Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

265results about How to "Improved compression set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrically conductive silicones and method of manufacture thereof

InactiveUS20030047718A1Manufacturing limitationImproved compression setConductive materialNon-conductive material with dispersed conductive materialPolymer scienceHydrogen atom

An electrically conductive silicone composition comprising an electrically conductive filler; organopolysiloxane mixture comprising a catalyst which promotes the addition of Si-bonded hydrogen onto alkenyl multiple bonds; an organopolysiloxane having at least two alkenyl groups per molecule; an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule; optionally, a fluid organopolysiloxane having a viscosity less than about 1000 centipoise; and optionally, an organopolysiloxane gel formulation, the composition, when cured, having a Shore A Durometer hardness of less than or equal to about 60 measured according to ASTMD-2240 and an electrical resistivity of less than or equal to about 10-6 ohm-cm.

Owner:WORLD PROPERTIES

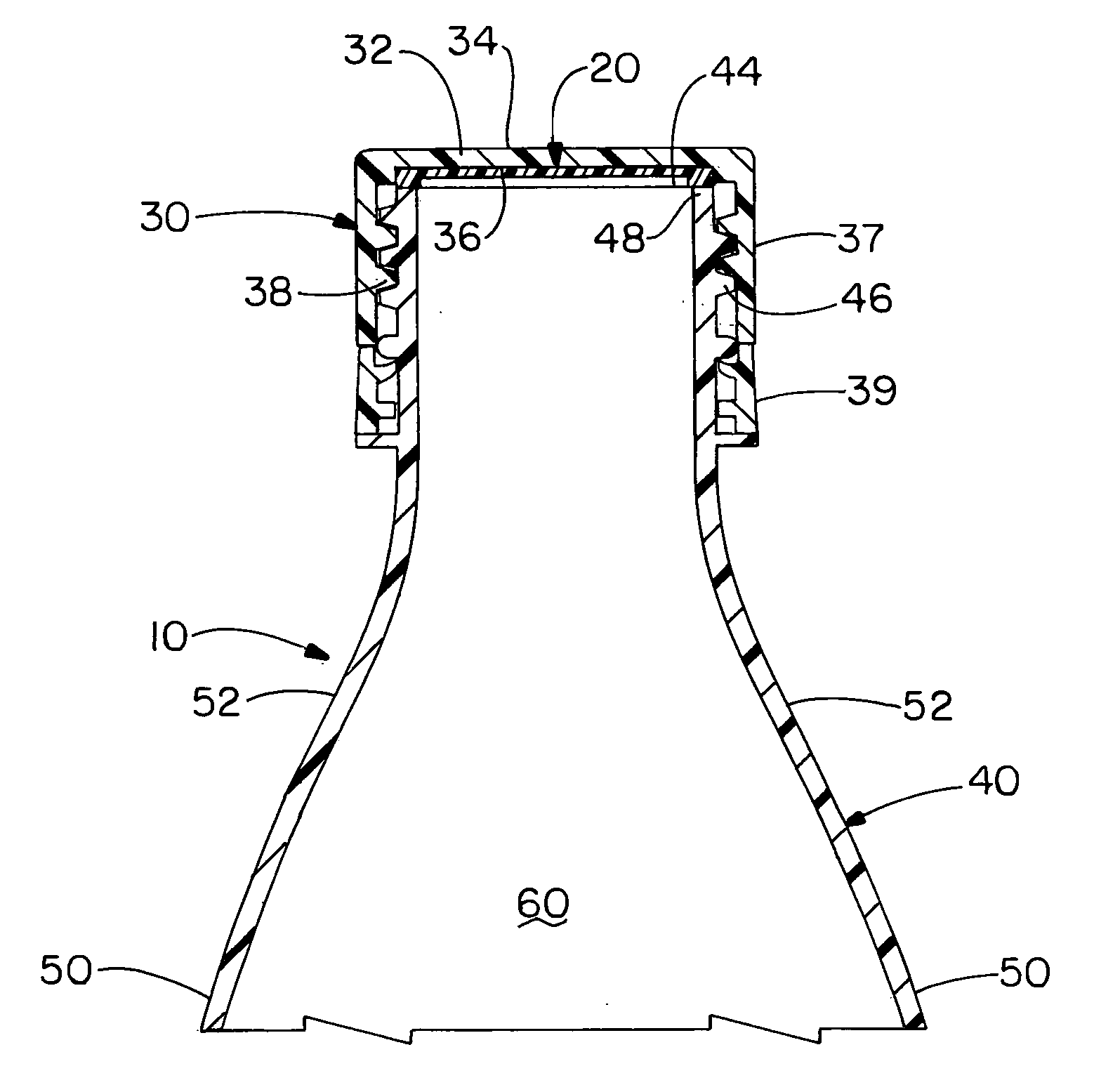

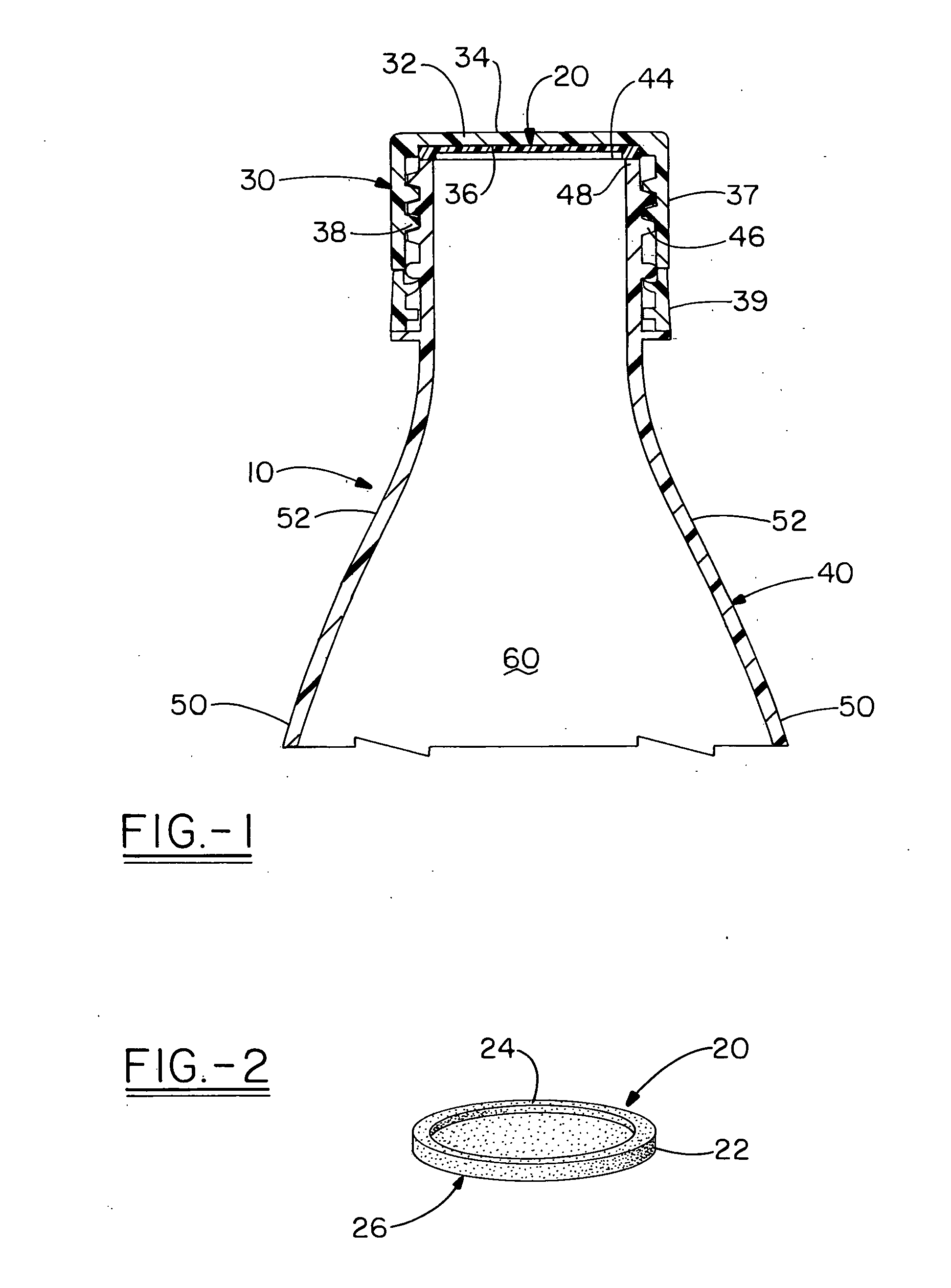

Retortable liners and containers

ActiveUS20100006532A1Improve sealingPrevent leakageSynthetic resin layered productsSealingPolyolefinPlastic packaging

Retort liners and containers including a container body such as a bottle or jar, a closure, and the retort liner, wherein the retort liners exhibit attractive properties such as low compression set under retort conditions, desirable adhesion to a polymeric closure such as a cap or lid, and beneficial oxygen barrier properties. In particular, the retort liners are thermoplastic elastomers formed from compositions including one or more styrenic block copolymers, one or more polyolefins and a softener. In a preferred embodiment, the retortable containers are all plastic packages, wherein the bottle or jar and the closure are thermoplastic compositions and the liner is a thermoplastic elastomer composition.

Owner:TEKNOR APEX

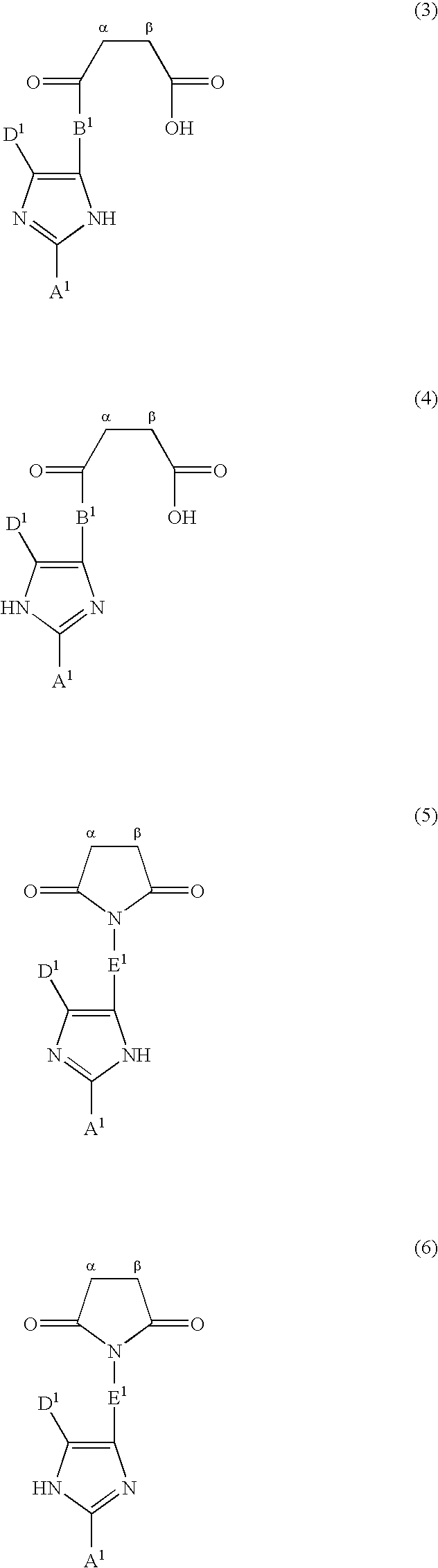

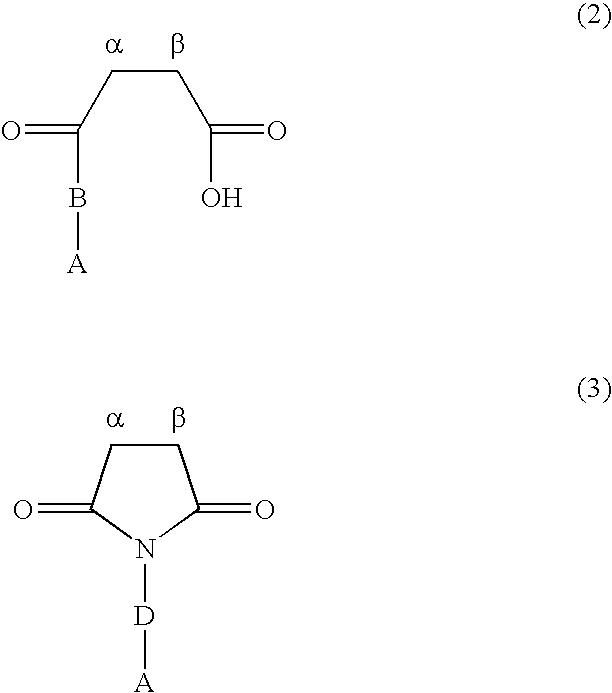

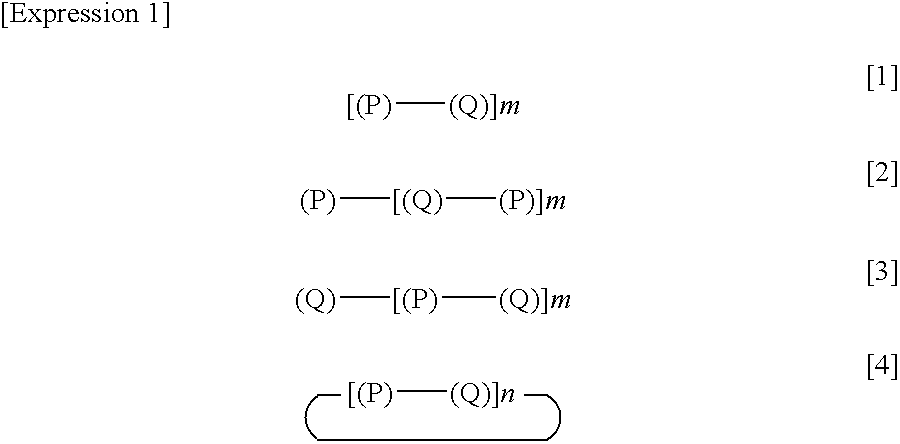

Thermoplastic elastomer and thermoplastic elastomer composition

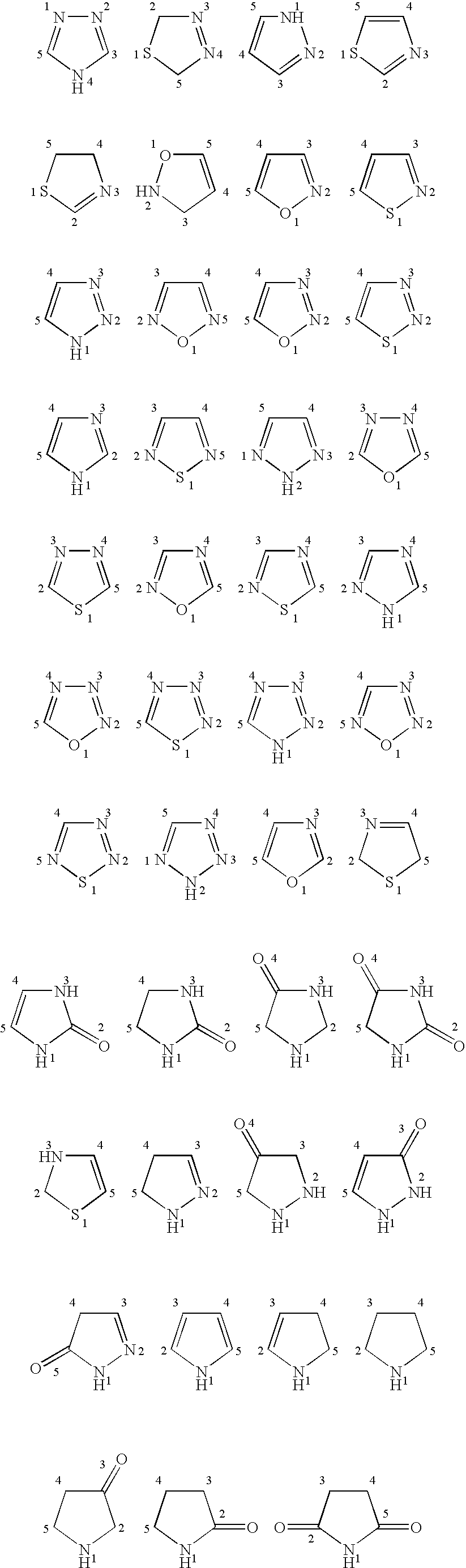

The objects of the present invention are to provide thermoplastic elastomers which retain an excellent recyclability while also having an excellent mechanical strength, particularly an excellent compression set, and to provide thermoplastic elastomer compositions which include such thermoplastic elastomers. These objects are achieved by the thermoplastic elastomers and thermoplastic elastomer compositions described below. One thermoplastic elastomer of the present invention is a hydrogen-bondable thermoplastic elastomer composed of an elastomeric polymer having, on side chains, carbonyl-containing groups and imidazole rings, which rings bear a hydrogen atom on a nitrogen atom and also bear an alkyl, aralkyl or aryl group. Another thermoplastic elastomer of the present invention is a thermoplastic polymer having side chains of a given structural formula that contain a carbonyl group and an imino group. The inventive thermoplastic elastomer compositions are compositions which include such thermoplastic elastomers.

