Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

587 results about "Single crystal film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High efficiency solar cells utilizing wafer bonding and layer transfer to integrate non-lattice matched materials

ActiveUS20060185582A1Polycrystalline material growthAfter-treatment detailsSemiconductor materialsEngineering

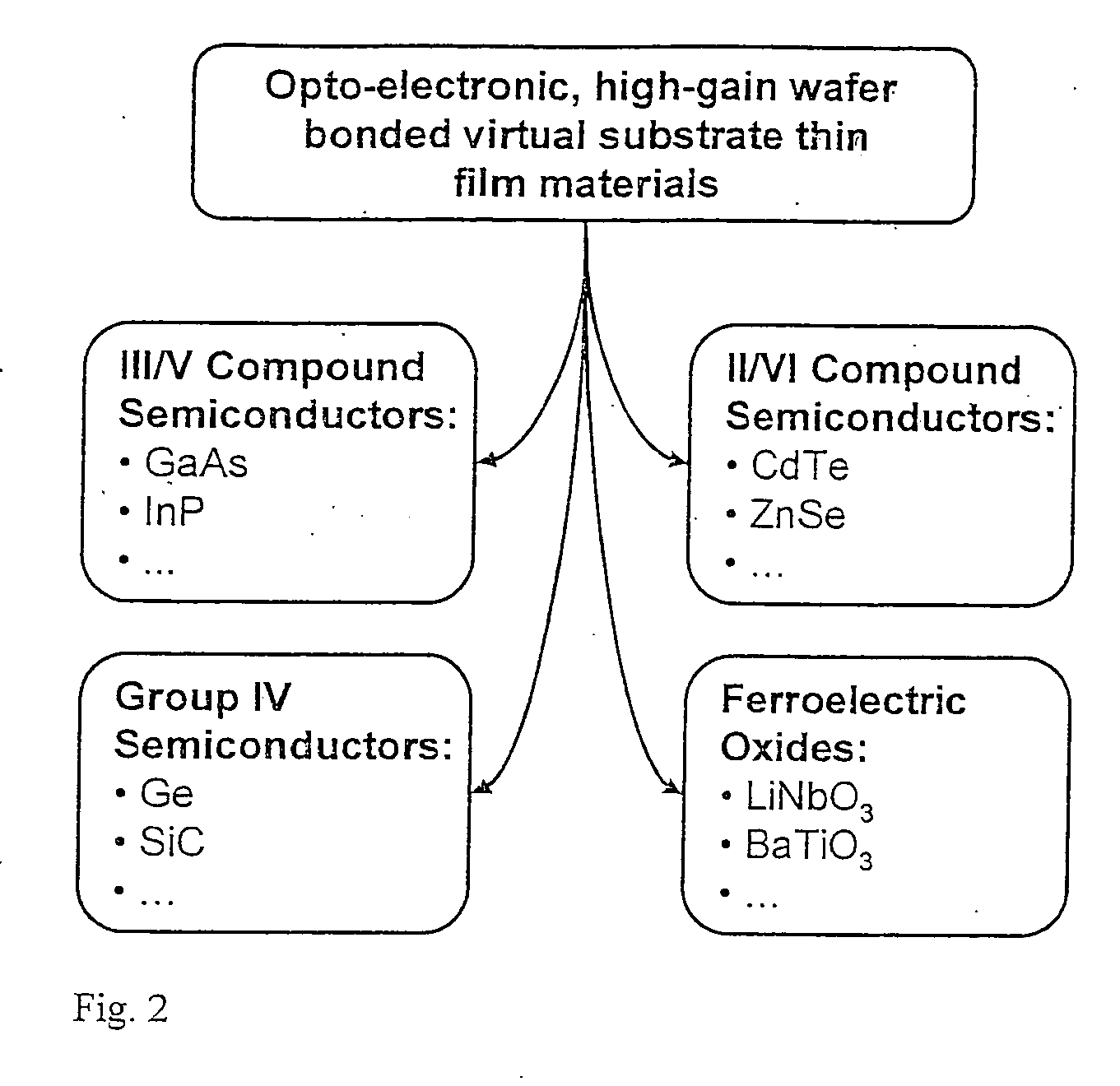

A method of making a virtual substrate includes providing a donor substrate comprising a single crystal donor layer of a first material over a support substrate, wherein the first material comprises a ternary, quaternary or penternary semiconductor material or a material which is not available in bulk form, bonding the donor substrate to a handle substrate, and separating the donor substrate from the handle substrate such that a single crystal film of the first material remains bonded to the handle substrate.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

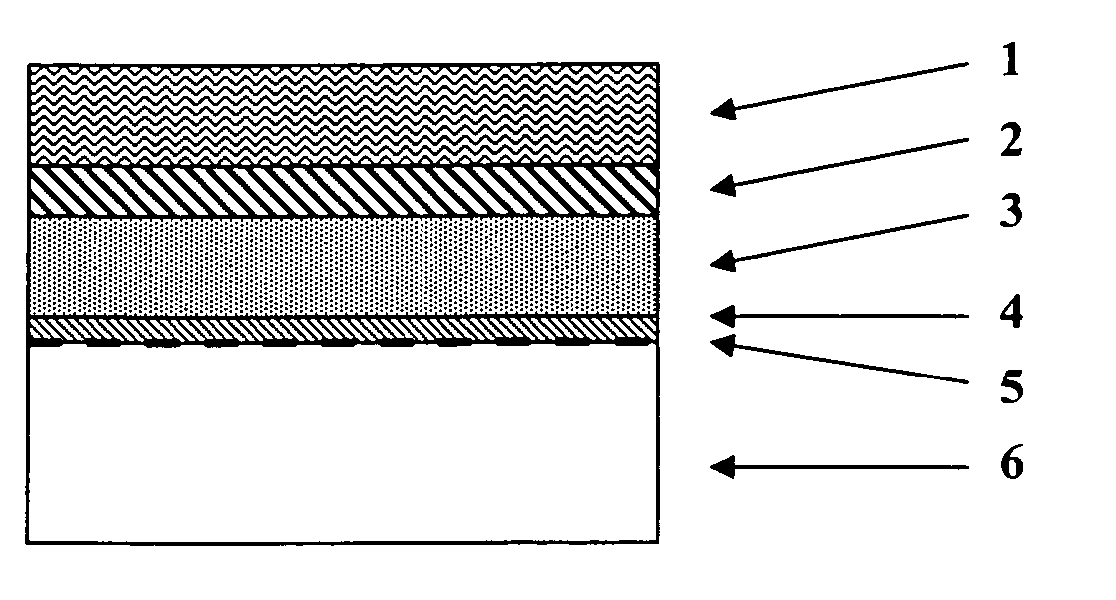

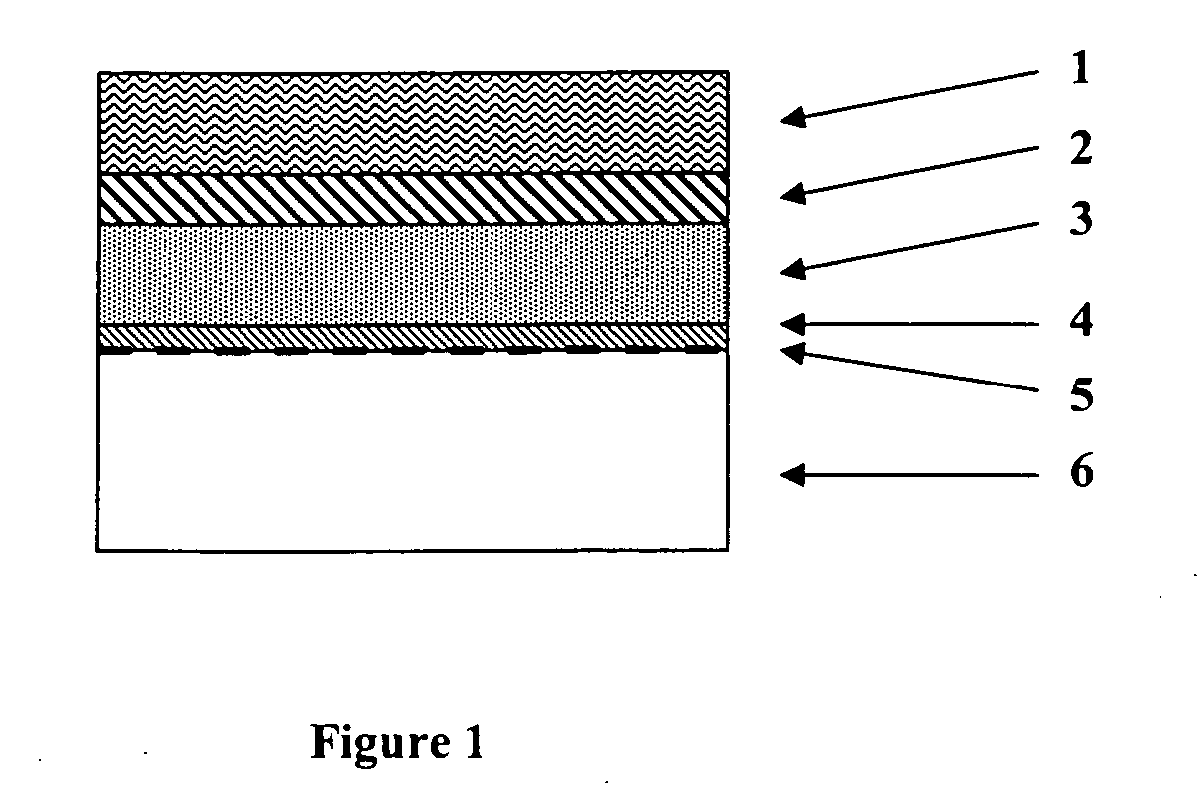

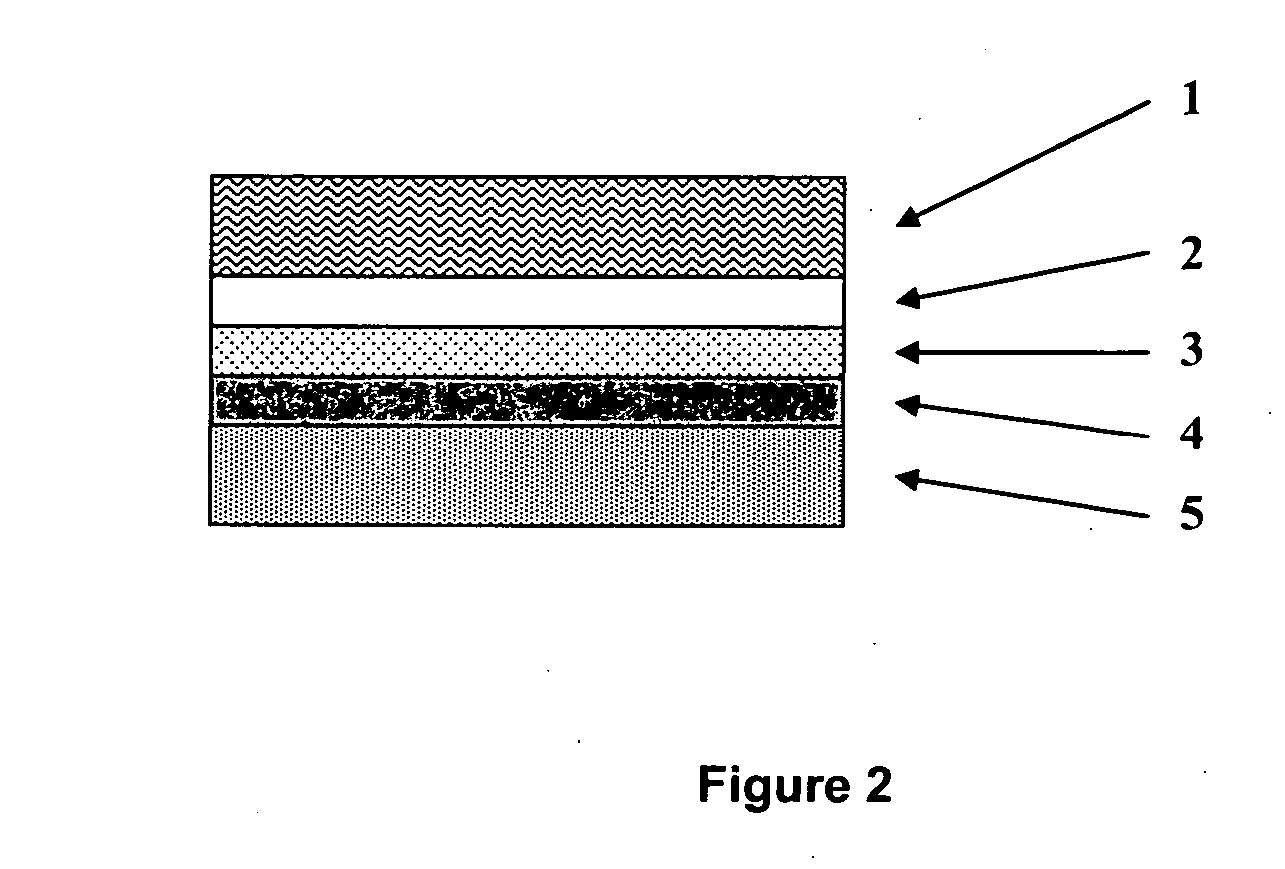

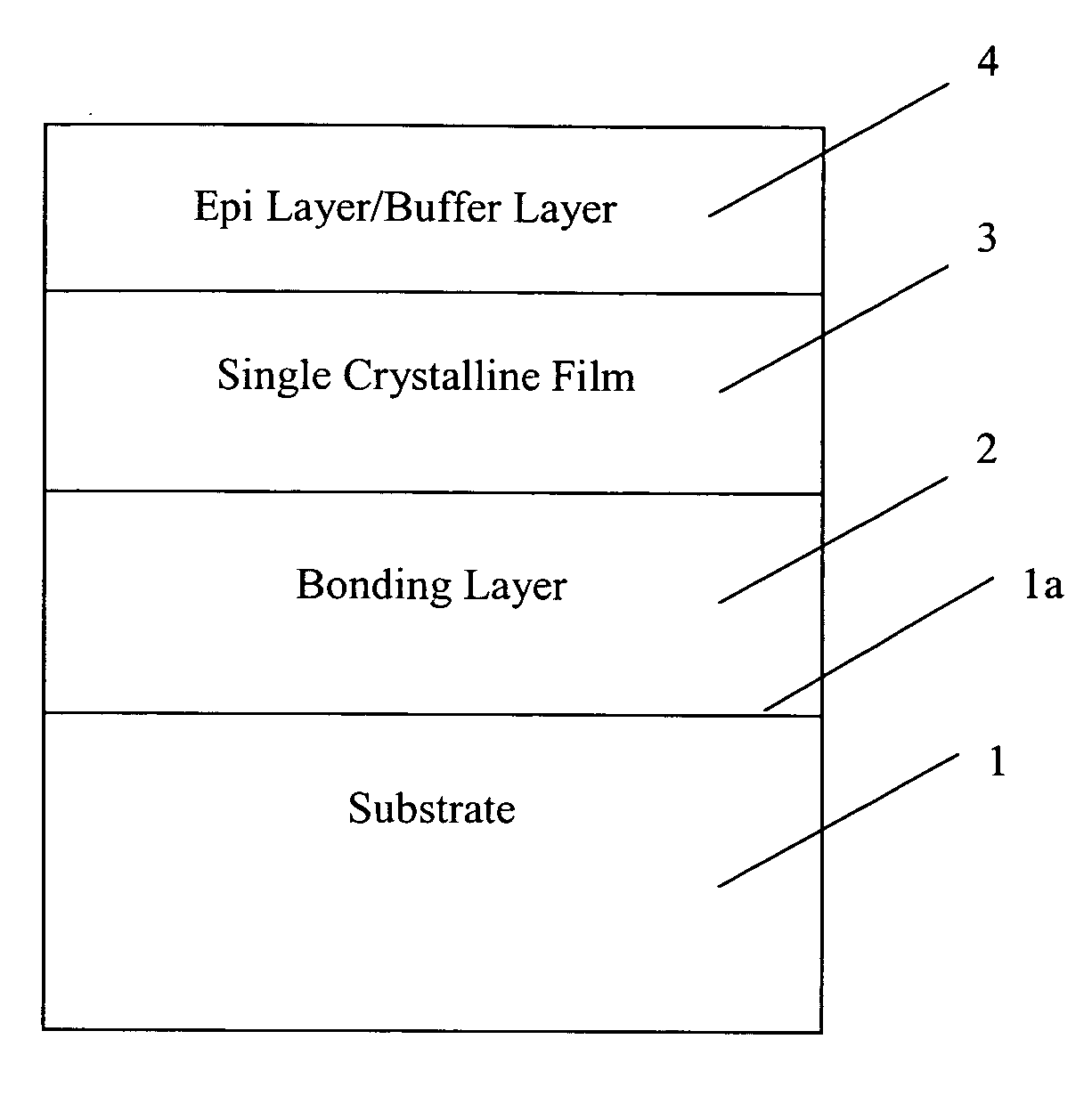

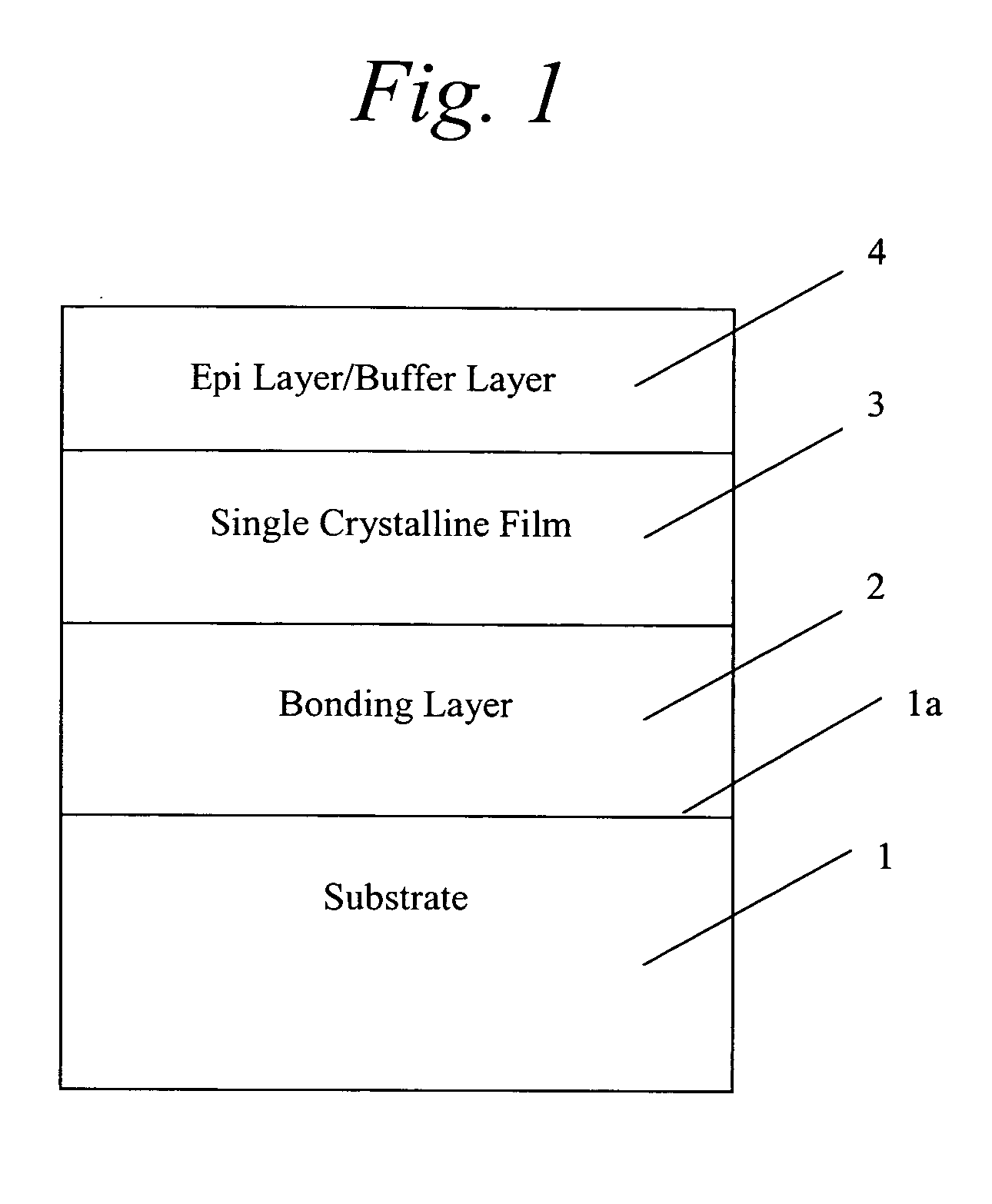

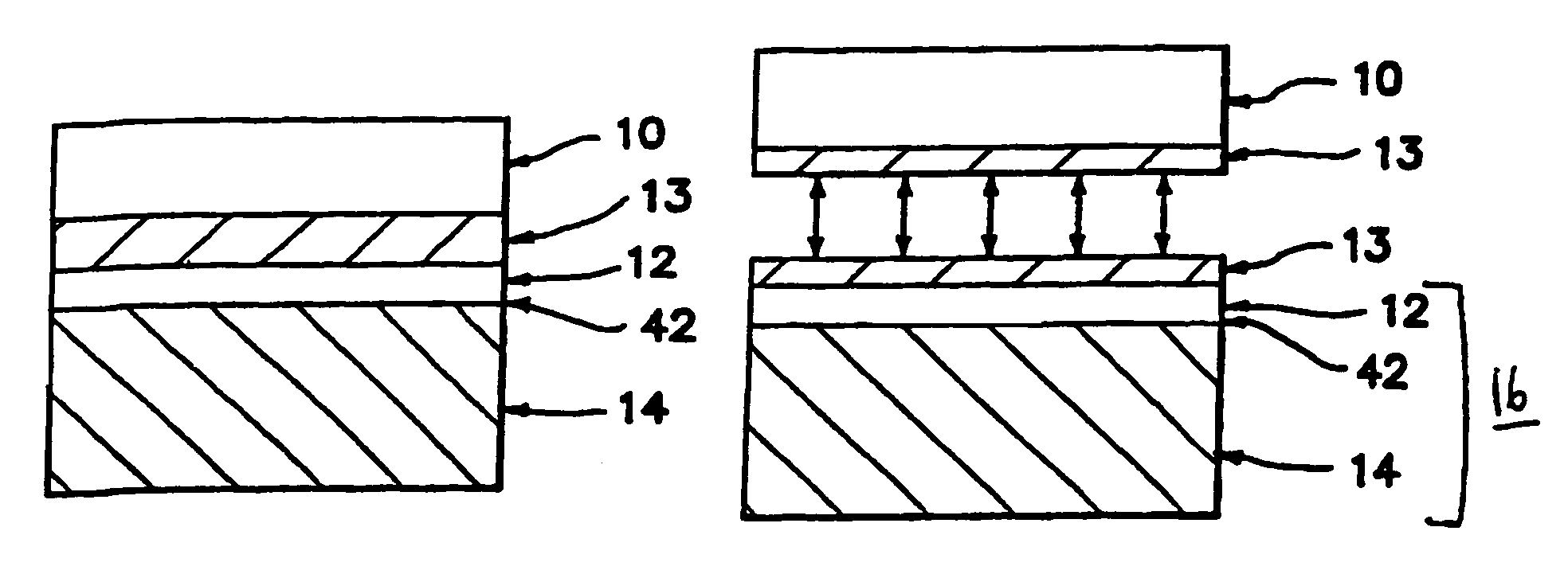

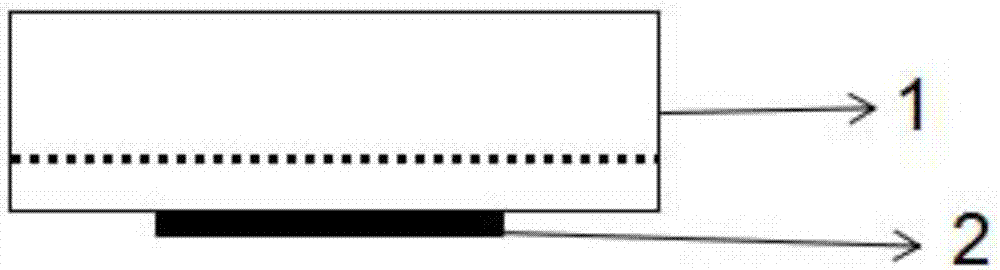

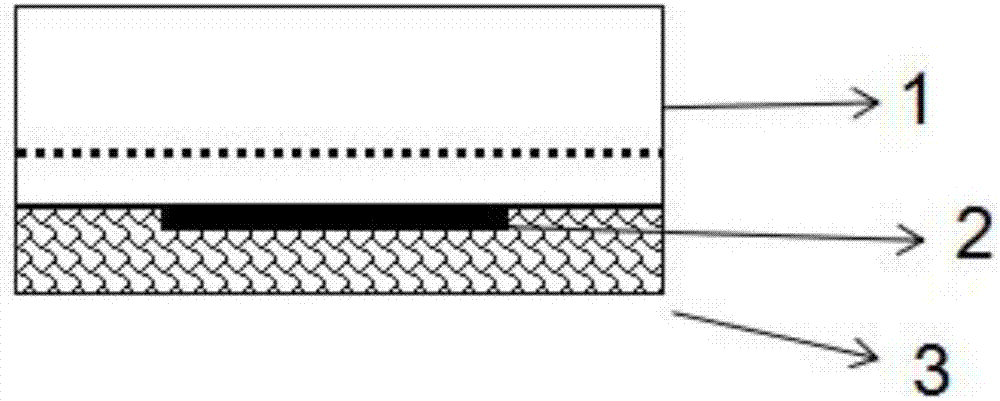

Electronic device with composite substrate

InactiveUS6497763B2Improve scalabilityImprove electronic performancePolycrystalline material growthSemiconductor/solid-state device manufacturingThermal coefficientComposite substrate

