Elastomer-based insulating cladding material for charging pile cable and preparation method of elastomer-based insulating cladding material

An insulating coating and elastomer technology, which is applied to organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high raw material cost and processing cost, easy exudation of flame retardant materials, and difficulty in meeting actual needs. Low production cost, aging resistance, improved system compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

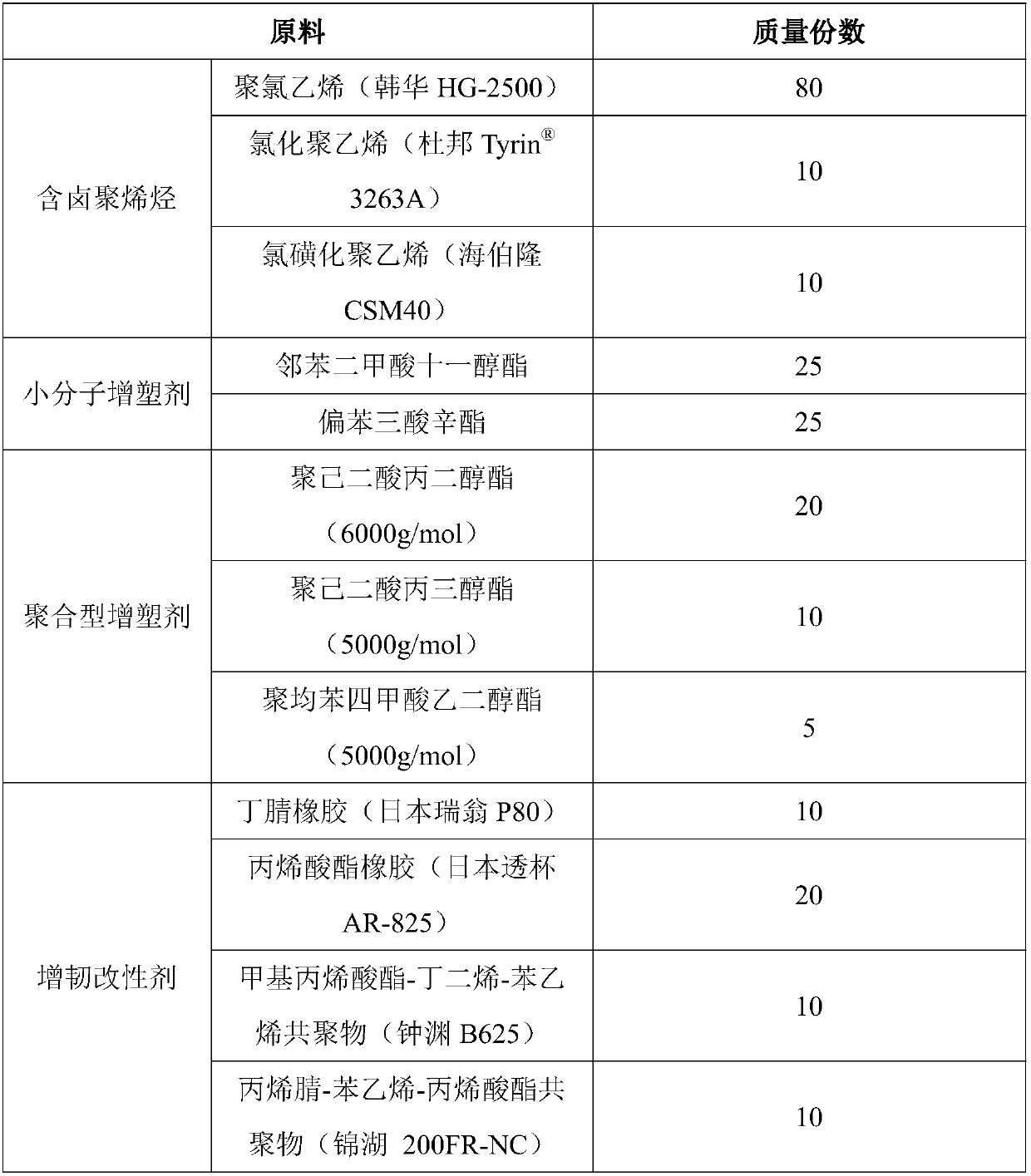

[0046] An elastomer insulating coating material used for charging pile cables, its raw material composition is shown in the following table:

[0047] Table 1 The raw material composition of an elastomeric insulating coating material used for charging pile cables

[0048]

[0049]

[0050] The preparation method of the above-mentioned elastomeric insulating coating material for charging pile cables includes the following steps: add the components in the table into a high-speed mixer, mix and stir at a high speed of 1400rpm for 10min, and then transfer the material to an aspect ratio of 25 :1 in a twin-screw extruder, melted and kneaded at 175°C and 800 rpm, and finally transferred the material to a single-screw extruder with a length-to-diameter ratio of 60:1 for extrusion and granulation.

Embodiment 2

[0052] An elastomer insulating coating material used for charging pile cables, its raw material composition is shown in the following table:

[0053] Table 2 The raw material composition of an elastomeric insulating coating material used for charging pile cables

[0054]

[0055]

[0056] The preparation method of the above-mentioned elastomer insulating coating material for charging pile cables includes the following steps: adding the components in the table into a high-speed mixer, mixing and stirring at a high speed of 1800rpm for 20min, and then transferring the material into : 1 in a twin-screw extruder, melted and kneaded at 165°C and 900 rpm, and finally transferred the material to a single-screw extruder with a length-to-diameter ratio of 40:1 for extrusion and granulation.

Embodiment 3

[0058] An elastomer insulating coating material used for charging pile cables, its raw material composition is shown in the following table:

[0059] Table 3 Raw material composition of an elastomeric insulating coating material used for charging pile cables

[0060]

[0061]

[0062] The preparation method of the above-mentioned elastomer insulating coating material for charging pile cables includes the following steps: add the components in the table into a high-speed mixer, mix and stir at a high speed of 1200rpm for 30min, and then transfer the material into :1 in a twin-screw extruder, melted and kneaded at 195°C and 400 rpm, and finally transferred the material to a single-screw extruder with a length-to-diameter ratio of 70:1 for extrusion and granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com