Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342results about How to "Solving Elasticity Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

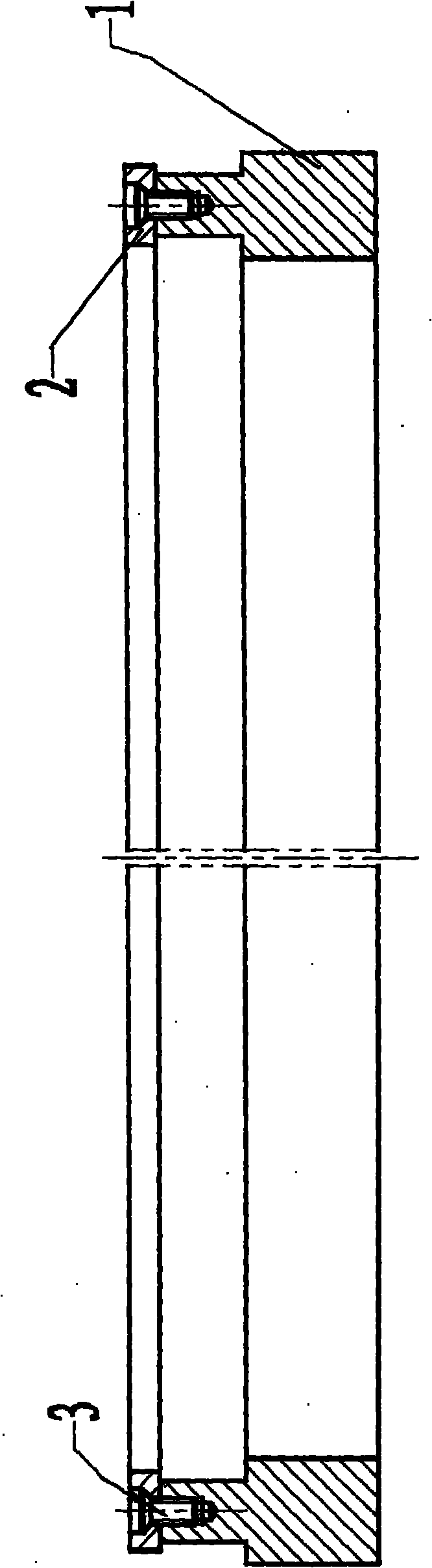

Multifunctional road soil roadbed freezing and thawing circulating test device

ActiveCN101923085ASolving Elasticity ProblemsReduce mistakesRoadwaysEarth material testingTest measurementFrost

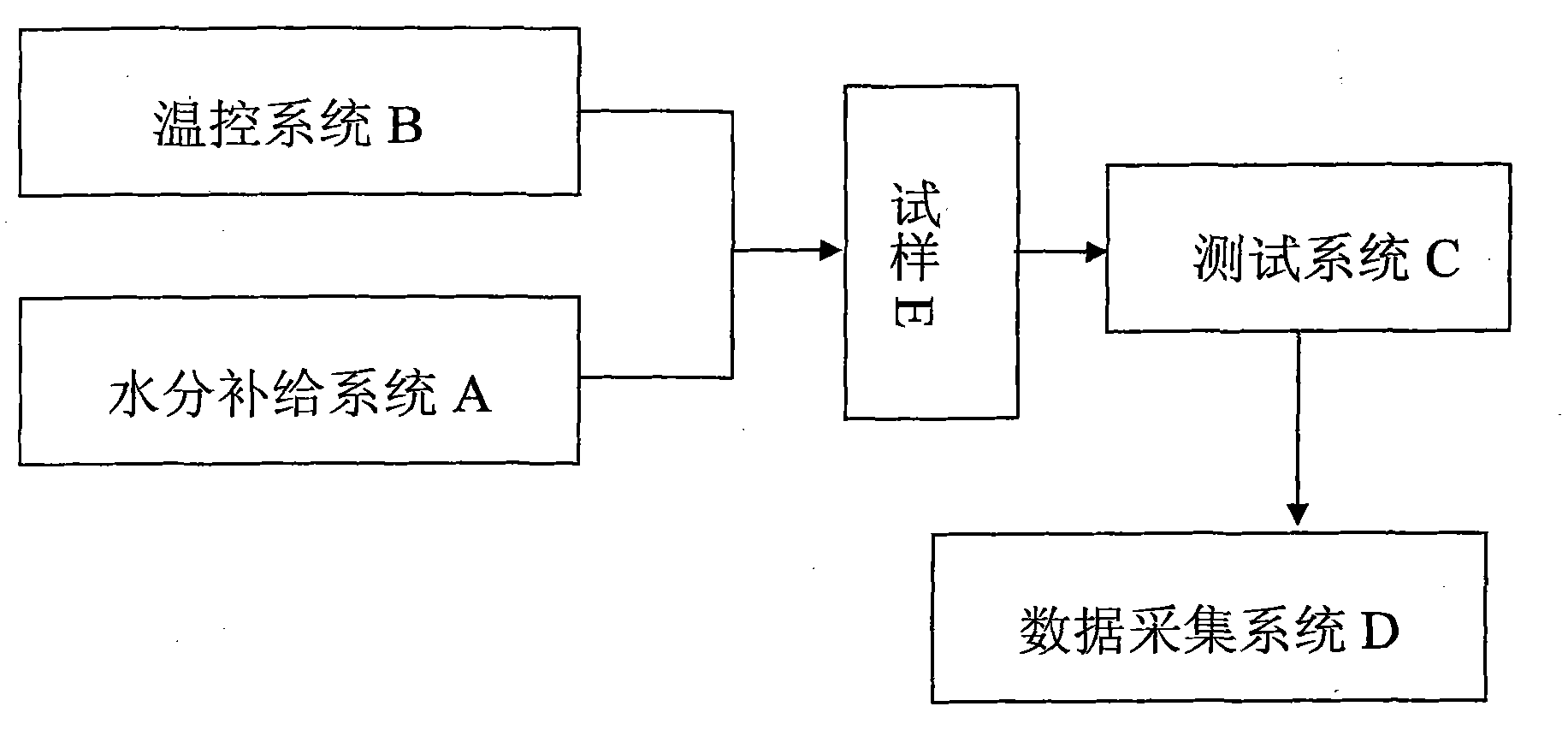

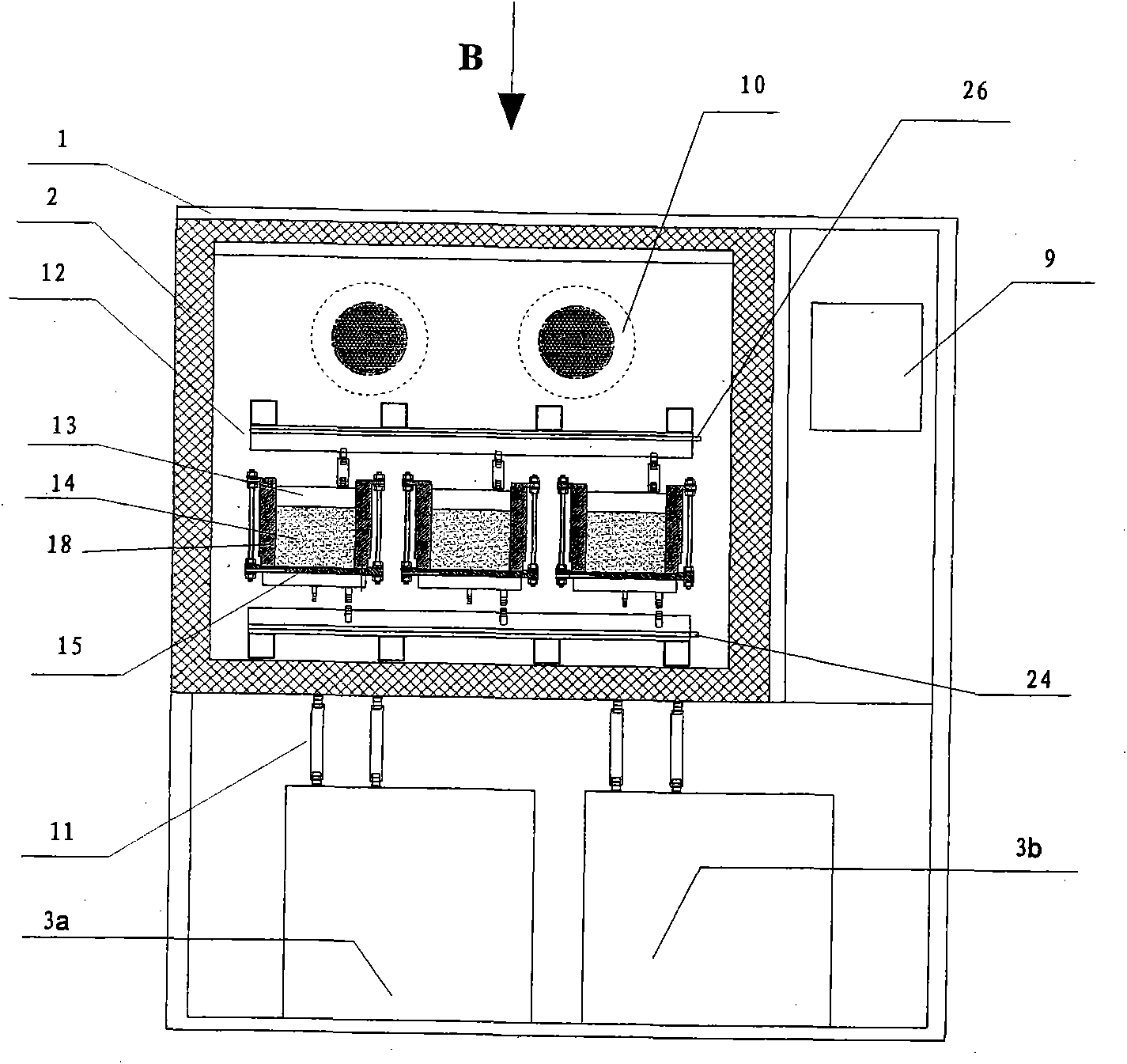

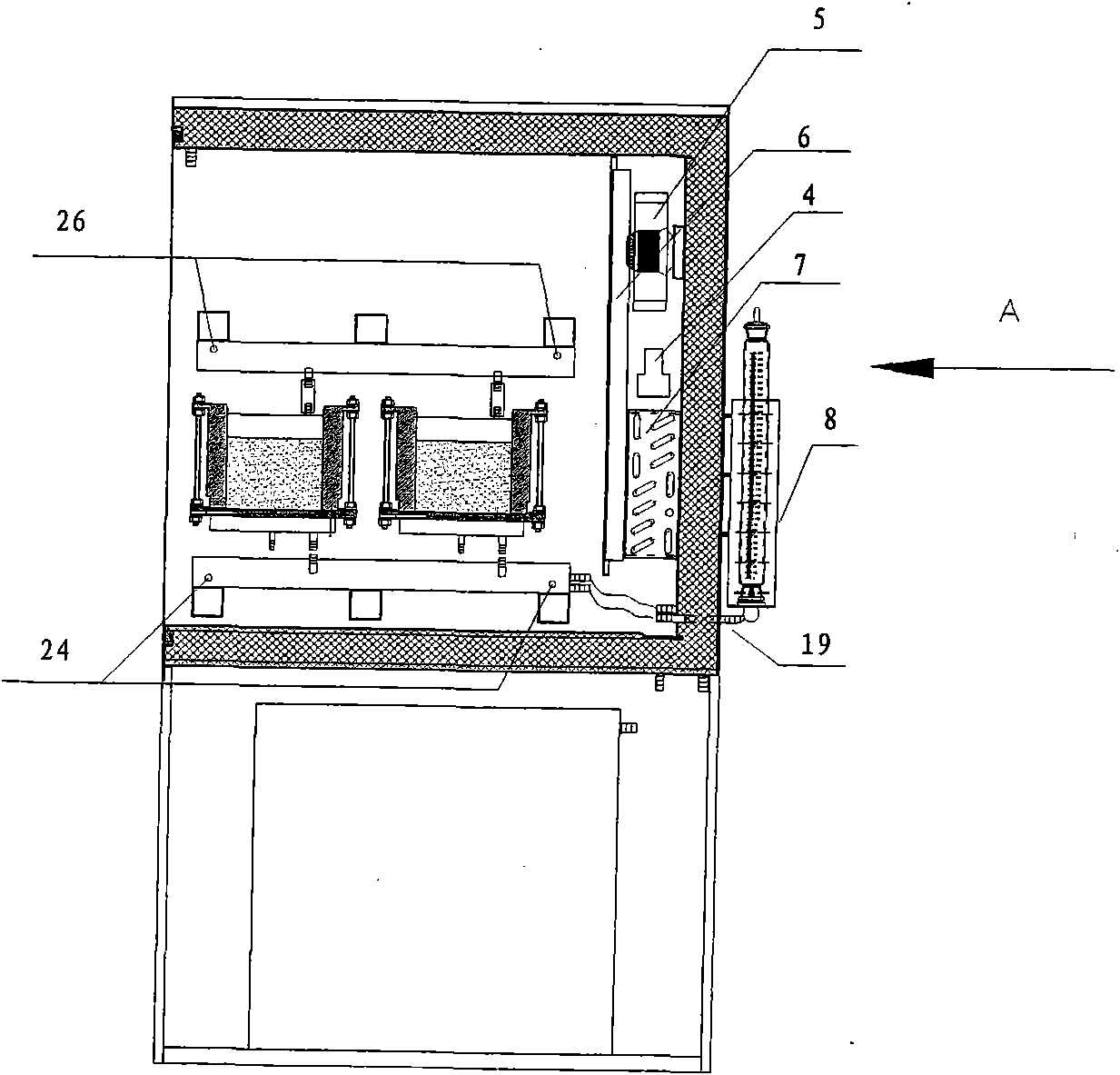

The invention discloses a multifunctional road soil roadbed freezing and thawing circulating test device. During a freezing and thawing circulating test, six samples are placed among six top plate heat exchangers and six bottom plate heat exchangers of a constant temperature system; the six top plate heat exchangers and the six bottom plate heat exchangers are respectively connected in parallel with a refrigeration circulating machine set; a moisture replenishment system is connected with the bottoms of six roadbed soil samples; a temperature sensor and a soil moisture sensor of a test systemare respectively buried in the six roadbed soil samples of the samples; a displacement sensor of the test system is in contact with the top of the top plate heat exchanger of a temperature control system; and the temperature sensor, the displacement sensor and the soil moisture sensor are connected with an acquisition channel of a data acquisition instrument of a data acquisition system. The multifunctional road soil roadbed freezing and thawing circulating test device has the advantages of simple structure, convenient use, high test precision and reliable result, can better complete the parallel test measurement of the engineering design parameters of roadbed soil modulus of resilience, CBR (Constants Bit Rate) intensity, and the like in a seasonal frost region under a least favorable state, which cannot be achieved by the traditional devices, and can directly provide necessary design parameters for engineering design.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Processing method of ultra-thin annular pieces

InactiveCN101774111AImprove rigidityNo elasticityPositioning apparatusMetal-working holdersSheet steelWork in process

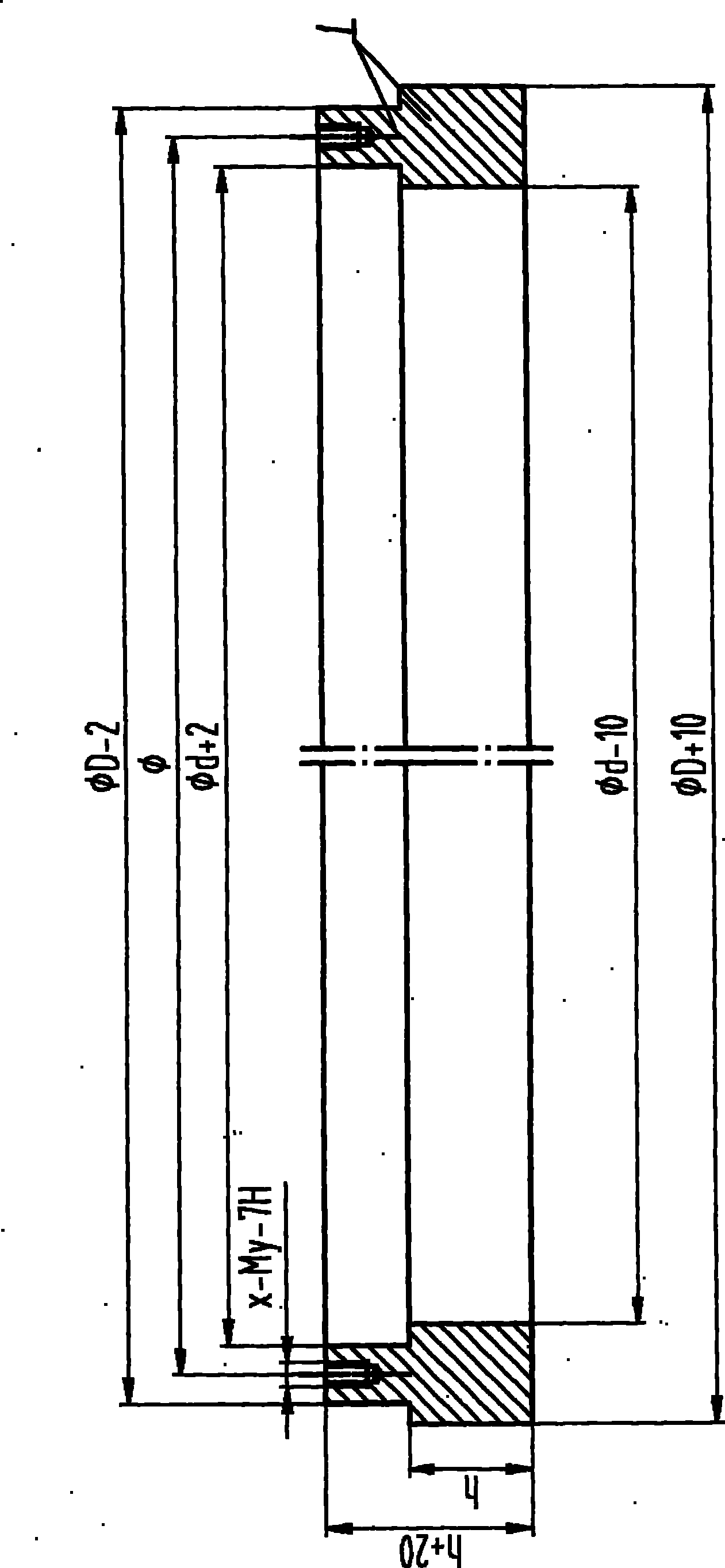

The invention relates to a processing method of ultra-thin annular pieces. The method comprises the following process flows of: (1) cutting a blank; (2) roughly turning; (3) drilling; (4) dividing single pieces; (5) manufacturing a tool clamp; (6) combining and fine turning; and (7) turning or grinding planes. 4-10 ultra-thin annular pieces are combined together, and meanwhile, steel plate flames are used for cutting and integrally blanking so as to improve the rigidity and ensure that no deformation occurs in the processing process. Semi-finished ultra-thin annular piece products to be processed, which are cut and blanked into single pieces, need to be combined together with the tool clamp, wherein the tool clamp is an annular piece with inner and outer steps between an upper section and a lower section. The circumference on the upper end surface of the tool clamp is uniformly provided with threaded holes according to the mounting hole sizes of the ultra-thin annular pieces, and then the single semi-finished products of the ultra-thin annular pieces to be processed are combined with the tool clamp into a whole by using bolts so as to enhance the rigidity of the semi-finished ultra-thin annular piece products, guarantee non-deformation during processing in subsequent working procedures, realize the localization of the ultra-thin annular pieces to replace imported pieces, greatly reduce the cost and meet the requirement of users.

Owner:MAANSHAN FANGYUAN SLEWING RING

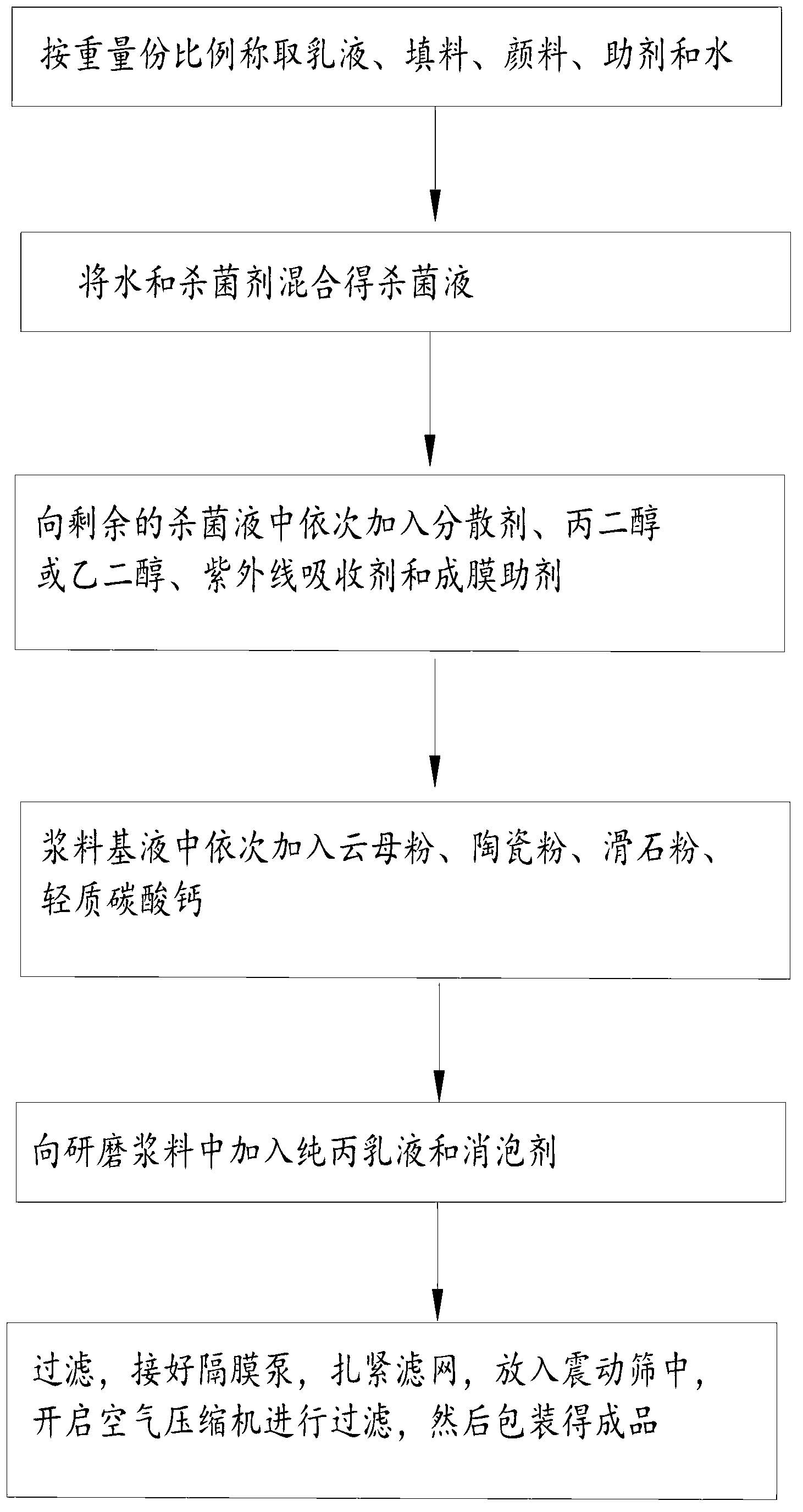

Waterborne polyurethane weather-proof elastic waterproof paint

InactiveCN103254752ASolve usabilitySolving Elasticity ProblemsPolyurea/polyurethane coatingsCrack resistanceUltraviolet lights

The invention provides a waterborne polyurethane weather-proof elastic waterproof paint. The paint comprises an emulsion, a filler, a pigment, an accessory ingredient and water, wherein the emulsion comprises an elastic waterproof emulsion and waterborne polyurethane prepolymer; the filler comprises talcum powder, ceramic powder and light calcium carbonate; the pigment is of mica powder; and the accessory ingredient comprises the following components: propylene glycol or ethylene glycol, film-forming accessory ingredient, a sterilizing agent, a flatting agent, a dispersing agent, a thickening agent, an antifoaming agent, an ultraviolet light absorber and a pH regulating agent. The problems of complicated using process of the paint, low elasticity, poor crack resistance and poor ultraviolet radiation in the prior art are solved. The invention also provides a production method of the paint, and is used for solving the production problem of the waterborne polyurethane weather-proof elastic waterproof paint.

