Winding device with plate and winding method

A technology of winding device and strip plate, which is applied in the direction of winding strips, transportation and packaging, coil manufacturing, etc., and can solve problems such as management, clamping rod diameter reduction, plastic deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

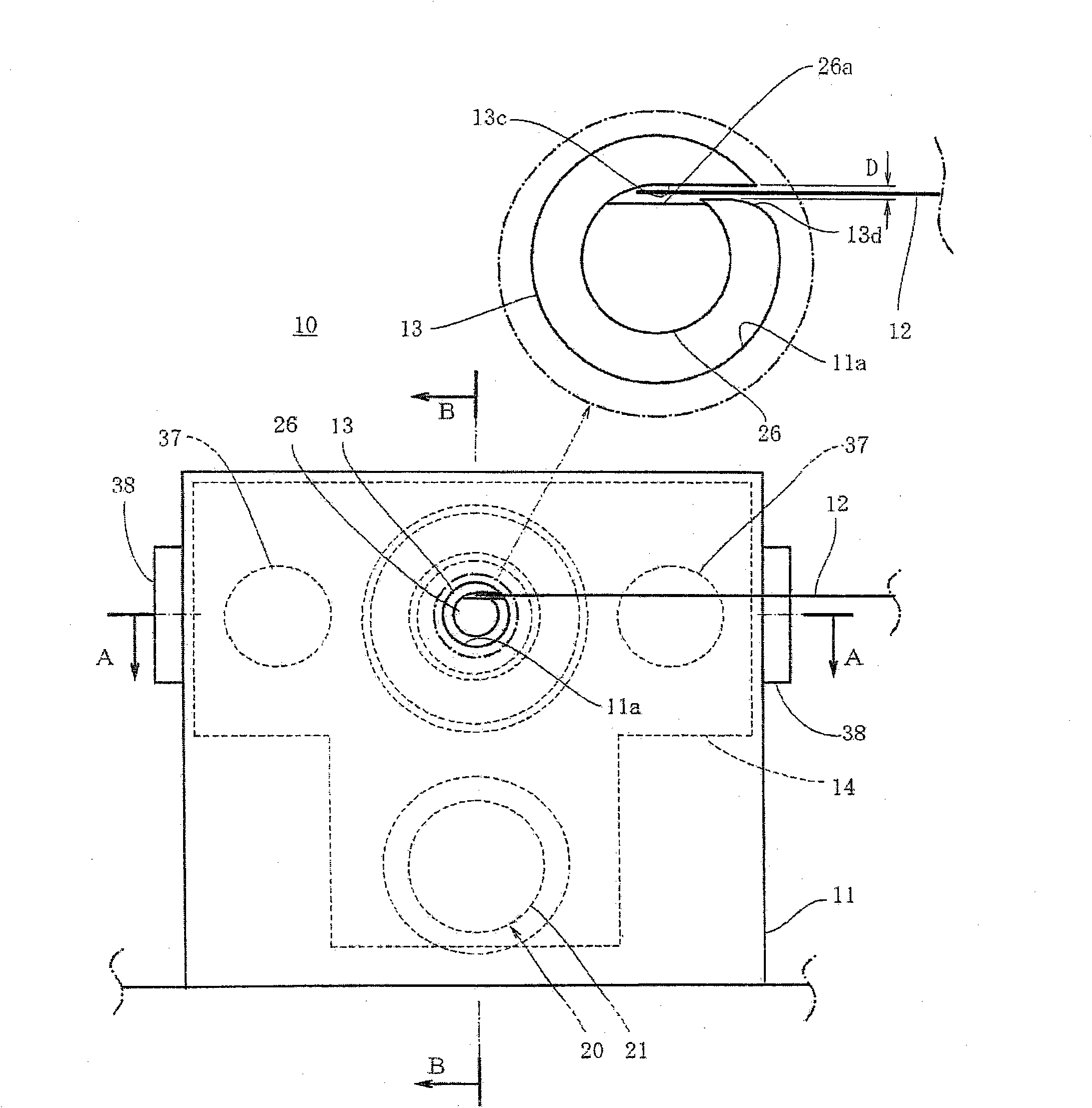

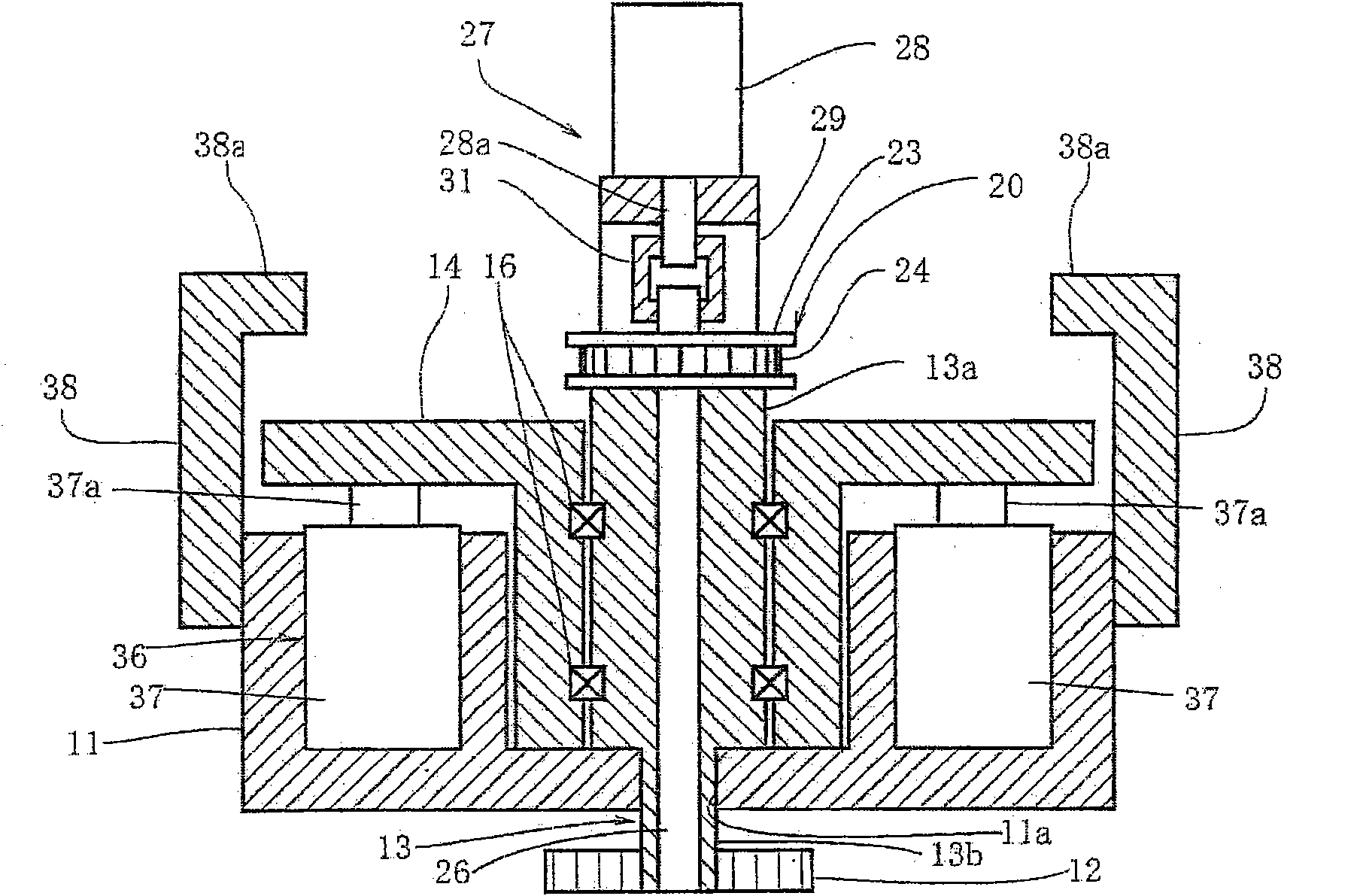

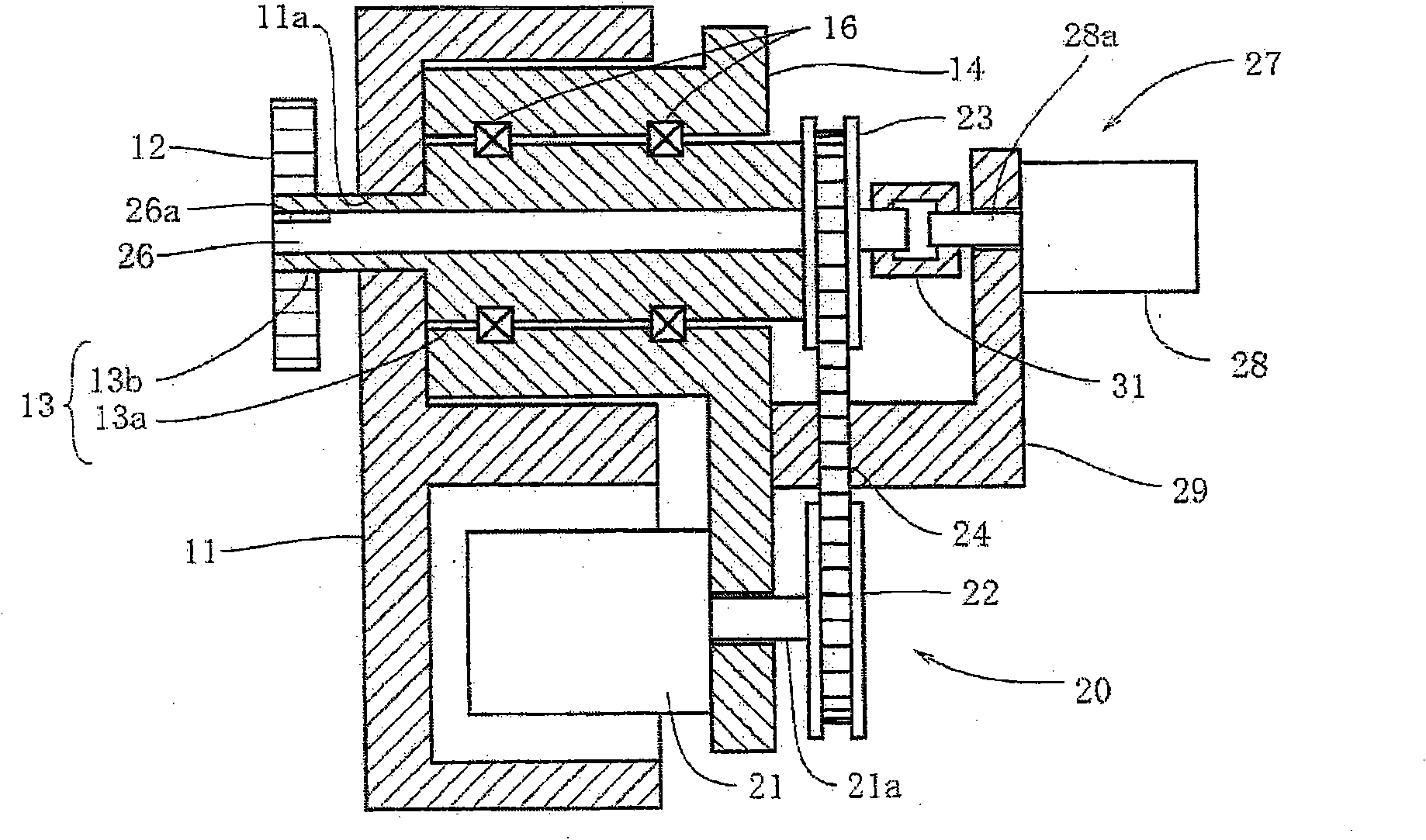

[0023] Next, the best mode for carrying out the present invention will be described based on the drawings.

[0024] exist Figure 1 ~ Figure 3 The winding device 10 of the present invention is shown in . The strip winding device 10 has a winding core 13 rotatably provided, the front end of which protrudes from the front of the main body 11 made of a rectangular body, and the magnetic strip 12 is wound around the front end. A strip-shaped thin plate made of amorphous metal or a strip-shaped thin plate made of silicon steel is exemplified as the magnetic strip 12 . Such as figure 2 and image 3 As shown, a bearing body 14 movable in the axial direction of the winding core 13 is provided on the back side of the main body 11 . The winding core 13 has a support cylindrical portion 13a, which is rotatably supported on the bearing body 14 via a bearing 16, and a front end cylindrical portion 13b, which is continuous with the support cylindrical portion 13a and connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com