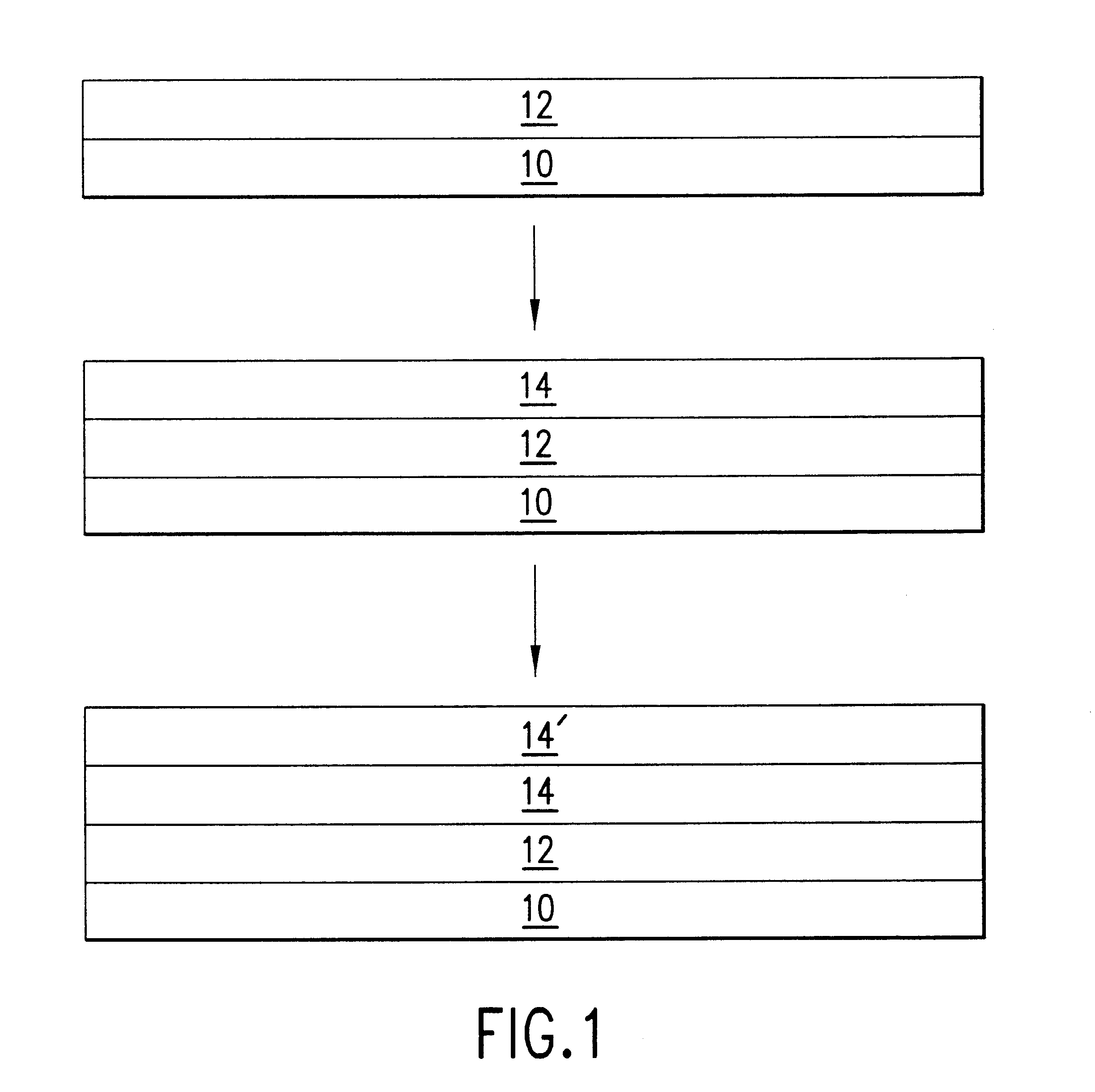

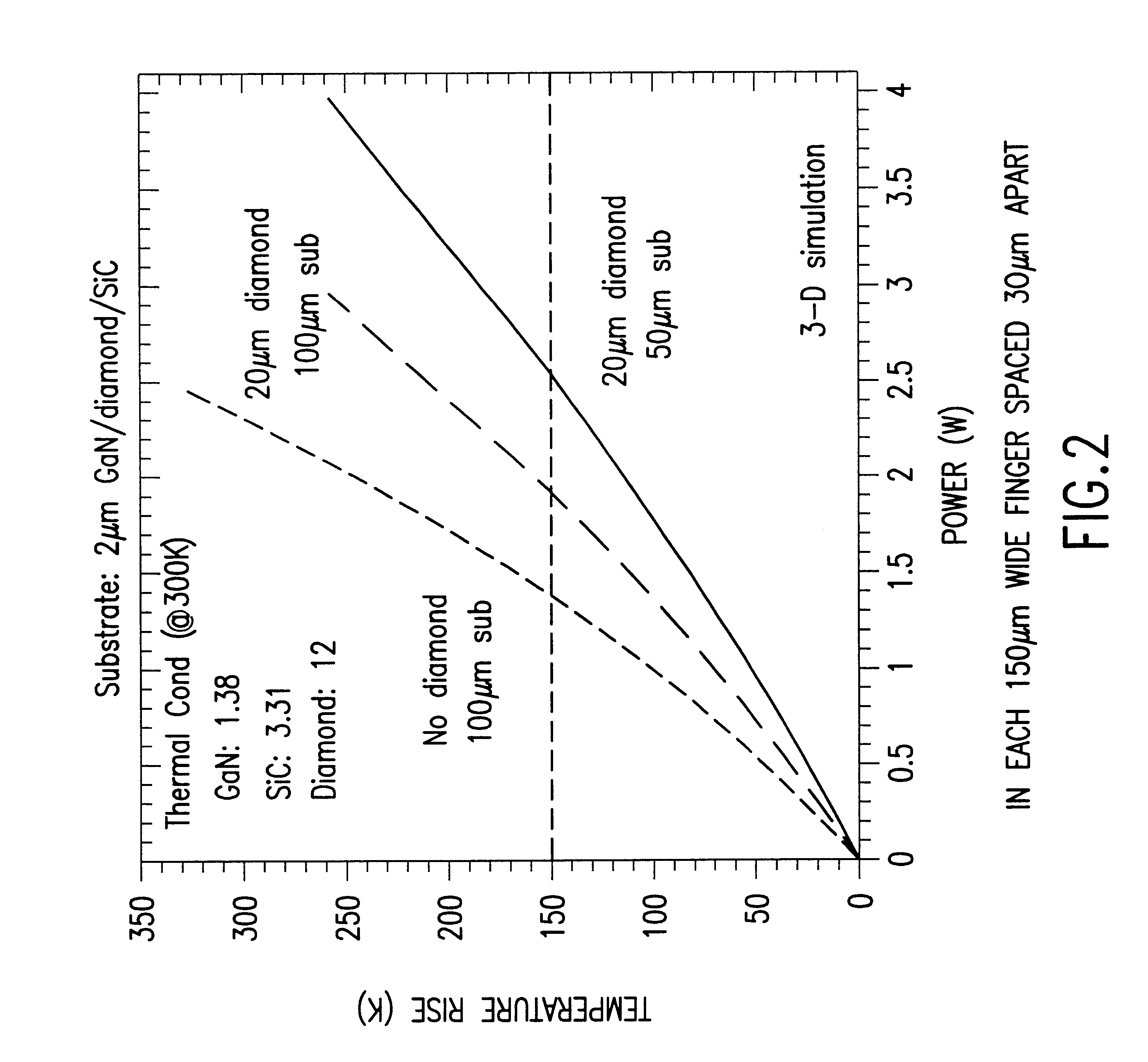

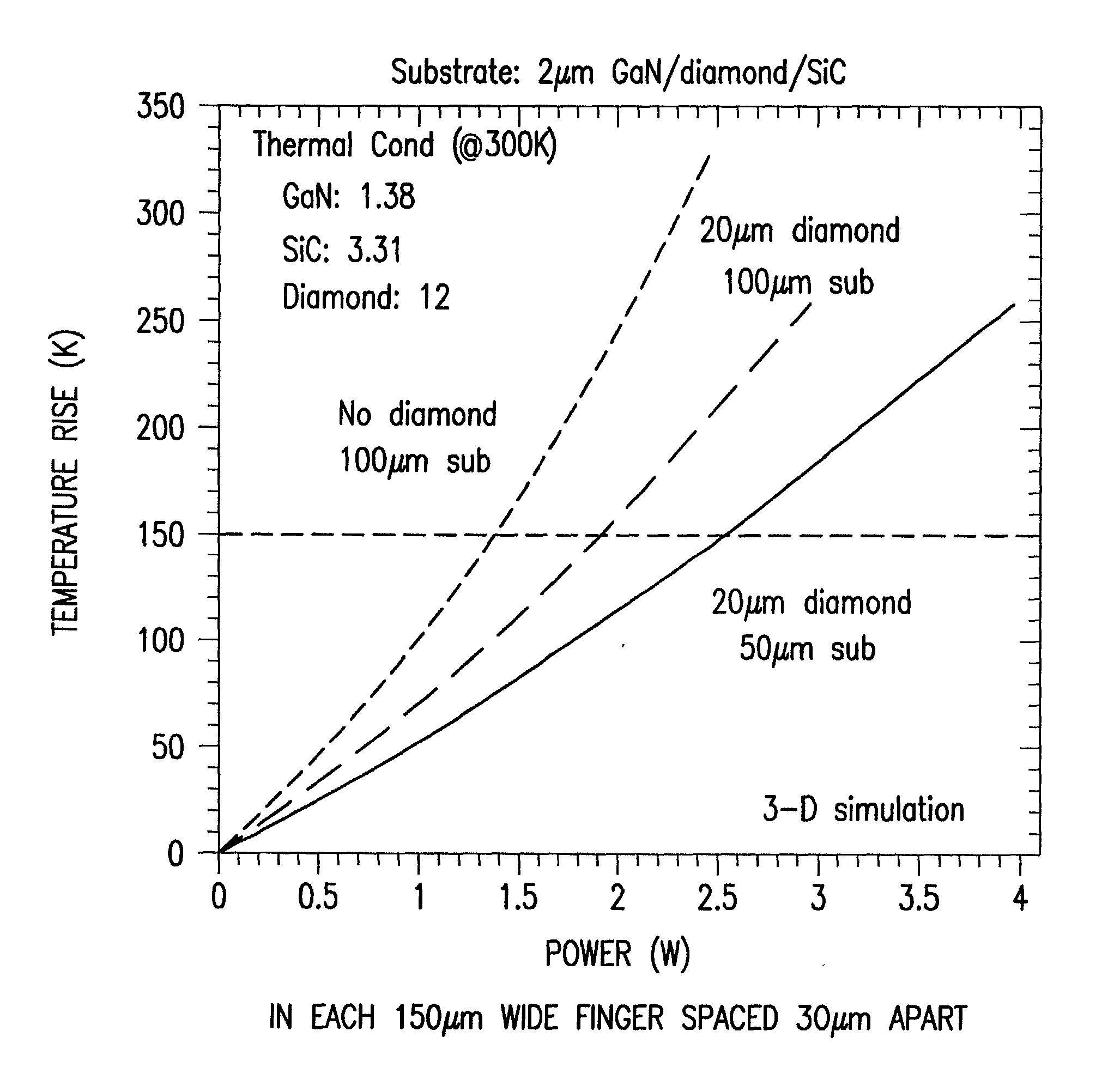

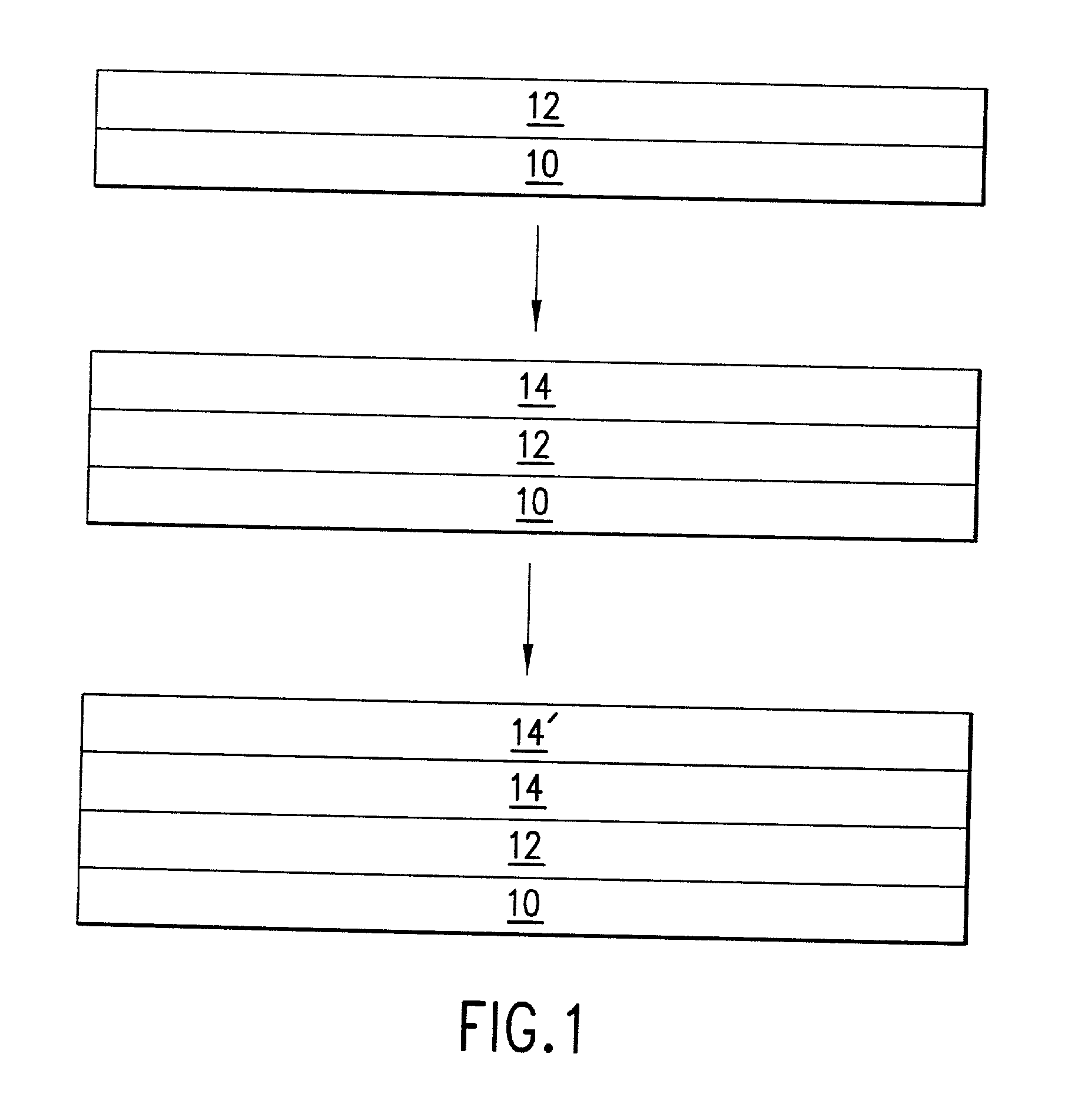

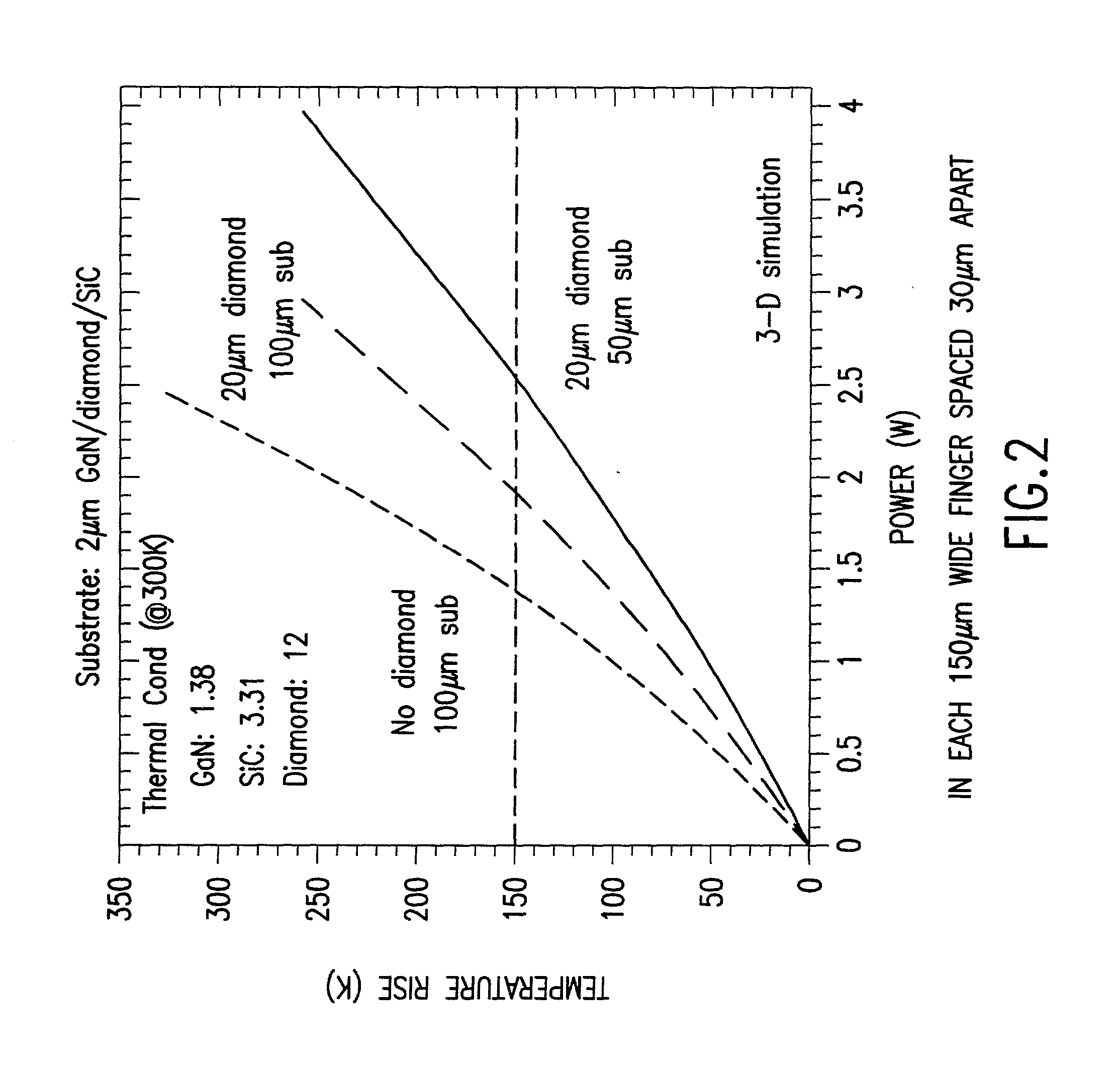

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Electronic device with composite substrate

InactiveUS20020096106A1Fast heat conductionGood thermal expansionPolycrystalline material growthSemiconductor/solid-state device manufacturingThermal dilatationComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

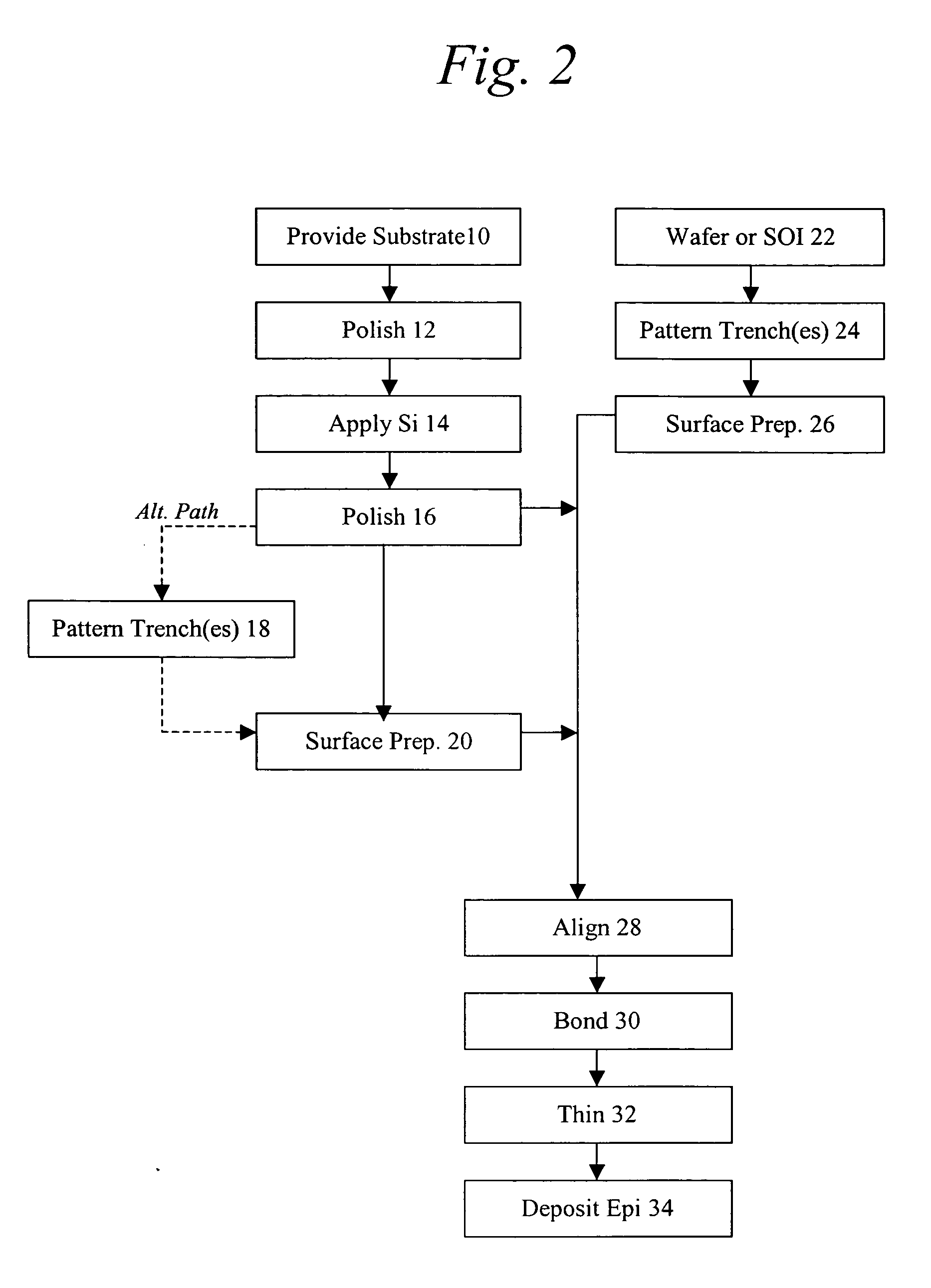

Wafer bonded epitaxial templates for silicon heterostructures

InactiveUS20050026432A1High mechanical strengthSimple methodSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSingle crystalWafer bonding

A heterostructure device layer is epitaxially grown on a virtual substrate, such as an InP / InGaAs / InP double heterostructure. A device substrate and a handle substrate form the virtual substrate. The device substrate is bonded to the handle substrate and is composed of a material suitable for fabrication of optoelectronic devices. The handle substrate is composed of a material suitable for providing mechanical support. The mechanical strength of the device and handle substrates is improved and the device substrate is thinned to leave a single-crystal film on the virtual substrate such as by exfoliation of a device film from the device substrate. An upper portion of the device film exfoliated from the device substrate is removed to provide a smoother and less defect prone surface for an optoelectronic device. A heterostructure is epitaxially grown on the smoothed surface in which an optoelectronic device may be fabricated.

Owner:CALIFORNIA INST OF TECH

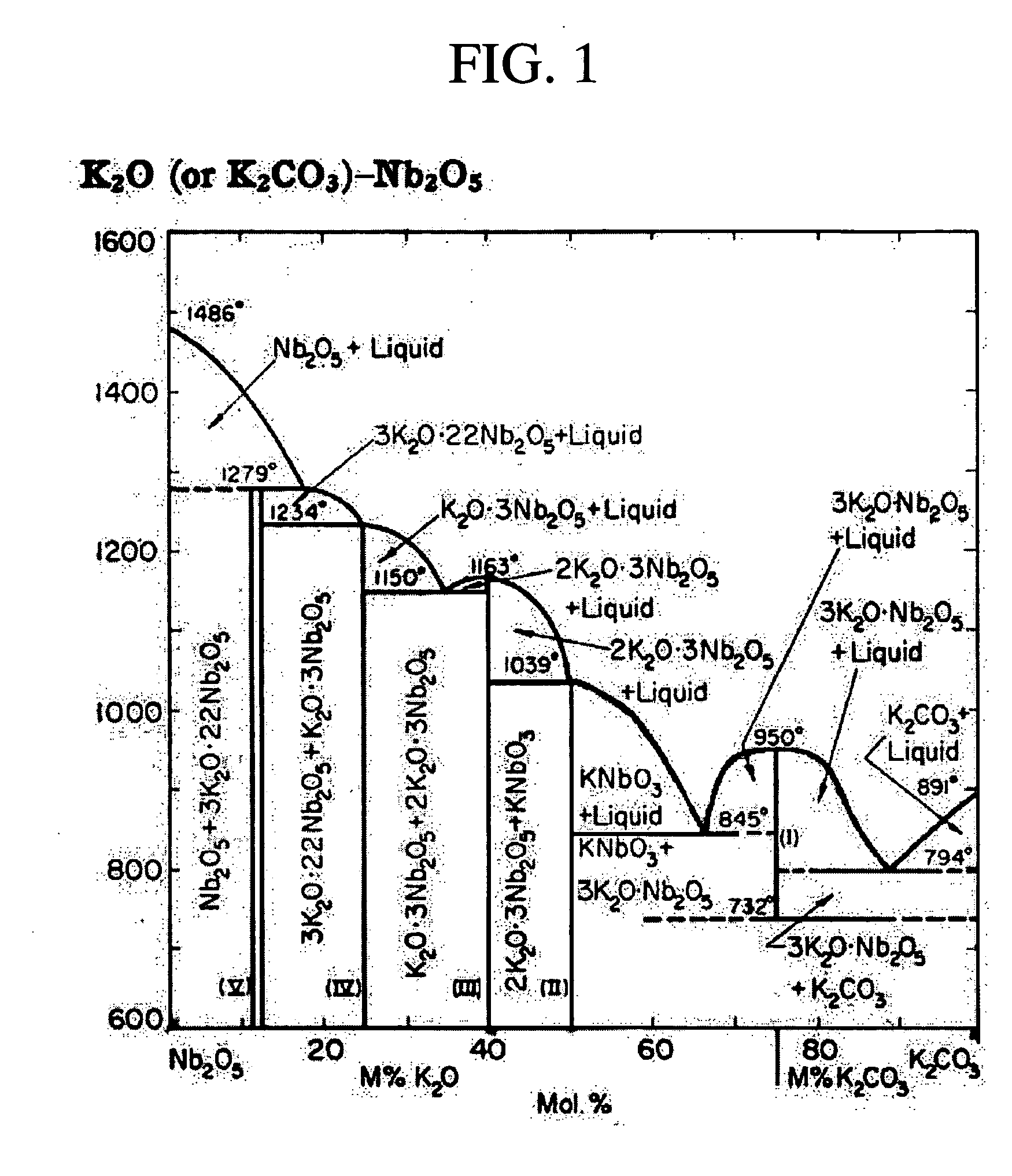

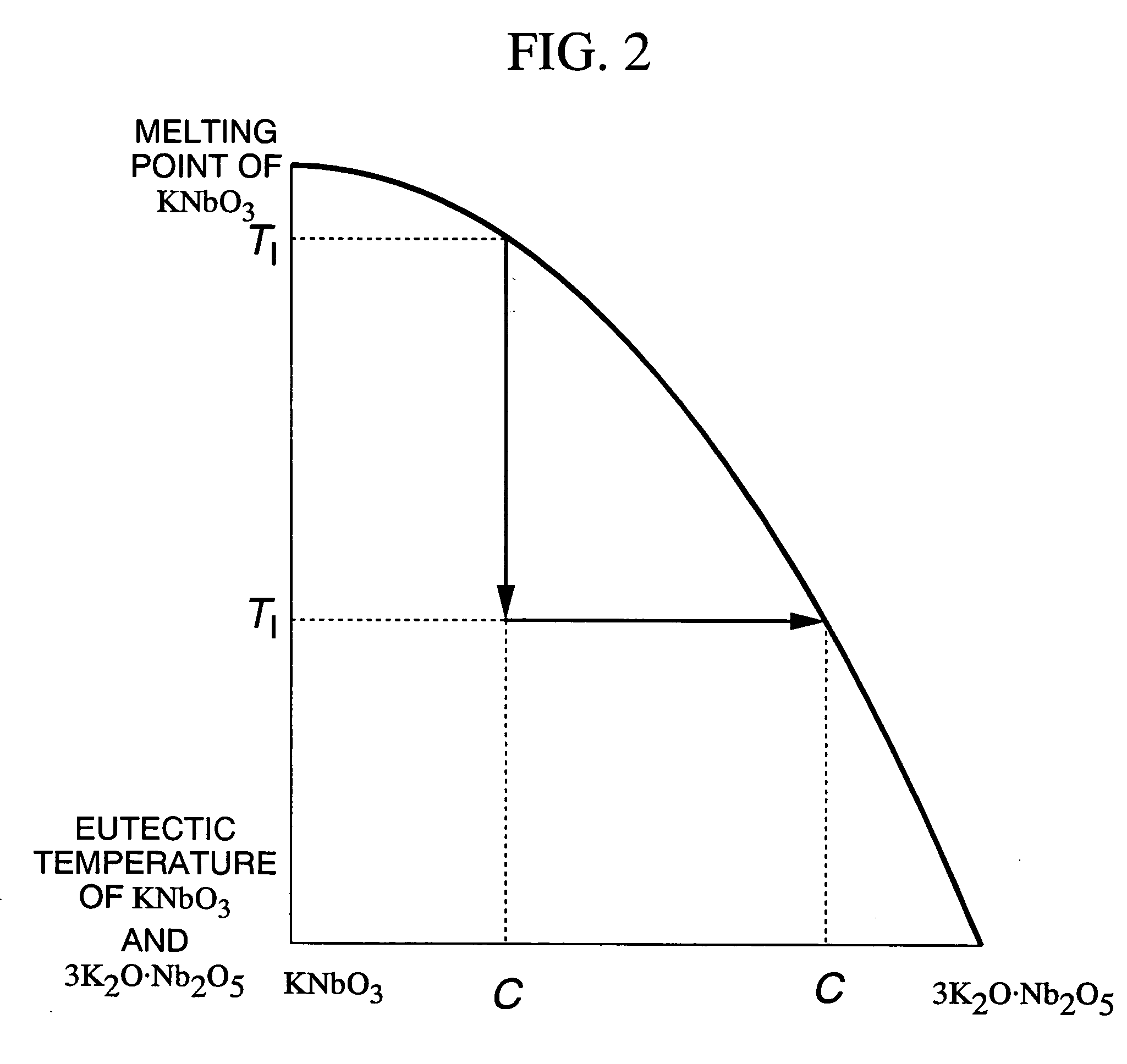

Method of manufacturing potassium niobate single crystal thin film, surface acoustic wave element, frequency filter, frequency oscillator, electric circuit, and electronic apparatus

InactiveUS20040197599A1Piezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthGas phaseSingle crystal

A method of manufacturing a potassium niobate (KNbO3) single crystal thin film, includes the steps of maintaining the substrate under a predetermined oxygen partial pressure; maintaining the substrate within a temperature region which is equal to or higher than an eutectic temperature of KNbO3 and 3K2O.Nb2O5 and is equal to or lower than complete melting temperature of KNbO3 and 3K2O.Nb2O5 so that a solid phase of KNbO3 and a liquid phase can coexist on the substrate; depositing a vapor phase material on the substrate in a state in which a solid phase and a liquid phase coexist; and precipitating KNbO3 on the substrate from the liquid phase as a solid phase to grow a KNbO3 single crystal thin film. The composition of a starting material to be vaporized to generate the vapor phase material is from K2O.Nb2O5=50:50 to K2O.Nb2O5=65:35.

Owner:SEIKO EPSON CORP

Wafer bonded epitaxial templates for silicon heterostructures

InactiveUS20050142879A1High mechanical strengthSmoother and less defect proneSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringSingle crystal

A heterostructure device layer is epitaxially grown on a virtual substrate, such as an InP / InGaAs / InP double heterostructure. A device substrate and a handle substrate form the virtual substrate. The device substrate is bonded to the handle substrate and is composed of a material suitable for fabrication of optoelectronic devices. The handle substrate is composed of a material suitable for providing mechanical support. The mechanical strength of the device and handle substrates is improved and the device substrate is thinned to leave a single-crystal film on the virtual substrate such as by exfoliation of a device film from the device substrate. An upper portion of the device film exfoliated from the device substrate is removed to provide a smoother and less defect prone surface for an optoelectronic device. A heterostructure is epitaxially grown on the smoothed surface in which an optoelectronic device may be fabricated.

Owner:CALIFORNIA INST OF TECH

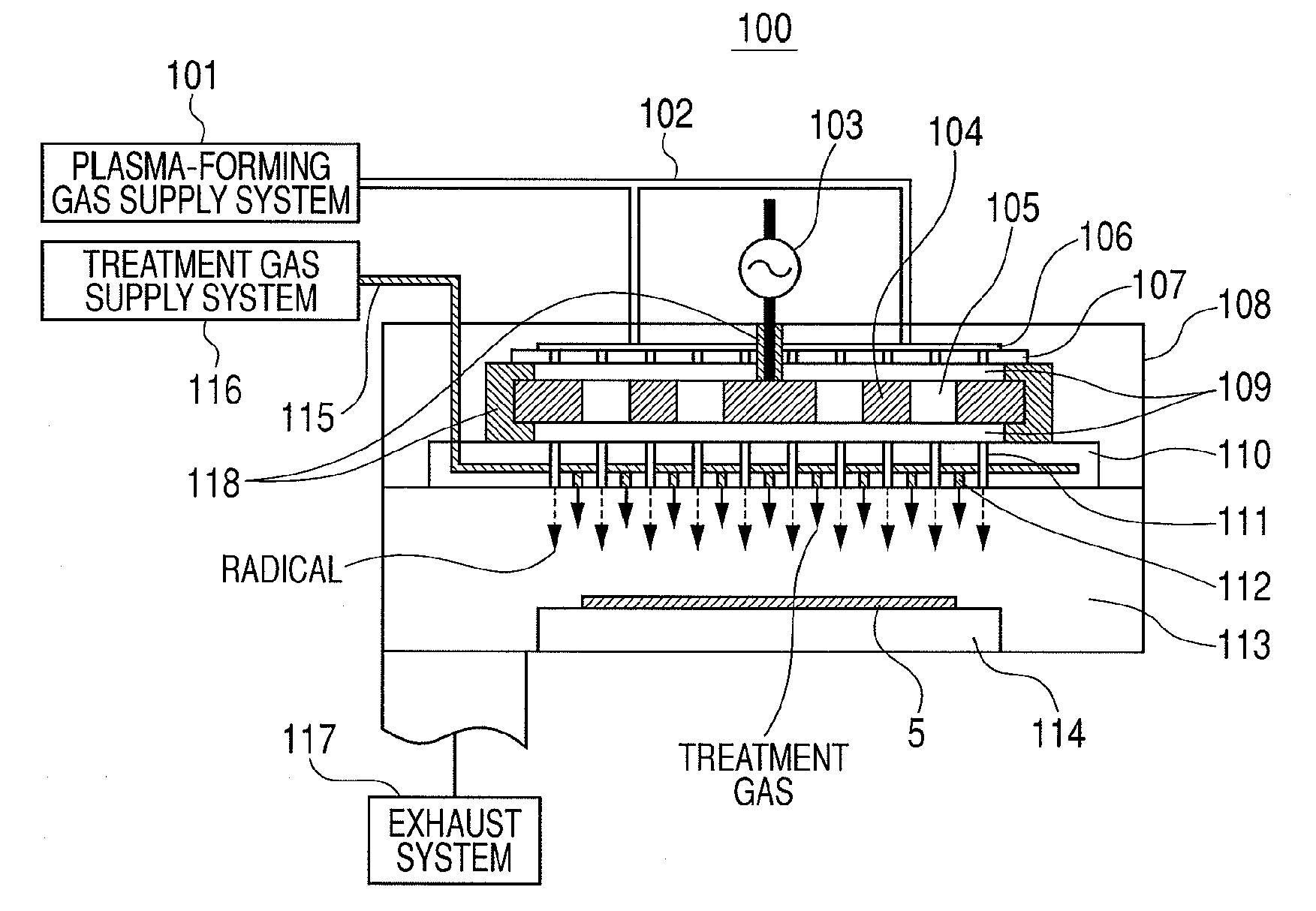

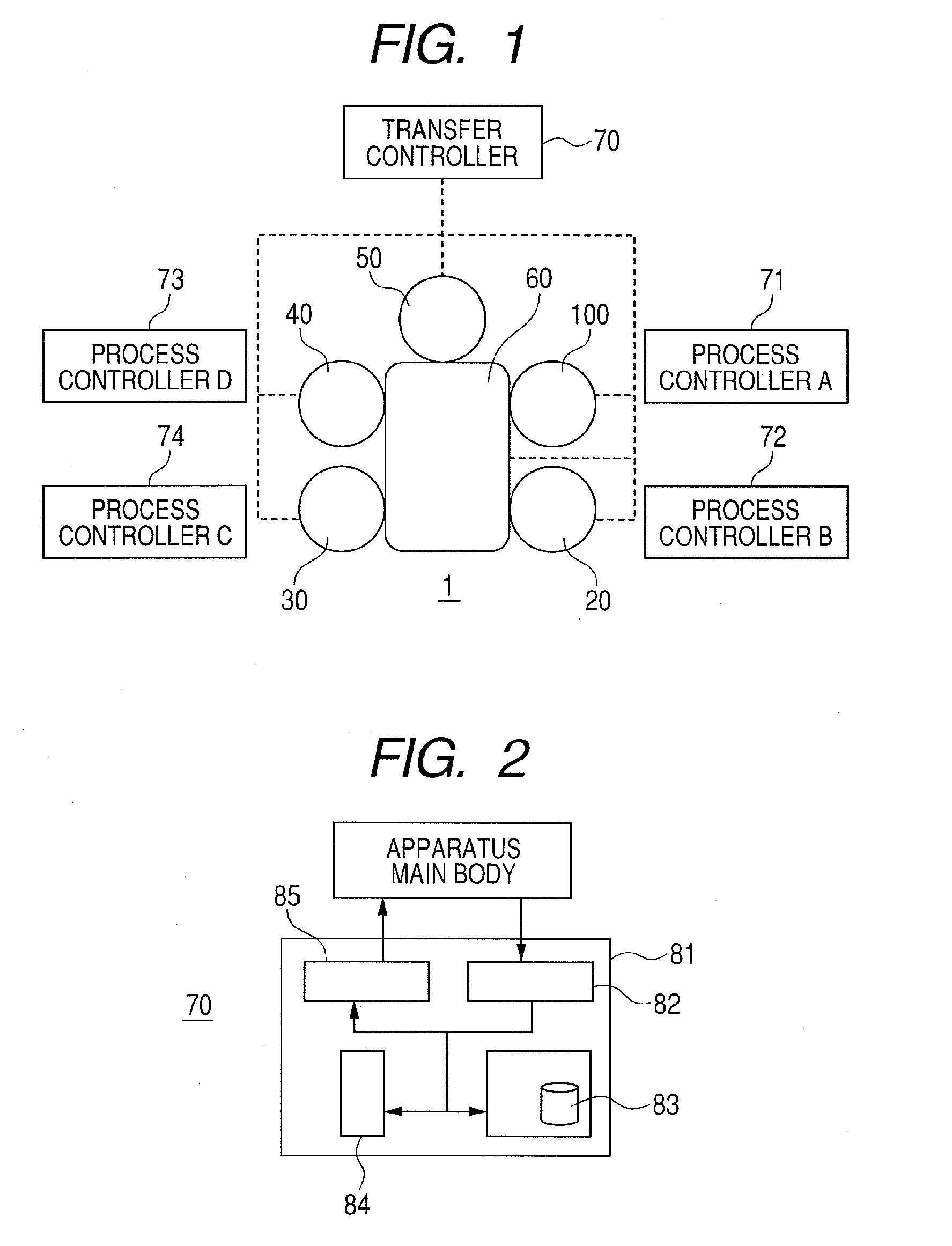

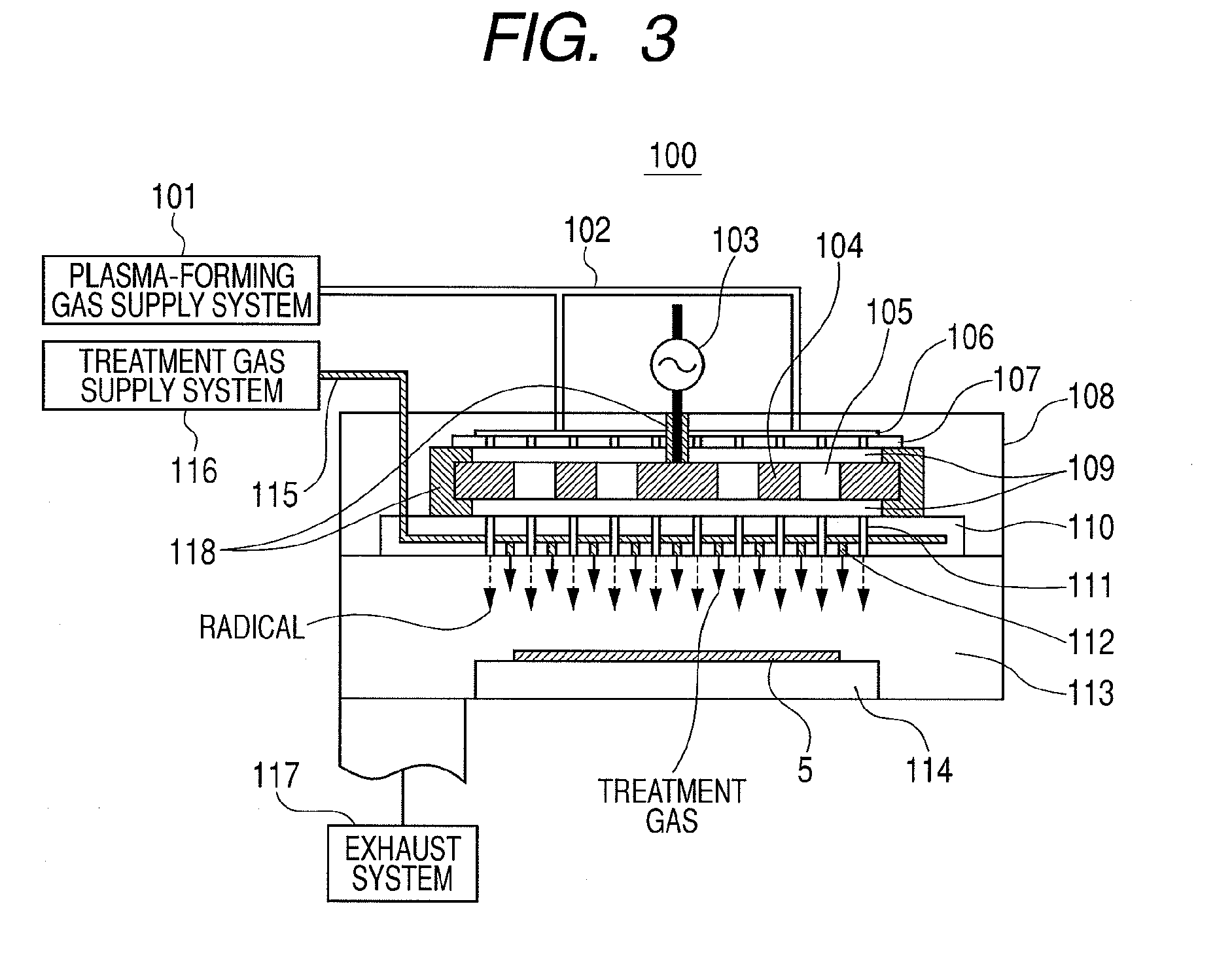

Surface treatment apparatus and surface treatment method

InactiveUS20100221895A1Decrease native oxide filmReduce organic impuritiesElectric discharge tubesSemiconductor/solid-state device manufacturingHysteresisAtmospheric air

