Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232 results about "Nickel copper alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

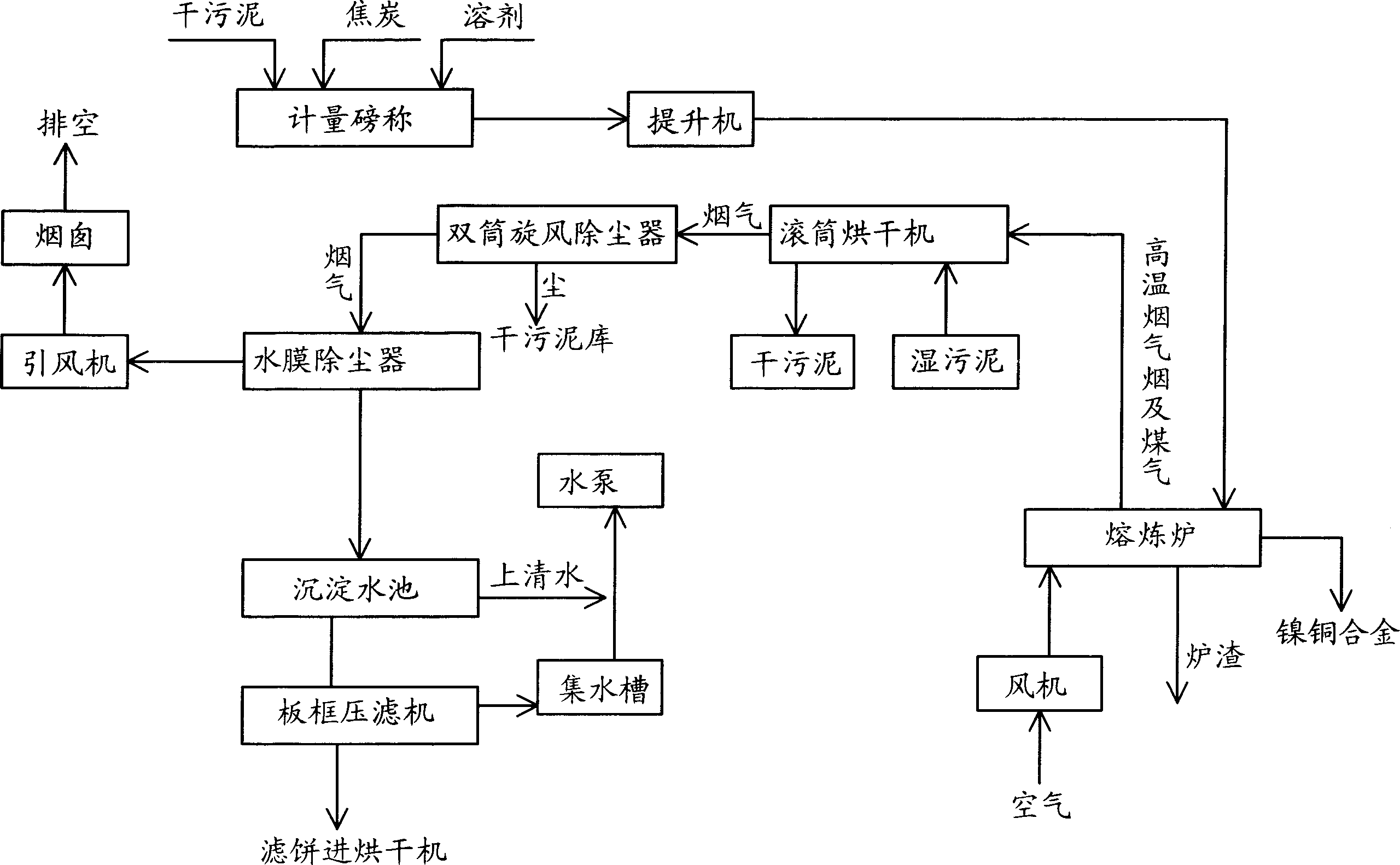

Resource recovery process of galvanizing sludge

InactiveCN1733628ASolve pollutionEfficient recyclingSludge treatment by oxidationSludgeHazardous substance

The invention relates to treatment technique for electroplated sludge, which comprises following steps: a. matching material by dried sludge, solvent and coke according to the weight proportion as 100:15~71:50~88; b. mixing the material evenly to put into melting furnace with temperature 1400~1600Deg for reducing melting, releasing the reduced nickel-copper alloy through ally output and liquid residue through slag hole; c. treating residue gas and discharging out. This method has well speed and high recovery ratio, and overcomes problems brought by slag.

Owner:台州盛世环境工程有限公司

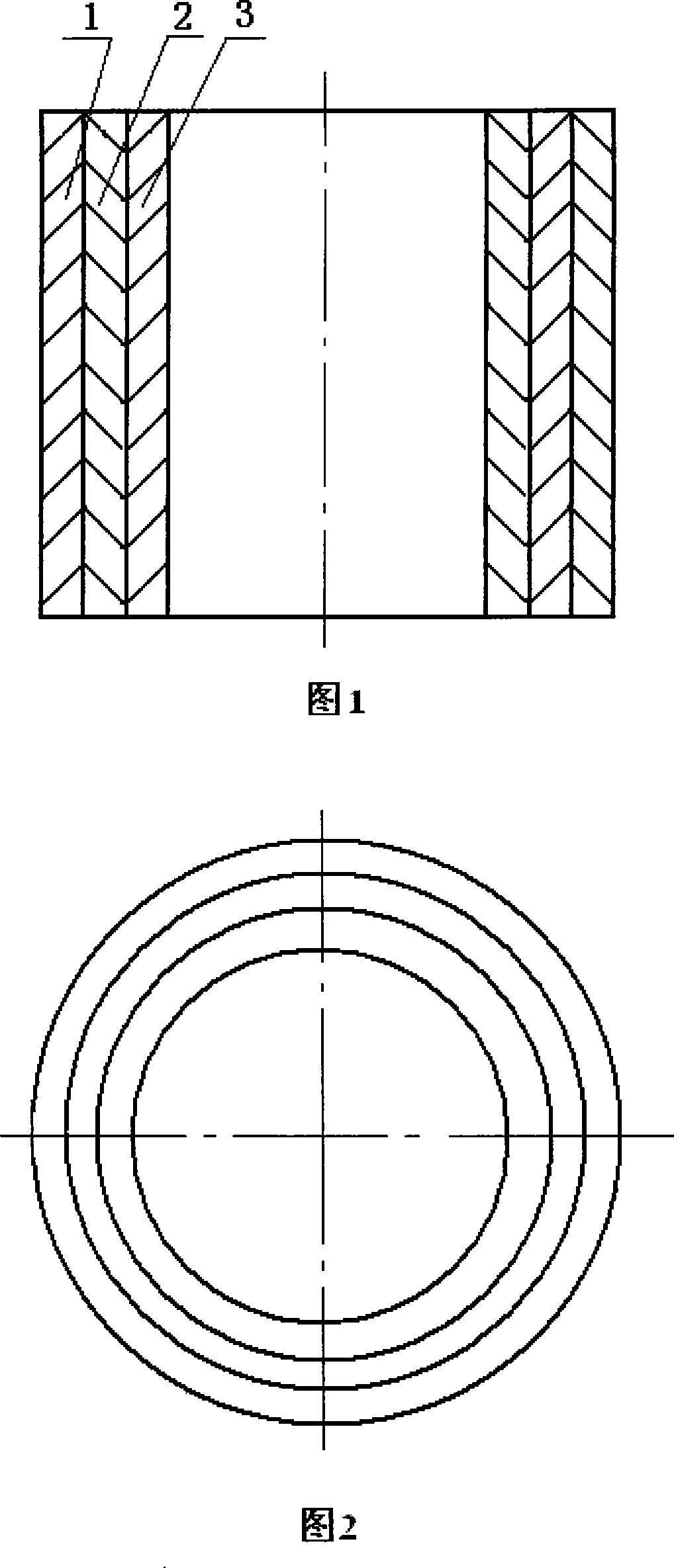

Sandwich type radial direction vibrating piezoelectric ceramic ultrasonic transducer

InactiveCN101111098AOptimization parametersRaise the resonant frequencyPiezoelectric/electrostrictive transducersElectromechanical coupling coefficientOmni directional

The present invention relates to a radial vibration sandwich piezoelectric ceramic ultrasonic transducer. A piezoelectric ceramic ring is arranged between a metal inner ring and a metal outer ring, the upper end surfaces of the metal inner ring, the metal outer ring and the piezoelectric ceramic ring are in the same plane, and lower end surfaces are also in the same plane. The metal inner ring and the metal outer ring can adopt steel rings, aluminum rings, brass or purple copper rings, titanium rings, aluminum nickel copper alloy rings and titanium alloy rings. The present invention realizes the high efficiency work of a radial composite transducer through a radial prestress impressed by the inner and outer metal rings, and realizes the parameter optimization of the transducer through reasonably designing the geometry size of the inner and outer metal rings simultaneously, such as resonance frequency, frequency bandwidth as well as electromechanical coupling coefficient. The present invention can be used for the high efficiency omni-directional acoustic source underwater and all kinds of supersonic processing high efficiency supersonic source in liquid.

Owner:SHAANXI NORMAL UNIV

A kind of manufacturing method of thin-walled, ultra-long nickel-copper alloy pipe

The invention discloses a method for manufacturing thin-wall and ultra-long nickel-copper alloy pipes. The method comprises the following steps of: 1, smelting nickel and copper serving as raw materials in a vacuum induction furnace to prepare nickel-copper alloy ingots; 2, drawing and forging the nickel-copper alloy ingots into bar billets, and machining the bar billets into light bars; 3, rolling the light bars into pipe billets by adopting a cone mill, and removing scales on the surfaces of the pipe billets; 4, performing cold rolling machining; 5, sequentially cogging the cold rolled pipebillets, and performing crystallization and annealing treatment and boring treatment to obtain pipes; 6, continuously rolling the pipes, and performing annealing treatment and acid washing to obtain finished pipes; and 7, straightening the finished pipes, and thus obtaining the thin-wall and ultra-long nickel-copper alloy pipes with diameter-thickness ratio of 50 to 70 and length of over 15,000 millimeters. The finished nickel-copper alloy pipes machined with high deformation and cold-rolled by a continuous rolling production process have high tensile strength and yield strength and meet the plasticity requirement.