Owner:YOKOHAMA RUBBER CO LTD

Thermoplastic elastomer composition

InactiveUS20040010090A1Improve recycling effectImproved compression setElastomerThermoplastic elastomer

Owner:YOKOHAMA RUBBER CO LTD

Unitary composite/hybrid cushioning structure(s) and profile(s) comprised of a thermoplastic foam(s) and a thermoset material(s)

InactiveUS8356373B2Improved compression setGuaranteed cushioning stabilityStuffed mattressesSpring mattressesCushioningThermoplastic

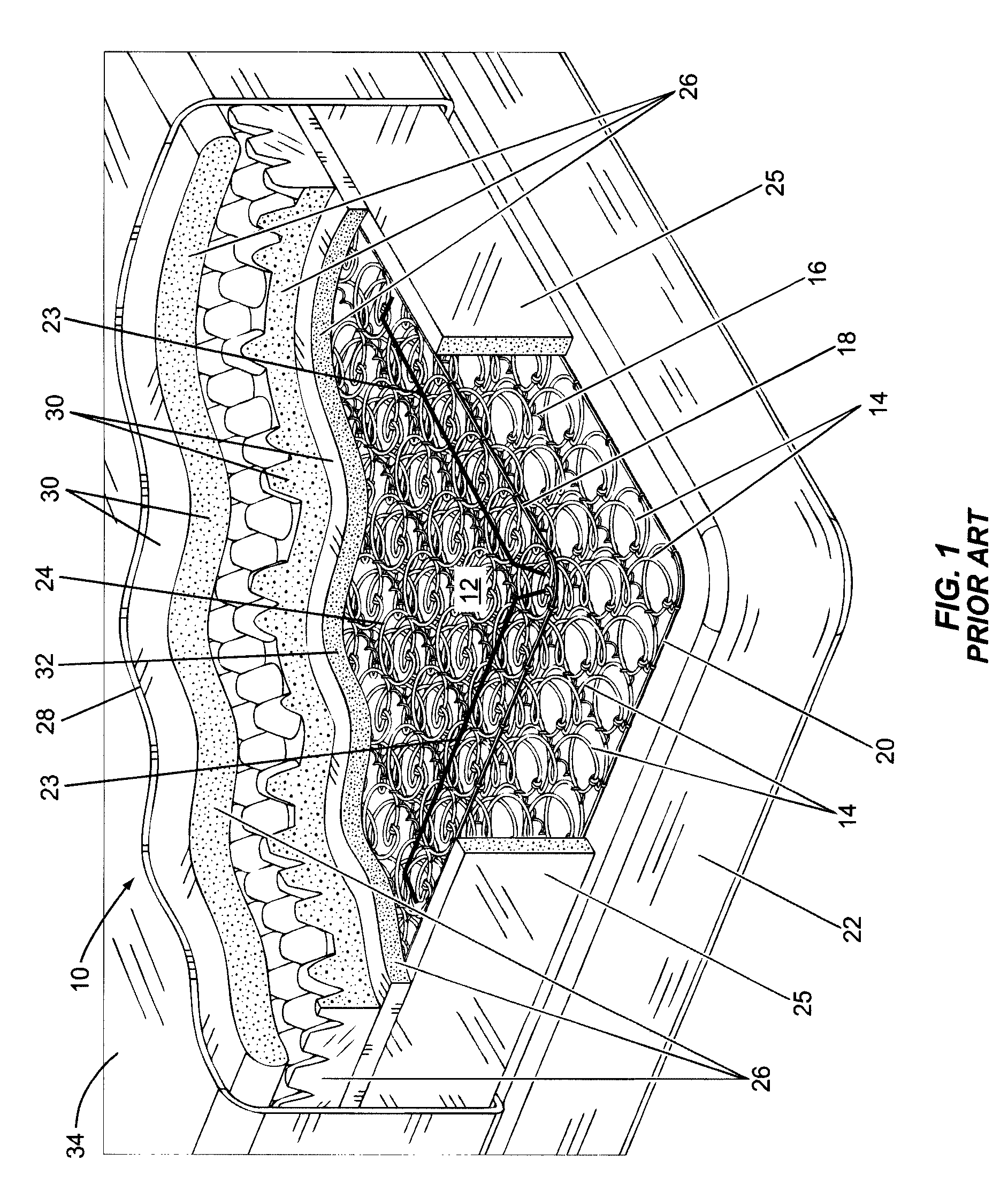

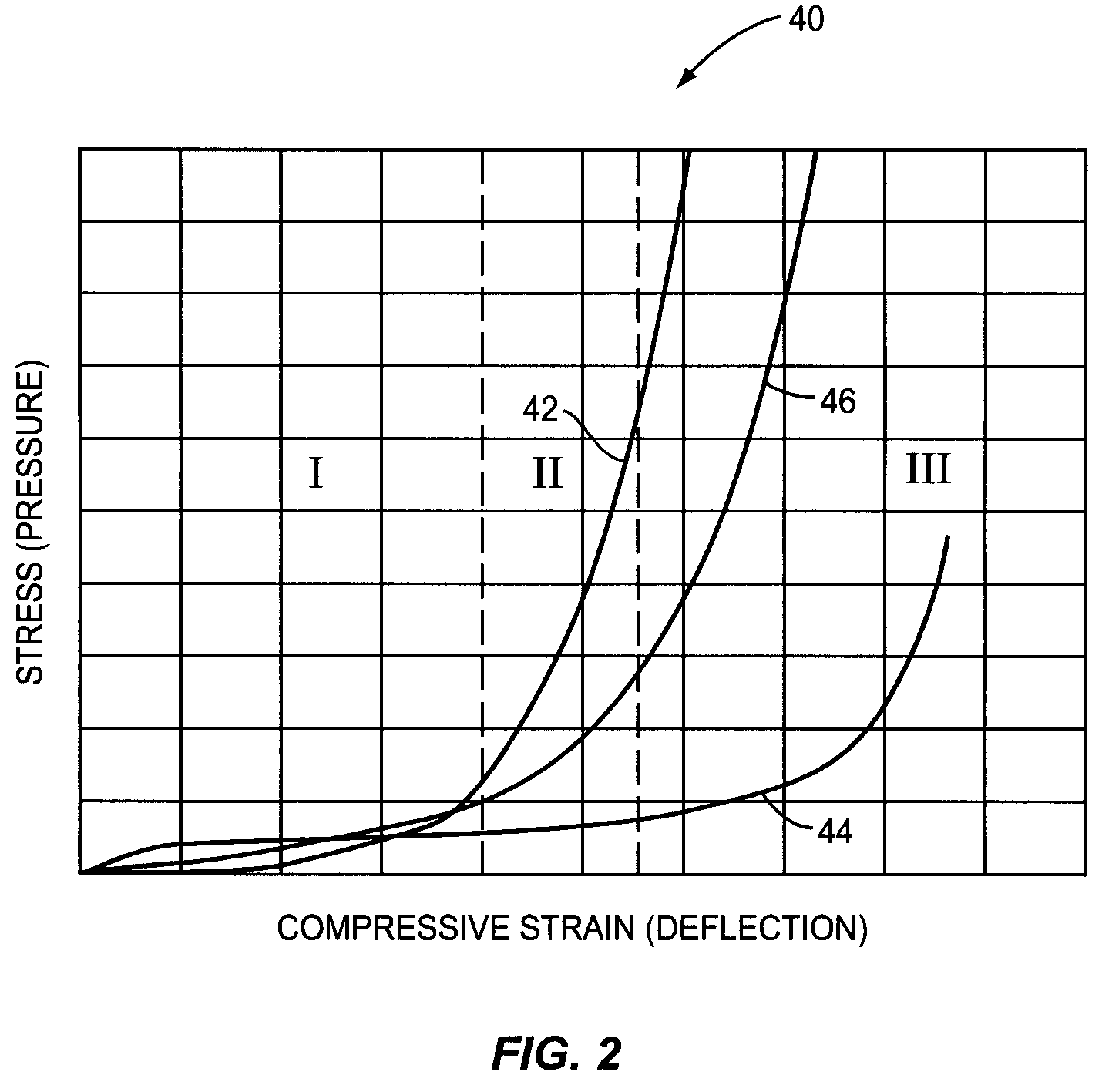

Embodiments disclosed in the detailed description include a unitary or monolithic composite or hybrid cushioning structure(s) and profile(s) comprised of a cellular thermoplastic foam and a thermoset material. The thermoset material may also be provided as cellular foam as well. In one embodiment disclosed herein, the unitary composite cushioning structure is formed from a cellular thermoplastic foam and a thermoset material. The cellular thermoplastic foam provides support characteristics to the unitary composite cushioning structure. The thermoset material provides a resilient structure with cushioning characteristics to the cushioning structure. A stratum is disposed between at least a portion of the cellular thermoplastic foam and at least a portion of the thermoset material to secure the at least a portion of the thermoset material to the at least a portion of the cellular thermoplastic foam to provide a unitary composite cushioning structure.

Owner:NOMACO

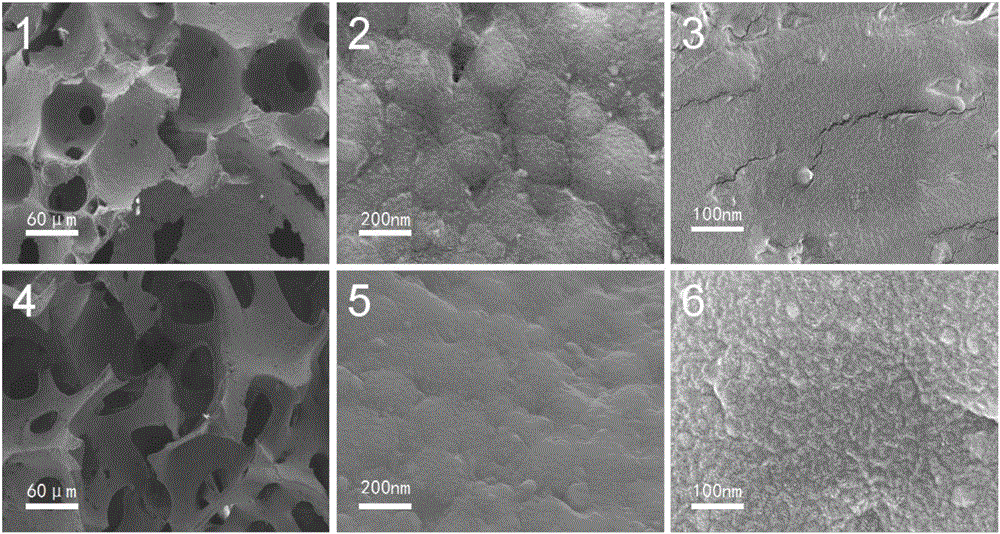

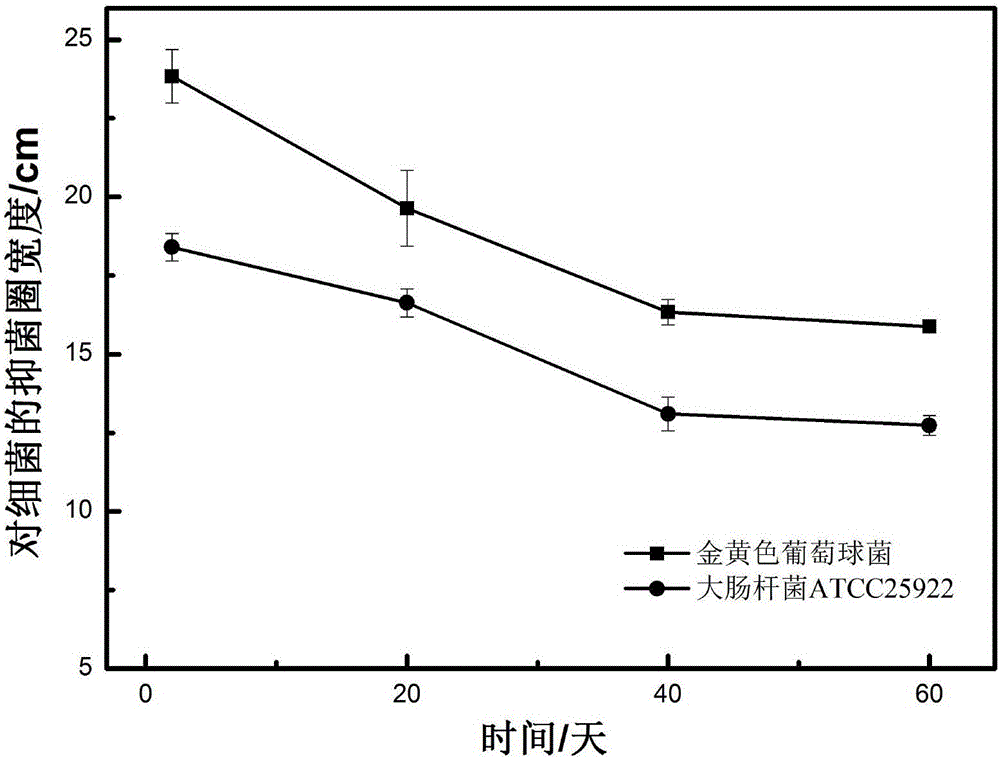

Antibacterial natural latex product based on quaternary ammonium salt antibacterial agent and preparation technology of antibacterial natural latex product

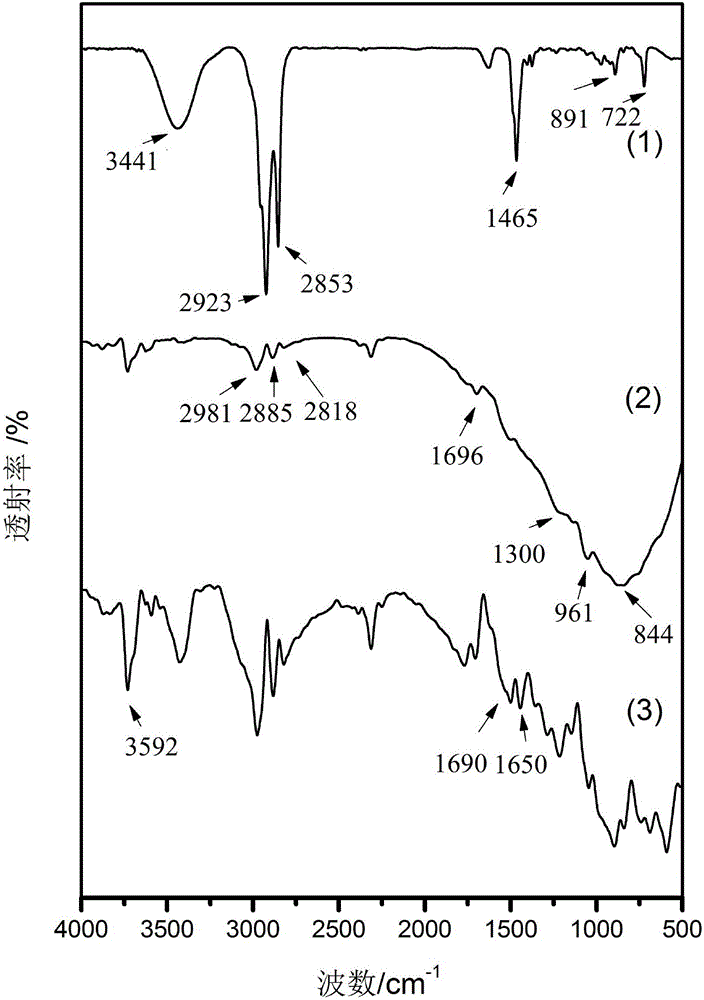

The invention discloses an antibacterial natural latex product based on a quaternary ammonium salt antibacterial agent and a preparation technology of the antibacterial natural latex product, and belongs to the technical field of latex materials. The antibacterial natural latex product is prepared from the following components by weight: 90 to 100 parts of natural latex, 1 to 9 parts of sulfur, 1 to 5 parts of a vulcanization accelerator, 1.5 to 2 parts of an anti-aging agent, 1 to 6 parts of zinc oxide, 0.5 to 2 parts of sodium fluosilicate, 1 to 3 parts of potassium castorate, 0.1 to 2 parts of potassium oleate, 0.5 to 1 part of potassium permanganate and 0.1 to 3 parts of the quaternary ammonium salt antibacterial agent. The antibacterial natural latex product is based on the antibacterial characteristic of a low-concentration quaternary ammonium salt compound. The adopted quaternary ammonium salt compound has the advantage of stable performance, and the compound is tightly combined with latex polymer molecules and cannot permeate the skin of people or an animal by changing the physicochemical property of material surface. The latex product prepared in the invention has the advantages of high antibacterial property, hygiene, high practicability and the like, and has a broad market prospect.