HF-originated radicals generated in a plasma-forming chamber are fed to a treatment chamber via feed holes, while HF gas molecules as the treatment gas are supplied to the treatment chamber from near the radical feed holes to suppress the excitation energy, thereby increasing the selectivity to Si to remove a native oxide film. Even with the dry-treatment, the surface treatment provides good surface flatness equivalent to that obtained by the wet-cleaning which requires high-temperature treatment, and further attains growth of Si single crystal film on the substrate after the surface treatment. The surface of formed Si single crystal film has small quantity of impurities of oxygen, carbon, and the like. After sputtering Hf and the like onto the surface of the grown Si single crystal film, oxidation and nitrification are applied thereto to form a dielectric insulation film such as HfO thereon, thus forming a metal electrode film. All through the above steps, the substrate is not exposed to atmospheric air, thereby suppressing the adsorption of impurities onto the interface, and thus obtaining a C-V curve with small hysteresis. As a result, good device characteristics are obtained in MOS-FET.

Owner:CANON ANELVA CORP

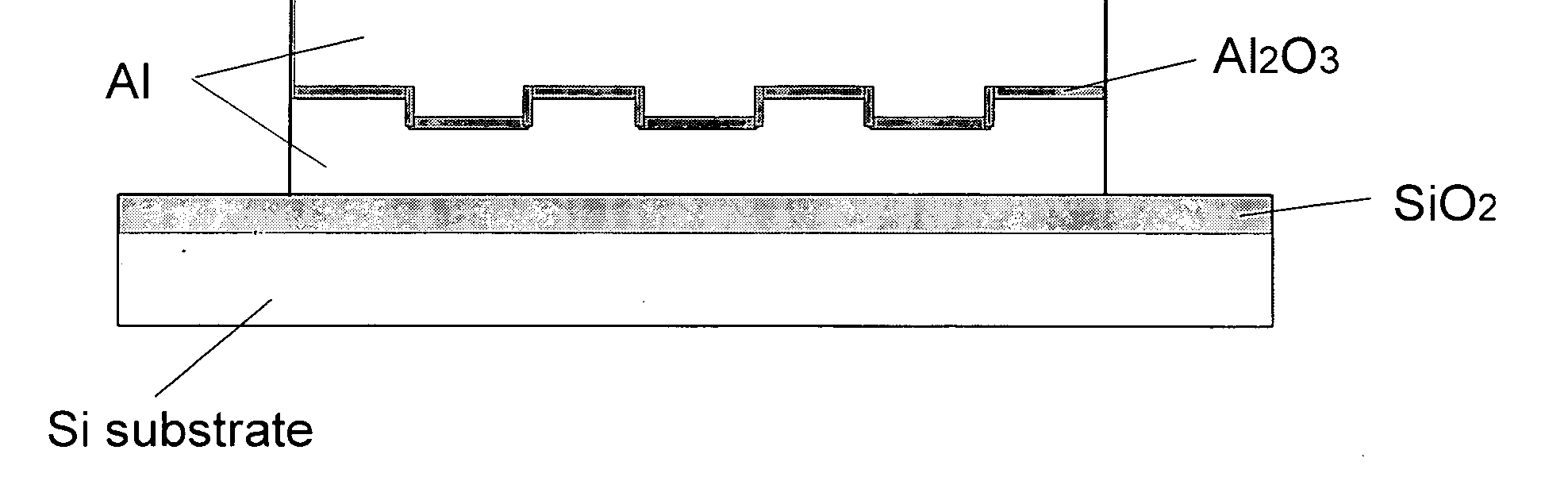

Method of fabrication of high temperature superconductors based on new mechanism of electron-electron interaction

InactiveUS20070108437A1Dissimilar materials junction devicesSemiconductor devicesHigh-temperature superconductivitySingle crystal

The present invention is a superconducting tunnel junction comprising two thin films characterized in that the thin films have an indented surface facing each other and are separated by an insulator layer. Typically, the depth of the indents is in the range of 5 to 10 nm, the width of the indents is in the range of 50 to 200 nm, the thickness of the insulator layer is in the range of 1 to 3 nm, and the thickness of the films is less than electron mean free path of a material comprising said films, and is typically in the range of 50 to 100 nm. Preferably the films are single crystal films or amorphous films.

Owner:TAVKHELIDZE AVTO

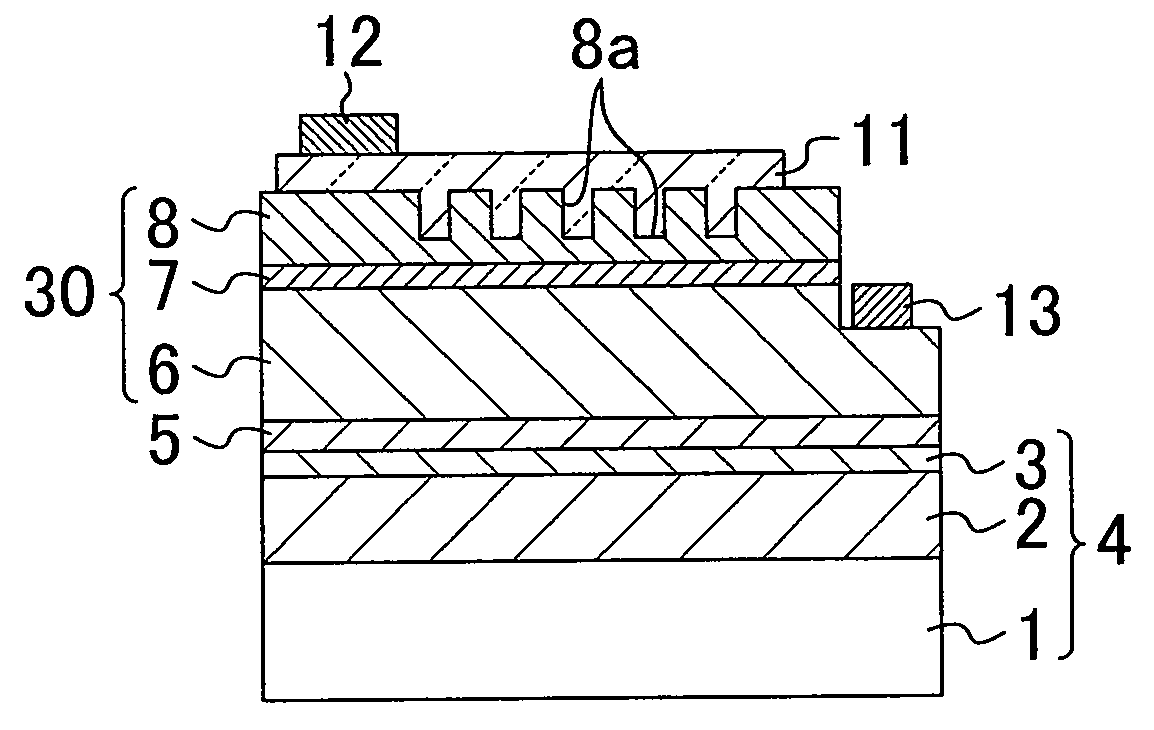

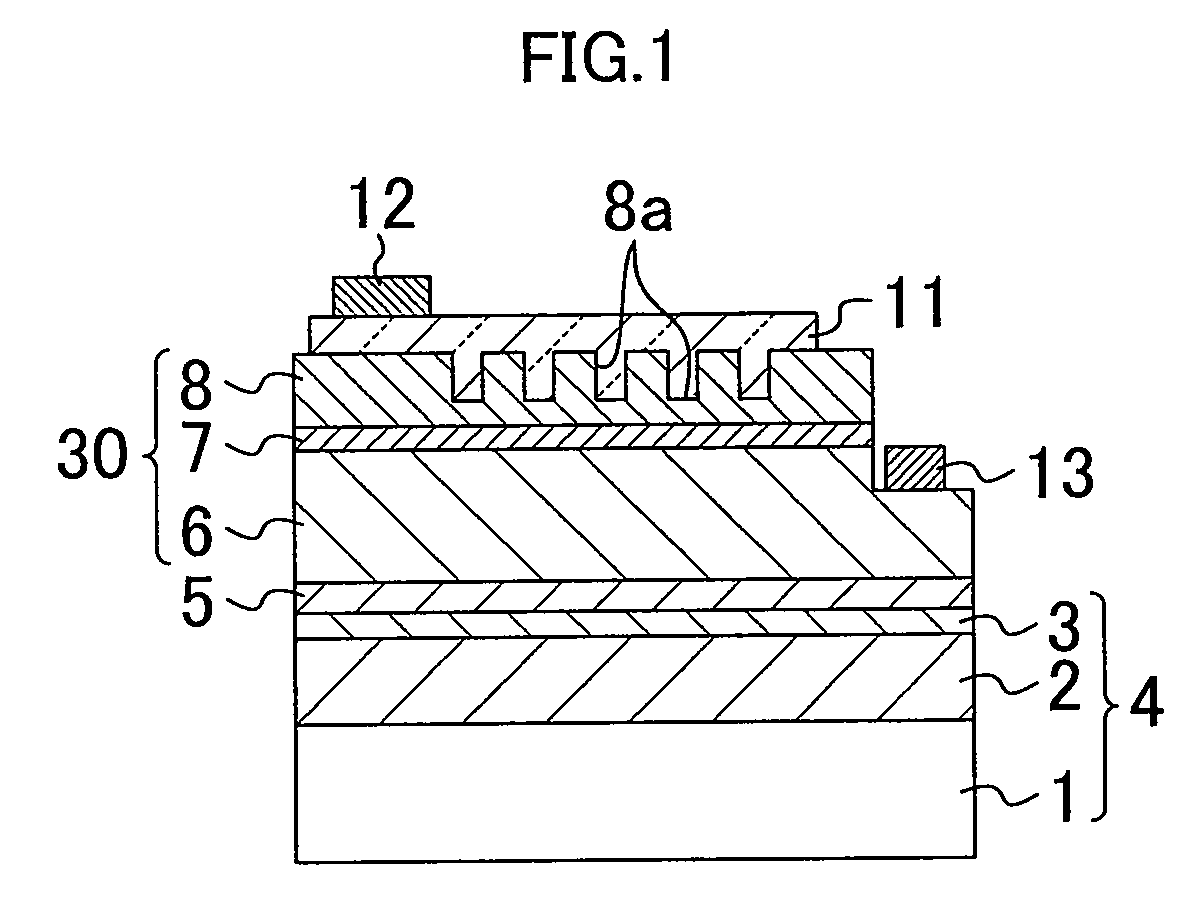

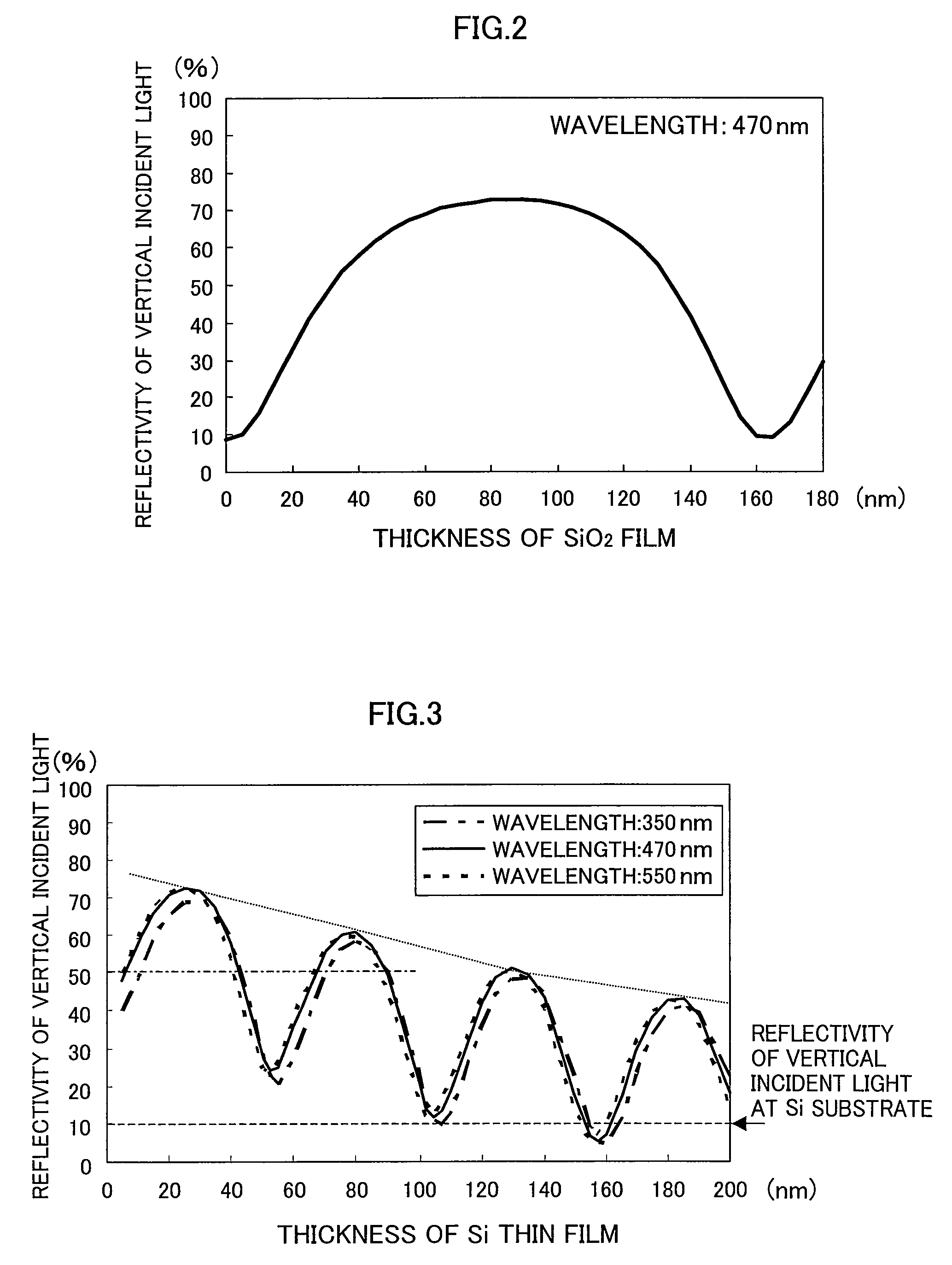

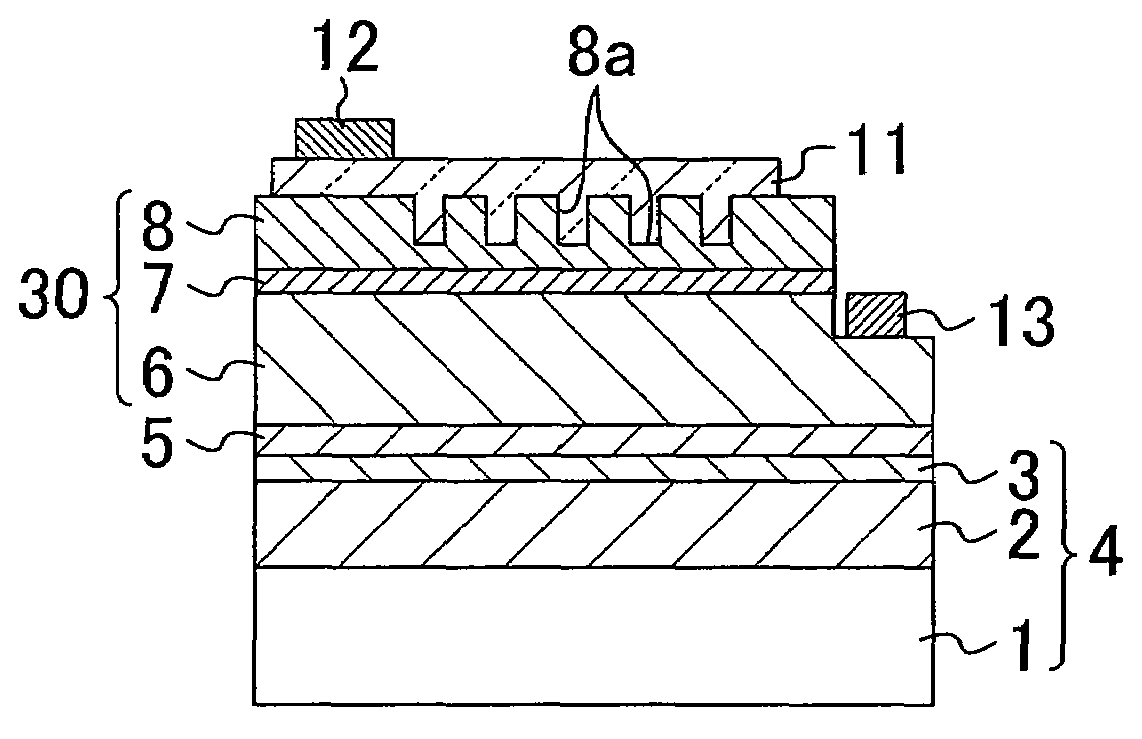

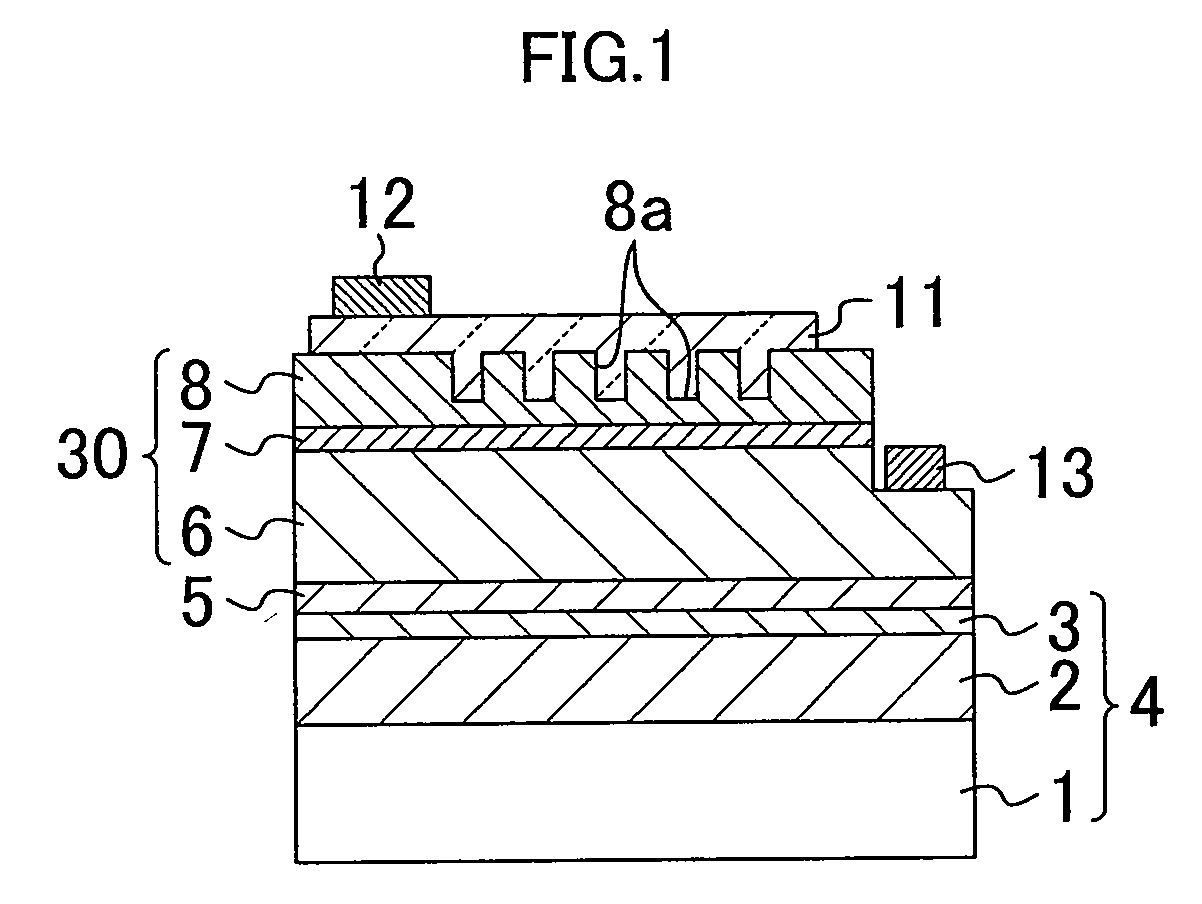

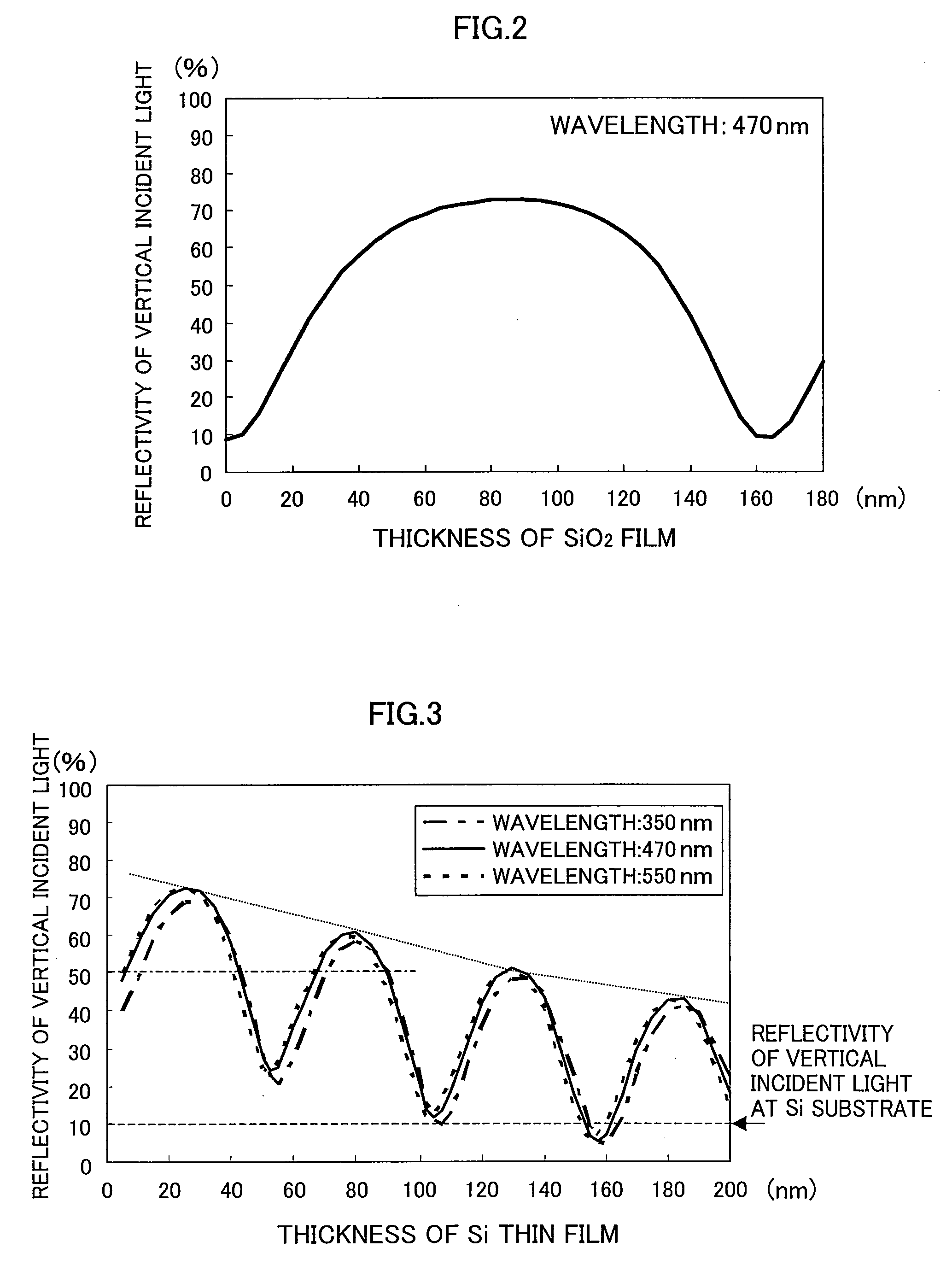

Nitride semiconductor light emitting device

ActiveUS7518153B2Small thicknessImprove reflectivitySolid-state devicesSemiconductor devicesSingle crystalLight emitting device

A nitride semiconductor light emitting device includes a substrate formed of silicon, an insulating film formed on the substrate and a single crystal thin film formed on the insulating film. On the single crystal film, a semiconductor laminated body including a light emitting layer of nitride semiconductor is formed.