Owner:WESTERN TITANIUM TECH

Nickel-copper alloy liquid for chemical plating and electroplating and method for preparing nickel-copper alloy noncrystalline-based composite coating

ActiveCN102703887AImprove performanceImprove wear resistanceLiquid/solution decomposition chemical coatingChemical platingNickel salt

The invention provides nickel-copper alloy liquid for chemical plating and electroplating. The nickel-copper alloy liquid for the chemical plating and the electroplating comprises 1-10g / L of copper salt, 20-60g / L of nickel salt, 10-20g / L of complexing agent and 1-10g / L of reducing agent by taking deionized water as a solvent. By using the nickel-copper alloy liquid, a nickel-copper alloy composite coating is prepared on the surface of a metal base by adopting a method of chemical plating and electroplating synergetic deposition. The coating not only is of a nanocrystalline structure but also is of a noncrystalline structure, and moreover, nanocrystallines are evenly distributed in a noncrystalline continuous phase. The coating is a nickel-copper alloy noncrystalline-based composite coating. The nickel-copper alloy noncrystalline-based composite coating has the properties of the noncrystalline structure and the crystalline structure, thus, the combination property of the coating is obviously improved, such as corrosion resistance, wear resistance, high strength, high hardness and excellent room-temperature ductility, and the application range of a metal matrix is greatly broadened.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

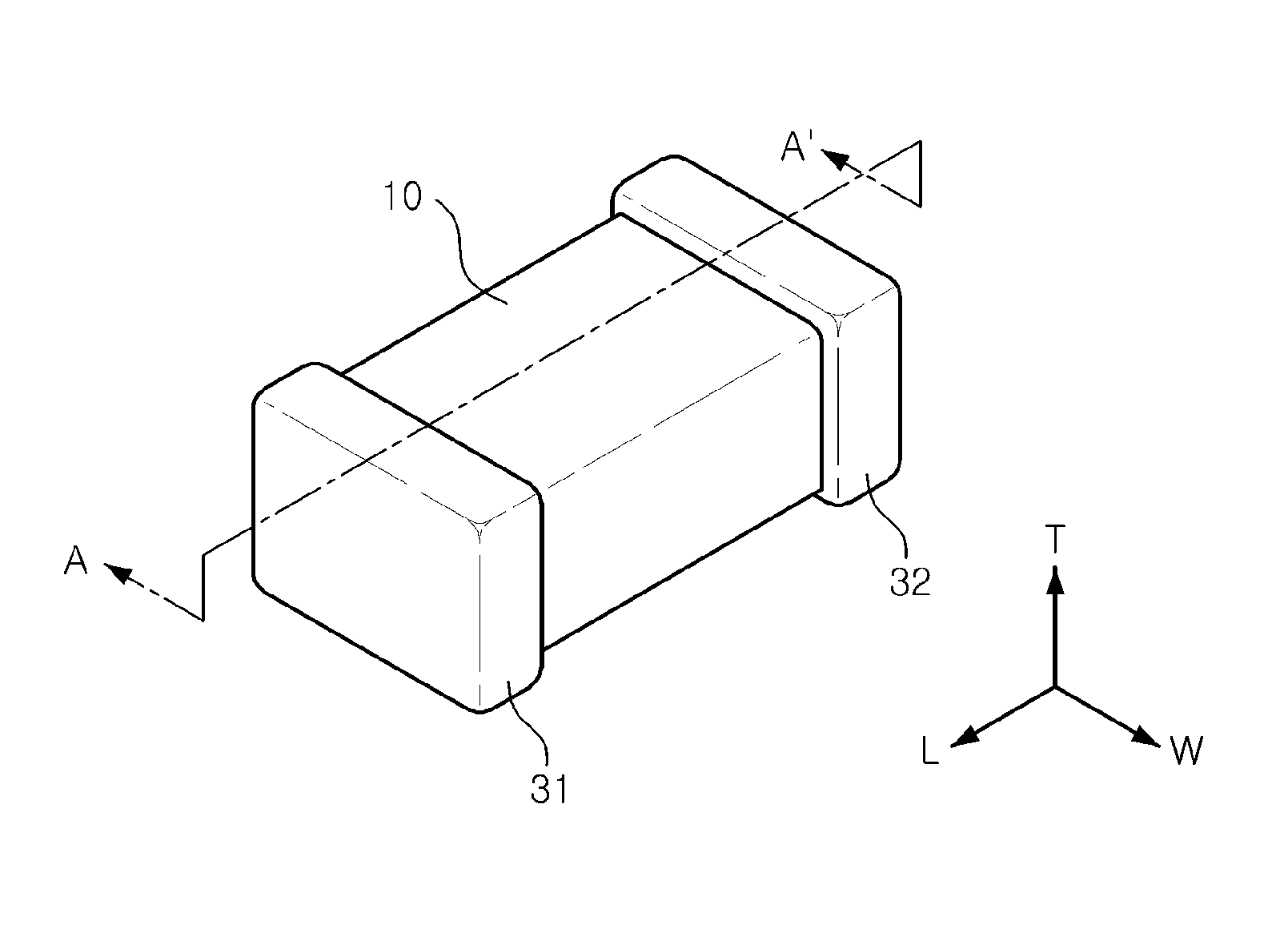

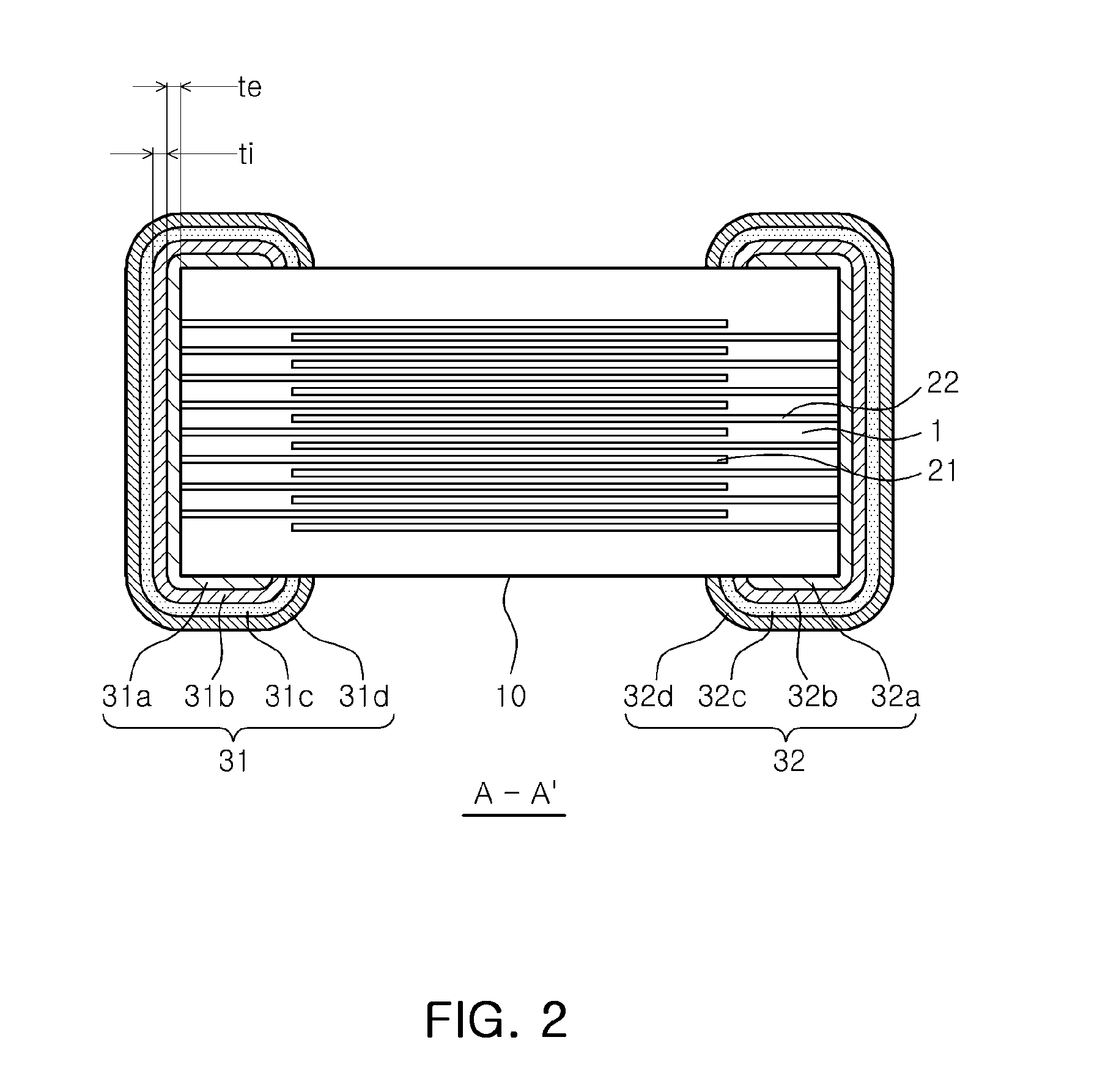

Multilayer ceramic electronic component and fabrication method thereof

InactiveUS20130258546A1Prevent penetrationFixed capacitor electrodesFixed capacitor dielectricElectronic componentDielectric layer

There are provided a multilayer ceramic electronic component and a fabrication method thereof. The multilayer ceramic component includes a ceramic main body in which internal electrodes and dielectric layers are alternately laminated; external electrodes formed on outer surfaces of the ceramic main body; intermediate layers formed on the external electrodes and including one or more selected from the group consisting of nickel, copper, and a nickel-copper alloy; and plating layers formed on the intermediate layers, whereby infiltration of a plating solution can be prevented.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Chemical copper plating solution and technique thereof

InactiveCN101078111AAvoid pollutionLow costLiquid/solution decomposition chemical coatingChemical solutionCopper plating

