Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181results about How to "No plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

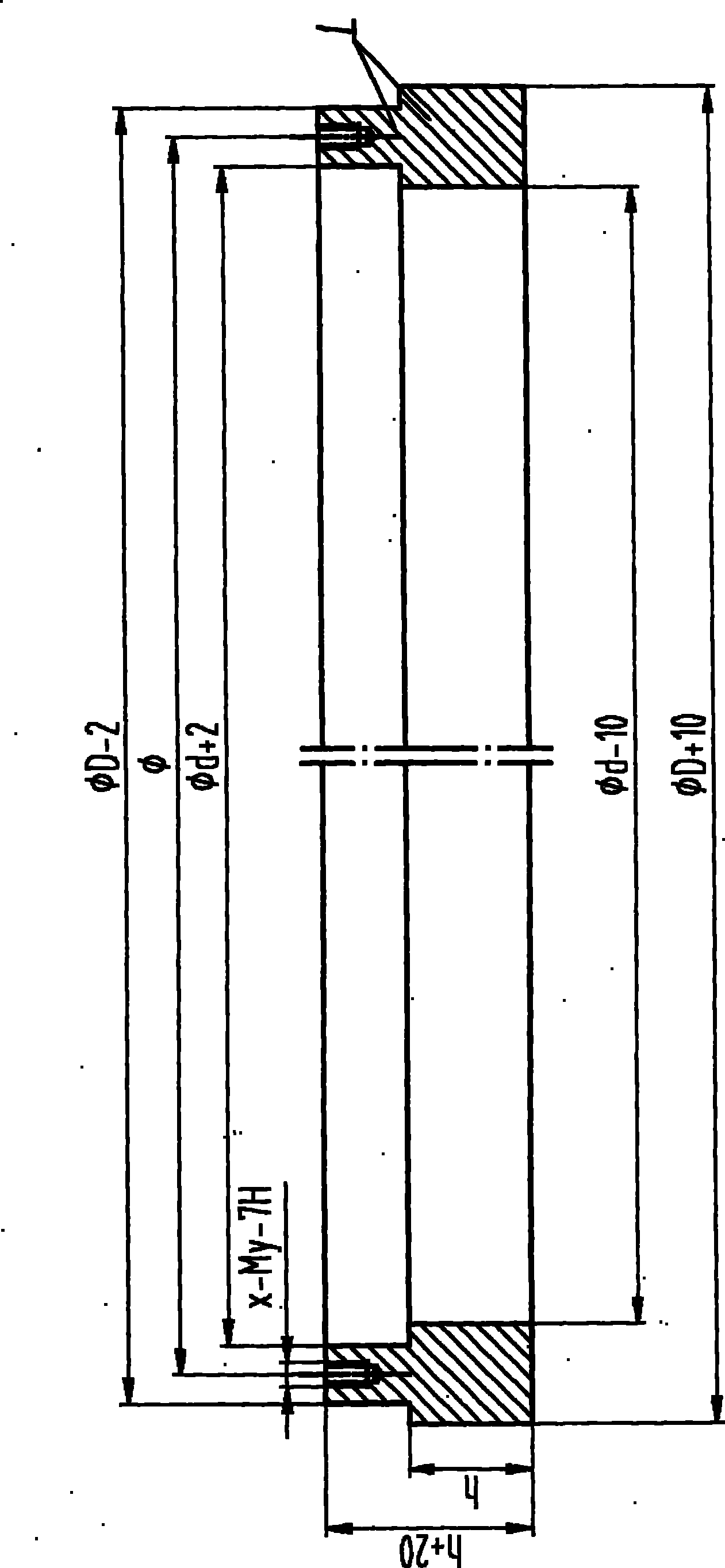

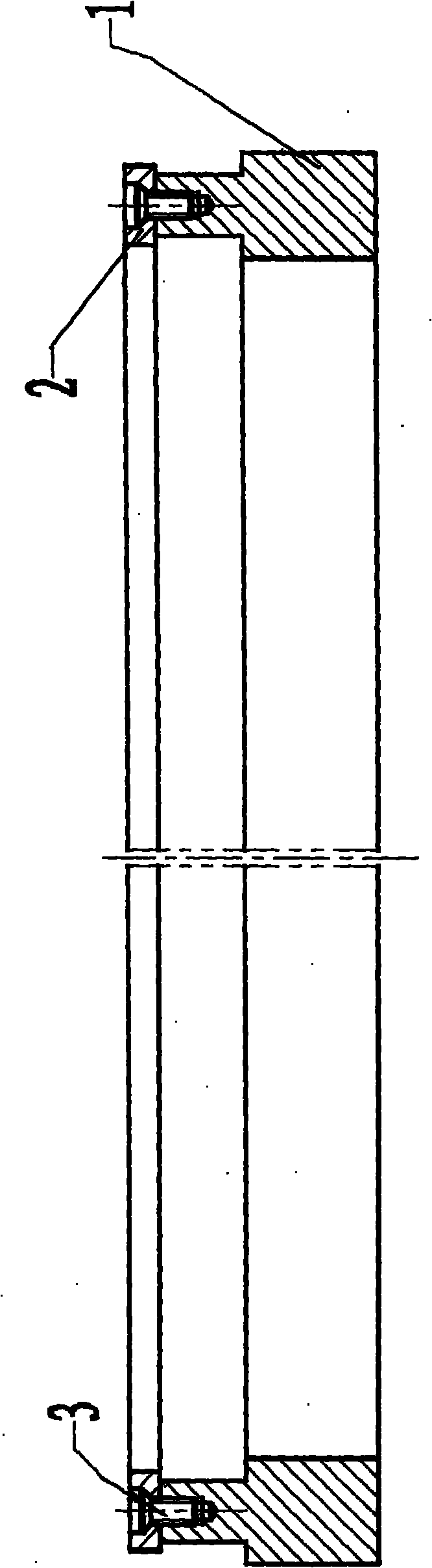

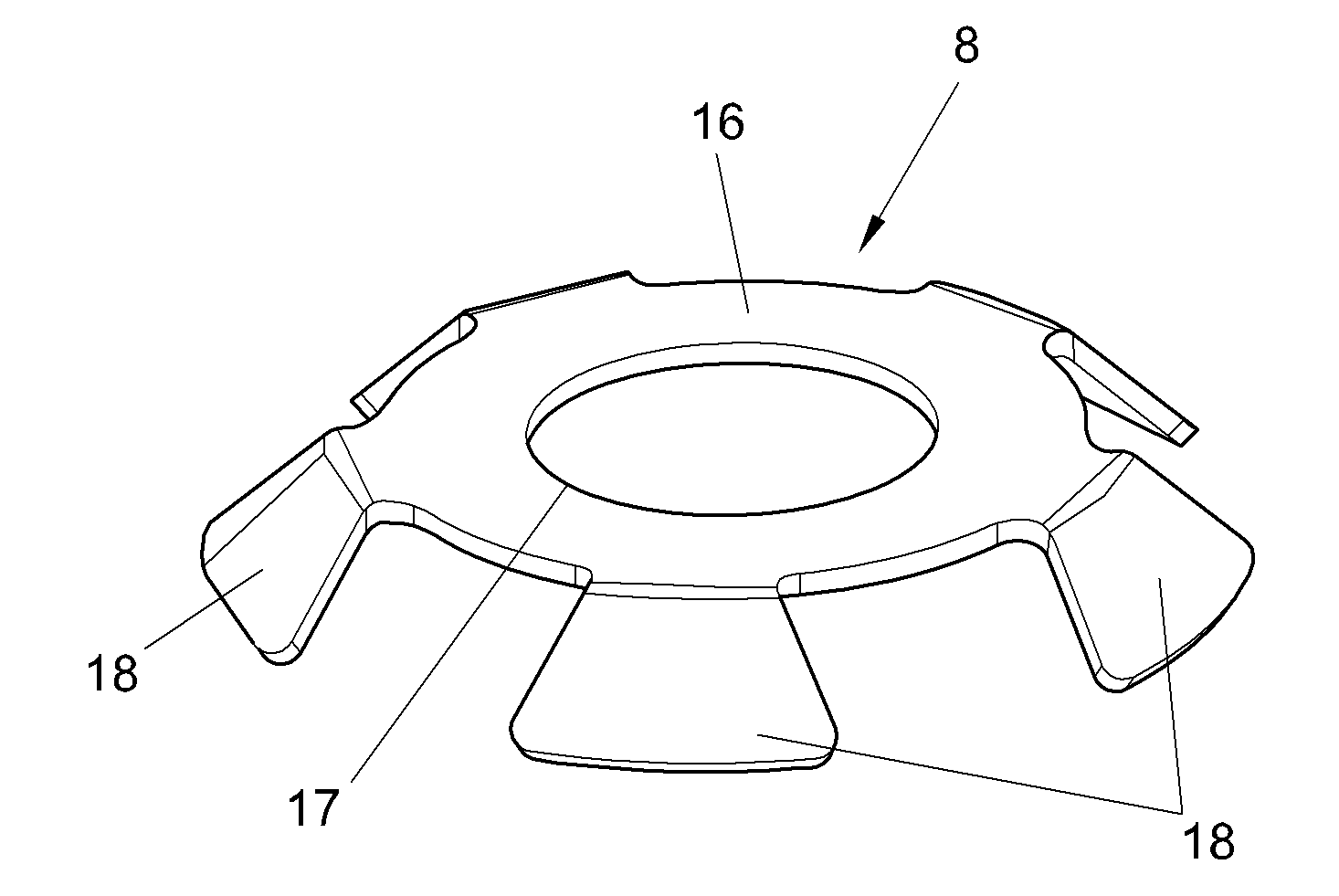

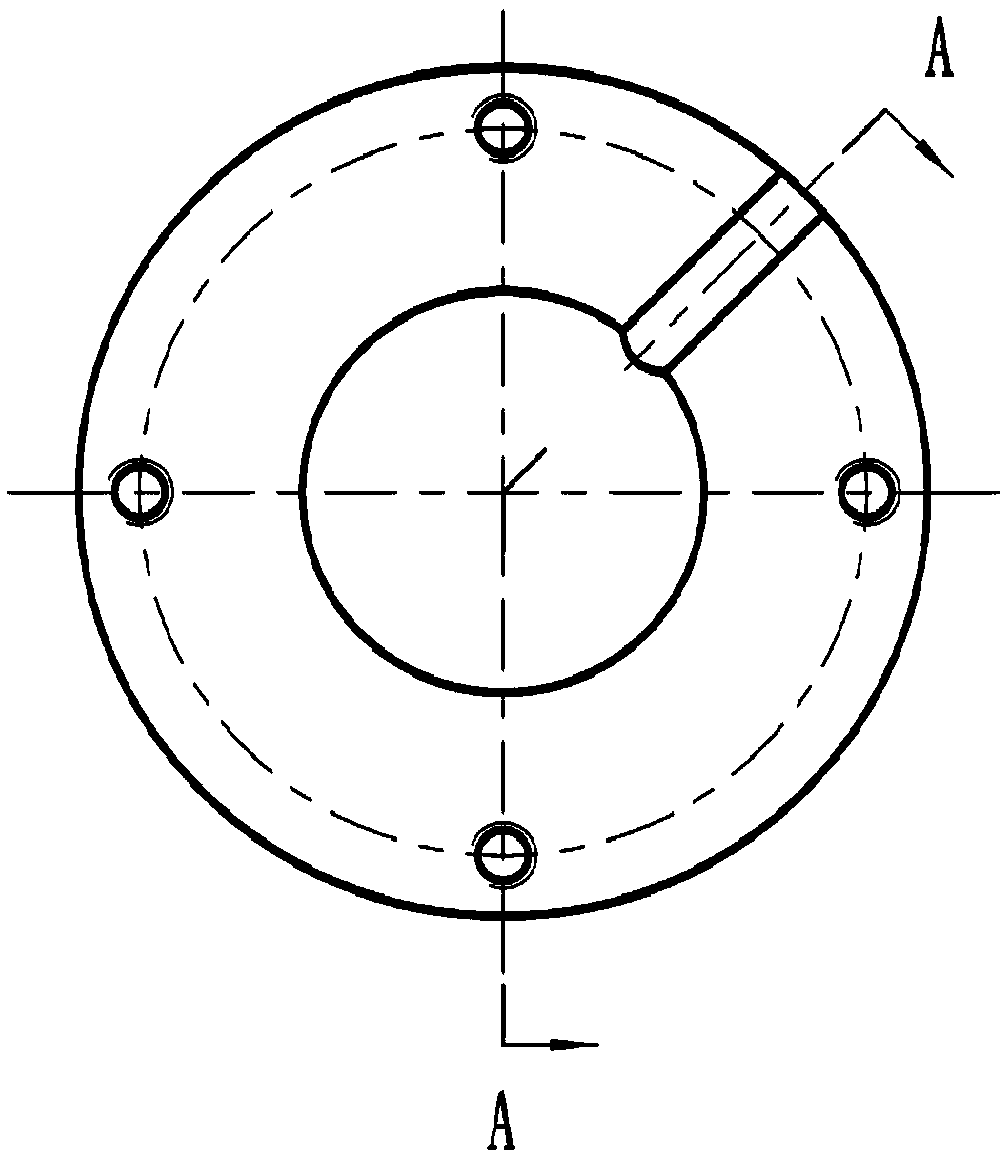

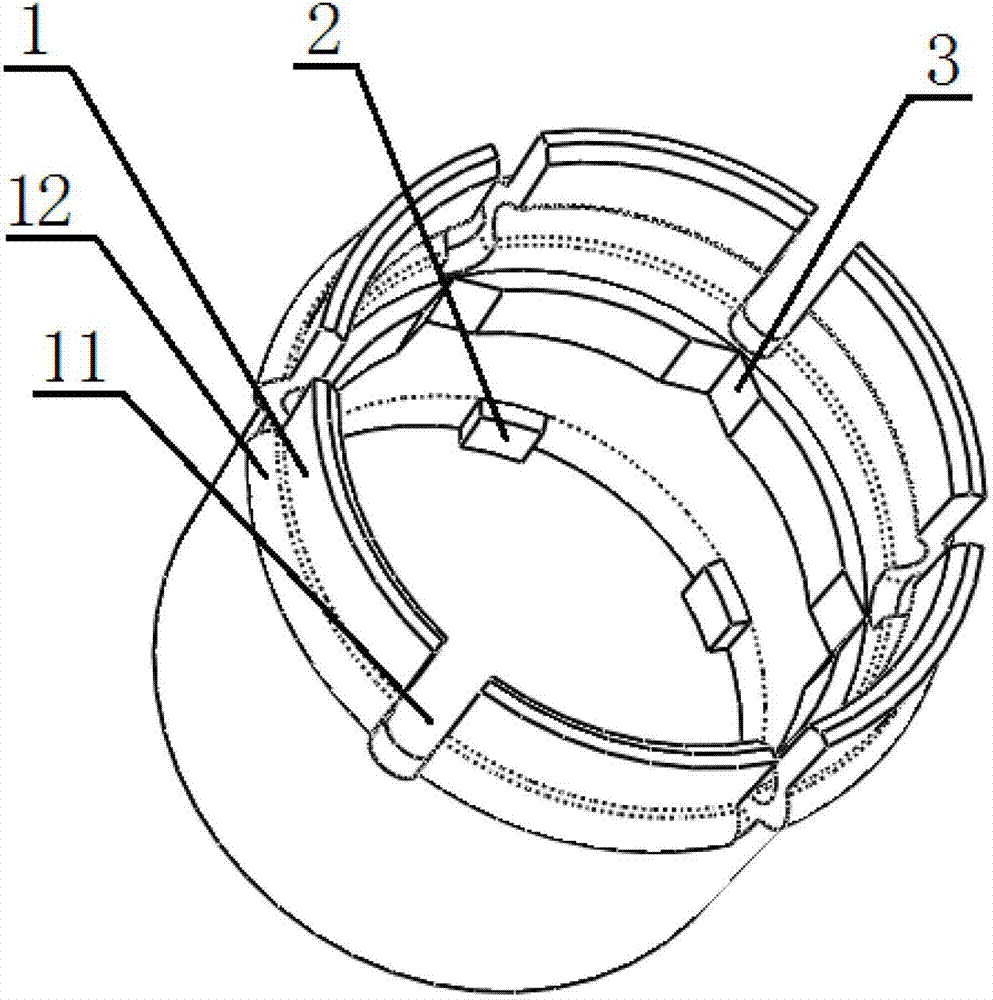

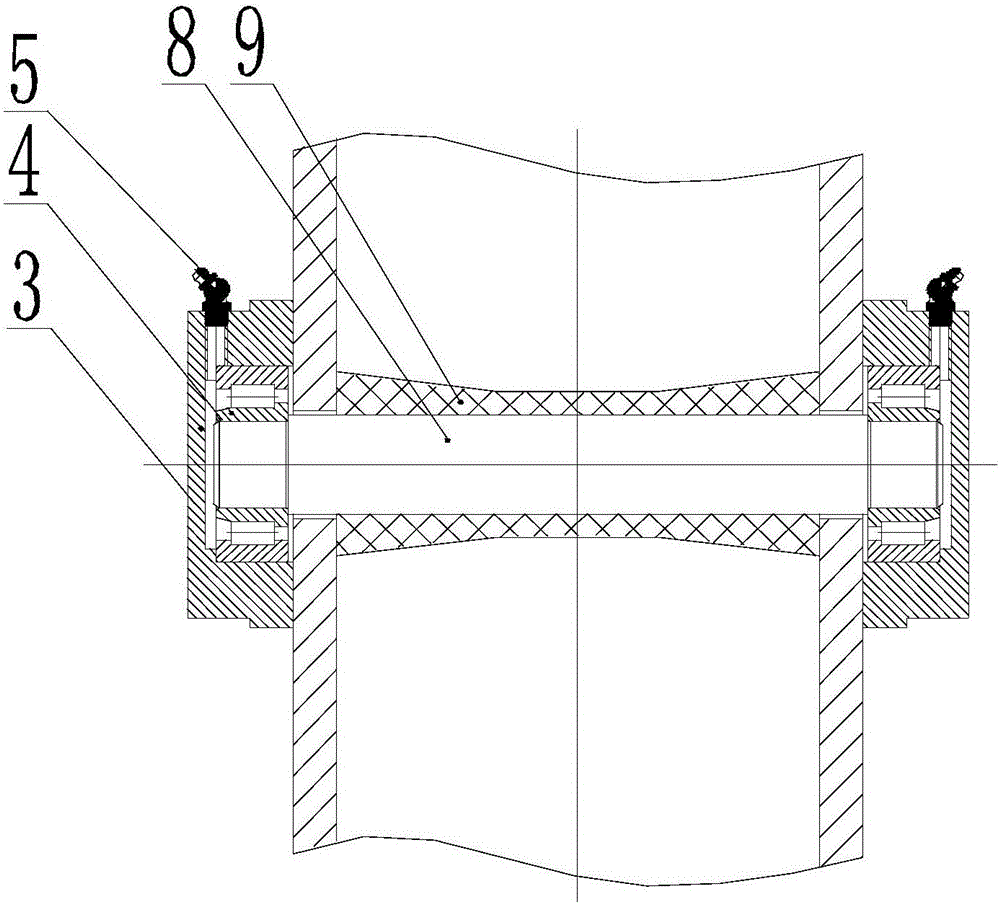

Processing method of ultra-thin annular pieces

InactiveCN101774111AImprove rigidityNo elasticityPositioning apparatusMetal-working holdersSheet steelWork in process

The invention relates to a processing method of ultra-thin annular pieces. The method comprises the following process flows of: (1) cutting a blank; (2) roughly turning; (3) drilling; (4) dividing single pieces; (5) manufacturing a tool clamp; (6) combining and fine turning; and (7) turning or grinding planes. 4-10 ultra-thin annular pieces are combined together, and meanwhile, steel plate flames are used for cutting and integrally blanking so as to improve the rigidity and ensure that no deformation occurs in the processing process. Semi-finished ultra-thin annular piece products to be processed, which are cut and blanked into single pieces, need to be combined together with the tool clamp, wherein the tool clamp is an annular piece with inner and outer steps between an upper section and a lower section. The circumference on the upper end surface of the tool clamp is uniformly provided with threaded holes according to the mounting hole sizes of the ultra-thin annular pieces, and then the single semi-finished products of the ultra-thin annular pieces to be processed are combined with the tool clamp into a whole by using bolts so as to enhance the rigidity of the semi-finished ultra-thin annular piece products, guarantee non-deformation during processing in subsequent working procedures, realize the localization of the ultra-thin annular pieces to replace imported pieces, greatly reduce the cost and meet the requirement of users.