Owner:PANASONIC CORP

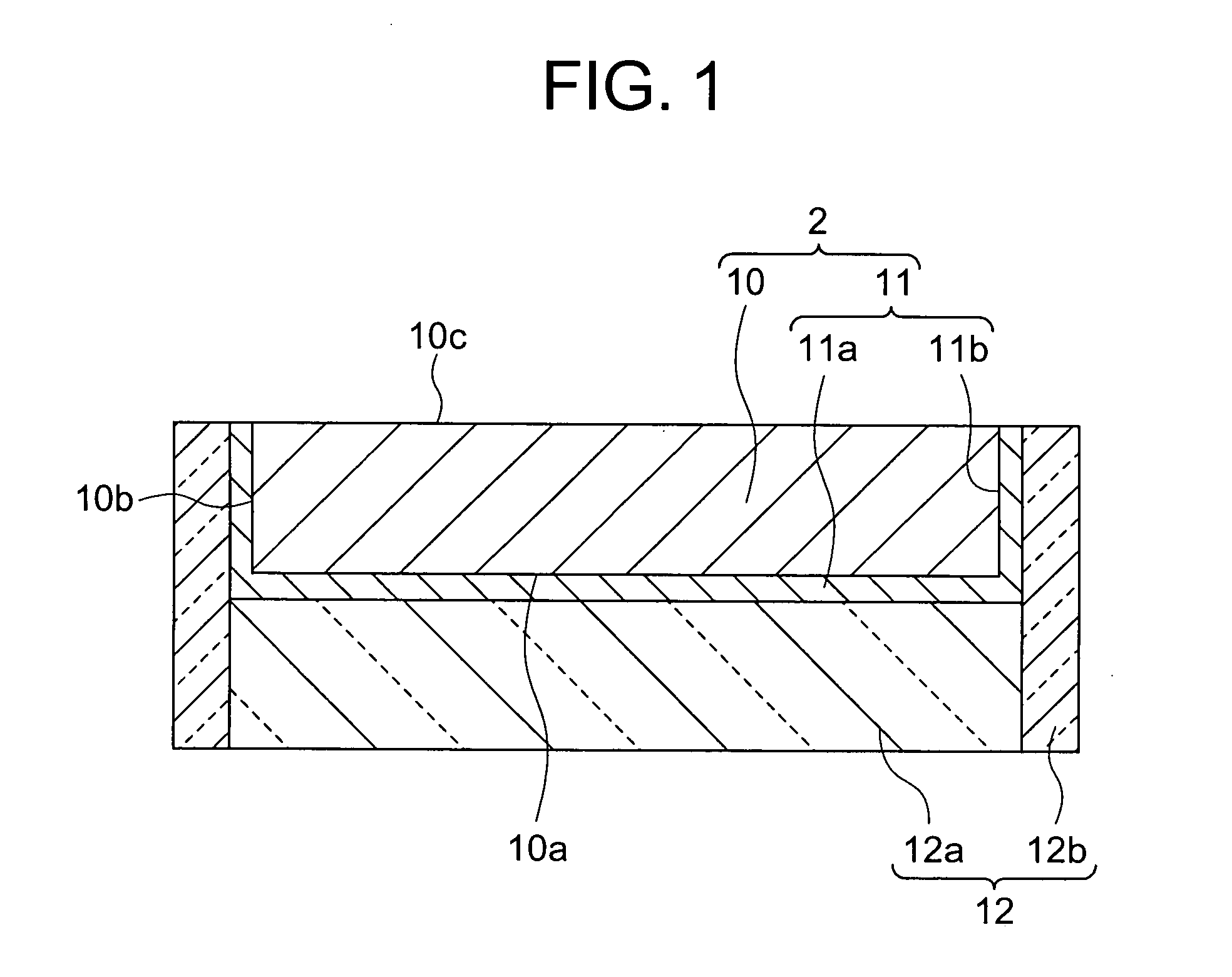

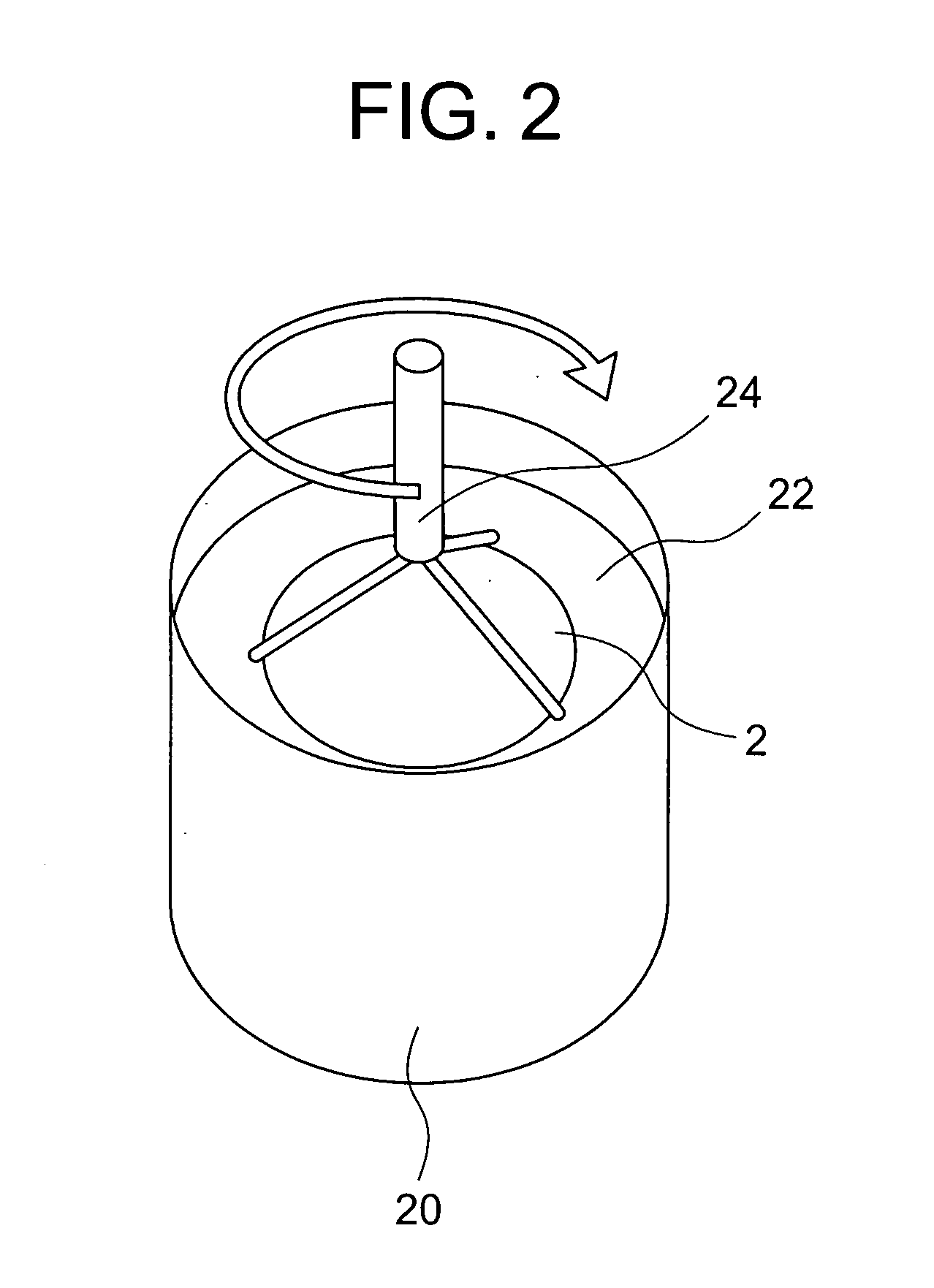

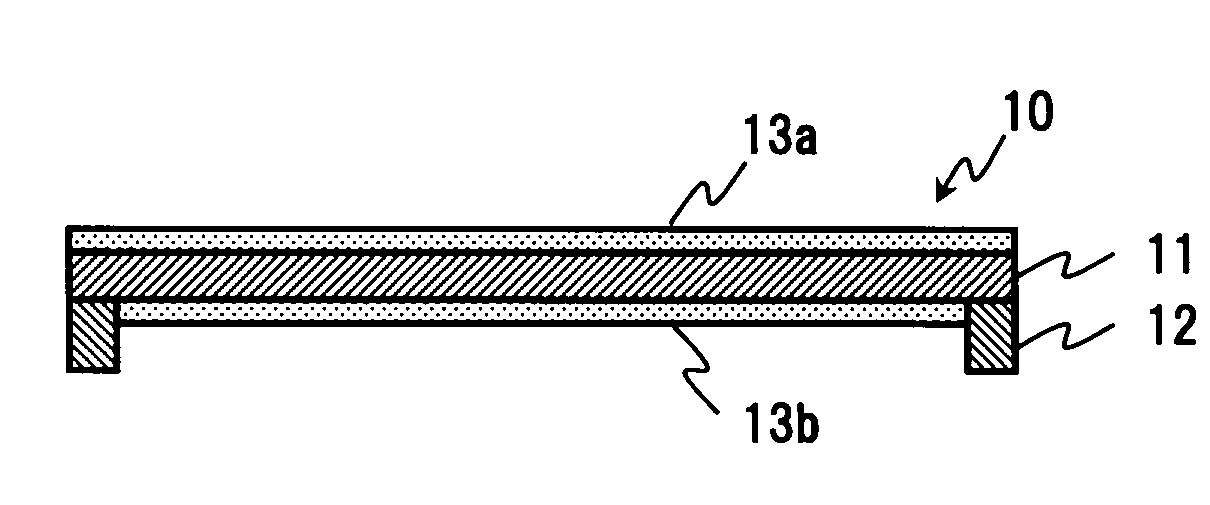

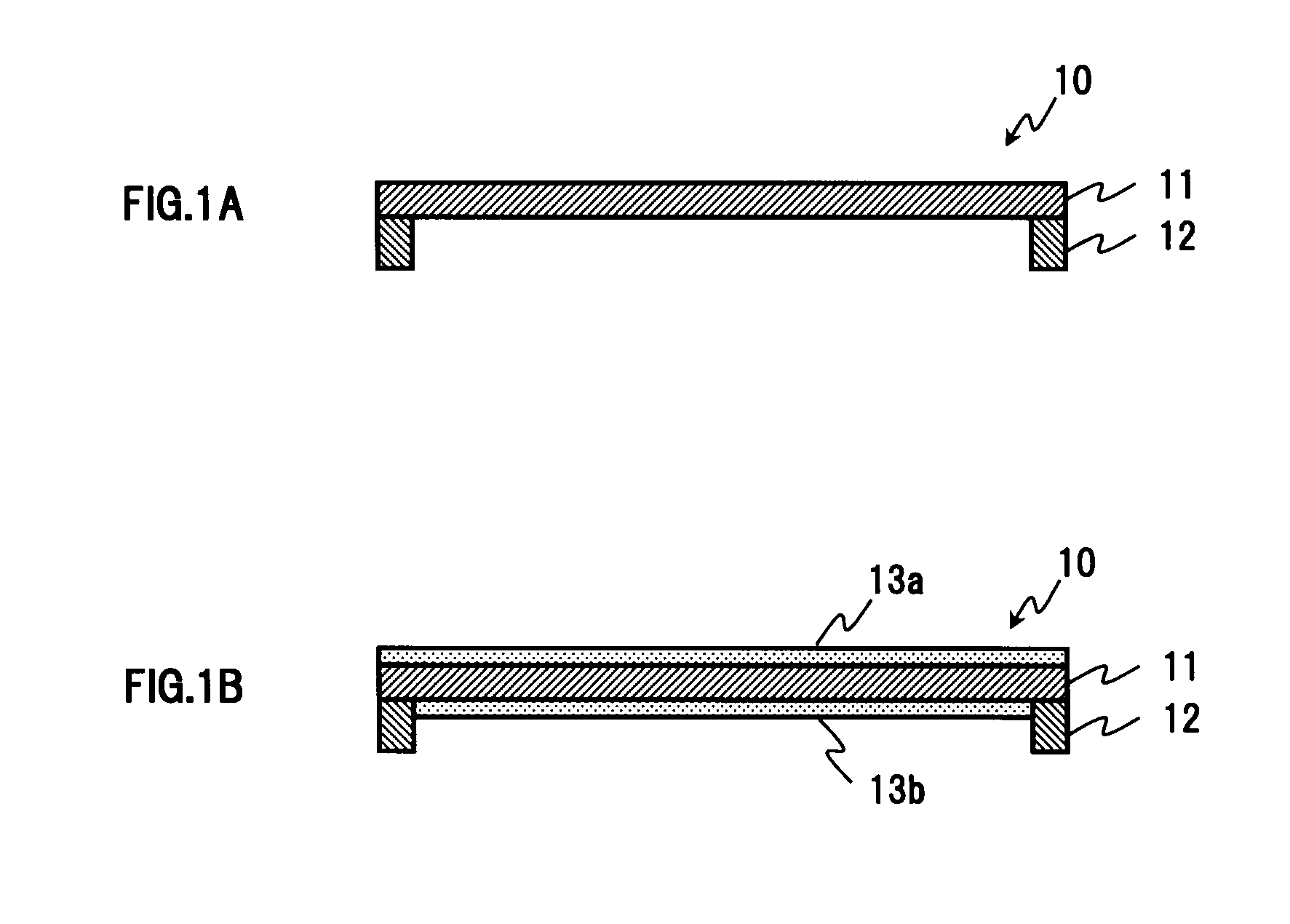

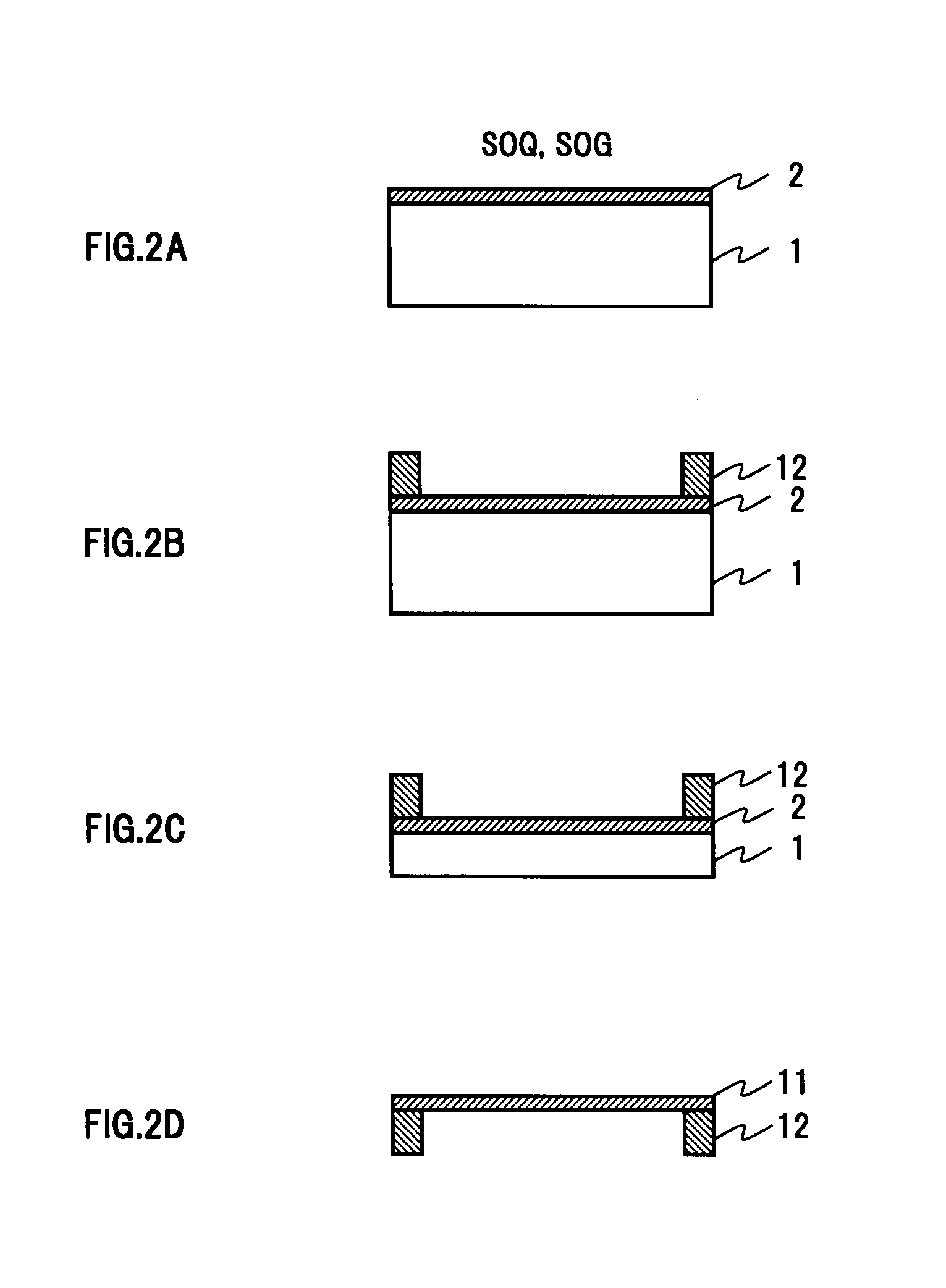

Magnetic garnet single crystal film formation substrate, optical element and production method of the same

InactiveUS20060112873A1Quality improvementImprove production yieldPolycrystalline material growthLiquid-phase epitaxial-layer growthOptical isolatorOptoelectronics

A magnetic garnet single crystal film formation substrate 2 for growing a thick magnetic garnet single crystal film, wherein crystal defects, warps, cracks and flaking, etc. are not caused, by liquid phase epitaxial growth is provided. The substrate 2 comprises a base substrate 10 composed of a garnet-based single crystal being unstable with a flux used for the liquid phase epitaxial growth; a buffer layer 11a composed of a garnet-based single crystal thin film formed on a crystal growing surface 10a of said base substrate 10 and being stable with said flux; and a protective layer 11b formed at least on side surfaces 10b of said base substrate 10 crossing with said crystal growing surface of said base substrate 10 and being stable with said flux. By using the substrate, a high quality magnetic garnet single crystal film can be produced. The magnetic garnet single crystal film is used as an optical element, such as a Faraday element, used for an optical isolator, optical circulator and magneto-optical sensor, etc.

Owner:TDK CORPARATION

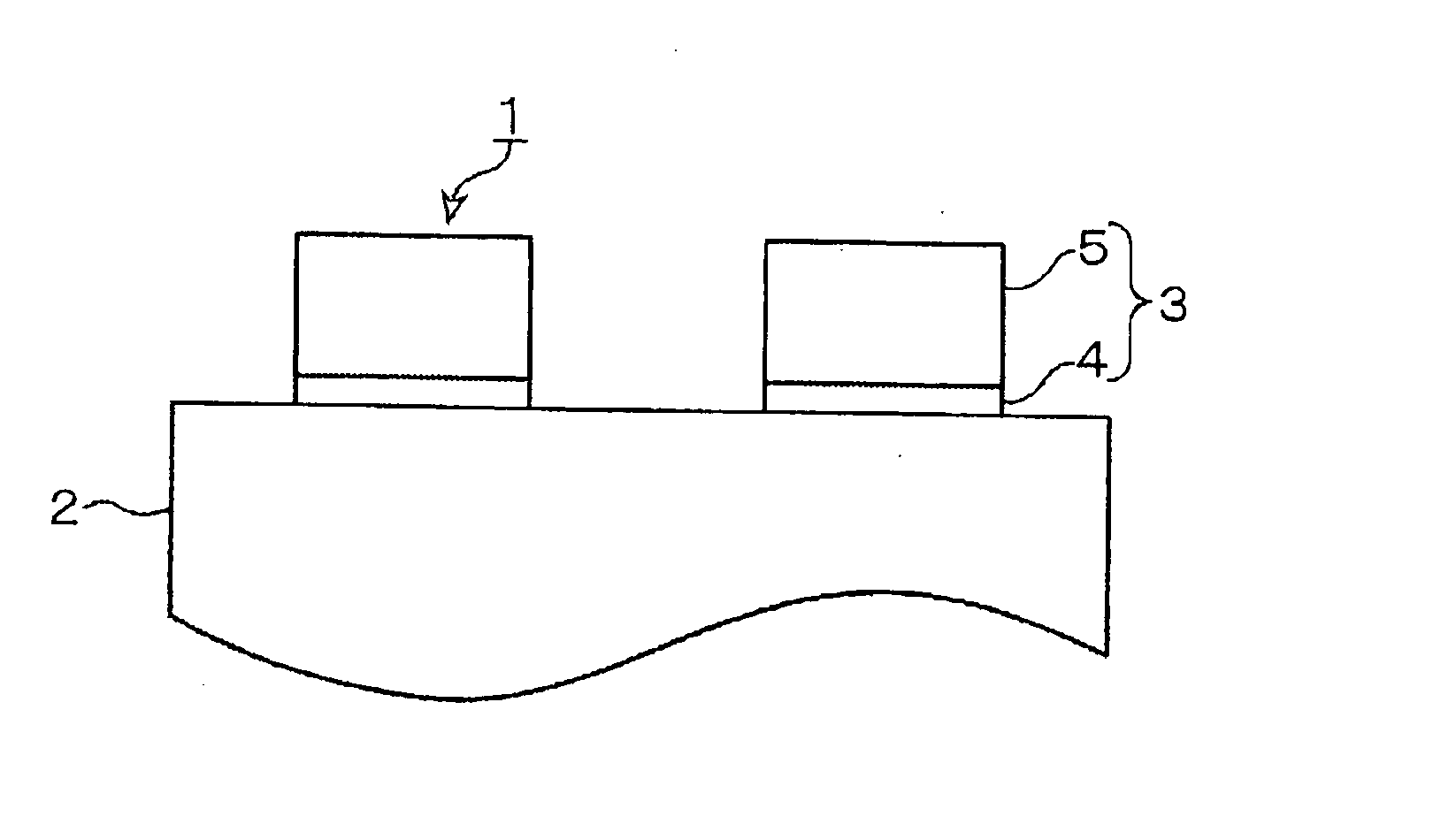

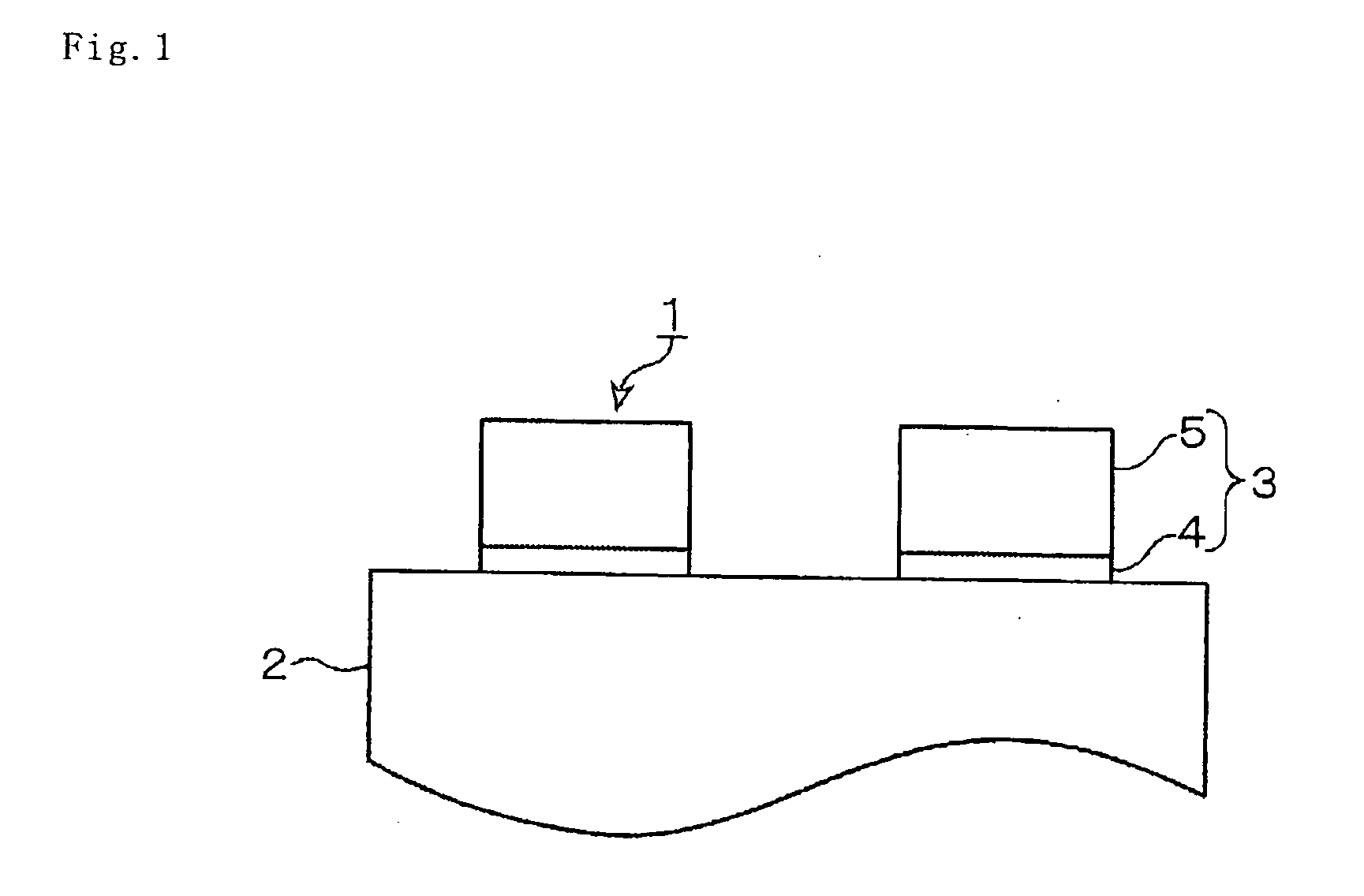

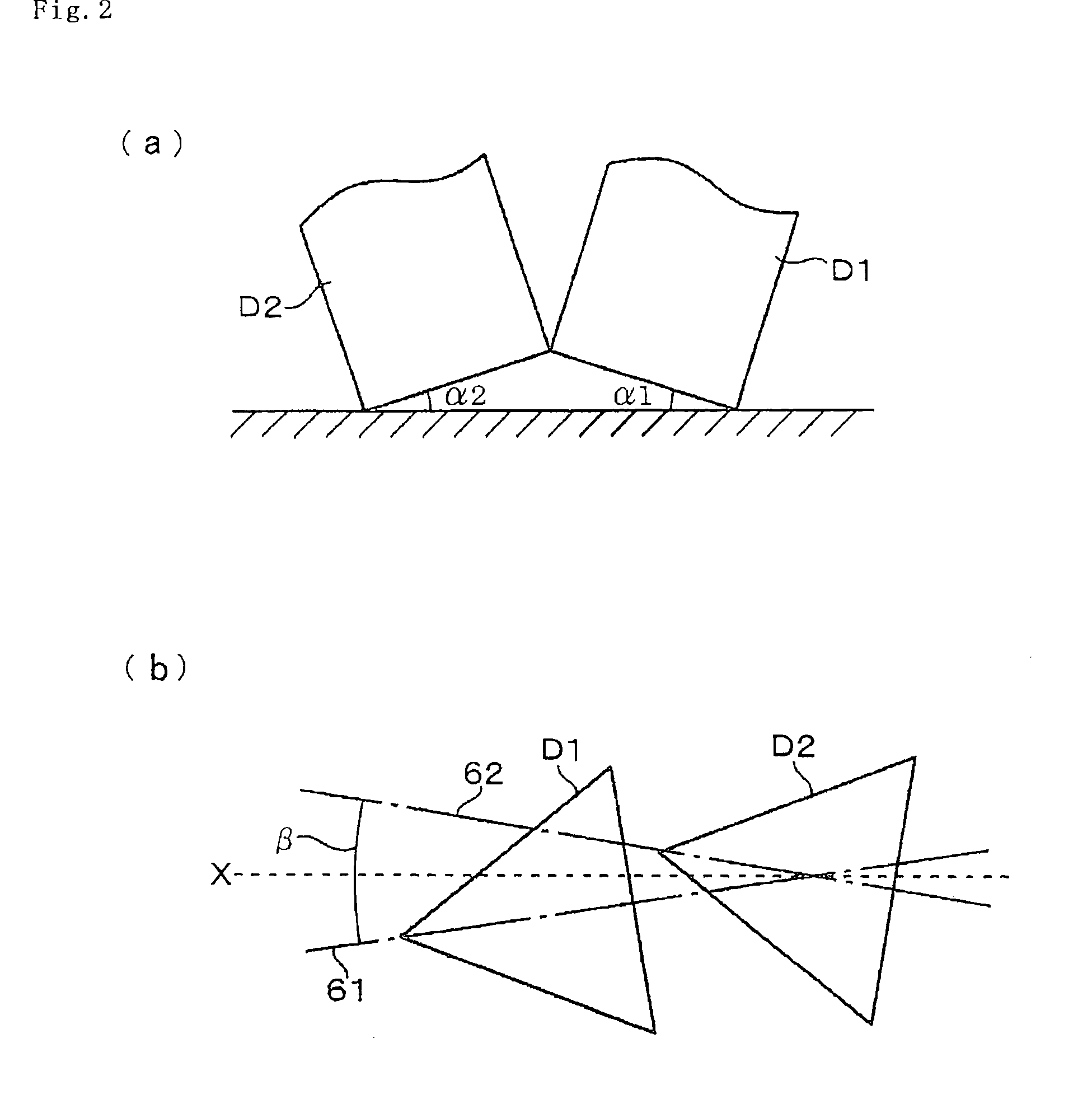

Surface acoustic wave device and method of manufacturing the same

ActiveUS20070103038A1Excellent power durabilityGood reproducibilityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksOptoelectronicsSingle crystal

In order to provide a surface acoustic wave device provided with a pseudo-single crystal aluminum electrode film, having excellent power durability, easy to manufacture, and possible to grow with good reproducibility, a titanium buffer film 4 and an electrode film composed of an aluminum film or an aluminum alloy film are formed on a piezoelectric substrate 2 composed of lithium tantalate or lithium niobate. The electrode film 5 comprises a pseudo-single crystal film composed of two (111) domains. Each of the <111> directions of two (111) domains tilts in the range of 0 to 10 degrees to the substrate surface, and the <11-2> directions in the respective (111) domain planes are 1 to 15 degrees apart.

Owner:NDK SAW DEVICES CO LTD

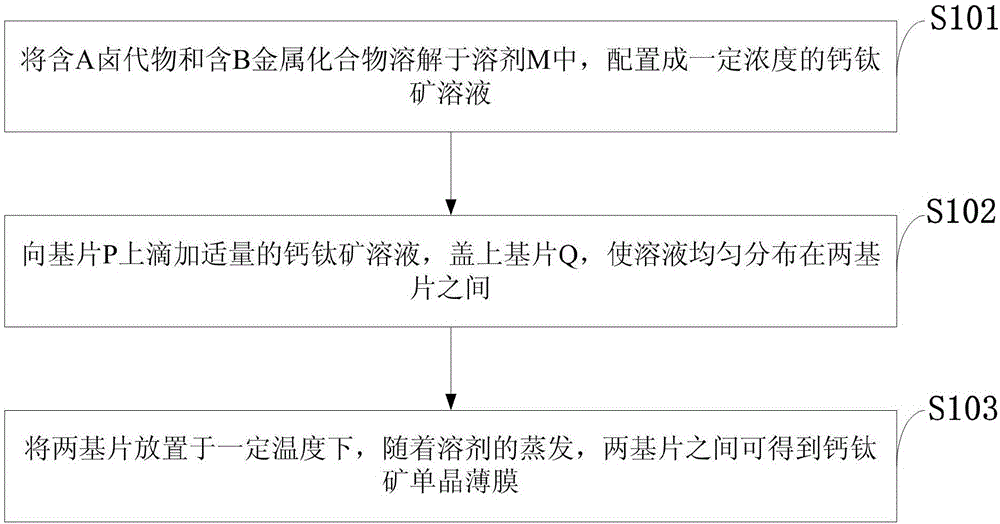

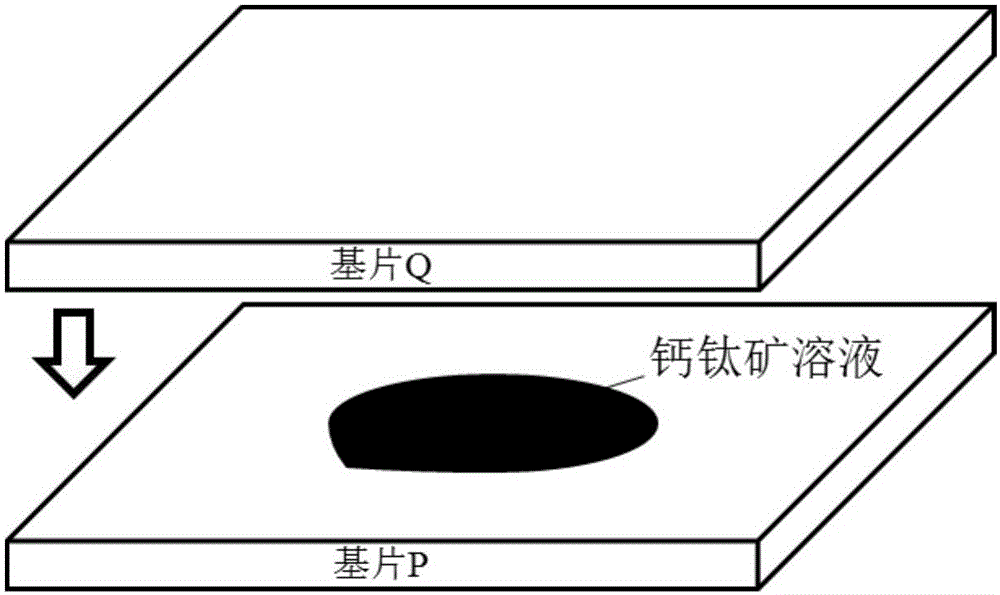

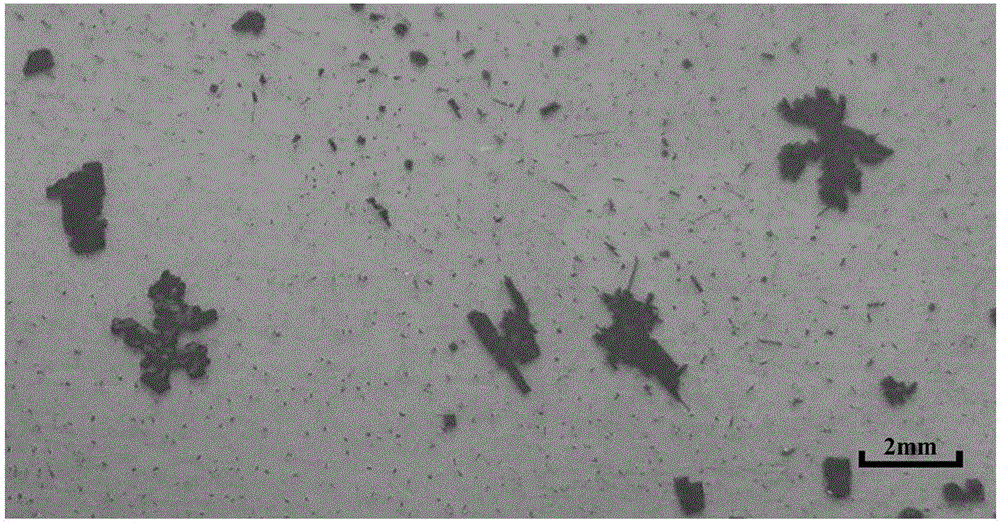

Method for preparing ABX3 perovskite single crystal film

InactiveCN106676631AAchieve preparationQuality improvementPolycrystalline material growthFrom normal temperature solutionsEvaporationSingle crystal

The invention discloses a method for preparing an ABX3 perovskite single crystal film. The method for preparing the ABX3 perovskite single crystal film comprises the following steps: dissolving A-containing halide and a B-containing metallic compound in a solvent M, and ensuring that the mole ratio of the A-contained halide to the B-contained metallic compound is 1:(0.1-2); preparing a perovskite solution with the concentration being 0.05 to 5.0mol / L; dropwise adding the perovskite solution onto a substrate P, and covering the substrate P with a substrate Q; controlling the growth direction of a perovskite single crystal through the substrate P and the substrate Q, so as to ensure that the crystal grows in a gap between the substrate P and the substrate Q, namely to ensure that the perovskite single crystal can grow only in two directions, and forming the perovskite single crystal film with the evaporation of the solvent in the perovskite solution between the two substrates. By adopting the method, a perovskite single crystal film with relatively high quality and relatively large size can be prepared; the method is simple in technology, high in operability and high in repeatability.