A kind of chemical solution used to copperize, the following are the weight percent of the major components of it: blue vitriod0.8-3, Fe vitriol 0-0.5, complex agent 3-6, sodium hypophosphorous acid 4-6, ammonia sulfate 0.5-1, sulfourea 0-0.01. The following is the procedure of the copper coating method with the above copper coating solution: to widen and activate the plastic board->to clean->to make it electric->to clean->to coat nickel-copper alloy on it by chemical method. The following are the content of the chemical method: the plastic pretreated according the above description will be immersed in the above chemical solution used to copperize, the pH of which has been adjusted to 10-13 by vitriol and stranger ammonia water, the working temperature of it is 20-70deg.C, the time to copperize is 5-20 minutes. The chemical solution used to copperize in this patent does not contain formaldehyde, it improve the working circumstance, and is easy to control, the cost of it is lower, and it own high economical benefit and society benefit.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

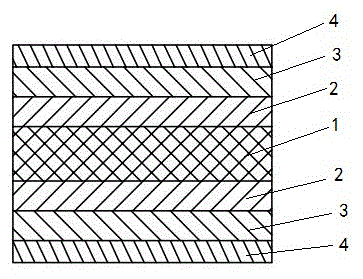

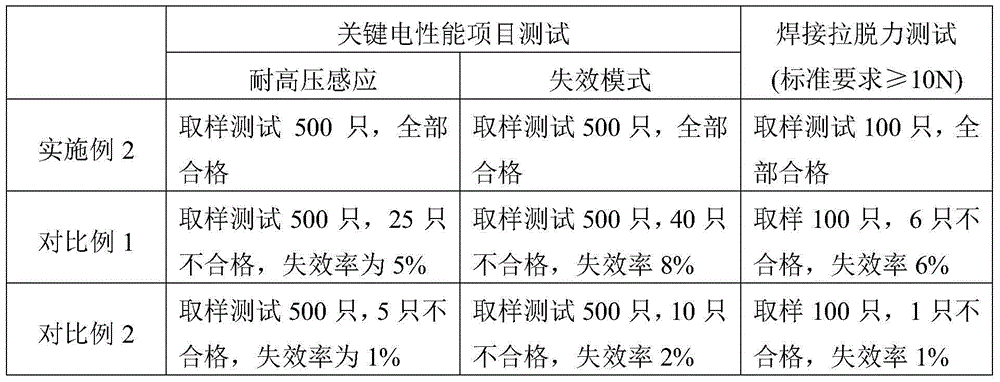

Vacuum sputtering electrode of ceramic thermistor and manufacturing method thereof

ActiveCN105006316AImprove bindingGood welding performanceResistor terminals/electrodesVacuum evaporation coatingSputteringThermistor

The invention discloses a vacuum sputtering electrode of a ceramic thermistor. The vacuum sputtering electrode comprises a transition layer, a barrier layer and a conducting layer which are sequentially sputtered on the surface of a substrate. The transition layer is nickel-chrome alloy with the thickness ranging from 4000 nm to 5000 nm, and the nickel-chrome alloy comprises, by mass, 80-85% of nickel. The barrier layer is nickel-copper alloy with the thickness ranging from 4000 nm to 5000 nm, and the nickel-copper alloy comprises, by mass, 25-30% of nickel. The conducting layer is silver with the thickness ranging from 2000 nm to 3000 nm. The invention further discloses a manufacturing method of the vacuum sputtering electrode of the ceramic thermistor. Firstly, vacuum sputtering is performed three times to form the nickel-chrome alloy transition layer; then, sputtering is performed three times to form the nickel-copper alloy barrier layer; finally, sputtering is performed two times to form the silver conducting layer. The ceramic thermistor with the vacuum sputtering electrode is stable in electrical performance, high in production efficiency and free of pollution, and the percent of pass can reach 100% in key electrical performance tests.

