Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232results about How to "Lower ESR" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

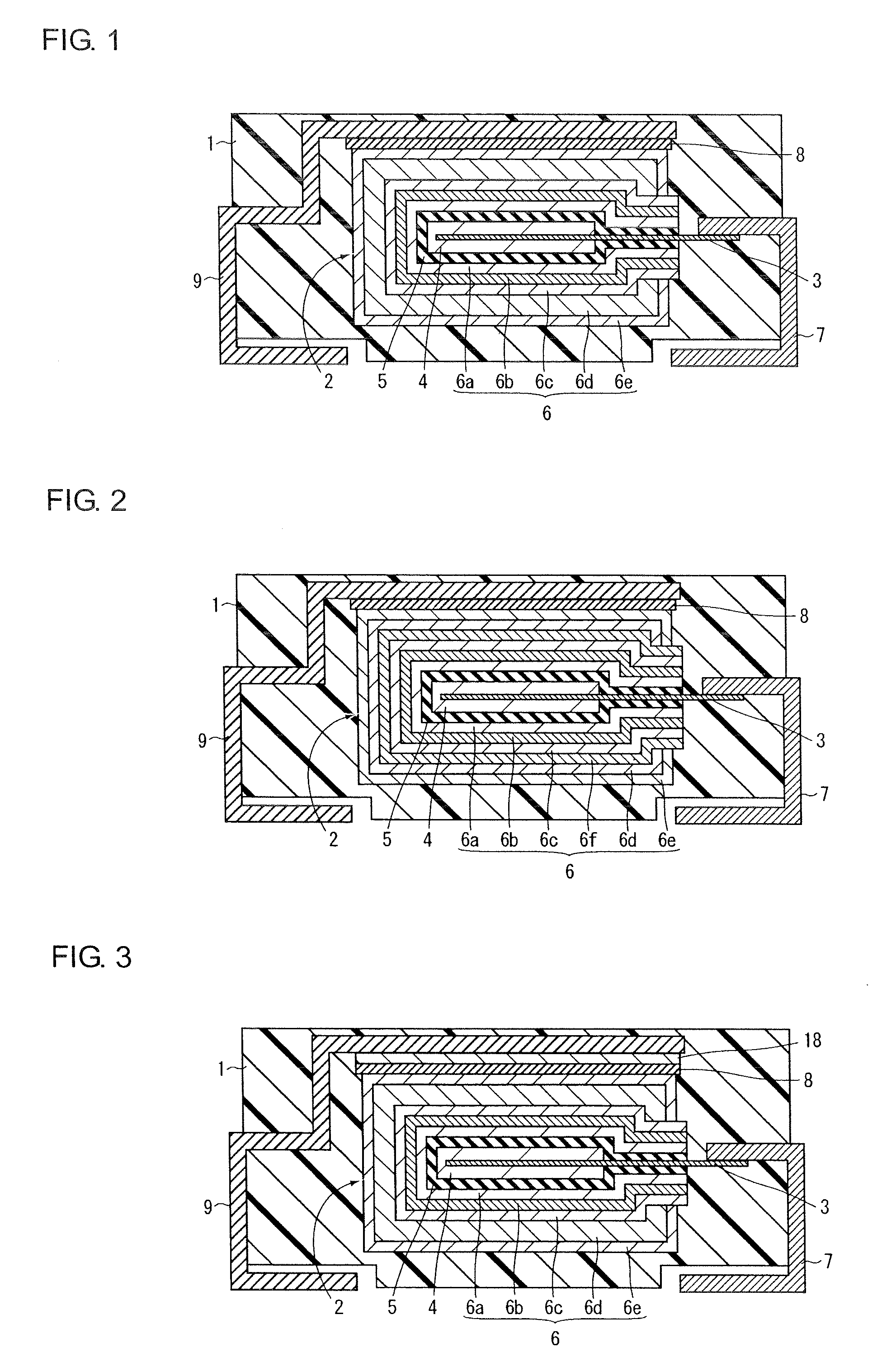

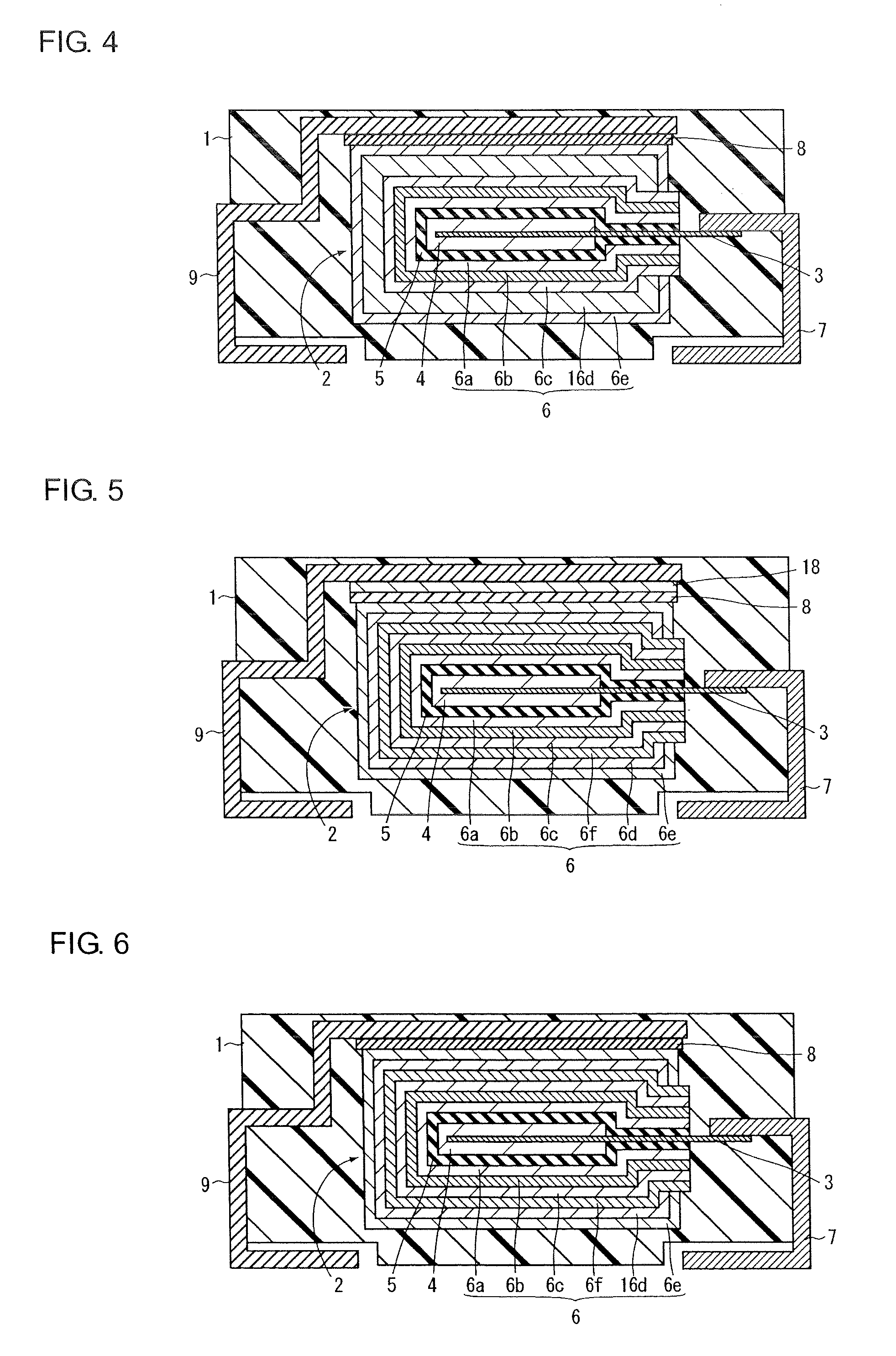

Method of manufacturing electrolytic capacitor and electrolytic capacitor

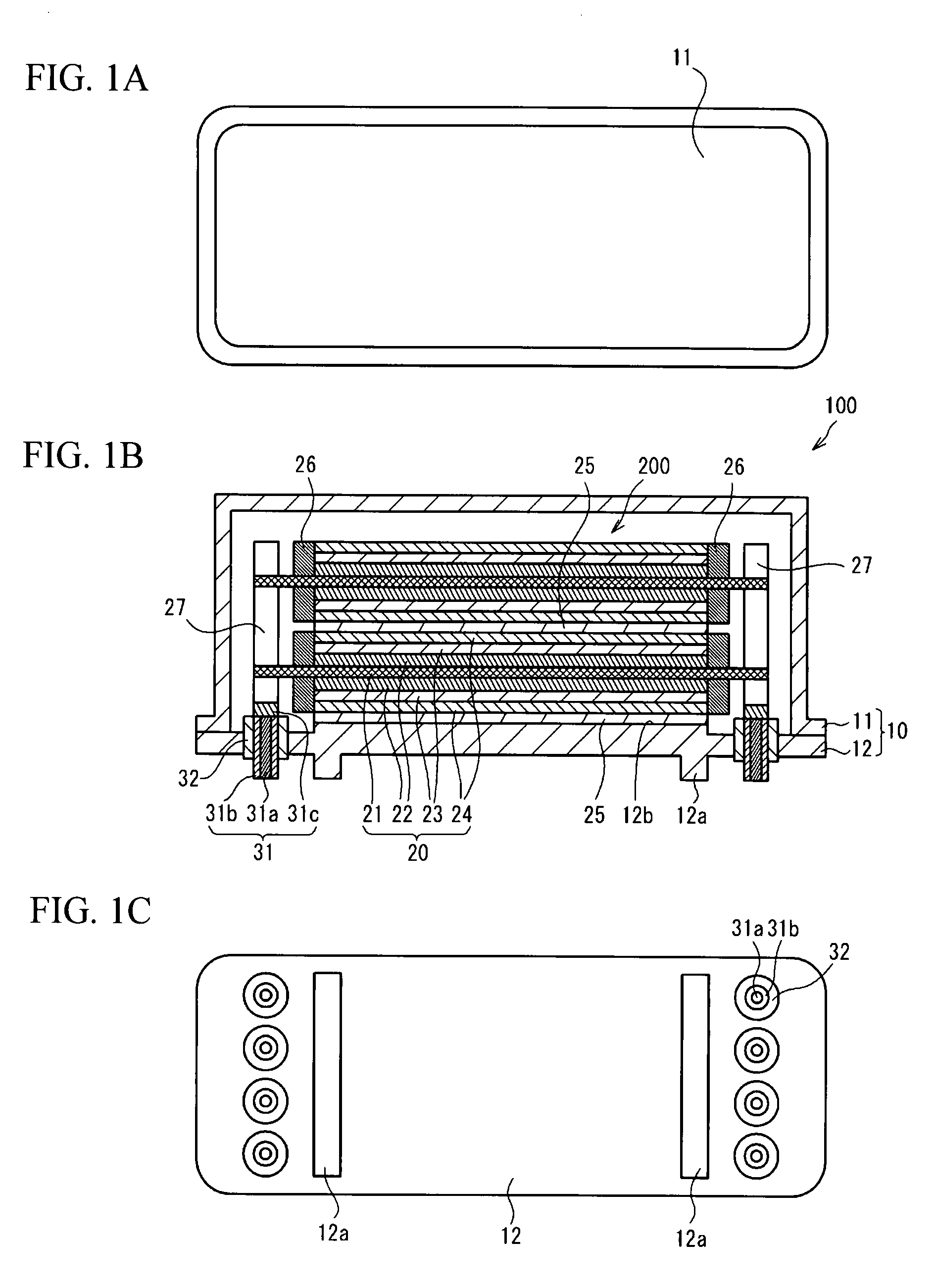

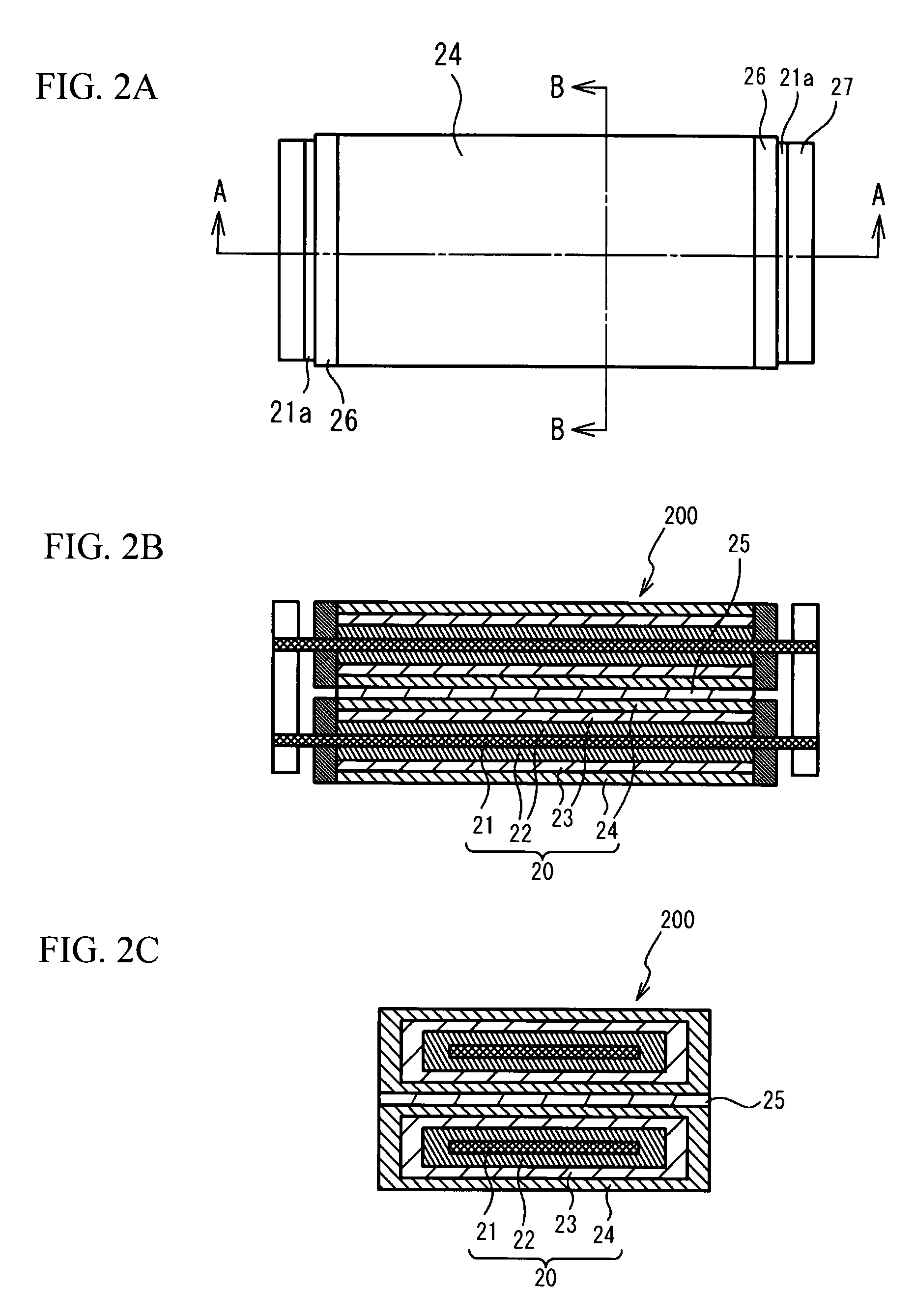

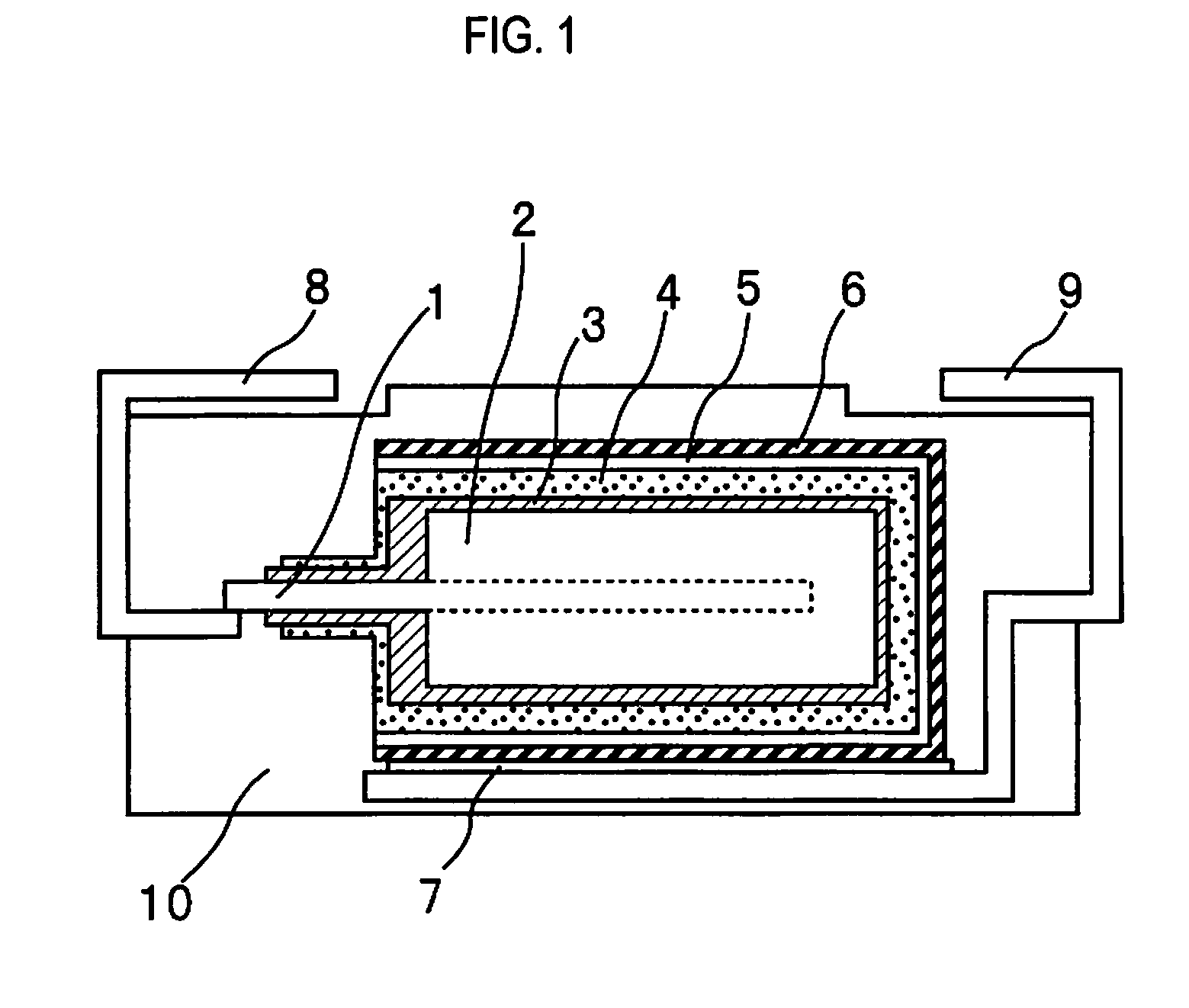

ActiveUS7497879B2Improve pressure resistanceSmall currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

