Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177results about How to "High resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid silicon rubber composition and preparation method thereof

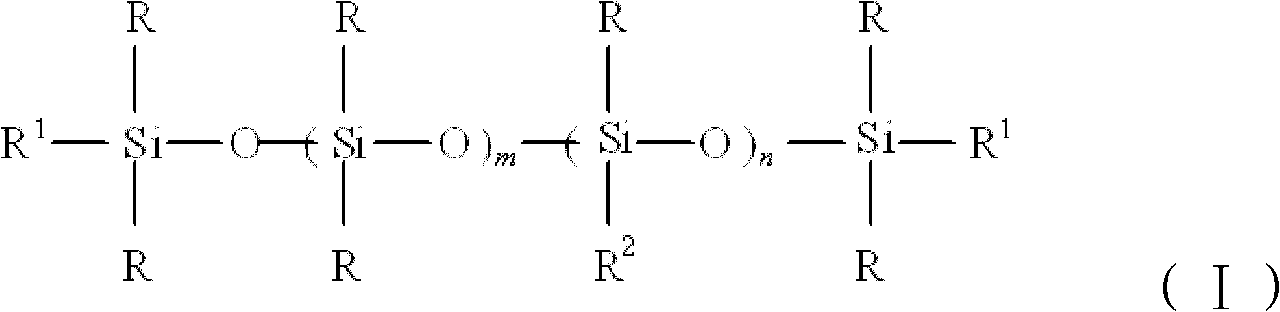

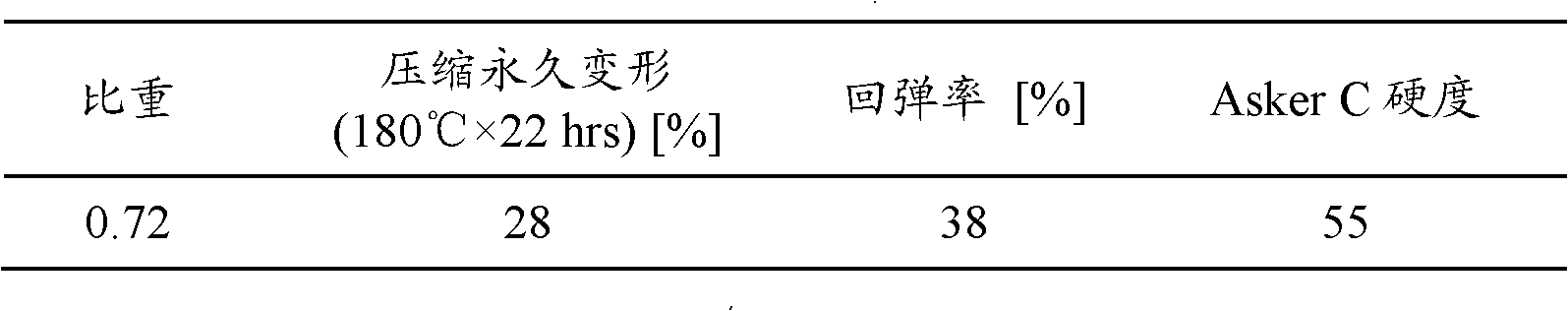

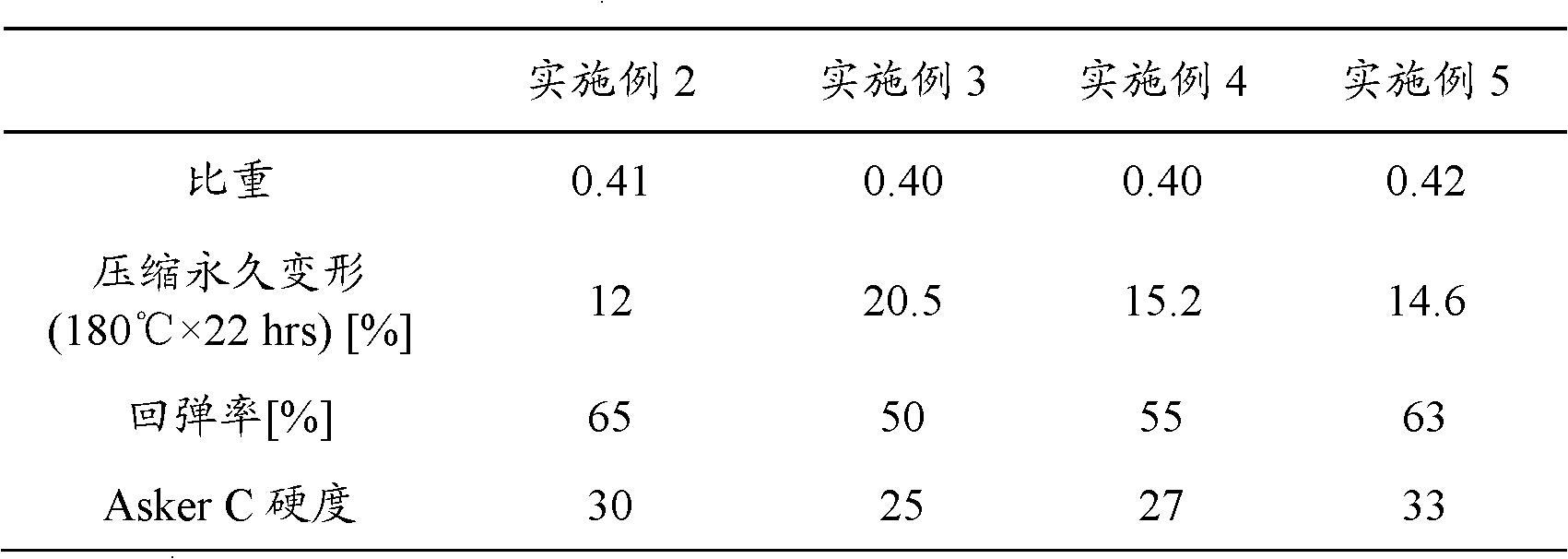

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

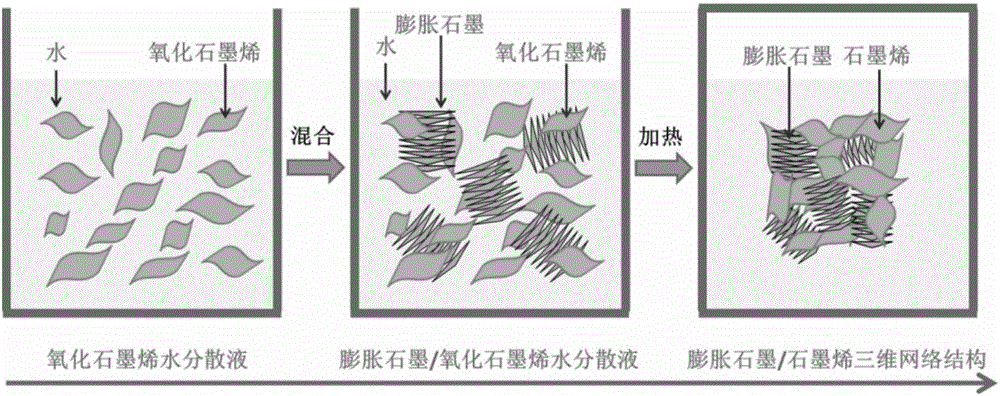

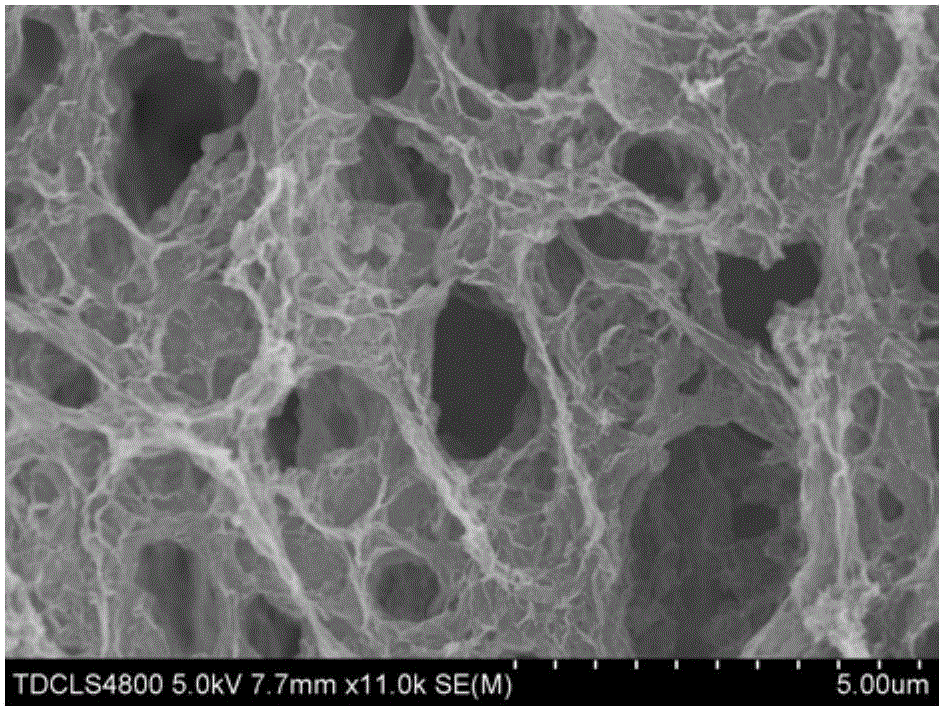

Expanded graphite and graphene composite material and preparation method therefor

The invention relates to an expanded graphite and graphene composite material and a preparation method therefor. The preparation method comprises the steps: preparing a graphene oxide water dispersion, of which the mass fraction is 0.1-10%; uniformly stirring and mixing expanded graphite, of which the expansion ratio is 100-300, and the graphene oxide water dispersion, so as to obtain a homodisperse expanded graphite / graphene oxide water dispersion; putting the expanded graphite / graphene oxide water dispersion in a closed vessel, putting the closed vessel in a muffle furnace, carrying out heat treatment for 1-24 hours at the temperature of 120-260 DEG C, carrying out cooling, then, taking out samples, and drying the samples, so as to obtain expanded graphite / graphene based carbon foam; and connecting expanded graphite by graphene sheet layers so as to jointly form a three-dimensional network structure, wherein the coefficient of thermal conductivity is greater than or equal to 50W / (m.K), and the rebound degree is greater than or equal to 90%. Compared with the traditional mesophase asphalt based carbon foam, graphene oxide based carbon foam and chemical vapor deposition based graphene based carbon foam, the rebound elasticity, thermal conducting capability, production cost and the like of the expanded graphite and graphene composite material are superior.

