Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Titanium ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium rings are jewelry rings or bands which have been primarily constructed from titanium. The actual compositions of titanium can vary, such as "commercial pure" (99.2% titanium) or "aircraft grade" (primarily, 90% titanium, 6% aluminum, 4% vanadium), and titanium rings are often crafted in combination with other materials, such as gemstones and traditional jewelry metals. Even with these variations in composition and materials, titanium rings are commonly referred to as such if they contain any amount of titanium.

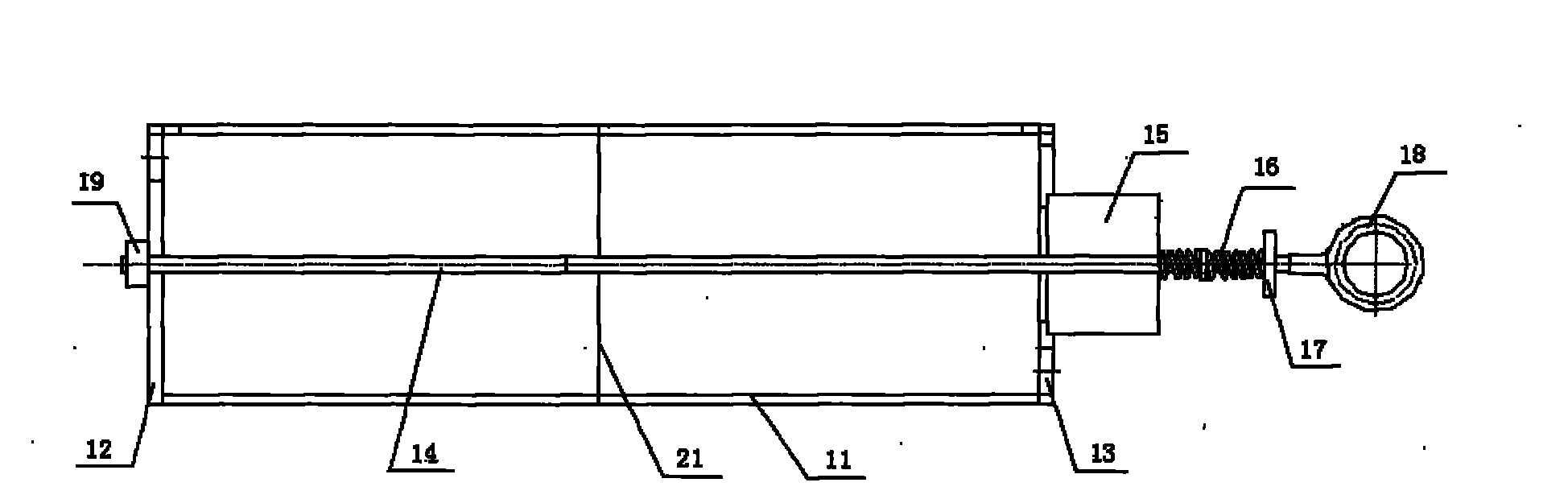

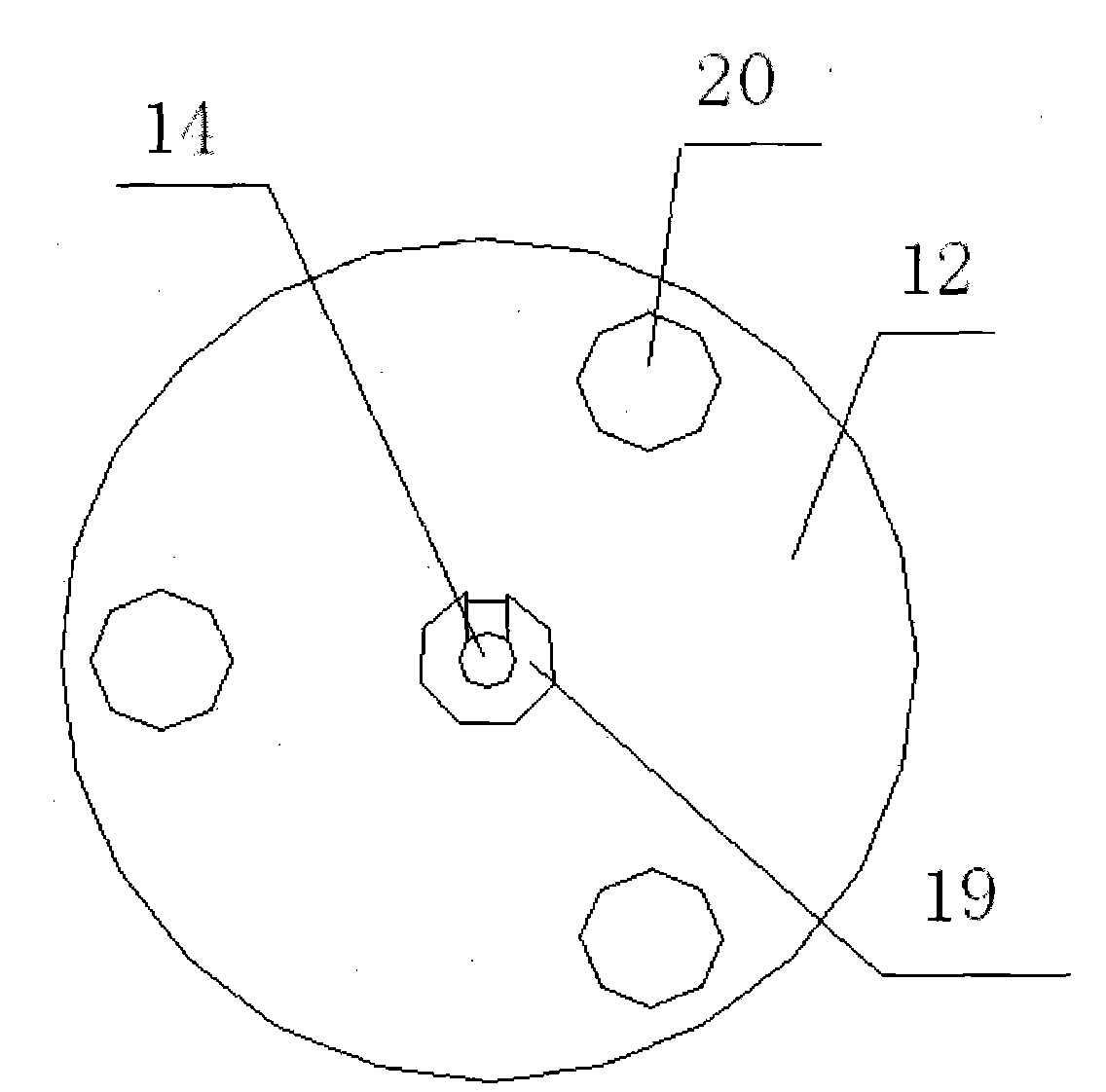

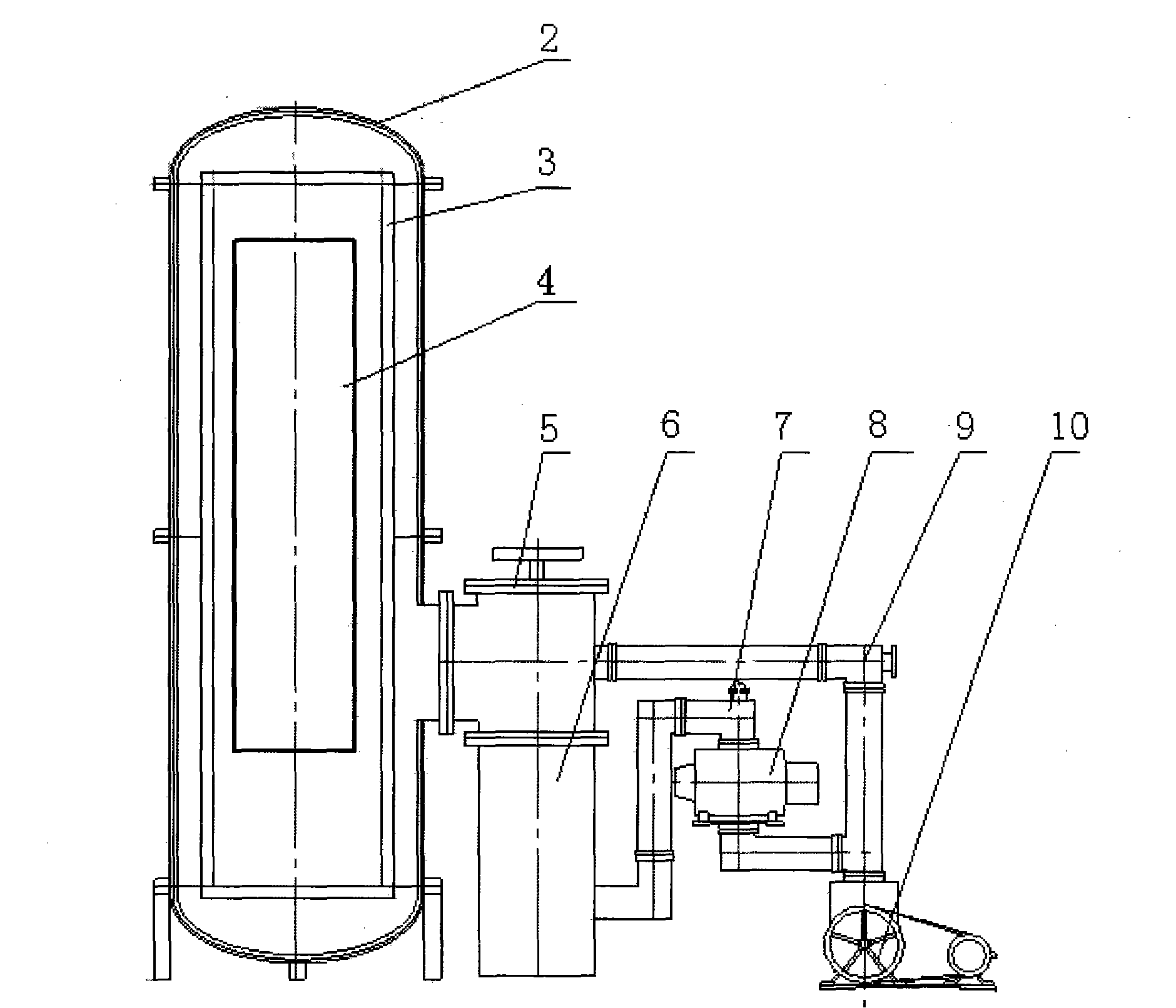

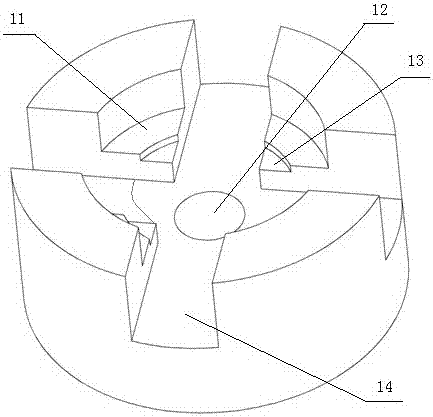

Underwater helicopter

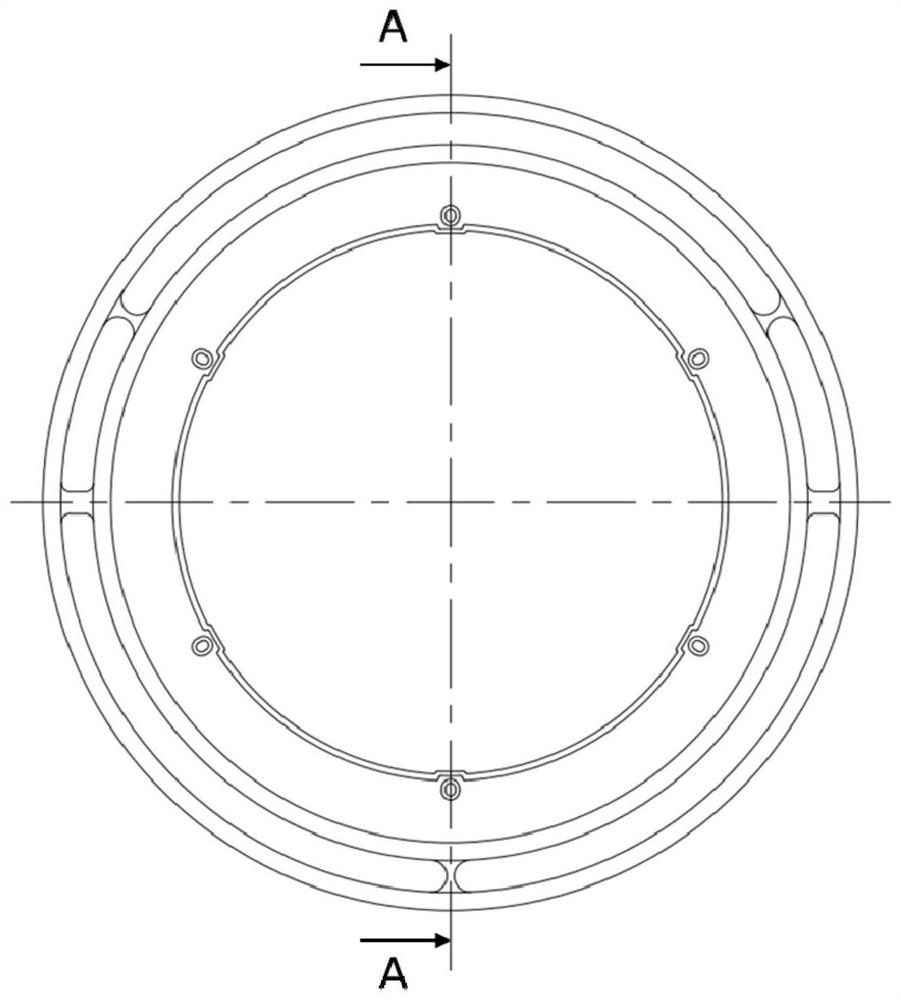

ActiveCN105947150AImplement the hover actionFreedom of movementUnderwater vesselsUnderwater equipmentFixed frameMarine engineering