Owner:江苏金世缘乳胶制品股份有限公司 +1

Fluorine-containing elastic copolymers, curable composition containing the same and sealant made therefrom

PCT No. PCT / JP96 / 03732 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Dec. 20, 1996 PCT Pub. No. WO97 / 24381 PCT Pub. Date Jul. 10, 1997A fluorine-containing elastomeric copolymer comprising 55 to 62 mole % of repeating units derived from tetrafluoroethylene and 38 to 45 mole % of repeating units derived from perfluoro(methyl vinyl ether) which is obtained by radically polymerizing the monomers in the presence of a diiodide compound of the formula: RI2 in which R is a saturated fluorohydrocarbon or chlorofluorohydrocarbon group having 1 to 16 carbon atoms, or a hydrocarbon group having 1 to 3 carbon atoms and which has a Mooney viscosity (ML1+10100 DEG C.) in the range between 20 and 150. This copolymer has an excellent compression set at high temperature, which is an important property for sealing members.

Owner:DAIKIN IND LTD

High-performance rubber seal gasket for car radiator and air conditioner, and its preparation process

InactiveCN1569930AImprove sealingImproved high temperature aging resistanceEngine sealsElastomerEngineering

The invention provides a high-performance rubber seal gasket for car radiator and air conditioner, and its preparation process, wherein the sealing gasket mainly comprises EP rubber and natural rubber, as well as added chloroprene rubber, butyronitrile rubber, butylbenzene rubber, epichlorohydrin rubber, methyl acrylate rubber, fluorine rubber, silicon rubber, sulphur, the gasket also contains reinforcing material, supplementary elastomer, anti-ageing agent and pigment known in the prior art.

Owner:SHANGHAI SIMING RUBBER & PLASTIC PRODS

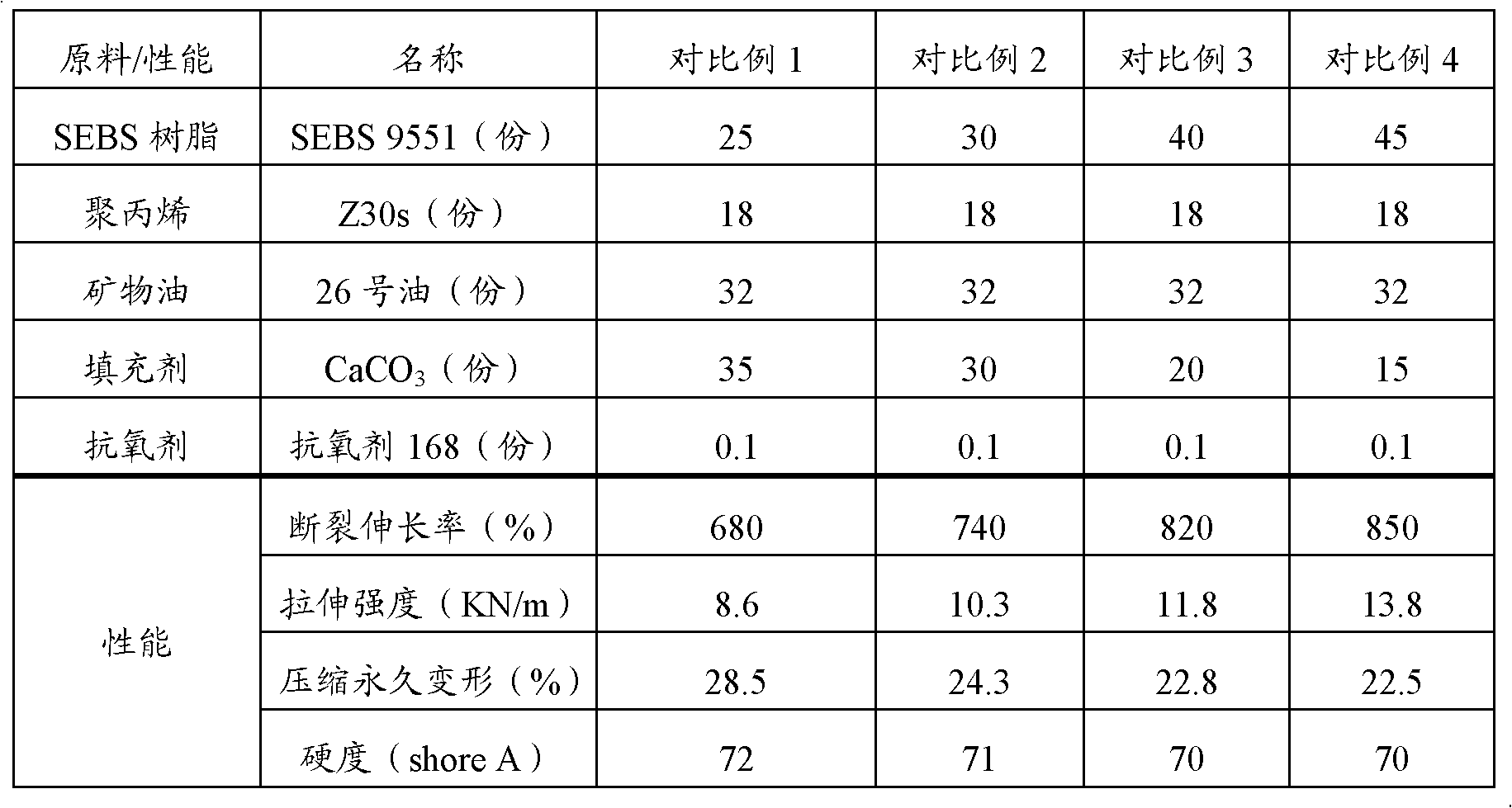

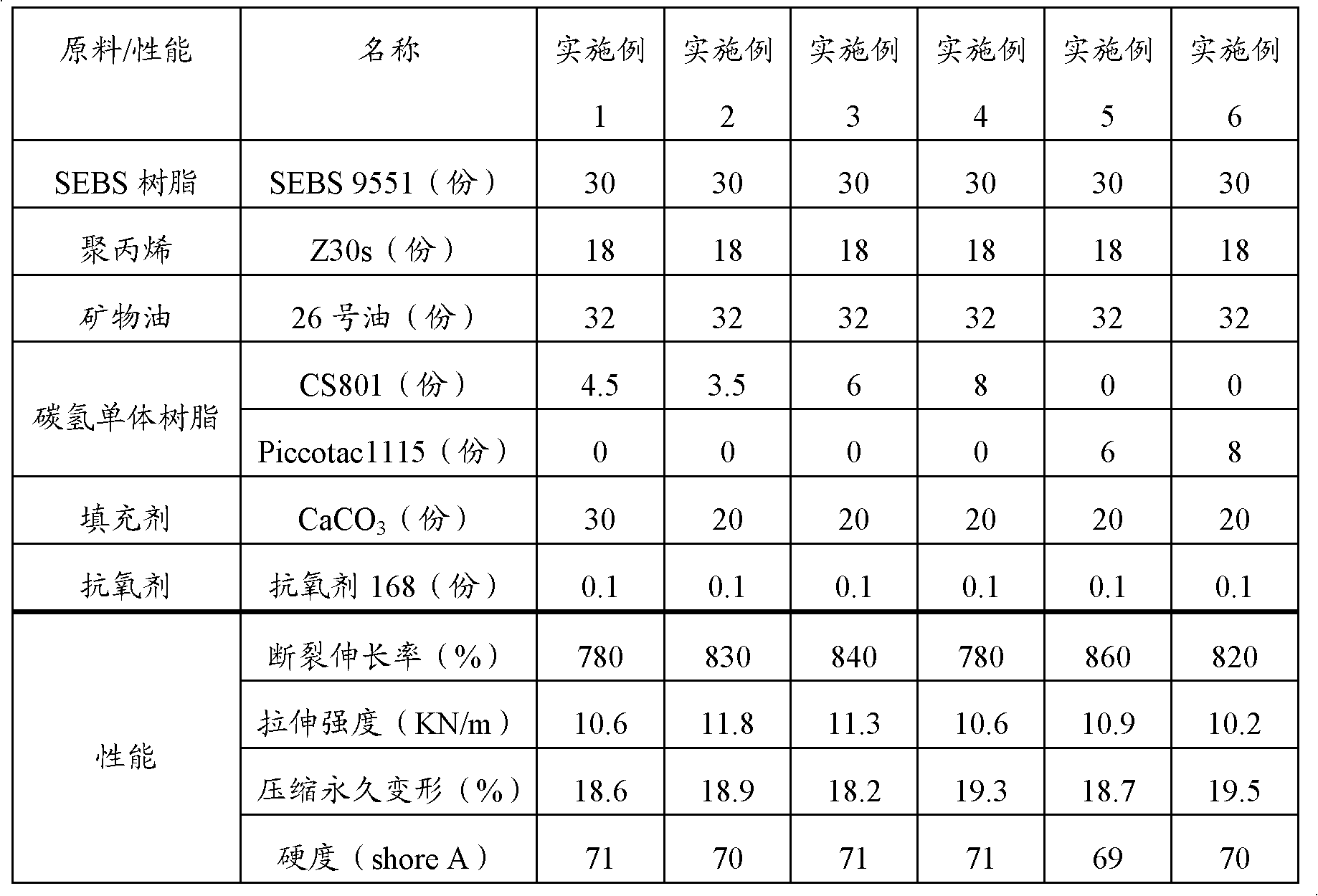

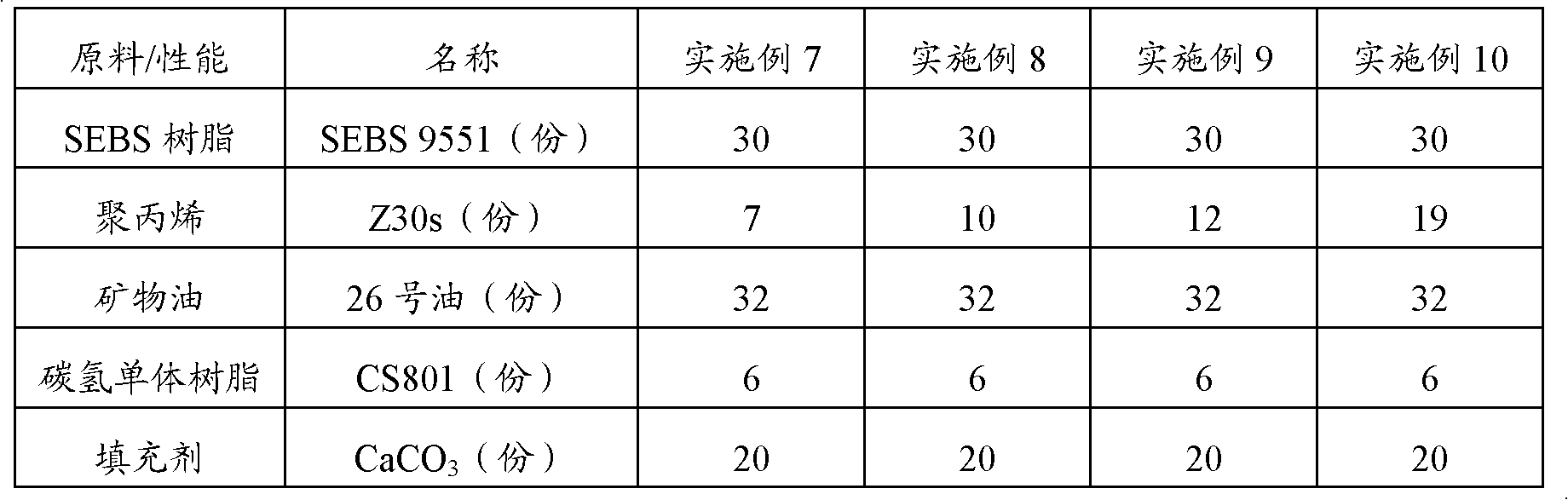

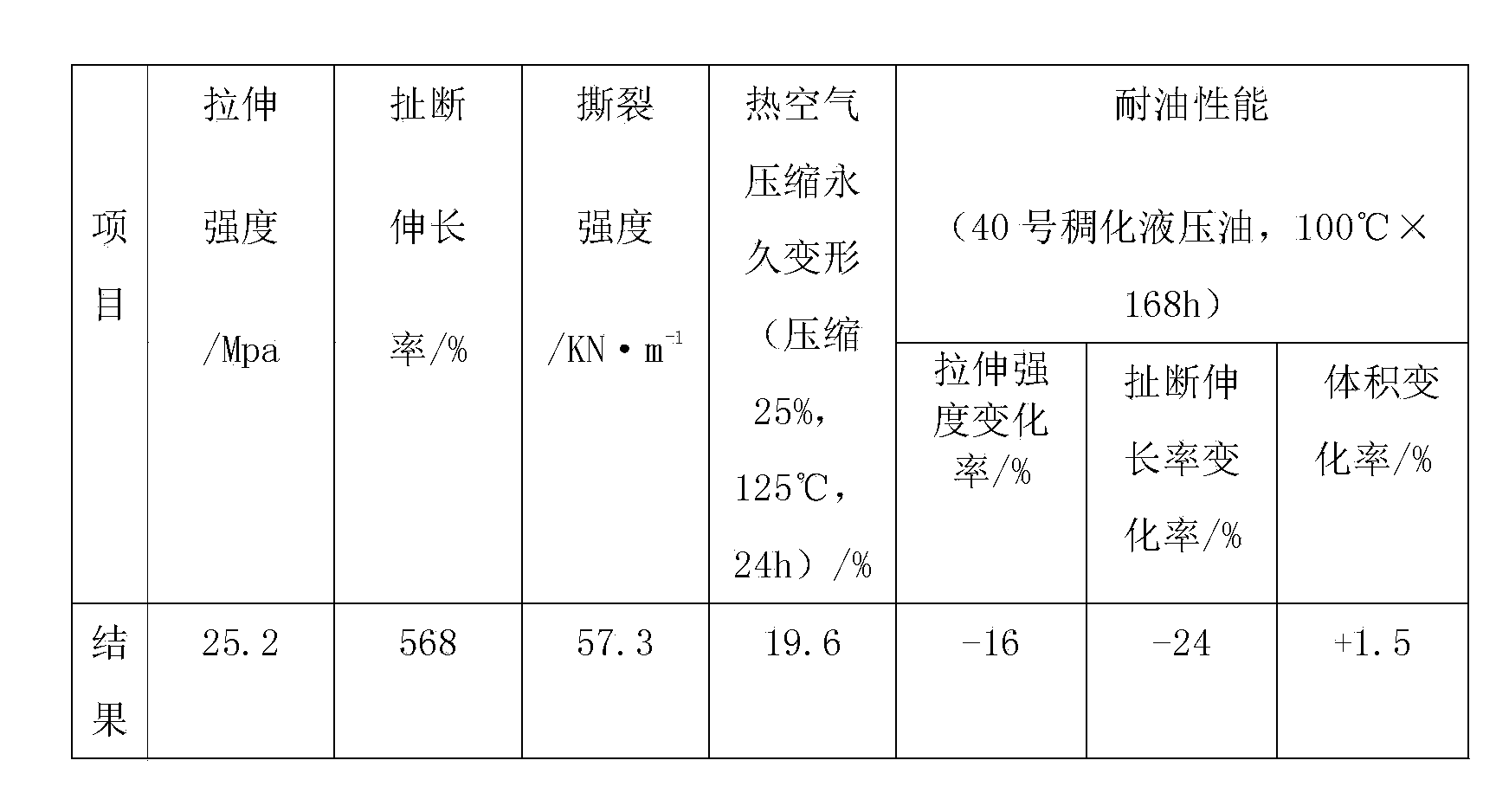

SEBS (styrenic block copolymer) thermoplastic elastomer and preparation method thereof

The invention provides an SEBS (styrenic block copolymer) thermoplastic elastomer. The SEBS thermoplastic elastomer comprises the following constituents in parts by weight: 30-40 of SEBS resin, 3-19 of polypropylene, 20-48 of mineral oil, 3.5-8 of carbon hydrogen monomer resin, 5-35 of a filler and 0.05-0.2 part of an antioxygen. The invention also provides another SEBS thermoplastic elastomer. The SEBS thermoplastic elastomer comprises the following constituents in parts by weight: 25- less than 30 of the SEBS resin, 3-19 of the polypropylene, 20-48 of the mineral oil, 3.5-8 of the carbon hydrogen monomer resin, 3-6 of the thermoplastic, 5-35 of the filler and 0.05-0.2 part of the antioxygen. According to the invention, the SEBS thermoplastic elastomer provided by provided by the invention has good compression set, simultaneously has excellent mechanical properties, and has wide application range. In addition, the invention also provides a preparation method of the SEBS thermoplastic elastomer, and the preparation method has the advantages of simple technology, small energy consumption and high efficiency, and is easy to operate and repeat.