Owner:QINGDAO KESHUN WATERPROOF MATERIAL

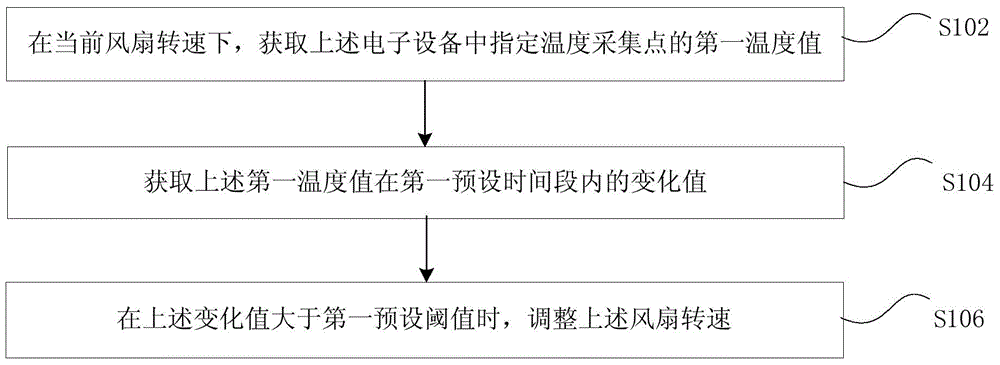

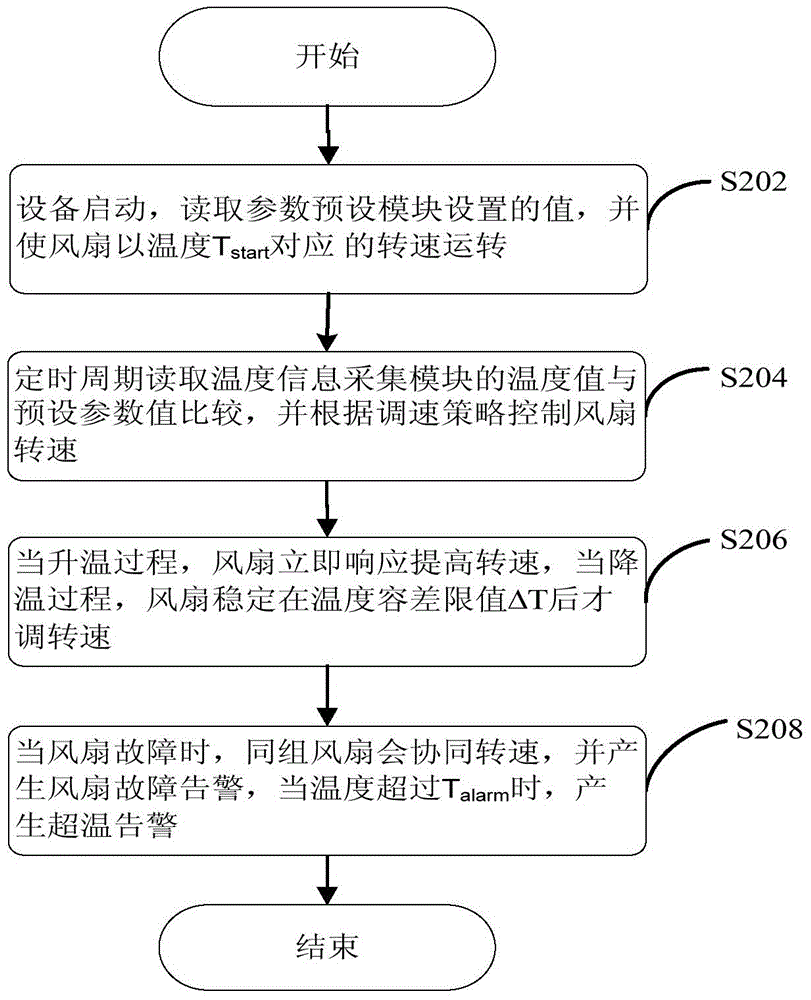

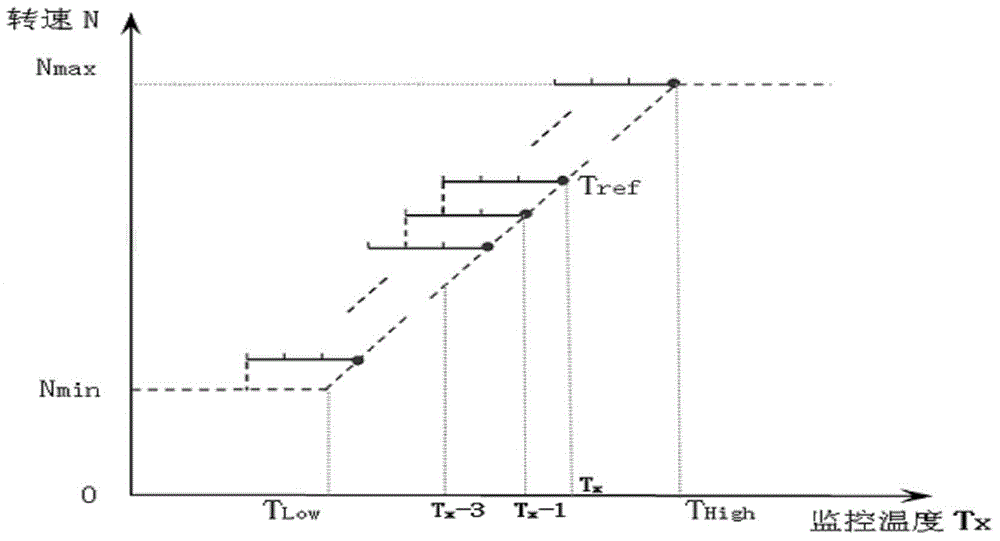

Method and device for controlling fan rotating speed of electronic equipment

ActiveCN104863881AEnsure stable operationExtended service lifeDigital data processing detailsTemperatue controlEngineeringElectronic equipment

A method and device for controlling a rotating speed of a fan in an electronic device. The method comprises the following steps: obtaining a first temperature value of a designated temperature collecting point in the electronic device at a current rotating speed of the fan (S102), obtaining a change value of the first temperature value in a first preset time period (S104); and adjusting the rotating speed of the fan while the change value is greater than a first preset threshold (S106). By the method and device mentioned above, the technical problem of rotating speed rebound or vibration can be solved during the radiating process of a speed adjustable fan, and thus the steady running of the fan is ensured in a certain degree and the service life of the fan is prolonged.

Owner:ZTE CORP

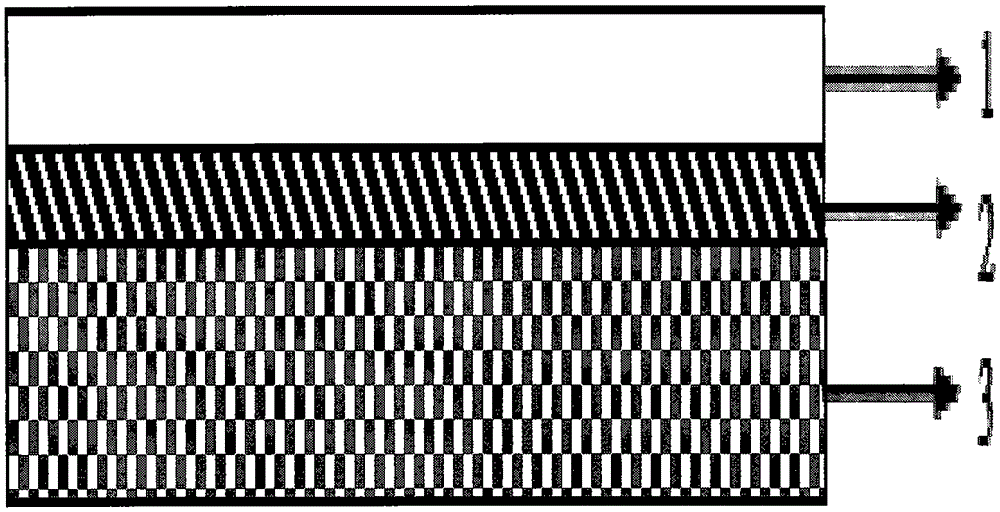

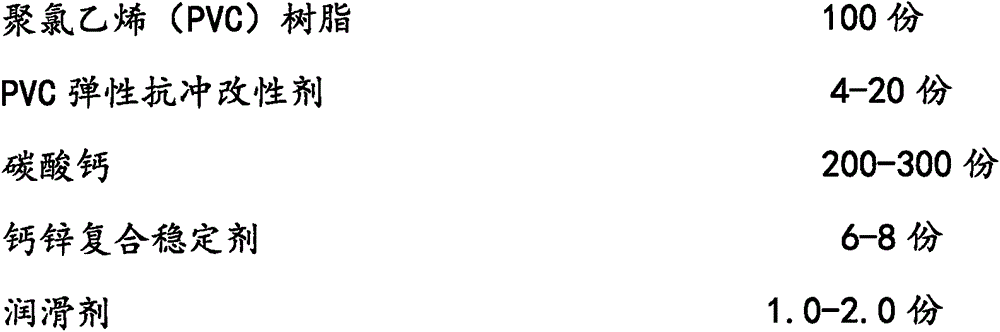

Novel PVC board and manufacturing method thereof

ActiveCN105295256ASimple processReduce production processConstruction materialCovering/liningsKnurlingPolyvinyl chloride

The invention provides a novel PVC (polyvinyl chloride) board and a manufacturing method thereof. The novel PVC board comprises a PVC transparent wearing layer, a PVC simulation pattern film layer and a PVC bottom layer from top to bottom, wherein the PVC bottom layer contains a PVC elastic anti-shock modifier; the PVC bottom layer, the PVC simulation pattern film layer and the PVC transparent wearing layer are together arranged between a first roller and a second roller, a composite layer is formed via rolling depression, and the composite layer is further treated to form the PVC board. By adopting the manufacturing method, production processes are reduced, the production efficiency is improved, the PVC board is firmer, and lines and knurling patterns are clearer and more attractive.

Owner:TAIZHOU HUALI PLASTIC

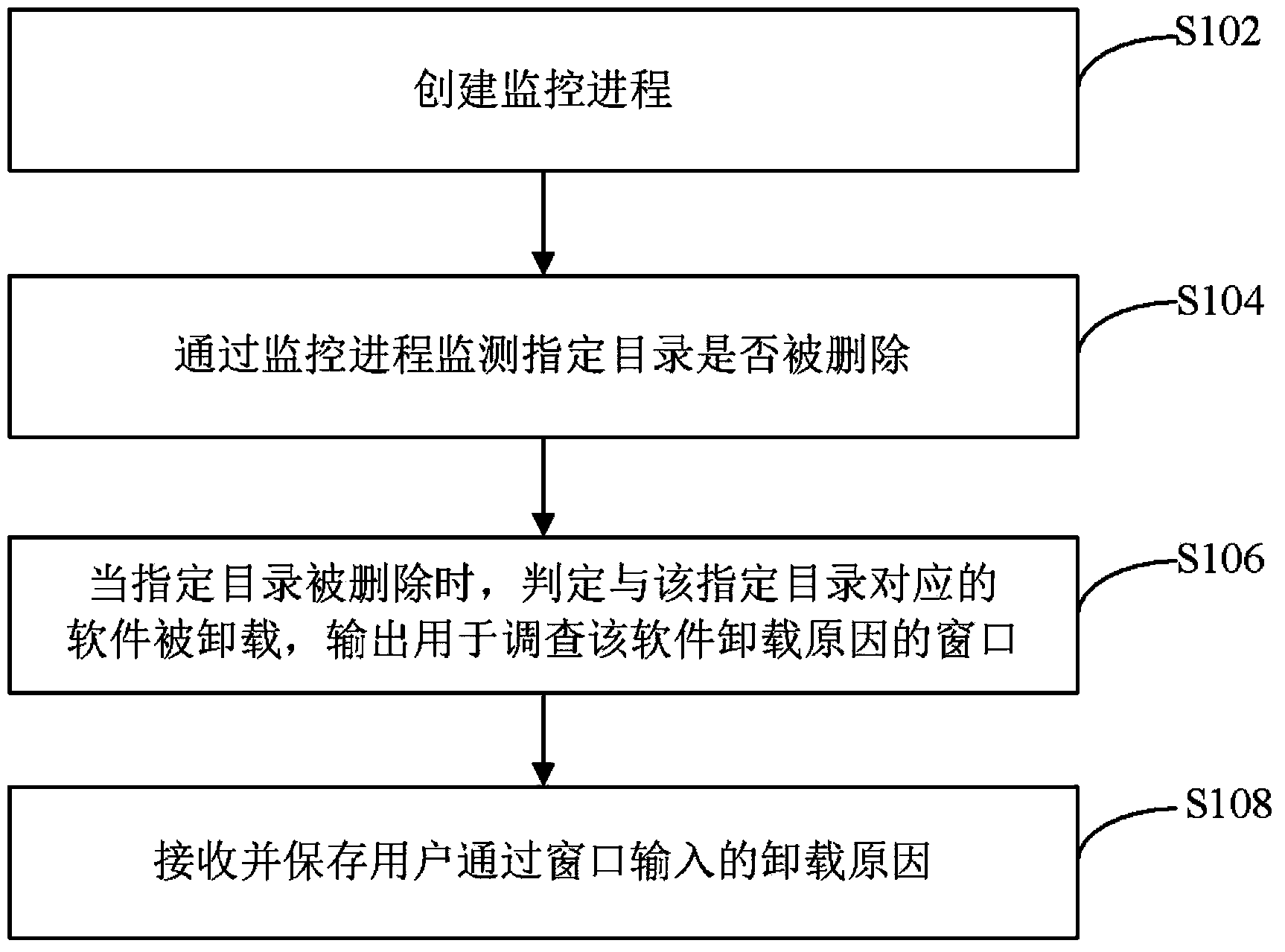

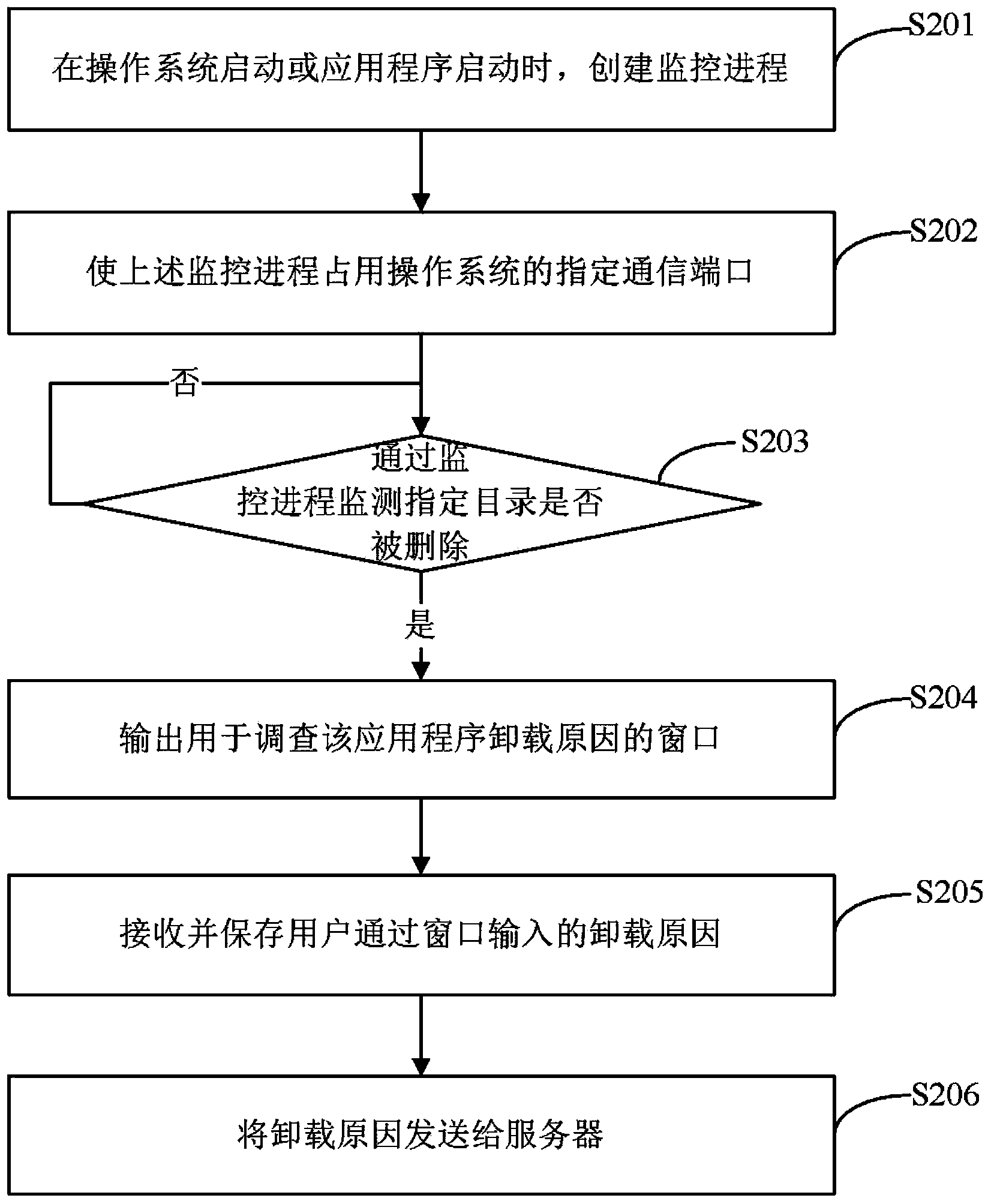

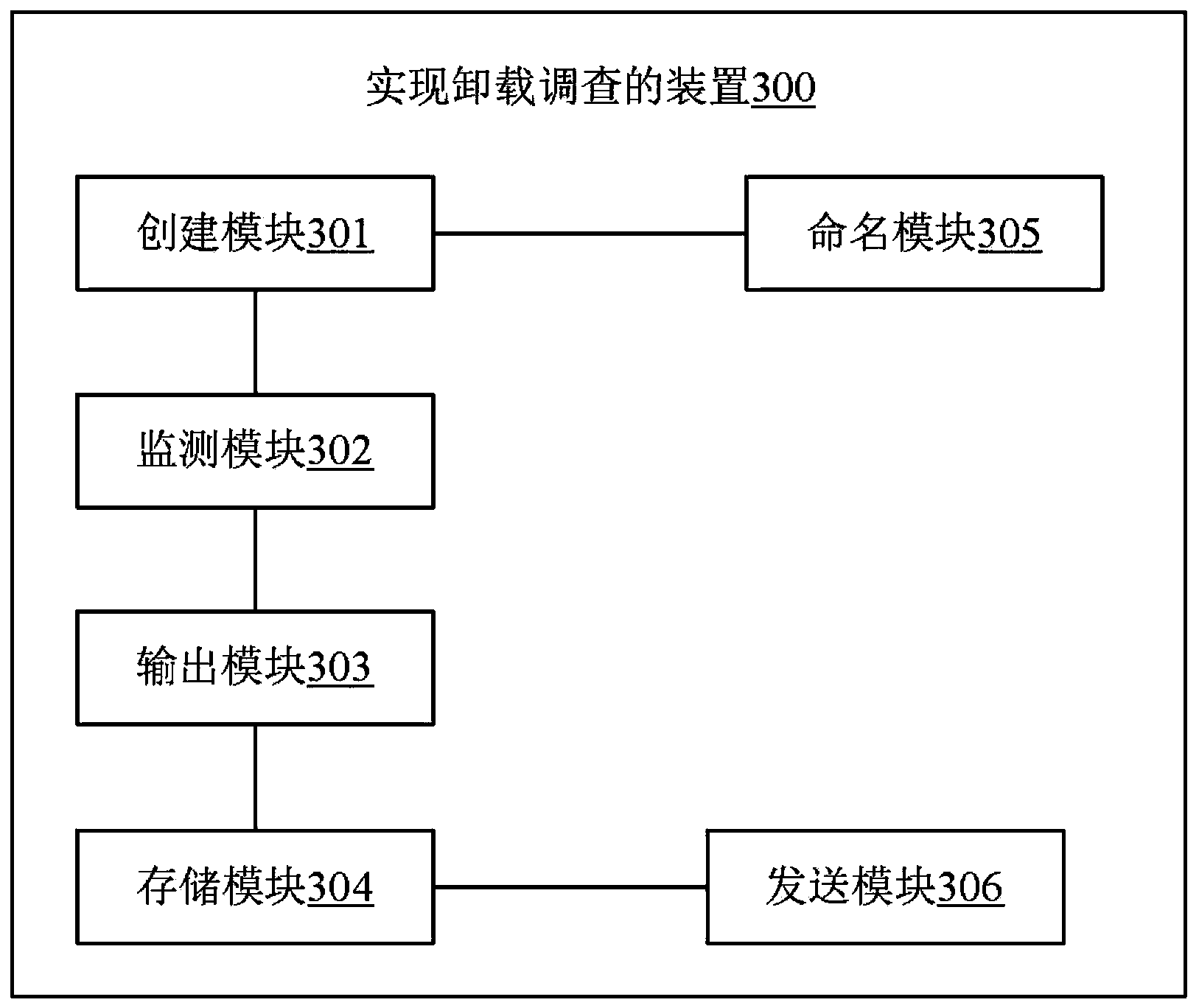

Method for realizing application uninstalling surveys

ActiveCN103761178ASolving Elasticity ProblemsEasy to collectHardware monitoringApplication softwareReal-time computing

The invention provides a method for realizing application uninstalling surveys. The method includes: creating a monitoring process; monitoring whether the appointed directory of an application is deleted or not through the monitoring process; if so, judging that the application corresponding to the appointed directory is uninstalled, and outputting a window for surveying the uninstalling reasons of the application; receiving and saving the uninstalling reasons input by a user through the window. By the method, the problem that when the application in an Android system is uninstalled, all processes are closed and popup survey is unavailable is solved, advices of users on the application can be collected conveniently by developers, and application modification can be performed.

