Small-diameter steel pipe pile side static-pressure hoop device

A steel pipe pile, small diameter technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of many connecting points, small length of single-section pile, warping and deformation of end pipe wall, etc. Processing and disassembly, reducing the number of joints, preventing shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

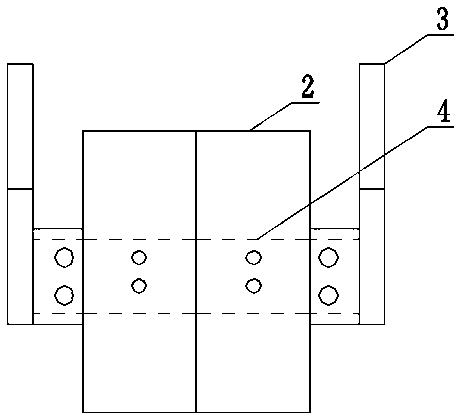

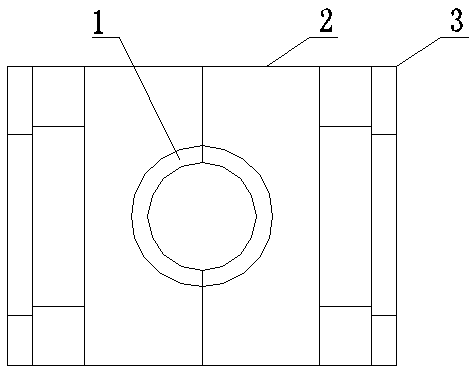

[0026] like figure 1 and figure 2 As shown, a small-diameter steel pipe pile side static pressure collar device includes two concave steel pipe collars 1, two collar fixing devices 2, two static pressure plates 3 and two fixing rods 4; The above two concave steel pipe clamps 1 are combined and spliced to form a column shape, and the outer side of each concave steel tube clamp 1 is fixed on the corresponding sleeve clamp fixing device 2 by bolts, and the outer side of each sleeve clamp fixing device 2 Both are provided with static pressure plates 3 , and the bottom ends of the static pressure plates 3 on both sides are fixedly connected by fixing rods 4 , and the fixing rods 4 cross the two clamping fixing devices 2 .

[0027] like image 3 As shown, the inner wall of each concave steel pipe clamp 1 is provided with threads 5 , and the outer wall of each concave steel tube clamp 1 is provided with a protruding skirt 6 .

[0028] like Figure 4 As shown, the inner side wa...

Embodiment 2

[0033] A small-diameter steel pipe pile side static pressure collar device, comprising two concave steel pipe collars 1, two collar fixing devices 2, two static pressure plates 3 and two fixing rods 4; the two The concave steel pipe clamps 1 are combined and spliced to form a column shape, and the outer side of each concave steel tube clamp 1 is fixed on the corresponding sleeve fixing device 2 by riveting, and the outer side of each sleeve fixing device 2 is provided with The static pressure plate 3 and the bottom ends of the static pressure plates 3 on both sides are fixedly connected by the fixed rod 4 respectively, and the fixed rod 4 crosses the two clamp fixing devices 2 .

[0034] Threads 5 are provided on the inner wall of each concave steel pipe clamp 1 , and protruding skirts 6 are provided on the outer wall of each concave steel tube clamp 1 .

[0035] The inner side wall of each of the clip fixing devices 2 is provided with a groove 7 that engages with the skirt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com