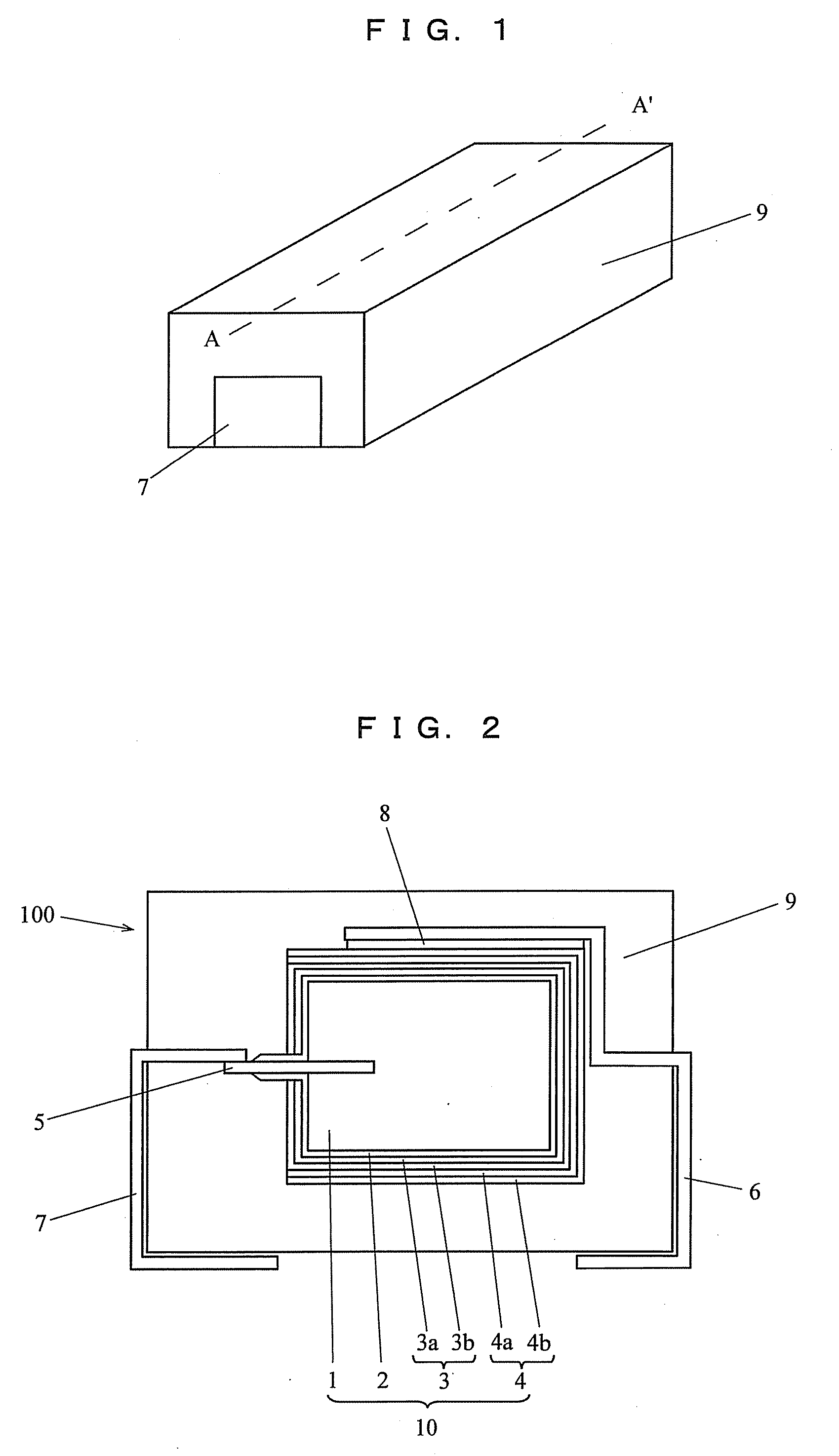

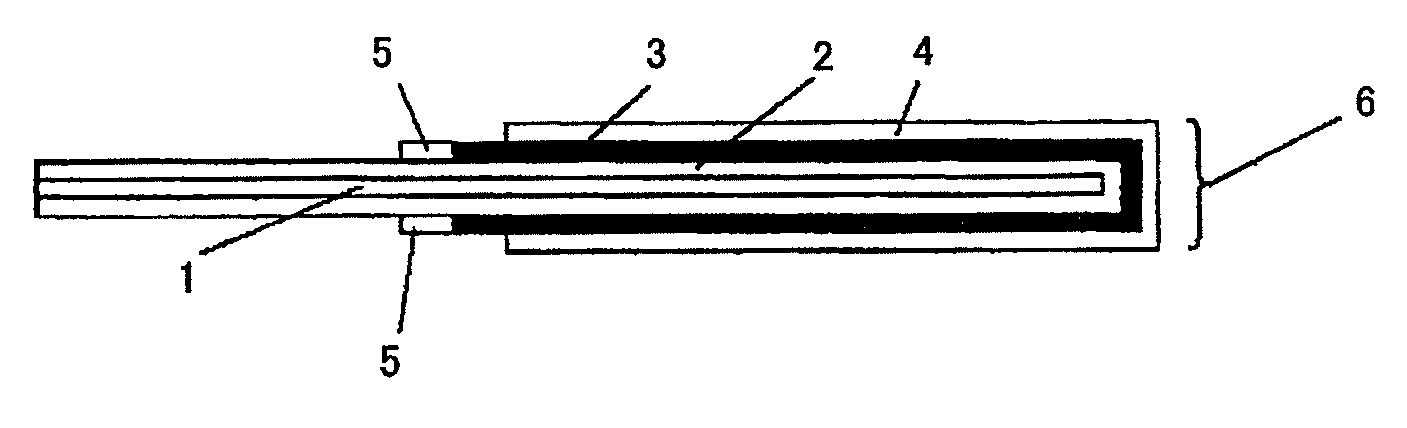

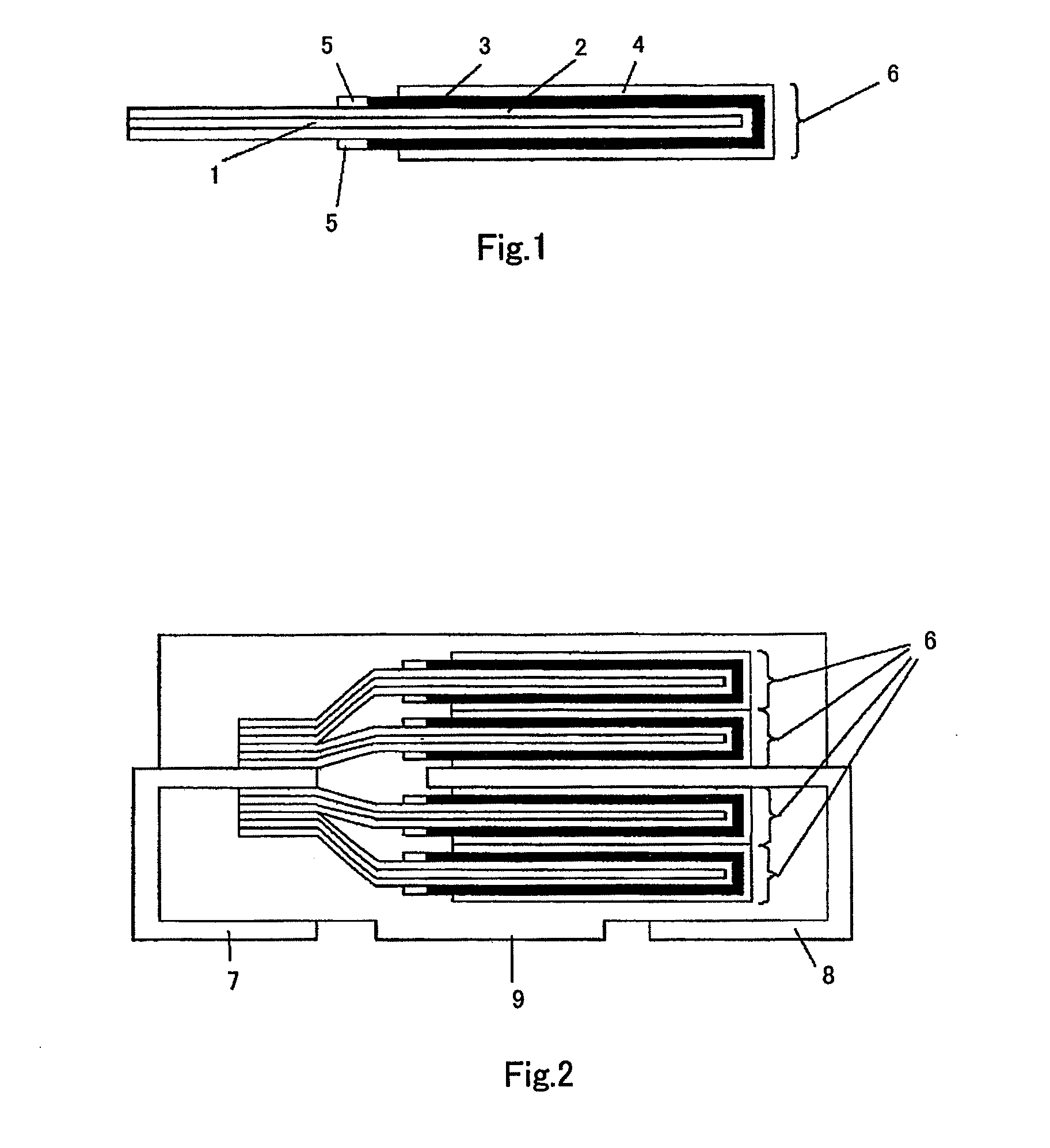

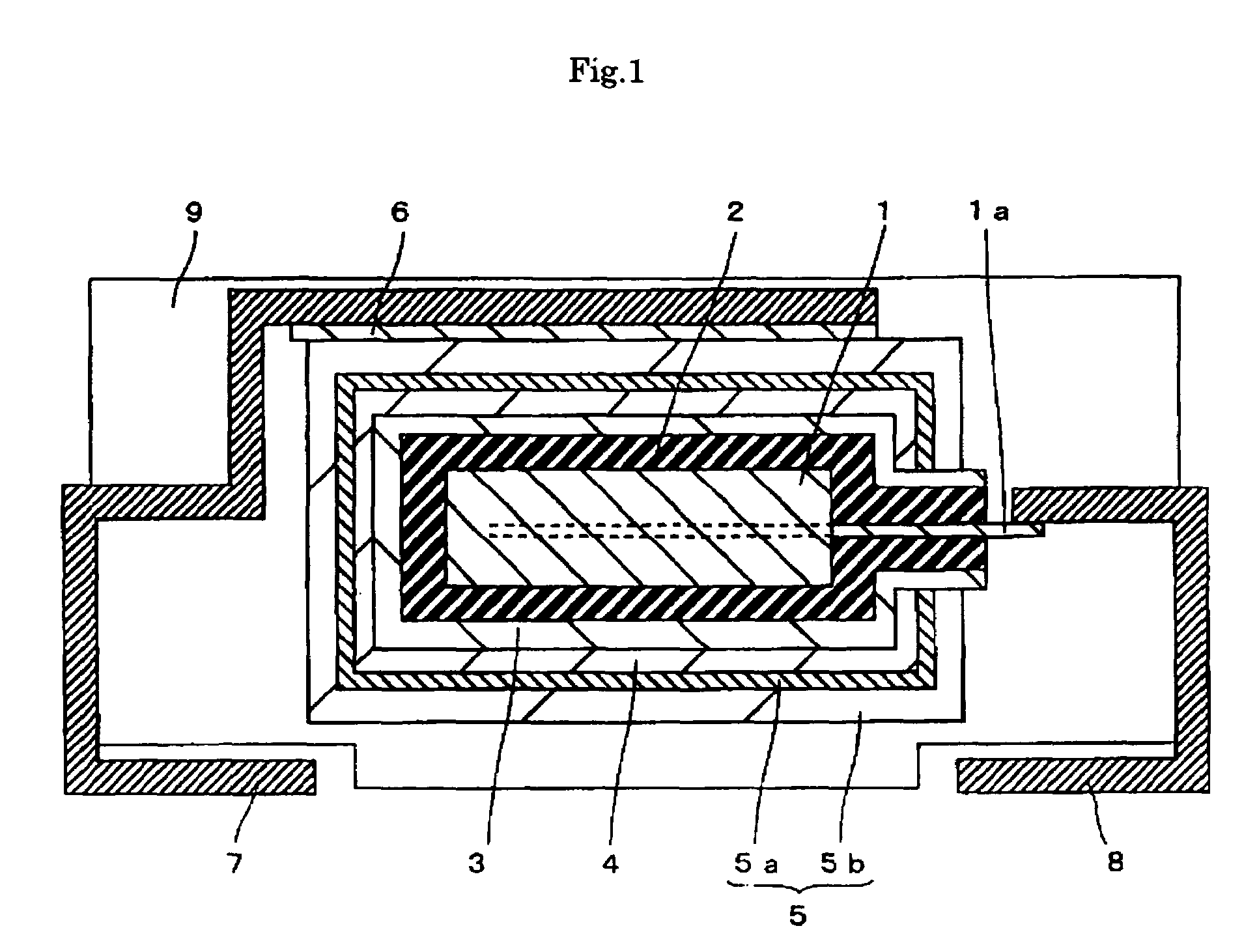

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

Method of manufacturing electrolytic capacitor and electrolytic capacitor

ActiveUS20080002334A1Improve pressure resistanceSolve the large leakage currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

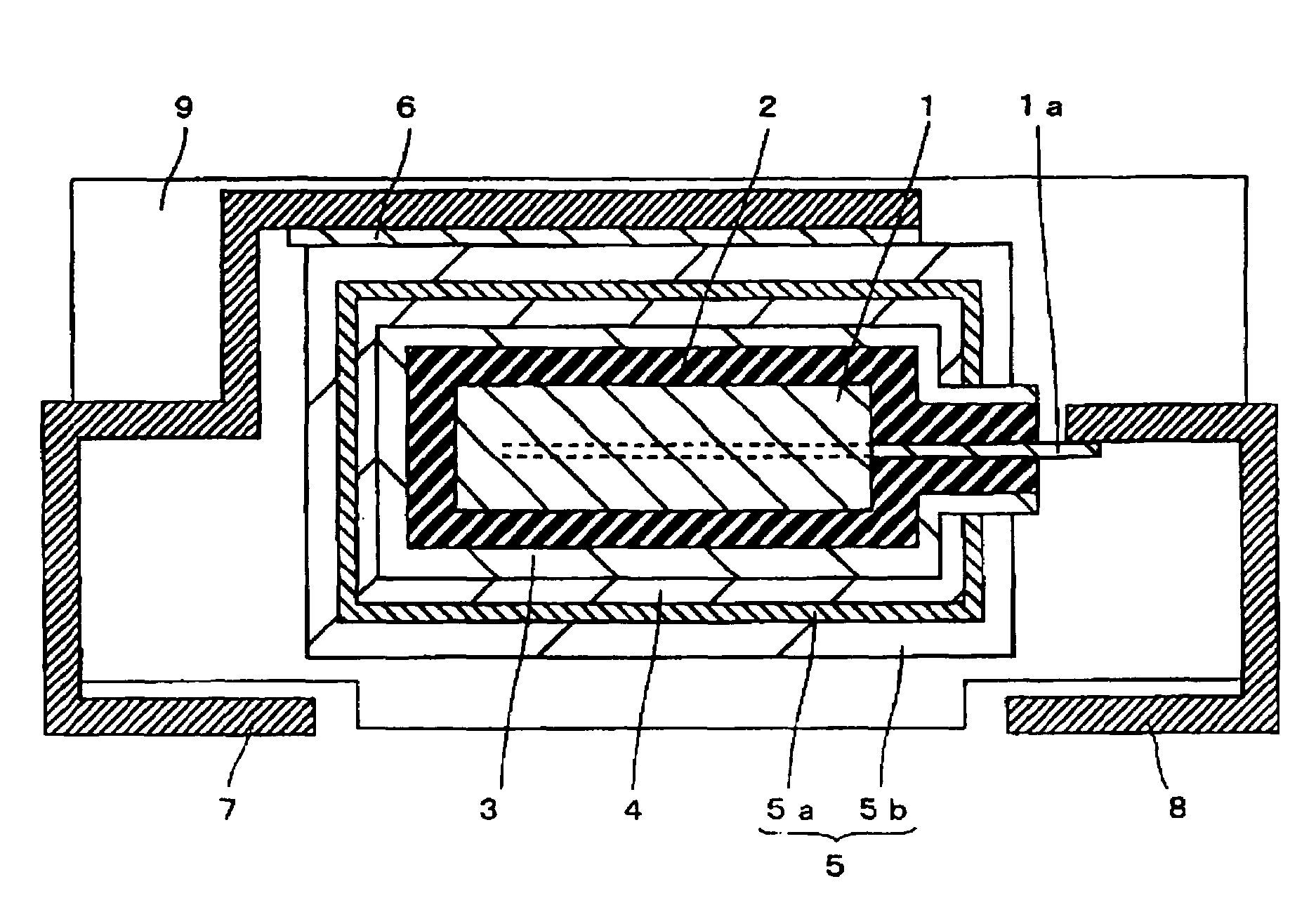

Solid electrolytic capacitor

InactiveUS7688571B2Lower ESRReduce humiditySolid electrolytic capacitorsLiquid electrolytic capacitorsThermal expansionElectrolytic capacitor

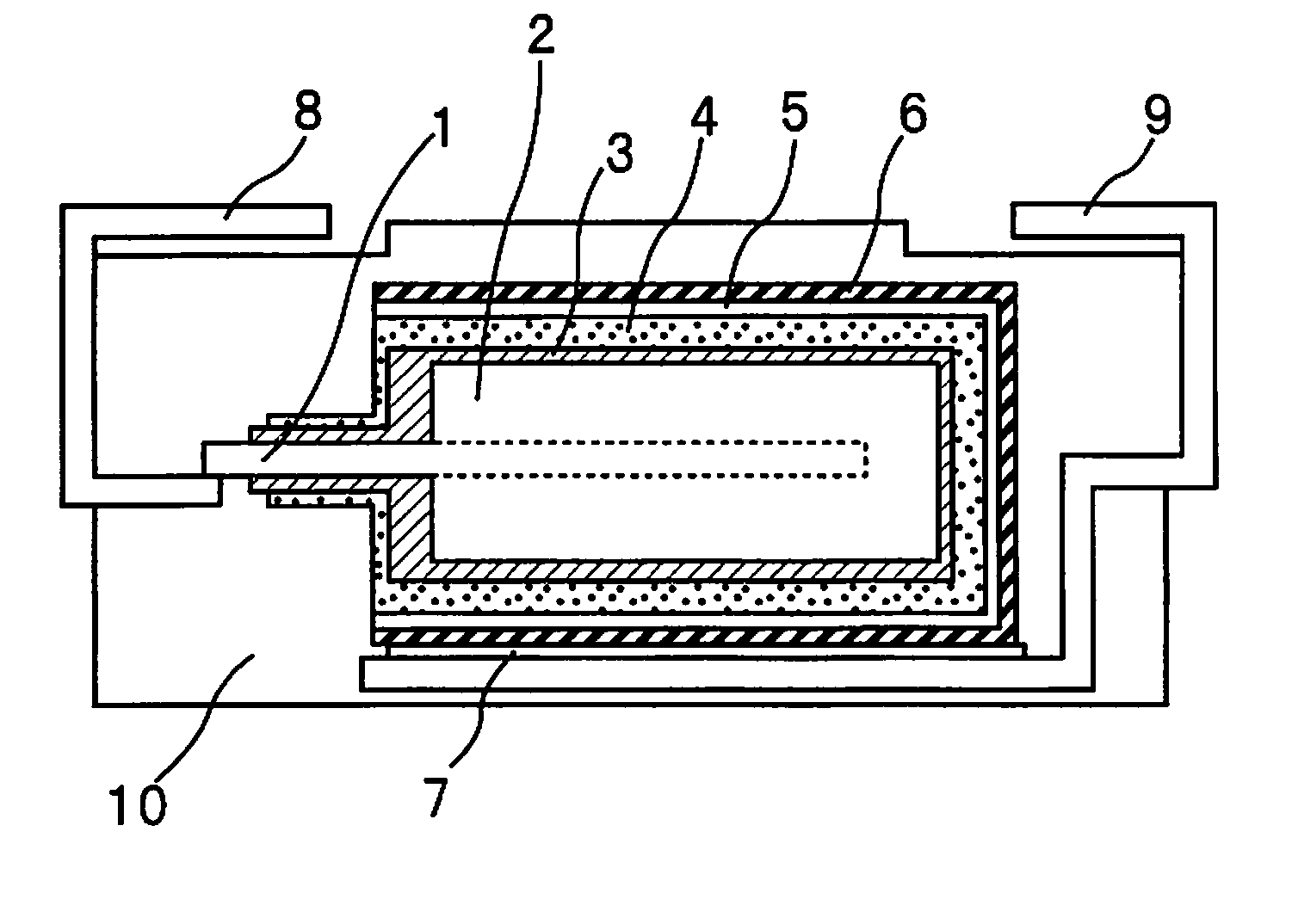

A solid electrolytic capacitor includes a base substrate, a capacitor element, a metal cap, an extractor terminal and an insulating member. The base substrate has electrical conductivity. The capacitor element is provided on the base substrate. The metal cap is coupled to the base substrate and covers the capacitor element. The extractor terminal passes through the base substrate, is coupled to an anode of the capacitor element, and includes a first conductive member acting as a core member and a second conductive member covering the first conductive member. The insulating member is provided between the base substrate and the extractor terminal. Electrical conductivity of the first conductive member is higher than that of the second conductive member. Thermal expansion coefficient of the second conductive member is less than that of the insulating member.

Owner:NICHICON CORP

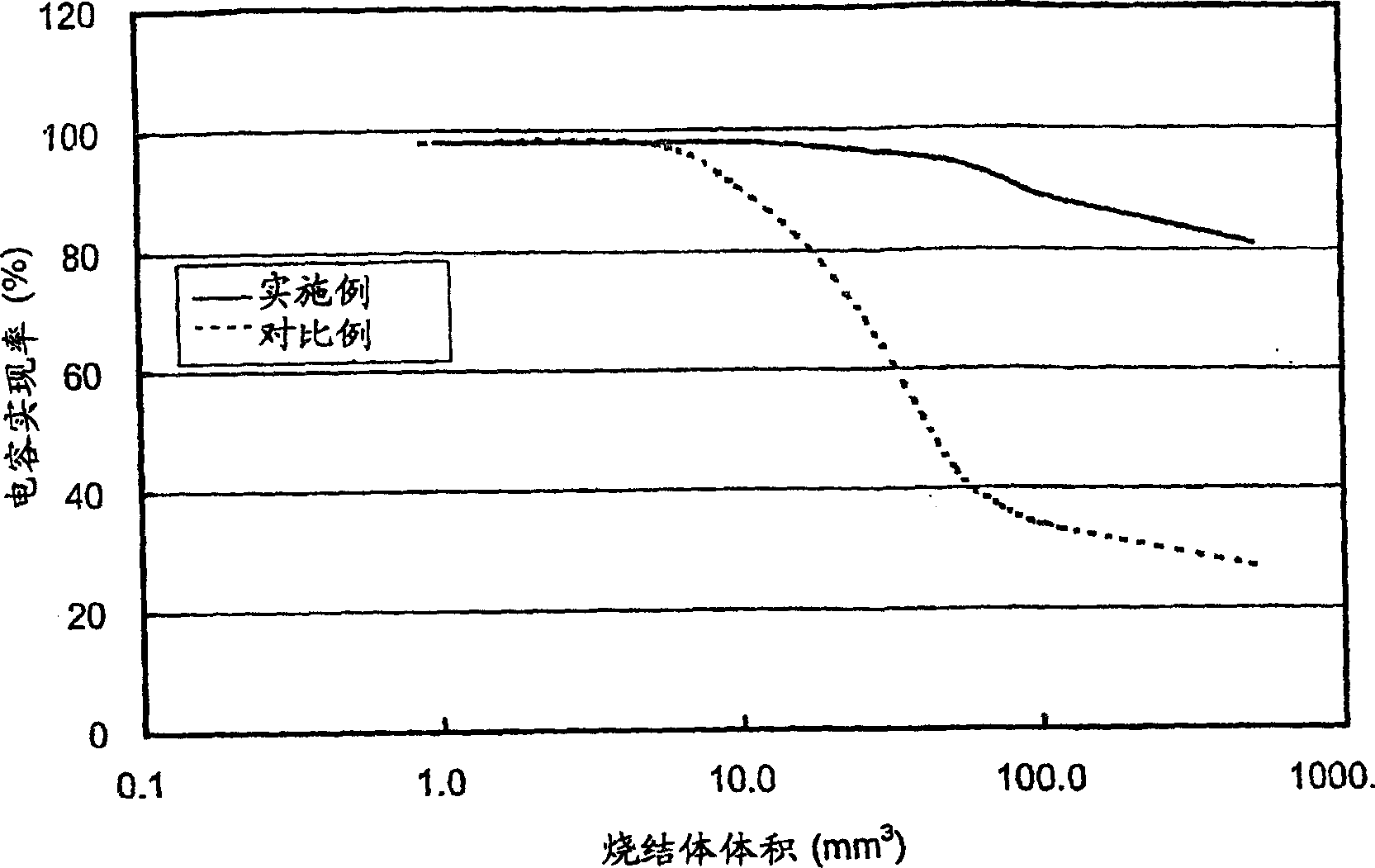

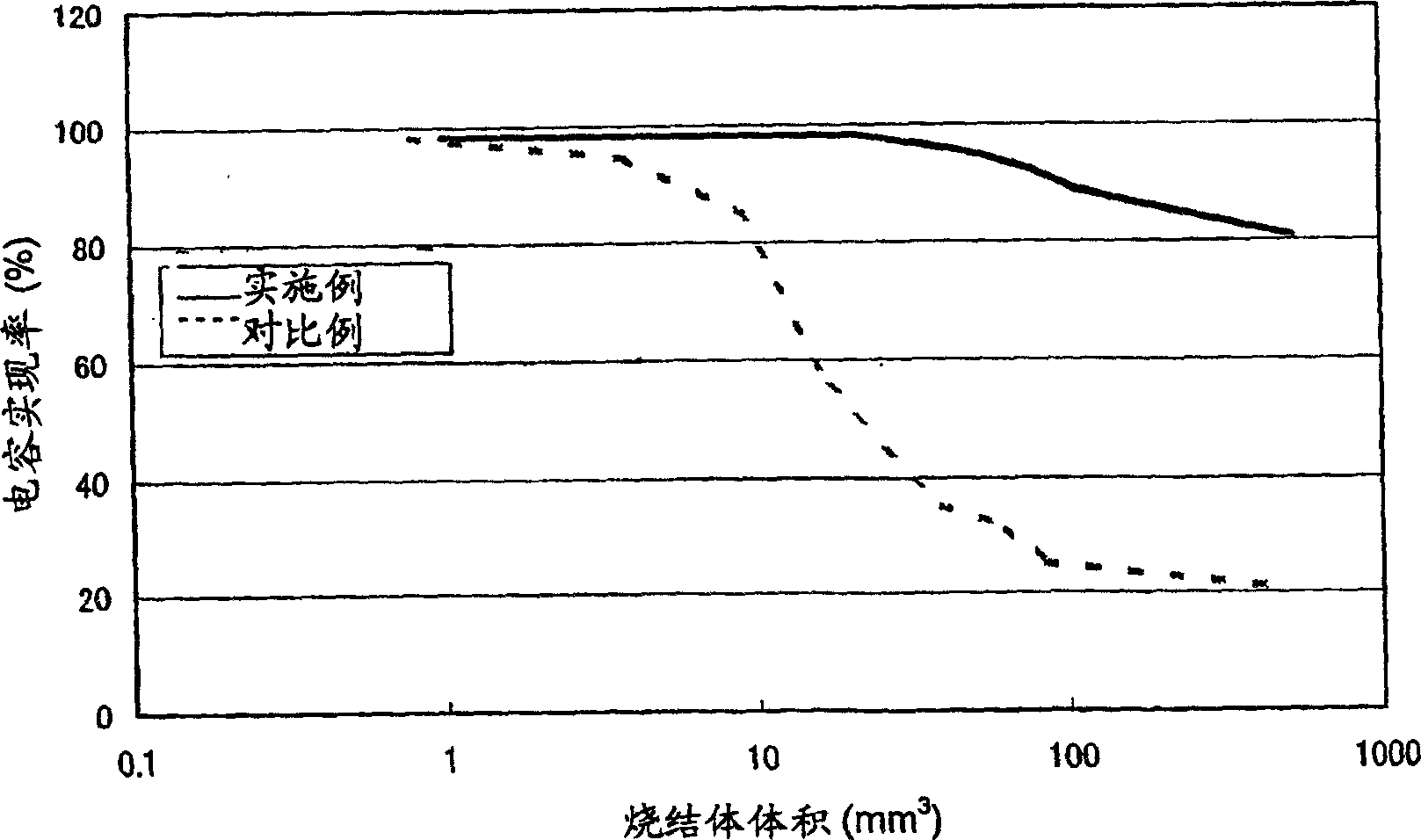

Valve acting metal sintered body, production method therefor and solid electrolytic capacitor

InactiveCN1813323AIncrease capacitanceImprove impregnation rateSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceElectrolysis

The invention provides a valve-acting metal sintered body for anode of a solid electrolytic capacitor, having a high capacitance, well impregnated with cathode material, and exhibiting excellent properties particularly when having a large volume, a capacitor having a low ESR, an excellent tan delta value and good long-term reliability such as moisture resistance and heat resistance by using the sintered body, and a production method therefor comprising the following steps: coating / printing / shaping a granulated product of a mixed dispersion containing a pore-forming agent, an organic binder and a primary powder or secondary aggregated powder of at least one member selected from valve-acting metal, a valve-acting metal compound and a valve-acting metal alloy or a granulated powder thereof, and a solvent, or compressing and shaping the granulated product of a mixture obtained by removing the solvent from the dispersion; sintering the shaped article containing a pore-forming agent; and removing the pore-forming agent from the sintered body.

Owner:RESONAC HOLDINGS CORPORATION

Solid electrolytic capacitor and method for producing the same

ActiveUS7800887B2Improve adhesionReduce contact resistanceHybrid capacitor electrolytesHybrid capacitor electrodesEpoxyElectrolysis

A solid electrolytic capacitor, having a small equivalent series resistance, is formed by burying a capacitor element inside an epoxy resin outer package. The capacitor element includes an anode, having part of an anode lead buried therein, a dielectric layer formed on the anode and containing a niobium oxide, and a cathode formed on the dielectric layer. The cathode includes a first electrolyte layer containing a conductive polymer and formed on the dielectric layer, an intermediate layer containing an organic silane and formed on the first electrolyte layer, a second electrolyte layer containing a conductive polymer and formed on the intermediate layer, a first conductive layer containing carbon particles and formed on the second electrolyte layer, and a second conductive layer containing silver particles and formed on the first conductive layer.