Owner:TIANJIN UNIV

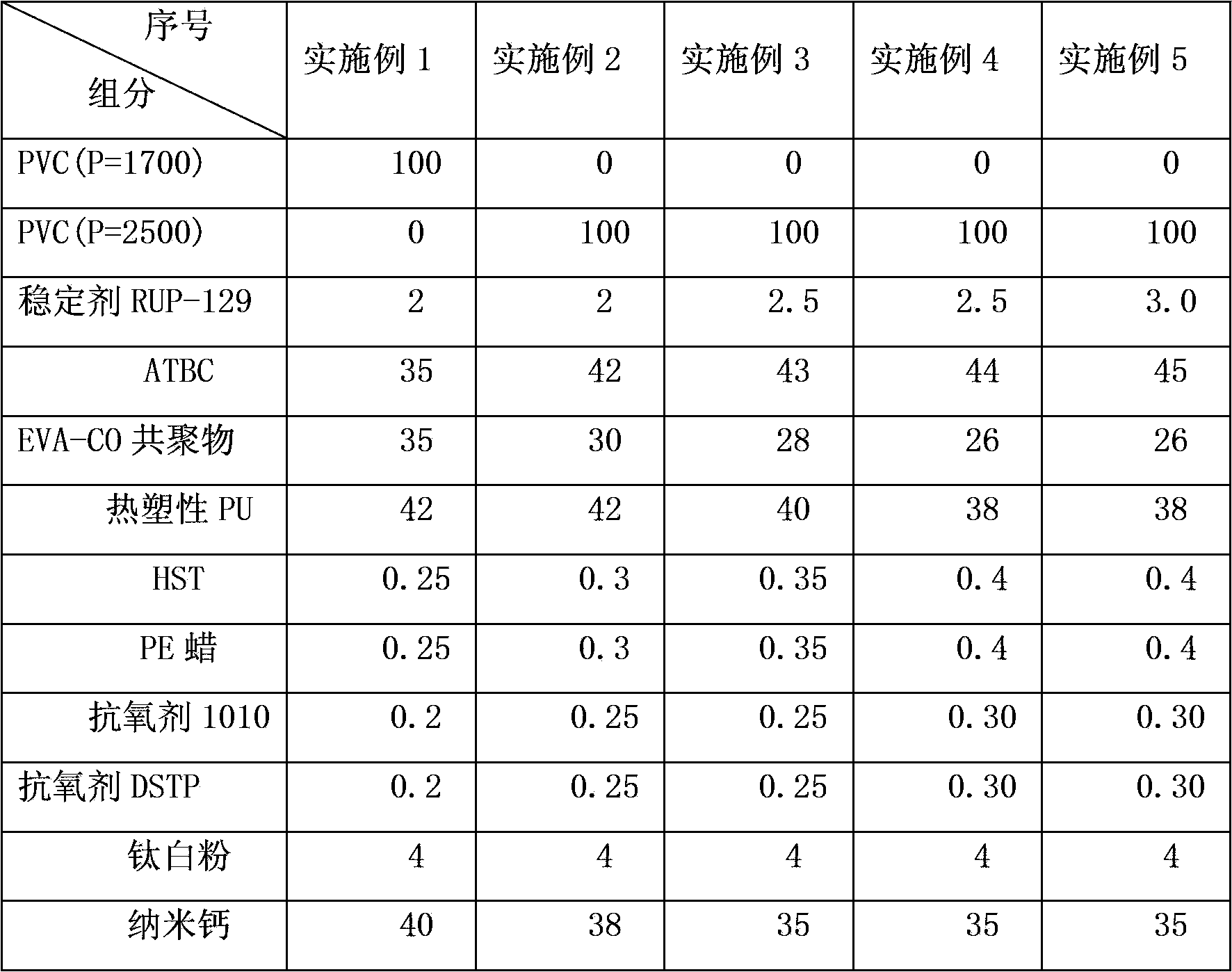

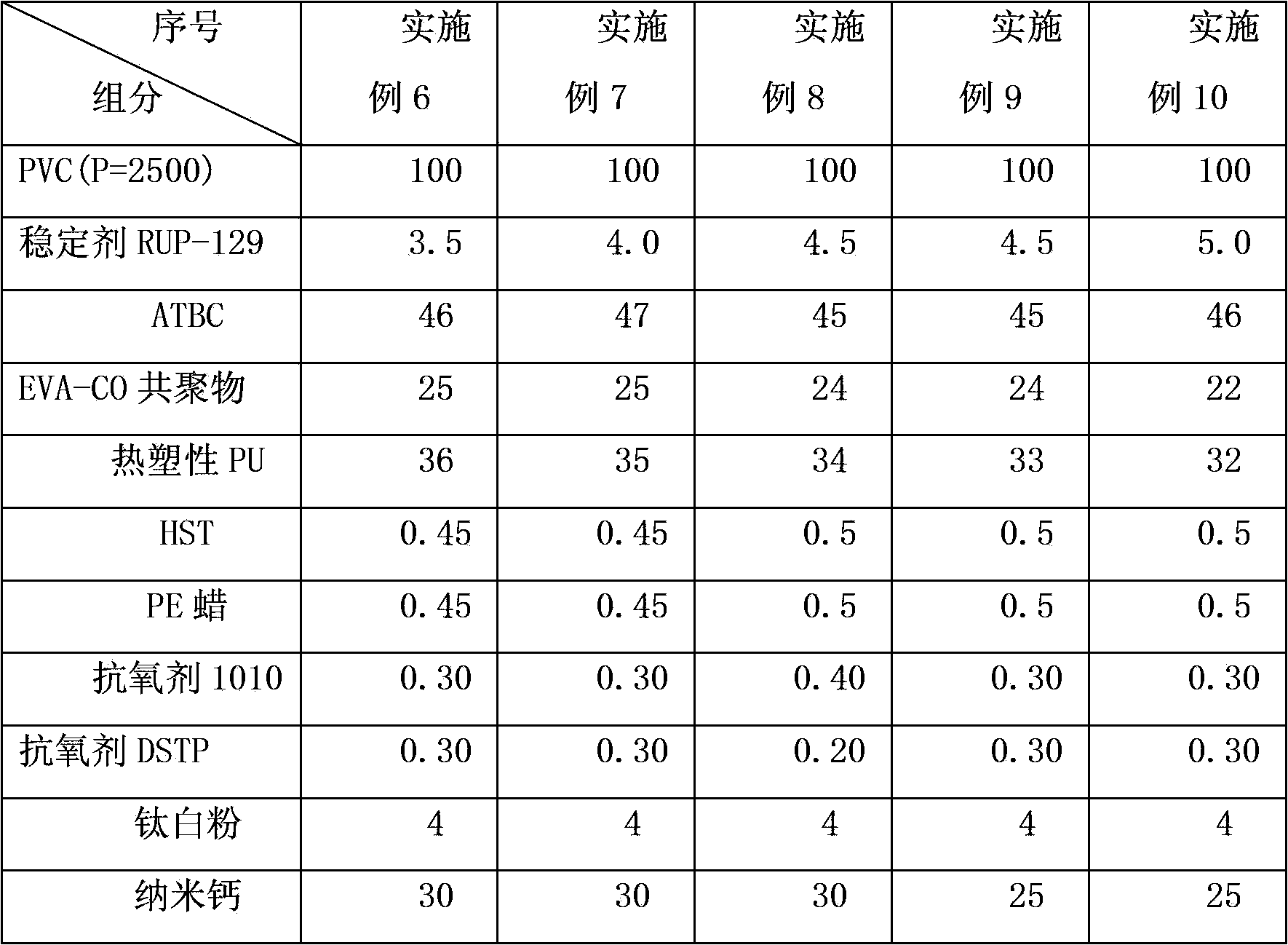

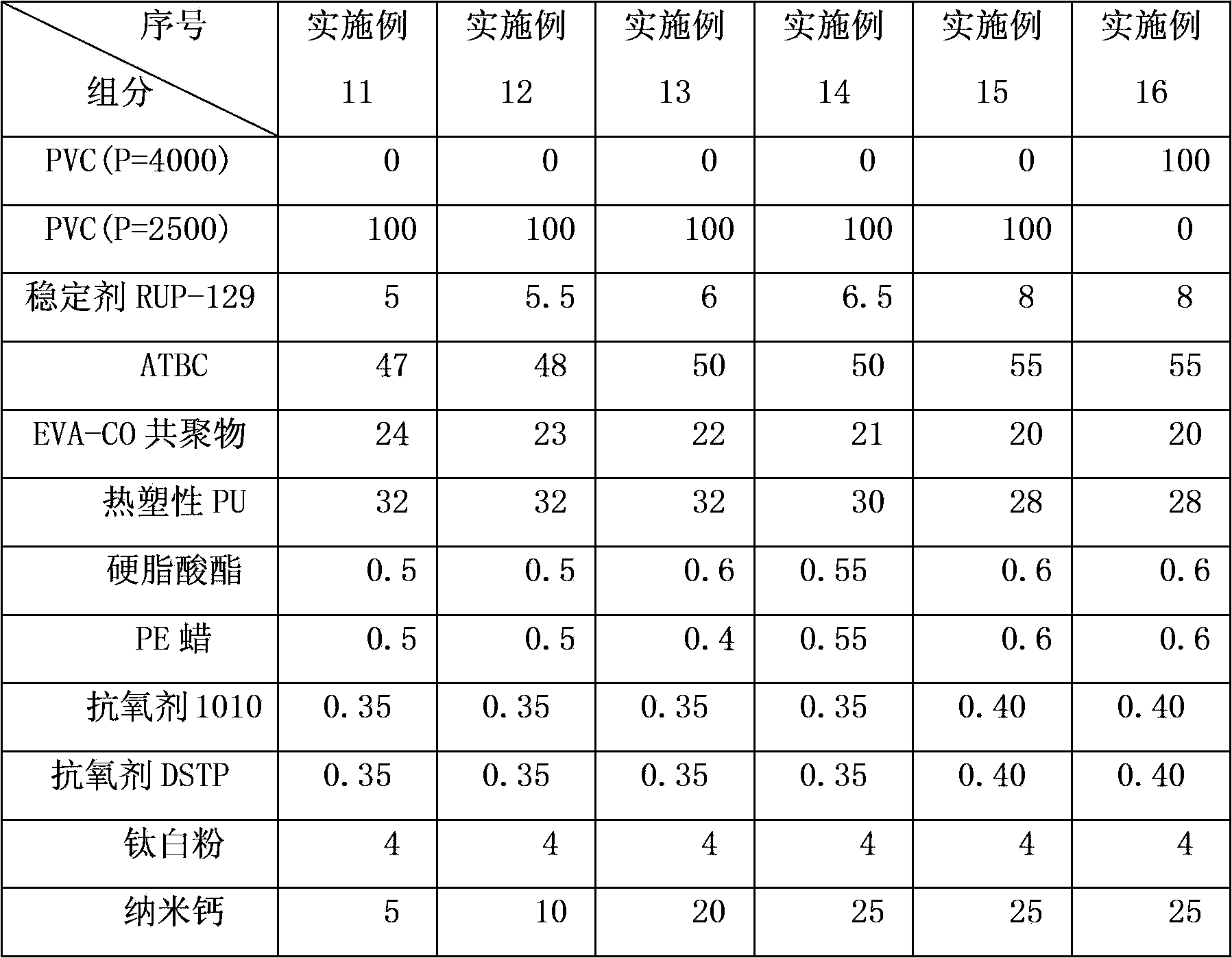

Polyvinyl chloride sealing strip composition for refrigerator

ActiveCN103524917AImprove mechanical propertiesImprove processing fluidityOther chemical processesPlasticizerPolyvinyl chloride

The invention discloses a polyvinyl chloride sealing strip composition for a refrigerator, belongs to the field of processing and application of macromolecular materials, and mainly relates to a polyvinyl chloride sealing strip composition for a refrigerator. The polyvinyl chloride sealing strip composition is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride, 35-55 parts of a plasticizer, 20-35 parts of modified ethylene vinyl acetate copolymer, 28-42 parts of a thermoplastic polyurethane elastomer, 2-8 parts of a thermal stabilizer, 0.5-1.2 parts of a lubricant, 0.4-0.8 part of an antioxidant and 9-44 parts of a filling agent. A polyvinyl chloride sealing strip, produced from the polyvinyl chloride sealing strip composition, for a refrigerator is cold-resistant and oil-resistant, has good elastic resilience and durability, and is of great significance in energy conservation and consumption reduction.

