Ethylene-propylene-diene rubber for rubber tube system of hydrogen energy powered automobile

A technology for EPDM rubber and power vehicles, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc. It can solve the problems of small hydrogen molecules and leakage, and achieve the effect of improving air tightness and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

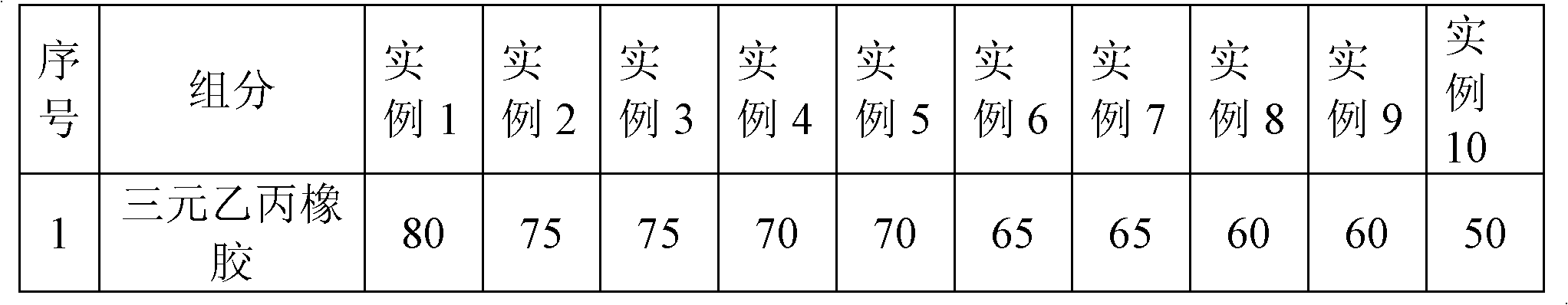

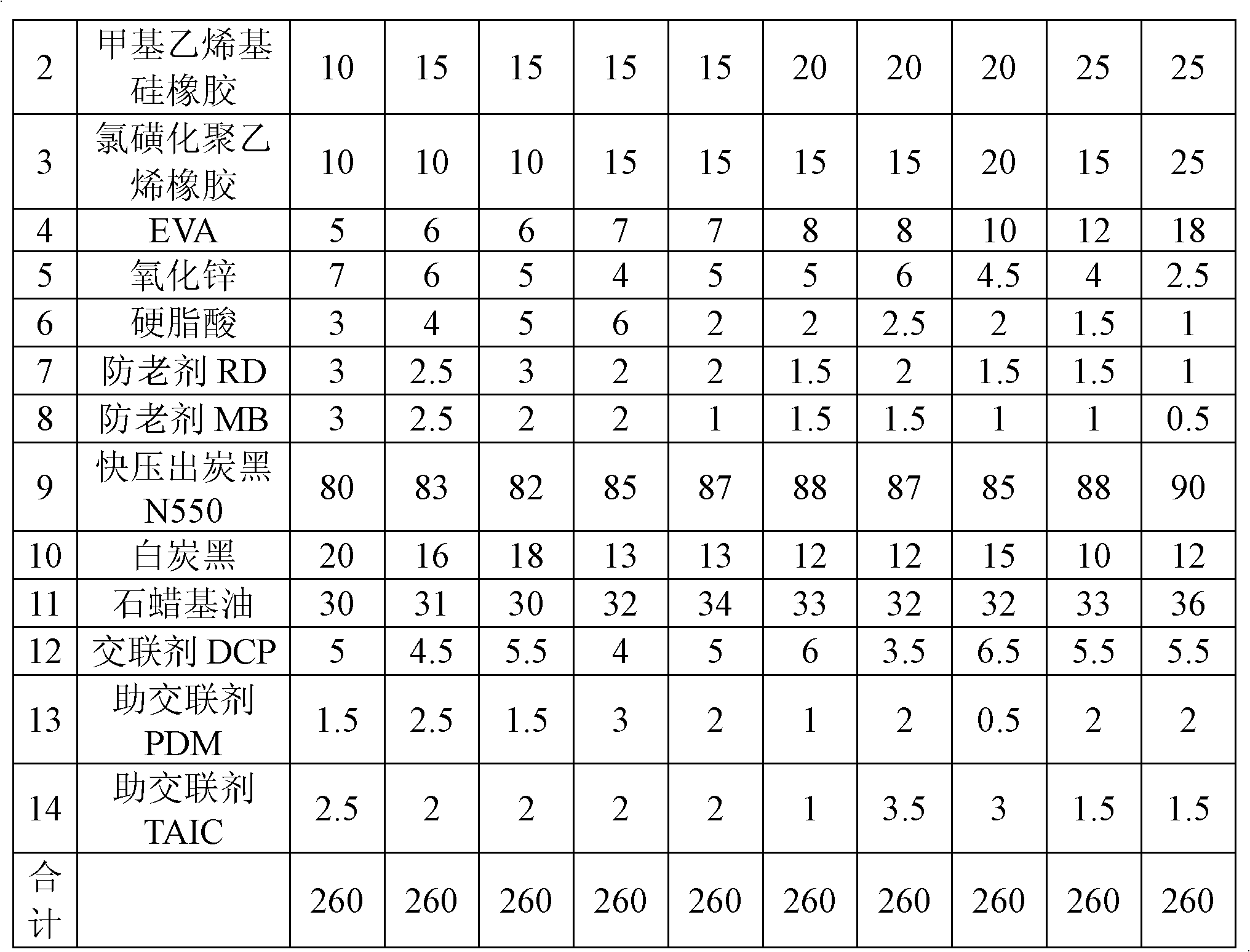

[0008] The present invention will be further described below in conjunction with specific examples.