Owner:SANYO ELECTRIC CO LTD

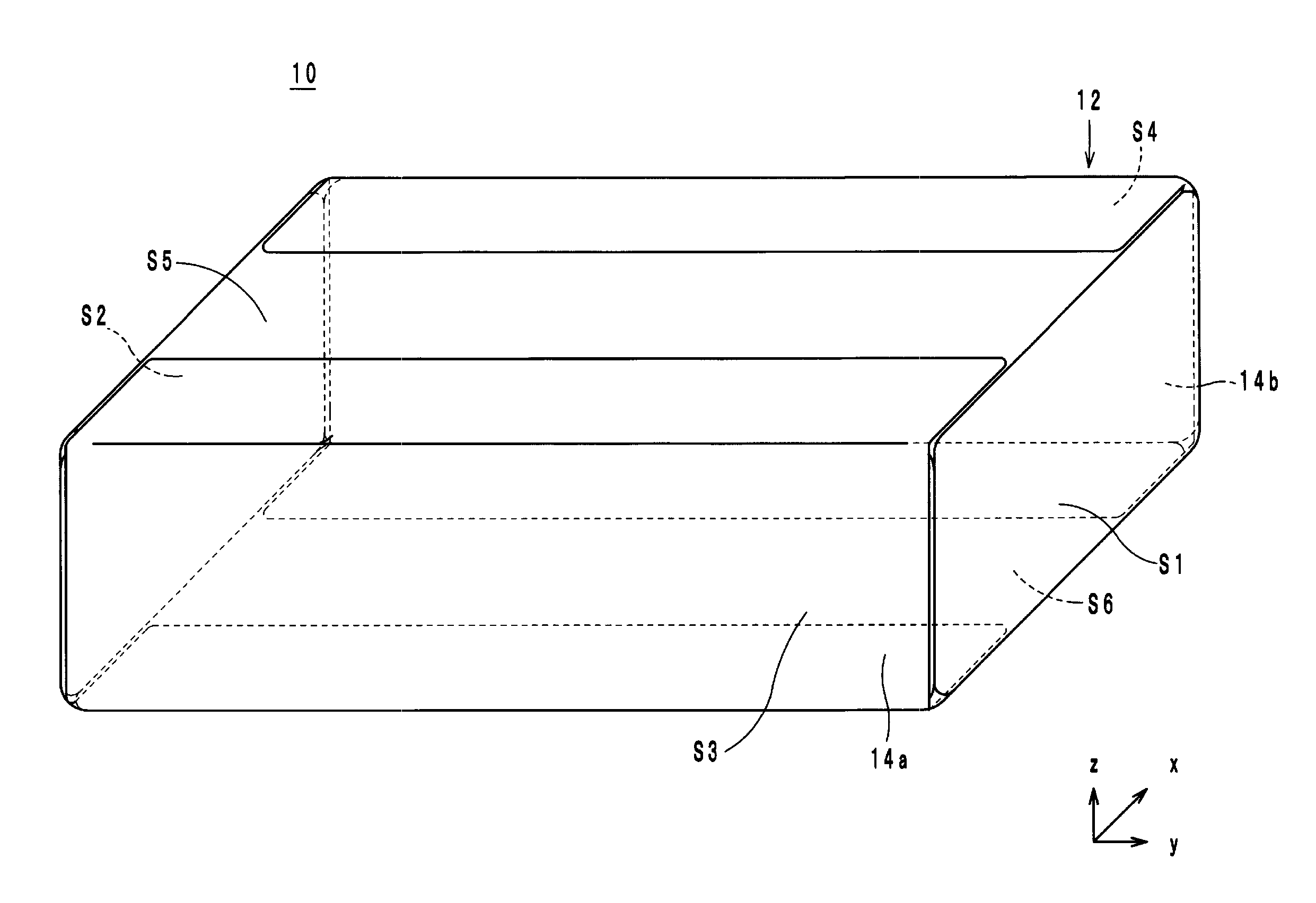

Multilayer ceramic electronic component

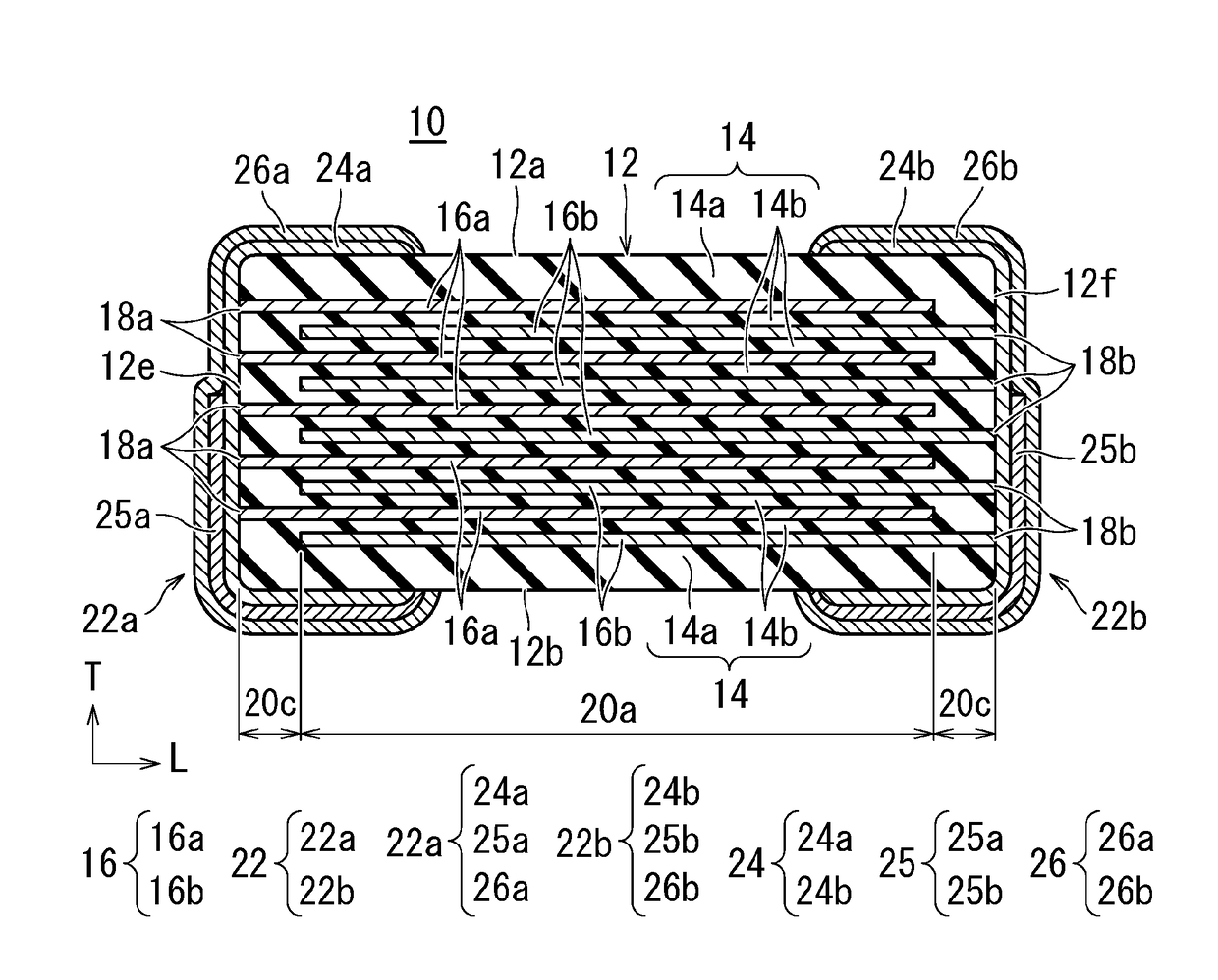

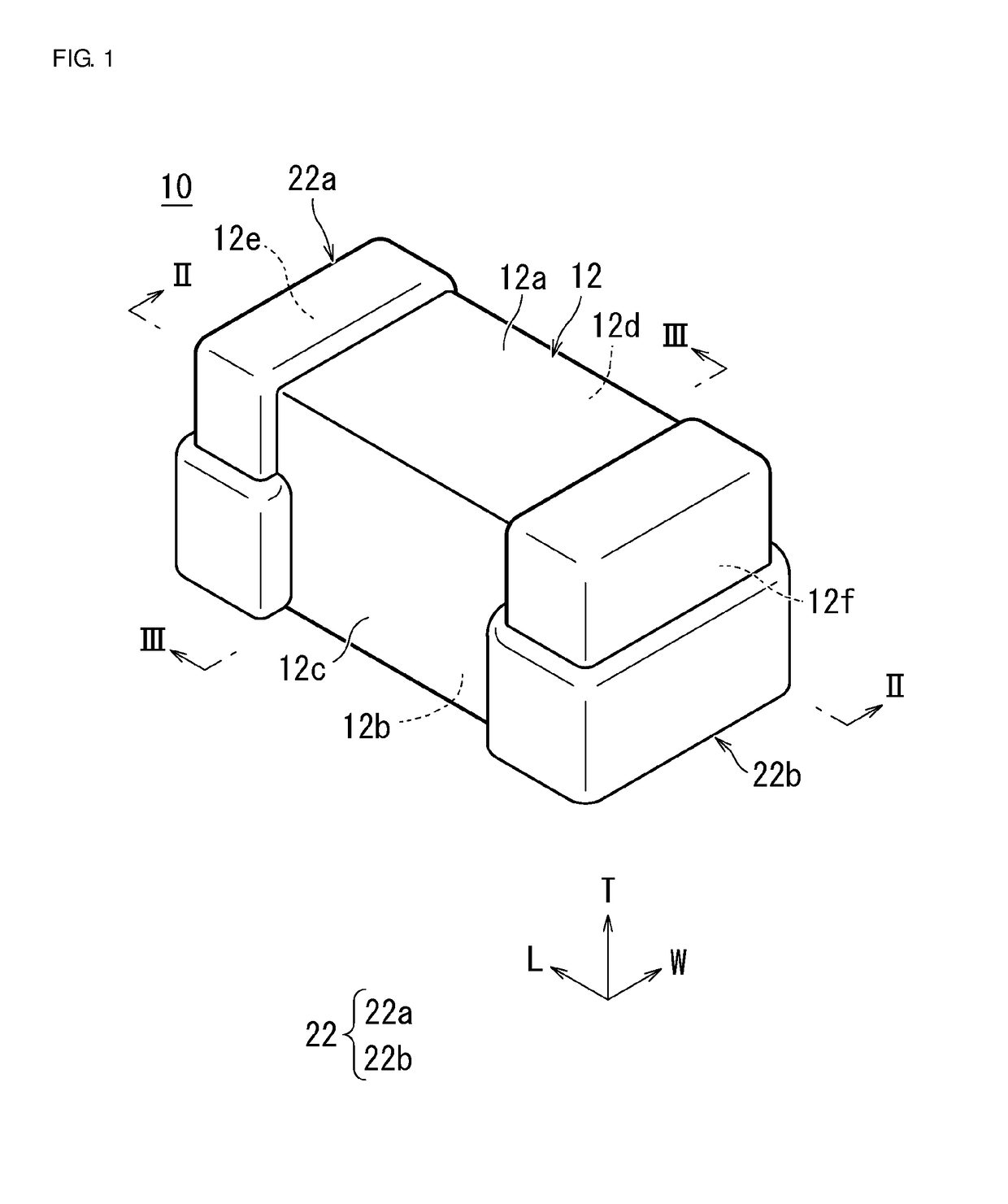

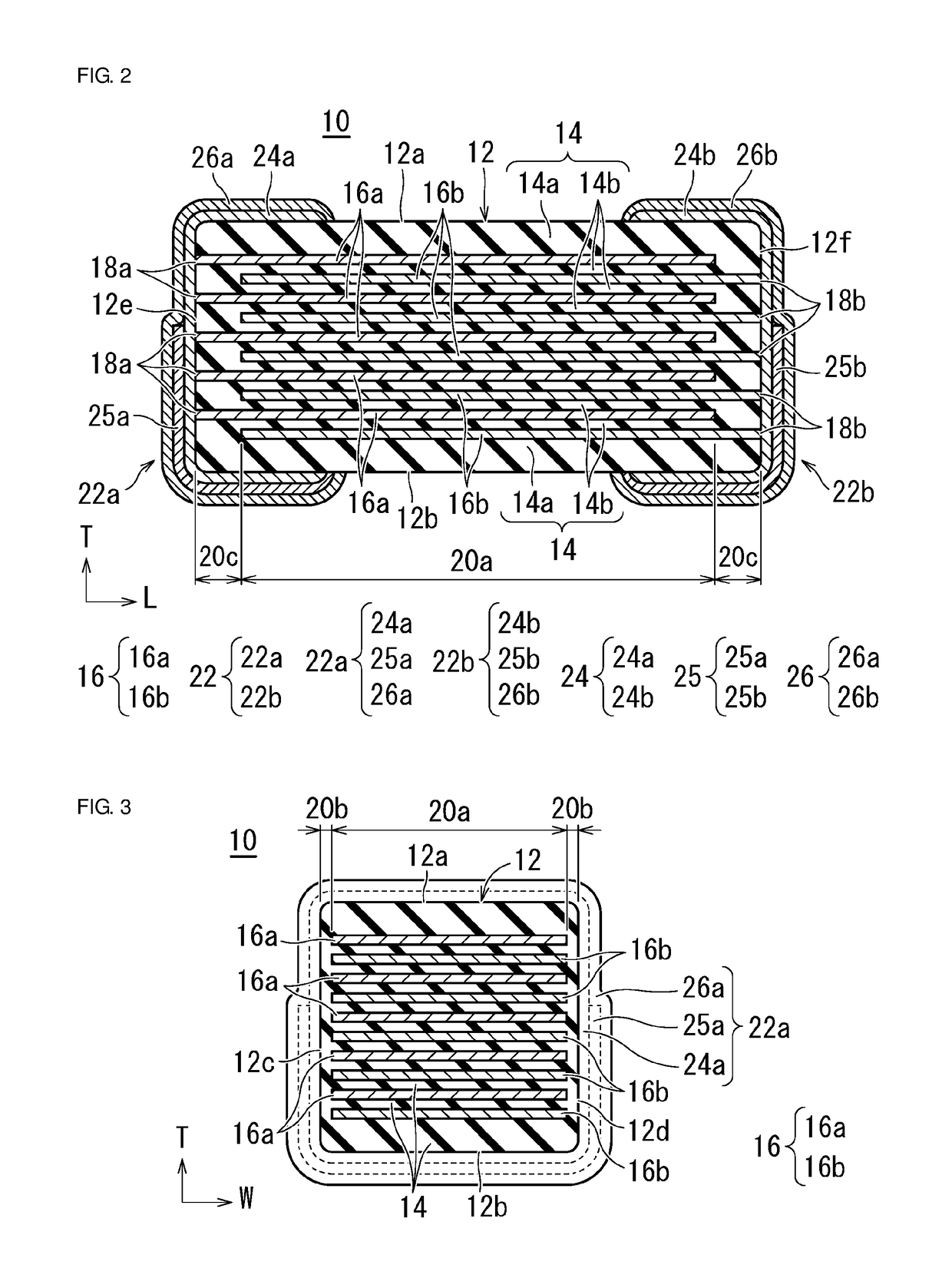

ActiveUS20180151296A1Easy to installImprove wettabilityFixed capacitor electrodesFixed capacitor dielectricElectronic componentMetal

A multilayer ceramic electronic component includes a multilayer body that includes a second main surface defining and functioning as a mounting surface. Outer electrodes include underlying electrode layers including a conductive metal and a glass component and conductive resin layers including a thermosetting resin and a metal component. The underlying electrode layers extend from first and second end surfaces onto at least the second main surface. The conductive resin layers extend onto the underlying electrode layers provided on the second main surface, portions of the second main surface, and portions of the underlying electrode layers provided on the first end surface and the second end surface and cover portions of the first and second end surfaces, the portions including areas corresponding to about 9% or more and about 82% or less of areas of the first and the second end surfaces.

Owner:MURATA MFG CO LTD

Method for manufacturing solid electrolytic capacitor

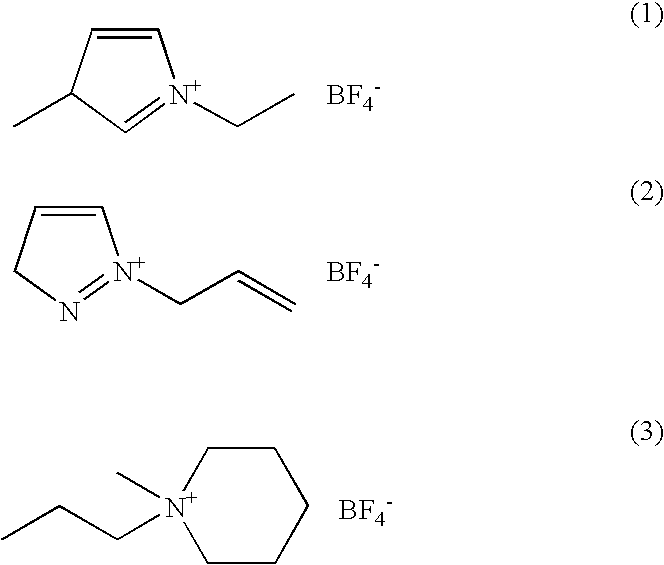

InactiveUS20090242415A1Increase capacitanceLower ESRAnodisationCapacitor electrolytes/absorbentsElectrolysisConductive polymer

A method for manufacturing a solid electrolytic capacitor having a capacitor element produced by the steps of: forming a dielectric coating layer on the surface of an anode body, forming a conductive polymer cathode layer on the dielectric coating layer, and forming a cathode lead-out layer on the conductive polymer cathode layer, wherein the step of forming the conductive polymer cathode layer includes an electrolytic polymerization step of forming the conductive polymer cathode layer on the surface of the anode body on which the dielectric coating layer is formed by electrolytic polymerization using an electrolytic polymerization solution containing at least a monomer to be polymerized into the conductive polymer and an ionic liquid.

