Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Stock removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stock removal is the process of removing material (stock) from a workpiece.

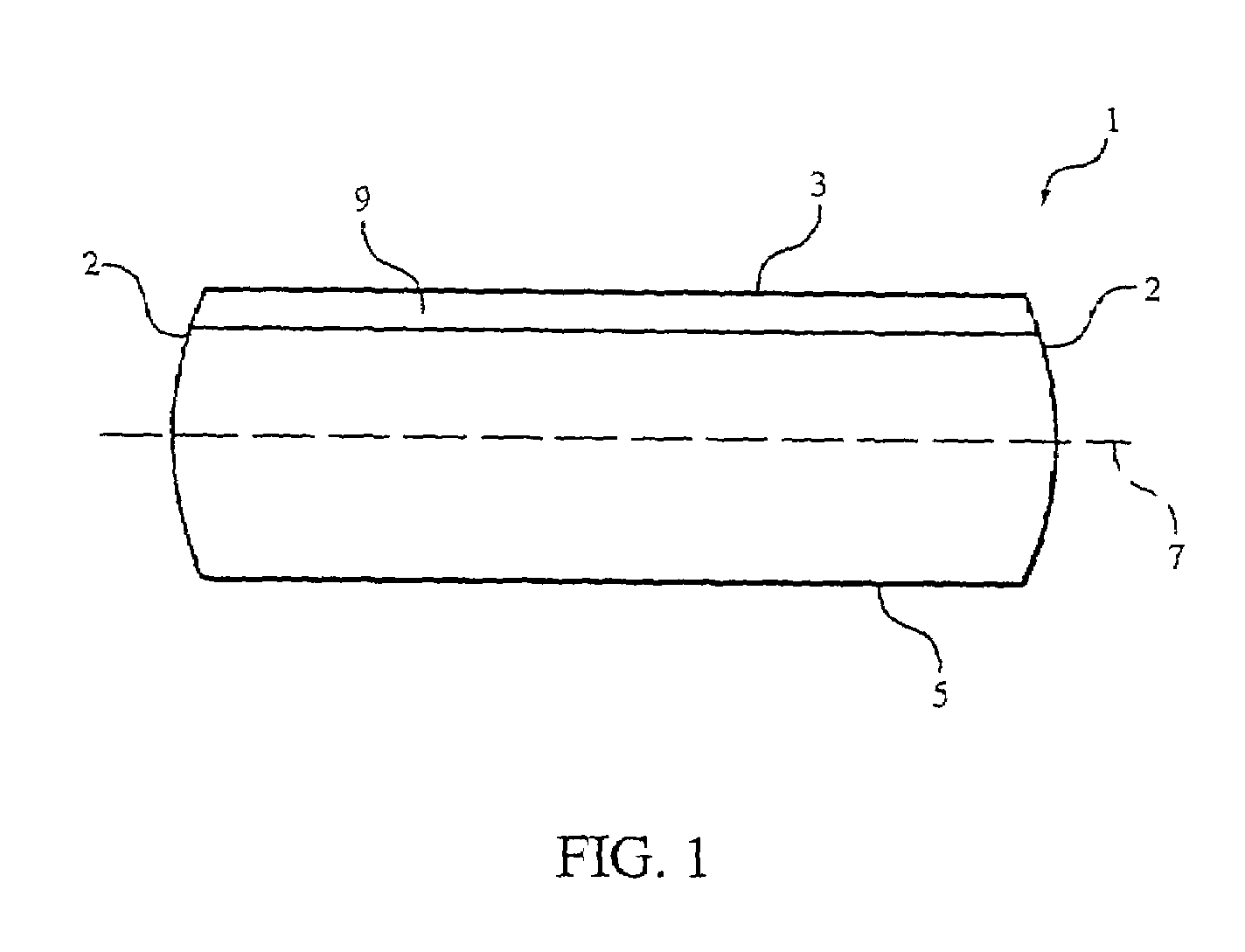

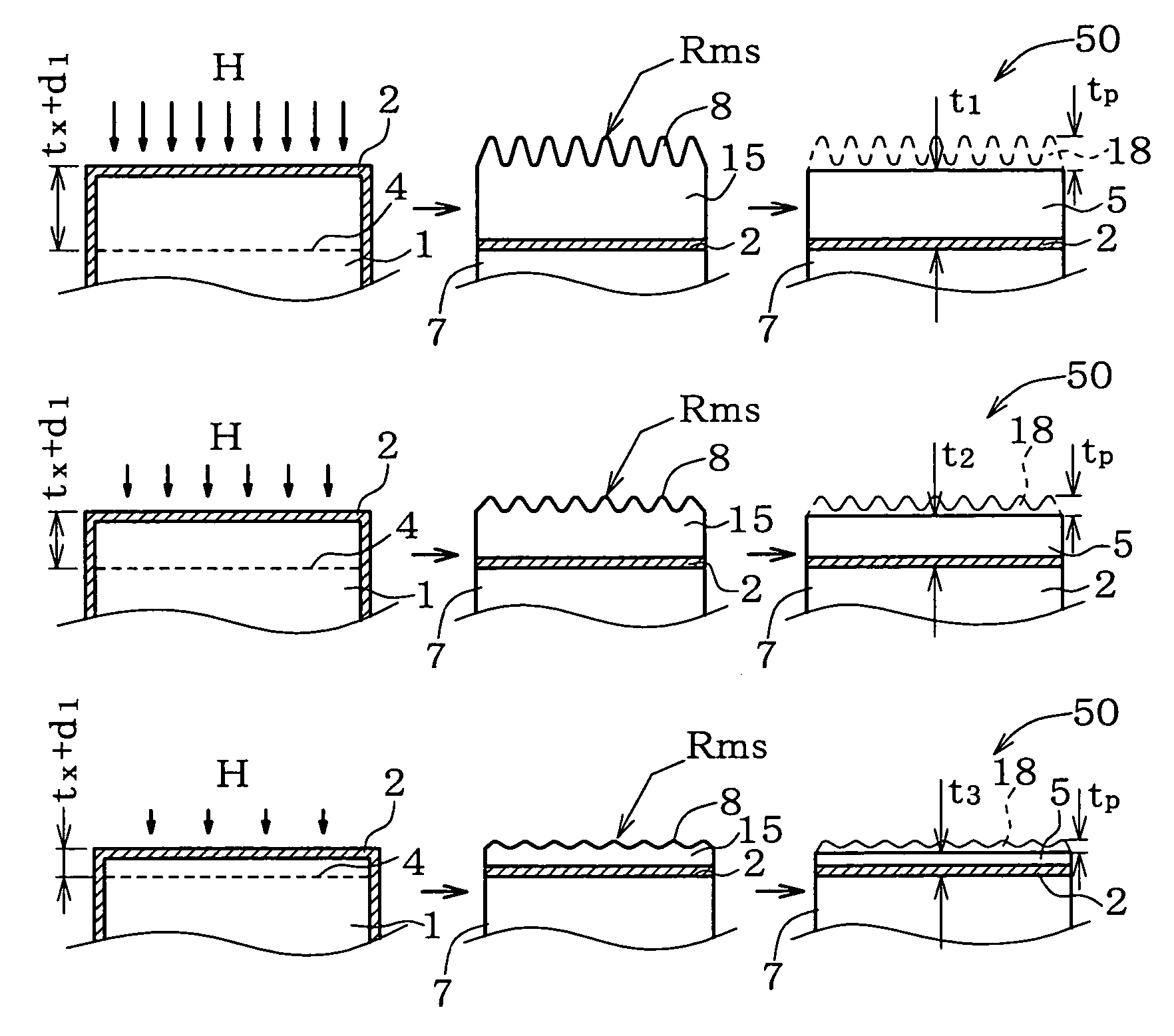

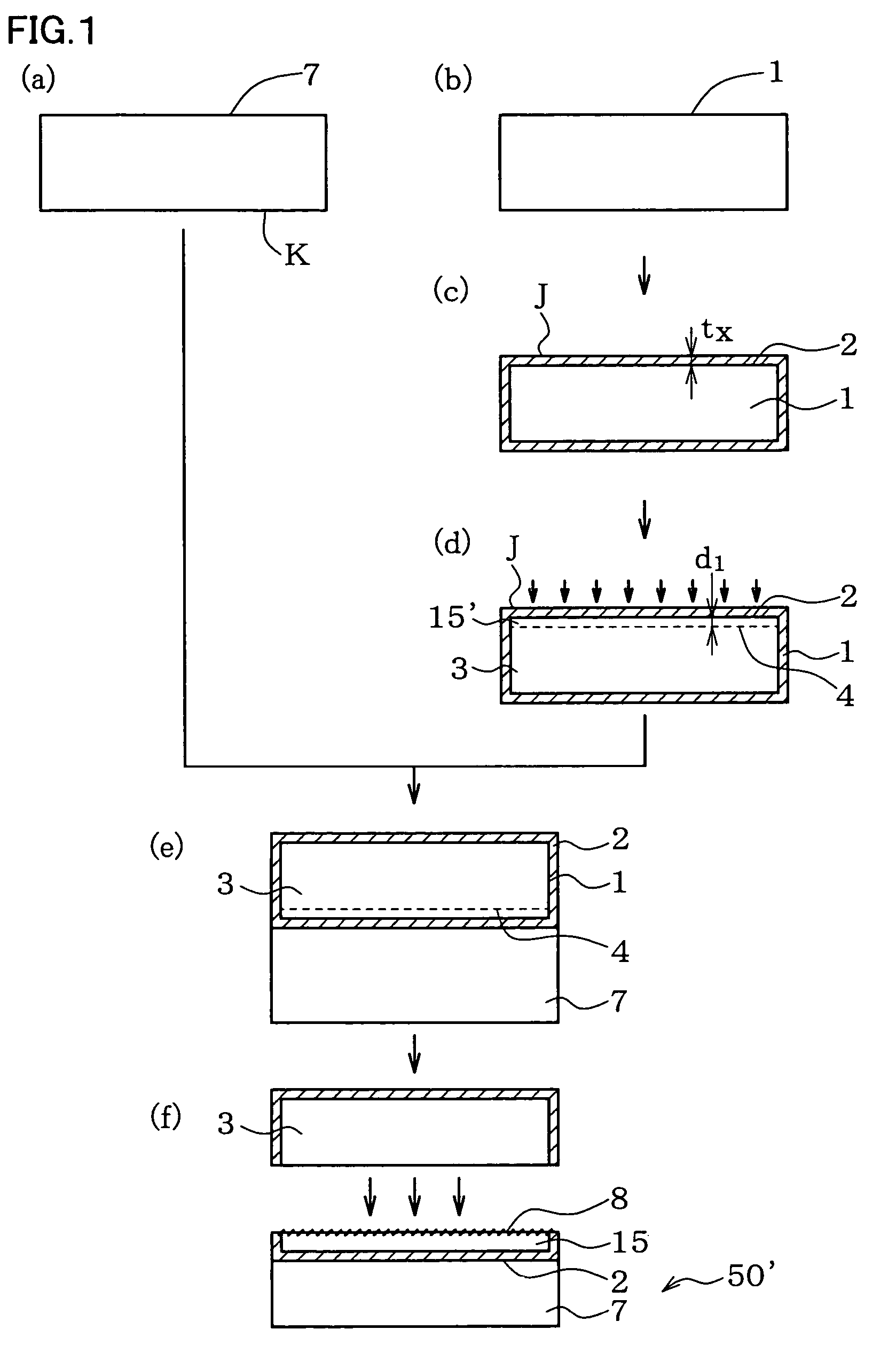

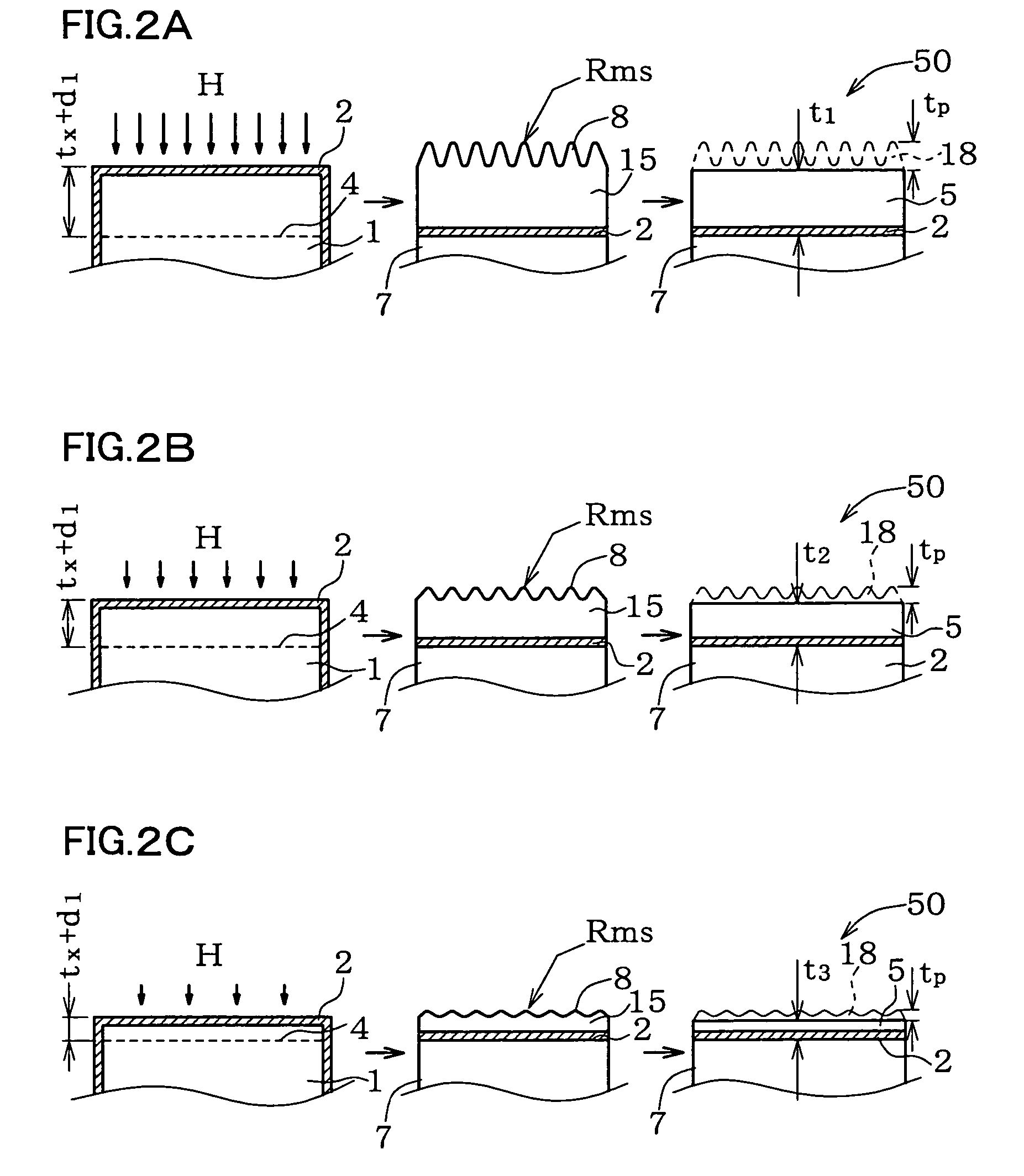

Soi wafer manufacturing method

ActiveUS20060040469A1Reduce roughnessImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface roughness