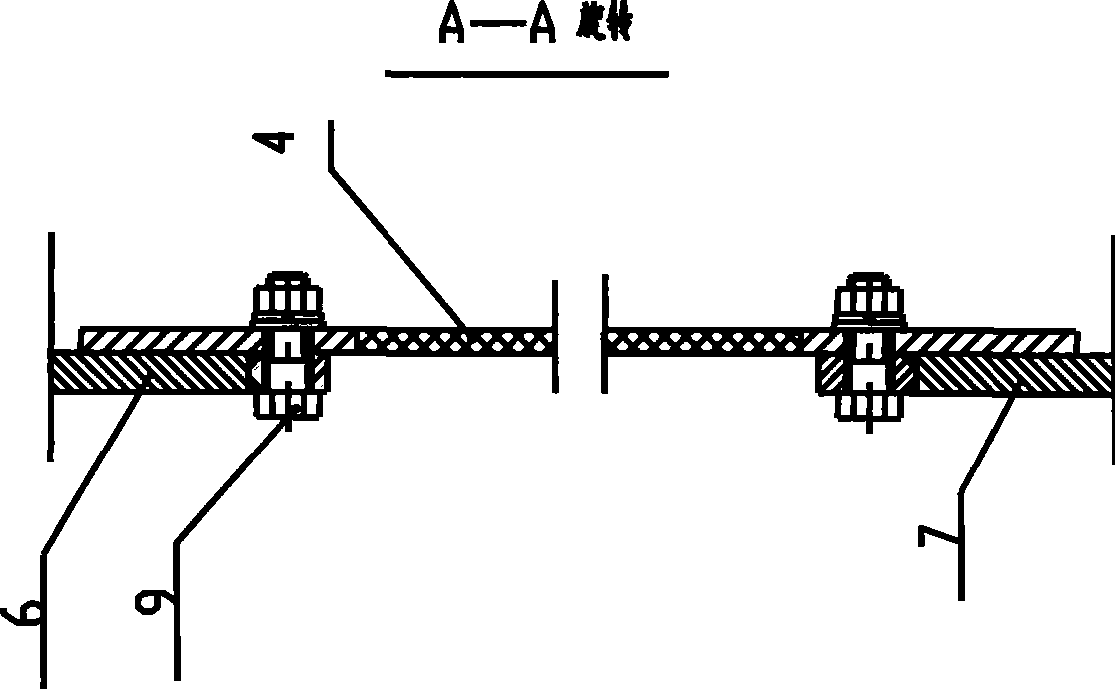

The invention provides an underwater helicopter. A main body part of the underwater helicopter is composed of an upper cover, a lower cover, thrusters, a titanium ring, a control barrel, a fixing frame, welding blocks, connecting blocks, fixing blocks and screw rods. The control barrel is fixed to the fixing frame. The welding blocks are welded to the tail ends of supporting rods of the fixing frame. The welding blocks, the connecting blocks and the titanium ring are fixed through bolts and nuts. The upper cover, the lower cover and the titanium ring are fixed with bolts penetrating through through holes. If the underwater helicopter needs to dive downwards or float upwards, only the horizontally-upward thrusters need to be controlled to rotate; if the underwater helicopter needs to go forward or backward, only the horizontal thrusters need to be controlled to rotate in a forward and reverse mode; and if the underwater helicopter needs to hover, only the horizontally-upward thrusters need to be controlled to offset the underwater mass of the underwater helicopter at the certain rotating speed. The underwater helicopter is easy and convenient to operate and very flexible.

Owner:浙江欧深泰海洋科技有限公司

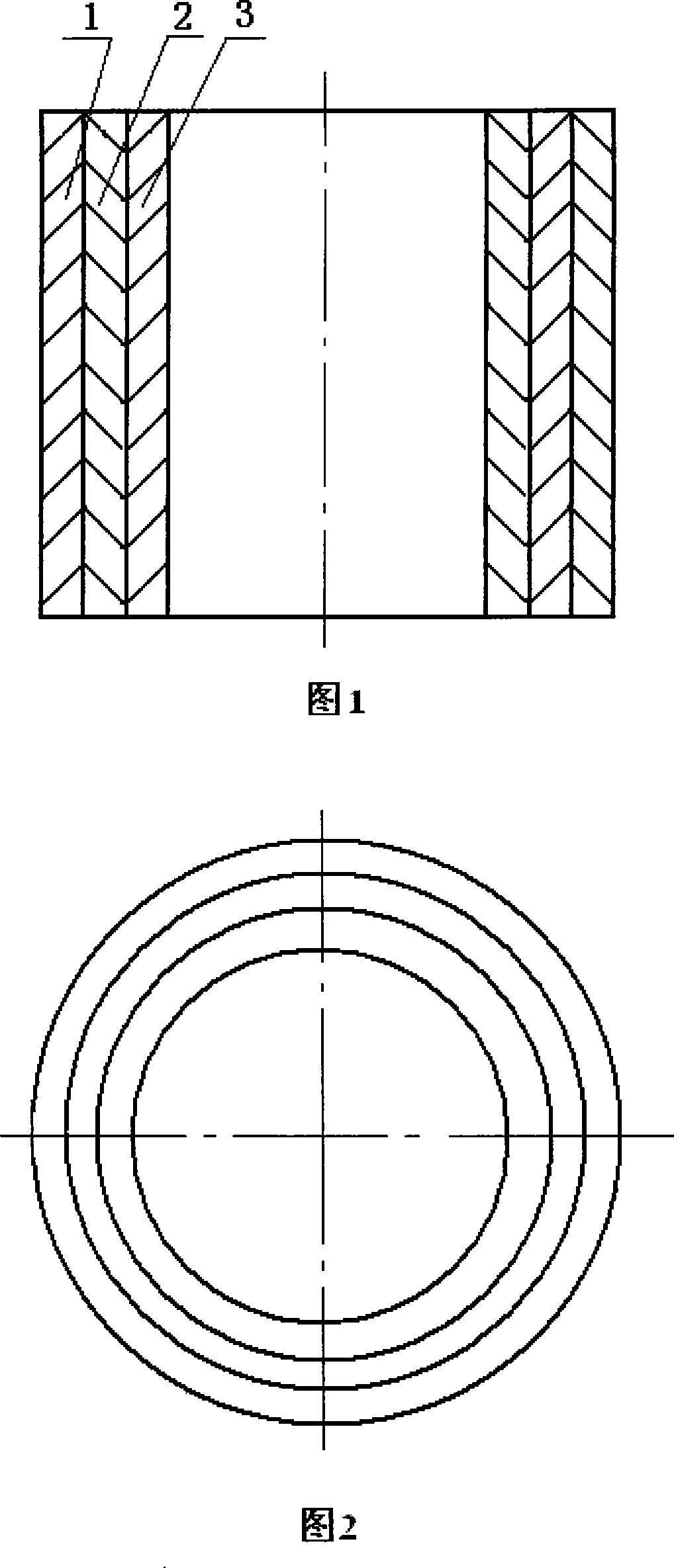

Sandwich type radial direction vibrating piezoelectric ceramic ultrasonic transducer

InactiveCN101111098AOptimization parametersRaise the resonant frequencyPiezoelectric/electrostrictive transducersElectromechanical coupling coefficientOmni directional

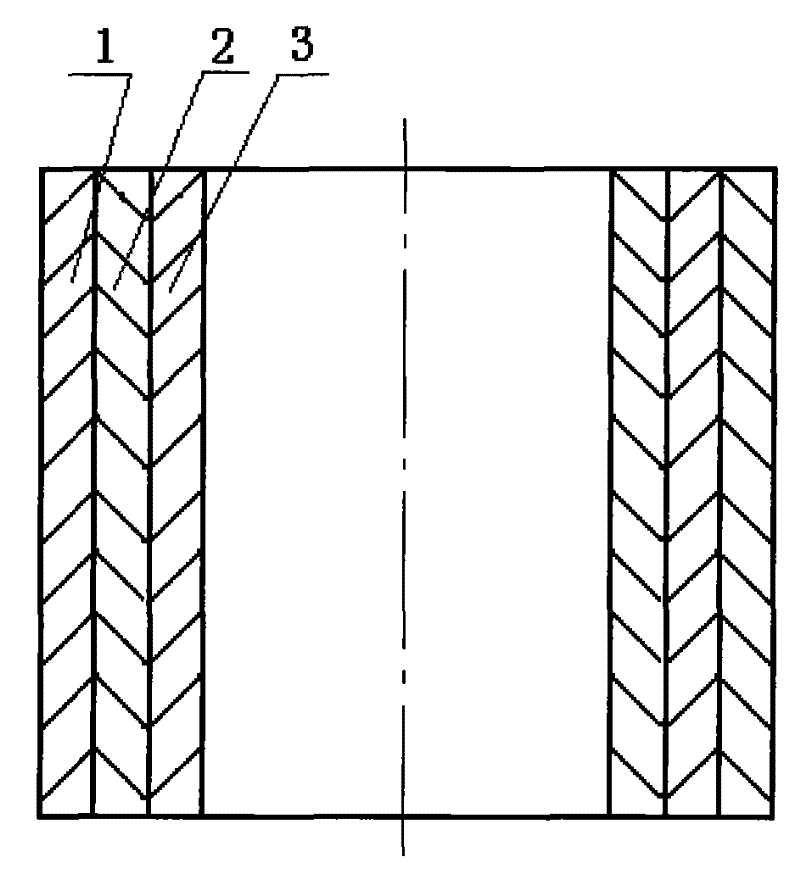

The present invention relates to a radial vibration sandwich piezoelectric ceramic ultrasonic transducer. A piezoelectric ceramic ring is arranged between a metal inner ring and a metal outer ring, the upper end surfaces of the metal inner ring, the metal outer ring and the piezoelectric ceramic ring are in the same plane, and lower end surfaces are also in the same plane. The metal inner ring and the metal outer ring can adopt steel rings, aluminum rings, brass or purple copper rings, titanium rings, aluminum nickel copper alloy rings and titanium alloy rings. The present invention realizes the high efficiency work of a radial composite transducer through a radial prestress impressed by the inner and outer metal rings, and realizes the parameter optimization of the transducer through reasonably designing the geometry size of the inner and outer metal rings simultaneously, such as resonance frequency, frequency bandwidth as well as electromechanical coupling coefficient. The present invention can be used for the high efficiency omni-directional acoustic source underwater and all kinds of supersonic processing high efficiency supersonic source in liquid.