Owner:CHINA PETROLEUM & CHEM CORP

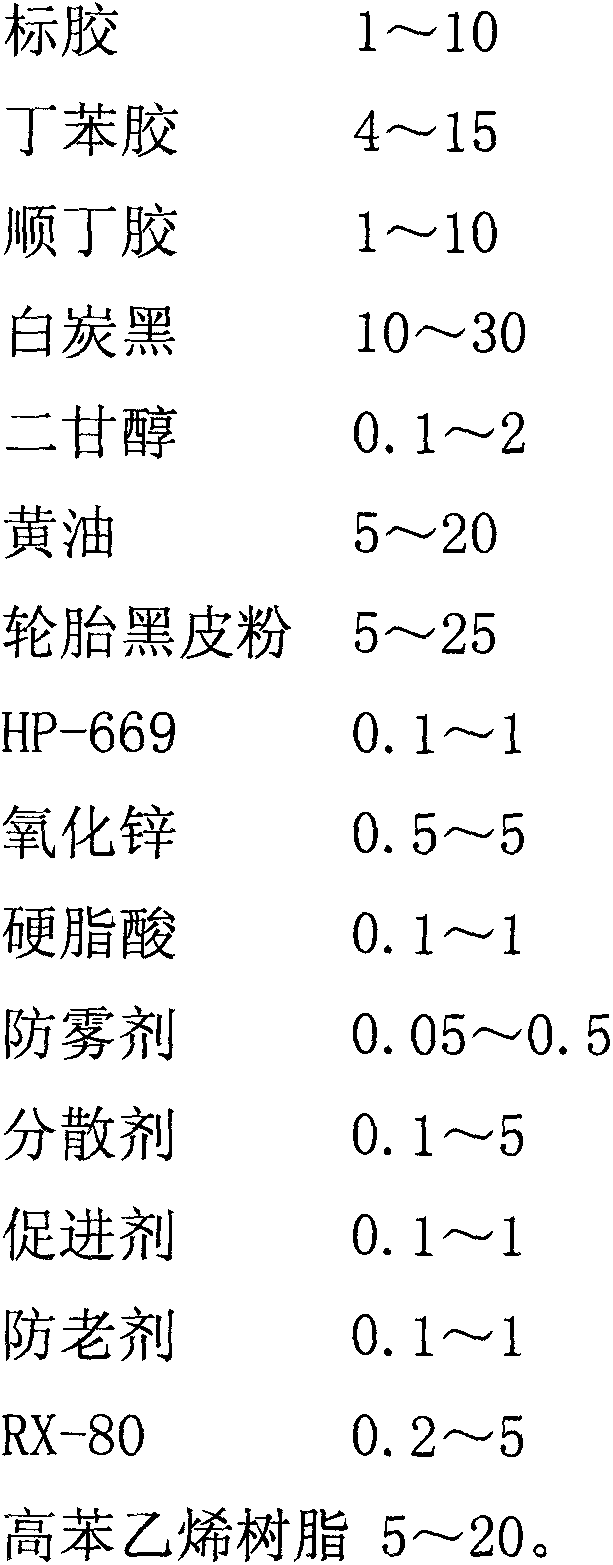

Wear-resistant sole material and preparation method thereof

InactiveCN103159999AAvoid thickening and lifting the moldReduce flash weightSolesRubber materialCrack resistance

The invention discloses a wear-resistant sole material which is prepared from standard rubber, styrene-butadiene rubber, cis-1,4-polybutadiene rubber, white carbon black, diethylene glycol, butter, tire black powder, HP-669, zinc oxide, stearic acid, antifogging agent, dispersing agent, accelerator, anti-aging agent, RX-80 and high styrene resin. The preparation method of the wear-resistant sole material comprises the following steps: evenly mixing the materials, adding into a Banbury mixer, banburying, adding the banburying mixture into a screw extruder, carrying out melt blending, granulating, mixing the granules in an open mill, and carrying out mold pressing to obtain the wear-resistant sole material. The wear-resistant sole material disclosed by the invention enhances the heat flowability of the rubber material in the die; and the wear-resistant sole material avoids rising the mold due to thickening, and reduces the burr weight of the product, thereby saving the cost and enhancing the yield of the product. The product prepared from the wear-resistant sole material disclosed by the invention has the advantages of favorable wear resistance, favorable resilience and excellent flex crack resistance.

Owner:叶建华

Functional gradient foamed sole material and preparation method thereof

The invention relates to an insole material of a sneaker and a preparation method thereof, and particularly relates to a functional gradient insole material of the sneaker and the preparation method thereof. The sole material mainly comprises ethylene-vinyl acetate copolymer (EVA), ethylene-octene copolymer (POE), a crosslinking agent, a filler, a foaming agent, and a foaming promoter. Two-layer or multi-layer heterogeneous expandable rubber compound of which the performance continuously changes in the thickness or length direction of the material is foamed and molded to prepare the foamed sole material in a once mold pressing manner on the basis that EVA and POE are foamed. The foamed sole material has the advantages that (1) the functionality (for example, rebound resilience and hardness) of the prepared foamed sole material forms gradient change along the thickness direction, the hardness of the foamed material at one side near pelma is small, the rebound resilience is high, energy feedback is facilitated, the foamed material at one side near outsoles is large and the elasticity is low so as to provide enough support, thus, the foamed sole material is more comfortable to wear in maximal extent; (2) compared with the comfortable foamed sole material in the market at present and the preparation method, the material cost of the binder is saved, labor charges are saved, the molding period is shortened, and environment protection is facilitated.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

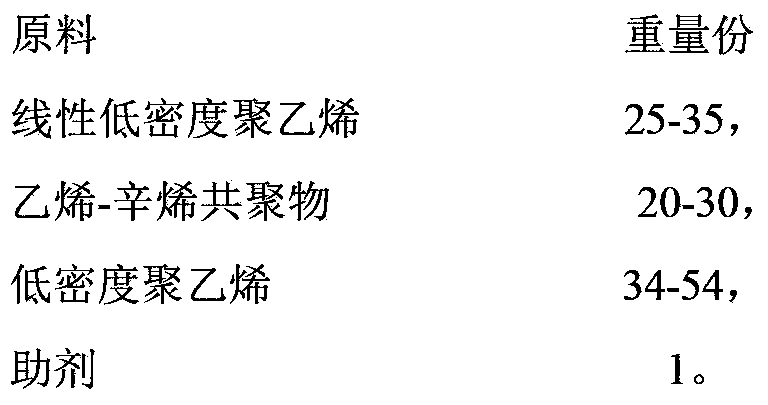

High-transparency polyolefin heat shrinkage film and production method thereof

ActiveCN103360664AGood heat sealing performanceHigh transparencyLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical field of a production method of a polymer film material for packaging and in particular discloses a high-transparency polyolefin heat shrinkage film and a production method thereof. The production method of the high-transparency polyolefin heat shrinkage film comprises the following steps of: extruding 25-35 parts by weight of linear low-density polyethylene, 20-30 parts by weight of ethylene-octylene copolymer, 34-54 parts by weight of low-density polyethylene and 1 part by weight of auxiliaries by a single-screw extruder; extruding the materials into a tube blank by an extruding mould head of a single-layer film blowing machine; cooling and pulling the tube blank into a stretching oven for carrying out transverse and longitudinal stretching of a certain times. According to the high-transparency polyolefin heat shrinkage film provided by the invention, the transparency of the film is improved for enabling the packaging of the printed goods to be more attractive; the strength of the film is improved to broaden the application field; the heat sealing performance of the film is improved for adapting to the mechanical production and improving the packaging resilience; and the product has a constant longitudinal-transverse shrinkage rate, so that the packaging stability can be ensured.

Owner:HUBEI ENG UNIV

Antibacterial and mildewproof latex foam material and preparation method thereof

The invention provides an antibacterial and mildewproof latex foam material and a preparation method thereof. The foaming material comprises, by weight, 100 parts of latex (based on dry weight), 0.58 parts of potassium hydroxide, 2-5 parts of potassium vegetable oleate, 1-2 parts of potassium ricinate, 4-6 parts of sulfur, 1-2 parts of an antiager, 1-2 parts of sodium silicofluoride, 1-1.5 parts of bentonite, 4-6 parts of a vulcanization accelerator nanometer zinc oxide, and 0.5-1 part of an inorganic silver-carrying zinc-carrying antibacterial agent. The preparation method comprises removing ammonia, stirring ingredients, aging the mixture, and carrying out foaming, material filling, setting, vulcanization, cleaning and drying setting. The antimicrobial efficiency of the antibacterial and mildewproof latex foam material is 99% or more. The anti-mildew performance of the antibacterial and mildewproof latex foam material reaches the level 0-1. The elasticity, rebound resilience, strength and hardness of the foam material are excellent.

Owner:福家汇(北京)电子商务有限公司

Bicomponent platinum catalyst vulcanizer and its preparation method

The present invention relates to a double-component platinum catalyst curing agent. It includes agent A and agent B which can be uniformly mixed when they are used, in which the agent A is mixture of vinyl raw rubber, gas phase white carbon black and platinum complex, and the agent B is mixture of vinyl raw rubber, gas phase white carbon black, silicon oil whose end contains hydrogen and inhibitor. When the agent A and agent B are mixed, their mass ratio is agent A: agent B = (0.8-1.0)(1.0-1.5). Said invention also provides the preparation method of said double-component platinum catalyst curing agent.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

Novel platinum vulcanizing agent and preparation technology thereof

InactiveCN104927363ATo achieve the purpose of cross-linking vulcanizationFast vulcanizationEnvironmental resistancePolymer science

The invention relates to the technical fields of a vulcanizing agent and a preparation technology of the vulcanizing agent, particularly to a novel platinum vulcanizing agent and a preparation technology thereof. The novel platinum vulcanizing agent comprises a component A and a component B which are respectively added while in use, wherein the component A is the mixture of methyl vinylsiloxane rubber and a 1,3-divinyltetramethyldisiloxane platinum complex compound; the component B is the mixture of methyl hydrogen polysiloxane, gas phase silicon dioxide and an inhibitor. Compared with the prior art, the novel platinum vulcanizing agent disclosed by the invention uses the methyl vinylsiloxane rubber as a carrier, and under the existence of a platinum catalyst, vinyl double bonds and the methyl hydrogen polysiloxane are liable to generate a silicon hydrogen addition reaction, so that the purpose of cross-linking vulcanization is realized; the gas phase silicon dioxide is added for adjusting the hardness of vulcanization products, the vulcanization speed is high and is 1 / 3-1 / 2 higher than the vulcanization speed of the conventional platinum vulcanizing agent, and the production efficiency is improved; the vulcanization temperature is 10%-30% lower than that of the conventional platinum vulcanizing agent, and the purposes of energy conversation and environmental protection are achieved; the addition proportion is 30%-50% lower than that of the conventional platinum vulcanizing agent, and the production cost is reduced; the inhibitor is used, the storage time is greatly prolonged, and the storage time can reach 20-48h; in addition, the hygiene grade and the environmental protection grade are high, and the preparation technology is simple.