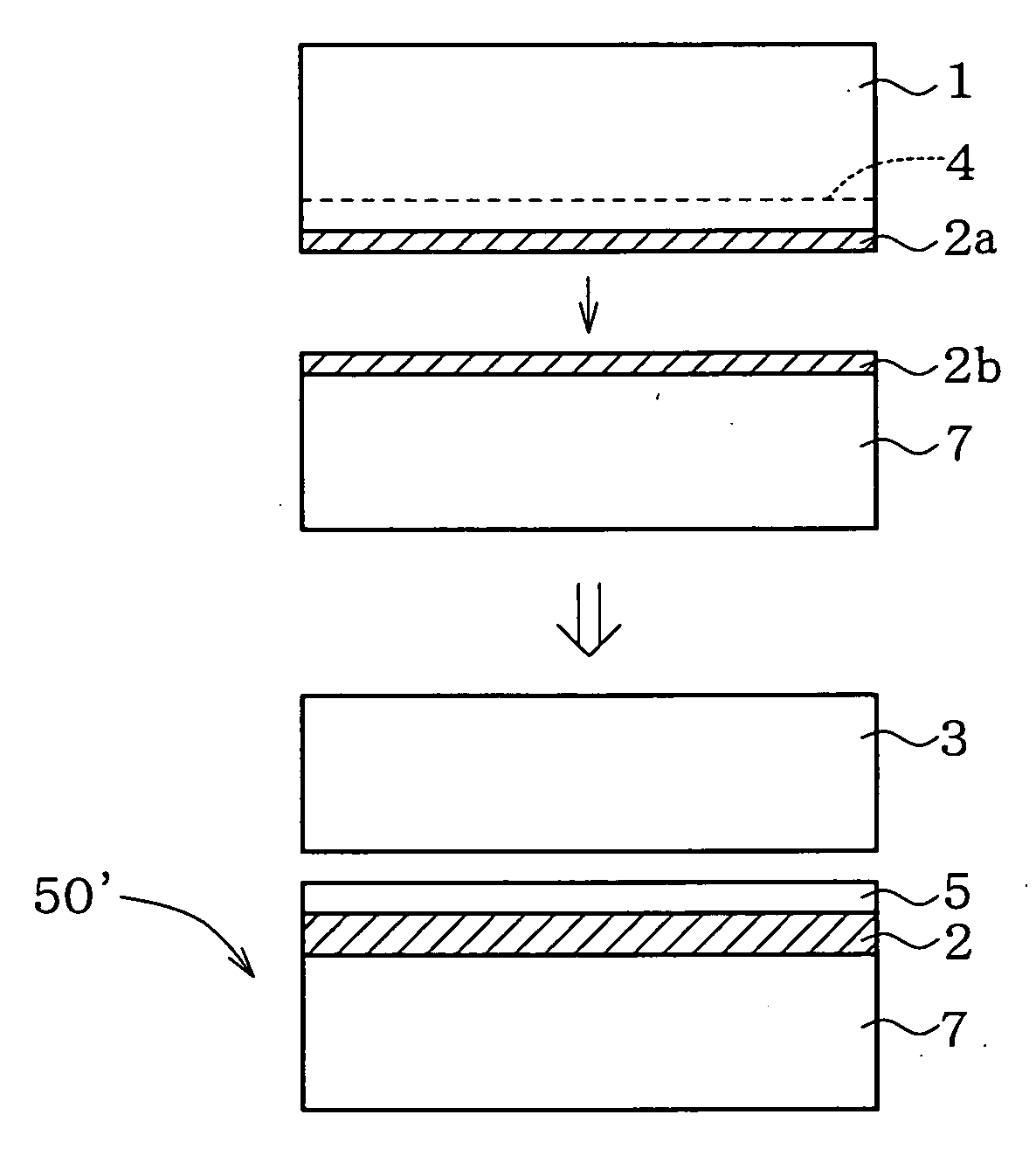

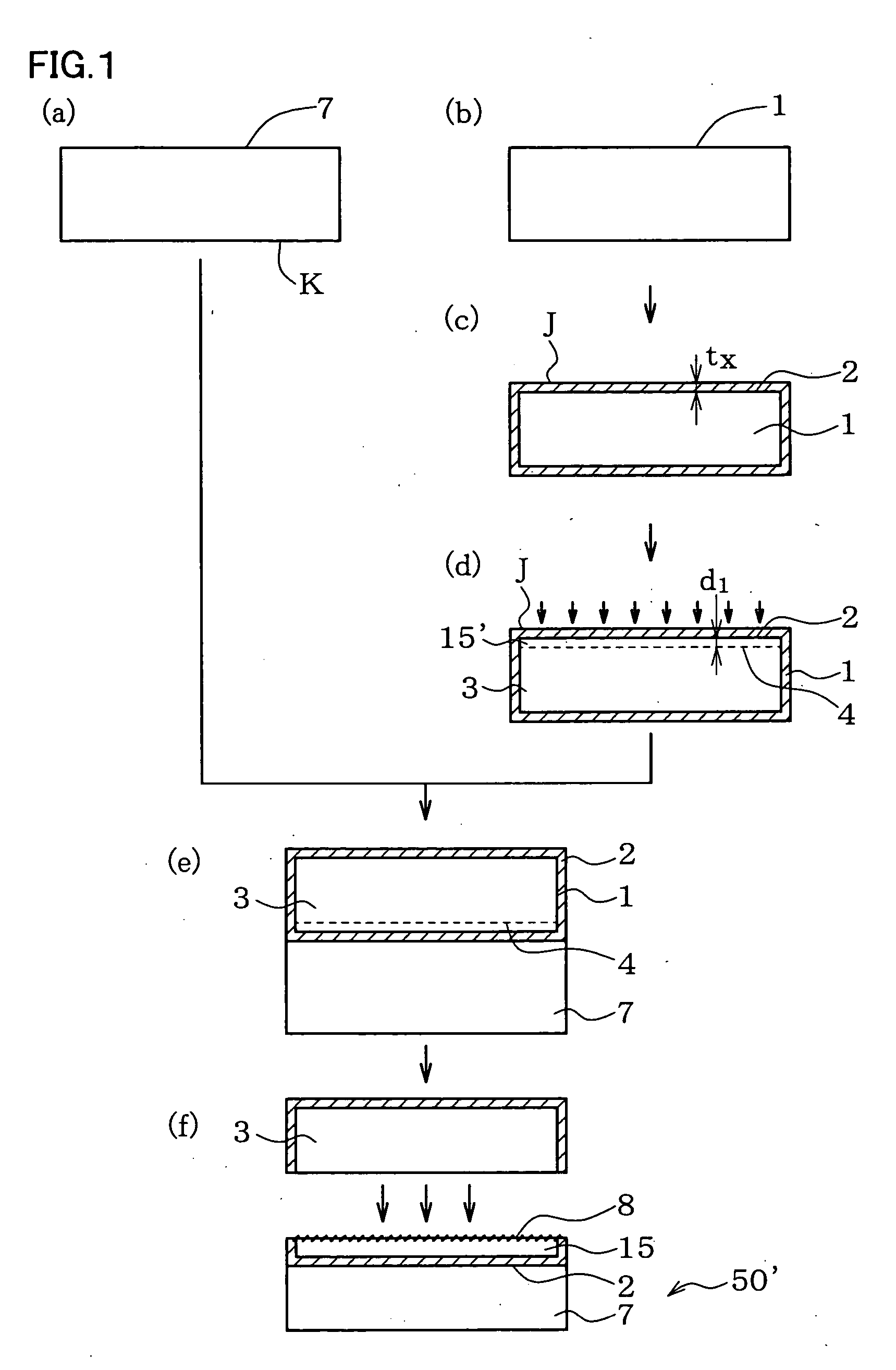

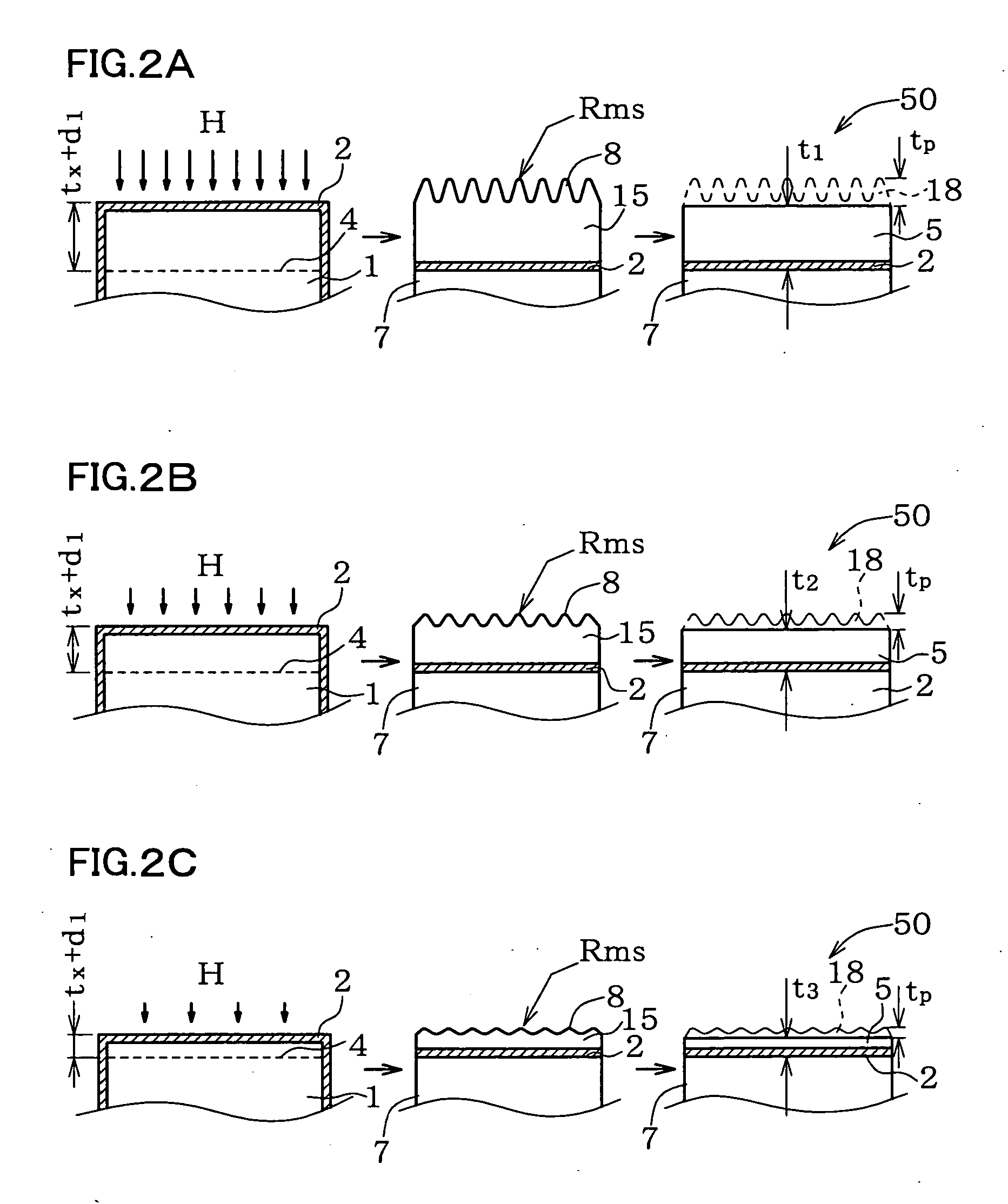

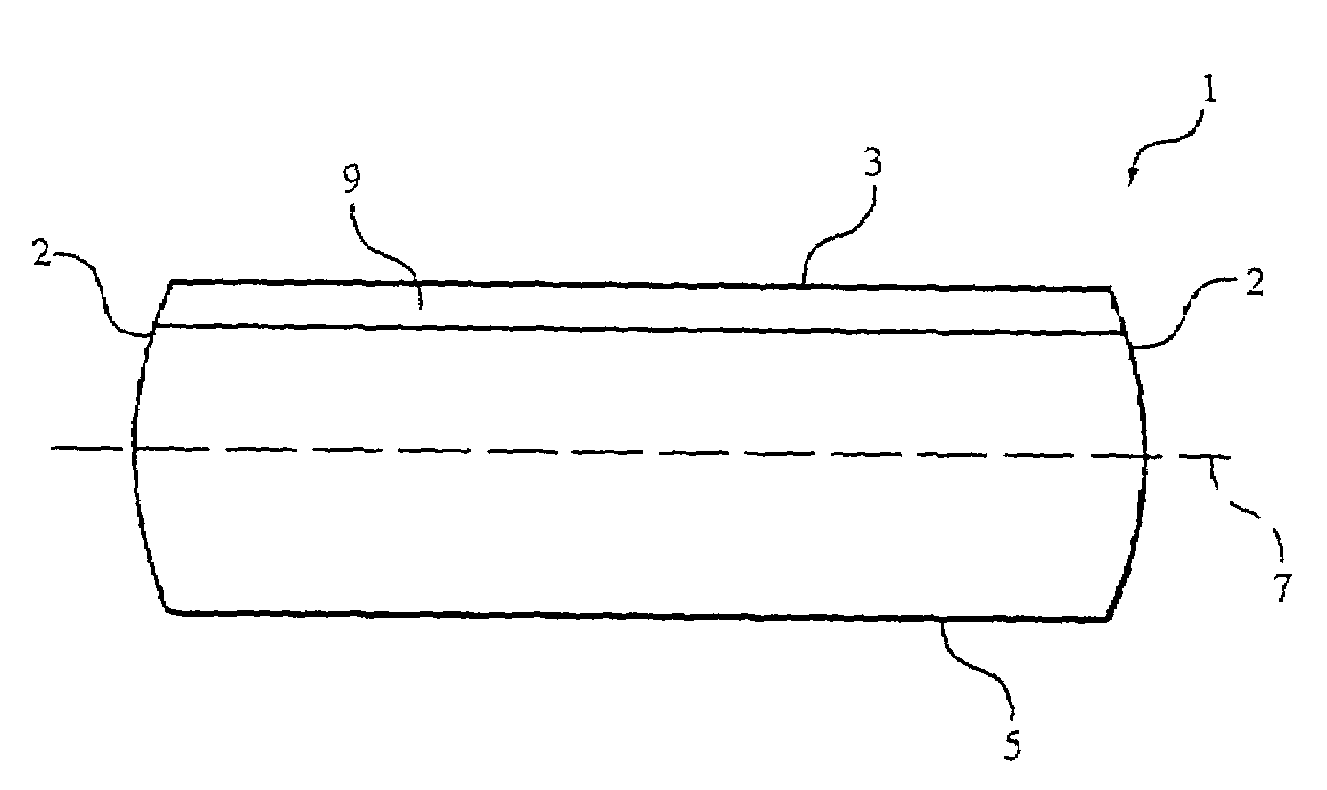

In order to adjust thickness of a bonded silicon single crystal film 15 depending of thickness of an SOI layer 5 to be obtained, depth of formation d1+tx of a separatory ion implanted layer 4, measured from a first main surface J, in the separatory ion implanted layer formation step is adjusted through energy of the ion implantation. Dose of the ion implantation is set smaller as the depth of formation measured from the first main surface J becomes smaller. A smaller dose results in a smaller surface roughness of the separation surface, and makes it possible to reduce polishing stock removal of the separation surface of the bonded silicon single crystal film in the planarization step. Uniformity in the thickness of the SOI layer can consequently be improved even for the case where a thin SOI layer has to be formed. The present invention is therefore successful in providing a method of fabricating an SOI wafer capable of suppressing variations in the intra-wafer and inter-wafer uniformity of the thickness of the SOI layer to a sufficiently low level, even for the case where a required level of the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method for machining stainless steel deep-hole thin-wall part

InactiveCN104625614AGuaranteed accuracy requirementsReduce labor intensityMachining processQuenching

Owner:陈建秋

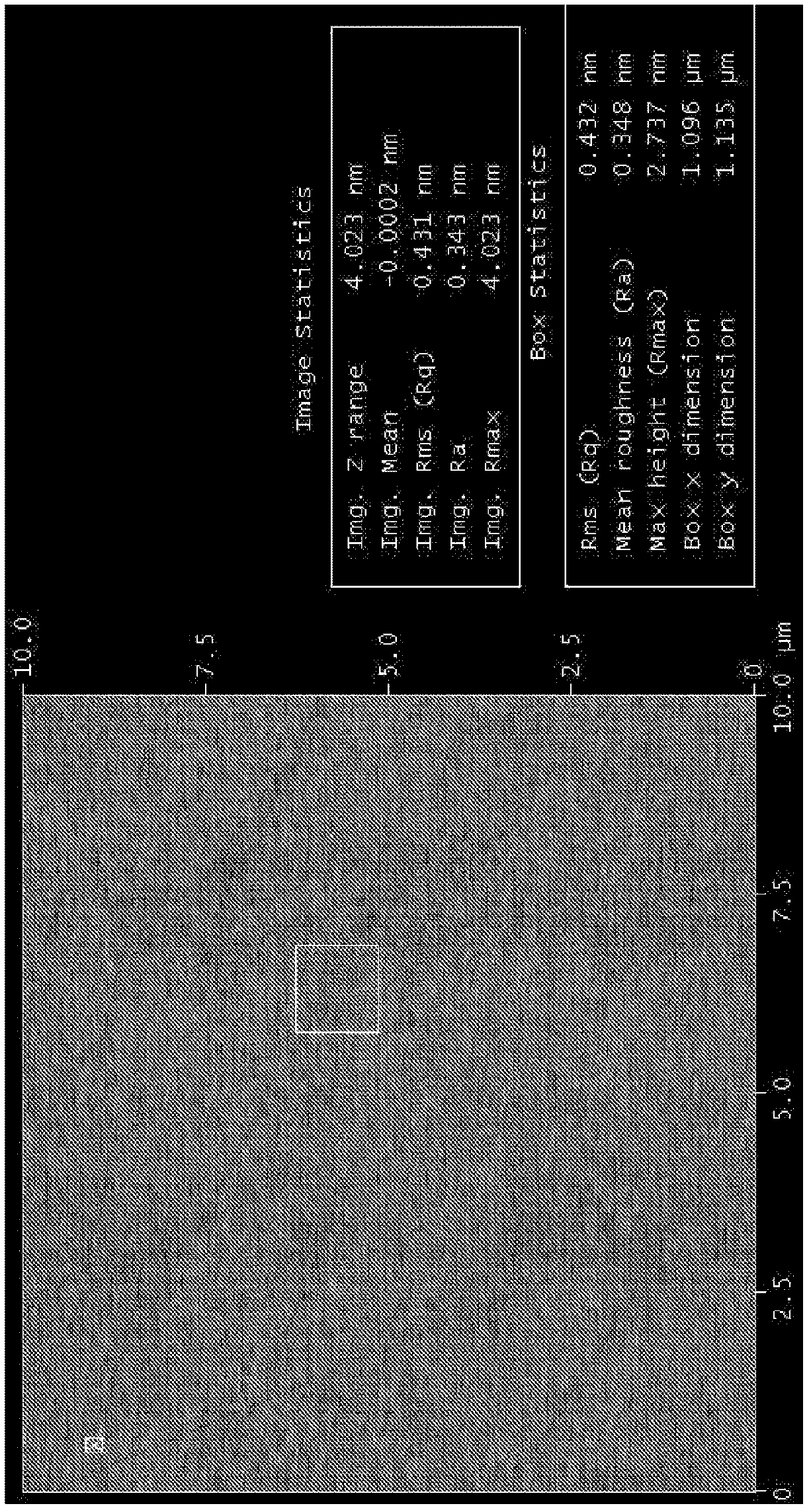

Epitaxially coated semiconductor wafer and process for producing it

InactiveUS6995077B2Reduce the risk of fracturesHigh yieldPolycrystalline material growthAfter-treatment detailsWaferingCelsius Degree

A semiconductor wafer with a front surface and a back surface and an epitaxial layer of semiconducting material deposited on the front surface, wherein the surface of the epitaxial layer has a maximum density of 0.14 localized light scatterers per cm2 with a cross section of greater than or equal to 0.12 μm, and the front surface of the semiconductor wafer, prior to the deposition of the epitaxial layer, has a surface roughness of 0.05 to 0.29 nm RMS, measured by AFM on a 1 μm×1 μm reference area. There is also a process for producing a semiconductor wafer with a front surface and a back surface and an epitaxial layer of semiconducting material deposited on the front surface. The process includes the following: (a) a stock removal polishing step as the only polishing step; (b) cleaning and drying of the semiconductor wafer; (c) pretreatment of the front surface of the semiconductor wafer at a temperature of from 950 to 1250 degrees Celsius in an epitaxy reactor; and (d) deposition of the epitaxial layer on the front surface of the pretreated semiconductor wafer.

Owner:SILTRONIC AG

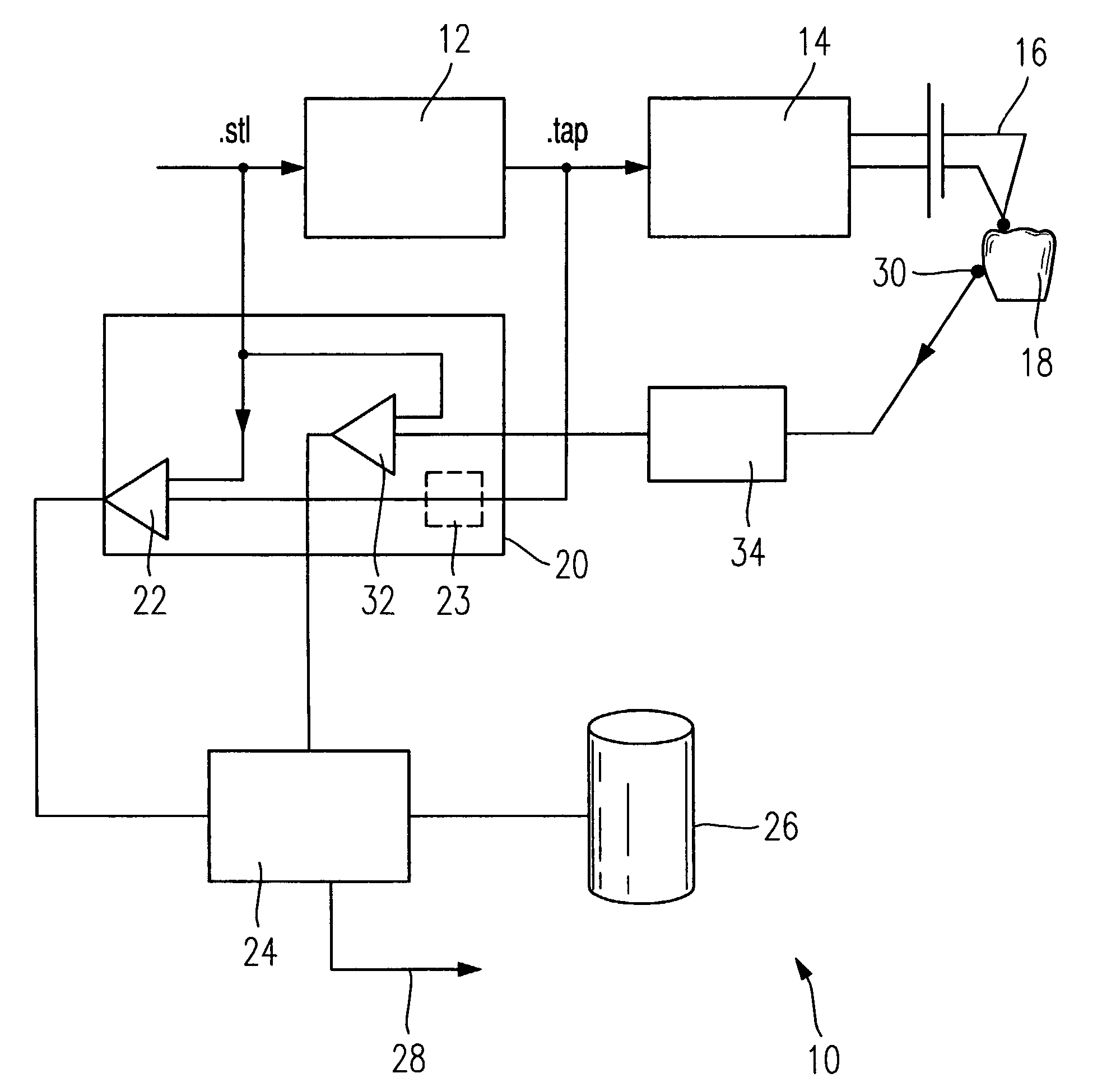

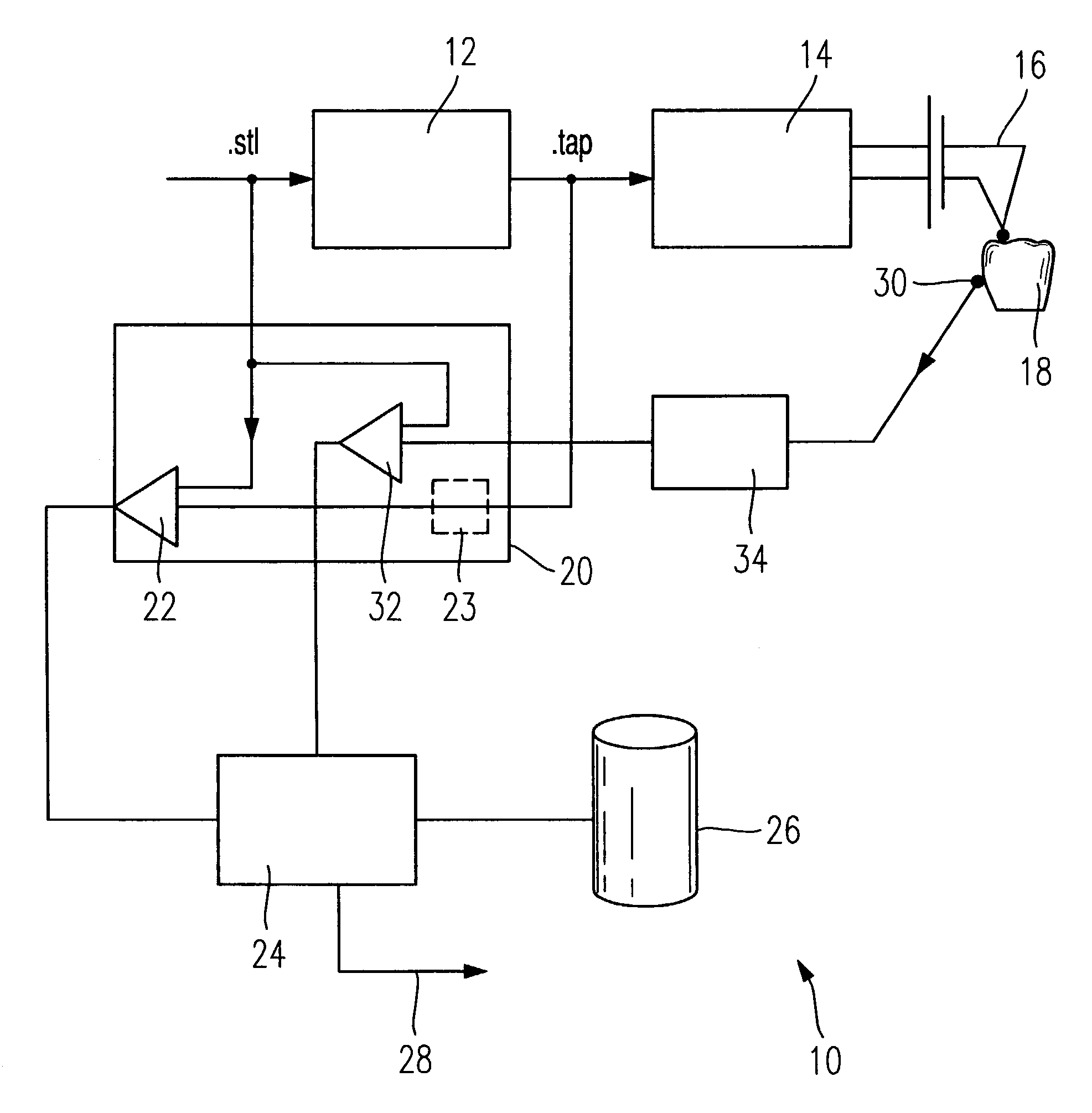

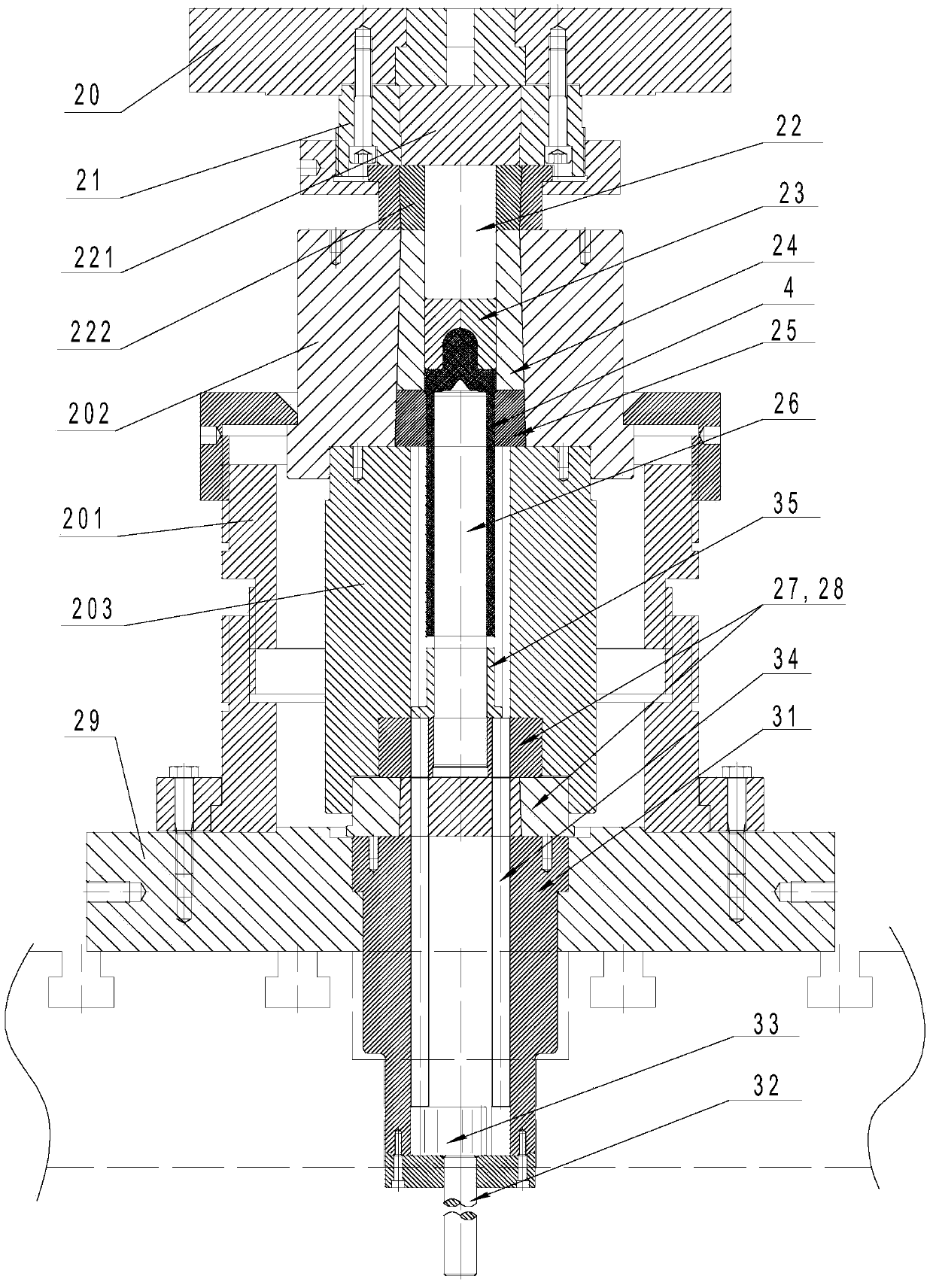

Method and apparatus for producing a dental product

InactiveUS6968247B2High rate of acceptanceHigh rateNuclear monitoringDigital computer detailsControl dataDental Product

A stock removal workshop for the production of a dental restoration product includes a stock removal machine operable to remove stock material from a blank such that there remains a dental product having the desired geometry requisitioned by a dental practice or a dental laboratory. A stock removal plotter controls the stock removal machine operation and converts requisition data received from the dental practice or the dental laboratory which characterizes a virtual model of the requisitioned dental product into control data for controlling the stock removal machine operation. A geometry following assembly characterizes the geometry of the produced dental product via a geometry following operation and a comparison device compares the geometry characterizing data relating to the produced dental product with the requisition data to determine deviations therebetween.