Owner:SHAANXI NORMAL UNIV

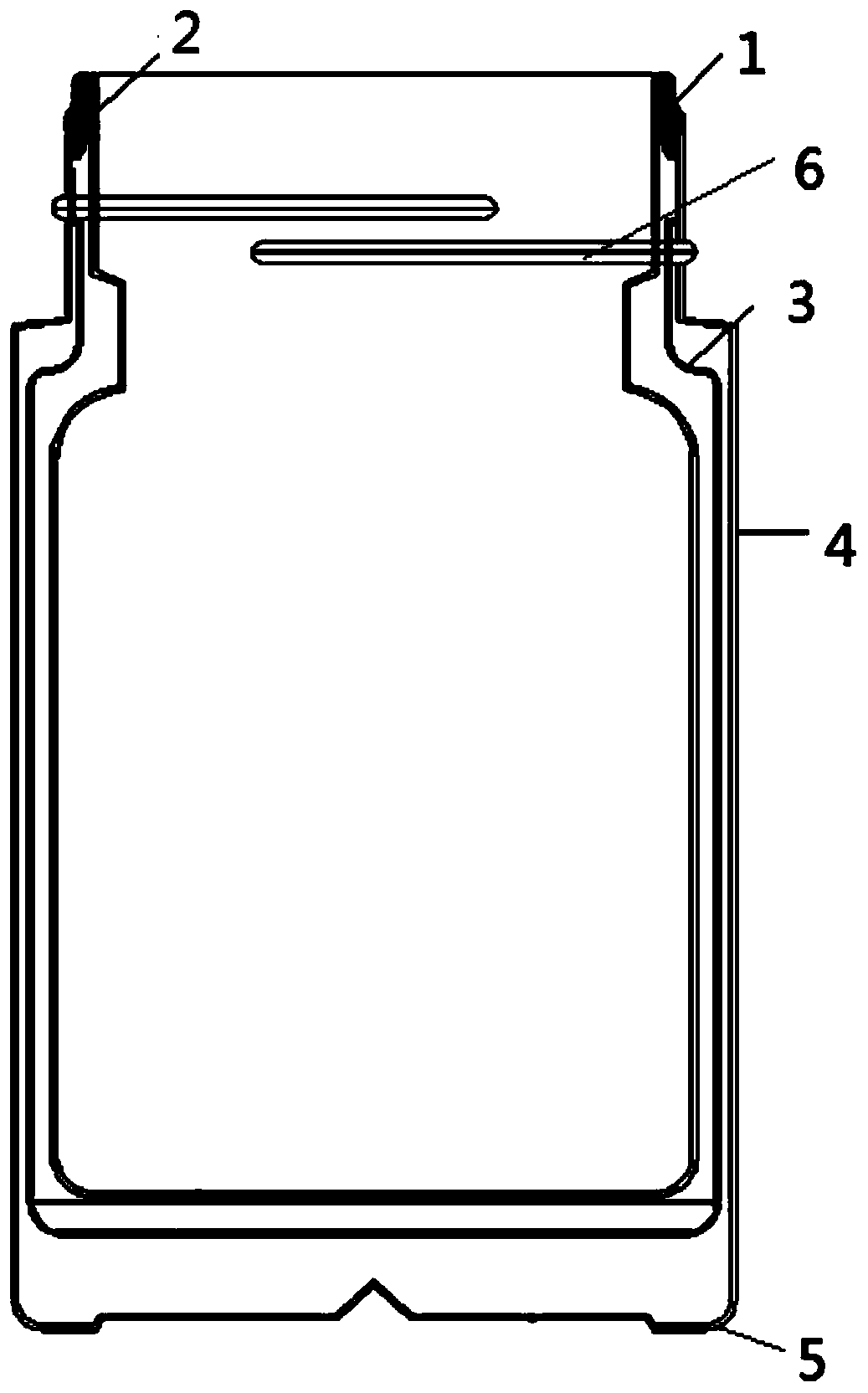

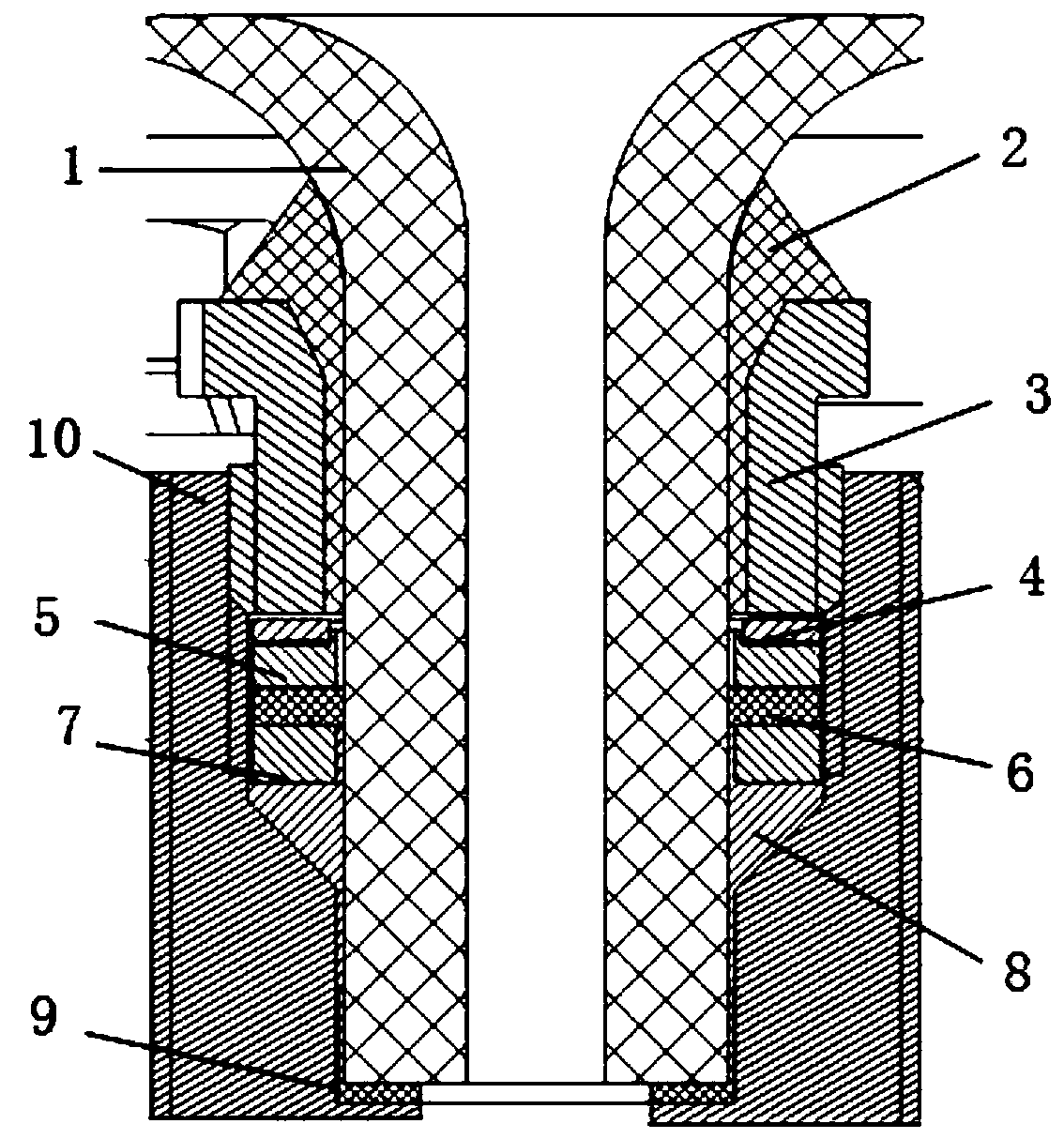

Three-layer vacuum titanium cup and preparation technology thereof

PendingCN110250859AAchieve the effect of vacuumImprove vacuuming effectWelding/soldering/cutting articlesDrinking vesselsThermal insulationTitanium

The invention belongs to the field of vacuum cup technical equipment, and particularly discloses a three-layer vacuum titanium cup and a preparation technology thereof. The three-layer vacuum titanium cup is sequentially provided with a titanium inner container, a stainless steel interlayer and a stainless steel outer layer at intervals from inside to outside, and stainless steel titanium rings used for sealing gaps among the titanium inner container, the stainless steel interlayer and the stainless steel outer layer are arranged at the tops of the titanium inner container, the stainless steel interlayer and the stainless steel outer layer. A thread is arranged at the top of the stainless steel outer layer. A protruding annular base is arranged at the bottom of the stainless steel outer layer. The three-layer vacuum titanium cup can improve the thermal insulation efficiency, and prolong the thermal insulation time.