Owner:BEIJING QIHOO TECH CO LTD

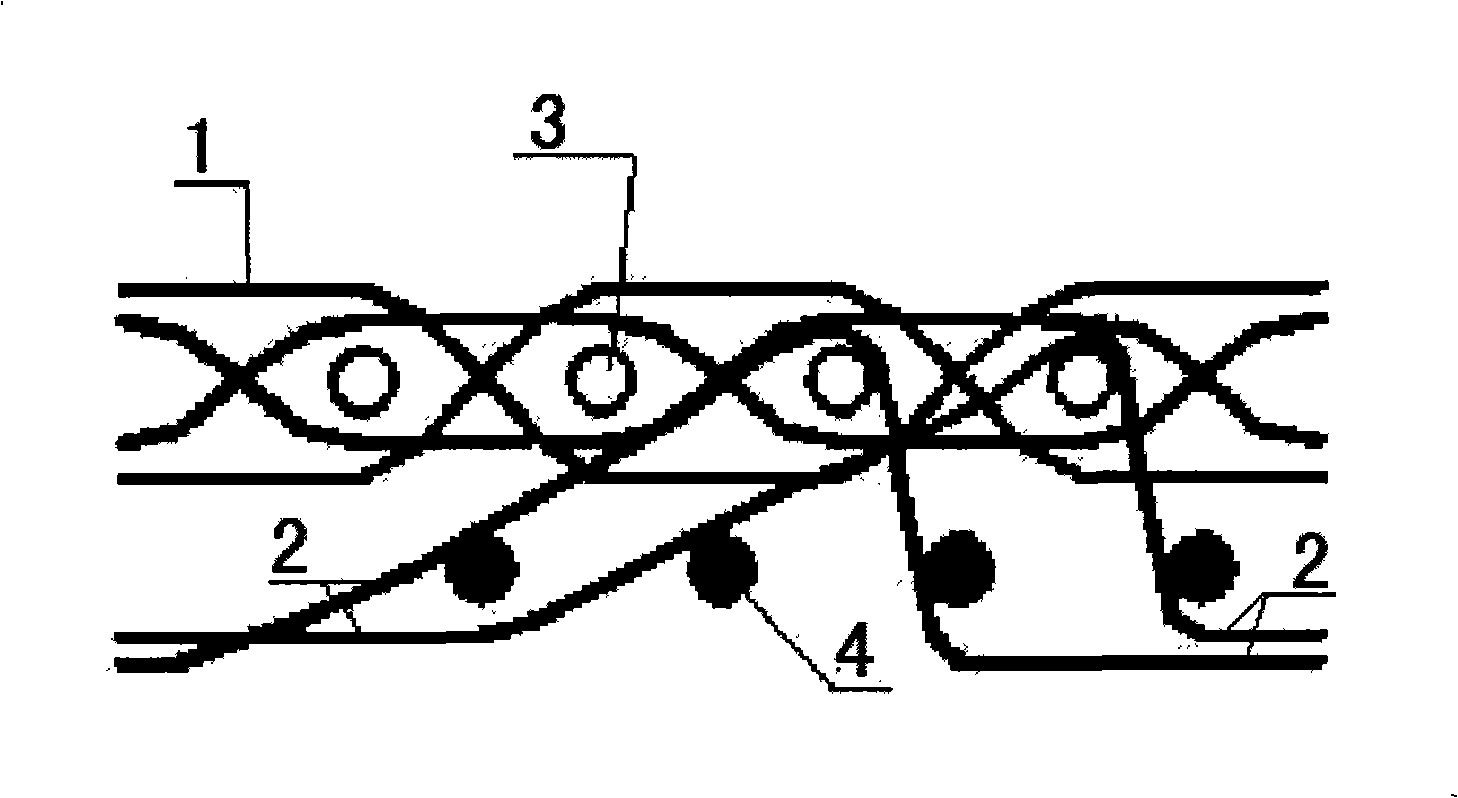

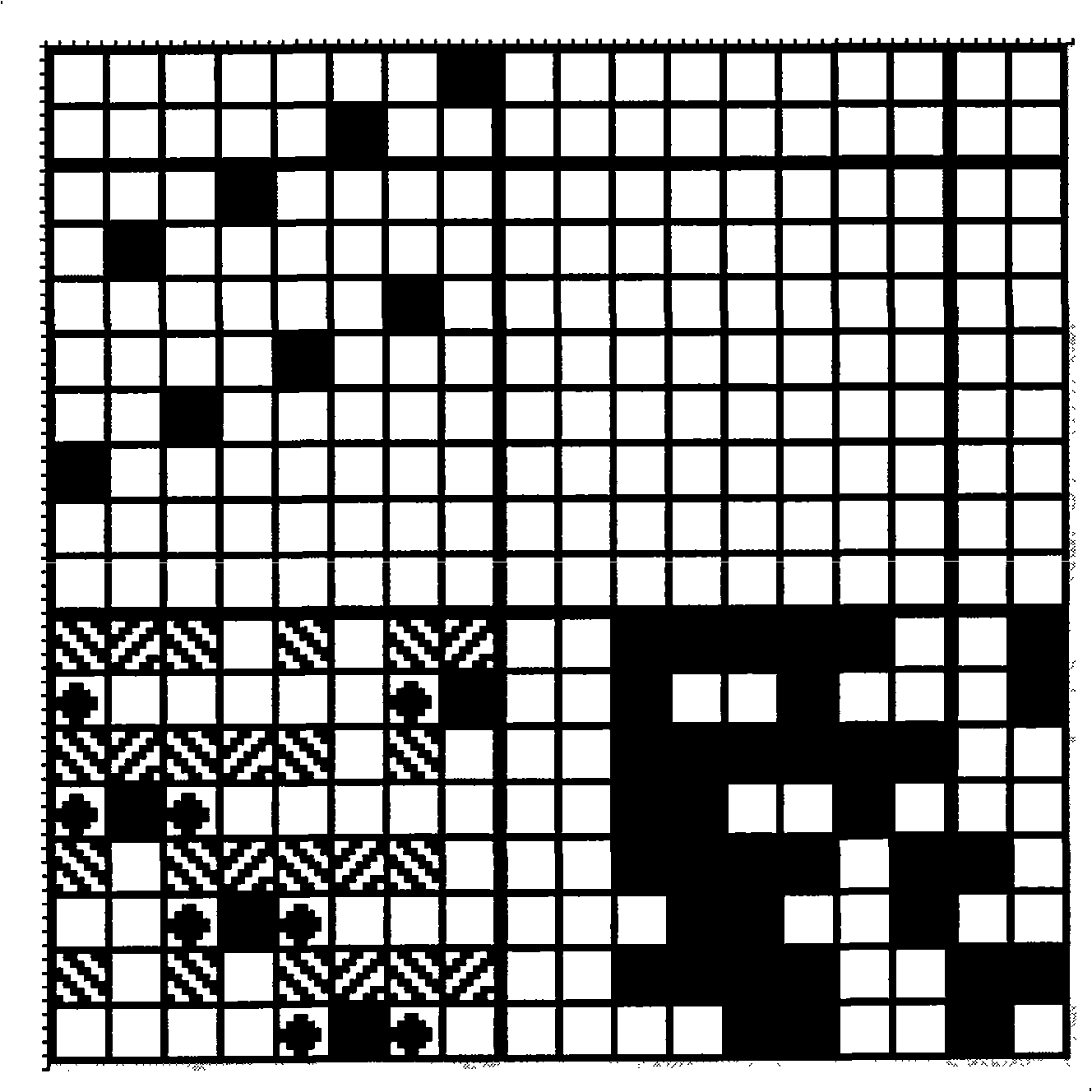

Ramie / terylene double fabric for textile wall cloth and curtain cloth and preparing method thereof

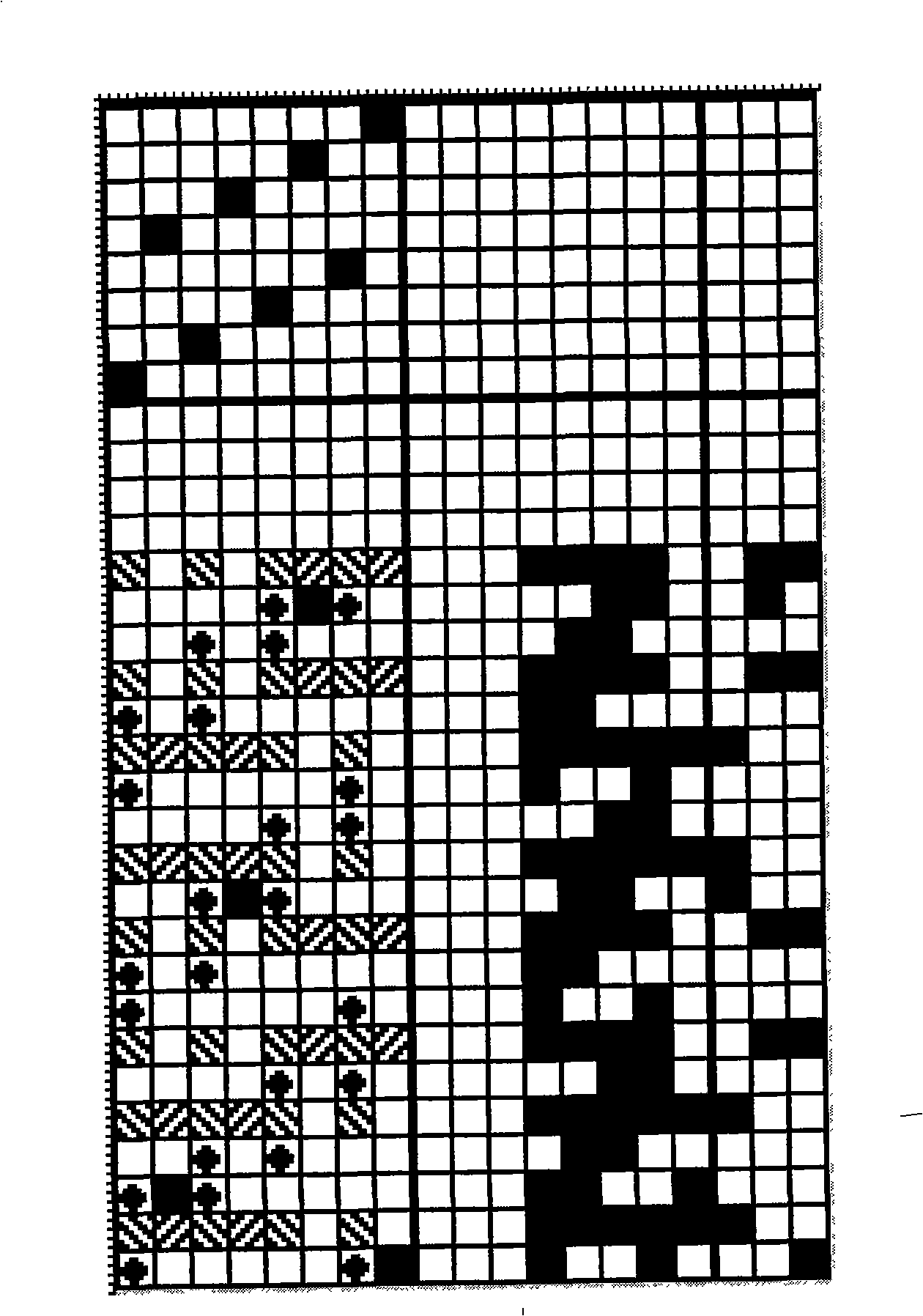

The invention relates to a ramee / terylene double woven fabric used for wall cloth and window blind fabrics, which comprises a surface layer and an inner layer, wherein, the surface layer is weaved by ramee yarns and the inner layer is weaved by terylene yarns, or the surface layer is weaved by terylene yarns and the inner layer is weaved by ramee yarns, and the surface layer and the inner layer are bond into a whole by binding joints which are not exposed on the right side and the reverse side of the fabric. The preparation method of the ramee / terylene double woven fabric adopts the ramee yarns and the terylene yarns as raw materials, and comprises a preparation procedure and a weaving procedure, and the fabric is prepared by adopting a shuttleless loom or loom with shuttles according to selected structure. When weaving by adopting the shuttleless loom, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting and winding; and when weaving by adopting the loom with shuttles, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting, winding and weft winding.

Owner:北京青山绿水苎麻制品有限公司 +1

Polyurethane resin used for skin-imitated superfine fiber synthetic leather, and preparation method thereof

The invention relates to polyurethane resin used for skin-imitated superfine fiber synthetic leather, and a preparation method thereof. The polyurethane resin used for skin-imitated superfine fiber synthetic leather is prepared from the following raw materials in percentage by weight: 6-10% of isocyanate, 16-22% of polyol compound, 1-3% of chain extender, 0.03-0.1% of terminator, 0.2-0.5% of auxiliary agent and 69-71% of N,N-dimethyl formamide. The polyurethane resin used for skin-imitated superfine fiber synthetic leather provided by the invention solves the problems that existing polyurethane resin used for napped leather has poor dyeing performance and poor rebound resilience; and the skin-imitated superfine fiber synthetic leather prepared using the polyurethane resin has the advantages of bright and uniform color, soft touch feeling, high elasticity and the like, has a touch feeling of similar skin, and can be used as decorative leather, garment leather and shoe leather.

Owner:HUADA CHEM GRP CO LTD

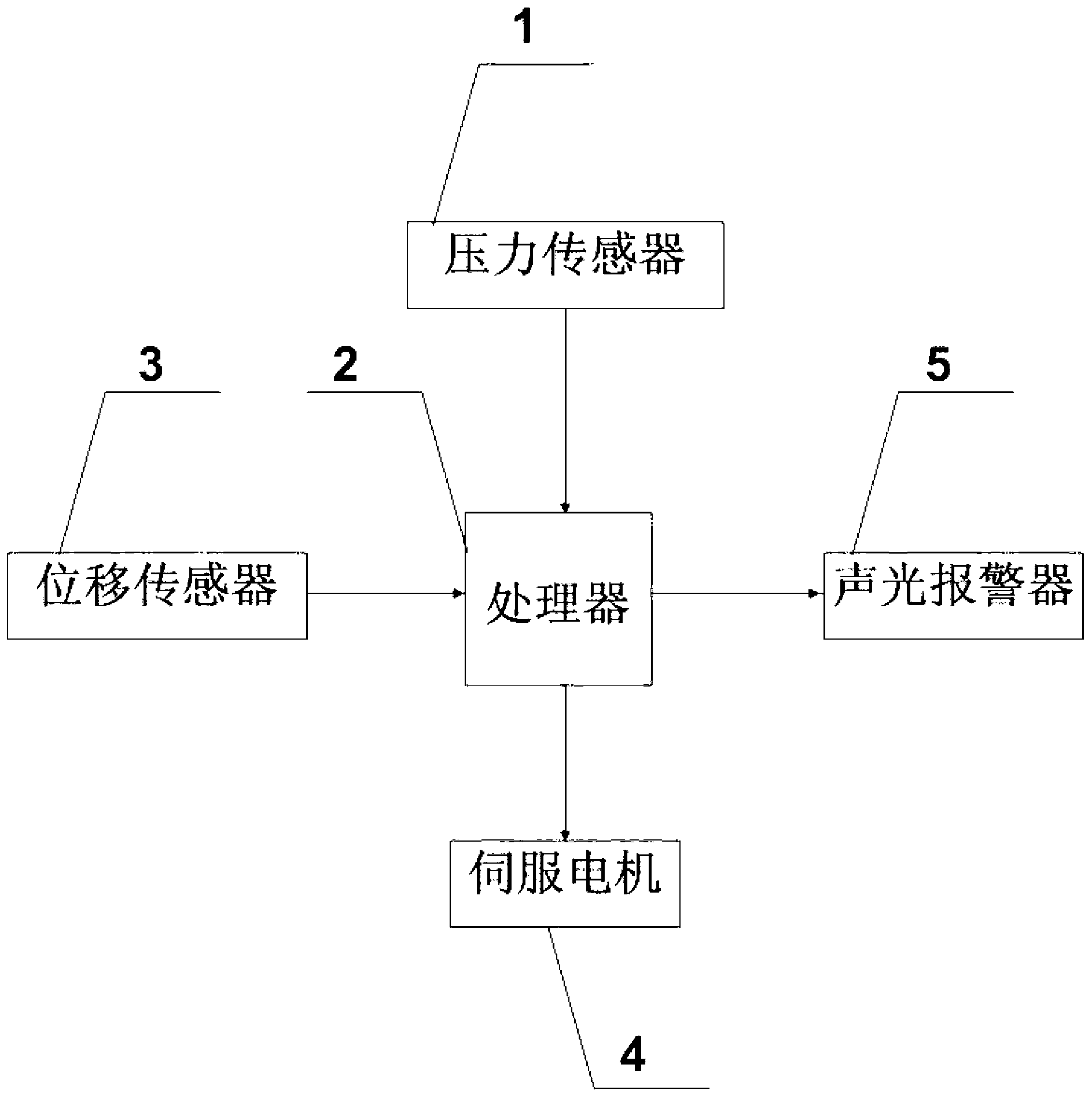

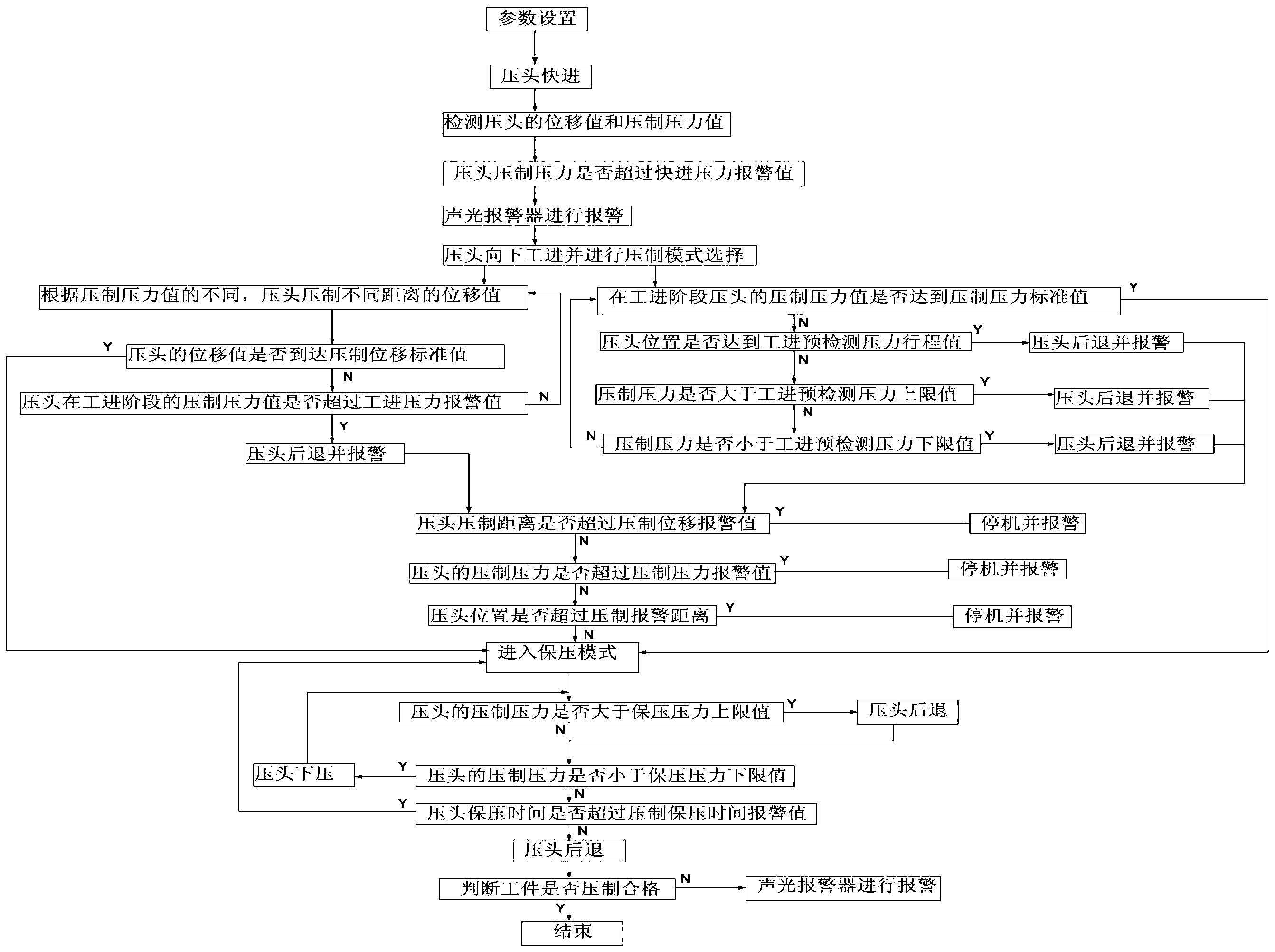

Full-route high-accuracy servo press mounting method

The invention discloses a full-route high-accuracy servo press mounting method and belongs to the technical field of numerical control machine tools. The full-route high-accuracy servo press mounting method integrates advanced technologies of servo control technology, sensing technology, industrial computer control technology and the like and solves the problem of inaccurate position and bounce of press-in workpieces of the previous production process. By means of the full-route high-accuracy servo press mounting method, pressure, speed and interference magnitude can be automatically adjusted according to different gaps, different roughness and different hardness, and stable and accurate positioning accuracy can be ensured. By monitoring the pressure and displacement during the whole pressing process, workpieces deformed elastically can be pressed accurately, errors caused by manual observation can be reduced, and qualified pressing on the workpeices deformed elastically can be ensured.