Owner:IVOCLAR VIVADENT AG

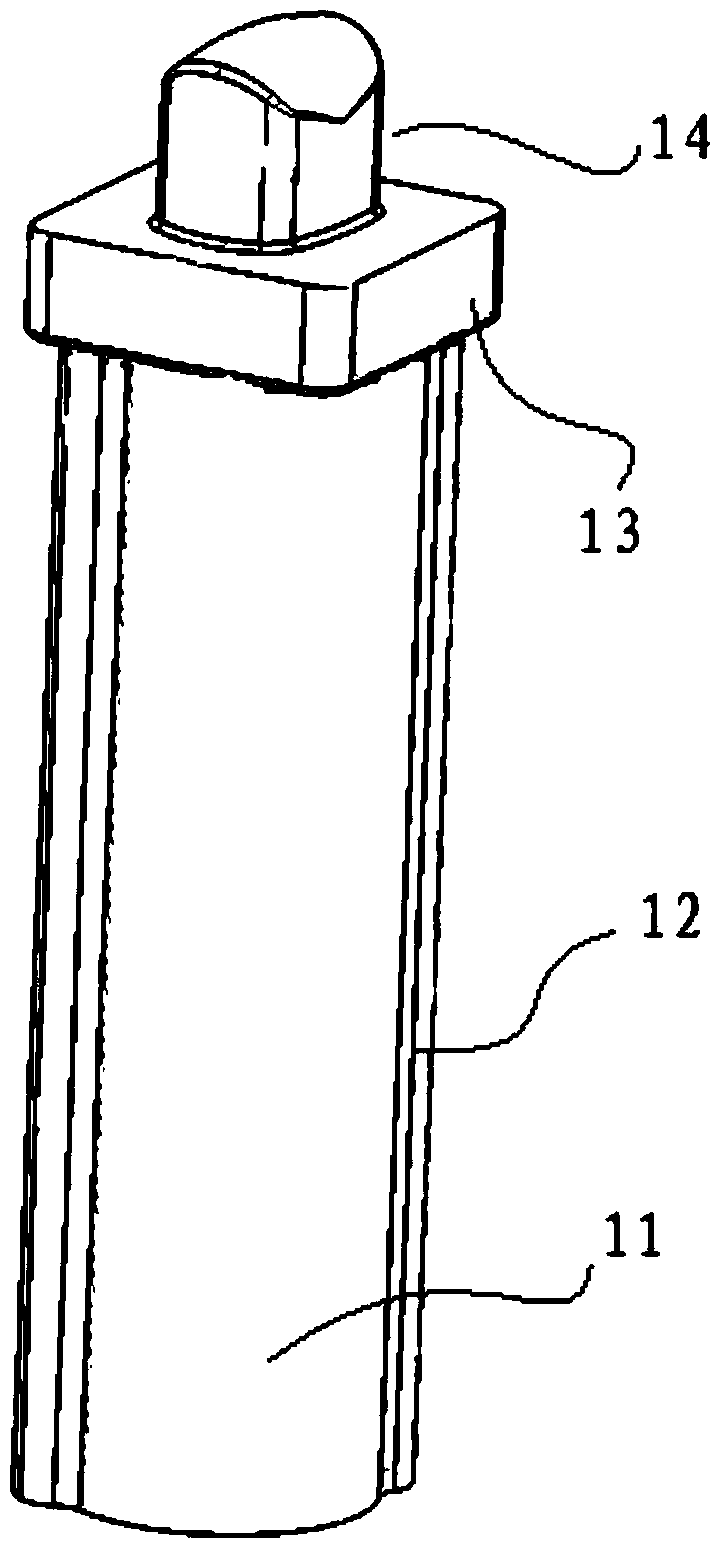

Surface treatment method of piston for quartering hammer

InactiveCN101574769AReduce distortionHigh surface hardnessSolid state diffusion coatingFurnace typesCarbonizationEngineering

The invention discloses a surface treatment method of a piston for a quartering hammer, which comprises the following steps: raw materials are forged and pressed to form a bar stock for the piston and then isothermal annealing is conducted; rough treatment is conducted on a plain lathe and finishing allowance of 2mm is left on a circumferential surface and a scope of attack; the piston is carburized to lead the depth of a carburized layer to be up to 3mm; the circumferential surface of the piston is cut by 1.5mm on a numerically controlled lathe and the scope of attack thereof is cut by 2mm for fine treatment; the piston is quenched and tempered; and the circumferential surface of the piston is grinded, and the like. The surface treatment method of the piston for the quartering hammer firstly utilizes carbonization and then machining, and uses a more removal of the scope of attack to cause the scope of attack to become a low-carbon martensite, thereby enhancing the surface hardness of the scope of attack so as to be capable of improving the shock resistance of the scope of attack. In addition, the method for firstly conducting carbonization and then machining and finally quenching is adopted to reduce the deformation of the piston, thus being capable of greatly reducing the stock removal, and increasing the qualification rate of products.

Owner:天津辰龙重工机械有限公司

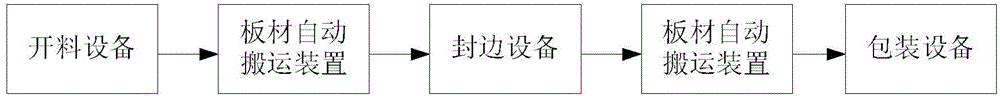

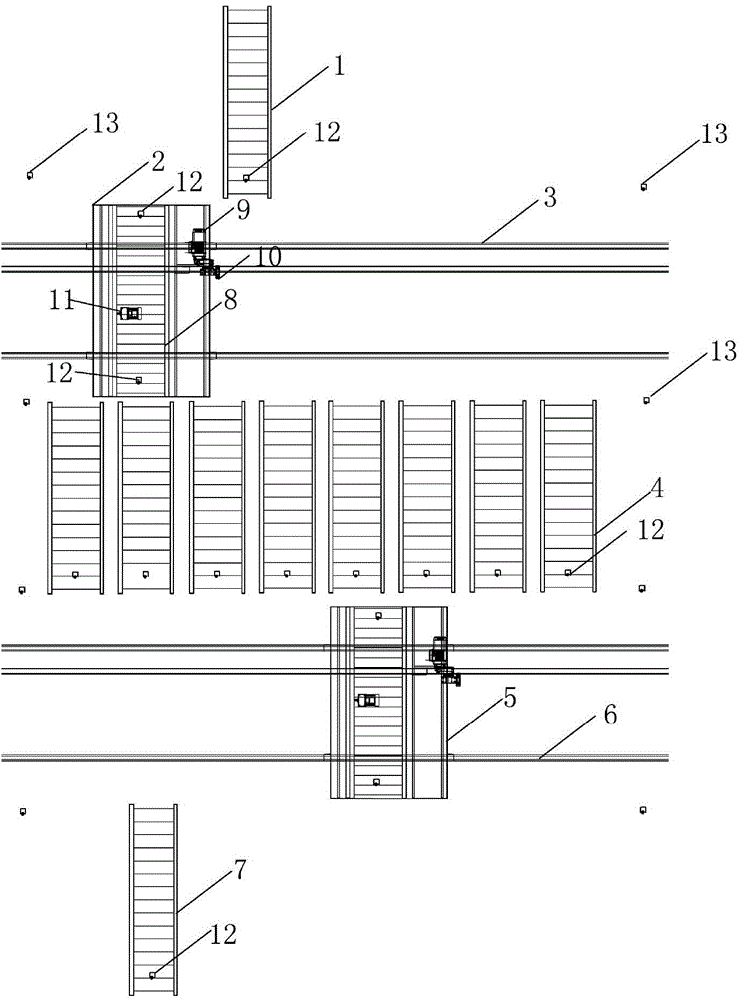

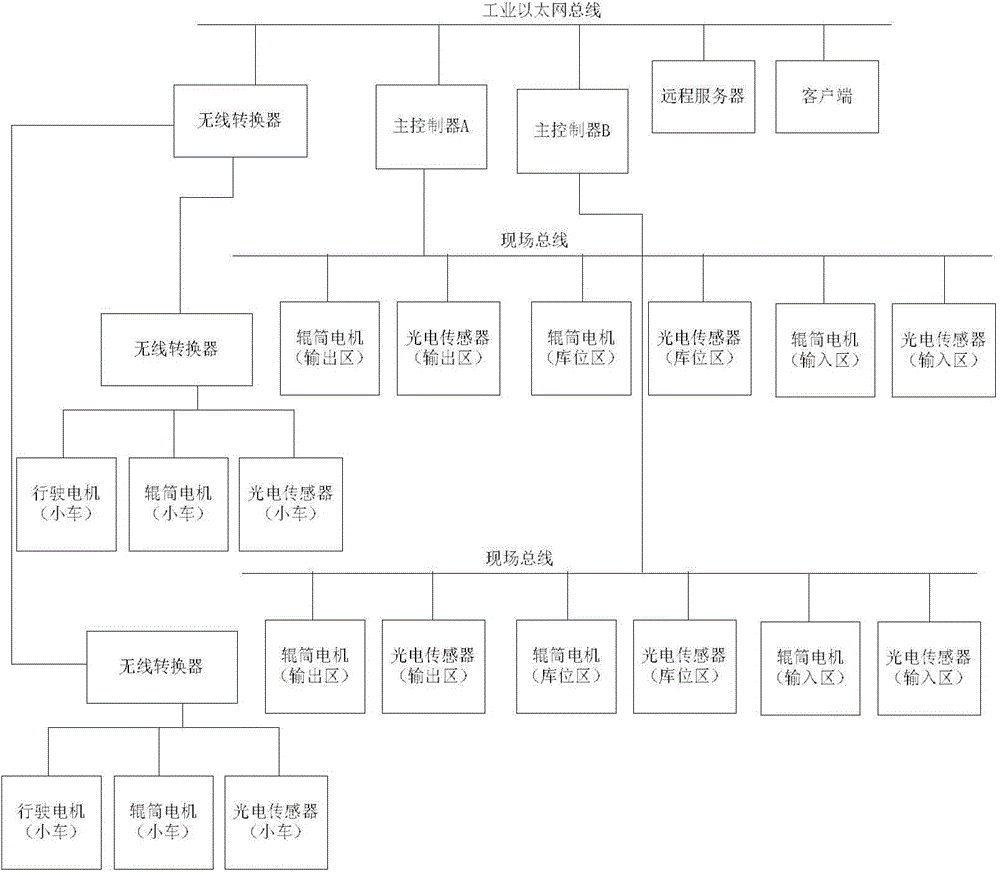

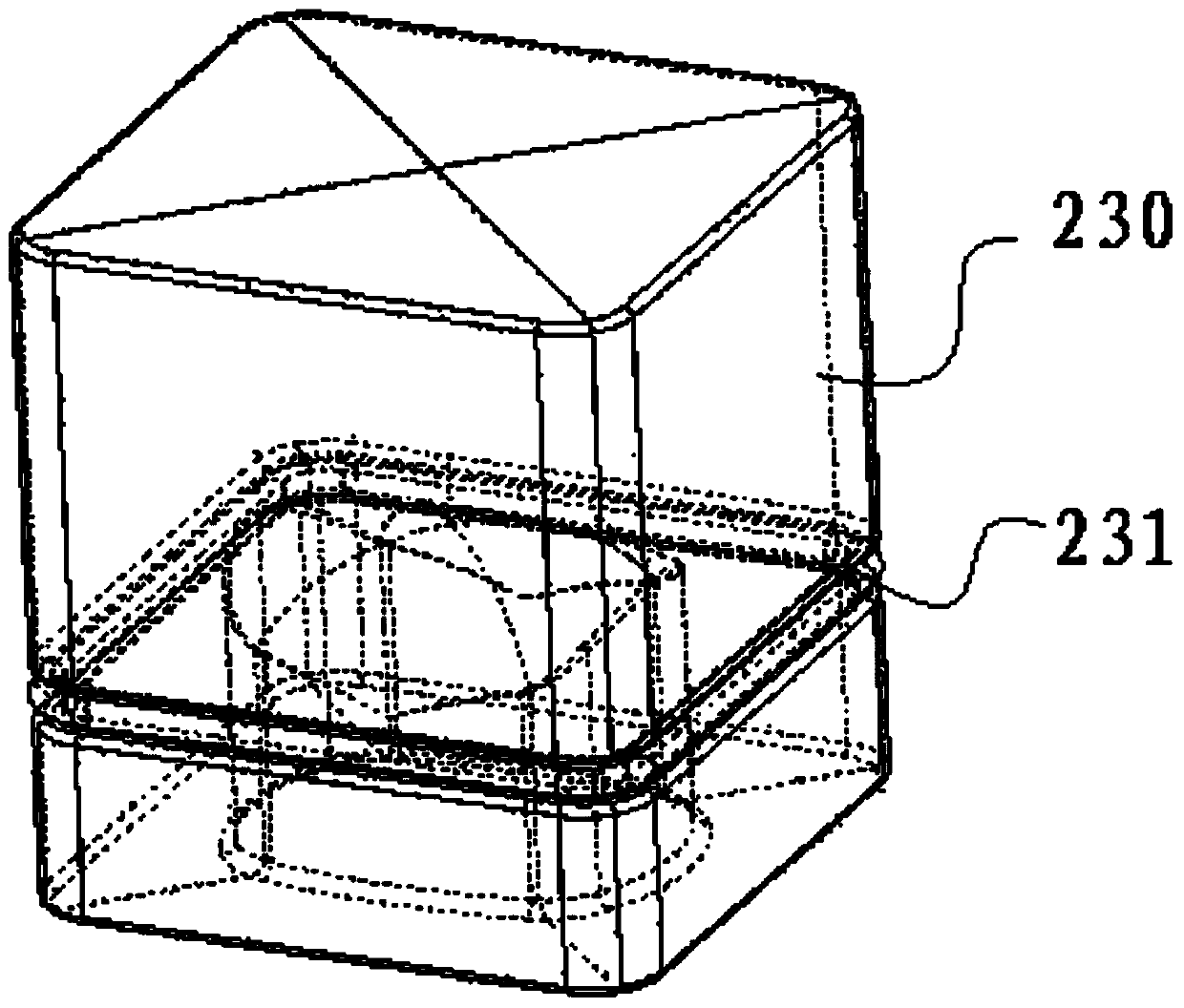

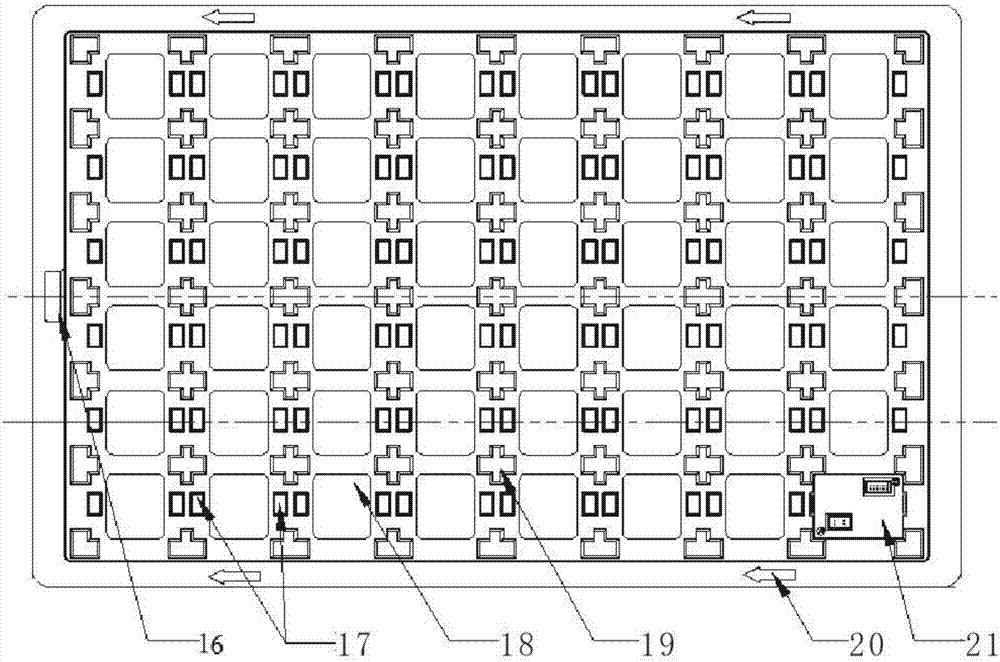

Automatic panel production line

ActiveCN104787569AEasy to expand and upgradeReasonable design layoutControl devices for conveyorsElectricityProduction line

The invention discloses an automatic panel production line. The automatic panel production line comprises a cutting device, an edge sealing device and a packaging device which are arranged in the panel machining direction, an automatic panel carrying device is arranged between each upstream machining device and the corresponding downstream machining device and comprises a panel conveyed-out area, a storage guide rail, a storage location area, a stock removal guide rail and a panel conveyed-in area; roller conveying machines are arranged in the panel conveyed-out areas and the panel conveyed-in areas respectively; a plurality of roller conveying machines are arranged in the storage location areas and are arranged to be in at least one row; two conveying trolleys are arranged on the storage guide rails and the stock removal guide rails respectively and are each provided with a traveling motor, a rotary encoder and a roller conveying machine; each roller conveying machine is provided with a drum motor, and a photoelectric sensor used for panel in-place detection is arranged at the output end of each roller conveying machine. The device further comprises a master controller which is electrically connected with drum motors, the photoelectric sensors, the traveling motors and the rotary encoders. The automatic panel production line is reasonable in design; the automatic panel carrying devices are introduced, so that the manpower is released, and the yield and the production safety performance are improved.

Owner:NANJING OLO HOUSEHOLD CO LTD

Method of fabricating SOI wafer

InactiveUS7320929B2Reduce roughnessImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

In order to adjust thickness of a bonded silicon single crystal film 15 depending of thickness of an SOI layer 5 to be obtained, depth of formation d1+tx of a separatory ion implanted layer 4, measured from a first main surface J, in the separatory ion implanted layer formation step is adjusted through energy of the ion implantation. Dose of the ion implantation is set smaller as the depth of formation measured from the first main surface J becomes smaller. A smaller dose results in a smaller surface roughness of the separation surface, and makes it possible to reduce polishing stock removal of the separation surface of the bonded silicon single crystal film in the planarization step. Uniformity in the thickness of the SOI layer can consequently be improved even for the case where a thin SOI layer has to be formed. The present invention is therefore successful in providing a method of fabricating an SOI wafer capable of suppressing variations in the intra-wafer and inter-wafer uniformity of the thickness of the SOI layer to a sufficiently low level, even for the case where a required level of the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

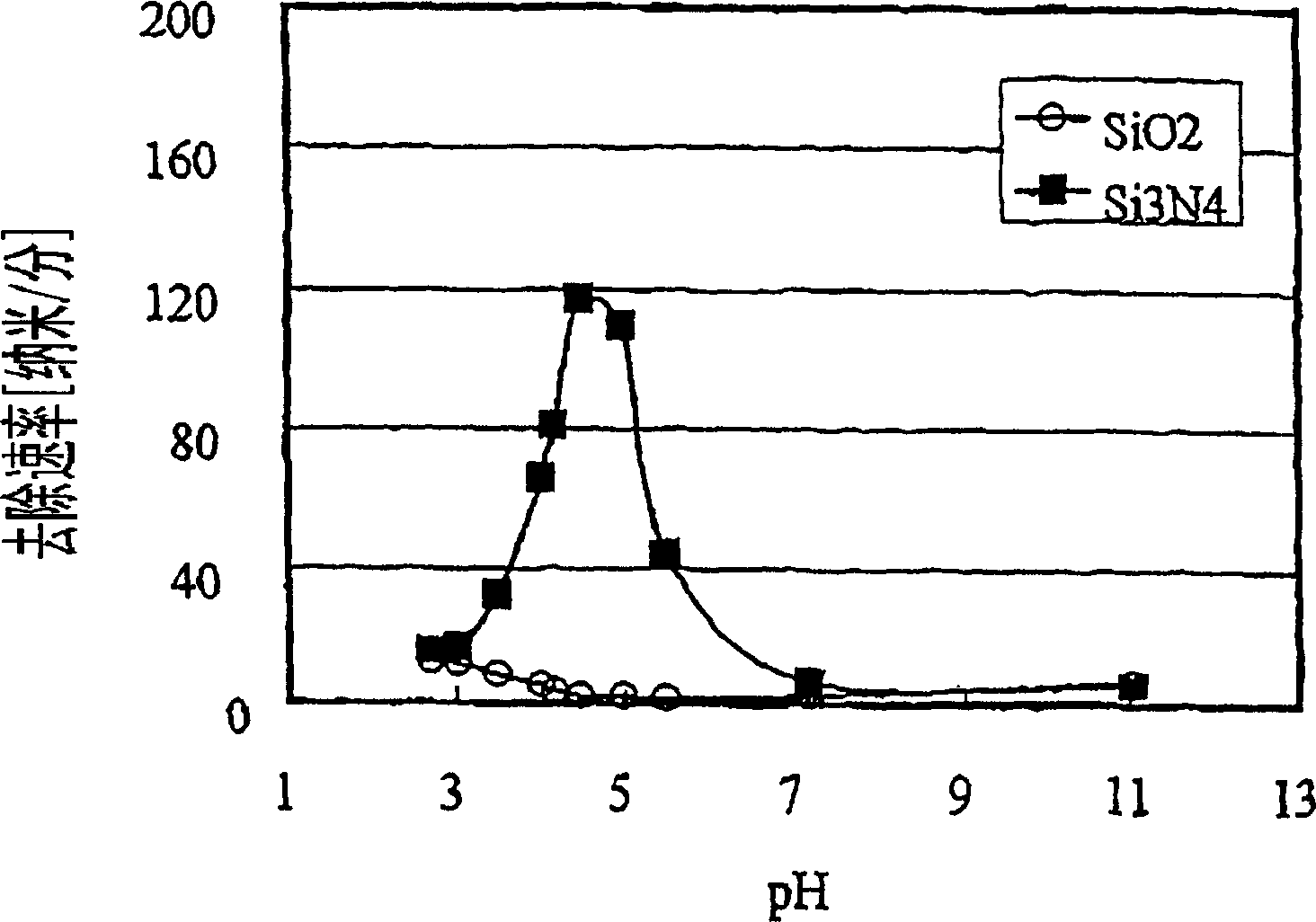

Composition for selectively polishing silicon nitride layer and polishing method employing it

ActiveCN1796482AAdequate removal rateEasy to handlePigmenting treatmentOther chemical processesMetallurgySilicon oxide

Provided is a polishing composition, the material removal rate of the silicon nitride layer is higher than the material removal rate of the silicon oxide layer, has basically no adverse effect on polishing planarization, can achieve a sufficient removal rate of the silicon nitride layer, and also provides A polishing method using the composition. A polishing composition comprising silicon oxide abrasive particles, an acid additive and water. When the acid additive forms an 85% by weight aqueous solution, the chemical etching rate of the silicon nitride layer is at most 0.1 nm / hour in an atmosphere of 80°C. . A particularly preferred composition is one in which the average particle size of the silicon oxide abrasive particles is 1-50 nanometers and the pH value is 3.5-6.5.