Owner:KUNMING UNIV OF SCI & TECH

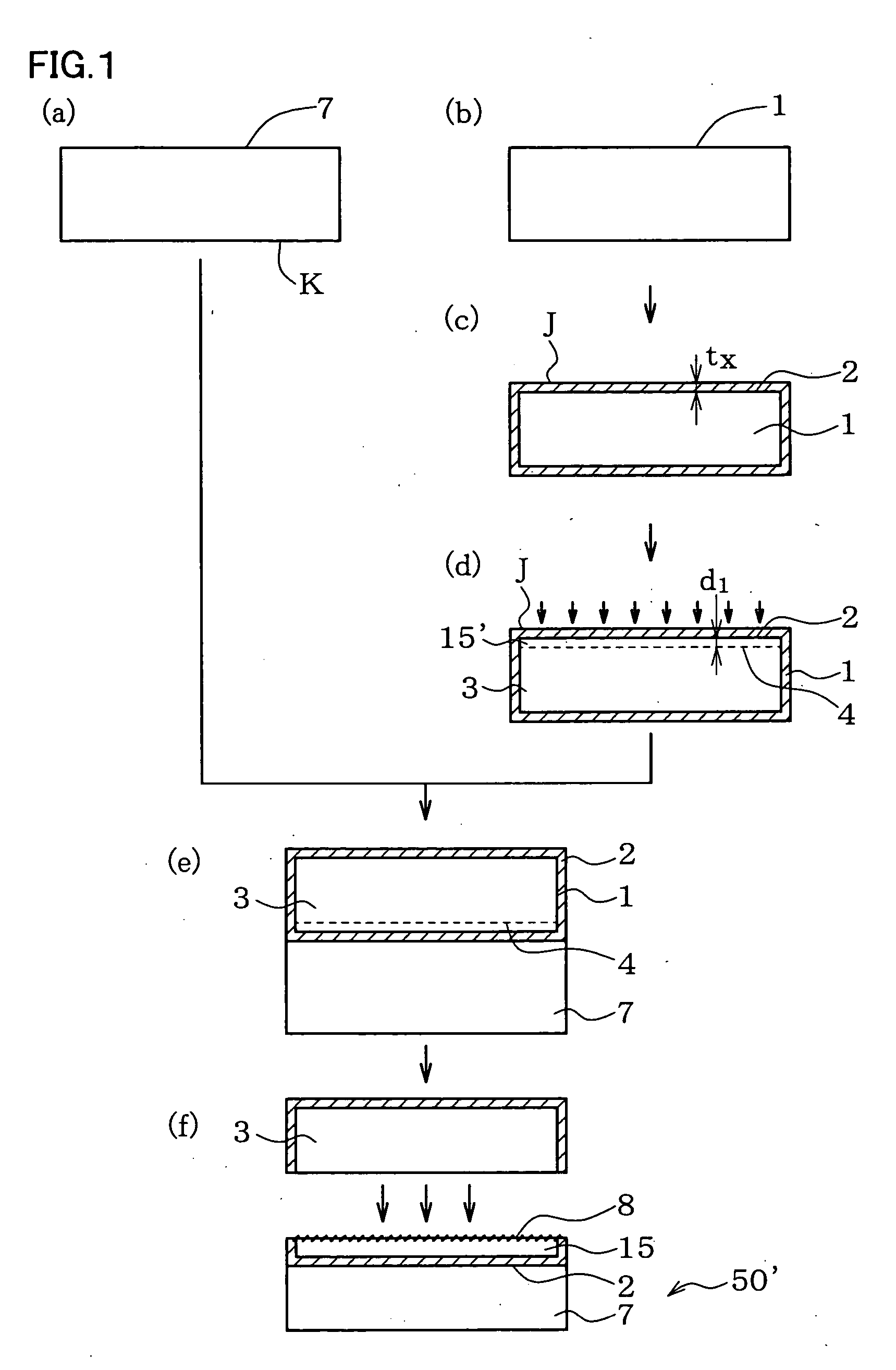

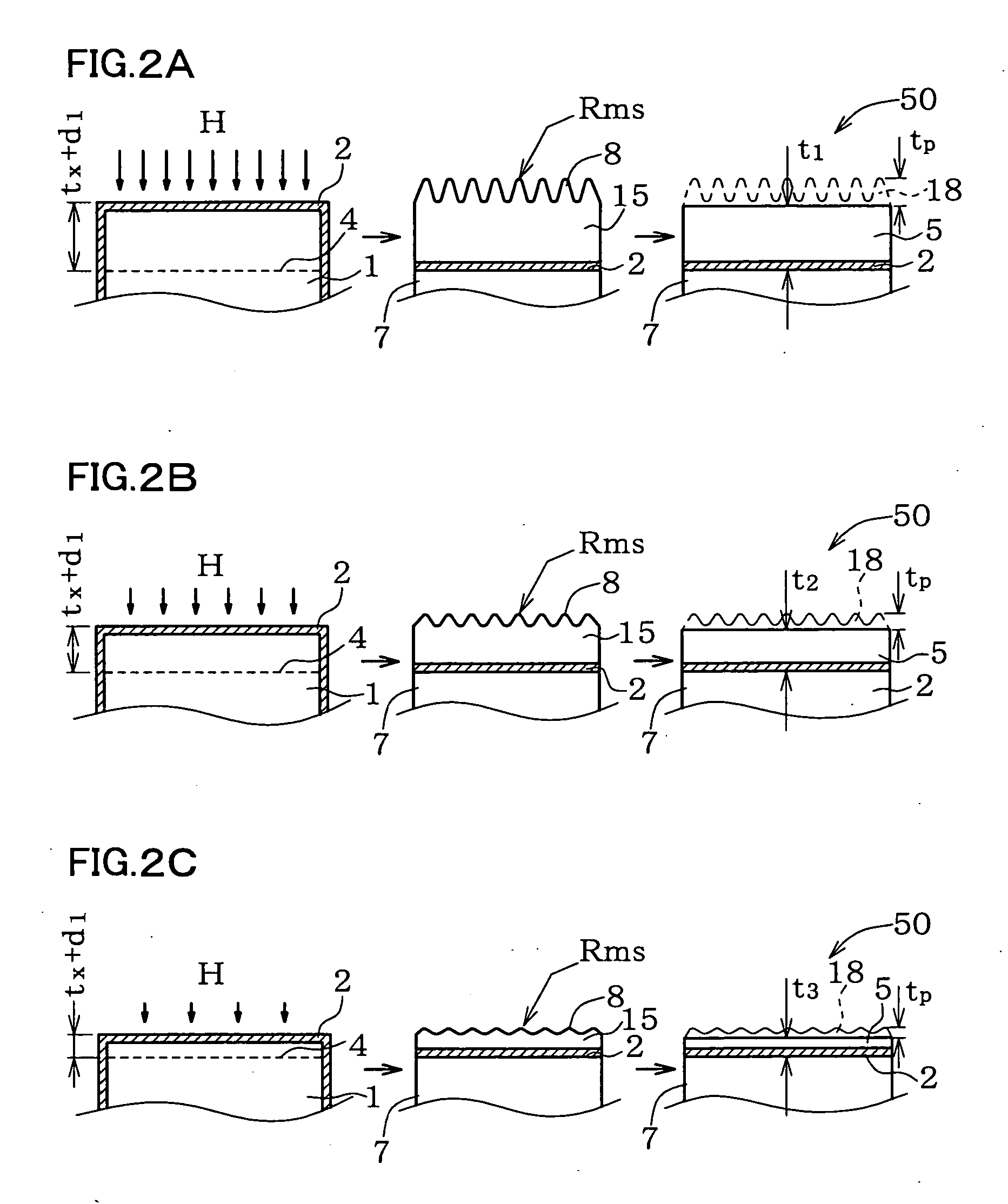

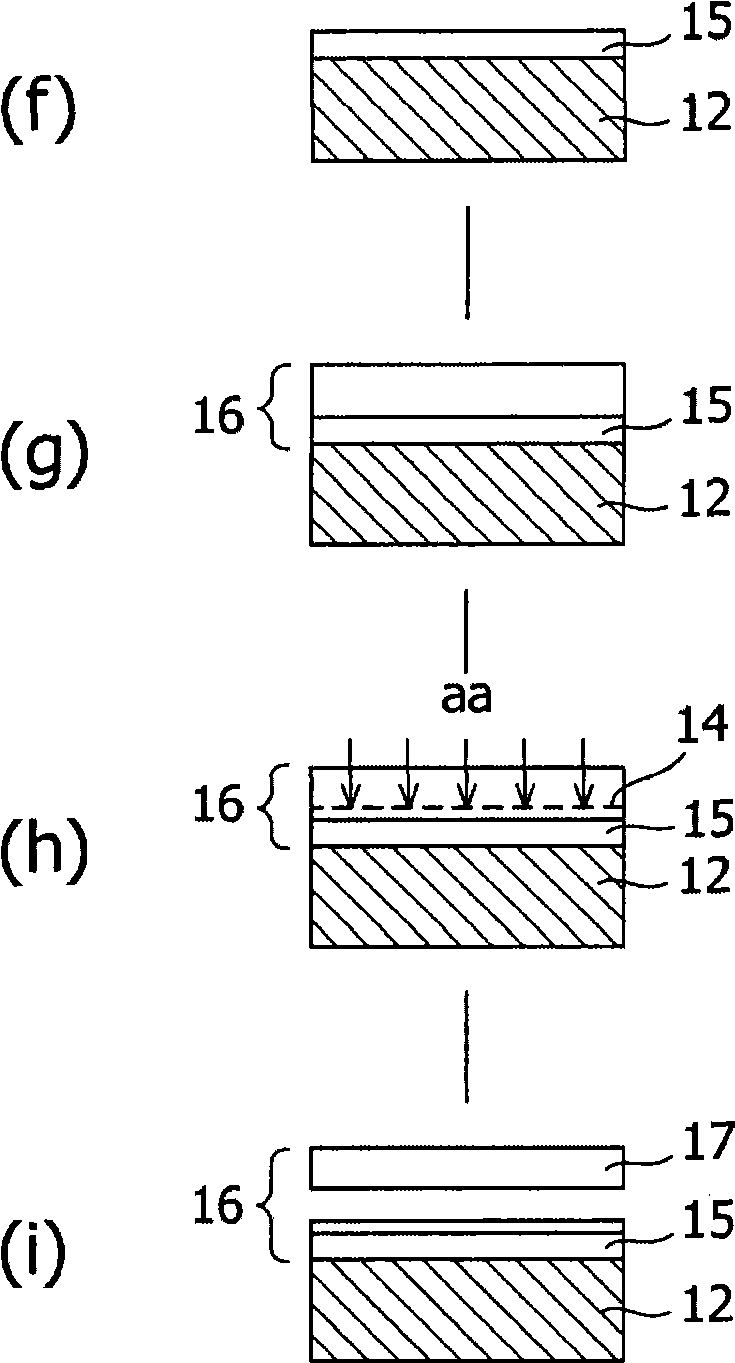

Soi wafer manufacturing method

ActiveUS20060040469A1Reduce roughnessImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface roughness

In order to adjust thickness of a bonded silicon single crystal film 15 depending of thickness of an SOI layer 5 to be obtained, depth of formation d1+tx of a separatory ion implanted layer 4, measured from a first main surface J, in the separatory ion implanted layer formation step is adjusted through energy of the ion implantation. Dose of the ion implantation is set smaller as the depth of formation measured from the first main surface J becomes smaller. A smaller dose results in a smaller surface roughness of the separation surface, and makes it possible to reduce polishing stock removal of the separation surface of the bonded silicon single crystal film in the planarization step. Uniformity in the thickness of the SOI layer can consequently be improved even for the case where a thin SOI layer has to be formed. The present invention is therefore successful in providing a method of fabricating an SOI wafer capable of suppressing variations in the intra-wafer and inter-wafer uniformity of the thickness of the SOI layer to a sufficiently low level, even for the case where a required level of the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

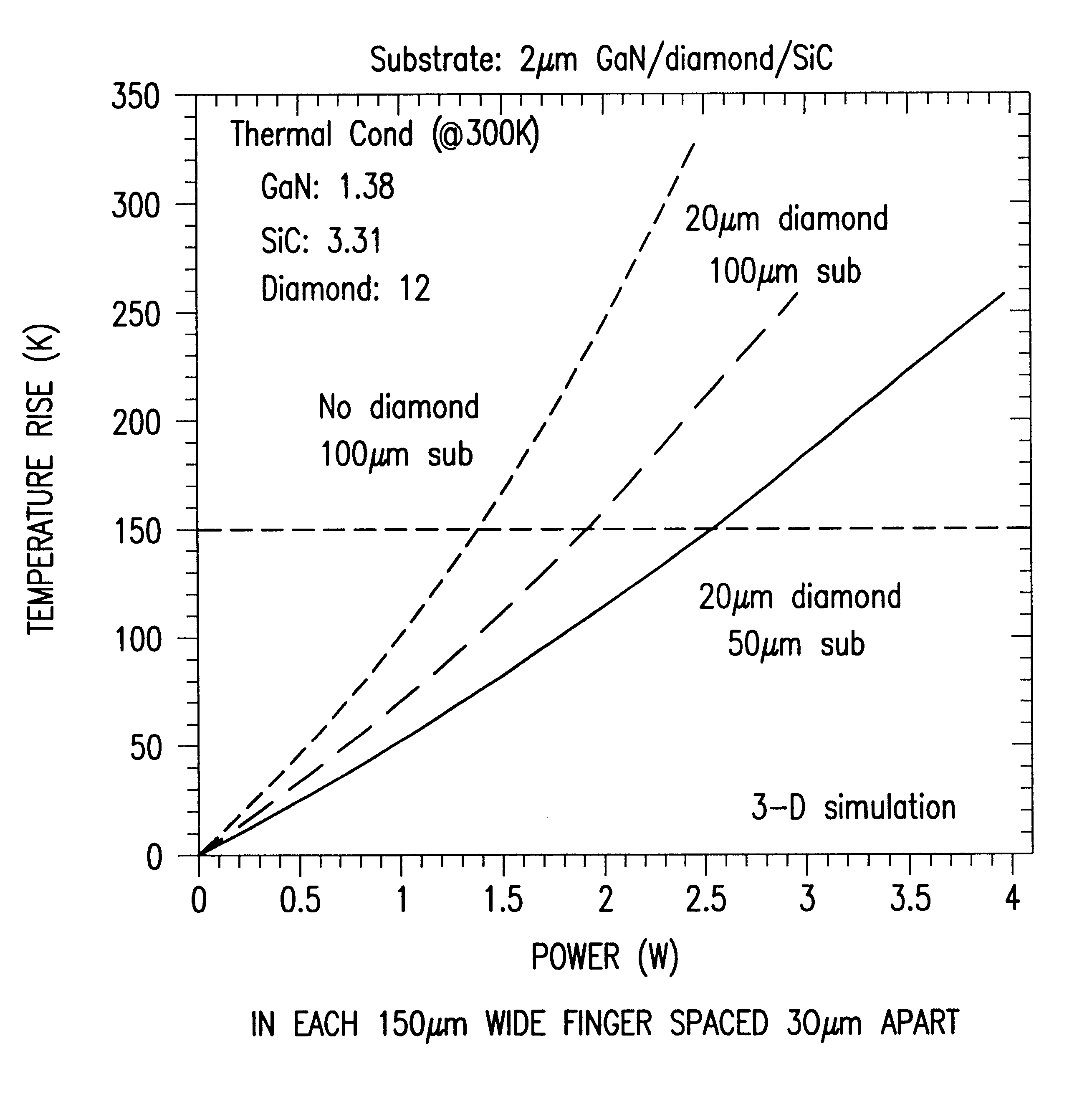

Multilayered substrate obtained via wafer bonding for power applications

InactiveUS20060284167A1Eliminate the problemSolid-state devicesSemiconductor/solid-state device manufacturingPower applicationWafering

A multi-layer semiconductor device utilizes the good thermal and electrical properties of a polycrystalline substrate with the electrical properties of single crystal film transferred via wafer bonding. The device structure includes a polycrystalline, e.g., silicon carbide substrate, which was polished. A planarization layer of silicon is formed on the surface, followed by chemical mechanical polishing. The substrate is then bonded to either a bulk silicon wafer or a silicon-on-insulator (SOI) wafer. The silicon (SOI) wafer is thinned to the desired thickness.

Owner:NORTHROP GRUMMAN SYST CORP

Single-crystal film bonding body and manufacturing method thereof

InactiveCN105420674AReduce direct reflectionReduce or even eliminate reflectionVacuum evaporation coatingSputtering coatingThin membraneSingle crystal

The invention provides a single-crystal film bonding body and a method for manufacturing the single-crystal film bonding body. The single-crystal film bonding body comprises a silicon substrate, a lithium niobate single-crystal film or lithium tantalate single-crystal film and a silicon-based film located between the silicon substrate and the lithium niobate single-crystal film or lithium tantalate single-crystal film. The silicon-based film is formed on the lithium niobate single-crystal film or lithium tantalate single-crystal film through deposition and is bonded with the silicon substrate through a direct bonding method, and the silicon-based film is a silicon film or a silicon dioxide film or a silicon nitride film. By means of the single-crystal film bonding body of the three-layer structure, the reflection effect of interfaces between the lithium niobate or lithium tantalate single-crystal film and the silicon substrate on optical waves and sound waves can be effectively reduced and even eliminated, and the interference caused by the reflection effect between the interfaces to optical or sound wave signals is reduced.

Owner:JINAN JINGZHENG ELECTRONICS

Nitride semiconductor light emitting device

ActiveUS20080179606A1Light extraction efficiencyIncrease brightnessSolid-state devicesSemiconductor devicesSingle crystalLight emitting device

A nitride semiconductor light emitting device includes a substrate formed of silicon, an insulating film formed on the substrate and a single crystal thin film formed on the insulating film. On the single crystal film, a semiconductor laminated body including a light emitting layer of nitride semiconductor is formed.