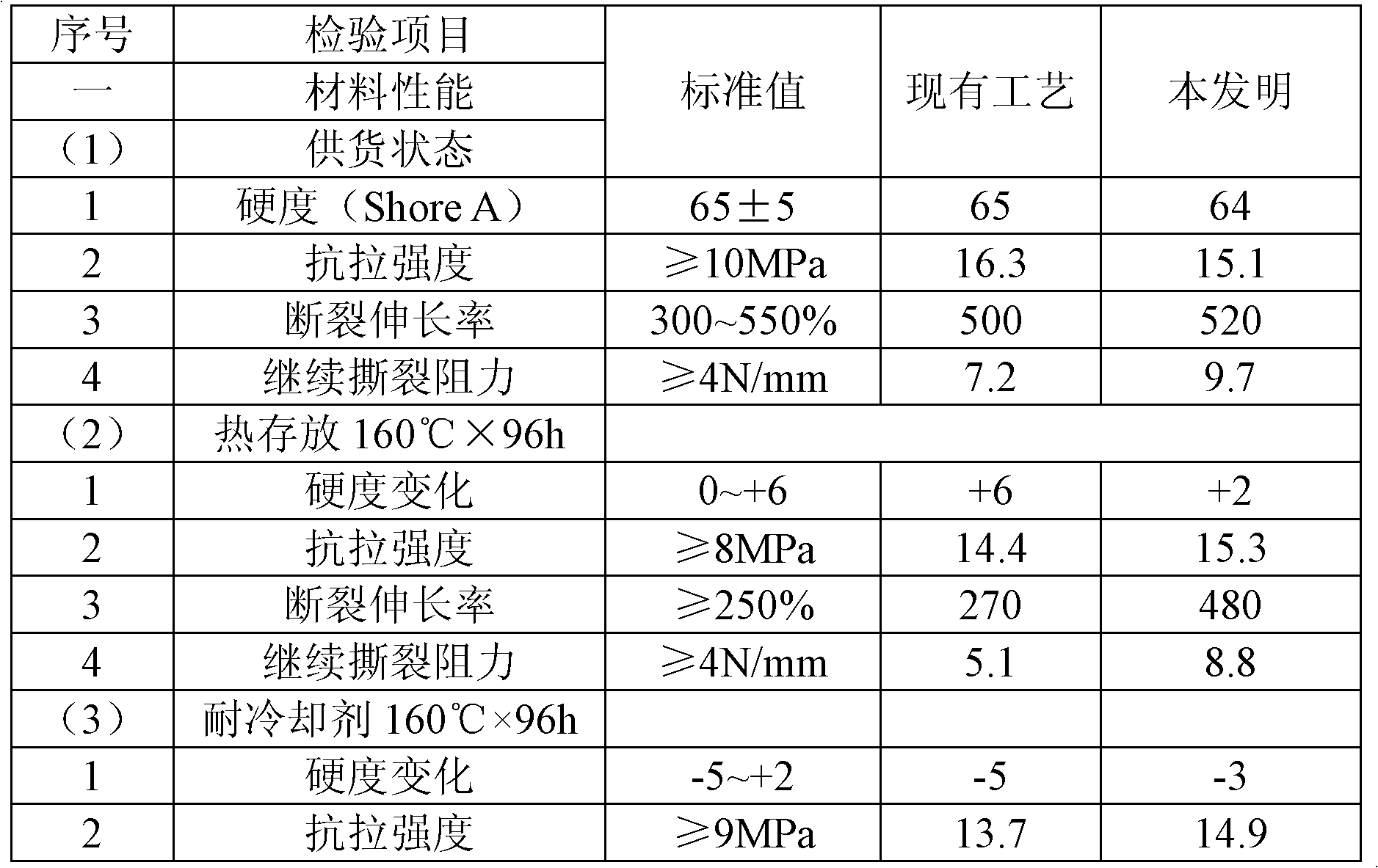

[0009] The present invention adopts EPDM rubber and methyl vinyl silicone rubber and chlorosulfonated polyethylene rubber to use together, selects the auxiliary vulcanization system that auxiliary crosslinking agent PDM and auxiliary crosslinking agent TAIC are used in combination, uses DCP as crosslinking agent, like this The rubber hose made not only improves the original high temperature resistance, corrosion resistance and fatigue resistance of EPDM rubber, but also greatly improves its air tightness, compression set and flame retardancy. is already in a leading position.

[0010] The polymer chain of EPDM rubber is fully saturated, so it has excellent heat resistance, ozone resistance, acid and alkali resistance, weather aging resistance, fatigue resistance, tear resistance and other properties, and is widely used in automobile manufacturing and construction industries ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com