Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Joints number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

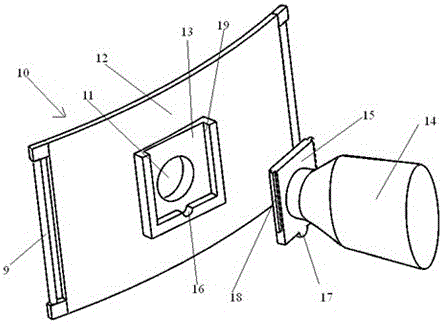

RGB-D and SLAM scene reconfiguration method based on FAST and FREAK feature matching algorithm

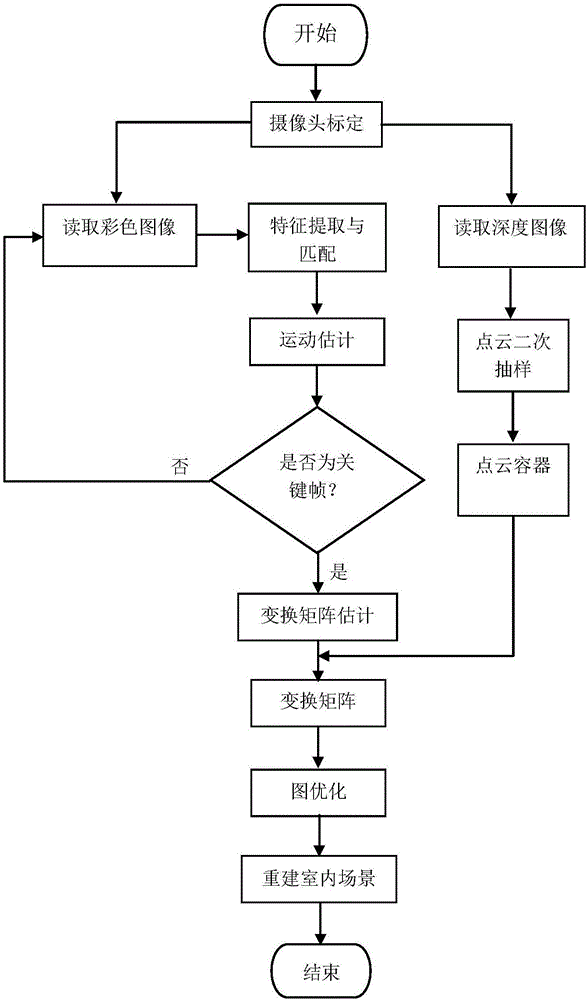

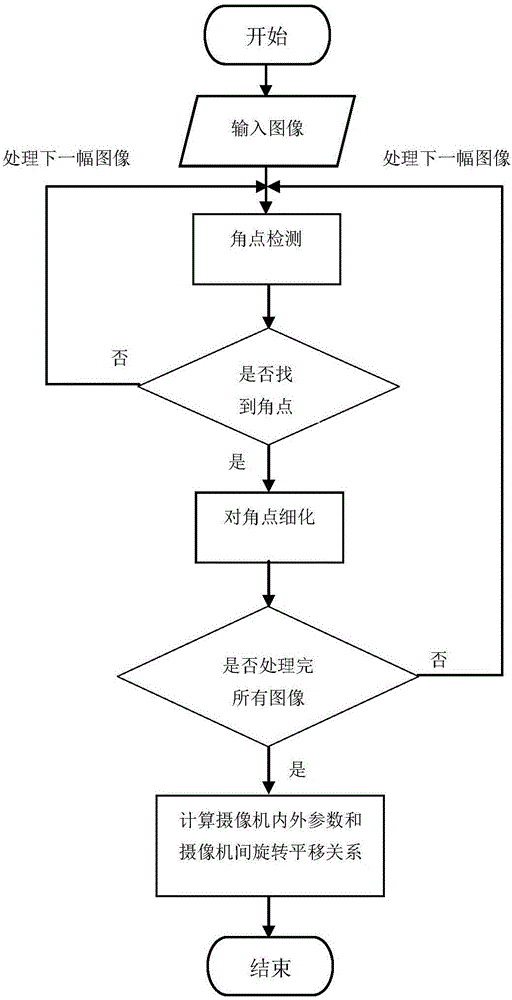

ActiveCN106384383AReduce splicing timesReduce accumulationImage enhancementImage analysisColor imageKey frame

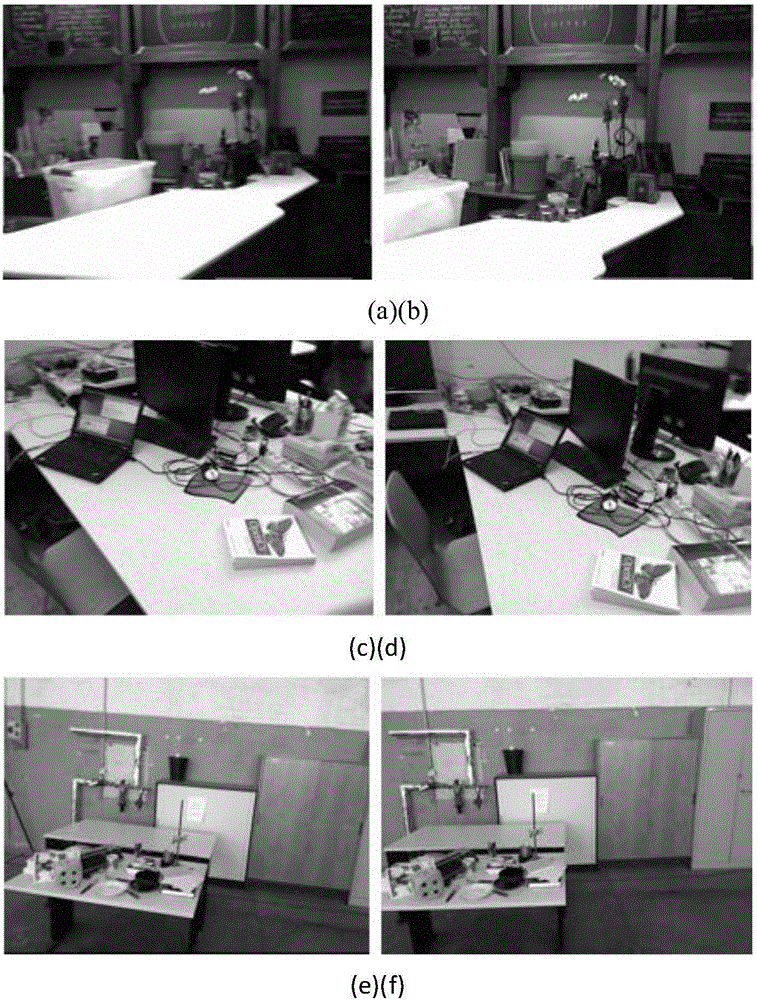

The present invention belongs to the computer graphics field, and concretely relates to a RGB-D and SLAM scene reconfiguration method based on the FAST and FREAK feature matching algorithm. The method comprises: performing calibration of the Kinect; performing FAST feature point extraction of a color image, employing the FREAK feature descriptors to perform image matching, employing the RANSAC algorithm of the feature points to reject the exterior points, and retaining the internal points. The RGB-D and SLAM scene reconfiguration method based on the FAST and FREAK feature matching algorithm screens the key frames and performs cloud point jointing of the key frames so as to greatly reduce the joint number of times of the cloud points. The RGB-D and SLAM scene reconfiguration method based on the FAST and FREAK feature matching algorithm employs the loop detection algorithm based on the graph optimization to construct a posture graph and perform global optimization so as to greatly reduce the error accumulation.

Owner:HARBIN ENG UNIV

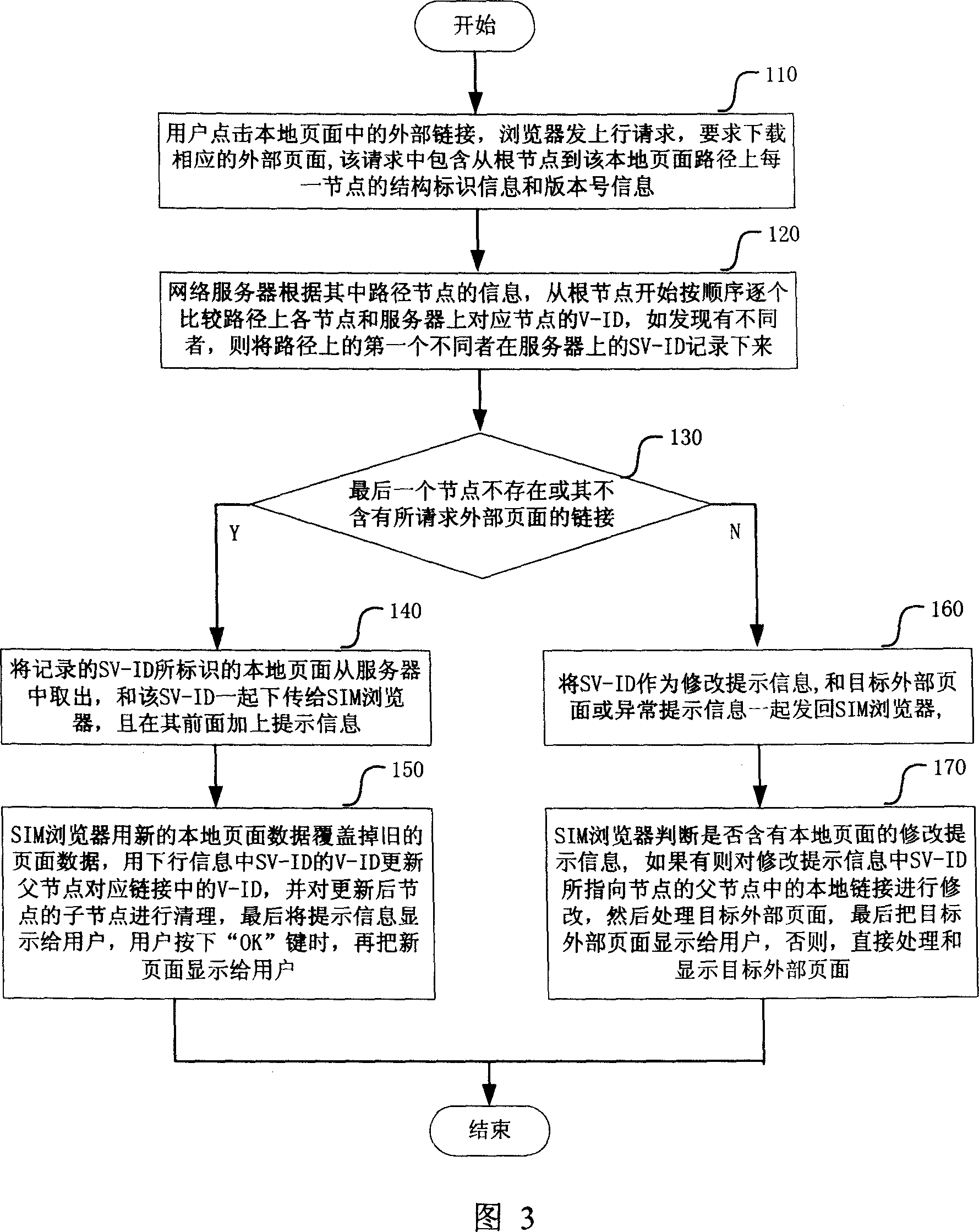

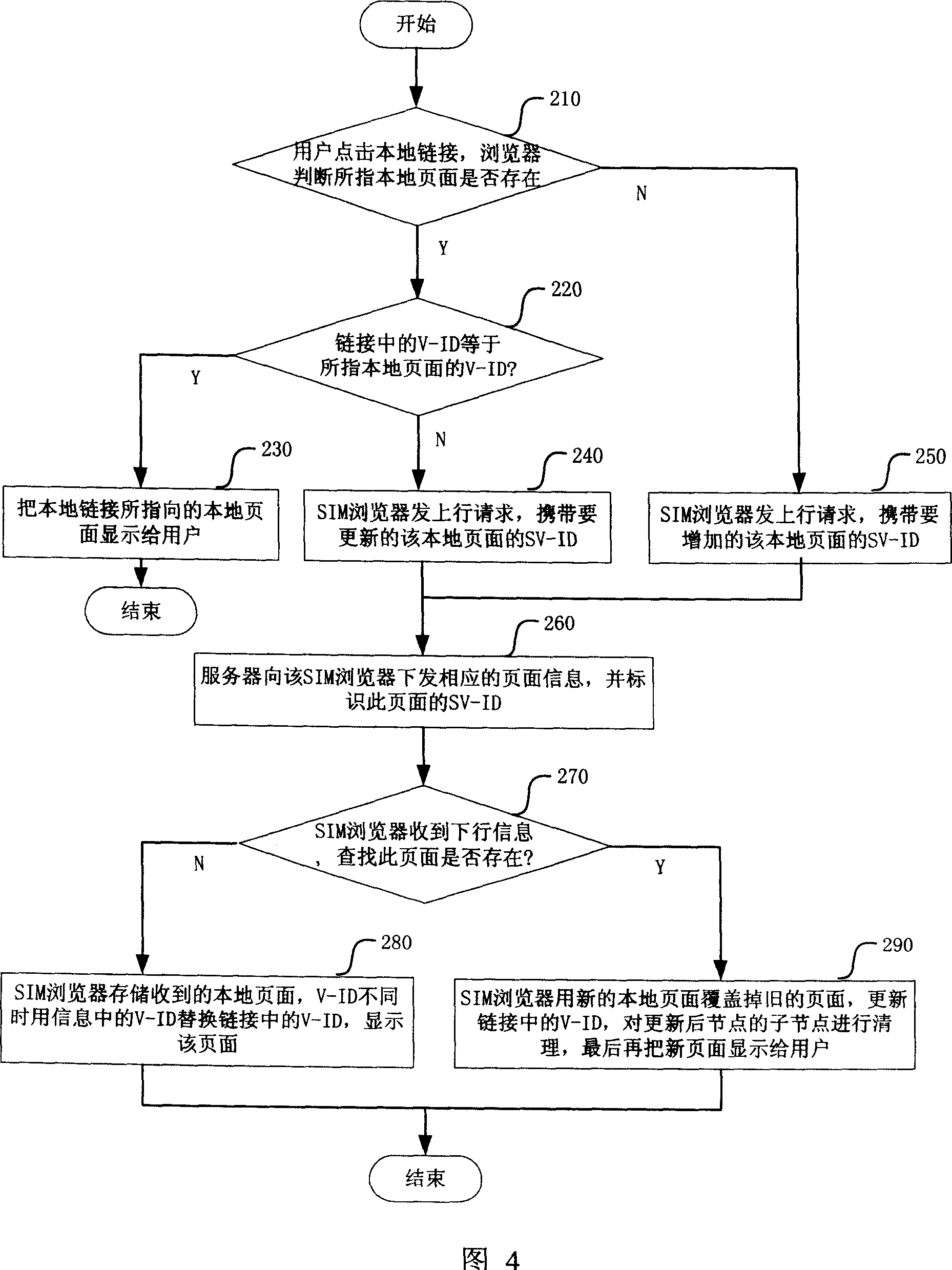

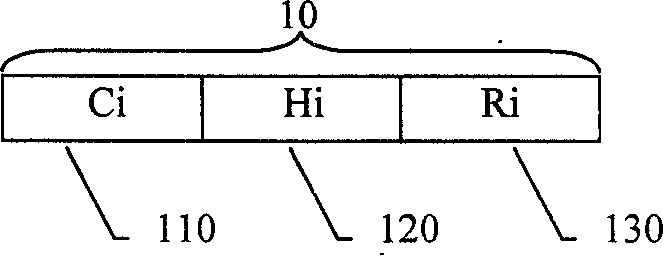

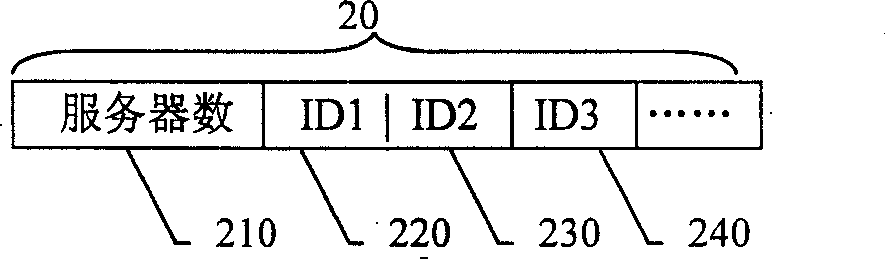

Storage and update method of browsers local page

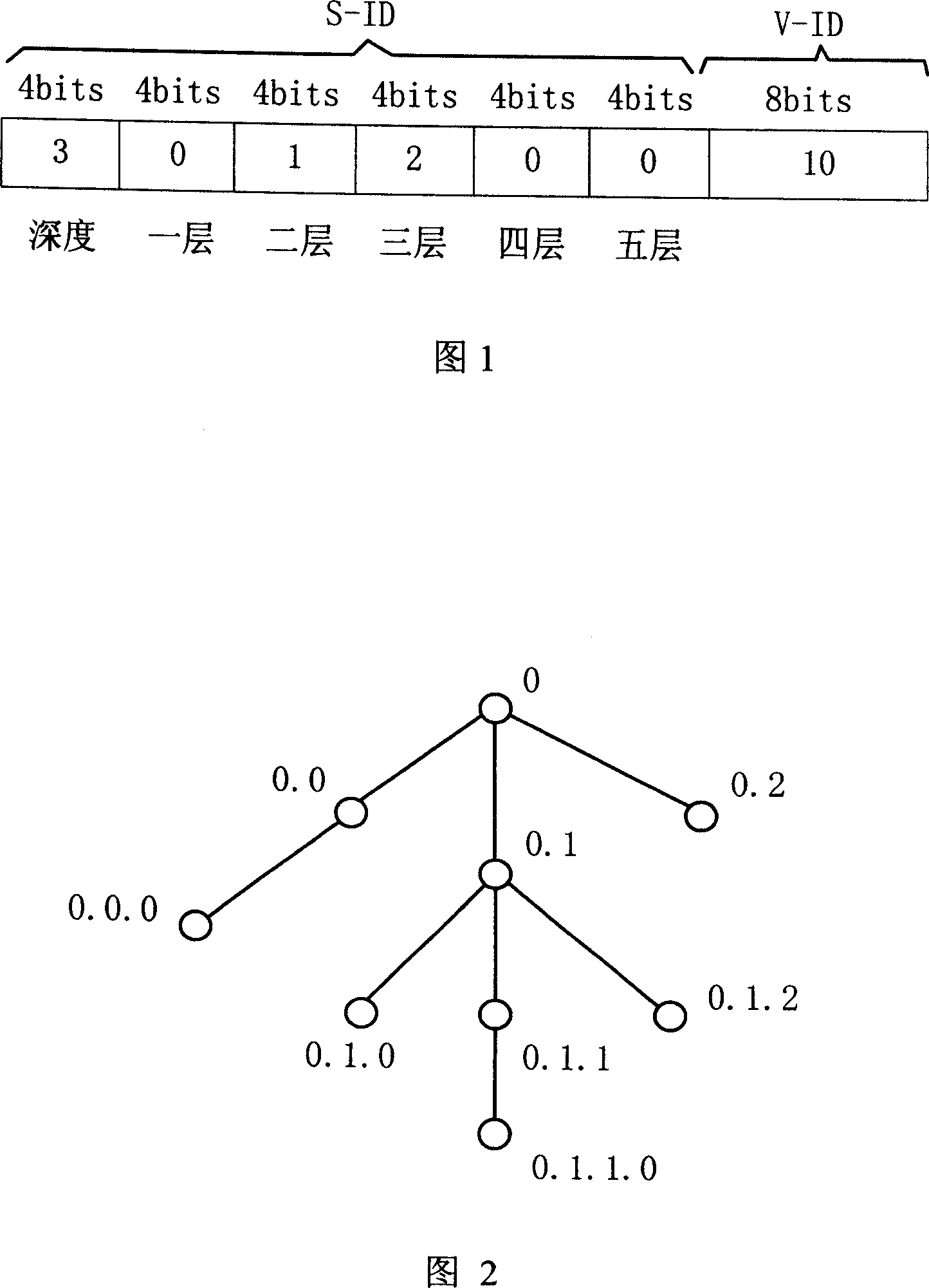

InactiveCN101082915ASolve storage problemsFix problems with updatesSpecial data processing applicationsRelationship - FatherJoints number

The invention discloses a storing and updating method of local page of browser, which comprises the following steps: recording the structure and version mark SV-ID of random node in the local page system of the browser; making the structure mark S-ID contain joint number of each node on the path from joint to joint; making local link contain directional successor node SV-ID; transmitting upward request with SV-ID of each node on the path from root node to local page node through browser after the user clicks the external linkage; returning SV-ID on the server of local page different from first version to the browser after the server receives the SV-ID; updating the version mark of local linkage in the father node of local page node after the browser receives SV-ID; judging whether the local page needs to be updated and finishes the updating according to the linked SV-ID when the user clicks the local linkage. The invention can finish the updating of local page automatically and reliably, which doesn't influence the browsing feel for users.

