A kind of production method of phenolic foam wall insulation material

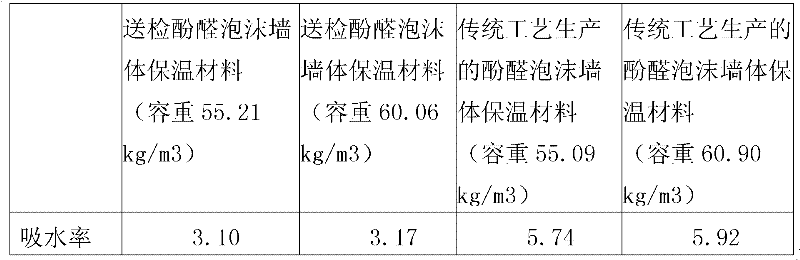

A technology of thermal insulation material and phenolic foam, which is applied in the production field of phenolic foam wall insulation material, can solve the problems of reducing thermal insulation effect and the like, and achieves the effect of reducing water absorption rate, reducing water absorption rate and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1), backup raw materials: 350kg of phenol, 175kg of paraformaldehyde for industrial use, 1.5kg of sodium hydroxide, 5kg of acrylamide, and 60kg of water;

[0021] (2), put the phenol, sodium hydroxide and water prepared in step (1) into the reaction kettle, heat up to 70-85°C, slowly add the industrial paraformaldehyde prepared in step (1), and finish adding within 1 hour;

[0022] (3) Put the acrylamide prepared in step (1) into the reaction kettle, slowly raise the temperature to 95-110°C, and keep the temperature at 95-110°C for 30-90 minutes;

[0023] (4), reduce the temperature in the reactor to 40°C, add 10kg of water, 5kg of epichlorohydrin, and 2kg of sodium hydroxide, raise the temperature to 50-70°C, and stir for 1 hour;

[0024] (5), the temperature in the reactor is lowered to 40°C, and a total of 1 kg of formic acid is slowly added to the reactor while stirring to adjust the pH value of the mixture in the reactor to neutral, and dehydrate 20 kg to obtain a...

Embodiment 2

[0027] (1), backup raw materials: 400kg of phenol, 225kg of industrial paraformaldehyde, 2kg of sodium hydroxide, 25kg of acrylamide, and 120kg of water;

[0028] Steps (2)~(3) are the same as in Example 1;

[0029] (4), reduce the temperature in the reactor to 40°C, add 60kg of water, 25kg of epichlorohydrin, and 10kg of sodium hydroxide, raise the temperature to 50-70°C, and stir for 6 hours;

[0030] (5), the temperature in the reactor is reduced to 40 DEG C, and a total of 9 kg of formic acid is slowly added to the reactor while stirring to adjust the pH value of the mixture in the reactor to neutrality, and 70 kg of dehydration is obtained to obtain an epoxy-modified phenolic resin;

[0031] (6), get step (5) gained epoxy modified phenolic resin 40kg, organosilicon foam stabilizer 1.3kg, n-pentane 2.5kg and p-toluenesulfonic acid, benzenesulfonic acid, phosphoric acid, Dissolve 2.2kg of sulfuric acid in 0.5kg of water, mix and stir evenly, pour into the preset mold, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com