Owner:JIANGSU NEW LINZHI ELECTRONIC TECH CO LTD

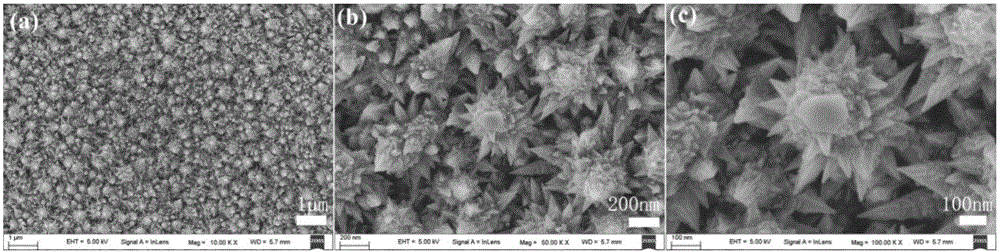

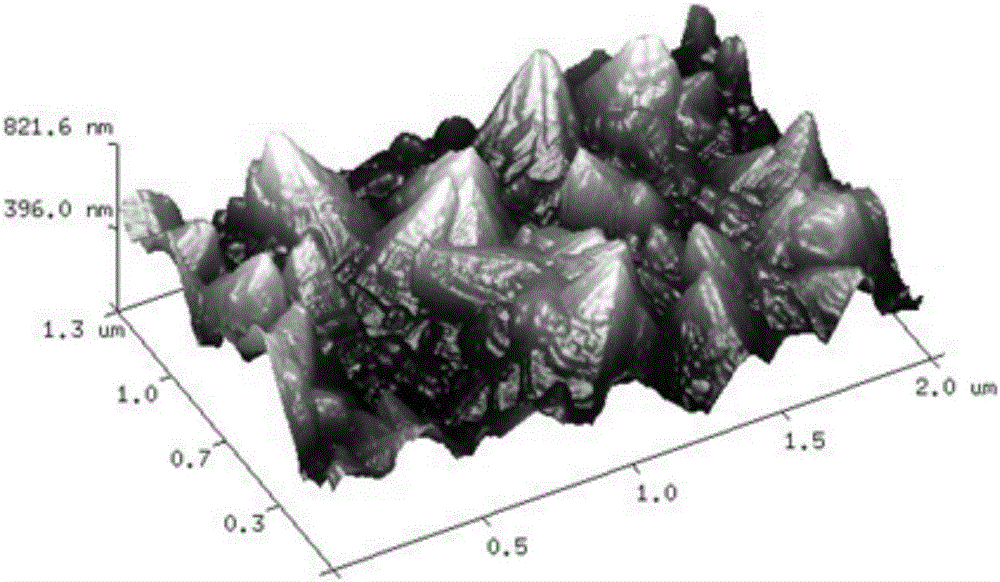

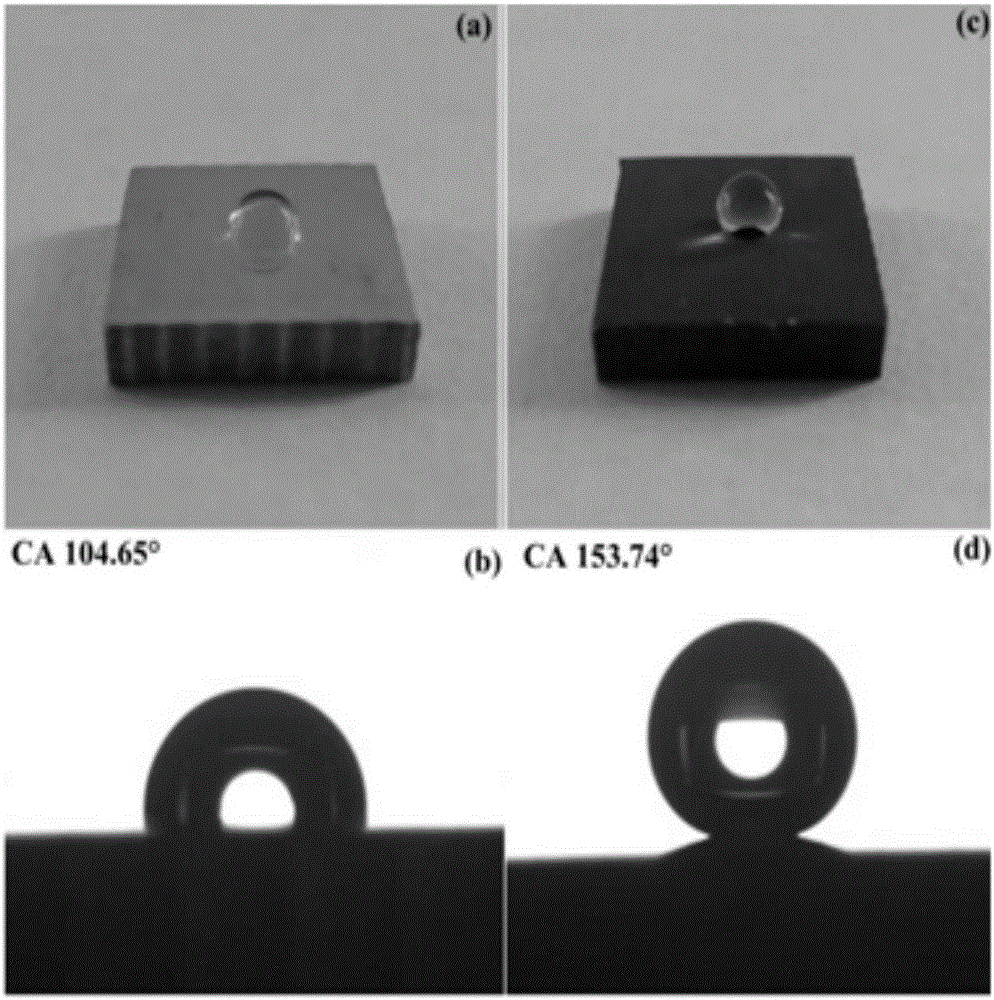

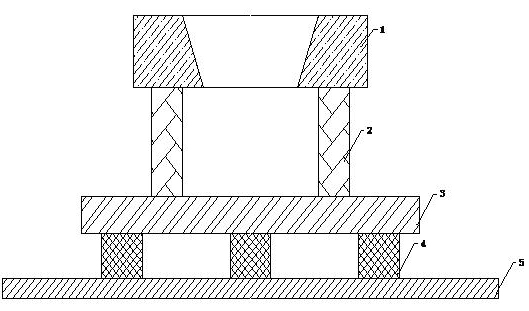

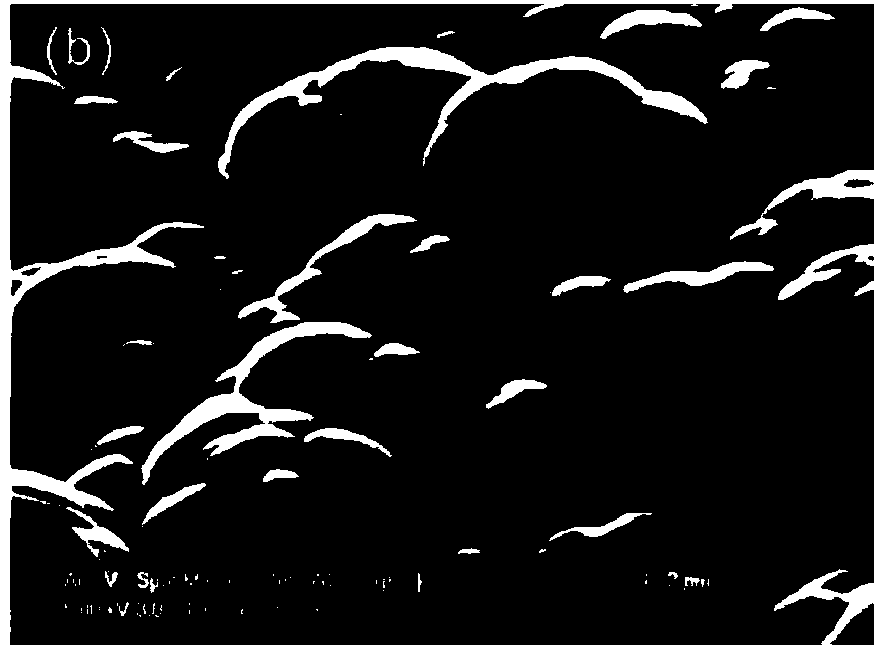

Super-hydrophobic stainless steel surface coating and preparation method thereof

The invention provides a super-hydrophobic stainless steel surface coating which comprises micro-nano structures arranged in arrays, wherein each micro-nano structure comprises a micon-sized pointed cone and a nano-sized whisker, and the nano-sized whisker radiates out by taking the micon-sized pointed cone as a center to form a petal type structure; the micro-nano structures are made of at least one of nickel, copper and nickel-copper alloy. The super-hydrophobic stainless steel surface coating can effectively block erosion and adhesion of a corrosive medium, bacteria and protein, thereby realizing corrosion resistance and an antifouling property. The invention further provides the method for preparing the super-hydrophobic stainless steel surface coating. The method comprises the step: directly deposing the super-hydrophobic stainless steel surface coating on the surface of a stainless steel material by a directional electrodeposition method. The method does not need a template, is not limited by the shape of the stainless steel material, and does not modification by an organic low surface energy material, thereby reducing the cost and reducing the technological process. Moreover, the growth and size of deposit sediments can be controlled.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

High-performance beryllium-copper alloy and preparation method thereof

The invention discloses a high-performance beryllium-copper alloy and a preparation method thereof. The high-performance beryllium copper comprises 1.6-2.2% of beryllium, 0.35-0.65% of cobalt and nickel, 0.03-0.1% of yttrium, 0.03-0.1% of titanium, 0.1-0.3% of boron, 0.1-0.3% of magnesium and the balance of copper in percentage by weight, wherein the beryllium is added in the form of a beryllium-copper immediate alloy and accounts for 3.8-4.2% of the beryllium-copper alloy; the cobalt and the nickel are also respectively added in the form of immediate alloys of a cobalt-copper alloy and a nickel-copper alloy and respectively account for 8-12% of the alloy; the titanium is added in the form of a titanium-copper immediate alloy and accounts for 4-6% of the alloy; and the yttrium is added in the form of a yttrium-copper immediate alloy and accounts for 8-12% of the alloy. By using the invention, the mechanical comprehensive performance is improved, the service life of the material is largely prolonged, and the service life of a beryllium-copper injection plunger head applied to a die casting machine is increased to more than 20000 mold times from the original 8000-12000 mold times.

Owner:DONGGUAN JIASHENG COPPER

Preparation method of high-performance lithium ion battery based on three-dimensional graphene bracket structure

InactiveCN103956520AAchieve ballistic transportStress reliefFinal product manufactureElectrolyte accumulators manufactureMethyl carbonateLithium-ion battery

The invention provides a preparation method of a high-performance lithium ion battery based on a three-dimensional graphene bracket structure. The method comprises the steps of carrying out ultrasonic cleaning on a nickel piece, a copper piece or a nickel-copper alloy piece by acetone, alcohol and deionized water respectively in sequence, drying and then putting the dried piece into a microwave plasma chemical vapor deposition chamber; heating, filling the microwave plasma chemical vapor deposition chamber with methane, and carrying out plasma treatment by hydrogen to form a three-dimensional graphene bracket; after that, putting the three-dimensional graphene bracket into a magnetron sputtering cavity, filling the magnetron sputtering cavity with argon, and carrying out sputtering with a lithium ion battery electrode material as a target; and finally, assembling in an argon-filled glove box to obtain the battery, wherein multi-space polypropylene is taken as a diaphragm, and LiPF6 and mixed liquid of ethylene carbonate, dimethyl carbonate and diethyl carbonate is taken as electrolyte. After the method is adopted, the high-quality three-dimensional graphene structure is obtained for the first time, and three-dimensional graphene is high in electrical conductivity, is a flexible material, and is capable of effectively relieving stress caused by lithium ions in the charge and discharge processes and greatly increasing the transport rate of electrons and lithium ions.

Owner:QUANZHOU NORMAL UNIV

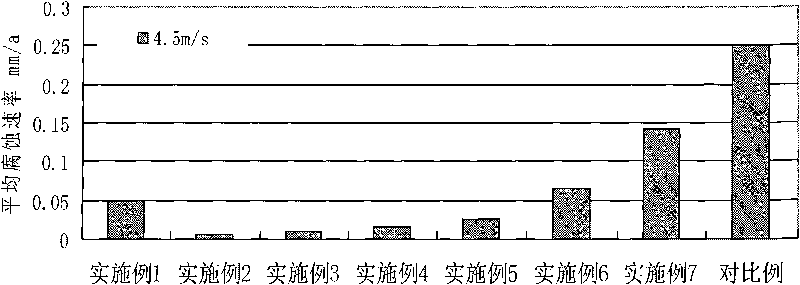

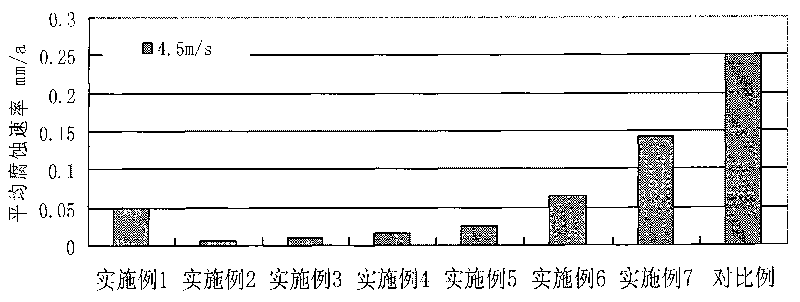

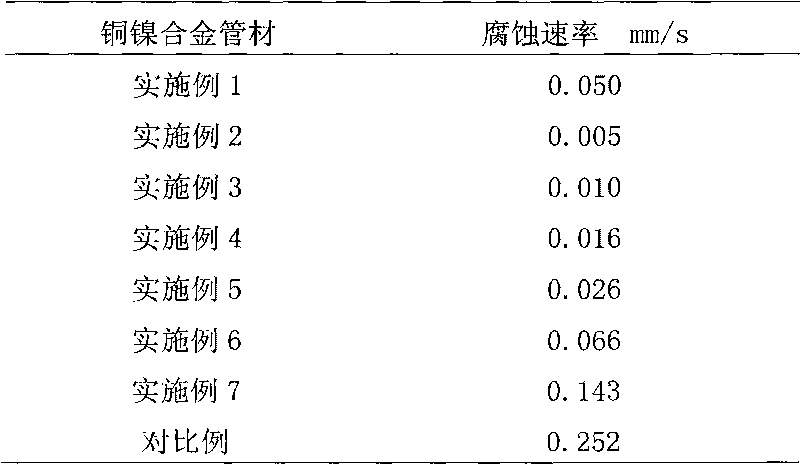

Seawater scouring corrosion resistant nickel-copper alloy and tubular product and preparation method thereof

InactiveCN101717878AHigh strengthHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationRare-earth elementElectrochemical corrosion

The invention relates to a seawater scouring corrosion resistant nickel-copper alloy and a tubular product and a preparation method thereof, belonging to the technical field of metallic material alloying and material corrosion prevention. The nickel-copper alloy tubular product consists of the nickel-copper alloy, and the nickel-copper alloy contains the following components in weight ratio: 5-15 percent of nickel, 2-8 percent of stannum, 1-6 percent of zinc, 0-3 percent of ferrum, 0-2 percent of rare earth elements, not more than 0.5 percent of impurities and the balance of copper. On one hand, the nickel-copper alloy improves the strength and the hardness of the alloy so as to ensure the seawater scouring corrosion resistance of the nickel-copper alloy, on the other hand improves the electrochemical corrosion resistance of the alloy; compared with the common nickel-copper alloy, the 4.5m / s seawater scouring corrosion resistance of the nickel-copper alloy tubular product is higher, and the corrosion rate is lower, thereby realizing that the material cost is reduced and the cost performance is improved, and enlarging the application of the nickel-copper alloy in the fields of condensation tubes and heat-exchanger tubes.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