Owner:陈鹰

Soft tissue deformation method based on mixing of gridding method and non-gridding method

ActiveCN105513130AMedical simulationSpecial data processing applicationsSoft tissue deformationEngineering

The invention relates to a soft tissue deformation method based on mixing of a gridding method and a non-gridding method. The non-gridding method is adopted in a large-deformation region of an operation, and the gridding method is adopted in a non-operation region. By means of the non-gridding method in the operation region, the gridding deformation problem during large deformation can be avoided, deformation is in smooth transition so that deformation-simulated real sense can be achieved easily, meanwhile, the region model joint number is small while the operation region is small, and the real-time requirement can be met when the non-gridding method is adopted for the operation region; a particle-spring-based gridding deformation method is adopted in the non-operation region so that the defect that non-gridding calculation efficiency is low can be avoided, the advantages of a particle spring on real-time performance are given play to, meanwhile, because the non-operation region deformation is small, gridding deformation will not occur even a particle-spring method is adopted, and a deformation simulating effect is good. By means of the soft tissue deformation method, advantages of the gridding method and the non-gridding method in deformation simulation are given play to, the real sense and the real-time performance compromise, and the soft tissue deformation method is applicable to virtual deformation operation simulation.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

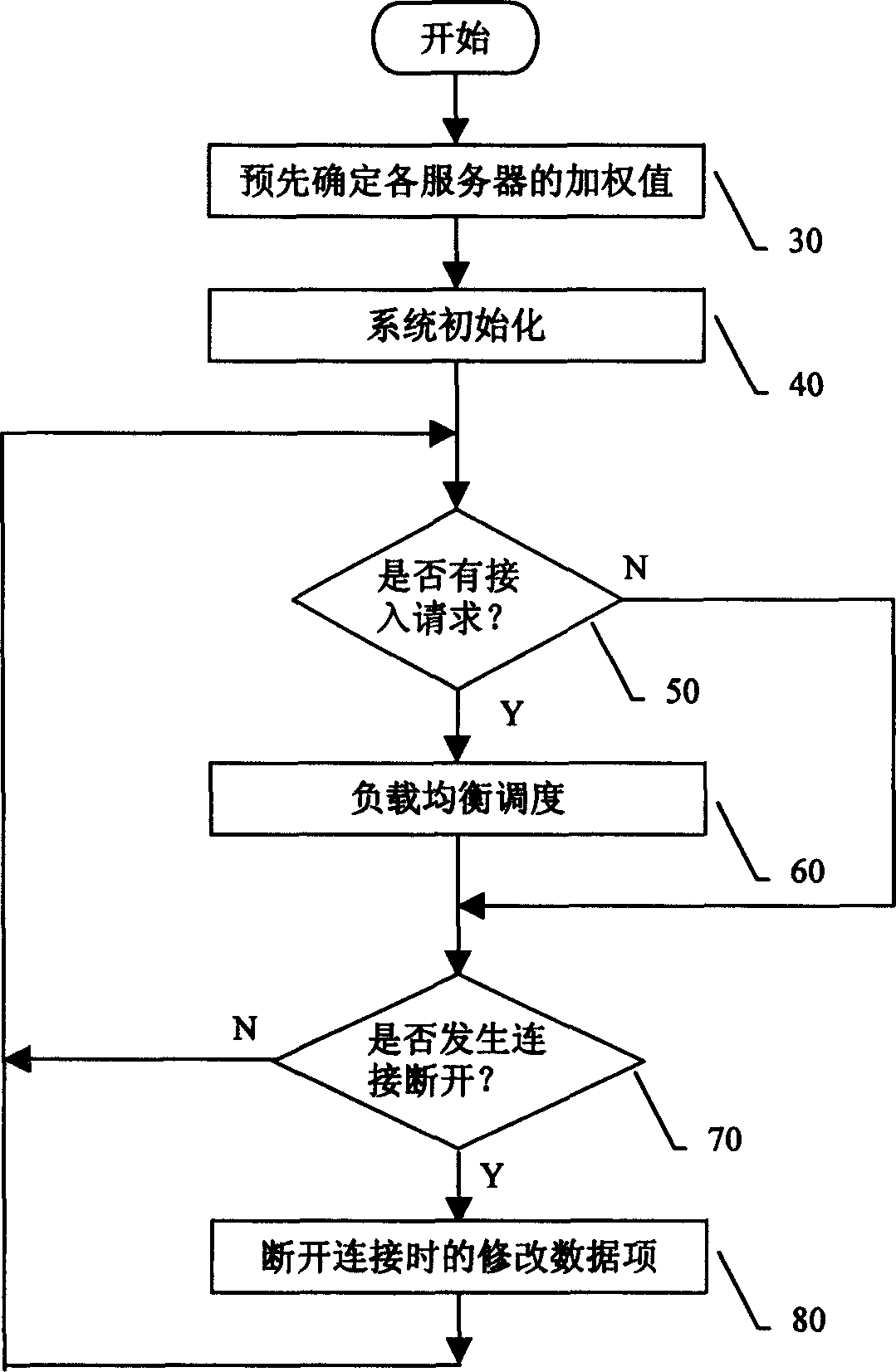

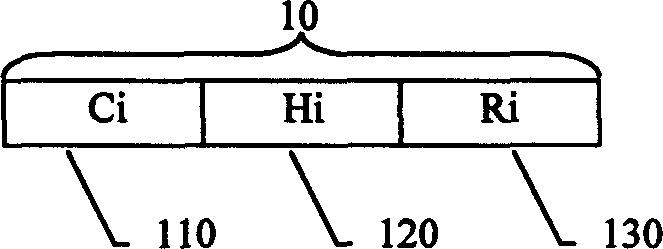

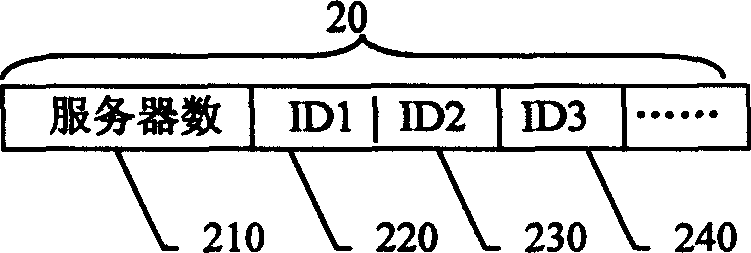

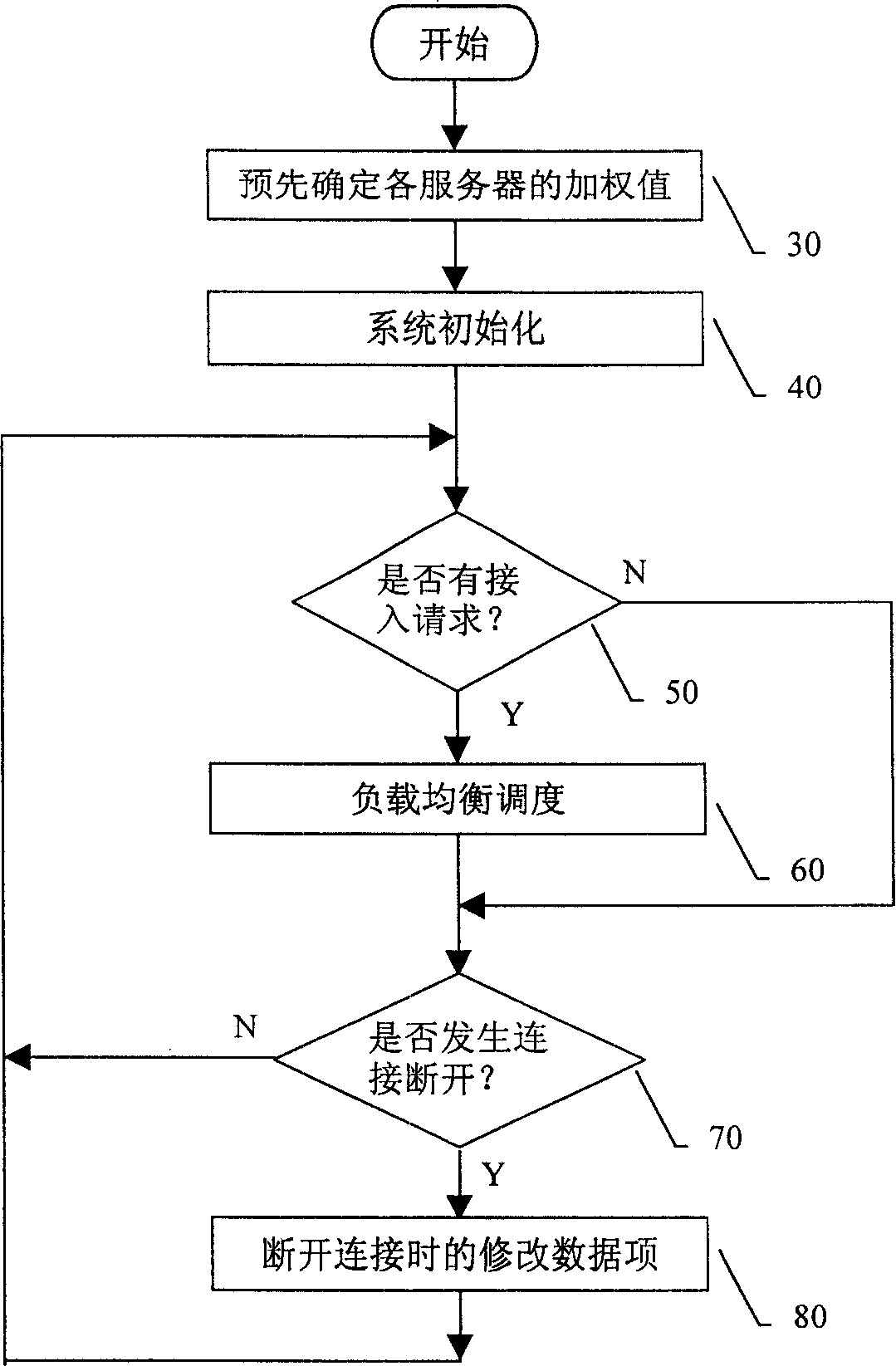

Server load equalization method for implementing weighted minimum linked allocation

This invention discloses a weight minimum joint number dispatch server load balancing method. The technique scheme of the invention are the following: to preset the state representing each server current connection information in the server group, wherein, the said state is represented by data structure with at least one data item comprising data representing the current load states of each server; the said current server load states is represented by the first data item in at least one data item; when load is evenly dispatched, it goes through all first set data items representing current server load states ; it selects server relevant to minimum first preset data set to switch in and at the same time to alter the data item.

Owner:HUAWEI TECH CO LTD

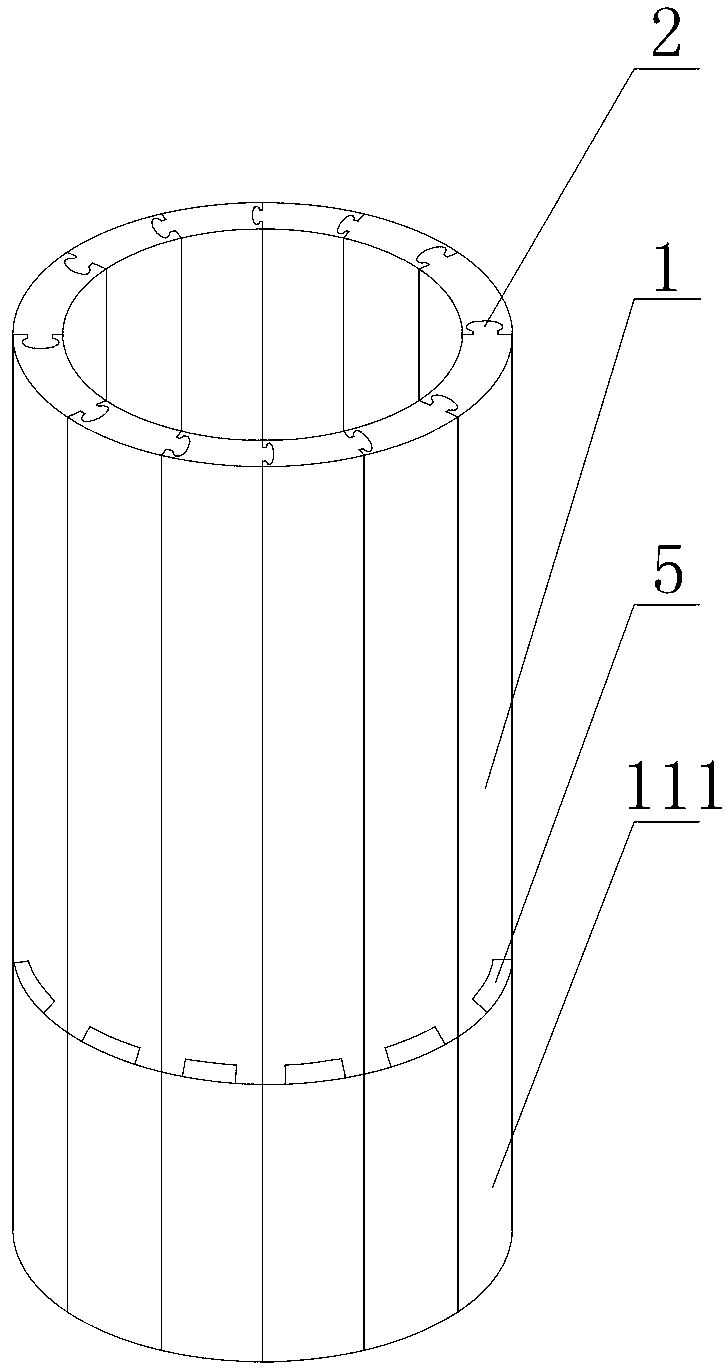

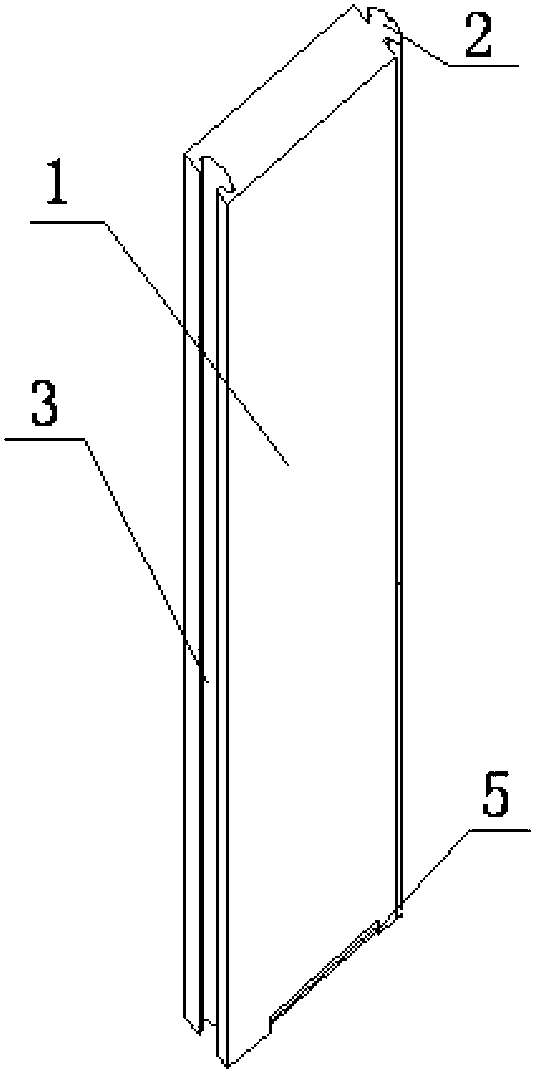

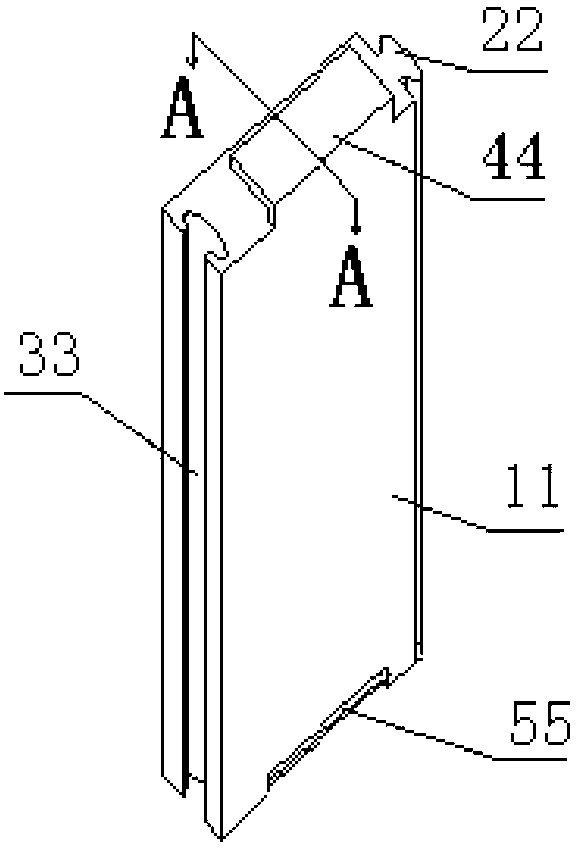

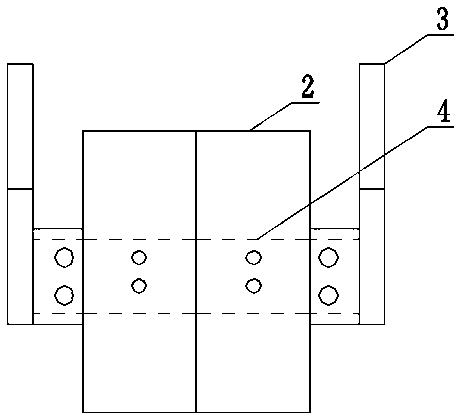

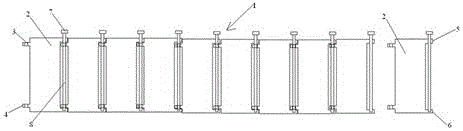

Circular miniature slide-resistant pile die with adjustable height and adjustable sectional area