Owner:FUJIMI INCORPORATED

Diamond abrasive material particles and production method therefor

InactiveUS20040033188A1Efficient stock removalLow worked surface roughnessOther chemical processesUltra-high pressure processesUltra high pressureDiamond-like carbon

One of the principal objectives is to provide a loose mass of single crystalline minute diamond particles for abrasive uses, which is prepared from a coarser crystalline product of a common static ultra high-pressure process. The novel particle abrasive can achieve improvement in both machining efficiency (stock removal per time) and worked surface roughness. An effective method for its production is also provided. The diamond particles of the invention, which have a D50 average size of over 5 mum but not exceeding 40 mum, have an explicit effect of a heat treament on either crystal structure or collective properties. The particles are further deposited on the surface with non-diamond carbon, amounting 0.5% or more by weight in relation to the diamond as a whole. Such diamond particles can be effectively obtained by heating diamond particles having said D50 particle size, in a non-oxidizing environment at a treatment temperature of 600° C., in order to convert the surface of diamond particle to non-diamond carbon.

Owner:2 KANAGAWA

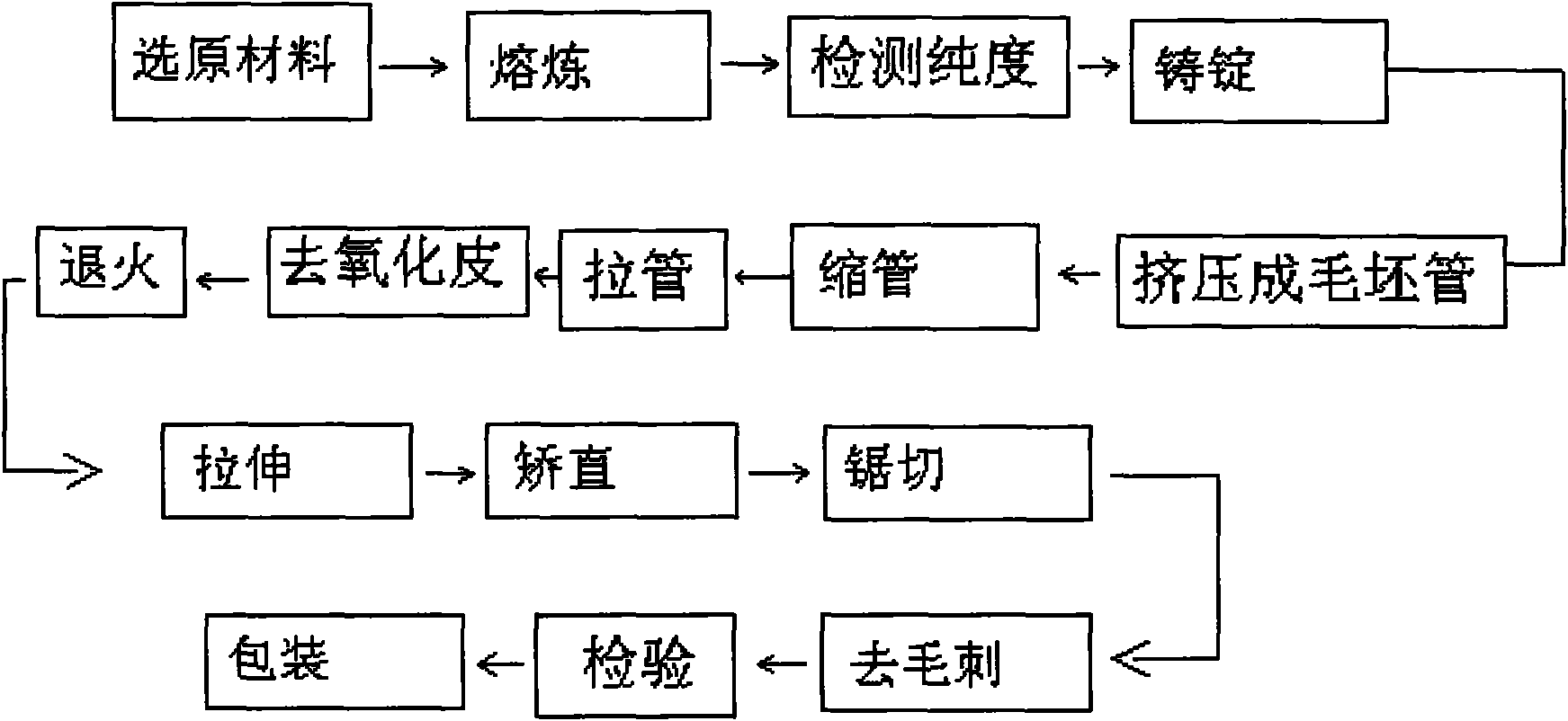

Method for manufacturing bronze pipe

InactiveCN101633011AEasy Shelling SqueezeMake sure you meet the requirementsColor/spectral properties measurementsFrequency conversionIngot

The invention discloses a method for manufacturing a bronze pipe, specifically comprising the following steps: selecting and melting raw materials; casting copper water into copper ingots; decladding the copper ingots and squeezing the copper ingots into various blank pipes; reducing one end of the blank pipe, removing oxide skins of the surface of the blank pipe; annealing the copper pipe to be softened; stretching the pipe materials to reach the requirement of customers through a frequency conversion stretcher; correcting the stretched copper pipe to the best straightness by a straightener; sawing the copper pipe into various lengths by a saw bit; removing burrs at two ends of the copper pipe; and testing to obtain finished goods. The method of manufacturing the bronze pipe provided by the invention has strong maneuverability, high efficiency, rational process design and high quality of the obtained bronze pipe.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

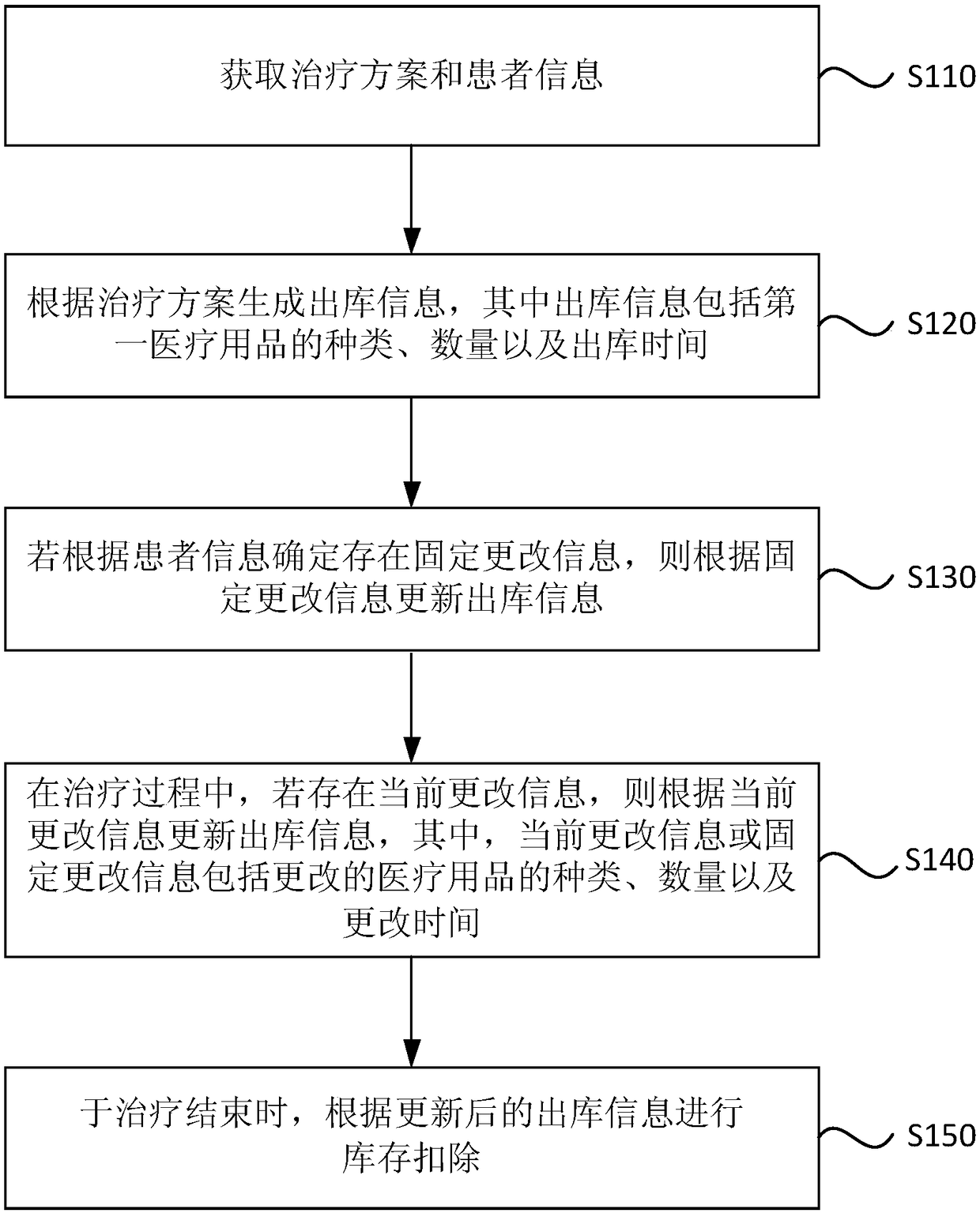

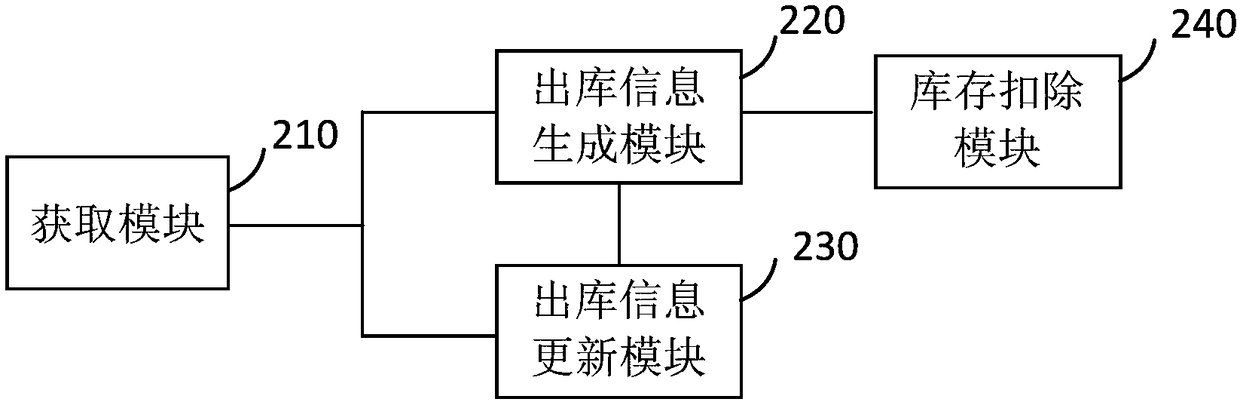

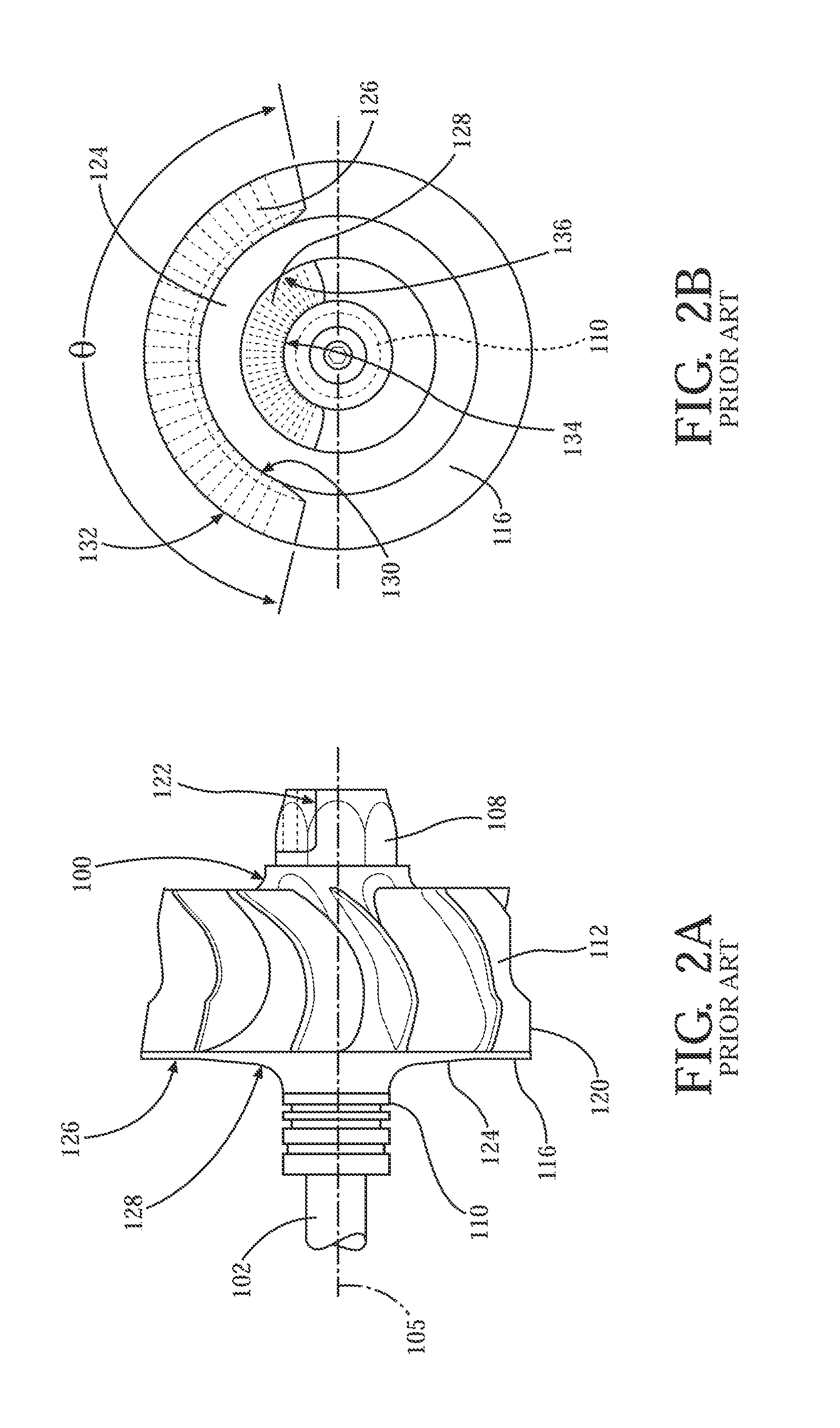

Stock removal method and device for medical supplies, terminal and computer readable medium

ActiveCN108133747ASolve real-timeResolve accuracyHealthcare resources and facilitiesLogisticsComputer terminalInventory management

An embodiment of the invention discloses a stock removal method and device for medical supplies, a terminal and a computer readable medium. The method includes acquiring a treatment scheme and patientinformation; generating stock removal information according to the treatment scheme; updating stock removal information according to fixed change information if the presence of fixed change information is determined according to the patient information; updating stock removal information according to current change information in the presence of current change information in a treatment process;performing stock removal according to the updated stock removal information when the treatment is completed. According to the invention, the stock removal information and the fixed change informationare generated through acquiring the treatment scheme and the patient information and the stock removal information is updated according to the fixed change information and the current change information, so that a problem that incapability of real time recording and low accuracy in stock removal of the medical can be effectively solved. Therefore, resource waste is avoided and stock control of themedical supplies is facilitated.

Owner:SUZHOU MEHDI HOUSTTON MEDICALSYST TECH

Power battery self-discharge detecting and grading process

PendingCN109188288AQuick and efficient selectionSave binning processAssembling battery machinesFinal product manufacturePower batteryEngineering

The invention relates to a power battery self-discharge detecting and grading process. The process comprises the following steps of: carrying out capacity grading on formed batteries and recording discharge capacities as C1; carrying out high-temperature aging on the capacity graded batteries at a temperature of 40-80 DEG C for 3-7 days; carrying out capacity keeping rate test on the high-temperature aged batteries, recording the discharge capacities as C2, calculating ratios K of C2 to C1, selecting batteries with relative large self-discharge through the K and grading the other batteries, wherein the batteries, the K of which is smaller than or equal to R, are batteries with large self-discharge, namely, unqualified batteries, and the batteries, the K of which is between R and 100, are divided into N grades according to the K; and carrying out stock removal on the graded batteries according to the grades. According to the process, batteries with relatively large self-discharge can berapidly and effectively selected, and the batteries are divided into different grades during the detection, so that the grading process of module grouping sections is saved.