Owner:永康市春佳工贸有限公司

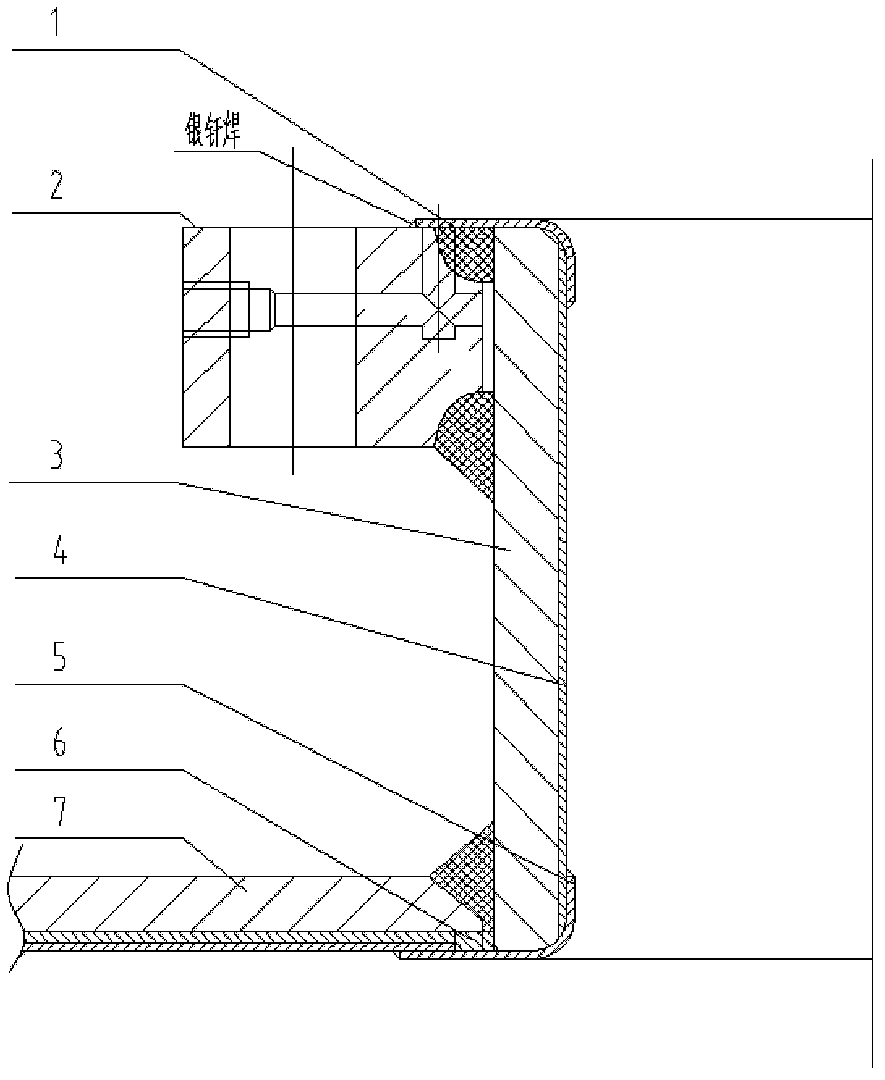

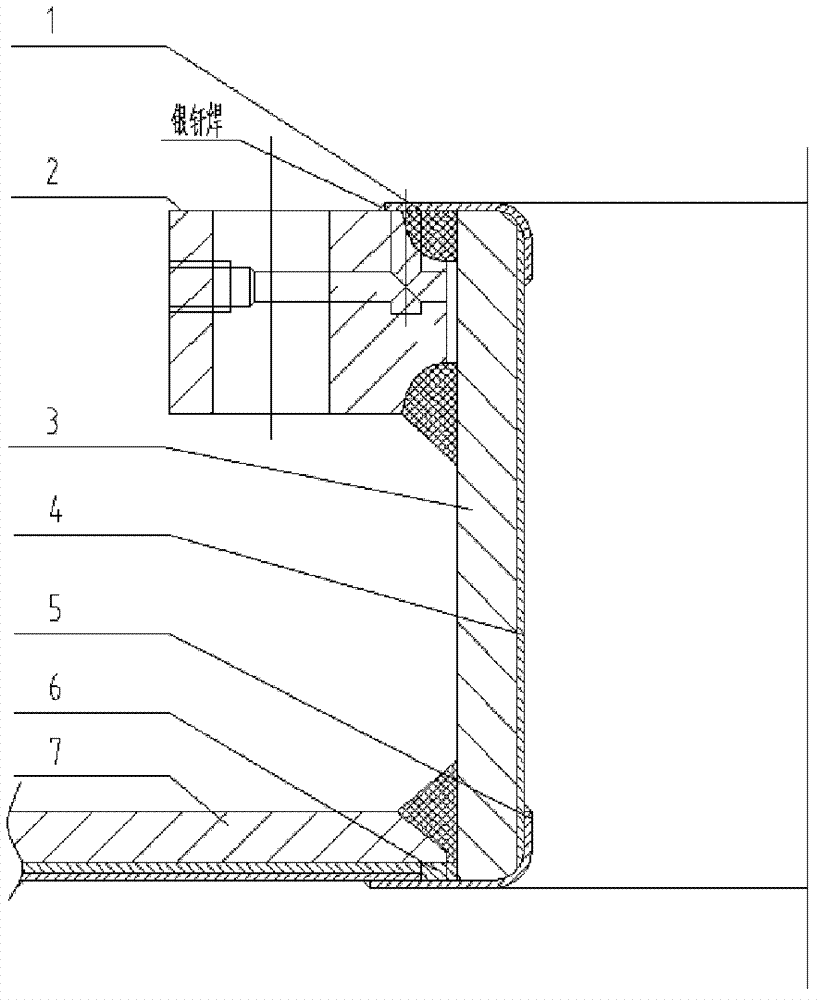

Method for braze-sealing of Al2O3 ceramic and titanium ring in artificial retina

ActiveCN105598542AAchieve biocompatible connectionsEye implantsSoldering apparatusTitanium ringRetina

The invention relates to a method for braze-sealing of an Al2O3 ceramic and a titanium ring in an artificial retina. Brazing filler metal is composed of, by mass, 6-85% of Ti powder and 15-94% of Ni powder. The granularity of the Ti powder and the Ni powder is 20-400 nm. The brazing filler metal obtained through ball milling is made into paste to be applied to a surface where the titanium ring and the Al2O3 ceramic are to be connected, a part to be welded is placed in a vacuum heating furnace, heating and heat insulation are conducted, and then welding is finished. By the adoption of the method, brazed connection of the titanium ring and the Al2O3 ceramic is achieved, and a reliable connector is obtained. The method is especially suitable for connection of the Al2O3 ceramic and the titanium ring in the artificial retina.

Owner:HARBIN INST OF TECH AT WEIHAI

High-strength and fatigue-resistant titanium ring and preparing method thereof

InactiveCN107012364AHigh precisionImprove impact resistanceLaser beam welding apparatusIngotTitanium

The invention provides a high-strength and fatigue-resistant titanium ring and a preparing method thereof. The high-strength and fatigue-resistant titanium ring is Ti-Al-Mo-V-Cr series alloy, wherein Ti alloy comprises a primary alpha phase of which the transverse-to-longitudinal ratio is 1-3. The preparing method specifically comprises: adopting sponge titanium, pure Al, pure Cr, Al-Mo intermediate alloy, Al-V intermediate alloy and Ti-Mo intermediate alloy as raw materials, pressing the materials into a consumable electrode under the condition that the purity is larger than 99%, and making a Ti-Al-Mo-V-Cr alloy ingot through the two-times smelting of a vacuum consumable electro-arc furnace; then, through cogging, deforming and repeated upsetting and drawing which are carried out at temperature lowered to 750-820DEG C, making a Ti ingot bar or plate after the accommodated deformation quantity is larger than 70%; after forging, rolling, heat treatment, levelling and machining, making a titanium plate; washing the titanium plate to remove dirt on the surface; then, engraving the grid surface of the titanium plate by using laser, and rolling the engraved titanium plate into the titanium ring by using a rolling machine; and finally carrying out washing and drying to obtain the high-strength and fatigue-resistant titanium ring.

Owner:郭和谦

Brazing process of ceramic vacuum pipe with diameter greater than 300mm and device

ActiveCN101767236AEnsuring natural capillarityEvenly distributedSoldering apparatusTubular articlesShielding gasNitrogen gas

The invention provides a brazing process of a ceramic vacuum pipe with diameter greater than 300mm and a device, comprising the following steps: firstly, cleaning the ceramic pipe and a titanium ring, then putting them into a vacuum furnace, conducting temperature-rising weld under vacuum condition, providing shielding gas after welding, taking the ceramic pipe out from the furnace, and completing the butt-weld of two ceramic vacuum pipes. The device provided by the invention comprises a first-class mechanical rotary vane pump, a second-class Roots pump, and a third-class oil diffusion pump; the pumps are arranged in serial, meanwhile, the device is provided with a pipeline for transmitting high-purity inert gas (such as nitrogen and argon) into the furnace. The advantages of the invention are as follows: the brazing process of the ceramic vacuum pipe with diameter greater than 300mm and the device is provided, the vacuum leak rate at welded joint of the welded ceramic pipes is less than 5 * 10-12Pa. M3 / s, and no crack exists on the ceramic pipe.

Owner:上海克林技术开发有限公司

Manufacturing method for tantalum composite board equipment

ActiveCN102513712AGuaranteed not to be directly solderedResolve connectionWelding apparatusSheet steelTitanium

The invention provides a manufacturing method for a piece of tantalum composite board equipment; tantalum-titanium-steel or tantalum-copper-steel composite boards are taken as main materials of the tantalum equipment; a connecting pipe adopts steel lining tantalum; a sealing surface is the turned structure of titanium welding tantalum ring; titanium lining outer edge is welded on the inner titanium layer of the connecting pipe; a flange is welded on the steel pipe of the connecting pipe; after being welded, the flange welds the weld joint between the flange and the connecting pipe by silver brazing; turned sides of the titanium ring are welded on the silver brazing so that titanium is directly welded with the steel; the manner of welding vertical and annular weld joint of the tantalum equipment is as follows: when two tantalum composite boards are opposite to each other, tantalum-titanium or tantalum-copper at the welding part of two tantalum-titanium-steel or tantalum-copper-steel composite boards removes a narrow strip; a copper board or tantalum board is welded on the steel board; two steel base boards are welded; and a tantalum sticker wider than the weld joint is welded with two tantalum boards. The manufacturing method ensures that the tantalum in the tantalum composite board equipment is not directly welded with steel, so that the connection problem of tantalum and steel is solved.

Owner:安徽宝泰特种材料有限公司

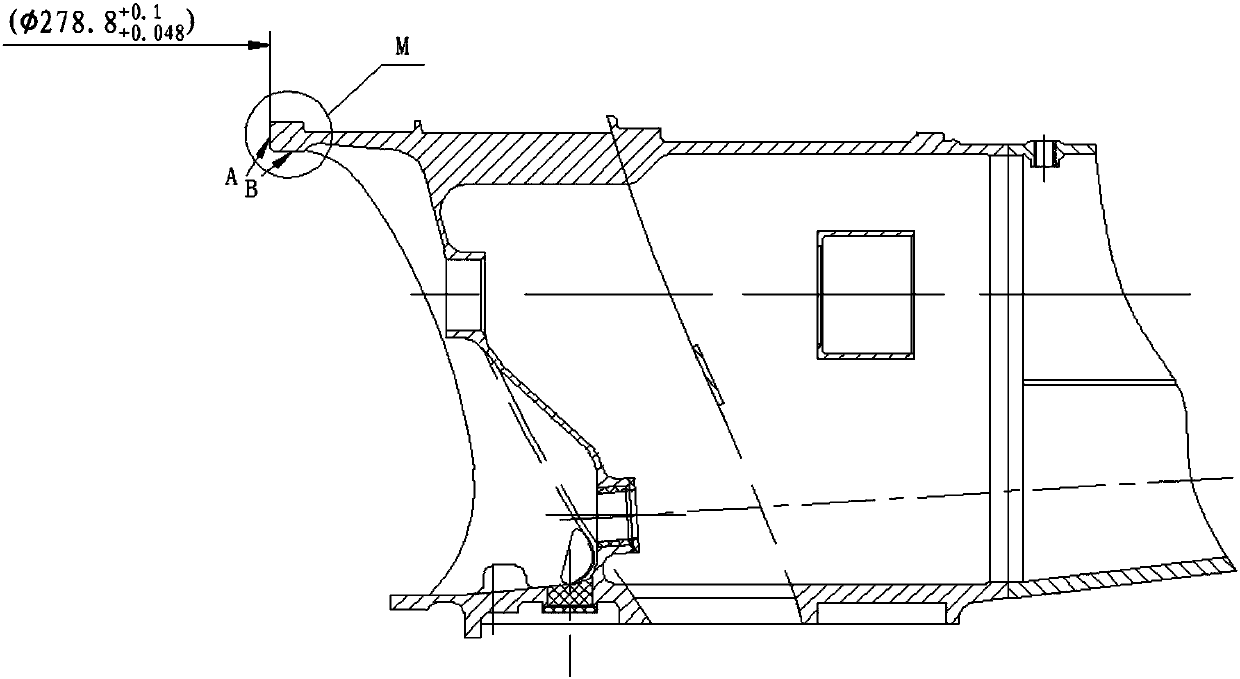

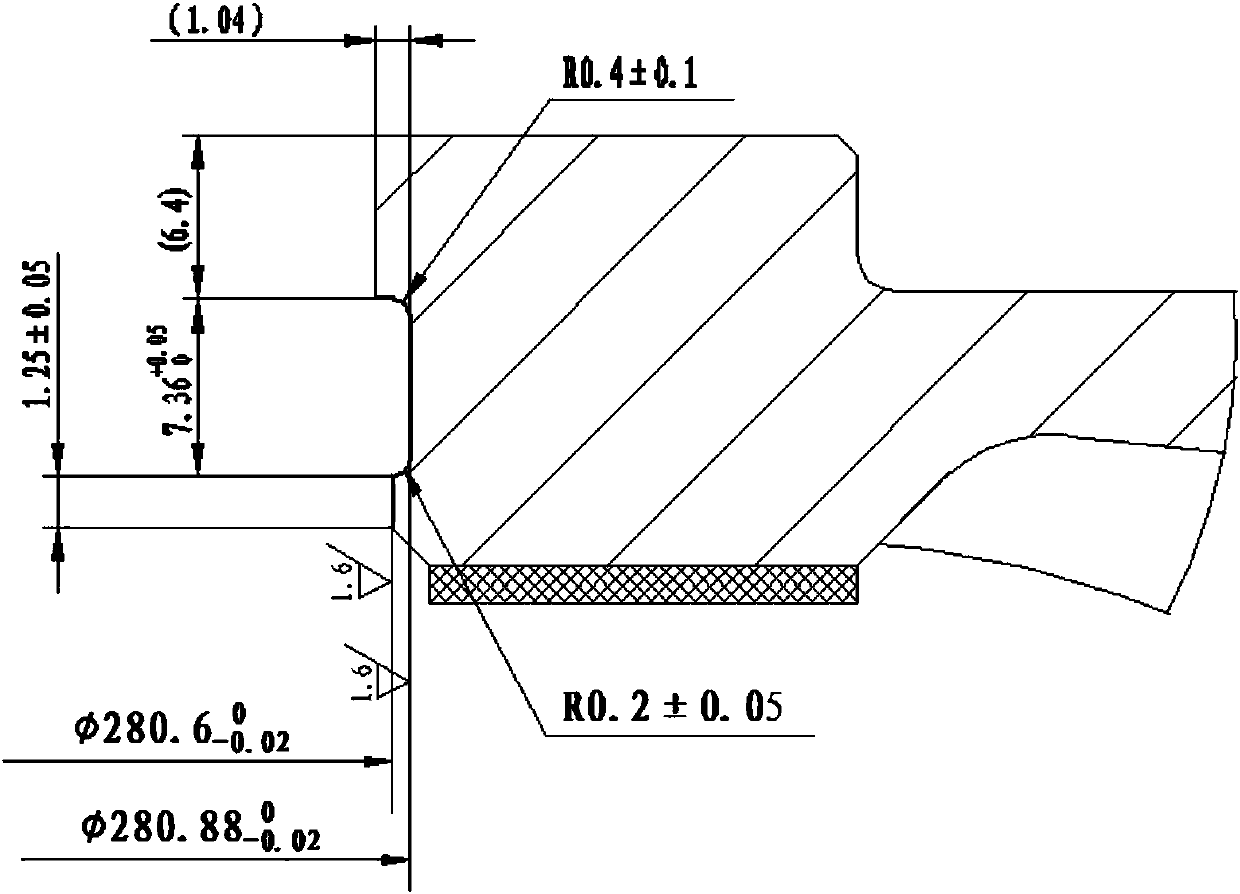

Repairing method for deformation of inner hole in rear end of intermediate case

The invention discloses a repairing method for deformation of an inner hole in the rear end of an intermediate case. The repairing method mainly comprises the following steps that 1, a positioning face of the intermediate case is turned, and the face A and the face B of a part needing to be repaired are turned; 2, turning burrs of the intermediate case are removed; 3, the surface and an inner cavity of a component are cleaned through alcohol; 4, fluorescent inspection is conducted on the turned repairing area of the intermediate case; 5, the surface and the inner cavity of the component are cleaned again; 6, a nickel-aluminum coating is plasma-sprayed on the face B; 7, an inner circular ring groove and a step are turned on the face A of the intermediate case; 8, a titanium ring is machined; 9, the titanium ring is assembled on the intermediate case; 10, the face A and the face B are machined; 11, the surface and the inner cavity of the component are cleaned through the alcohol; and 12,the component is checked, and thus repairing is completed. The repairing method has the advantages of being novel, easy to operate, convenient, effective, low in cost, obvious in application effect and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