ActiveCN103252832AHigh impact strengthImprove toughnessMould separation apparatusTransverse grooveJoints number

The invention relates to a circular miniature slide-resistant pile die with an adjustable height and an adjustable sectional area. Plug boards are utilized as parts for forming the die in a split joint mode, and the plug boards are divided into major plug boards, minor plug boards and bottom plug boards according the positions where the plug boards are located on a cylinder structure when the plug boards are assembled, the major plug boards are located on the upper layer positions on the cylinder structure, the minor plug boards are located on the middle layer positions on the cylinder structure, and the bottom plug boards are located on the lower layer positions on the cylinder structure. The lengths and widths of all the plug boards in the same die are the same, the heights of the major plug boards are the same, the heights of the minor plug boards are the same, and the heights of the bottom plug boards are the same. One edge of each plug board in the vertical direction is machined with a vertical plug bar, and a vertical plug groove is formed in the other edge of each plug board. A transverse plug groove is formed in the transverse lower side edge of each major plug board, and a transverse plug groove is formed in the transverse lower side edge of each minor plug board. A transverse plug bar is formed in the upper side edge of each major plug board, and a transverse plug bar is formed in the upper side edge of each minor plug board. Each transverse plug bar on each upper side edge is matched with each transverse groove in each lower side edge. When the plug boards are assembled, the major plug boards, the minor plug boards and the bottom plug boards are connected in an up-and-down left-and-right split joint mode to form the die which is in a nearly cylindrical shape. According to the circular miniature slide-resistant pile die with the adjustable height and the adjustable sectional area, the sectional area can be adjusted through changing of a left-and-right split joint number of the plug boards, the height can be adjusted through changing of an up-and-down connecting layer number of the plug boards, the circular slide-resistant pile die with the adjustable height and the adjustable sectional area can be spliced through only one set of plug boards, and the circular miniature slide-resistant pile die with the adjustable height and the adjustable sectional area is simple in structure, easy to splice and low in use cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

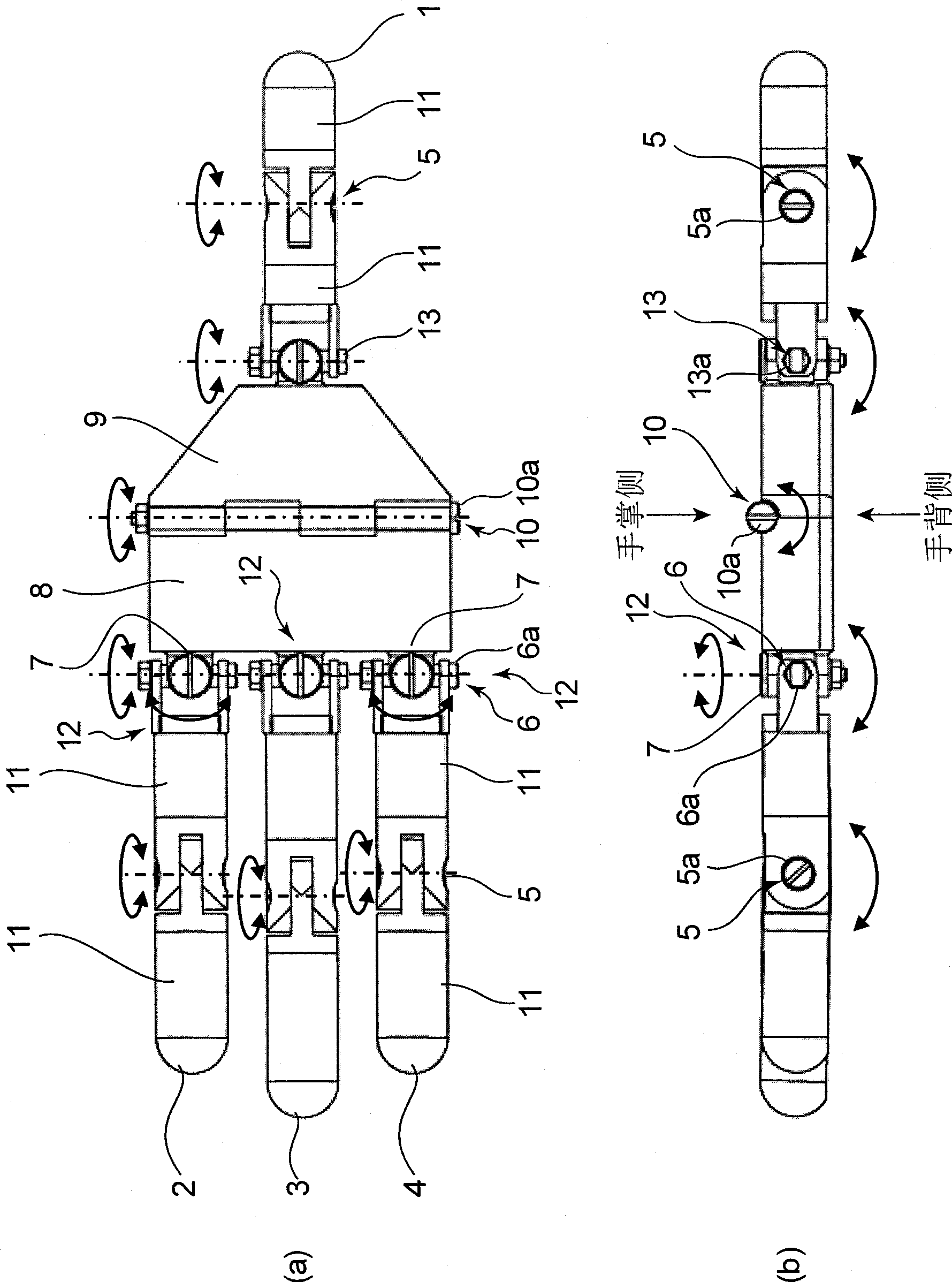

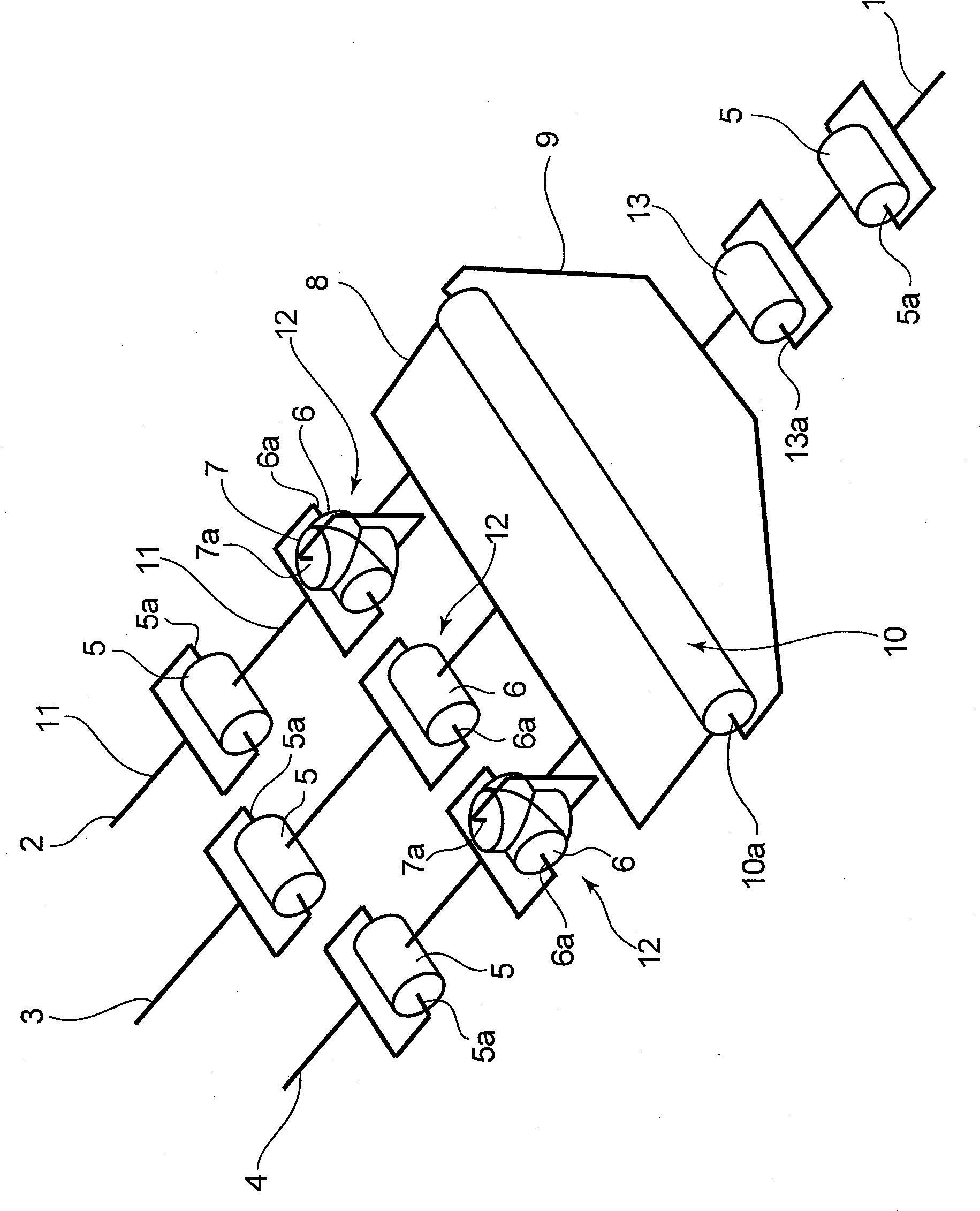

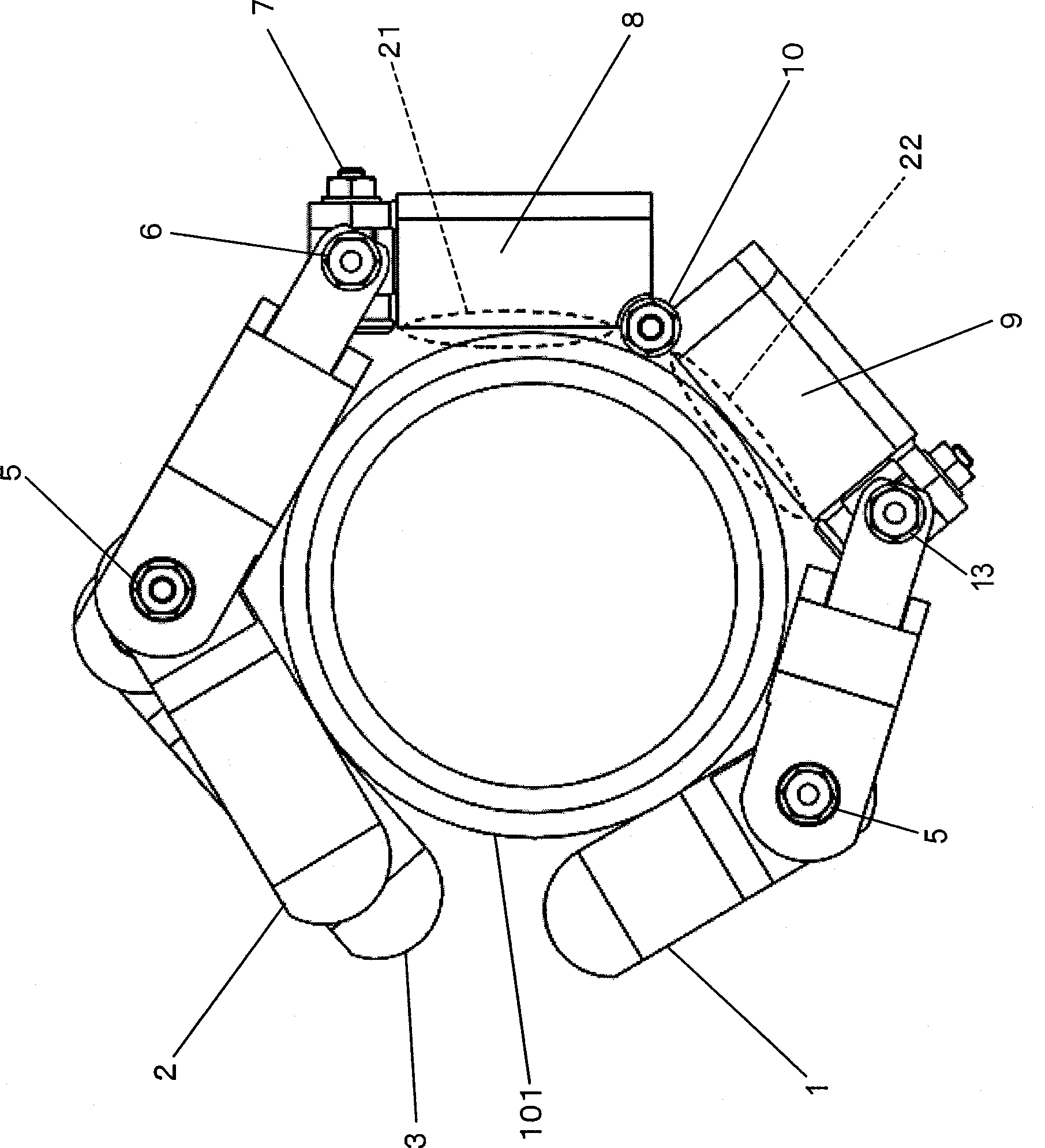

Multi-fingered robot hand

To provide a multi-fingered robot hand capable of stably gripping various articles, while restraining an increase in the joint number of a finger mechanism. This multi-fingered robot hand has a first palm part 8 connected with three finger mechanisms 2, 3 and 4 via a root joint 12, a second palm part 9 connected with one finger mechanism 1 via a root joint 13, and a palm joint 10 connecting the first palm part 8 and the second palm part 9. The palm joint 10 is constituted so as to permit a connecting angle of the second palm part 9 to the first palm part 8 to change. Both the palm joint 10, a bending joint 5, a bending joint 6 of the root joint 12 and the root joint 13, have a mutually parallel rotary shaft, and bend by rotary operation around this rotary shaft.

Owner:PANASONIC CORP

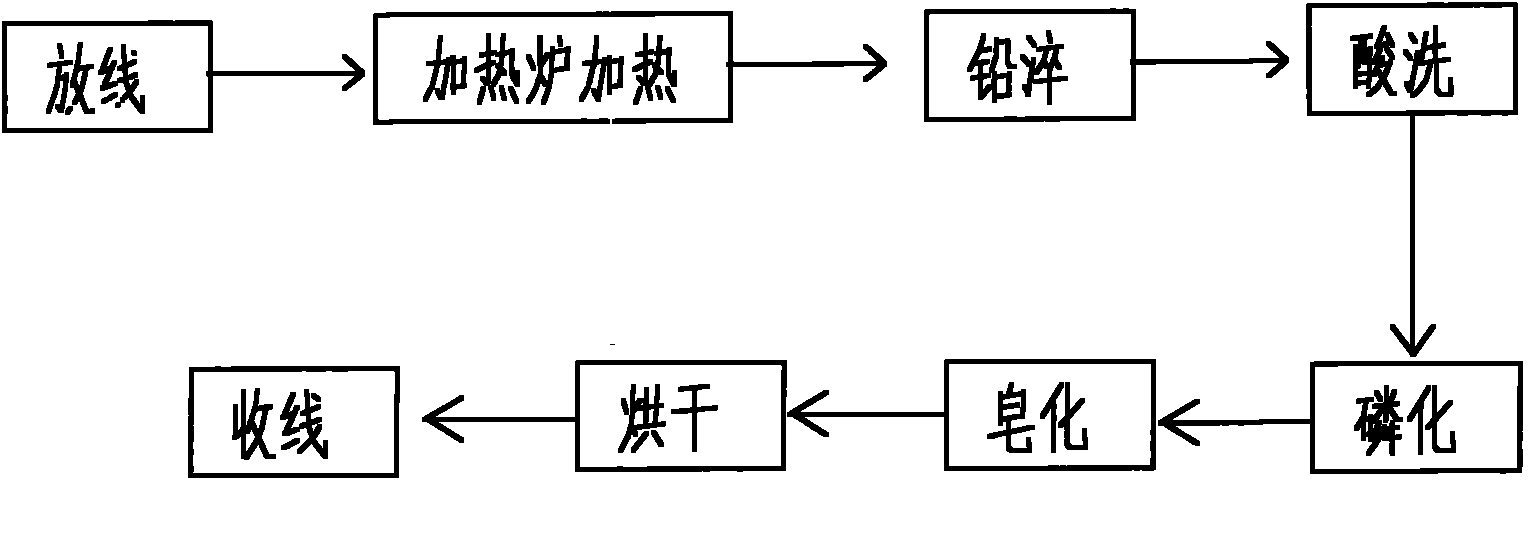

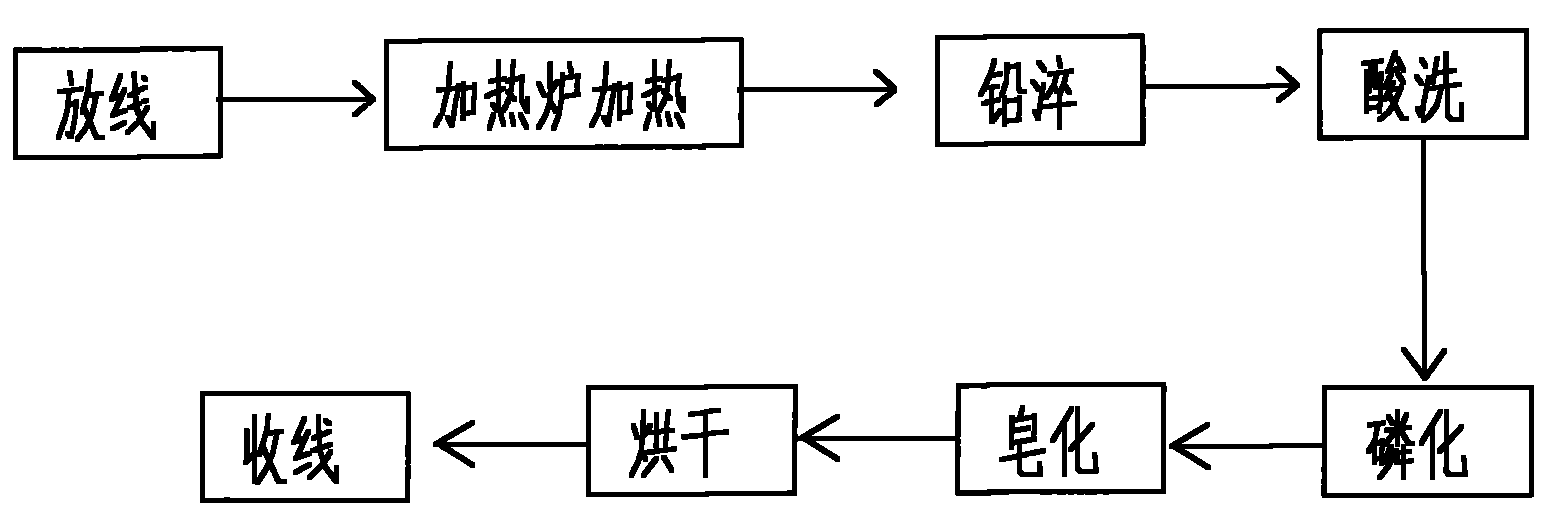

Continuous heat processing technology of steel wire

ActiveCN101985754AQuality improvementReduce the number of jointsFurnace typesMetallic material coating processesHeating furnaceQuenching

