Long igniter

A technology of igniters and firearms, which is applied in the direction of combustion ignition, ignition by electric spark, and combustion methods, etc., which can solve the problems of high precision requirements, heavy assembly workload, and affecting the stability of igniters, so as to reduce the number of joints and improve Stability, easy ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

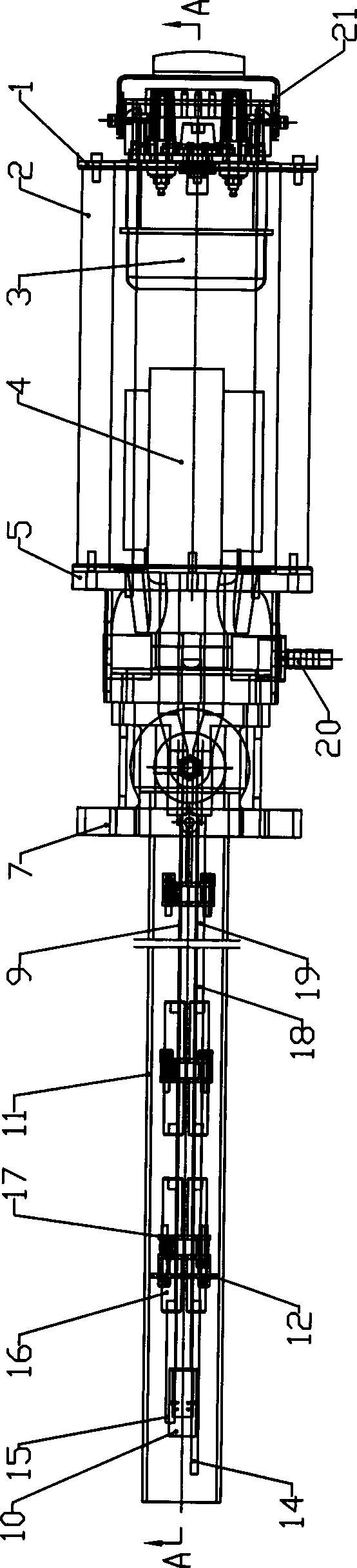

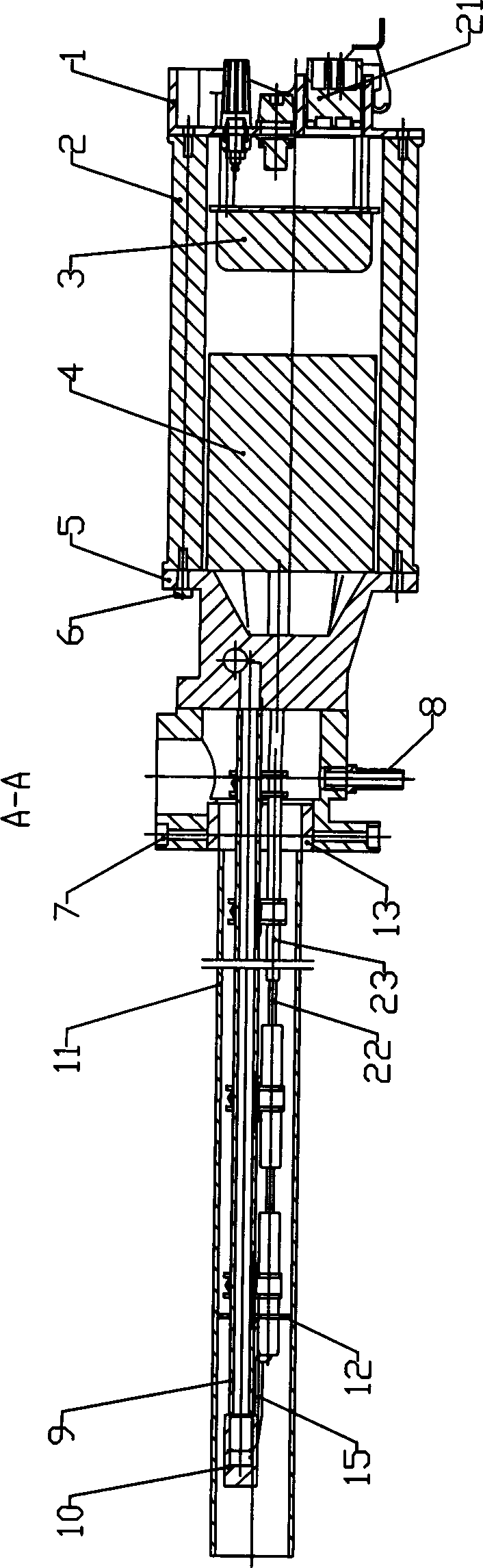

[0016] figure 1 , figure 2 Including rear end cover 1, cylinder body 2, circuit board 3, transformer 4, inner end cover 5, screw 6, outer end cover 7, air joint 8, gas pipe 9, nozzle 10, outer pipe 11, rotary fire spray Sheet 12, nut 13, detection rod 14, ignition needle 15, ceramic tube 16, bracket 17, detection rod connection steel wire 18, detection rod cable 19, gas connector 20, electrical plug 21, ignition needle connection steel wire 22, ignition needle cable 23 etc.

[0017] like figure 1 , figure 2 As shown, the present invention is a long igniter, including a cylinder 2 made of aluminum alloy material, and a circuit board 3 and a transformer 4 are fixed in the cylinder 2 .

[0018] One end of the cylinder body 2 is connected with a rear end cover 1 made of aluminum alloy, and an electrical plug 21 connected with the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com