High-tubular thin-walled pure titanium ring stable rolling process

The invention discloses a high-tubular thin-walled pure titanium ring stable rolling process. The process steps are as follows: free forging performing, roughing and ring rolling. The above-mentionedhigh-tubular thin-walled pure titanium ring stable rolling process adopts free forging performing. On the one hand, the potential defects such as shrinkage cavities, shrinkage, and pores ect. in the titanium billet are eliminated, so that the titanium billet has higher mechanical properties. On the other hand, the preforming of the titanium billet makes the rolling amount of the ring rolling smaller, thereby providing conditions for one heat complete ring rolling process in a rolling temperature range of the pure titanium material while improving the rolling stability, so that the grain size of the ring can be increased; the roughing before the ring rolling can remove the surface defects to reduce the incidence of roll creeping, skull patch and ellipse when rolling the ring; in the ring rolling, a support of the ring by a carrier roller can greatly reduce the friction force, thereby improving the stability of the ring during rolling, in addition, the setting of each parameter in the ring rolling can improve the stability of the rolling, thereby reducing the incidence of roll creeping, skull patch and ellipse.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

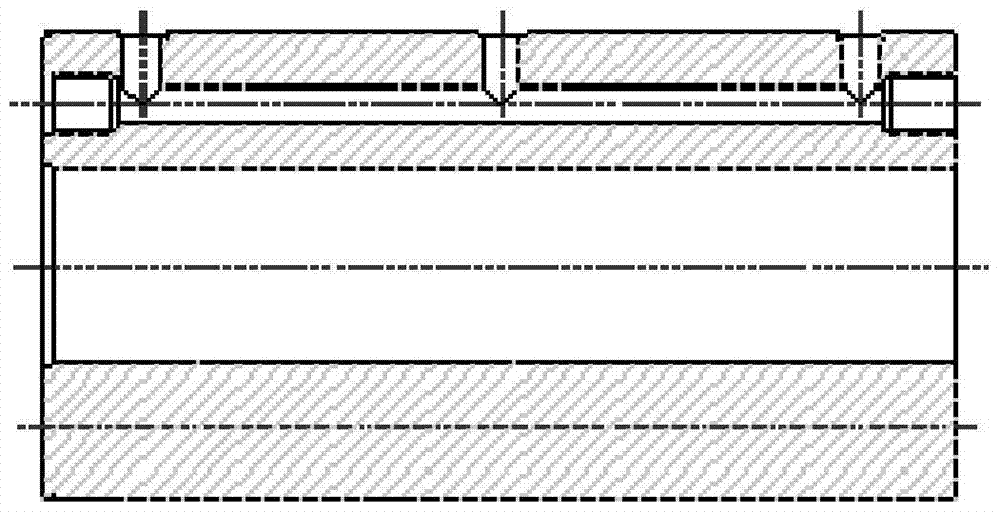

Soft conductive structure in cathode roller of foil manufacturing machine and calculating method of conductive belt section area

ActiveCN101392393AImprove conductivityImprove uniformityElectroforming processesCarrying capacityEngineering

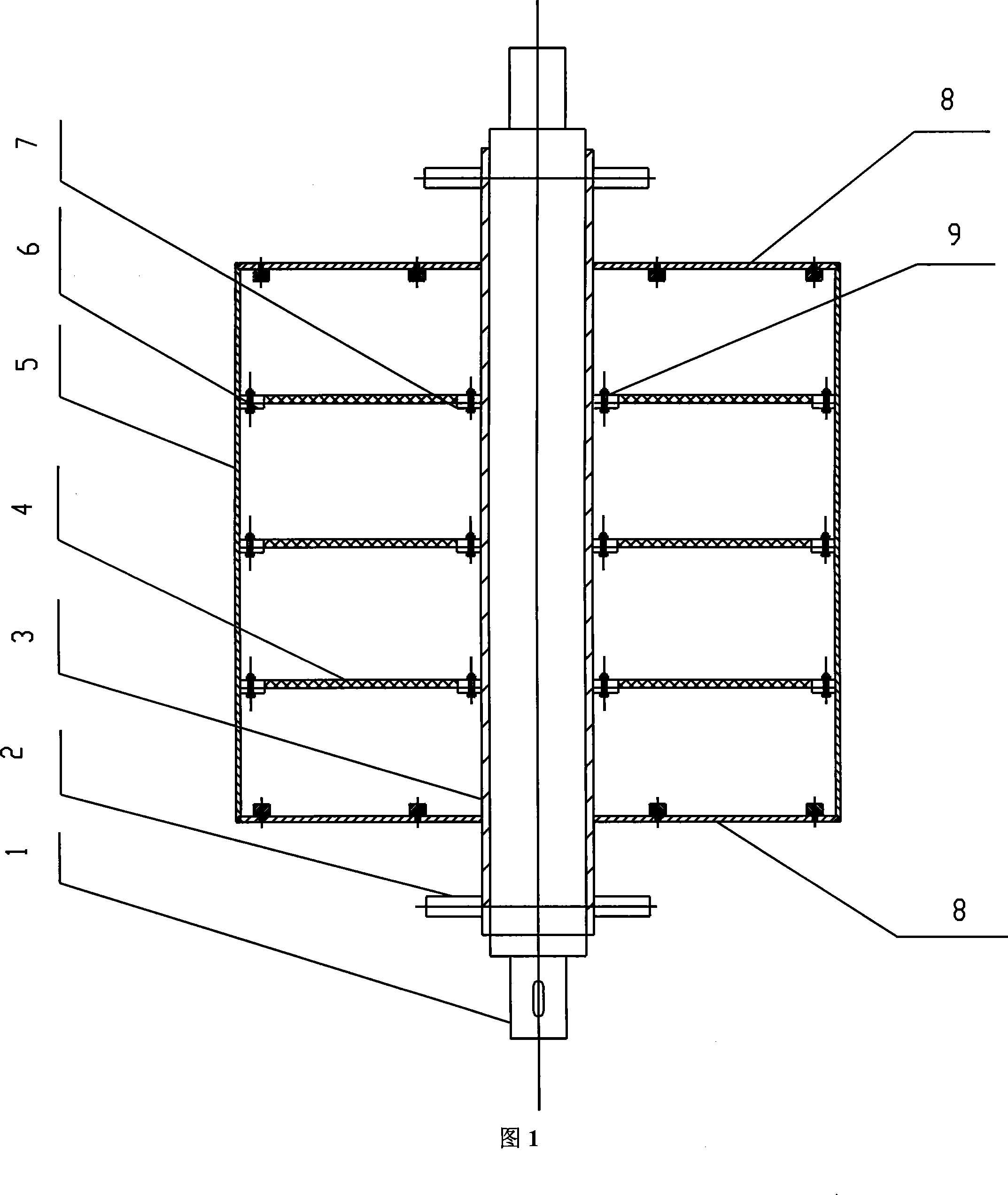

The invention relates to a soft conductive structure inside a cathode roll of a crude foil engine. The structure comprises a conductive belt (4), a conductive sleeve (3), a titanium ring (6), a conductive copper ring (2), a sleeve flange (7) and connector sleeves (10). The conductive belt (4) is intertwined with pure copper threads and has connector sleeves at both ends. Through the connector sleeves, both ends of the conductive belt are respectively and fixedly connected with the titanium ring (6) and the sleeve flange (7). The surfaces of both the conductive belt (4) and the connector sleeves (10) are plated with silver or stannum. In this invention, the conductive belt is intertwined with pure copper threads, thereby the soft connection between the conductive sleeve and the surface of the cathode roll is realized, the conductivity of the conductive belt is strengthened and the conductivity uniformity of the surface of the cathode roll is improved. The soft conductive structure also overcomes the deficiency of distortions caused by vibration and thermal inflation of the conductive belt and the movability of the connecting parts, and improves the conductive efficiency and current carrying capacity. The soft conductive structure is characterized by the stable connection, convenient maintenance and processing, simple operation and high production efficiency.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

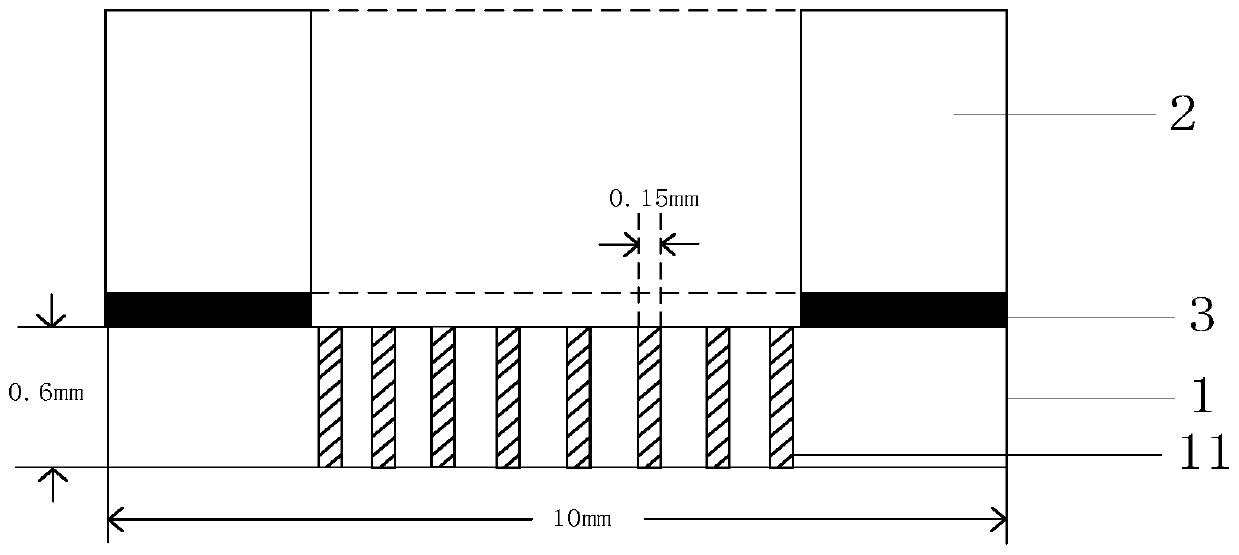

Preparation method forlarge-grain and low-hardness sputtering titanium ring

InactiveCN107904563AReduce residual stressAvoid deformationVacuum evaporation coatingSputtering coatingSputteringManufacturing technology

The invention discloses a preparation method for a large-grain and low-hardness sputtering titanium ring, and belongs to the technical field of manufacturing of magnetron sputtering targets. The method comprises the steps of providing a high-purity titanium ingot, carrying out first heat treatment, carrying out hot heading, carrying out cold rolling, carrying out second heat treatment, carrying out cutting, carrying out edge rolling and carrying out third heat treatment. The method has the advantages that the titanium ingot is subjected to heat treatment and deformation so as to obtain the large-grain and low-hardness sputtering titanium ring; a port of the sputtering titanium ring is in an upright S shape, the grain size of the large crystal grain is larger than 200 microns, the hardnessvalue of the low hardness is lower than the Vickers hardness 70; and compared with a traditional sputtering titanium ring, the large-grain and low-hardness sputtering titanium ring has the advantagesthat the size of the prepared titanium ring is large, the deformation resistance of the sputtering ring is small, the titanium ring is convenient to mount and dismount, damage to the surface of the sputtering ring in the mounting and dismounting processes can be reduced, and therefore the product quality can be improved, and the operation difficulty can be reduced.