The invention relates to a continuous heat processing technology of a steel wire, which is characterized in that the steel wire penetrates into a heat processing heating furnace for heating by a pay-off rack, penetrates into a lead pool for lead quenching, penetrates into a pickling tank for pickling, then penetrates into a parkerising pool, penetrates into a saponification pool, penetrates through a drying box and finally is wound up. The continuous heat processing technology of the steel wire in the invention has the advantages that a continuous heat processing line is used, the pickling and parkerising are carried out in a mode of one line, and a steel wire technology for each specification can be adjusted by adjusting speed of the steel wire heat processing, thus reducing production cost and improving production efficiency; and all processing procedures are linked compactly; and weight of parts is improved to reduce joint number in the steel wire so as to improve quality of the steel wire.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

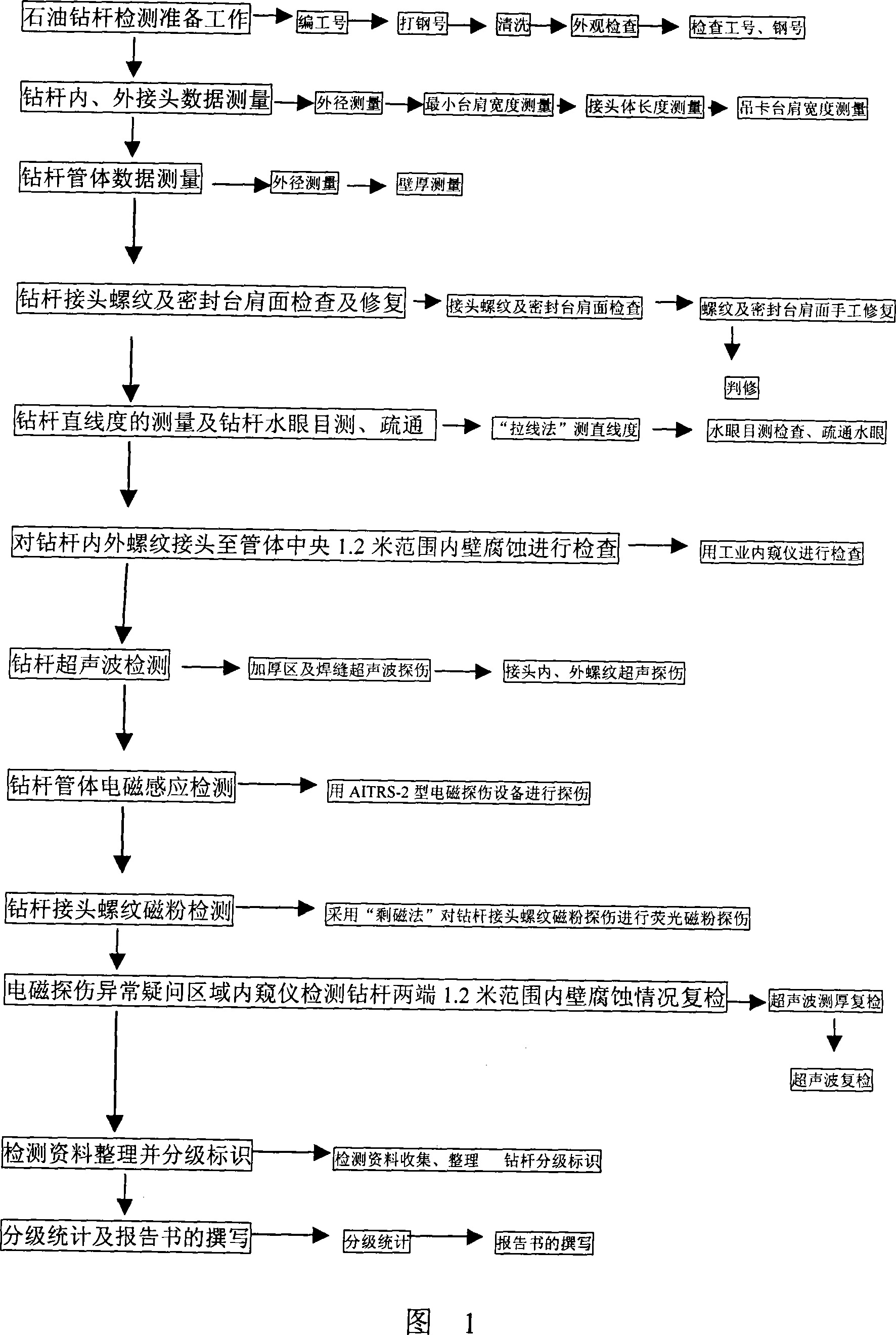

On-service petroleum drill pipe detection and classification evaluation method

InactiveCN101086202AAvoid the status quo of frequent accidents of all kindsDrilling rodsDrilling casingsOil fieldHydrophthalmos

A in-service oil drill rob detecting, grading and evaluation method includes the following steps: 1, oil drill rob detecting preparatory work; 2, measuring the drill rob inner and outer joints number; 3, measuring the drill rob pipe body number; 4, detecting and repairing the drill rob joint thread and the sealing shoulder surface; 5, measuring the straightness of the drill rob, visual measuring and depopulating the drill rob hydrophthalmos; 6, detecting the inner wall corrosion from the drill rob inner and outer thread joints to the pipe body in the 1.2 m scope of the pipe body centre; 7, detecting the drill rob with ultrasonic; 8, detecting drill rob electromagnetic induction; 9, detecting the drill rob joints thread magnetic powder; 10, electromagnetic detecting the abnormal zone and re-detecting the inner wall corrosion in the scope of 1.2 m of two ends of drill rob with endoscope; 11, classifying the detection data and marking in different levels; 12, writing the classify statistics and reports. The beneficial effects of the invention are: comprehensive total detecting and classifying evaluating the old in-service oil drill rob, it can effectively avoid the frequent condition of various accidents in the oil field drilling construction using in-service oil drill rob.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Adaptive multi-step variable domain solder joint layout optimization method based on topology optimization for automotive components

InactiveCN109063357AGuaranteed reasonablenessReduce the number of solder jointsGeometric CADDesign optimisation/simulationElement modelEngineering

The invention provides an adaptive multi-step variable domain optimization method for automobile component solder joint layout based on topology optimization, Based on the finite element model of continuous solder joint element, the definition of multi-step variable domain solder joint topology optimization problem, the criteria of multi-step iteration progression and termination, and the verification of optimization scheme, the optimization design of structural solder joint number and layout form is completed. The technical proposal of the invention solves the problems that the existing solder joint topology optimization method in the prior art cannot simultaneously optimize the number of solder joints and the position of the solder joint arrangement, and the existing solder joint screening strategy will lead to the uncertainty of the design proposal. The technical proposal of the invention solves the problems that the existing solder joint topology optimization method cannot simultaneously optimize the number of solder joints and the position of the solder joint arrangement.

Owner:DALIAN UNIV OF TECH

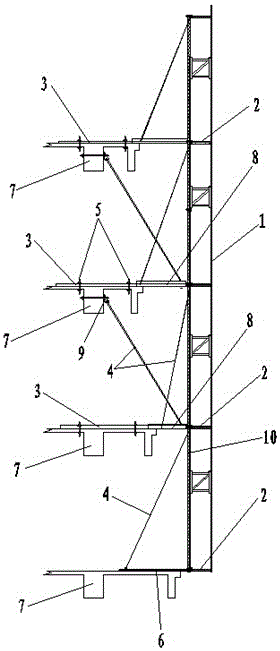

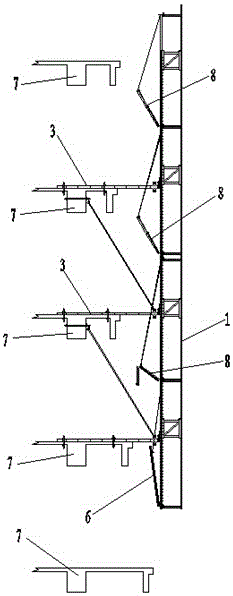

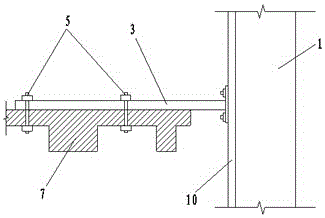

Bamboo joint type exterior facade super-high building structure attached climbing frame and lifting method

InactiveCN105525745AGuaranteed sealing performancePrevent falling objectsScaffold accessoriesBuilding support scaffoldsFloor slabKeel

The invention discloses a bamboo joint type exterior facade super-high building structure attached climbing frame and a lifting method. The climbing frame is characterized in that one side, near a building structure, of a climbing frame body is fixedly connected with a guide rail arranged on the climbing frame body through horizontal wall attaching elements; the horizontal wall attaching elements are fixed on floor slabs of the building structure through embedded screw bolts; each keel plate arranged in the climbing frame body is movably connected with one end of a corresponding foldable turning plate through an automobile hinge; and the other end of each foldable turning plate is lapped on the corresponding floor slab of the building structure. The foldable turning plates are arranged between the building structure and the climbing frame body, and the length and the joint numbers of the turning plates can be changed along with the change of the contour of the exterior facade of a building, so that when the outer contour of the building structure is changed, the normal sealing of a gap between the building structure and the climbing frame body can still be ensured; the high-altitude object falling or high-altitude falling can be effectively prevented; the potential safety danger is eliminated; and great social influence and economic loss are avoided.

Owner:CCFED THE FIRST CONSTR & ENG

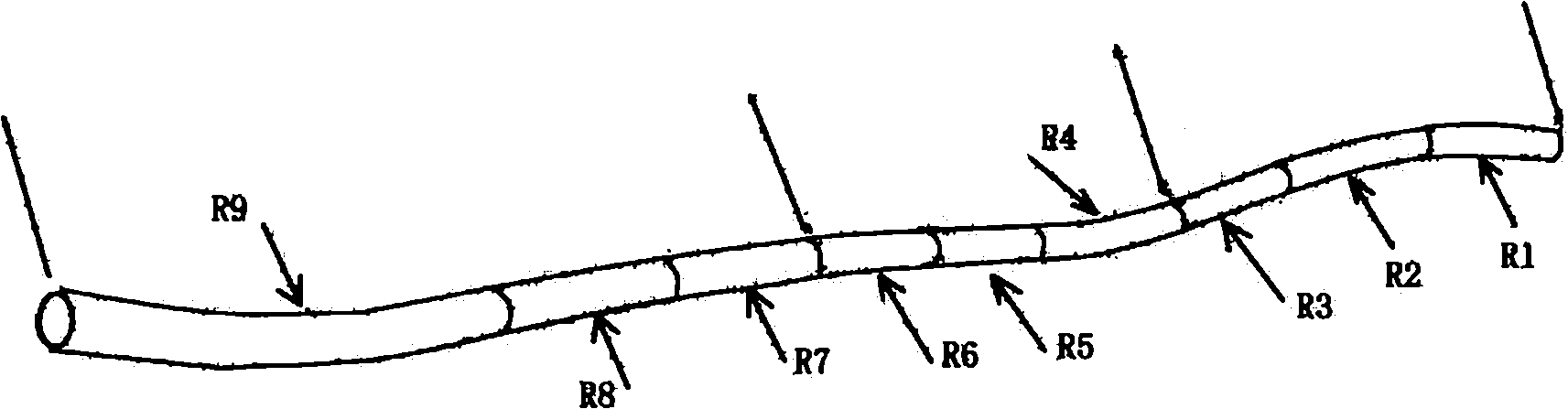

Multi-curvature radius twisted steel pipe and making method thereof

The invention discloses a multi-curvature radius twisted steel pipe. The twisted steel pipe consists of two or more curvature radius subsections. The invention also provides a making method of the twisted steel pipe. The method comprises the following steps of: making an integral model of the multi-curvature radius twisted steel pipe; dividing the integral model into subsections according to single curvature radius; dividing two or more subsections into a subarea, placing the subarea on a steel pipe, and machining and shaping; and making an assembly jig frame of the twisted steel pipe, hoisting the finished subareas onto the assembly jig frame, positioning, assembling and welding. The multi-curvature radius twisted steel pipe has attractive shape and smooth transition; compared with the conventional machining method, the method reduces the joint number of the twisted steel pipe; working time and energy are saved; and the quality of the twisted steel pipe is greatly improved, and the service life of the twisted steel pipe is prolonged.

Owner:JIANGSU HUNING STEEL MECHANISM

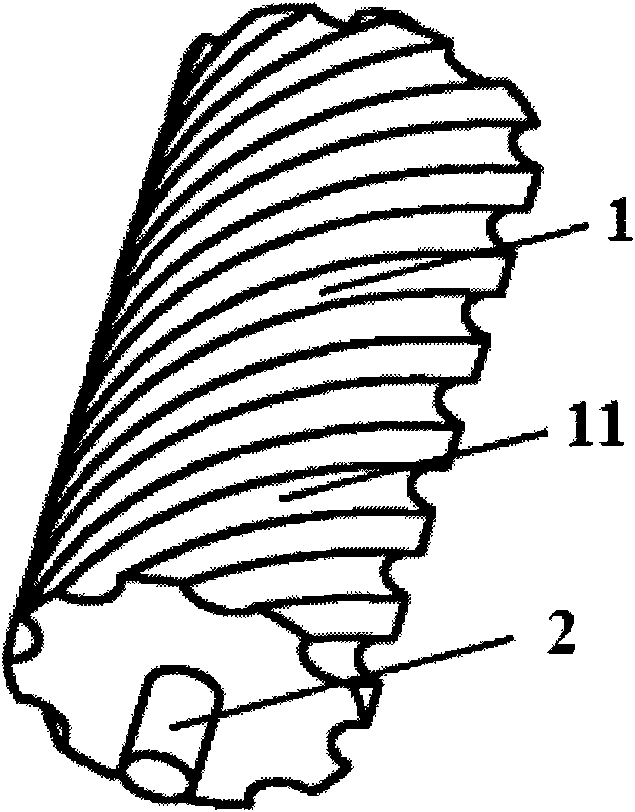

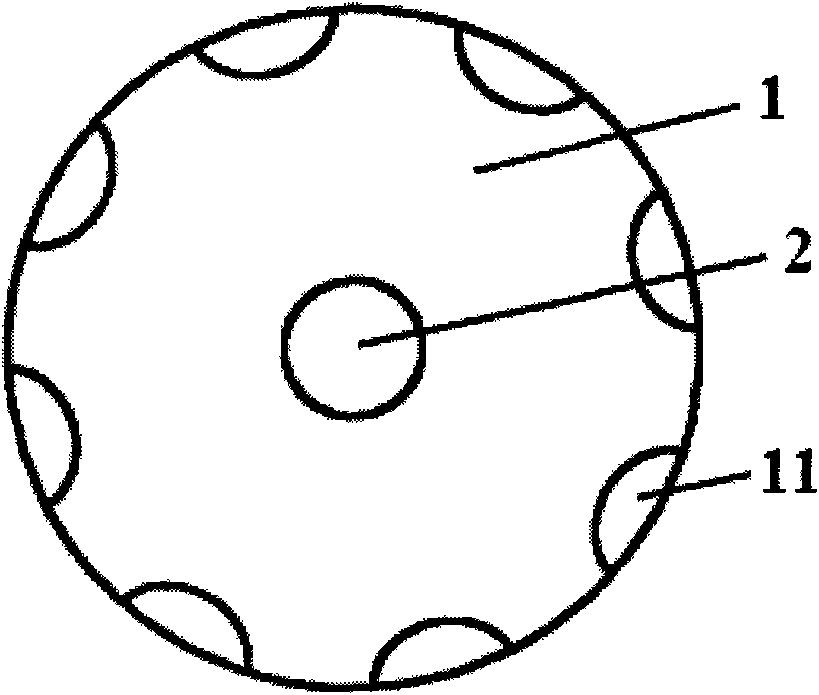

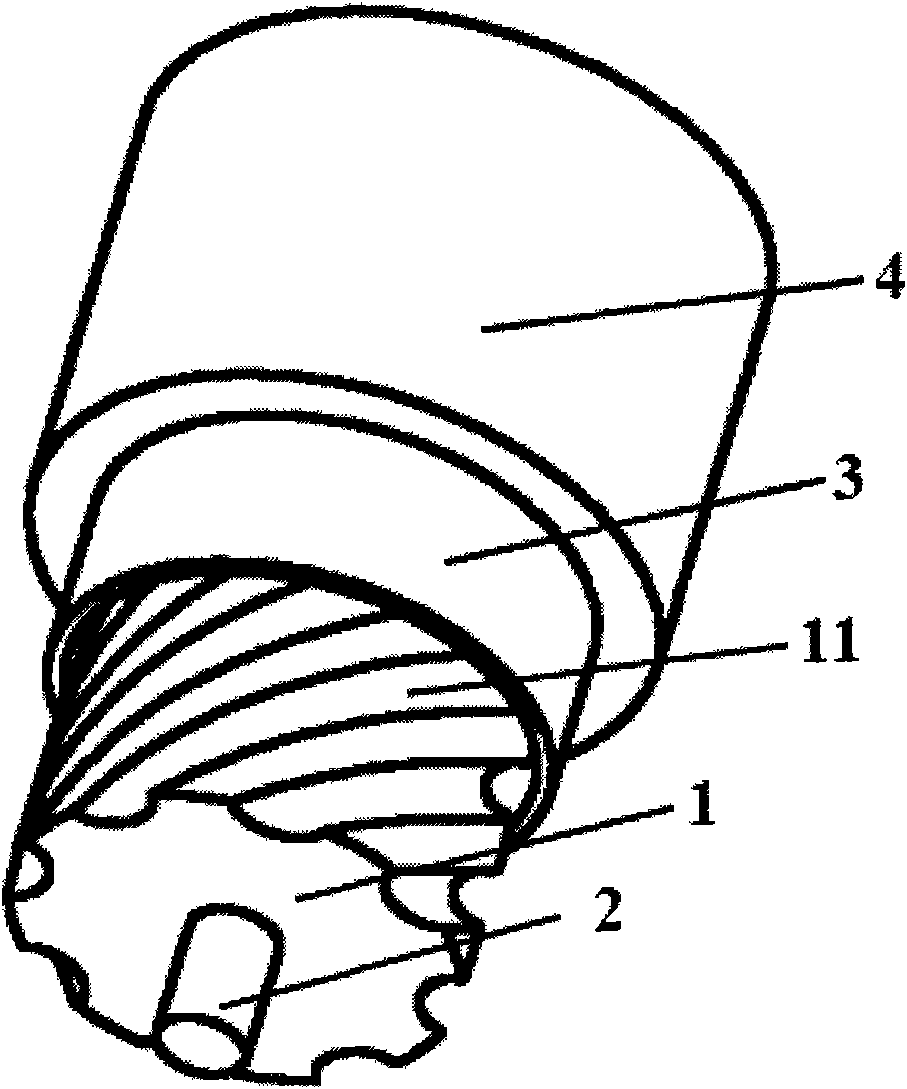

Skeleton cable

InactiveCN101685682AReduce the number of jointsReduce lossInsulated cablesInsulated conductorsEngineeringProtection layer

The invention relates to the technical field of cables, in particular to a skeleton cable, which comprises at least one group of cable conductors (5), and is characterized in that: the skeleton cablealso at least comprises a skeleton (1), a protective layer (3) and an outer protection layer (4); the skeleton is at least provided with two skeleton grooves (11); the protective layer (3) is positioned outside the skeleton; the outer protection layer (4) is positioned outside the protective layer; and the cable conductors (5) are positioned in the skeleton grooves (11). The skeleton cable has thefollowing advantages of effectively reducing joint number of the whole cable, effectively reducing connection loss, saving connection time, improving the reliability of a system, decreasing unnecessary expenses in the connection process, saving cost, and having more convenient maintenance.