Owner:东莞市圣力堡有机硅科技有限公司

Polyphenylether cable compound for adjusting hardness and preparation method thereof

InactiveCN102516742AReduce dosageReduce hardnessPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention discloses a polyphenylether cable compound for adjusting hardness and a preparation method. The compound comprises the following ingredients in part by weight: 20 to 30 parts by weight of polyphenylether resin (PPE), 20 to 40 parts by weight of elastomer, 10 to 20 parts by weight of polyolefine, 20 to 35 parts by weight of flame retardant agent, 20 to 60 parts by weight of plasticizer, 5 to 15 parts by weight of inorganic filler, 0.1 to 0.3 part by weight of lubricant and 0.1 to 1.0 part by weight of antioxidant. Due to the adoption of the method, the hardness of the PPE cable compound can be effectively adjusted, and an economical and feasible technique can be provided to prepare the PPE cable compound with smooth appearance, good hand touch feeling, excellent mechanical property, high flame retardant property and high elasticity.

Owner:CHINA NAT BLUESTAR GRP CO LTD

High performance polyurethane waterproof coating material and preparation thereof

InactiveCN101475772AImprove flexibilityEasy to slipAntifouling/underwater paintsPaints with biocidesTO-18Polyester

The invention discloses a polyurethane waterproof coating for building and a method for preparing the same. The polyurethane waterproof coating consists of a composition A and a composition B according to the weight ratio of 1.0:1.0-2.5, wherein the composition A comprises 50 to 130 portions of polyester oligomer with high crystallization degree, 18 to 45 portions of polyisocyanate, 5 to 15 portions of phthalate and 0.1 to 0.8 portion of a catalyst; the composition B comprises 3 to 15 portions of a curing agent, 10 to 25 portions of a reinforcing agent, 17 to 35 portions of a lubricant, 20 to 36 portions of a filler, and 5 to 18 portions of paint. The method selects linear polyester with stronger polarity and higher crystallization degree and the polyisocyanate for reaction to prepare the composition A; the composition A and the composition B have good matching performance; and a high-elasticity material formed through the mixing and curing of two compositions is subjected to rapid oriented crystallization under the action of drawing force, so that the material has high tensile strength.

Owner:XIAN TONGRUI NEW MATERIAL DEV

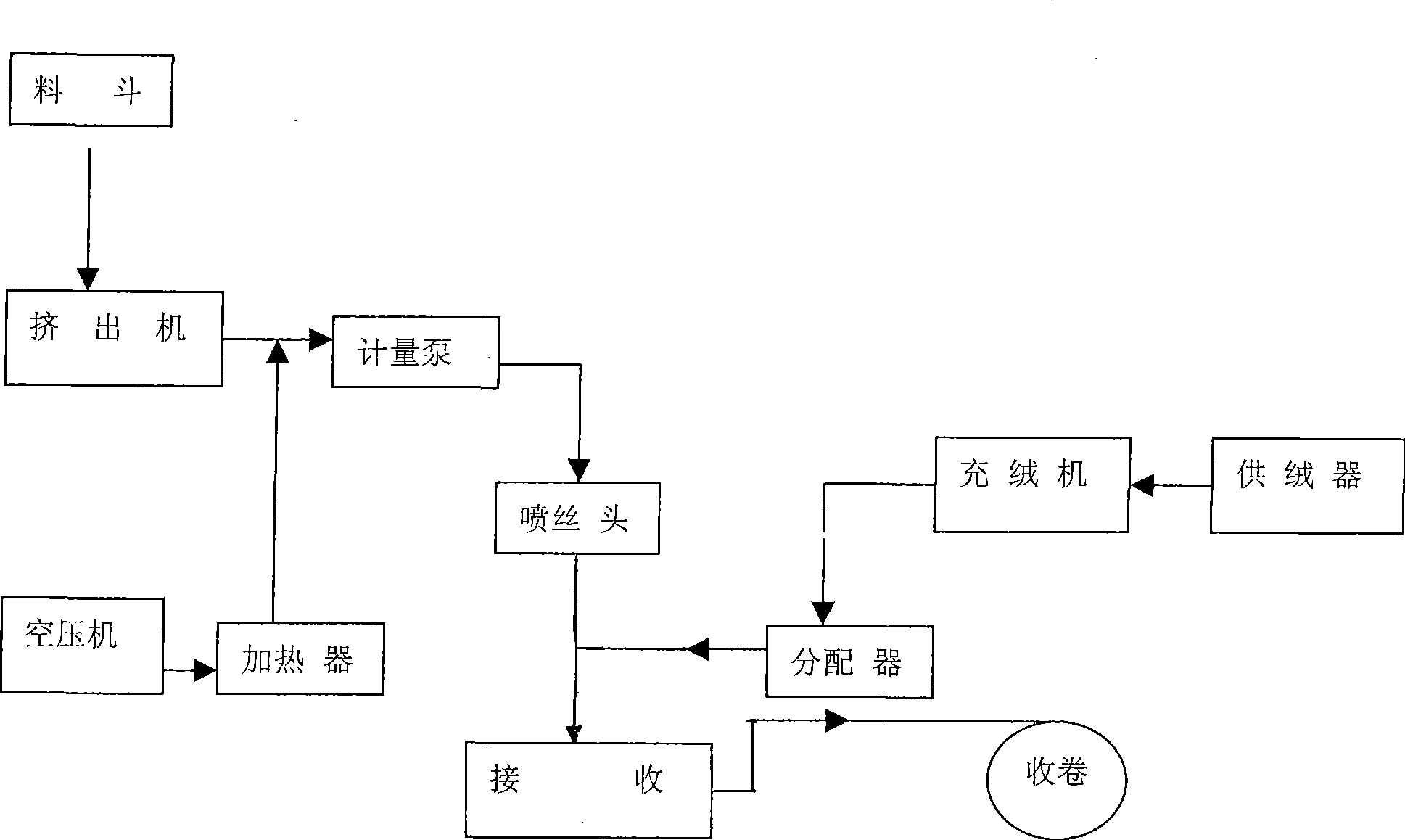

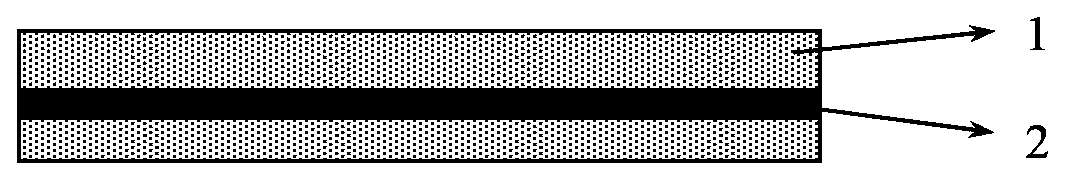

Method for producing melt-blown nonwoven down dual constituent thermal insulating interlining

InactiveCN101392432AHigh resilienceHigh longitudinal and transverse tensile strengthNon-woven fabricsMolten stateInterlining

The invention relates to a method for forming dual-component heat-insulating wadding by combining molten-spraying nonwoven fabrics and down. Specifically, the method comprises the following steps: heating polymer resin slices into molten state, then extruding, measuring and distributing the resin slices evenly to a hole of a spinneret device, and then stretching the resin slices into superfine fiber by hot air. Then the down is adhered with polymer fiber which is treated with fiber-stretching and is still not cured so as to form a net after being distributed by loosening, velvet-supplying and velvet-filling , and then a receiver and a finishing reel wind the net into the wadding. The invention adds down material into the existing molten-spraying production process, which can improve the heat-insulating rate and rebound elasticity of the wadding and can improve the transverse and longitudinal tensile strength of the wadding.

Owner:郭武胜

High-resilience closed flame-retardant foam silicon rubber material and preparation method thereof

The invention discloses a high-resilience closed flame-retardant foam silicon rubber material. The high-resilience closed flame-retardant foam silicon rubber material is prepared from the following components in parts by weight: 40-60% of silicon rubber, 30-50% of additive, 0.5-2% of foaming agent, 1-3% of crosslinking agent, 0.5-2% of catalyst, 0.5-2% of inhibitor and 0.5-1.5% of coloring agent.

Owner:JIAXING ZHONGYI CARBON TECH

Ultra-extinction memory fiber and preparation method

InactiveCN103628180APrevent wire breakageAvoid the phenomenon of insufficient drapeMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses an ultra-extinction memory fiber and a preparation method. The ultra-extinction memory fiber is prepared by a method for differentially distributing titanium dioxide content in a skin-core composite structure. The problems that the conventional complete-extinction fiber has poor ultraviolet resistance, breakage in the weaving process is relatively serious, and clothes produced have a low sagging degree are solved. The ultra-extinction memory fiber adopts the skin-core structure, and has the average titanium dioxide content of more than 3% and high ultraviolet resistance; fabric woven by the ultra-extinction memory fiber is bright in color, comfortable, sagging, stiff and smooth and high in resilience, and has much higher dyeing property and ultraviolet resistance than the conventional polyester and other complete-extinction fibers.

Owner:SHENGHONG GRP CO LTD

Sealing gasket and manufacturing method

The present invention relates to a method for preparing gasket seal. Said preparation method includes according to size requirement cutting metal ring; according to compression ratio of graphite plate and density of gasket cutting out width of graphite tape, according to the specification size required for gasket selecting proper mould; placing the graphite tape into the mould by turns and prepressing graphite ring; moulding the metal ring and graphite ring by means of mould and nesting metal ring with graphite ring together; demoulding; and edging and shaping so as to obtain the gasket seal.

Owner:NINGBO TIANSHENG SEALING PACKING

Environment-friendly high-elasticity rubber material

The invention discloses an environment-friendly high-elasticity rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of powder nitrile-butadiene rubber, 10-18 parts of polyvinyl chloride thermoplastic elastomer, 10-20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3-5 parts of p-tert-butyl phenol-formaldehyde resin, 1.5-2 parts of sulfur, 1.2-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of zinc oxide, 5-8 parts of epoxy soybean oil, 0.5-1 part of paraffin, 1-3 parts of zinc-barium stabilizer, 2-3 parts of organophosphate, 20-30 parts of modified kaolin, 15-20 parts of silica white, 1.5-3 parts of carbon master batch and 0.5-1.5 parts of novel rubber reinforcing agent XRE. The rubber material has the advantages of excellent elasticity, wear resistance, favorable tear resistance and low cost, and reduces the hazard to the environment.