Owner:SANYO ELECTRIC CO LTD +1

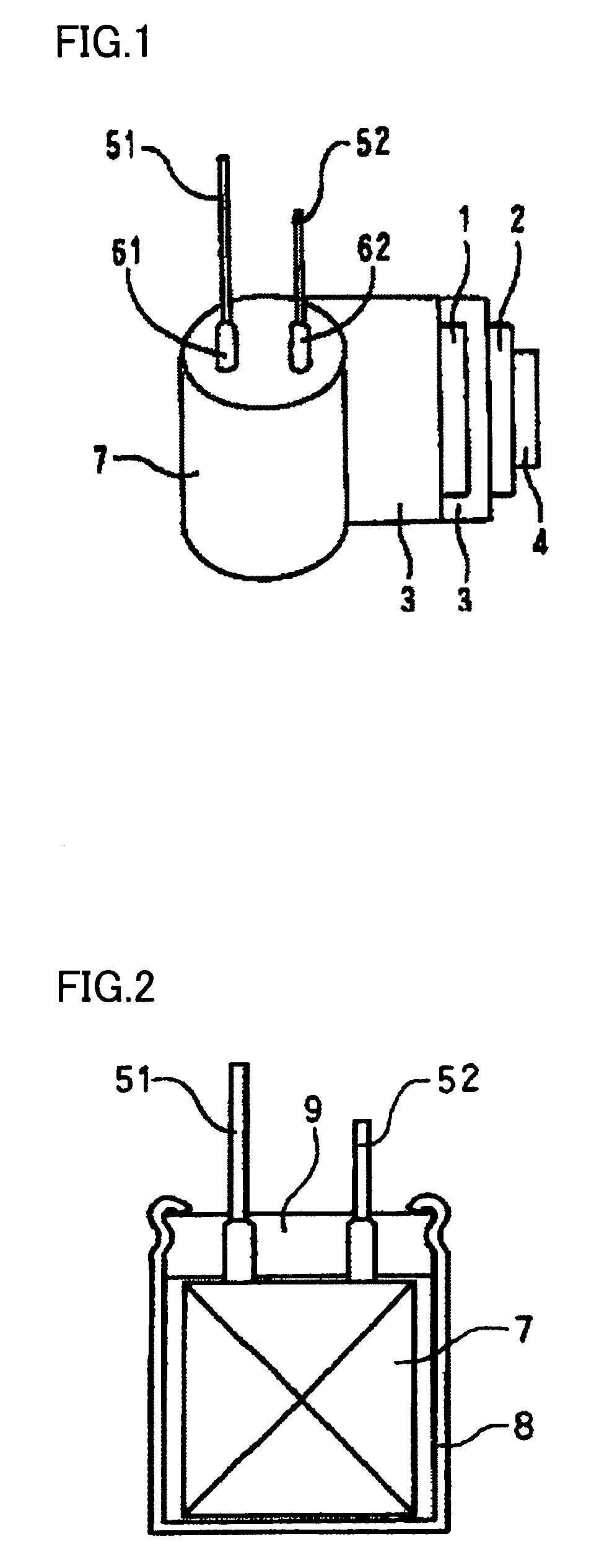

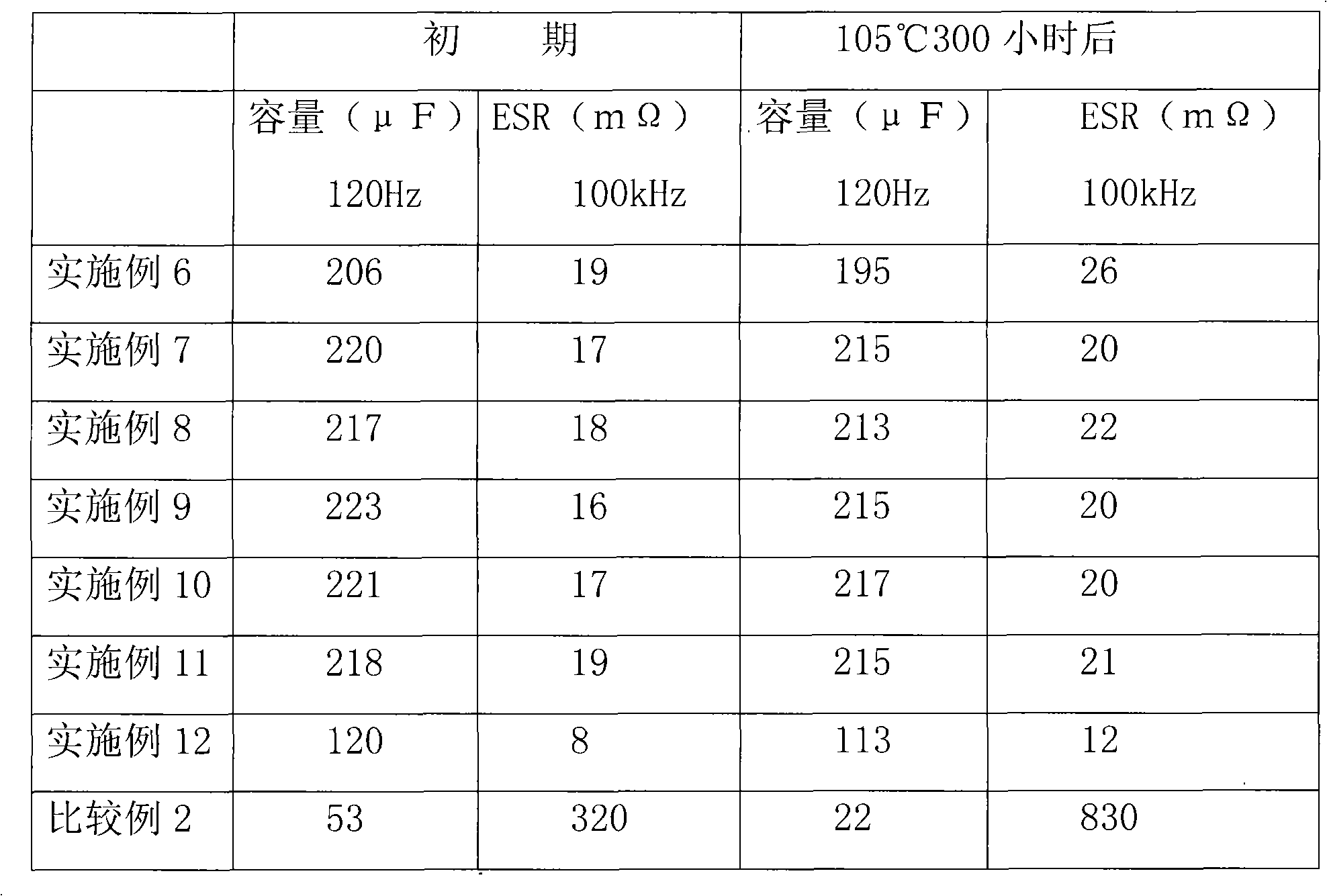

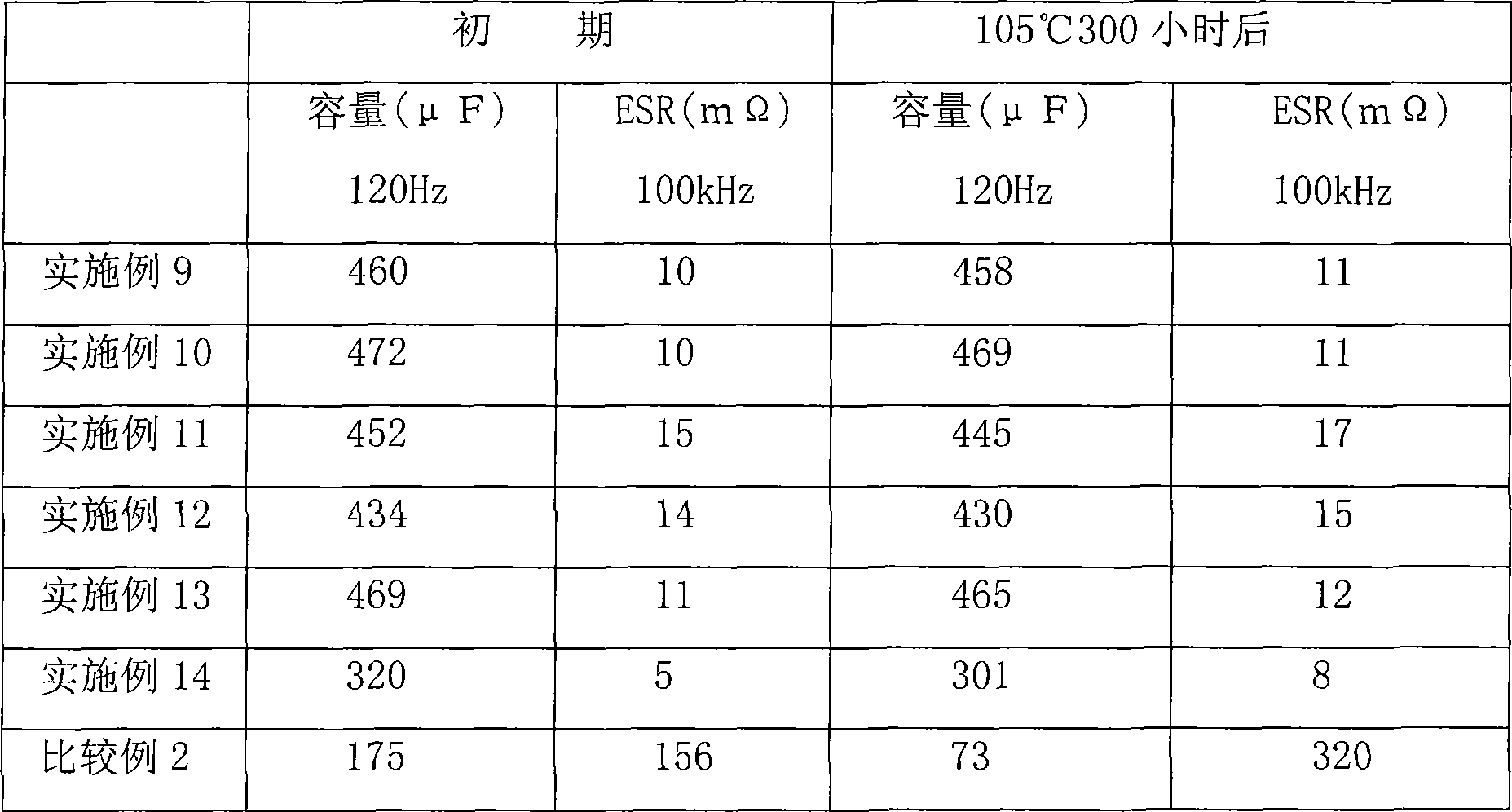

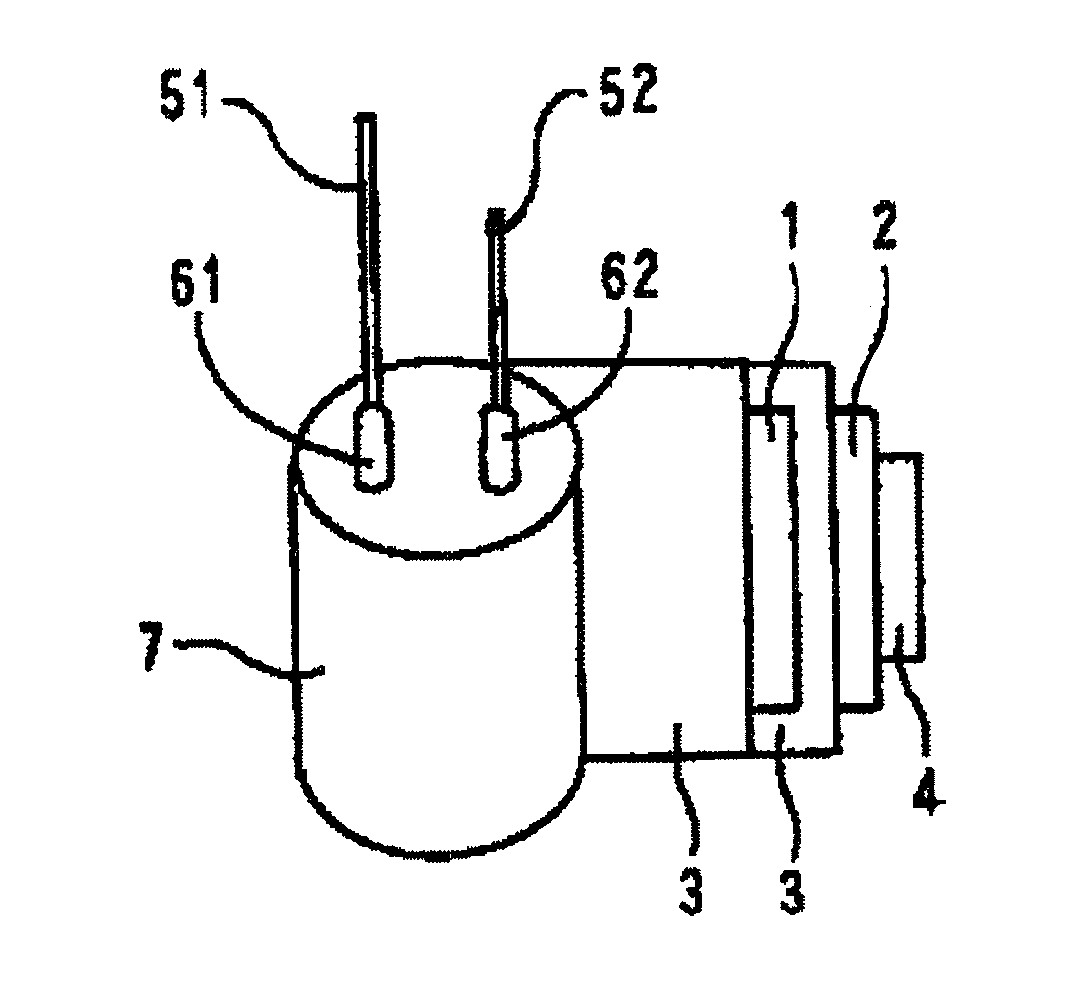

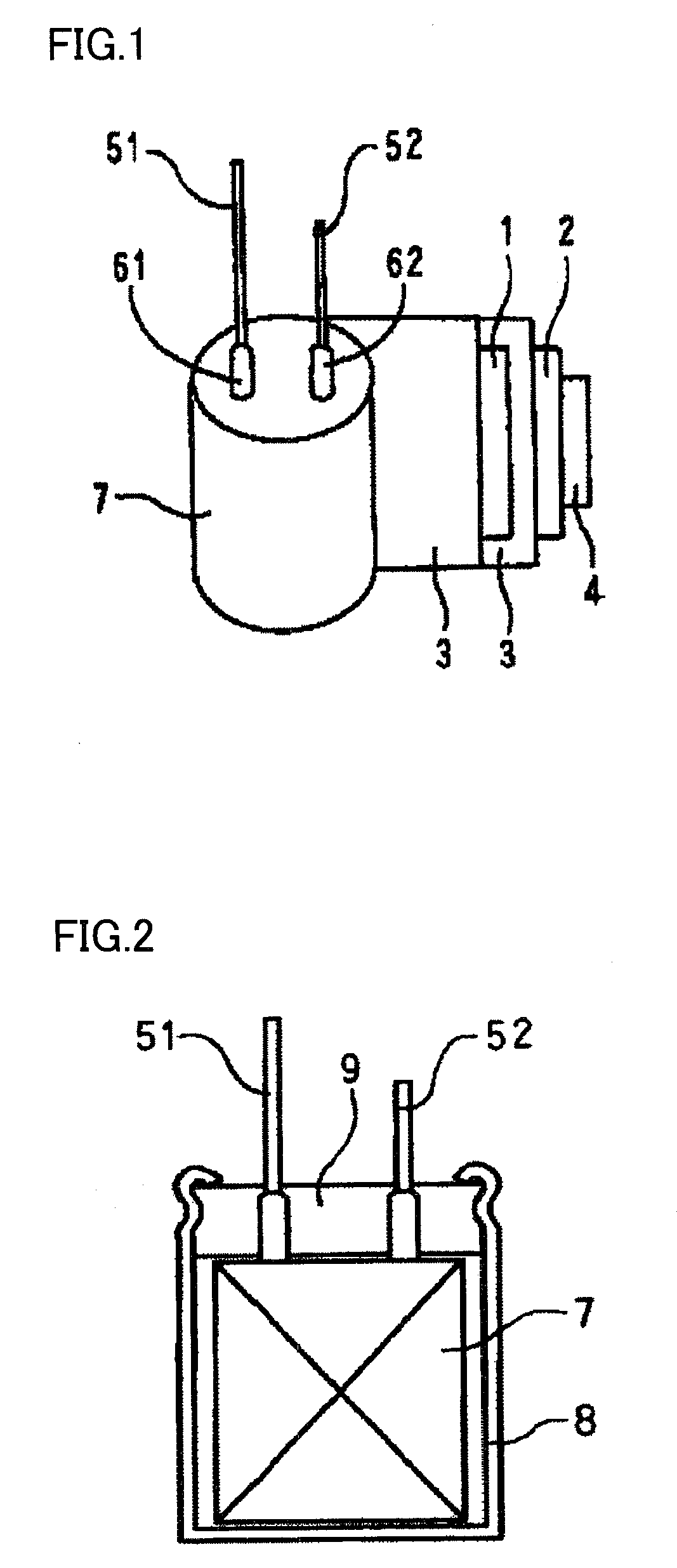

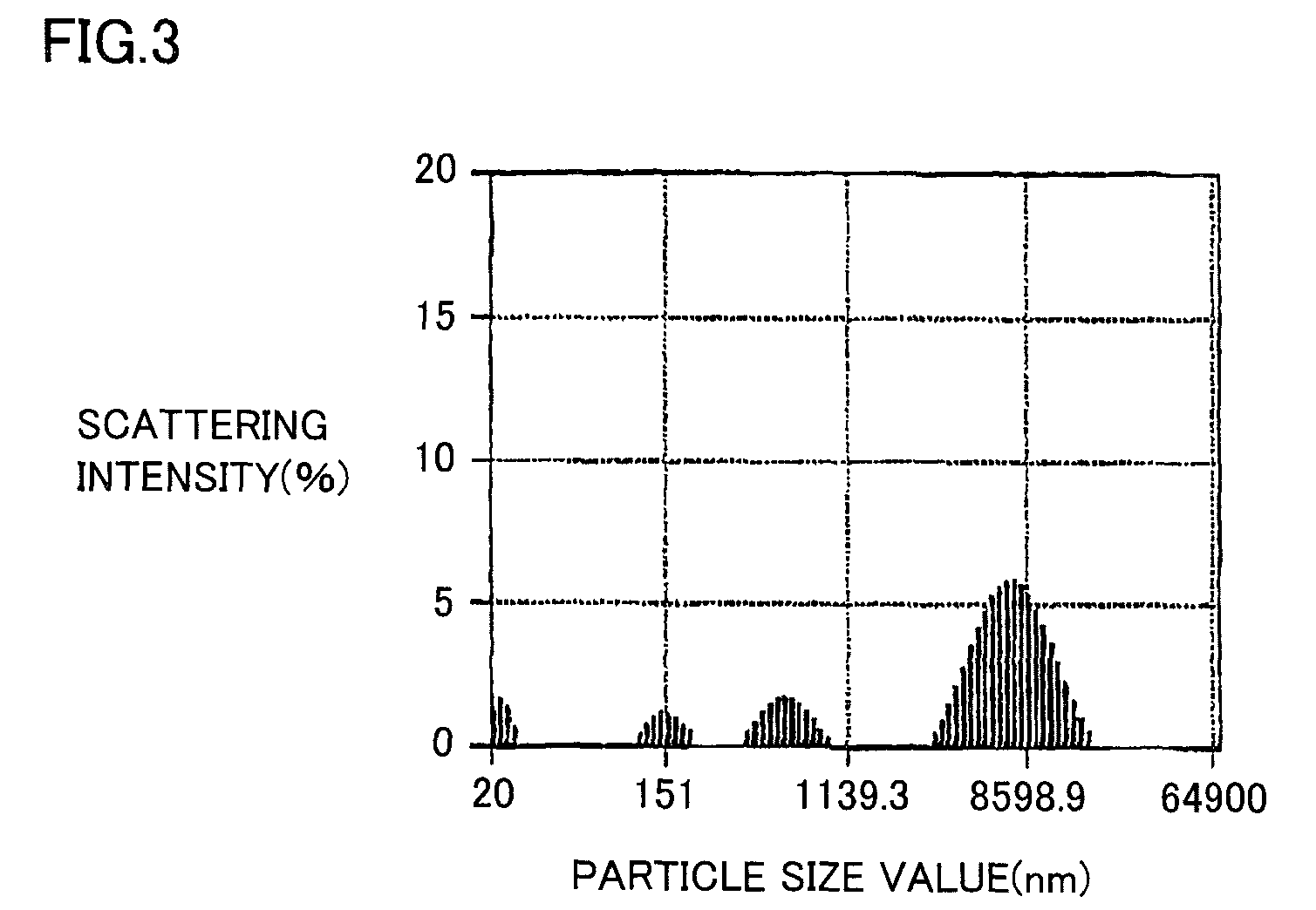

Electrolytic capacitor and method of producing the same

ActiveUS20080247119A1Improve pressure resistanceReduce leakage currentClosuresLiquid electrolytic capacitorsElectrolysisLow leakage

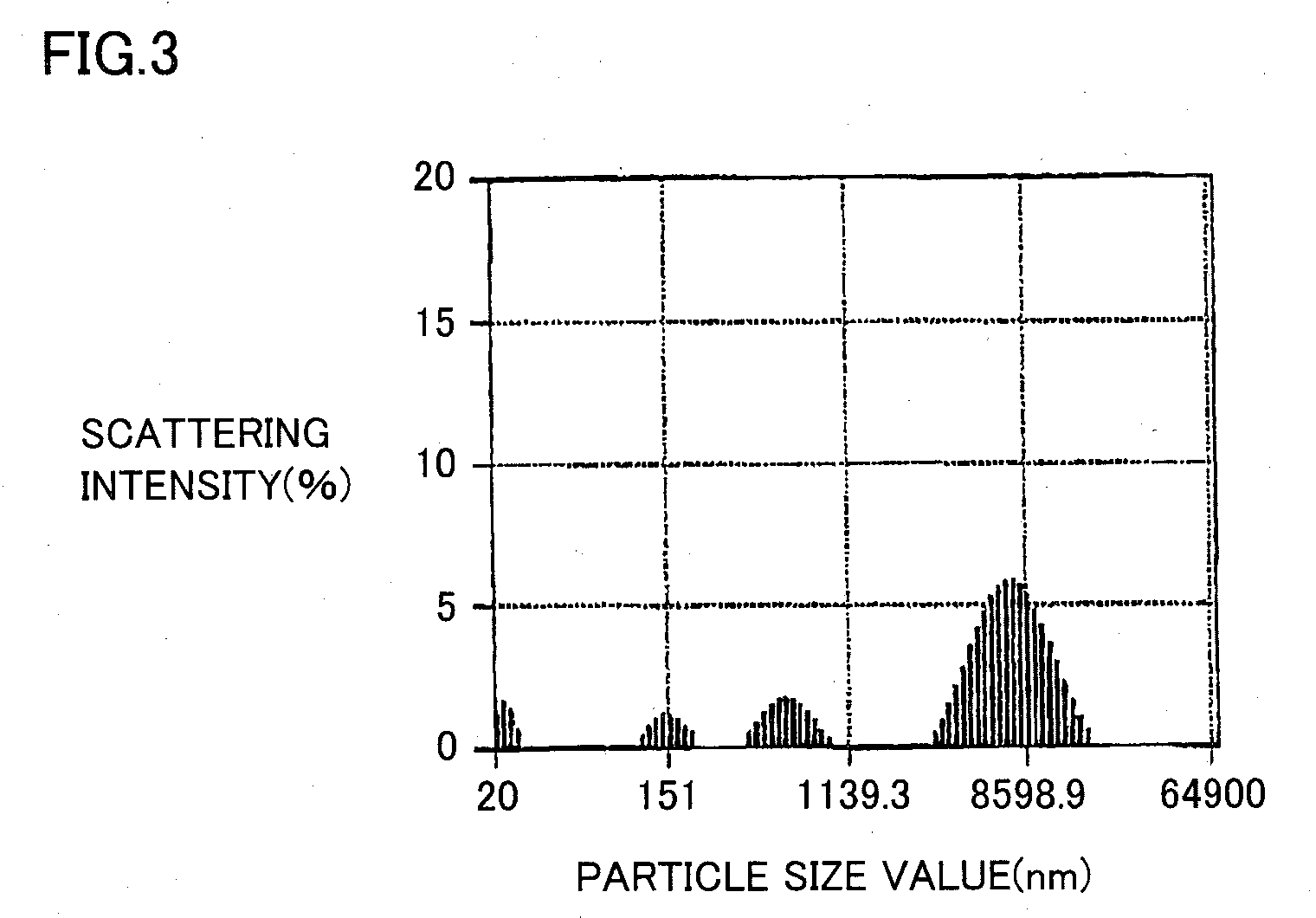

An electrolytic capacitor includes a cathode body. The cathode body includes a conductive solid layer having particles of conductive solid, formed using a dispersion including particles of conductive solid and a solvent. The particles of the conductive solid in the dispersion have a first particle size distribution peak and a second particle size distribution peak satisfying μ1>μ2, where μ1 and μ2 are the average particle size of the first and second particle size distribution peaks, respectively, in particle size distribution measurement. Accordingly, there is provided an electrolytic capacitor reduced in ESR, and further having high withstand voltage and low leakage current.

Owner:SANYO ELECTRIC CO LTD +2

Solid electrolytic capacitor and method for manufacturing the same

InactiveUS20100149729A1Lower ESRSolid electrolytic capacitorsLiquid electrolytic capacitorsMetallic materialsPeak value

A solid electrolyte capacitor comprising an anode with a valve action composed of a metal material or a conductive oxide and having a dielectric layer, a solid electrolyte and a conductive layer, formed in this order on the surface thereof, characterized in that said conductive layer comprises conductive powders which have a particle diameter distribution wherein at least two peaks of particle diameter are present, and the minimum peak particle diameter thereof is in the range of larger than 100 nm but not larger than 1 μm. The conductive powder preferably has at least one peak having a particle size 8 to 75 times the minimum peak of particle size. The solid electrolyte capacitor has very low equivalent series resistance (ESR).

Owner:MURATA MFG CO LTD

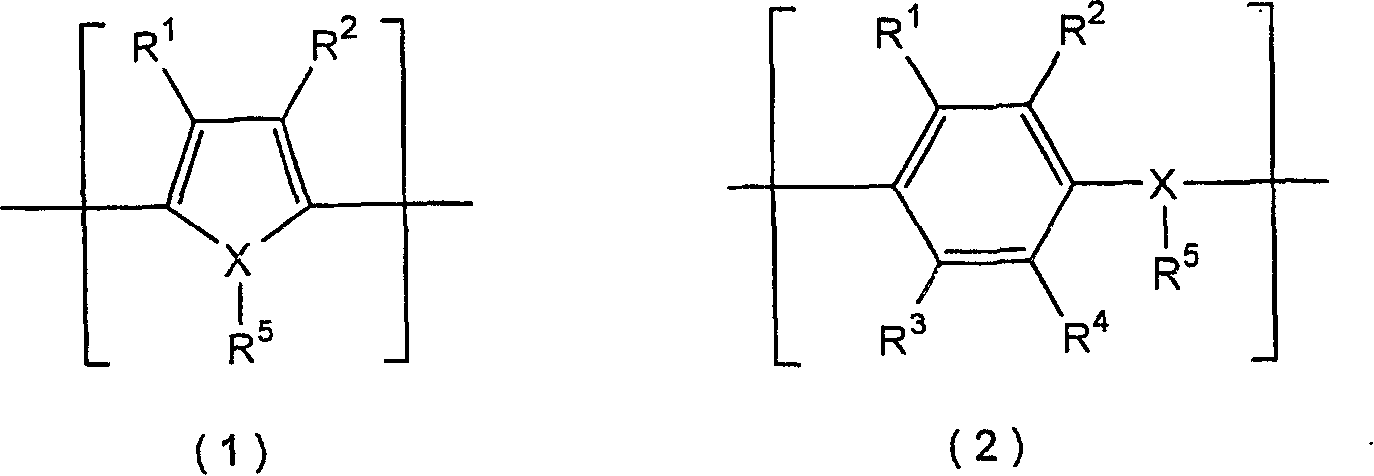

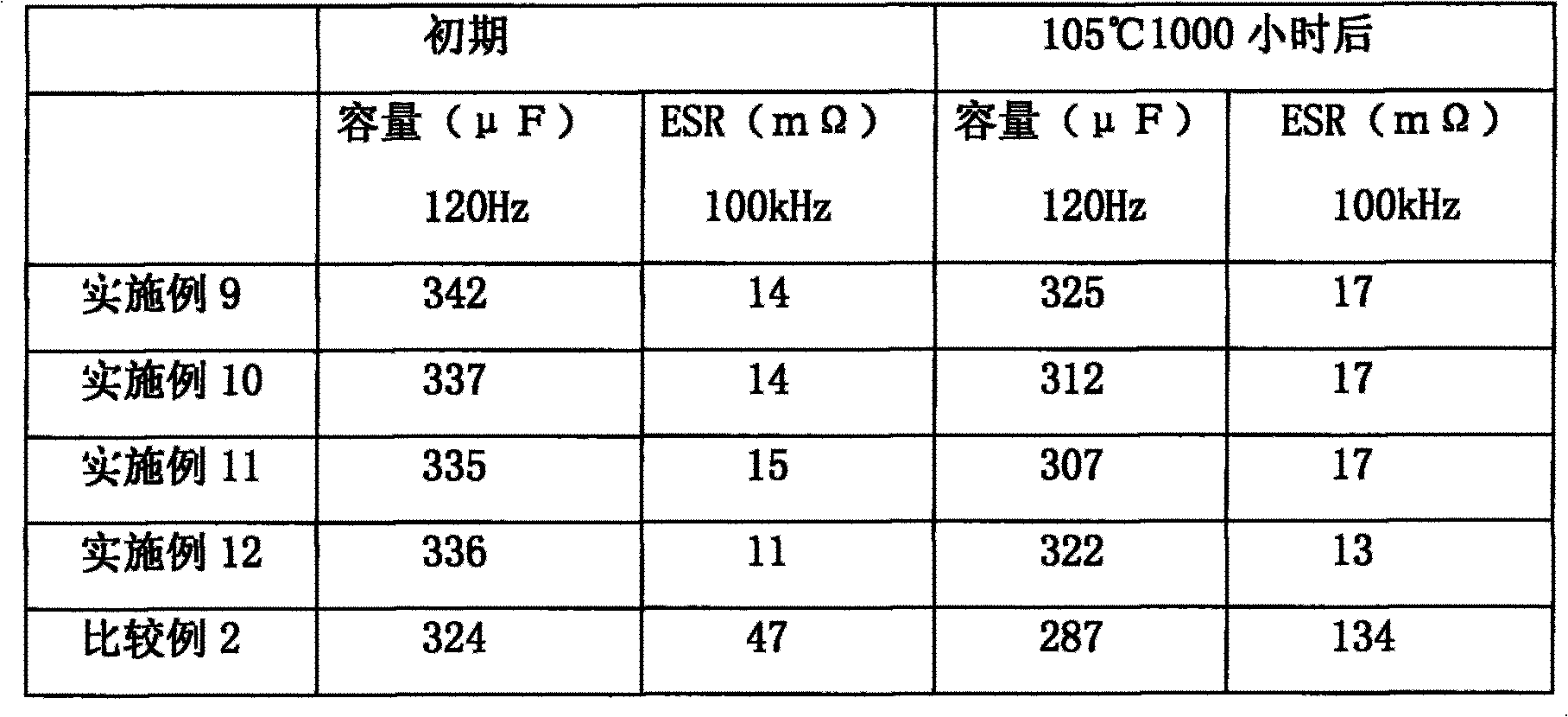

Conductive polymer composition and solid electrolyte capacitor using the same

ActiveCN101302339AImprove conductivityImprove stabilityHybrid capacitor electrolytesSolid electrolytic capacitorsPolypyrroleElectrolytic capacitor

The invention provides a conducting polymer composition, which contains polypyrrole and derivates thereof, polythiophene and derivates thereof, polyaniline and derivates thereof, polyacetaldehyde and derivates thereof, poly 1, 2-vinylidene thiophene and derivates thereof, and a conducting polymer compound of polysulfonic acid and conducting polymer formed by copolymers, and contains more than three hydroxy reducible compounds. The conducting polymer composition has high conductibility, and can maintain the conductibility in a high-temperature environment. A solid electrolytic capacitor contains the conducting polymer compound of the conducting polymer and the polysulfonic acid and more than three hydroxy reducible compounds in a solid electrolyte layer. The solid electrolytic capacitor has excellent ESR property and high-temperature invariability.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH

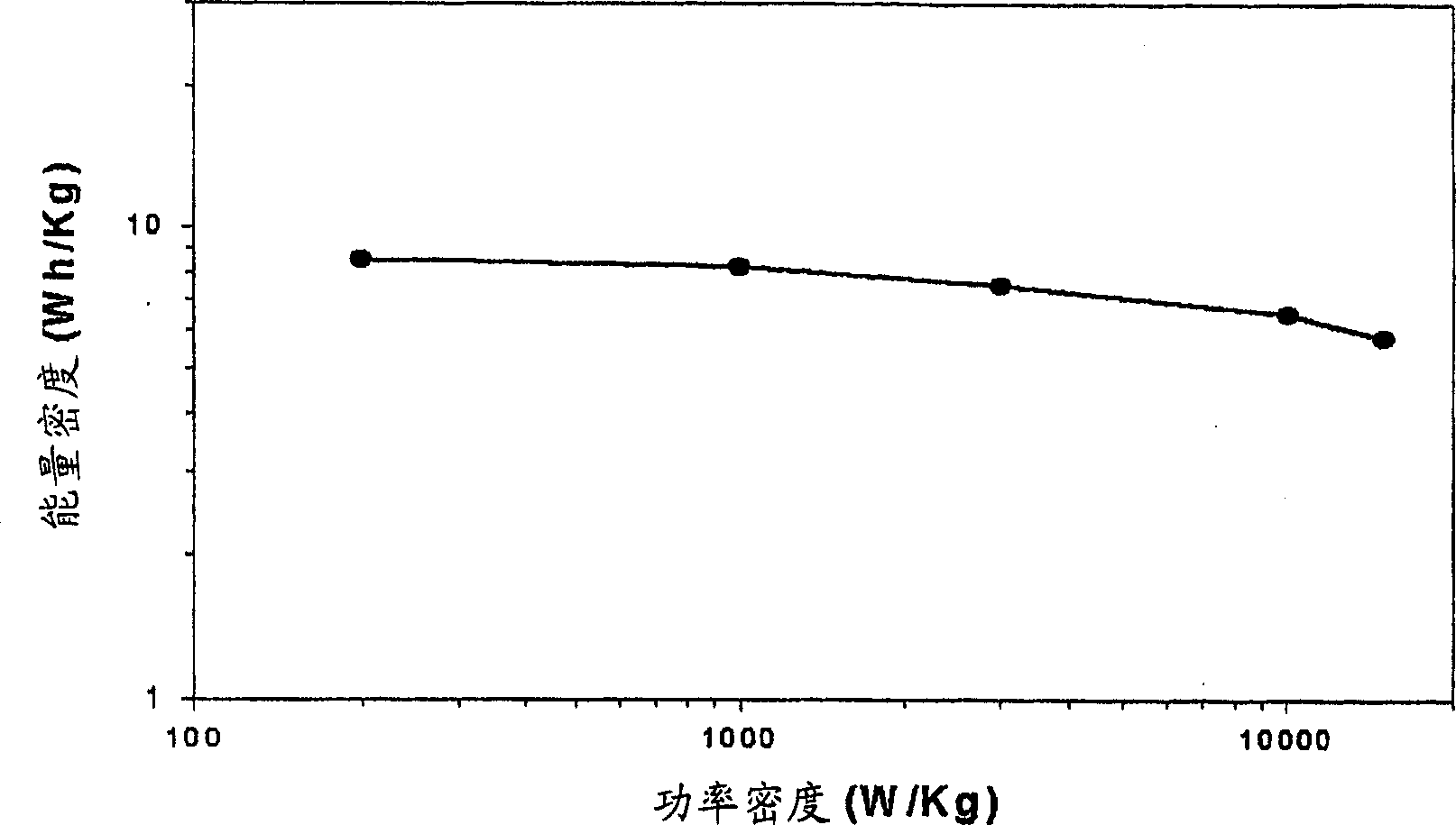

Carbon nanotube or carbon nanofiber electrode comprising sulfur or metal nanoparticles as a binder and process for preparing the same

InactiveCN1910771AIncreased durabilityReduce contact resistanceMaterial nanotechnologyMicroscopic fiber electrodesFiberFuel cells

The present invention provides an electrode made of carbon nanotubes or carbon nanofibers and a process for preparing the same. The electrode comprising a current collector, sulfur or metal nanoparicles as a binder, and carbon nanotubes or carbon nanofibers is characterized in that the sulfur or metal nanoparticles are bonded, deposited, or fused on the surfaces of the carbon nanotubes or carbon nanofibers so that the carbon nanotubes or carbon nanofibers are bonded to each other and also bonded to the current collector. The electrode prepared according to the present invention exhibits low internal resistance, strong durability and low equivalent series resistance, and therefore the electrode can be effectively used for secondary batteries, supercapacitors or fuel cells.