Owner:奥世达弹性体(深圳)有限公司

Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Slow-rebound memory sponge insole material

The invention relates to a slow-rebound memory sponge insole material which is characterized by comprising the following main raw materials: polyalcohol, isocyanate, pore forming agent, pore reforming agent, catalyst, foaming agent, glycerol and MDI (methylenediphenyl diisocyanate) prepolymer. The polyalcohol is composed of polyether polyalcohol and polymer polyalcohol, the hydroxyl value of the polyether polyalcohol is 30-350 mg KOH / g, the molecular weight is 700-3000, and the consumption is 30-60 wt%; the hydroxyl value of the polymer polyalcohol is 28-32 mg KOH / g, the molecular weight is 5000-7000, and the polymer polyalcohol accounts for 30-50 wt% of the polyalcohol; the isocyanate accounts for 30-60 wt% of the polyether polyalcohol; the catalyst is composed of an amine catalyst and a tin catalyst, the amine catalyst accounts for 0.15-0.45 wt% of the polyether polyalcohol, and the tin catalyst accounts for 0.03-0.3 wt% of the polyether polyalcohol; the foaming agent is water, and accounts for 0.9-2.5 wt% of the polyalcohol; the pore forming agent is polyoxypropylene ether, and accounts for 1.5-5 wt% of the polyalcohol; and the pore reforming agent is polysiloxane polyether copolymer, and accounts for 0.8-2 wt% of the polyalcohol. The insole material provided by the invention has the characteristics of light weight, slow rebound and the like.

Owner:JIANGSU HEALTHCARE TECH CO LTD

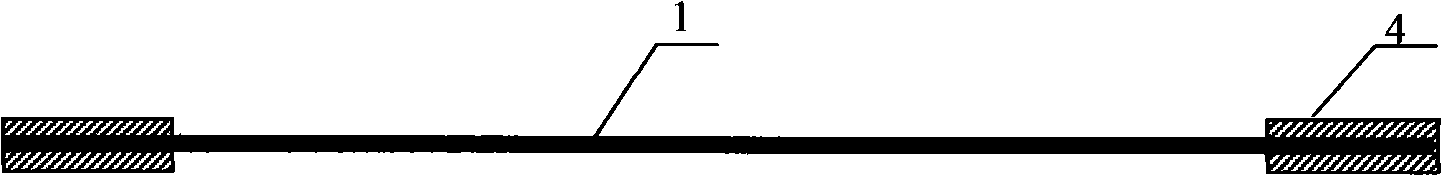

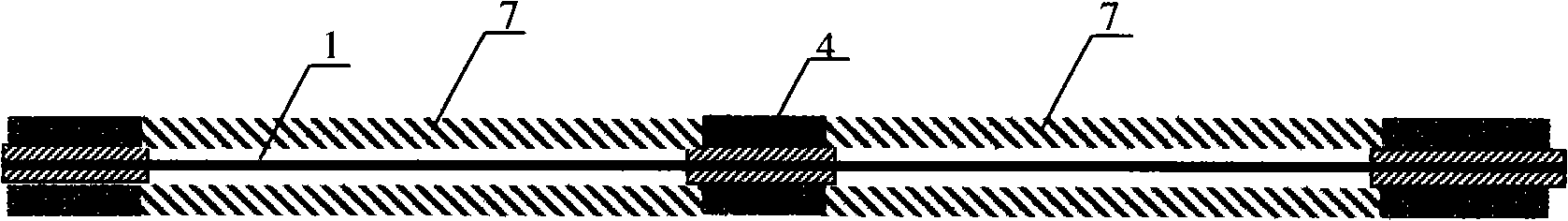

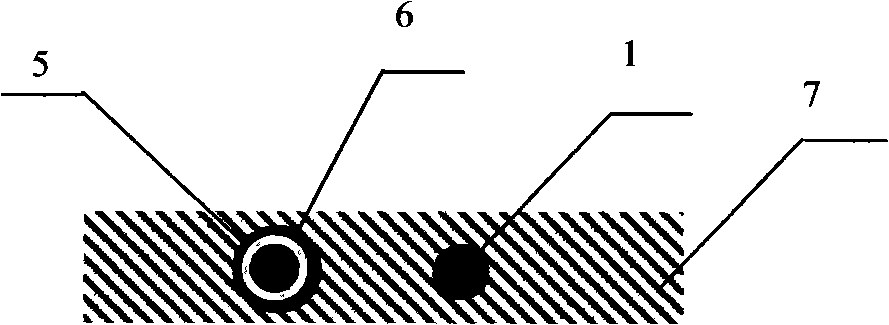

Distributed type non-slippage optical fiber strain sensor and manufacturing method thereof

ActiveCN101275916AImproved compression setGood for measuring compression setOptically investigating flaws/contaminationUsing optical meansEpoxyBare fiber

A distributed no-slippage optical fiber stain sensor and a manufacturing method thereof are a distributed no-slippage Brillouin scattering optical fiber which is used for the health detection and monitoring of the structural facility and the manufacturing method thereof. The invention is characterized in that the sensor uses an UV resin signle mode fiber as a substrate, and a single mode bare fiber part which is eliminated with an UV resin coating layer is provided thereon. The exterior part of the bare fiber is provided with a basalt fiber packaging layer to form an optical fiber strain sensor. To the total adhibition packaging mode, the exterior part is immersed with epoxy resin and is packaged. To the fixed-point adhibition packaging optical fiber, a sleeve pipe is provided outside the bare optical fiber. A certain space is preserved between the sleeve pipes. The bare fiber between the sleeve pipes and the sleeve pipes are fixed on the immersed basalt fiber through the epoxy resin. The distributed no-slippage optical fiber sensor of the invention has high precision and high sensitivity. The long-distance and large-area structural stain information can be accurately obtained, and the manufacturing method is simple and easy.

Owner:SOUTHEAST UNIV +1

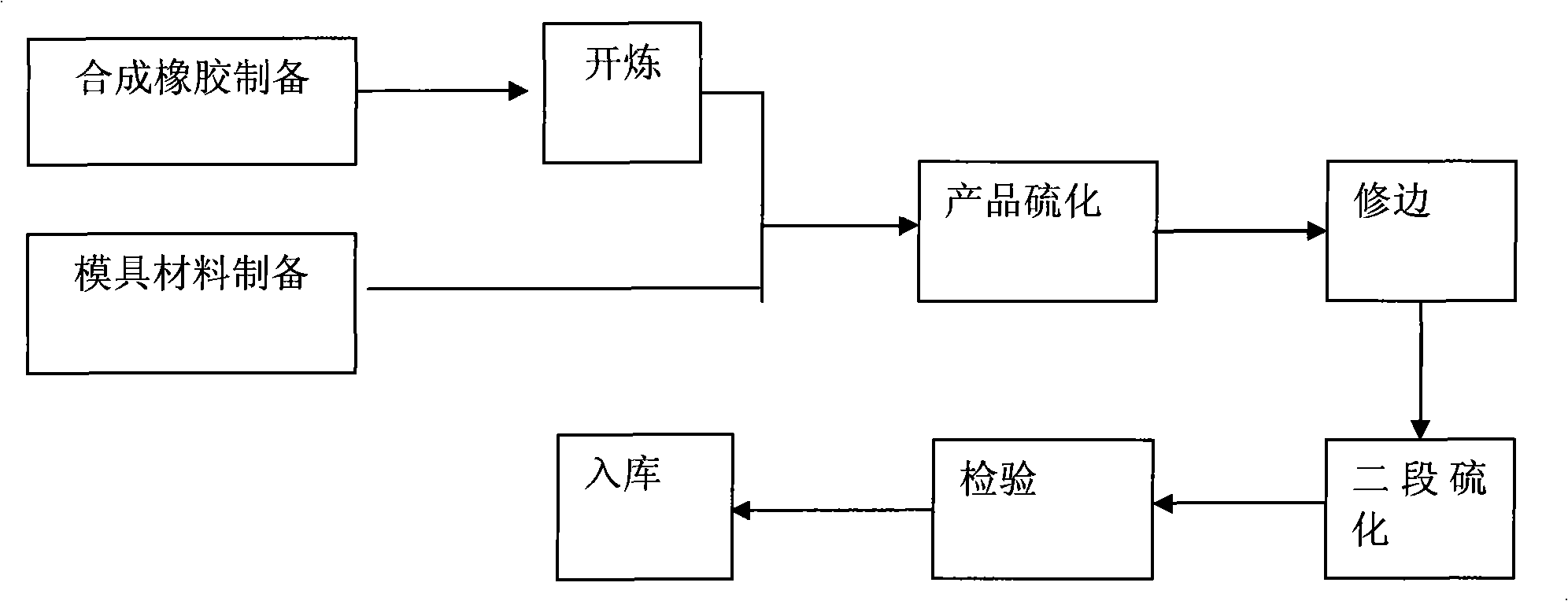

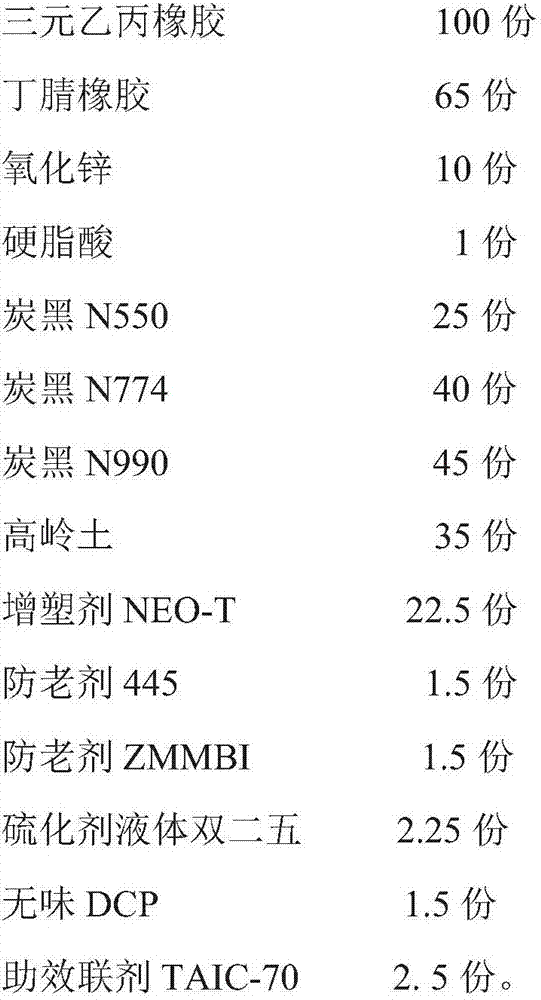

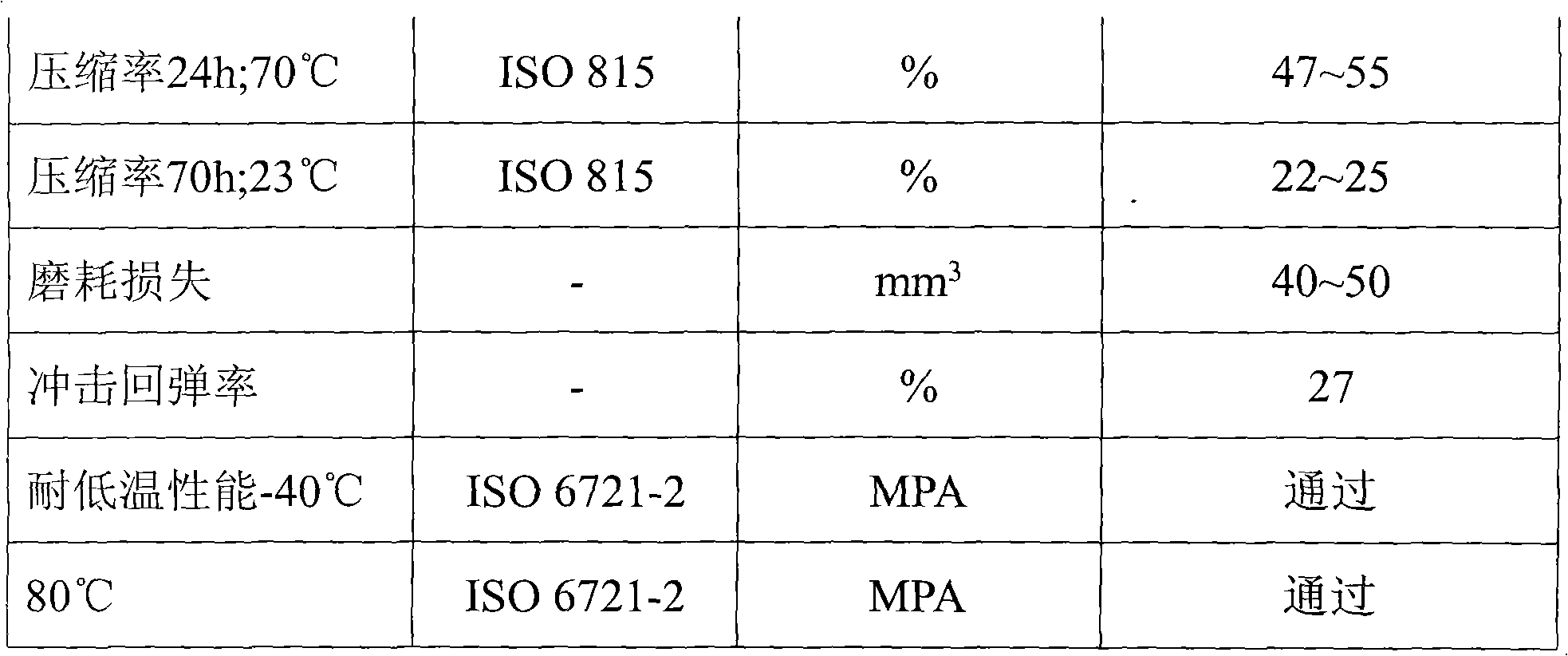

Car engine cooling system heat radiator plate-type rubber seal strip assembly and manufacturing process thereof

InactiveCN101402763AHigh breaking strengthHigh elongation at breakOther chemical processesDomestic articlesSulfurEngineering

The invention provides a radiator plate-typed sealing strip assembly in an automobile engine cooling system and a manufacturing process thereof. The radiator plate-type sealing strip assembly in the automobile engine cooling system consists essentially of EPDM rubber, carbon black and the like; the manufacturing process mainly comprises the steps of: synthesizing rubber, sulfur treatment, trimming, two-process sulfur treatment, testing and putting into storage. The radiator plate-type sealing strip assembly manufactured by the process has good tensile strength at break, good elongation at break, good tear strength, good compression deformation and time effect of high-temperature resistance and cooling fluid resistance, thus ensuring good sealing property.