Owner:CHONGQING INST OF MECHANICAL & ELECTRICAL ENG

Non-yellowing alkali weight reduction wet-process dyed polyurethane resin for superfine fiber synthetic leather and preparation method thereof

ActiveCN102276783AImprove hydrolysis resistanceExcellent acid and alkali resistanceTextiles and paperPolyurethane elastomerAlcohol

The invention belongs to a polyurethane elastomer material and a preparation method thereof and in particular relates to non-yellowing alkali deweighting wet method dyeing polyurethane resin for superfine fiber synthetic leather and a preparation method thereof. The invention adopts the following technical scheme that: the non-yellowing alkali deweighting wet method dyeing polyurethane resin for the superfine fiber synthetic leather is characterized by mainly comprising the following components based on the total mass of the polyurethane resin: 16 to 20 percent of macromolecular dihydric alcohol compound, 2.5 to 4 percent of chain extender, 7.5 to 10.5 percent of diisocyanate and 68 to 72 percent of solvent, wherein the chain extender consists of dihydric alcohol, diamine and an alcohol amine compound. According to the above scheme, the invention provides the non-yellowing alkali deweighting wet method dyeing polyurethane resin for the superfine fiber synthetic leather and the preparation method thereof so as to solve the problems at present.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

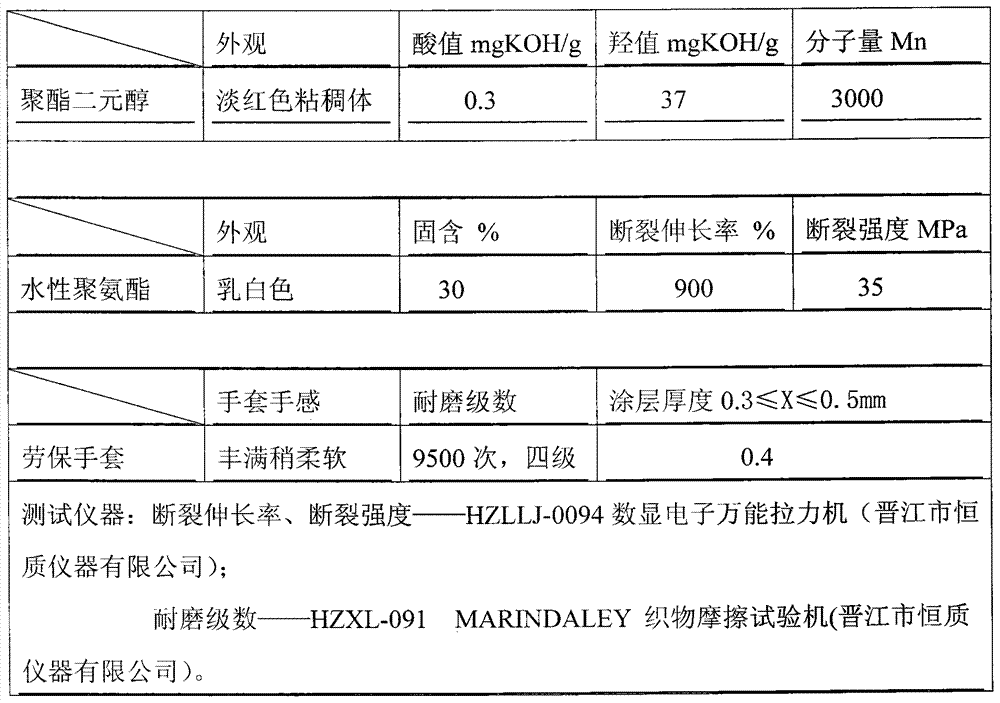

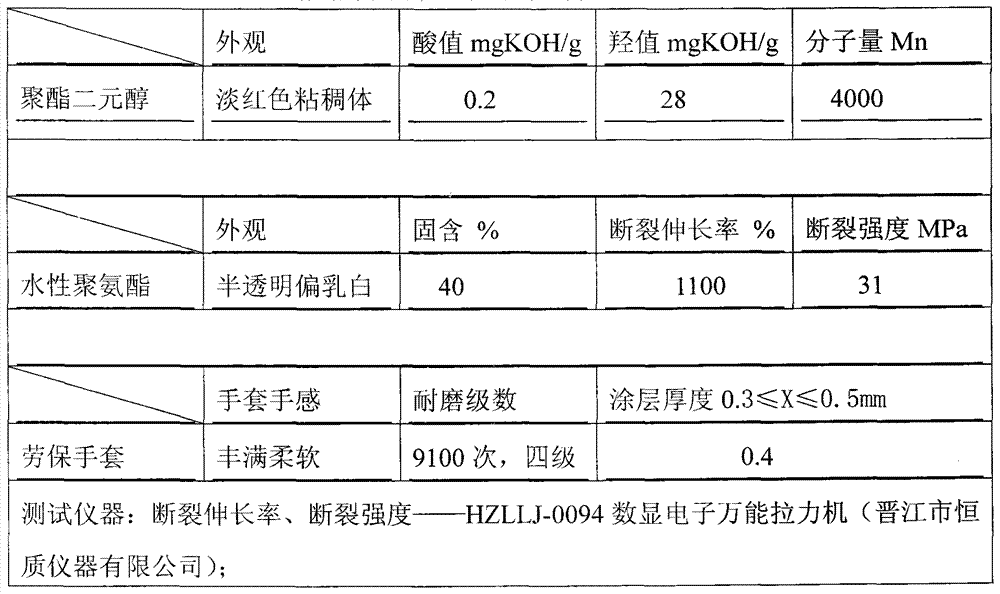

Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

InactiveCN104497258ASolve the hard feelingSolving Elasticity ProblemsAbrasion resistant fibresPolyesterSlurry

The invention discloses super-elastic wear-resisting waterborne polyurethane resin which is prepared by polymerizing polyester glycol and polyisocyanates. The invention further discloses a preparation method of the resin. By adopting the super-elastic wear-resisting waterborne polyurethane resin disclosed by the invention, slurry can be prepared to coat the surfaces of knitted gloves, so that the problems that in the prior art, knitted gloves made by using a conventional method are hard in hand feeling, poor in resilience, low in wearing resistance, and the like.

Owner:ANHUI LINGDA CHEM TECH

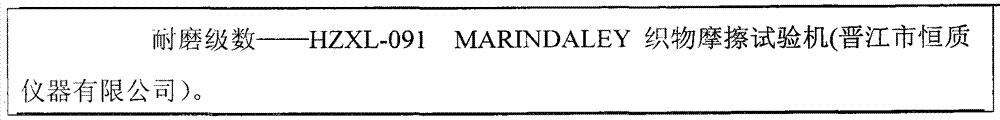

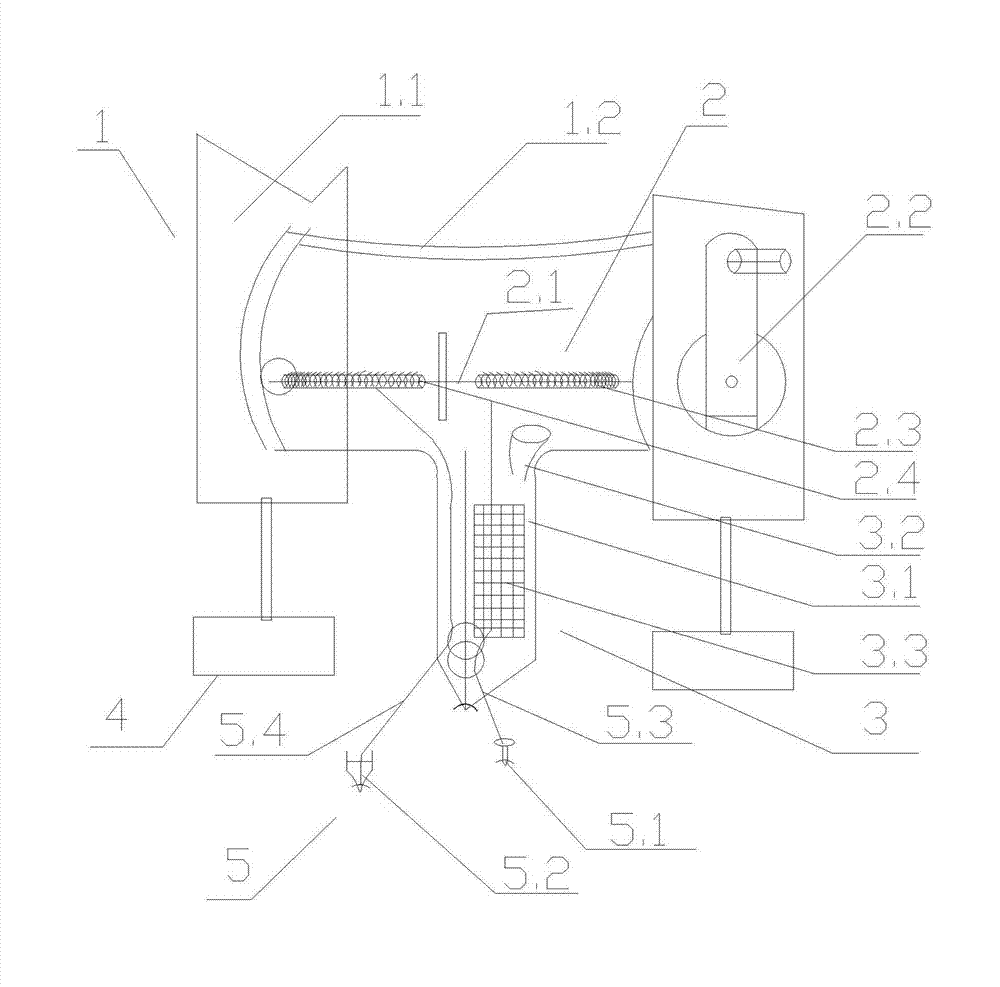

Precision control method of springback radius and springback angle for numerical control forming of bent pipe

The invention relates to a precision control method of a springback radius and a springback angle for numerical control forming of bent pipe, which comprises the steps of compensating for the springback radius first; and then compensating for the springback angle at the forming radius after the forming radius meets the forming precision. Numerical control compensation of the springback radius of the bent pipe uses a corrected die method by reduction of the bending radius so that the forming radius after springback of the bent pipe meets the precision requirement. Numerical control compensation of the springback angle of the bent pipe uses an over-bending method by over-bending of the pipe across a certain angle so that the forming angle after springback of the bent pipe meets the precision requirement. The method provided by the invention meets the pipe bending precision required by aviation standards by means of compensating for the bending radius first and then compensating for the bending angle, and has the advantages of being simple and reliable in process method, high in efficiency and low in process cost. The method can be applied to numerical control bending forming of a high-strength titanium pipe, and solves the control problems of the remarkable springback angle and the remarkable springback radius of the high-strength titanium pipe, so as to obtain the titanium pipe that meets the high precision requirement of physical dimensions.

Owner:JIANGSU NEW HENGJI SPECIAL EQUIP

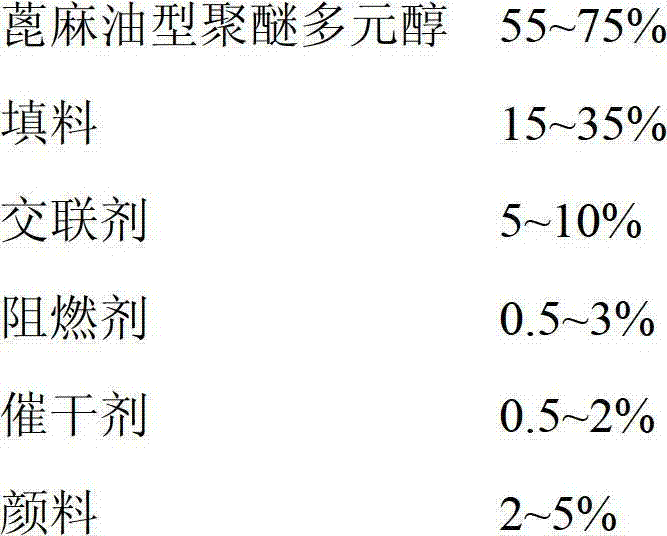

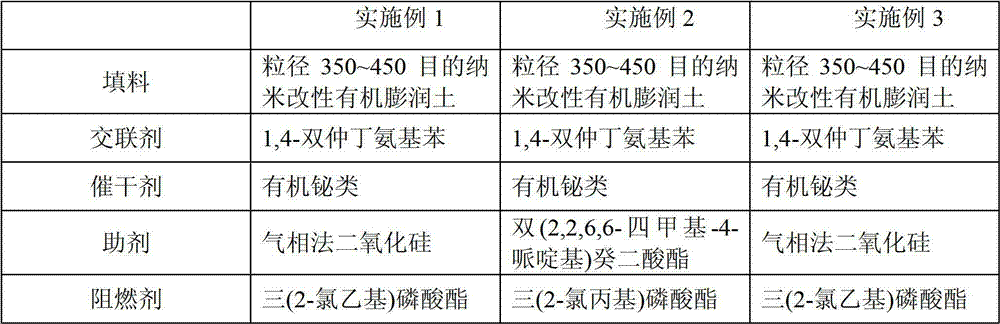

Polyurethane composition for jogging area of plastic venue and preparation method thereof

The invention relates to a polyurethane composition, in particular to a polyurethane composition for the jogging area of the plastic venue and a preparation method of the polyurethane composition. The polyurethane composition comprises the component A and the component B. The component A comprises 55-75% by mass of castor-oil type polyether polyol, 15-35% by mass of filler, 5-10% by mass of cross-linking agent, 0.5-3% by mass of flame retardant, 0.5-2% by mass of drier, 2-5% by mass of pigment, 0.1-2% of additive and 1-5% by mass of foaming agent. The component B comprises 50-60% by mass of castor-oil type polyether polyol and 40-50% by mass of isocyanate. The polyurethane composition solves the problems of high hardness, poor flexibility, low elongation, poor impact absorption performance and low vertical deformation of the conventional jogging area of the plastic venue, can better protect the joints of the athletes in the warm-up process and is beneficial to improving the competition achievements of the athletes. The preparation method of the polyurethane composition is easy and practical and is easy to implement.

Owner:SHANDONG INOV POLYURETHANE

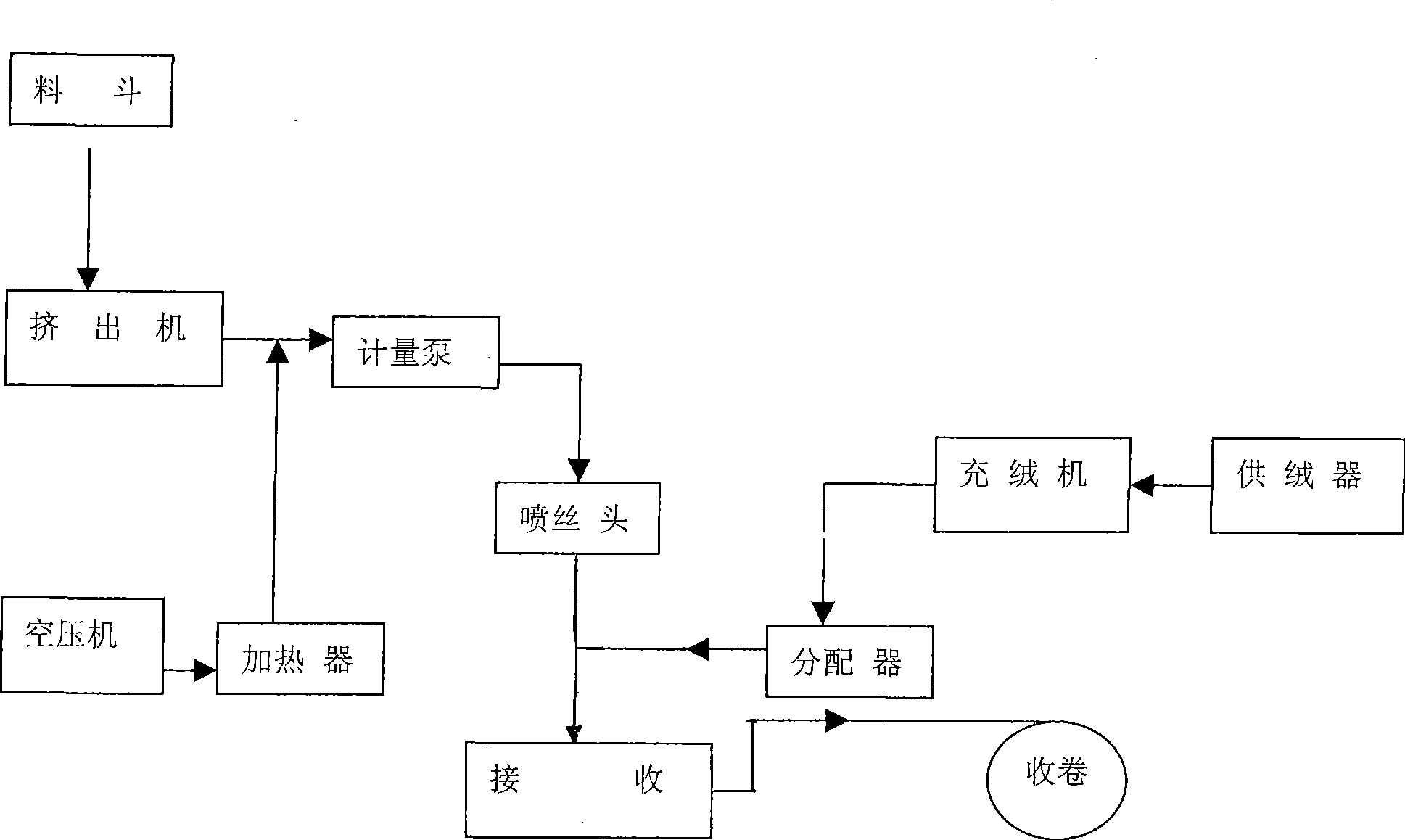

Method for producing melt-blown nonwoven down dual constituent thermal insulating interlining

InactiveCN101392432AHigh resilienceHigh longitudinal and transverse tensile strengthNon-woven fabricsMolten stateInterlining

The invention relates to a method for forming dual-component heat-insulating wadding by combining molten-spraying nonwoven fabrics and down. Specifically, the method comprises the following steps: heating polymer resin slices into molten state, then extruding, measuring and distributing the resin slices evenly to a hole of a spinneret device, and then stretching the resin slices into superfine fiber by hot air. Then the down is adhered with polymer fiber which is treated with fiber-stretching and is still not cured so as to form a net after being distributed by loosening, velvet-supplying and velvet-filling , and then a receiver and a finishing reel wind the net into the wadding. The invention adds down material into the existing molten-spraying production process, which can improve the heat-insulating rate and rebound elasticity of the wadding and can improve the transverse and longitudinal tensile strength of the wadding.