Owner:宁国日格美橡塑股份有限公司

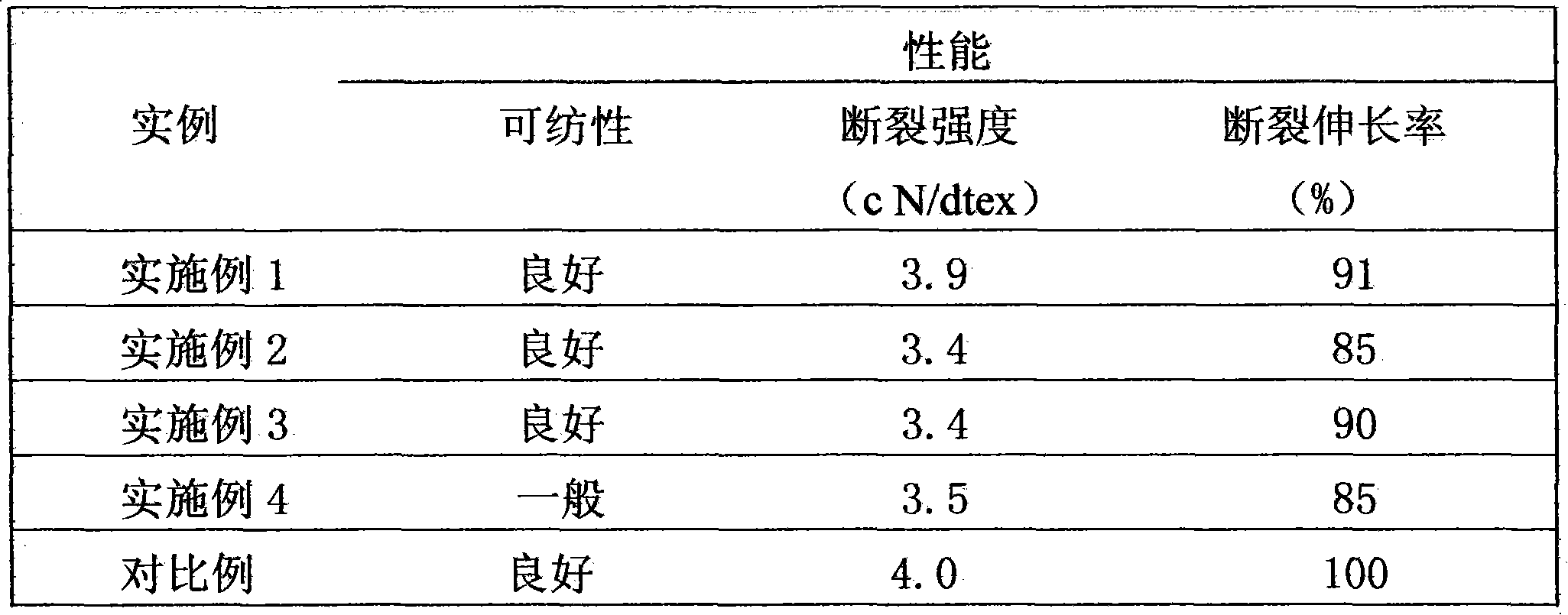

Nylon 66/tackified polyester composite sheath core fiber and preparation method thereof

ActiveCN101880920AHigh water transmissibility andHigh resilienceMelt spinning methodsConjugated synthetic polymer artificial filamentsLinear densityNylon 66

The invention discloses a nylon 66 / tackified polyester composite sheath core fiber and a preparation method thereof. The fiber comprises the following components by weight percent: 15-85% of nylon 66 and 85-15% of tackified polyester, wherein the nylon 66 serving as a sheath has a relative viscosity of 2.5-45.0% while the tackified polyester serving as a core has a relative viscosity of no less than 0.64%. The fracture strength of the fiber is no less than 3.6cN / dtex, the elongation at break thereof is no less than 80%, and the linear density thereof is 1.1-143dtex. The preparation method is as follows: compounding the nylon 66 into the sheath at the temperature of 300-310 DEG C and at the pressure of 5.0-35.0MPa, compounding the tackified polyester into the core at the temperature of 290-300 DEG C and at the pressure of 15-35.0MPa, and spinning, wherein the temperature, humidity and speed of cooling air are respectively15-28 DEG C, 75-100% and 0.8-2.5m / s, and the spinning speed is 400-1500m / s; drawing in an oil bath at the temperature of 50-90 DEG C, wherein the oil bath drawing times is 3.0-5.0; and drawing with steam at the temperature of 90-120 DEG C, wherein the steam drawing times is 1.1-1.5. The fiber can satisfy requirements on raw material fibers from customers like industrial woolen cloth, and greatly lowers the production cost.

Owner:JIANGSU ZHONGSHI FIBER CO LTD

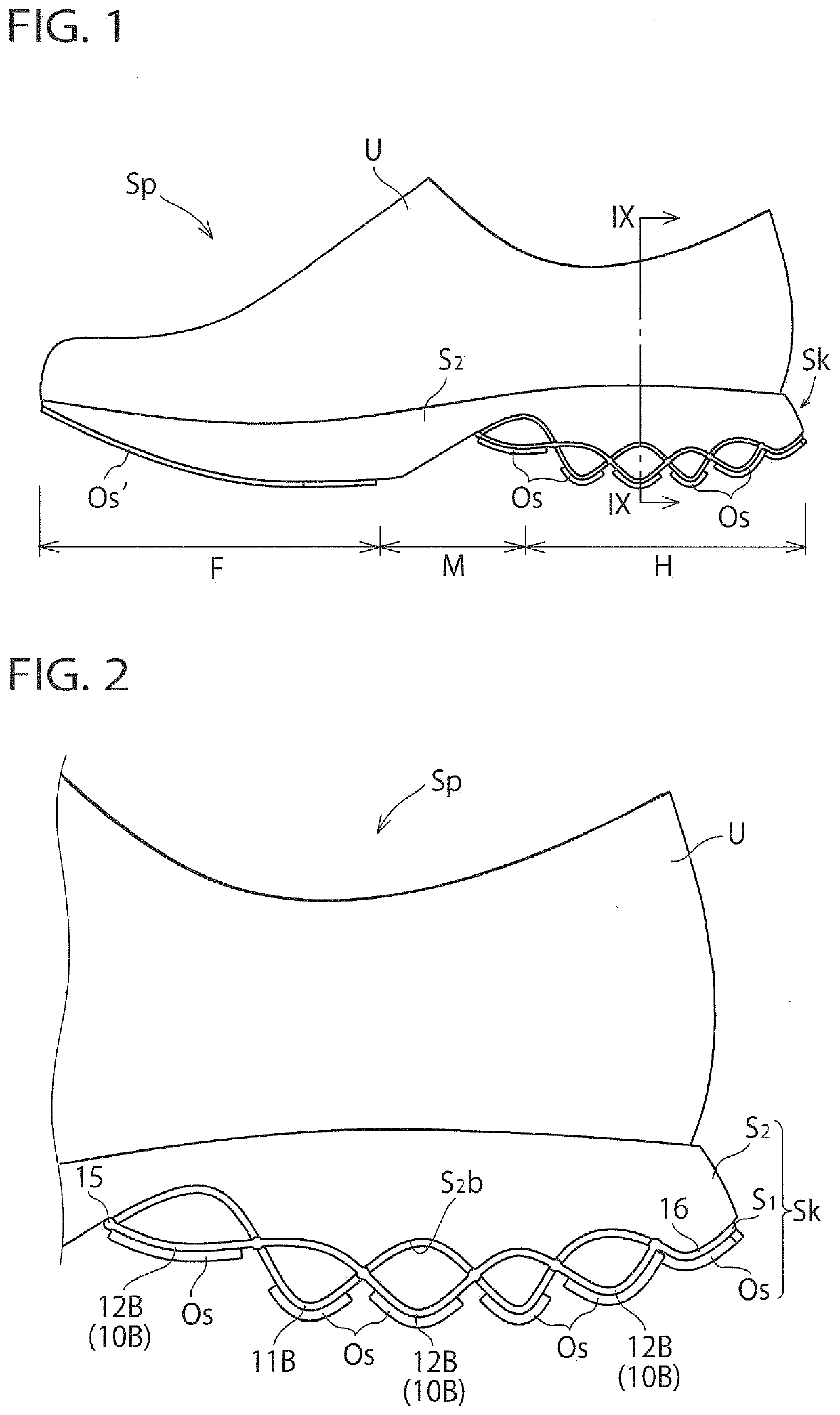

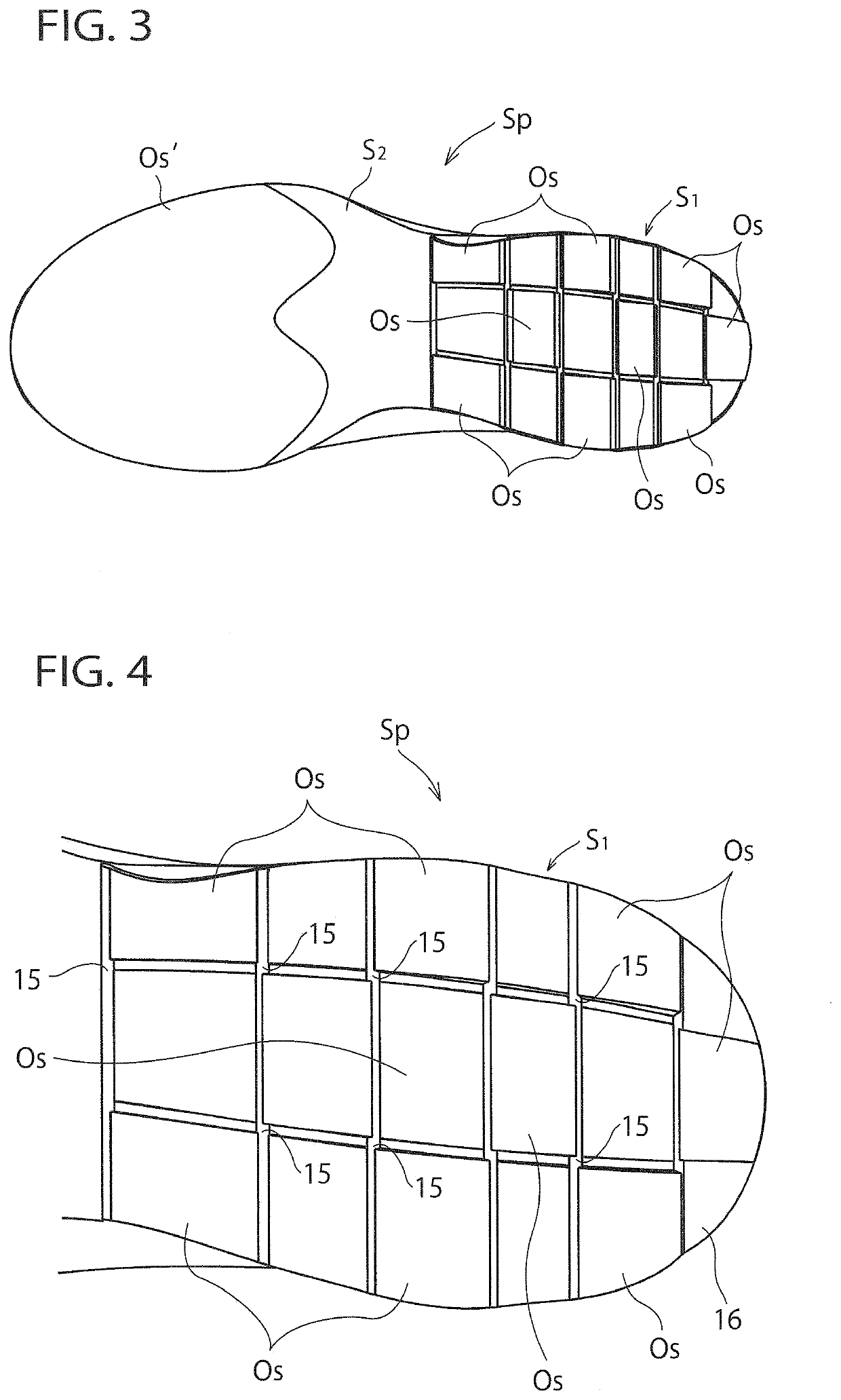

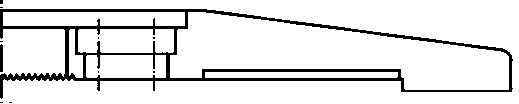

Sole Structure for a Shoe

The sole structure includes a sole body comprising a wavy structure and a midsole, and an outsole disposed below the sole body and having a ground contact surface. The wavy structure comprises a plurality of wavy extending parts that respectively extend in a wavy shape in the foot-length direction and that are disposed side by side in the foot-width direction, and a connecting portion that connects the wavy extending parts respectively in the foot-width direction. A thickness center plane of the wavy structure extends curvedly in the vertically direction toward the foot-length direction. The midsole is formed of a soft elastic member and includes a lower surface and an upper surface. The lower surface has a contact surface that the wavy structure is in contact with. The upper surface is fitted to an upper of a shoe.