Owner:ANHUI ZHONGDING SEALING PARTS

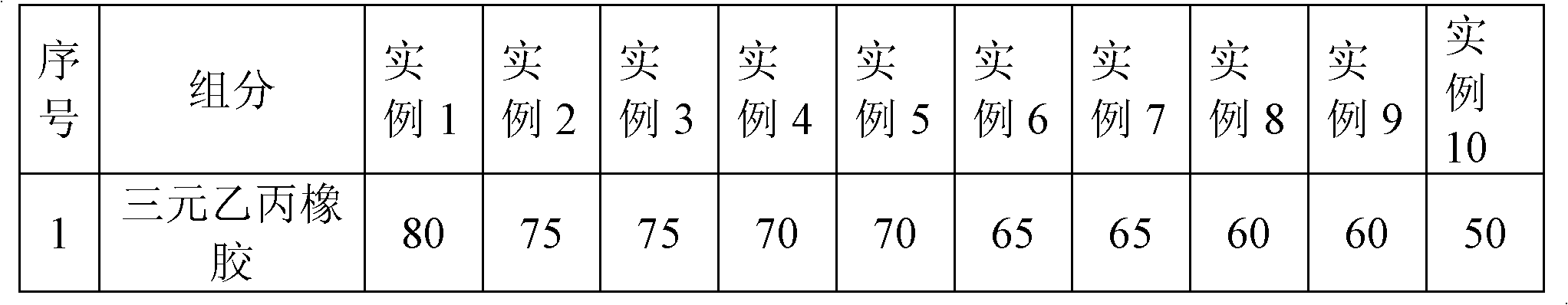

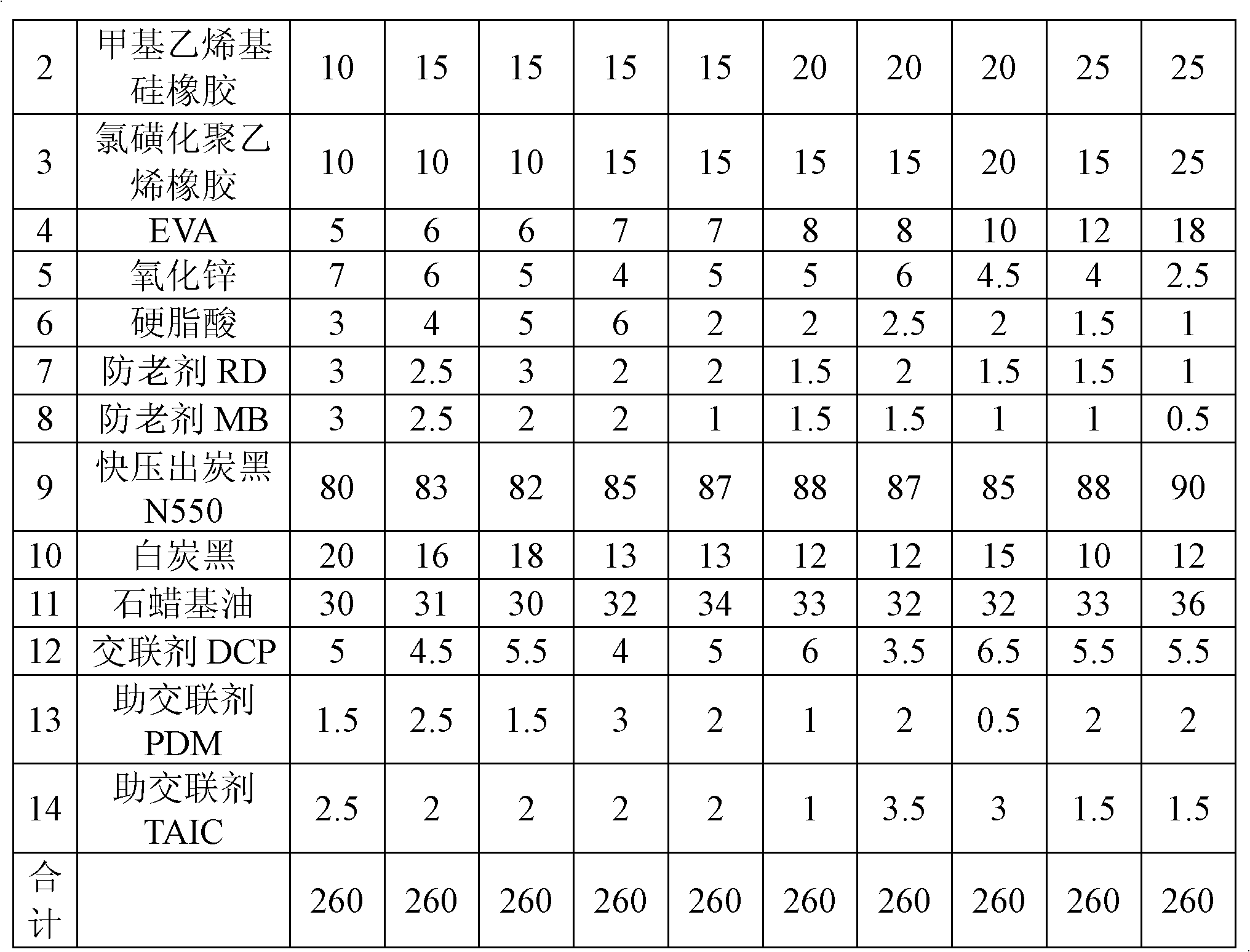

Ethylene-propylene-diene rubber for rubber tube system of hydrogen energy powered automobile

ActiveCN102492229AImprove air tightnessImproved compression setFlexible pipesPolymer scienceTemperature resistance

The invention relates to ethylene-propylene-diene rubber for a rubber tube system of a hydrogen energy powered automobile. The ethylene-propylene-diene rubber is characterized by comprising the following components by part by weight: 50-80 parts of ethylene-propylene-diene rubber, 10-25 parts of methyl vinyl silicone rubber, 10-25 parts of chlorosulfonated polyethylene rubber, 5-15 parts of bulking agent, 2-8 parts of zinc oxide, 1-7 parts of stearic acid, 1-5 parts of antiager RD, 1-5 parts of antiager MB, 40-90 parts of fast extruding furnace black N550, 10-30 parts of silica, 10-40 parts of paraffin based oil, 1-8 parts of cross-linking agent DCP, 1-8 parts of assistant crosslinker TAIC and 1-8 parts of assistant crosslinker PDM. The bulking agent is an ethylene-vinyl acetate copolymer. The ethylene-propylene-diene rubber provided by the invention completely conforms to technical standards, meets the performance requirements of products, excellently improves the airtightness, compression set and flame retardancy of an ethylene-propylene-diene rubber tube, and improves the high-temperature resistance, corrosion resistance and fatigue durability of the ethylene-propylene-diene rubber tube.

Owner:WUXI NO 2 RUBBER

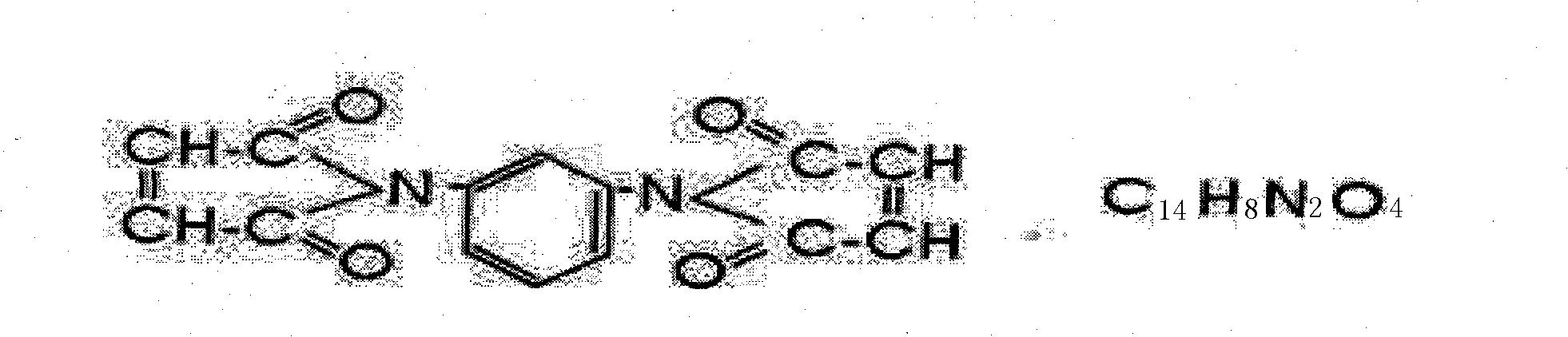

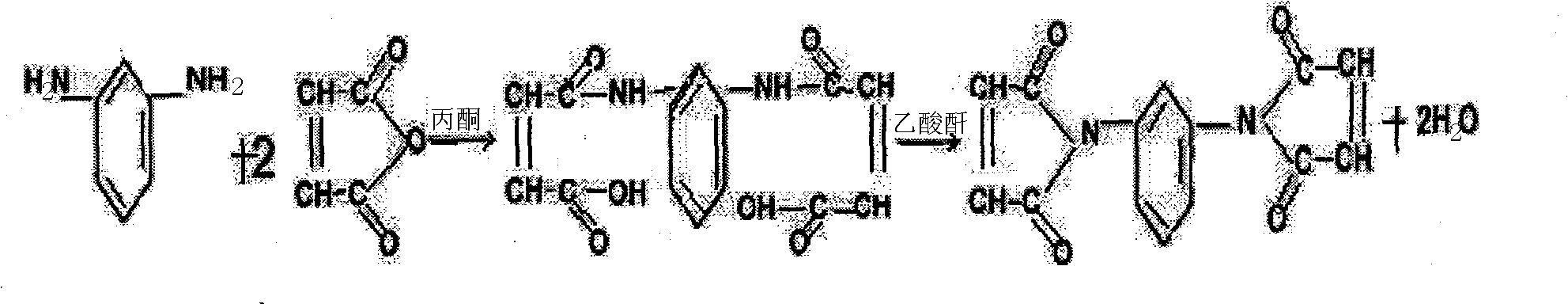

Preparation method of N,N'-m-phenylenebismaleimide

ActiveCN101805280ASolve the hardnessSolving Elasticity ProblemsOrganic chemistryPolymer scienceAcetic anhydride

The invention relates to a preparation method of N,N'-m-phenylenebismaleimide (HA-8). The preparation method is mainly technically characterized by firstly adding m-phenylenediamine in a reaction kettle equipped with a stirrer and a thermometer, then adding a solvent, stirring for fully dissolving the m-phenylenediamine, further adding maleic anhydride, keeping the temperature for 2 hours after completion, then adding acetic anhydride, completing the reaction, further evaporating, recovering the solvent of acetone, finally carrying out centrifugal washing for obtaining a crude product, drying, smashing and obtaining a finished product. The yield is calculated to be 91.5% by taking the m-phenylenediamine as a standard substance. The product is mainly used in natural rubber and various types of synthetic rubber, and can prevent reversion by being matched with sulfur, improve the heat resistance and the anti-aging property, reduce the heat production of the rubber and improve the bonding property between the rubber and metal fabric.

Owner:咸阳三精科技股份有限公司

Thermoplastic elastomer foam material and preparation method thereof

The invention relates to the technical field of a foam material, in particular to a thermoplastic elastomer foam material and a preparation method thereof. The thermoplastic elastomer foam material consists of following raw materials in parts by weight: 20 to 30 parts of styrene-ethylene butylene-styrene (SEBS), 20 to 30 parts of white mineral oil, 25 to 35 parts of calcium carbonate, 3 to 8 parts of ethylene vinyl acetate (EVA), 1 to 5 parts of polyolefin elastomer (POE) and 0.1 to 0.5 parts of zinc stearate. Multiple raw materials such as calcium carbonate, EVA and POE are selected to be matched with the SEBS to use, so that the prepared foam material is not only low in cost and good in abradability and compression deformation, but also other physical indexes such as hardness, elasticity and the like are improved. The preparation method is simple in process and low in cost.

Owner:东莞市鑫塑源塑胶科技有限公司

Preparation method of liquid silicone rubber composition

The invention relates to a preparation method of a liquid silicone rubber composition. The preparation method includes mixing polydimethylsiloxane, silica powder, magnesium carbonate, silane modificated conductive carbon black, fumed silica and treating agent to obtain a mixture, subjecting the mixture to heat treatment at 100-150 degrees for 0.5-5h, heating the mixture to 120-160 DEG C, evacuating the mixture under vacuum of -0.04--0.1MPa for 2-6hs, and grinding the mixture 2-4 times to obtain base gum after cooling the same to the indoor temperature; adding and mixing polydimethylsiloxane attenuation and platinum catalyst in the base gum at the normal temperature to obtain material A; adding and mixing polydimethylsiloxane attenuation, cross-linking agent and negative catalyst in the base gum at the normal temperature to obtain material B; mixing the material A and the material B, by weight, in the proportion of 1:1, subjecting the mixture to solidification at 100-200 DEG C for 0.1-50h to obtain the liquid silicone rubber composition. The preparation method is simple, and the liquid silicone rubber contains ultra-low low-molecular-weight content and is high in compression permanent deformation rate.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Hydrosilation in high boiling natural oils

An improved process is provided for the preparation of siloxane-oxyalkylene and siloxane-alkyl copolymer compositions via a hydrosilation reaction in the presence of high boiling point natural vegetable oils as the reaction solvent. The reaction solvent need not be removed from the block copolymer product, and indeed is beneficial to remain with the copolymer particularly when the copolymer is used as a surfactant for polyurethane foam formulations. Soybean oil and linseed oil are the preferred high boiling natural oil solvents when the copolymer product is to be used in the preparation of the surfactants for polyurethane foams. High resiliency polyurethane foam prepared with these natural oils present in the surfactant preparation afforded improved compression sets, wet compression sets and humid aged compression sets. Additionally, the use of the surfactants made with natural oils as a reaction solvent or consequently surfactants post diluted with natural oils when employed in the preparation of polyurethane foam afforded foams with greatly reduced amounts of "glass fogging".

