Metal and plastic composite self-lubricating material and preparation method thereof

A self-lubricating material, metal-plastic technology, applied in metal layered products, chemical instruments and methods, lamination, etc., can solve the problems of poor bonding between metal and plastic, easy peeling of metal and plastic, limitation of use of metal tiles, etc. The effect of improving bonding strength, high rigidity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare as follows:

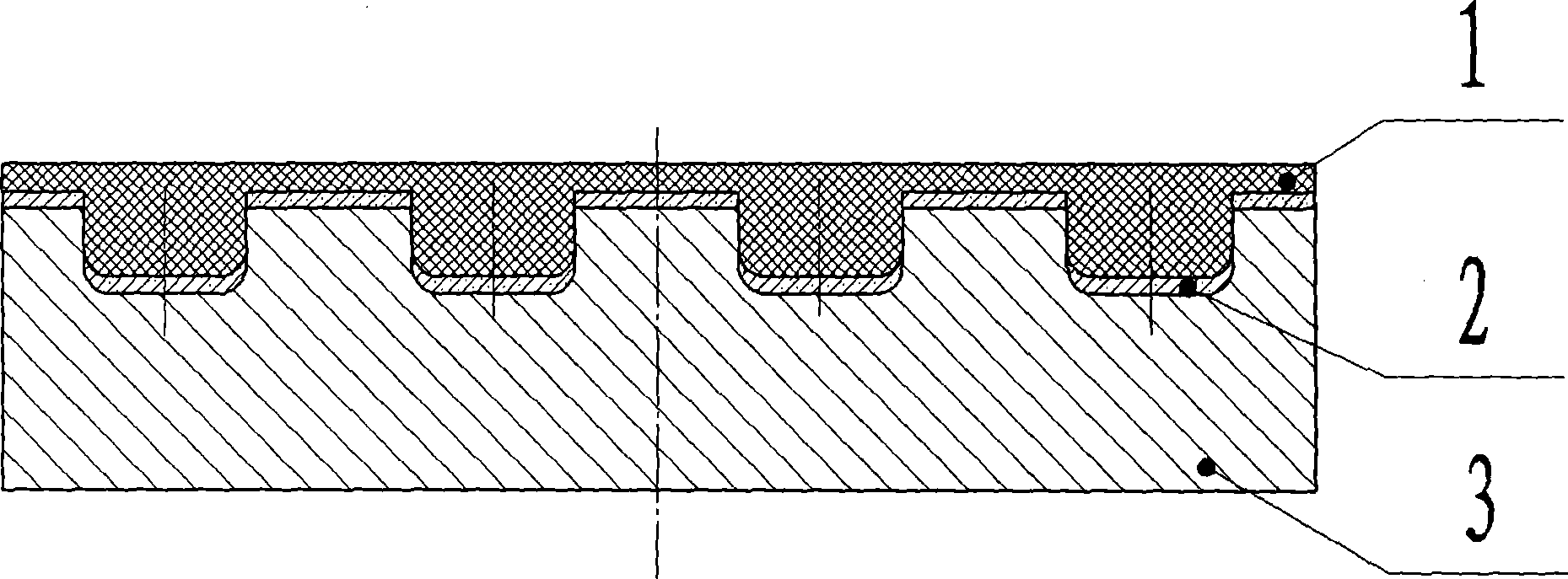

[0030] (1) Milling pits with a set diameter and depth on the metal layer 3 by a milling lathe according to the preset pit arrangement;

[0031] (2) Carry out pretreatment before spraying on the metal surface, remove oil stains and oxides on the surface, and carry out phosphating treatment on the surface to improve the bonding performance of the metal and plastic layers;

[0032] (3) Plastic working layer 1 Take 70 parts of polyether ether ketone, 12 parts of polytetrafluoroethylene, 7 parts of graphite, 1 part of molybdenum disulfide, and 10 parts of aluminum oxide as raw materials, mix and dry. For the plastic bonding layer 2, 72 parts of polyether ether ketone, 18 parts of polyphenylene sulfide, and 10 parts of aluminum oxide were mixed and dried;

[0033](4) Mix the plastic bonding layer 2 in the above (3), and spray a bonding layer with a thickness of 50um to the surface of the milled metal layer 3 by an electrostatic sprayer;

[0034] (5) Pu...

Embodiment 2

[0038] Prepare as follows:

[0039] Steps (1) to (4) follow the same process as in Example 1; the difference is: 75 parts of polyether ether ketone, 7 parts of polytetrafluoroethylene, 7 parts of graphite, and 1 part of molybdenum disulfide are used for the plastic working layer 1. 10 parts of aluminum oxide; 72 parts of polyether ether ketone, 18 parts of polyphenylene sulfide, and 10 parts of aluminum oxide for the plastic bonding layer 2;

[0040] (5) Put the metal combination in the above (4) into the cavity of the hot pressing mold as an insert, and then spread the plastic working layer 1 mixture in the above (3) on the steel back of the milled metal layer 3 On, the thickness is 6mm, pressurize to 5MPa, then raise the temperature at a rate of 15°C / min, wait for the temperature to rise to 340°C, keep the temperature for 20 minutes, then pressurize to 12MPa, and raise the temperature to 370°C, keep the temperature for 30 minutes, then Cooling under pressure-holding conditi...

Embodiment 3

[0044] Prepare as follows:

[0045] Steps (1) to (4) follow the same process as in Example 1, except that: 80 parts of polyether ether ketone, 4 parts of polytetrafluoroethylene, 7 parts of graphite, and 1 part of molybdenum disulfide are used for the plastic working layer 1. Parts, 8 parts of aluminum oxide; 80 parts of polyether ether ketone, 10 parts of polyphenylene sulfide, and 10 parts of aluminum oxide for the plastic bonding layer 2;

[0046] (5) Put the metal combination in the above (4) into the cavity of the hot pressing mold as an insert, and then spread the plastic working layer 1 mixture in the above (3) on the steel back of the milled metal layer 3 Above, the tile thickness is 10mm, pressurize to 5MPa, then raise the temperature at a rate of 20°C / min, wait for the temperature to rise to 360°C, keep the temperature for 30 minutes, then pressurize to 15MPa, and raise the temperature to 380°C, keep the temperature for 20 minutes , and then cooled under pressure-ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com