Owner:郭武胜

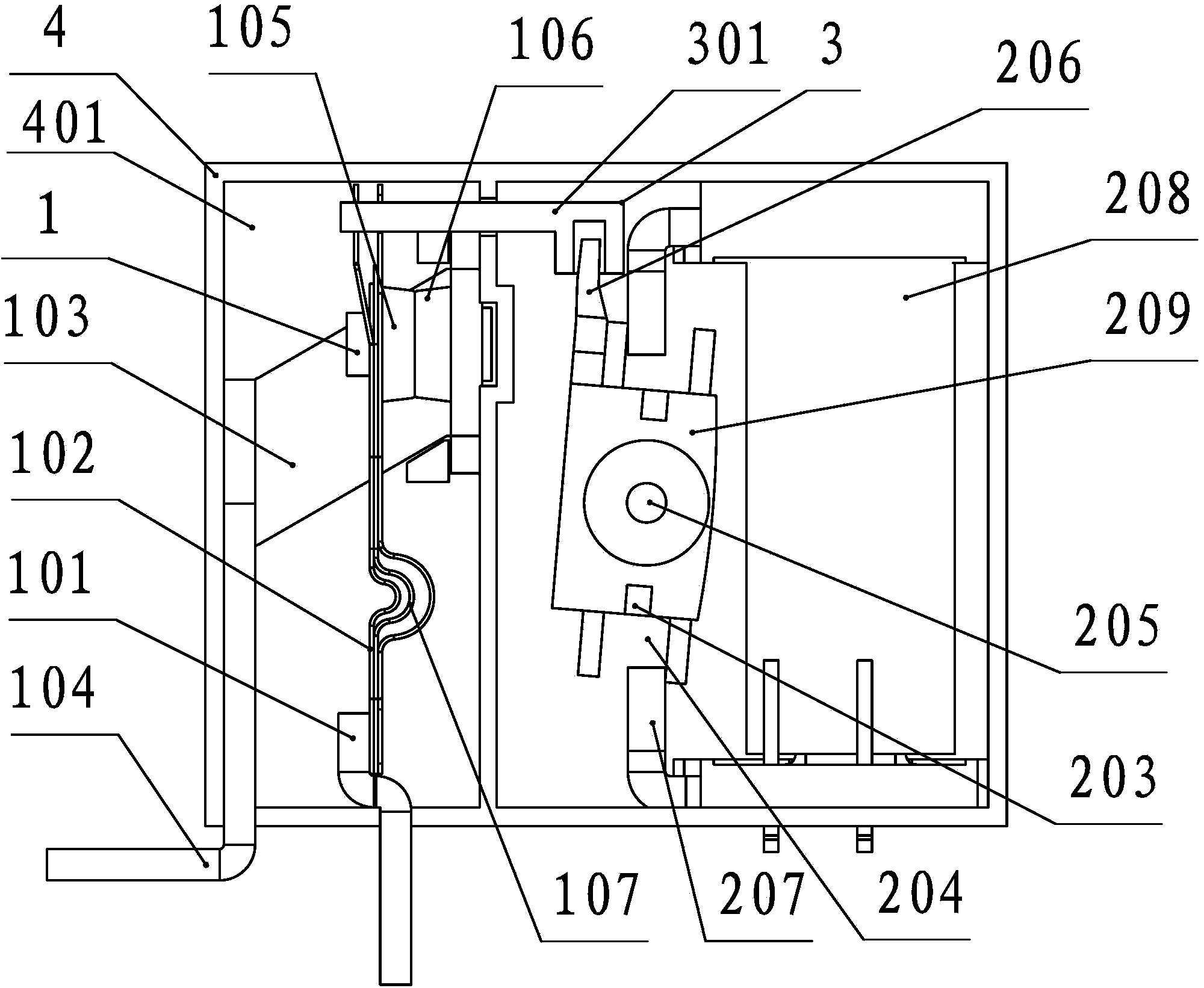

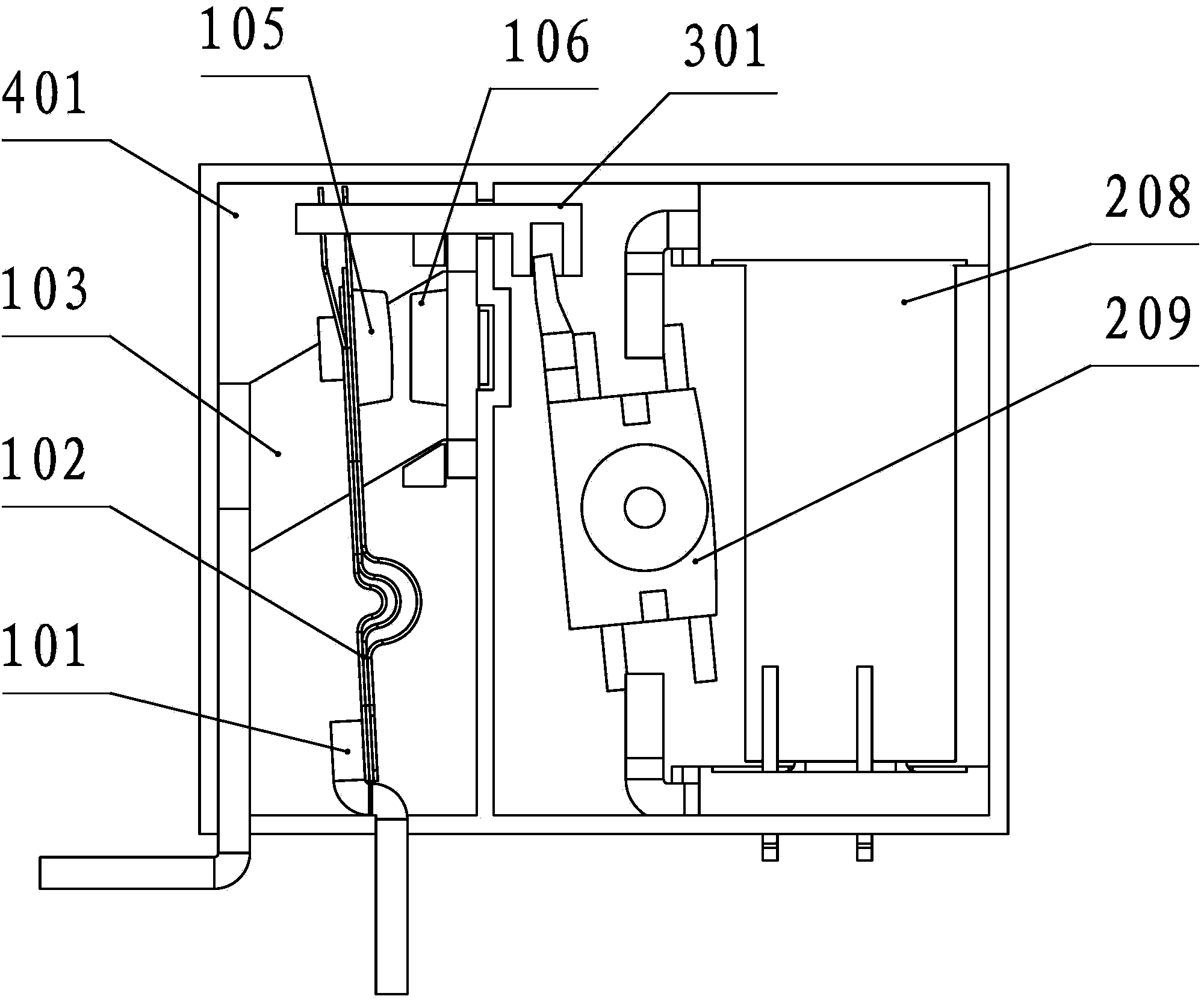

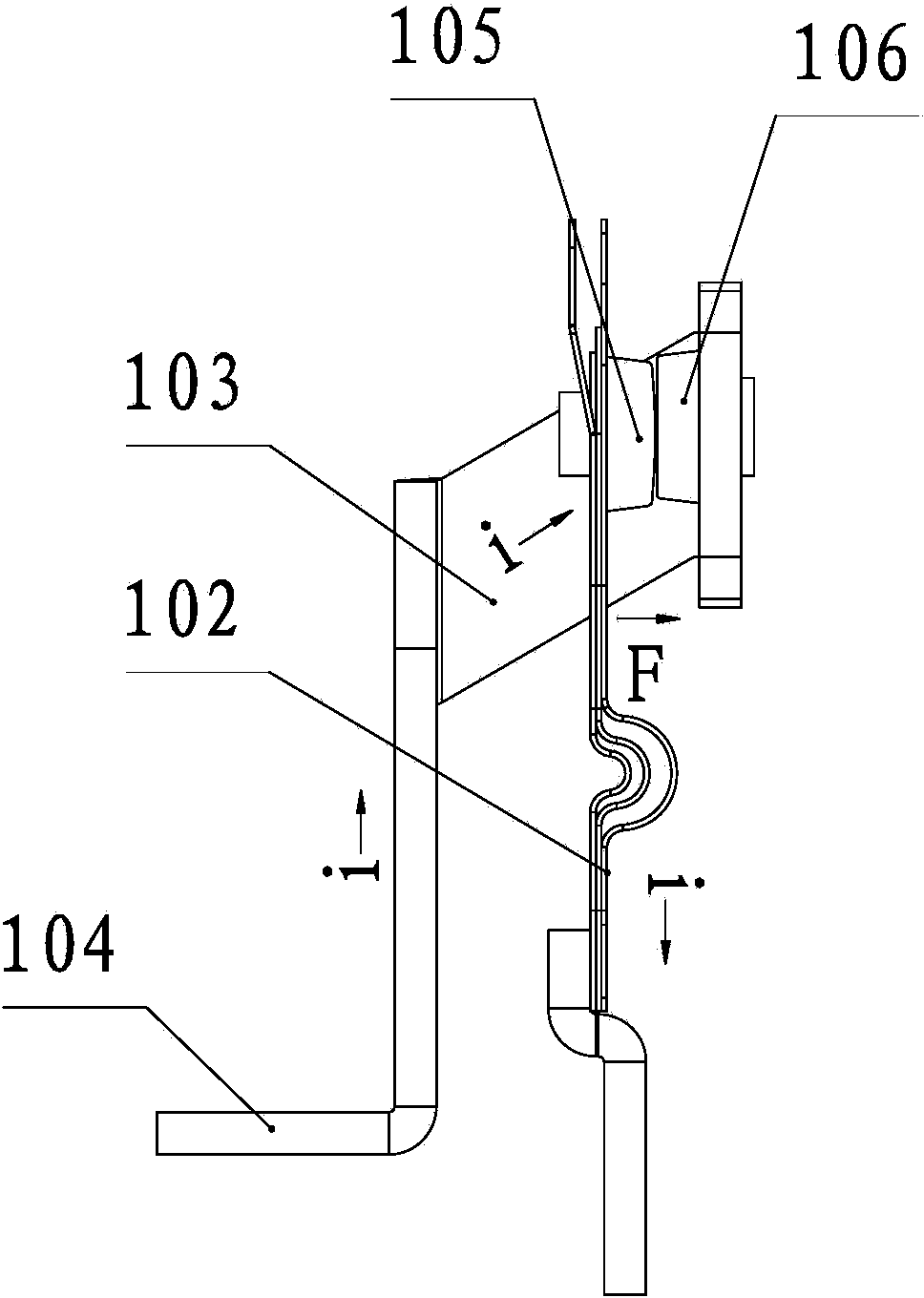

Relay capable of preventing large-current contact separation

A relay capable of preventing large-current contact separation comprises a shell, a contact system, an electromagnetic system and pushing part, wherein the contact system, the electromagnetic system and the pushing part are arranged in the shell. The contact system comprises a static piece provided with a static contact and a movable contact spring provided with a movable contact; the movable contact spring is connected with the pushing part which is connected with the electromagnetic system, the electromagnetic system drives the movable contact spring to swing through the pushing part to have the movable contact and the static contact separated or jointed, the static piece is of a U-shaped structure, the static contact is arranged on the inner wall of the U-shaped structure, the movable contact spring extends into the cavity of the U-shaped structure, the movable contact is arranged corresponding to the static contact 106, and the direction of electrodynamic force F is the direction from the movable contact to the static contact when the contact system is closed. The relay is simple in structure and low in cost; by the arrangement of the static piece of the U-shaped structure, the electrodynamic force F is enabled to push the movable contact to press the static contact when the contact system is closed, and problems about the contact separation and bouncing of the contacts during large current can be effectively solved.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

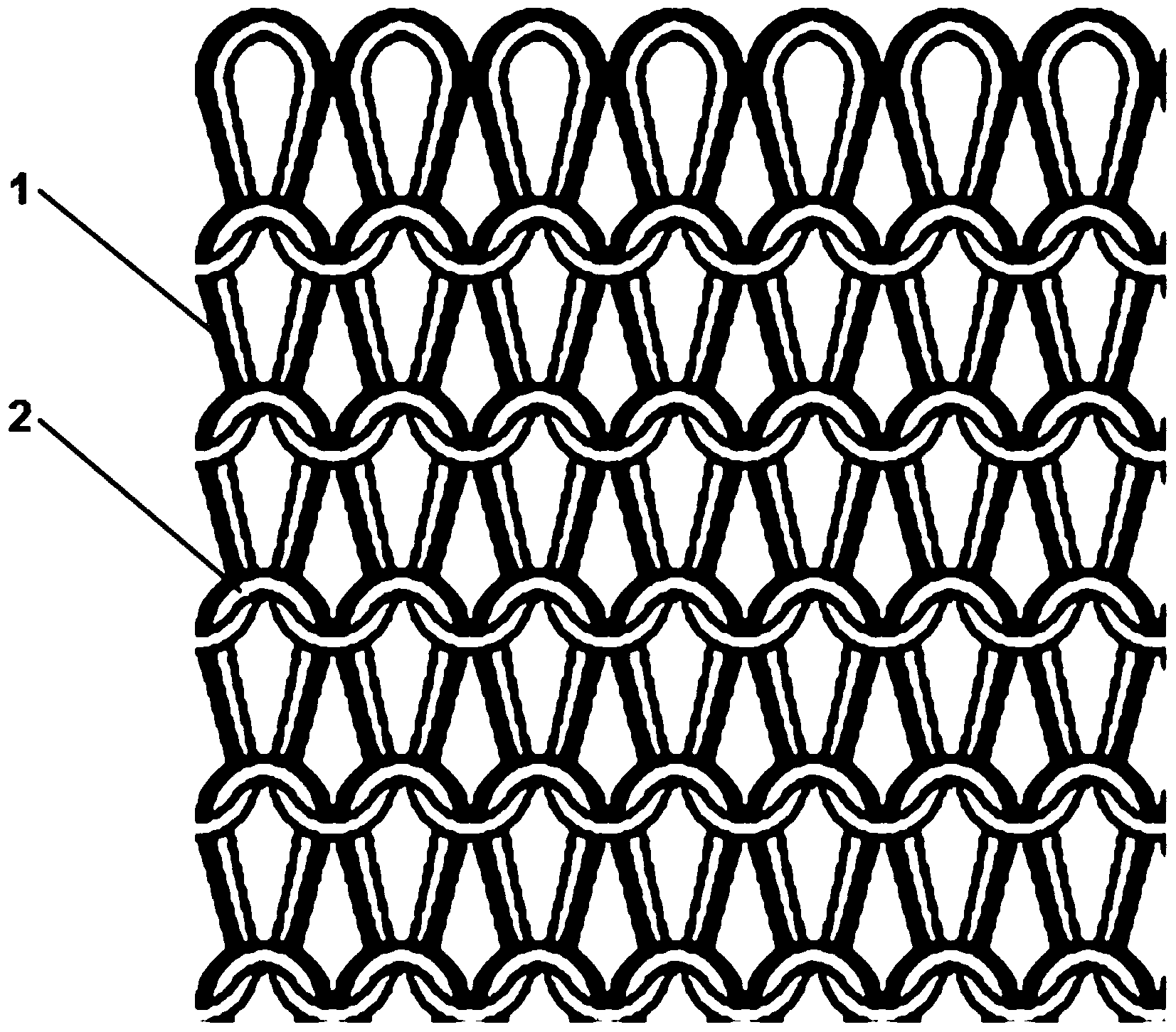

Purl high-density functional knitted fabric and manufacturing method thereof

ActiveCN104223382AGood moisture absorptionImprove dehumidification effectSucessive textile treatmentsWeft knittingBursting strengthHigh density

The invention provides a purl high-density functional knitted fabric and a manufacturing method thereof. The fabric is of a knitted structure formed by interweaving regenerated cellulose fibers and synthetic fibers; the synthetic fibers include first synthetic fibers and second synthetic fibers; the regenerated cellulose fibers and the first synthetic fibers are positioned on the front surface of the fabric by virtue of blending and cover the second synthetic fibers positioned at the back surface of the fabric. The invention further provides a manufacturing method of the hurl high-density functional knitted fabric. The hurl high-density functional knitted fabric does not contain cotton fibers, but has the smooth and soft hand feeling and wearing comfort of cotton fibers, furthermore is bright in color and full in appearance, has an antibiotic function, a deodorizing function, a moisturizing function and the like and can be used for solving the problems of poor bursting strength and insufficient elasticity of a common fiber fabric.

Owner:NINGBO DAQIAN TEXTILE

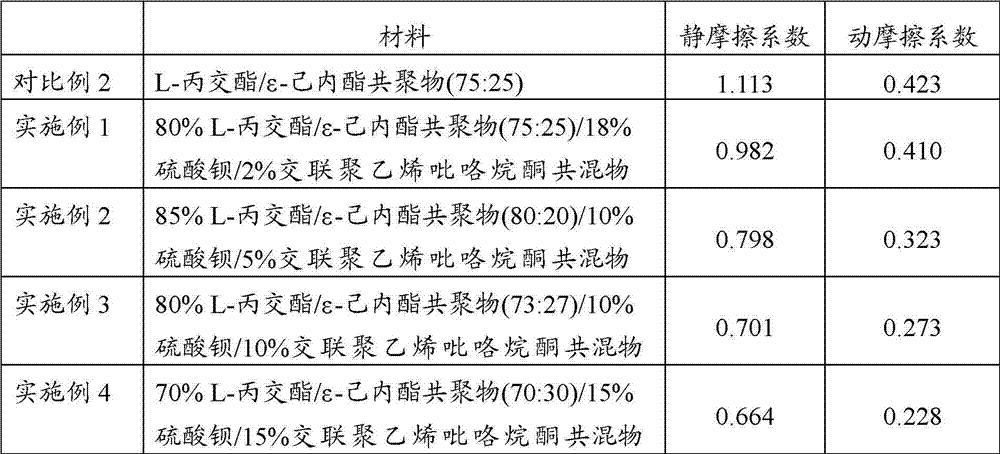

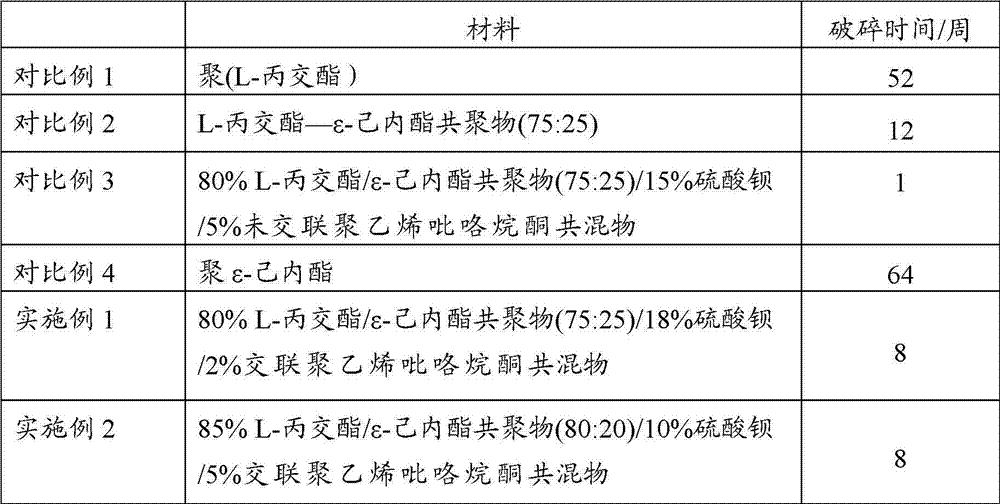

Composite material for making degradable ureteral stent and application thereof

ActiveCN103041454AIncreased degradation rateAvoid cloggingStentsSurgeryBiocompatibility TestingCross-linked polyethylene

The invention provides a kind of composite material for making a degradable ureteral stent, comprising: 60-98% by weight of L-lactide / Epsilon-caprolactone copolymer, and 2-40% by weight of polyvinylpolypyrrolidone. The L-lactide / Epsilon-caprolactone copolymer in the composite material is elastomeric material with good biocompatibility, and the polyvinylpolypyrrolidone can reduce a surface friction coefficient of the prepared degradable ureteral stent, and simultaneously raises the degradation speed of the degradable ureteral stent. The invention also discloses a degradable ureteral stent prepared by the composite material. The degradable ureteral stent has good biocompatibility, is easy to degrade, and can be used in an operation in urinary surgery.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +2

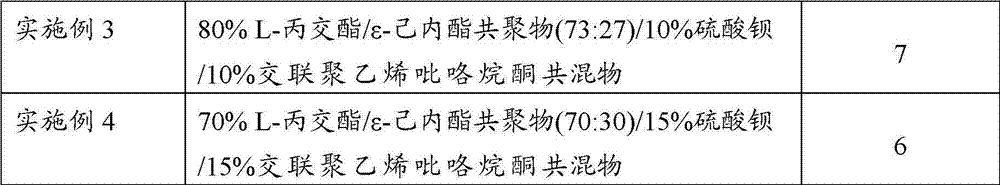

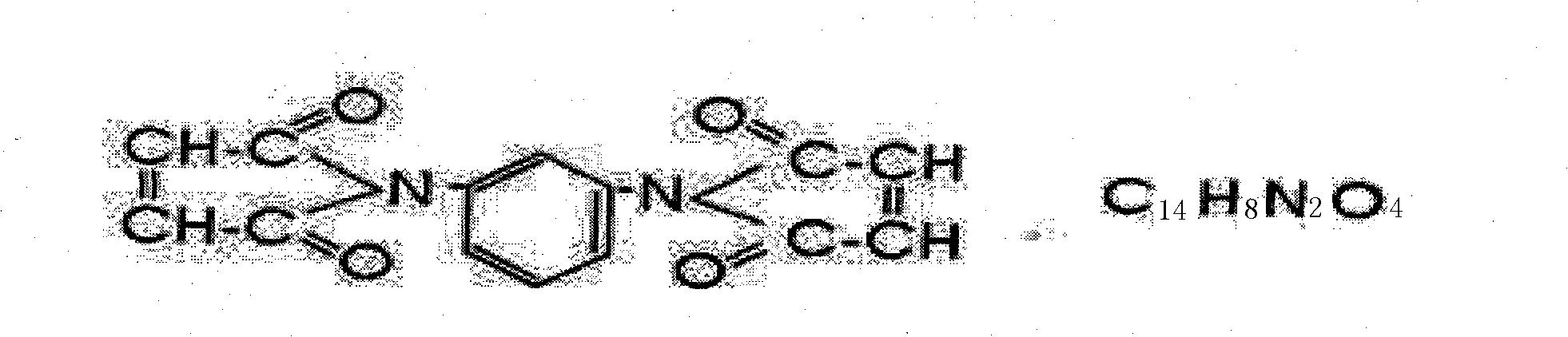

Preparation method of N,N'-m-phenylenebismaleimide

ActiveCN101805280ASolve the hardnessSolving Elasticity ProblemsOrganic chemistryPolymer scienceAcetic anhydride

The invention relates to a preparation method of N,N'-m-phenylenebismaleimide (HA-8). The preparation method is mainly technically characterized by firstly adding m-phenylenediamine in a reaction kettle equipped with a stirrer and a thermometer, then adding a solvent, stirring for fully dissolving the m-phenylenediamine, further adding maleic anhydride, keeping the temperature for 2 hours after completion, then adding acetic anhydride, completing the reaction, further evaporating, recovering the solvent of acetone, finally carrying out centrifugal washing for obtaining a crude product, drying, smashing and obtaining a finished product. The yield is calculated to be 91.5% by taking the m-phenylenediamine as a standard substance. The product is mainly used in natural rubber and various types of synthetic rubber, and can prevent reversion by being matched with sulfur, improve the heat resistance and the anti-aging property, reduce the heat production of the rubber and improve the bonding property between the rubber and metal fabric.

Owner:咸阳三精科技股份有限公司

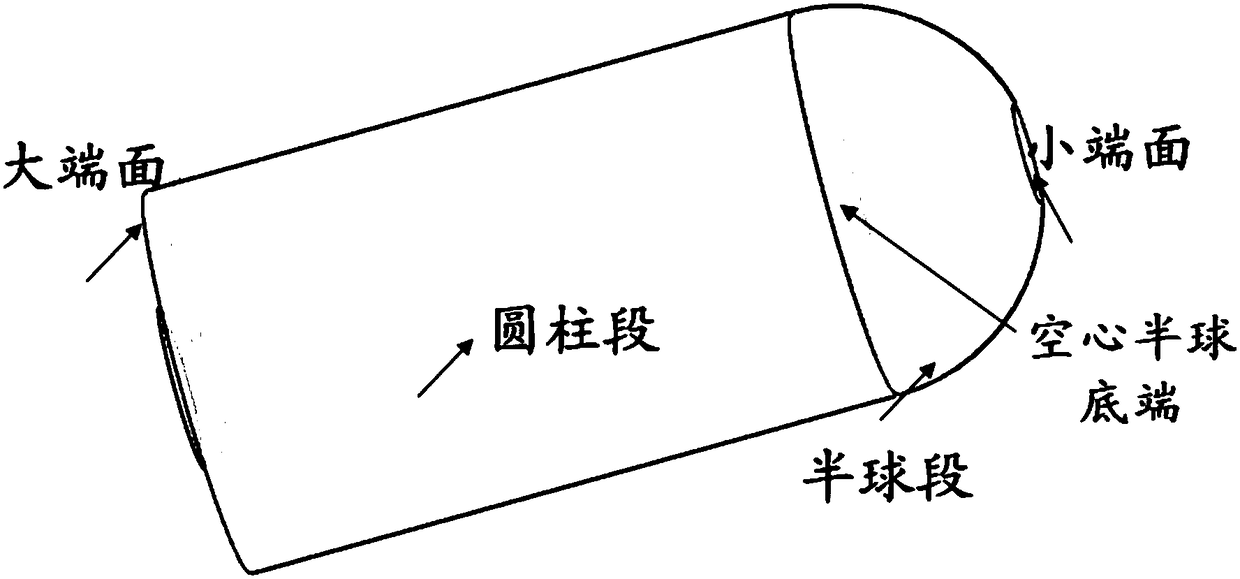

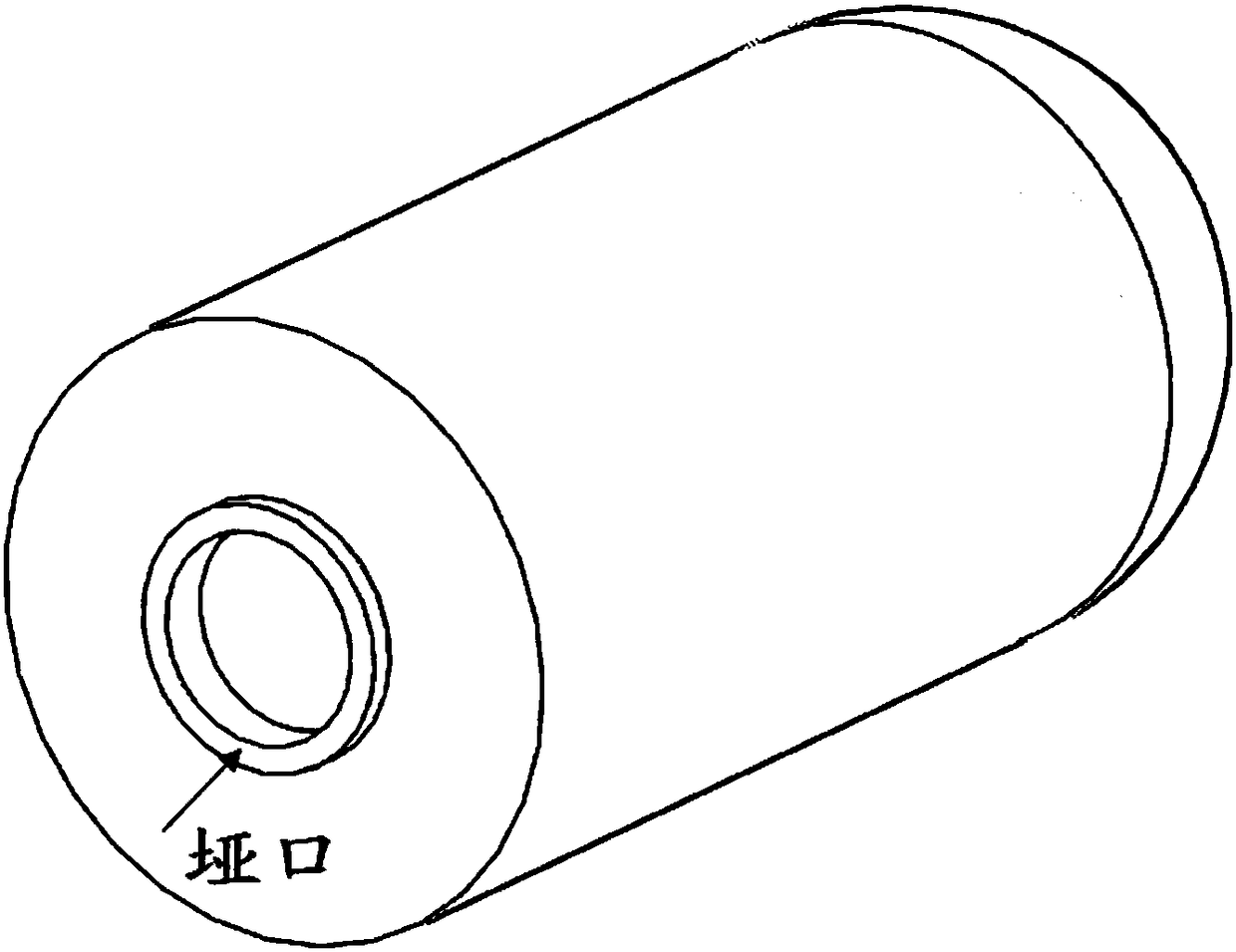

Spinning forming method for large-diameter ratio thin-walled aluminum alloy special-shaped member