Owner:GRIKIN ADVANCED MATERIALS

Sandwich type radial direction vibrating piezoelectric ceramic ultrasonic transducer

InactiveCN101111098BPiezoelectric/electrostrictive transducersElectromechanical coupling coefficientOmni directional

Owner:SHAANXI NORMAL UNIV

Production process of high-strength Ti75 titanium ring

PendingCN112893760AHigh tensile strengthHigh strengthFurnace typesEngine componentsHeating timeShrinkage rate

The invention discloses a production process of a high-strength Ti75 titanium ring. The production process comprises the following steps: materials are fed; inspection is carried out; for the first fire, 4500 T equipment is used, preheating is conducted for 1.8-2.2 hours at the temperature of 750-850 DEG C, then the temperature is increased to 1,110-1,150 DEG C, the heat preservation time is 400-460 min, and the temperature rise rate is kept at 10 DEG C / min in the temperature rise process; for the second fire, 2000T equipment is used, and heat preservation is carried out for 215-245 minutes at the temperature of 970-1,000 DEG C; for the third fire, 2000T equipment is used, and heat preservation is conducted for 215-245 min at the temperature of 930-955 DEG C; for the fourth fire, 2000T equipment is used, and heat preservation is conducted for 215-245 min at the temperature of 900-928 DEG C; for the fifth fire, 2000T equipment is used for the fifth fire, the overall remelting temperature is increased to 890-910 DEG C, and the heating time is 20-40 minutes; for the sixth fire, a 2000 T device is used, and mandrel drawing and mandrel supporter reaming are conducted at the temperature of 860-895 DEG C; for the seventh fire, heat preservation is conducted for 15-25 min at the temperature of 700-740 DEG C, and stress relief annealing is conducted; The tensile strength, the yield strength, the elongation, the shrinkage rate, the impact strength and the hardness of the Ti75 titanium ring obtained through the production process are all superior to those of an existing Ti75 titanium ring, and the Ti75 titanium ring has the advantage of being high in strength.

Owner:陕西茂松科创有限公司

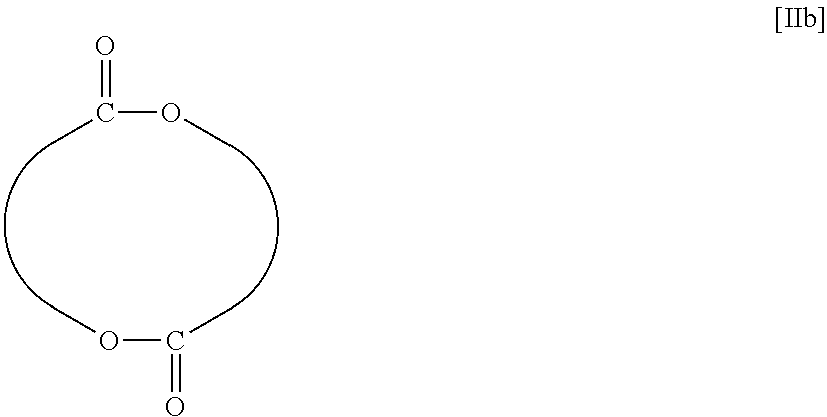

Method for producing polyester

A cyclic ester such as lactides and the like is mixed, in an organic solvent, with an alkyl aluminum compound such as trimethyl aluminum, triethyl aluminum and the like, and then, to the resulting mixture, at least one selected from the group consisting of an organic lithium ring-opening polymerization catalyst, an organic sodium ring-opening polymerization catalyst, an organic potassium ring-opening polymerization catalyst, an organic zinc ring-opening polymerization catalyst, an organic magnesium ring-opening polymerization catalyst, an organic tin ring-opening polymerization catalyst, an organic calcium ring-opening polymerization catalyst, an organic titanium ring-opening polymerization catalyst, and an amine ring-opening polymerization catalyst to allow ring-opening polymerization of the cyclic ester, thereby a polyester is obtained.

Owner:NIPPON SODA CO LTD

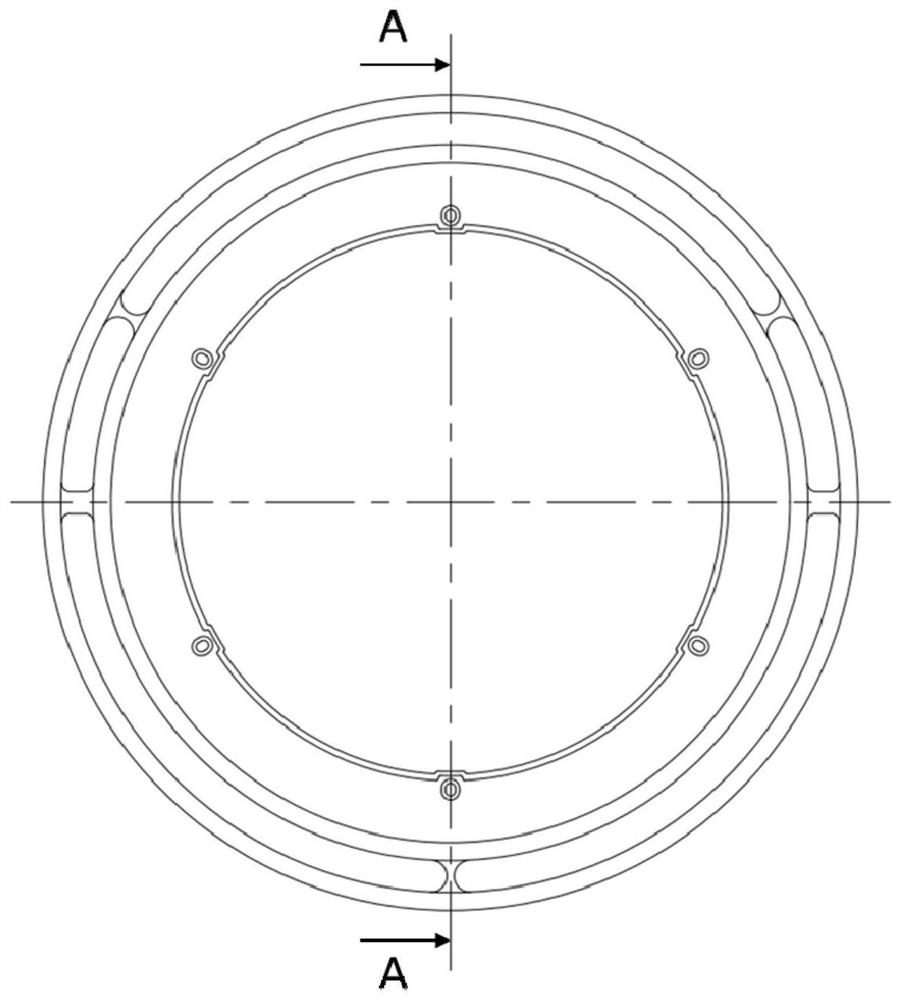

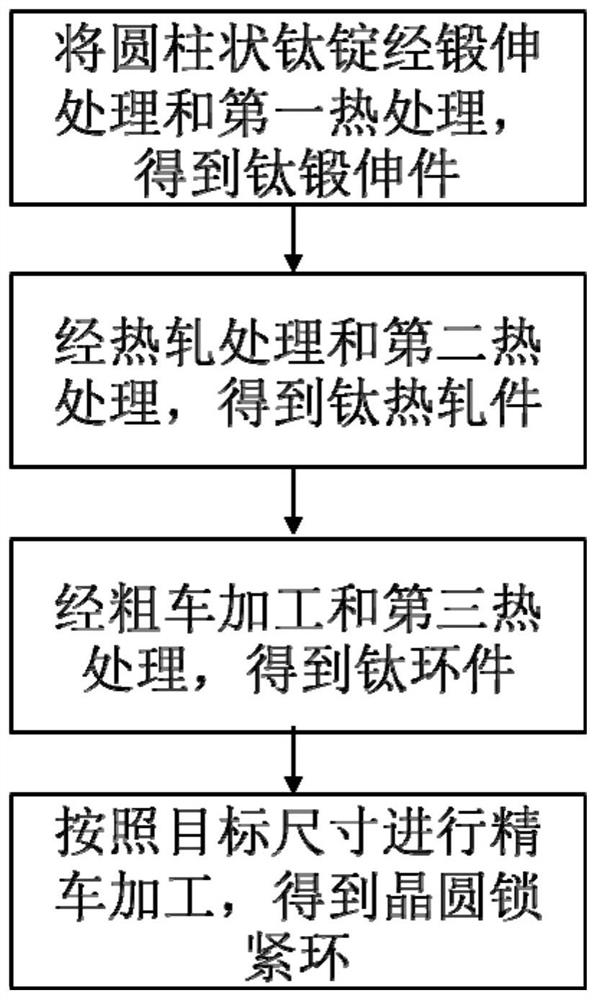

Preparation method of wafer locking ring

ActiveCN112589383AEliminate defects such as as-cast porositySimple structureVacuum evaporation coatingMetal-working apparatusWaferIngot

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

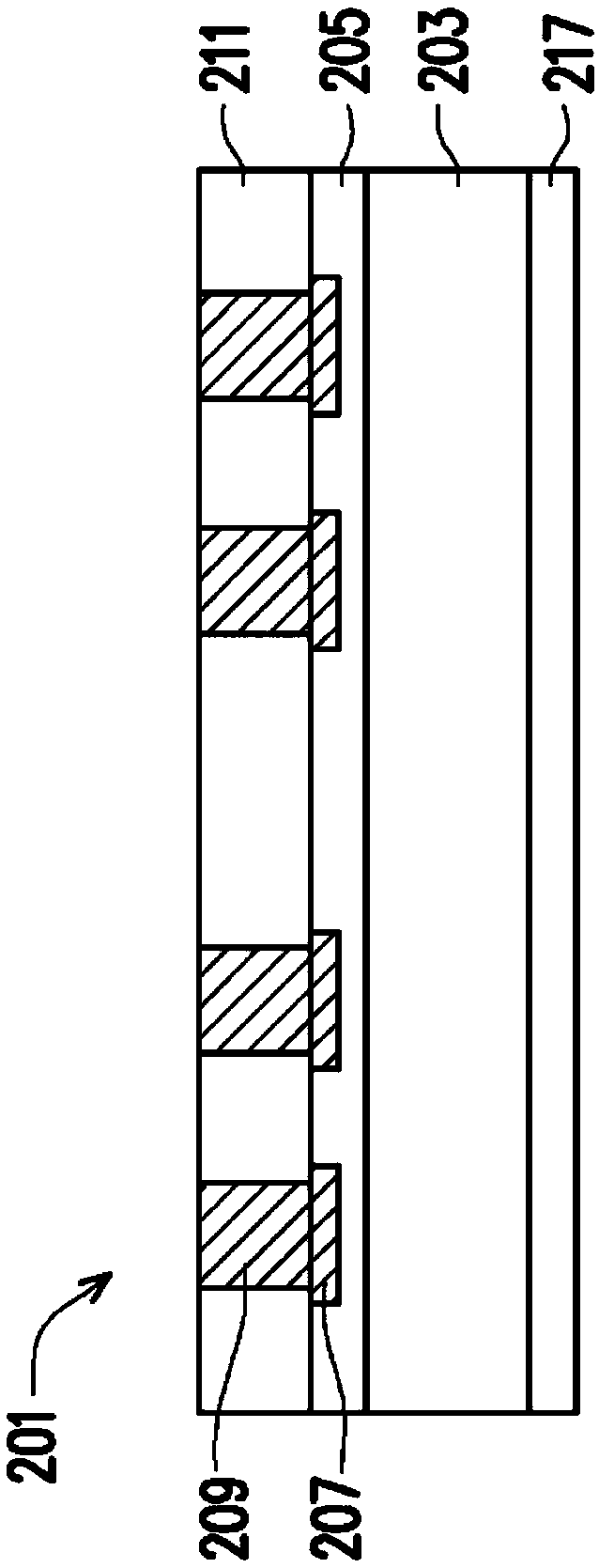

Semiconductor device and method of manufacture

ActiveCN109786274ASemiconductor/solid-state device detailsSolid-state devicesDevice materialTitanium ring

An integrated fan out package on package architecture is utilized along with de-wetting structures in order to reduce or eliminated delamination from through vias. In embodiments the de-wetting structures are titanium rings formed by applying a first seed layer and a second seed layer in order to help manufacture the vias. The first seed layer is then patterned into a ring structure which also exposes at least a portion of the first seed layer.