Owner:KH CHEM CO LTD

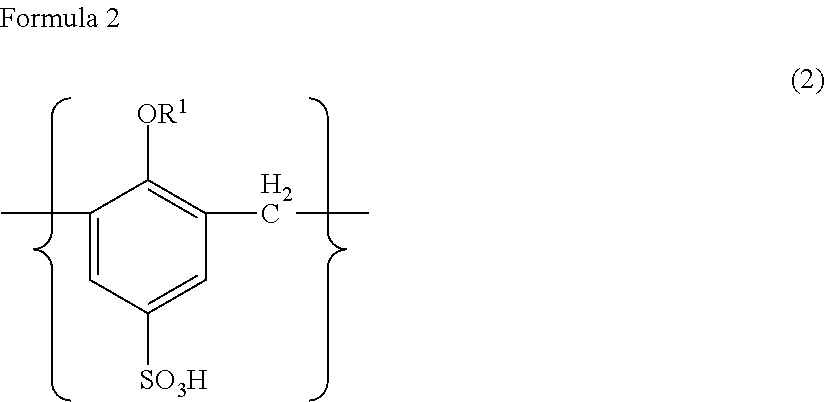

Conductive polymer composition, solid electrolyte and solid electrolyte capacitor using the conductive polymer

ActiveCN101486839AImprove conductivityImprove stabilitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsConductive polymerElectrolytic capacitor

An electroconductive polymer compound contains electroconductive high molecules, polyanion and aromatic compound with at least one functional group of alkoxide, nitryl and amino. The electroconductive polymer compound has high conductivity and can even maintain the high conductivity in high temperature environment. In the solid electrolyte layers of a solid electrolytic capacitor, at least one layer contains electroconductive high molecules, polyanion and aromatic compound that has at least one functional group of alkoxide, nitryl and amino. The capacitor has excellent ESR property and stability in high temperature condition.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH +1

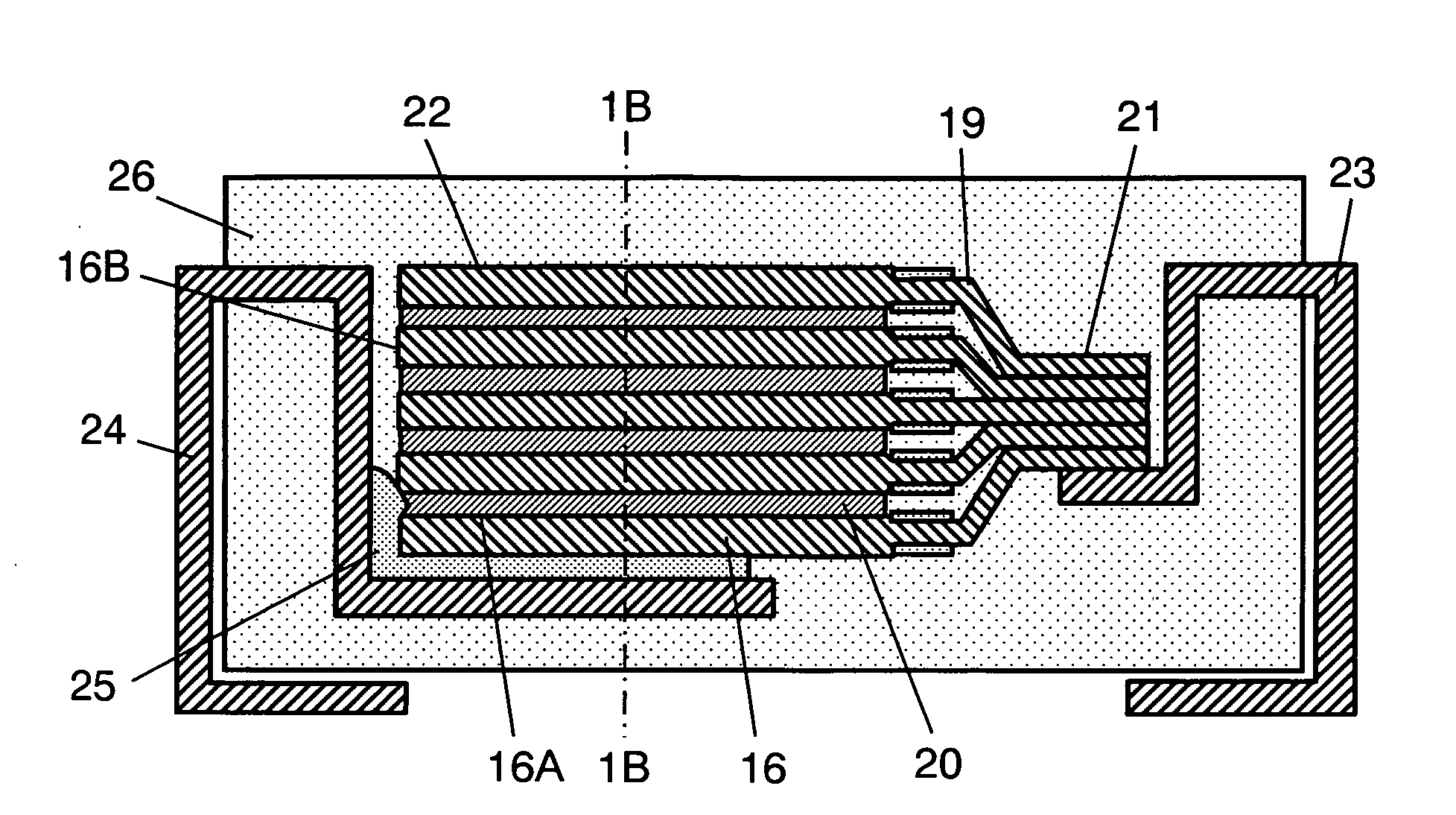

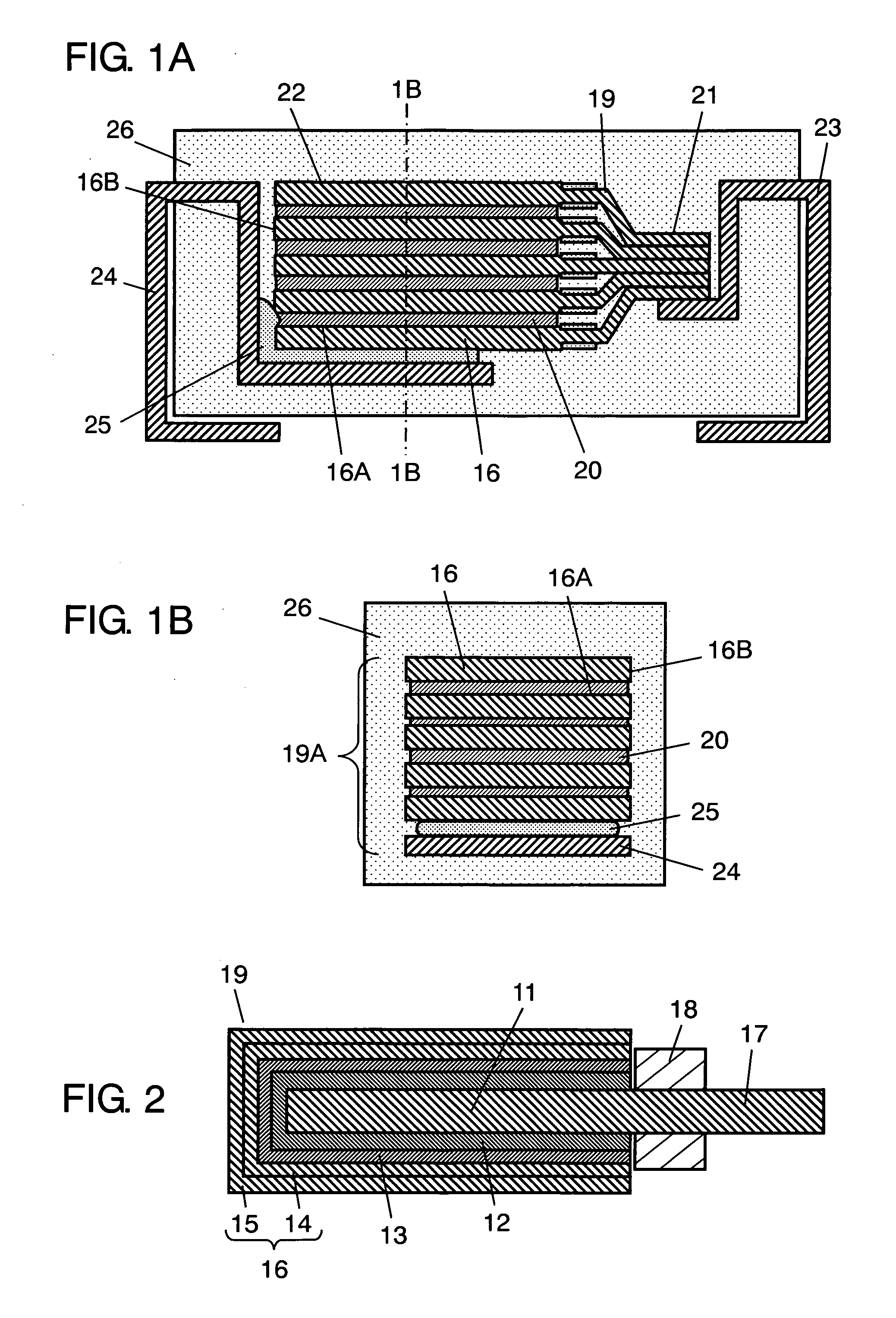

Solid electrolytic capacitor

ActiveUS20060262486A1Lower ESRImprove leakage currentClosuresLiquid electrolytic capacitorsElectrolysisElectrolytic capacitor

A solid electrolytic capacitor includes a plurality of laminated capacitor elements; an anode terminal connected to an anode portion where anode exposed portions of the capacitor elements are connected together; and a cathode terminal connected to a cathode portion where cathode layers of the capacitor elements are bonded together. Between lamination planes of the cathode layers of the capacitor elements, a conductive sheet is disposed. The capacitor elements are coated with a packaging resin layer in such a manner that a part of the anode terminal and a part of the cathode terminal are exposed.

Owner:PANASONIC CORP

Conductive composite body, conductive polymer composition and electronic component using the conductive polymer composition

InactiveCN101302340AImprove long-term stabilityExcellent solvent solubilityOrganic conductorsConductive polymerDisplay device

The invention provides a conducting complex which is combined by a conducting polymer A and a compound B except for the conducting polymer, and also can comprise polyanion, wherein, the compound B is polyethylene and derivates thereof, polyvinyl ether and derivates thereof, polyacrylamide and derivates thereof, polyacrylic acid and derivates thereof, etc. The conducting complex improves clinging property and filming property for matrix, and can maintain low specific resistance in a high-temperature environment. A conducting polymer composition comprises the conducting complex, has reduced specific resistance, and can maintain low specific resistance in a high-temperature environment. The invention also provides an electronic element with excellent performance through using a coating of the conducting complex and the conducting polymer composition. The coating of the conducting complex or the conducting polymer composition can be used in a solid electrolytic capacitor, a solar cell, an organic light emitting diode, an electroluminance, a display, an electrostatic copying part, a transfer printing part, a battery, epaper, a touch panel, an organic thin-filmtransistor, a field emission display (FED) and so on.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH

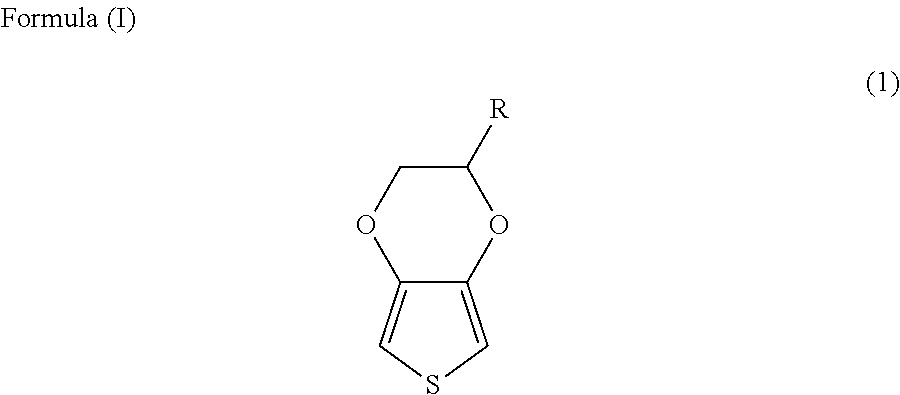

Dispersion of electrically conductive polymer, and electrically conductive polymer and use thereof

ActiveUS20140211374A1Improve conductivityImprove heat resistanceSolid electrolytic capacitorsHybrid capacitor electrodesMethacrylateHydrolysate

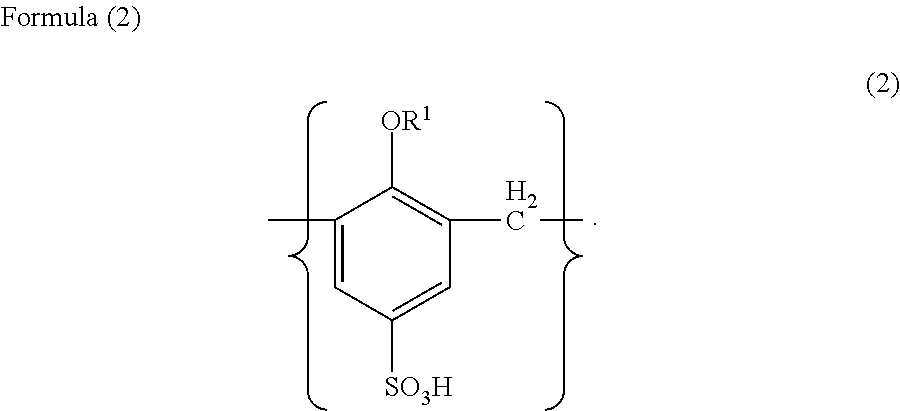

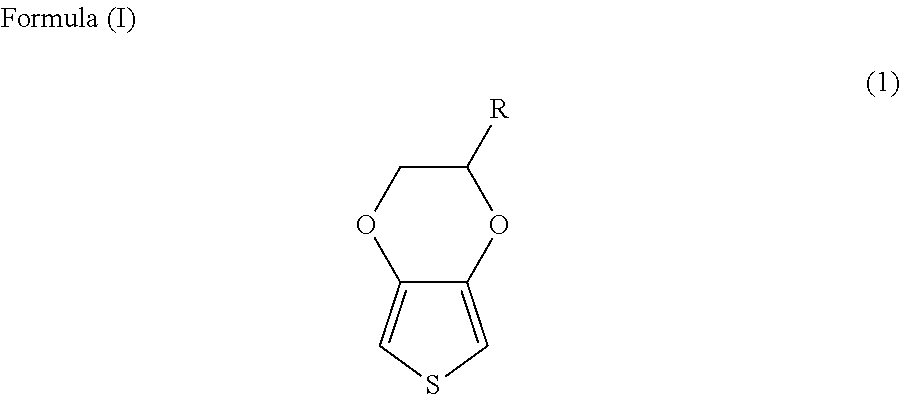

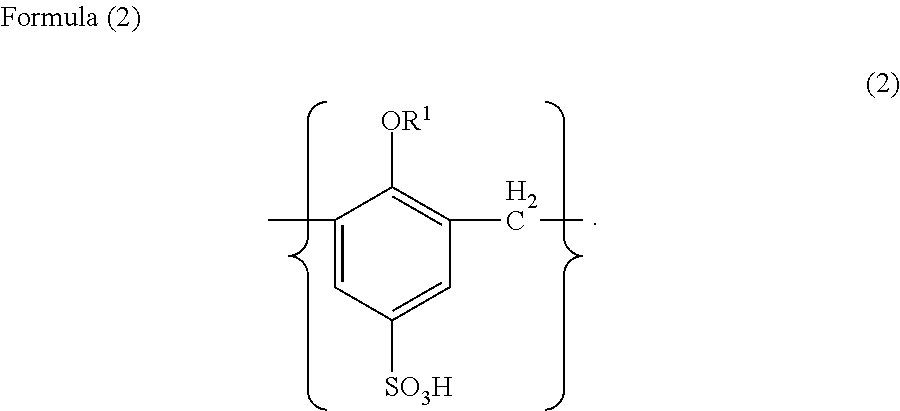

There is provided a conductive polymer having high conductivity with excellent heat resistance. Using the conductive polymer, there can be provided solid electrolytic capacitors having low ESR, high reliability, and less leakage current. There can be also provided conductive films having high conductivity and superior heat resistance. There is provided a conductive polymer dispersion liquid obtained by a method in which in the presence of a copolymer from styrenesulfonic acid, and at least one kind of a non-sulfonic acid monomer selected from the group consisting of methacrylate, acrylate, and an unsaturated hydrocarbon containing alkoxysilane compound or its hydrolysate, thiophene or its derivative is polymerized by oxidation polymerization in water, or in an aqueous solution comprising a mixture of water and a water miscible solvent to produce the conductive polymer dispersion liquid. Using the conductive polymer as solid electrolyte, a solid electrolyte capacitor can be provided. Also, using the conductive polymer, a conductive film can be provided.

Owner:TAYCA CORP

Electrode foil, current collector, electrode, and energy storage element using same

ActiveCN103380469APrevent oxidationImprove interface resistanceSolid electrolytic capacitorsHybrid capacitor electrodesCarbon layerCapacitance

This negative electrode foil for a solid electrolyte capacitor: increases capacitance, reduces ESR and leakage current, improves heat resistance, and reduces manufacturing costs; and improves the power density, achieves rapid charging / discharging, and improves the lifespan characteristics of energy storage elements such as rechargeable batteries, electric double-layer capacitors, and hybrid capacitors. The negative electrode foil or a current collector is used, which: is obtained by forming a metal layer, a mixed layer obtained by mixing a material constituting the metal layer with carbon, and a carbon layer substantially comprising carbon, on a metal foil; and is configured in such a manner as to change as the components of the mixed layer change from a component containing only the material substantially constituting the metal layer to a component substantially containing only carbon, and from the metal layer to the carbon layer.