Owner:沈群华

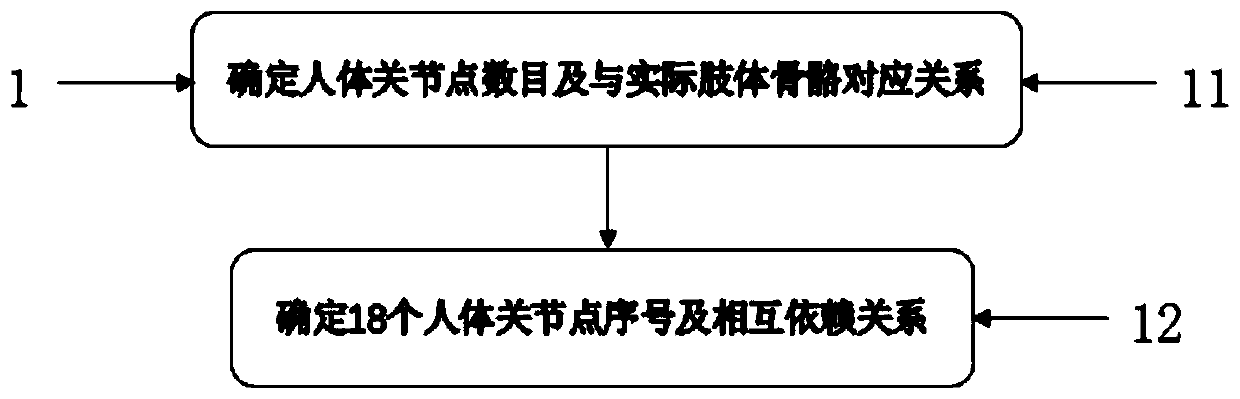

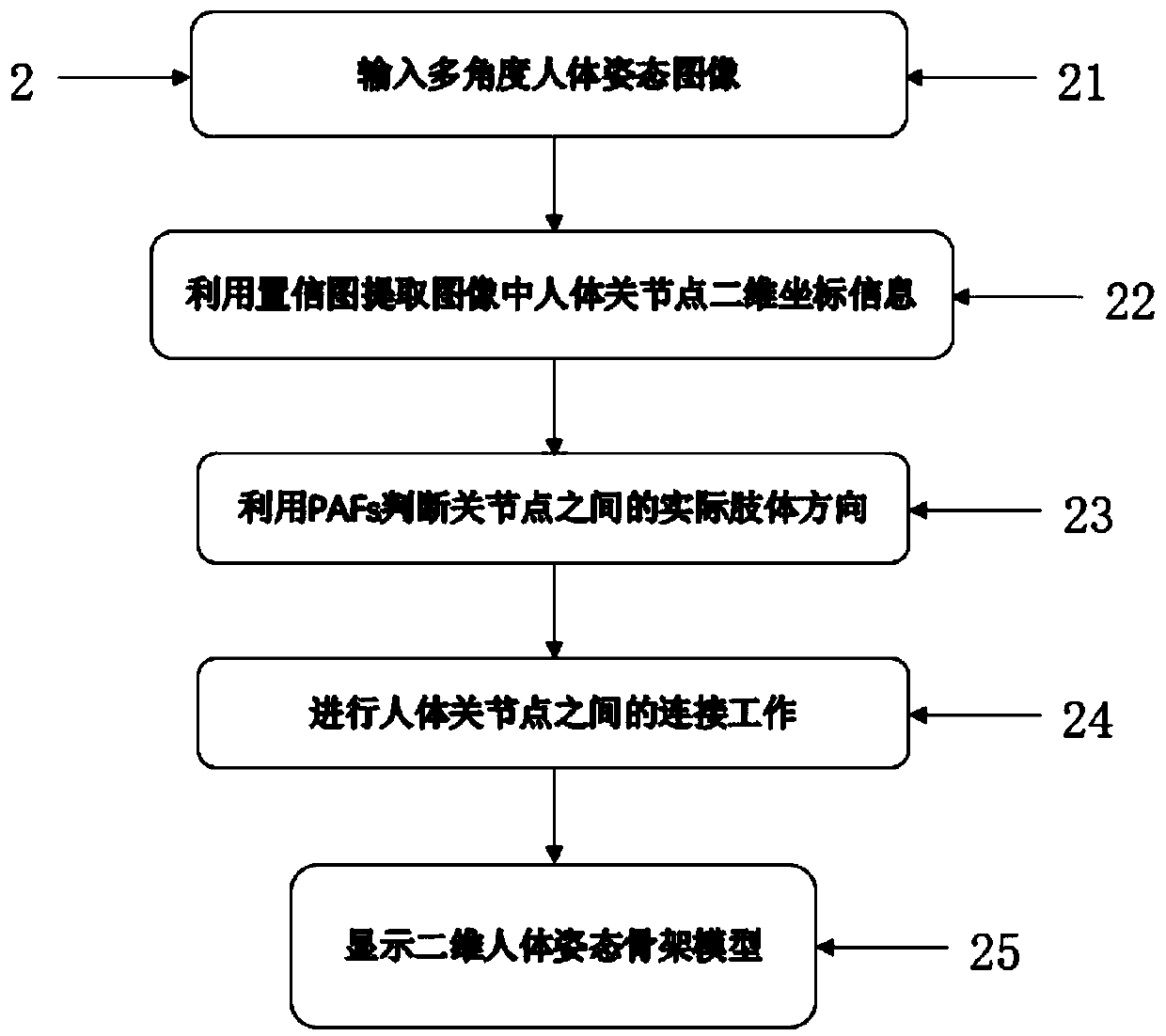

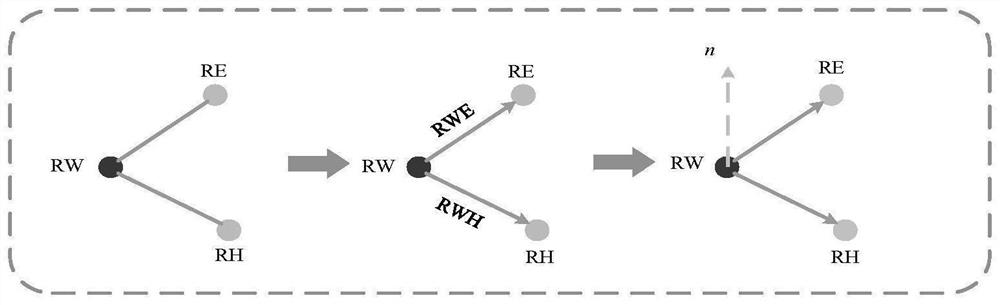

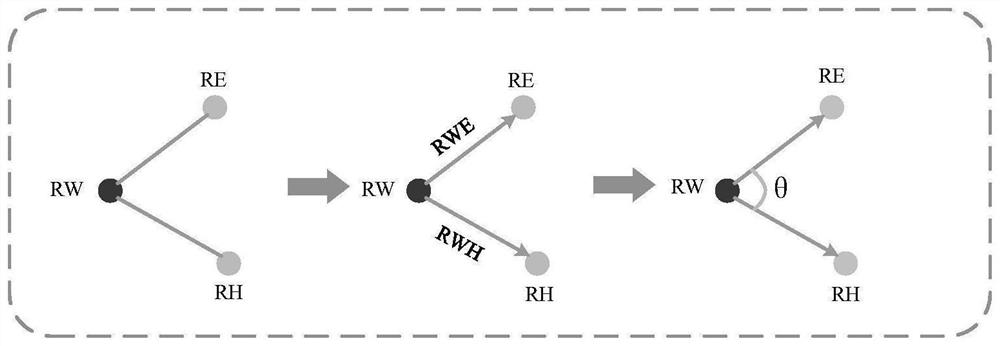

Optical unmarked three-dimensional human body motion capture method

InactiveCN110633005AExpand range of motion posturesAvoid shared disadvantagesInput/output for user-computer interactionNeural architecturesHuman bodyThree-dimensional space

The invention provides an optical unmarked three-dimensional human body motion capture method, solves the problem of constraint of traditional non-optical and optical marked human body motion capturemethods on human body motion, and reduces the duration of single human body motion capture to a certain extent. The method comprises the following steps: determining a human body joint number and a connection relationship among all joint points by utilizing a corresponding relationship between positions of different joint points and a real human body; performing two-dimensional joint point extraction of the multi-angle human body image and limb skeleton connection lines between joint points by utilizing a deep convolutional neural network and combining the serial number and the connection relationship to obtain two-dimensional coordinate information of the human body joint points; and drawing a human body skeleton model in a three-dimensional space by utilizing a conversion relationship between different coordinate systems and the two-dimensional coordinate information of the human body articulation points.The skeleton model reflects real human body posture motion information in the three-dimensional space, and the motion capture method is conveniently applied to the field of human body motion analysis subsequently.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Machining process of directly pulling steel round rope into flat rope

InactiveCN101564738ARoll weight increaseOmit the pickling processFurnace typesHeat treatment furnacesProduction rateEngineering

The invention discloses a machining process of directly pulling steel round wire into flattened wire, including a pre-flattening step, an annealing step, a finishing step. The pre-flattening step includes a flattening step and a filament pulling step. Comparing with the prior art, the pickling step is eliminated, copper consumption is lowered; the pre-flattening step is continuous on-line production, the coil weight of the flattened wire is enhanced to 400-1000kg, joint number of the finishing step is reduced, so that the entire production rate is enhanced.

Owner:ANHUI XINKE NEW MATERIALS

Small-diameter steel pipe pile side static-pressure hoop device

InactiveCN105507323ASimple structureEasy to processBulkheads/pilesArchitectural engineeringLocal pressure

The invention discloses a small-diameter steel pipe pile side static-pressure hoop device. The device comprises two concave steel pipe sleeve clamps, two sleeve clamp fixing devices, two static-pressure plates and two fixed rods; the two concave steel pipe sleeve clamps are combined and spliced to form a cylinder; the outer sides of the two concave steel pipe sleeve clamps are separately fixed on the corresponding sleeve clamp fixing devices; the static-pressure plates are separately arranged on the outer sides of the two sleeve clamp fixing devices; two ends of the bottoms of the static-pressure plates on two sides are fixedly connected through the fixed rods; and the fixed rods transversely penetrate through the two sleeve clamp fixing devices. The small-diameter steel pipe pile side static-pressure hoop device adopts the pile side pressure application to transfer the pile top static-pressure position to the static-pressure plate positions on two sides of a hoop so as to solve the deformation problem caused by local pressure of a pile head; and the small-diameter steel pipe pile side static-pressure hoop device can continuously change the clamping position, has no need to cut off more steel pipes under the condition of height limit, effectively reduces the joint number of steel pipe piles, and improves the working efficiency.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LIANYUNGANG POWER SUPPLY CO +3

Technical yarns, textile fabric and use

InactiveCN101285226AReduced number of jointsFew jointsMonocomponent polyethers artificial filamentContinuous wound-up machinesYarnEngineering

The invention discloses an industrial yarn and an industrial fabric as well as a use thereof. Yarn is the yarn which is made from a raw material of heat resistant fiber, after the yarn is weaved, the joint number of the yarn in a fabric is below 10 / 100m2. Tensile strength of the fabric, of which the longitude direction is above 500 N / 5cm based on JIS L 10968.12.1A law, and the fabric is applied in the filtering material field and a reinforcement fabric of non-woven fabric. The invention has the advantages of reducing the joint number of the yarn, reducing unevenness of yarn twist, improving strength of the fabric and stability of ventilation degree value and improving overall performance of the finished product.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

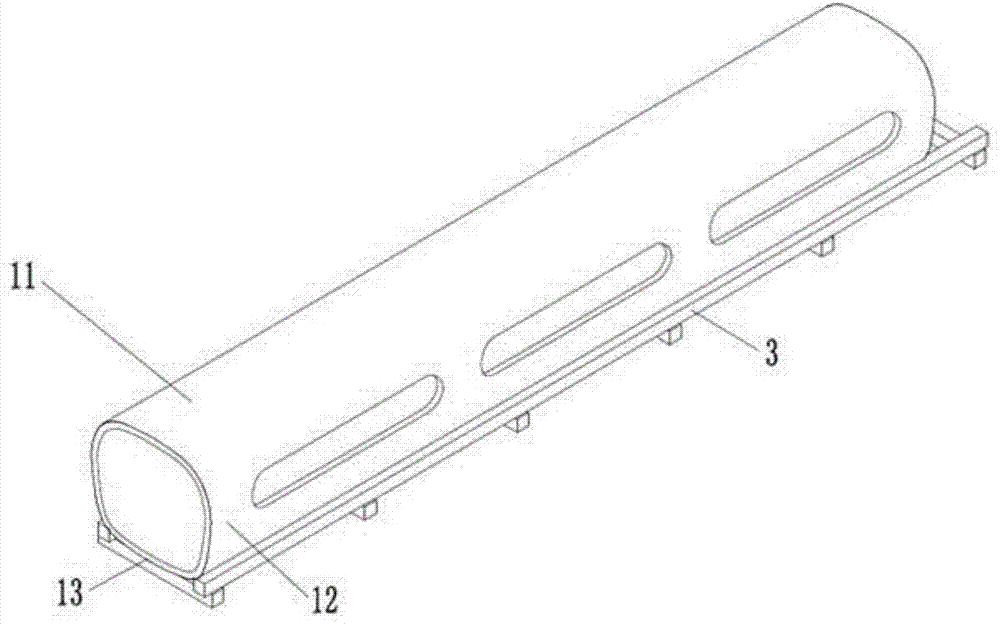

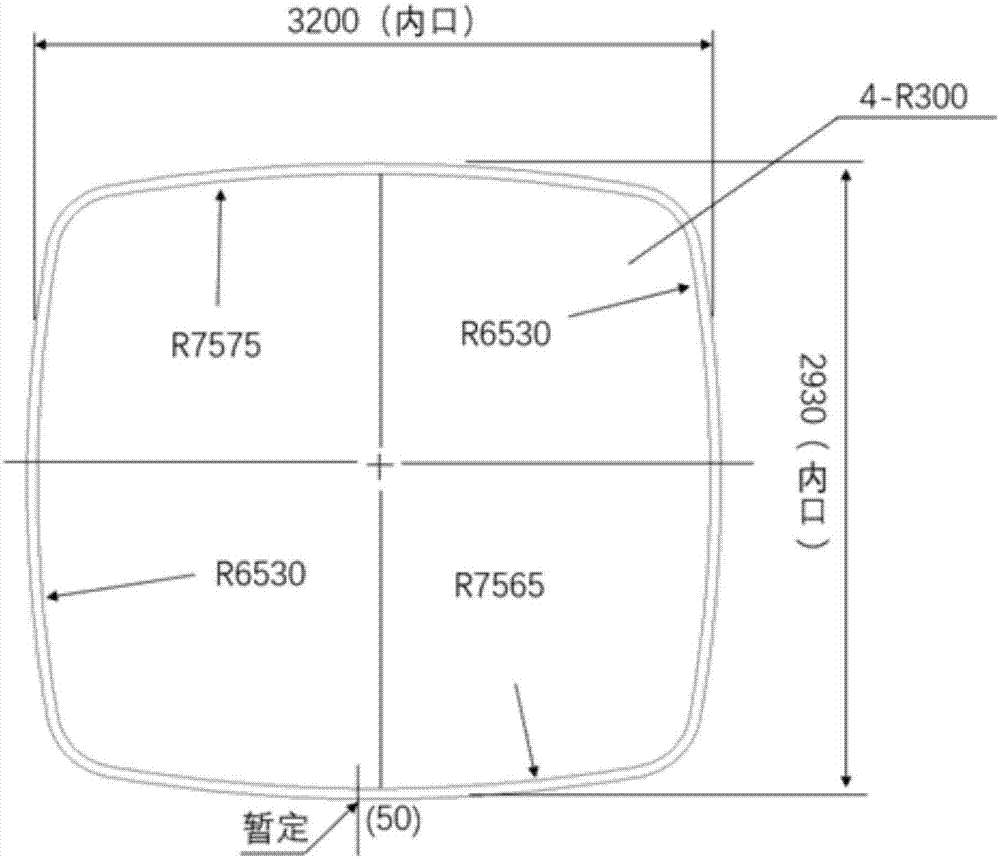

Finite element simulating and testing system and method of bamboo winding vehicle body

ActiveCN107330154AThe detection data is accurateEasy to operateGeometric CADDesign optimisation/simulationElement modelVehicle frame

The invention discloses a finite element simulating and testing system and method of a bamboo winding vehicle body. The simulating and testing system comprises a vehicle body structure finite element model module, a vehicle body structure condition setting module and a simulating and testing module. The vehicle body structure finite element model module firstly establishes finite element models of a vehicle frame and a vehicle shell, sets the fixed connection mode of the bottom face of the vehicle shell and the bottom face of the vehicle frame, sets the unit numbers, the joint numbers and the unit types of all parts of the finite element models of the vehicle frame and the vehicle shell, and sets the materials of the vehicle frame, end plates and the vehicle shell. The vehicle body structure condition setting module sets bamboo winding vehicle body boundary constraint conditions and loads. The simulating and testing module executes simulating and testing according to two stages. By means of the system and method, a large number of true and effective test data is accumulated, and advantageous data support is provided for reliability design, production and use of a novel vehicle.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

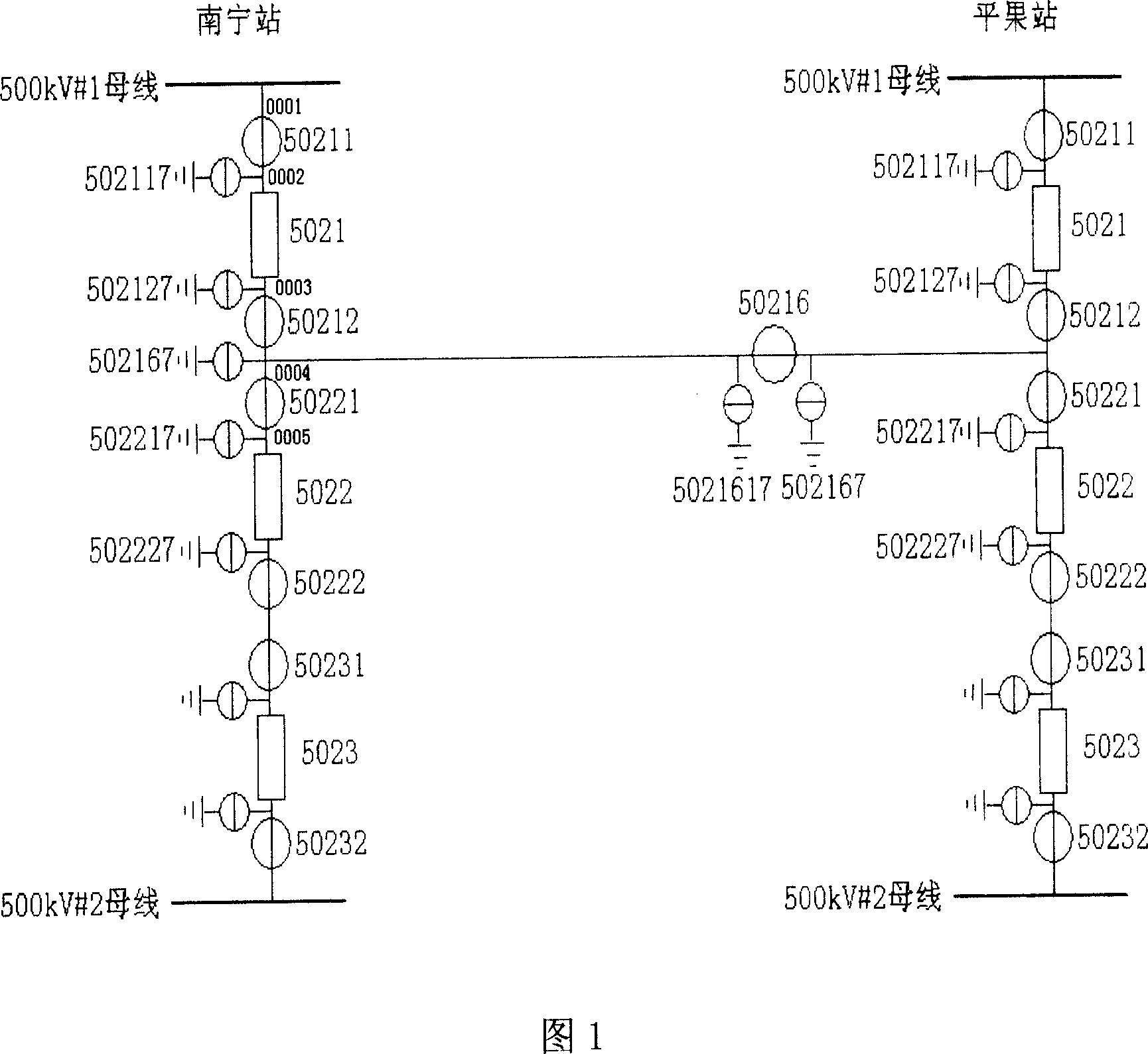

Zone control network topology five-preventing system for 500KV converting station

InactiveCN1929241AImprove securityReduce human misjudgmentPower network operation systems integrationCircuit arrangementsEngineeringNetwork topology

This invention relates to 500kv transducer station area control network topological system, which defines repeated joint number of each network device to judge whether each device is connected; device controller collects electricity network device status data to computer system to judge whether the device has electricity to determine whether to process remote operations.