Owner:MIZUNO CORPORATION

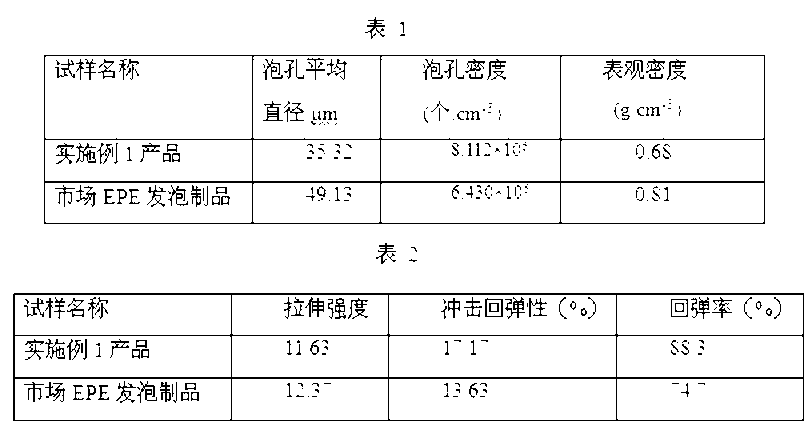

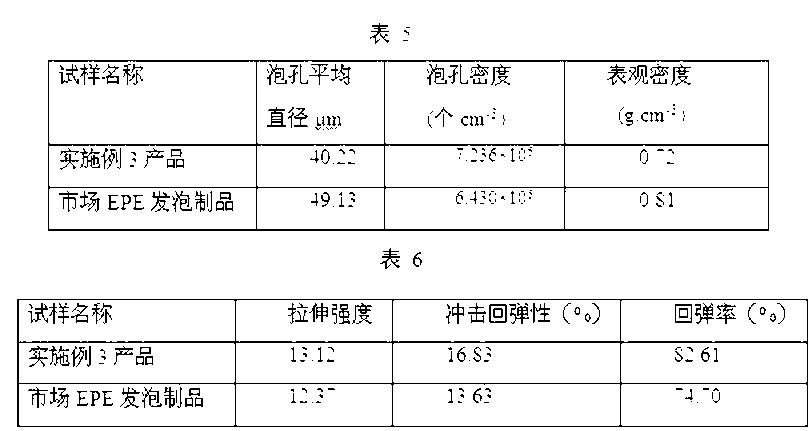

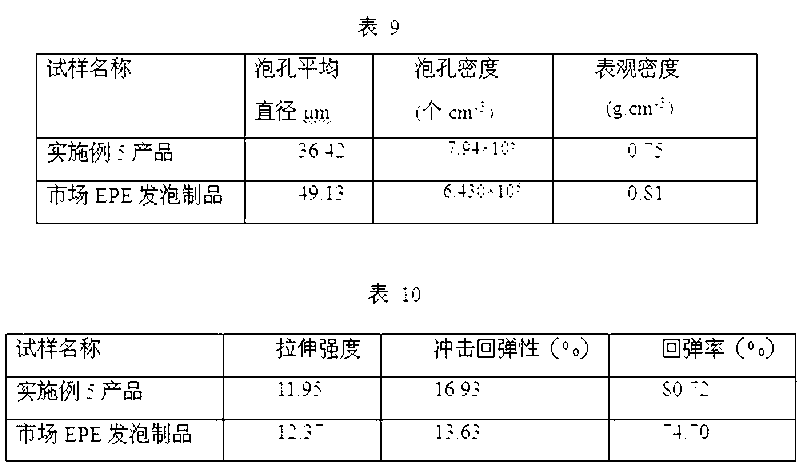

High-elasticity low-density polyethylene foaming composite material and preparation method thereof

ActiveCN103224662AIncreased decomposition temperature rangeBroaden the decomposition temperature rangeLow-density polyethyleneElastomer

The invention discloses a high-elasticity low-density polyethylene foaming composite material and a preparation method thereof. The high-elasticity low-density polyethylene foaming composite material is prepared from the following raw material components in parts by weight: 85-95 parts of low-density polyethylene, 5-15 parts of elastomer, 0.1-0.3 part of crosslinking agent, 1-2 parts of foaming agent and 0.2-0.8 part of blowing promoter. The foaming composite material prepared by the following steps of: burdening, extrusion, drying and injection molding has a high foaming ratio and improved rebound resilience reaching above 16.3%. Compared with present low-density polyethylene foaming sheets on the market, the high-elasticity low-density polyethylene foaming composite material has high cost performance and can be used for solving the problem that the rebound resilience of conventional foaming composite materials prepared by low-density polyethylene (LDPE) generally does not exceed 14%, and as the conventional foaming composite materials cannot reach technical requirements, have high cost and the like, the application of the conventional foaming composite materials in industries is limited.

Owner:GUIZHOU NORMAL UNIVERSITY

Antibacterial low temperature-resistant heat insulation material

The invention provides an antibacterial low temperature-resistant heat insulation material. The antibacterial low temperature-resistant heat insulation material comprises, by weight, 10-25 parts of LDPE resin, 5-10 parts of modified melamine resin, 20-30 parts of an antibacterial agent, 15- silicone rubber, 20-30 parts of ethylene propylene rubber, 15-25 parts of butadiene rubber, 10-20 parts of styrene butadiene rubber, 3-5 parts of aromatic oil, 1-3 parts of stearic acid, 2-4 parts of a coupling agent, 5-8 parts of a compatibilizer, 10-15 parts of a foaming agent, 5-20 parts of a filler, 1-2 parts of an antioxidant, 1-3 parts of an antioxidant, 3-7 parts of a plasticizer, 5-10 parts of paprika, 5-10 parts of a mildew inhibiotor, 15-25 parts of high-low temperature resistance carbon black, 3-5 parts of nanometer calcium carbonate, 5-15 parts of glass fibers, 5-15 parts of ceramic fibers, 20-35 parts of a flame retardant, 5-10 parts of methylvinyldimethoxysilane and 10-15 parts of kaolin. The antibacterial low temperature-resistant heat insulation material has the advantages of good heat and cold resistance, excellent heat insulation performance, excellent mechanical properties and strong antibacterial property.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

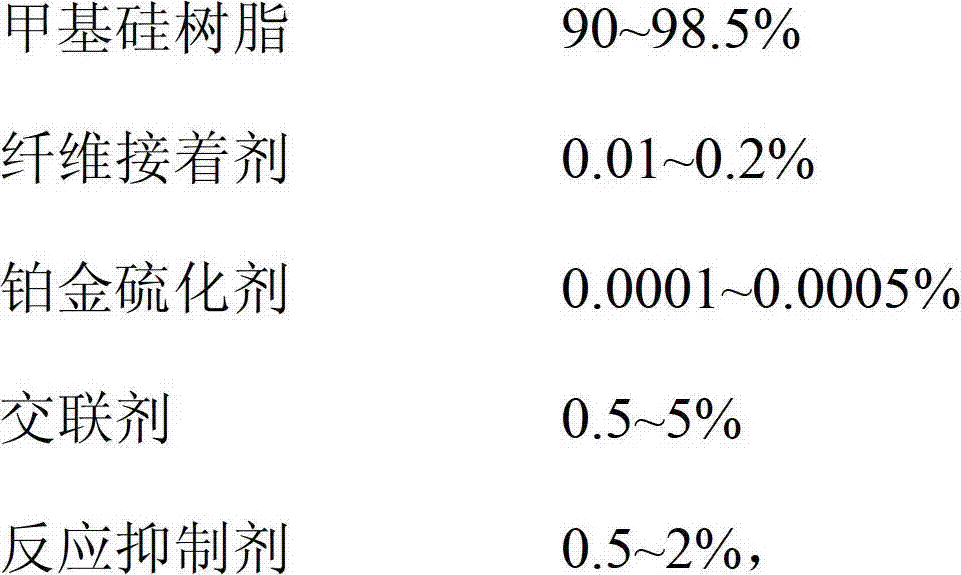

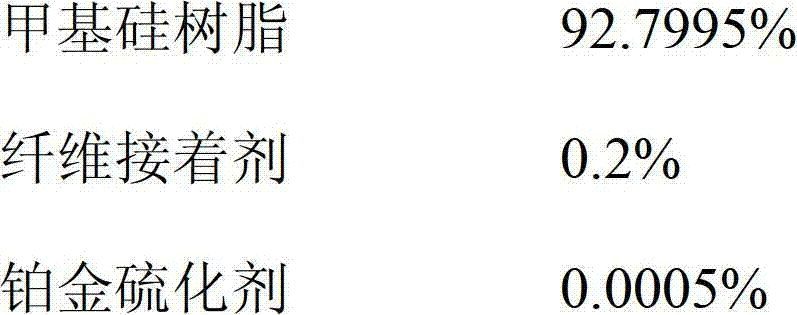

Silicone rubber halogen-free wire/cable or sleeve, and preparation method thereof

ActiveCN102876043AMeet food grade requirementsOvercome the disadvantages of easy agingRubber insulatorsInsulated cablesCross-linkPlatinum

The invention relates to silicone rubber halogen-free wire / cable or sleeve, and a preparation method thereof. A braided layer is wound around outer surface of silicone rubber, and coated outside with protective rubber. The protective rubber is prepared from methyl silicone resin, a fiber binding agent, a platinum vulcanizing agent, a cross-linking agent and reaction inhibitor by blending, and vulcanizing at 160-240 DEG C for 15-50 min. The method overcomes the defect of easy aging in prior art, guarantees excellent performance, and prolongs service life.