Owner:JAPAN CAPACITOR IND CO LTD

Activated carbon blacks

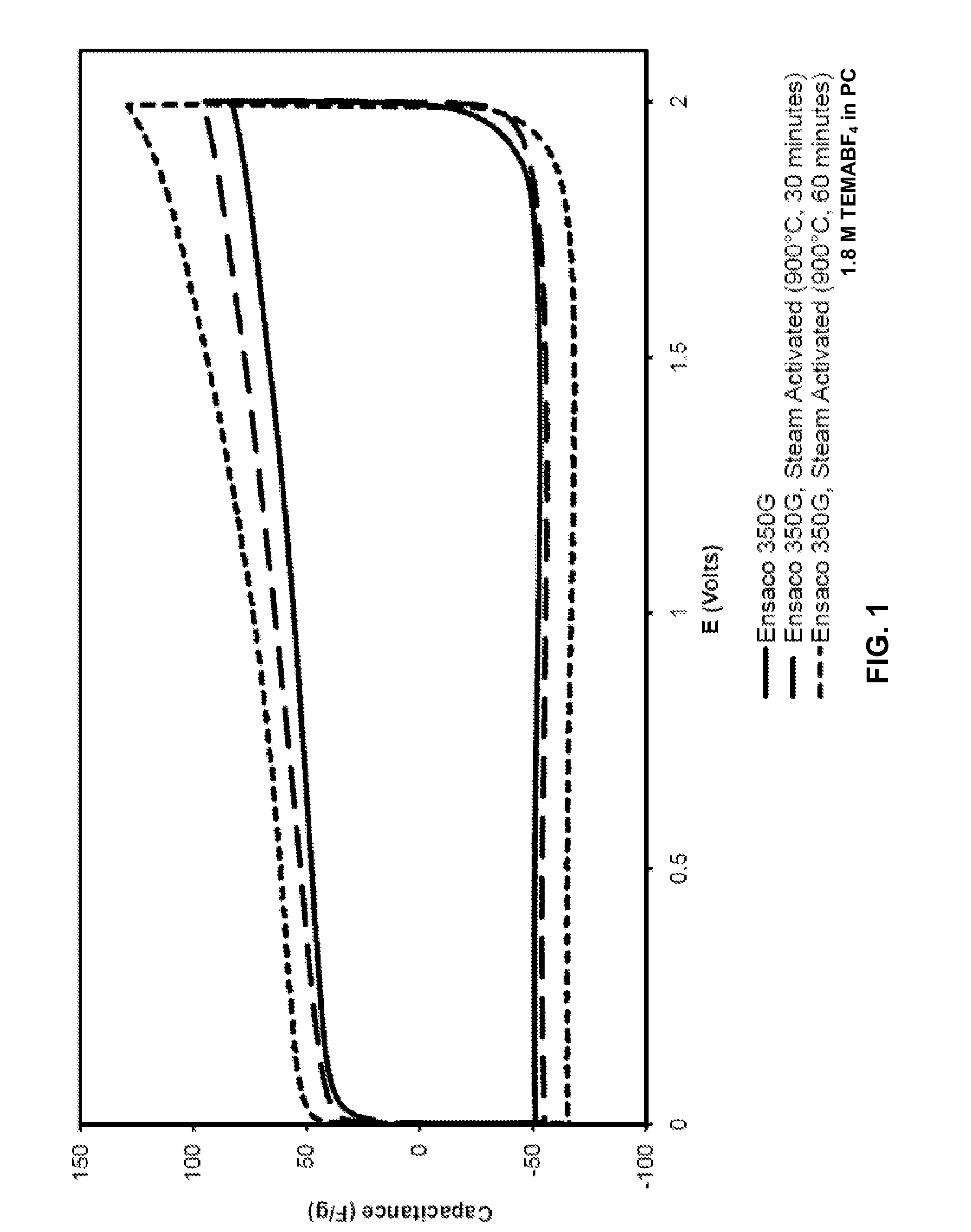

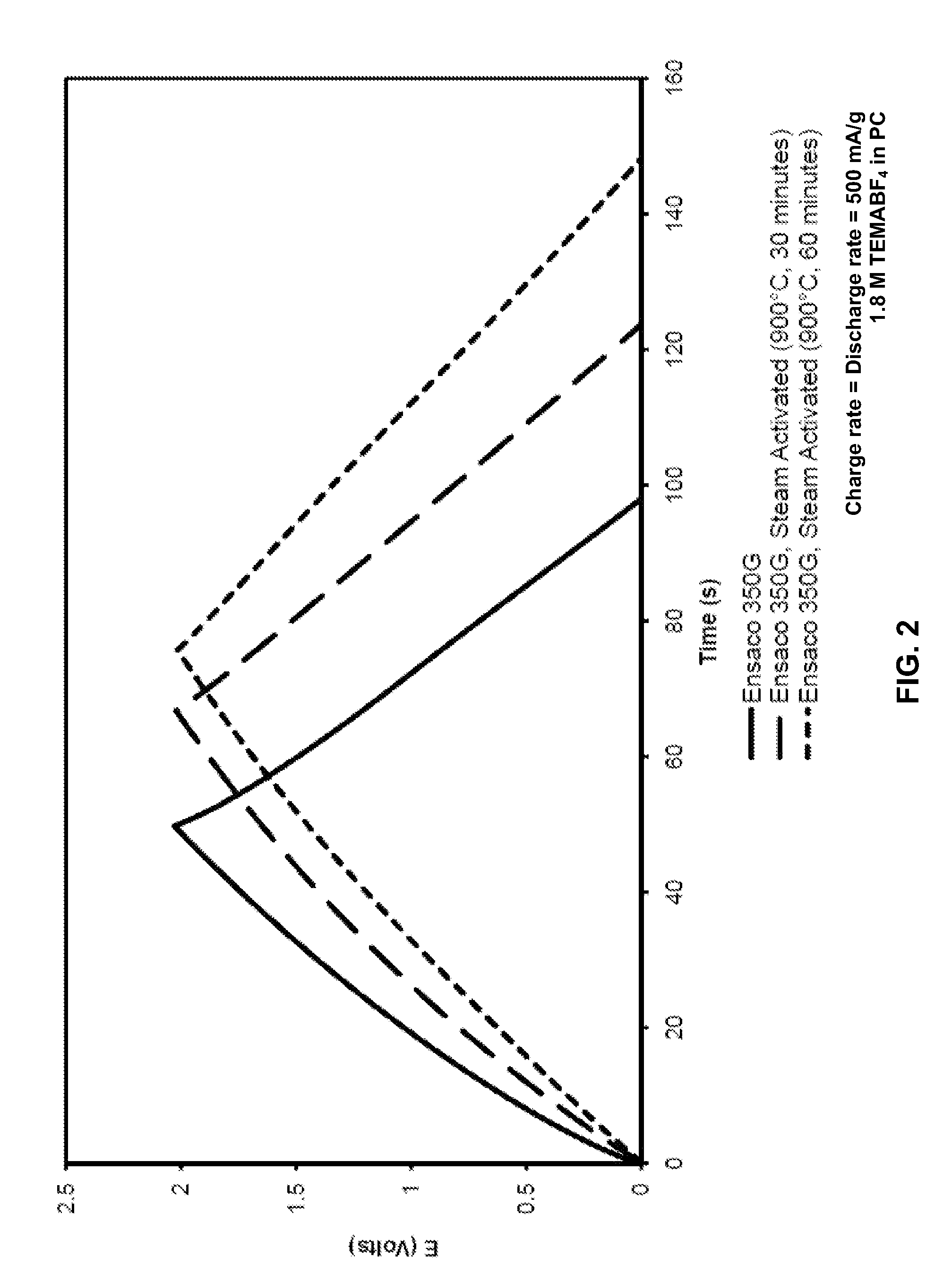

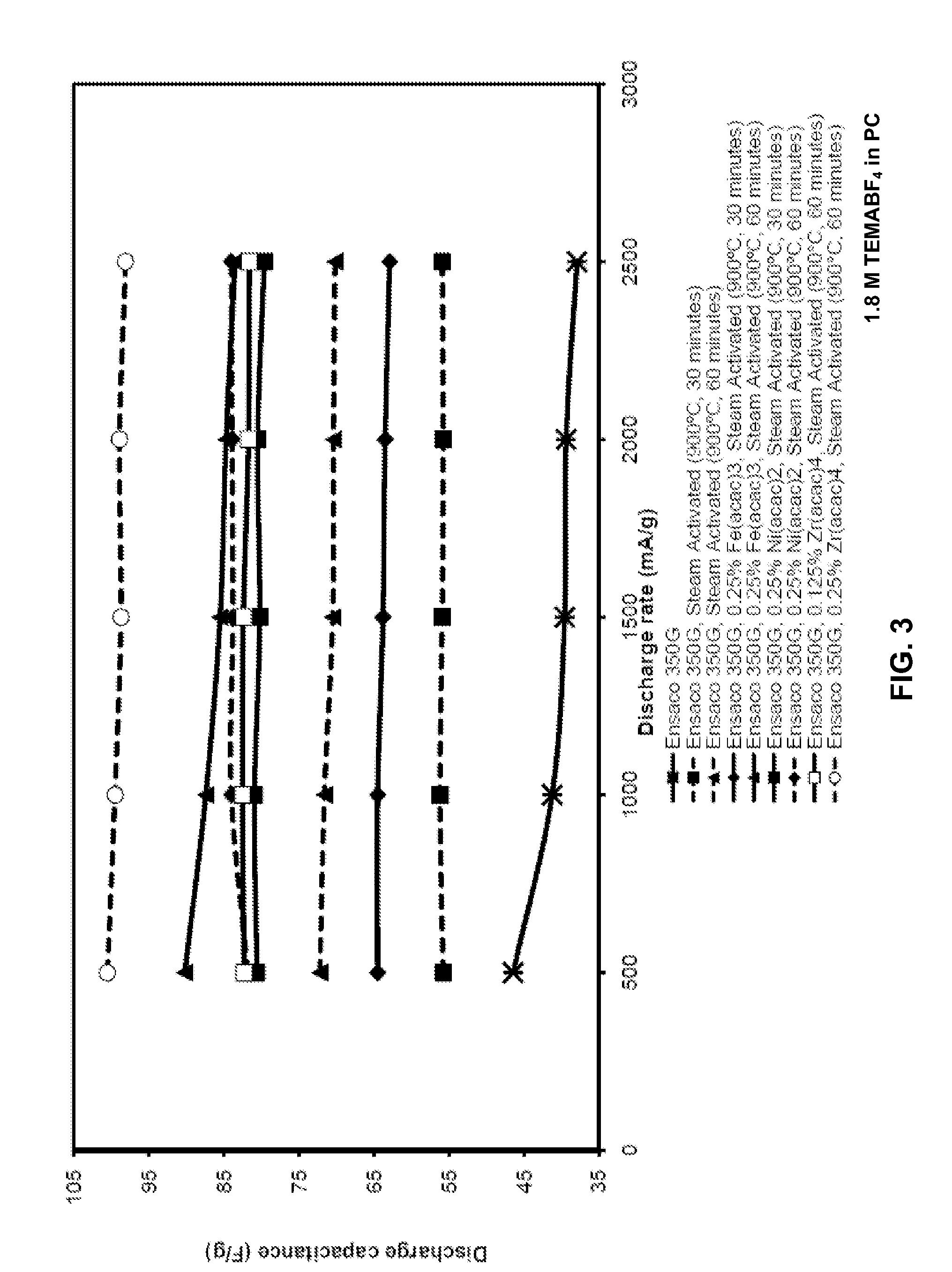

InactiveUS20120007027A1Increased specific capacitanceLower ESRMaterial nanotechnologyHydrogenActivated carbonNanoparticle

Activated carbon blacks and the enhanced methods of preparing activated carbon blacks have been discovered. In order to form an activated carbon black, a conductive carbon black is coated with nanoparticles containing metal, and then catalytically activated in steam and an inert gas to form a catalytically activated mesoporous carbon black, where the mass of the catalytically activated carbon black is lower than the mass of the carbon black. The nanoparticles may serve as catalysts for activation rugosity of mesoporous carbon blacks. The catalytically activated carbon black material may be used in all manner of devices that contain carbon materials.

Owner:UNIV OF KENTUCKY RES FOUND +1

Chinese medicinal composition for treating cardiovascular and cerebrovascular diseases, preparation method and application thereof

ActiveCN1965966AOvercoming the disadvantages of traditional dosage formsGuaranteed clinical efficacyPowder deliveryAnthropod material medical ingredientsSalvia miltiorrhizaAdjuvant

The invention provides a Chinese medicinal composition for treating cardiovascular and cerebrovascular diseases which comprises the following raw material herbs (by weight portions): astragalus root 480-660, radix salvia miltiorrhiza 60-160, red peony root 60-160, rhizome of Sichuan lovage 60-160, Chinese angelica root 60-160, safflower 60-160, leech 40-90, ground beetle 40-90, peach kernel 60-160, artificial ox gallstone 10-40, antelope's horn 10-40, buthus martensi kirsch 50-140, polygala root 60-160, acorus gramineus soland 60-160 and medicinal adjuvant. The invention also provides the method for preparation and use of the composition.

Owner:天津市石天药业有限责任公司

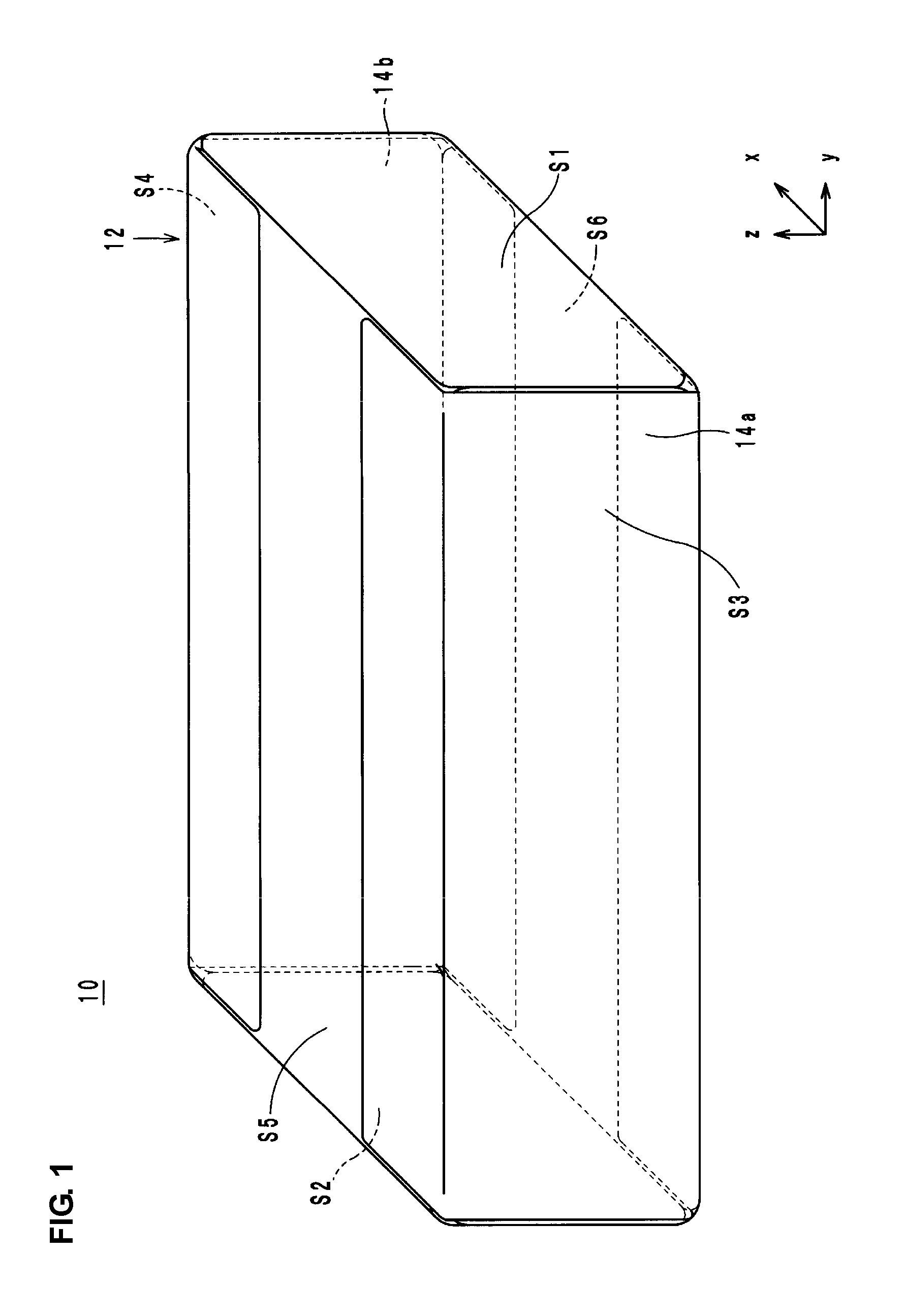

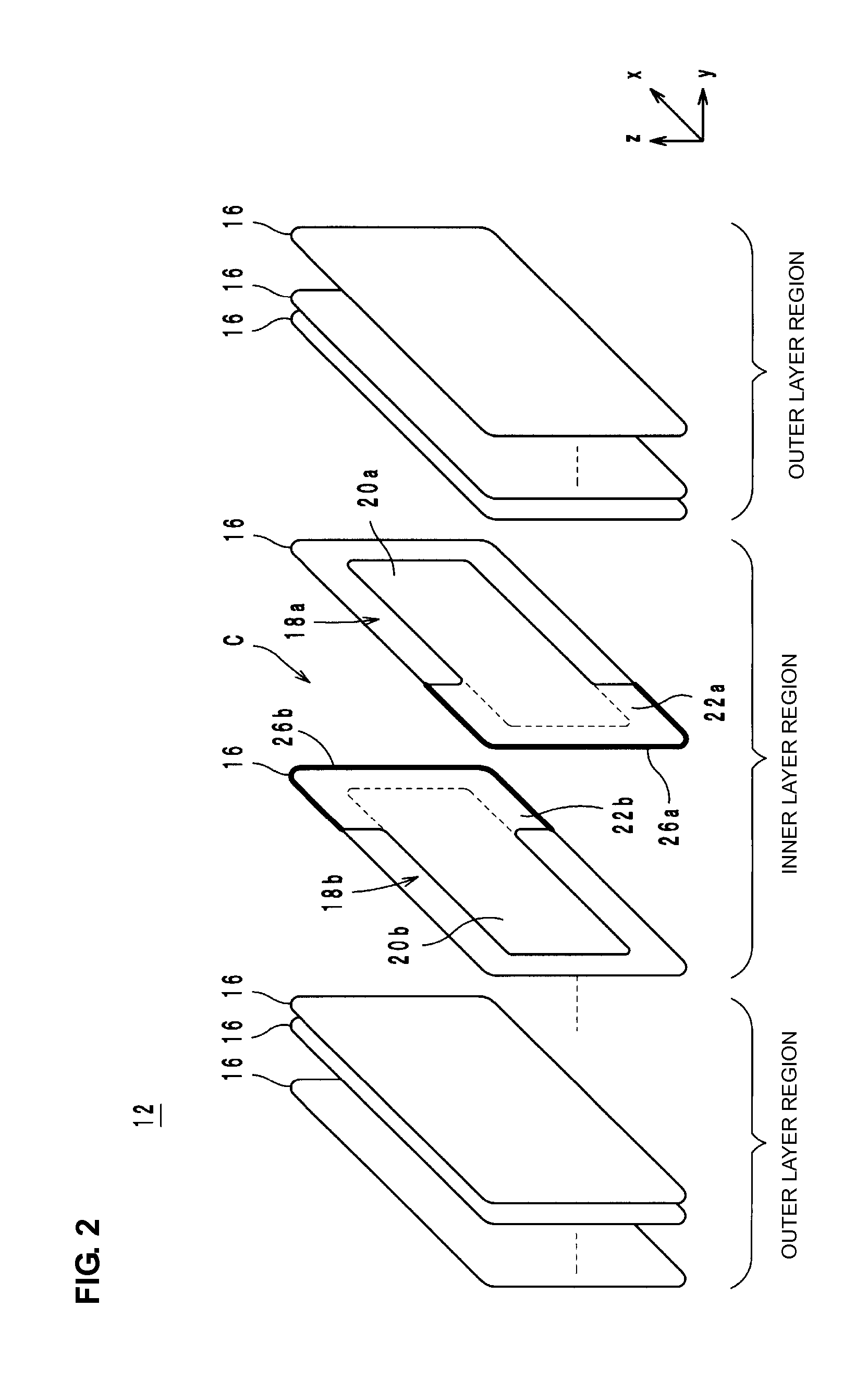

Electronic component

ActiveUS20110267736A1Reduce ESRPrevent generationFixed capacitor electrodesFixed capacitor dielectricEngineeringElectrical conductor

A laminate includes insulating layers laminated to each other. Capacitor conductors are embedded in the laminate and have exposed portions exposed between the insulating layers at respective surfaces of the laminate. The capacitor conductors define a capacitor. External electrodes are provided by plating on the respective surfaces of the laminate so as to directly cover the respective exposed portions. When the laminate is viewed in plan in a y axis direction, the length of each of the exposed portions is approximately 35% to approximately 45% of the length of an outer periphery of the insulating layer.

Owner:MURATA MFG CO LTD

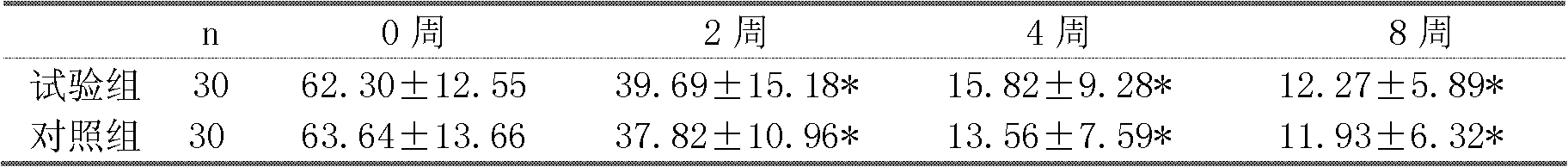

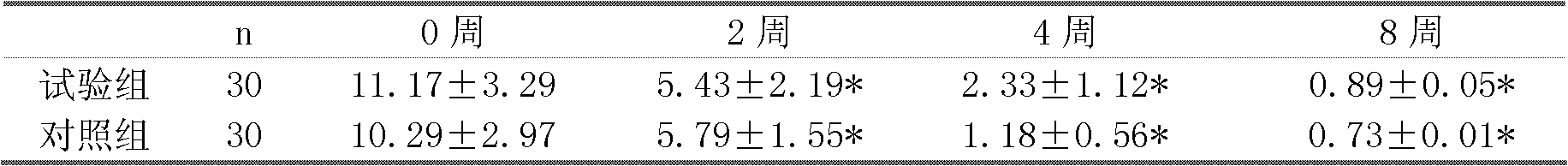

Traditional Chinese medicine composition for treating subacute thyroiditis and preparation method thereof

ActiveCN103099902AImprove clinical symptoms and signsLow recurrence rateAntiviralsUnknown materialsDrug withdrawalClinical study

The invention discloses a traditional Chinese medicine composition for treating subacute thyroiditis. The composition is a preparation prepared from the following raw materials by weight: 15-30 parts of hedyotis diffusa, 9-15 parts of honeysuckle, 15-30 parts of dandelion, 15-30 parts of Chinese violet, 9-15 parts of root of common peony, 9-15 parts of radix scrophulariae, 9-15 parts of peach kernel, 9-15 parts of baked turtle shell and 15-30 parts of sweet wormwood. According to clinical study on the treatment of subacute thyroiditis, the traditional Chinese medicine composition provided by the invention has total effective rate of 93.34%, which is significantly better than 73.33% of a prednisone group, and can effectively reduce erythrocyte sedimentation rate and CRP of subacute thyroiditis patients, and effectively improve clinical symptoms of the patients; although the cooling time, improvement time of neck pain and regression time of neck tenderness are longer than those of the prednisone group, the goiter or nodule disappearance time shows no obvious difference from those of the prednisone group; relapse rate after drug withdrawal is 3.33%, which is significantly lower than 20% of the prednisone group; and the composition has little adverse reaction, which is significantly lower than that of the prednisone group. The invention also discloses a preparation method of the traditional Chinese medicine composition granules.

Owner:LONGHUA HOSPITAL SHANGHAI UNIV OF TRADITIONAL CHINESE MEDICINE

Electrolytic capacitor and method of producing the same

ActiveUS7859829B2Sufficient low ESRImprove pressure resistanceClosuresHybrid capacitor electrodesElectrolysisLow leakage

Owner:SANYO ELECTRIC CO LTD +2

Conductive macromolecular solution, preparation thereof, conductive polymer coated film and solid electrolyte capacitor

InactiveCN101486836AImprove conductivityHigh light transmittanceCapacitor electrolytes/absorbentsOrganic conductorsElectrolysisPolymer science

An electroconductive polymer solution contains electroconductive high molecules and polyanion. Under 25 DEG C, the oxygen content in the electroconductive polymer solution is below 8 weight ppm. An electroconductive coating film using the solution has high transmittance and low resistance. Applied to a solid electrolytic capacitor, the electroconductive polymer solution can improve the conductivity of solid electrolysis and filling behavior, therefore, a solid electrolytic capacitor with low ESR and other excellent properties is obtained.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH +1

Solid electrolytic capacitor element, solid electrolytic capacitor, and manufacturing method therefor

ActiveUS7262954B1Reduce contact resistanceGood adhesivenessSolid electrolytic capacitorsLiquid electrolytic capacitorsPolypyrrolePolyethylene glycol

The objective of the current invention is to provide a solid electrolytic capacitor element with low equivalent series resistance. In this solid electrolytic capacitor element, an anode including a porous sintered body, and a dielectric layer are sequentially formed on an anode lead so as to cover a portion of the anode lead. An intermediate layer including polyethylene glycol is formed on the dielectric layer so as to cover an area around the dielectric layer. An electrolyte layer that includes polypyrrole is formed on the intermediate layer so as to cover an area around the intermediate layer. A cathode that includes: a first electrically conductive layer mainly including graphite particles and a second electrically conductive layer mainly including silver particles is formed on the electrolyte layer so as to cover an area surrounding the electrolyte layer.