Owner:MAANSHAN FANGYUAN SLEWING RING

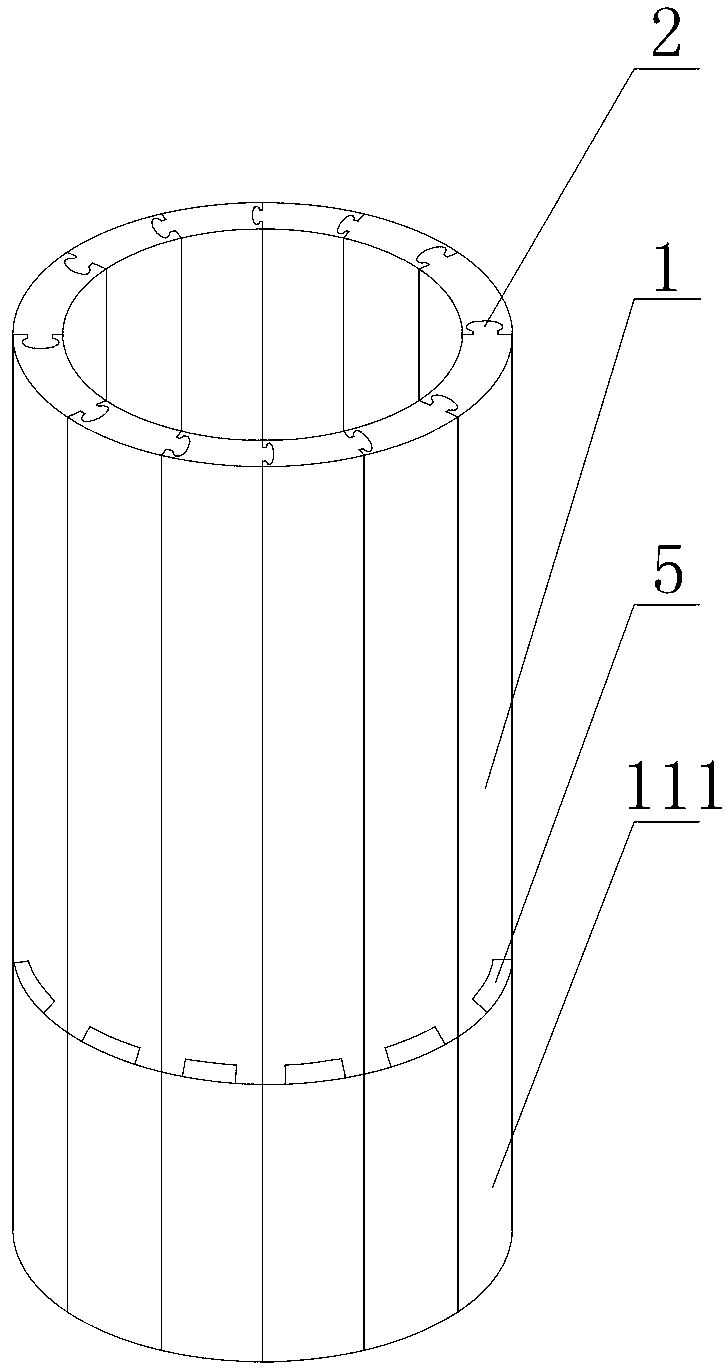

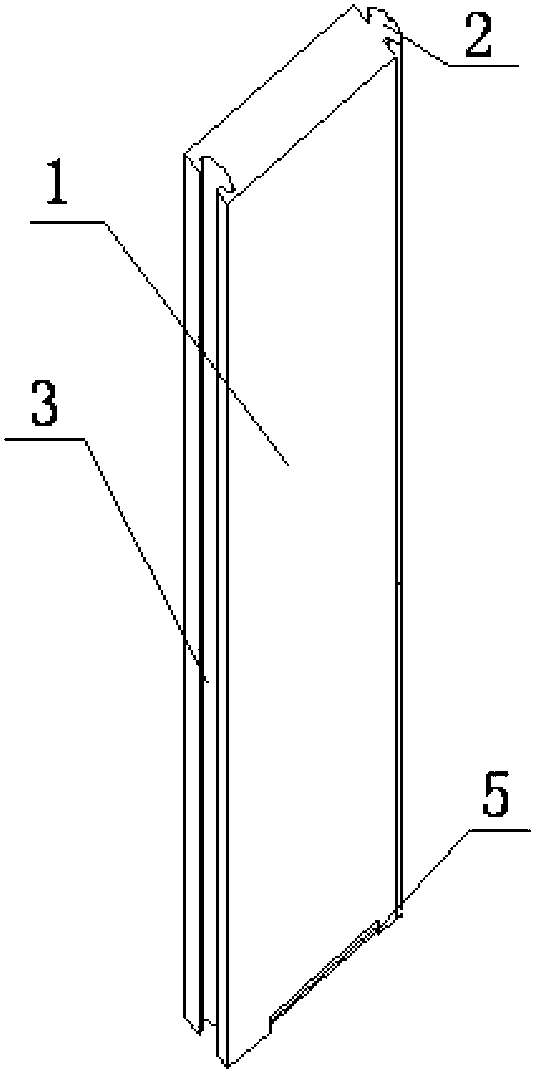

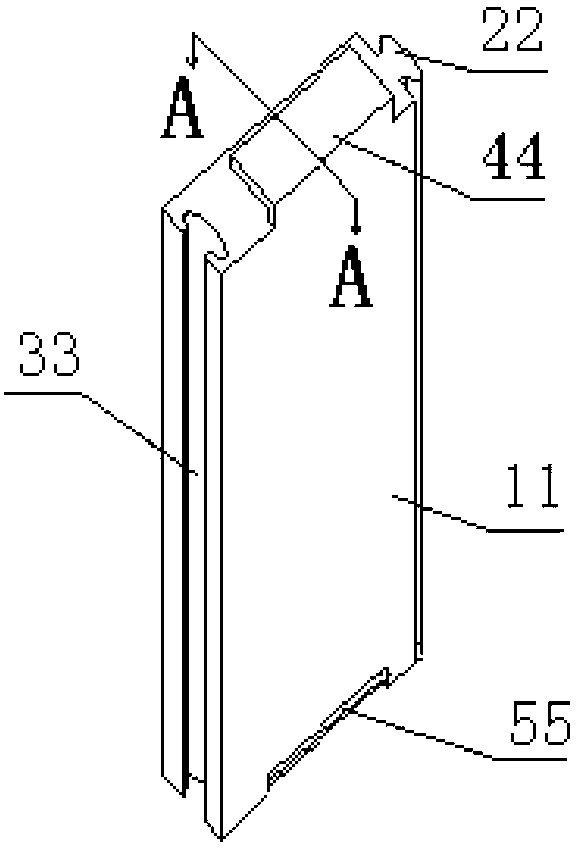

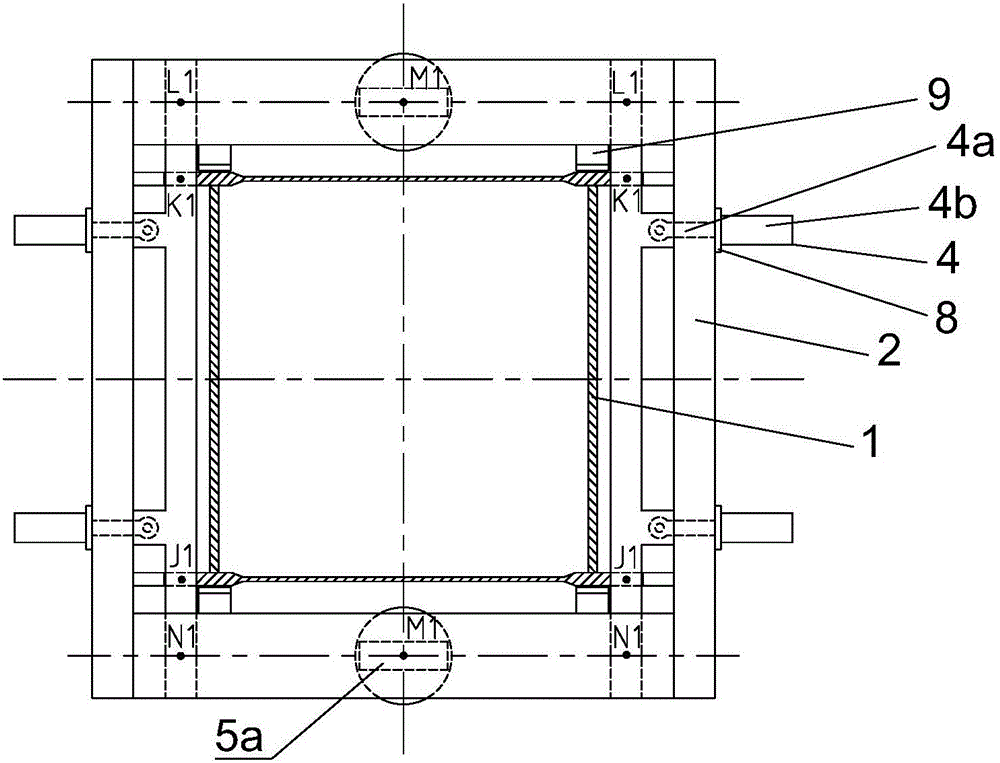

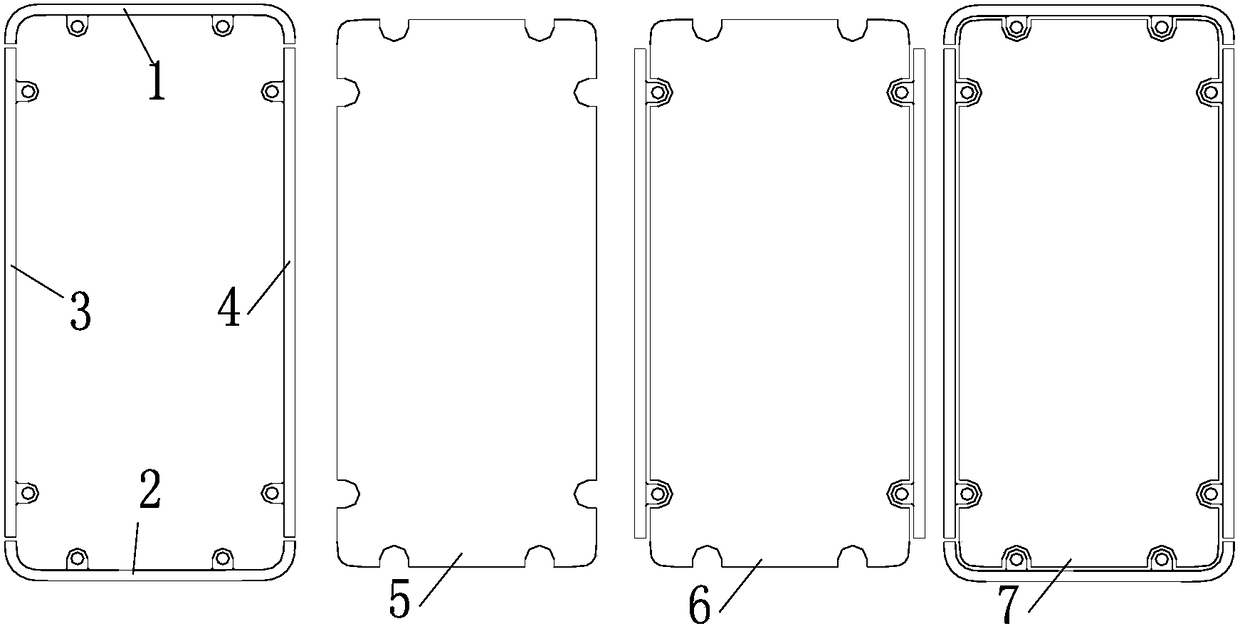

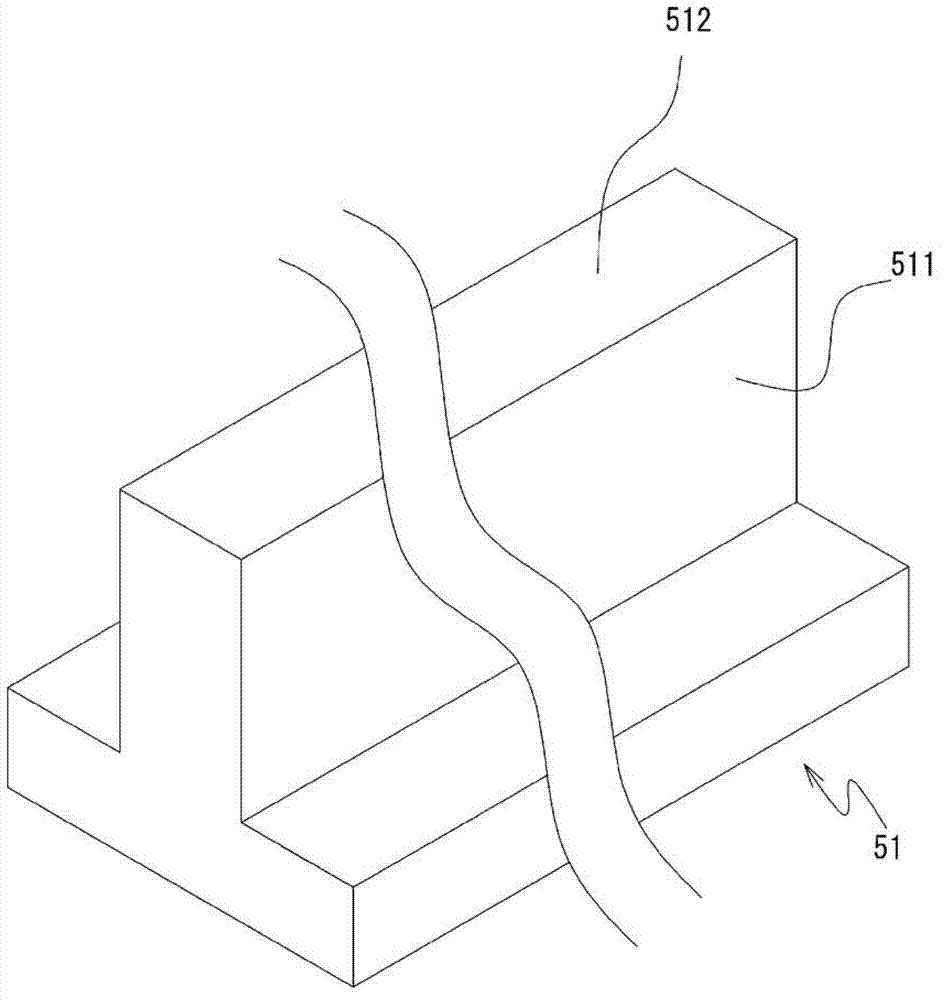

Circular miniature slide-resistant pile die with adjustable height and adjustable sectional area

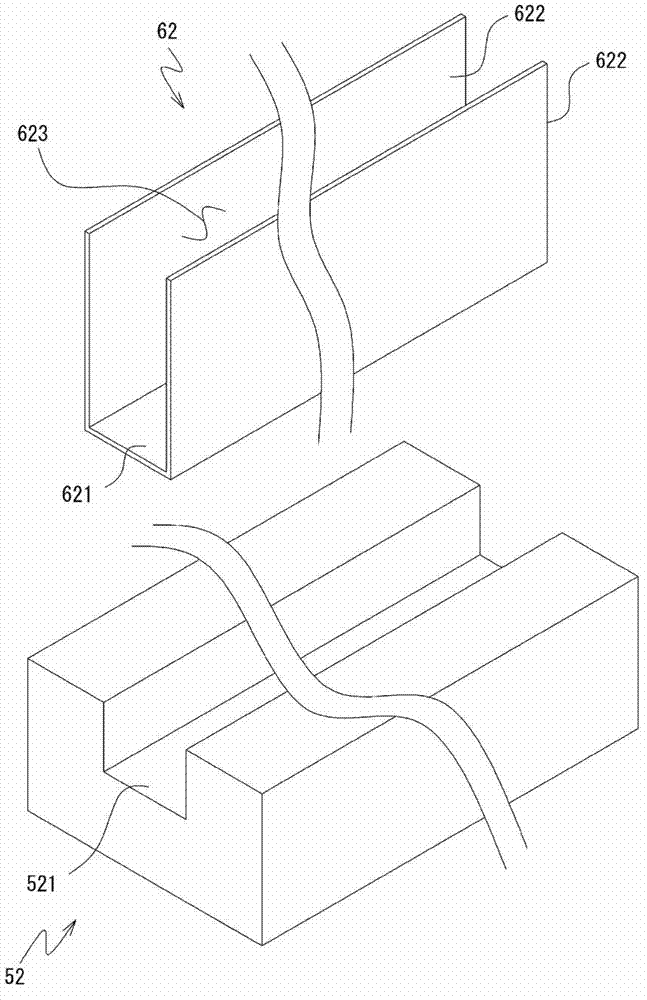

ActiveCN103252832AHigh impact strengthImprove toughnessMould separation apparatusTransverse grooveJoints number

The invention relates to a circular miniature slide-resistant pile die with an adjustable height and an adjustable sectional area. Plug boards are utilized as parts for forming the die in a split joint mode, and the plug boards are divided into major plug boards, minor plug boards and bottom plug boards according the positions where the plug boards are located on a cylinder structure when the plug boards are assembled, the major plug boards are located on the upper layer positions on the cylinder structure, the minor plug boards are located on the middle layer positions on the cylinder structure, and the bottom plug boards are located on the lower layer positions on the cylinder structure. The lengths and widths of all the plug boards in the same die are the same, the heights of the major plug boards are the same, the heights of the minor plug boards are the same, and the heights of the bottom plug boards are the same. One edge of each plug board in the vertical direction is machined with a vertical plug bar, and a vertical plug groove is formed in the other edge of each plug board. A transverse plug groove is formed in the transverse lower side edge of each major plug board, and a transverse plug groove is formed in the transverse lower side edge of each minor plug board. A transverse plug bar is formed in the upper side edge of each major plug board, and a transverse plug bar is formed in the upper side edge of each minor plug board. Each transverse plug bar on each upper side edge is matched with each transverse groove in each lower side edge. When the plug boards are assembled, the major plug boards, the minor plug boards and the bottom plug boards are connected in an up-and-down left-and-right split joint mode to form the die which is in a nearly cylindrical shape. According to the circular miniature slide-resistant pile die with the adjustable height and the adjustable sectional area, the sectional area can be adjusted through changing of a left-and-right split joint number of the plug boards, the height can be adjusted through changing of an up-and-down connecting layer number of the plug boards, the circular slide-resistant pile die with the adjustable height and the adjustable sectional area can be spliced through only one set of plug boards, and the circular miniature slide-resistant pile die with the adjustable height and the adjustable sectional area is simple in structure, easy to splice and low in use cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Bimetal metallurgical composite pipe and manufacturing method thereof

The invention discloses a bimetal metallurgical composite pipe and a manufacturing method thereof. The manufacturing method comprises the following steps of manufacturing a pipe blank of the bimetal metallurgical composite pipe by adopting a vacuum water-cooling die casting technology, specifically inner metal and outer metal are metallurgically combined in a high-temperature diffusion mode, and the two ends of the pipe blank are covered by the inner metal; carrying out hot rolling forming on the obtained pipe blank of the bimetallic metallurgical composite pipe so as to enable the pipe diameter and the wall thickness of the bimetallic metallurgical composite pipe to meet the preset standard and make the inner metal meet the preset thickness requirement; and carrying out quenching and tempering treatment on the whole hot-rolled bimetallic metallurgical composite pipe to make the outer metal meet the preset strength requirement, and completing the manufacturing of the bimetallic metallurgical composite pipe. According to the method, the high strength of an oil pipe column is ensured, and meanwhile, the integrity of corrosion resistance of the inner wall is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

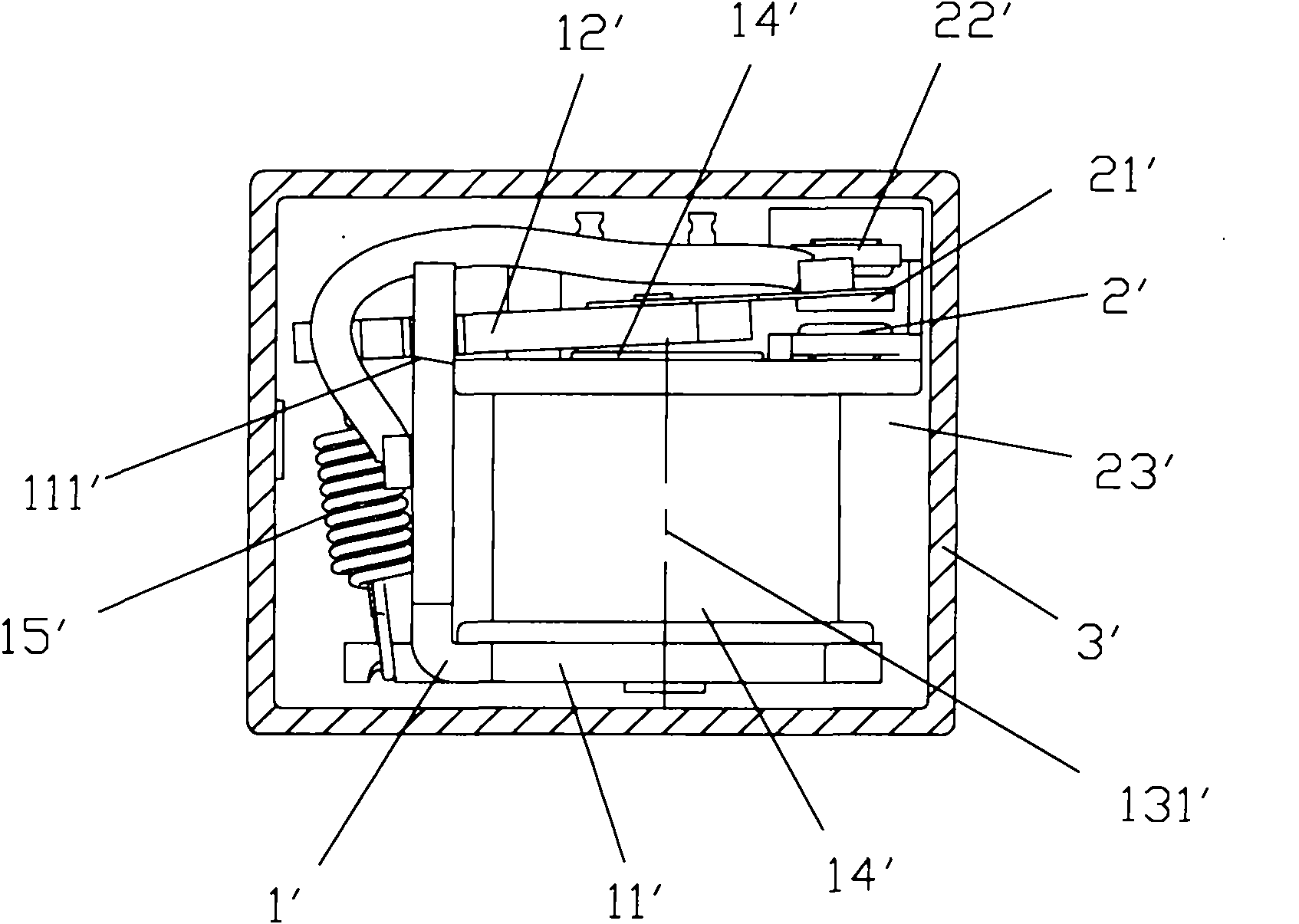

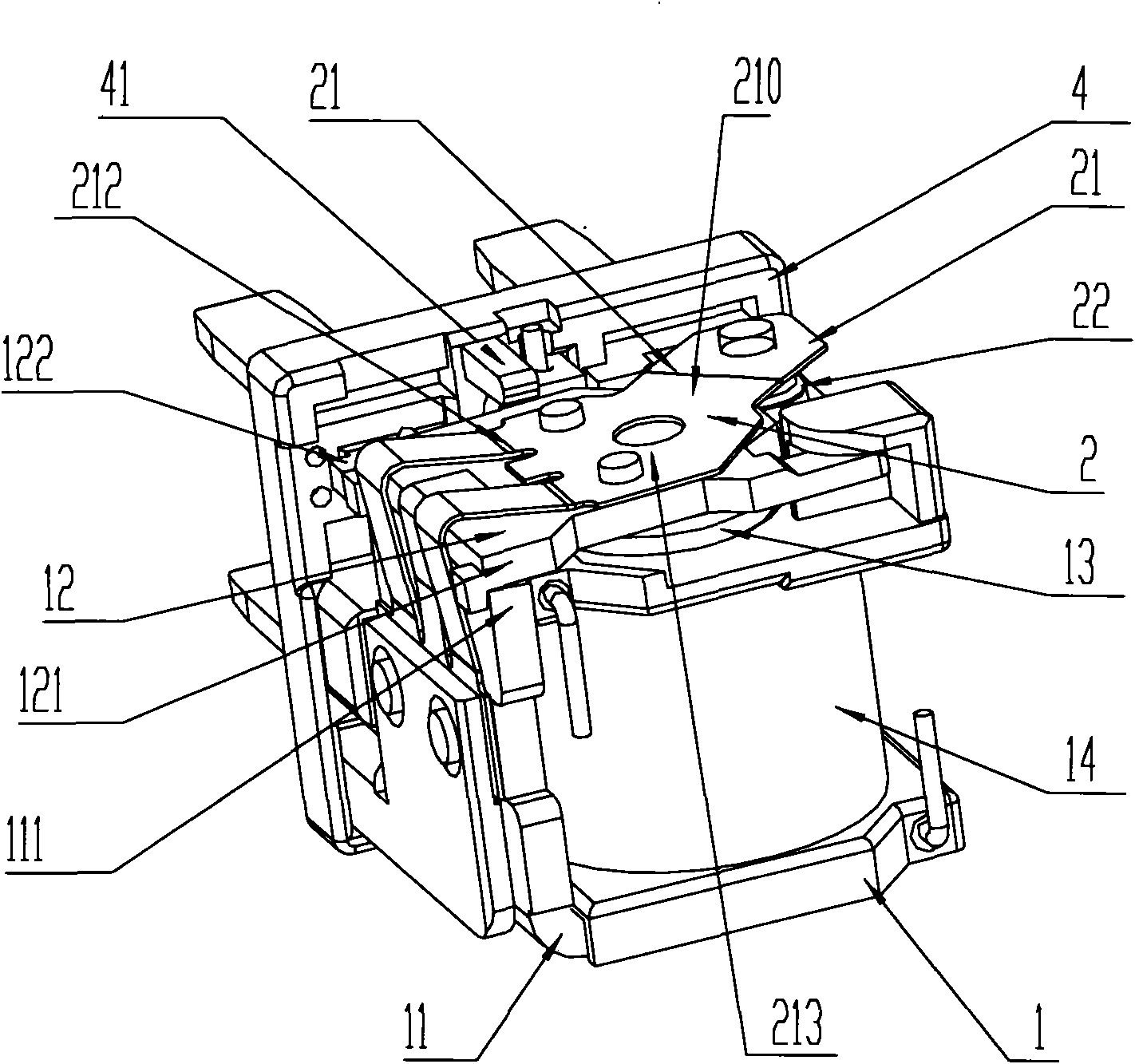

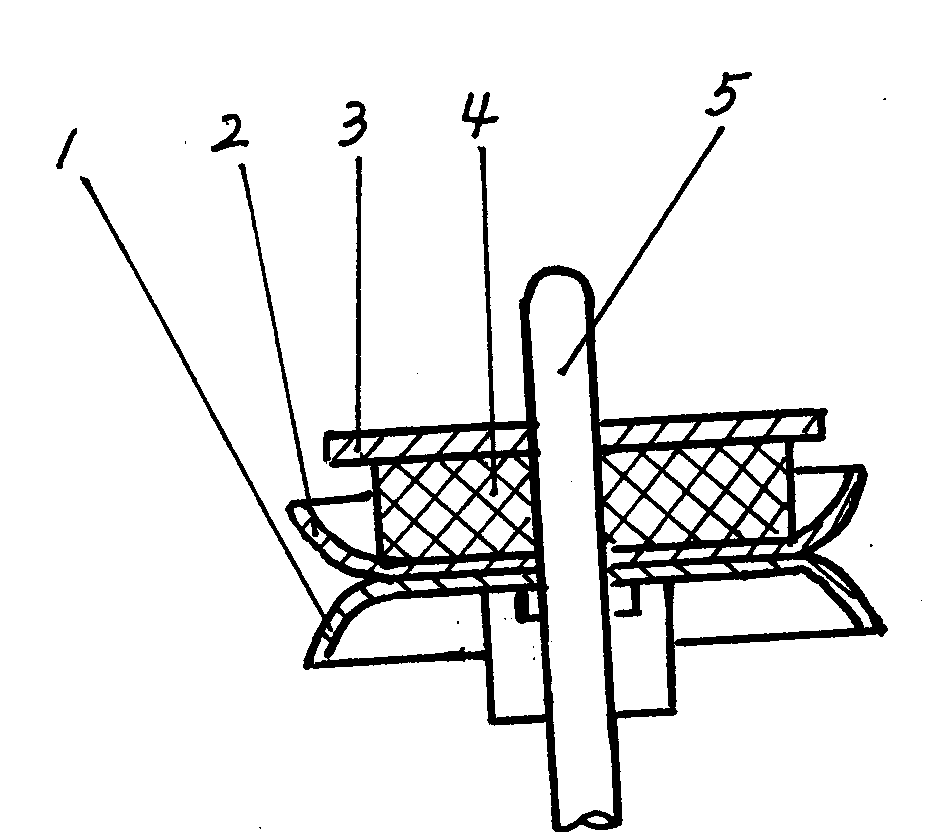

Electromagnetic relay with good anti-falling performance

ActiveCN102097254AGood anti-drop performanceNo plastic deformationElectromagnetic relay detailsEngineeringRelay

The invention discloses an electromagnetic relay with good anti-falling performance. The electromagnetic relay comprises a magnetic circuit part, a contact part, a shell and a base, wherein the magnetic circuit part is horizontally installed on the base and comprises a coil, a yoke, an armature and an iron core; the axis of the iron core is parallel to the board of the base; the contact part comprises a moving spring with moving contacts and a static spring with static contacts; the moving spring is connected between the yoke and the armature in a buckling manner; the yoke and the armature are orthogonally arranged; the moving spring is provided with a first buckling line corresponding to the orthogonal part of the yoke and the armature and a second buckling line sticking to the armature;the moving spring section outside the second buckling line abuts against and is fixed on the armature and forms a moving spring and armature assembly capable of moving with the armature; and limitingconvex plates for limiting the moving spring and armature assembly to move towards the direction far away from the iron core are respectively arranged on the base and on the inner wall of the shell at the side opposite to the base. With the structure, the electromagnetic relay has good anti-falling performance and simultaneously has the characteristics of simple structure, low cost and better manufacturability.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