Owner:江西安驰新能源科技有限公司

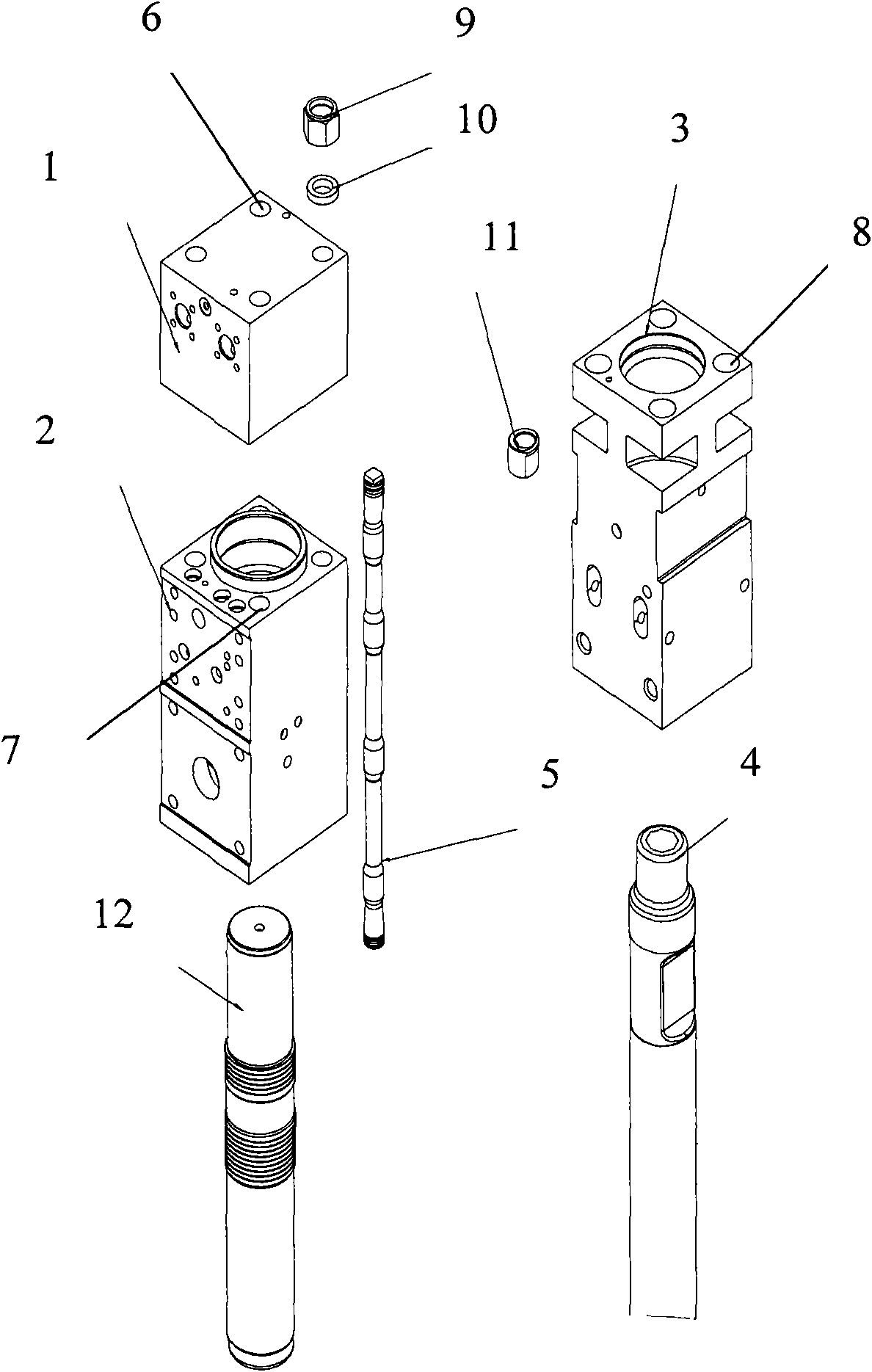

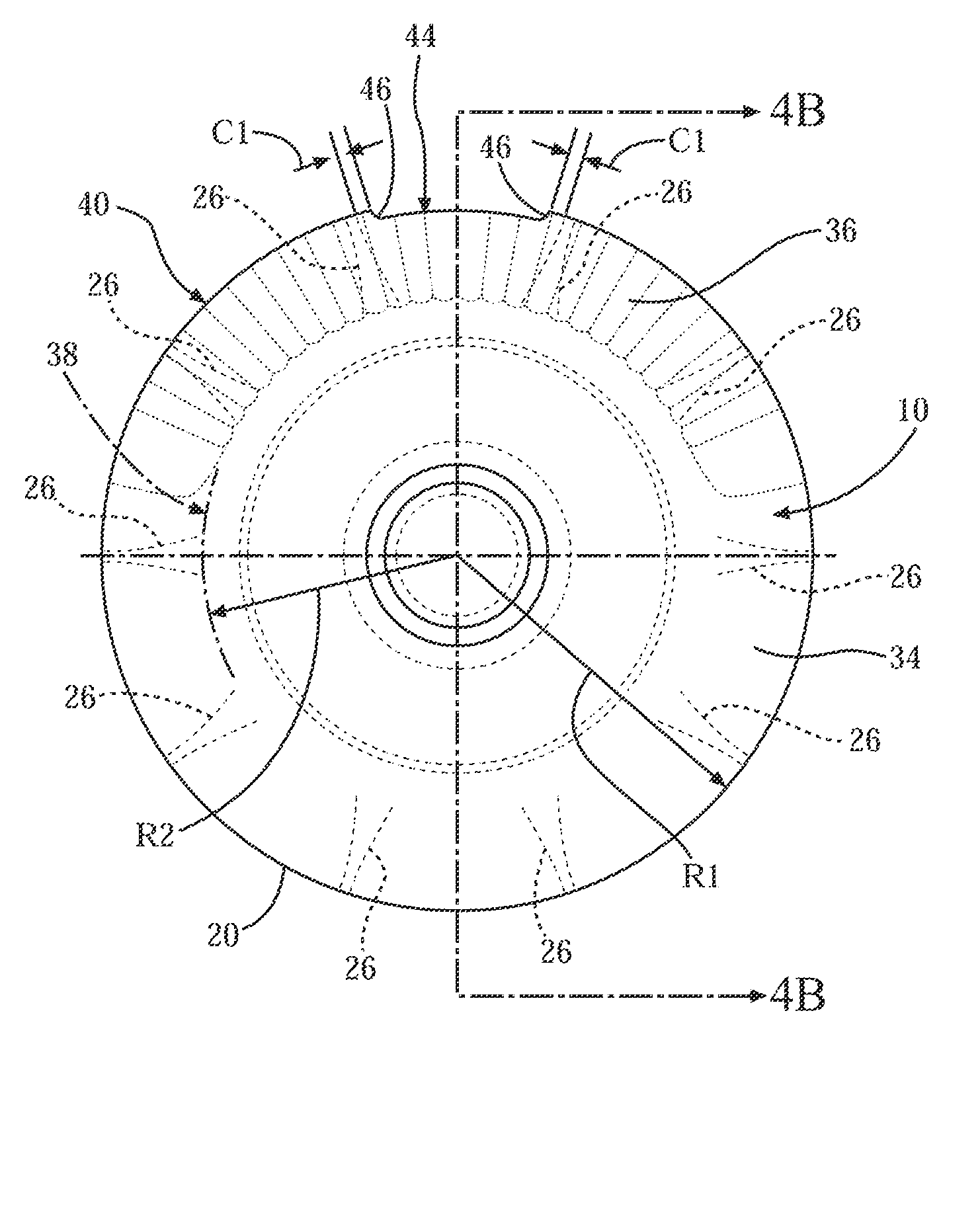

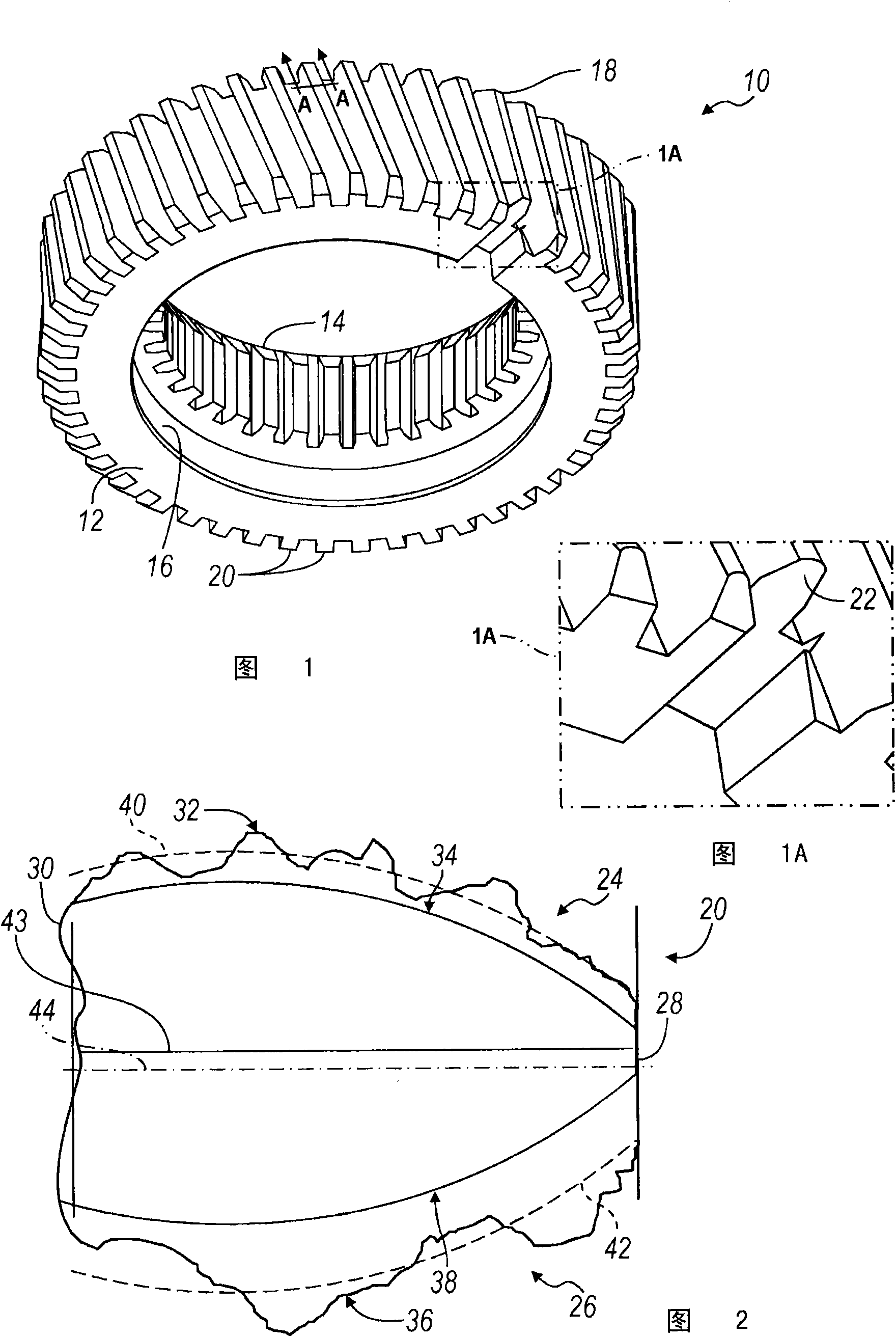

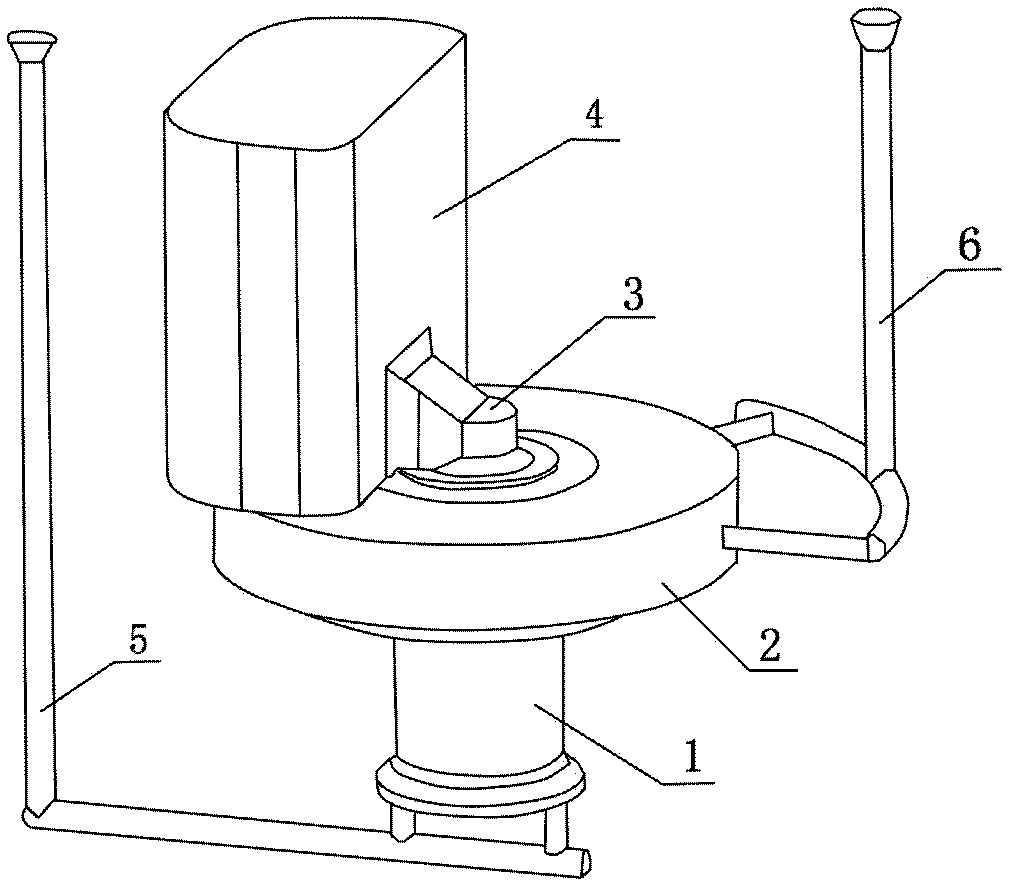

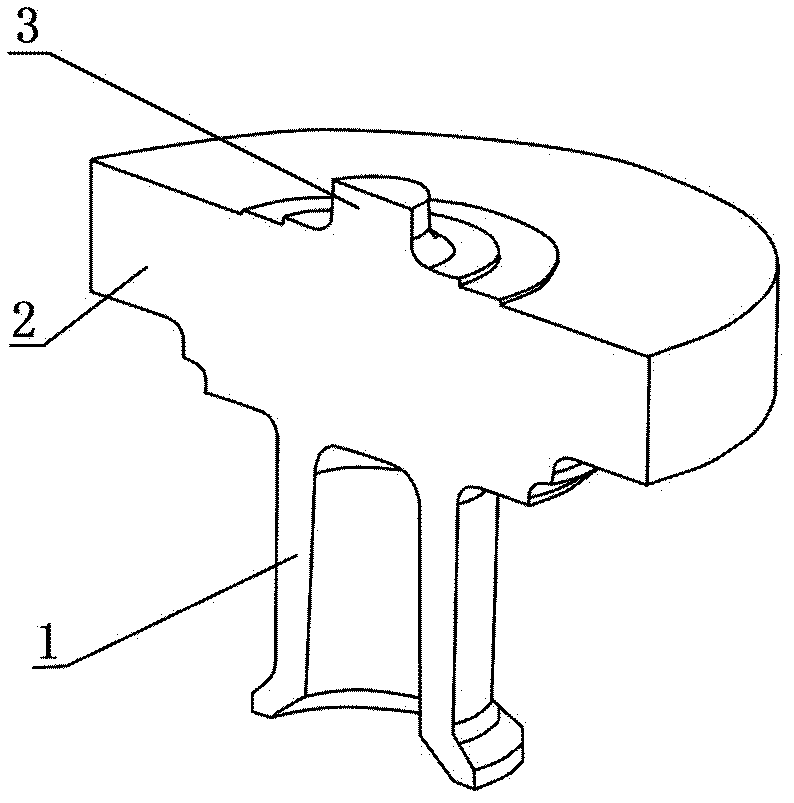

Method for turbine wheel balance stock removal

A turbine wheel (10) for a turbocharger includes a hub (12) extending in an axial direction between a nose (14) and a back-wall (22). The hub (12) defines an axis of rotation (28) extending in the axial direction and the back-wall (22) includes a peripheral edge (20). A plurality of turbine blades (26) is coupled to the hub (12) and is disposed in a circumferential direction generally at equal intervals around the axis of rotation (28). At least one scallop (44, 48) is formed in the peripheral edge (20) of the back-wall (22) for balancing the turbine wheel (10). The at least one scallop (44, 48) is positioned along the peripheral edge (20) such that the peripheral edge (20) is not symmetrical in the circumferential direction about the axis of rotation (28).

Owner:BORGWARNER INC

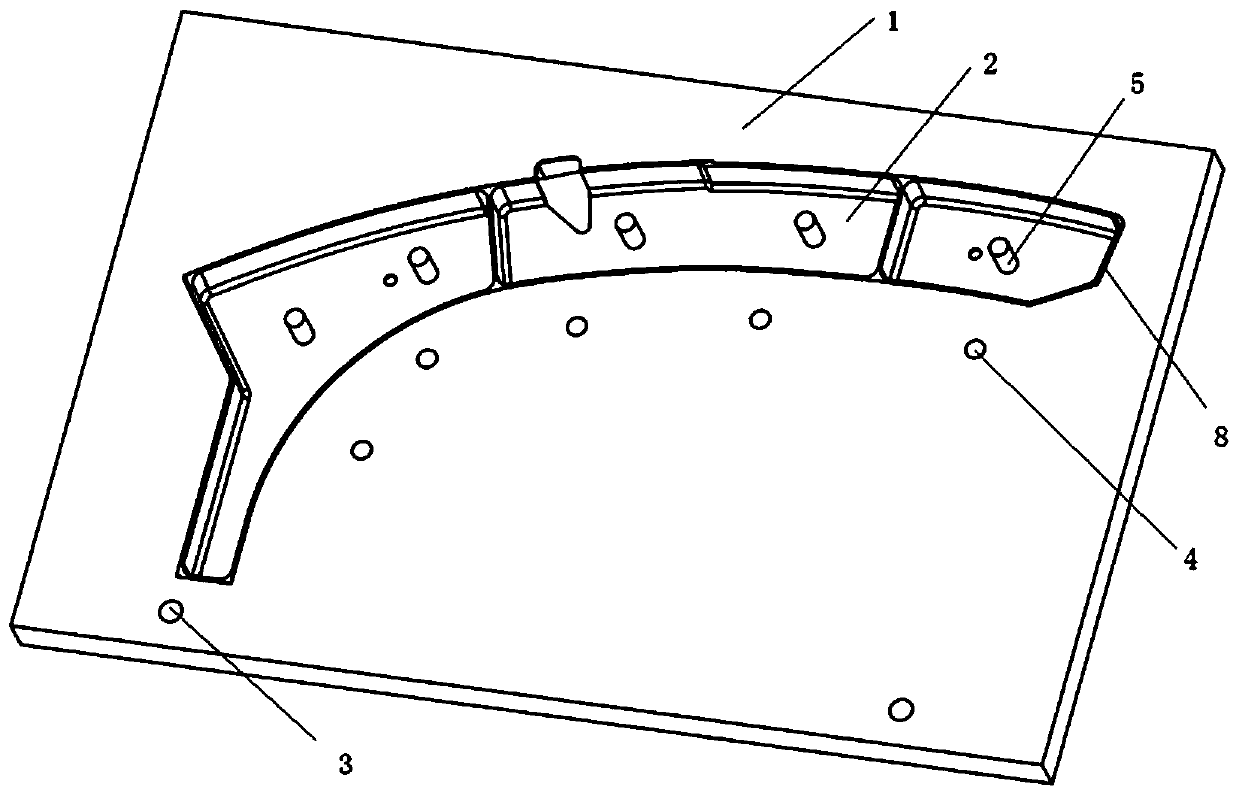

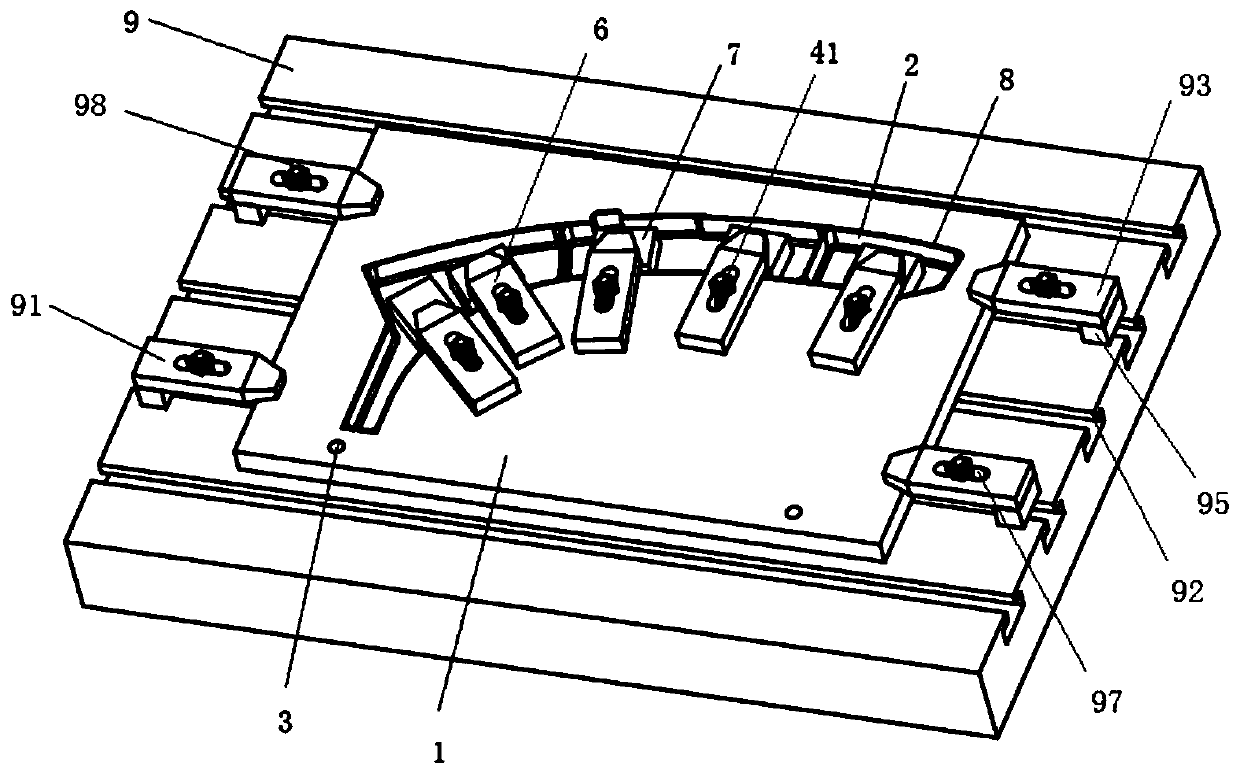

Machining method for specially-shaped thin-wall shell body part

The invention discloses a machining method for a specially-shaped thin-wall shell body part. The machining method for the specially-shaped thin-wall shell body part comprises the steps of plate preparation, rough milling, alignment, aging treatment, finish machining for an end surface of a cavity, finish milling for a bottom surface and a shape, finish milling for the cavity, and blank removal. According to the machining method for the specially-shaped thin-wall shell body part, accurate location is carried out in a machining process through a location pin hole, the part is installed on a fixed clamp in a clamping manner to be fixed, and the effects of supporting and preventing vibration are acted by reserving a process cylinder in the cavity, so that complete machining for the specially-shaped thin-wall shell body part can be realized; and the machining method for the specially-shaped thin-wall shell body part has the advantages of facilitating to clamping, and being capable of preventing the part from being deformed, saving production for a special fixture, and increasing the machining efficiency, the machining accuracy, the production efficiency and the product qualification ratio.