The invention relates to a spinning forming method for a shell of a large-diameter ratio thin-walled aluminum alloy special-shaped member for aerospace, and belongs to the technical field of storage tank forming. A circular plate blank is adopted, precise numerical control spinning forming of the shell of the large-diameter ratio thin-walled aluminum alloy special-shaped member is directly carriedout, and auxiliary processes such as pre-forming and intermediate heat treatment are not required; and through process design and precise control, a spinning path is adopted, specifically, firstly, 11-times (hot strong spinning-hot normal spinning) forming is alternately performed in a circulating mode, and then finishing is carried out through one-time hot strong spinning. Only one set of spinning dies is needed, one-time loading clamping is needed, precise spinning forming of the shell of the large-diameter ratio thin-walled aluminum alloy special-shaped member can be achieved in one numerical control program, the process flow is shortened, the production efficiency is improved, the forming precision of the member can be greatly improved, the unilateral clearance between the inner profile of the shell of the formed special-shaped member and the theoretical profile template is less than 0.1mm, and the wall thickness difference is less than 0.2mm.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

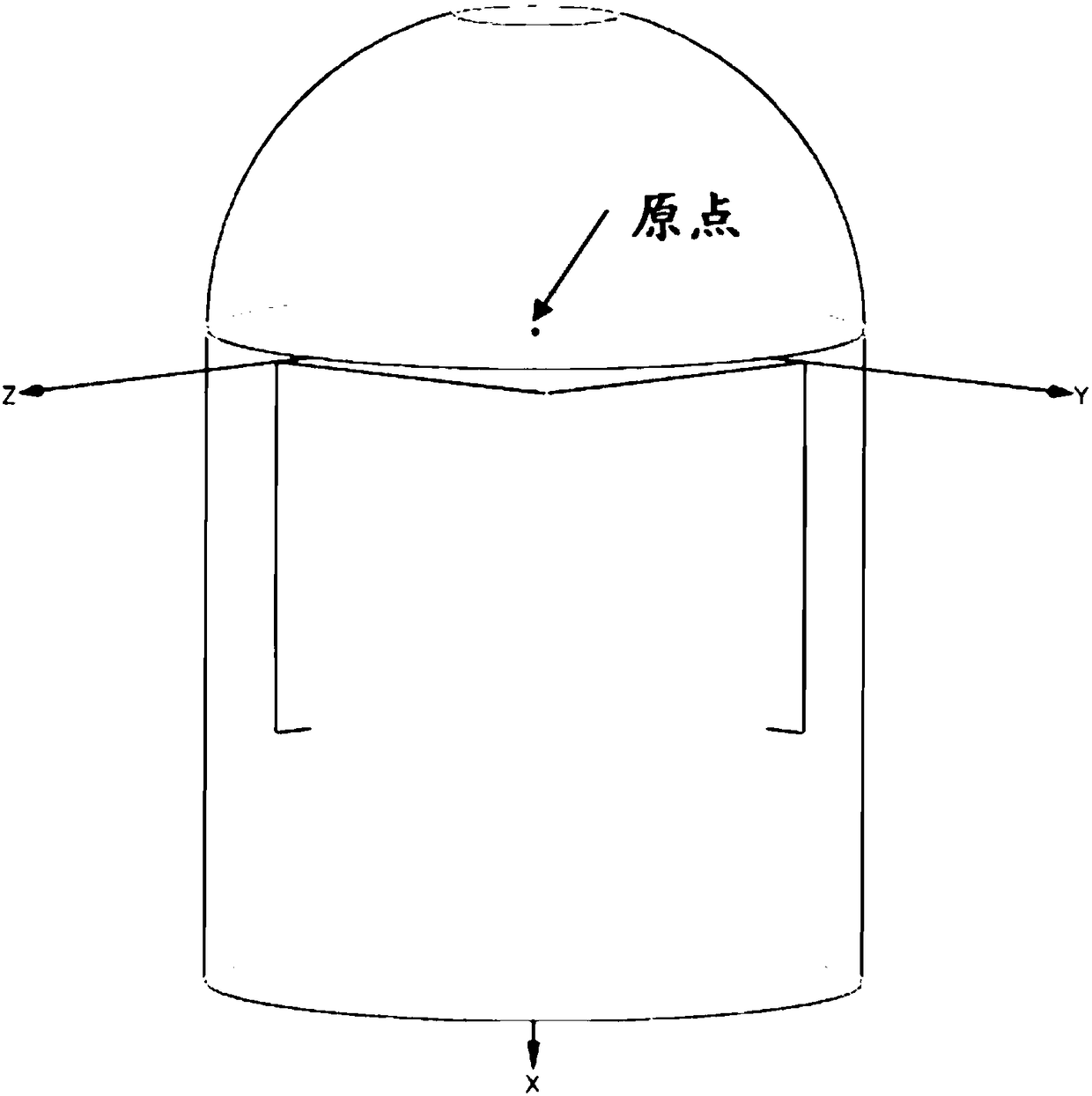

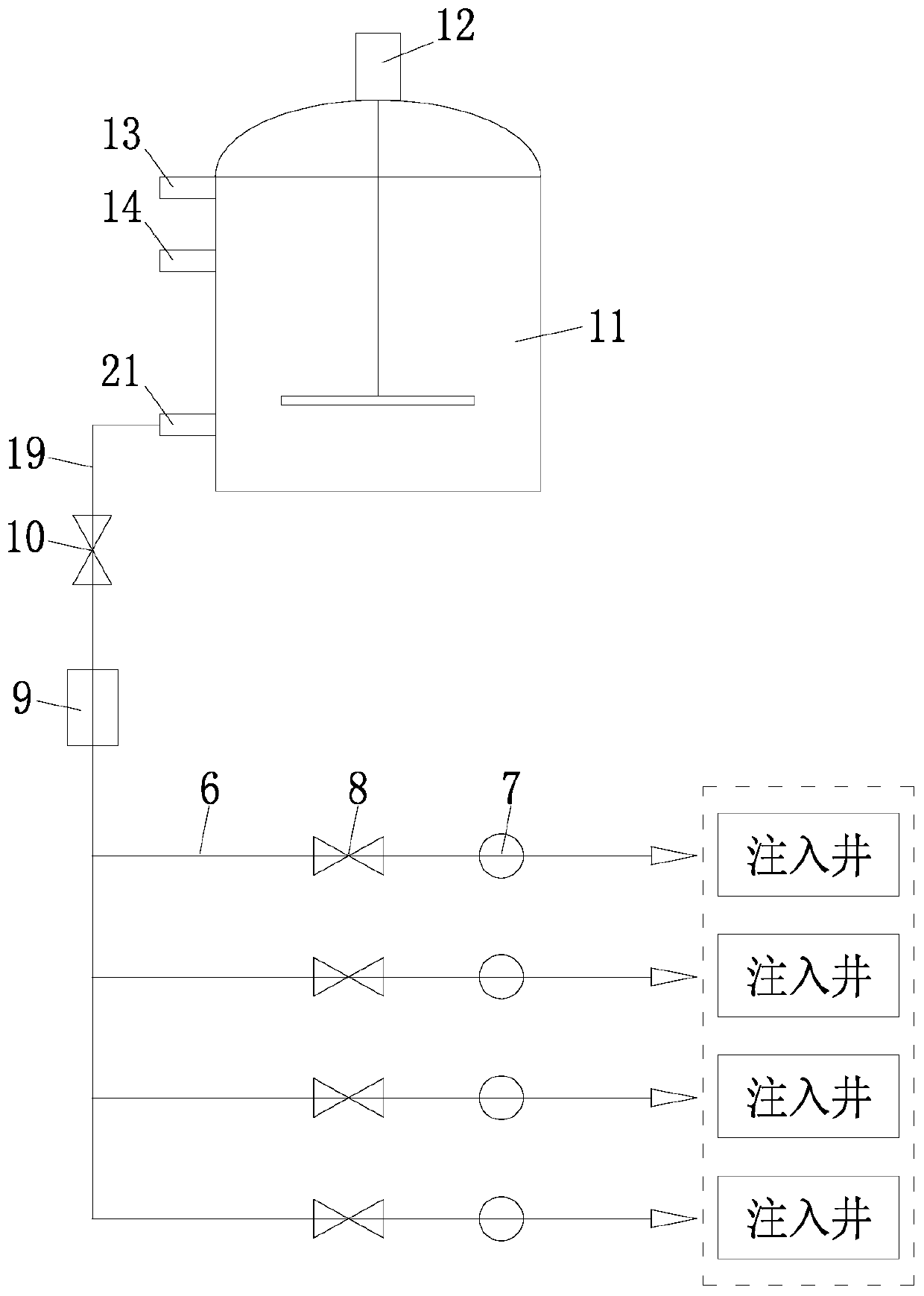

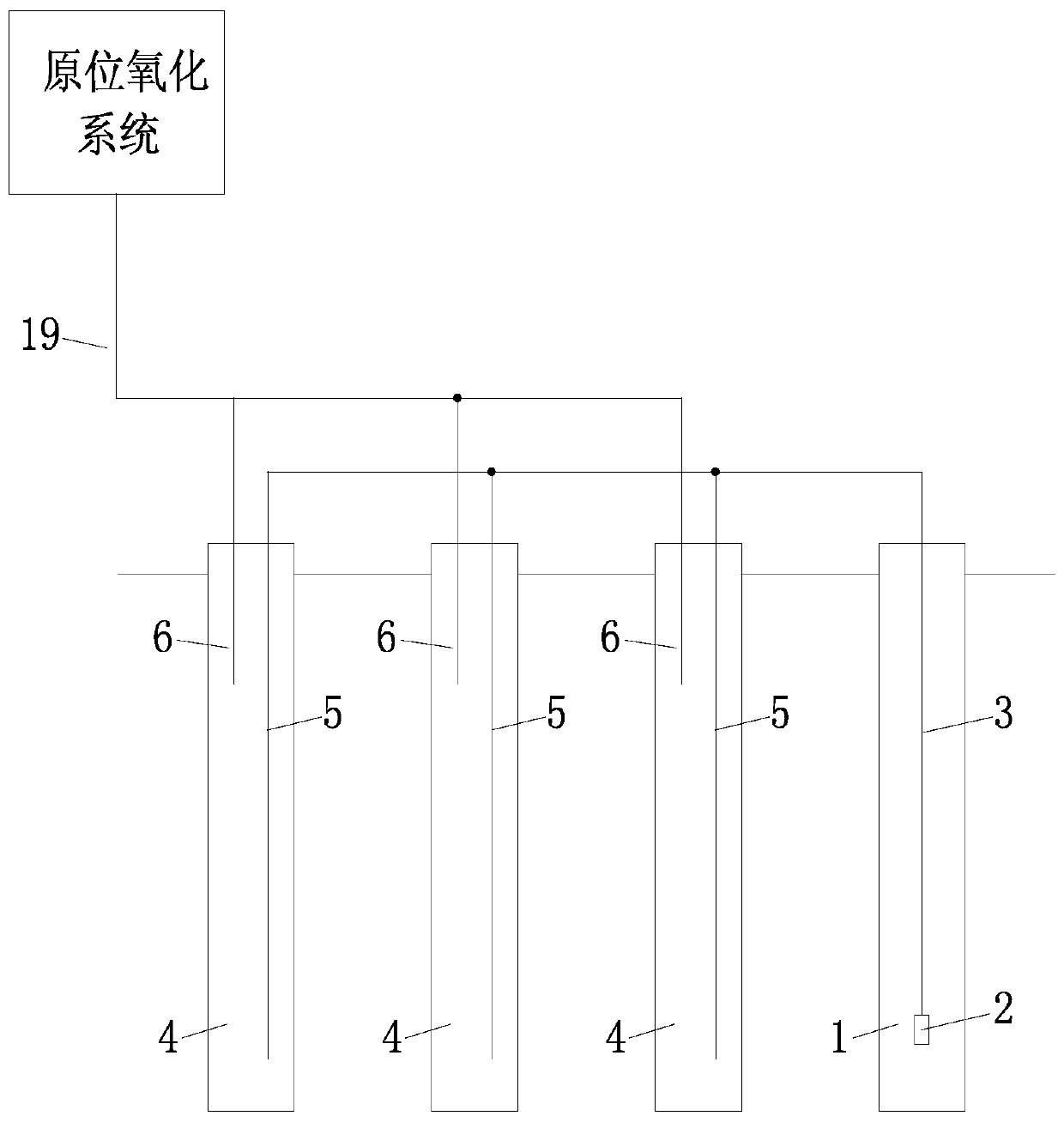

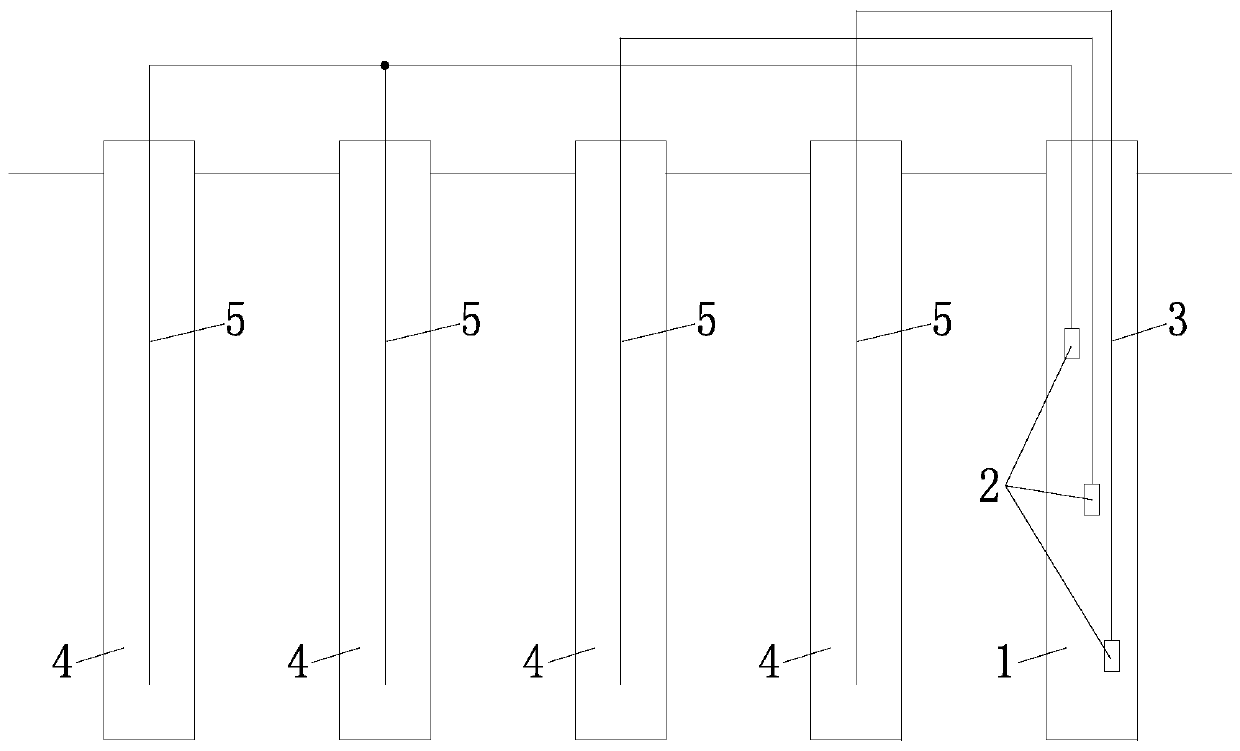

In-situ oxidation circulation extraction remediation system and remediation method for organic contaminated underground water

PendingCN111003792ASolve the \"smear phenomenon\"Solving Elasticity ProblemsWater treatment parameter controlWater contaminantsInjection wellGroundwater pollution

The invention belongs to the field of groundwater pollution remediation. A purpose of the invention is to provide an in-situ oxidation circulation extraction remediation system and a remediation method for organic contaminated underground water. According to the system and the method, the real-time monitoring and evaluation of the in-situ oxidation remediation effect of organic polluted underground water can be realized, the agent adding frequency is effectively guided, the secondary pollution risk is reduced, the agent cost is saved, and the construction period is shortened. According to thetechnical scheme, the in-situ oxidation circulation extraction remediation system for organic polluted underground water comprises an in-situ oxidation system, a circulation extraction system and a monitoring system, wherein the circulation extraction system comprises an extraction well arranged in an organic pollution area, an injection well arranged around the extraction well, at least an extraction pump arranged in the extraction well, at least an extraction pipe extending into the extraction well and communicated with the extraction pump, and a circulation injection pipe extending into theinjection well and communicated with the extraction pipe.