Owner:PANASONIC CORP

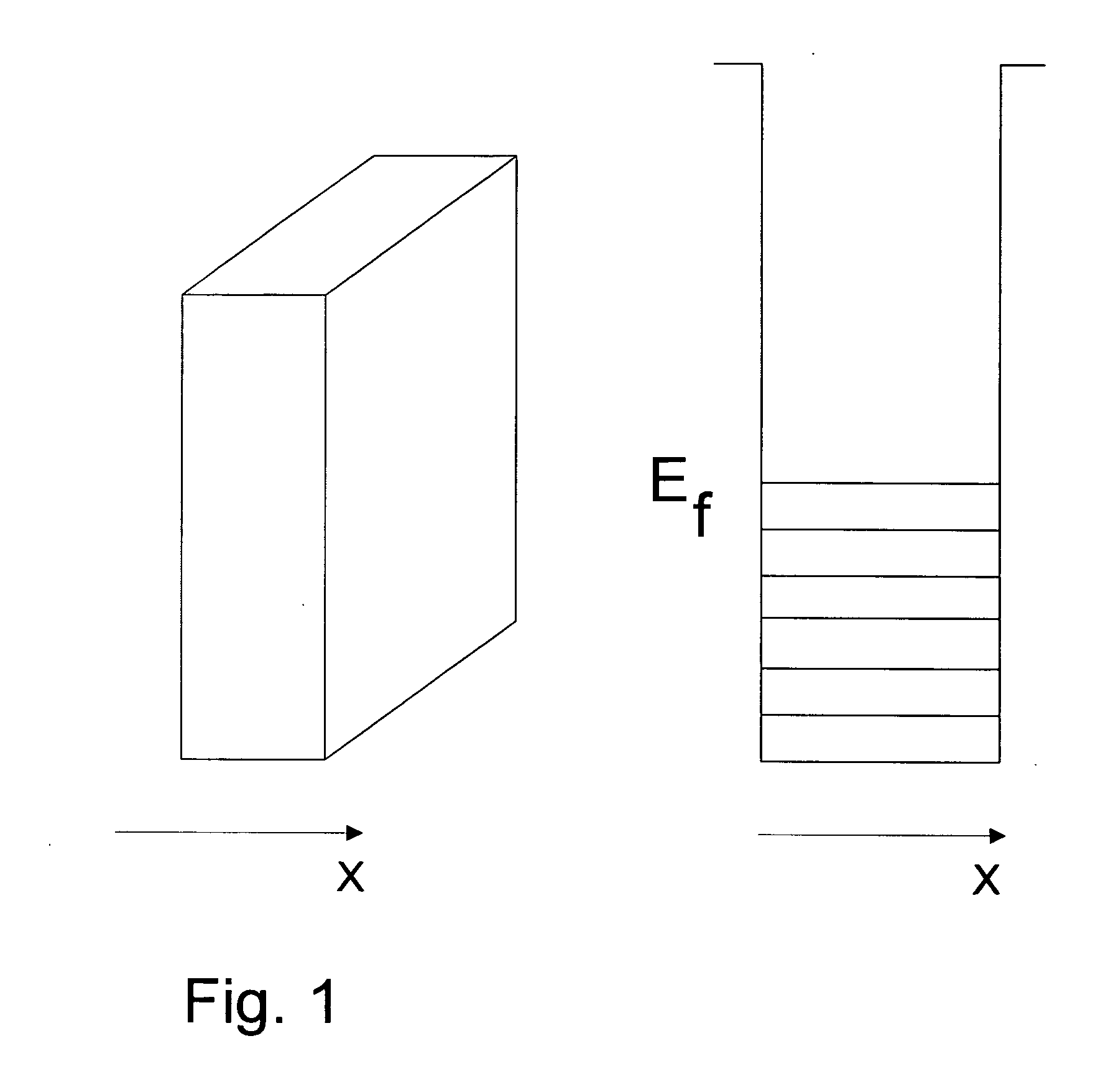

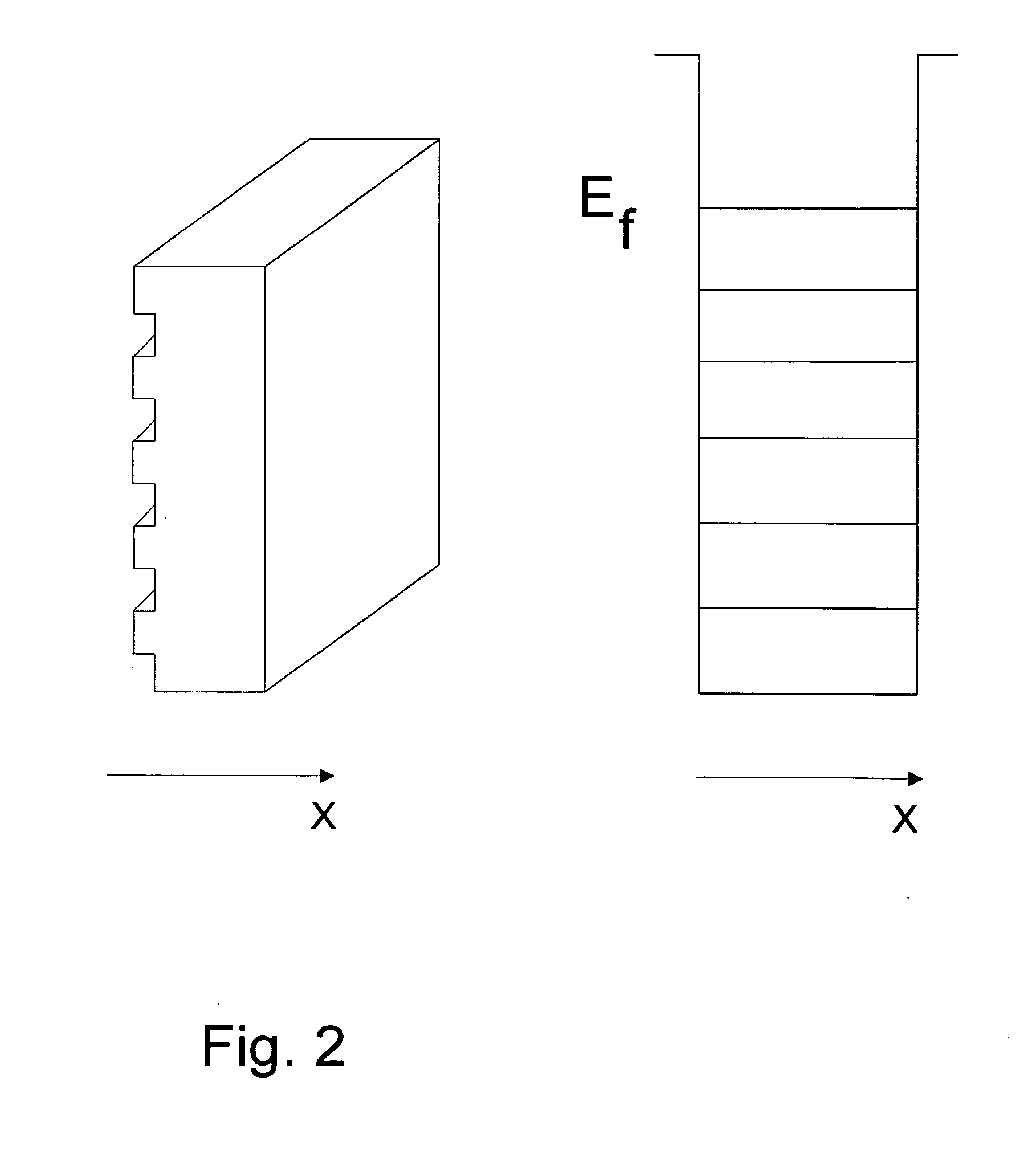

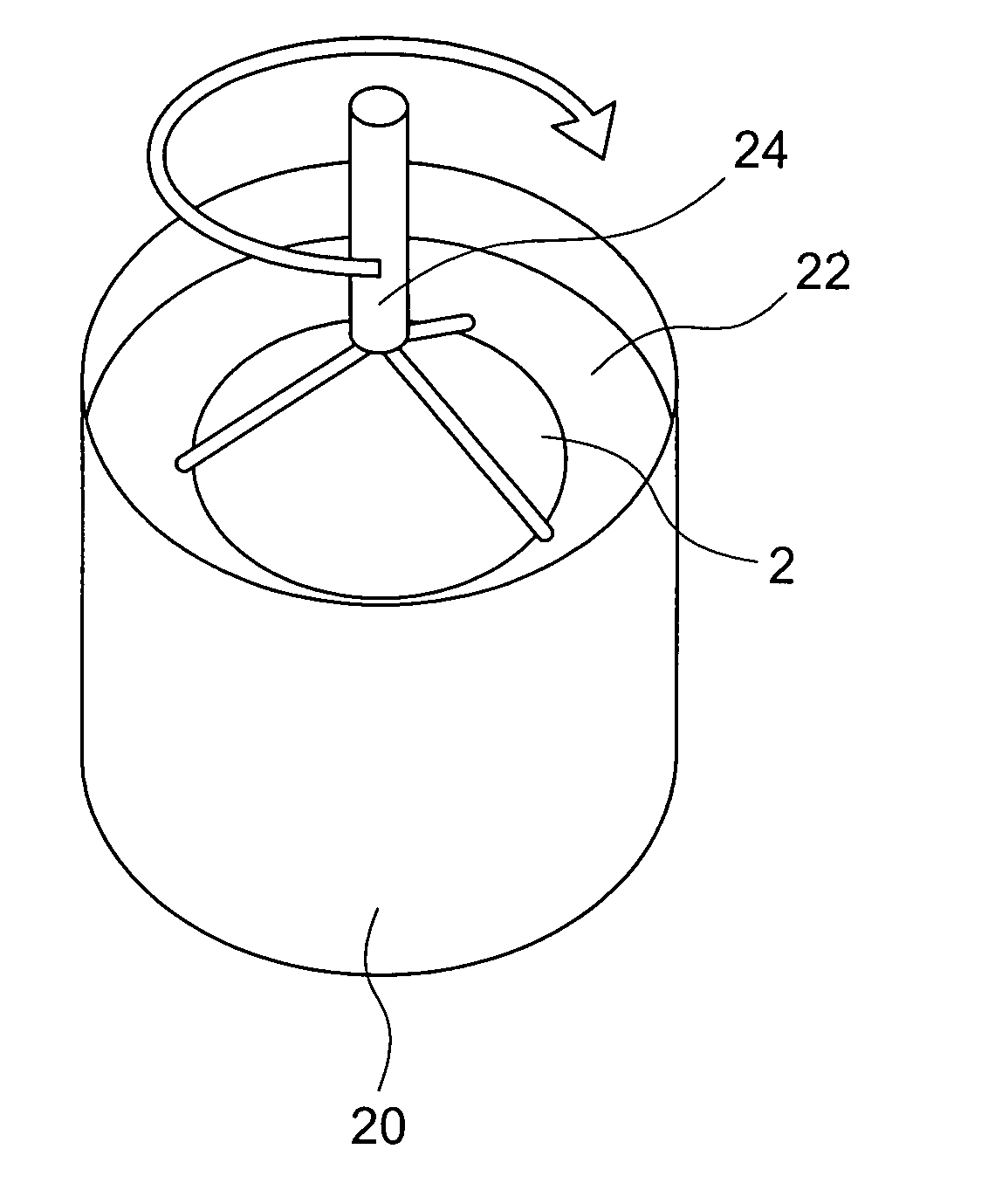

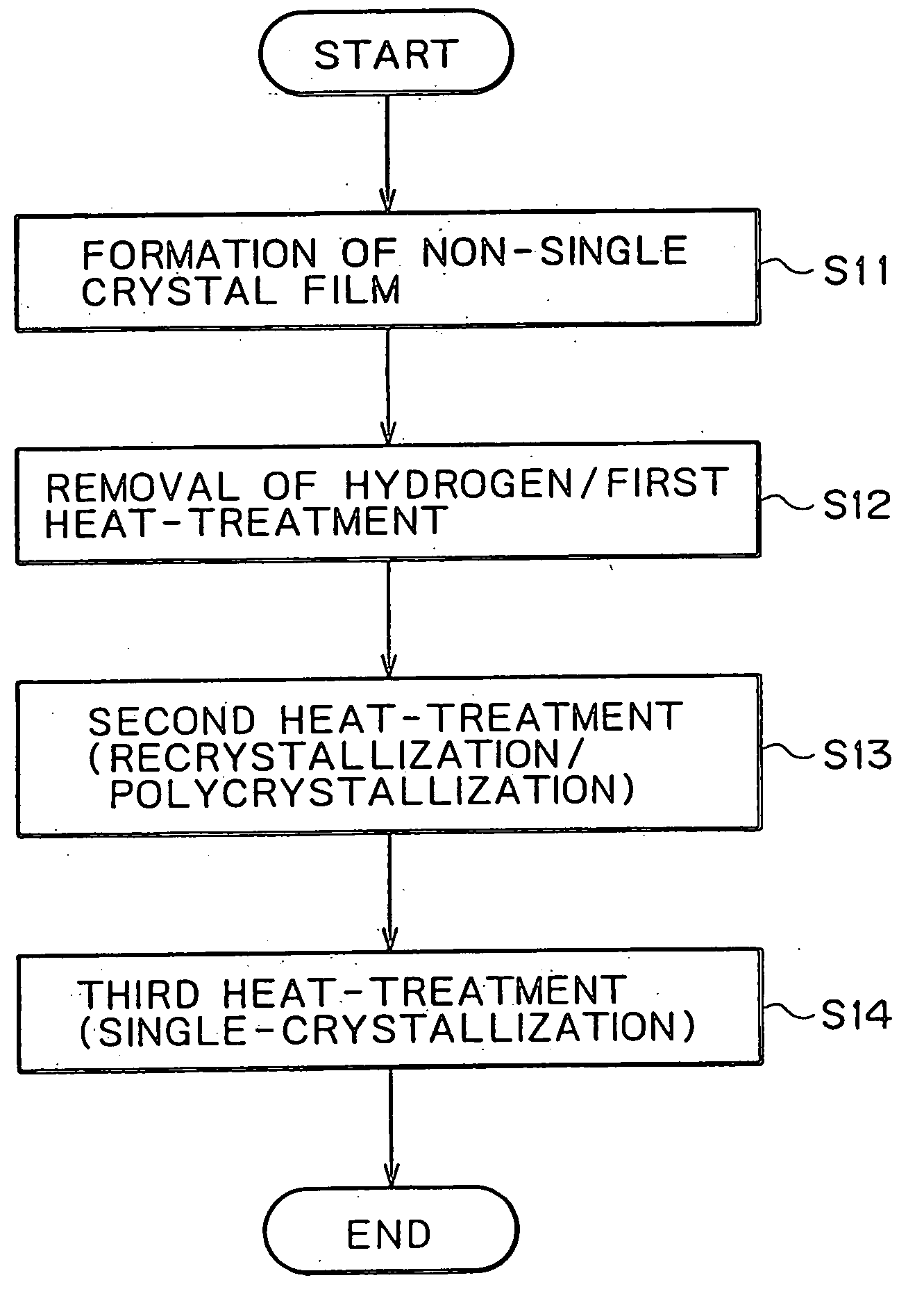

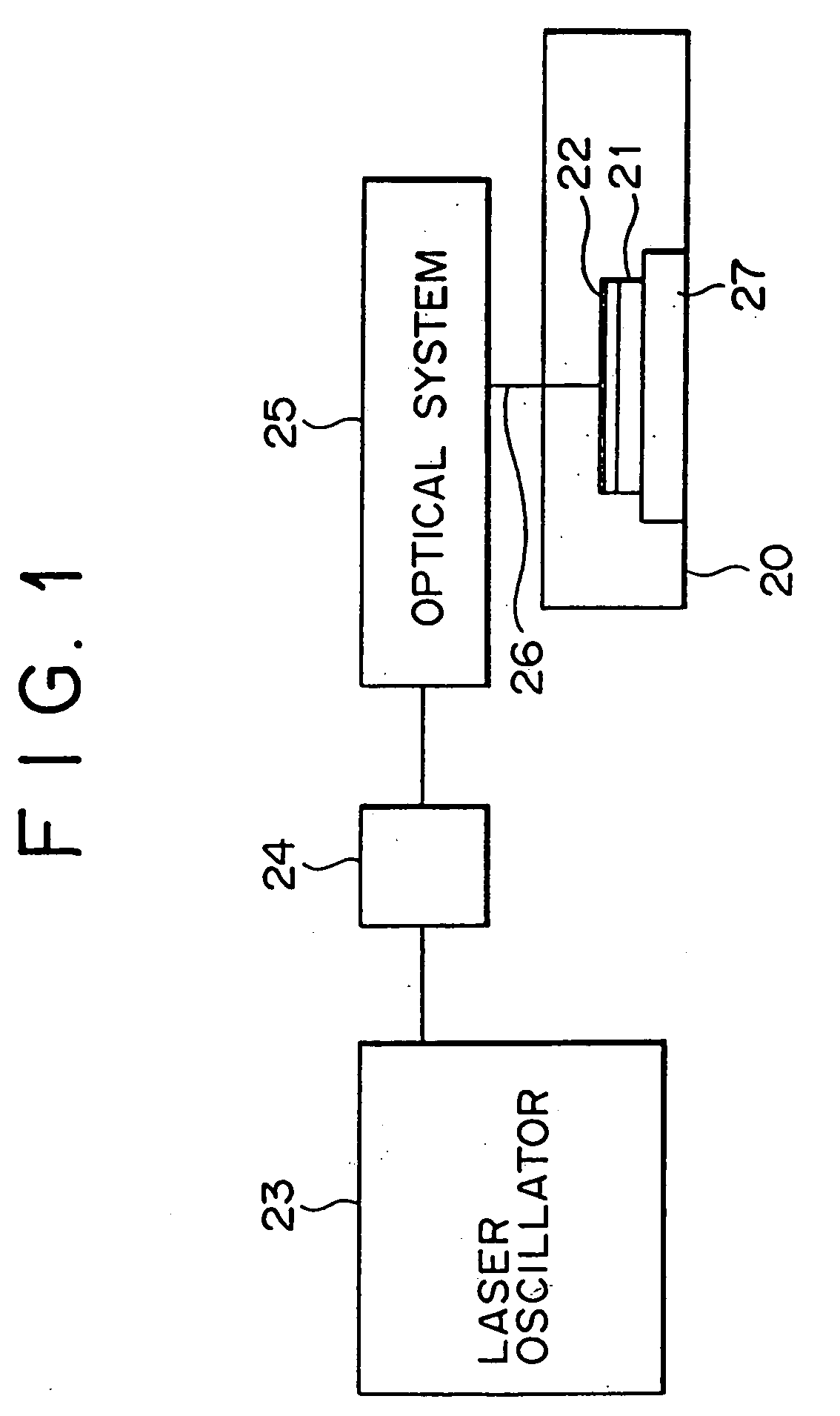

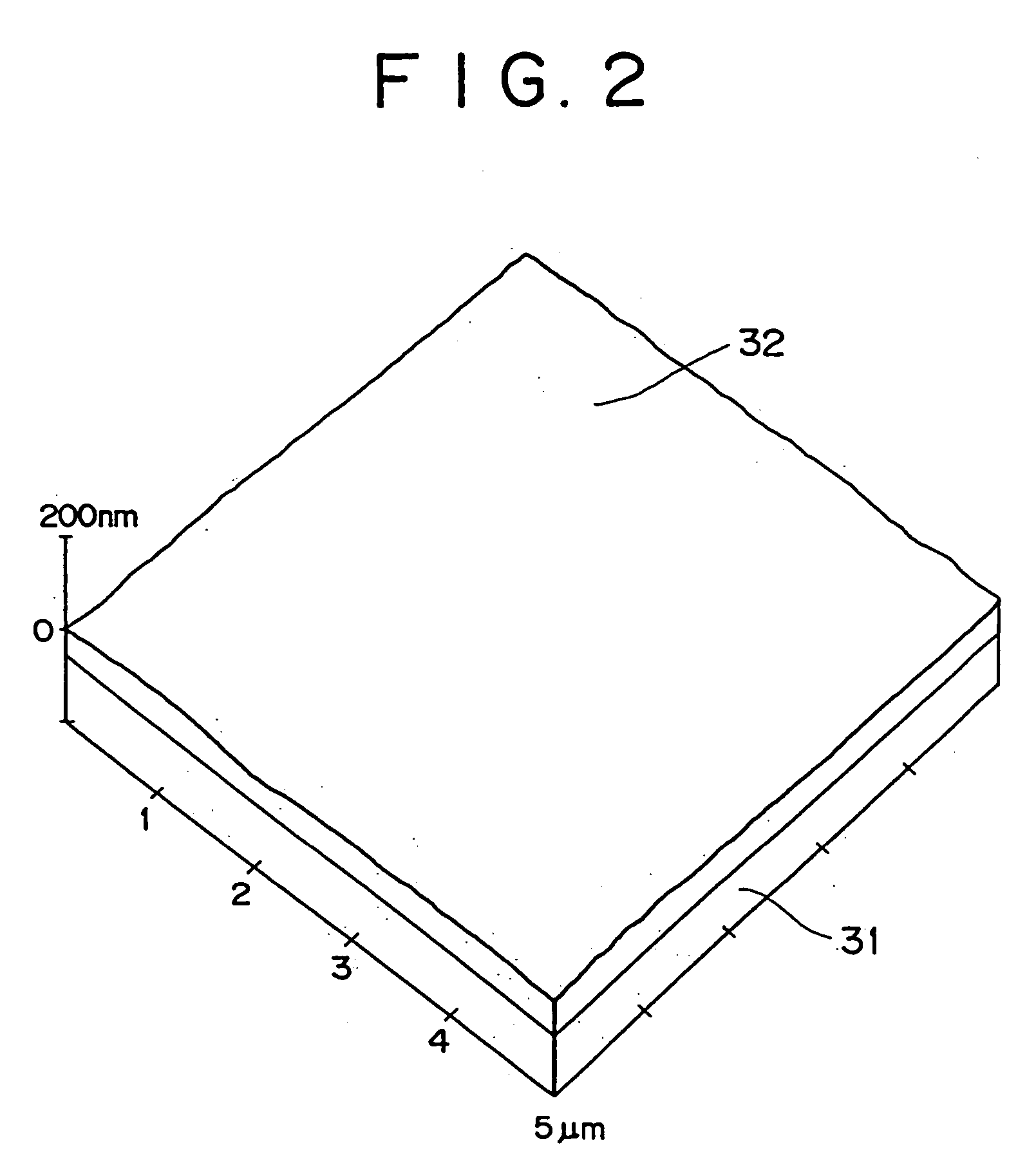

Semiconductor thin film and method of fabricating semiconductor thin film, apparatus for fabricating single crystal semiconductor thin film, and method of fabricating single crystal thin film, single crystal thin film substrate, and semiconductor device

InactiveUS20050104125A1Shorten the timeEliminate needPolycrystalline material growthRadiation pyrometryRegular patternDevice material

A method of fabricating a single crystal thin film includes forming a non-single crystal thin film on an insulating base; subjecting the non-single crystal thin film to a first heat-treatment, thereby forming a polycrystalline thin film in which polycrystalline grains are aligned in an approximately regular pattern; and subjecting the polycrystalline thin film to a second heat-treatment, thereby forming a single crystal thin film in which the polycrystalline grains are bonded to each other. In this method, either the first heat-treatment or the second heat-treatment may be performed by irradiation of laser beams, preferably, emitted from an excimer laser. A single crystal thin film formed by this fabrication method has a performance higher than a related art polycrystalline thin film and is suitable for fabricating a device having stable characteristics. The single crystal thin film can be fabricated for a short-time by using laser irradiation as the heat-treatments.

Owner:SONY CORP

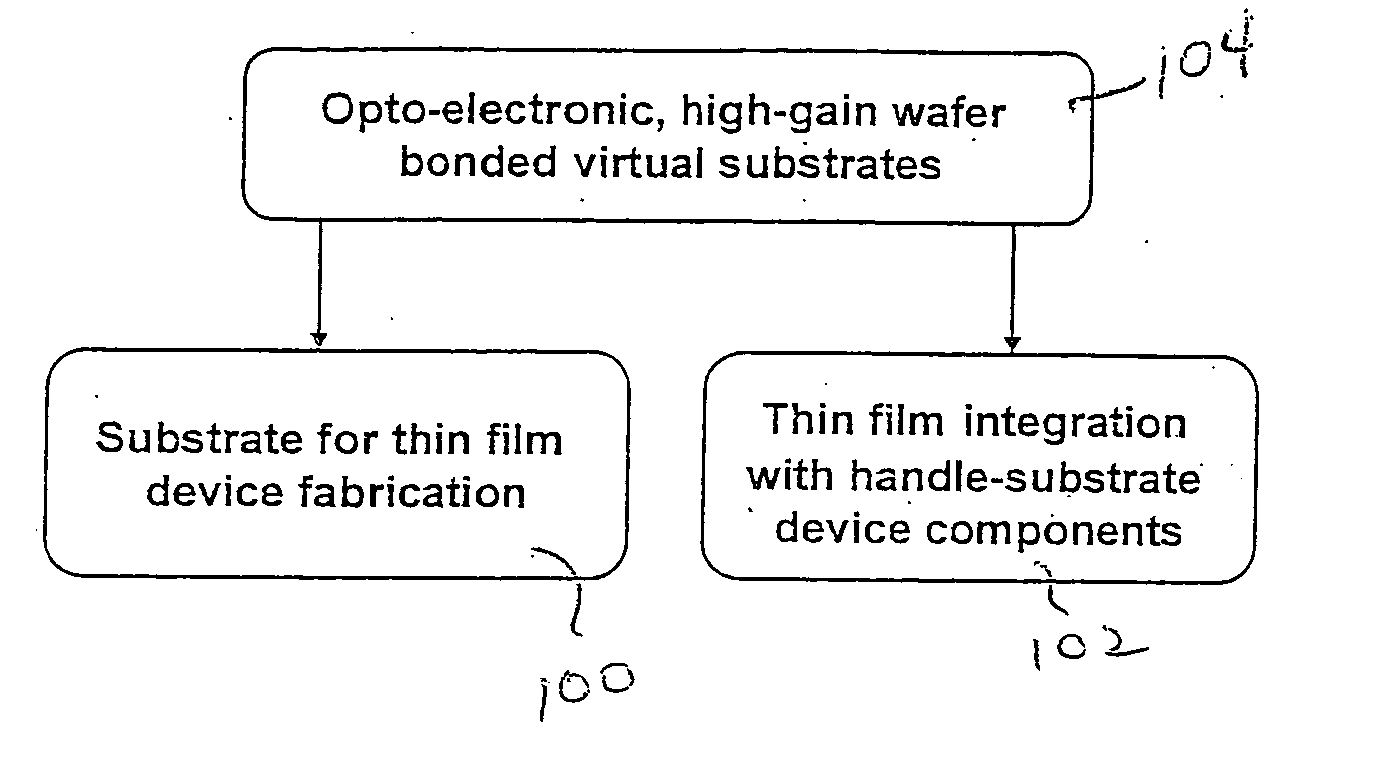

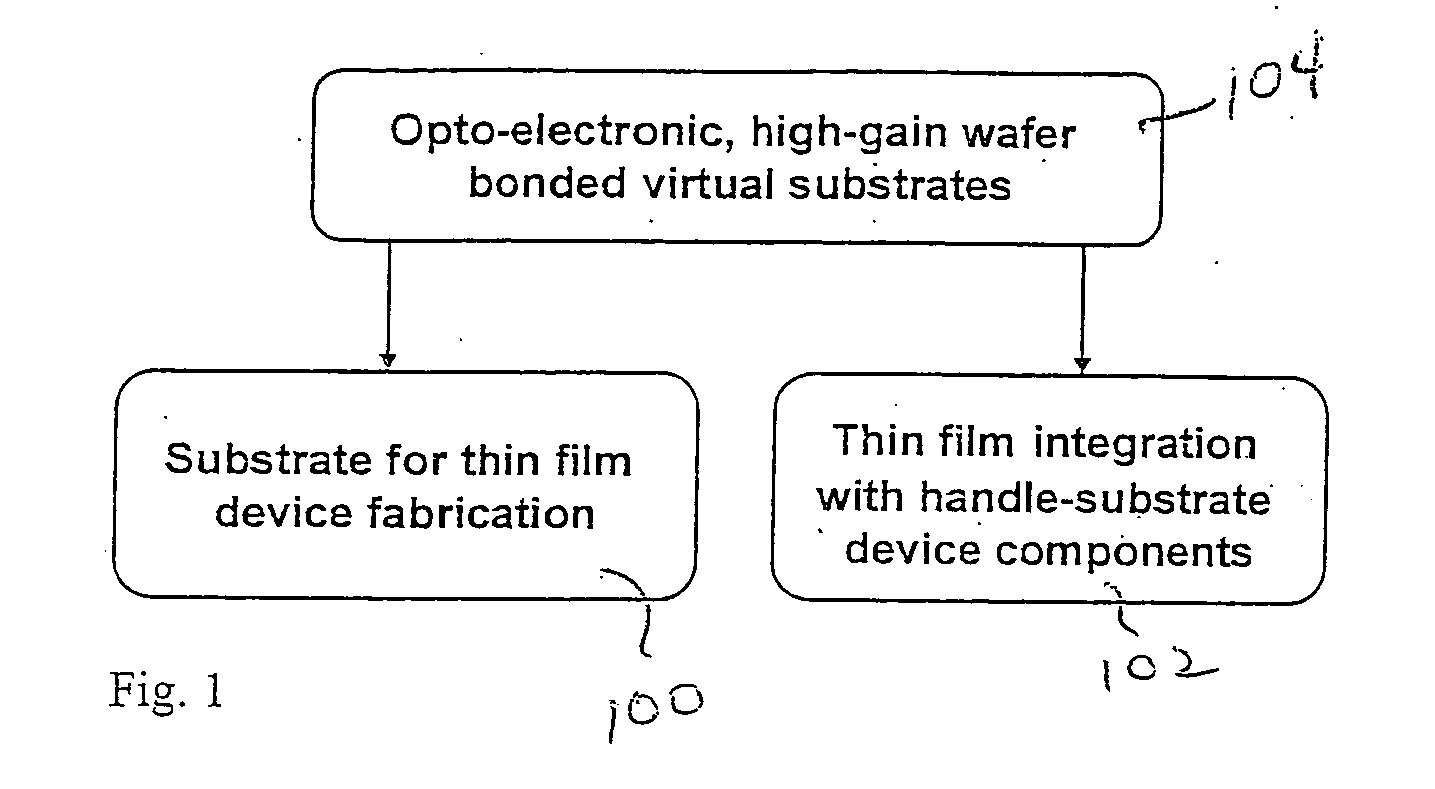

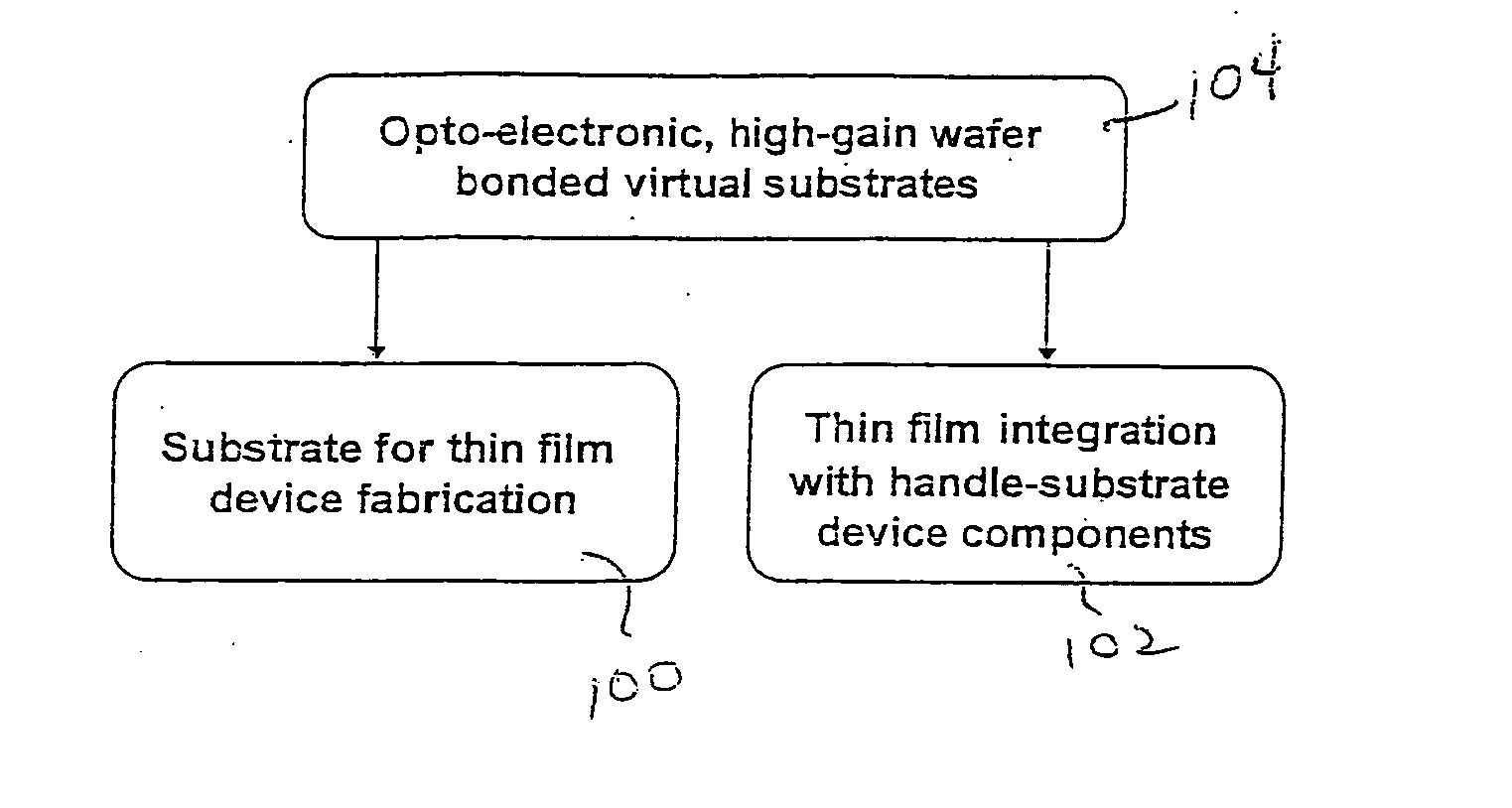

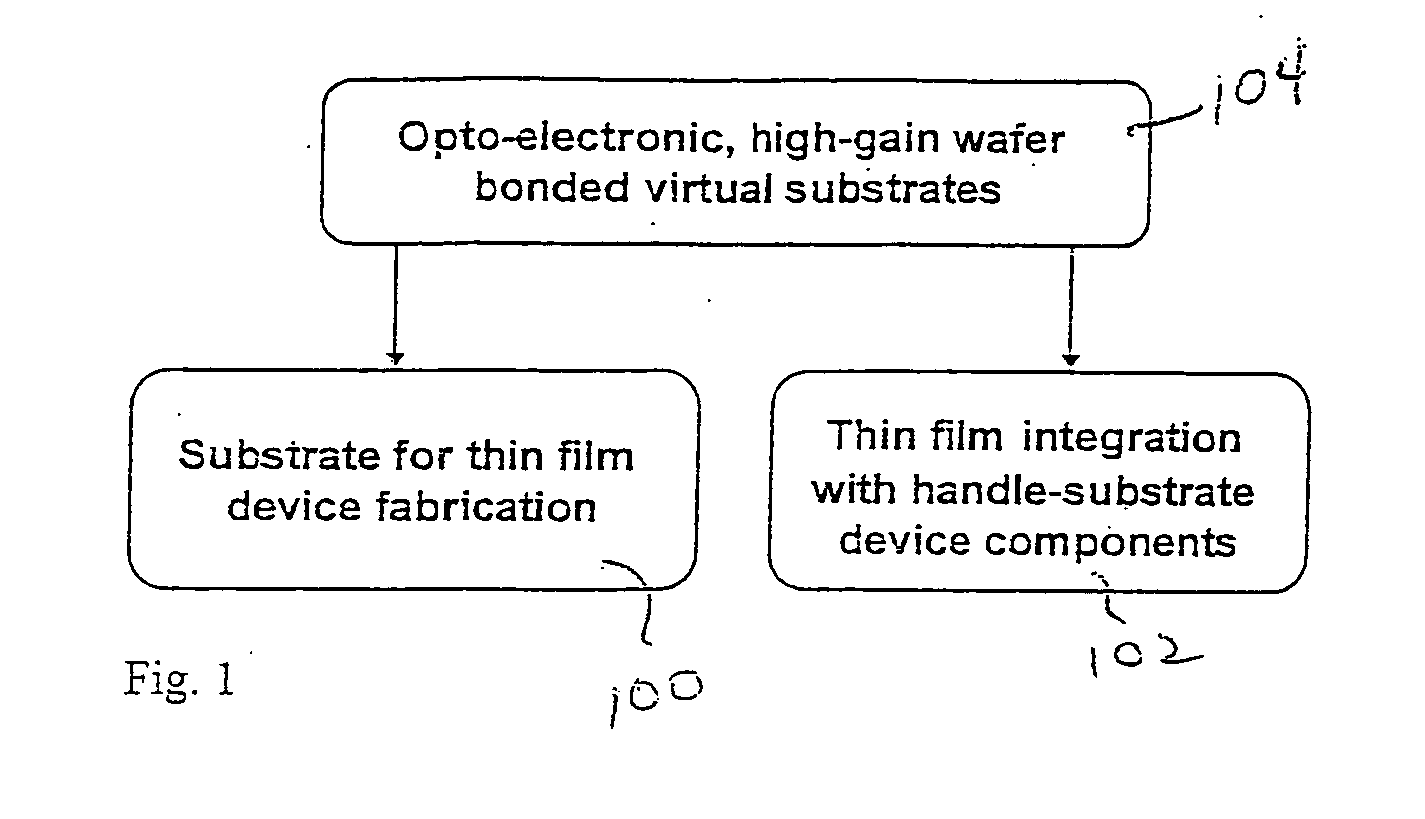

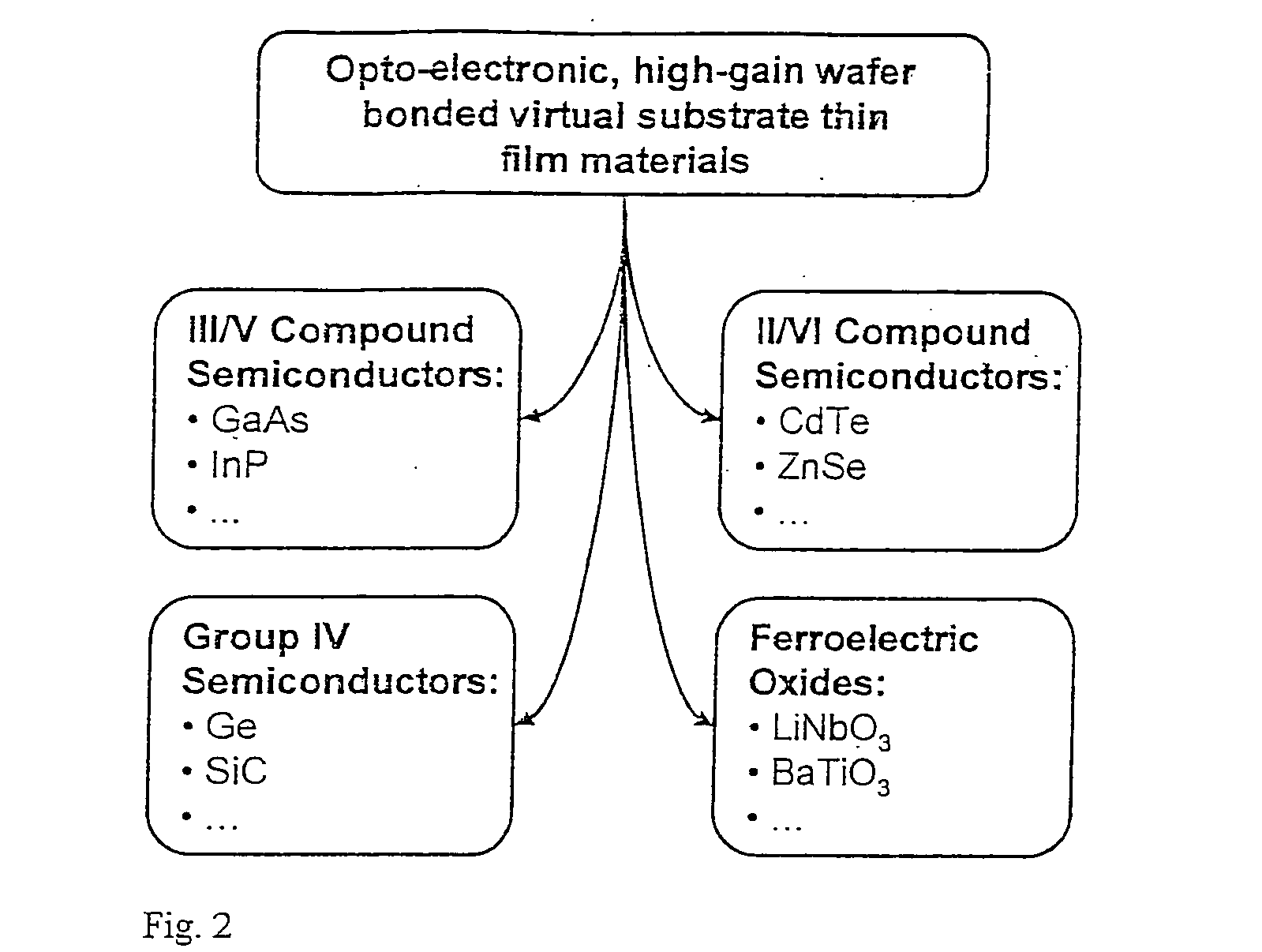

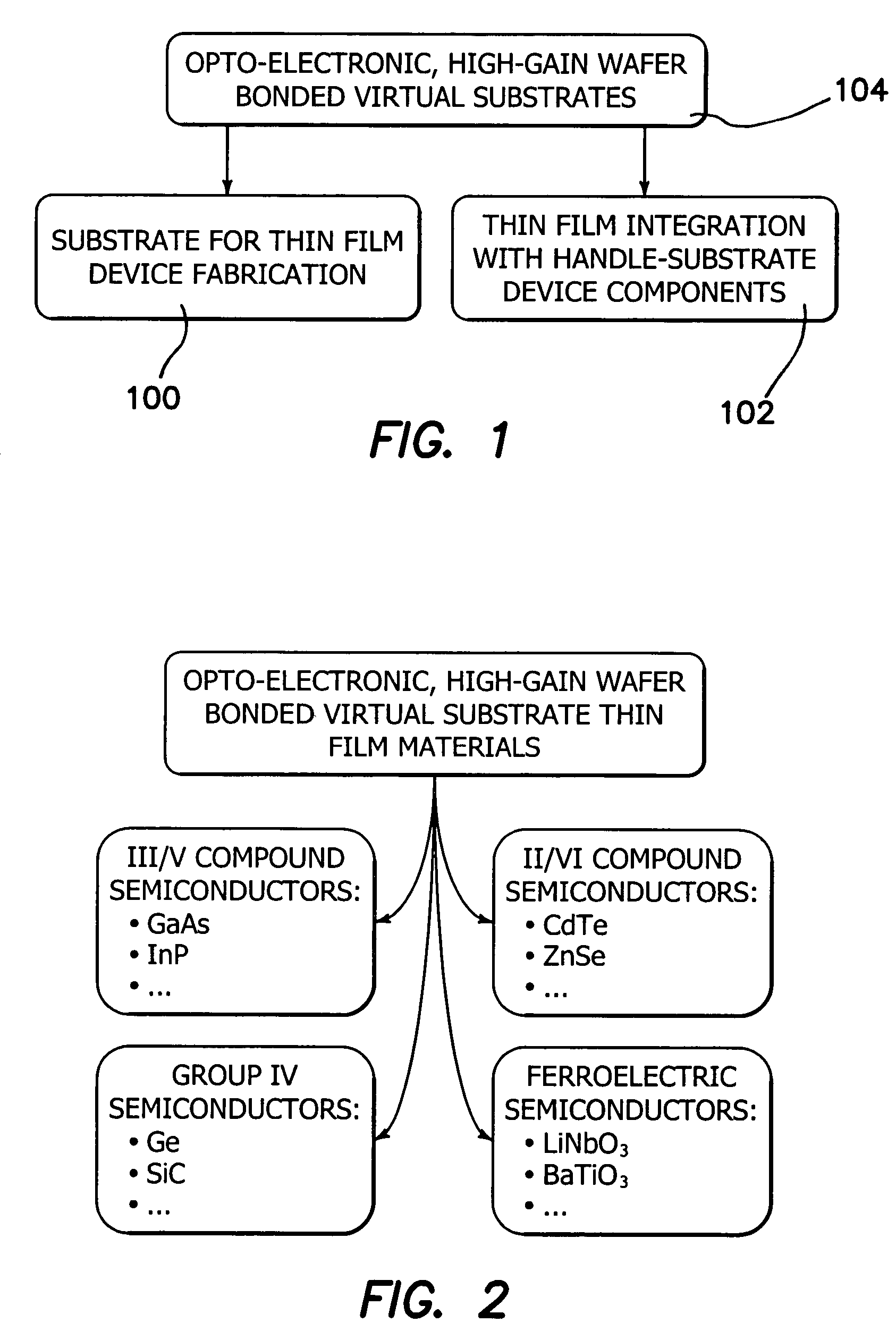

Wafer bonded virtual substrate and method for forming the same

InactiveUS7238622B2Improving and increasing mechanical strength of bondBonding strengthSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringSingle crystal

A method of forming a virtual substrate comprised of an optoelectronic device substrate and handle substrate comprises the steps of initiating bonding of the device substrate to the handle substrate, improving or increasing the mechanical strength of the device and handle substrates, and thinning the device substrate to leave a single-crystal film on the virtual substrate such as by exfoliation of a device film from the device substrate. The handle substrate is typically Si or other inexpensive common substrate material, while the optoelectronic device substrate is formed of more expensive and specialized electro-optic material. Using the methodology of the invention a wide variety of thin film electro-optic materials of high quality can be bonded to inexpensive substrates which serve as the mechanical support for an optoelectronic device layer fabricated in the thin film electro-optic material.

