Carbon nanotube or carbon nanofiber electrode comprising sulfur or metal nanoparticles as a binder and process for preparing the same

A technology of metal nanoparticles and carbon nanofibers, which is applied in the direction of microscopic fiber electrodes, electrode manufacturing, hybrid capacitor electrodes, etc., can solve the problems of internal resistance increase and achieve low contact resistance, low ESR, and strong durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

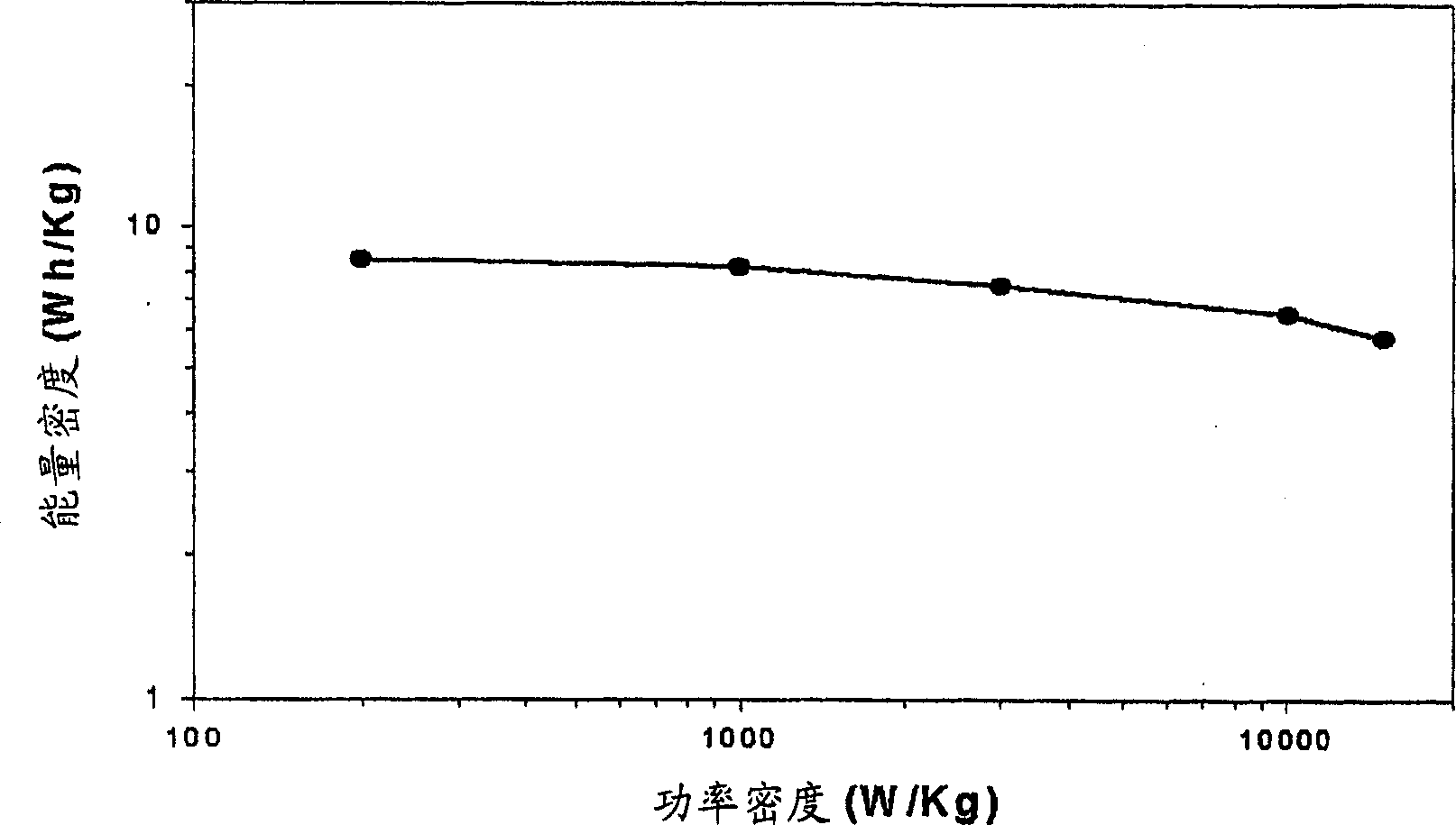

Image

Examples

preparation example Construction

[0073] In the process for preparing a carbon nanotube electrode or carbon nanofiber electrode according to the present invention, it is important to uniformly mix carbon nanotubes or carbon nanofibers with sulfur nanoparticles or metal nanoparticles used as a binder, but not Their methods are not particularly limited. As the mixing method, physical mixing, ultrasonic mixing, general dispersion in a solvent and then removing the solvent, and the like are mentioned.

[0074] In the description of the present invention, the word "metal" is not particularly limited literally, and refers to any material having electrical conductivity. For example, it represents in addition to nonmetals (elements in group VIII of the periodic table, F, Cl, Br and I in group VII, O in group VI, N in group V, H in group I) and semi-metals Any element other than a metal (B in Group IIIB, C, Si and Ge in Group IV, Se, Te and Po in Group V). In particular, the term "metal" in the present invention is n...

example 1

[0088] This example shows the fabrication of carbon nanotube electrodes or carbon nanofiber electrodes using copper (Cu) nanoparticles as a binder by depositing copper compound nanoparticles on carbon nanotubes and then reducing these nanoparticles of.

[0089] Carbon nanotubes (CNTs) used as electrode materials were synthesized by catalytic evaporation with an average diameter of 1 nm and 210 m 2 Single-walled nanotubes (SWCNT) (KH Chemicals Co., Ltd.) with a surface area of / g.

[0090] The copper compound Cu(NO 3 ) 2 deposited on carbon nanotubes. The carbon nanotubes deposited with copper compound nanoparticles were dried at 110°C for one day, and then reduced in hydrogen at 400°C for two hours. These Cu nanoparticle-deposited carbon nanotubes thus prepared were formed into discs under a pressure of 10 atm.

[0091] The Cu nanoparticle-deposited carbon nanotube disk was placed on a 75-μm-thick nickel foil as a current collector, and then kept at 900° C. for ten minu...

example 2

[0093] The Cu nanoparticle-deposited carbon nanotube powder prepared as in Example 1 was dispersed on a nickel foil as a current collector, and then kept at 1100° C. while applying pressure in nitrogen, thereby producing an electrode. The applied pressure was 10 atm, and the pressurization time was 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com