Oil-proof ethylene propylene diene monomer material and preparation method thereof

An EPDM and oil-resistant technology, which is applied in the field of oil-resistant EPDM materials and their preparation, can solve the problems of large changes in tensile strength and volume, reduced water pump sealing effect, and inability to adapt well. Avoid the risk of whitening, improve shrinkage permanent deformation performance, and excellent compression set performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of oil-resistant EPDM material of the present invention comprises the following steps:

[0034] (1) Mixing of EPDM masterbatch: put EPDM rubber, zinc oxide, and stearic acid in a banbury mixer for 30-50 seconds, then add carbon black N550 and carbon black N774, and banbury After 90-120 seconds, the mixing temperature reaches 110-125°C for debinding, and the master batch is parked for more than 12 hours;

[0035] (2) Mixing of nitrile rubber masterbatch: put the nitrile rubber in the internal mixer for 30-50 seconds, then add anti-aging agent 445 and anti-aging agent ZMMBI, after banburying for 20-30 seconds, add carbon black N990, kaolin, and plasticizer NEO-T, after banburying for 90-120 seconds, the mixing temperature reaches 120-135°C for debinding, and the masterbatch is parked for more than 12 hours;

[0036] (3) Vulcanization of masterbatch: Put the parked EPDM masterbatch and nitrile rubber masterbatch in the internal mixer for 30-50 secon...

Embodiment 1

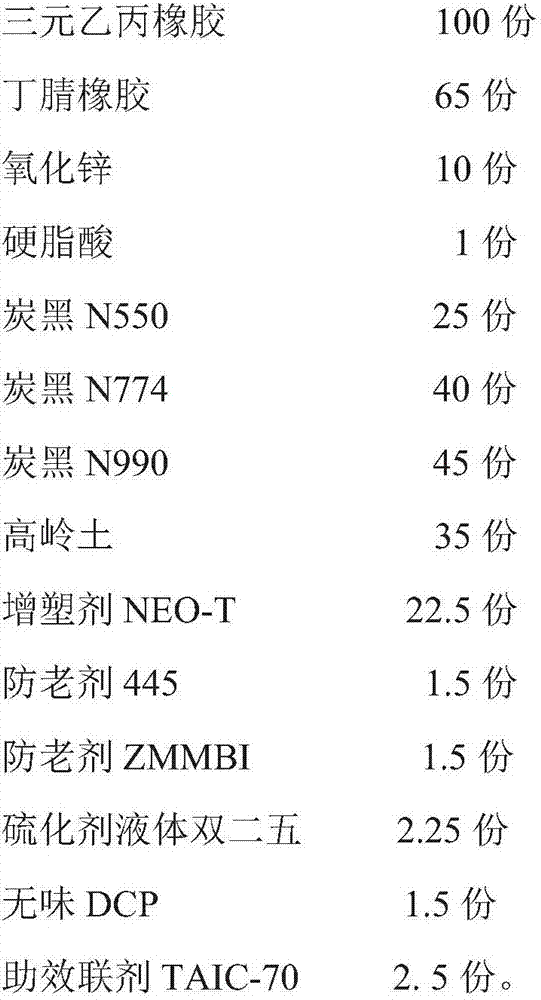

[0040] The oil-resistant EPDM material of this example, the proportioning of this material according to parts by weight is as follows:

[0041]

[0042] The preparation method of oil-resistant EPDM material of the present invention comprises the following steps:

[0043] (1) Mixing of EPDM masterbatch: put EPDM rubber, zinc oxide, and stearic acid in a banbury mixer for 30 seconds, then add carbon black N550 and carbon black N774, and banbury for 90 seconds Finally, the mixing temperature reaches 110°C for debinding (temperature priority), and the masterbatch is parked for more than 12 hours;

[0044] (2) Mixing of nitrile rubber masterbatch: put the nitrile rubber in the mixer for 30 seconds, then add anti-aging agent 445, anti-aging agent ZMMBI, after banburying for 20 seconds, add carbon black N990, kaolin, For plasticizer NEO-T, after banburying for 90 seconds, the mixing temperature reaches 120°C for debinding (temperature priority), and the master batch is parked for...

Embodiment 2

[0048] The oil-resistant EPDM material of this example, the proportioning of this material according to parts by weight is as follows:

[0049]

[0050] The preparation method of oil-resistant EPDM material of the present invention comprises the following steps:

[0051] (1) Mixing of EPDM masterbatch: put EPDM rubber, zinc oxide, and stearic acid in a banbury mixer for 40 seconds, then add carbon black N550 and carbon black N774, and banbury for 105 seconds Finally, the mixing temperature reaches 127°C for debinding (temperature priority), and the masterbatch is parked for more than 12 hours;

[0052] (2) Mixing of nitrile rubber masterbatch: put the nitrile rubber in the mixer for 40 seconds, then add anti-aging agent 445, anti-aging agent ZMMBI, after banburying for 25 seconds, add carbon black N990, kaolin, For plasticizer NEO-T, after banburying for 105 seconds, the mixing temperature reaches 127°C for debinding (temperature priority), and the masterbatch is parked fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com