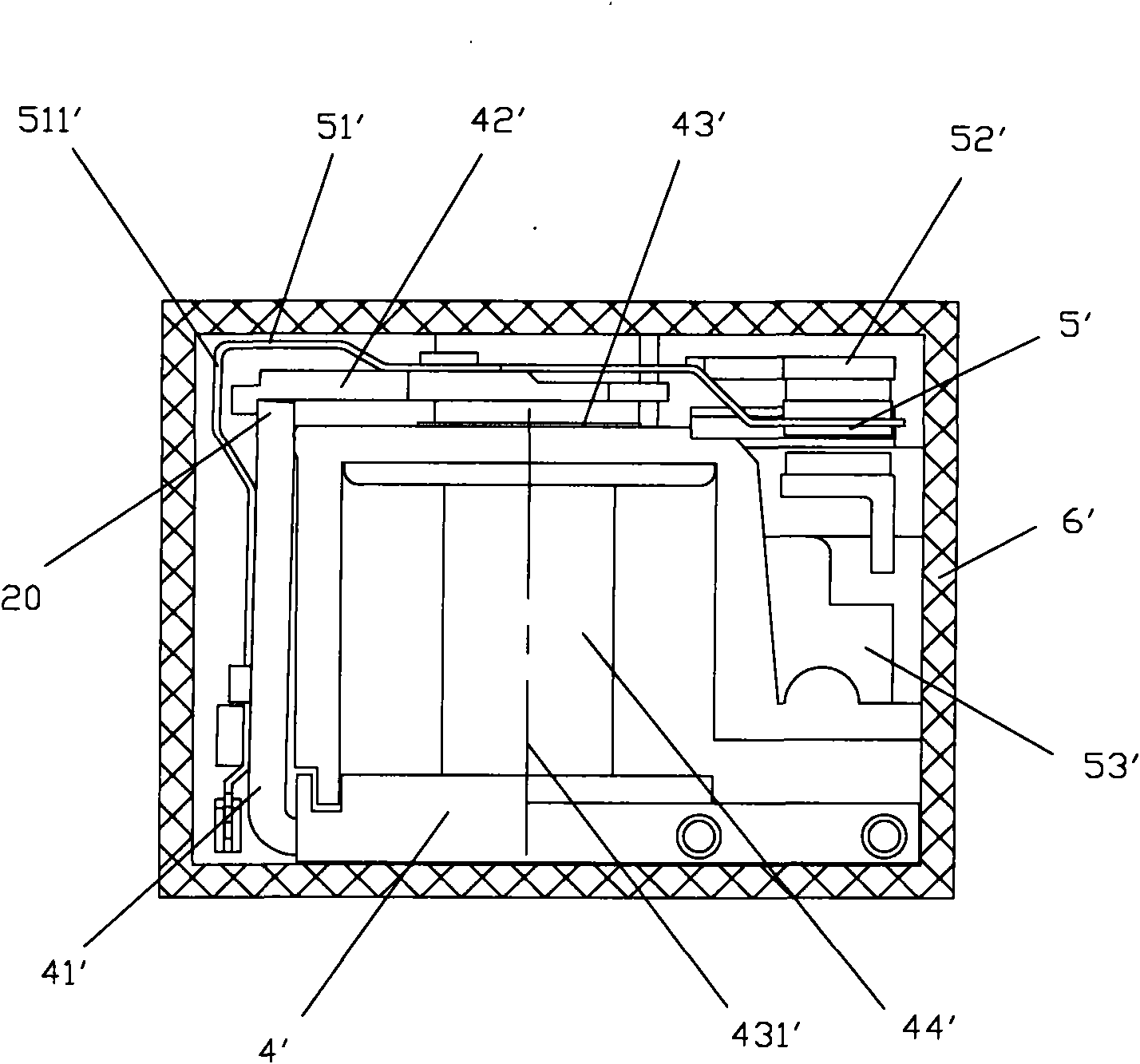

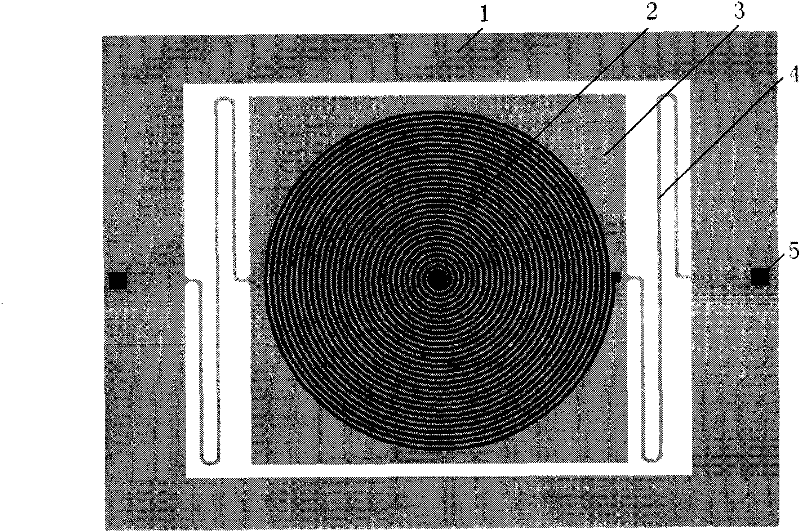

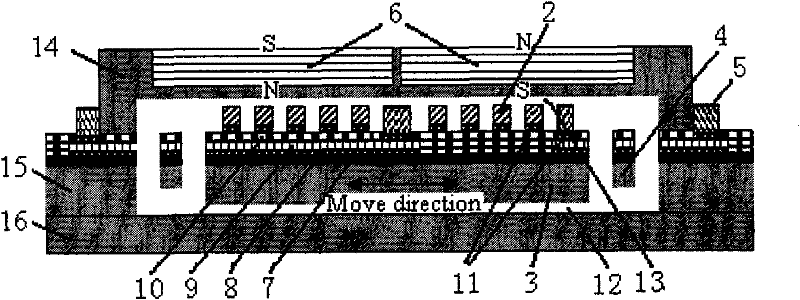

Miniature electromagnetic type vibration energy collector and manufacturing method thereof

InactiveCN102176637AEasy to prepareIncrease flexibilityDecorative surface effectsDynamo-electric machinesMicro nanoMechanical energy

The invention relates to a miniature electromagnetic type vibration energy collector and a manufacturing method thereof. The electromagnetic type vibration energy collector consists of a centre mass block, an outer support frame, two folded elastic beams, a plane spiral coil, two permanent magnets, an upper cover plate, a substrate and the like. In the electromagnetic type vibration energy collector, vibration structures (including the centre mass block and the folded elastic beams) are manufactured by using bulk silicon micromachine processing technique, the plane spiral coil is manufactured by using a surface micromachine processing technique and is manufactured on the upper surface of the centre mass block; and the two permanent magnets are located above the plane spiral coil in parallel. The energy absorber can work in a low frequency range, and mechanical energy vibrated in the environment is converted into electrical energy, thereby solving the problem that a wireless sense network or micro-nano device and the like depend on a battery to achieve supply feed. The energy absorber has the advantages of small volume, simple manufacturing method, wide application prospect and the like, and is easy to produce in batches.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

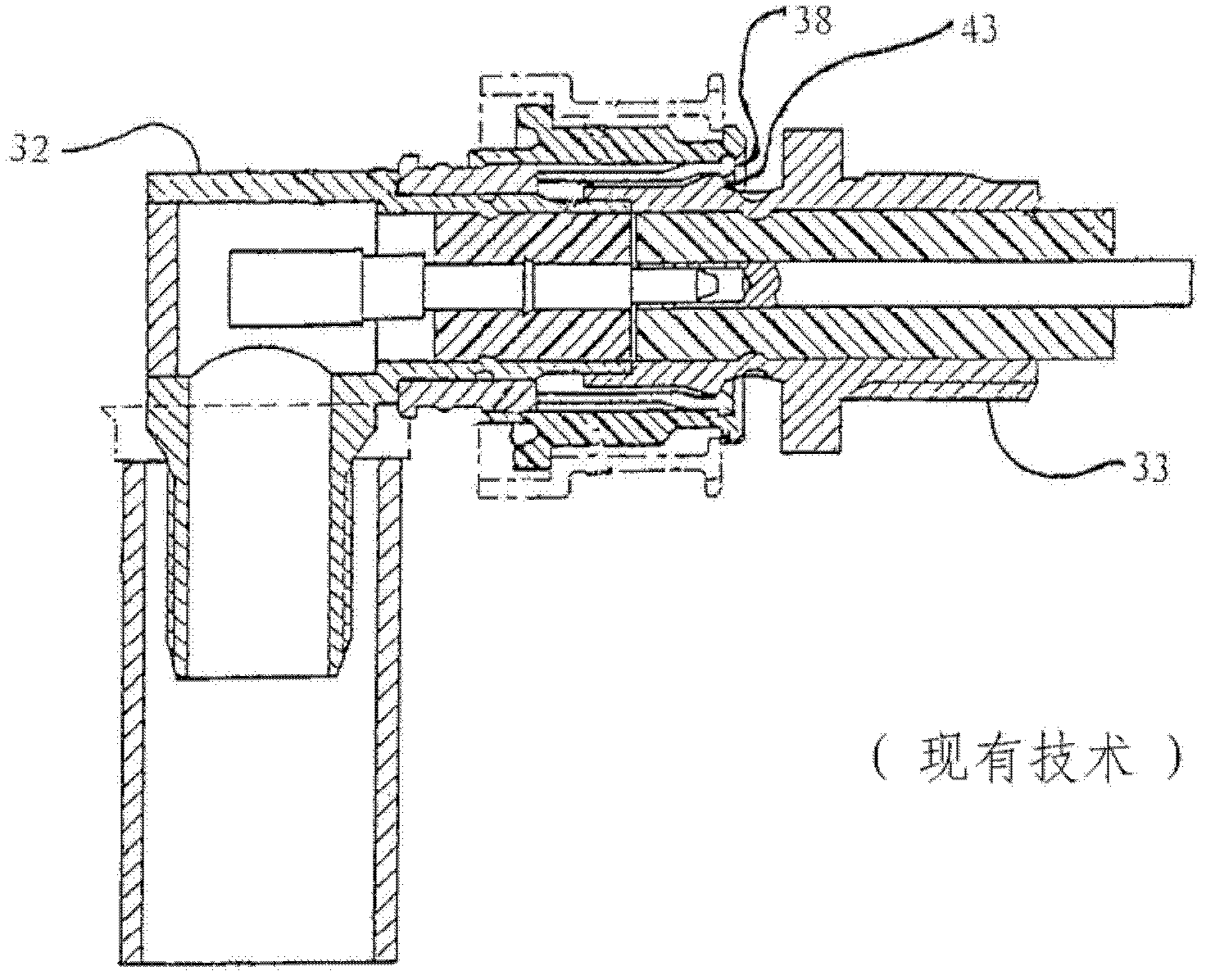

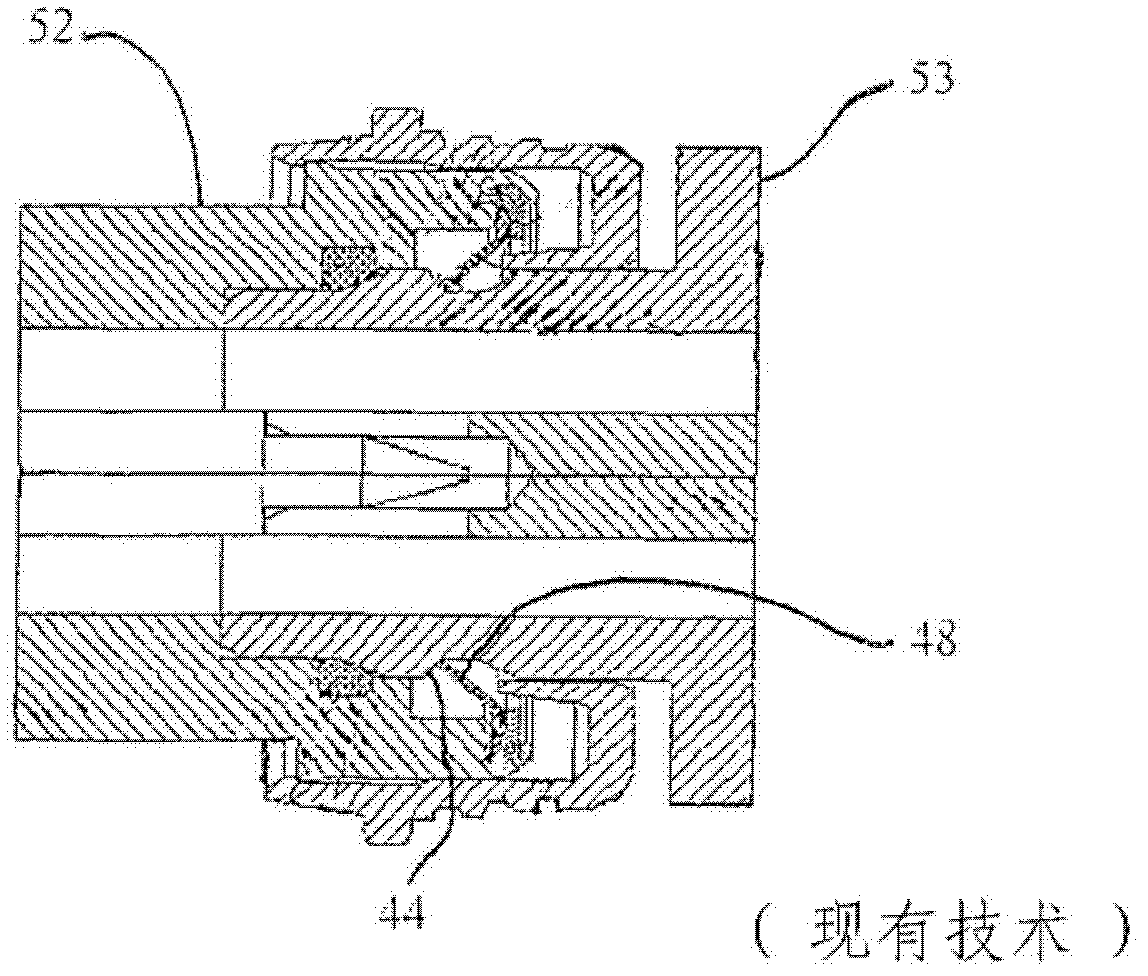

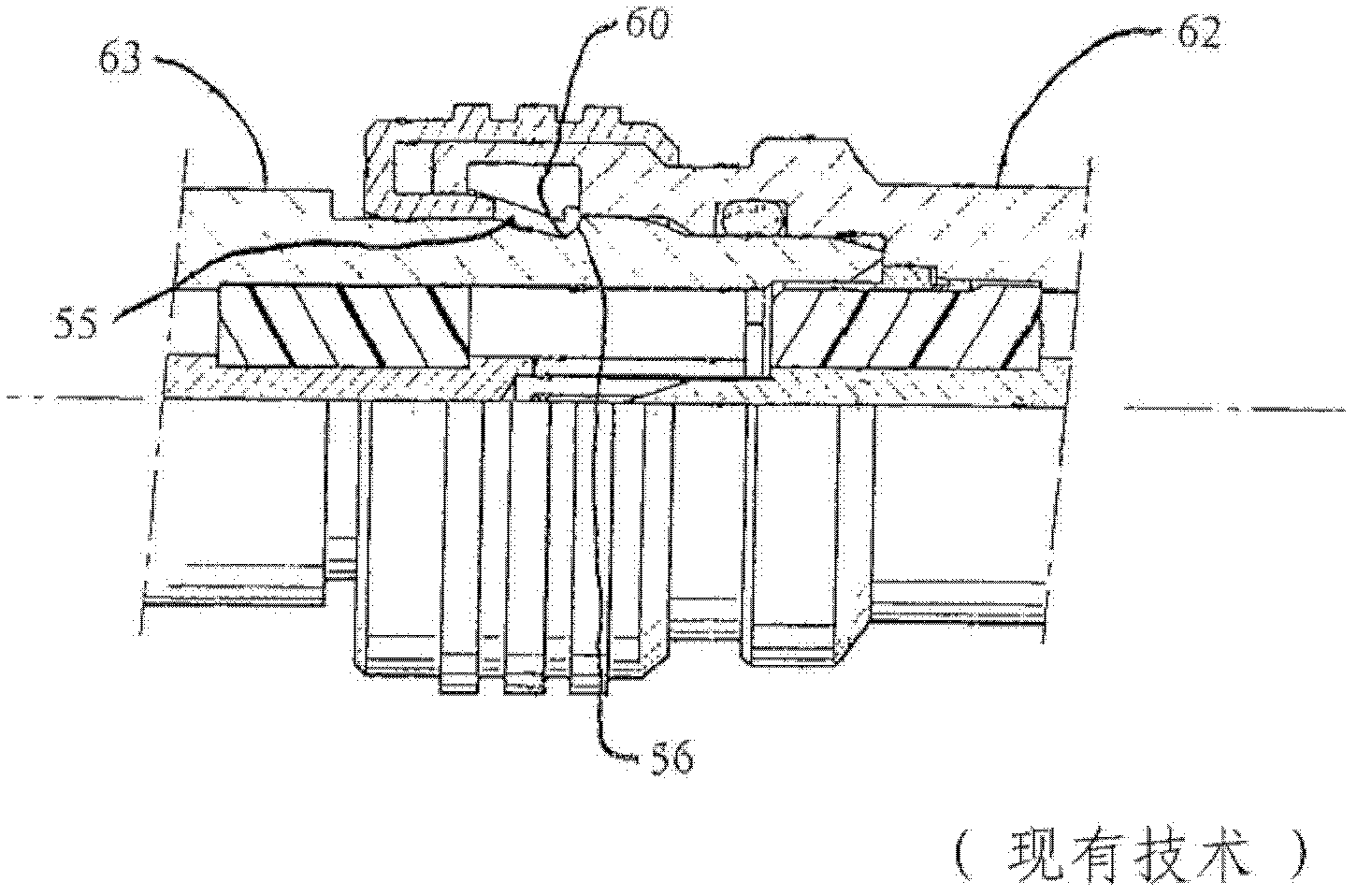

Coaxial connector with coupling spring

InactiveCN102484336ANo plastic deformationNo significant signal noiseTwo pole connectionsCoupling device detailsEngineeringElectrical conductor

The device includes an inner conductor, a dielectric material, an outer conductor, a coupling spring, and a sliding sleeve. The dielectric material surrounds the inner conductor. The outer conductor surrounds the dielectric material. The sliding sleeve is slidably attached to the outer conductor. The coupling spring is attached to the outer conductor. The coupling spring includes a plurality of beam tines. Each beam tine includes a lever tine. An adjacent pair of beam tines is separated by a slot where the slot has a root. A first distance is defined from the root to an edge of the beam tine. A second length is defined from the root to a distal end of the lever tine. The first length is greater than the second length.

Owner:EMERSON NETWORK POWER CONNECTIVITY SOLUTIONS

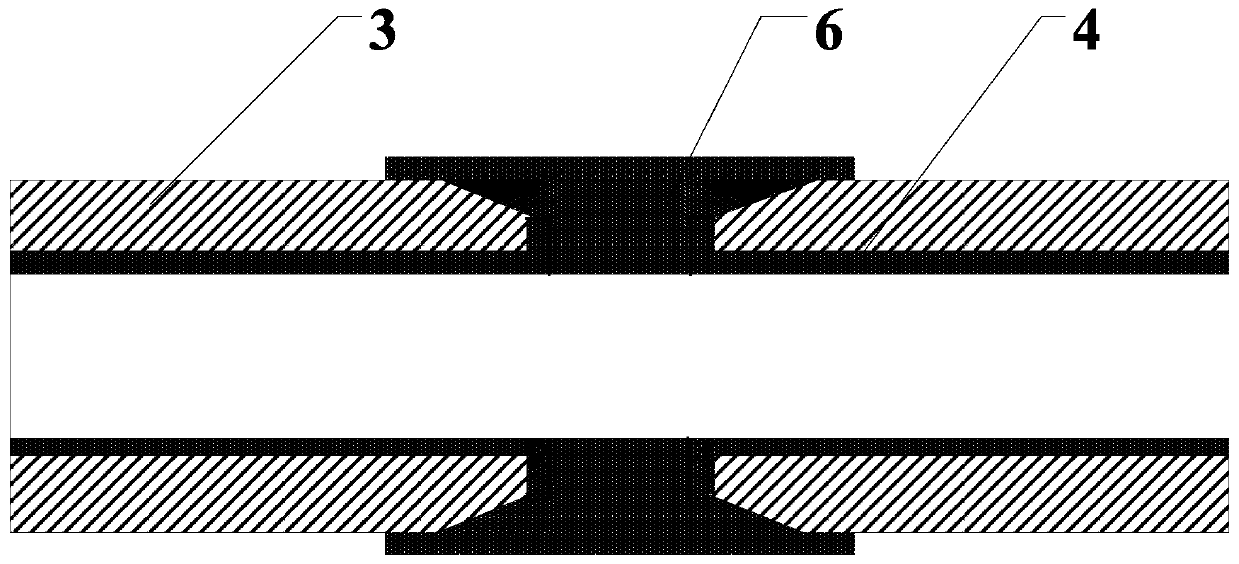

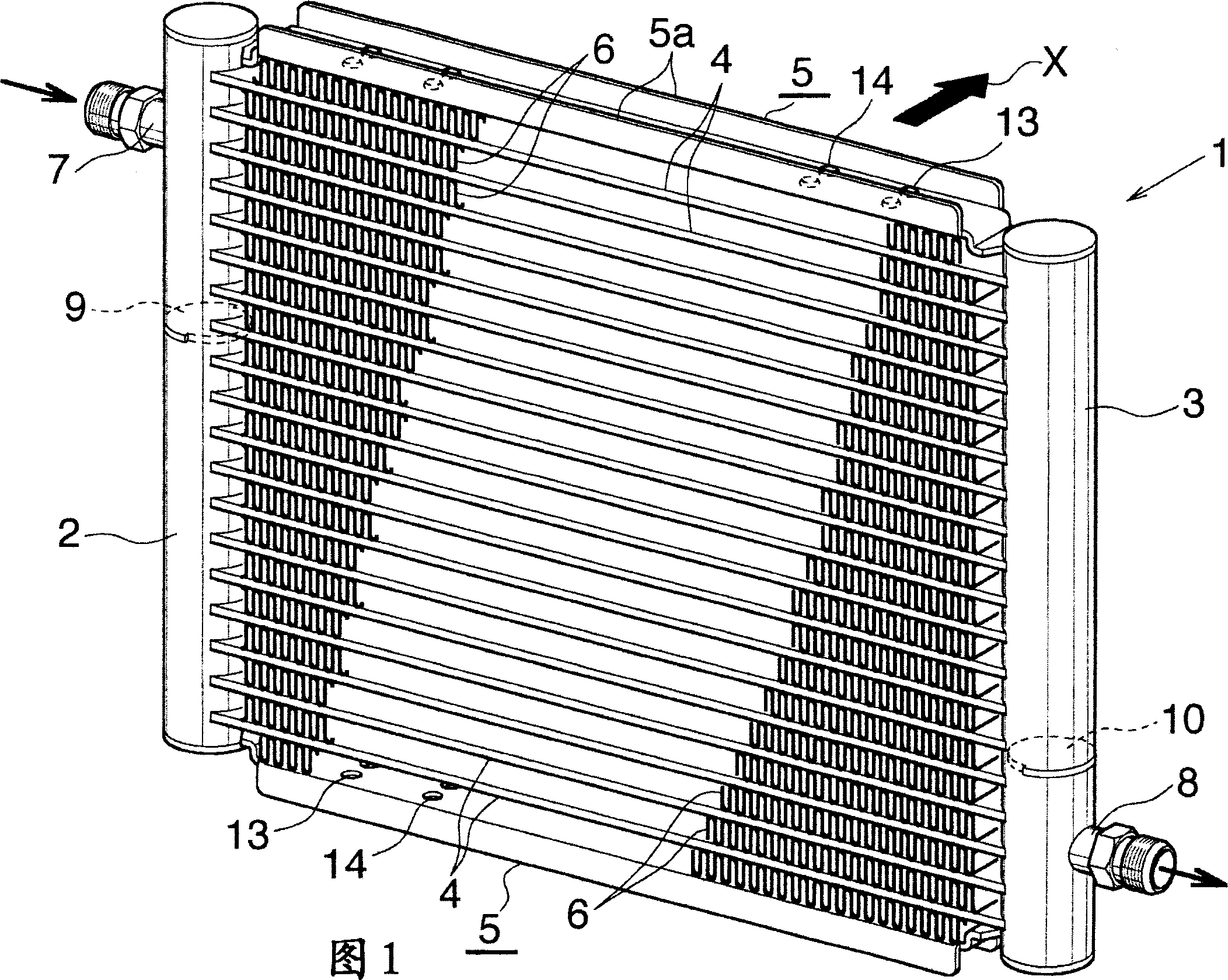

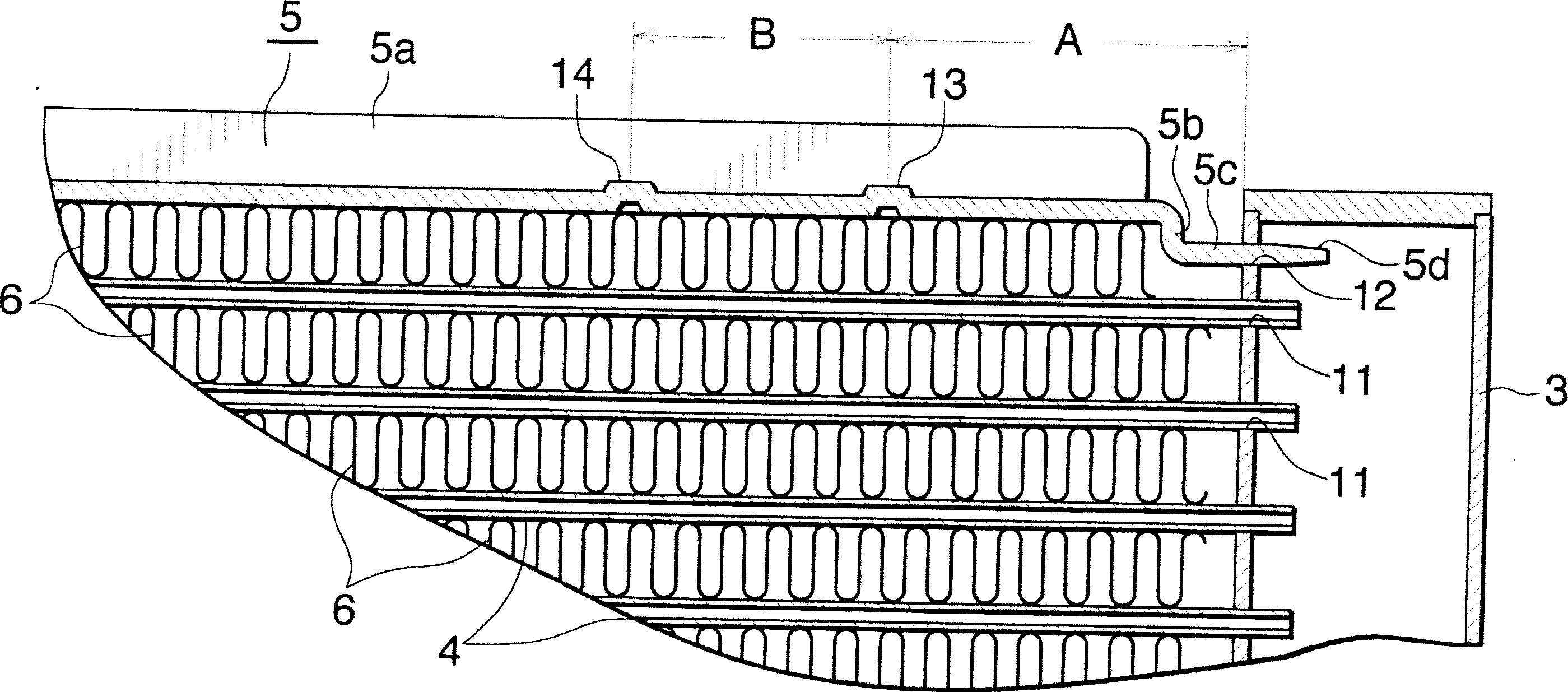

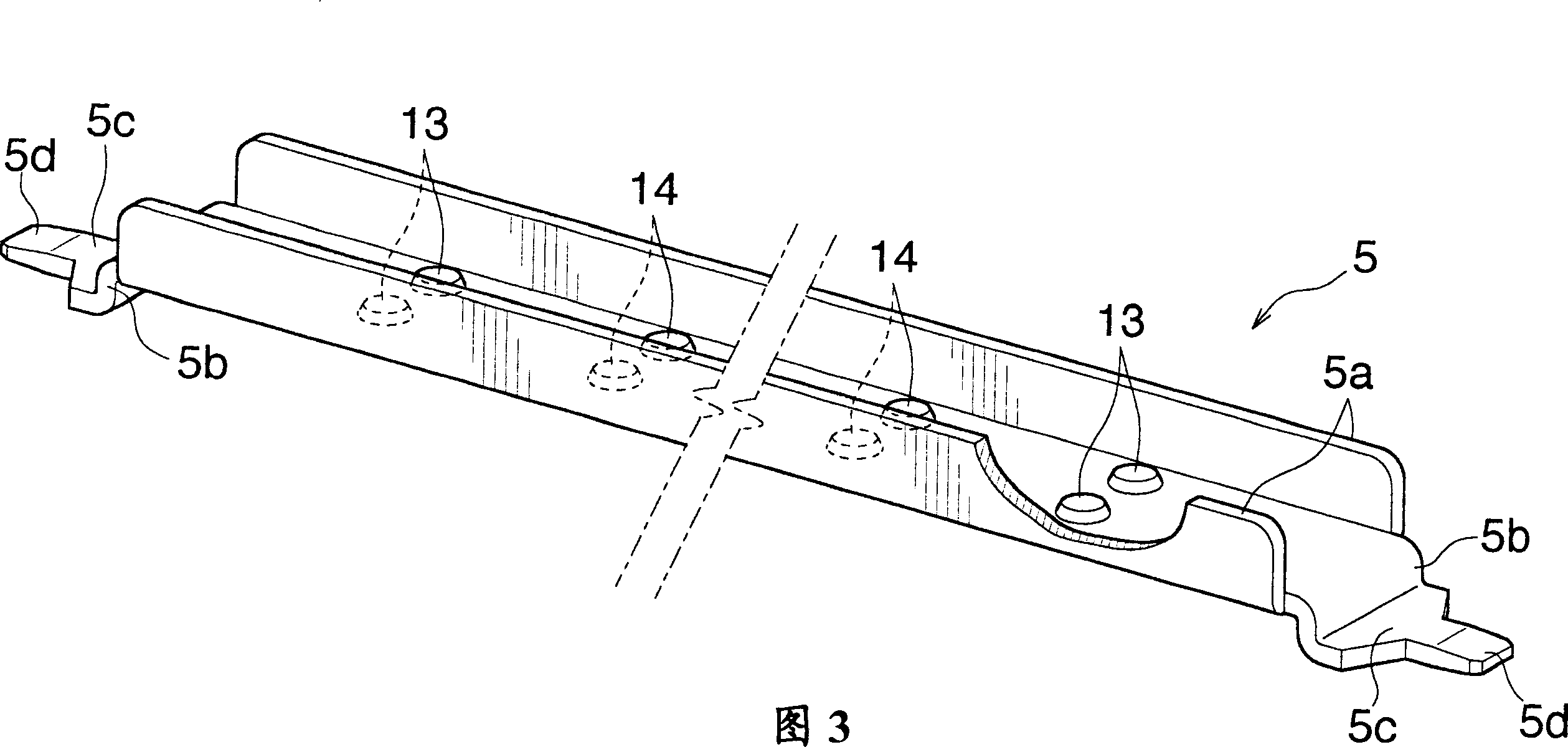

Side plate for heat exchanger, heat exchanger, and method of manufacture heat exchanger