Owner:CSG EHV POWER TRANSMISSION

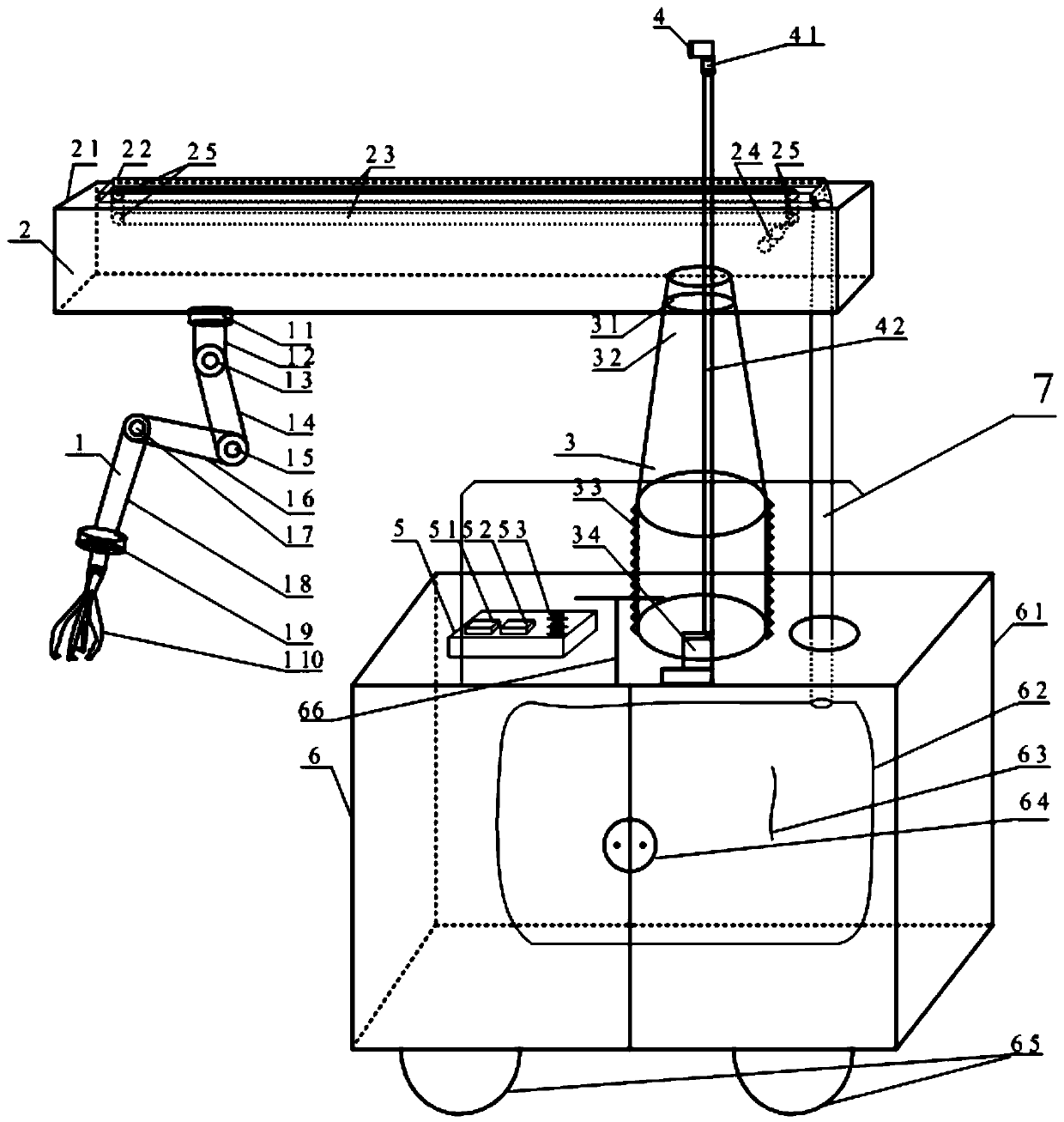

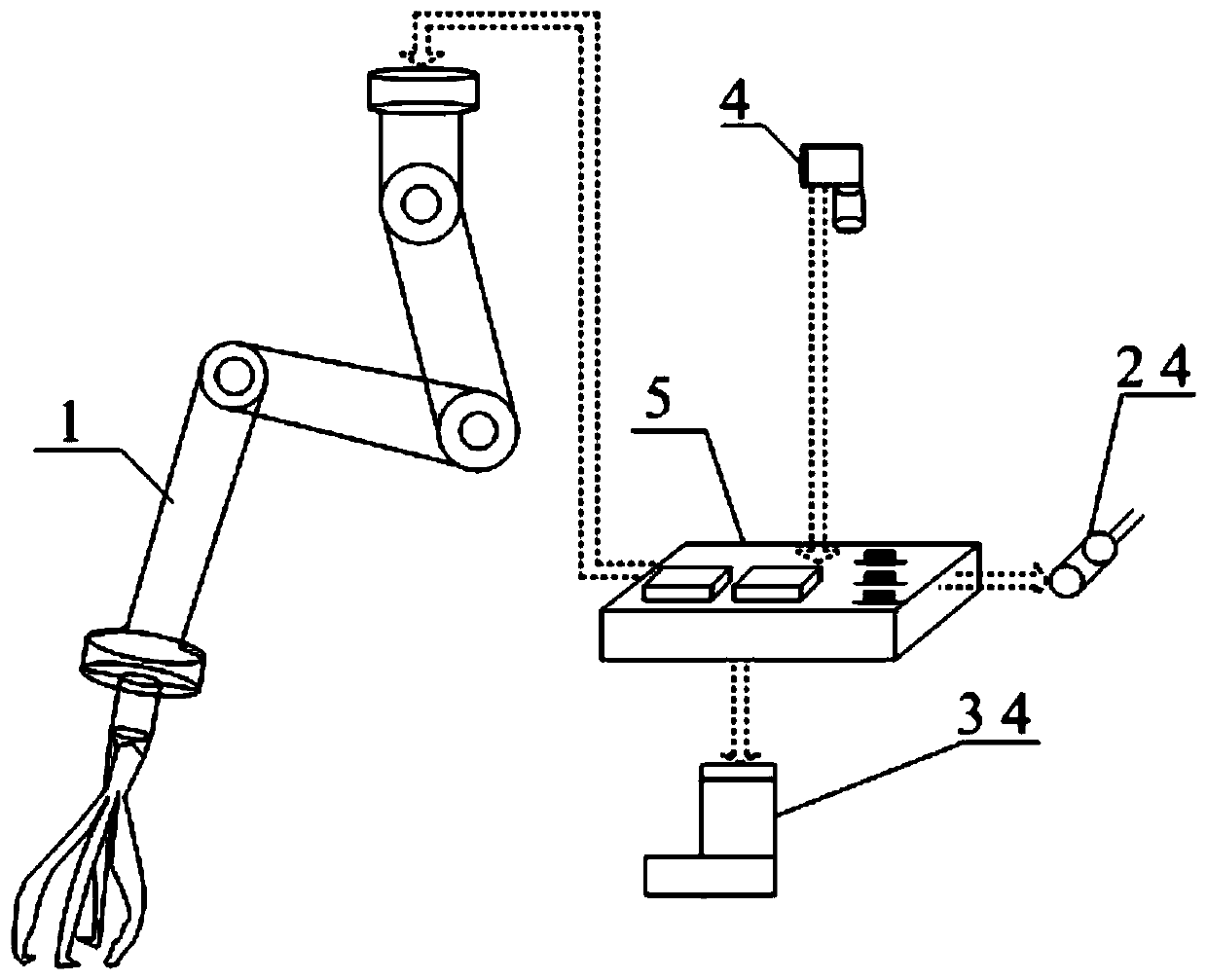

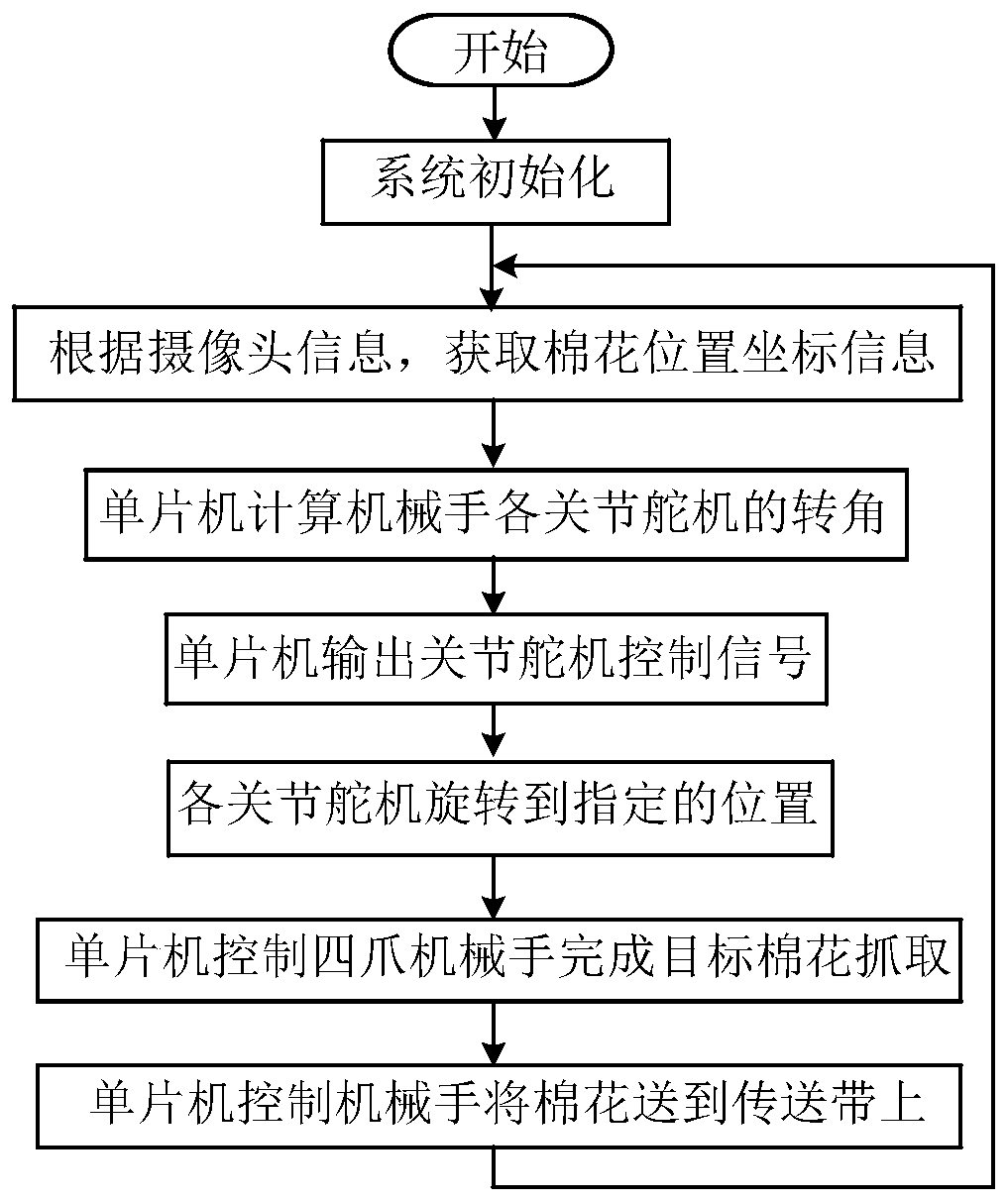

Intelligent cotton picker and control method thereof

The invention discloses an intelligent cotton picker and a control method thereof. The intelligent cotton picker comprises a cotton picking manipulator, a tower arm, a tower pole, a camera shooting component and a cotton receiving component; the tower pole is installed on the top of the cotton receiving component, the tower arm is installed on the top of the tower pole, the cotton picking manipulator is installed at the bottom of the other end of the tower arm, the camera shooting component penetrates through the tower arm to be fixed to the tower pole, a single-chip microcomputer control component is arranged at one end of the top of the cotton receiving component, and a cotton sampling hose is arranged at the other end of the top of the cotton receiving component. The invention further discloses the intelligent cotton picker control method. The whole system is simple in structure and easy to control, the joint number and arm length of the cotton picking manipulator are reduced, the control difficulty is reduced, the complexity of a control program is lowered, the cotton picking speed is increased, and the cotton picking efficiency is improved.

Owner:YANCHENG ZHENGBANG ENVIRONMENTAL PROTECTION TECH +1

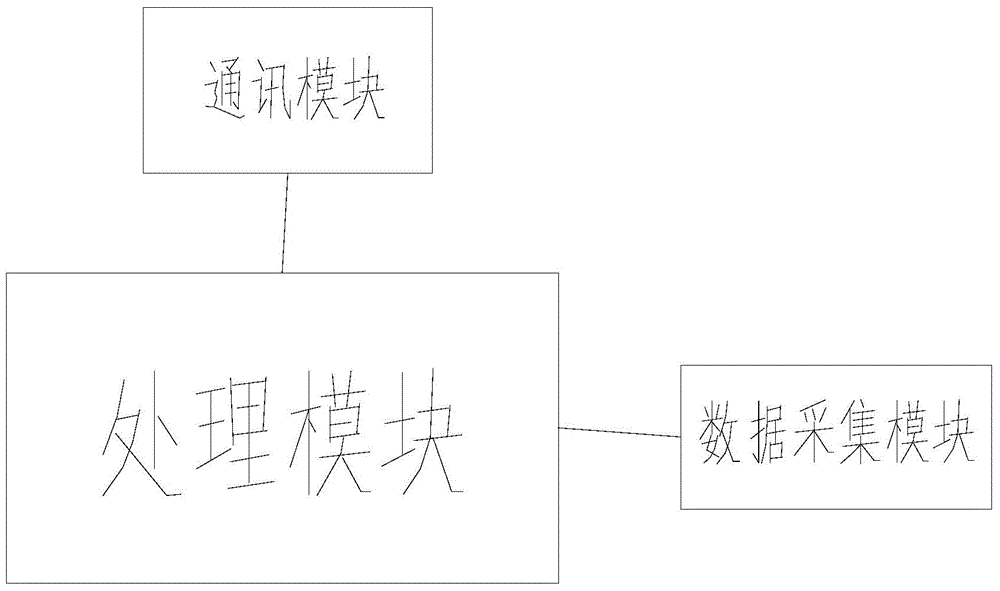

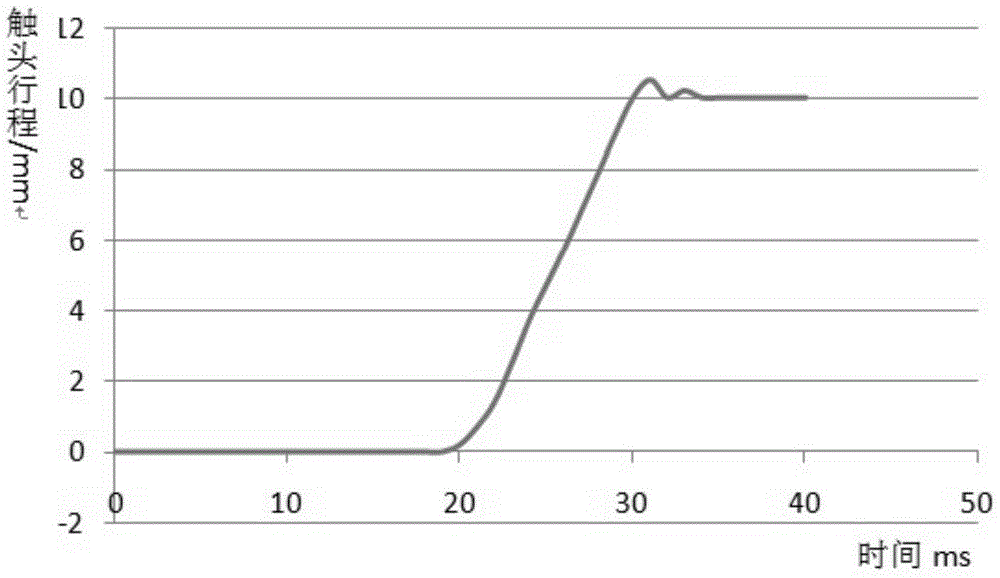

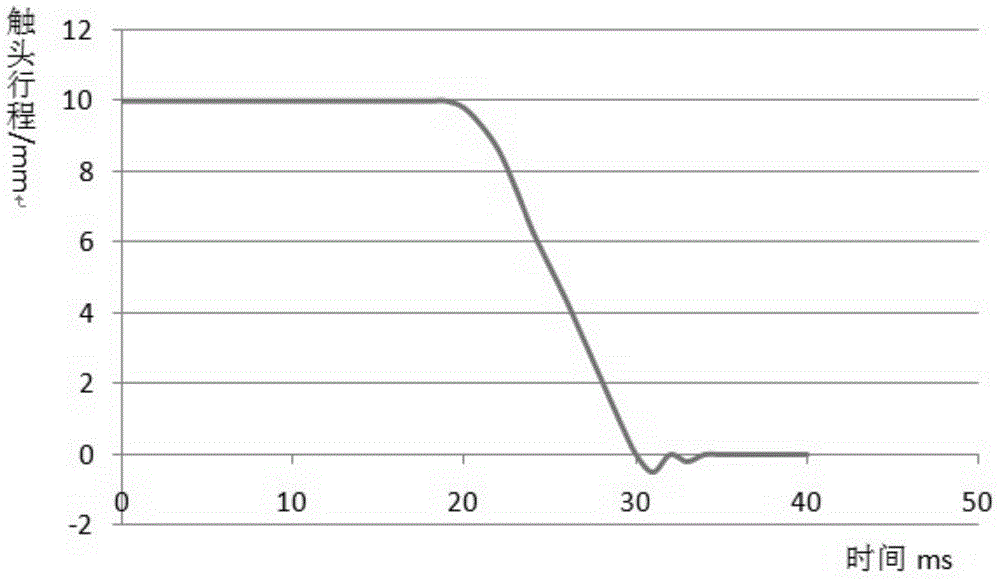

Online monitoring device for circuit breaker operating mechanism

The invention provides an online monitoring device for a circuit breaker operating mechanism. The online monitoring device comprises a data acquisition module, a processing module and a communication module, wherein the output end of the data acquisition module is connected with the input end of the processing module; the communication module is connected with the processing module and comprises multiple uplink network interfaces; and the data acquisition module is used for acquiring a switching-closing signal of the circuit breaker and a contact travel signal of the circuit breaker. According to the online monitoring device for the circuit breaker operating mechanism, the cable number is greatly reduced, in addition to cables used by the power supply, the other control signals, status signals, monitoring information and the like can be transmitted to a switch cabinet or the background by virtue of digital signals (electric or optical communication signals), namely all the signals can be transmitted by virtue of a network cable. Meanwhile, the status signal contact number of auxiliary switches and the like and the aviation plug joint number are correspondingly reduced, secondary wiring is effectively simplified, and the switch cabinet production efficiency is improved.