Owner:GENERAL ELECTRIC CO

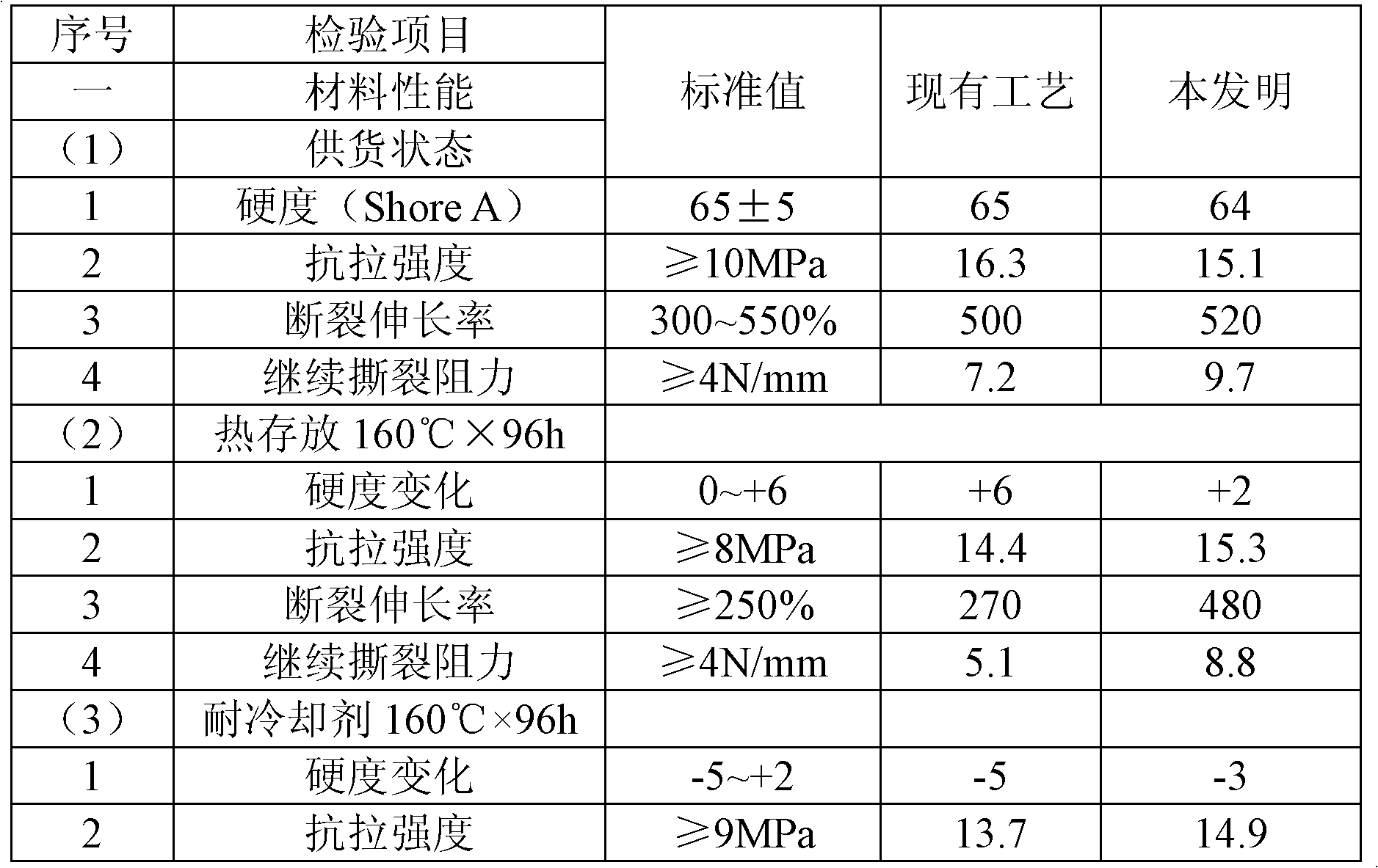

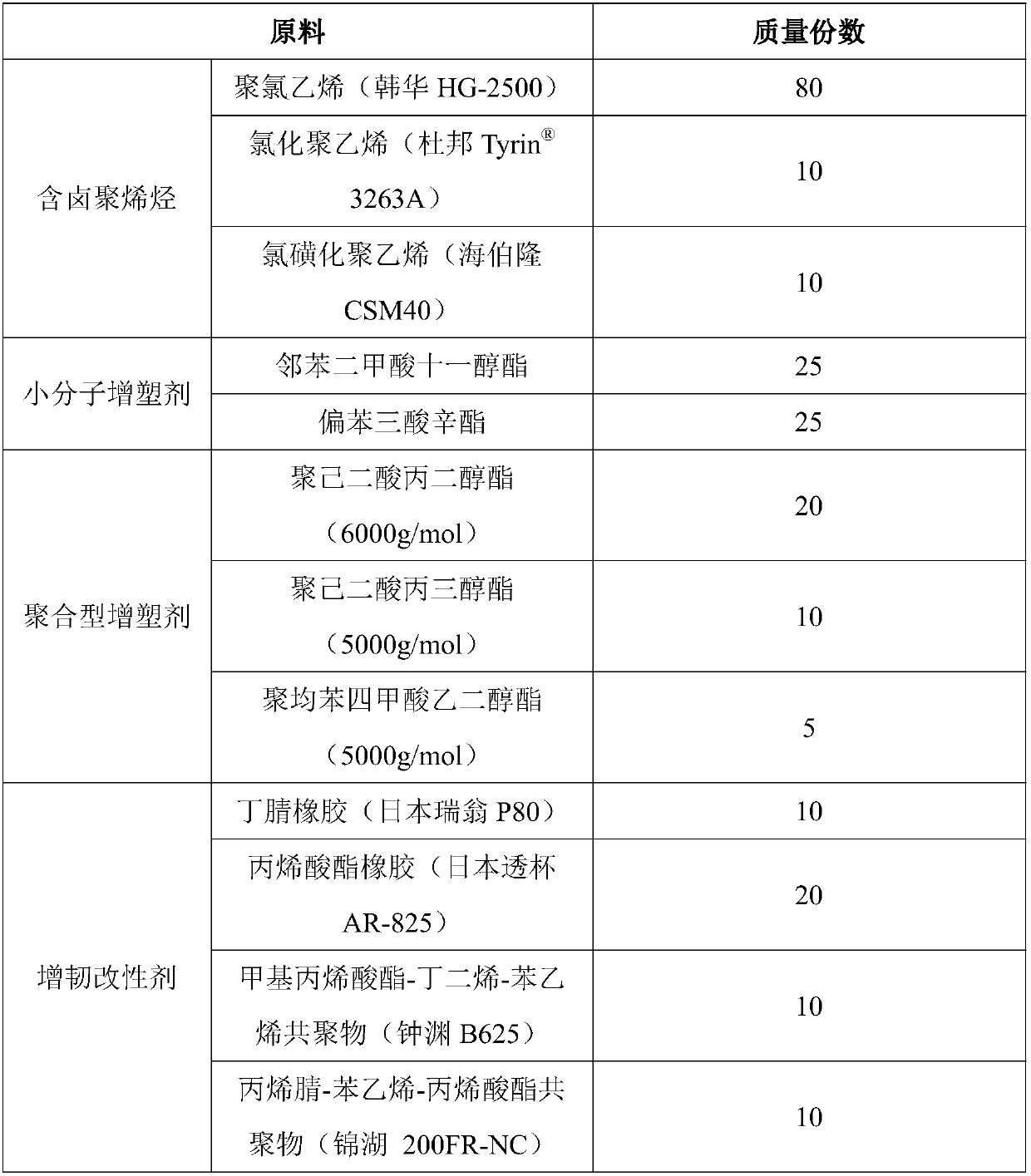

Elastomer-based insulating cladding material for charging pile cable and preparation method of elastomer-based insulating cladding material

ActiveCN107556645AGood high and low temperature resistanceExcellent resistance to solvent extractionPlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses an elastomer-based insulating cladding material for a charging pile cable and a preparation method of the elastomer-based insulating cladding material. The insulating claddingmaterial is prepared from the following raw materials in parts by mass: 100 parts of halogen-containing polyolefin, 35-85 parts of a small-molecule plasticizer, 15-45 parts of a polymeric plasticizer,30-80 parts of a toughening modifier, 10-25 parts of a flame-retardant compatible agent, 3-9 parts of a flame retardant, 3-9 parts of a lubricant, 5-25 parts of a heat stabilizer, 3-9 parts of an antioxidant, 3-9 parts of an ultraviolet stabilizer, 3-9 parts of a smoke suppressant and 15-45 parts of filler. The preparation method of the elastomer-based insulating cladding material is simple, thematerials are mixed uniformly and subjected to melting mixing and extrusion pelletizing, and the insulating cladding material can be obtained. The elastomer-based insulating cladding material for thecharging pile cable has the excellent properties of high and low temperature resistance, solvent extraction resistance, tear resistance, heat resistance, weather resistance, aging resistance and the like, and has advantages of high strength, high toughness, excellent flame retardancy and insulation performance and low smoke; the preparation process is simple, and the preparation cost is low.

Owner:东莞海铂新材料科技有限公司

Composite seal ring and manufacturing process thereof

The invention discloses a composite seal ring and a manufacturing process of the composite seal ring, and belongs to the field of manufacturing of a rubber seal ring. The composite seal ring comprises the materials of 10-100 parts of natural rubber, 10-100 parts of butadiene styrene rubber, 10-100 parts of high styrene resin, 2-10 parts of zinc oxide, 1-3 parts of stearic acid, 0.5-2 parts of accelerant DM, 0.5-2 parts of accelerant CBS, 1-3 parts of antiager RD, 1-3 parts of antiager 4010NA, 2-10 parts of petroleum resin, 20-100 parts of high abrasion furnace black, 20-100 parts of general purpose furnace black, 0.5-4 parts of sulphur, and 3-20 parts of vinylon cut fiber masterbatch. The manufacturing process provided by the invention innovatively manufactures the vinylon cut fiber masterbatch first, and additionally uses a short fiber to directionally arranged in the rubber during extruding formation, so that a working surface has a higher tear strength, and the subsection sulfuration in the sulfuration process leads to uniform and consistent sulfuration degree. The seal ring manufactured by using the manufacturing process has the effects of low compression deformation, excellent elasticity, high hardness, excellent tearing strength, and good sealing effect.

Owner:MAANSHAN HONGLI RUBBER PROD

Fluorine-containing elastomer for molding fuel system parts and composition thereof

InactiveUS20100068436A1Uniform physical propertiesImprove compression set characteristicLiquid fuel feeder/distributionLayered productsHexafluoropropyleneIntrinsic viscosity

A fluorine-containing elastomer for molding fuel system parts, which has a copolymer composition comprising 10-40% by weight of tetrafluoroethylene (TFE), 80-30% by mole of vinylidene fluoride (VdF), and 10-30% by mole of hexafluoropropylene (HFP), as copolymerized in the presence of an iodine and bromine-containing compound represented by the following general formula: RBrnIm (where R is a fluorohydrocarbon group, a chlorofluorohydrocarbon group, or a hydrocarbon group, each having 1-10 carbon atoms, and n and m each are 1 or 2), and has an intrinsic viscosity of 20-180 ml / g, Mw (weight average molecular weight) / Mn (number average molecular weight) ratio of 2-20, and a molecular weight distribution of monopeak or multipeak type, and a fluorine-containing elastomer composition, which comprises the fluorine-containing elastomer, at least one of a polyol vulcanizing agent and a polyamine vulcanizing agent, an organic peroxide, and a polyfunctional unsaturated compound. The composition is suitable for use in molding fuel system parts to give fluorine-containing elastomer moldings with distinguished moldability, vulcanizate physical properties, chemical resistance, photostability and economy.

Owner:UNIMATEC CO LTD

Oil-proof ethylene propylene diene monomer material and preparation method thereof

InactiveCN107141617AGood oil resistanceImprove high temperature resistancePolymer scienceStearic acid

The invention discloses an oil-proof ethylene propylene diene monomer material and a preparation method thereof and belongs to the technical field of rubber preparation. The material is prepared from the following components in parts by weight: 100 parts of ethylene propylene diene monomer, 65 parts of nitrile butadiene rubber, 10 parts of zinc oxide, 1 part of stearic acid, 25 parts of carbon black N550, 40 parts of carbon black N774, 40-50 parts of carbon black N990, 35 parts of kaolin, 20-25 parts of plasticizer NEO-T, 1.5 parts of anti-aging agent 445, 1.5 parts of anti-aging agent ZMMBI, 2-2.5 parts of vulcanizing agent liquid 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane, 1.3-1.7 parts of odorless DCP and 3-4 parts of synergistic agent. According to the oil-proof ethylene propylene diene monomer material disclosed by the invention, after the material is soaked for 70 hours in 5W30 engine oil at 150 DEG C, the hardness change is -2 Shore A, the elongation change is 0-(-15%), the tensile strength change is 0-(-17%), the volume change is less than or equal to 25%, and the high temperature resistance, oil-proof property and compression set property are excellent.

Owner:南京金三力高分子科技有限公司

Preparation method, product and use of modified vinylene chloride plastics

InactiveCN102140211AImprove thermal stabilityImprove toughnessPlastic/resin/waxes insulatorsInsulated cablesPlasticizerPolyvinyl chloride

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD

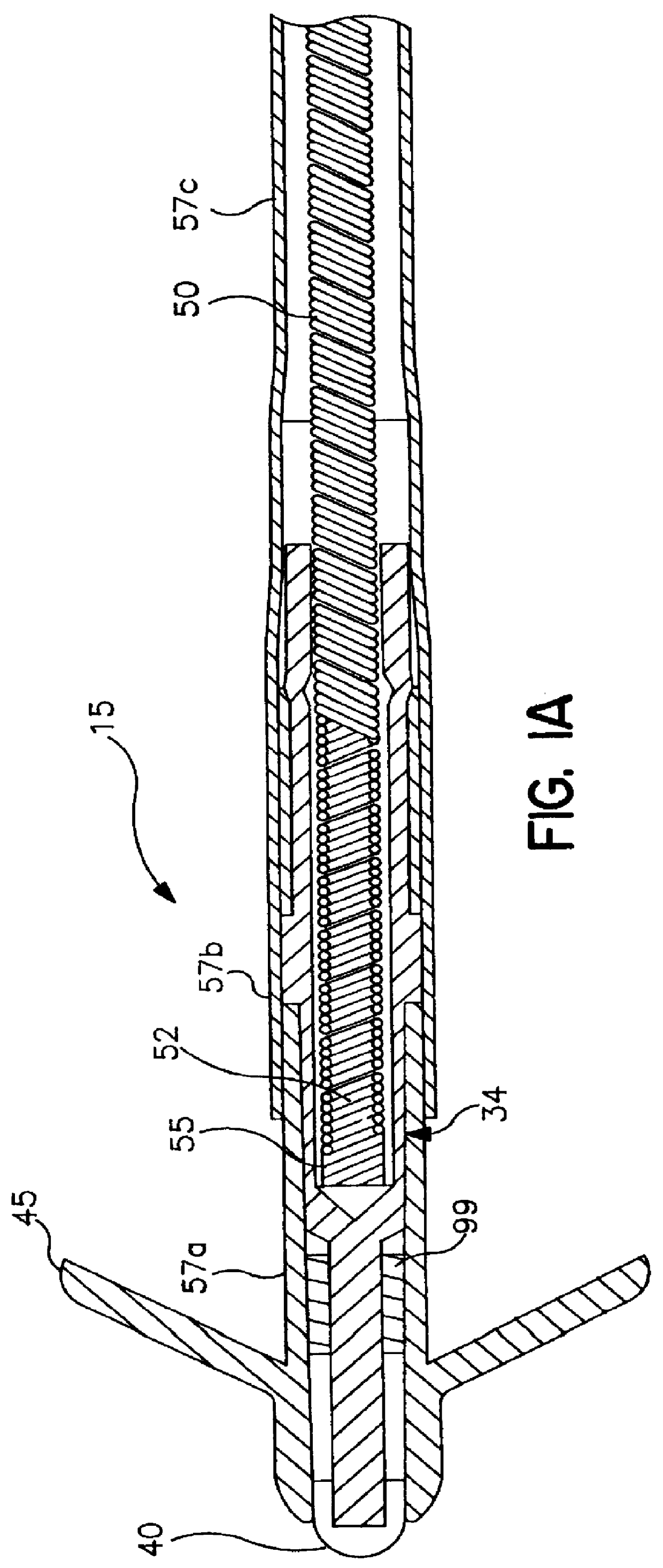

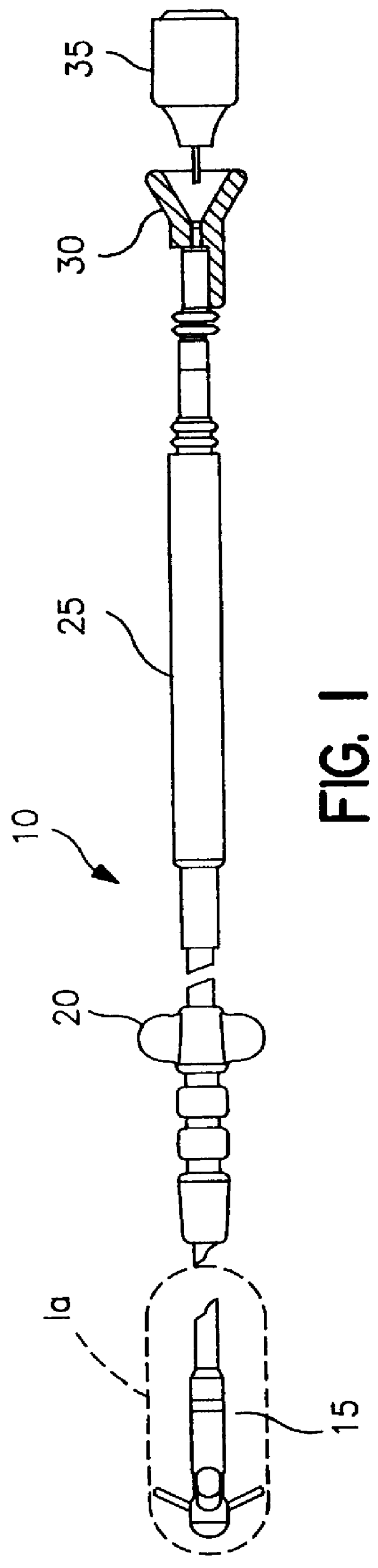

Medical electrical lead and reinforced silicone elastomer compositions used therein

InactiveUS6040369AImprove mechanical propertiesImproved compression setRubber insulatorsPlastic/resin/waxes insulatorsVulcanizationElectrical conductor

A medical electrical lead and a reinforced silicone elastomer used therein. The silicone elastomer used therein is preferably made from a novel silica reinforced polysiloxane material, which after vulcanization by cross-linking exhibits improved mechanical properties. The medical electrical lead features a an electrode at a distal end thereof, a connector at a proximal end thereof and an elongated electrical conductor extending between the electrode and the connector, the conductor in electrical contact with the electrode at a distal end and in electrical contact with the connector at a proximal end, the conductor comprised of a plurality of wires or wire bundles wound in a multifilar coil configuration.