Owner:DONGGUAN SUNTRACK WIRE

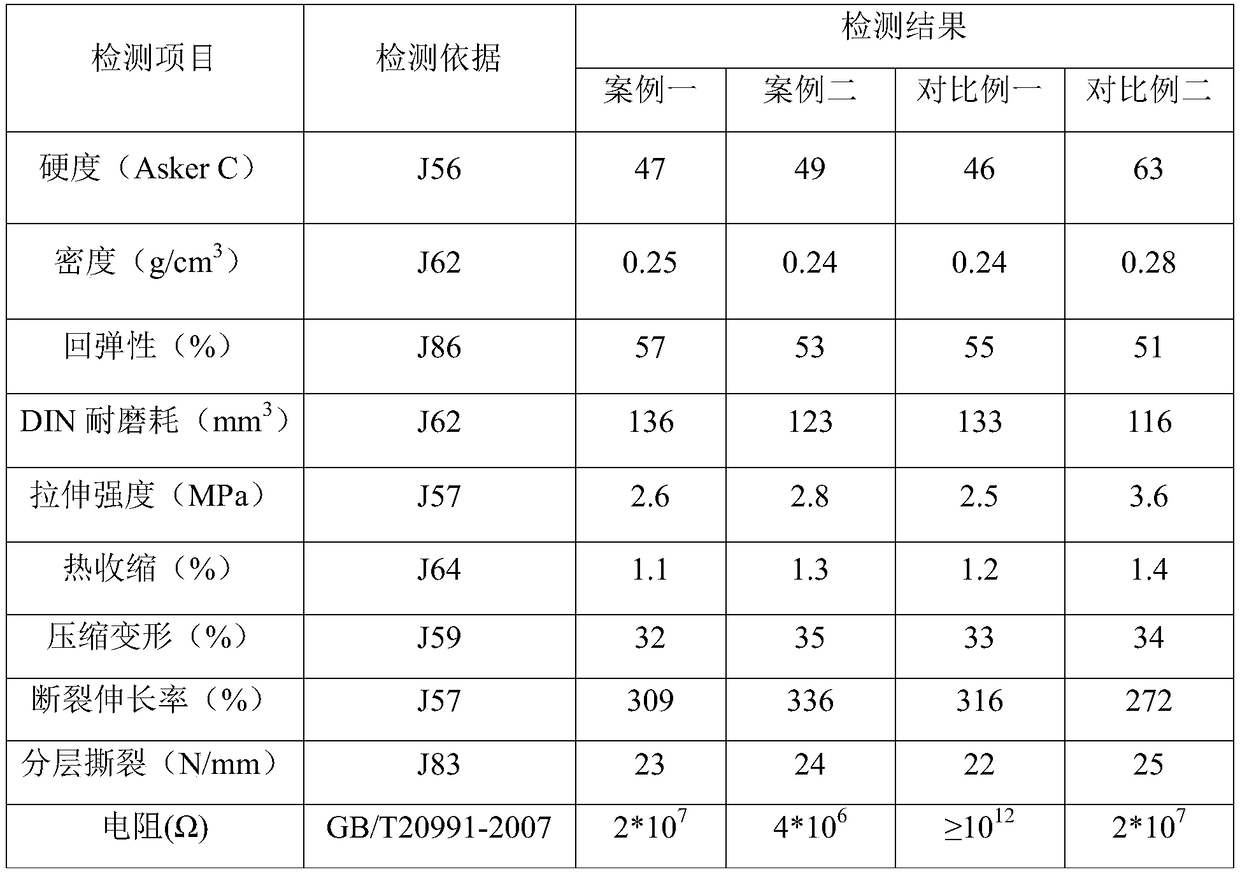

Soft high-elasticity wear-resisting electrostatic-discharge EVA (ethylene-vinyl acetate) composite foam material and preparation method thereof

The invention discloses soft high-elasticity wear-resisting electrostatic-discharge EVA (ethylene-vinyl acetate) composite foam material and a preparation method thereof. The soft high-elasticity wear-resisting electrostatic-discharge EVA composite foam material is made by material mixing, granulating and foaming; materials include, by weight, 25-50 parts of ethylene-vinyl acetate copolymer, 15-35parts of polyolefin thermoplastic elastomer, 15-25 parts of ethylene propylene diene monomer rubber, 10-20 parts of polyolefin block copolymer, 1-3 parts of graphene oxide, 3-8 parts of a wear resistant, 4-6 parts of a filling agent, 0.4-0.6 part of an activator, 0.7-1.2 parts of a crosslinking agent, 2.5-3.5 parts of a foaming agent, and 2.1-4.3 parts of aids, wherein vinyl acetate accounts for26-40% by mass of the ethylene-vinyl acetate copolymer. The soft high-elasticity wear-resisting electrostatic-discharge EVA composite foam material has good softness and comfort, excellent elasticityand excellent wear resistance, and has good electrostatic discharge performance; the preparation method of the soft high-elasticity wear-resisting electrostatic-discharge EVA composite foam material is simple and easily operable.

Owner:ANTA CHINA

Polyurethane elastomer forming method and sports safety protective article made by adopting polyurethane elastomer forming method

The invention relates to a foamed polyurethane elastomer forming method. The method comprises the following steps: mixing pre-foamed resin granules, with different densities, of a foamed polyurethane elastomer; injecting the granules into a cylinder of a foaming forming machine, then pushing the granules into a mold, and fulfilling the mold with the granules; pressing the granules in the mold; heating the pressed granules by virtue of steam to form a hot-melt integrated pre-formed body; cooling the pre-formed body, removing the mold, finally drying, and stereotyping the pre-formed body to obtain the resin formed body of the foamed polyurethane elastomer. The invention also provides a foamed polyurethane elastomer resin sports safety protective article made according to the method. Compared with an EVA material, for the resin formed boy of the foamed polyurethane elastomer, made according to the method, the elasticity is obviously improved, and the safety protection performance of a product can be improved.

Owner:DONGGUAN TANGXIA YIFENG SPORTS TECH CO LTD

Pure cotton ply yarn hard twisted natural elastic fabric and processing technic thereof

InactiveCN102080289AGood moisture absorption and air permeabilityHigh resilienceWoven fabricsVegetal fibresWoolSizing

The invention provides a pure cotton ply yarn hard twisted natural elastic fabric and a processing technic thereof. The fabric is characterized in that the warp yarns of the fabric are JC9.7tex*2 S twist yarns with 1600 twists / m; the weft yarns of the fabric are JC7.3tex*2 S twist yarns with 1700 twists / m; the warp density of the fabric is 861 warp yarns per 10cm; and the weft density of the fabric is 370 weft yarns per 10cm. The processing technic is characterized by adopting special treatment methods in sizing and weaving technics. The invention has the following beneficial effects: the fabric has lasting resilience, gloss and smoothness and has the characteristics of stiffness and smoothness of hemps, comfort and skin feeling of cottons, full appearances of wool fabrics and the like; and through breakthrough of the product in research and development and technics, references are provided for development of the high-grade individual fabrics, marketing development is guided and good economic benefits are created for the enterprises.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Run-flat tire side support rubber, preparation method and tire structure thereof

InactiveCN109438787AGood physical and mechanical propertiesImprove heat generationTyre partsSteering wheelTear resistance

The invention relates to the technical field of tires and in particular to run-flat tire side support rubber, a preparation method and a tire structure thereof. Neodymium series butadiene rubber usedby a sizing material is polybutadiene with high cis-form-1,4-structure content obtained by using a neodymium compound as a main catalyst, so the support rubber has higher tensile property and resilience property, good carbon black dispersing performance, and more excellent aging-resistant performance. White carbon black adopts a 1115MP type with high dispersion and a low superficial area. The high-dispersion-type low-superficial-area white carbon black is capable of effectively improving tear resistance and thermal aging resistance of a support rubber part, and effectively reducing 15% of thermogenesis performance. Through a formula of the relayed sizing material, the prepared support rubber has stronger physical characteristics of tear resistance, high stretching, high strength, high temperature resistance and the like. Through a special design and a matching ratio in structure and formula aspects, the tires can be guaranteed to be continuously driven still in a speed of 80 km / h in azero air pressure state, and a steering wheel cannot be easily deviated from a driving direction in a driving process, until a next maintenance point is found out.

Owner:万达集团股份有限公司 +1

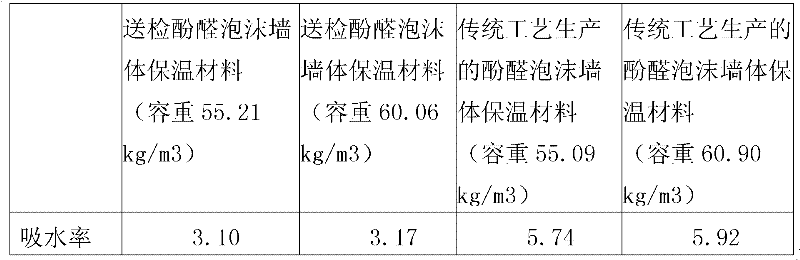

A kind of production method of phenolic foam wall insulation material

The invention discloses a production method of a phenolic foam wall insulation material. The production method comprises (1) preparing raw materials of phenol, paraformaldehyde for industrial purposes, sodium hydroxide, acrylamide and water, (2) putting phenol, sodium hydroxide and water into a reactor, heating, and adding slowly paraformaldehyde for industrial purposes into the reactor, (3) putting acrylamide into the reactor and heating slowly, (4) adding water, chloropropylene oxide and sodium hydroxide into the reactor, heating and stirring, (5) cooling, adding formic acid into the reactor and carrying out dehydration, and (6) mixing an epoxy modified phenolic resin obtained by the step 5, an organic silicone foam stabilizer, n-pentane and one or more of p-toluenesulfonic acid, benzenesulfonic acid, phosphoric acid and sulfuric acid, and pouring the mixture into a mold for foaming to obtain a desired product. The phenolic foam wall insulation material produced by the production method has the advantages of low cost, energy saving and fire resistance. Compared with similar products, the phenolic foam wall insulation material has low water absorption and strong ageing resistance, and thus the phenolic foam wall insulation material can be utilized widely for the field of thermal insulation building walls.

