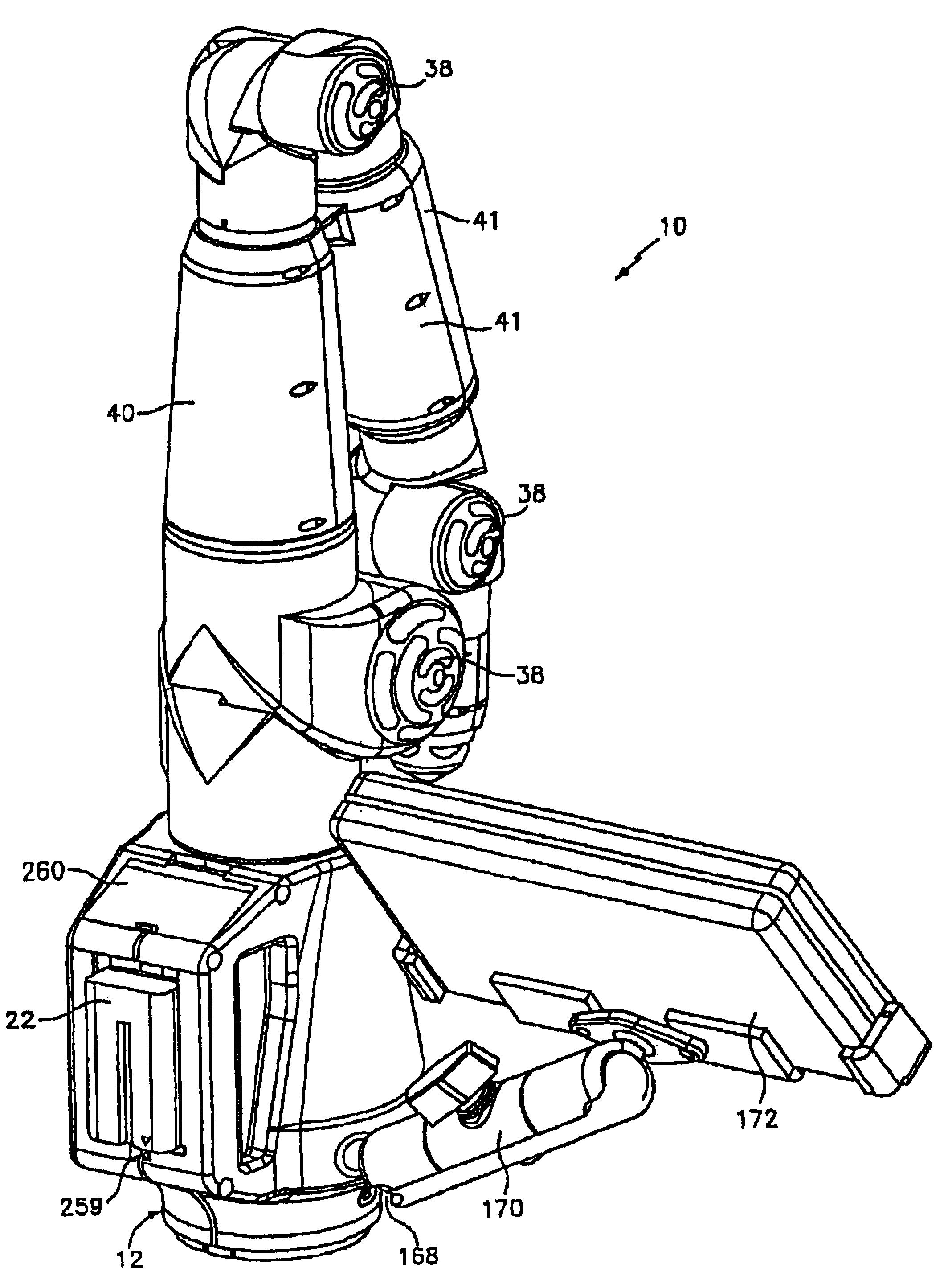

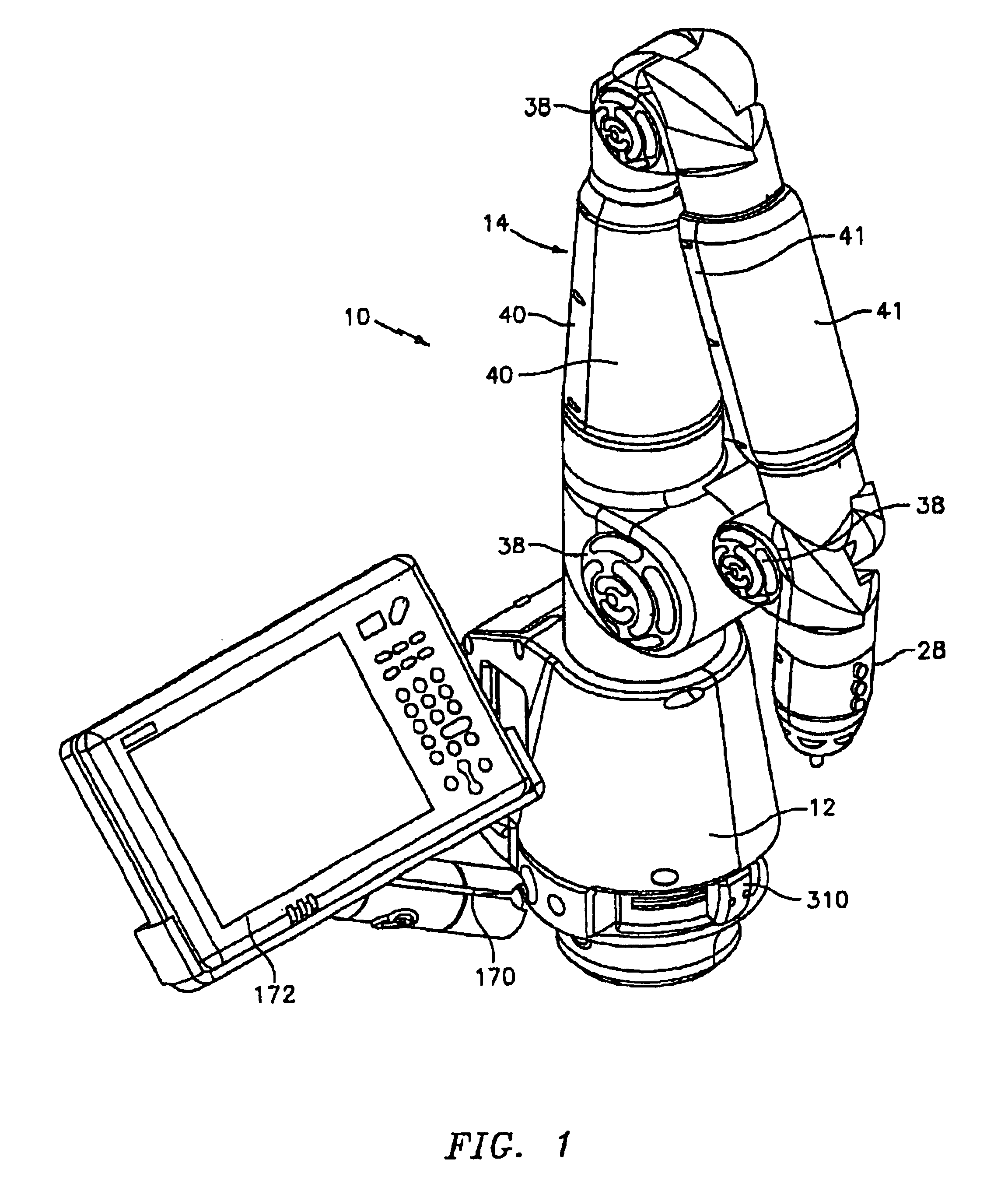

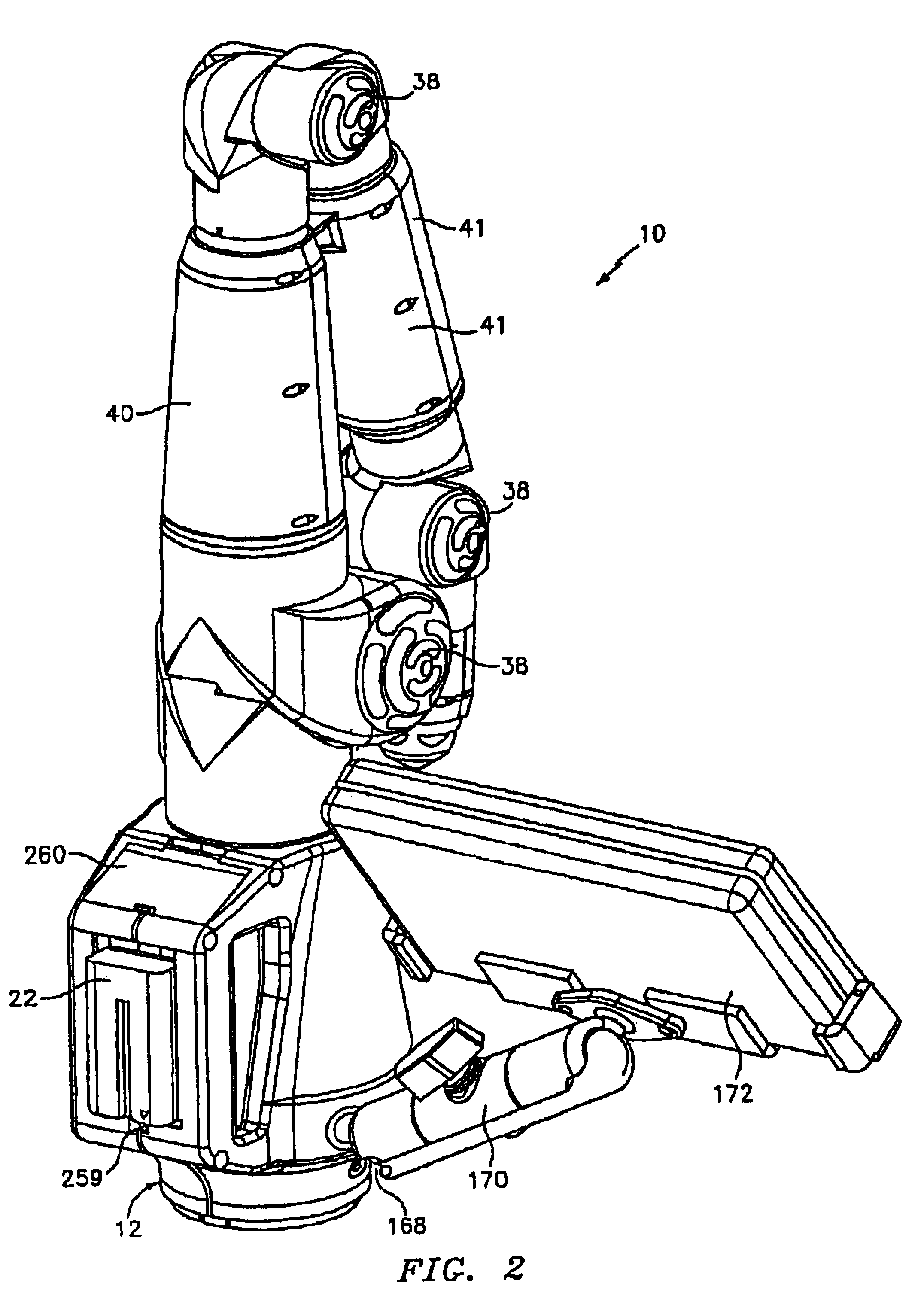

[0081]Referring first to FIGS. 1-3, the CMM of the present invention is shown generally at 10. CMM 10 comprises a multijointed, manually operated, articulated arm 14 attached at one end to a base section12 and attached at the other end to a measurement probe 28. Arm 14 is constructed of basically two types of joints, namely a long joint (for swivel motion) and a short joint (for hinge motion). The long joints are positioned substantially axially or longitudinally along the arm while the short joints are preferably positioned at 90° to the longitudinal axis of the arm. The long and short joints are paired up in what is commonly known as a 2-2-2 configuration (although other joint configurations such as 2-1-2, 2-1-3, 2-2-3, etc. may be employed) Each of these joint pairs are shown in FIGS. 4-6.

[0082]FIG. 4 depicts an exploded view of the first joint pair, namely long joint 16 and short joint 18. FIG. 4 also depicts an exploded view of the base 12 including a portable power supply elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com