System for the detachable connection of thick parts

A large-thickness, parts-based technology, applied in the field of systems for detachably connecting large-thickness parts, can solve problems such as damage to rivet shells, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

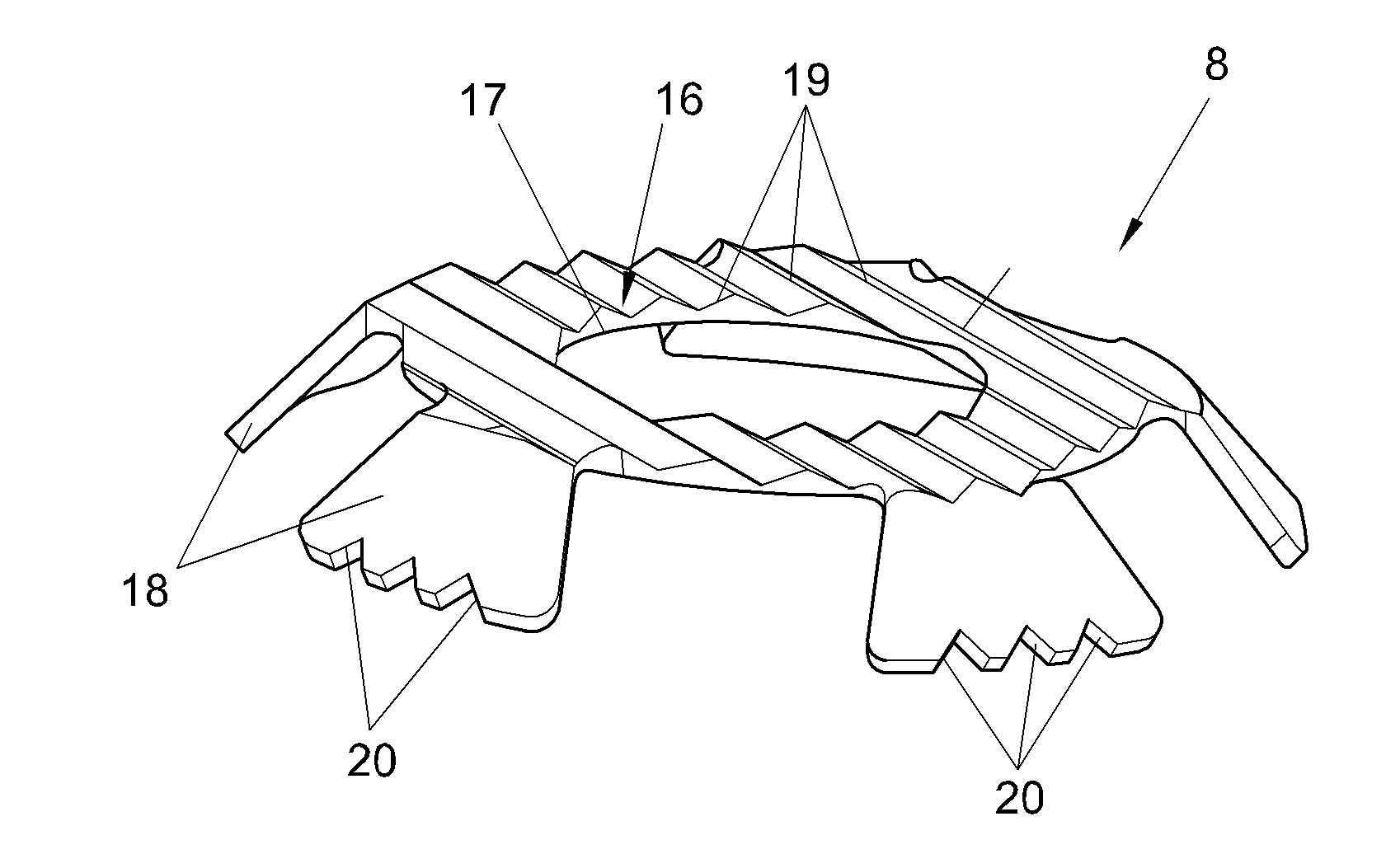

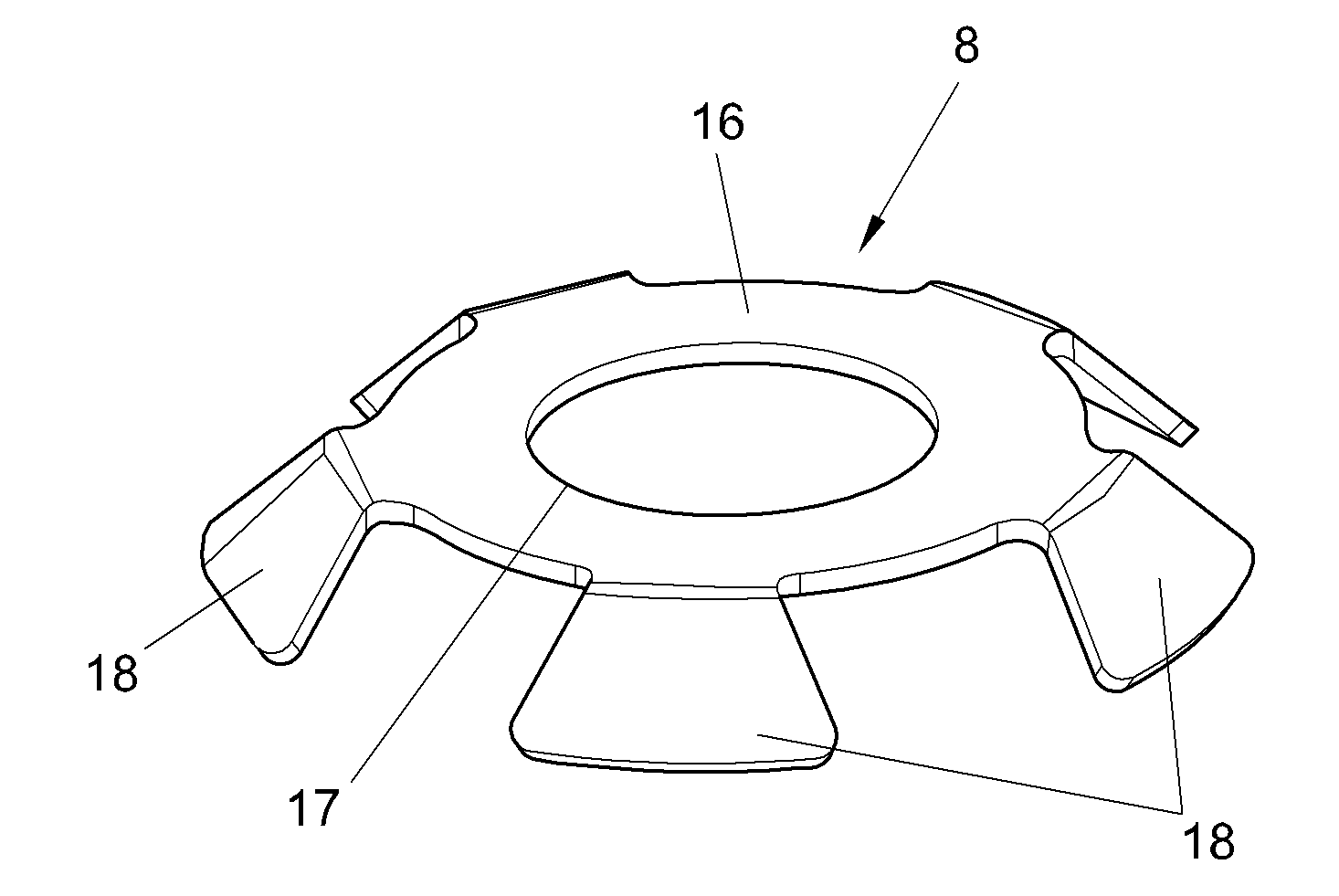

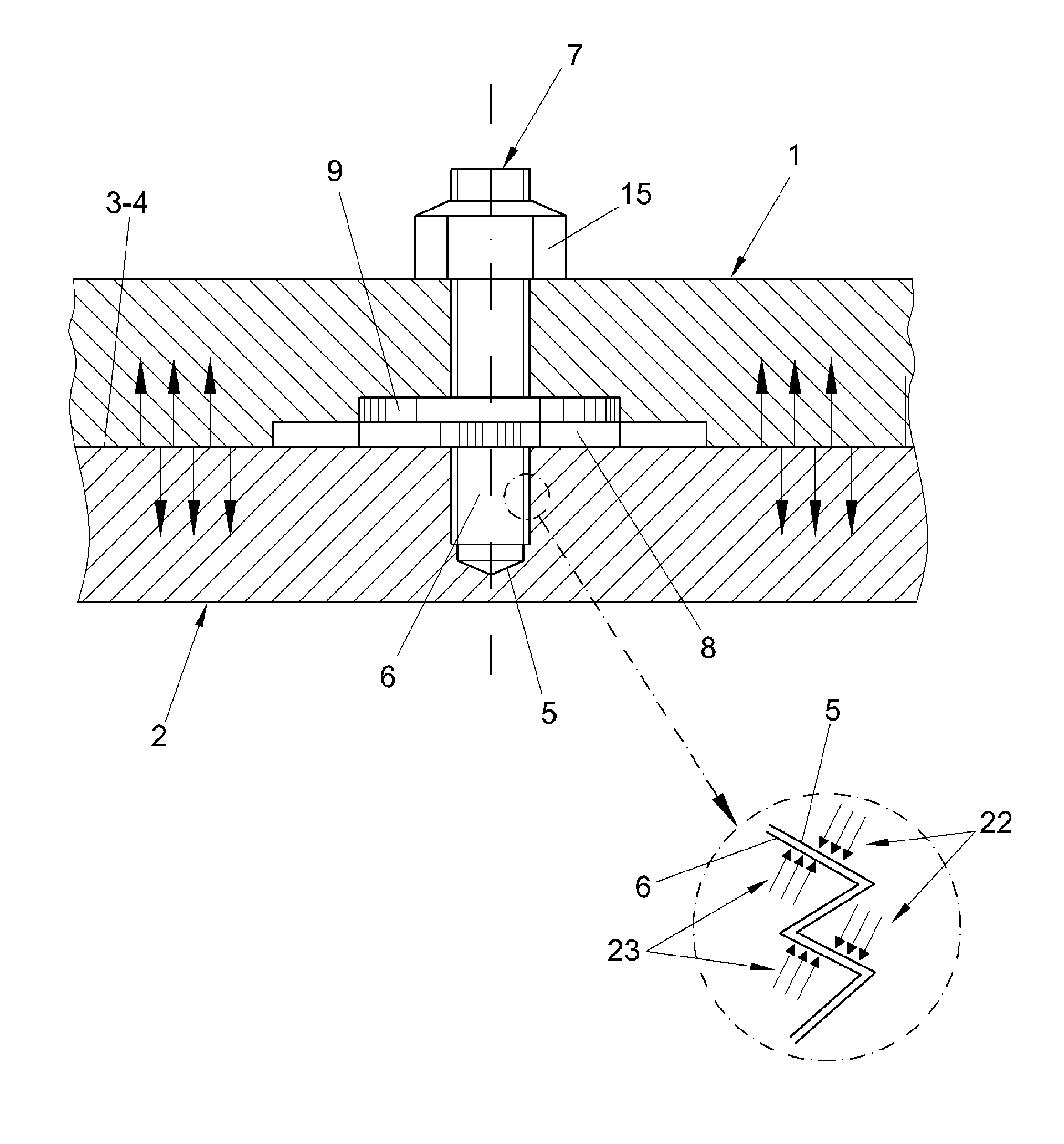

[0027] Taking into account the reference numerals used in the drawings, the system for detachably connecting parts of large thickness is intended for coupling two parts, namely an upper part 1 and another lower part 2, said upper part 1 and said lower part 2 are in direct contact through their respective inner end faces 3 and 4, so that the inner end face 4 of said lower part 2 comprises blind holes 5 provided with first strips for coupling bolts 7 the thread of the end section 6 of the thread, and the insertion of the characteristic elastic washer 8 in such a way that it comes into contact with the inner end face 4 of said lower part 2 and also brings it into contact with the annular extension 9 integrally formed with the bolt 7 itself, This ensures that the screws 7 are fastened to the lower part 2 . Thus, the annular extension 9 separates the lower part 10 corresponding to the lower part 2 from the upper part 11 corresponding to the upper part 1 .

[0028] Said elastic was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com