Owner:ZHEJIANG ZONE KING ENVIRONMENTAL SCI&TECH CO LTD

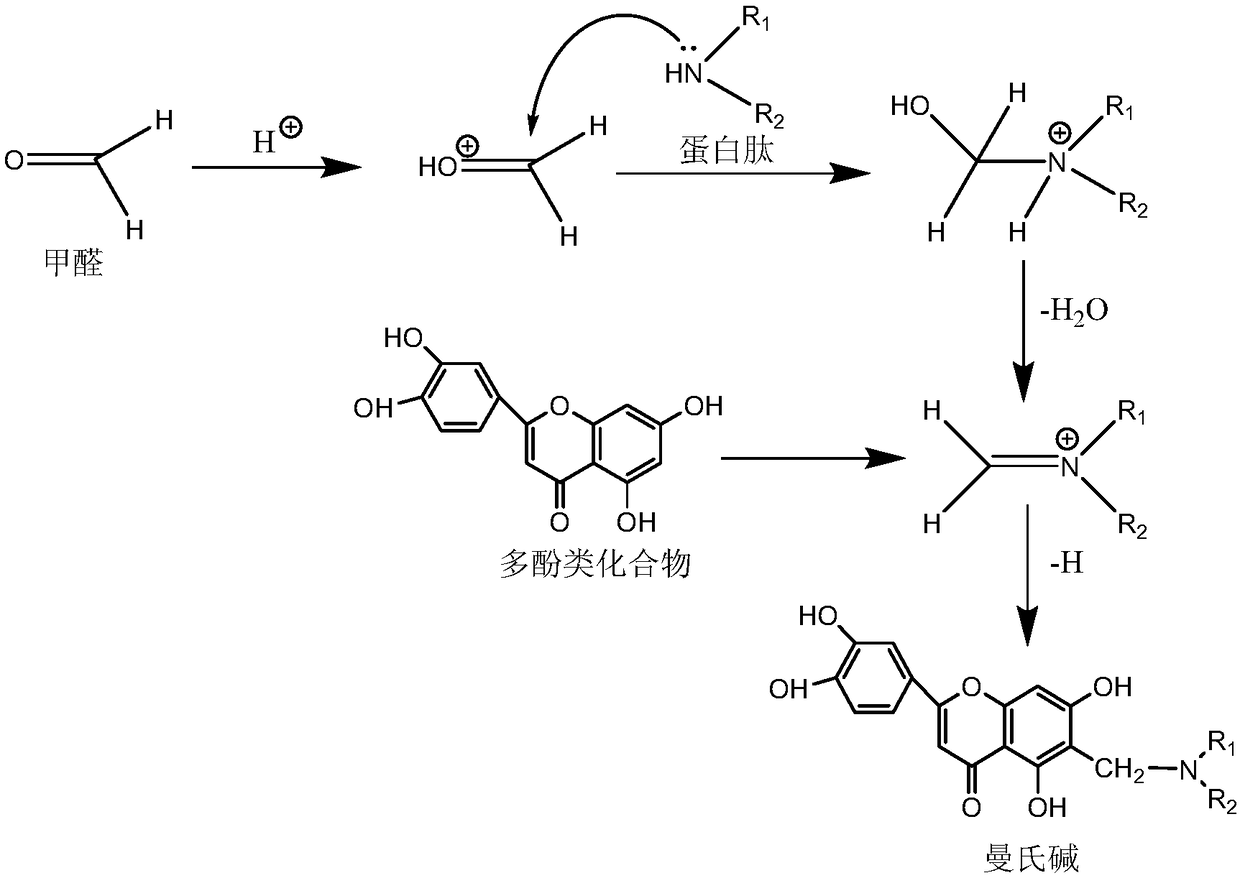

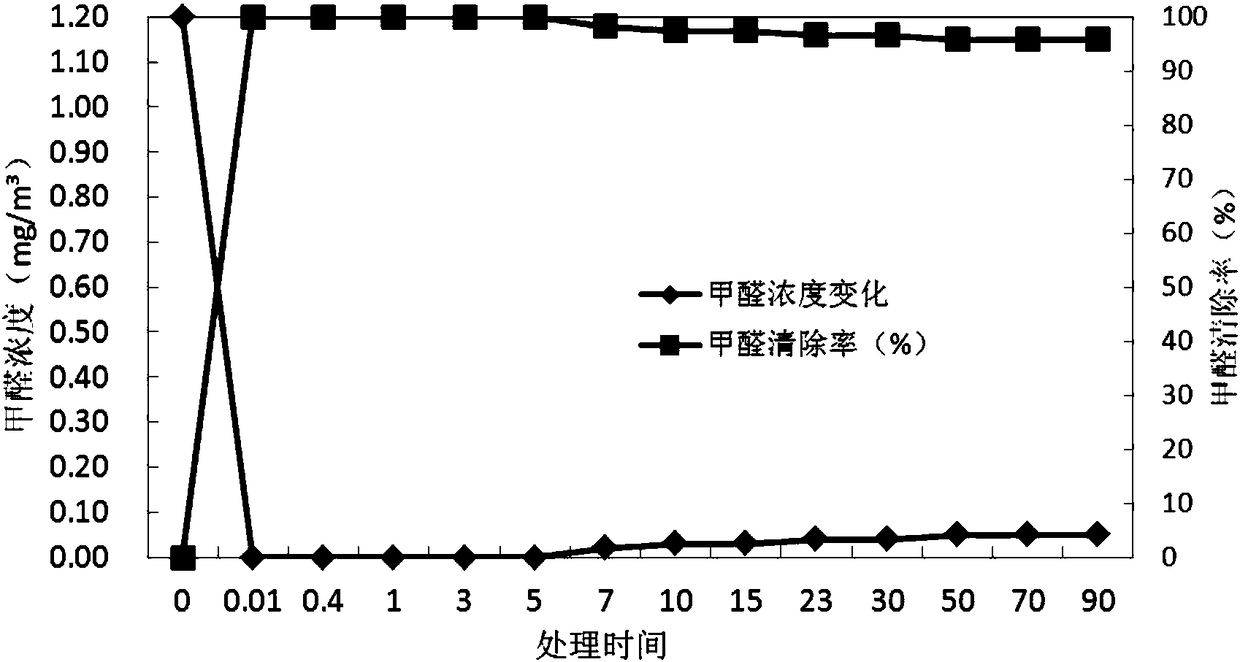

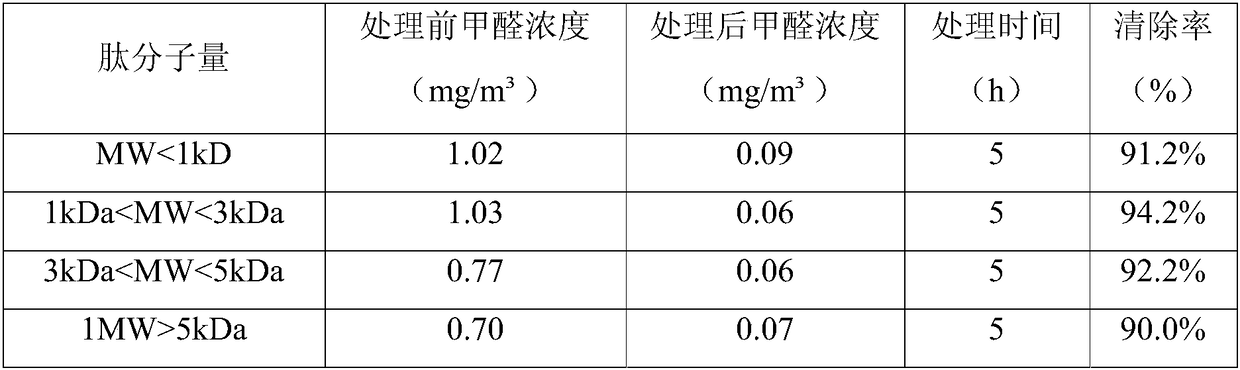

Collagen polypeptide rich in glycine and formaldehyde scavenger prepared therefrom

InactiveCN108130355AAchieve high valueHigh viscosityConnective tissue peptidesDispersed particle separationGlycineFormaldehyde product

The invention belongs to the technical field of functional polypeptides and discloses a collagen polypeptide rich in glycine and a formaldehyde scavenger prepared therefrom. The collagen polypeptide is prepared from the following steps: extracting collagens by means of a hot water extraction method; and then preparing the collagen polypeptide rich in glycine by enzymolysis of the collagens by means of protease by taking Tilapia mossambica waste as a raw material. By being combined with plant polyphenol compounds, the quick, long-acting, safe and edible formaldehyde scavenger is prepared. The formaldehyde removal rate of the formaldehyde scavenger can reach 95% or above within 10 min, so that the problem that a single amino acid is not ideal in removing formaldehyde is solved. A colloid film which is 2-10 microns can be formed on the surface of an object such as furniture if being dried to inhibit further release of formaldehyde. The formaldehyde removal rate can be kept at 95% or abovewithin three months, an effect of removing formaldehyde for a long time is achieved, and the problem that existing formaldehyde removal products are rebound in effect and short in effective period issolved.

Owner:SOUTH CHINA UNIV OF TECH

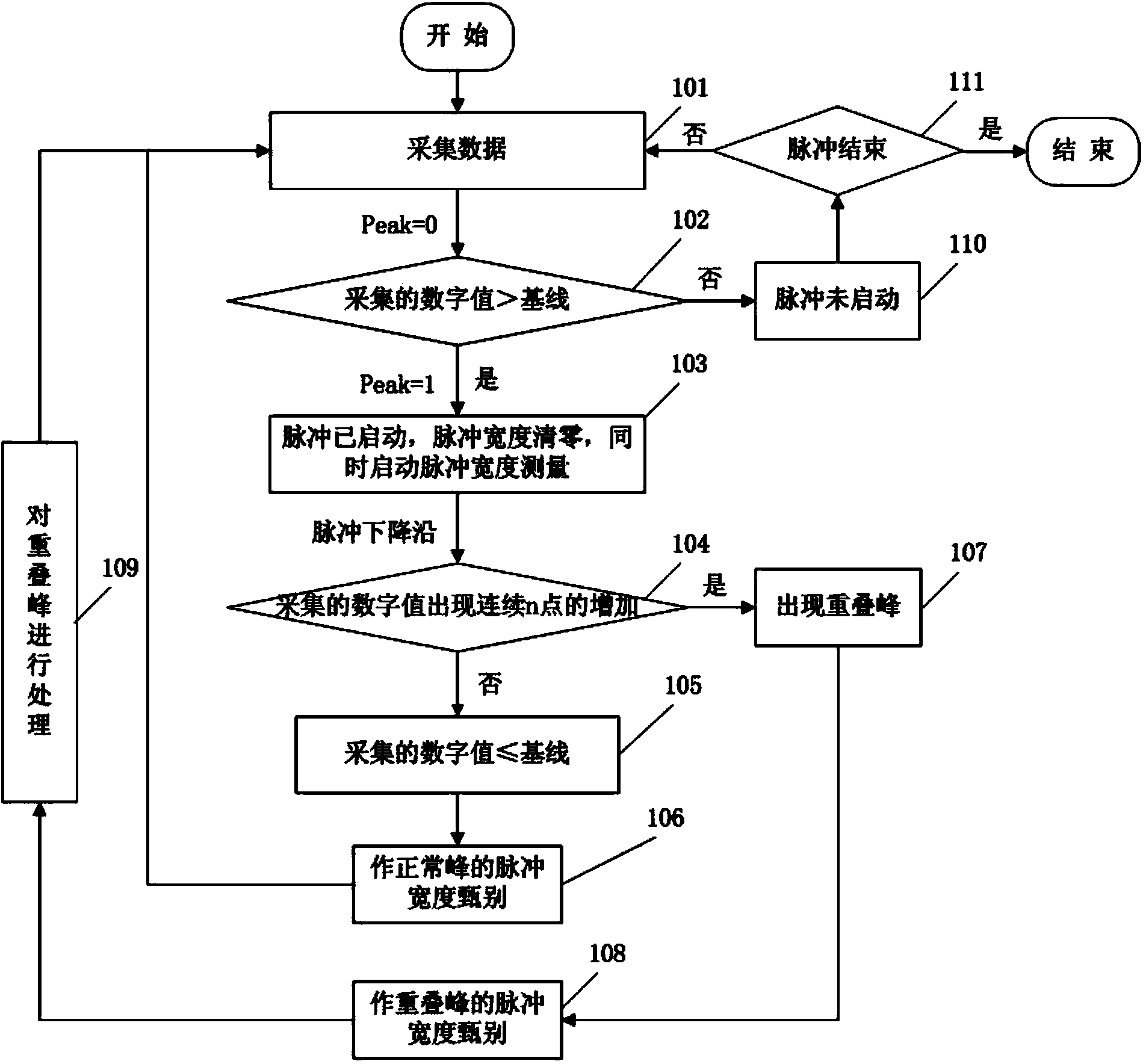

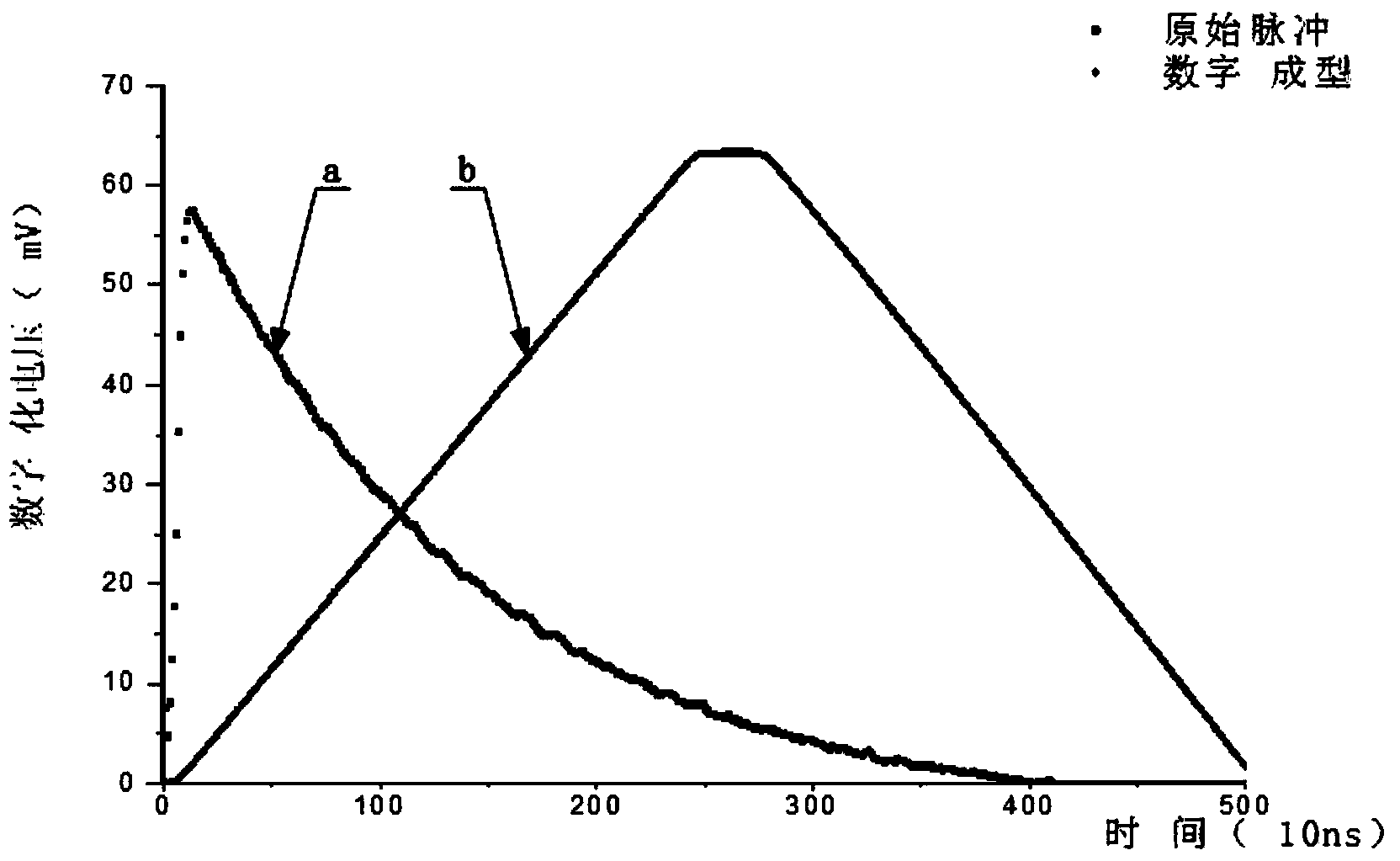

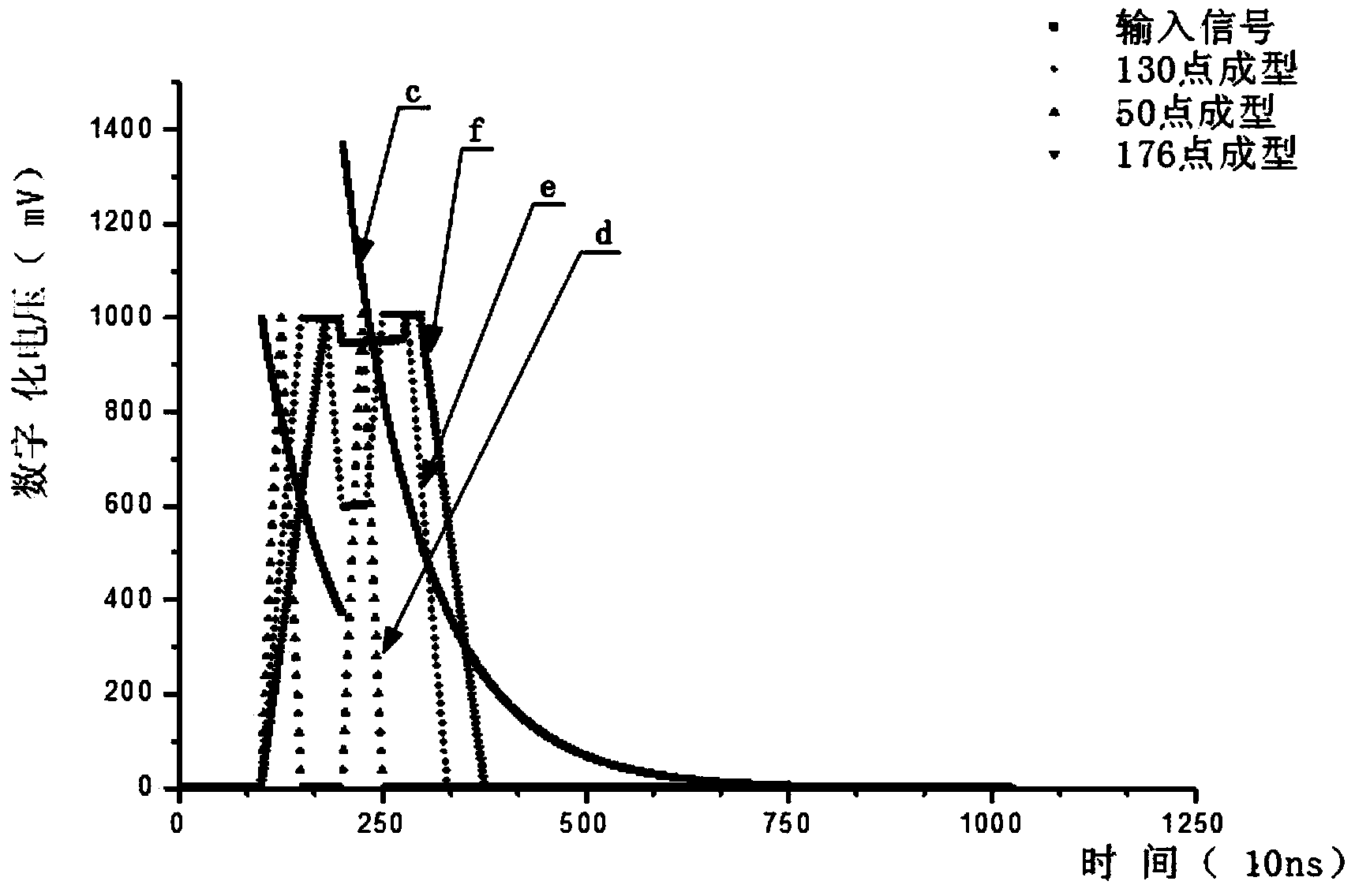

Nuclear pulse signal high speed digital separation method and system and digital spectrometer

ActiveCN103713310AHigh Resolution FeaturesSolve the noiseX-ray spectral distribution measurementImage resolutionImaging spectrometer

The invention discloses a nuclear pulse signal high speed digital separation method. Data is collected in real time. When collected digital value is larger than a base line, pulse amplitude data start to be collected in real time, and pulse width measurement is started. Meanwhile, the trapezoidal algorithm is used for real-time formation treatment, and consecutive digital pulses are obtained. In the descending process of the pulse amplitude, if the collected digital value is increased by consecutive n points, overlapping peaks occur, and at the moment, the pulse width measurement is stopped, and the overlapping peaks are processed. n is an integer larger than one. The method can identify and process a part of information of the overlapping peaks in real time and achieves the purpose of maintaining good energy resolution ratio on a high radioaction occasion.