Owner:乐清竞取电气有限公司

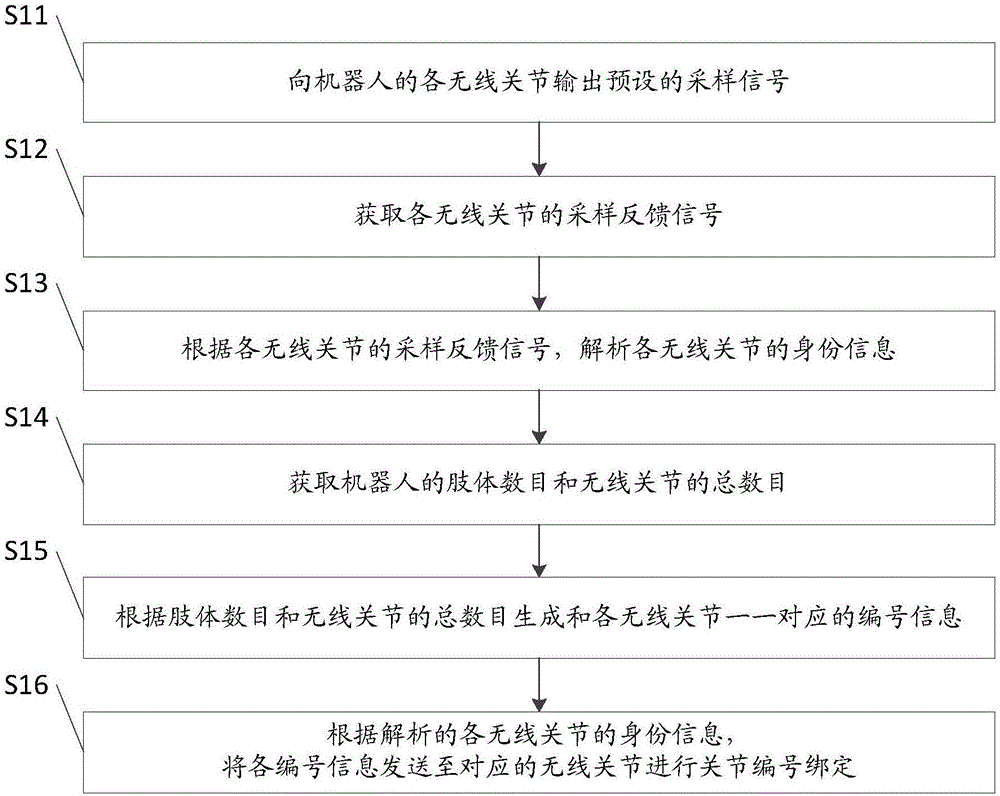

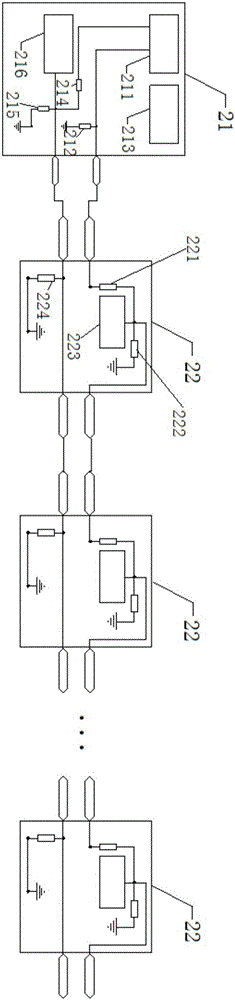

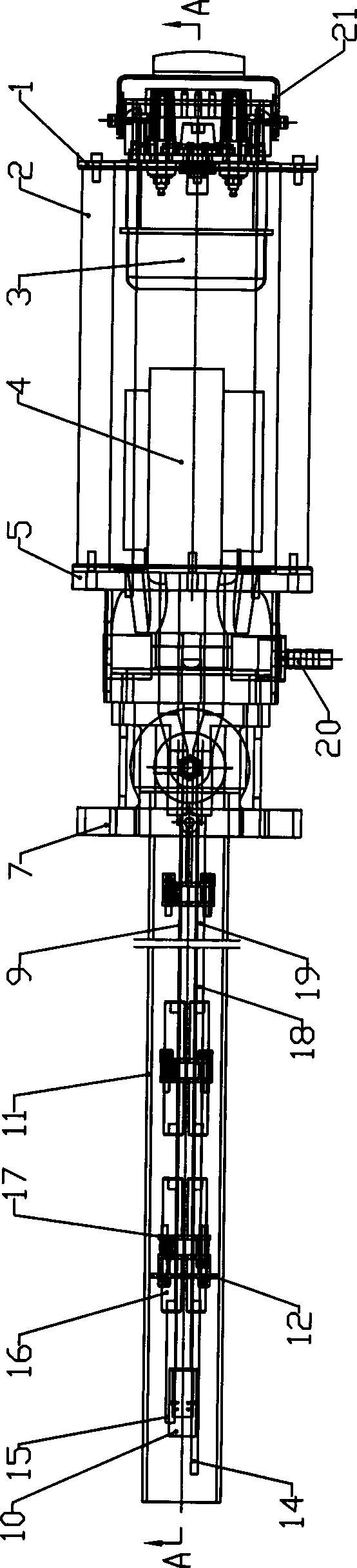

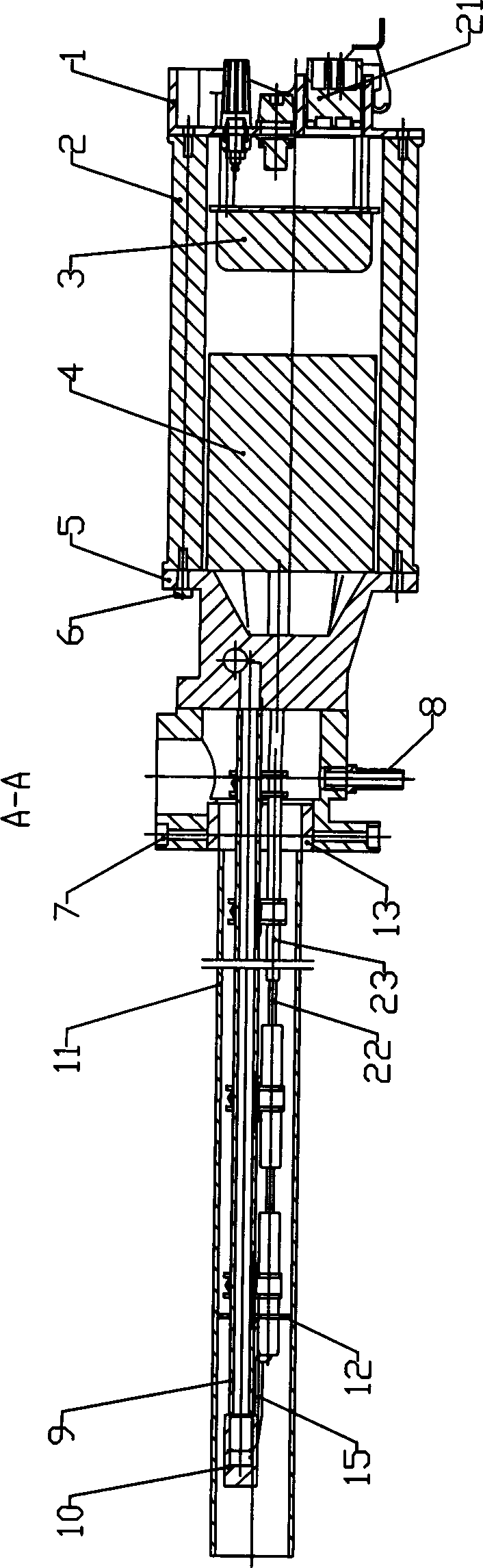

Wireless joint number control method and system for robot

ActiveCN106773853ARealize the networking numberEasy to manageNetwork topologiesProgramme control in sequence/logic controllersComputer scienceJoints number

The invention discloses a wireless joint number control method and system for a robot. The method includes: outputting a preset sampling signal to each wireless joint of the robot in advance; acquiring the sampling feedback signal of each wireless joint; analyzing the identity information of each wireless joint according to the sampling feedback signal of each wireless joint; acquiring the number of the limbs of the robot and the total number of wireless joints; generating number information in one-to-one correspondence to the wireless joints according to the number of the limbs and the total number of the wireless joints; transmitting each number information to the corresponding wireless joint according to the analyzed identity information of each wireless joint to perform joint number binding. The wireless joint number control method has the advantages that the networking numbering of the wireless joints is achieved simply and conveniently; when one wireless joint needs to be replaced, the number of the to-be-replaced wireless joint does not change due to the fact the sampling feedback signal fed back by the to-be-replaced wireless joint does not change, the problem of wrong number is avoided, and wireless joint management is facilitated.

Owner:GUANGDONG UNIV OF TECH

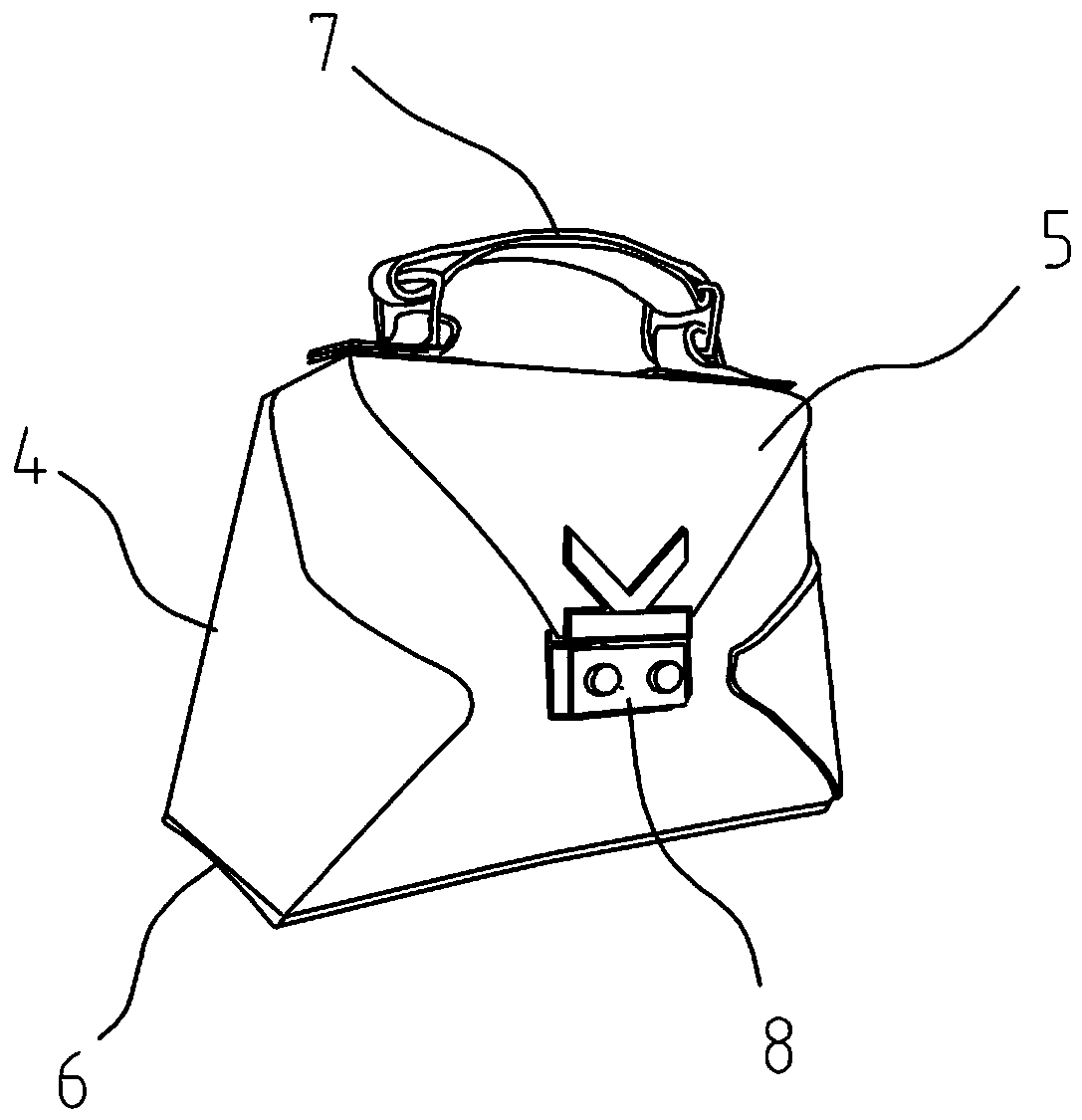

Flat knitted bag and making method thereof

PendingCN110037408AImprove cohesionExquisite processing technologyWeft knittingHandbagsComputer programmingJoints number

The invention discloses a flat knitted bag and a making method thereof. The flat knitted bag comprises a bag body, the bag body is formed by a body outer layer and a body inner layer which are closelyattached, the body outer layer is a one-piece or multi-piece two-dimensional formed knitted fabric, and the making method of the knitted bag comprises the step that the bag body is knitted through computer programming. According to the flat knitted bag and the making method thereof, by means of digitally engineered knitting process, materials adopted for making the bag and joints are remarkably reduced, and the knitted bag which is light, stylish, small in joint number and even almost free of joints can be made.

Owner:LANBOZHIYEPEIXUNXUEXIAOTONGXIANGYOUXIANGONGSI

Parastomal hernia abdominal bandage

The invention discloses a parastomal hernia abdominal bandage. The parastomal hernia abdominal bandage comprises a main abdominal bandage body and a chain abdominal bandage body; the main abdominal bandage body is provided with an ostomy hole corresponding to an ostomy, the chain abdominal bandage body is connected to the two ends of the main abdominal bandage body, the chain abdominal bandage is arranged in a joint removable mode, and the length of the chain abdominal bandage body can be adjusted conveniently by increasing or decreasing the joint number. According to the parastomal hernia abdominal bandage, a chain connecting structure is adopted, the length of the hernia abdominal bandage can be adjusted at any time by selecting appropriate number of joint elastic bands according to the weight and physique of a patient, the using effect is improved, loosening cannot occur, and the ostomy cannot be compressed to cause ischemic necrosis of intestines; meanwhile, by means of the chain structure, the air permeability is enhanced, the comfort of the patient is improved, and the skin of the patient is guaranteed.

Owner:LUOYANG CENT HOSPITAL

Server load equalization method for implementing weighted minimum linked allocation

InactiveCN100388183CEvenly distributedBalanced schedulingRandom number generatorsCurrent loadData set

This invention discloses a weight minimum joint number dispatch server load balancing method. The technique scheme of the invention are the following: to preset the state representing each server current connection information in the server group, wherein, the said state is represented by data structure with at least one data item comprising data representing the current load states of each server; the said current server load states is represented by the first data item in at least one data item; when load is evenly dispatched, it goes through all first set data items representing current server load states ; it selects server relevant to minimum first preset data set to switch in and at the same time to alter the data item.

Owner:HUAWEI TECH CO LTD

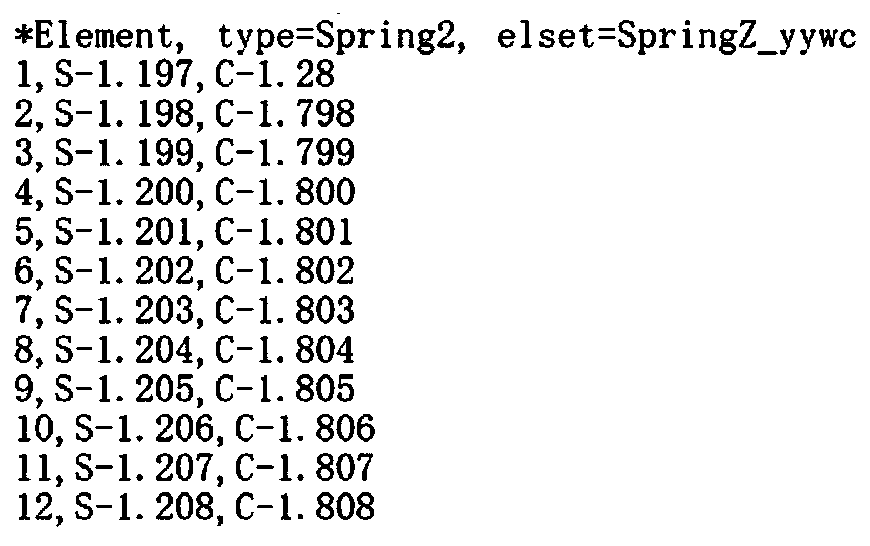

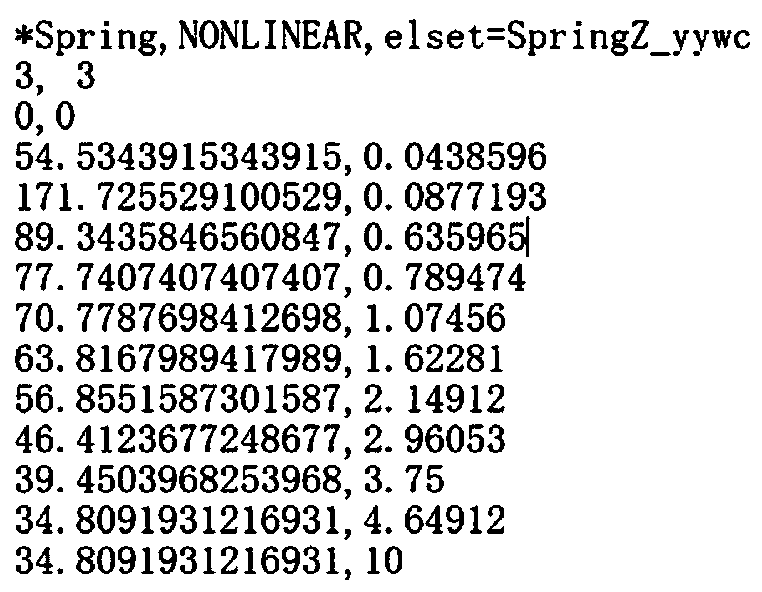

Spring unit modeling method of SRC component finite element model based on Excel

ActiveCN110147565AComplete efficientlyAccurately doneGeometric CADDesign optimisation/simulationElement modelBond slip