InactiveCN1781010APrevent slippageNo plastic deformationHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a side plate (5) for a condenser (1), which comprises a pair of headers (2, 3) spaced apart from each other, a plurality of headers (2, 3) spaced apart from each other and arranged in parallel at the header Flat refrigerant tubes (4) between the tubes (2, 3) and both ends of which are connected to respective headers, and corrugated fins (6) arranged between adjacent refrigerant tubes (4). The side plate (5) is arranged outside and at a distance from the refrigerant tube (4) at each of the two ends of the tube arrangement. Corrugated fins (6) are provided between the side plate (5) and the end refrigerant tube (4) adjacent thereto. The side plate (5) has a protrusion (13) at each of both ends of the opposite surface of its surface in contact with the corrugated fin (6). The side plate (5) is used to prevent the fins (6) from slipping from between the refrigerant tube (4) and the side plate (5) when the condenser (1) is manufactured.

Owner:SHOWA DENKO KK

Electrolytic polishing liquid of tungsten alloy or molybdenum alloy and electrolytic polishing method

The invention discloses electrolytic polishing liquid of a tungsten alloy or a molybdenum alloy. The electrolytic polishing liquid is prepared by mixing sodium hydroxide, sodium carbonate, sodium molybdate and water. In addition, the invention further discloses a method for conducting electrolytic polishing on the tungsten alloy or the molybdenum alloy through the electrolytic polishing liquid. The method includes the steps that the tungsten alloy or the molybdenum alloy is placed in the electrolytic polishing liquid to be used as an anode; stainless steel is used as a cathode; the temperature of the electrolytic polishing liquid and the voltage and current density of a direct-current stabilized power supply are regulated; and electrolytic polishing is conducted on the surface of the tungsten alloy or the molybdenum alloy. The electrolytic polishing liquid is an aqueous solution of the sodium hydroxide, the sodium carbonate and the small amount of sodium molybdate, no pollution gas is generated in the process of conducting electrolytic polishing through the electrolytic polishing liquid, and therefore safety and environment protection are achieved, no insoluble electrolytic products are generated on surfaces of workpieces, the surfaces of the workpieces do not need to be cleaned, and the polishing efficiency is high.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

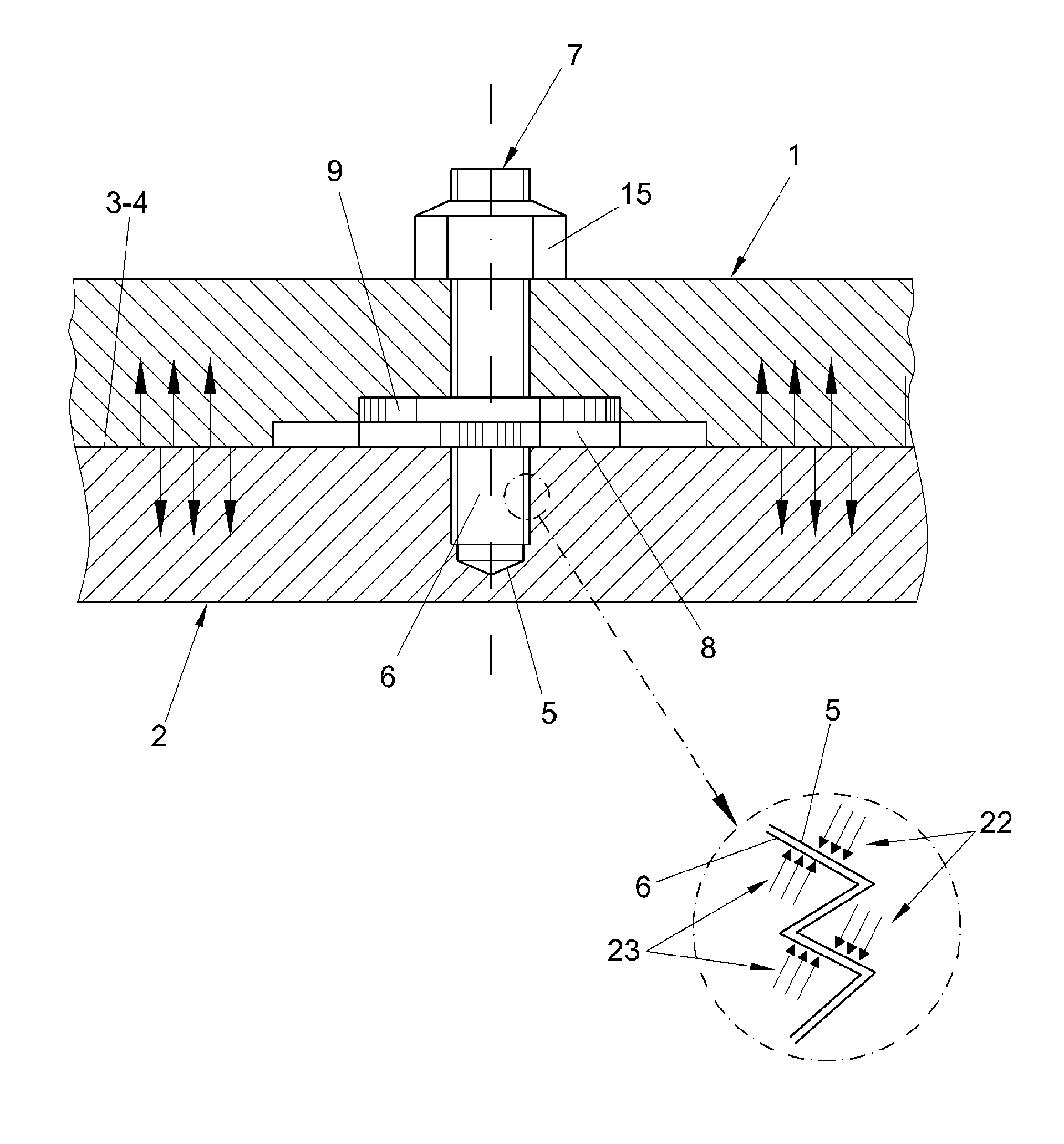

System for the detachable connection of thick parts

Owner:AIRBUS OPERATIONS SL

Process for manufacturing rare earth high-carbon low-alloy steel liner

InactiveCN1843656AStrong wear resistanceNot easy to breakFoundry mouldsFoundry coresRiver sandDistortion

The invention discloses a method for producing rare earth high-carbon low alloy steel scaleboard, which comprises shaping step, smelting step and thermal treating step. Wherein, the shaping step comprises wet sand shaping step and EPC disappear mould shaping step; the wet sand shaping step uses 40-100 deals of artificial quartz sand while the silicon content is not less than 98%; the back sand uses river sand; the material ration is: quartz sand in 100%, alta-mud in 7-8%, water in 4-6%; and said step also uses separate sand, pestle sand, gas hole, draw plate, and shaping tank; EPC disappear mould shaping step uses quartz sand, one-dimension vibration shaping; the smelting step uses acidic furnace liner and double slag method; the thermal treating step first heats the scaleboard to 600-650Deg. C to keep said temperature for 1-2 hours, and than heats it to 900-960Deg. C and keeps 2-3 hours, than cooling it with water to 380-420Deg. C, to be cooled into room temperature via air, at last heats it to 200-400Deg. C and keeps 3-5 hours, than cooling it via air. The ball grinder scaleboard produced by said method has high friction resistance, without plastic distortion and breakage, while it has lower cost and easy maintenance.

Owner:孙荣玖

Impact-type high-temperature hardness test method

InactiveCN102226746ANo plastic deformationLittle elasticityInvestigating material hardnessFree fallingKnoop hardness test

An impact-type high-temperature hardness test method belongs to the technical field of hardness tests. The invention can solve the problems of low test precision and insufficient upper limit of test temperatures commonly seen in current hardness tests. In a current high-temperature hardness test, the temperature of a pressure head is the same as the test ambient temperature; elastic deformation or even plastic deformation of the pressure head can result in a bigger test error, which is also a main reason why the upper limit of the test temperature is limited at a lower level. The high-temperature hardness test method particularly comprises the following procedures: heating a sample to a set test temperature; allowing the part for hardness test to be in low-temperature environment through a water cooling system; when the sample reaches the set test temperature, rapidly moving a test head into the high-temperature region where the sample is located, realizing the free-falling control of the test head by an electromagnetic mechanism of the part for hardness test; allowing the pressure head to impact the upper surface of the sample in a free-falling manner and to fall again after rebound, determining the time interval between two impacts so as to obtain the high-temperature hardness value of the sample to be tested. The invention has an upper temperature limit of up to 1600 DEG C, and a test error of less than 2%.

Owner:HARBIN INST OF TECH

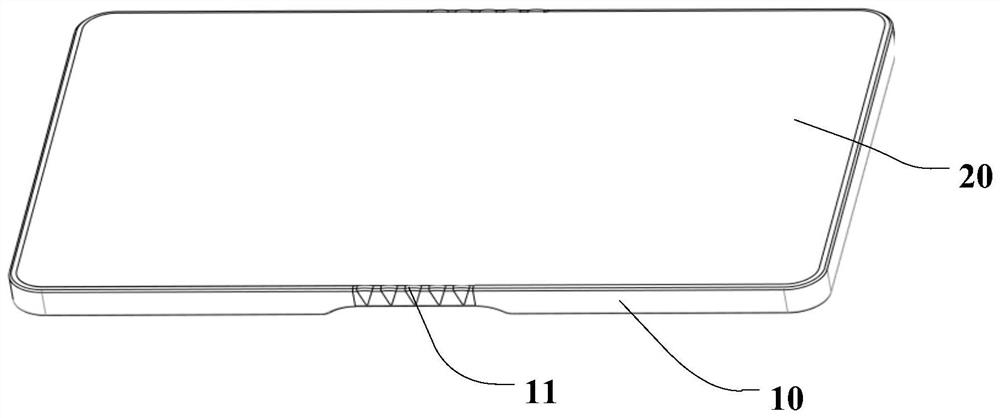

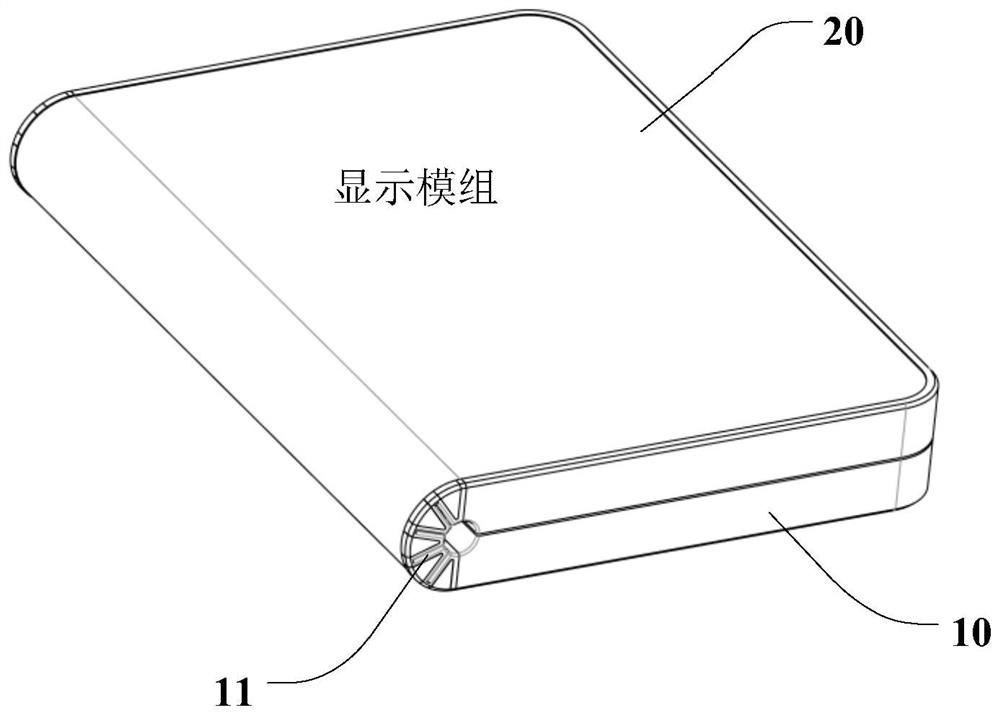

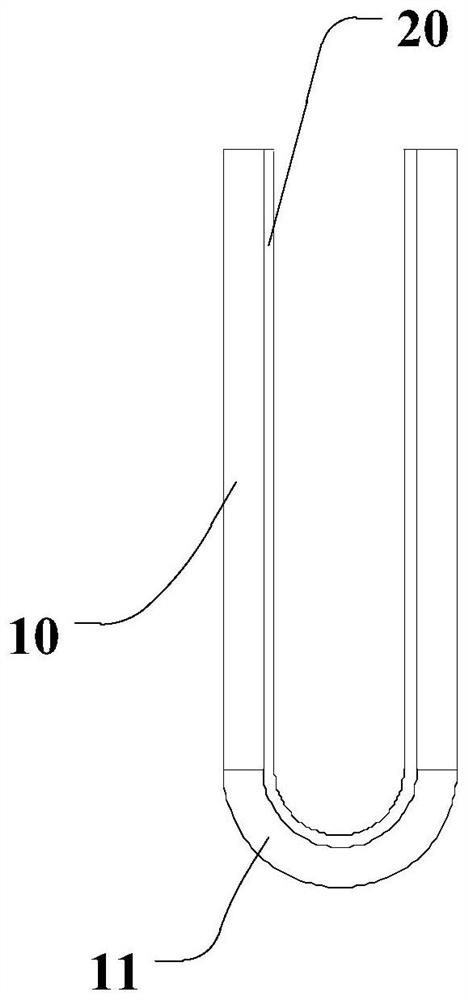

Flexible display cover plate, flexible display module and flexible display device

InactiveCN112185247AImprove appearance and textureReduce scratchesProtective equipmentDigital data processing detailsEngineeringStructural engineering

The invention provides a flexible display cover plate, a flexible display module and a flexible display device. The flexible display cover plate is used for covering a flexible screen of the flexibledisplay module. The flexible display module is applied to the flexible display device and has bendability. The flexible display cover plate comprises at least two layers of stacked structures, namelya glass layer and a hardened layer, and the hardened layer is located on the side, away from the flexible screen, of the glass layer, namely the outer side of the glass layer. Except the basic glass layer and the hardened layer, an anti-explosion layer is arranged on the side, close to a display screen, of the glass layer, or a flexible protection layer is added to the periphery of the glass layer, so that the impact resistance and fragmentation resistance of the glass layer are improved, and the stability and reliability of the display cover plate are improved.