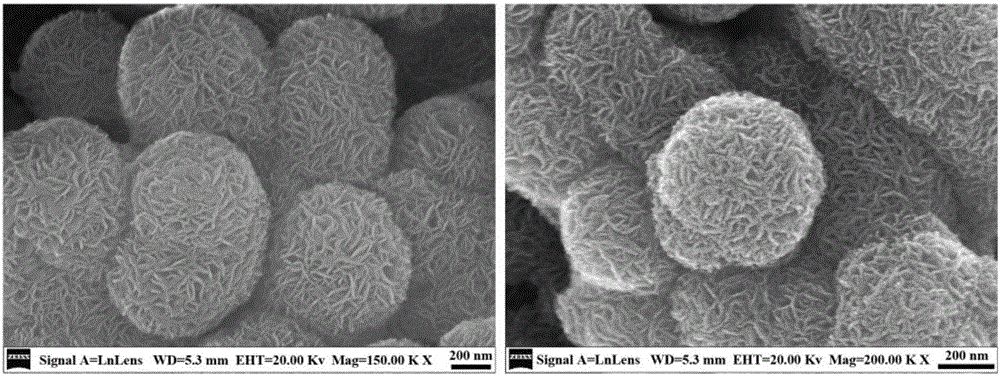

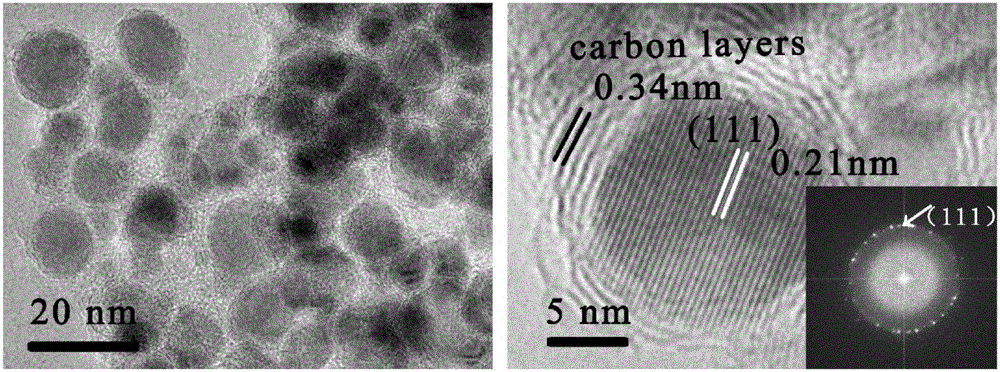

Supported nickel-copper alloy nano-catalyst and preparation method thereof and application to catalytic hydrogenation

InactiveCN106179353ALarge specific surface areaHigh catalytic activityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystCrystallinity

The invention discloses a supported nickel-copper alloy nano-catalyst and a preparation method thereof and application to catalytic hydrogenation. Self-assembly is carried out in a water solution through the simple coprecipitation synthetic technology, layered copper nickel hydroxide intercalated by a large amount of organic anions is obtained and serves as a precursor, and the nickel-copper alloy / carbon nano composite catalyst with high catalytic activity and stability is obtained through one-step in-situ solid-state pyrolysis in the inert atmosphere. According to the method, high-crystallinity nickel-copper alloy nano-particles can be evenly dispersed in a graphitized carbon matrix, and metal and a carrier have high interaction. No additional reducing agent or surfactant or organic solvent is used, the production cost is reduced, and the product purity is improved. In a catalytic hydrogenation reaction performance test, the prepared nickel-copper alloy / carbon nano composite catalyst shows higher catalytic activity and stability compared with a commercialized platinum / carbon catalyst, and high catalytic efficiency is still achieved after eight times of magnetic separation, recycling and cyclic utilization.

Owner:BEIJING UNIV OF CHEM TECH

Phosphorus chemical nickel plating concentrated solution and plating process

ActiveCN104328395AFast deposition rateGood bath stabilityLiquid/solution decomposition chemical coatingSodium phosphatesPolyethylene glycol

The invention discloses a phosphorus chemical nickel plating concentrated solution and a plating process, the concentrated solution comprises three parts of an A solution, a B solution and a C solution, a main salt, a brightening agent, an accelerating agent and deionized water are mixed into the A solution at room temperature; a first buffer, a first complexing agent, sodium hypophosphite, a stabilizer, polyethylene glycol 6000, a brightening agent and deionized water are mixed into the B solution at room temperature; a second buffer, a second complexing agent, the stabilizer, the sodium hypophosphite, the polyethylene glycol 6000, the accelerating agent, the brightening agent, ammonia and the deionized wate are mixed r at room temperature into the C solution; the A solution and the B solution are used for grooving, and the A solution and the C solution are used for replenishment. According to the volume percentage, the A solution, the B solution, and dilution water are mixed into a chemical nickel plating solution for plating, the nickel content in the nickel plating solution is lower than 4.0g / L, and the A solution and the C solution are replenished. When the concentrated solution is used for nickel plating, deposition rate is quick, coating hardness and wear resistance are high, and the concentrated solution is suitable for chemical nickel plating of aluminum alloy, all kinds of iron alloy, copper alloy, nickel iron alloy, nickel copper alloy and some non conductive substrates.

Owner:JINCHUAN GROUP LIMITED

Preparation method of porous fuel cell anode material NiCu/C

InactiveCN102315459AAddress operational complexityAddress operating conditionsCell electrodesCalcinationNickel copper alloy

Belonging to the technical field of metal material preparation, the invention relates to a preparation method of a porous fuel cell anode material NiCu / C. The method is characterized by: adopting activated carbon with a high specific surface as a hard template to impregnate a precursor solution of a metal nitrate or a metallorganic compound; in an anaerobic environment and by means of a calcination technology, carrying out heating at a proper heating rate, first decomposing the metal salt and organic compound, then subjecting the obtained metal oxide and the carbon of the hard template to a reduction reaction so as to form single metals, and finally after melting at a metal melting temperature and copying the 3D structure of activated carbon, leaving the single metals to cool to a room temperature naturally, thus obtaining a nanometer grade nickel-copper alloy material of high specific surface. And the material has an expression of MM' / C, wherein, M and M' are Ni / Cu metallic elements, and the component ratio can be distributed according to requirements. With the method of invention, a nanometer grade nickel-copper alloy material of high specific surface can be obtained through a simple and convenient operation process.

Owner:DALIAN UNIV OF TECH

Resource recovery process of galvanizing sludge

InactiveCN100506727CSolve pollutionEfficient recyclingSludge treatment by oxidationSludgeHazardous substance

The invention relates to a process for treating electroplating sludge. The invention not only can eliminate the poisonous and harmful substances in the electroplating sludge, but also solves the technical problem of high treatment cost. The resource treatment process of the electroplating sludge comprises the following steps: a, ingredients: after the electroplating sludge is dried by a dryer, it is mixed with flux and coke according to the weight ratio of 100:15~71:50~88 ; b. Smelting: Stir and mix the above-mentioned materials with a good proportion, put them into a melting furnace for smelting reduction smelting at a temperature of 1400°C to 1600°C, and release the nickel-copper alloy obtained by smelting reduction through the alloy port , The liquid slag is released from the slag outlet; c. Tail gas treatment: the tail gas obtained during the above smelting is treated by the purification system and then emptied. The present invention has fast main reaction speed, high nickel recovery rate, forward charging, low batching cost, and overcomes the viscous slag and easy formation of nodules during reduction smelting of electroplating sludge, difficulty in descending furnace charge, extremely short furnace life, and frequent death Furnace problem.

Owner:台州盛世环境工程有限公司

Thick-wall red copper and austenitic stainless steel non-prewarming arc melting and welding method

InactiveCN101323044ASolve Welding ProblemsSolve the problem of hot cracking tendencyArc welding apparatusWelding/soldering/cutting articlesCrazingShielding gas

The invention discloses a non-preheating electric arc melting welding method of thick-wall red copper and austenitic stainless steel, which includes the following processing steps: 1. the method adopts tungsten electrode helium arc welding added with nickel-copper alloy welding wires of Phi 2 to 4mm for welding; the welding current is 180 to 400A; protective gas is pure helium, the flow volume of which is 10 to 15L per minute; the diameter of the tungsten electrode is Phi 4 to 5mm; the length for positioned welded joints is 10 to 15mm and the distance between the two welded joints is 100 to 150mm; 2. the method adopts the tungsten electrode helium arc welding added with the nickel-copper alloy welding wires of Phi 2 to 4mm for welding under the non-preheating condition; the welding current is 180 to 400A; the protective gas is helium, the flow volume of which is 10 to 15L / min; 3. after the backing welding, the non-preheating welding is used for filling the welded joint. The method solves the problems of the non-preheating welding of the thick-wall red copper and austenitic stainless steel and the hot cracking trend, which improves the solidification temperature, strength and plasticity of the welded joint and prevents the hot cracking and stomata by adding the nickel-copper alloy welding wire by hand.

Owner:中国船舶集团渤海造船有限公司

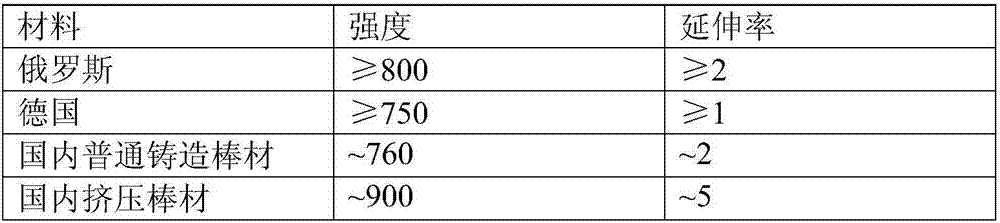

Tungsten-nickel-copper alloy and preparation method thereof

The invention relates to a tungsten-nickel-copper alloy and a preparation method thereof, in particular to a tungsten-nickel-copper alloy. The tungsten-nickel-copper alloy is characterized by having a tensile strength of above 650MPa, preferably above 750MPa, more preferably above 800MPa. The invention also relates to a method for preparing the tungsten-nickel-copper alloy, comprising the following steps: (1) mixing oxide powder of tungsten, oxide powder of nickel and oxide powder of copper to obtain powder of the mixed materials; (2) reducing the powder of the mixed materials obtained in the step (1) to obtain mixture powder of tungsten, nickel and copper; (3) moulding the mixture powder of tungsten, nickel and copper obtained in the step (2) into green bodies; and (4) sintering the green bodies obtained in the step (3) to obtain the tungsten-nickel-copper alloy.