Owner:TAIWAN SEMICON MFG CO LTD

al in a welded artificial retina 2 o 3 Clamps for ceramic and titanium rings

ActiveCN105598619BGood for full heat exchangeReasonable compositionEye implantsWelding/cutting auxillary devicesFilling materialsTitanium

Owner:HARBIN INST OF TECH AT WEIHAI

Hydrogen atom frequency standard storage bubble opening vacuum sealing device and vacuum sealing method

The invention discloses a hydrogen atom frequency standard storage bubble opening vacuum sealing device and a vacuum sealing method. The hydrogen atom frequency standard storage bubble opening vacuumsealing device comprises a copper nut which is arranged outside the upper part of a longitudinal tubular storage bubble opening in a sleeving mode, wherein a longitudinal tubular adhesive layer is arranged between the storage bubble opening and the copper nut, an annular waveform elastic pad, a first titanium ring, a polytetrafluoroethylene ring, a second titanium ring and an indium wire ring which are arranged outside the storage bubble opening in a sleeving mode are sequentially arranged below the copper nut, the lower end of the storage bubble opening is provided with an annular polytetrafluoroethylene cap, and a longitudinal tubular titanium connecting piece is correspondingly arranged outside the lower part of the copper nut, the waveform elastic pad, the first titanium ring, the polytetrafluoroethylene ring, the second titanium ring, the indium wire ring and the polytetrafluoroethylene cap in a sleeving mode. According to the hydrogen atom frequency standard storage bubble opening vacuum sealing device, a hydrogen atom frequency standard can be protected against microleakage at the vacuum sealing position of the bubble opening in the assembling and adjusting process or even in the later use process, the sealing reliability is improved, and the long-term reliable operation of the hydrogen atom frequency standard can be guaranteed.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Manufacturing method for tantalum composite board equipment

ActiveCN102513712BGuaranteed not to be directly solderedResolve connectionWelding apparatusSheet steelTitanium

The invention provides a manufacturing method for a piece of tantalum composite board equipment; tantalum-titanium-steel or tantalum-copper-steel composite boards are taken as main materials of the tantalum equipment; a connecting pipe adopts steel lining tantalum; a sealing surface is the turned structure of titanium welding tantalum ring; titanium lining outer edge is welded on the inner titanium layer of the connecting pipe; a flange is welded on the steel pipe of the connecting pipe; after being welded, the flange welds the weld joint between the flange and the connecting pipe by silver brazing; turned sides of the titanium ring are welded on the silver brazing so that titanium is directly welded with the steel; the manner of welding vertical and annular weld joint of the tantalum equipment is as follows: when two tantalum composite boards are opposite to each other, tantalum-titanium or tantalum-copper at the welding part of two tantalum-titanium-steel or tantalum-copper-steel composite boards removes a narrow strip; a copper board or tantalum board is welded on the steel board; two steel base boards are welded; and a tantalum sticker wider than the weld joint is welded with two tantalum boards. The manufacturing method ensures that the tantalum in the tantalum composite board equipment is not directly welded with steel, so that the connection problem of tantalum and steel is solved.

Owner:安徽宝泰特种材料有限公司

Ceramic product forming device and forming method

InactiveCN108202386AAppropriate thermal conductivityImprove liquidityMouldsInjection pressureHot runner

The invention provides a ceramic product forming device. The ceramic product forming device comprises a hot nozzle, mold core inserts, an upper mold and a lower mold, wherein the hot nozzle comprisesa valve needle, hot nozzle bodies, heating parts, titanium rings, phenolic plastics caps and high heat conduction rings, wherein the heating part is used for heating a forming raw material in the hotnozzle a hot runner is arranged in the hot nozzle, the valve needle penetrates through the hot runner, and a needle point of the valve needle extends out of the hot runner; and the mold core inserts are arranged on the radial outer sides of the hot nozzle bodies, and a sprue matched with the needle point is arranged at one axial end of the mold core inserts, and the distance between the needle point and the sprue is used for controlling fluidity and static state of the forming raw material. The invention further provides a ceramic product forming method. According to the ceramic product forming device and forming method, an injection pressure loss in an injection molding process is small, heat loss is small, and the fluidity of the forming raw material is good, the produced ceramic productdoes not generate a flow line and scab and the quality of the product is guaranteed.

Owner:LENS TECH CHANGSHA

Application of Titanium Alloy Piston and Connecting Rod Group on Diesel Locomotive and Its Process Method

The invention discloses a titanium alloy. According to mass percentage, the content of Al is 5.5-6.5%, the content of Mo is 0.5-1.5%, the content of V is 3.5-4.5%, the content of Fe is less than 0.25%, and the content of O is less than 0.15%. , and the remainder is Ti. The process method of manufacturing piston connecting rod group with titanium alloy, the first step is melting and casting ingot; the second step is forging; the third step is heat treatment; the fourth step is machining; the fifth step is ultrasonic flaw detection; the sixth step is finished product. The titanium alloy piston crown is rough machined after finish machining; the titanium alloy piston ring is surface polished; the titanium alloy piston pin is surface polished; the titanium alloy connecting rod is polished; Hair pieces, and then finishing. The invention reduces the weight of the piston system of the diesel locomotive by 35-50%, has higher strength than the steel piston pin, longer service life than the steel piston pin, and far better corrosion resistance than the steel piston pin.

Owner:沈阳泰恒通用技术有限公司

Ceramic feed-through, solder and welding method

PendingCN110014203AMeet biocompatibilityMeet air tightness requirementsWelding/cutting media/materialsSoldering mediaHigh densityAdhesive

The invention discloses a ceramic feed-through, solder and a welding method. The ceramic feed-through, the solder and the welding method solve the problems of high processing cost and complex manufacturing process in the prior art. The solder comprises a solid powder material and an ethyl cellulose adhesive, wherein gold powder accounts for 95-98wt% of the solid powder, active powder accounts for2-5wt% of the solid powder, and the addition amount of the ethyl cellulose adhesive is 10-40wt% of the solid powder. The titanium ring welding method for the high-density ceramic feed-through comprises at least printing the solder on a ceramic feed-through sheet. A titanium ring is placed on the ceramic feed-through sheet and then placed in a vacuum furnace for welding. The ceramic feed-through welded with the titanium ring comprises the ceramic feed-through sheet, the titanium ring and a welding layer. The ceramic feed-through sheet is fixedly connected with the titanium ring. The welding layer is used for welding the ceramic feed-through sheet and the titanium ring. According to the ceramic feed-through and welding method, on the premise of simplifying the production process and reducingthe production cost, a product can still meet requirements of biocompatibility, air tightness and reliability on an implanted medical device.