Owner:NUSIL TECH

Preparation method for novel rubber strip for sealing of automobile doors and windows and product

The invention relates to a preparation method for a novel rubber strip for sealing of automobile doors and windows and a product. The preparation method employs ethylene propylene diene monomers as basic materials with cooperation of certain amounts of carbon black, calcium carbonate, paraffin oil, zinc oxide, stearic acid, polyvinyl alcohol, high-molecular wax, compound antioxidants, dispersants, compound accelerants, vulcanizing agents, fire retardants and the like. The above materials are subjected to mixing, open milling and vulcanization technologies to obtain the rubber strip. The preparation method has advantages of simple formula, simple production technology, short vulcanizing time, high production efficiency, relatively low production cost, easy industrialization enforcement and the like. The rubber product for sealing is advantaged by good sealing performance, uniform structure, resistance to corrosion, resistance to high and low temperature, flame resistance, environment protection and comfort.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

High strength nanophase ceramic composite insulation material and preparation method thereof

InactiveCN101723692AHigh strengthLow thermal conductivityManufacturing convertersCeramic compositeCompressive deformation

The invention discloses a high strength nanophase ceramic composite insulation material which comprises the following raw materials in parts by weight: 120-180 parts of floating beads, 10-50 parts of siliceous dust, 35-60 parts of potassium titanate whisker, 500-600 parts of silicone gel, inorganic bond or mixture of silicone gel and inorganic bond, 5-24 parts of titanium dioxide, 8-12 parts of kaoline, 10-16 parts of kieselguhr and 50-108 parts of alumina silicate fibre mesh cloth. The nanophase ceramic composite insulation material has high compressive strength, small heat conductivity factors, high temperature resistance of 800 DEG C to 1000 DEG C, very high compressive deformation rate, light material volume weight as well as good economic benefic and social benefit.

Owner:SHANGHAI GUOKE CHEM NEW MATERIAL

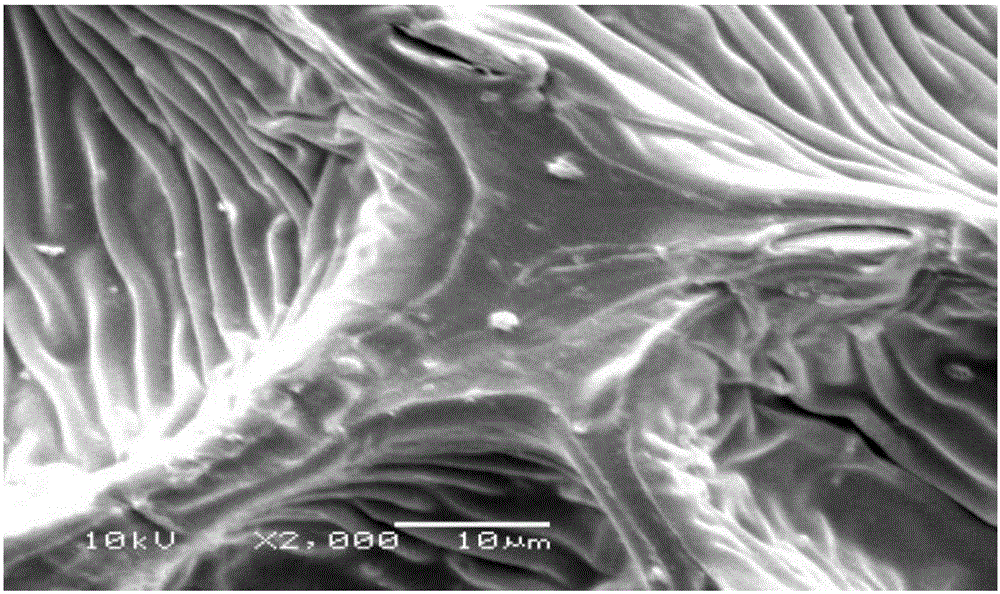

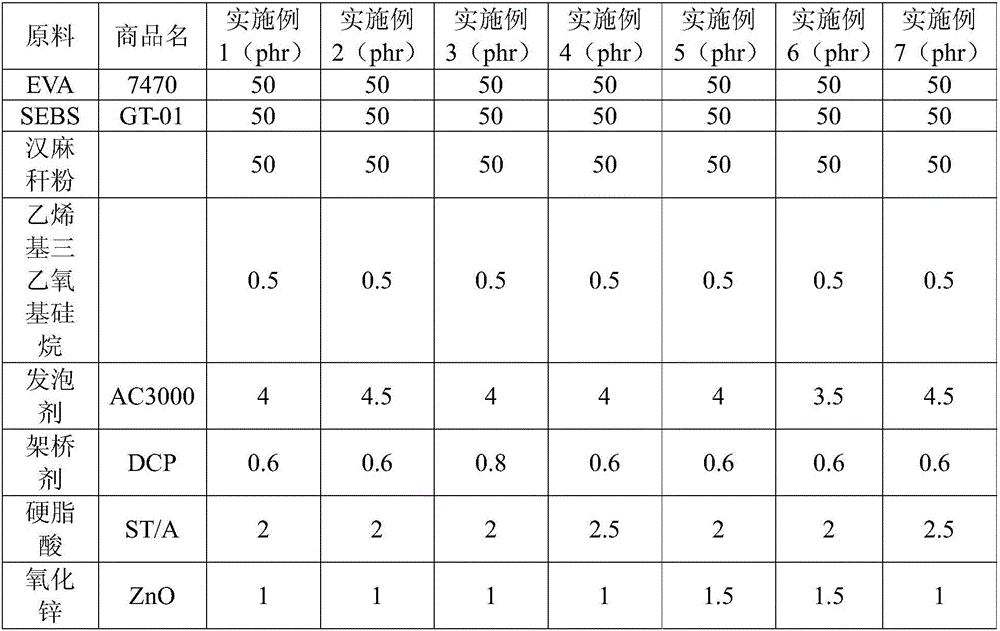

High-resilience aging-resistant EVA foamed material and preparation method thereof

The invention provides a high-resilience aging-resistant EVA foamed material and a preparation method thereof. The method comprises the following steps that 1, lignocellulose powder is modified through a silane coupling agent to obtain modified lignocellulose powder; 2, part of a hydrogenated styrene butadiene polymer, an ethylene-vinyl acetate polymer and the modified lignocellulose powder are added into an internal mixer to be mixed; 3, a foaming agent, a bridging agent, an activating agent and zinc oxide are added into the internal mixer to be mixed; 4, the materials mixed through the step 2 and the step 3 are granulated, injection foaming is conducted, cooling forming is conducted, and then the high-resilience aging-resistant EVA foamed material is obtained. After EVA is foamed by adding kenaf stalk powder, compressive deformation of EVA is obviously improved, and compressive deformation generated when EVA is foamed by adding the kenaf stalk powder is 15% higher than that generated when EVA is foamed without adding the kenaf stalk powder. A shoe insole made of the modified foamed body is light, durable, capable of reducing shock, high in resilience and good in tear resistance, and the EVA foamed material is suitable for various athletic and leisure shoe insoles and has an important application value.

Owner:湖北福力德鞋业有限责任公司 +2

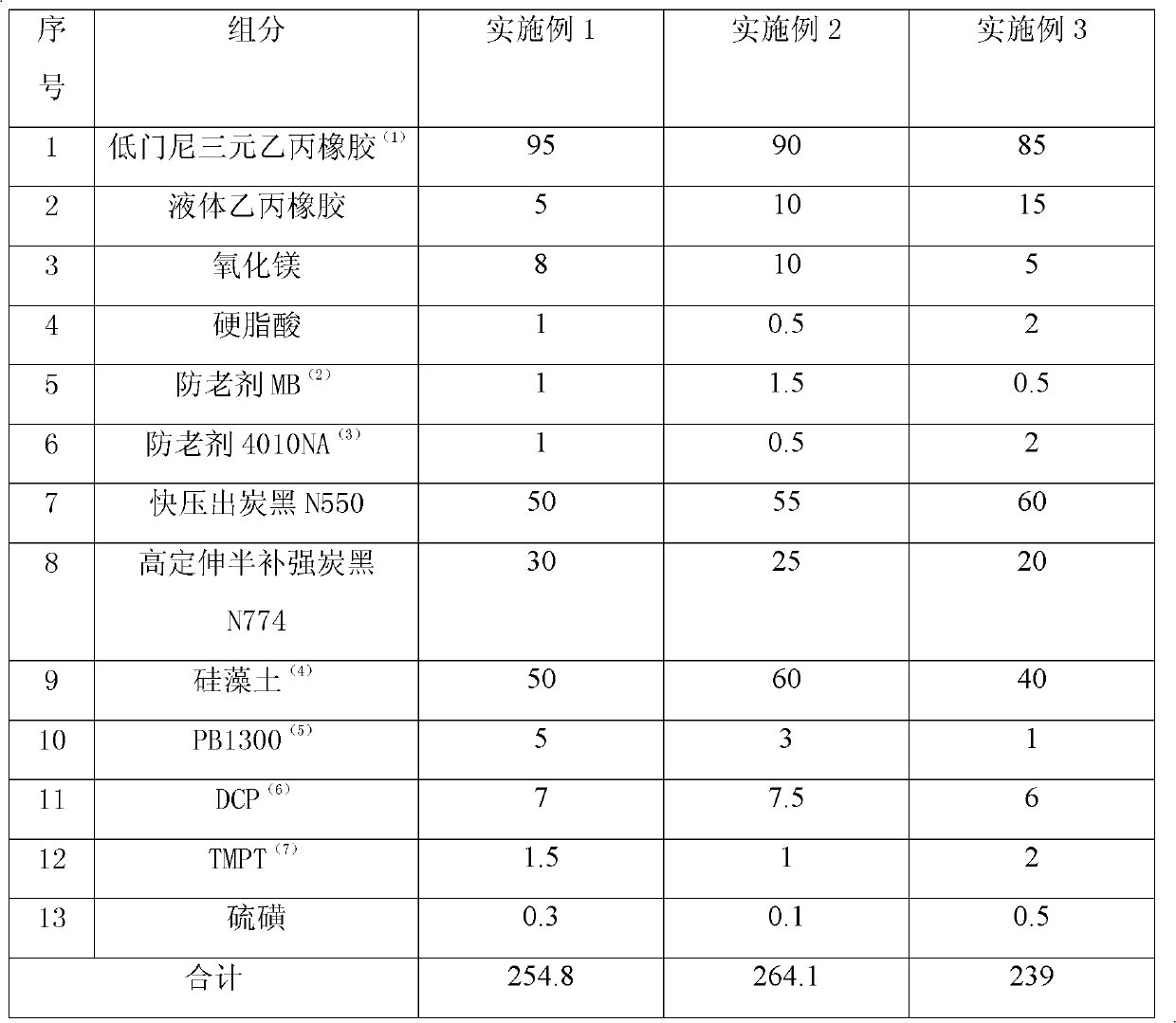

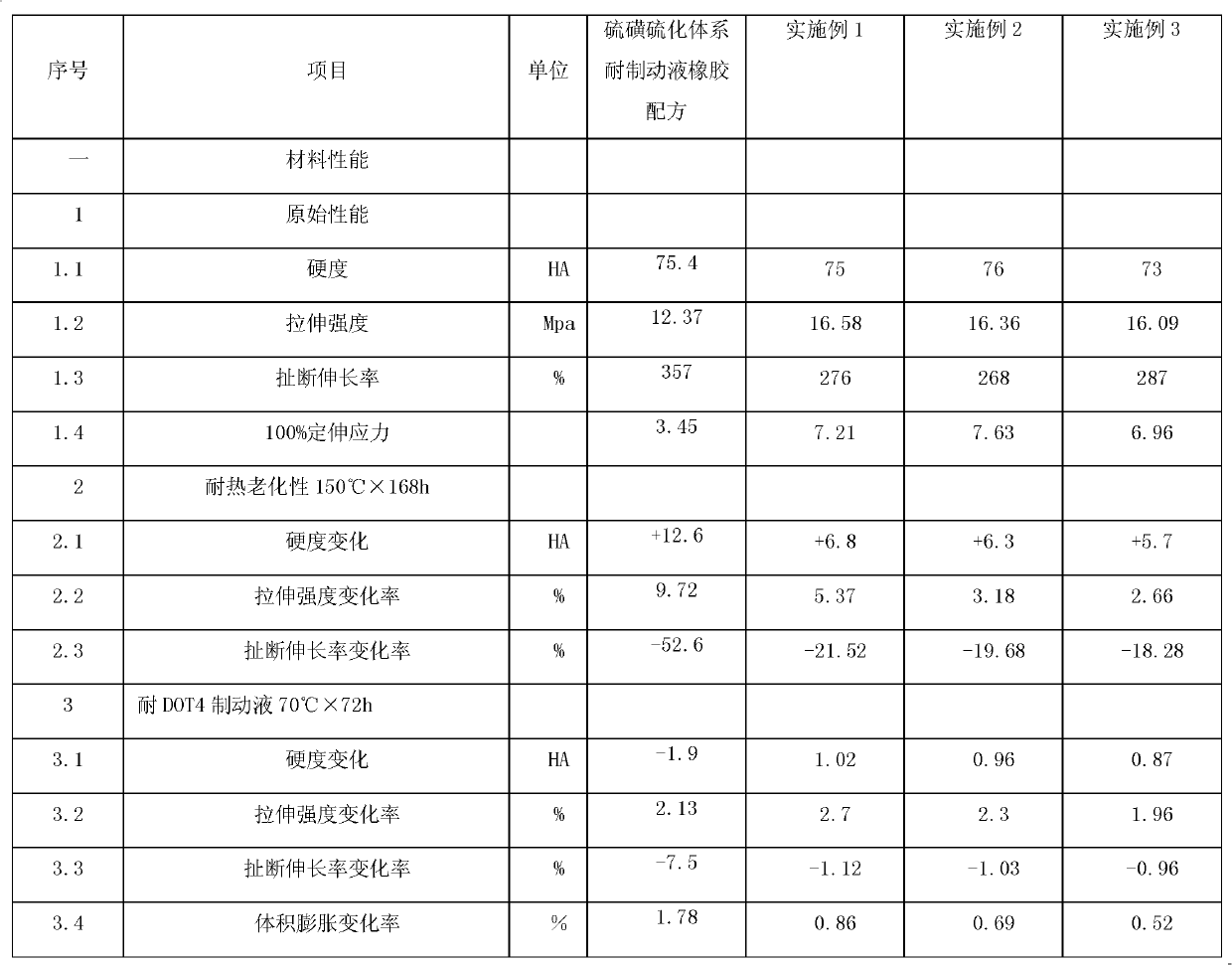

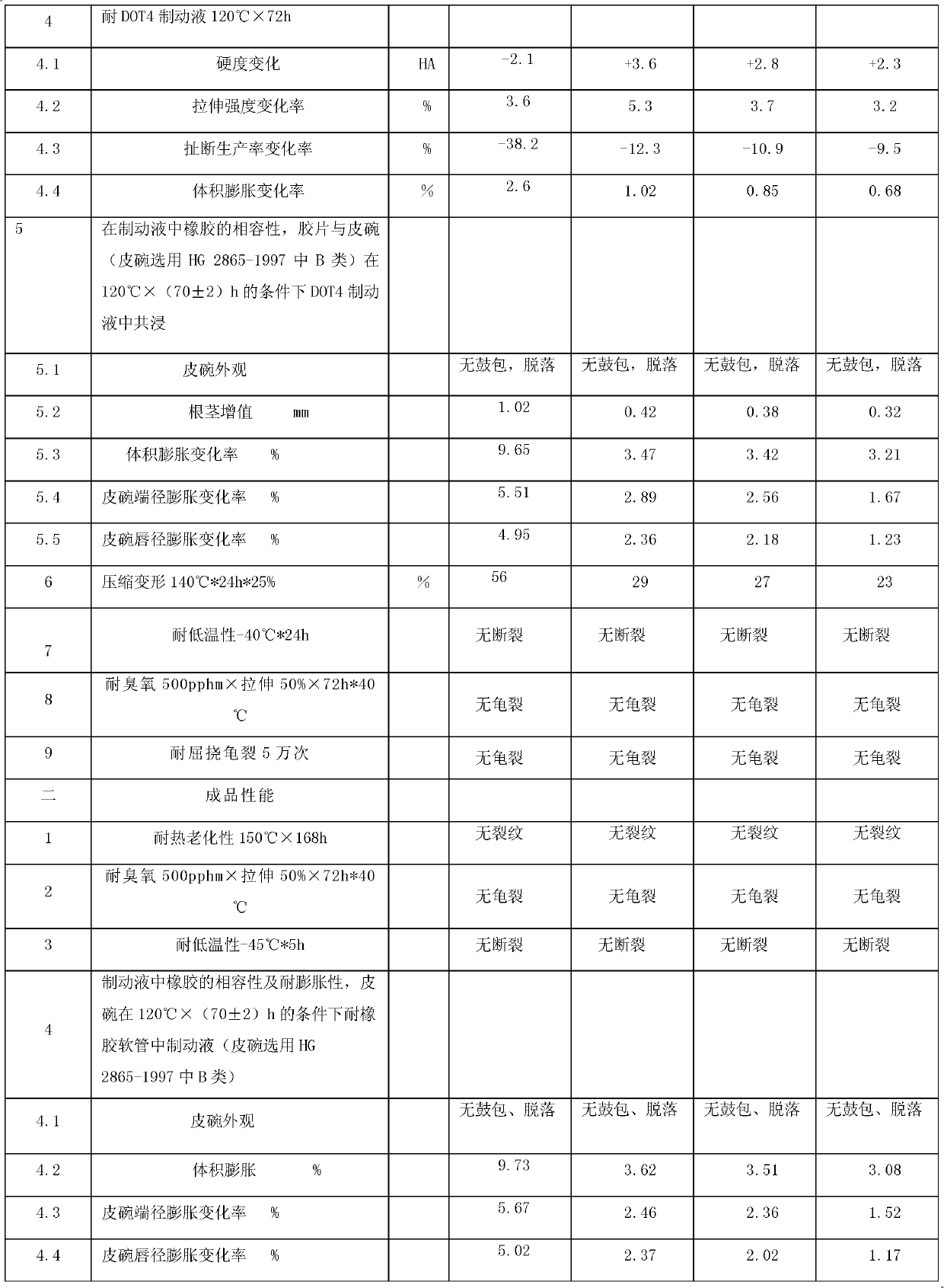

Rubber composition capable of resisting expansibility of synthetic brake fluid of motor vehicle