Owner:HUAWEI TECH CO LTD

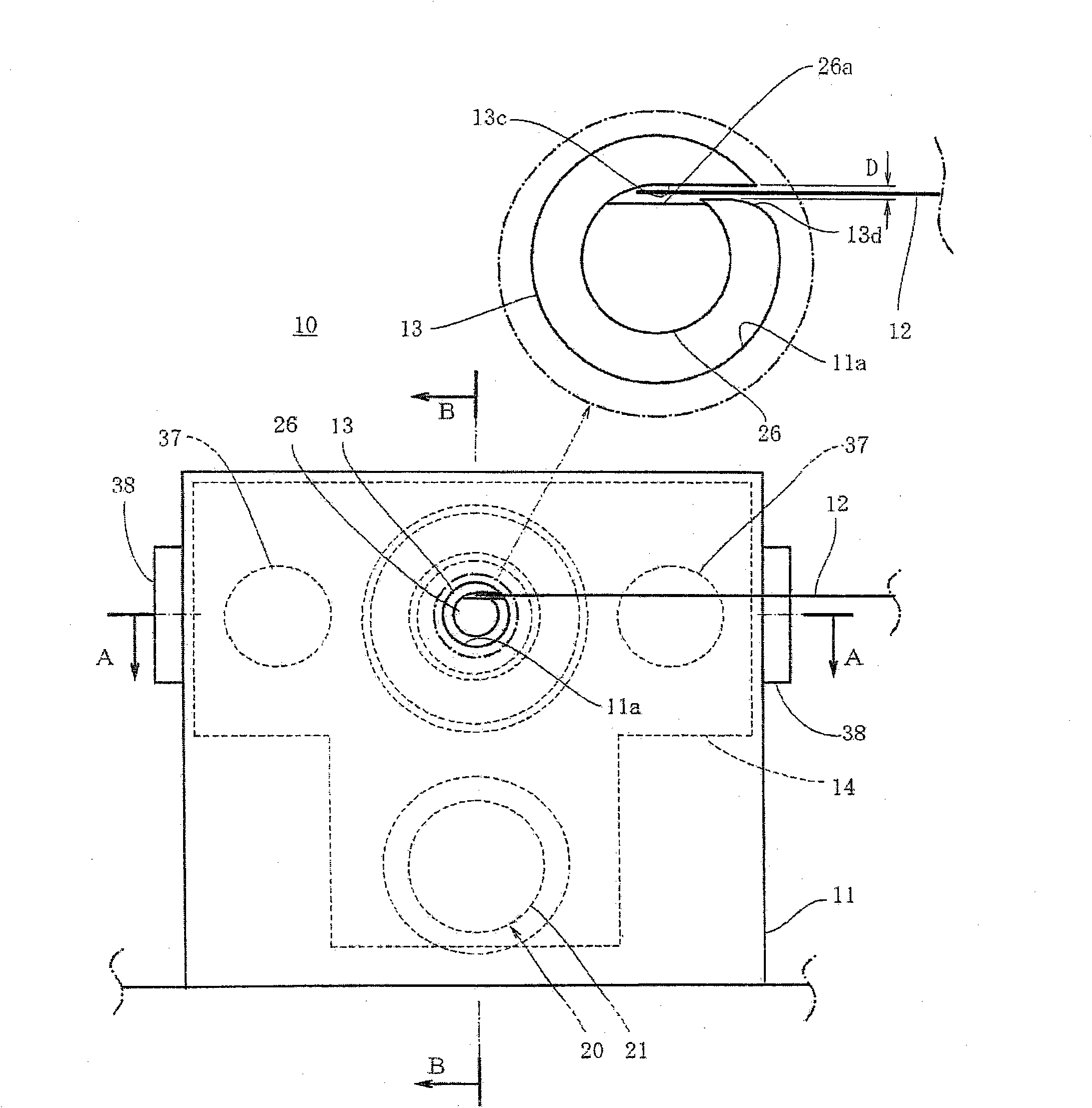

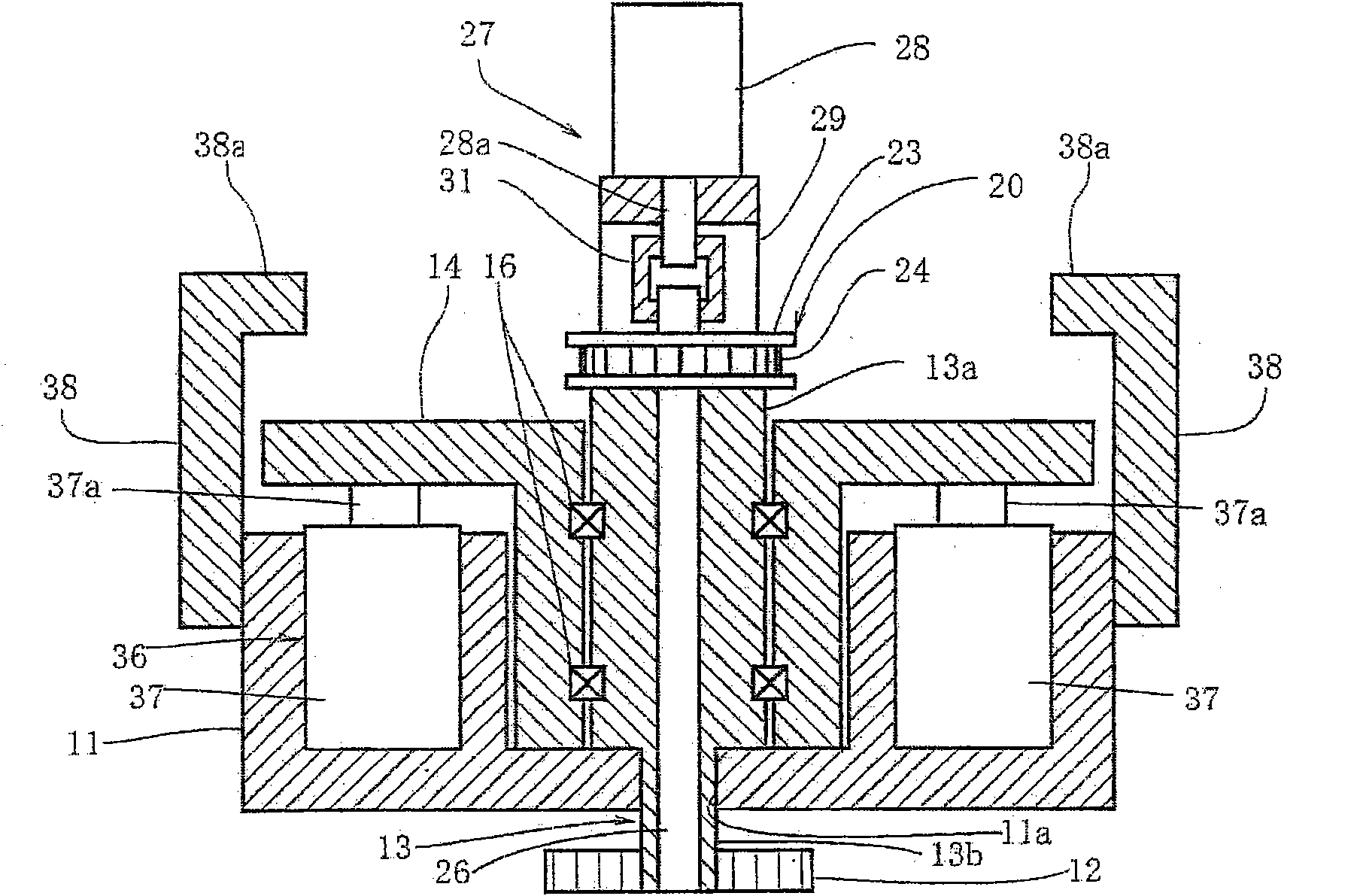

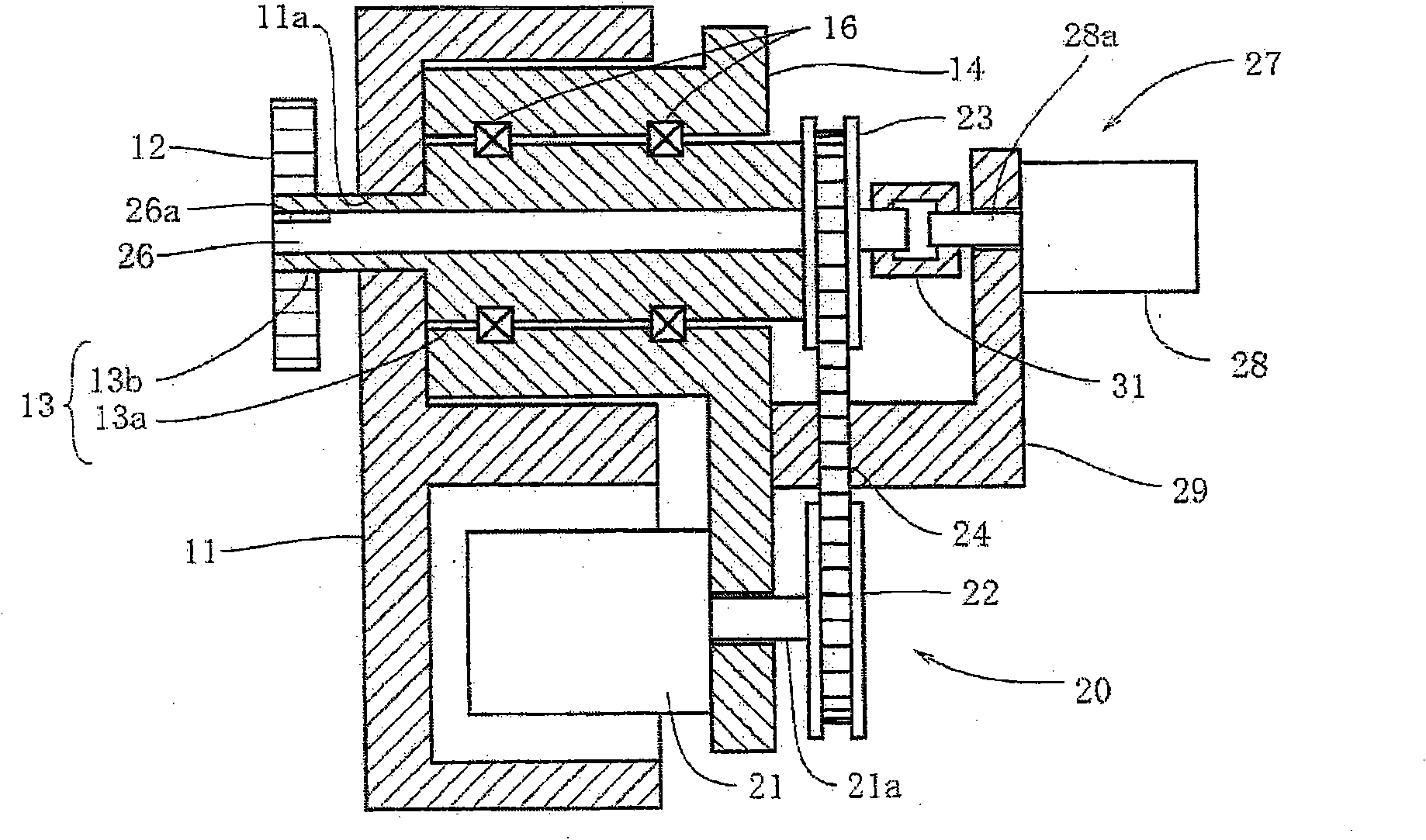

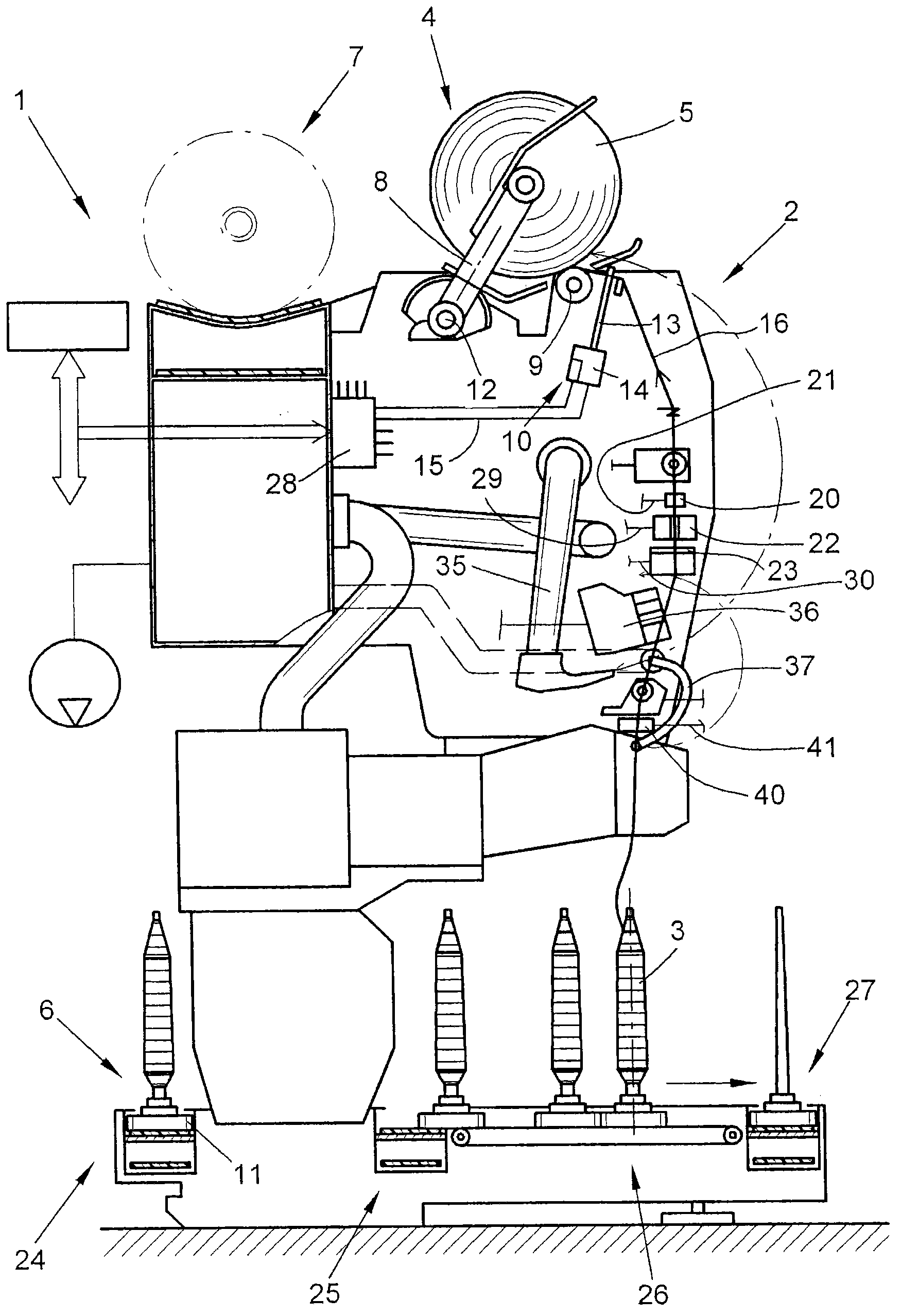

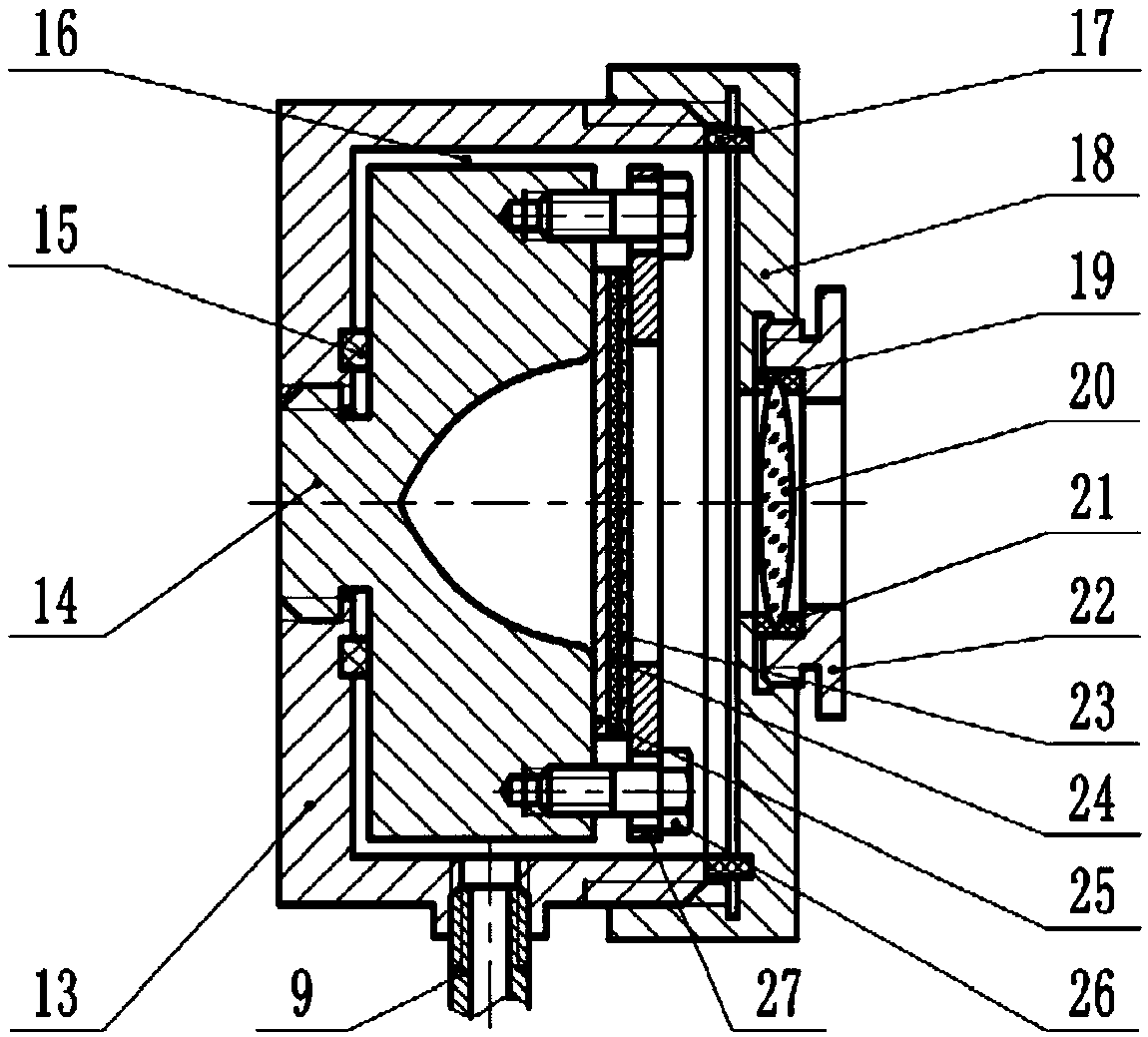

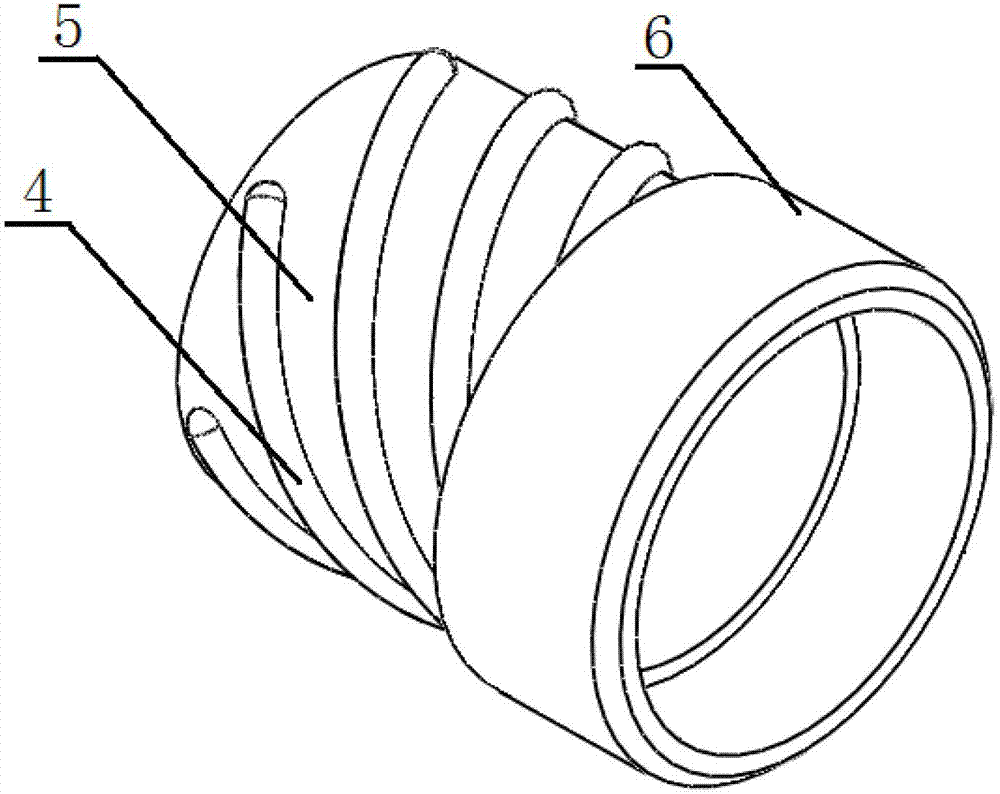

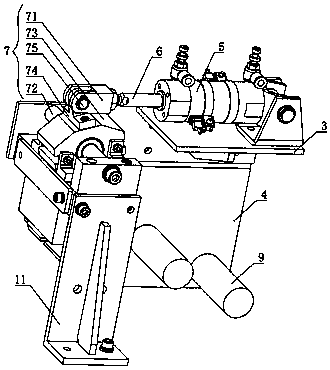

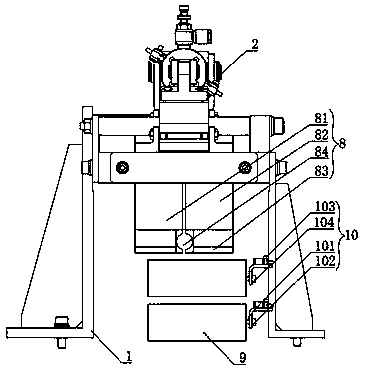

Winding device with plate and winding method

InactiveCN101950664ANo plastic deformationCoils manufactureWebs handlingEngineeringMechanical engineering

The invention provides a winding device with a plate and winding method to obtain a approximately round iron core whose inner diameter is equal to the outer diameter of a coil core. The winding device with a plate comprises a cylinder-shaped coil core (13), a clamping rod (26) and a clamping rod rotating drive mechanism (27). The coil core is provided with a slit (13c) for a magnetic band plate (12) to insert into from the outer periphery to the inner periphery, and the coil core rotates through a coil core rotating drive mechanism (20) and winds the band plate on the outer periphery. The clamping rod is inserted into the coil core and is provided with a gap (26a) which is communicated to the slit and can be inserted by the front end of the band plate. The clamping rod rotates with respect to the coil core, and the gap moves with respect to the slit and holds the front end of the magnetic plate, and the front end of the magnetic plate is loosened from the gap and from the slit at opposite direction. The winding device with a plate is preferably formed by the tangent of the inner side of the cylinder-type coil of the slit, and a rounding is disposed at the side angle of the obtuse angle between the outer periphery of the coil and the slit.

Owner:NITTOKU ENG CO LTD

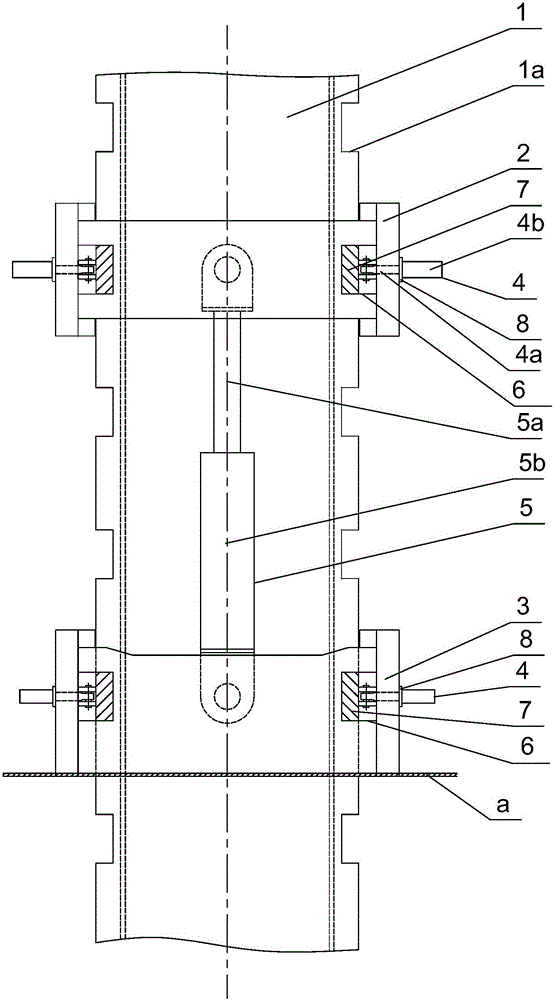

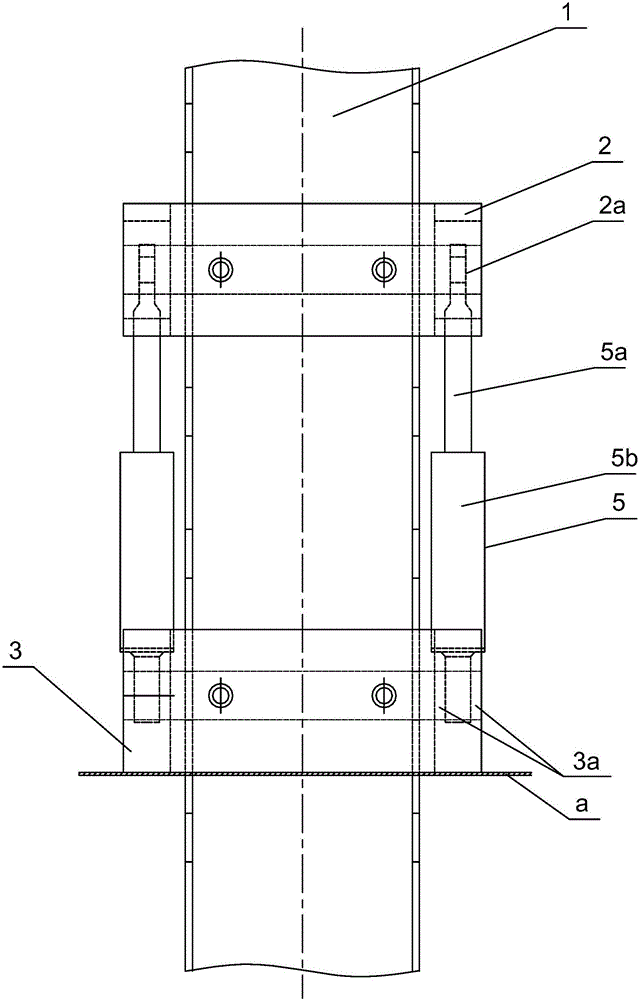

Step-type hydraulic bolt lifting mechanism

ActiveCN105714750ASmall shapeOverall small sizeArtificial islandsUnderwater structuresStructural engineeringUltimate tensile strength

The invention discloses a step-type hydraulic bolt lifting mechanism, and belongs to the field of self-elevating offshore platforms. The step-type hydraulic bolt lifting mechanism comprises a pile leg, a movable ring beam and a fixed ring beam, wherein a plurality of grooves are horizontally formed in two opposite side walls of the pile leg in the length direction of the pile leg respectively; horizontal chutes communicating with the grooves are formed in positions, corresponding to the grooves, on the movable ring beam and the fixed ring beam; sliding blocks, which can be inserted into the grooves in a clamped manner, are arranged in the horizontal chutes in a horizontally sliding manner, and are fitted with the grooves; the length of the sliding blocks is consistent with that of the square ring beams; horizontal oil cylinders are mounted at positions, corresponding to the sliding blocks, on the movable ring beam and the fixed ring beam respectively; the piston rods of the horizontal oil cylinders face to the pile leg, and are connected with the sliding blocks correspondingly; and the sliding blocks can extend into the grooves correspondingly. As the limitation on the shape and the size of the sliding blocks is low, the strength of the sliding blocks is much higher than that of a bolt, and plastic deformation of the sliding blocks in a user process can be avoided.

Owner:WUHAN MARINE MACHINERY PLANT

Process for manufacturing middle frame of mobile phone by liquid metal die-casting molding technology

The invention discloses a process for manufacturing a middle frame of a mobile phone by liquid metal die-casting molding technology. The appearance structure of the middle frame of the mobile phone ismade of a bulk amorphous alloy, namely, liquid metal. The glass forming ability (GFA) of the bulk amorphous alloy is more than 1 mm during copper mold pouring, the solid microstructure of the bulk amorphous alloy is of a short-range ordered and long-range disordered arrangement structure, and the solid microstructure is similar to microstructure in liquid and similar to the microstructure of theglass, so the bulk amorphous alloy is further called liquid metal or metallic glass. The process for manufacturing the middle frame of the mobile phone by the liquid metal die-casting molding technology comprises main technological processes of full vacuum die casting of the liquid metal, machining treatment 1, combination of aluminum / magnesium middle plate, machining treatment 2, NMT, machining treatment 3, polishing, and PVD. According to the process for manufacturing the middle frame of the mobile phone by the liquid metal die-casting molding technology, the middle frame of the liquid metalmobile phone has high strength, high hardness, high elasticity, abrasion resistance, corrosion resistance, almost no plastic deformation, low thermal conductivity and attractive and high-grade appearance, and the production of high performance, high efficiency and low cost is achieved.

Owner:上海驰声新材料有限公司

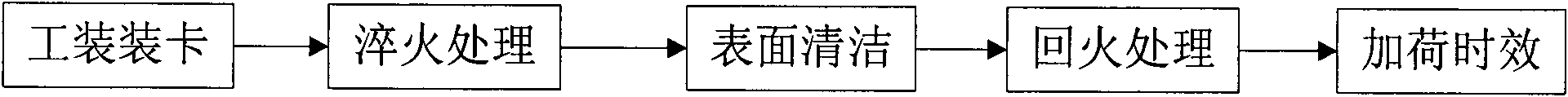

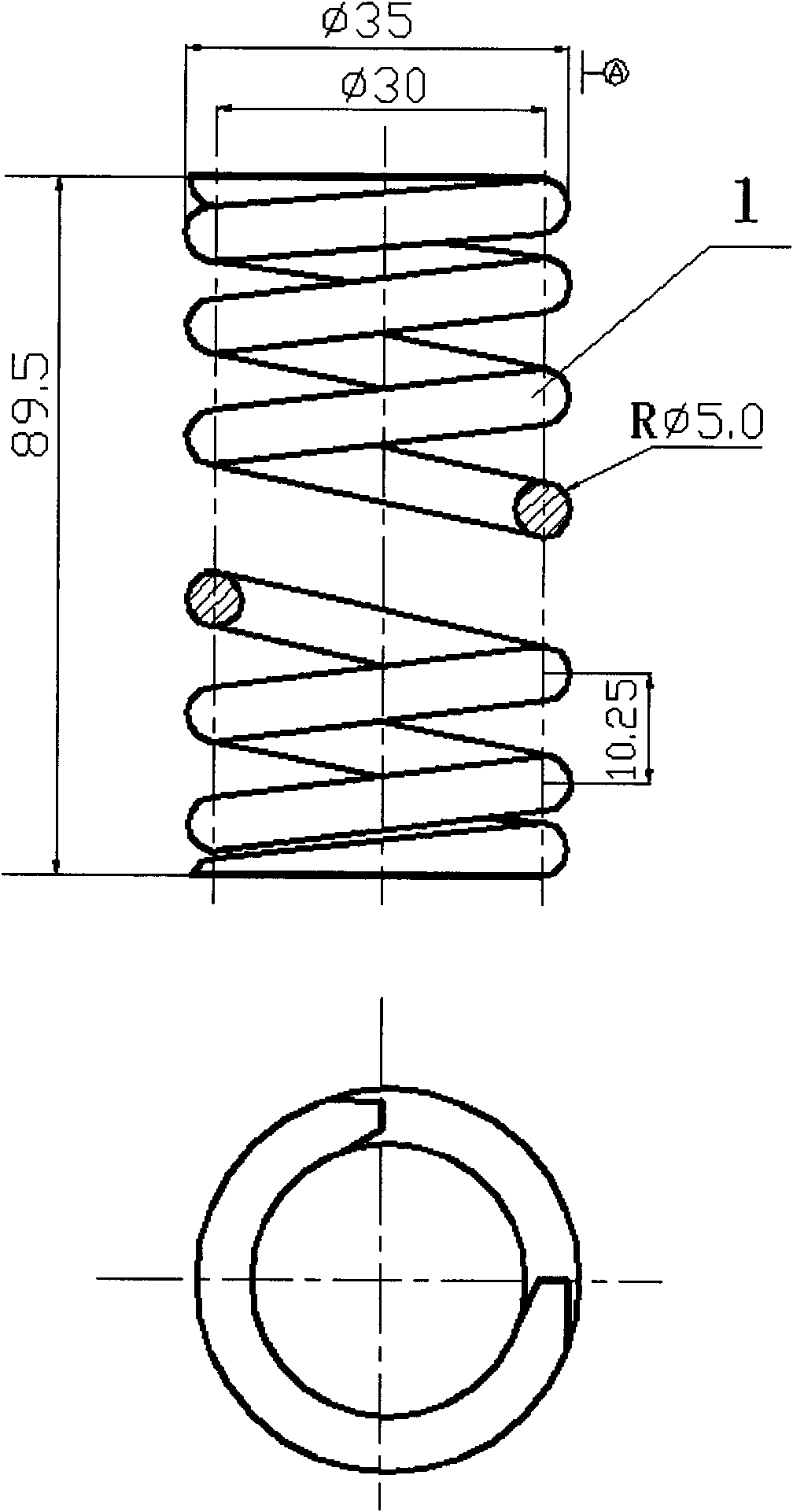

Precise heat treatment method of high-precision elastic element

ActiveCN102134633AAchieve oxidation-free treatmentFull convectionFurnace typesHeat treatment furnacesStress relaxationGraphite particle

The invention relates to a precise heat treatment method of a high-precision elastic element. In the invention, quenching is carried out by adopting a fluidized particle furnace and elastic element quenching treatment equipment, wherein graphite particles are used as a heating medium and optimized design is carried out on the quenching temperature, the heat preservation time and the cooling manner so that the non-oxidation quenching treatment of the high-precision elastic element is realized and the surface quality and the size precision of the high-precision elastic element are improved; according to the quenching rigidity of the high-precision elastic element, proper technological parameters are selected to carry out tempering treatment; and loading ageing treatment is conducted to the element by adopting elastic element loading treatment equipment so that the stress relaxation property of the elastic element is improved, the stress in the winding process is reduced and the micro-yield strength is effectively improved. Through the heat treatment method of the invention, the high-precision elastic element is free of oxidation on the surface, free of deformation on the size and stable in mechanical property after the quenching, and the reliability and the quality of the heat treatment of the high-precision elastic element are improved.