Owner:安泰天龙钨钼科技有限公司

Nickel-copper alloy with high strength and high corrosion resistance and manufacturing method thereof

The invention discloses a nickel-copper alloy with high strength and high corrosion resistance and a manufacturing method thereof. The method takes electrolytic copper and electrolytic nickel as major components, a small amount of manganese, iron, silicon, metal magnesium and metal titanium is added, and the impurity accounts for less than or equal to 0.5%. According to the invention, the components are sequentially put into a smelting furnace and subjected to the steps of smelting, stirring and slag extraction, refining, casting formation and the like to obtain a finished product of the nickel-copper alloy. Through the invention, the tensile strength is 670-720Rm / MPa, the elongation is 6-7.5, the strength is improved by 15% over the existing domestic nickel-copper alloy, and the corrosion resistance is improved by about twice. The nickel-copper alloy disclosed by the invention is widely applicable, has long service life and the like, can be used for producing plates, belts, pipes, rods, lines and forgings, and is applied to the industries such as shipbuilding, chemical industry, machinery manufacturing, aerospace, electronics and the like. The manufacturing method disclosed by the invention changes the original vacuum casting process, adopts a semi-continuous smelting method and reduces the production cost.

Owner:沈阳有色金属研究所有限公司

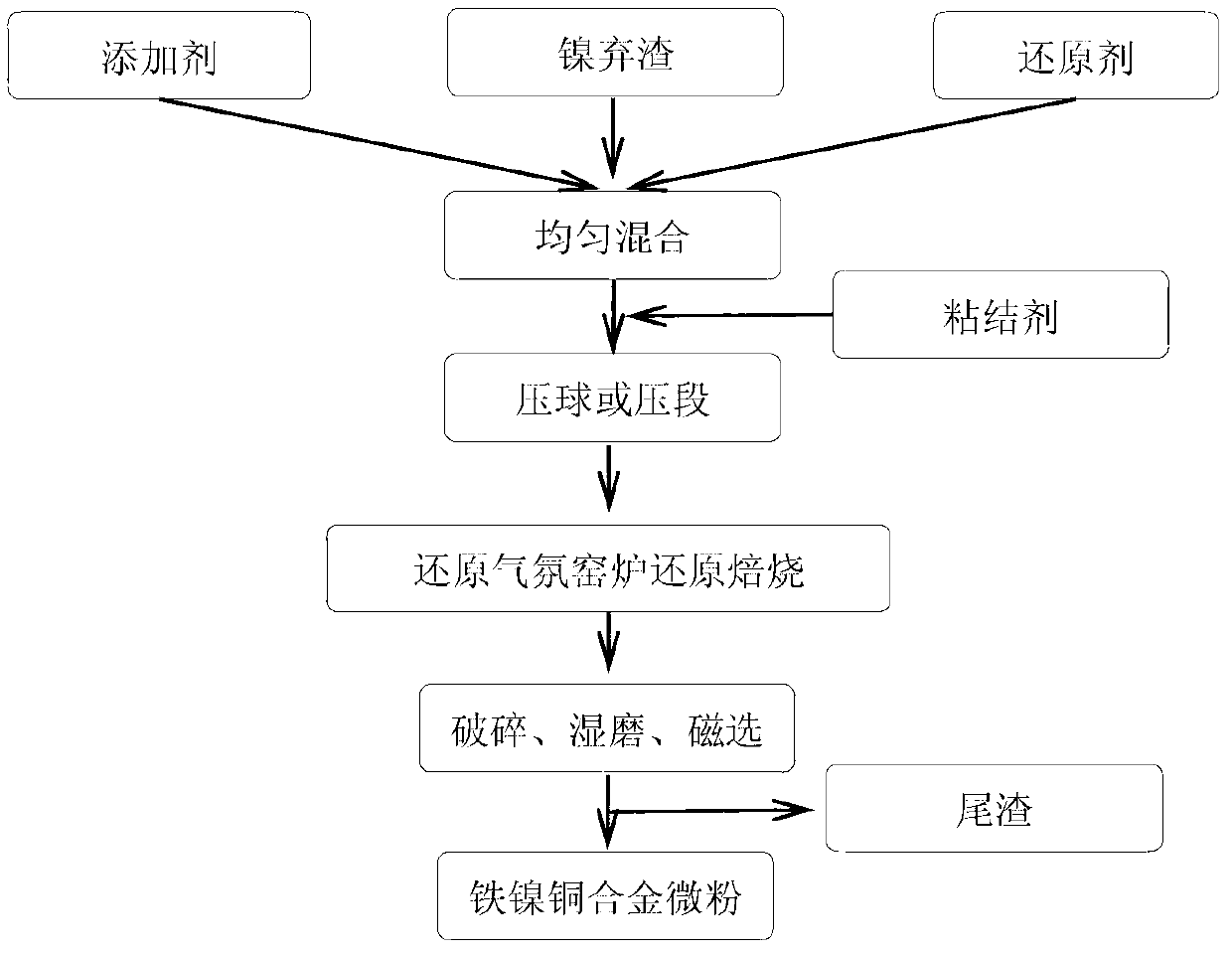

Method for rapidly reducing nickel slag to produce iron-nickel-copper alloy powder in kiln under reducing atmosphere

ActiveCN103276294AIncrease added valueEnable recyclingProcess efficiency improvementSlagNickel copper alloy

The invention relates to a method for rapidly reducing nickel waste slag to produce iron-nickel-copper alloy powder in a kiln under the reducing atmosphere. The method is characterized by comprising the following steps of: proportionally mixing the nickel waste slag, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, and uniformly mixing; preparing small balls with the diameter of 15-33 mm or small cylinders with the diameter and the height of 15-30 mm by using a ball press machine or a section making machine; drying; flatly paving the materials at the bottom of the kiln, wherein the thickness of the material layer is 20-45 mm, the reducing temperature of the material layer is 1,250-1,450 DEG C, and the reducing time is 10-40 minutes; and performing cooling, crushing, wet grinding and wet magnetic separation on the reduced balls or sections to obtain iron-nickel-copper alloy micropowder with the iron recovery rate of 85-99 %, wherein in the obtained product, the iron content is 88-98 %, the nickel content is 0.13-1.98 %, the copper content is 0.14-1.29 % and the particle size is 3-100 microns, and the product can serve as a raw material for smelting weather-resistant steel. The tailings after wet grinding and wet magnetic separation can serve as raw materials for extracting aedelforsite or producing hollow sintered bricks.

Owner:UNIV OF SCI & TECH BEIJING

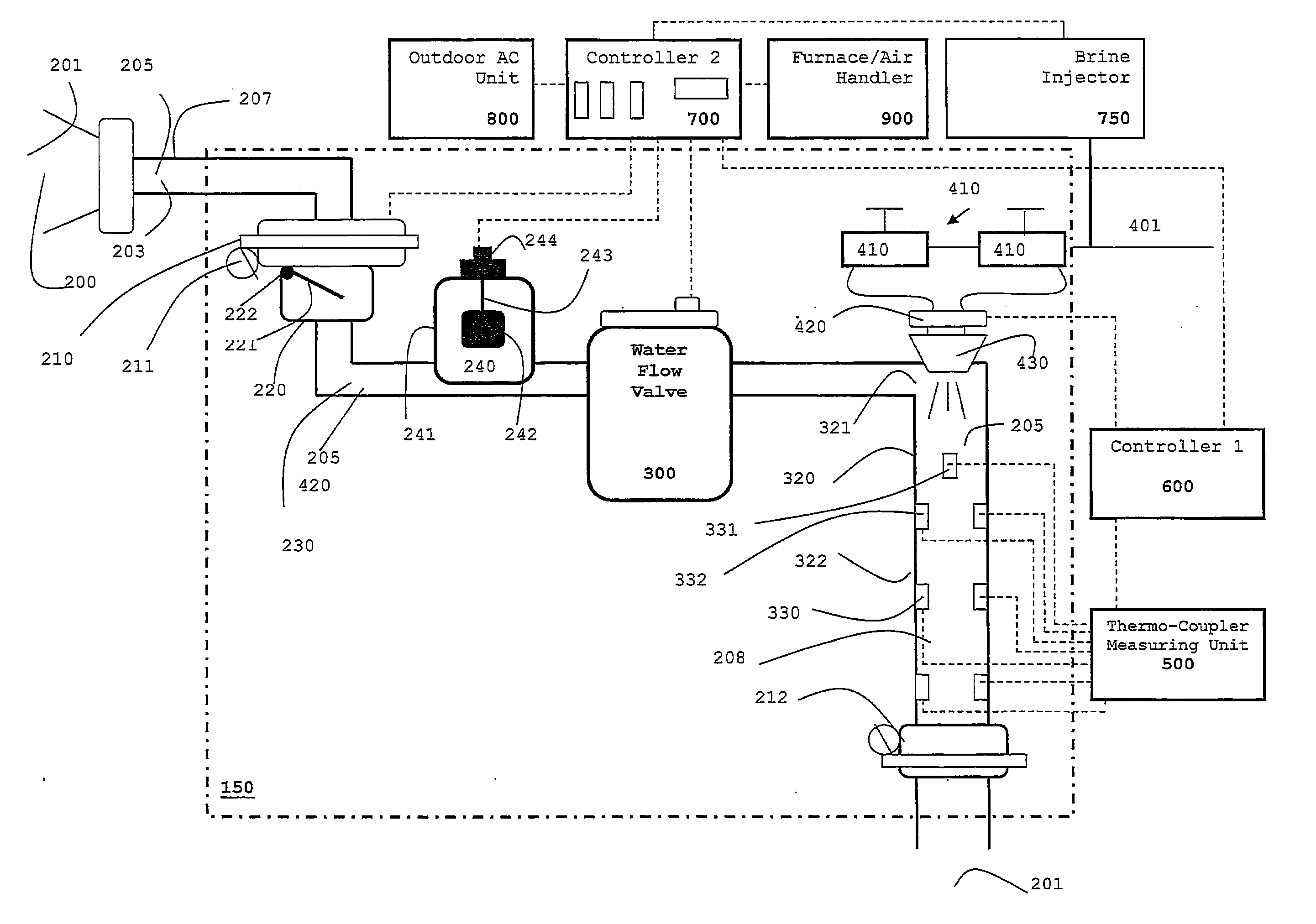

Combination Anti-Microbial Drain Pan Float and High Temperature Brine Injected Automated Drain Cleaner

InactiveUS20110308557A1Reduce and impede growthPrevent freezingLighting and heating apparatusHollow article cleaningSaline waterSludge

The invention is directed toward a brine injector for sanitizing a condensate drain to reduce sludge and pathogens. The bring injector, which attaches to a spray assembly within the condensate drain, supplies brine (23.3% sodium chloride and 76.7% hot water) into the a saddle valve of the spray assembly. The brine injector may include a brine reservoir having a polyethylene non-corrosive coating, a pump to draw brine out of the brine reservoir, and a filter casing. The filter casing is coated with a polyethylene interior lining. Filter casing further includes 15-micron nickel copper alloy weaved filter cloth. The brine reservoir may include an electric heater to heat the brine prior to injection. A main controller communicates with the treatment chamber and spray assembly. Such main controller is capable of engaging the spray assembly to disperse a sufficient quantity and pressure of hot water within the shaft to dislodge any sludge.