Owner:SANYO ELECTRIC CO LTD

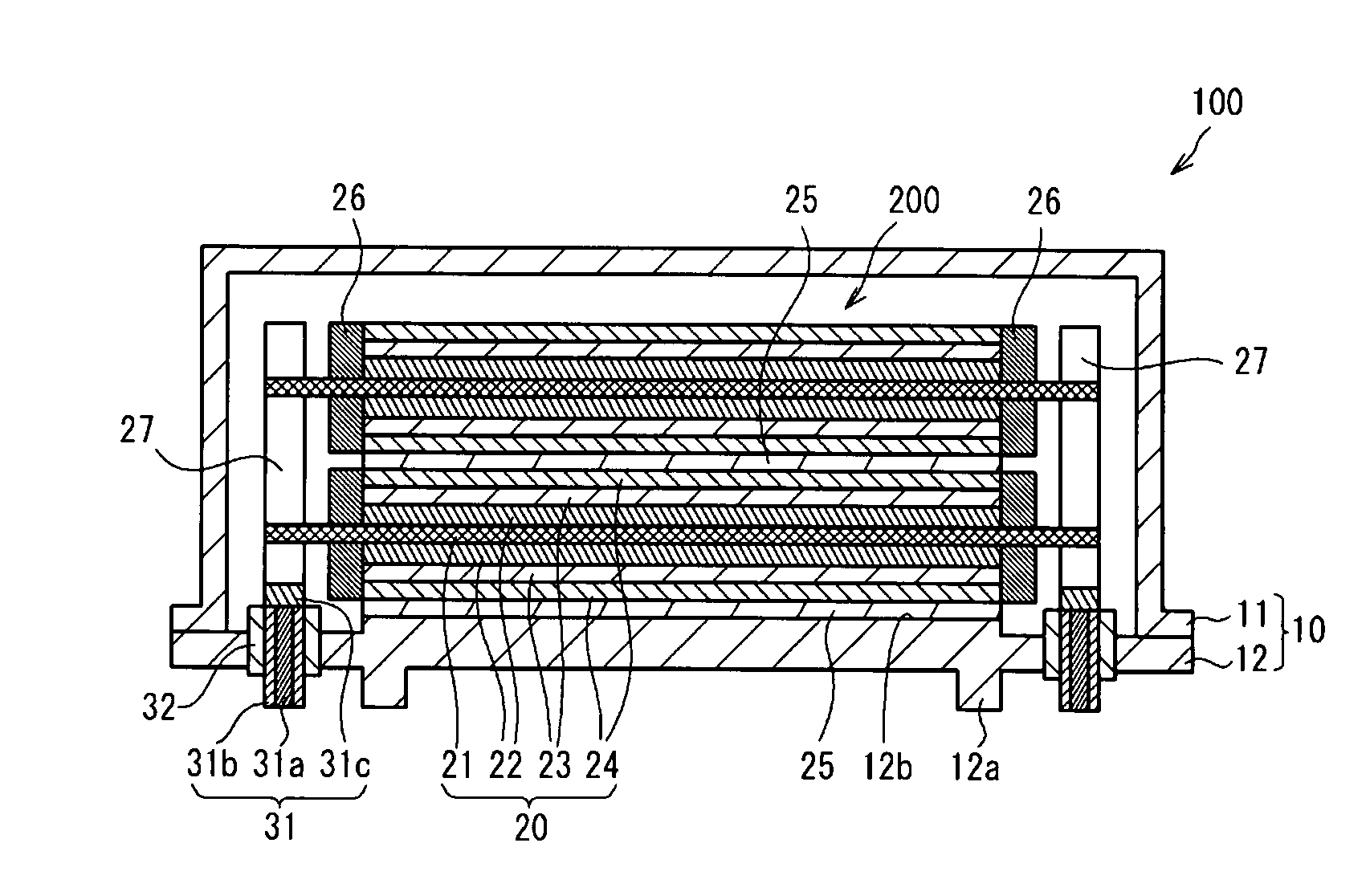

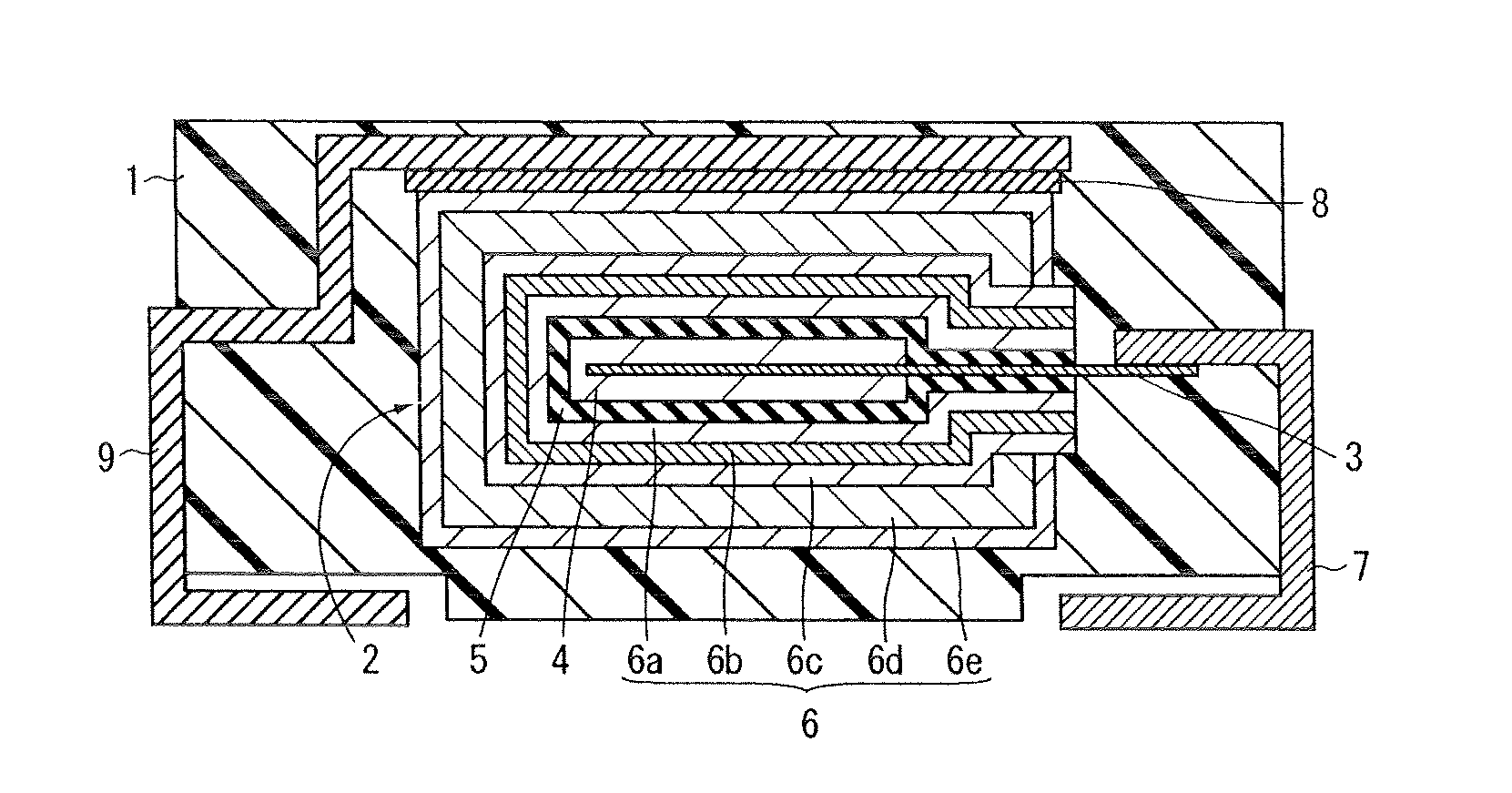

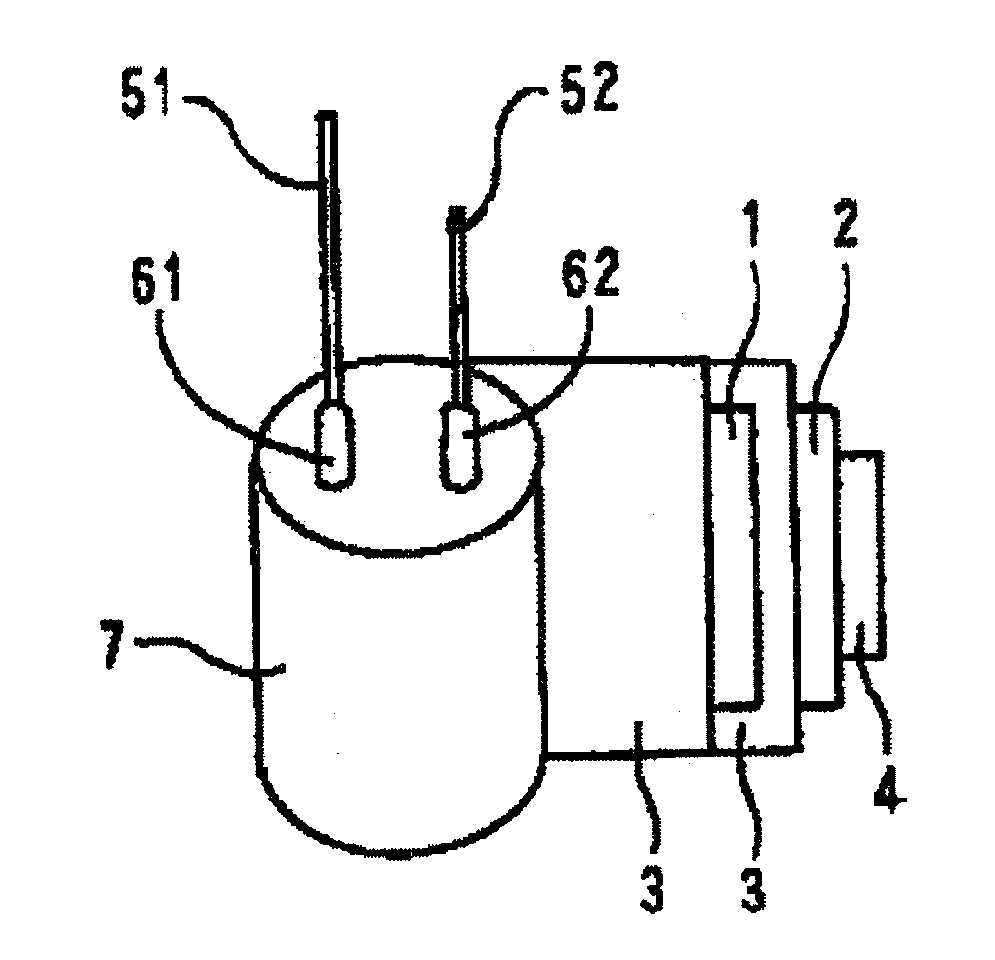

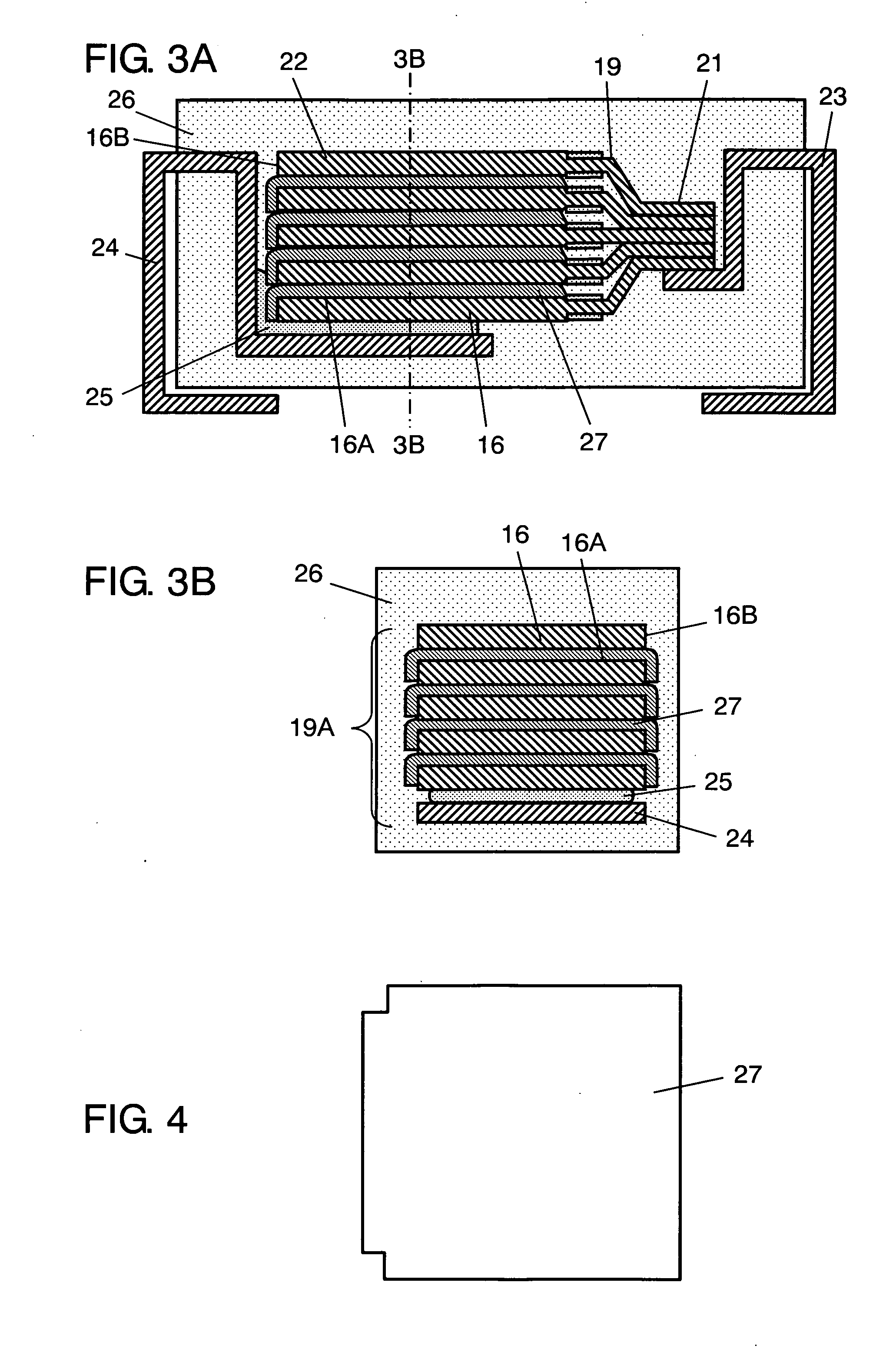

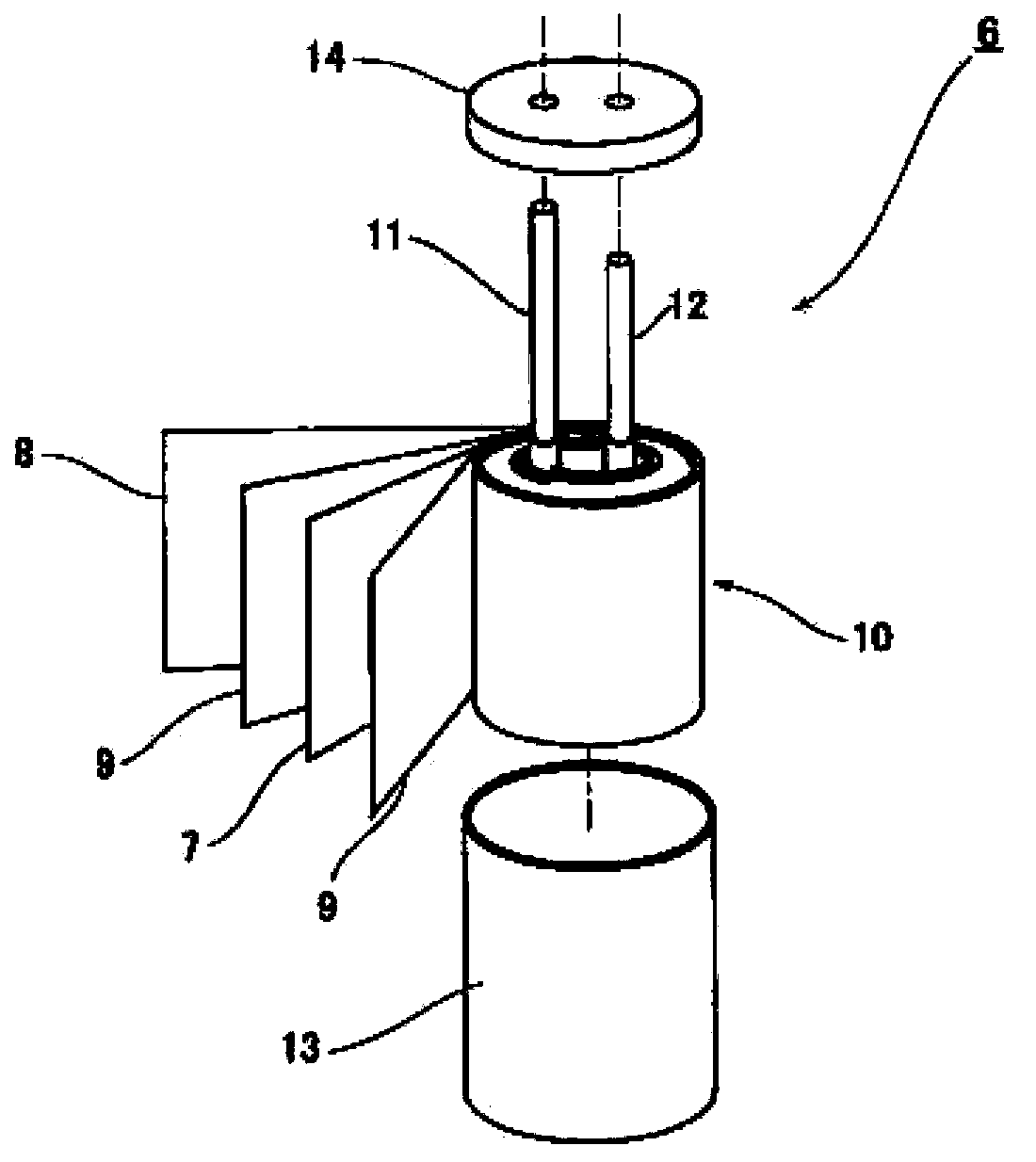

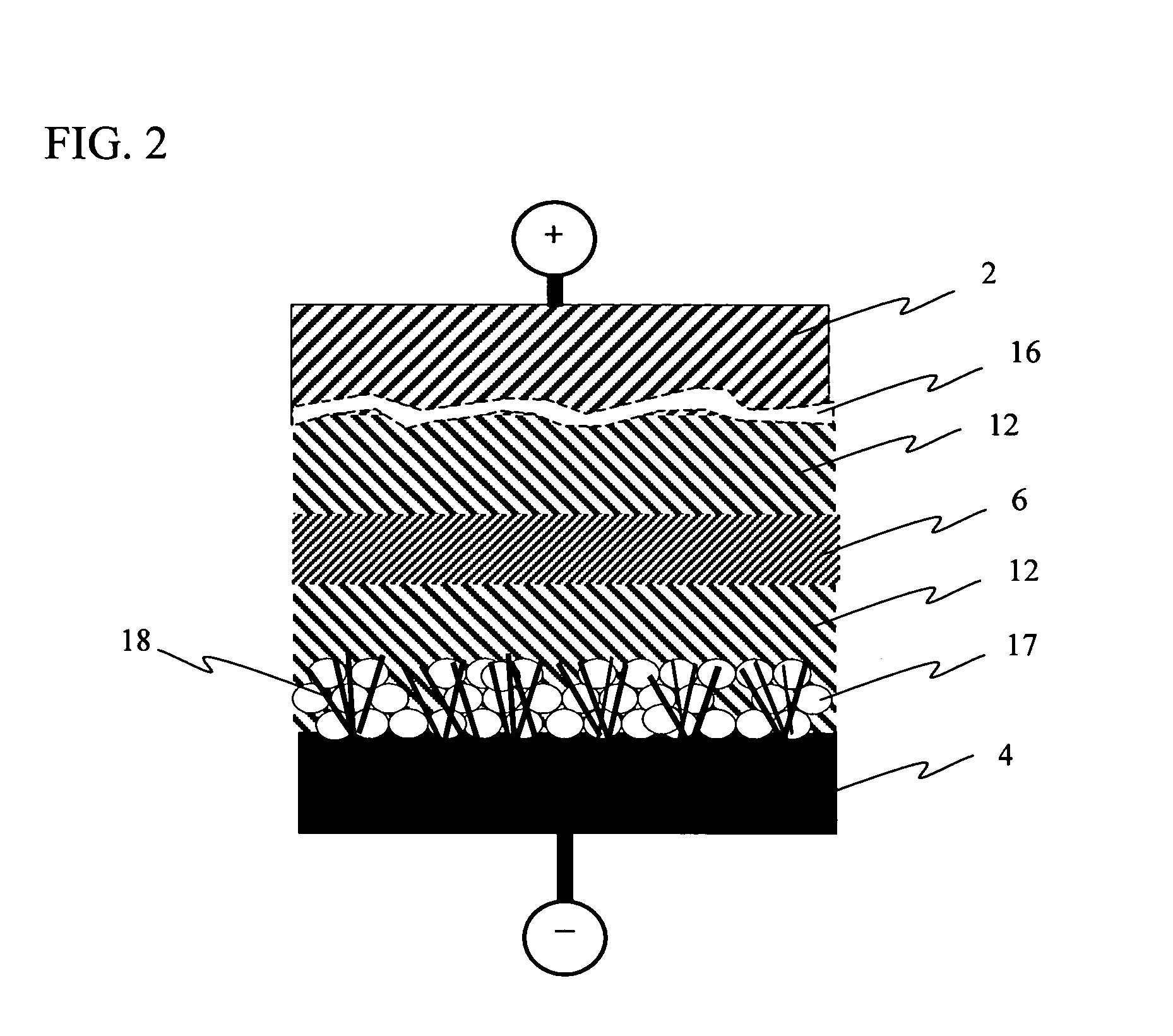

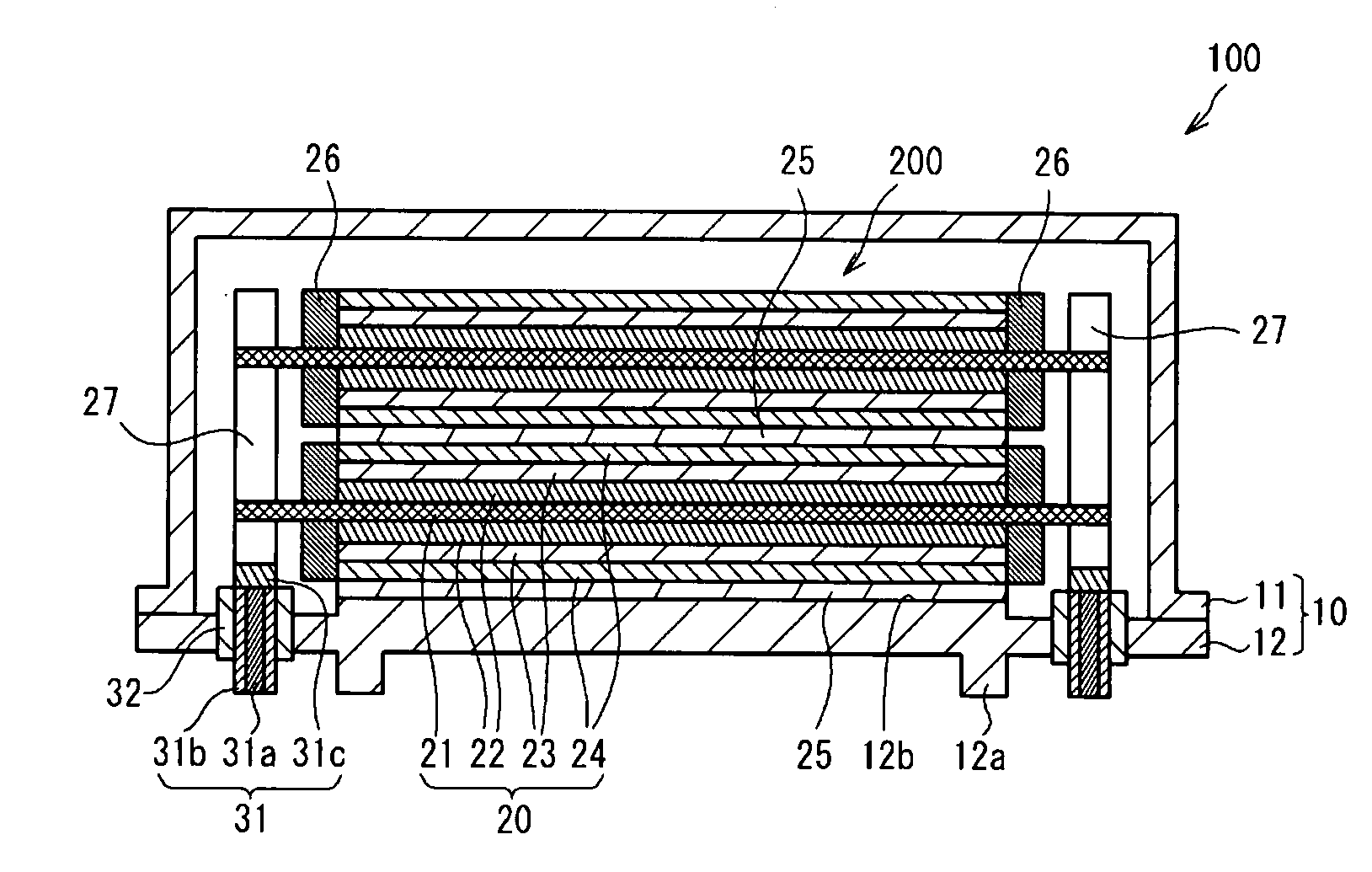

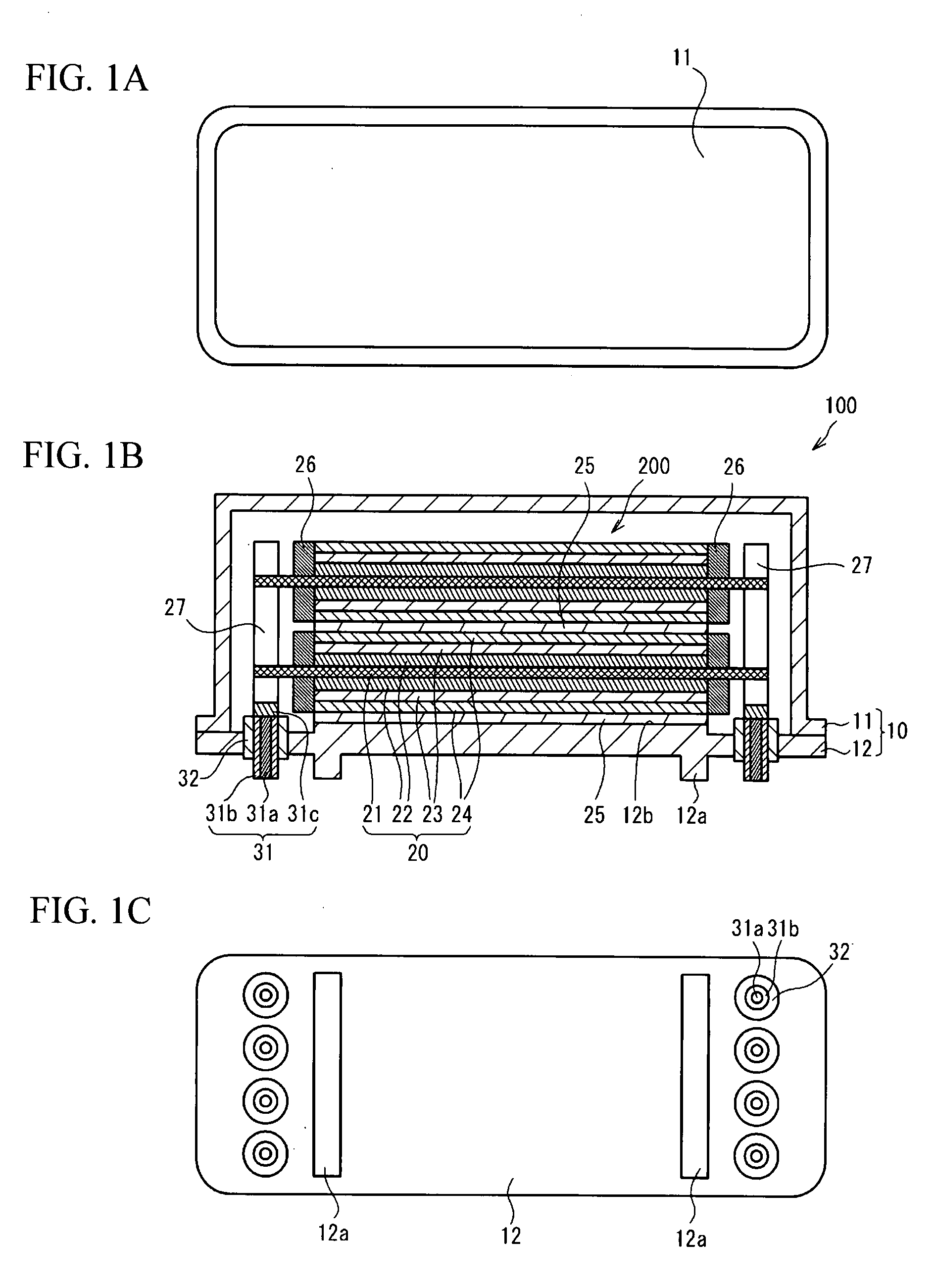

Solid electrolytic capacitor and manufacturing method of the same

ActiveUS7006348B1Improve frequency responseLarge capacitySolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisConductive polymer

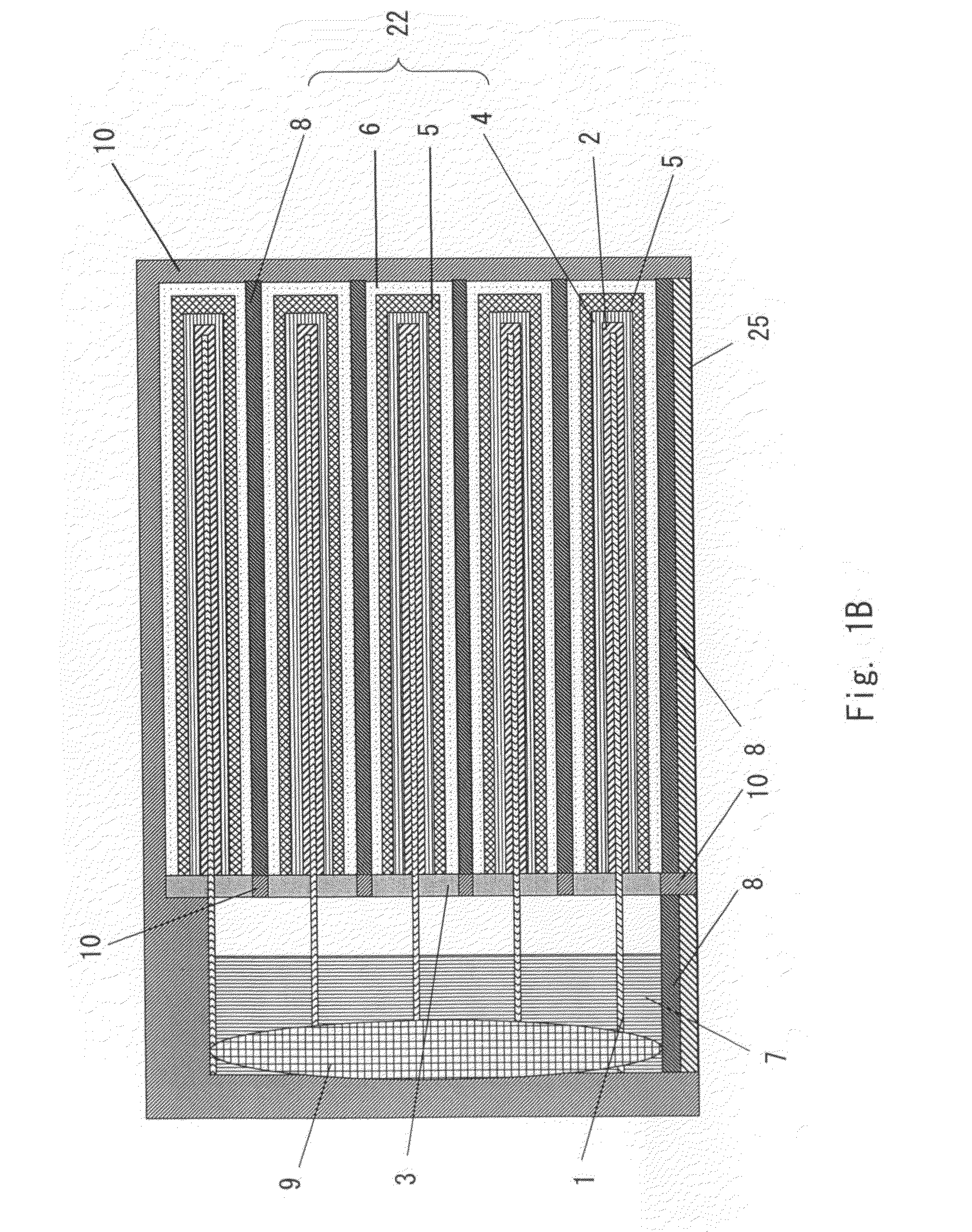

A solid electrolytic capacity has an anode foil 2 having dielectric oxide layer 16 formed on surface thereof, a cathode foil 4 having whiskers 18 that are formed on surface thereof and hold carbide grains 17, a separator paper 6 and solid electrolytic layers 12 formed of a conducting polymer. The anode foil 2 and the cathode foil 4 were rolled together across the separator paper 6. The solid electrolytic layers 12 are formed between the anode foil 2 and the cathode foil 4. Thickness of a layer where the whiskers 18 hold the carbide grains 17 is 1 μm to 5 μm. A method of manufacturing a solid electrolytic capacitor having steps of generating whiskers on surface of a cathode foil after coating carbide grains on the surface of the cathode foil and drying the carbide grains, rolling the cathode foil and an anode foil having dielectric oxide layer formed on surface thereof across a separator, impregnating polymerizable monomers and an oxidizing reagent into the separator, polymerizing the polymerizable monomers and forming solid electrolyte layers between the cathode foil and the anode foil.