The invention discloses a spring unit modeling method of an SRC component finite element model based on Excel. The spring unit modeling method comprises the steps: establishing a finite element modelof an SRC component, and storing an inp file; copying profile steel node information in the inp file to the first column of Sheet1 and dividing the profile steel node information into four columns; copying the concrete node information to the fifth column and dividing the concrete node information into four columns; copying the first column of profile steel node numbers to the tenth column, searching concrete node numbers with the same coordinates as the profile steel nodes in the 2nd, 3rd and 4th columns of the first row from the concrete nodes, and obtaining profile steel and concrete node numbers with the same coordinates in the 10th and 11th column of each row; obtaining section steel and concrete joint numbers required by the spring units; obtaining a spring unit required by the inp file in the twelfth column; and copying the twelfth column of spring units to a required position in the inp file, and adding attributes of the spring units in front of the first spring unit. Accordingto the spring unit modeling method, the addition of the spring unit can be efficiently and accurately completed, so that the spring unit modeling method is used for finite element simulation analysisof the SRC component or structure considering the bonding slip performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

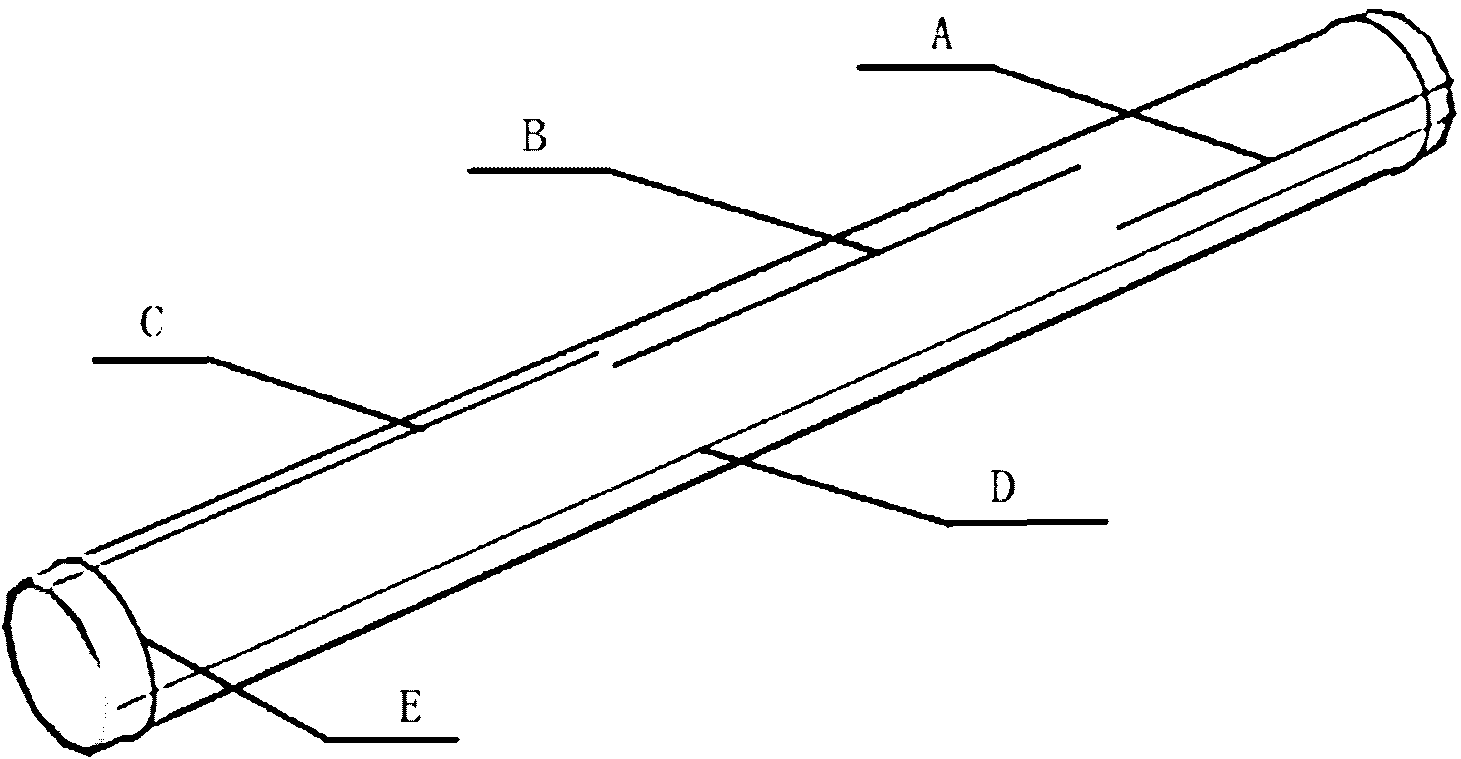

Long igniter

ActiveCN103512043AReduce the number of jointsImprove stabilityElectric spark ignitersTransformerJoints number

The invention relates to a long igniter which comprises a barrel body. A circuit board and a transformer are fixed in the barrel body, one end of the barrel body is connected with an electrical plug, the other end of the barrel body is sequentially connected with an installing flange and an outer tube, a gas tube is arranged in the outer pipe, an air connector and a gas connector are arranged on the installing flange, the air connector is communicated with the outer tube, and the gas connector is communicated with the gas tube. The outer end of the gas tube is connected with a spray head, an ignition needle and a detection bar are arranged nearby the spray head, the ignition needle is connected with the transformer through a detection bar connecting steel wire and a detection bar cable, and the detection bar is connected with the circuit board through an ignition needle connecting steel wire and an ignition needle cable. Most parts of the detection bar connecting steel wire and the ignition needle connecting steel wire are replaced by the detection bar cable and the ignition needle cable, only a small part of connecting steel wires located in a high-temperature region is reserved, the joint number of the connecting steel wires is decreased, the stability of the igniter is improved, and the cost of the igniter is reduced.

Owner:JIANGSU SINOSTEEL REFINING TECH INSTR

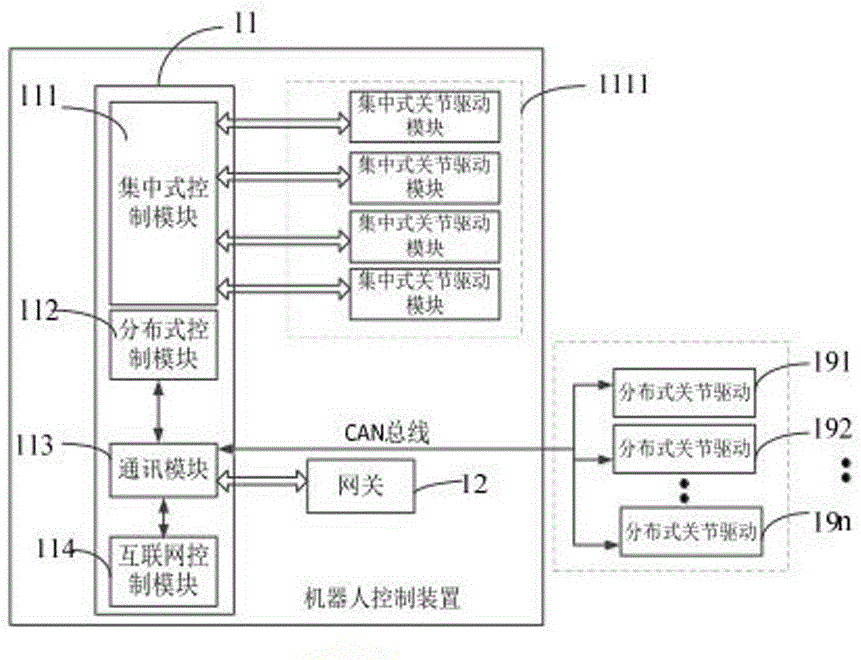

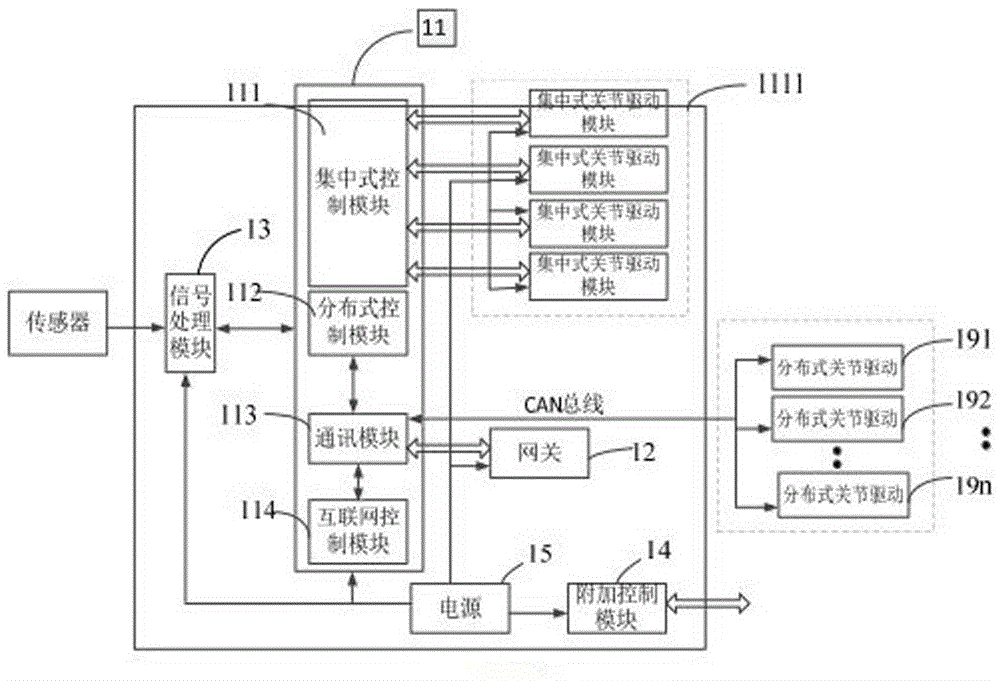

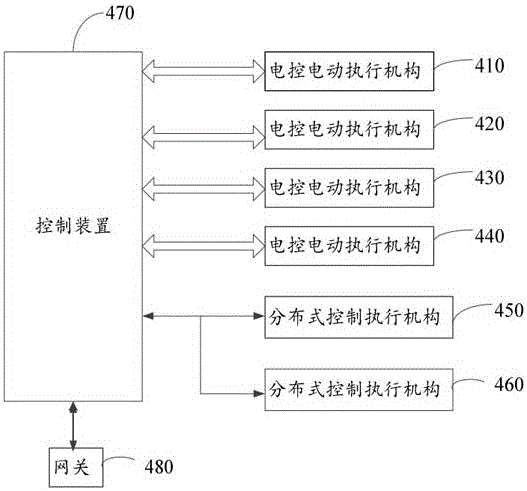

Hybrid robot control device

The invention discloses a hybrid robot control device, and belongs to the technical field of control of robots. The control device comprises a central processing unit, a centralized control module and a communication module; the central processing unit includes the centralized control module and a distributed control module; the centralized control module is provided with at least one driving control channel; the number of the driving control channels is higher than or equal to the number of first-type joints; each driving control channel is connected with one centralized joint driving module; each centralized joint driving module is electrically connected with a servo motor of one first-type joint to realize centralized control of the first-type joints; and the distributed control module is in driving connection with distributed joints of second-type joints through the communication module to realize distributed control of the second-type joints. The control device can control robots with any joint number, and is higher in generality.

Owner:广东戈兰玛汽车系统有限公司

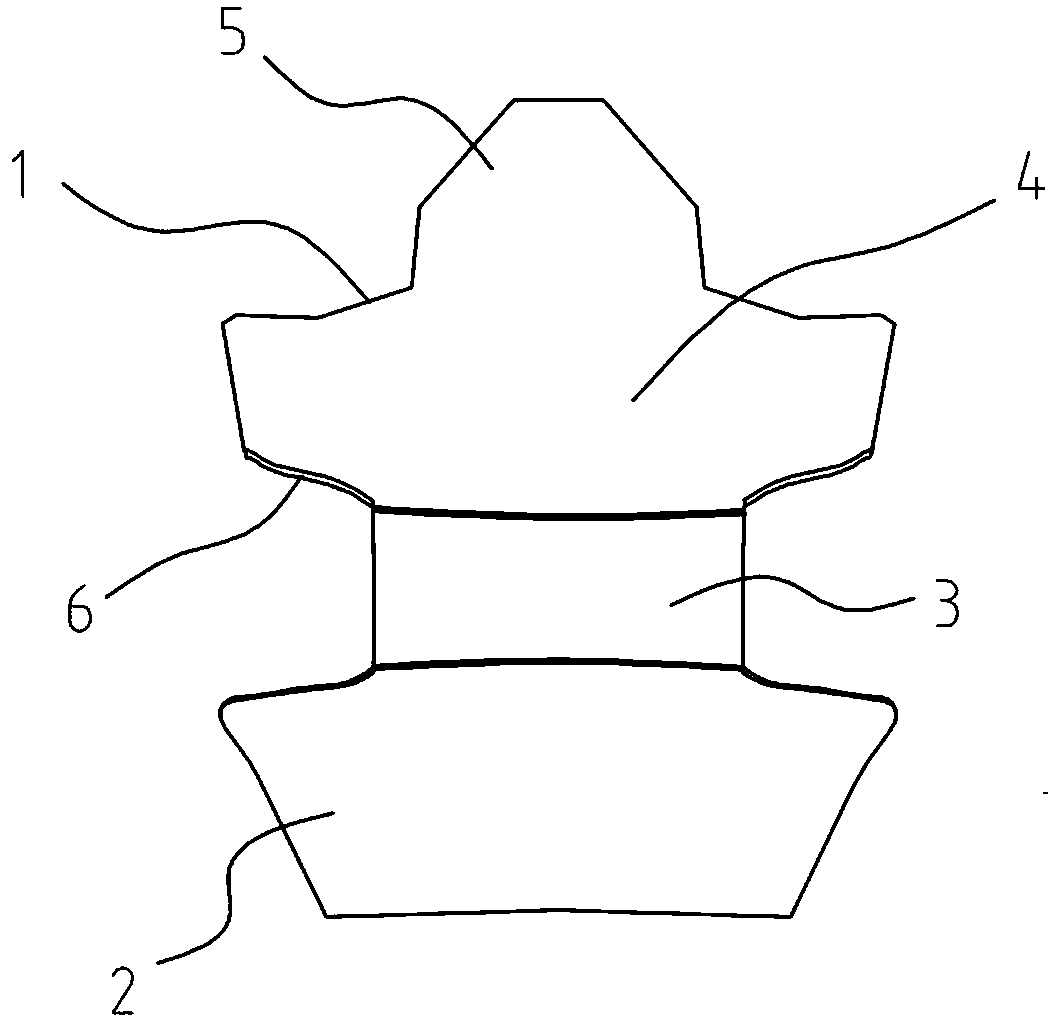

Application of methazolamide in preparing medicament for treating ankylosing spondylitis

The invention discloses a new application of methazolamide, in particular to application in preparing a medicament for treating ankylosing spondylitis. In a concrete application method, a patient orally administrates two methazolamide tablets of 25mg every day after a meal respectively in the morning and at night; and the methazolamide takes effect commonly for one month and can obviously improve and reduce BASDAI and BASFI of the ankylosing spondylitis, lighten neck ache, back ache and hip ache, reduce morning stiffness time and ache joint number and obviously lower the blood sedimentation and immune globulin level of the patient.

Owner:常晓天 +3

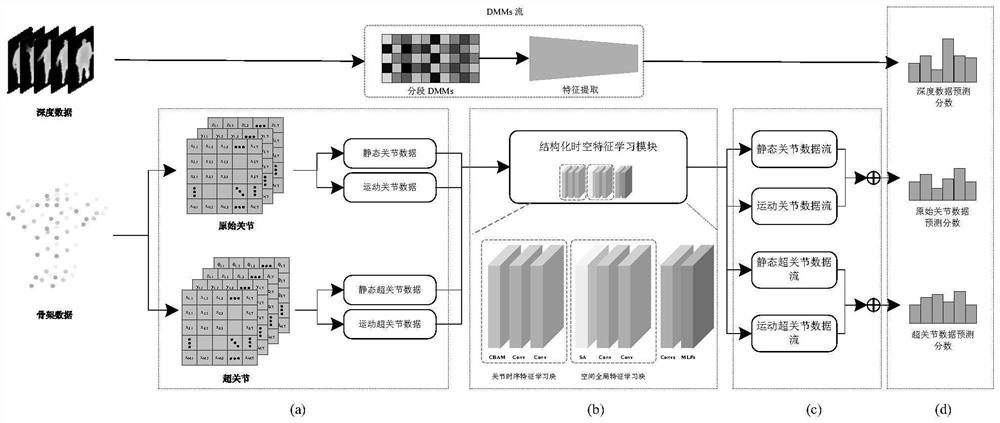

Super-joint and multi-modal network and behavior identification method thereof

PendingCN114782992AImprove motion recognition performanceEasy to identifyBiometric pattern recognitionNeural architecturesHuman bodyData stream

The invention relates to the technical field of neural networks, in particular to a hyper-articular and multi-modal network and a behavior recognition method thereof, and the method comprises the steps: collecting a human body depth map, carrying out the feature extraction of the depth map through a DMMS flow, and calculating a depth data prediction score; the method comprises the following steps: collecting a human skeleton sequence, respectively extracting original joint and hyper-joint data, constructing skeleton information by combining hyper-joints and common joints, sending the skeleton information into a structured spatial-temporal feature learning model to obtain static and dynamic joint data streams and static and dynamic hyper-joint data streams, and carrying out adaptive weight fusion on the data streams of the original joints and the hyper-joints to obtain a structured spatial-temporal feature learning model; respectively obtaining a joint data prediction score and a super joint prediction score; and adding the classification prediction scores of the DMMS stream and the skeleton stream to generate a final prediction score. According to the method, rich texture information of a human body part in space is learned from a depth map, and rich spatial-temporal characteristics in motion posture changes are learned from a skeleton sequence.

Owner:CHANGZHOU UNIV

long igniter

ActiveCN103512043BReduce the number of jointsImprove stabilityElectric spark ignitersTransformerEngineering

The invention relates to a long igniter which comprises a barrel body. A circuit board and a transformer are fixed in the barrel body, one end of the barrel body is connected with an electrical plug, the other end of the barrel body is sequentially connected with an installing flange and an outer tube, a gas tube is arranged in the outer pipe, an air connector and a gas connector are arranged on the installing flange, the air connector is communicated with the outer tube, and the gas connector is communicated with the gas tube. The outer end of the gas tube is connected with a spray head, an ignition needle and a detection bar are arranged nearby the spray head, the ignition needle is connected with the transformer through a detection bar connecting steel wire and a detection bar cable, and the detection bar is connected with the circuit board through an ignition needle connecting steel wire and an ignition needle cable. Most parts of the detection bar connecting steel wire and the ignition needle connecting steel wire are replaced by the detection bar cable and the ignition needle cable, only a small part of connecting steel wires located in a high-temperature region is reserved, the joint number of the connecting steel wires is decreased, the stability of the igniter is improved, and the cost of the igniter is reduced.

Owner:JIANGSU SINOSTEEL REFINING TECH INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com