Owner:BEIJING SATELLITE MFG FACTORY

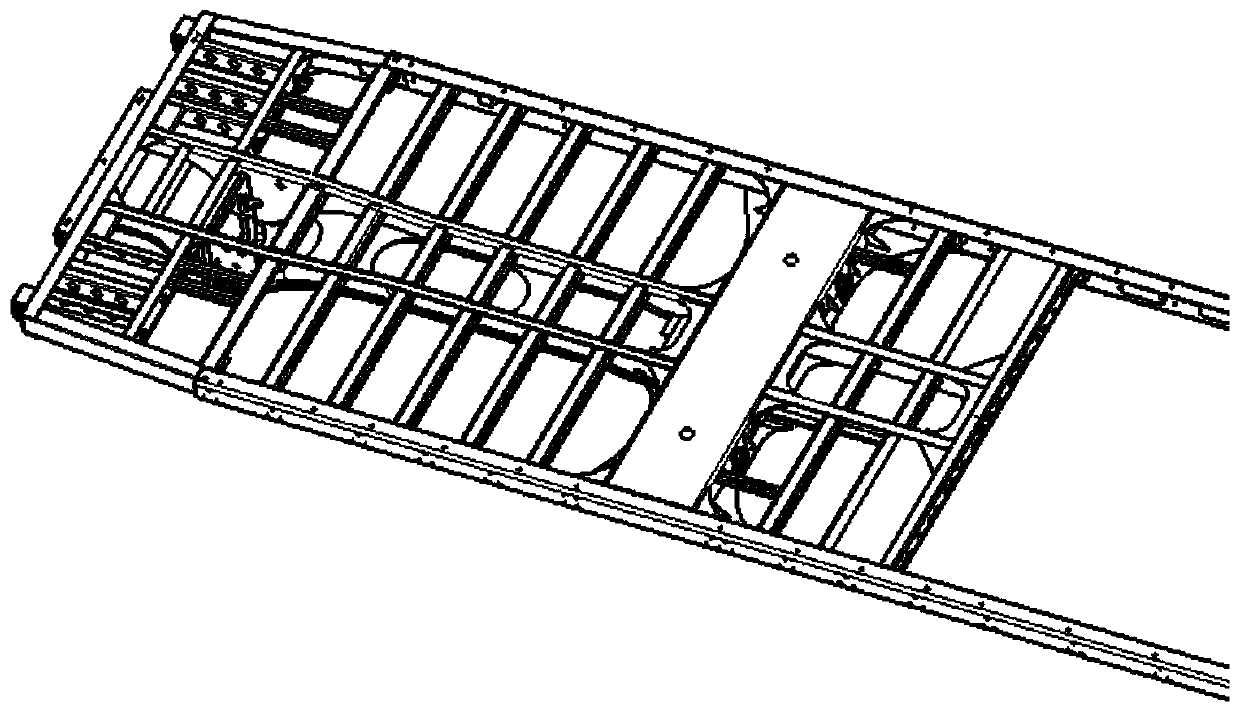

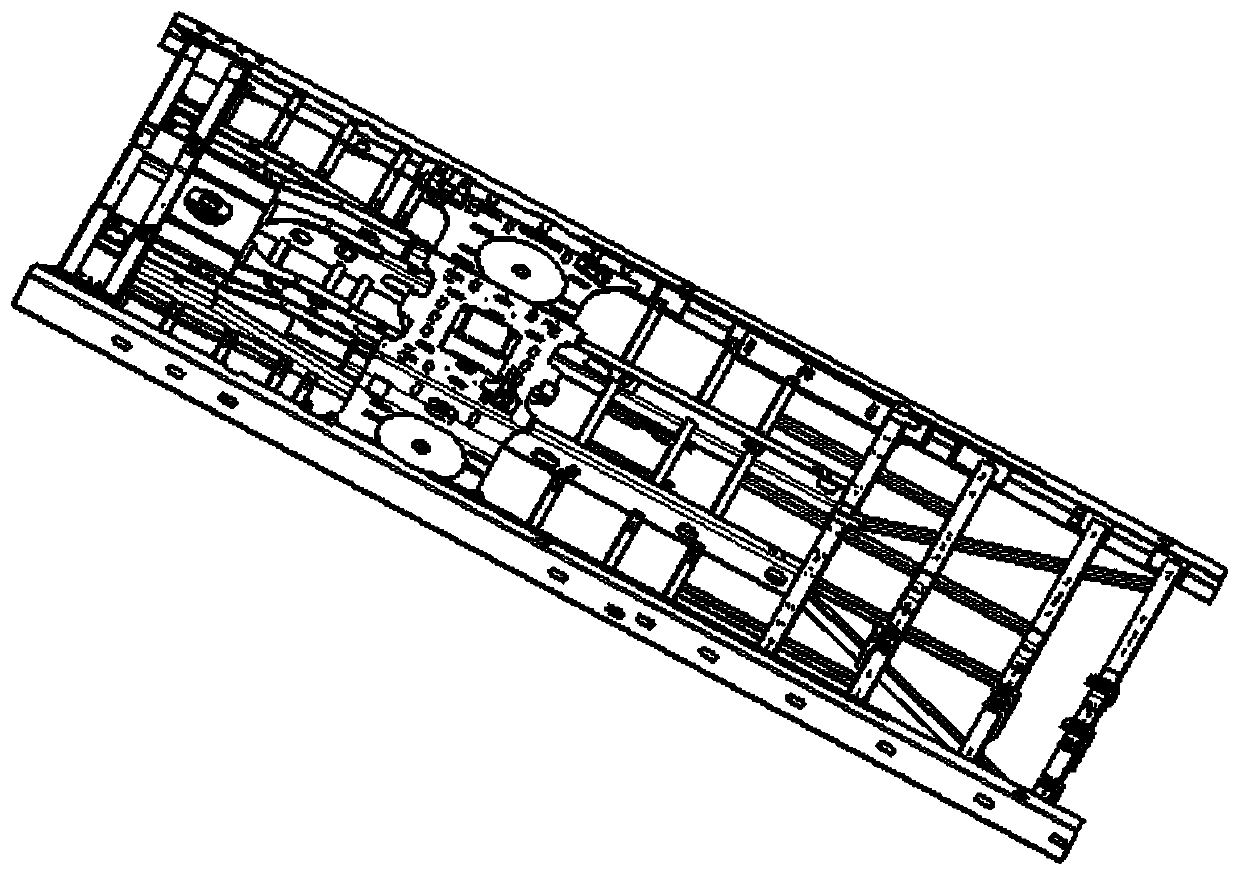

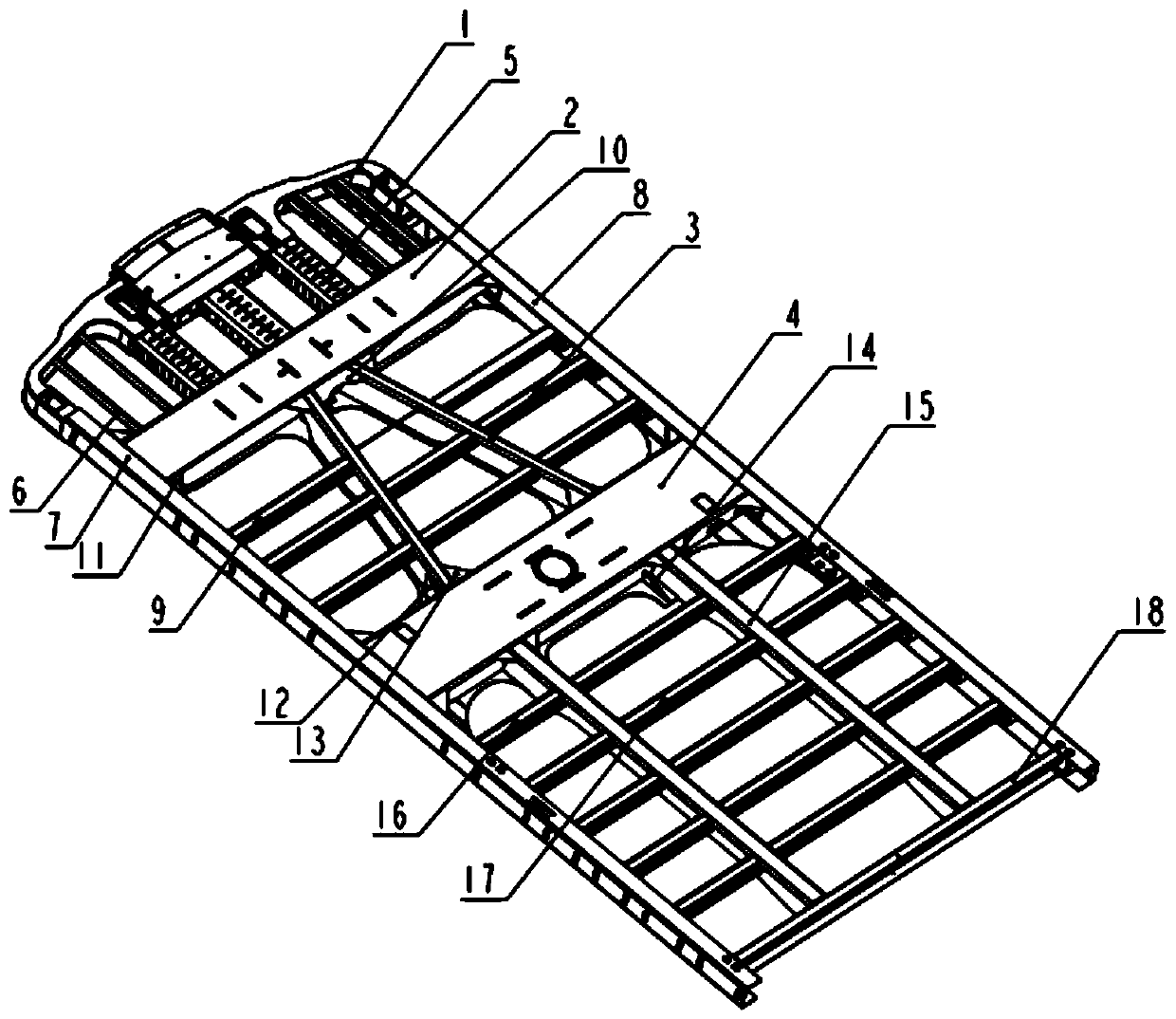

Subway car end underframe structure

PendingCN110126868AReasonable arrangementExquisite structureRailway wheel guards/bumpersUnderframesStress concentrationMaintainability

The invention relates to a subway car end underframe structure. The subway car end underframe structure comprises a front-end anti-creeper assembly, a crushing box assembly, a coupler seat assembly and a sleeper beam assembly. The subway car end underframe structure is characterized in that the crushing box assembly is welded between the front-end anti-creeper assembly and the coupler seat assembly; connecting beams are arranged on the two side parts between the front-end anti-creeper assembly and the coupler seat assembly; a buffer beam assembly is connected between the coupler seat assemblyand the sleeper beam assembly; the tail end of the end part of the underframe is a main cross beam; and a longitudinal beam assembly is connected between the sleeper beam assembly and the main cross beam; and the front-end anti-creeper assembly, the crushing box assembly, the coupler seat assembly, the buffer beam assembly, the sleeper beam assembly, the longitudinal beam assembly and the main cross beam are sequentially connected into a whole, and the two sides of the whole structure and carbon steel side beam assemblies are welded into a closed structure. The subway car end underframe structure is exquisite and concise, the arrangement of the cross beam and the longitudinal beams is reasonable, and on the premise of ensuring the continuity of force transmission, the installation space and maintainability of other systems are met as far as possible; through the reasonable arrangement of reinforcing parts, the continuity of force transmission is realized through various connectors, andstress concentration and excessive local stress are avoided; light weight requirements are met; and the operability of replacement is ensured, and the maintainability is good.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

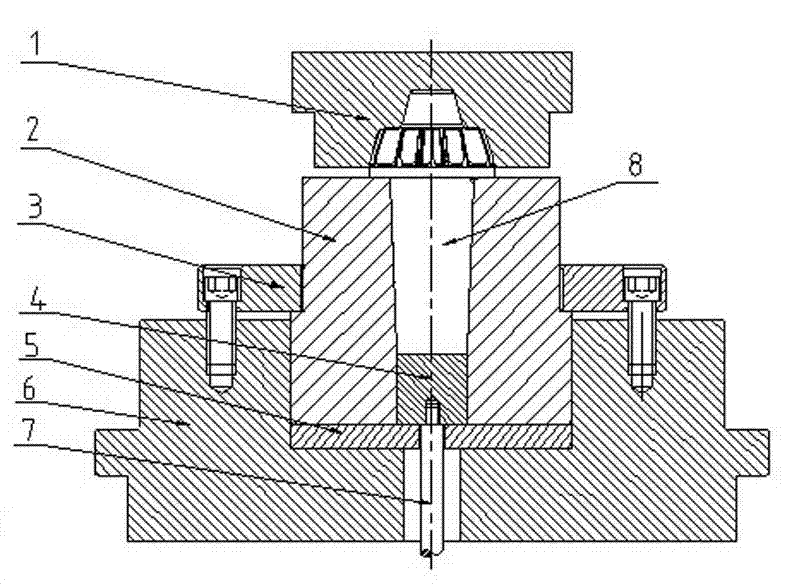

Shaft end bevel gear forging mould

InactiveCN103480786ASimple structureEasy to manufactureForging/hammering/pressing machinesEngineeringGravity center

The invention discloses a shaft end bevel gear forging mould which comprises an upper mould, a lower mould, a pressing plate, a mandrel, a base plate, a mould base and an ejector rod. An axial through hole in clearance fit with the ejector rod is formed in the middle of the base plate, the base plate is flatly arranged at the bottom of a cavity in the upward end face of the mould base, the lower mould is inserted into the cavity of the mould base and axially positioned by taking the base plate as a base, the pressing plate sleeved on the outer wall of the lower mould is connected with the mould base, the mandrel is axially inserted into a mould cavity of the lower mould from top to bottom until the base plate is axially limited, the ejector rod is an elongated rod relative to the mandrel and penetrates the through hole in the middle of the base plate, the ejector rod and the mandrel are connected into a whole, and the gravity center of the structure is low, so that the mandrel is conveniently reset after a workpiece is ejected. As the diameter of the ejector rod is much smaller than that of the mandrel, the hole for matching the ejector rod with the base plate is also small, the contact area of the mandrel and the base plate is enlarged, plastic deformation of the base plate is avoided in the forging process, and the forging quality of the workpiece is ensured.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

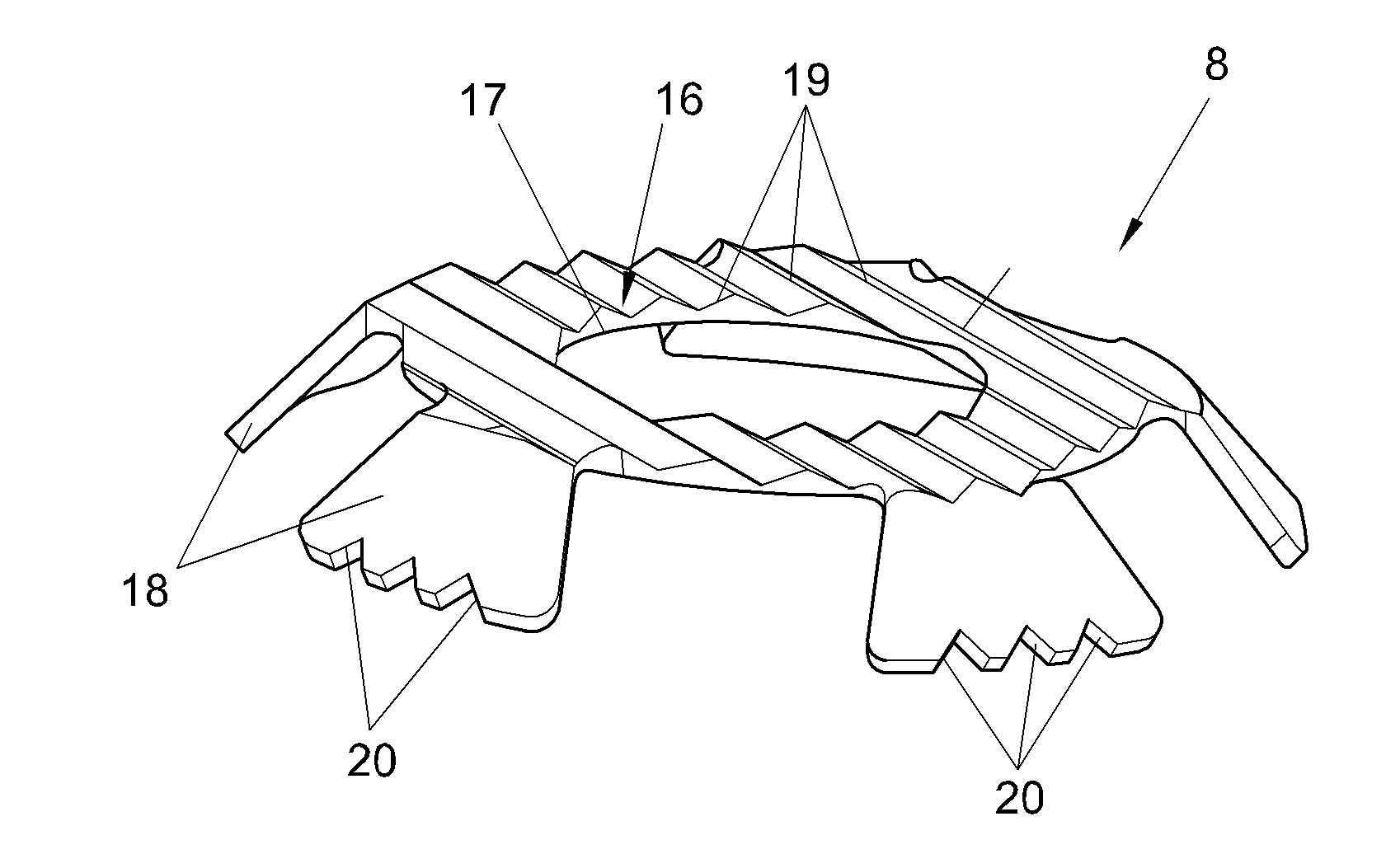

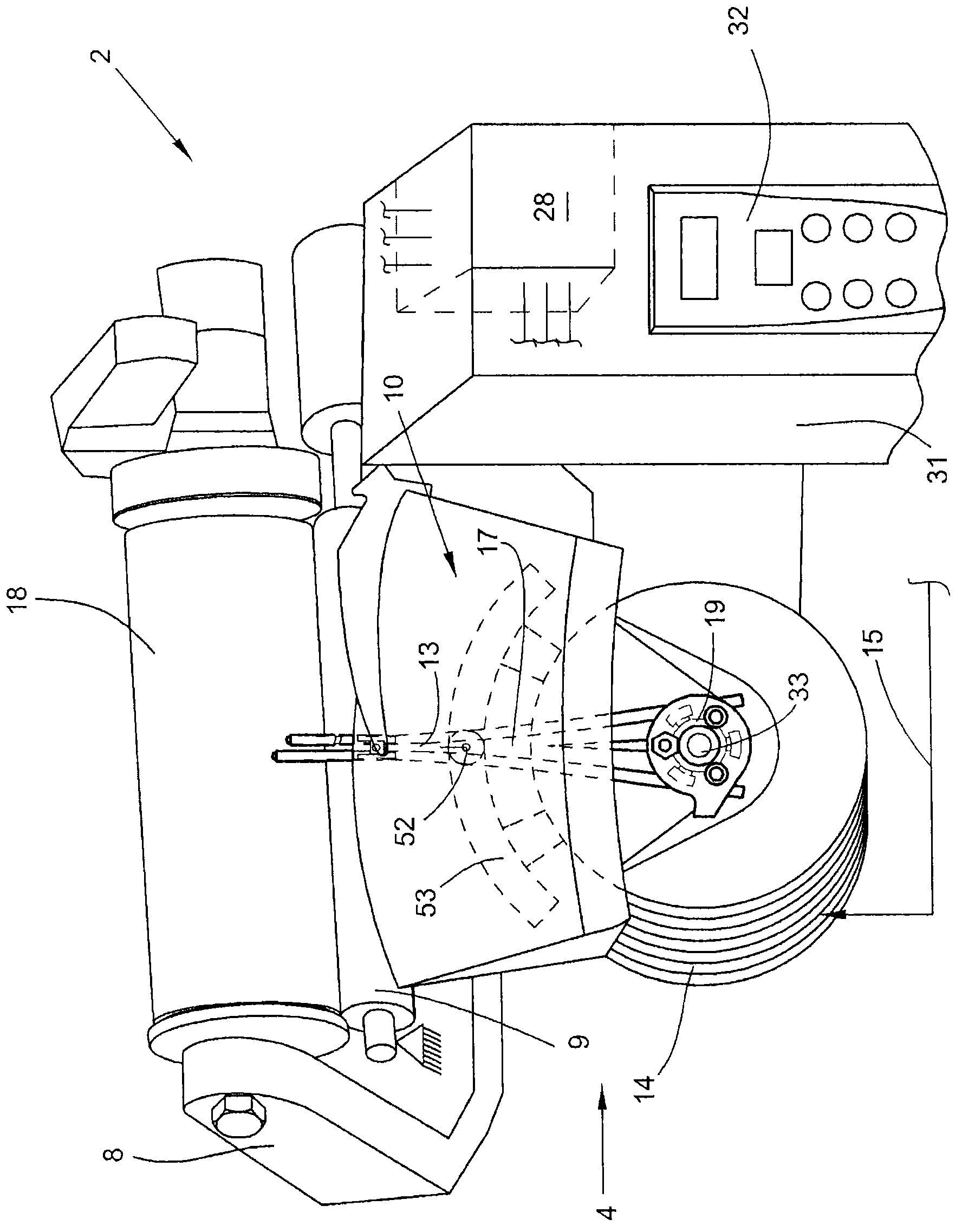

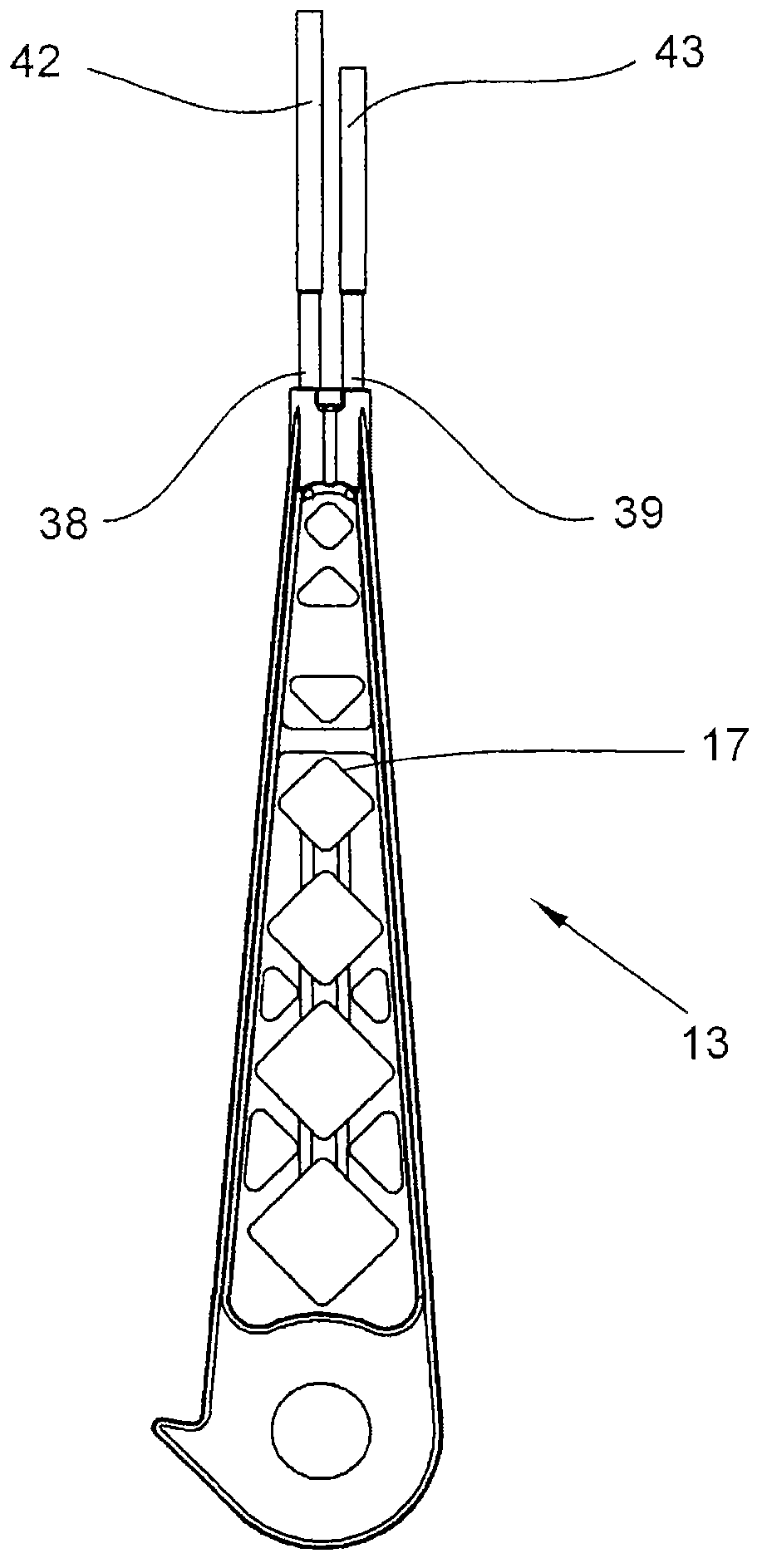

Finger yarn guide

The finger thread guide unit (13) comprises an elongated base body (17) made of plastic with abrasion resistant thread guide elements (42,43) at its free end that traverse a thread running on the surface of a cross-wound spool during the winding operation. The carbon fiber rods (44,45) extending along the length of the base body(17) and a fastening and locking element (19) are molded in the base body, where the abrasion resistant protective units are oxide-ceramic tubes or chrome-plated steel tubes, which are partially molded in the base body.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