Owner:CALIFORNIA INST OF TECH

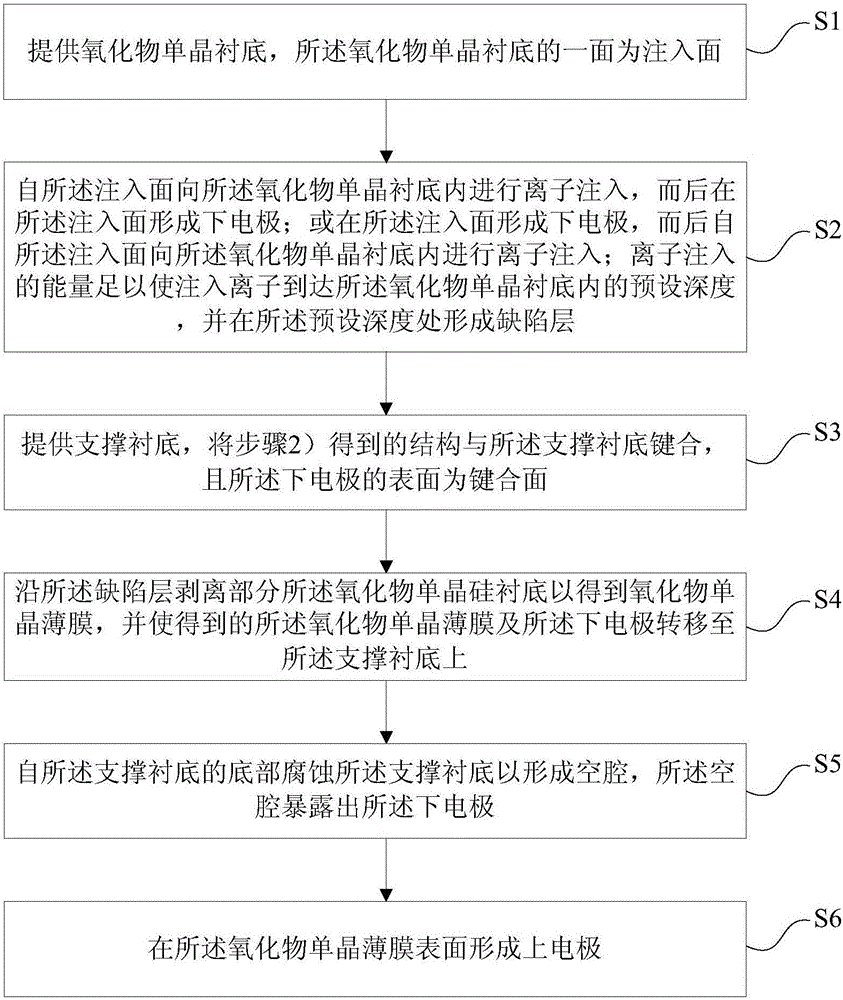

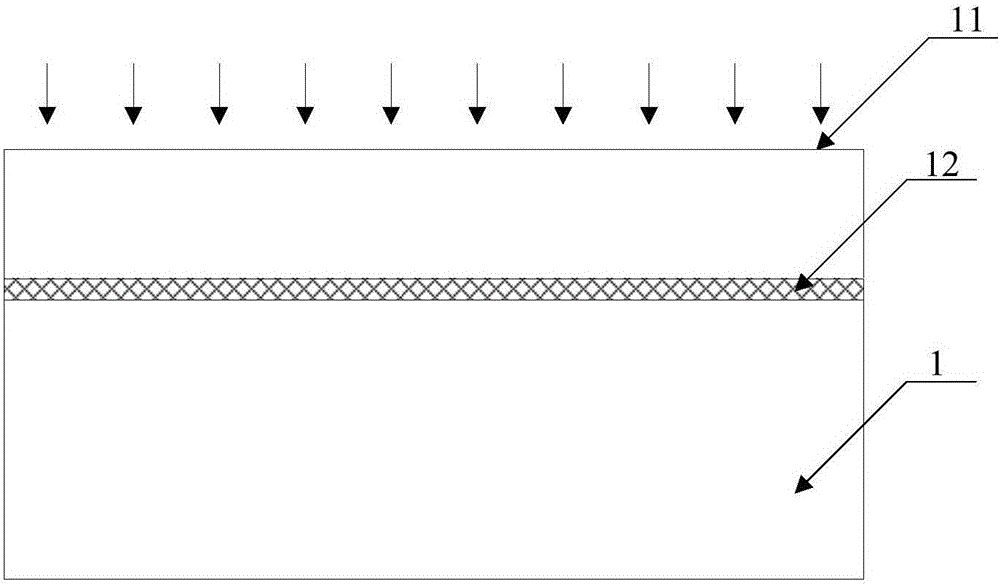

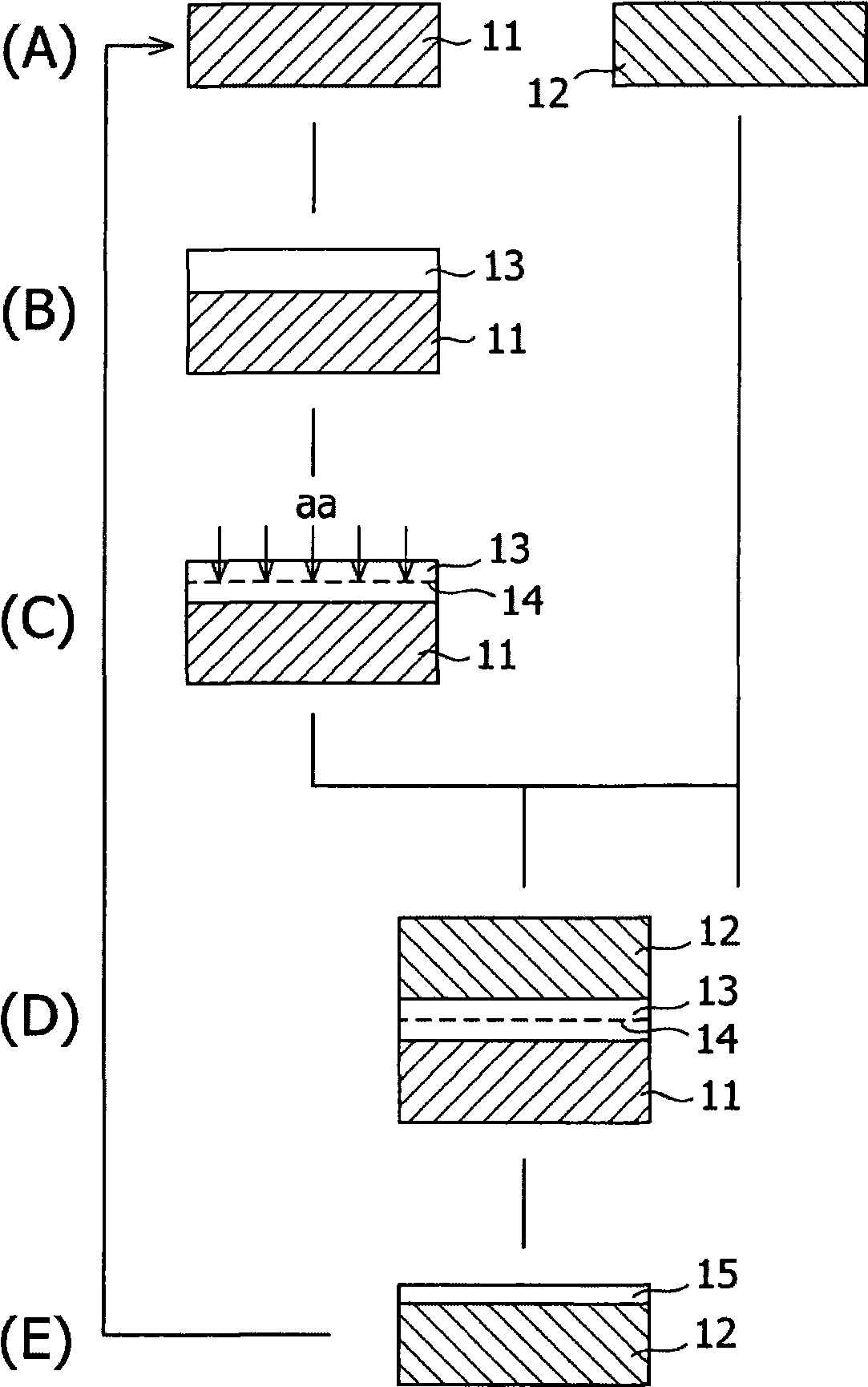

Method of using film transfer technology to manufacture film bulk acoustic wave device

ActiveCN106209003ASolve the problem that single crystal oxide cannot be preparedImpedence networksSingle crystal substrateSingle crystal

The invention provides a method of using a film transfer technology to manufacture a film bulk acoustic wave device. The method comprises the following steps of 1) providing an oxide single crystal substrate; 2) carrying out ion implantation from an injection surface to an internal portion of the oxide single crystal substrate and then forming a lower electrode on the injection surface; or forming the lower electrode on the injection surface and then carrying out ion implantation from the injection surface to the internal portion of the oxide single crystal substrate; 3) providing support substrate and bonding a structure acquired from the step 2) with the support substrate; 4) peeling a part of oxide single crystal substrate along a defect layer so as to acquire an oxide single crystal film, and transferring the oxide single crystal film and the lower electrode to the support substrate; 5) corroding the support substrate so as to form a cavity; and 6) forming an upper electrode on an oxide single crystal film surface. The invention provides a new method to manufacture a film bulk acoustic wave filter core structure of a metal electrode-single crystal oxide-metal electrode, and a problem that the single crystal oxide can not be manufactured between the metal electrodes is effectively solved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Making method for IV-VI semiconductor single crystal film and the heterogeneous structure

InactiveCN101106092AQuality improvementPrecise and controllable thicknessSemiconductor/solid-state device manufacturingFrom condensed vaporsBeam sourceUltra-high vacuum

The invention discloses a method to produce IV-VI semiconductor single-crystal thin film and the hetero-structure thereof. Under the condition of accurately controlled ultra-high vacuum, IV-VI atom and molecular beams vaporized from a beam source furnace encounter a clean single-crystal liner surface with good crystal surface orientation, and atom and molecular reaching the surface of the liner form high-quality single-crystal thin film after processes such as attachment, transition, and crystallization on the surface of liner. Through the accurate control of growth conditions, such as beam runoff and linear temperature, extended IV-VI compounds grow on the surface of linear by a molecular layer and a molecular layer. The method can grow IV-VI semiconductor hetero-structures, including quantum-well and super-lattice. The production cost is low, and the quality is high.

Owner:ZHEJIANG UNIV

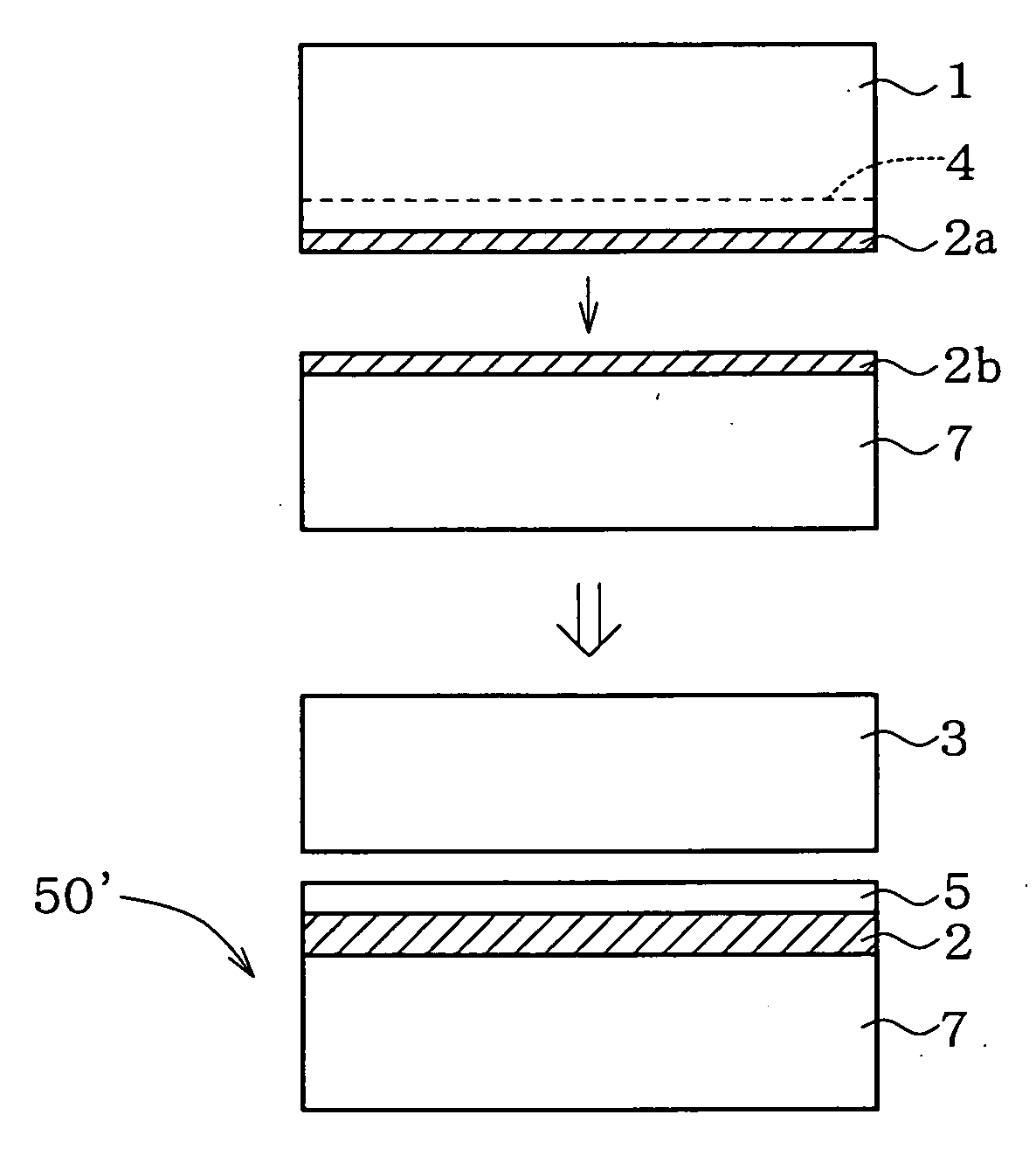

Method for preparing substrate having monocrystalline film

ActiveCN101521155AReduce crystal defectsReduce defectsSemiconductor/solid-state device manufacturingSingle crystalCrystallographic defect

Provided is a method for easily preparing a substrate comprising a monocrystalline film thereon or thereabove with almost no crystal defects without using a special substrate. More specifically, provided is a method for preparing a substrate comprising a monocrystalline film formed on or above a handle substrate, the method comprising: a step A of providing a donor substrate and the handle substrate; a step B of growing a monocrystalline layer on the donor substrate; a step C of implanting ions into the monocrystalline layer on the donor substrate so as to form an ion-implanted layer; a step D of bonding a surface of the monocrystalline layer of the ion-implanted donor substrate to a surface of the handle substrate; and a step E of peeling the bonded donor substrate at the ion-implanted layer existing in the monocrystalline layer so as to form the monocrystalline film on or above the handle substrate; wherein at least the steps A to E are repeated by using the handle substrate having the monocrystalline film formed thereon or thereabove as a donor substrate.

Owner:SHIN ETSU CHEM IND CO LTD

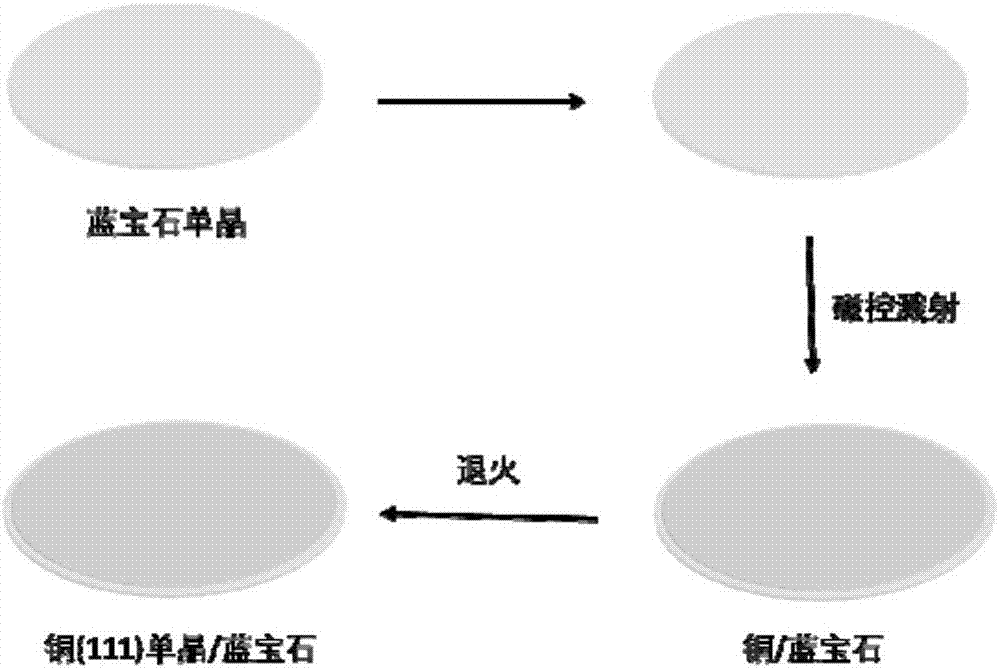

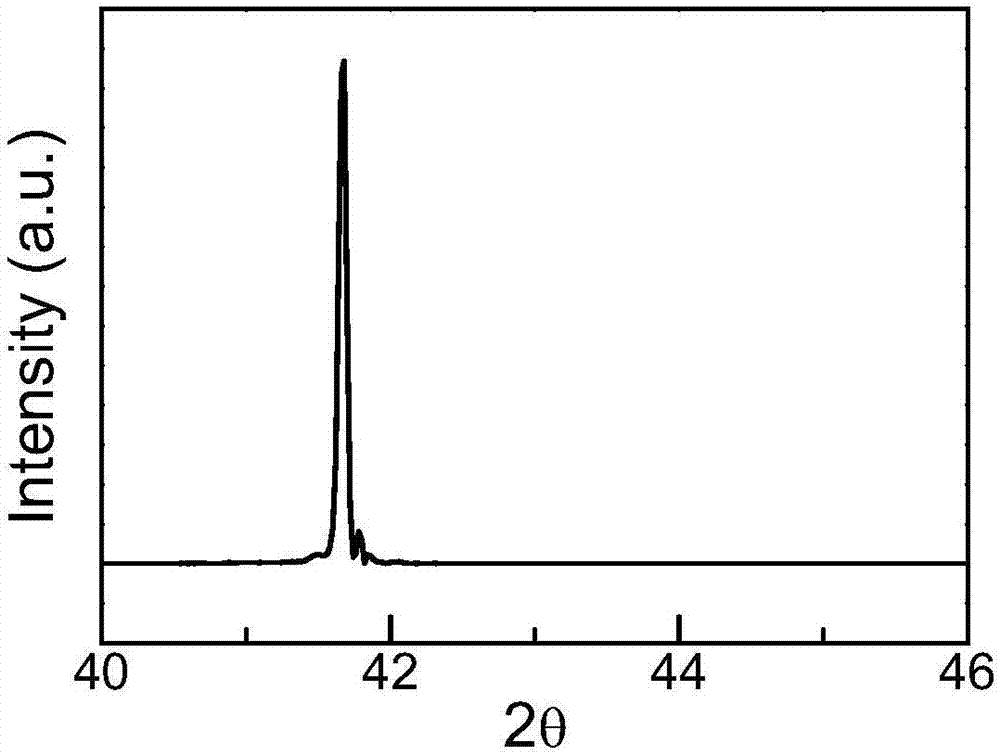

Method for preparing ultra-flat copper monocrystalline film

ActiveCN107354506AFlat surfaceControllable diameterPolycrystalline material growthVacuum evaporation coatingSputteringThin membrane

The invention discloses a method for preparing an ultra-flat copper monocrystalline film. The method for preparing the copper monocrystalline film, provided by the invention, comprises the following steps: taking a sapphire monocrystal as a growth substrate, carrying out copper target magnetron sputtering, and carrying out annealing, thereby obtaining the copper monocrystalline film. According to the method, sapphire is adopted as an epitaxial substrate of copper, a magnetron sputtering method is adopted, a copper film with consistent orientation is deposited on the surface of a c-face sapphire substrate, and copper with consistent orientation is aged and grows up during subsequent annealing so as to form a consistent-orientated monocrystalline copper (111) film without in-plane twin crystals. The monocrystalline copper (111) film prepared by the method is extremely flat in surface, controllable in diameter and high in repeatability and has a very extensive application prospect in the fields of communications, electronics, graphene preparation and the like.

Owner:PEKING UNIV

Pellicle and method for producing pellicle

ActiveUS20090274962A1Reduce generationImprove transmittancePicture framesNanoinformaticsBond densityLattice plane

A silicon single crystal film having a crystal plane as its principal plane, the crystal plane being inclined at 3 to 5° from any lattice plane belonging to {100} planes or {111} planes is used as a pellicle film. The silicon single crystal having such a crystal plane as its principal plane has effective bond density and Young's modulus thereof which are about 40% to about 50% higher than those of a silicon single crystal with <100> orientation, and therefore a cleavage and crack do not easily occur. Moreover, the silicon single crystal has a high chemical resistance such as hydrofluoric acid resistance, and hardly causes an etch pit and void. Accordingly, the present invention can provide a pellicle comprising a pellicle film for EUV having high transmission, and excellent mechanical and chemical stability, as well as having a high yield, and being practical also in cost.

Owner:SHIN ETSU CHEM IND CO LTD

A method for making IV-VI sector semiconductor single crystal film on CdZnTe underlay

InactiveCN101236905AQuality improvementClear interfaceSemiconductor/solid-state device manufacturingFrom condensed vaporsBridgman methodGas phase

The invention provides a method for preparing an IV-VI semiconductor single crystal thin film on a CdZnTe substrate, wherein, in a molecular beam epitaxy(MBE) device, by adopting an MBE growth method and utilizing molecular beam sources of different IV-VI compounds and under different growth temperatures(200 to 425DEG C), the single crystal thin film is epitaxially grown on the CdZnTe single crystal substrate materials; the CdZnTe substrate has a general formula of Cd1-xZnxTe, wherein X is equal to 0 to 0.3; the single crystal thin film grows by the vertical Bridgman method or vapor transport method, is cut along the (111) crystal orientation or (100) crystal orientation, is mechanically polished by Al2O3 powder and then is chemically polished by the bromine-methanol, the concentration of which is 1 percent. The method for preparing an IV-VI semiconductor single crystal thin film on a CdZnTe substrate has the advantages of being capable of realizing the controllable growth of device structures such as hetero junction, quantum well and superlattice, etc.

Owner:ZHEJIANG UNIV

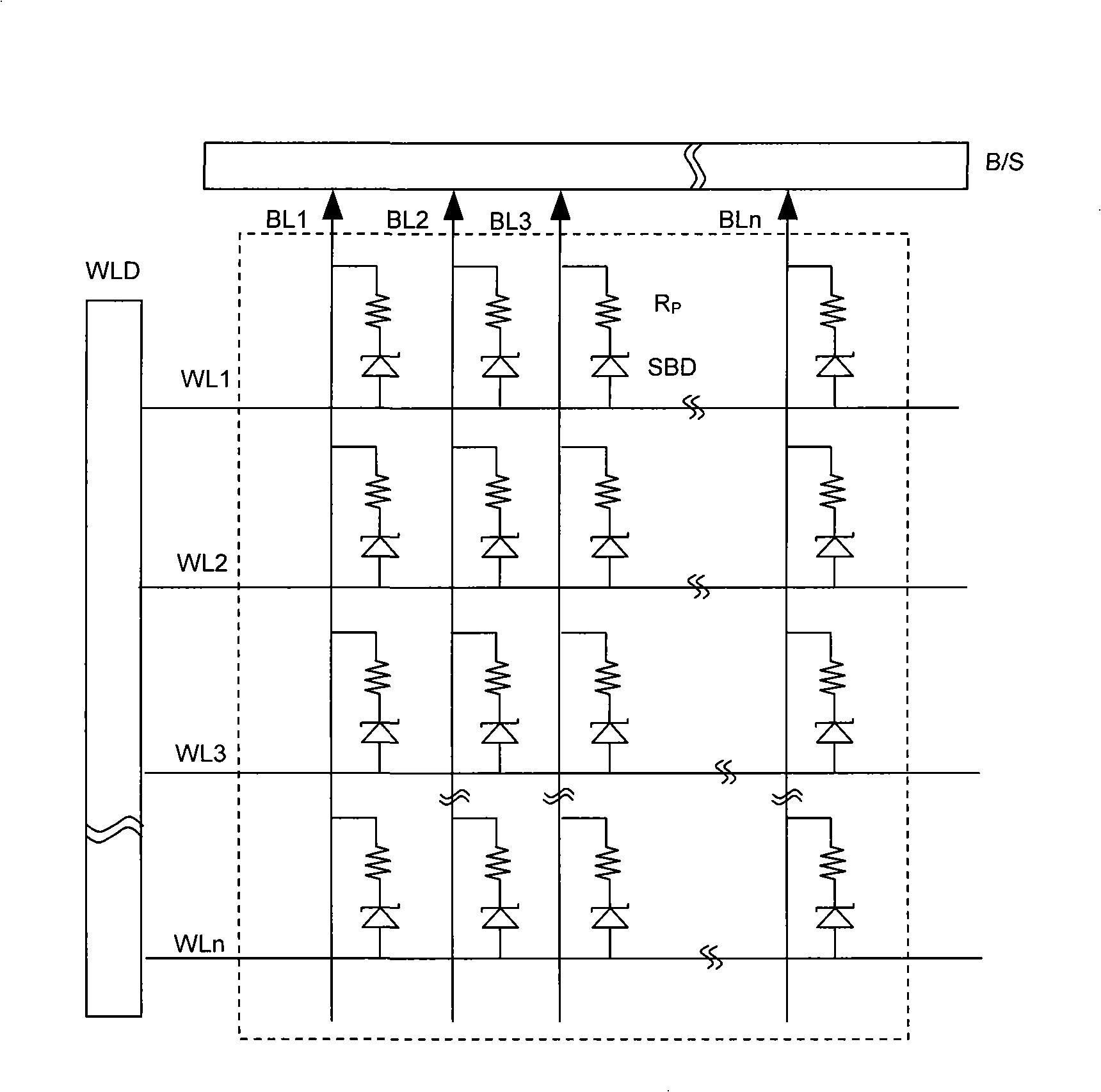

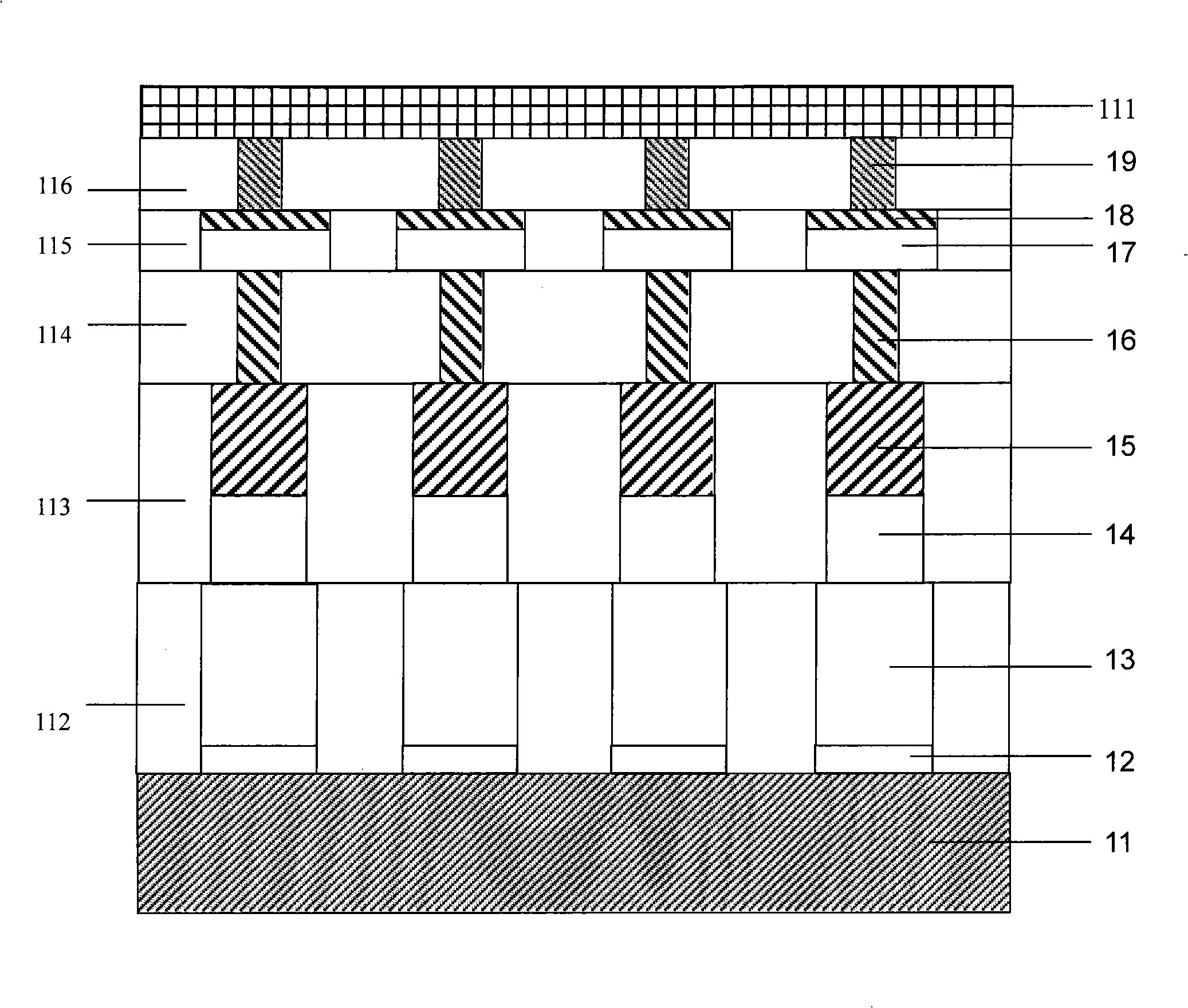

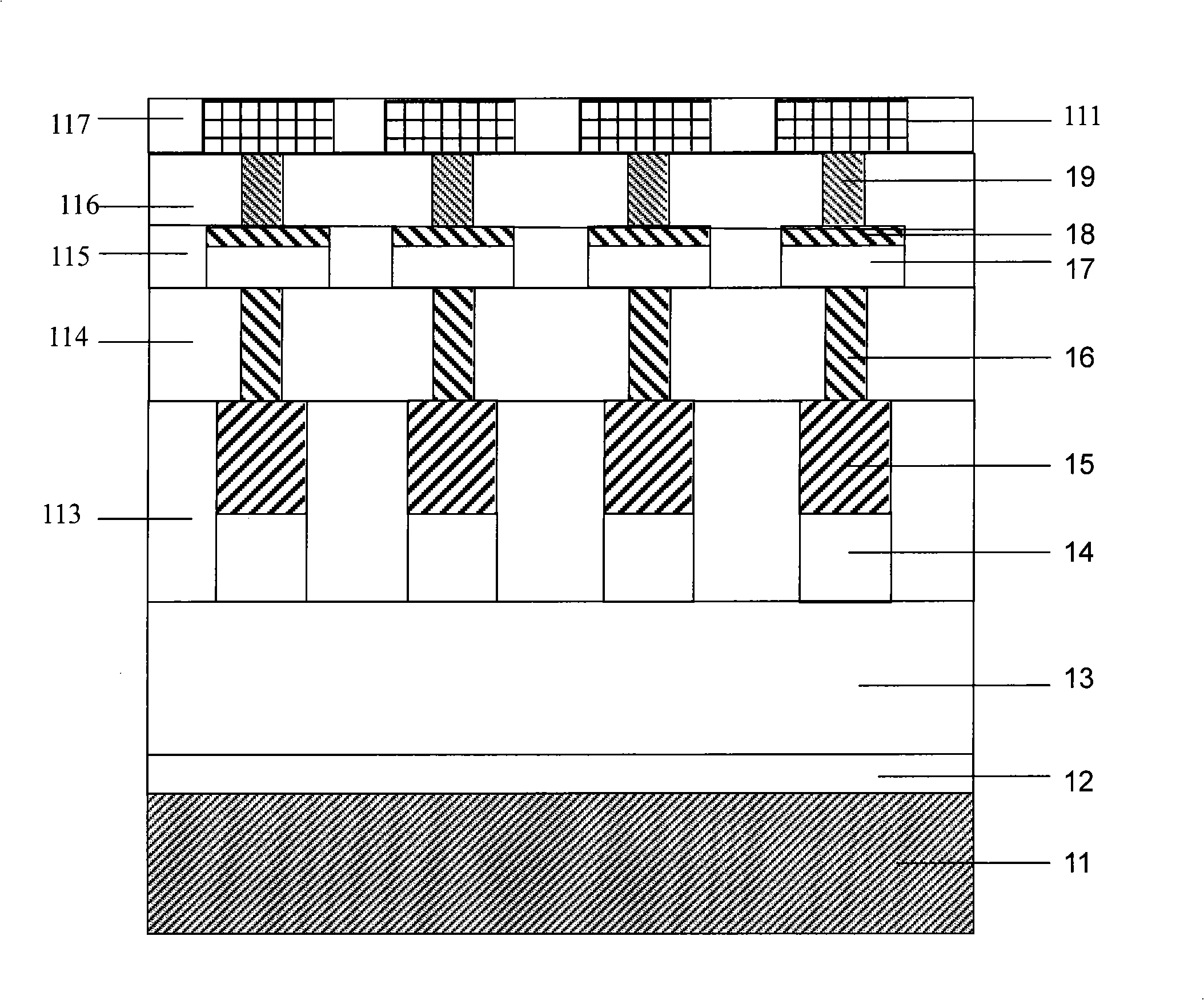

Phase change storage unit using Schottky base diode as selection tube and its making method

InactiveCN101262005AImprove stabilityImprove consistencySemiconductor/solid-state device detailsSolid-state devicesDriving currentPhase-change memory

The invention pertains to the technical field of micro-electronics and discloses a phase change memory device provided with a Schottky diode and a preparation method thereof. The phase change memory device is basically characterized in that a structural unit is composed of the Schottky diode and the phase change memory device; the Schottky diode serves as a gate tube of the phase change memory device; the Schottky diode produces an N-type or P-type Si single crystal film by solid epitaxial technique and the N-type or P-type single crystal film forms a metal semiconductor contact together with a metal film. The Schottky diode prepared by the method has the advantages of stable performance, fast speed and great drive current. The structure disclosed by the invention is characterized in that the structure is applied to highly intense phase change memory devices and can lower the production cost of the phase change memory devices at the same time.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