Owner:河北躬责科技有限公司

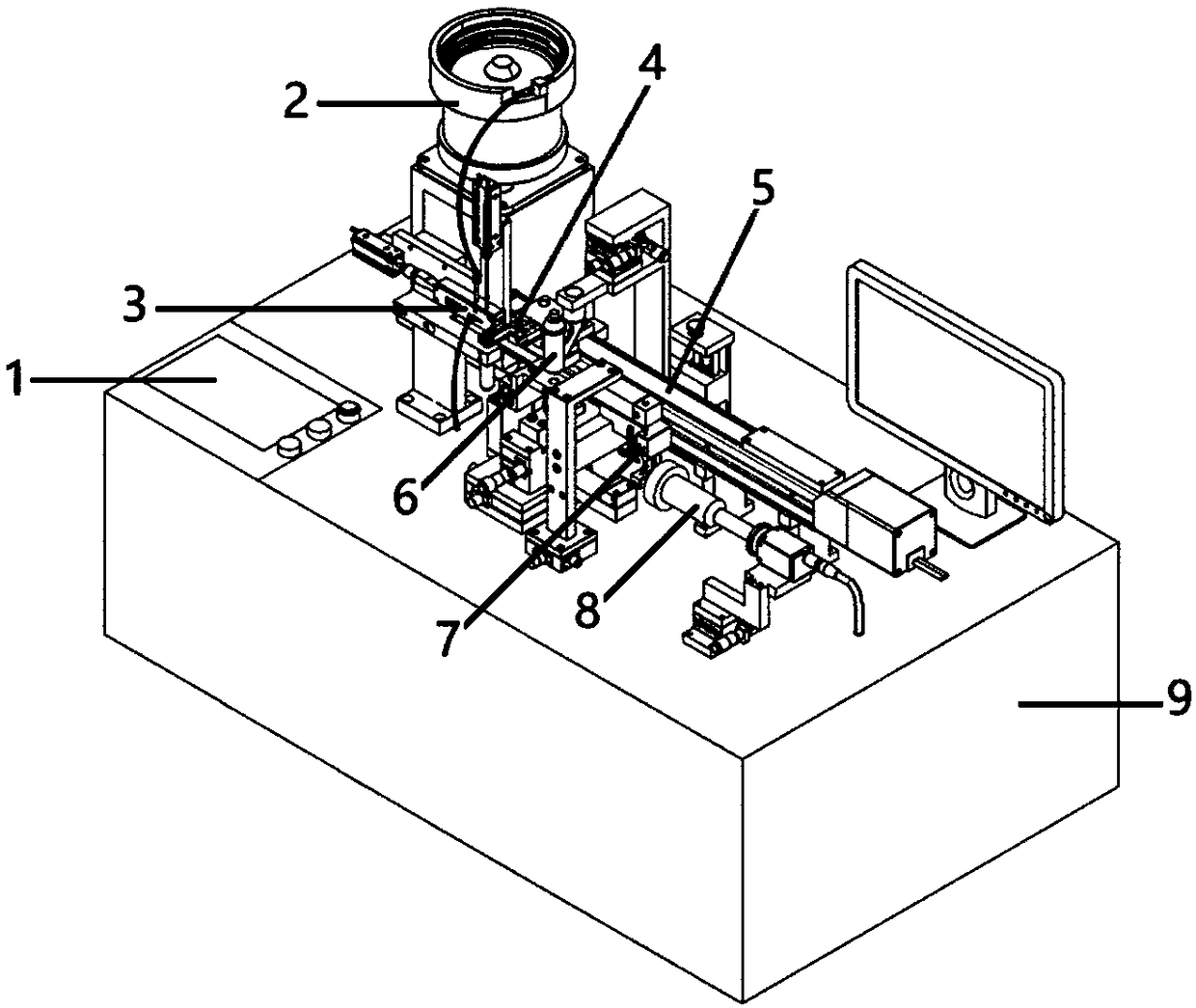

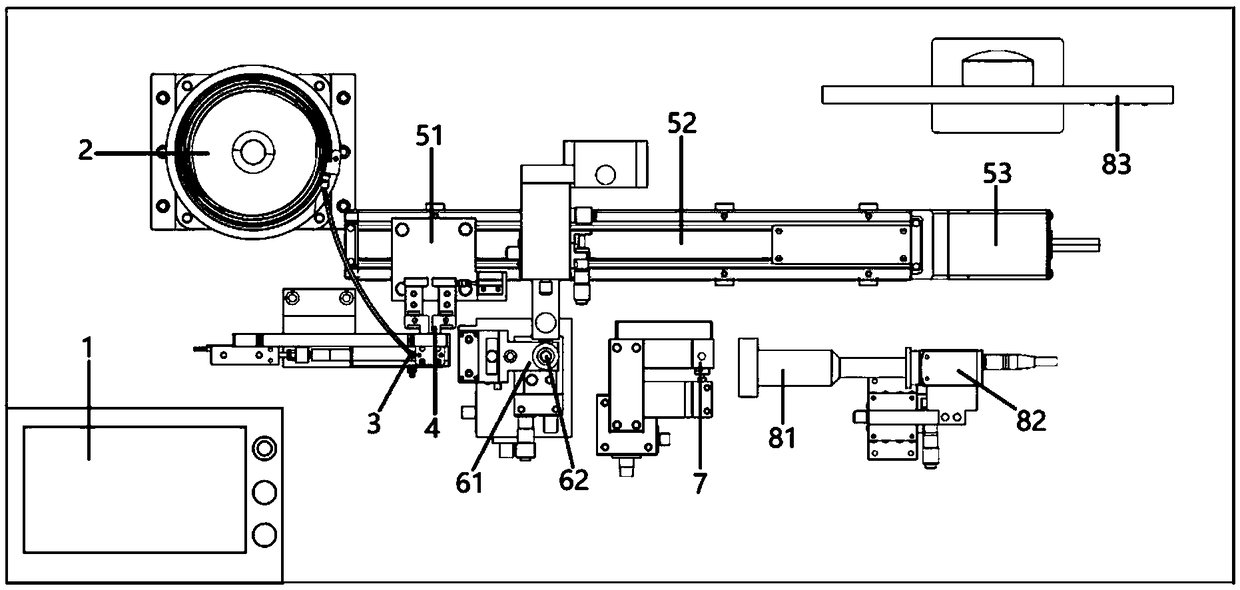

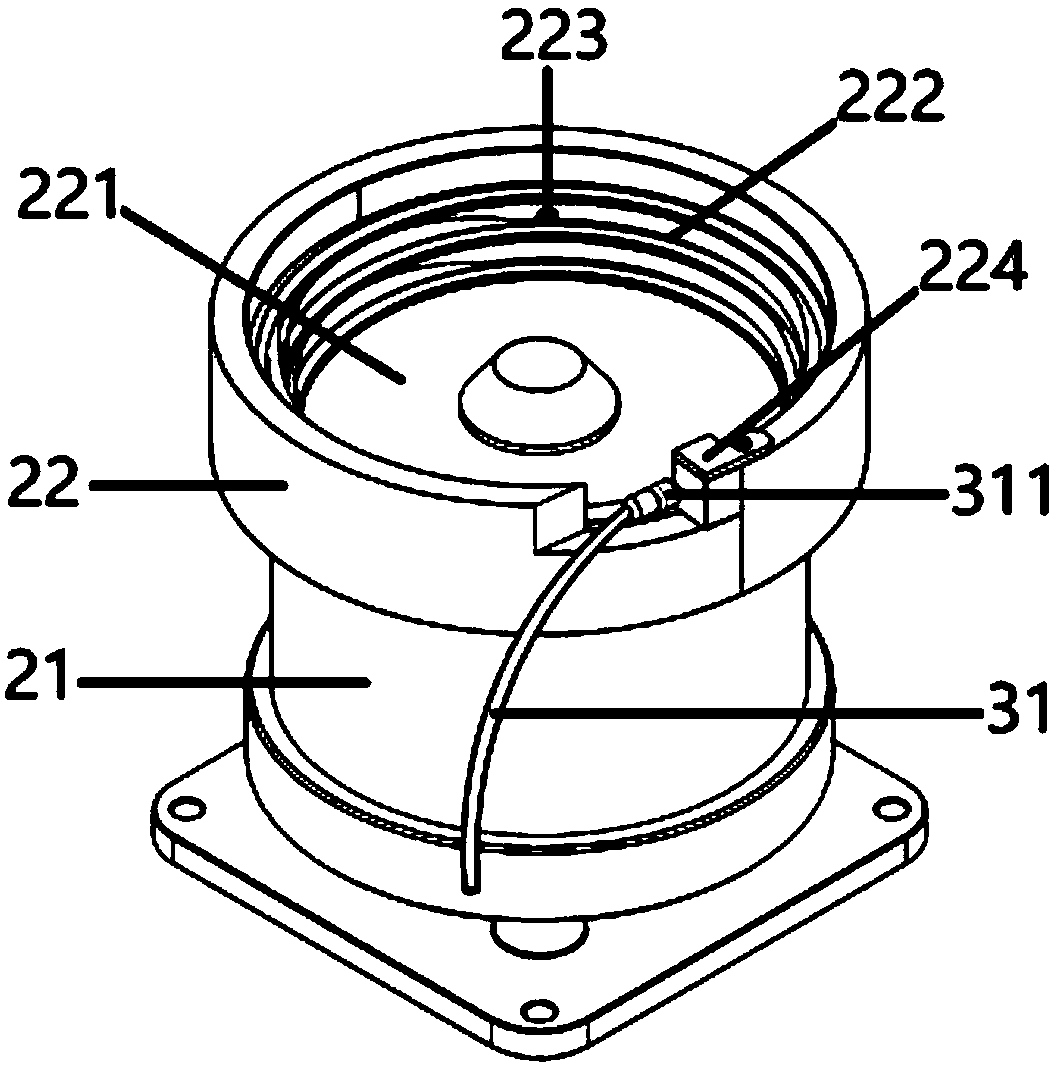

Automated welding device and method for titanium tube sealing

ActiveCN108927615AReduce work intensityHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesControl systemTitanium

The invention belongs to the technical field of metal tube welding and sealing and particularly relates to an automated welding device and method for titanium tube sealing. The automated welding device comprises a feeding system (3) connected with a vibrating spiral platform (2) and a mechanical clamping system (4) arranged on a sliding rail system (5) and further comprises a welding system (6) and a discharging system (7). Under the control of a control system (1), a titanium tube output by the vibrating spiral platform (2) is clamped by the mechanical clamping system (4) after being conveyedby the feeding system (3) and is conveyed to the welding system (6) and the discharging system (7) in sequence through the sliding rail system (5), one end of the titanium tube is welded, and a titanium ring is made and released. The automated welding device is high in automated degree, high in production efficiency and high in product yield, and the titanium ring is attractive in welding spot and free of oxidizing discoloration; and meanwhile, the work intensity of operators can also be lowered, and labor protection is facilitated.

Owner:HTA CO LTD

al 2 o 3 Ceramic and titanium ring brazing sealing method

ActiveCN105598542BAchieve biocompatible connectionsEye implantsSoldering apparatusThermal insulationGranularity

The present invention relates to Al in an artificial retina 2 O 3 In the brazing and sealing method of ceramic and titanium ring, the brazing filler metal is composed of Ti powder and Ni powder, and the mass fractions of Ti powder and Ni powder in the brazing filler metal are 6-85% and 15-94% respectively. The particle size of Ti powder and Ni powder is 20~400nm. The solder obtained by ball milling is made into paste and coated on titanium ring and Al 2 O 3 On the surface to be connected of the ceramics, the parts to be welded are placed in a vacuum heating furnace, heated and kept warm, and the welding is completed. The present invention realizes the titanium ring and Al 2 O 3 The brazing connection of ceramics is obtained and a reliable connection joint is obtained. Especially suitable for Al in artificial retina 2 O 3 The connection between the ceramic and the titanium ring.

Owner:HARBIN INST OF TECH AT WEIHAI

Bicycle aluminum ring surface treatment method

ActiveCN112246569APromotes rapid oxidationStable structureLiquid surface applicatorsMaterial gluingElastomerMegasonic cleaning

The invention discloses a bicycle aluminum ring surface treatment method. The bicycle aluminum ring surface treatment method comprises the following steps that firstly a bicycle aluminum ring is ultrasonically cleaned; the surface of the bicycle aluminum ring is pretreated after being cleaned; meanwhile, anticorrosive paint and an elastic body are sprayed on the pretreated surface of the bicycle aluminum ring, and the surface of the elastic body is rapidly heated to melt the elastic body; and after the surface of the elastic body is solidified, an annular air bag ring is bonded to the outer ring of the bicycle aluminum ring, and a nickel-titanium ring sleeves the annular air bag ring. According to the bicycle aluminum ring surface treatment method, firstly, temperature-controlled drying isadopted after spraying of the anticorrosive paint is completed, and the anticorrosive paint can evenly cover the exterior of the bicycle aluminum ring; secondly, the elastic body is arranged outsidea bicycle, so that shock on the outside of the aluminum ring is reduced, and the aluminum ring is prevented from being damaged; and thirdly, a bicycle inner tube can be fixed by bonding the annular air bag to the outer ring of the bicycle aluminum ring, so that the matching property of the bicycle outer ring and the inner tube is improved.

Owner:江苏信轮美合金发展有限公司

Soft conductive structure in cathode roller of foil manufacturing machine and manufacturing method

ActiveCN101392393BImprove conductivityImprove uniformityElectroforming processesCarrying capacityTitanium

Owner:西安航天新能源装备科技有限公司

A kind of preparation method of wafer locking ring

ActiveCN112589383BAvoid large amount of deformationImprove yieldMetal-working apparatusVacuum evaporation coatingWaferIngot

The invention relates to a method for preparing a wafer locking ring. In the preparation method, a cylindrical titanium ingot is first subjected to forging treatment, first heat treatment, hot rolling treatment and second heat treatment to obtain a titanium hot-rolled piece, and then undergoes rough Turning hollows out the central part of the titanium hot-rolled piece, then performs a third heat treatment to obtain a titanium ring, and finally performs finish turning on the titanium ring according to the target size to obtain a wafer locking ring. The preparation method of the present invention adds a third heat treatment between rough turning and finishing turning, which effectively prevents the problem of large deformation in the process of transforming cylindrical hot-rolled titanium parts into titanium ring parts, and then prepares flatness ≤ The 0.1mm wafer locking ring greatly improves the yield.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Production process of high-strength Ti80 titanium ring

PendingCN112916791AHigh tensile strengthHigh yield strengthFurnace typesEngine componentsShrinkage rateEngineering

The invention discloses a production process of a high-strength Ti80 titanium ring. The production process comprises the following steps: 1, cogging and forging are conducted, 4500T equipment is used, preheating is conducted at 750-845 DEG C for 1.5-2.5 hours, heating to 985-1125 DEG C, and heat preservation is conducted for 385-405 minutes; 2, 2000T equipment is used, and heat preservation is carried out at the temperature of 1000-1065 DEG C for 185-235 minutes; 3, the 2000T equipment is used, and heat preservation is conducted at the temperature of 945-995 DEG C for 185-240 min; 4, the 2000T equipment is used, and heat preservation is conducted at the temperature of 935-985 DEG C for 105-155 min; 5, the 2000T equipment is used to obtain a finished product at the temperature of 925-975 DEG C; and 6, annealing is conducted at the temperature of 755-805 DEG C. Through the production process of the Ti80 titanium ring, the tensile strength, the yield strength, the ductility, the shrinkage rate, the impact strength and the hardness of the Ti80 titanium ring in experimental data are all superior to those of standard requirements after detection and comparison, so that the requirements of various practical applications are met.

Owner:陕西茂松科创有限公司

Stable Rolling Process of High Cylindrical Thin Wall Pure Titanium Ring

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

Preparation method of ozone heterogeneous oxidation solid catalyst

InactiveCN107051455AEvenly dopedImprove adsorption capacityCatalyst carriersOther chemical processesUltrasound - actionPyrophyllite

The invention relates to a preparation method of an ozone heterogeneous oxidation solid catalyst and belongs to the technical field of environment protection and chemical engineering catalysts. The preparation method includes using erionite, garnet, light shale ceramisite, pyrophyllite, expanded vermiculite and gehlenite as carriers; subjecting the carriers to pore expanding through lithium hypochlorite and bis(acetylacetone)beryllium, and adding a surfactant chlorinated dodecyl trimethyl ammonium, activating under ultrasonic action; enabling the activated carriers to be in hydrothermal reaction with composite mineralizing agent borax and potassium sulfate, catalytic active auxiliary precursor isoproscandia (III), tri(hexafluoroacetylacetone)yttrium (III) dihydrate, 1, 1, 1-trifluoroacetylacetone neodymium and lutenium chloride hydrate and catalytic activity central precursor dicyclopentadienyl titanium ring substituted salicylate complex, pyruvate iso-nicotinazone vanadium, L-molybdenum aspartate and potassium tetrachloroaurate in a hydrothermal reaction kettle under action of an emulsifier octadecyl dimethyl ethoxyammonium perchlorate; drying for removing water; firing in a muffle furnace to obtain the ozone heterogeneous oxidation solid catalyst.

Owner:SICHUAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com