Owner:PLEXAIRE

Nickel-copper alloy bar and preparing method thereof

The invention relates to a nickel-copper alloy rod and a preparation method thereof, belonging to the technical field of metal processing. The formula ratio is as follows in terms of mass percentage: Cu 30%-32%, Si 3.9%-4.3%, Fe 1.5%-2.8%, Mn 0.5%-1.5%, impurity elements ≤ 0.3%, and the rest are Ni; through the master alloy Preparation of ingot, casting rod, solution heat treatment and aging heat treatment to obtain nickel-copper alloy rod. The invention adopts vacuum induction smelting, can obtain ultra-pure ingot with uniform composition, reduces defects such as inclusions, and can reduce surface defects of rods through investment precision casting, and can avoid the problem of shrinkage cavity in the core of the rod. Finally, after solid solution and aging heat treatment, high-strength and high-plastic rods can be obtained.

Owner:江苏隆达超合金股份有限公司

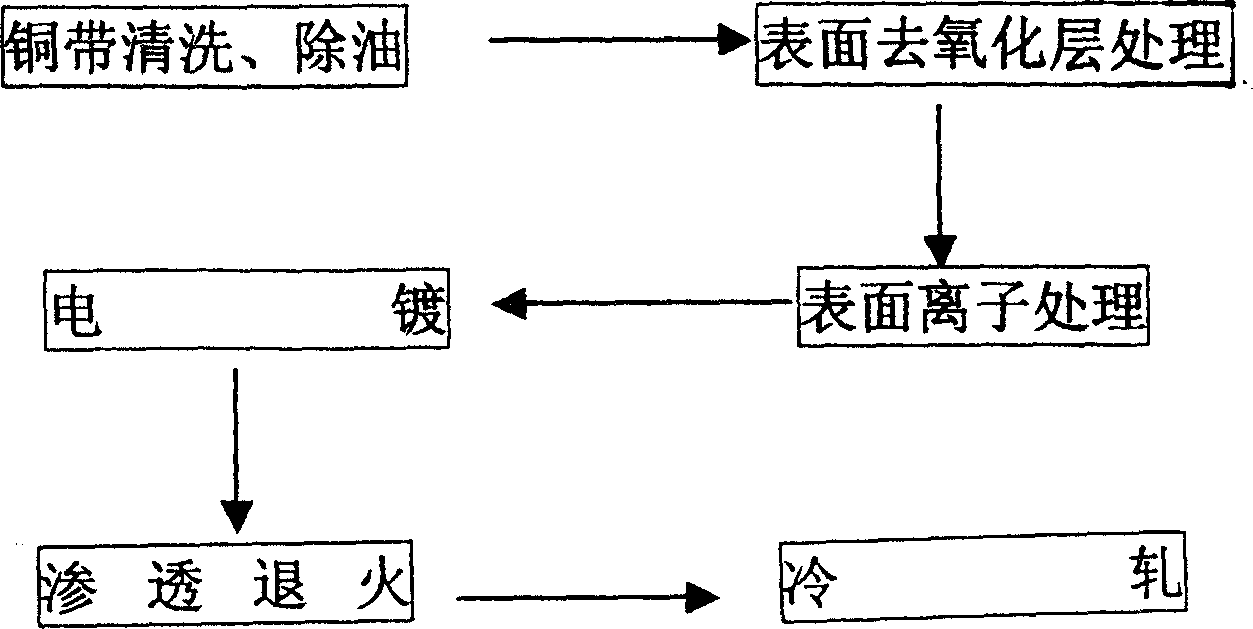

Ear-pole of battery inner and electric sheet metal between batteries and processing method

InactiveCN1722493AGood spot weldabilityImprove performanceConductive materialCell component detailsMetal sheetElectroplating

This invention relates to electrode ear in the cell and conductive metal sheet among the cells and their processing method, with the advantages of low price, good weldability, conductivity and comprehensive property better than pure nickel and nickel-plating steel. The invention comprises base plate in copper material, characterized in that the base plate surface is nickel-copper alloy layer, and comprising the following steps: cleaning the copper belt, eliminating oil, dealing deoxidation and ion treatment to the copper belt surface, then electroplating, percolation annealing and at last cold rolling.

Owner:YIXING HUIHUA COMPOSITE MATERIAL CO LTD

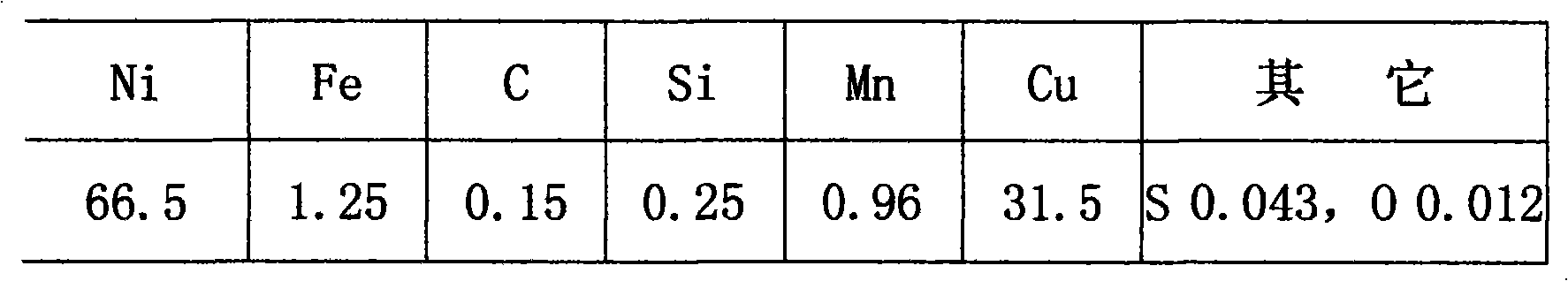

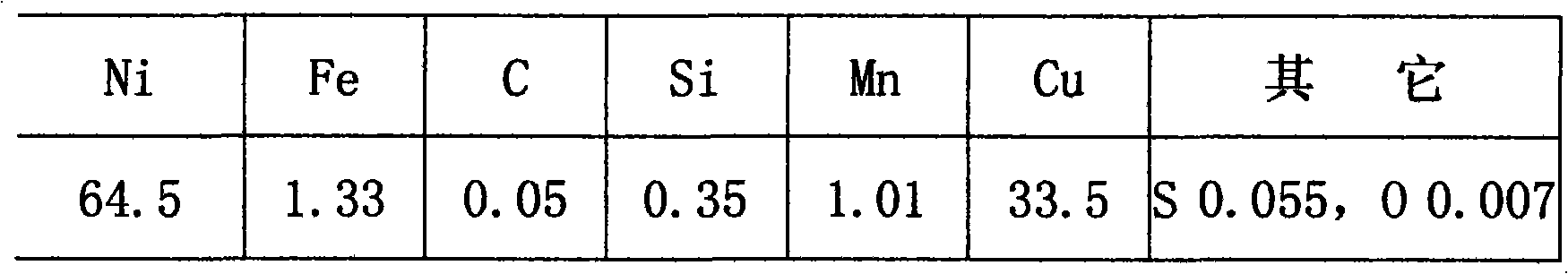

Preparation for free-cutting adnic alloy

A free-cutting nickel-copper alloy is disclosed whose ingredients by percent are that: carbon<=0.3, manganese <=2.0, iron<=2.5, sulphur 0.025-0.060, silicon<=0.5, copper 28.0-34.0, the rests are nickel, the manufacturing method of the free-cutting nickel-copper alloy comprises the steps of: 1, loading and vacuumizing; 2, controlling the temperature within the range from 1500 to 1650 DEG C, refining for 5 to 25 minutes, adding deoxidizer and finally the sulphide to lead the sulphur content in the nickel-copper alloy to be between 0.020% and 0.08%, the optimized sulphur content is 0.040% 0.06%, the sulphide is one of manganese sulphide, iron sulphide, copper sulphide and high nickel matte or mixture thereof, the deoxidizer is one of carbon and nickel-magnesium alloy, calcium-silicon alloy, and copper-zirconium alloy or the mixture thereof; 3, measuring the temperature and casting at the temperature between 1400 and 1500 DEG C for 30 seconds at most, and vacuumizing for at least 10 minutes; the good cutting performance of the steel remarkably improves the cutability of steel, reduces the cutting force and cutting temperature, conspicuously prolonging the life of cutting tool, lessens the surface roughness of working piece and improves the cut-processing performance.