ActiveCN102516670AGood expansion performanceGood compatibilityFlexible pipesThermal ageingCross-link

The invention relates to a rubber composition capable of resisting expansibility of synthetic brake fluid of a motor vehicle. The composition comprises the following components: ternary ethylene propylene diene monomer with low mooney viscosity, liquid ethylene propylene diene monomer, magnesium oxide, magnesium oxide, age resister MB, age resister 4010NA, fast extruding carbon black N550, high-modulus semi-reinforcing carbon black N774, kieselguhr, low-molecular-weight polyisobutylene PB1300, cross-linking agent DCP, assistant cross-linking agent TMPT and sulphur. Due to the utilization of the composition, the hardness change after thermal ageing (150 DEG C*168h) is +6.8 Shore A, the compression set (140 DEG C*24h*25 percent) is 29 percent, the volume expansion change rate in DOT4 brake fluid (70 DEG C*72h and 120 DEG C*72h) is 0.86 percent and 1.02 percent, a sample and a packing leather are soaked in the DOT4 brake fluid for 72h at temperature of 120 DEG C, the expansion change rate of the end diameter and the lip diameter of the packing leather is within 3.0 percent, and the expansion change rate of the end diameter and the lip diameter of the packing leather after resisting the brake fluid in a pipe is within 2.5 percent. The composition provided by the invention can meet the requirement of compatibility of the rubber in the brake fluid of a GB12981-2003 motor vehicle andthe requirement of change rate of the end diameter and the lip diameter of the rubber after resisting the brake fluid in an HG2865-1997 motor vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

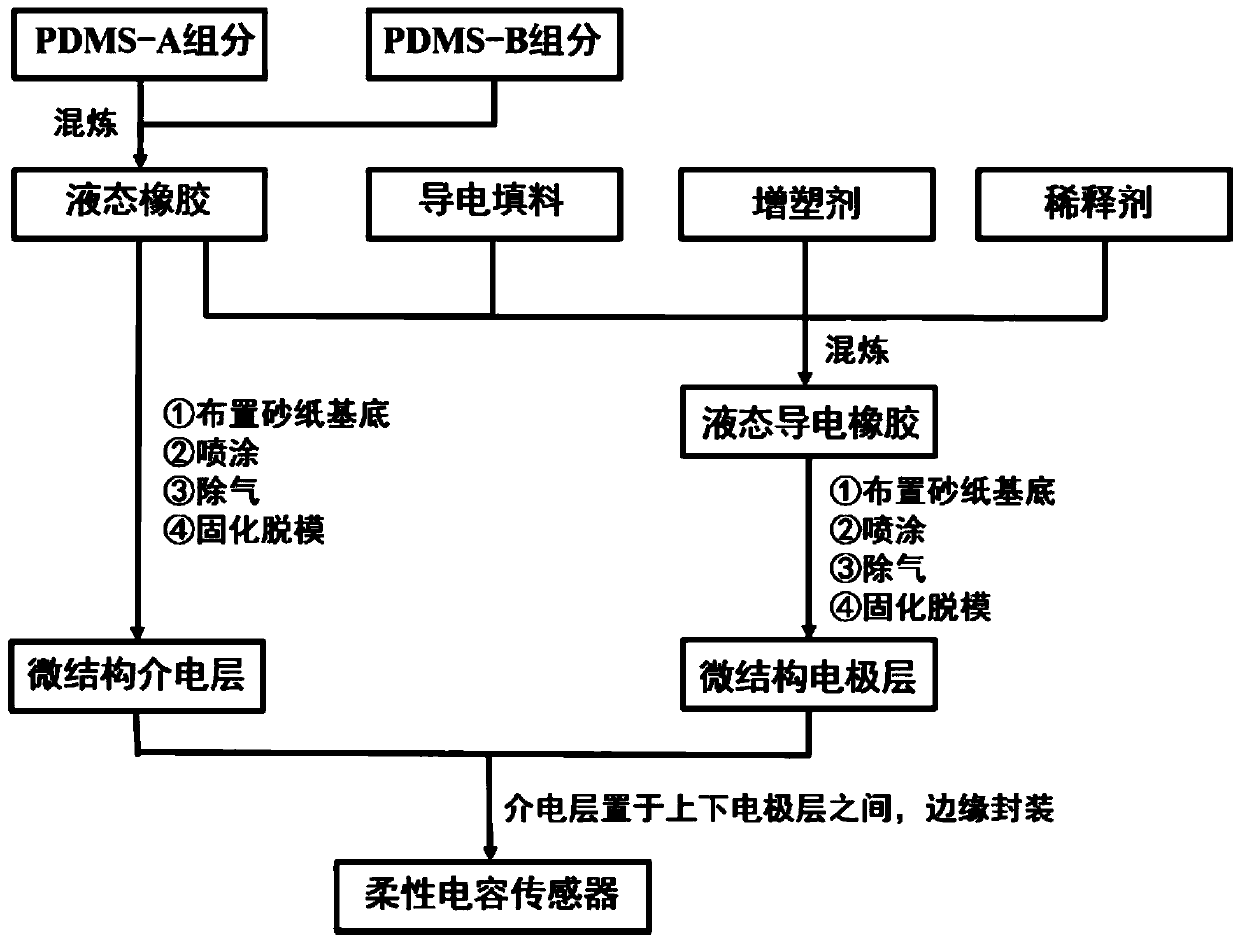

Preparation method of capacitive flexible sensor

InactiveCN111024272AImprove responsivenessImprove production efficiencyForce measurementFluid pressure measurement using capacitance variationCapacitanceSignal response

The invention provides a preparation method of a capacitive flexible sensor. Flexible conductive silicone rubber and pure silicone rubber are respectively used as an upper electrode layer, a lower electrode layer and a middle dielectric layer of the sensor. After surface microstructures with different roughness are introduced into the electrode layers and the dielectric layer, the prepared sensorhas different sensitivities and can be used for human body motion signal detection. The pure rubber used as the dielectric layer of the sensor is prepared by mixing liquid component A base rubber anda component B curing agent, the conductive rubber used as the conductive layers of the sensor is prepared by mixing the liquid component A base rubber, the component B curing agent, a conductive filler, a plasticizer and a diluent, and the flexible capacitive sensor with good mechanical signal response is obtained after spraying, curing and assembling. The capacitive flexible sensor has the characteristics of high sensitivity, short response time, small lag, strong stability and the like.

Owner:BEIJING UNIV OF TECH

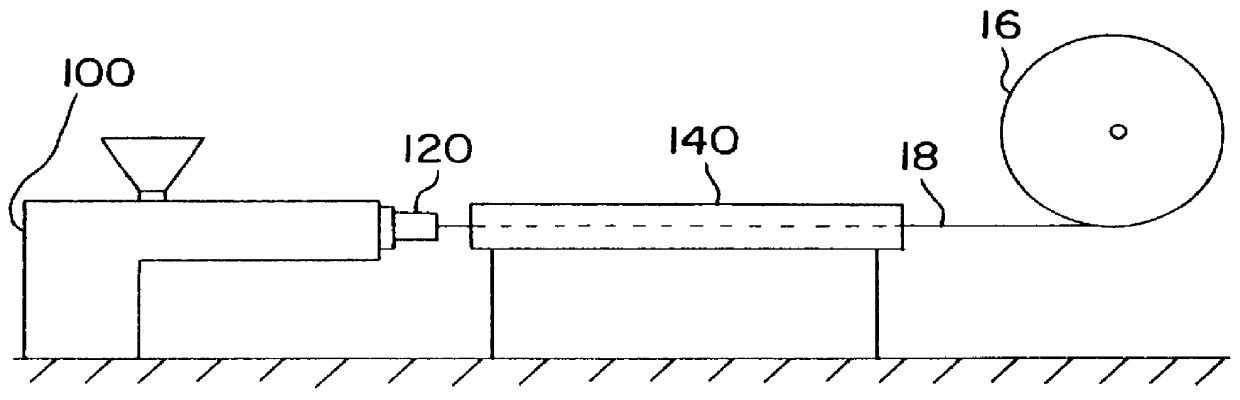

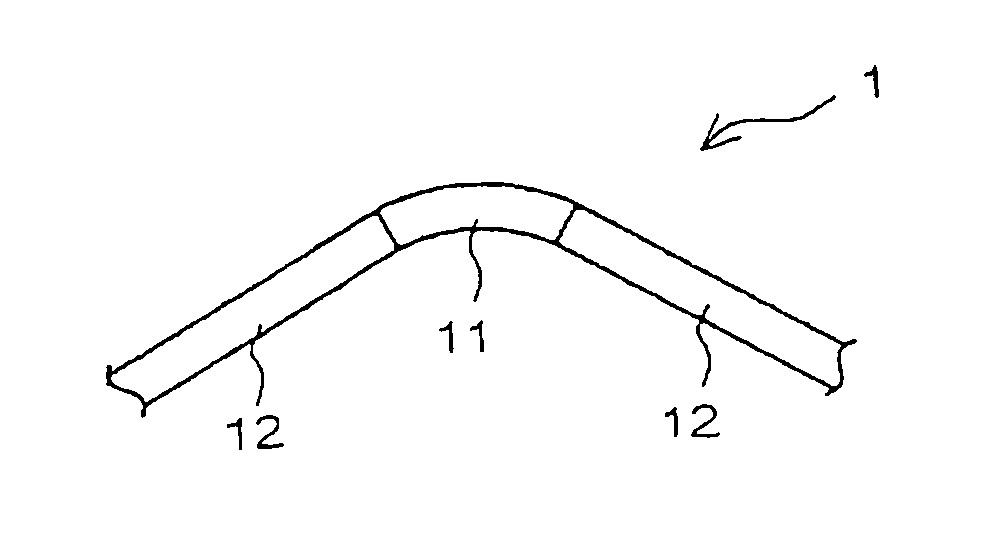

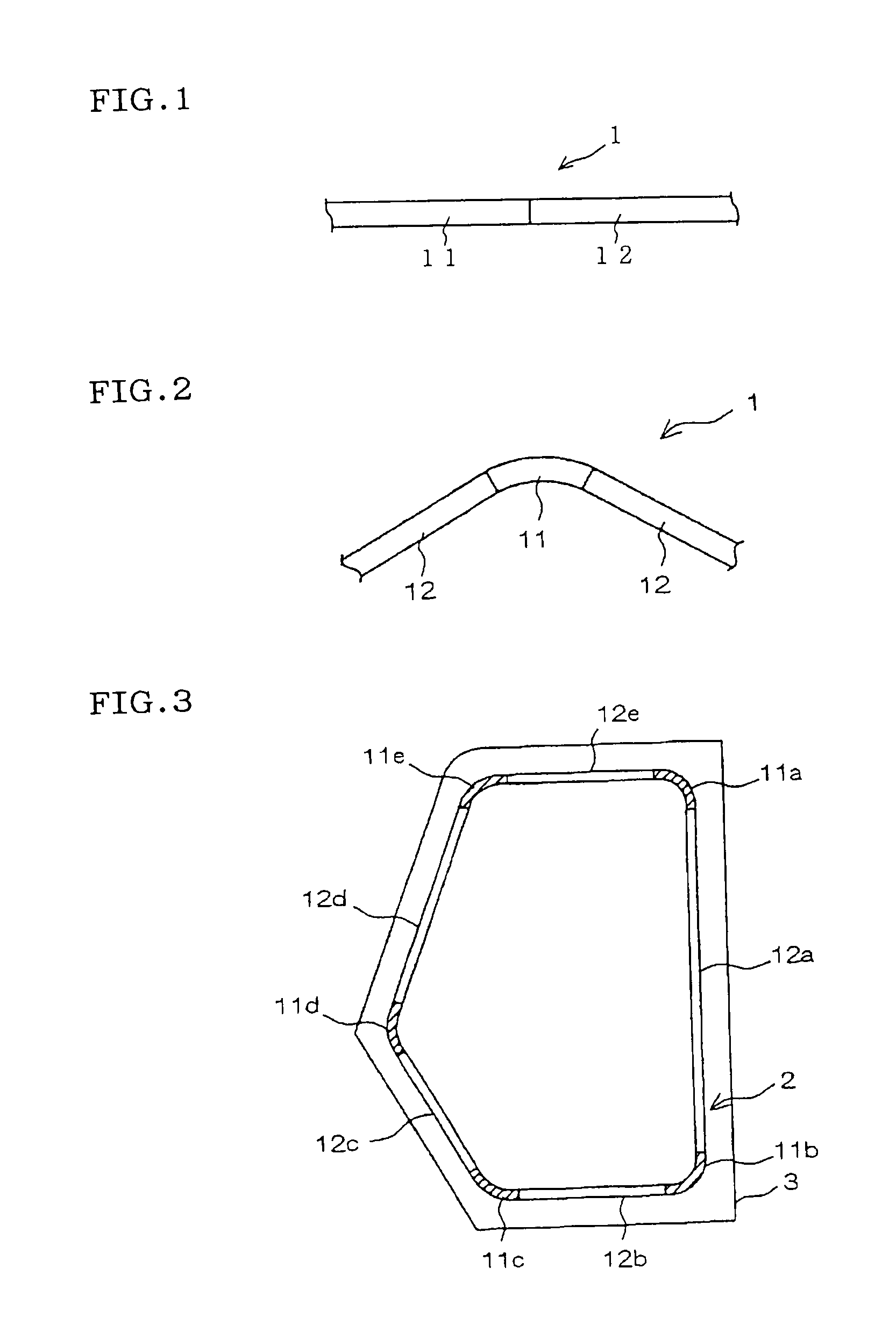

Molded Composite Material and Process for Production Thereof

InactiveUS20090176045A1Improved compression setGood adhesivenessMouldsSynthetic resin layered productsPolyolefinPolymer science

A molded composite comprising a first molded part 11 and a second molded part 12 which is bonded to the surface and / or a cross-sectional surface of the first molded part 11 is disclosed. The first molded part 11 is obtained by extrusion foam molding of an olefin thermoplastic elastomer composition, comprising (A) an ethylene-α-olefin copolymer rubber having an intrinsic viscosity [η] of 3.5 to 6.8 dl / g as measured at 135° C. in a decalin solvent, (B) a polyolefin resin, and (C) a mineral oil-based softener in a predetermined proportion and obtained by dynamically heat-treating a mixture of at least (A) the ethylene-α-olefin copolymer rubber and (B) the polyolefin resin in the presence of a cross-linking agent, at an expansion ratio of 1.2 times or more and the second molded part 12 is obtained by injection molding of the olefin thermoplastic elastomer composition and / or another thermoplastic elastomer composition and bonded to the surface and / or a cross-sectional surface of the first molded part 11.

Owner:JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com