Owner:四川新先达测控技术有限公司

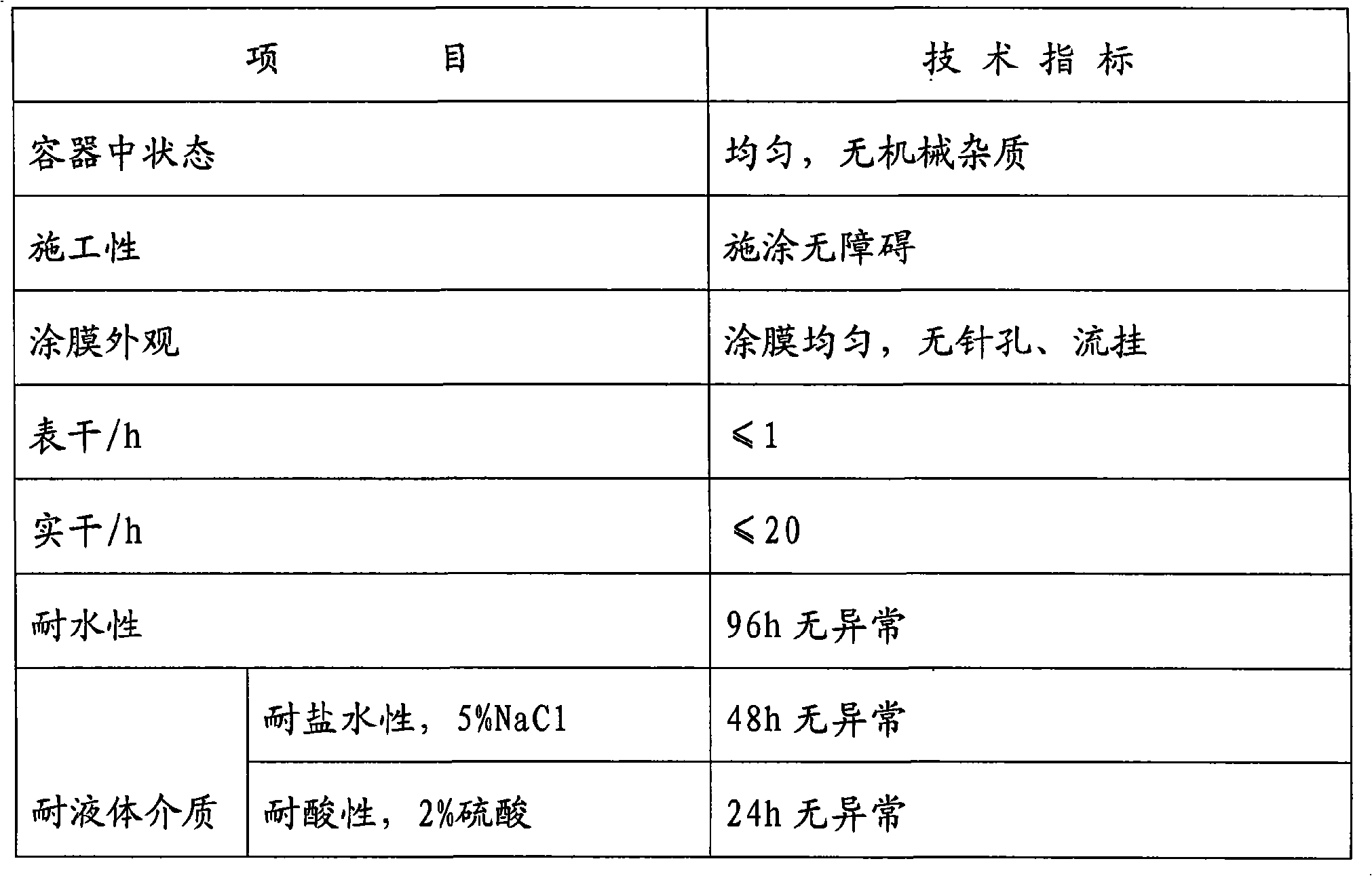

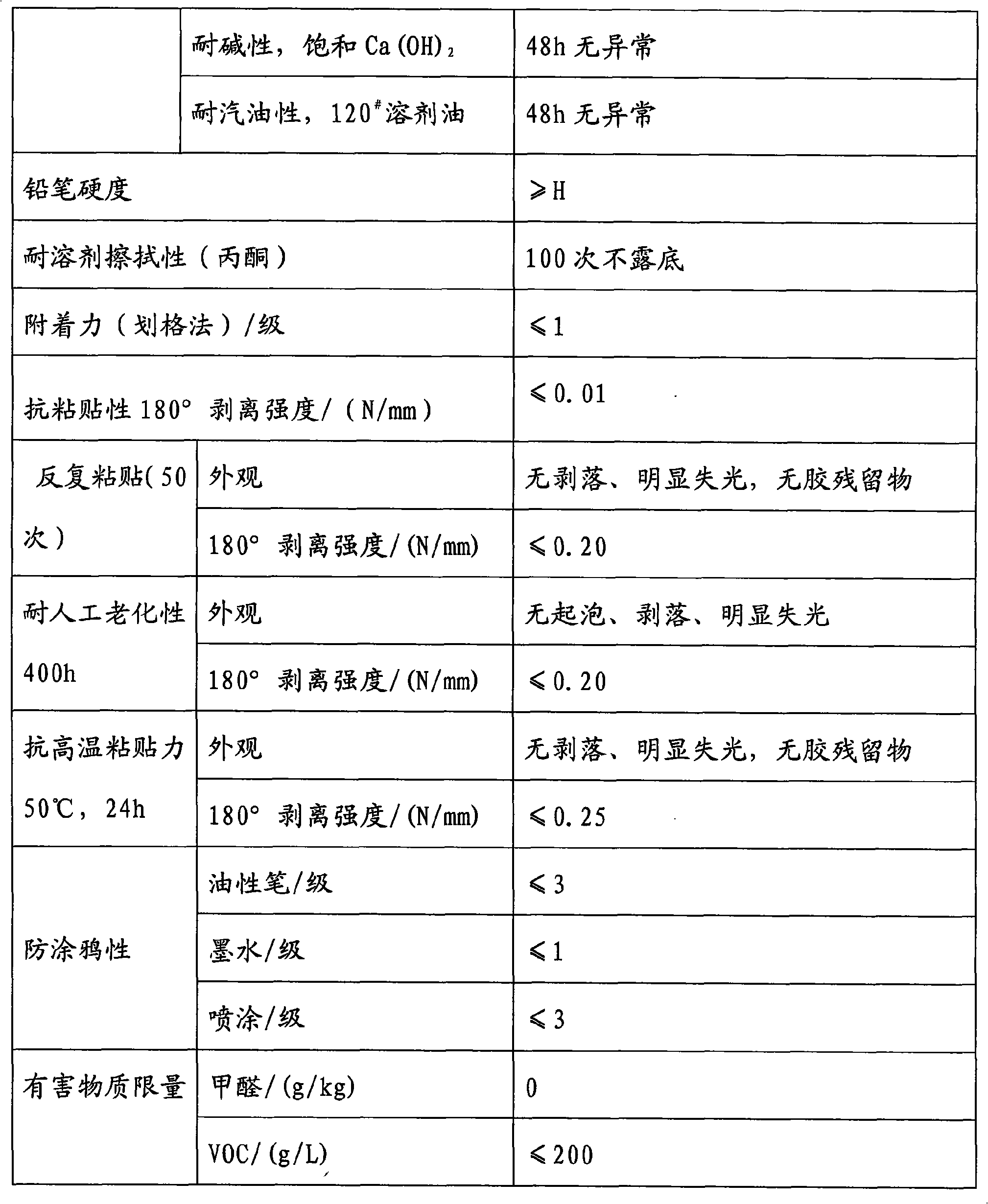

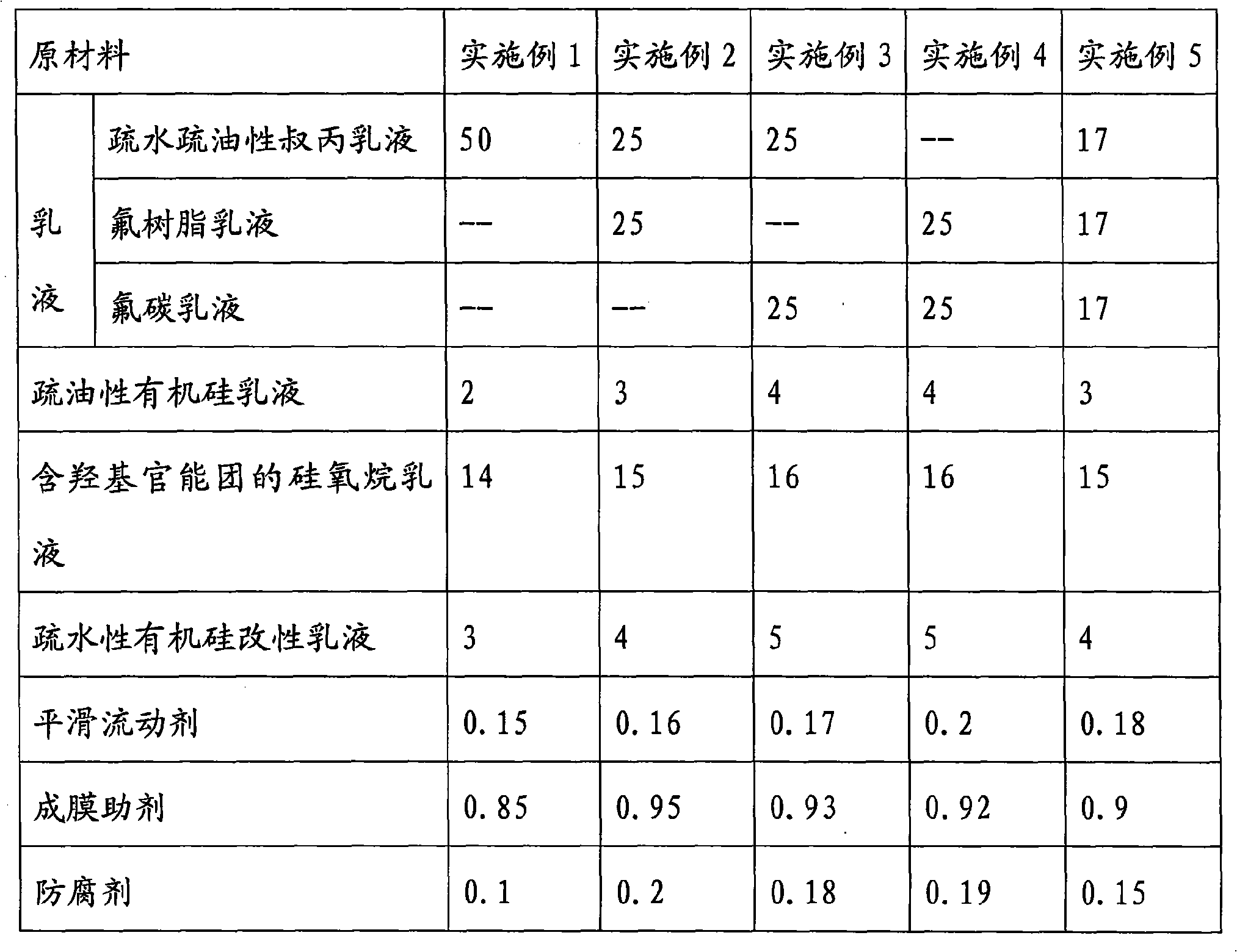

Aqueous anti-graffiti adhesion resistant paint and preparation method thereof

InactiveCN101585990AIncrease elasticityGood resistance to acid, alkali and saltCoatingsEmulsionPreservative

The invention discloses aqueous anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. The paint consists of the following components by weight portion: 50 to 55 portions of emulsion, 2 to 4 portions of organic silicon emulsion, 14 to 16 portions of siloxane emulsion containing hydroxy functional group, 3 to 5 portions of hydrophobic organic silicon modified emulsion, 0.15 to 0.2 portion of smooth flow agent, 0.85 to 0.95 portion of film forming assistant, 0.1 to 0.2 portion of preservative, 0.1 to 0.2 portion of mildew preventive, 0.8 to 1 portion of ethylene glycol, 5 to 7 portions of hydrophobic agent, 0.1 to 0.2 portion of thickening agent, and 23 to 25 portions of deionized water. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has zero formaldehyde, benzene and heavy metals, has low VOC, and is typical environment-friendly paint.

Owner:LANZHOU XUNMEI PAINT IND TECH

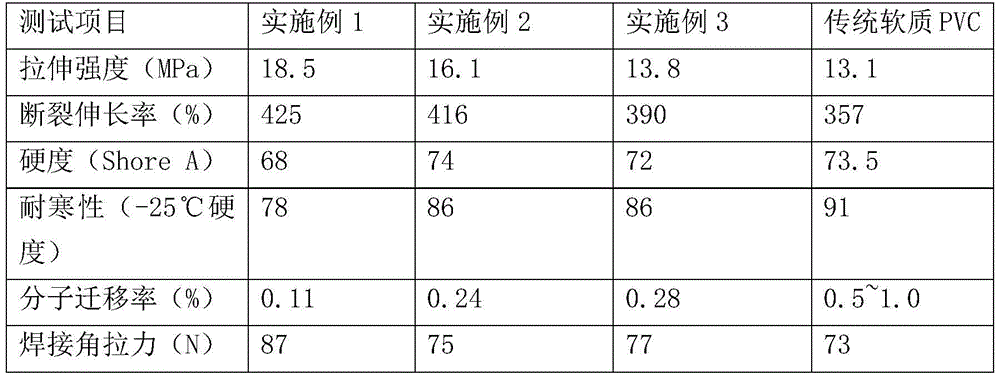

Modified polyvinyl chloride door seal and preparation method thereof

The invention belongs to the technical field of door seal materials, and relates to a modified polyvinyl chloride door seal and a preparation method thereof. The door seal is prepared from, by weight, 40-50 parts of polyvinyl chloride resin powder, 5-15 parts of anti-yellowing thermoplastic elastomer, 0-5 parts of 1,2-cyclohexane dicarboxylic acid di-isononyl ester, 5-20 parts of trioctyl trimellitate, 0-5 parts of dioctyl adipate, 5-10 parts of epoxidized soybean oil, 5-10 parts of polyester oligomer, 10-15 parts of filler, 1-3 parts of a stabilizer, 1-3 parts of a compatilizer, 1-3 parts of a lubricating agent and 0.1-1 part of pigment. Fat diisocyanate is two of hexamethylene diisocyanate (HDI), isophorone diisocyanate (IPDI) and hexamethylene diisocyanate (HMDI). The defects that the hardness of a traditional soft PVC door seal is sharply increased at low temperature and elasticity becomes poor are overcome, the tensile strength and the breaking elongation of the door seal are improved, the welding angle pull force of the door seal is increased, and the service life of the door seal is prolonged.

Owner:QINGDAO NEW MATERIAL TECH IND PARK DEV

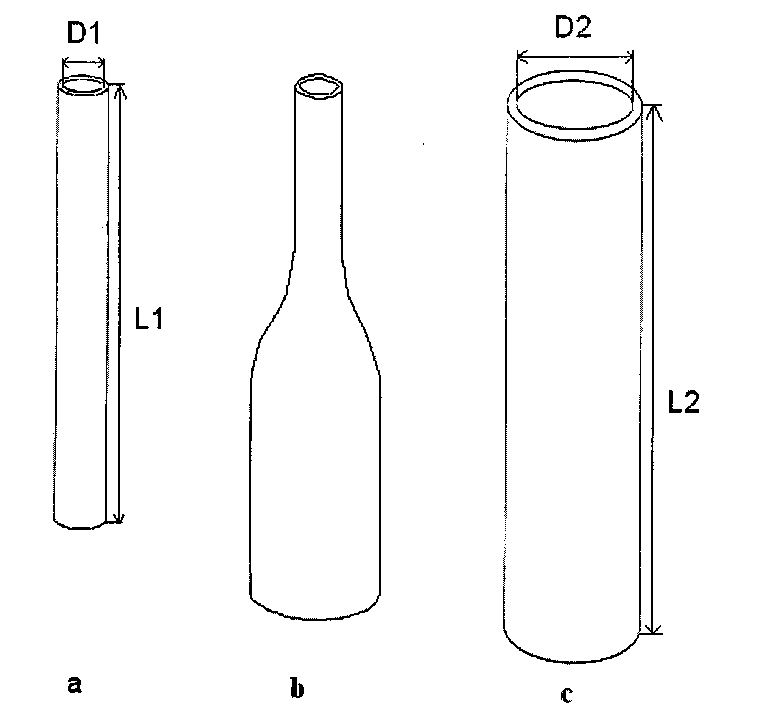

Deformed polymer tube and completely biodegradable polymer stent prepared by same

The invention provides a deformed polymer tube, which mainly consists of L-PLA type polylactic acid (L-poly- lactic acid) with the molecular weight ranging from 5W to 50W. The weight percentage of each L-PLA type polylactic acid monomer ranges from 80% to 95%, the crystallinity of each L-PLA type polylactic acid monomer ranges from 30% to 60%, the inner diameter of the tube ranges from 1.50mm to 5.00mm, the wall thickness ranges from 0.05mm to 1.00mm, and the radial strength ranges from 240kpa to 280kpa. The invention further provides a completely biodegradable polymer stent prepared by the deformed polymer tube, the completely biodegradable polymer stent has good radial strength and toughness, instant resilience rate and later-period resistance rate of the completely biodegradable polymer stent after being implanted in a human body are reduced, and the completely biodegradable polymer stent is not easy to crack when supporting blood vessels. The deformed polymer tube is simple in preparation process, easy to be reproduced and suitable for industrial production.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

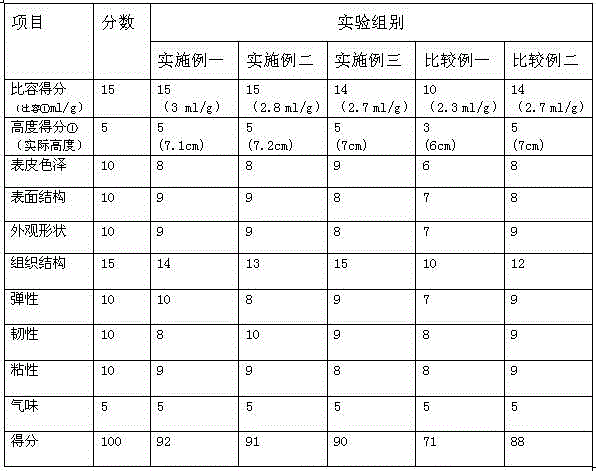

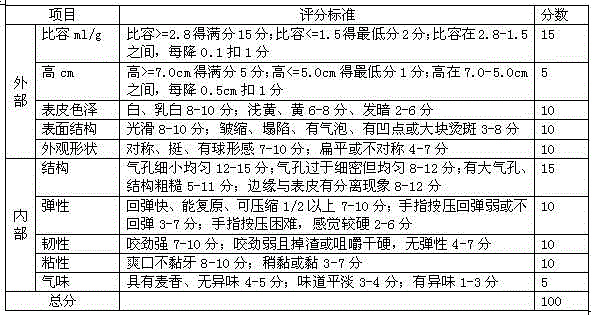

Steamed bun modifier and application method thereof in making southern steamed buns

ActiveCN104304847ASolving for Structural UniformitySolve fineFood ingredientsFood preparationBiotechnologyAmylase

The invention relates to a steamed bun modifier, which comprises following raw materials by mass percent: 90-96% of corn starch, 1-5% of monocalcium phosphate, 1-5% of calcium sulfate, 1-5% of vitamin C, 0.1-0.5% of fungus amylase, 0.1-0.5% of lipase, 0.1-0.5% of xylanase, and 0.1-0.5% of notatin. The steamed bun modifier has the advantages of containing no inhibited calcium peroxide, thoroughly solving the problem in production that the steamed bun made by the modifier without calcium peroxide has no uniform tissue, is not compact, is not soft, has poor elasticity, is not tough and soft in taste, and has short service life, improving the product quality, and also improving the production efficiency and quality of the product.

Owner:GUANGZHOU BAOTAO FOOD CO LTD

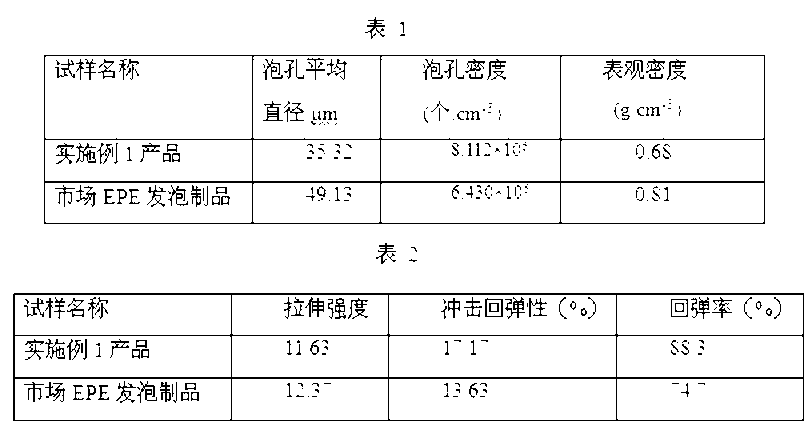

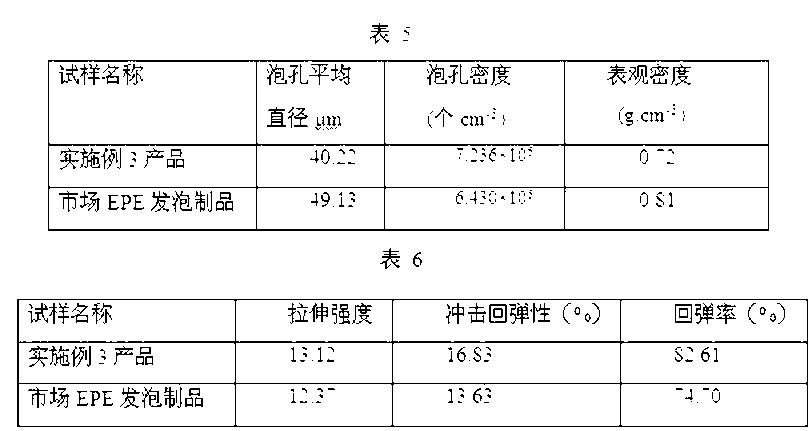

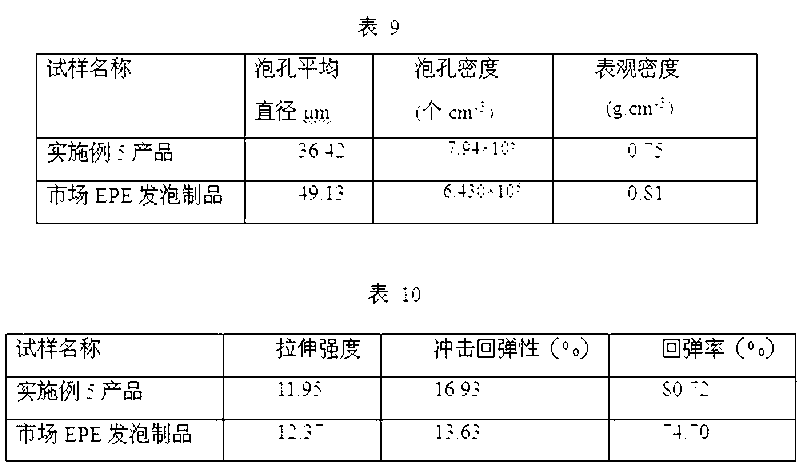

High-elasticity low-density polyethylene foaming composite material and preparation method thereof

ActiveCN103224662AIncreased decomposition temperature rangeBroaden the decomposition temperature rangeLow-density polyethyleneElastomer

The invention discloses a high-elasticity low-density polyethylene foaming composite material and a preparation method thereof. The high-elasticity low-density polyethylene foaming composite material is prepared from the following raw material components in parts by weight: 85-95 parts of low-density polyethylene, 5-15 parts of elastomer, 0.1-0.3 part of crosslinking agent, 1-2 parts of foaming agent and 0.2-0.8 part of blowing promoter. The foaming composite material prepared by the following steps of: burdening, extrusion, drying and injection molding has a high foaming ratio and improved rebound resilience reaching above 16.3%. Compared with present low-density polyethylene foaming sheets on the market, the high-elasticity low-density polyethylene foaming composite material has high cost performance and can be used for solving the problem that the rebound resilience of conventional foaming composite materials prepared by low-density polyethylene (LDPE) generally does not exceed 14%, and as the conventional foaming composite materials cannot reach technical requirements, have high cost and the like, the application of the conventional foaming composite materials in industries is limited.

Owner:GUIZHOU NORMAL UNIVERSITY

Method for preparing thermoplastic elastomer rubber tube of ethylene-propylene rubber/polypropylene

ActiveCN1843745ASolving Elasticity ProblemsSolve loading difficultiesTubular articlesThermoplastic elastomerEngineering

The invention discloses a method for preparing ethylen-propylene rubber / polypropylene thermoplastic flexible tube, which uses single-screw plastic extruder to mold tube. And said method comprises: (a) drying that drying rubber in 50-100Deg. C for 1-4 hours; (b) extruding: selecting single-screw plastic extruder whose length-diameter rate is 20-38:1; and the temperature at each step of extruder is: head temperature in 145-220Deg. C, extruding section in 145-220Deg. C, plastifying section in 140-210Deg. C, feeding section in 140-200Deg. C; and selecting pin and pourer according to the size of final tube; (c) cooling that when the plastic is extruded from the head, using cycle water to cool and mold it in 140-200Deg. C. the invention can avoid sulfuration, and prepare EPDM+PP tube in one molding process. And it can solve the defects of low flexibility and hard transportation of present PVC tube; and inventive tube has better original, anti-aging and anti-oil properties to meet the demand of vehicle industry.

Owner:TIANJIN PENGYI GRP CO LTD

Method for manufacturing S-shaped longitudinal beam of automobile

The invention aims to provide a method for manufacturing an S-shaped longitudinal beam of an automobile. The method is used for solving the problems of torsion, bouncing, warping and the like of the S-shaped longitudinal beam and improving the yield of a single piece and the loading accuracy. The method for manufacturing the S-shaped longitudinal beam of the automobile comprises the steps of (A) blanking, (B) drawing, (C) first-time trimming, (D) flanging, (E) reshaping, (F) second-time trimming, and (G) punching. The method for manufacturing the S-shaped longitudinal beam of the automobile has the advantages that by the repeated reshaping and trimming processes, the problems of torsion, bouncing, warping and the like of the S-shaped longitudinal beam are solved, and the problems of cracking, micro-cracking and the like of flanges caused by different directions of burrs are avoided. The punching process is carried out finally, the problems of warping, torsion, bouncing and the like are solved before the final punching process, and the problems of low hole position accuracy, hole deformation and the like caused by punching prior to reshaping are avoided, so that the yield of the single piece and the loading accuracy are improved.

Owner:CHERY AUTOMOBILE CO LTD

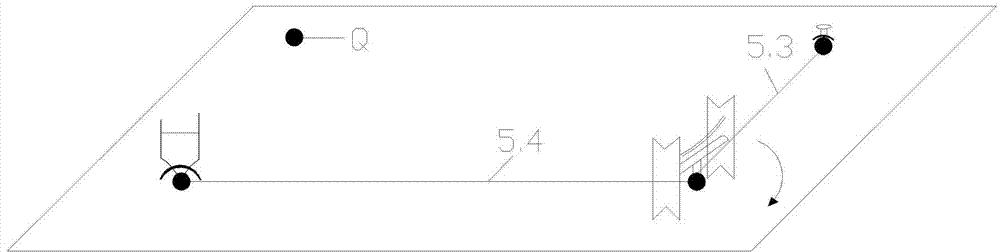

Drawing snapping line releaser and line drawing method in building construction

The invention discloses a drawing snapping line releaser and a line drawing method in building construction and belongs to the technical field of construction engineering. The drawing snapping line releaser is composed of a line frame, a line shaft, a leveler, a rubber cup and drawing snapping line devices. The whole process of a line releasing method in building construction of the drawing snapping line releaser is operated by one person. Before line snapping, angular points of each layer are measured by a theodolite. The method for connecting the angular points includes: firstly respectively placing the two drawing snapping line devices on the angular point portions at a diagonal position, fixing the drawing snapping line devices through the rubber cup, then respectively drawing two lines perpendicular to each other from the drawing snapping line devices to form drawing lines and snapping lines, respectively drawing the drawing lines and the snapping lines to the other angular points, checking and inspecting that the dimensions of all positions and the dimensions of diagonals are right, and performing line snapping. The drawing snapping line releaser and the line drawing method in building construction have the advantages of being used in line drawing operation of building construction, improving line releasing progress, being accurate and reasonable in construction, reducing labor cost, saving resources and reducing danger sources.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com