Owner:沈阳金纳新材料股份有限公司

Method for manufacturing nickel-copper alloy valve body for precision casting

ActiveCN103469006AImprove ductilityImprove densification performanceMetal impuritiesNickel copper alloy

The invention discloses a method for manufacturing a nickel-copper alloy valve body for precision casting. The valve body is characterized by comprising the following chemical components in percentage by weight: 15-17 percent of Ni, 3-4 percent of Al, 8-9 percent of Mg, 0.03-0.04 percent of Sn, 0.03-0.04 percent of Sb, 0.01-0.02 percent of Ca, 0.03-0.04 percent of Bi, 0.01-0.02 percent of Ti, 0.01-0.02 percent of Mn, 0.02-0.03 percent of Y, 0.03-0.04 percent of Mo, and the balance of copper and inevitable non-metal impurities. According to the method, a precision casting and shot blasting technology is adopted, so that the compactness of the valve body can be improved, the process can be simplified, the production efficiency can be improved, and the production cost can be reduced.

Owner:苏州华宇精密铸造有限公司

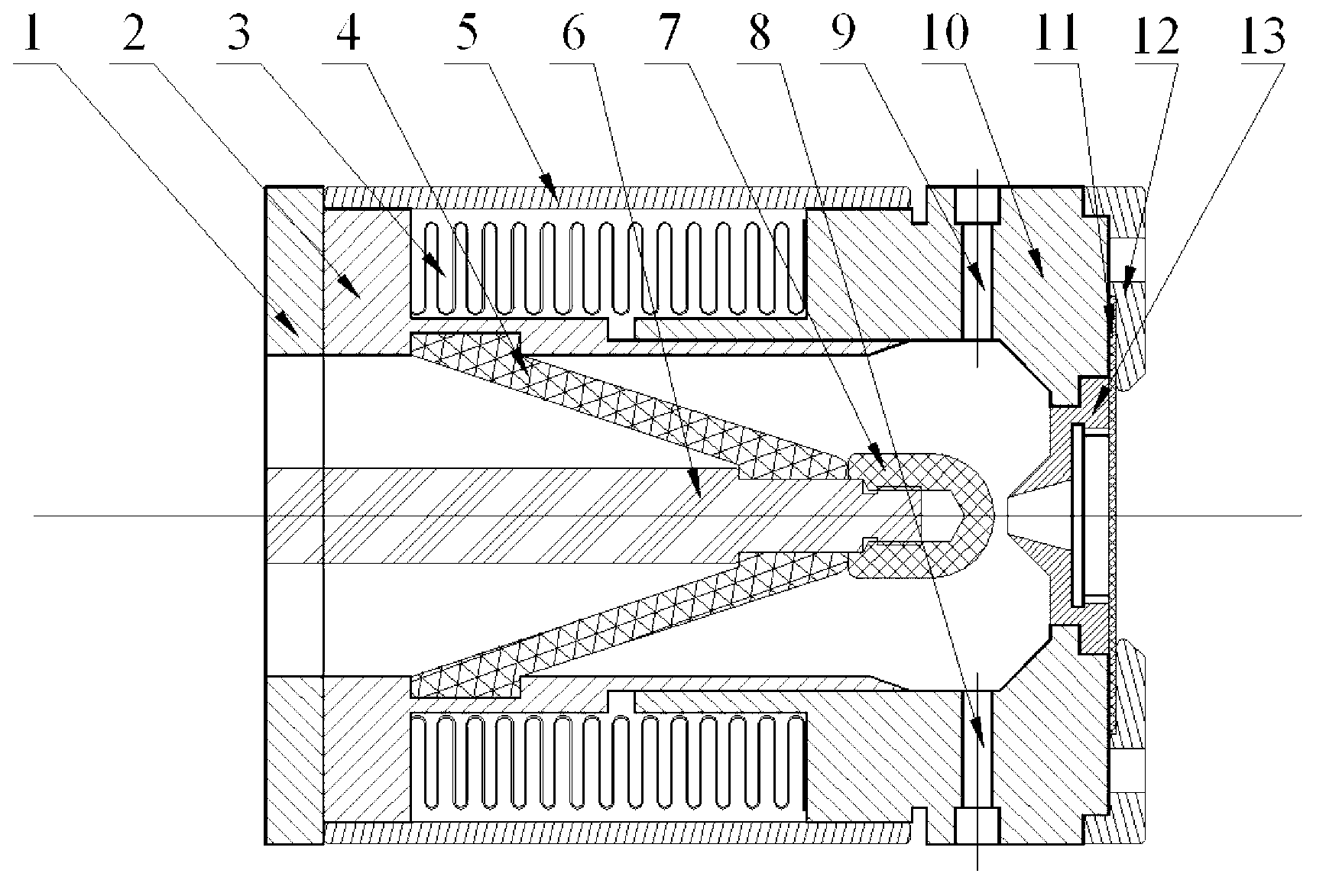

Vacuum diode with high current, small focal spot and long service life

ActiveCN103077875AIncrease beam intensityShort pulse timeX-ray tube electrodesX-ray tube vessels/containerHard X-raysElectron

The invention relates to a vacuum diode with high current, small focal spot and long service life. The original diode in a repetition frequency fast-pulse hard X-ray generator is modified, the structure and the material of movable cathode and anode assemblies are improved, a cathode head is made of tungsten nickel copper alloy materials and is seated on a movable support, a conical hole structure inwards forming a sharp end bulge is used for emitting electrons and is aligned with X rays, and an anode target is made of metal tantalum materials and is fixedly arranged on a copper core wire through screw threads. The conical annular cathode structure is improved, the radius of sent plasmas is favorably controlled, dense plasmas can be conveniently obtained, the self pinching condition in the electronic beam transporting process is met, submillimeter beam spots are formed, and the detailed imaging requirement of the pulse imaging field is met.

Owner:NORTHWEST INST OF NUCLEAR TECH

Nickel-copper (111) alloy single crystal film and preparation method thereof

PendingCN108754608AMaintain catalytic performanceNo breakagePolycrystalline material growthAfter-treatment detailsCopper atomCrystal orientation

The invention relates to a method for preparing a nickel-copper (111) alloy single crystal film. The method comprises: S1, providing a sapphire base, S2, depositing a metal film with thickness of 50 to 5000 nm on the crystal plane Al2O3 (0001) of the sapphire base to obtain a sapphire substrate on which a nickel-copper alloy is deposited, wherein the metal film is an alloy thin film composed of 1-40% of nickel atoms, and copper atoms, and S3, putting the sapphire substrate in a chemical vapor deposition furnace and carrying out annealing treatment in a gas atmosphere of argon gas and hydrogengas to obtain a single crystal thin film with (111) crystal orientation. The invention also relates to a nickel-copper (111) alloy single crystal film obtained by the method. The nickel-copper (111) alloy single crystal film greatly improves the performances of graphene and lays a foundation for the application of graphene in the field of microelectronics.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Preparation method of copper-nickel conducting fabric

ActiveCN104357816AImprove flexibilityLiquid/solution decomposition chemical coatingFiberMetal coating

The invention discloses a preparation method of a copper-nickel conducting fabric, which sequentially comprises the following steps: carrying out oil removal treatment on the base fabric surface, coarsening the base fabric surface, carrying out palladium-free activating treatment on the base fabric surface, carrying out chemical plating on the nickel-copper alloy plating solution, and the like. The ultraviolet radiation dry-state oxidation is used instead of the traditional caustic soda wet-process coarsening technique to construct the fiber hydrophilic coarse surface, thereby being beneficial to adsorption of the subsequent activator on the fibers and increasing the binding force between the metal coating and fibers. The method belongs to dry-state processing, effectively avoids chemical pollution, and reduces the two steps of dehydration and drying in the traditional coarsening.

Owner:江苏联泰纺织有限公司

Nickel-copper alloy and preparation process for same

The invention belongs to the technical field of alloy materials, and particularly relates to a nickel-copper alloy and a preparation process for the same. The technical problems that in the prior art, manufacturing cost is high and the mechanical property is not enough are solved by the nickel-copper alloy and the preparation process for the same. The preparation process comprises the following steps of A, primary melting, B, standing and C, casting. Compared with the prior art, the nickel-copper alloy and the preparation process for the same have the advantages that the content of nickel is low, the material cost can be greatly reduced, and the cost is reduced; the mechanical property is good, and balance between the material cost and the mechanical property is achieved.

Owner:浙江海帆机械有限公司

Preparation method of rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy

InactiveCN104651653AResolve the assigned stateOvercome the adverse effects of mechanical propertiesNitrateHigh density

The invention relates to a preparation method of a rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy. The preparation method comprises the following steps: firstly, preparing tungsten nitrate, nickel nitrate, copper nitrate, yttrium nitrate and water into a mixed solution according to a preset metering ratio, then preparing an alkali solution together with certain concentration of ammonia water solution, stirring the alkali solution, crystallizing, filtering, washing and drying to obtain precursor powder; placing the precursor powder into a reducing atmosphere furnace for dissociating and reducing, to obtain yttrium-containing tungsten-nickel-copper alloy powder; and grinding the alloy powder and mixing together with a forming agent and press-forming, dewaxing the formed blank and performing high-temperature sintering to finally obtain the rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy. The tungsten-nickel-copper alloy prepared by taking the rare earth microalloyed tungsten-nickel-copper alloy powder prepared by adopting a liquid / liquid doping method as a raw material through a proper powder metallurgy technology has the advantages that the density is more than or equal to 18.1g / cm<3>, the tensile strength is more than or equal to 850MPa, and the yielding strength is more than or equal to 690MPa.

Owner:SHAANXI UNIV OF TECH

Micron fine-grained titanium-nickel-copper alloy block constant-diameter corner extrusion preparation method

The invention is an equant bending-angle extrusion preparing method of micron microlite Ti, Ni-Cu alloy block, vacuum-melting Ti, Ni and Cu, where their atomic percents are 48-55%, 35-47% and 5-10% in turn, to make the Ti, Ni-Cu alloy cast ingot, cutting the alloy block into blanks, polishing and coating glass lubricant, adopting the equant bending-angle extrusion mould whose extrusion channel angle is 90-120 degrees and whose molding cavity surface is coated with graphitic lubricant, heating the blanks and the mould and preserving heat, at the same time taking out the blanks and the mould from the heating furnace for equant bending-angle extrusion and finally obtaining good -intensity and -plasticity Ti, Ni-Cu alloy block.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com