Owner:NICHICON CORP

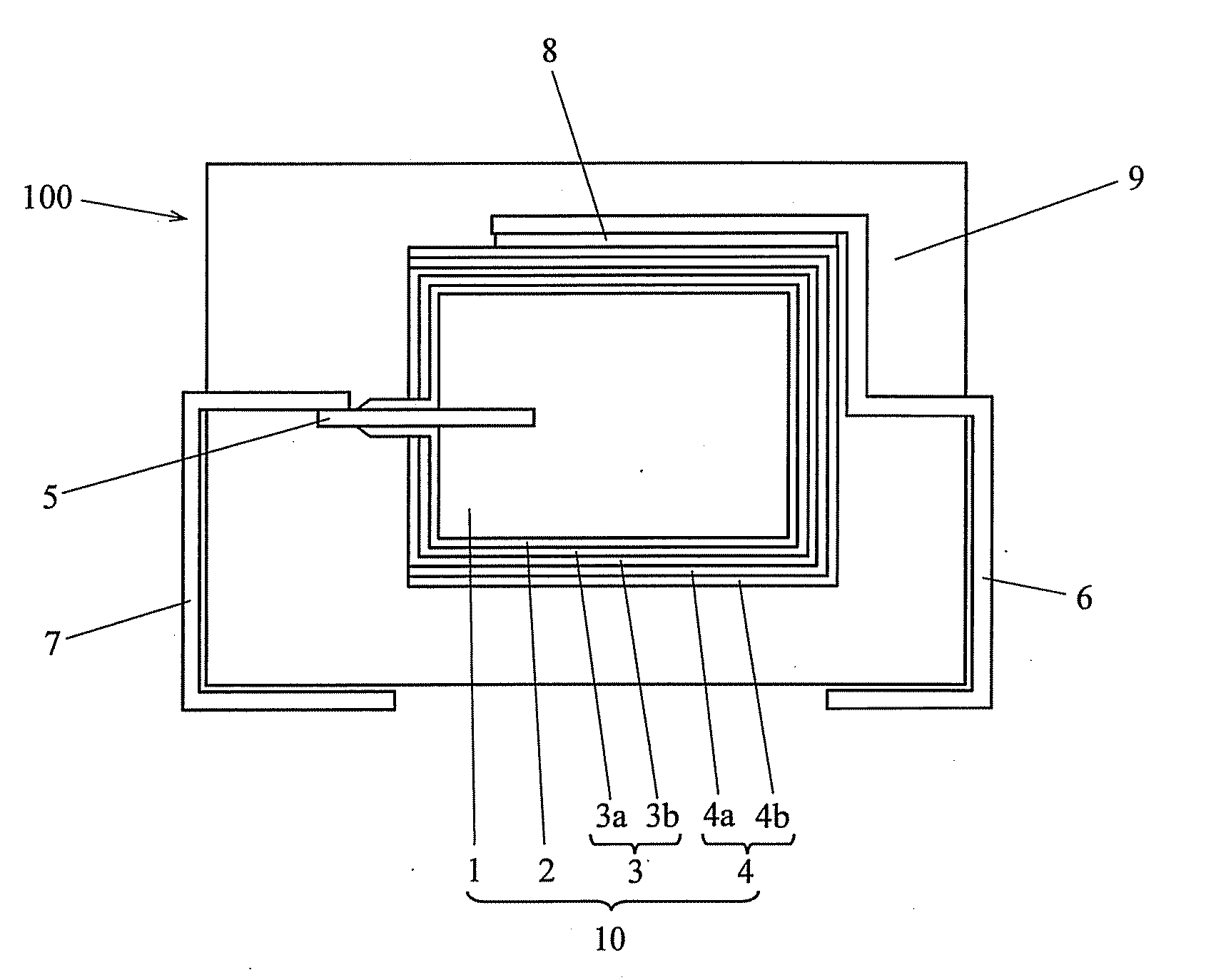

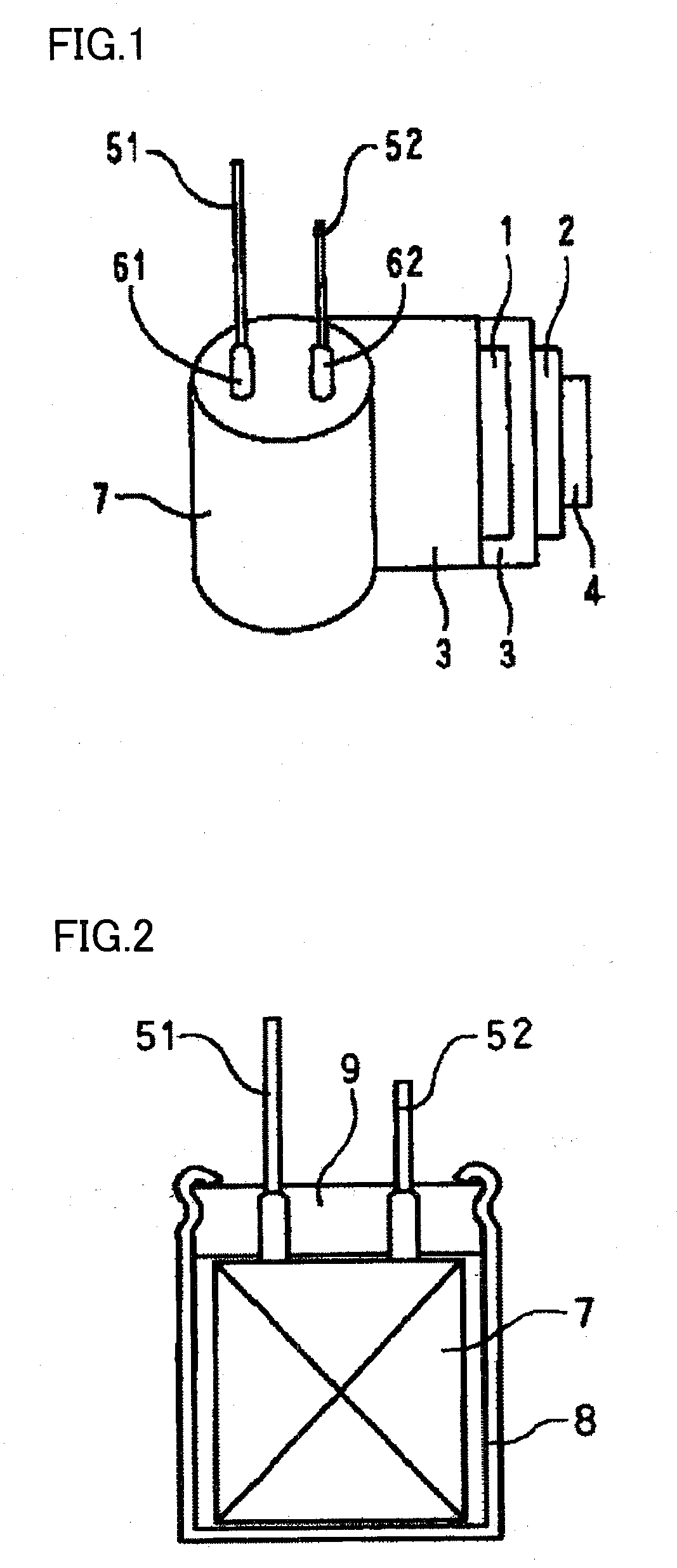

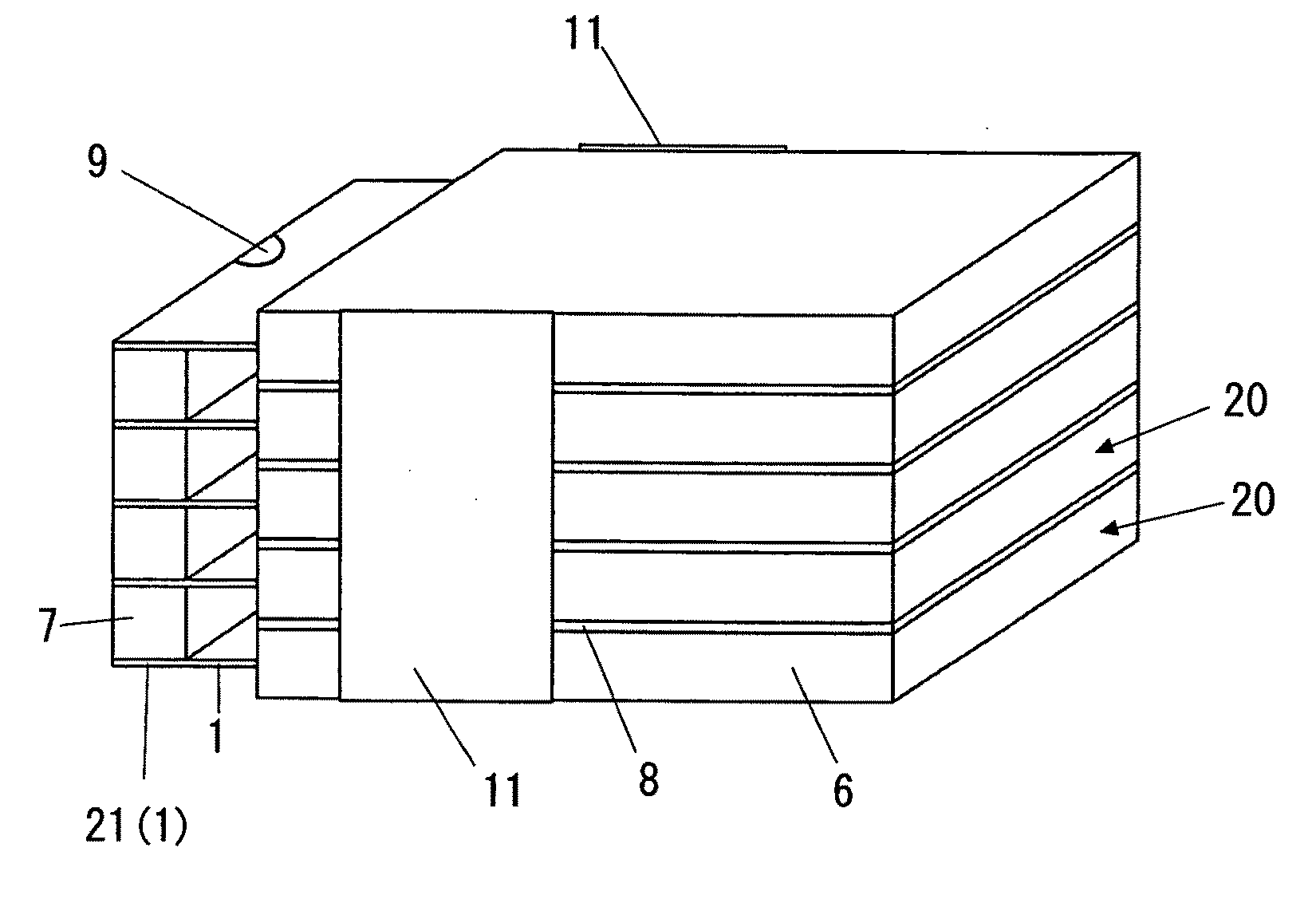

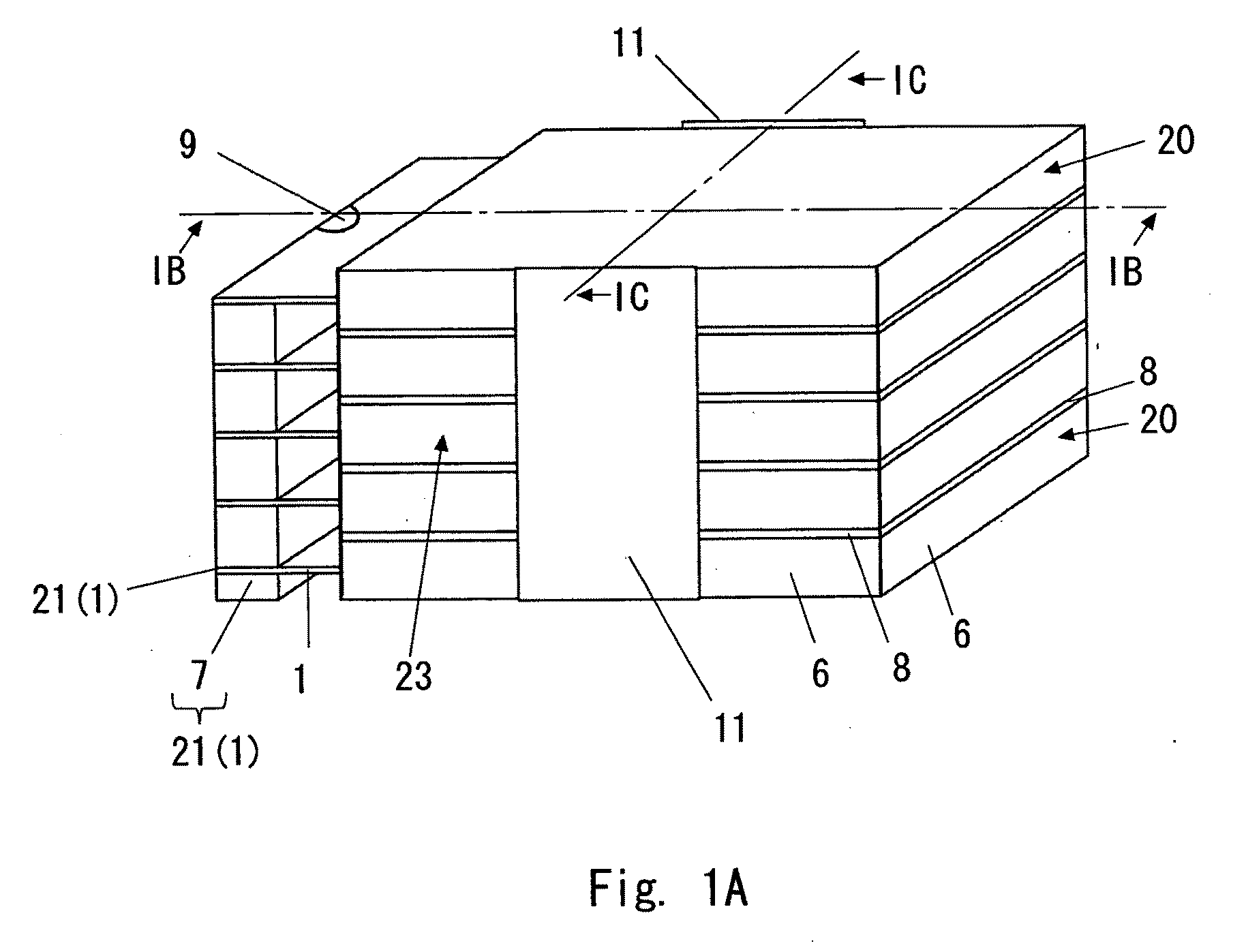

Stacked solid electrolytic capacitor

ActiveUS20090168304A1Lower ESRIncrease the number ofSolid electrolytic capacitorsFixed capacitor dielectricDielectricElectrolysis

The present invention provides a stacked solid electrolytic capacitor that allows further reducing ESR by increasing the number of stacked layers. The stacked solid electrolytic capacitor according to the present invention is a stacked solid electrolytic capacitor having a plurality of stacked solid electrolytic capacitor elements, and each solid electrolytic capacitor element comprises an anode formed of a valve action metal, an anode section formed on an end of the anode, a dielectric formed on the surface of the valve action metal and comprising an oxide of the valve action metal, and a cathode layer formed on the dielectric. The cathode layers and the anode sections of the solid electrolytic capacitor elements are respectively connected to each other across the plurality of stacked solid electrolytic capacitor elements. A conductive layer extending in the stacking direction is formed on at least part of a side face of an area where the cathode layers of the solid electrolytic capacitor elements are formed.

Owner:TOKIN CORP

Solid electrolytic capacitor

InactiveUS20080089014A1Reduce electric resistanceReduce ESRSolid electrolytic capacitorsLiquid electrolytic capacitorsEngineeringElectrical and Electronics engineering

A solid electrolytic capacitor includes a base substrate, a capacitor element, a metal cap, an extractor terminal and an insulating member. The base substrate has electrical conductivity. The capacitor element is provided on the base substrate. The metal cap is coupled to the base substrate and covers the capacitor element. The extractor terminal passes through the base substrate, is coupled to an anode of the capacitor element, and includes a first conductive member acting as a core member and a second conductive member covering the first conductive member. The insulating member is provided between the base substrate and the extractor terminal. Electrical conductivity of the first conductive member is higher than that of the second conductive member. Thermal expansion coefficient of the second conductive member is less than that of the insulating member.

Owner:NICHICON

Solid electrolytic capacitor and method for manufacturing the same

ActiveUS20090161297A1AdhesivenessImprove adhesionSolid electrolytic capacitorsLiquid electrolytic capacitorsCarbon layerSilver paste

Solid electrolytic capacitors are provided with decreased equivalent series resistance (ESR). The solid electrolytic capacitors include: an anode containing a valve metal or an alloy that is mainly made of a valve metal; a dielectric layer formed on a surface of the anode; an electrolyte layer formed on the dielectric layer; a carbon layer formed on the electrolyte layer; and a silver paste layer formed on the carbon layer, wherein the silver paste layer contains a nonionic surfactant.

Owner:SANYO ELECTRIC CO LTD

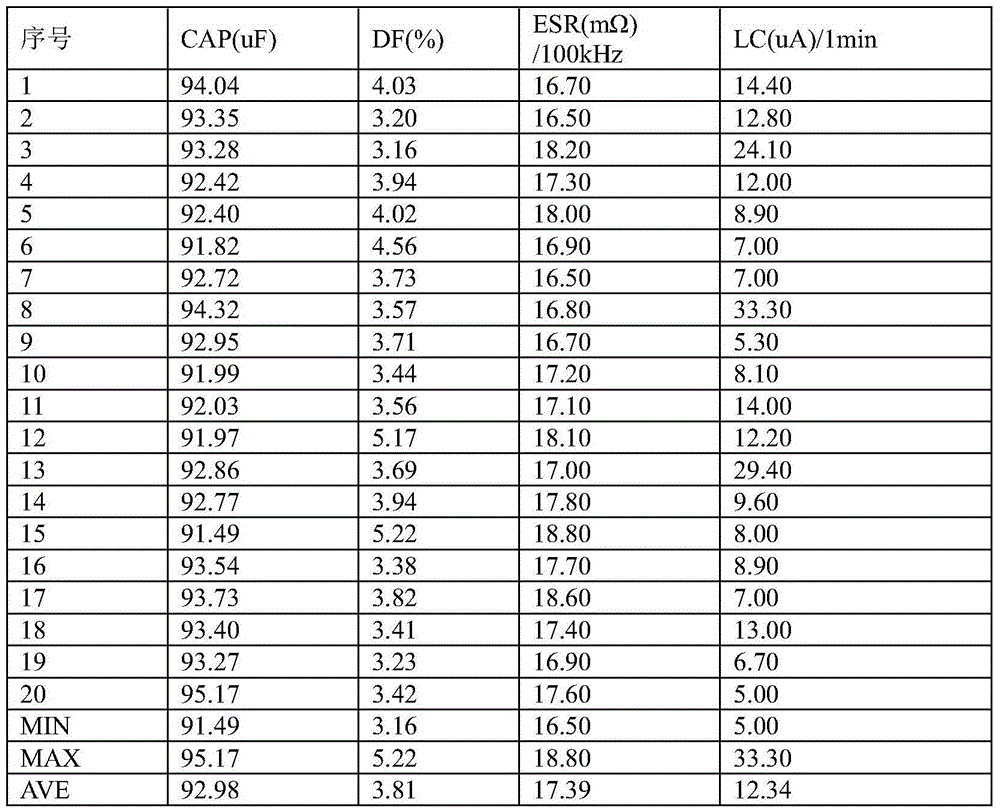

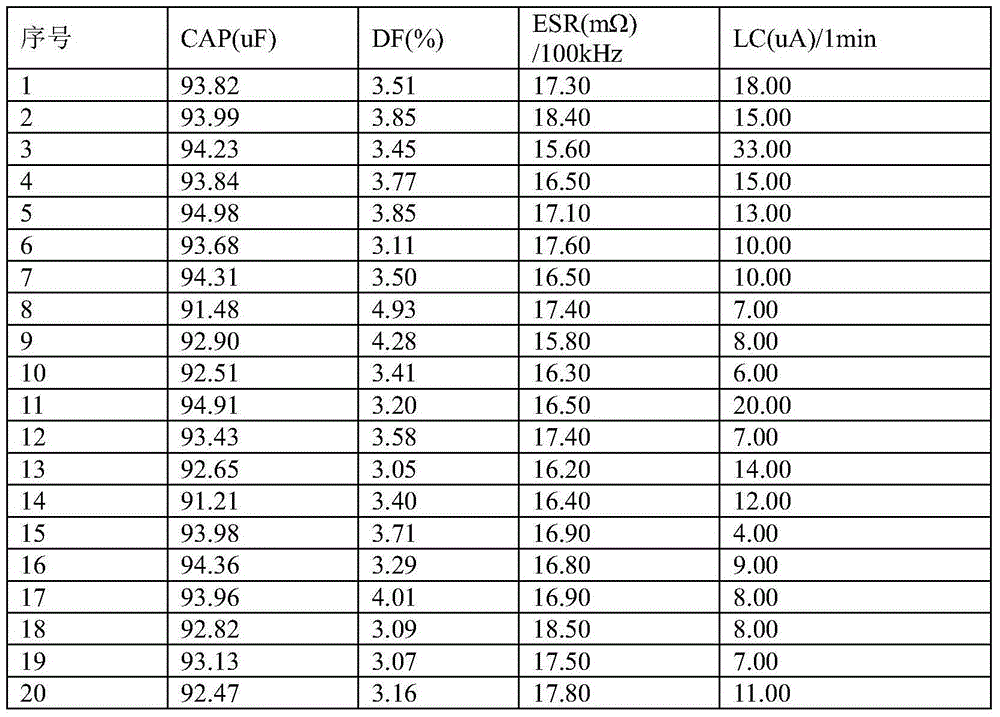

Manufacturing method for high-voltage solid electrolyte aluminum electrolytic capacitor

ActiveCN104637687AFully generatedImprove electrical performanceSolid electrolytic capacitorsCapacitor electrolytes/absorbentsConductive polymerOptoelectronics

The invention discloses a manufacturing method for a high-voltage solid electrolyte aluminum electrolytic capacitor. The manufacturing method comprises the following steps: firstly, welding a core cladding on an iron bar, applying voltage for formation, and then performing cleaning and drying; secondly, immersing the dried core cladding in a dispersoid A for 1-30 minutes; thirdly, moving the core cladding out of the dispersoid A, vacuumizing the core cladding and then immersing the core cladding into the dispersoid A for 1-10 minutes; fourthly, retaining the core cladding in the dispersoid A, breaking vacuum and then pressurizing, and maintaining the immersion time for 1-10 minutes; fifthly, retaining the core cladding into the dispersoid A, deflating to normal voltage and maintaining the immersion time for 1-10 minutes; sixthly, taking out the core cladding, placing the core cladding at the temperature 65-100DEG C and drying for 20-60 minutes, placing the core cladding at the temperature of 135-165DEG C and drying for 20-60 minutes; seventhly, at least repeating the third step to the sixth step once; eighthly, placing the treated substance in a casing, sealing and performing ageing treatment, wherein the dispersoid A is a dispersoid containing conducting polymer. According to the manufacturing method, a solid-state capacitor with a lower ESR (Equivalent Series Resistance) value and a higher voltage resisting value can be obtained; meanwhile, lower leak current is obtained.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Solid electrolyte capacitor and a method for manufacturing the same

ActiveUS20140334066A1Reduce conductivityImprove heat resistanceHybrid capacitorsDouble layer capacitorsOrganic solventBoiling point

There is provided an electrolyte capacitor, which has a low ESR, and is superior in the heat resistance and reliable under a hot condition. The electrolyte capacitors in constructed by including a conductive polymer and a conductive auxiliary liquid having a lower conductivity than usual electrolyte, having a structure below. The conductive auxiliary liquid includes a high boiling point organic solvent having a boiling point of 150° C. or more, and an aromatic compound having at least one hydroxyl group. The aromatic compounds preferably includes an aromatic compound having at least one carboxyl group or an aromatic compound having at least one nitro group, or a combination of an aromatic compound having at least one carboxyl group with an aromatic compound having at least one nitro group.

Owner:TAYCA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com