On-service petroleum drill pipe detection and classification evaluation method

A technology of oil drill pipe and evaluation method, which can be used in drill pipe, drill pipe, earth-moving drilling, etc., and can solve problems such as serious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

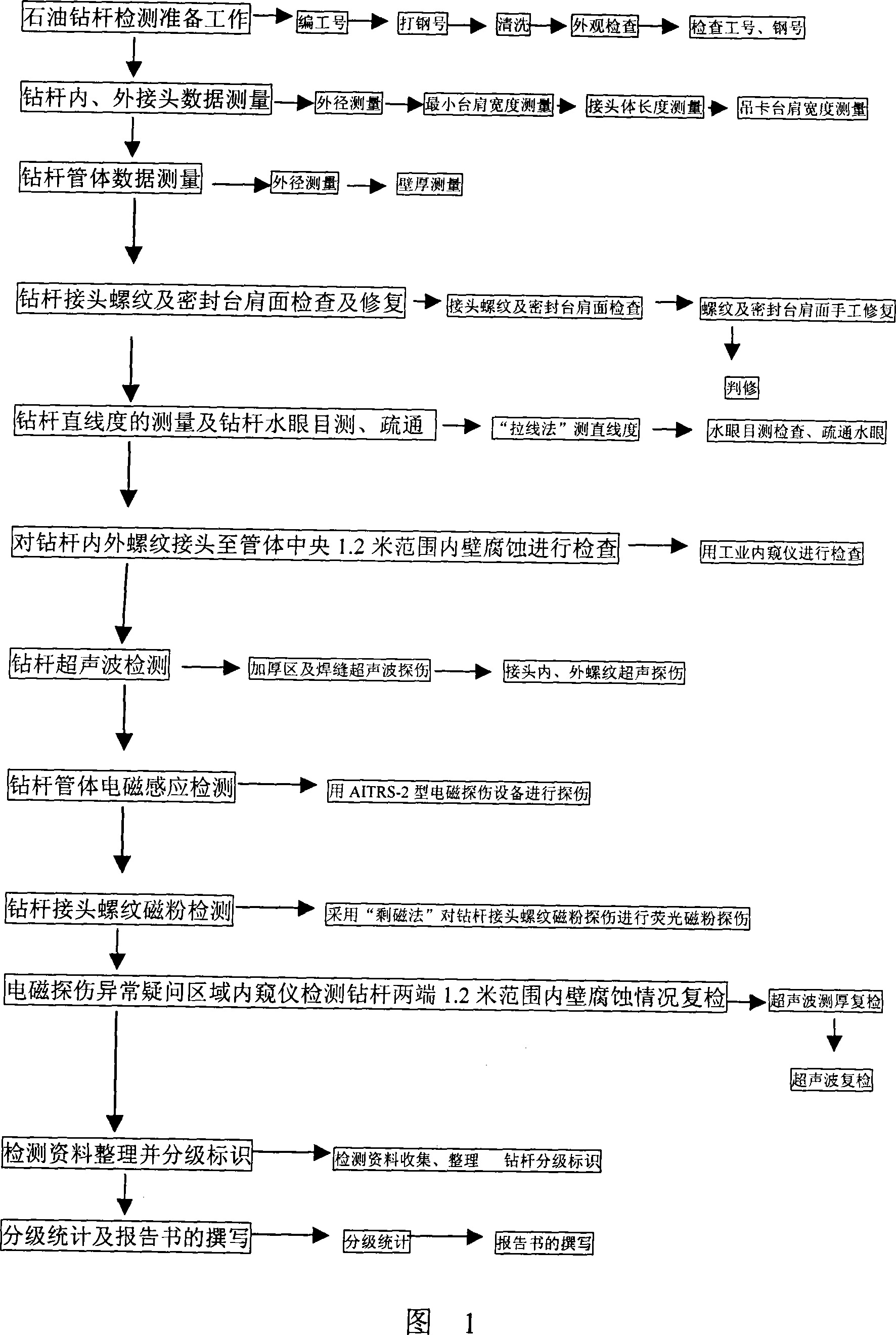

[0021] See Figure 1:

[0022] A method for testing and grading evaluation of in-service oil drill pipes, comprising the following steps:

[0023] 1. Preparations for the inspection of in-service oil drill pipes:

[0024] 1. The in-service oil drill pipes to be inspected are placed on the inspection platform and arranged neatly and assigned job numbers.

[0025] 2. The steel stamp number is stamped on the external thread joint end of the oil drill pipe, and the steel number is compiled according to the user unit, steel grade, specification, delivery time and inspection serial number. For example, the codes of drill pipes of various specifications use 11 digits, expressed as : XXXXXXXX-XX-XX, the first digit represents the drill pipe steel grade X, G or S, etc., the second and third digits represent the year of manufacture, the four, five, six, and seven digits represent the inspection serial number of the drill pipe, and the eighth , Nine digits represent the unit that the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com