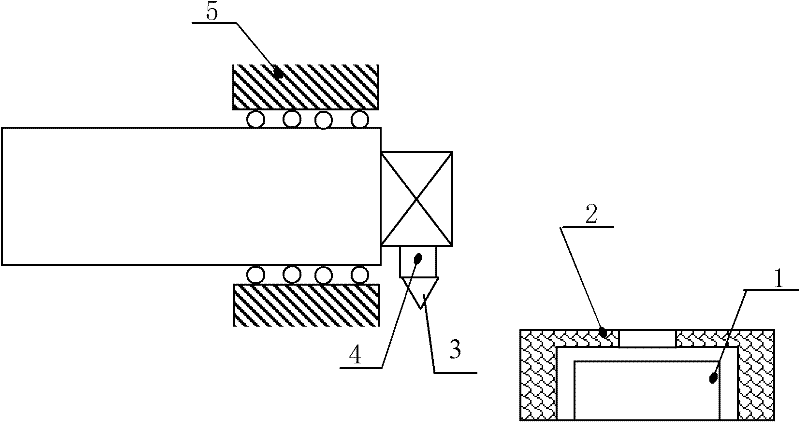

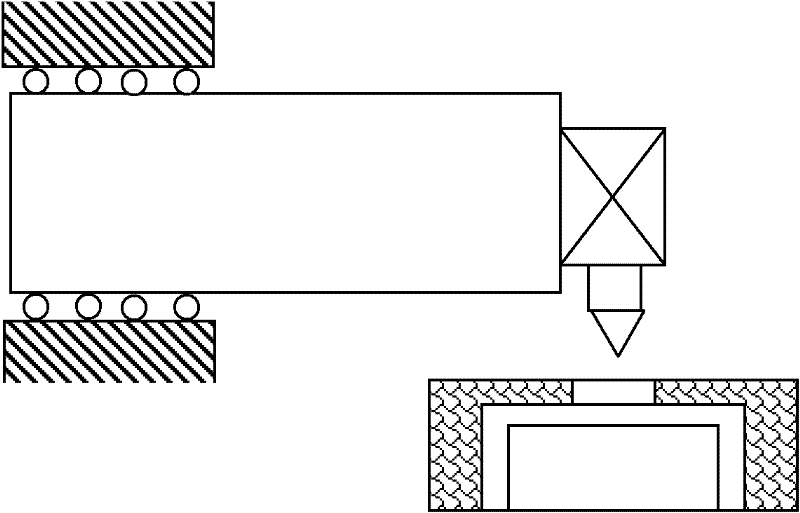

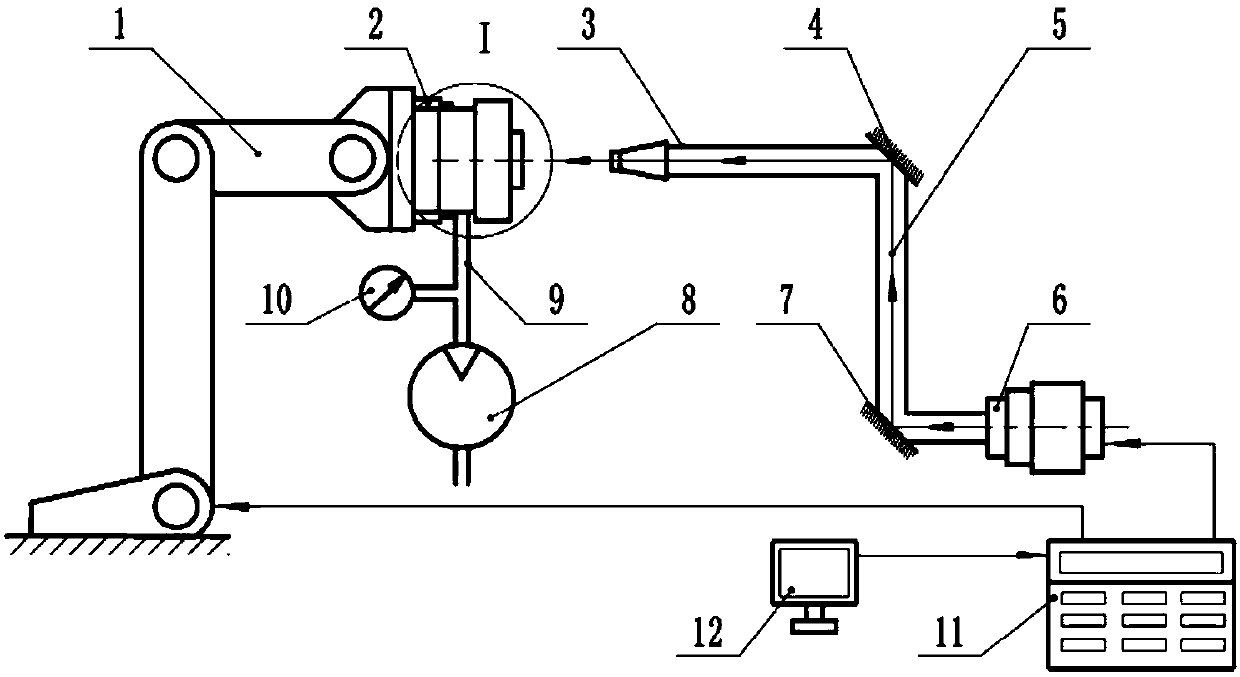

Laserstamping forming method and device

The invention discloses a laser stamping forming method and device, and belongs to the technical field of laser processing. The laser stamping formingdevice comprises a laser, a light guide system, aworkpiece die system and a control system. According to the laser stamping forming method, first a plate and a die are placed in a sealed cavity, a vacuum pump is used forpumping air out from the sealed cavity, so that a close-to-vacuum state is formed in a die cavity, and then the plate is formed by using laser-induced shock waves. The laser stamping forming method and device have simple equipment and donot need complicated dies,flexible processing can be realized by controlling the position of a manipulator, processing parameters are good in controllability, safe and reliable operation is achieved, and the laser stamping forming method and device have potential market application value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

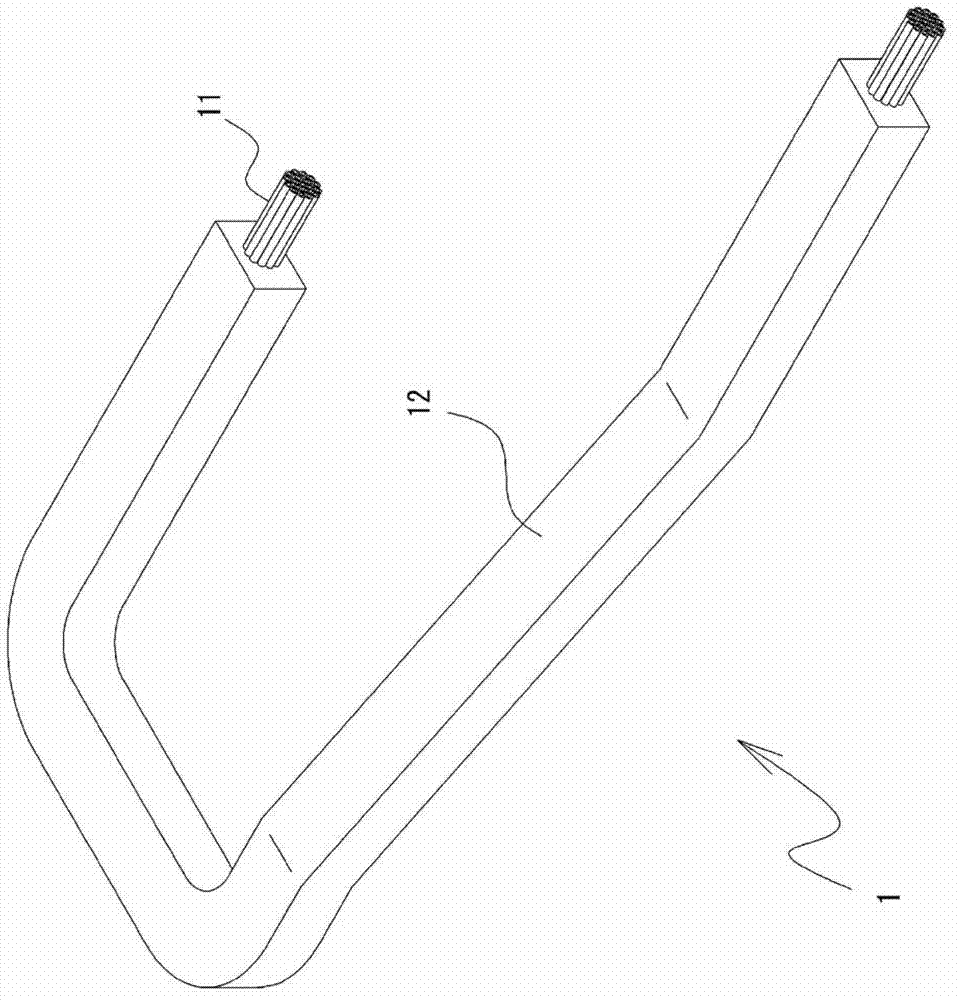

Manufacturing method for wire harness

InactiveCN102741946AReduce in quantityThe content of the process is simpleInsulated cablesManufacturing wire harnessesEngineeringElectric wire

Disclosed is a manufacturing method for a wire harness having a shape-retaining member and protector comprising a thermoplastic material, said manufacturing method enabling the easy formation of the axial shape of the shape-retaining member and protector into a predetermined shape during a manufacture process. The manufacturing method has: a first step, in which the periphery of an electrical wire is coated by a body (13) to be molded comprising a thermoplastic material, and in which the body (13) to be molded is formed into a predetermined cross-sectional shape and dimensions by applying pressure thereto while heating the body (13) to be molded at a temperature at which plastic deformation is possible because of the thermoplasticity; and a second step, after the first step, in which the body (13) to be molded is formed into a predetermined axial shape while at the temperature at which plastic deformation is possible because of the thermoplasticity, and is cooled after being formed into the predetermined axial shape. In the second step, the shape-retaining member (12) obtained through the first step is inlaid in a molding section (721) formed in a lower mold (72) of a second molding body (7), forming the axial shape of the shape-retaining member (12), which is then cooled.

Owner:AUTONETWORKS TECH LTD +2

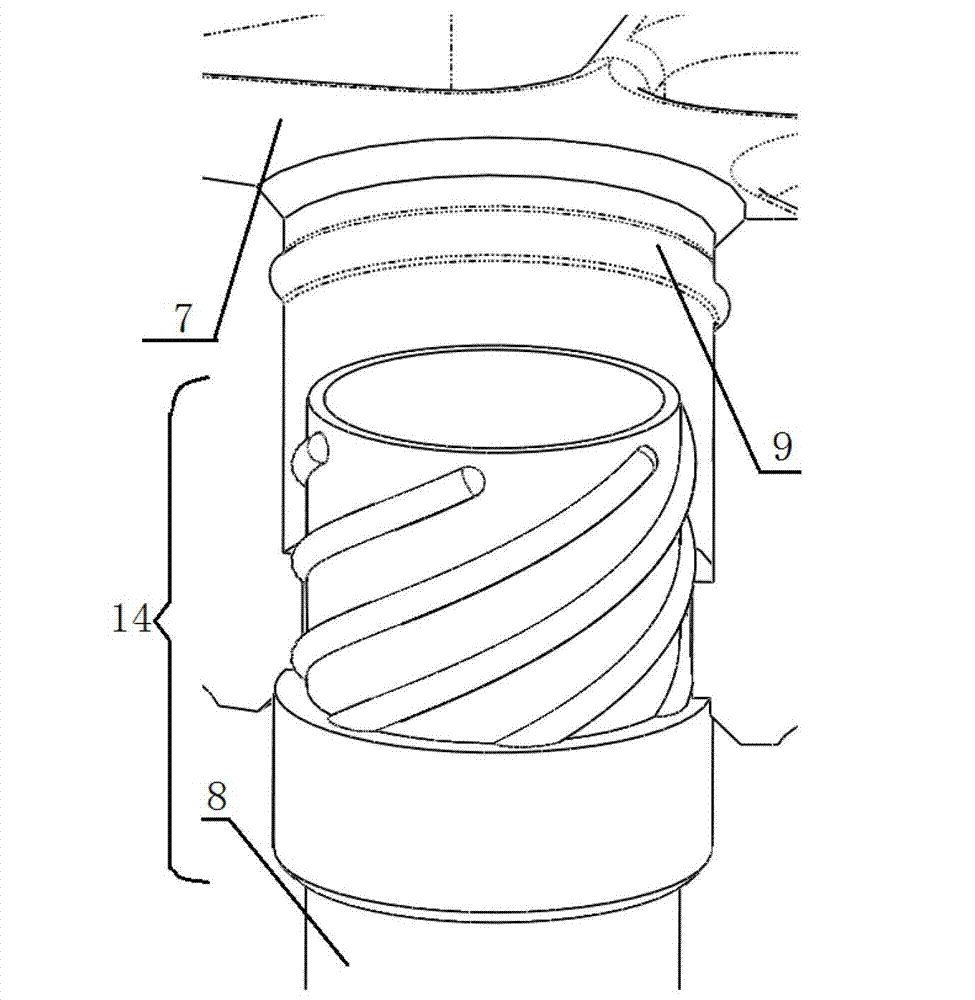

Rotary detachable guide pipe-upper pipe seat connecting piece

ActiveCN103928059AFirmly connectedWon't hurtNuclear energy generationRod connectionsEngineeringMechanical engineering

The invention discloses a rotary detachable guide pipe-upper pipe seat connecting piece which comprises a turnbuckle cap (13) and a turnbuckle sleeve (14), wherein the turnbuckle cap (13) and the turnbuckle sleeve (14) are each of a round pipe structure, are in close fit and are connected through a turnbuckle structure; the upper part of the turnbuckle cap (13) is provided with an elastic skirt (1); the middle lower part of the elastic skirt (1) is provided with a semicircular bulge (12); a plurality of longitudinal grooves (11) are uniformly formed on the elastic skirt (1) along the circumferential direction; the elastic skirt (1) is divided into a plurality of sections through the longitudinal grooves (11). Through the specific turnbuckle structure and a loose design, reliable connection between an upper pipe seat and a guide pipe of a fuel assembly is achieved, and the connecting piece is conveniently and remotely operated and detached when required. The connecting piece is connected by means of a mechanical mode and is elastically locked, plastic deformation is not produced basically, and the connecting piece and the upper pipe seat are prevented from being damaged during mounting and detaching.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

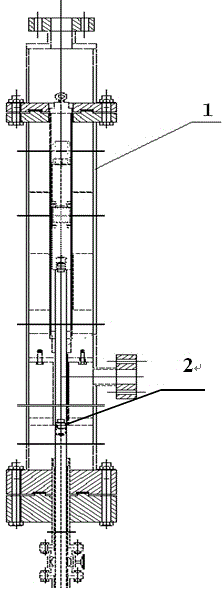

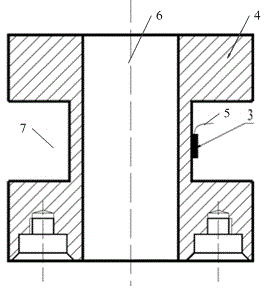

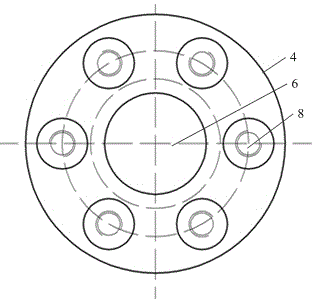

Measuring device used for measuring drop impact force of control rod

ActiveCN104931181ASimple structureEasy to processApparatus for force/torque/work measurementDrop impactMeasurement device

The invention discloses a measuring device used for measuring the drop impact force of a control rod. The technical problem that a conventional force sensor cannot be used to measure the impact force in the prior art is solved. The device comprises a hollow cylinder. A through hole is vertically arranged in the center of the hollow cylinder. A groove is arranged on the outer surface of the middle part of the cylinder in vertical direction. Through the groove, the middle part of the cylinder has uniform wall thickness and is cylindrical. A number of waterproof strain gages can be conveniently axially arranged in the groove. A number of waterproof strain gages are uniformly arranged at the middle part of the groove of the cylinder at circumferential equal intervals. The device is arranged on a pressing ring structure of a buffer component of the control rod in a replacement manner. Without changing the drop height of the control rod, impact force data measurement of a drop test buffer structure is accurate and effective. The measuring device has the advantages of simple structure and easy processing and installation. Test cost and time are saved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

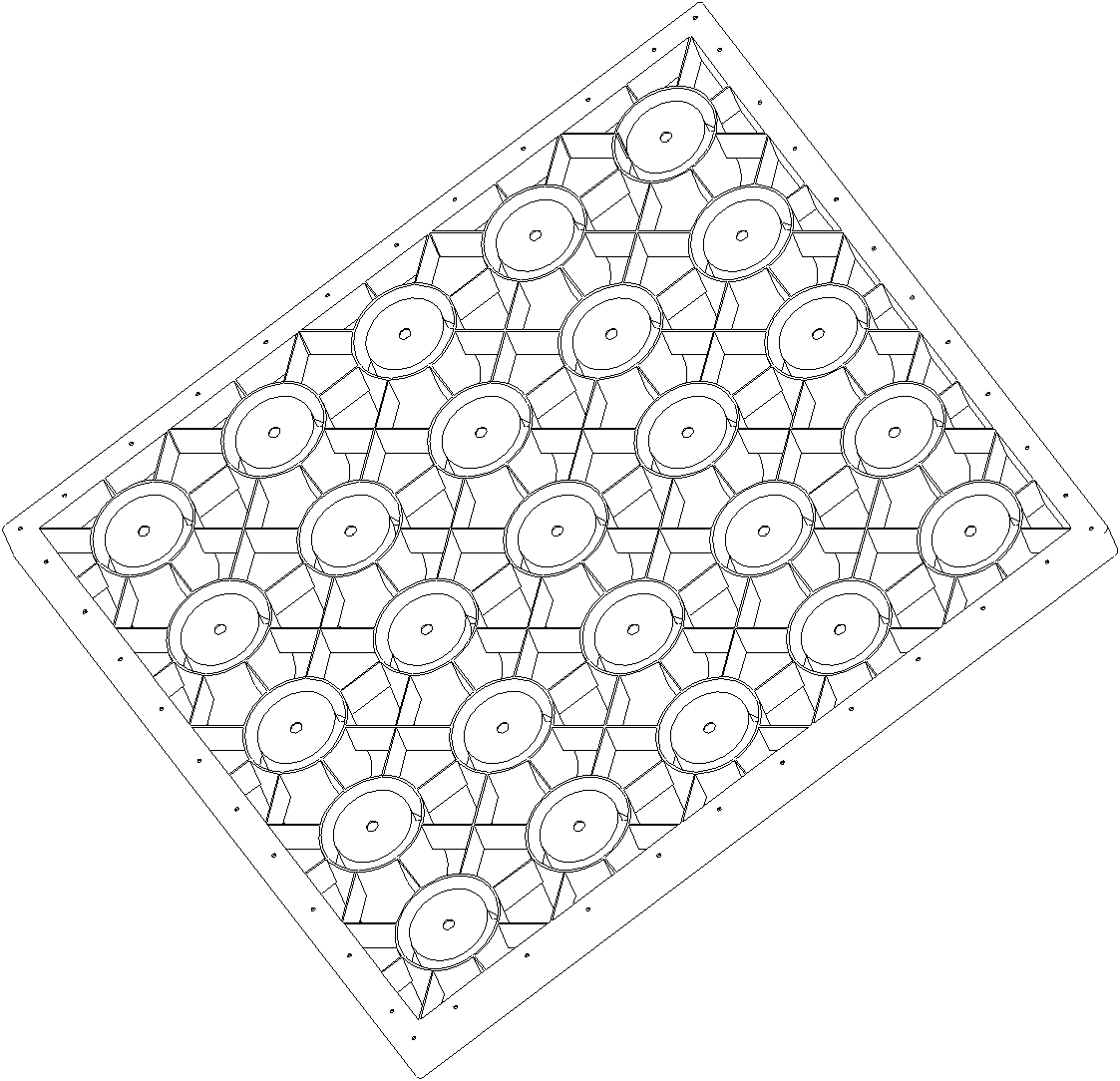

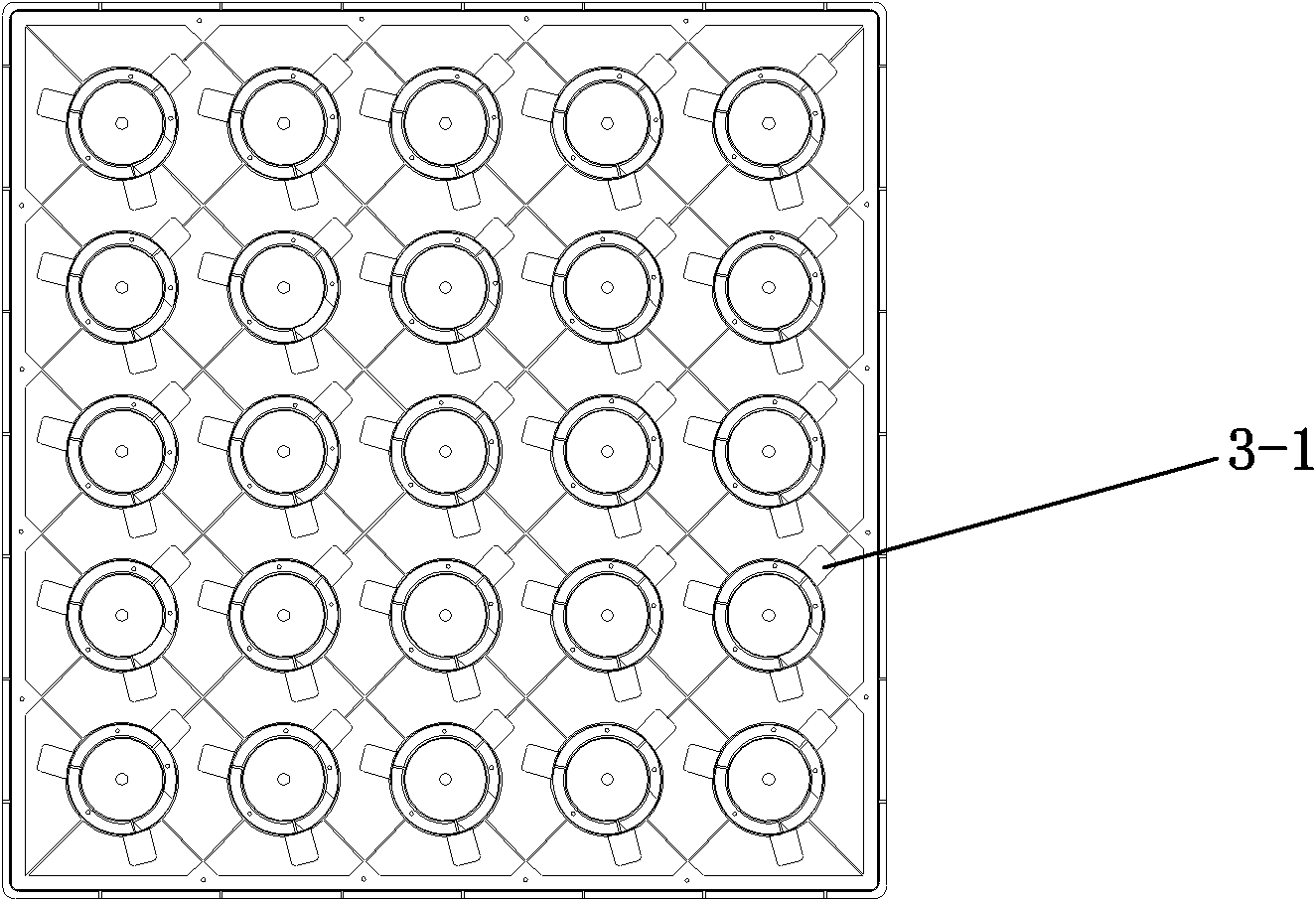

Packaging assembly of air-conditioner compressor

ActiveCN103158937AGuaranteed to be used multiple timesNo plastic deformationPackaging vehiclesContainers for machinesCorrosion resistantEngineering

The invention relates to a packaging assembly of an air-conditioner compressor. The packaging assembly is formed by arranging two or three of an upper fixing plate, a middle fixing plate and a lowering fixing plate up and down. Compared with the prior art, the packaging assembly has the advantages of being high in strength, resistant to shock, corrosion resistant and the like.