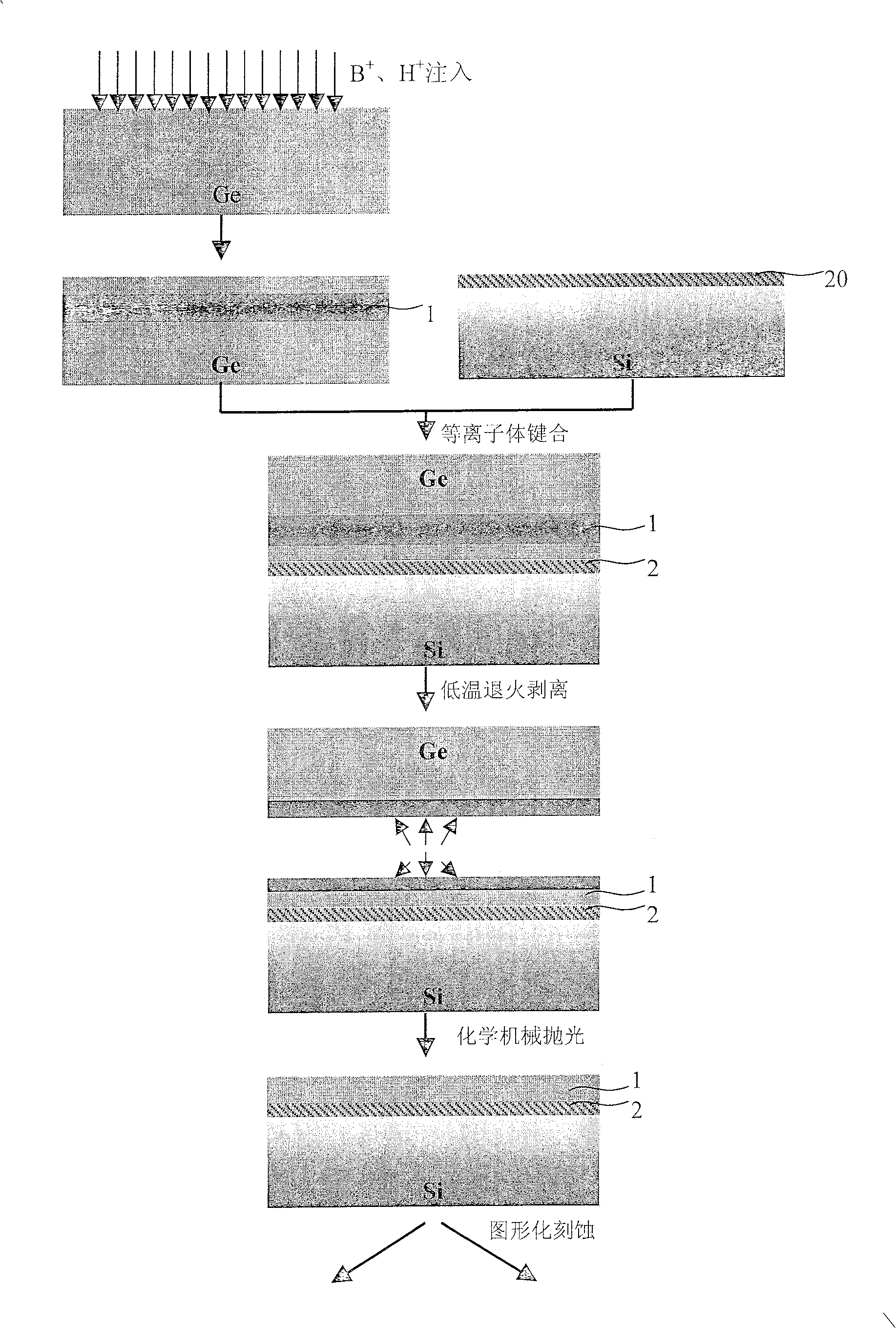

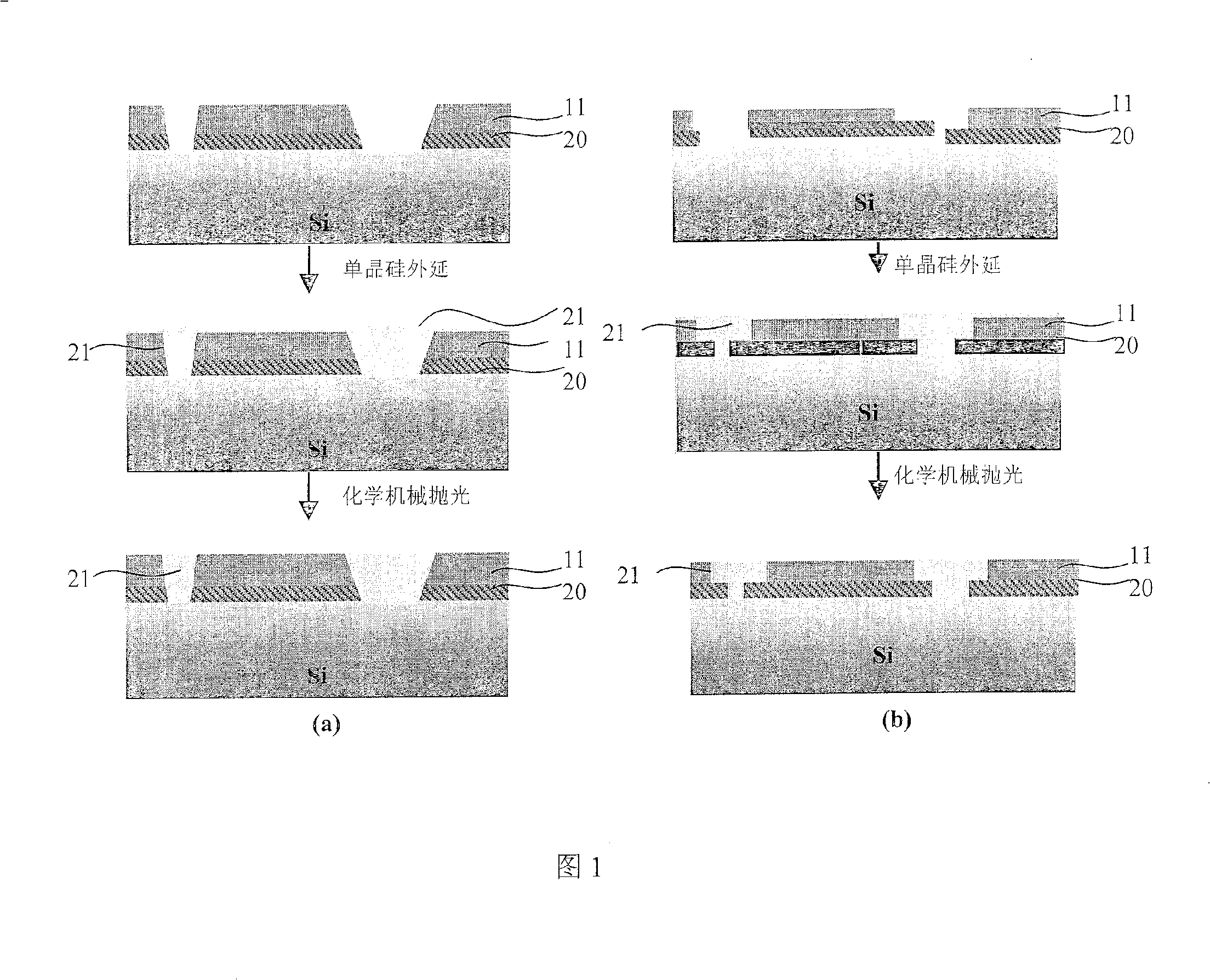

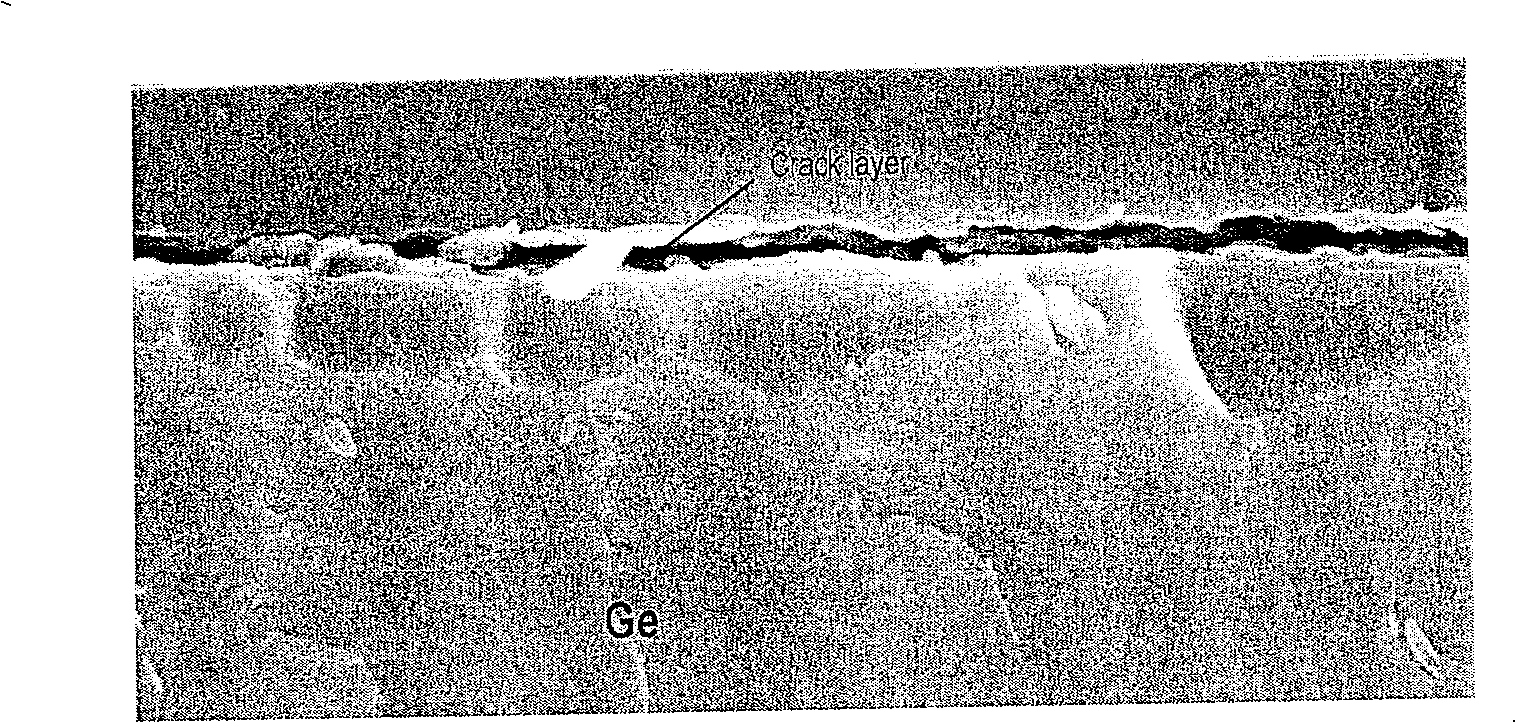

Germanium-painting structure for insulating layer of mixed graphical monocrystaline silicon as well as method and application thereof

InactiveCN101325154AReduce leakage currentWork fasterSemiconductor/solid-state device manufacturingCMOSPhotodetector

The invention relates to a germanium-on-insulator (GeOI) structure mixed with patterned single-crystal silicon and a manufacturing method thereof. The GeOI structure is characterized in that an active layer is composed of single-crystal germanium and single-crystal silicon, and the crystal orientation of the single-crystal silicon is determined by substrate silicon. The key point for preparing the structure is to prepare a GeOI single-crystal film. The substrate with the GeOI structure mixed with patterned single-crystal silicon is prepared by the steps of: transferring a single-crystal germanium film on an insulator by using plasma low temperature bonding and low temperature stripping techniques, and performing selective etching and single-crystal silicon epitaxy on the single-crystal germanium film. The inventive GeOI structure mixed with patterned single-crystal silicon can be used for gallium arsenide epitaxy, so as to integrate with III-V semiconductors. Meanwhile, the patterned single-crystal silicon material can be used for conventional CMOS processing to prepare conventional devices and circuits, so as to effectively solve the self healing effect of an embedded oxidation layer. The GeOI structure mixed with patterned single-crystal silicon has important application prospects in high-speed high-performance CMOS devices, optoelectronic integrated circuits, high-speed photodetectors, etc.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

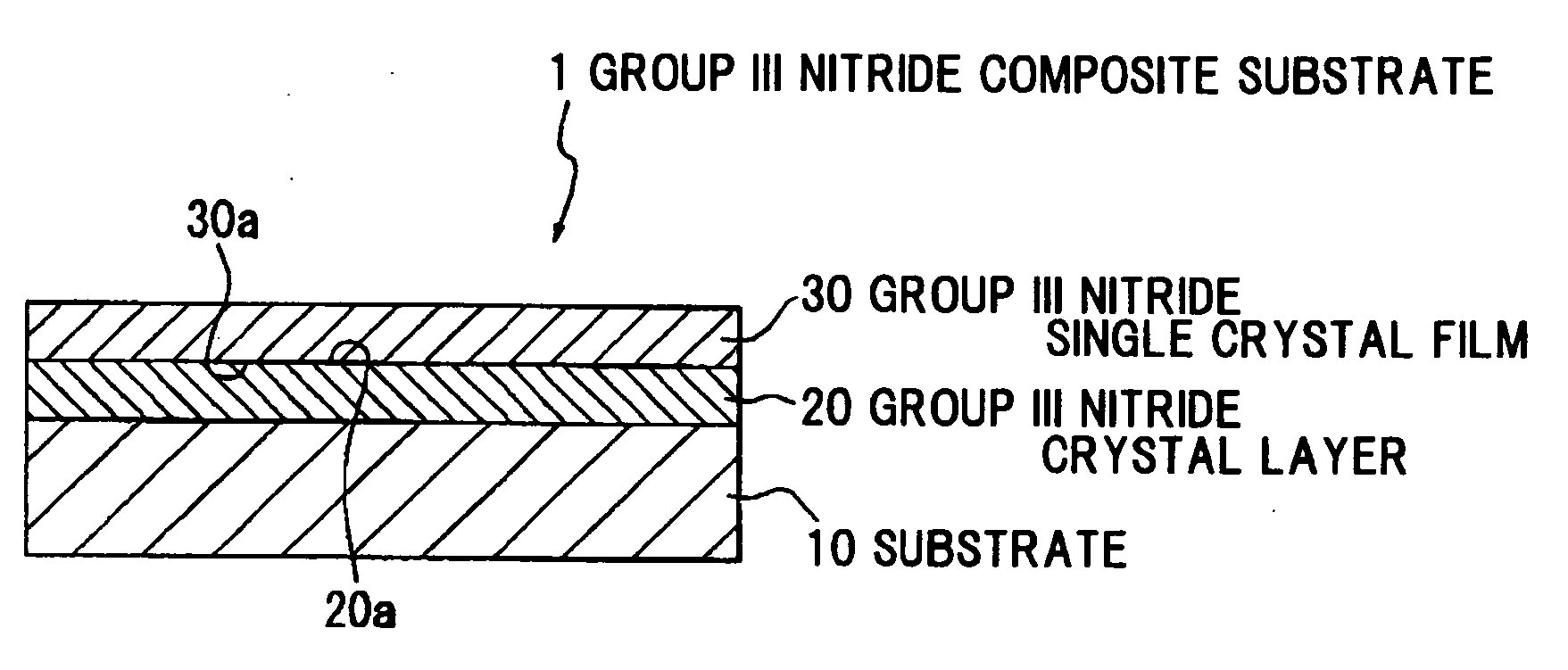

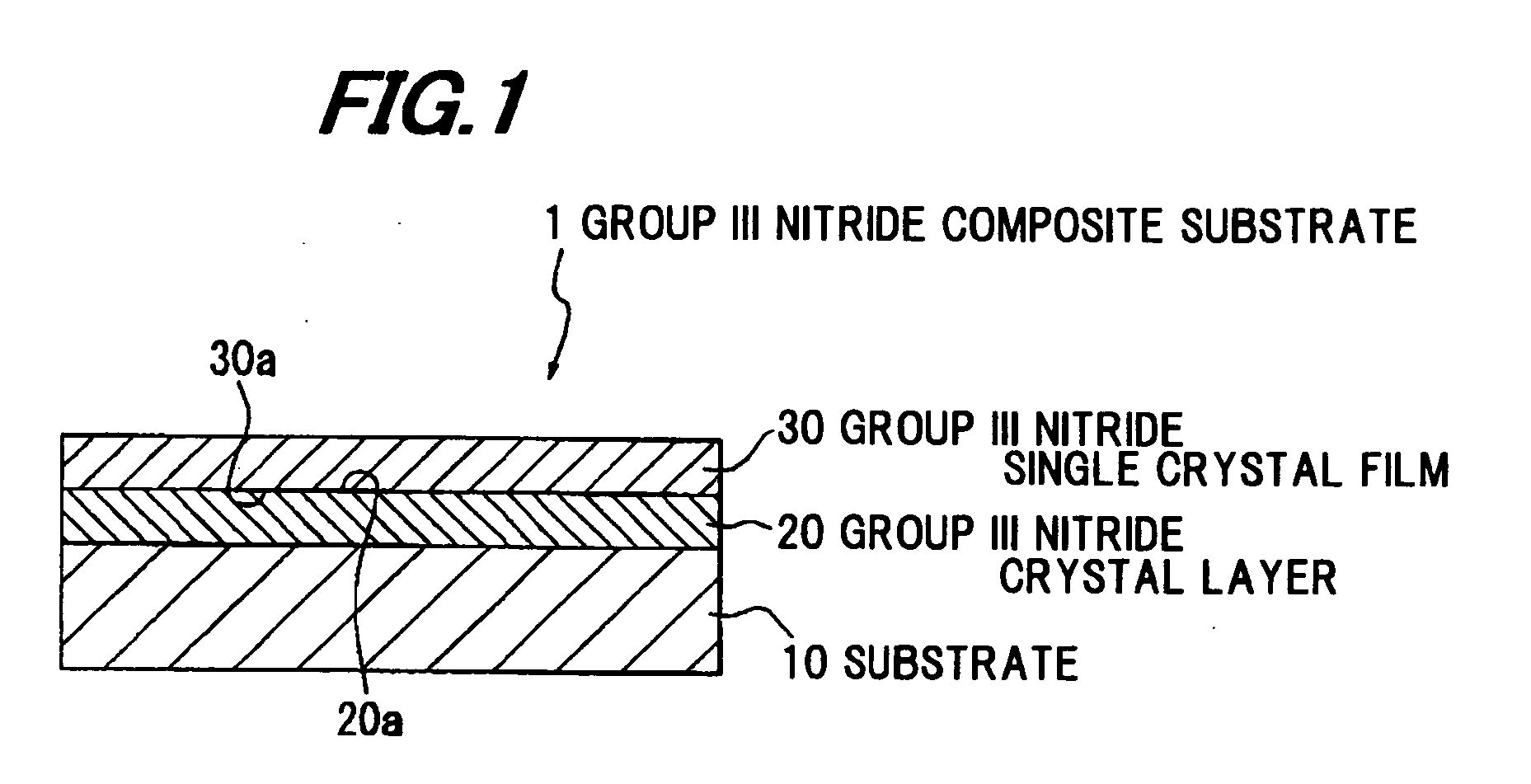

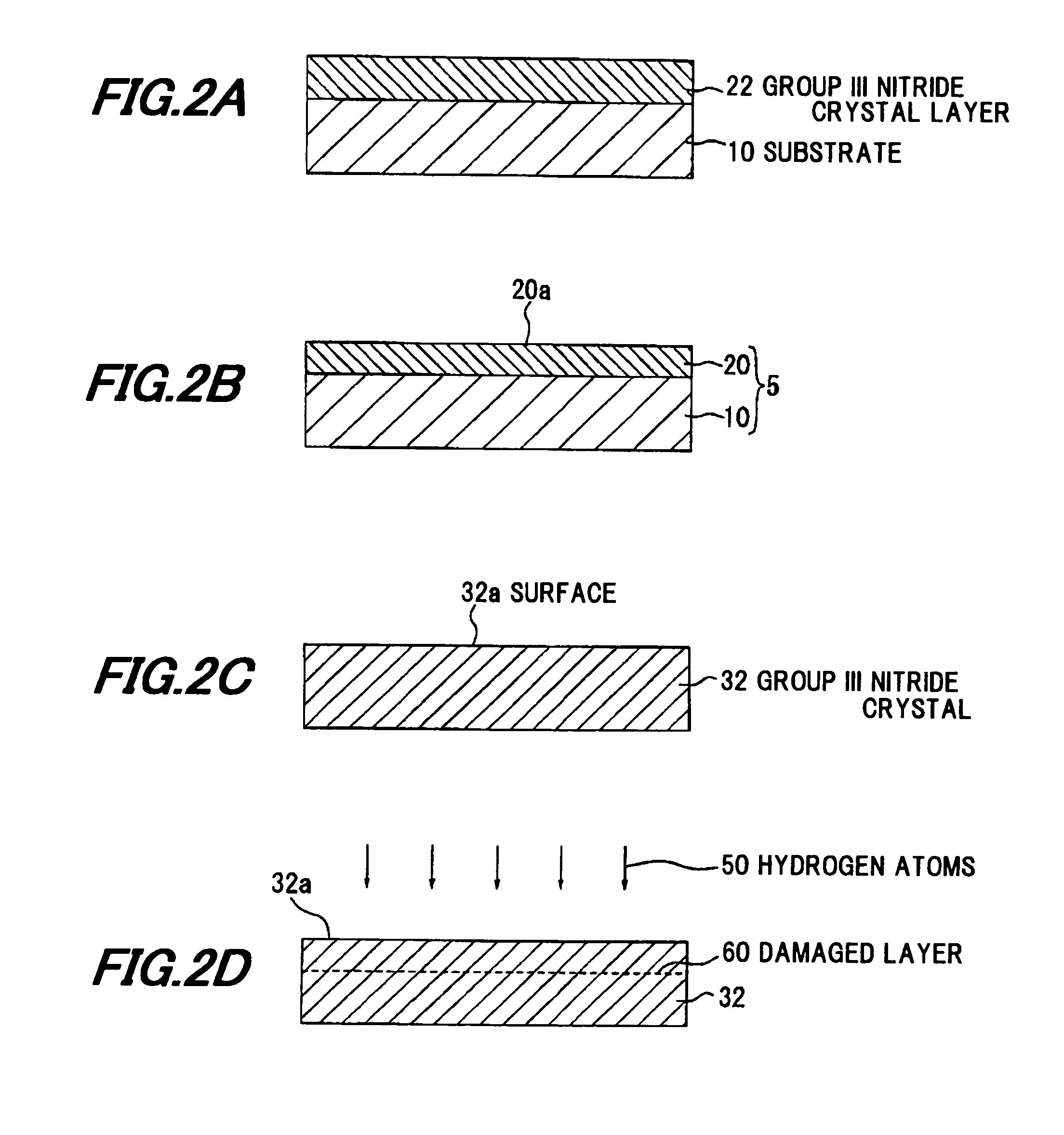

Group III nitride semiconductor composite substrate, group III nitride semiconductor substrate, and group III nitride semiconductor composite substrate manufacturing method

InactiveUS20100244196A1Reduce generationAvoid separationPolycrystalline material growthAfter-treatment detailsComposite substrateSingle crystal

A group III nitride semiconductor composite substrate includes a substrate composed of a conductive material having a melting point of not less than 100° C., a group III nitride layer provided on the substrate, and a group III nitride single crystal film provided on the group III nitride layer. The group III nitride layer includes an undulation including a periodic roughness in a surface of the group III nitride layer contacted with the group III nitride single crystal film. The undulation includes a 1-dimensional power spectral density of less than 500 nm3 in the spatial wavelength region of not less than 0.1 ( / μm) and less than 1 ( / μm).

Owner:HITACHI CABLE

Method for preparing gallium nitride single crystal film

InactiveCN1500919APromote lateral growthImprove quality characteristicsPolycrystalline material growthFrom chemically reactive gasesGas phaseSingle crystal

The present invention is epitaxial growth method of monocrystal GaN film on heterogenous substrate. Monocrystal GaN film is grown on heterogenous substrate or sapphire substrate inside chemical vapor deposition apparatus. The growth process includes introducing hydrogen into reactor, heating the substrate to 1200; lowering the temperature after 10 min, leading in ammonia in the flow rate of 3000-8000 ml / min and hydrogen carried trimethyl gallium in the flow rate of 1-10 ml / min to grow GaN or AlN nucleating layer; in-situ annealing; maintaining substrate temperature at 700-1300 deg.c, leading trimethyl gallium into reactor to grow 1-500 nm GaN layer; lowering the molar V / III ratio to 0.5-2 and further growing GaN to 1-10000 nm thickness. The said process suppresses default generation, provides optimal monocrystal GaN film growing condition and thus has greatly raised crystal quality and photoelectronic characteristic.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Preparation method for film bulk acoustic wave resonator

ActiveCN107508569ATroubleshoot difficult-to-graph problemsSolve the strength problemImpedence networksThin-film bulk acoustic resonatorResonant cavity

The invention relates to the technical field of a film bulk acoustic wave resonator and specifically relates to a preparation method for the film bulk acoustic wave resonator. According to the method, wafer bonding is carried out through adoption of polymer; SiO<2> hydrophilic bonding frequently used by a traditional ion injection stripping method is replaced; an electrode covered by the polymer can be patterned according to a design of the film bulk acoustic wave resonator. The polymer has fluidity, so the polymer can be flattened under the effect of pressure in a wafer bonding process; and the patterned electrode can be nested into the polymer and the stripping of LiNbO<3> single crystal film is not influenced, so the problem that the electrode is difficult to pattern in a bonding transfer process of the single crystal film is solved. The polymer is taken as an acoustic reflection layer of the film bulk acoustic wave resonator, the problem that an air resonant cavity is low in structure strength and a Bragg acoustic reflection cavity is high in preparation difficulty is solved, a preparation technology of a device is simple, and the prepared device is high in structure strength.

Owner:成都芯仕成微电子有限公司

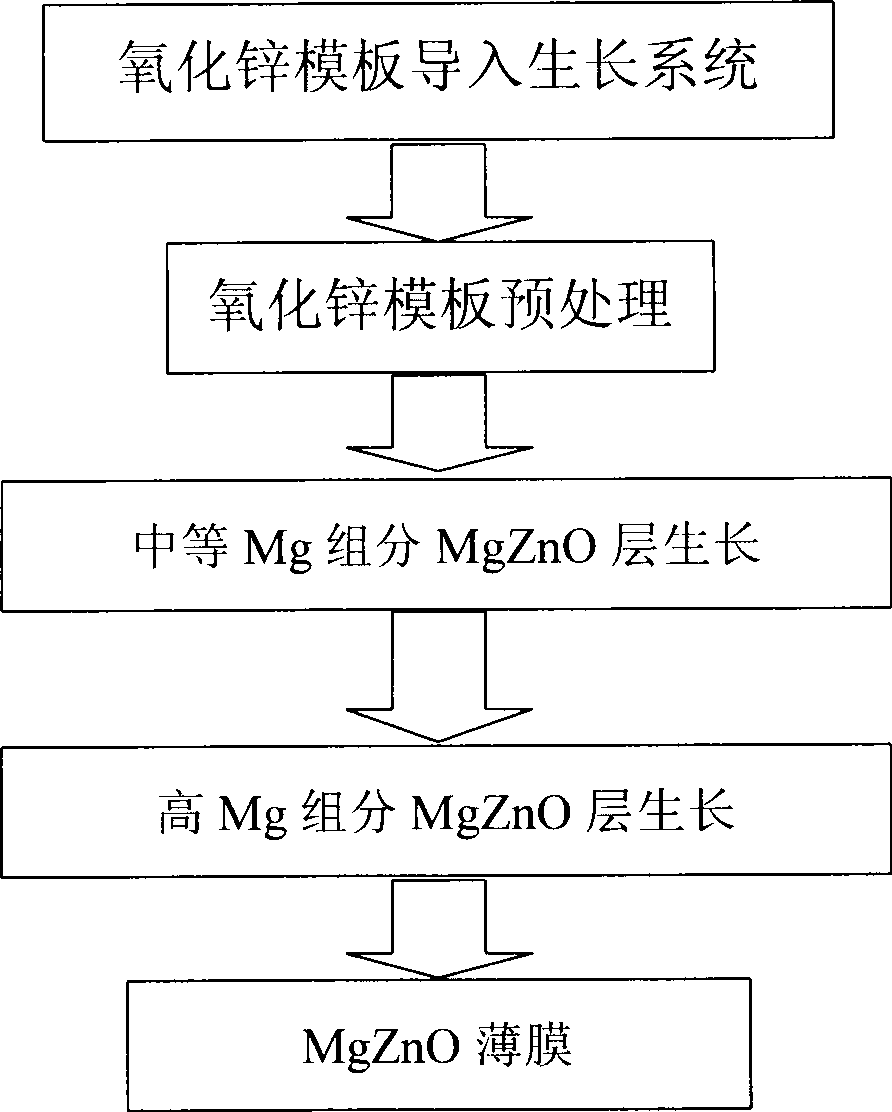

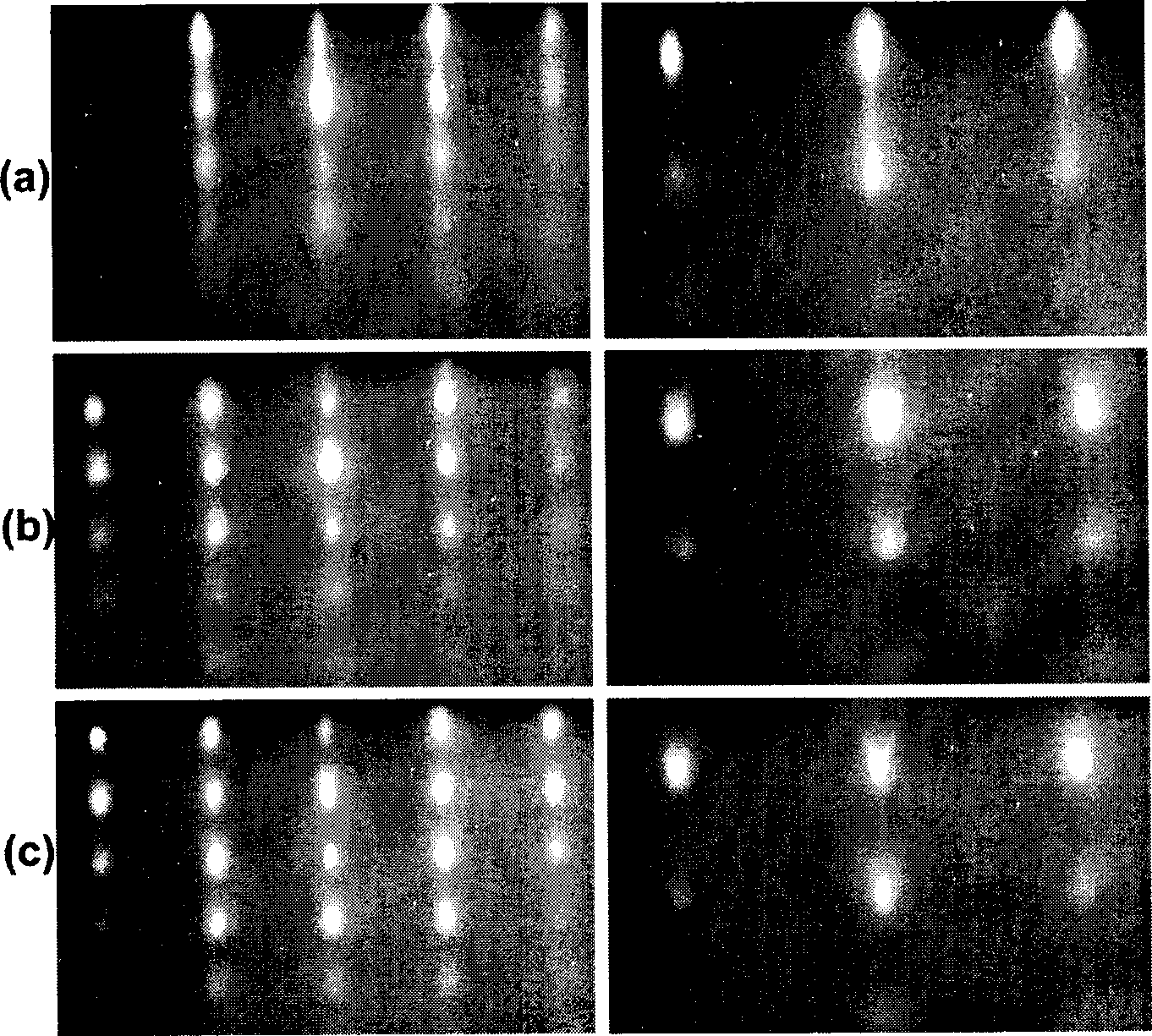

Method for preparing MgZnO single crystal film

ActiveCN101381891APromote growthInhibits the formation of phase separationPolycrystalline material growthFinal product manufactureAlloySingle crystal

The invention discloses a method for preparing an MgZnO single crystal film. In the method, a MgZnO buffer layer with middle Mg component is utilized to effectively alleviate the influence generated due to the lattice distortion brought by the Mg-O bond with strong ionicity, thereby facilitating the following growth of a MgZnO film with high Mg component. By utilizing the method, the invention has the advantages of accurately controlling the Mg component in the MgZnO alloy film, solving the difficult problem of the phase separation easily occured during the growth of the MgZnO alloy film and further obtaining the high-quality alloy film with wide forbidden band and a matching structure; moreover, the preparation method also has excellent repeatability and controllability, and can be applied to the preparation of high-performance MgZnO-based photoelectron and microelectron devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com