Owner:三河建华高科有限责任公司

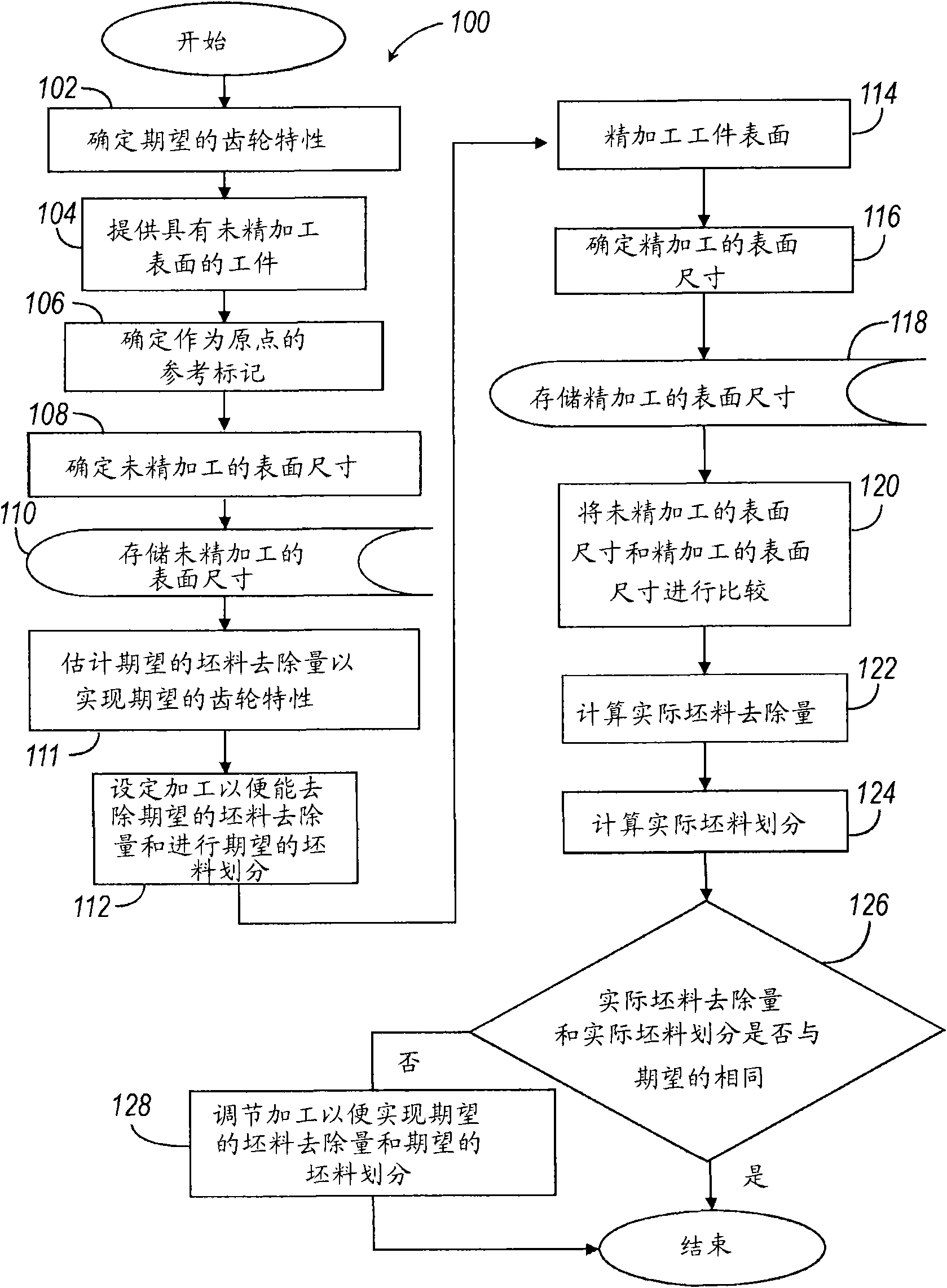

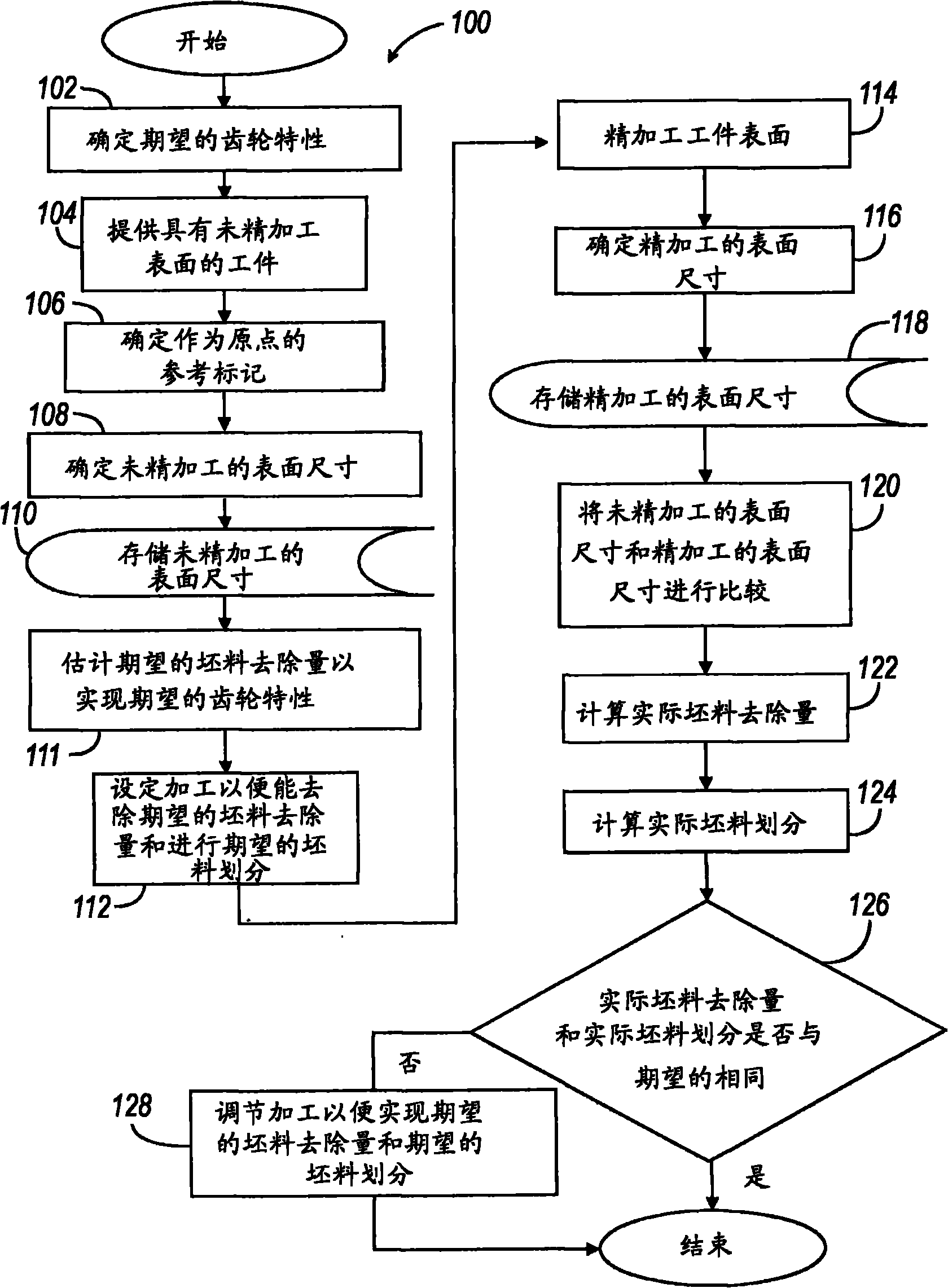

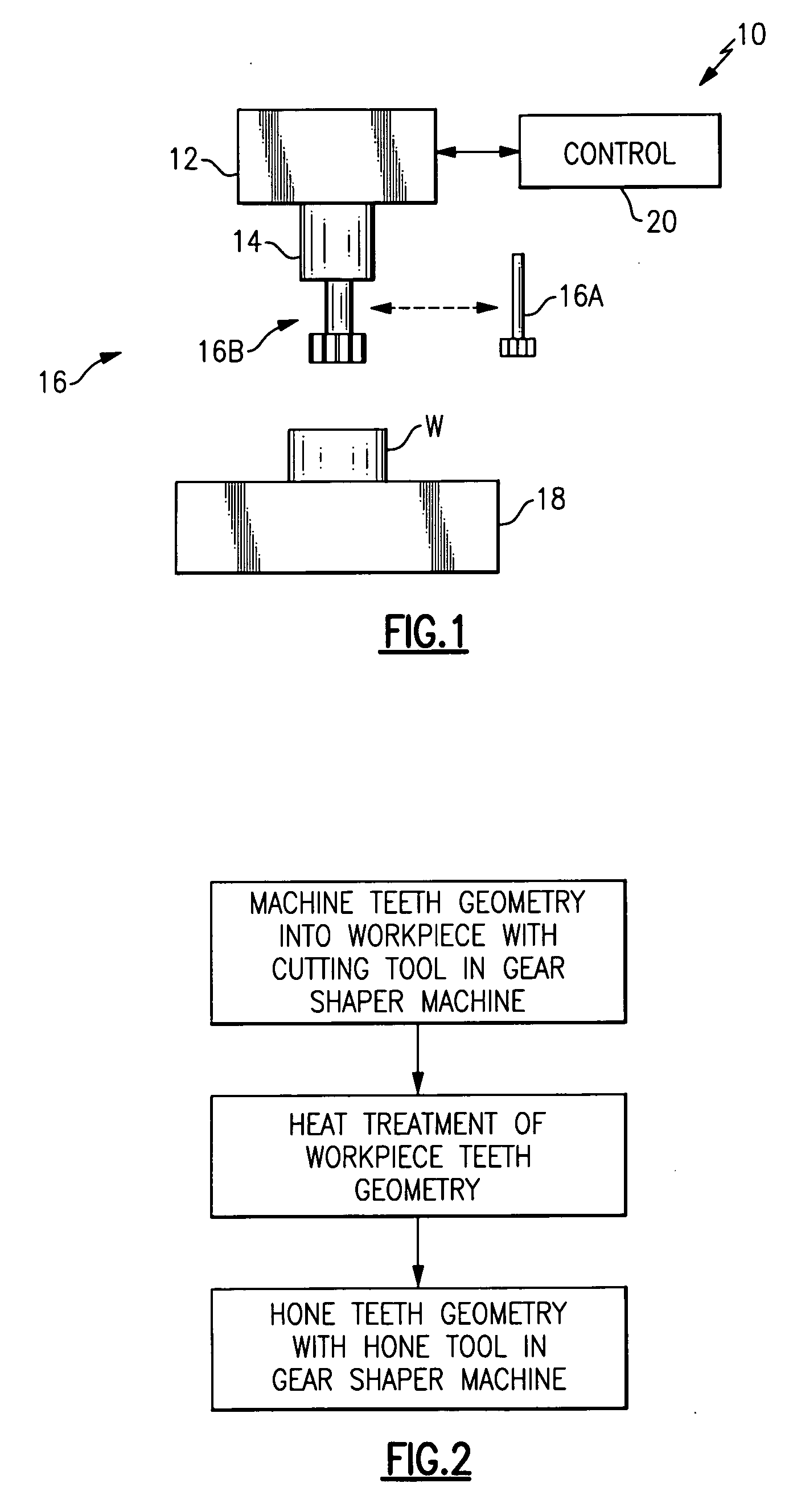

Method for finishing a gear surface

A method for manufacturing a gear having a plurality of gear teeth includes the steps of: determining a desired finished gear characteristic, determining a reference feature on the gear to establish an origin on the gear, determining an unfinished dimension of a surface of at least one of the plurality of gear teeth relative to the origin, estimating a desired stock removal that will achieve the desired finished gear characteristic, finishing the gear using a finishing tool, determining a finished dimension of the surface of the at least one of the plurality of gear teeth relative to the origin, determining actual stock removal by comparing the unfinished dimension with the finished dimension, and comparing the actual stock removal with the desired stock removal.

Owner:GM GLOBAL TECH OPERATIONS LLC

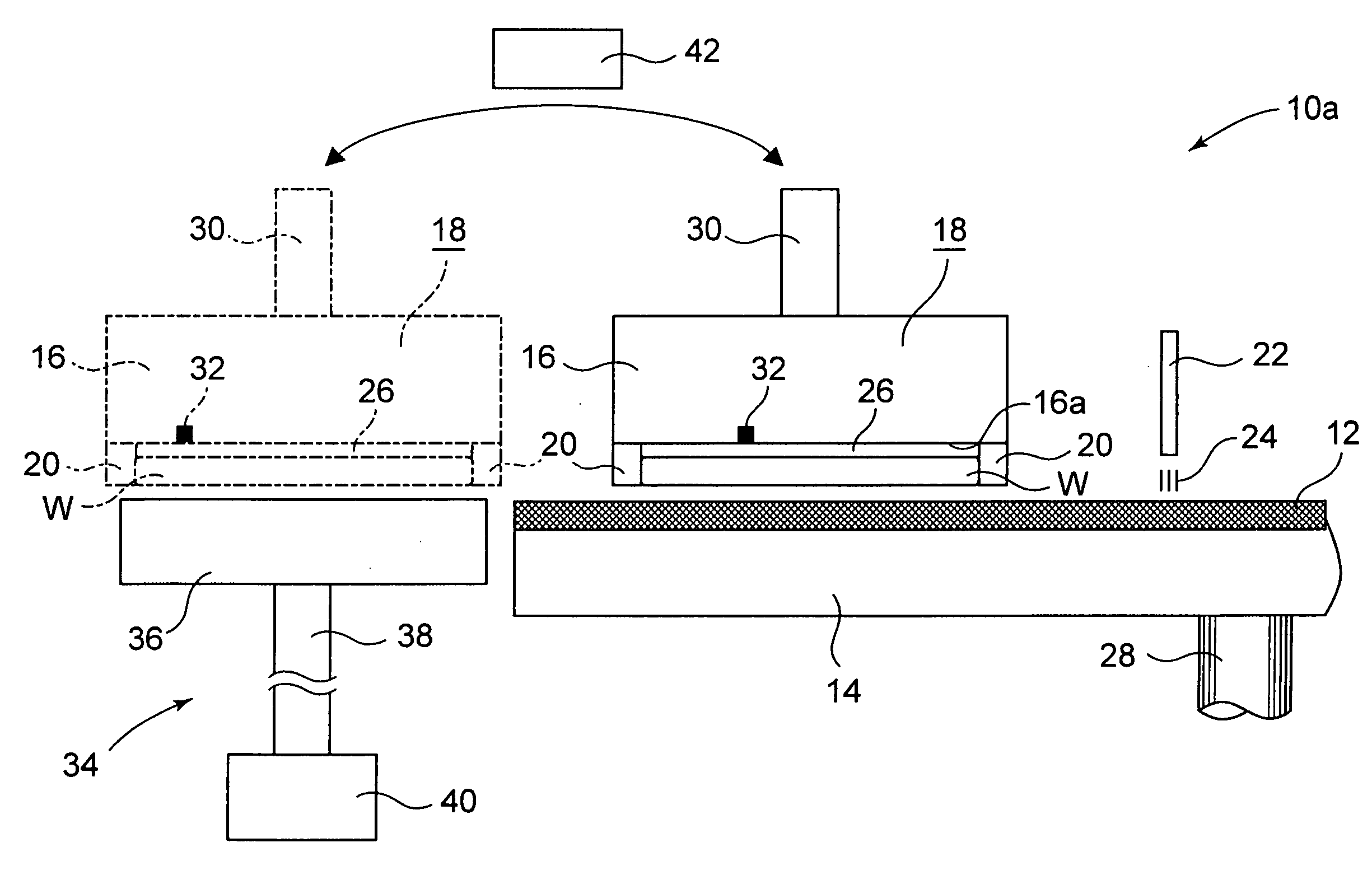

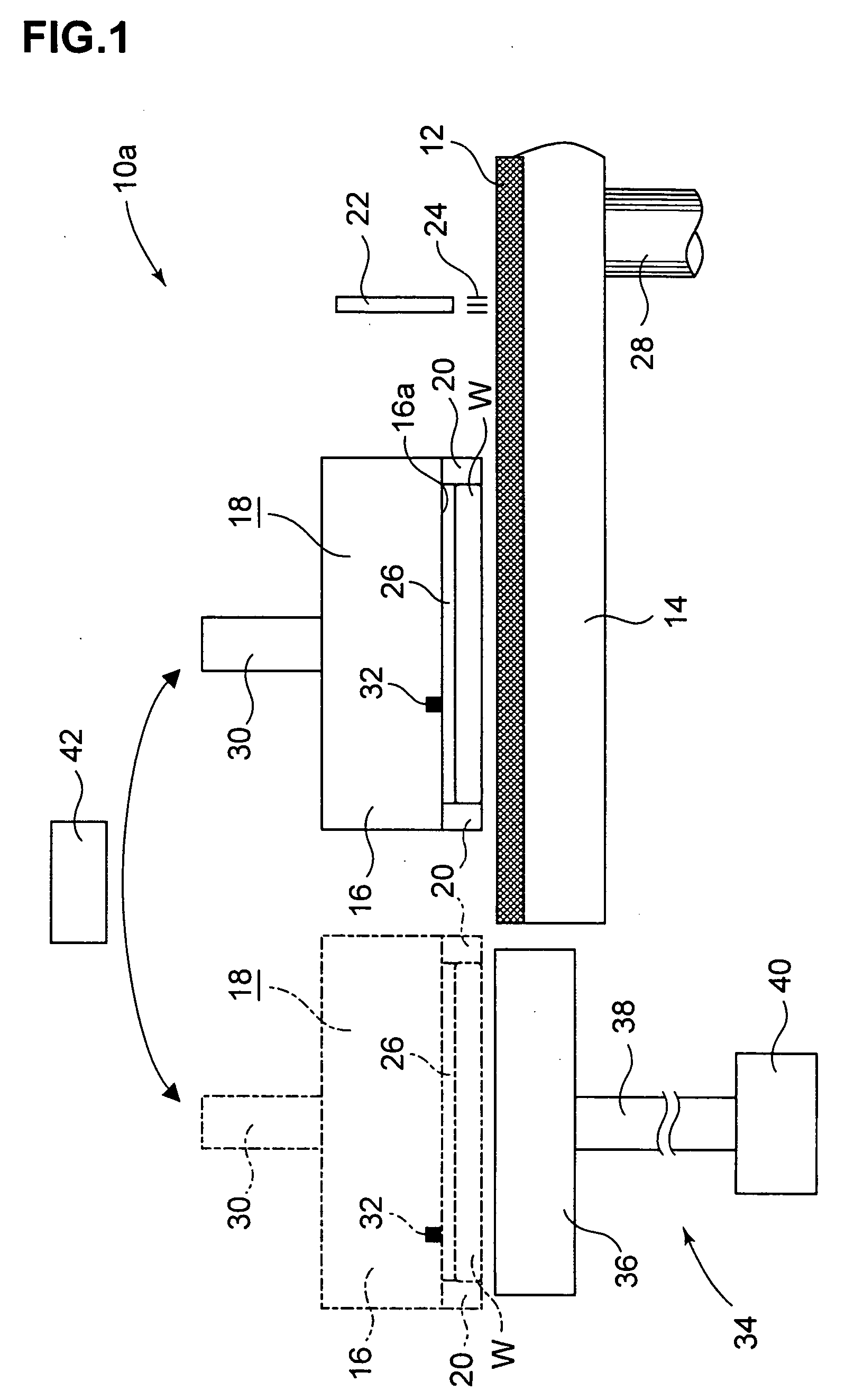

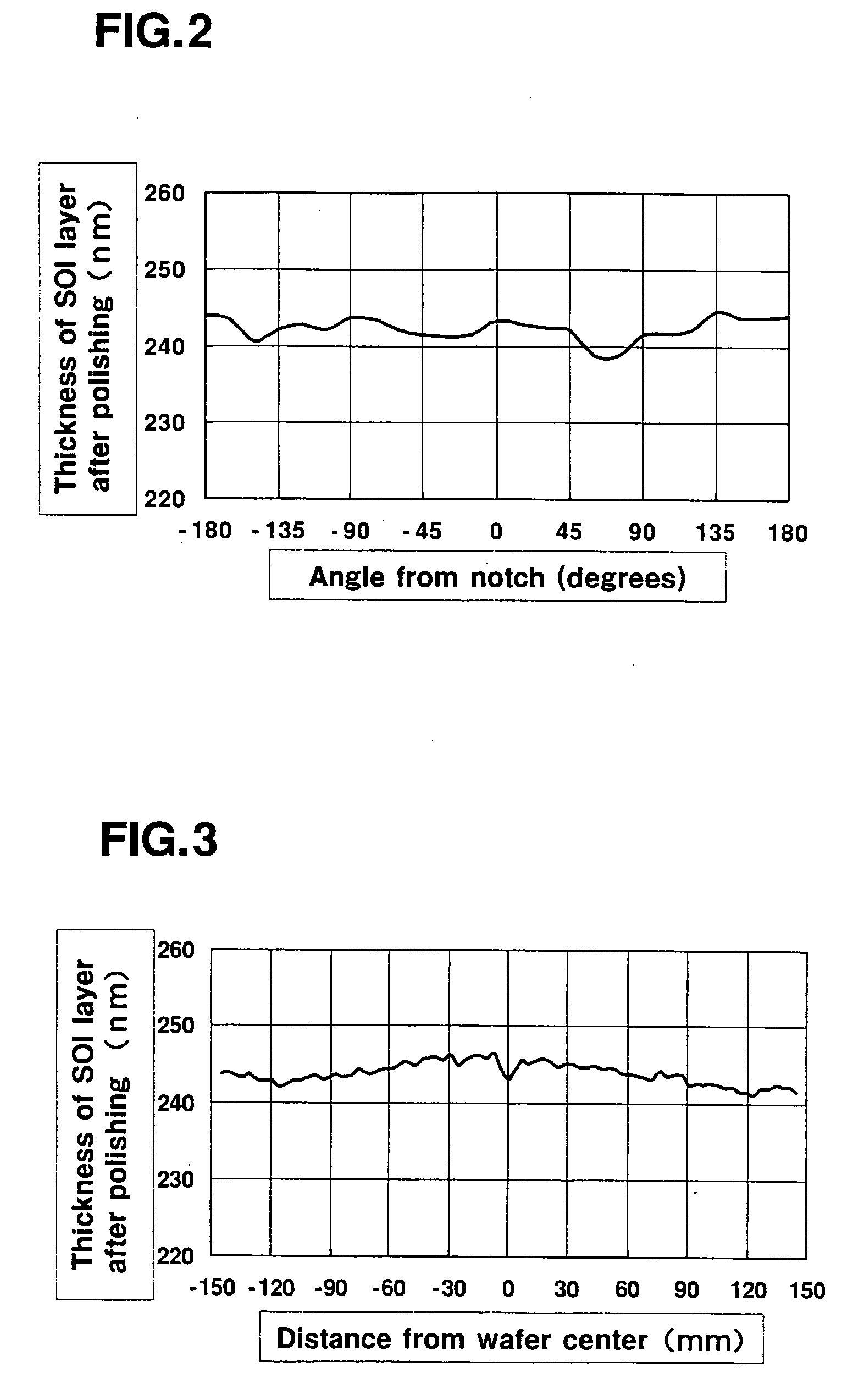

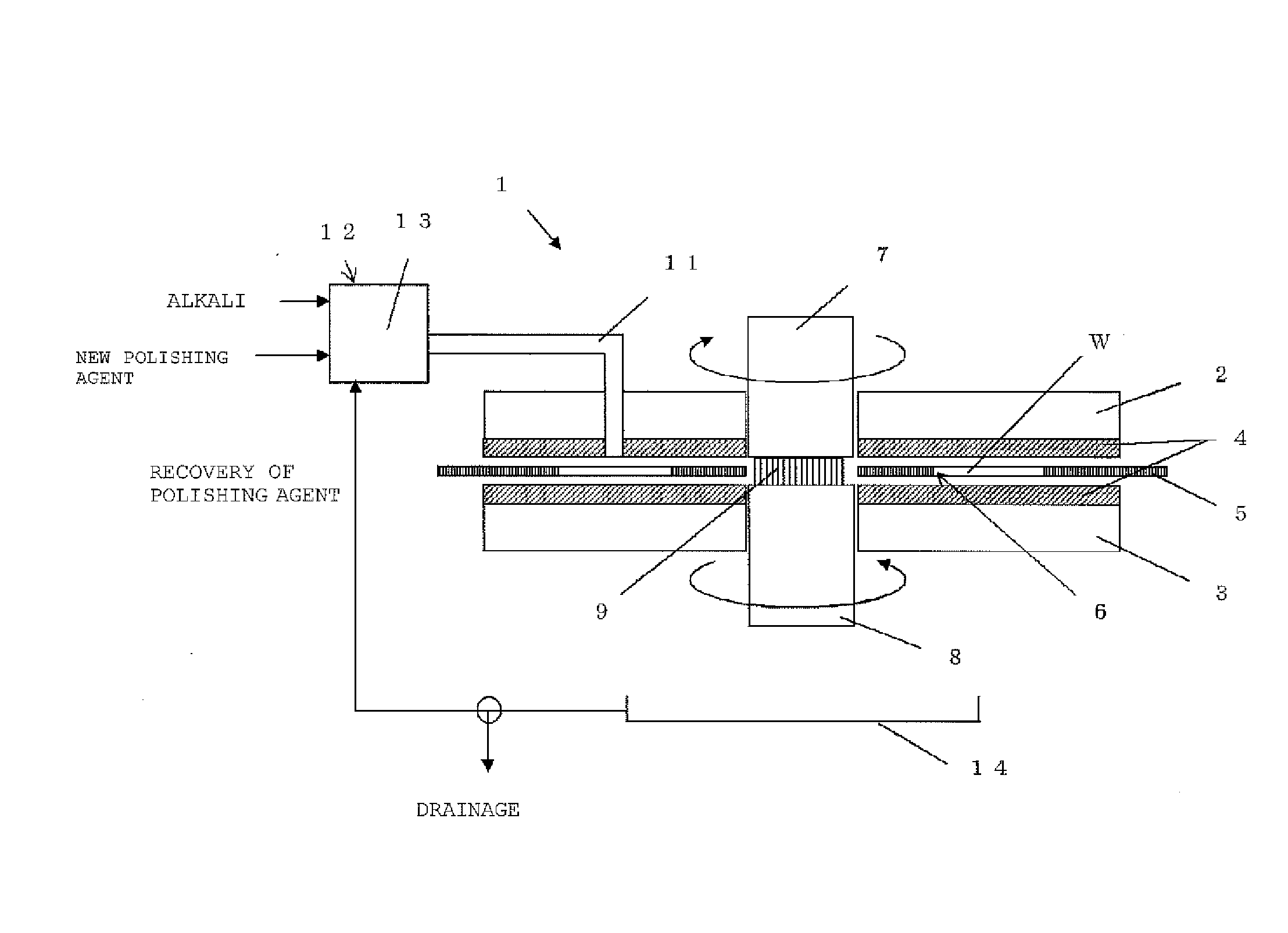

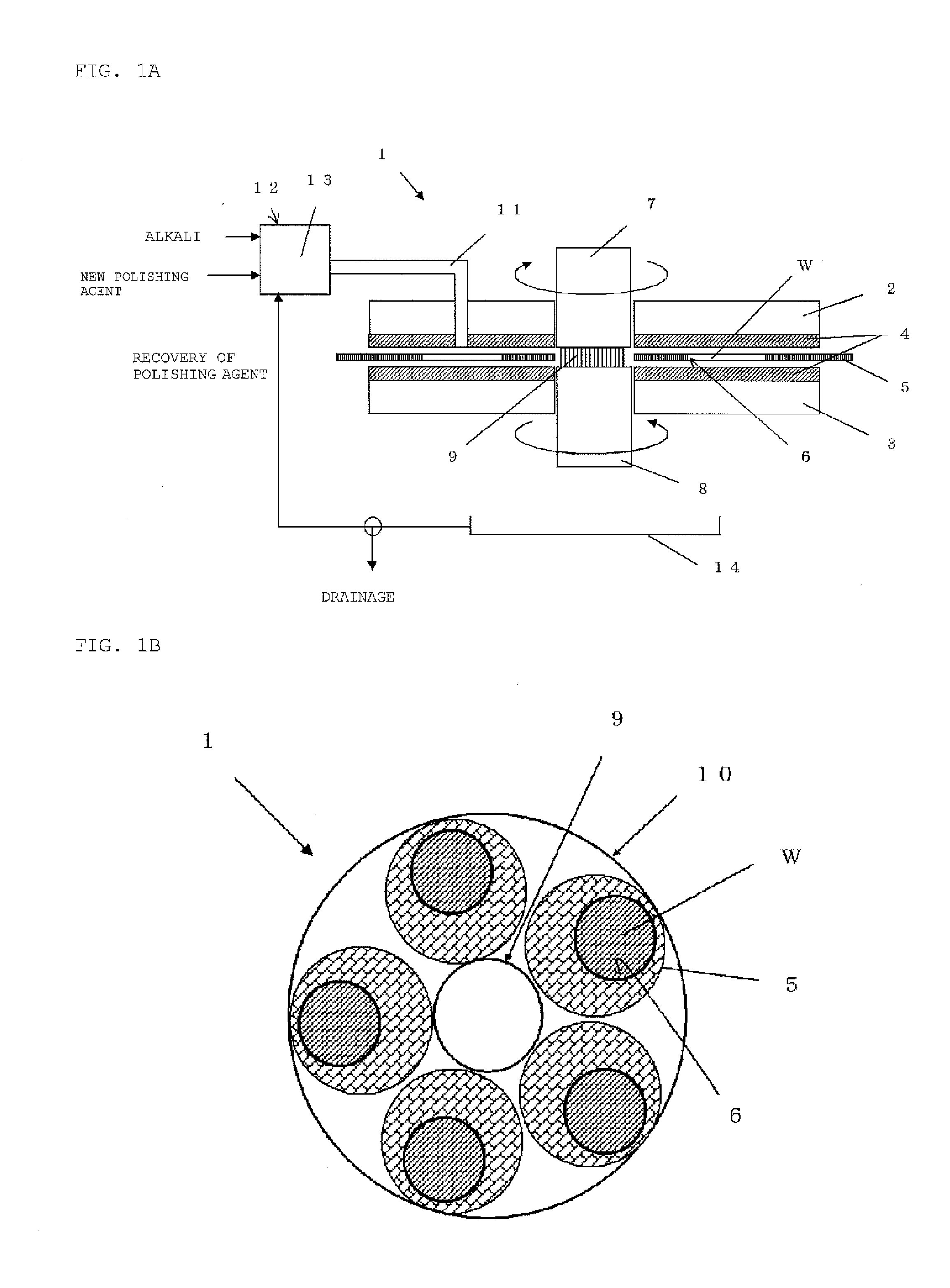

Wafer polishing method and apparatus

ActiveUS20060068681A1Improve flatnessPreventing peripheral sags of a waferSemiconductor/solid-state device manufacturingLapping machinesEngineeringStock removal

The present invention provides a wafer polishing method and a polishing apparatus which are capable of preventing peripheral sags of a wafer due to polishing and then manufacturing the wafer, especially an SOI wafer at a high flatness level. There is provided a wafer polishing method using a polishing apparatus which comprises a rotatable table having a polishing cloth adhered thereon and a polishing head equipped with a wafer holding plate opposing to the table and in which the back surface of the wafer is held by a holding surface of the wafer holding plate and the front surface of the wafer is pressed to and polished by the polishing pad, comprising a polishing step of polishing the front surface of the wafer to a predetermined total polishing stock removal without changing the polishing apparatus, wherein the polishing step is divided into plural sub-steps and a holding position of the wafer in a subsequent sub-step is different from a holding position of the wafer in a previous sub-step.