Owner:HEFEI GENIUS NEW MATERIALS

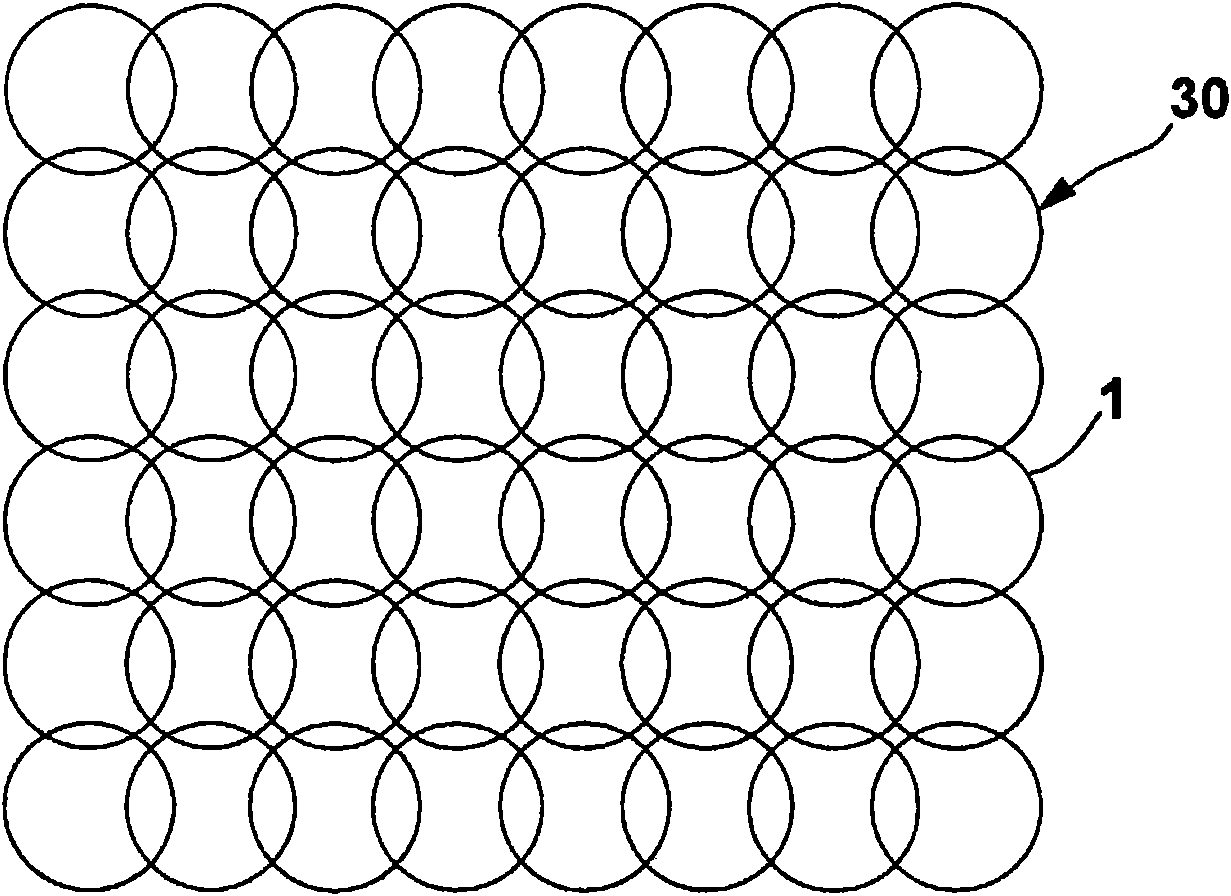

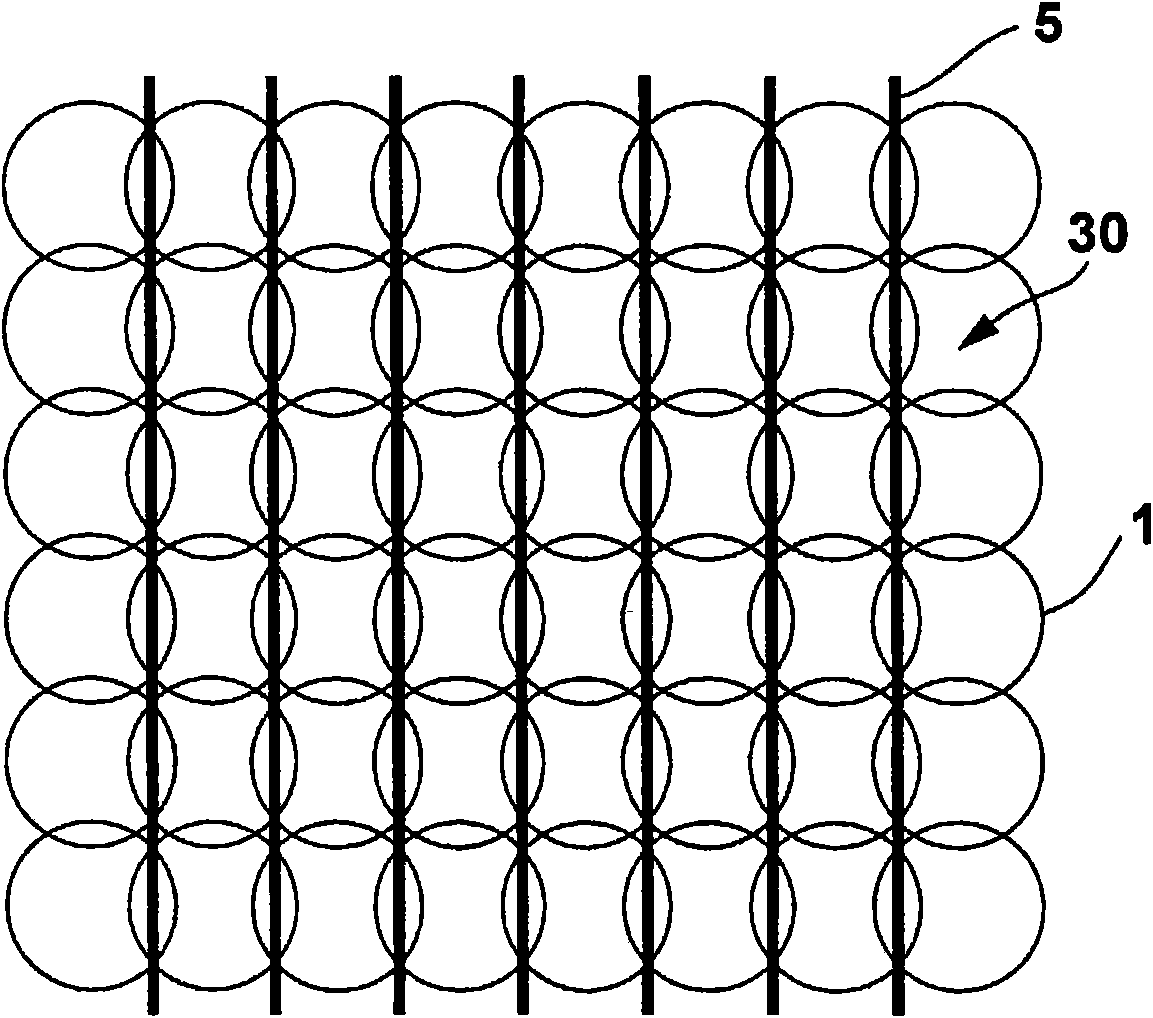

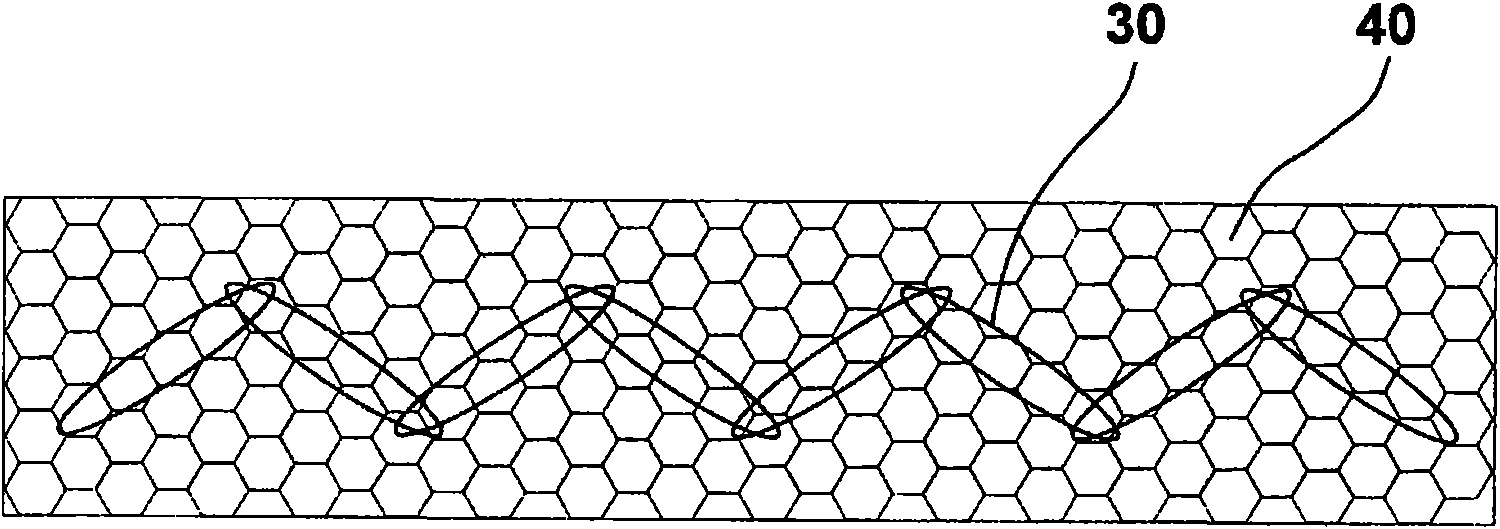

Material web for the production of a bellows of a transitional section, particularly between two articulated vehicle parts

InactiveCN101616834ANot affected littleLittle impactAxle-box lubricationThin material handlingArticulated vehicleEngineering

The invention relates to a material web for the production of a bellows of a transitional section, particularly between two articulated vehicle parts, by means of an annular fabric (30).

Owner:HUBNER GMBH

Novel disk type tension device

InactiveCN103496615AImprove physical stabilityIncrease elasticityFilament handlingFiberCircular disc

The invention relates to a textile machine, in particular to an improvement of a novel disk type tension device. The novel disk type tension device comprises a mandrel, an upper tension disk, a lower tension disk and a tension washer. The mandrel is movably sleeved with the upper tension disk, the lower tension disk and the tension washer, the upper tension disk and the lower tension disk are arranged oppositely, the upper tension disk is located over the lower tension disk, the tension washer is located over the upper tension disk, a cocoon cotton polyester fiber washer is installed between the tension washer and the upper tension disk, and the thickness of the cocoon cotton polyester fiber washer ranges between 1mm and 20mm. The novel disk type tension device can absorb bounce energy of the tension disks and bounce energy of the tension washer stably and efficiently for a long time and apply uniform additional tension force to yarn.

Owner:东台立文色织有限公司

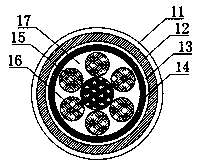

Heating cable and extrusion equipment thereof

ActiveCN107705893AGood flexibilityPrevent twistingClimate change adaptationFlexible cablesElectrical conductorFilling materials

The invention discloses a heating cable, and relates to special equipment or methods for manufacturing conductors or cables. The problems of the twisting and the bending of a cable, the non-rounding condition and the instable forming degree of the extruded cable, the loosening of a cable core, the reduced tensile strength and the shape deformation of the cable, due to the turnover of a special-shaped insulating wire core after the adoption of an existing cable extruding machine and the addition of heating and filling materials containing EPDM rubber 40 nm in grain diameter, can be solved. Theheating cable comprises an outer protective layer, an armor layer, an inner protective layer, an insulating layer and a conductor layer, wherein the above layers are sequentially wrapped from outsideto inside. Four to six anti-shielding layers are distributed on the outer ring of the conductor layer. The anti-shielding layers are located between the conductor layer and the insulating layer. Heating and filing materials are filled between the conductor layer and the insulating layer. According to the technical scheme of the invention, the twisting and the bending of the cable, caused by the turnover of the special-shaped insulating wire core, can be avoided. The invention further discloses equipment for machining and extruding the heating cable.

Owner:欧耐特线缆集团有限公司

Al2O3 ceramic and titanium ring diffusion connection method

The invention relates to an Al2O3 ceramic and titanium ring diffusion connection method. The method comprises putting an Al2O3 ceramic and a titanium ring to be connected into acetone, carrying out ultrasonic cleaning for 5-10min, putting the titanium ring of which the surface to be connected faces down on a surface of the Al2O3 ceramic slice to be connected, assembling the Al2O3 ceramic slice and the titanium ring to obtain an Al2O3 ceramic / titanium ring assembly, putting the assembly in a vacuum heating furnace, applying pressure until 1-15MPa, when a degree of vacuum is (1.3-2.0)*10<-3> Pa, carrying out electrical heating at a heating rate of 5-15 DEG C / min until a temperature of 900-1000 DEG C, carrying out thermal insulation for 60-120min, cooling the assembly to a temperature of 300 DEG C at a cooling rate of 3-10 DEG C / min, and carrying out furnace cooling so that Al2O3 ceramic and titanium ring diffusion connection is realized. The Al2O3 ceramic / titanium ring joint has a compact structure and high strength and can be used for an artificial retina structure.

Owner:HARBIN INST OF TECH AT WEIHAI

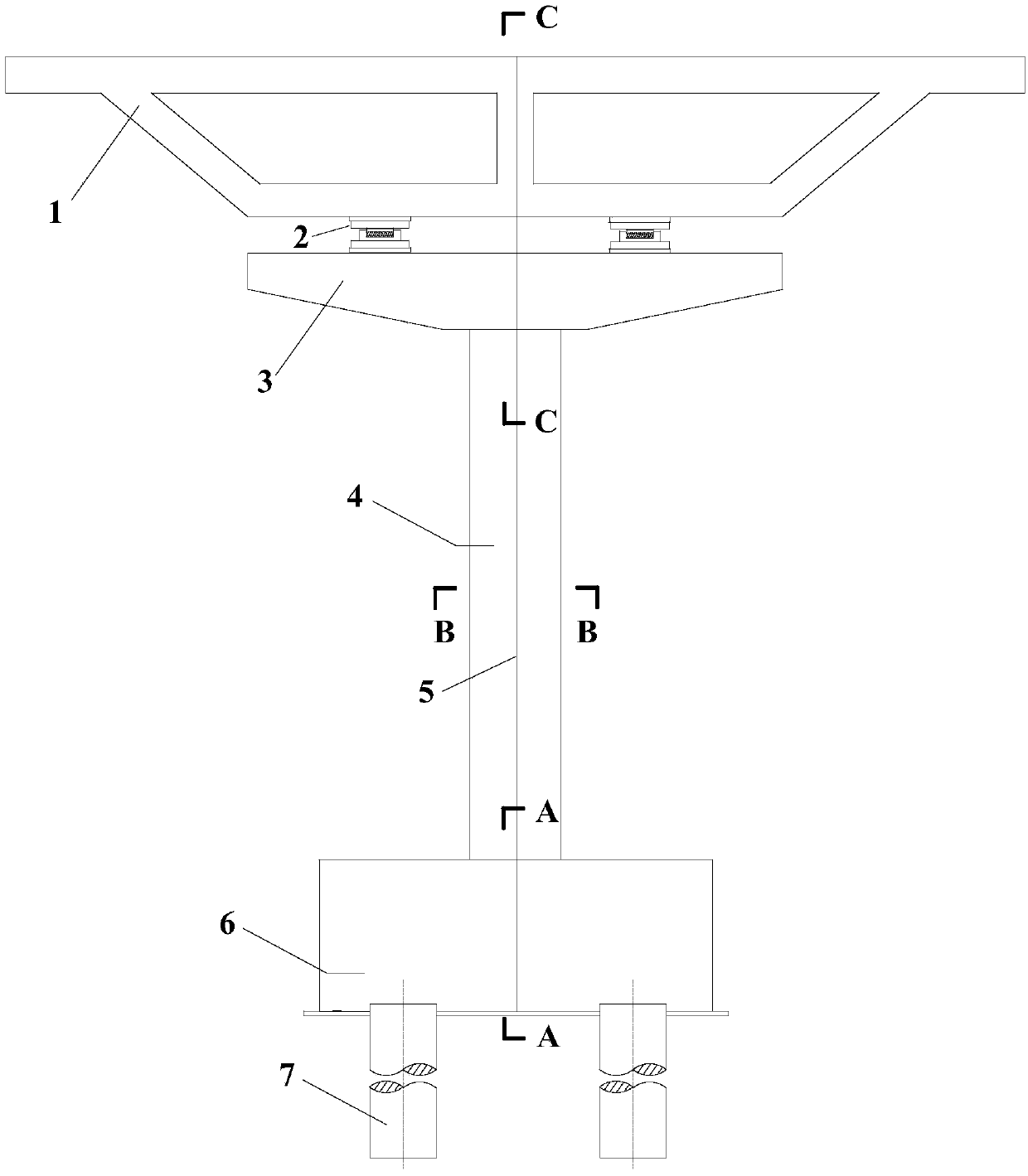

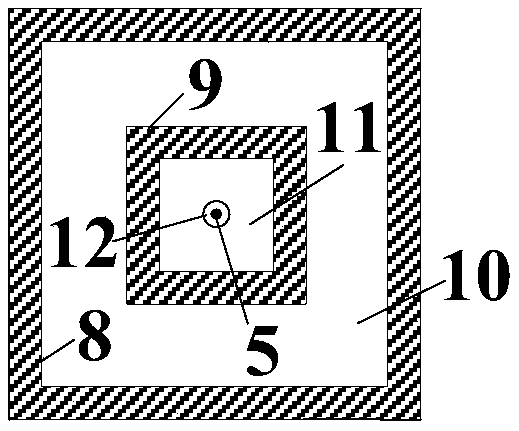

Energy-dissipation self-resetting double-layer rectangular hollow concrete-filled steel tube swing pier structure system

ActiveCN108677690ARemarkable effect of shock absorption and isolationPrevent premature yieldBridge structural detailsBridge materialsFiberBridge engineering

The invention discloses an energy-dissipation self-resetting double-layer rectangular hollow concrete-filled steel tube swing pier structure system, and belongs to the field of bridge engineering. Theswing pier structure system is mainly composed of main beams, supporting seats, a coping, a double-layer rectangular hollow concrete-filled steel tube pier, a bearing platform, a non-bonded prestressed fiber reinforced polymer (FRP) reinforcement with a self-resetting function and anti-buckling dog-bone-shaped metal dampers. The double-layer rectangular hollow concrete-filled steel tube pier andthe coping are cast in place to form a whole to be placed on the bearing platform, and are connected with the bearing platform through non-bonded prestressed FRP reinforcement and the anti-buckling dog-bone-shaped metal dampers so as to play the role of self-resetting and dissipate seismic energy. The designed swing pier structure system is clear in mechanical mechanism, on the premise of ensuringsufficient strength and stiffness of the structure system, the seismic action borne by the structure can be reduced by local lift-off of the pier on the bearing platform, the effective energy dissipation capacity and self-resetting capacity are provided, and the problems of serious damage and large residual deformation of a traditional cast-in-situ pier after an earthquake action can be solved.

Owner:BEIJING UNIV OF TECH

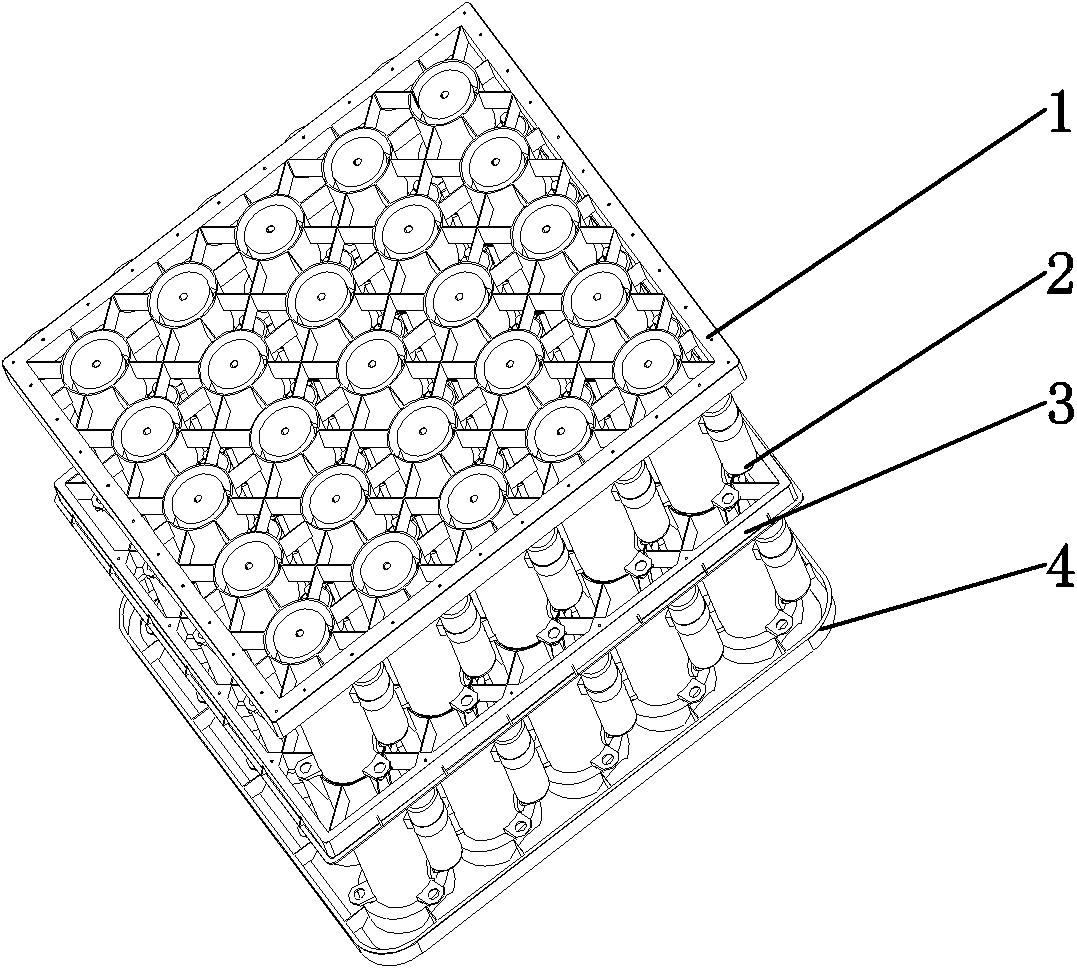

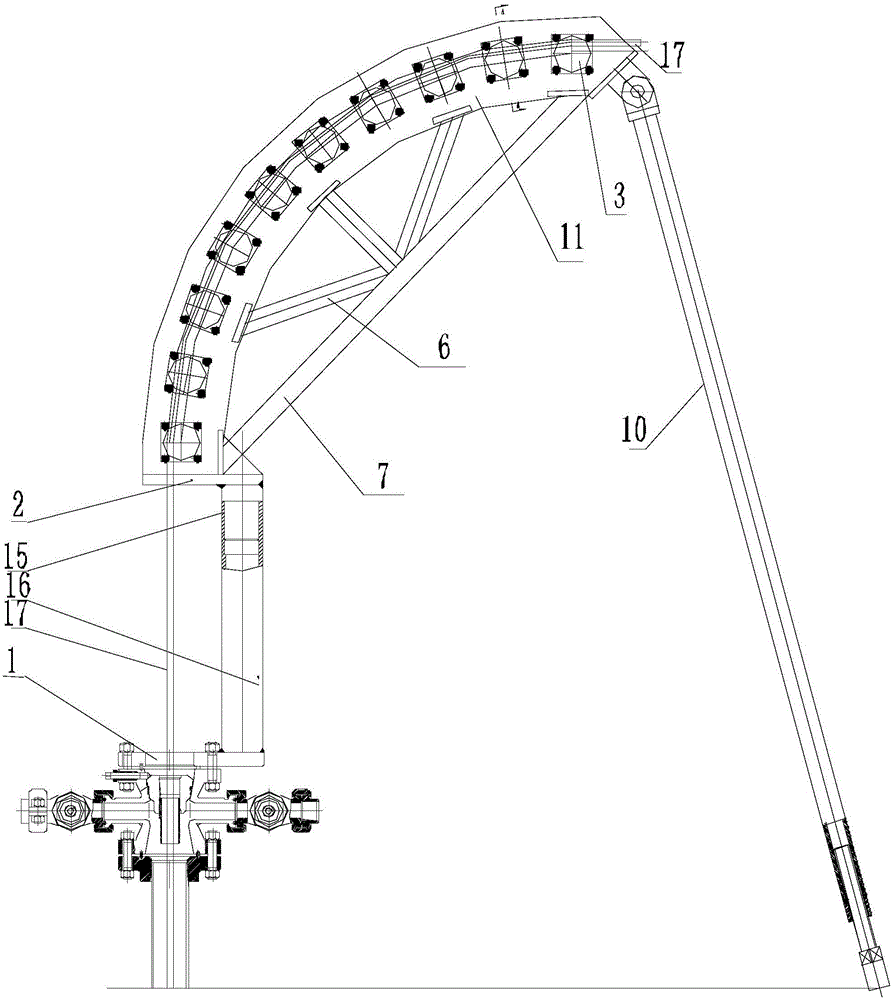

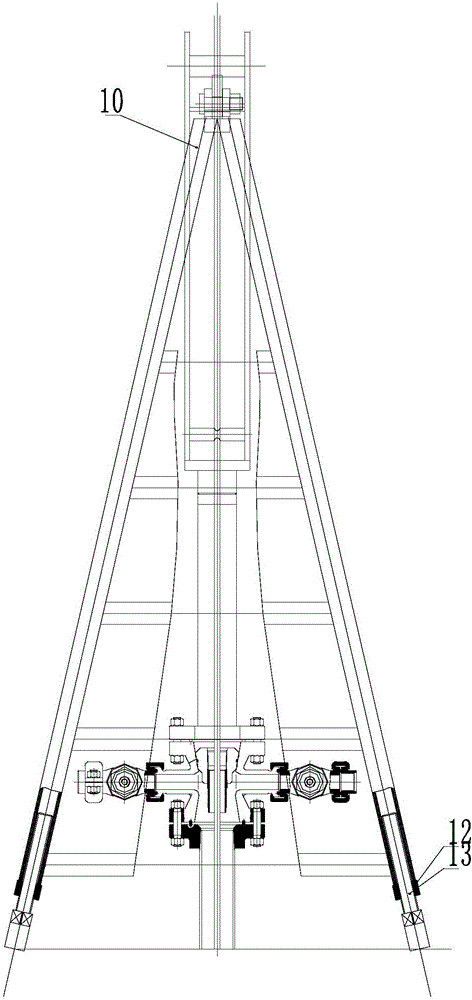

Carbon fiber flexible continuous sucker rod operation equipment

ActiveCN106285504AGuaranteed intactNo plastic deformationDrilling rodsDrilling casingsFiberStress concentration

The invention provides carbon fiber flexible continuous sucker rod operation equipment which comprises two arc-shaped plates arranged in parallel. A bottom plate is fixed between the two ends of each arc-shaped plate, supporting plates are fixed between each bottom plate and the corresponding arc-shaped plate, and rotating shafts are evenly arranged between the two arc-shaped plates at intervals. The outer walls of the rotating shafts are sleeved with rubber sleeves with the arc-shaped surfaces. A support is hinged to one ends of the two arc-shaped plates, and adjusting screws are connected to the lower ends of two supporting rods of the support correspondingly. The other ends of the two arc-shaped plates are fixedly connected with an operation frame which is inserted into a rotating base, and the rotating base is mounted on the well mouth. By means of the operation equipment, it can be guaranteed that a carbon fiber flexible continuous sucker rod can be smoothly taken off, stress concentration caused by mechanical abrasion on the carbon fiber flexible continuous sucker rod operation equipment is avoided, and the service life of the equipment is prolonged; and by the adoption of the equipment, the carbon fiber flexible continuous sucker rod is protected against plastic deformation during operation, and normal use of the carbon fiber flexible continuous sucker rod operation equipment is guaranteed.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com