Owner:湖南中野高科技特种材料有限公司

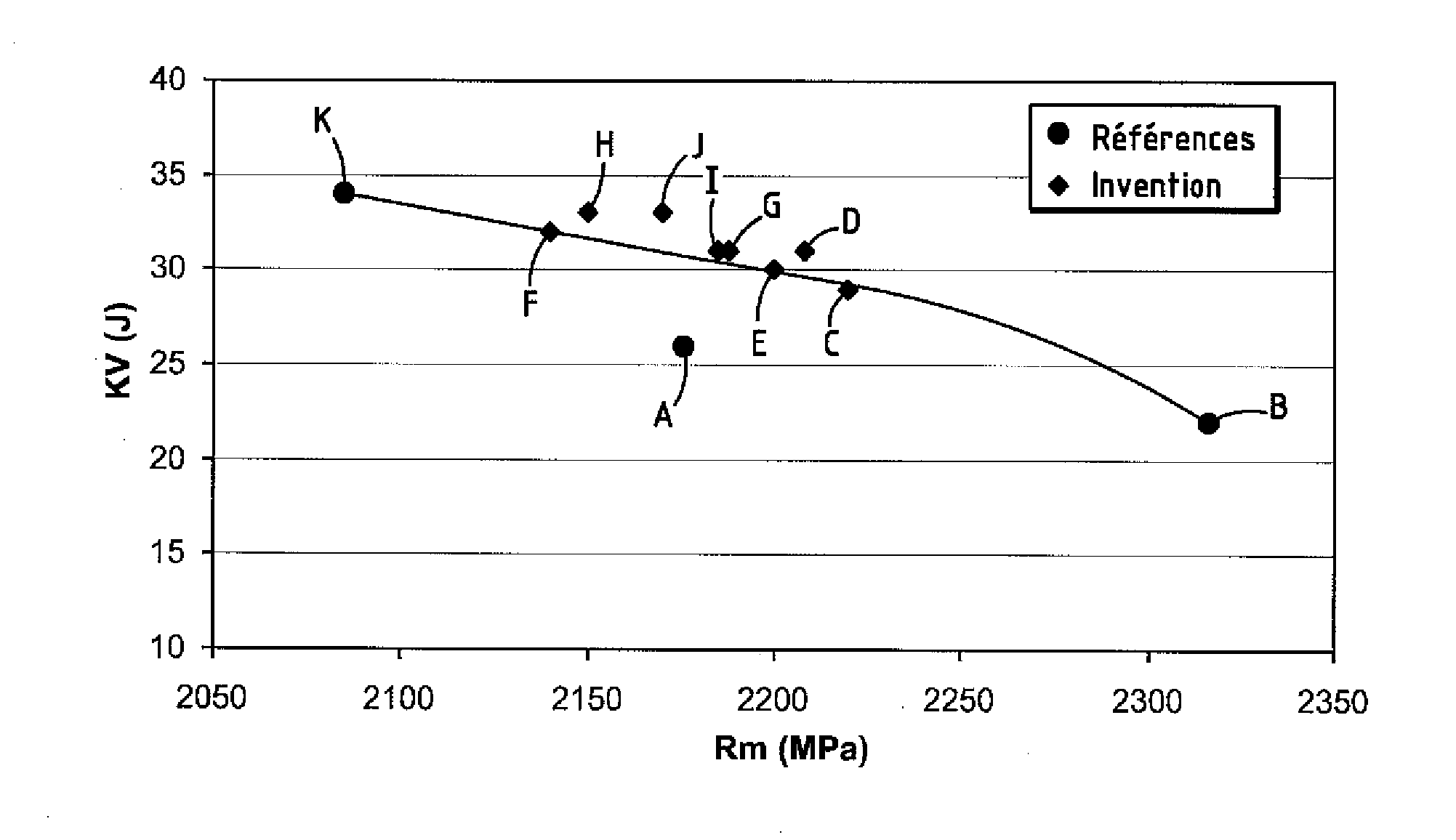

Hardened Martensitic Steel Having a Low Cobalt Content, Process for Manufacturing a Part from Steel, and Part thus Obtained

ActiveUS20110226386A1High resilienceHigh mechanical strengthSolid state diffusion coatingFurnace typesSmeltingCobalt

A steel characterized in that its composition is percentages by weight:C=0.18-0.30%Co=1.5-4%Cr=2-5%Al=1-2%Mo+W / 2=1-4%V=traces-0.3%Nb=traces-0.1%B=traces-30 ppmNi=11-16% where Ni≧7+3.5 AlSi=traces-1.0%Mn=traces-4.0%Ca=traces-20 ppmRare earths=traces-100 ppmif N≦10 ppm, Ti+Zr / 2=traces-100 ppm where Ti+Zr / 2≦10 Nif 10 ppm<N≦20 ppm, Ti+Zr / 2=traces-150 ppmO=traces-50 ppmN=traces-20 ppmS=traces-20 ppmCu=traces-1%P=traces-200 ppmthe remainder being iron and inevitable impurities resulting from the smelting. A process for manufacturing a part from this steel, and part thus obtained.

Owner:AUBERT & DUVAL FR

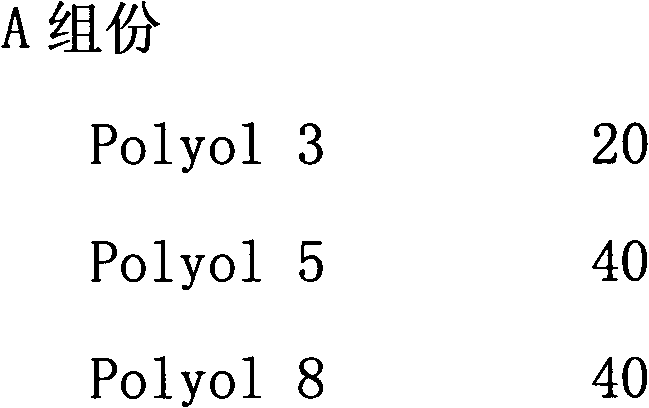

Polyurethane reaction ball and preparing method thereof

The invention discloses a polyurethane reaction ball which is a microcellular polyurethane elastomer prepared through raw materials including polymer component A and prepolymer component B. The invention further discloses a method for preparing the reaction ball, which includes: mixing and stirring polyether polyols, foaming agents, chain extenders, color paste and catalysts to obtain the polymer component A; and evenly mixing and stirring the polymer component A and the prepolymer component B according to a certain proportion at temperature of 5-32 DEG C, and pouring the mixture into a reaction ball mold for aging to obtain the polyurethane reaction ball. The foam density of the reaction ball is 100-600kg / m<3>, hardness of the reaction ball is Shore A40+ / -10, free-falling resilience can reach 80-90%, and property requirements of high-level reaction balls are met. In addition, the polyurethane reaction ball and the preparing method thereof have good technology processing characteristics, spalling during contraction and mold opening is avoided, and product defective percentage is reduced.

Owner:WANHUA CHEM BEIJING +2

Method for producing cocoon fiber quilt for dermatitis prevention

InactiveCN101536852AHigh resilienceStrong moisture permeabilityAnthropod material medical ingredientsFibre treatmentHerbFiber

The invention discloses a method for producing cocoon fiber quilt for dermatitis prevention, relating to the production process of health-care cocoon fiber quilt. The method is characterized in that cicada shell, frutus cnidii, perilla shell, glabrous greenbrier rhizome, fructus leonuri, lightyellow sophora root, rhizoma atractylodis, zaocys dhumnade, stiff silkworm, white snail, cocklebur, unprocessed polygonum and red paeonia are decocted by water, filtered to obtain Chinese herb liquid, and silk floss is dipped in the mixed liquid consisting of swelling agent, silk softening agent and the Chinese herb liquid, dried and solidified into cocoon fiber cotton containing medicament. The invention is capable of regulating the microcirculation of organism and promoting the absorption by human body with the smell of Chinese herb, and has the function of dermatitis prevention.

Owner:江苏丝乡丝绸股份有限公司

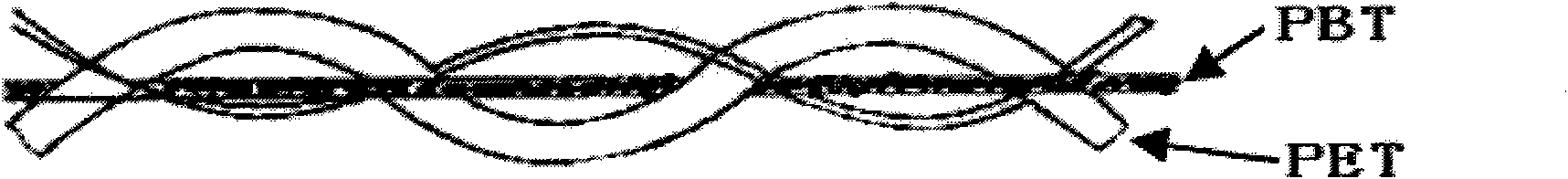

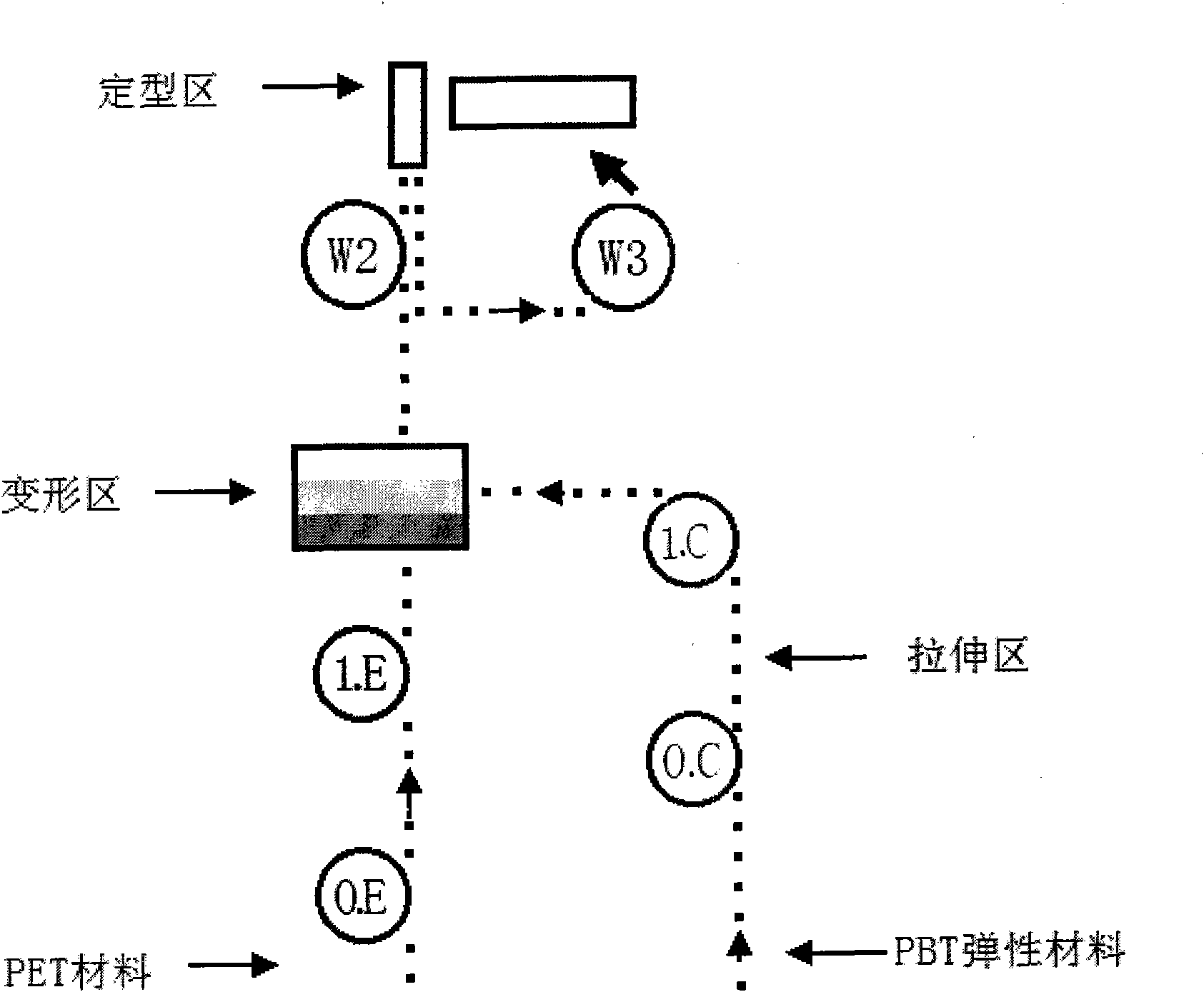

Novel production method of vehicular ATY (Air Texturing Yarn) elastic fiber

The invention relates to the field of production of seat fabrics, in particular to a novel production method of vehicular ATY (Air Texturing Yarn) elastic fiber. The production method comprises the following steps of: first drafting POY (Polyester Pre-Oriented Yarn) to form a PET (polyethylene terephthalate) material and simultaneously drafting the POY to form a PBT (polybutylene terephthalate) elastic material; preheating the PET material and the PBT elastic material, carrying out air texturing by taking the PET elastic material as core yarns and the PET material as outer skin, and simultaneously, intertwining and wrapping to form the air texturing yarns; and finally sizing and winding the air texturing yarns. According to the novel production method disclosed by the invention, the production process route is simple, the rebound resilience of the ATY elastic fiber product is improved, and economy and environmental-friendliness are achieved.

Owner:KUANGDA TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com