Owner:SHIN-ETSU HANDOTAI CO LTD

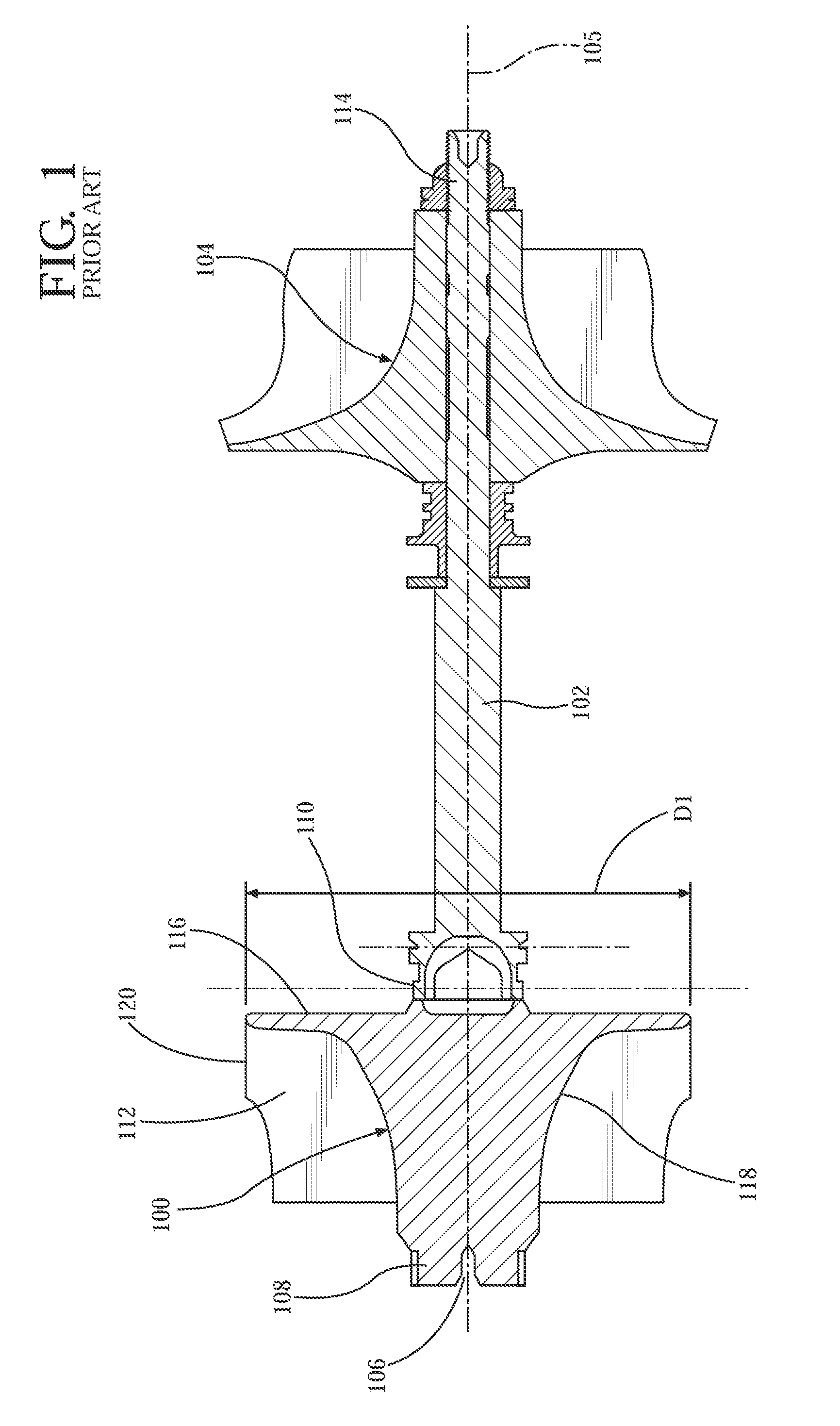

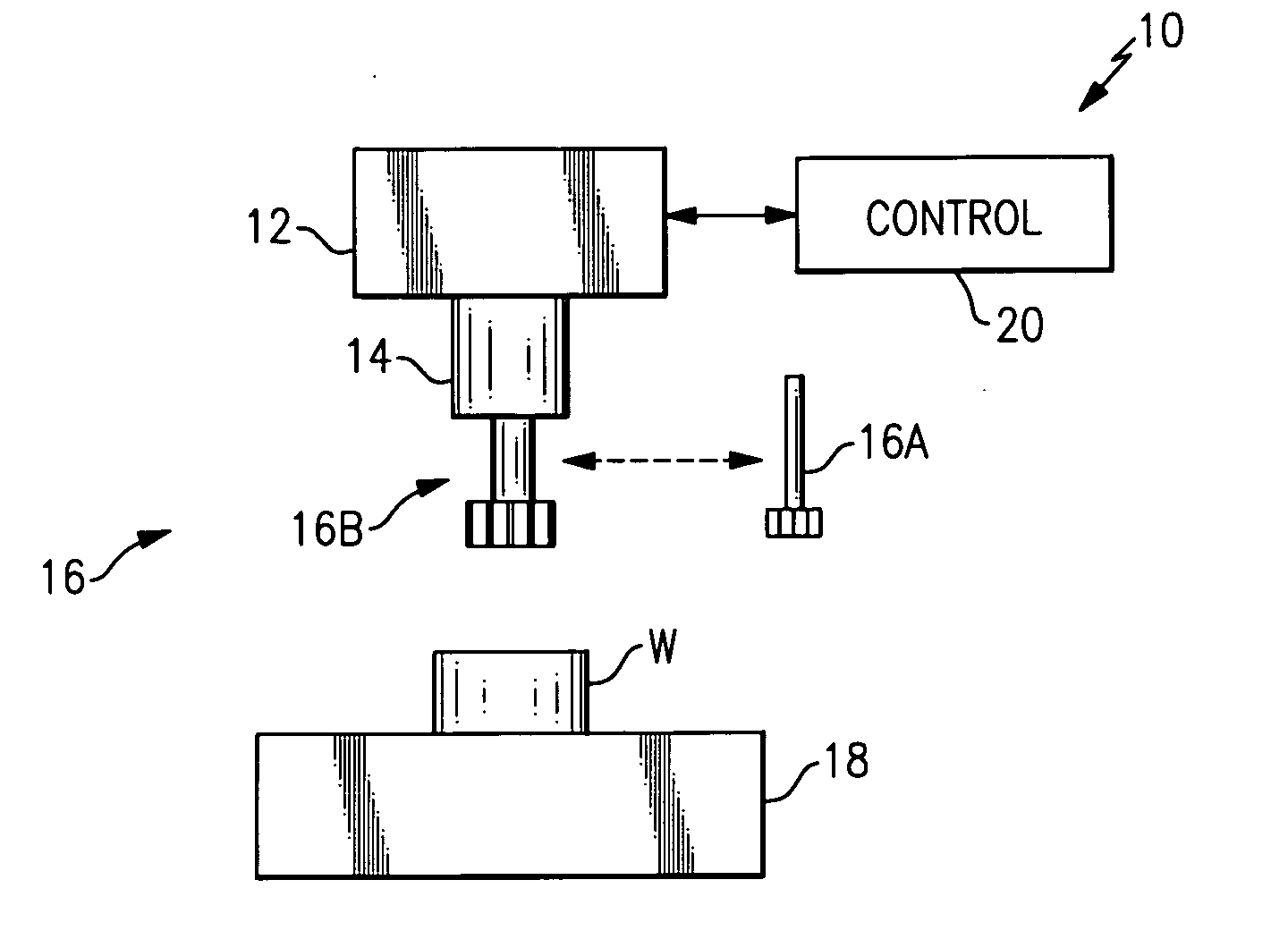

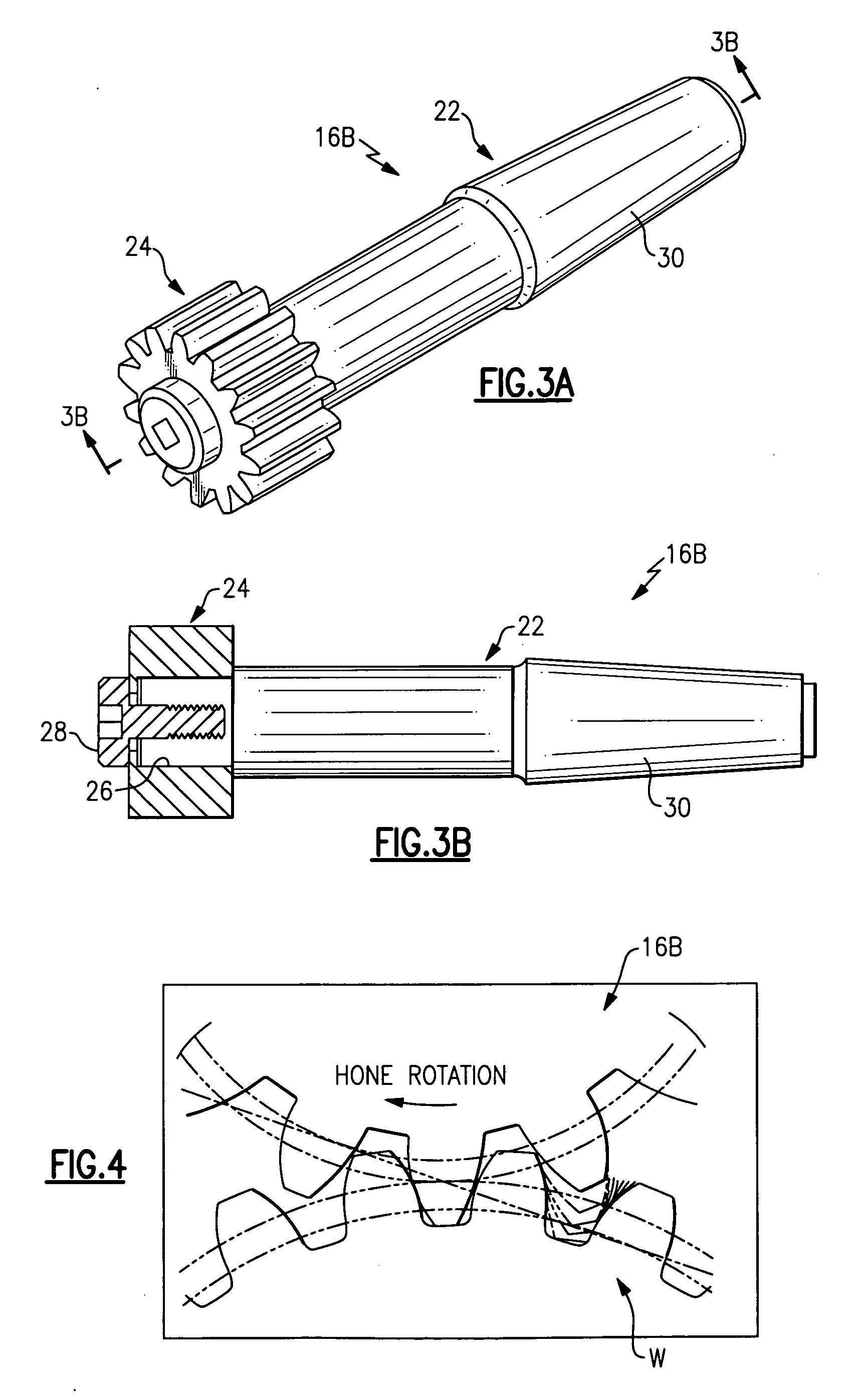

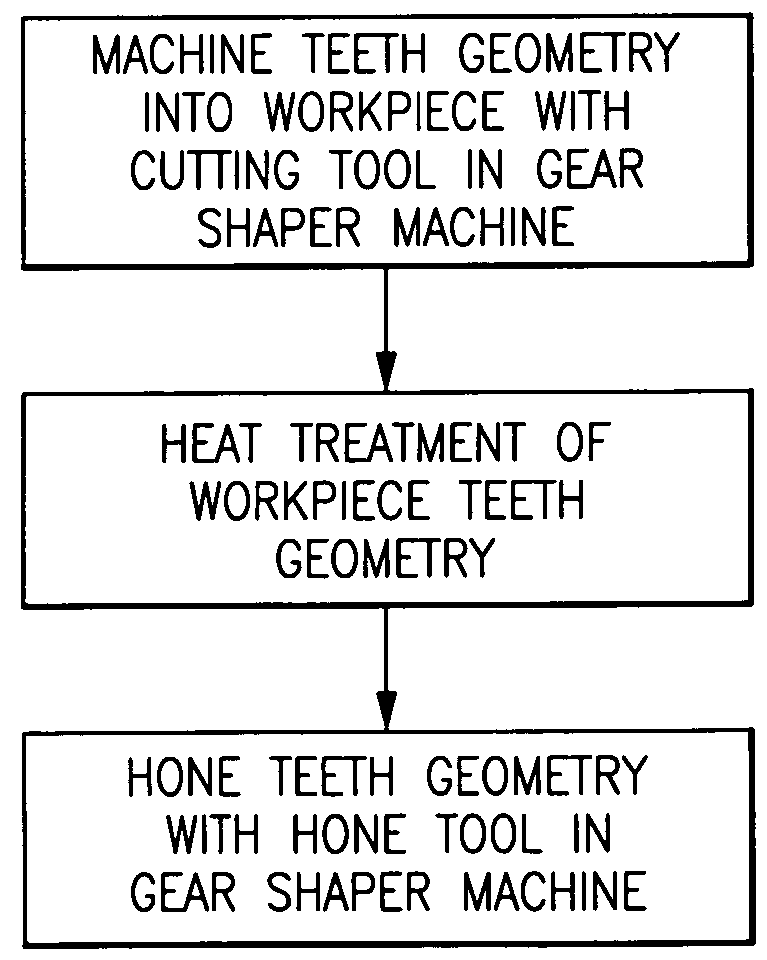

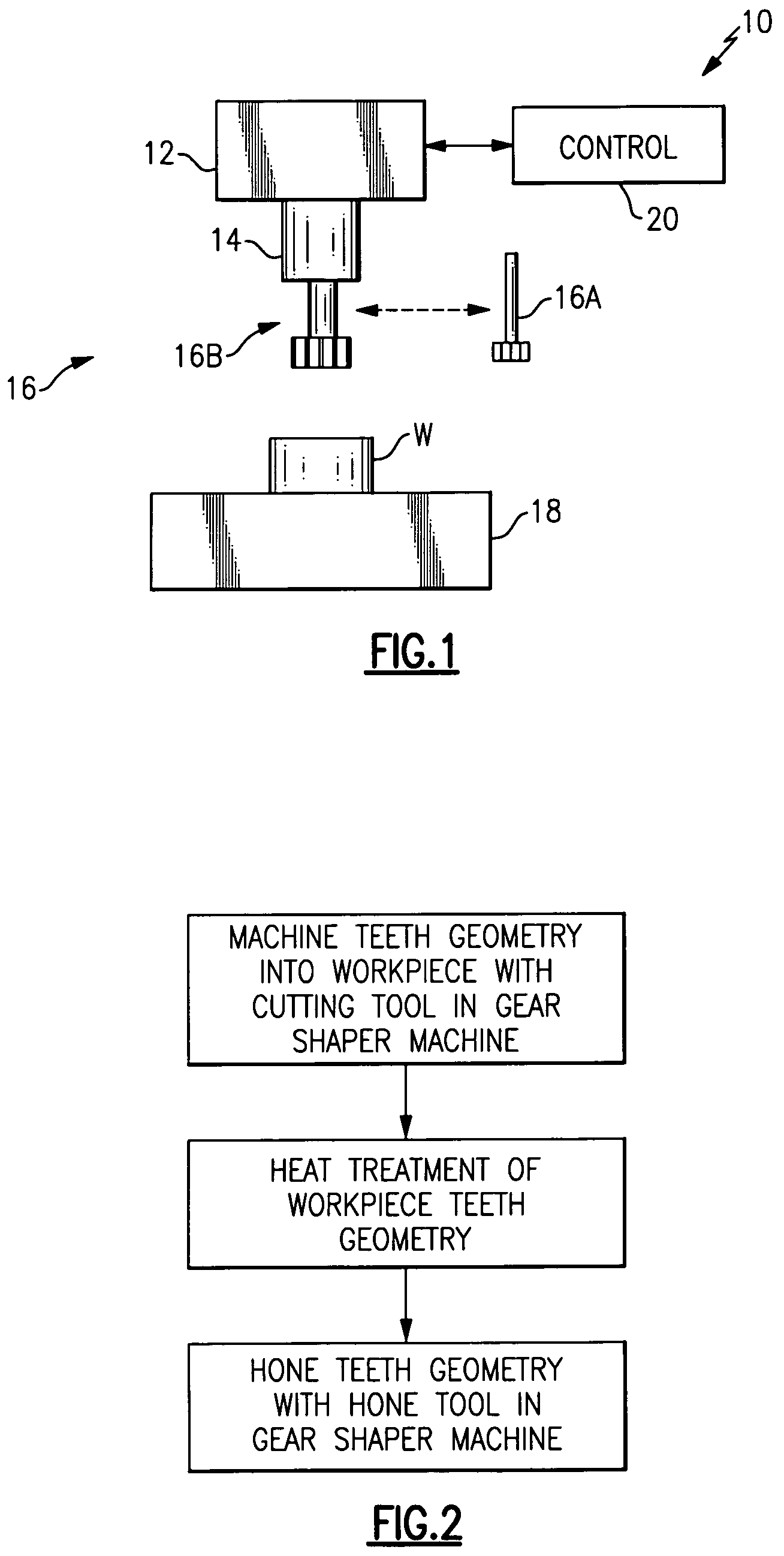

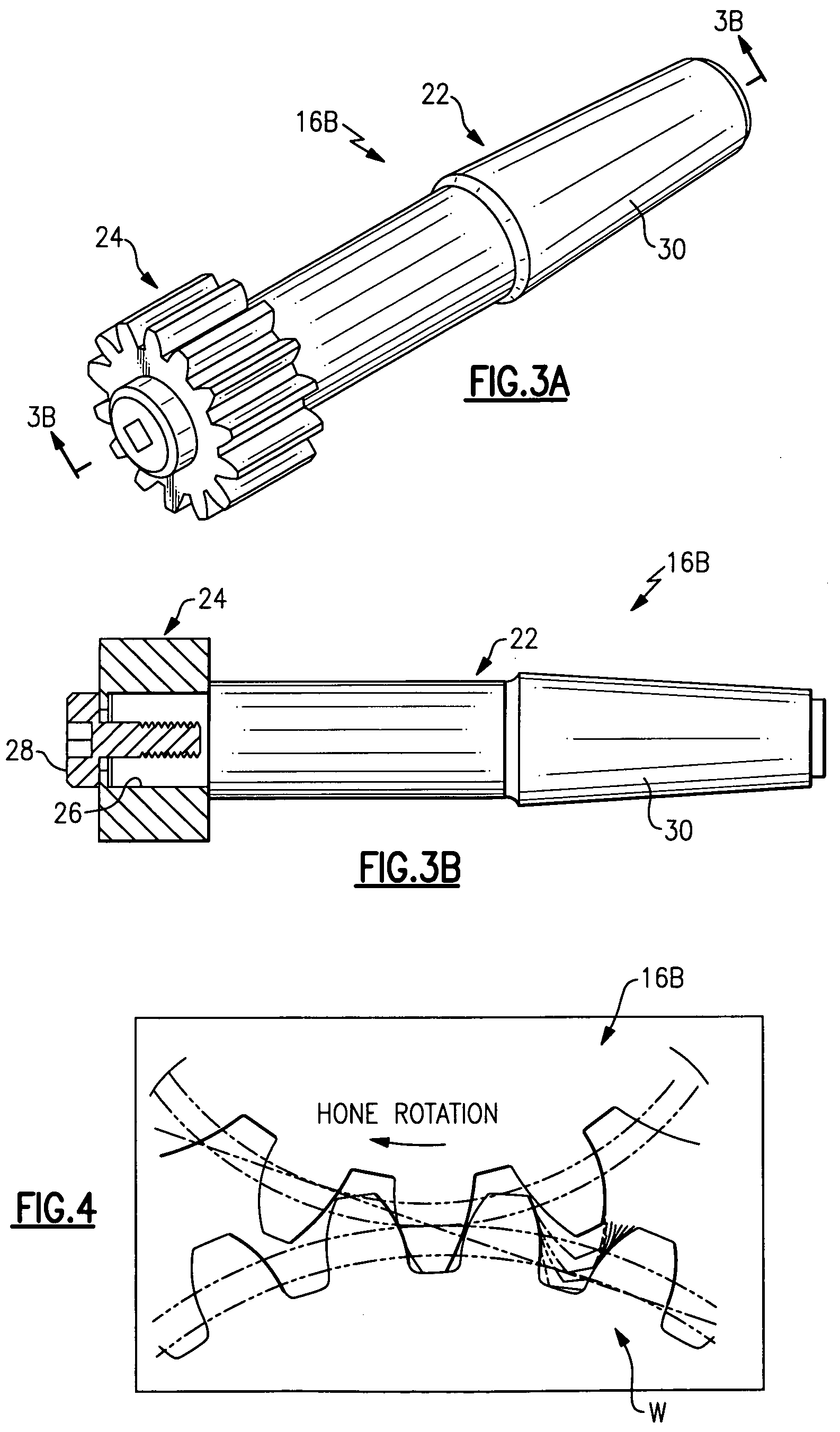

System and method for precision machining of high hardness gear teeth and splines

ActiveUS20060240746A1Minimize impact loadingSignificant economic advantageEdge grinding machinesRevolution surface grinding machinesReciprocating motionGear wheel

A gear shaper machine system drives and maneuvers a hone tool to generate teeth geometry in a manner the teeth were machined prior to a hardening process. After heat treatment, the hone tool is indexed to the teeth geometry spacing of the workpiece so as to divide the stock removal evenly between the drive and coast sides. The hone tool may be driven with rotational and reciprocating synchronous teeth generating motion in which the hone tool reciprocates along the length of the teeth parallel to the centerline of the workpiece while the workpiece and hone tool rotate with synchronous motion.

