Soft high-elasticity wear-resisting electrostatic-discharge EVA (ethylene-vinyl acetate) composite foam material and preparation method thereof

An electrostatic discharge and composite foaming technology, applied in the field of sports shoe sole materials, can solve the problems of poor cushioning and rebound performance of materials, affecting the wearer's wearing comfort, affecting the wearer's experience, etc., to achieve resilience Good, improved physical and mechanical properties, good rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In the embodiment of the present invention, the mass ratio of the materials contained in the soft, high-elastic and electrostatically releasable EVA composite foam material is as follows:

[0054] Ethylene-vinyl acetate copolymer: 35 parts by mass

[0055] Polyolefin thermoplastic elastomer: 25 parts by mass

[0056] EPDM rubber: 20 parts by mass

[0057] Polyolefin block copolymer: 15 parts by mass

[0058] Anti-wear agent: 5 parts by mass

[0059] Graphene oxide: 1.2 parts by mass

[0060] Filler: 5 mass

[0061] Zinc oxide ZnO: 2 parts by mass

[0062] Stearic acid St: 0.5 parts by mass

[0063] Zinc stearate ZnSt: 1.0 parts by mass

[0064] Cross-linking auxiliary agent: 0.1 parts by mass

[0065] Crosslinking agent: 1.0 parts by mass

[0066] Foaming agent: 3.1 parts by mass

[0067] Among them, the model of ethylene-vinyl acetate copolymer is EVA7470M, produced by Formosa Plastics; the model of polyolefin thermoplastic elastomer is polystyrene elastomer,...

Embodiment 2

[0073] In the embodiment of the present invention, the mass ratio of the materials contained in the soft, high-elastic and electrostatically releasable EVA composite foam material is as follows:

[0074] Ethylene-vinyl acetate copolymer: 35 parts by mass

[0075] Polyolefin thermoplastic elastomer: 20 parts by mass

[0076] EPDM rubber: 18 parts by mass

[0077] Polyolefin block copolymer: 12 parts by mass

[0078] Wear-resistant agent: 6 parts by mass

[0079] Graphene oxide: 2 parts by mass

[0080] Filler: 5 parts by mass

[0081] Zinc oxide ZnO: 2 parts by mass

[0082] Stearic acid St: 0.5 parts by mass

[0083] Zinc stearate ZnSt: 0.8 parts by mass

[0084] Cross-linking auxiliary agent: 0.17 parts by mass

[0085] Crosslinking agent: 1.0 parts by mass

[0086] Foaming agent: 3.0 parts by mass

[0087] Among them, the model of ethylene-vinyl acetate copolymer is EVA265, produced by DuPont; the model of polyolefin thermoplastic elastomer is 6058, produced by Qua...

Embodiment 3

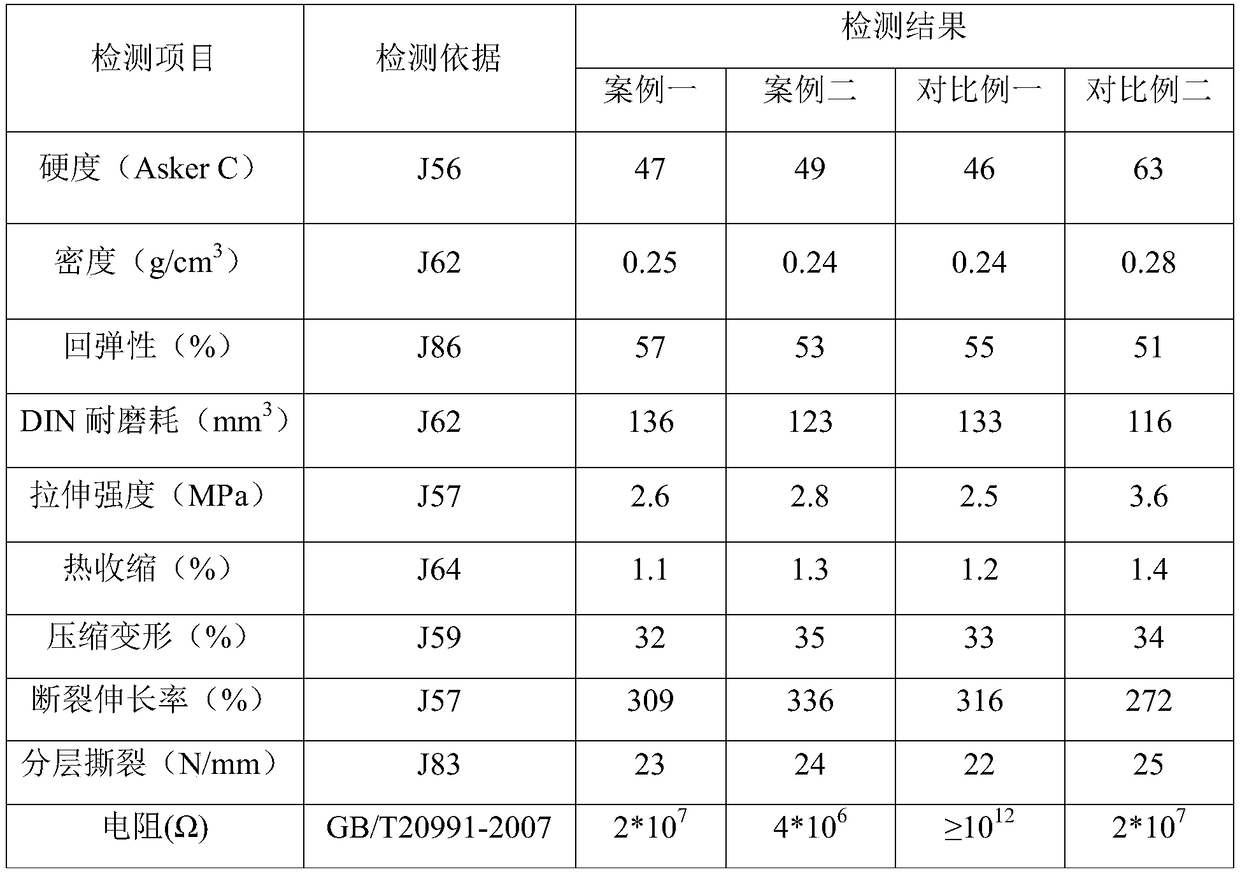

[0093] The foamed product obtained in the above implementation case is tested for physical properties, and the following comparative examples are tested: Comparative Example 1: Compared with the formula in Example 1, the use of graphene oxide is canceled, and other components and parts by mass remain unchanged , to test the physical properties of the prepared EVA composite foam material; Comparative Example 2: Using the same mass parts of conductive carbon black as the electrostatic discharge carrier to replace the graphene oxide in the formula of Example 1, other components and mass parts unchanged, test the physical properties of the prepared EVA composite foam material; the test results are shown in Table 1.

[0094] The physical property test is carried out to the EVA composite foam material obtained in the above embodiment one and embodiment two and comparative example one and comparative example two, the results are shown in Table 1, and table 1 shows two kinds of embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com