Owner:SIKORSKY AIRCRAFT CORP

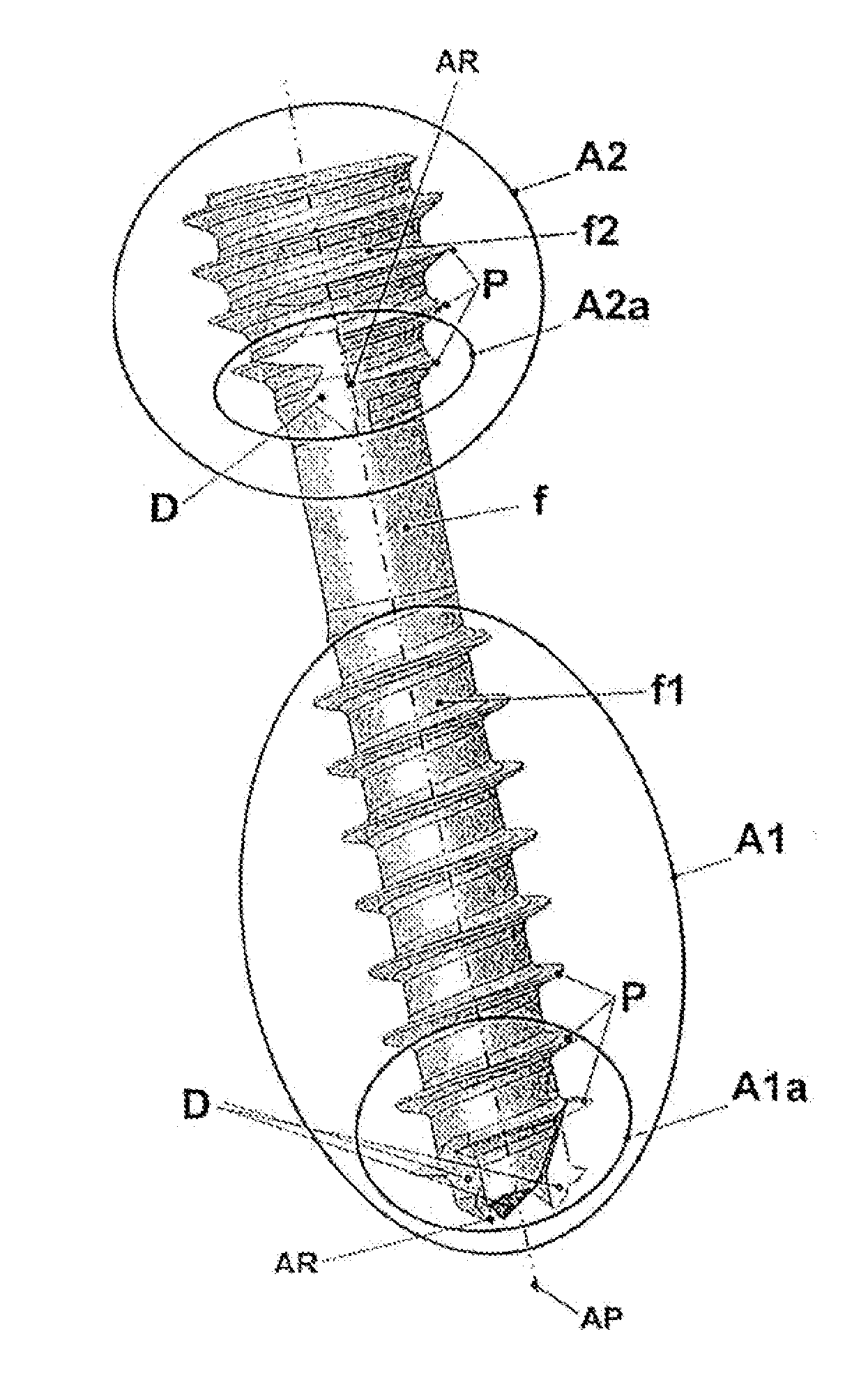

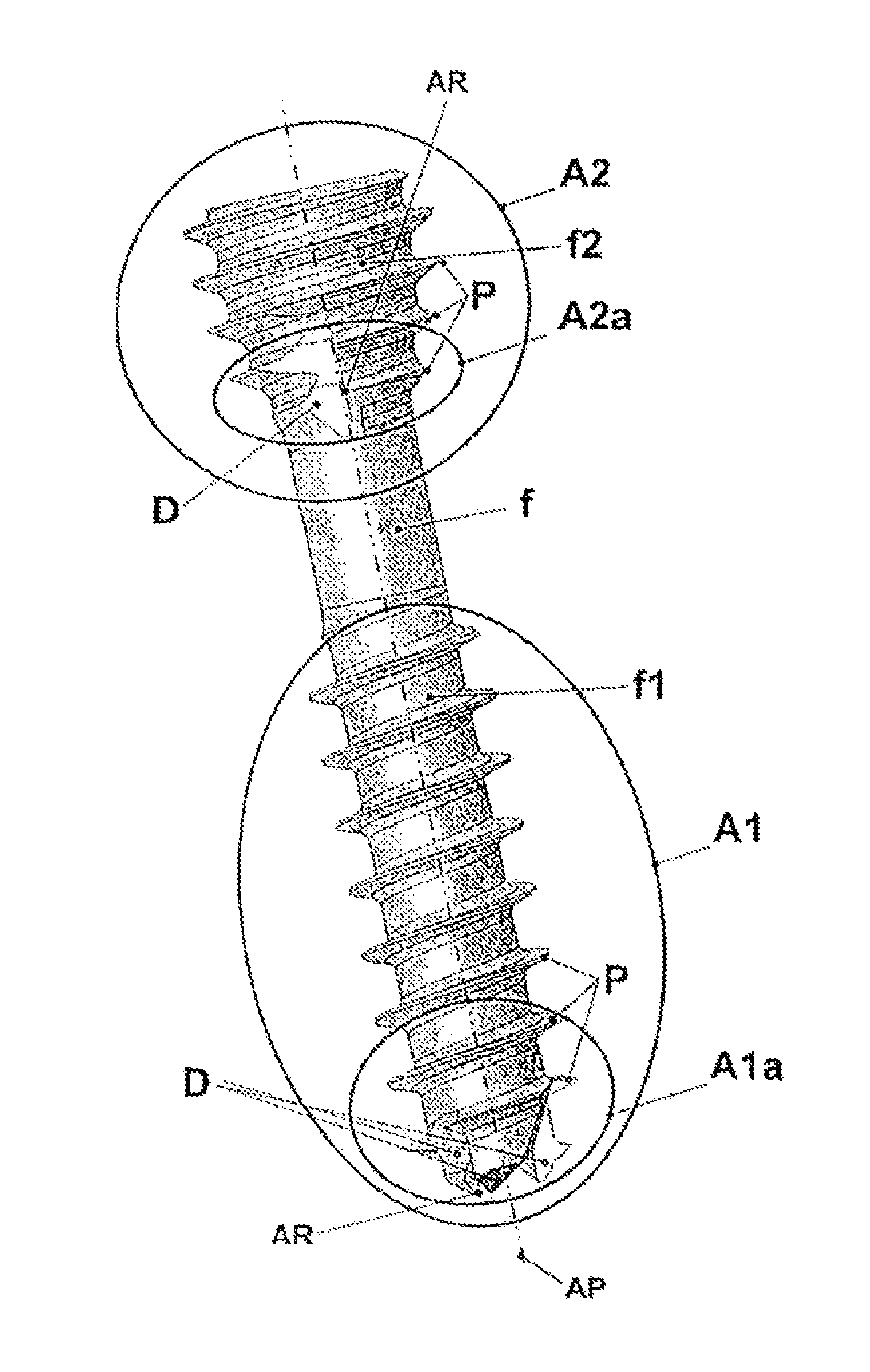

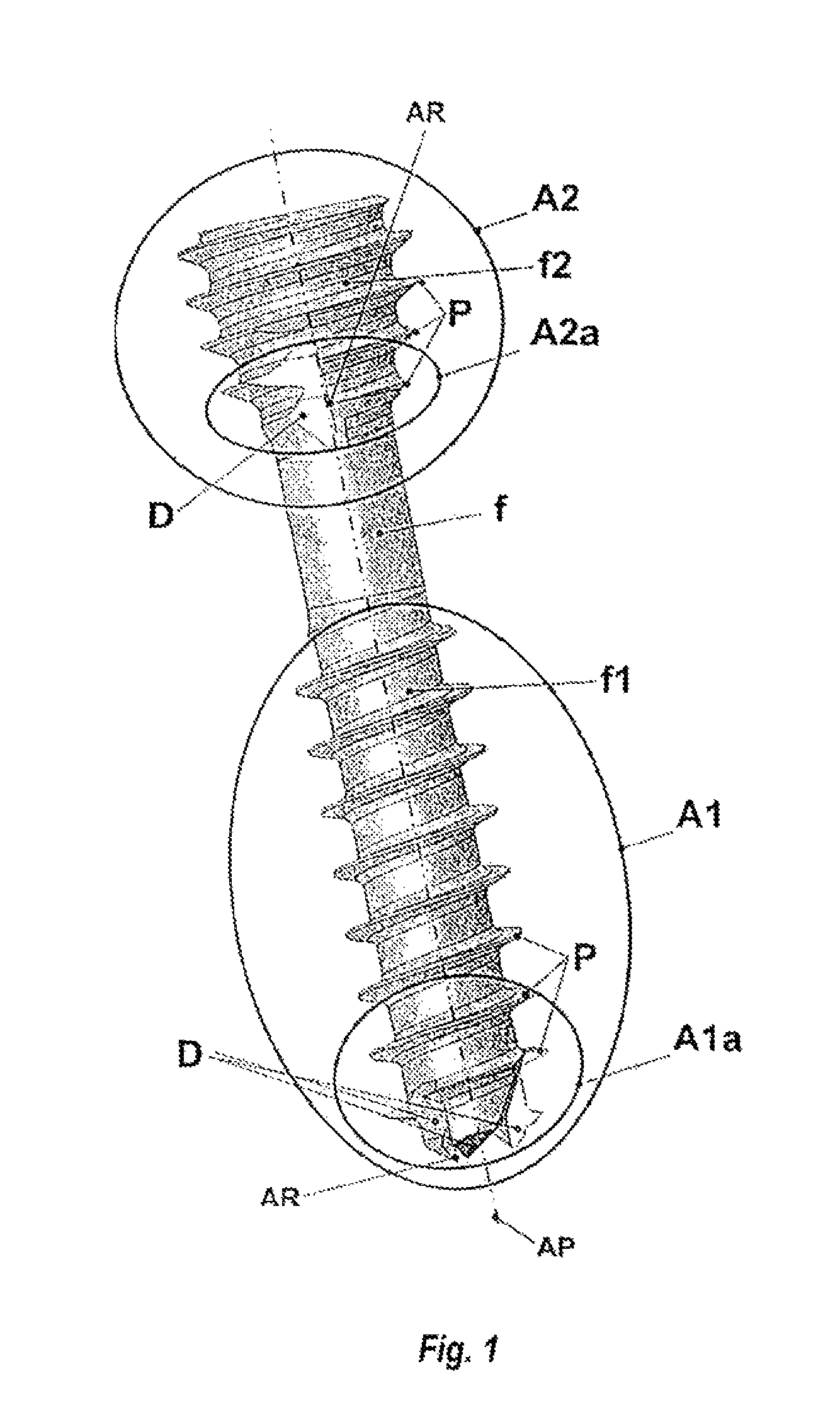

Screw for osteosynthesis and arthrodesis

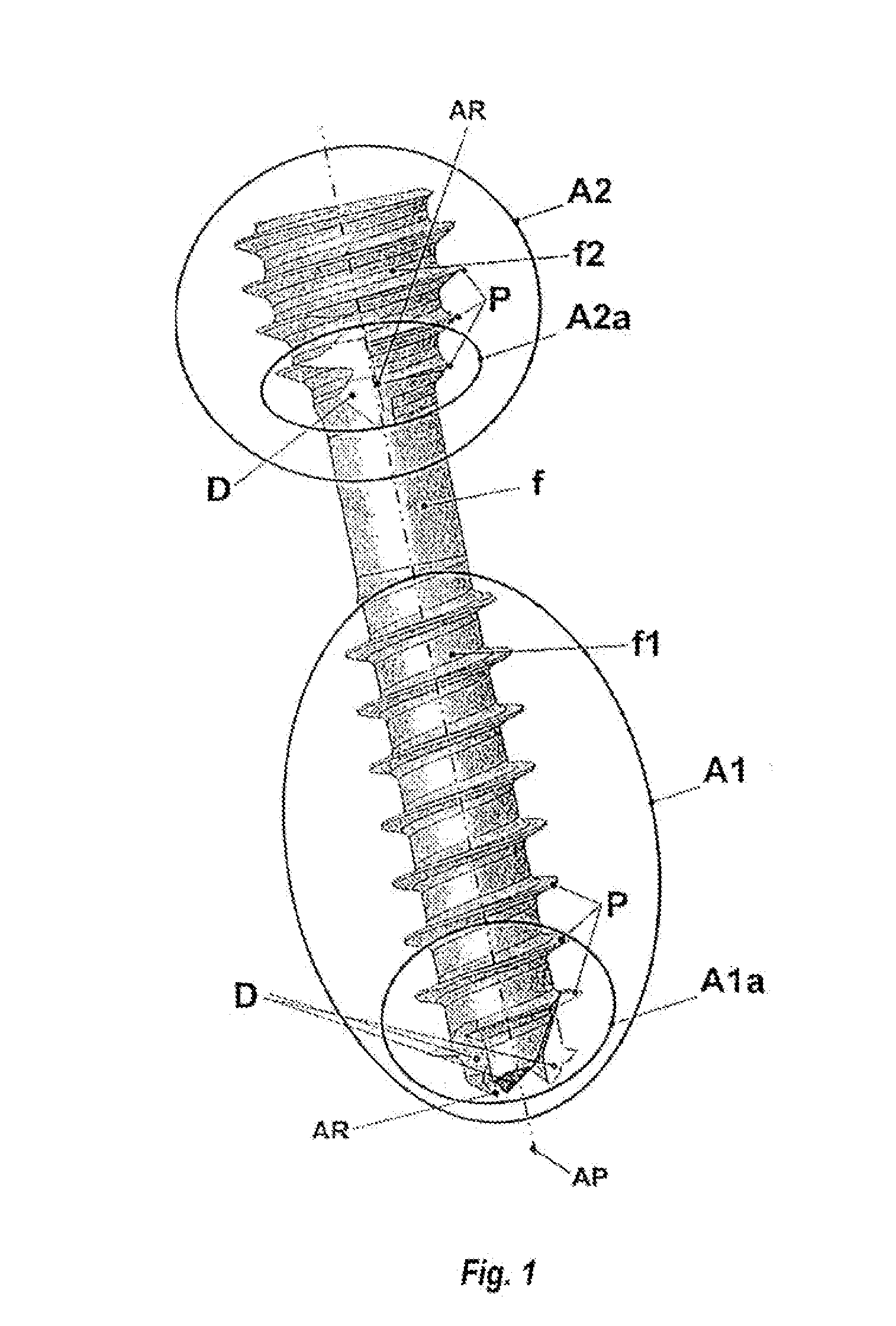

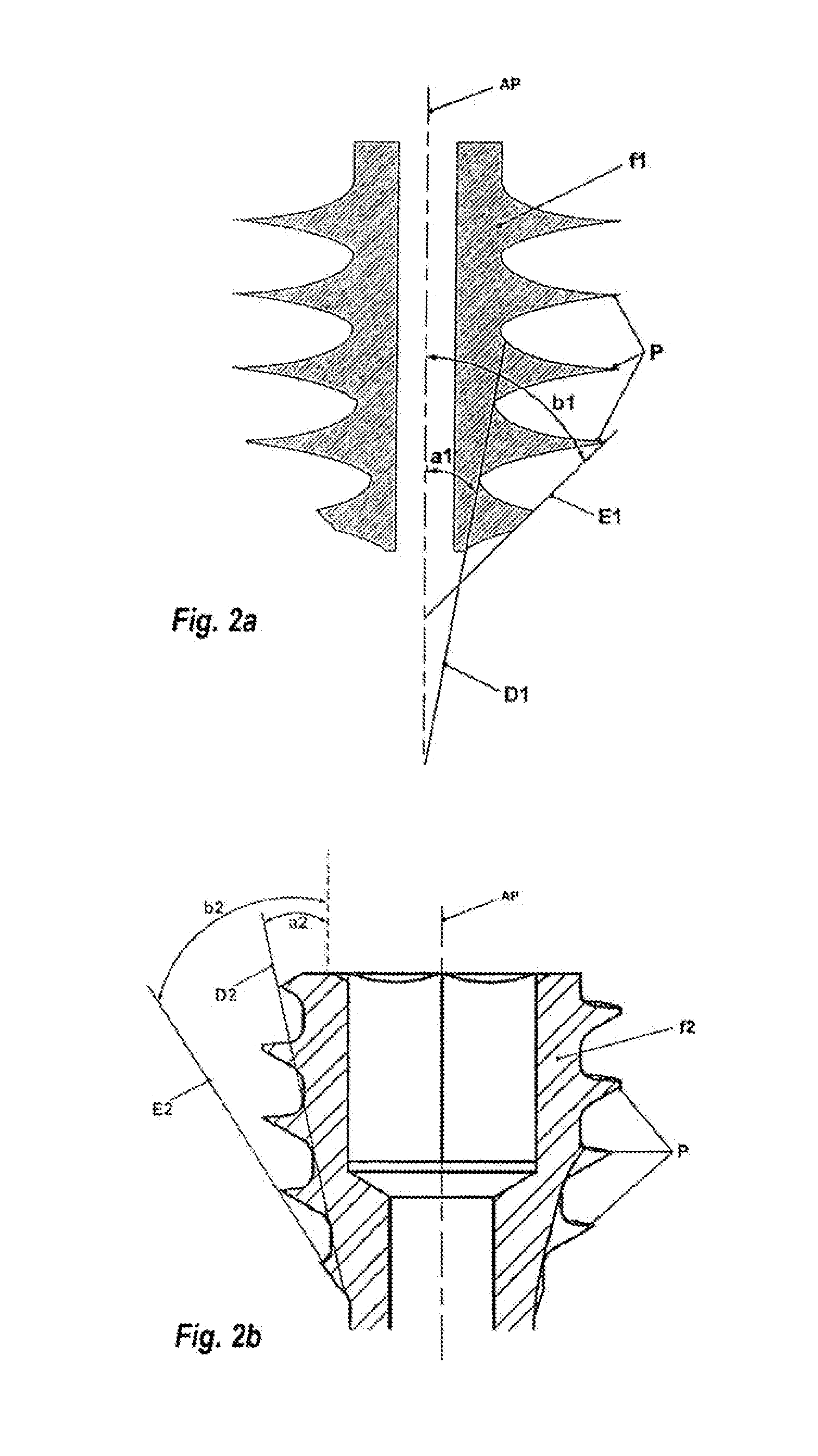

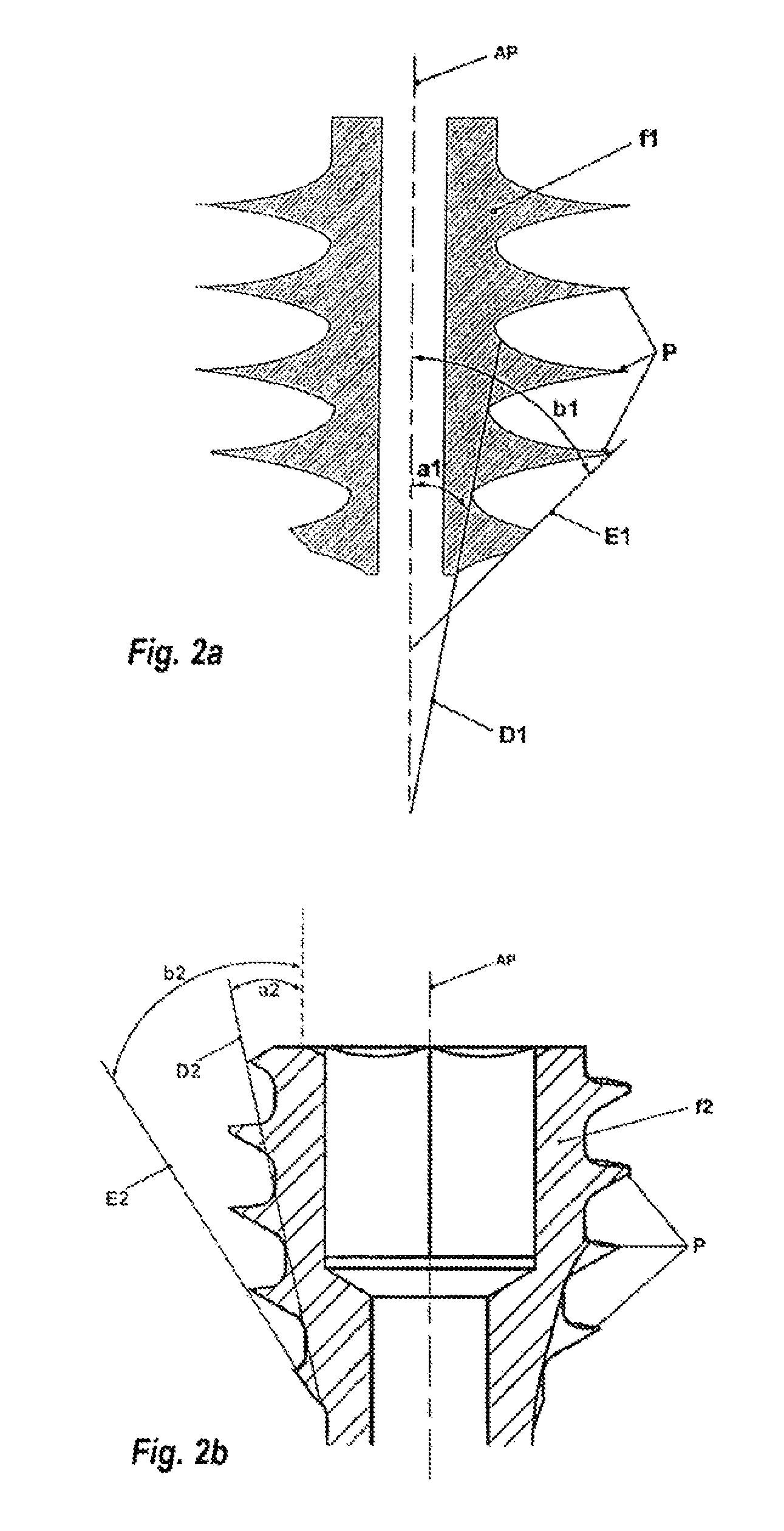

The invention relates to a self-tapping and self-boring osteosynthesis screw for compressive orthopaedic surgery, characterised in that, in the bone engagement regions, at both the distal portion (A1a) and at the proximal portion (A2a), the sum of the angles defining the outer taper of the shank (f) and the taper of the crest line of the screw thread pitch (P) is higher than 45°, and in that the leading portion (i.e. the most distal one) of each thread includes a plurality of cutting edges (AR) obtained by stock removal.

Owner:STRYKER EURO OPERATIONS HLDG LLC

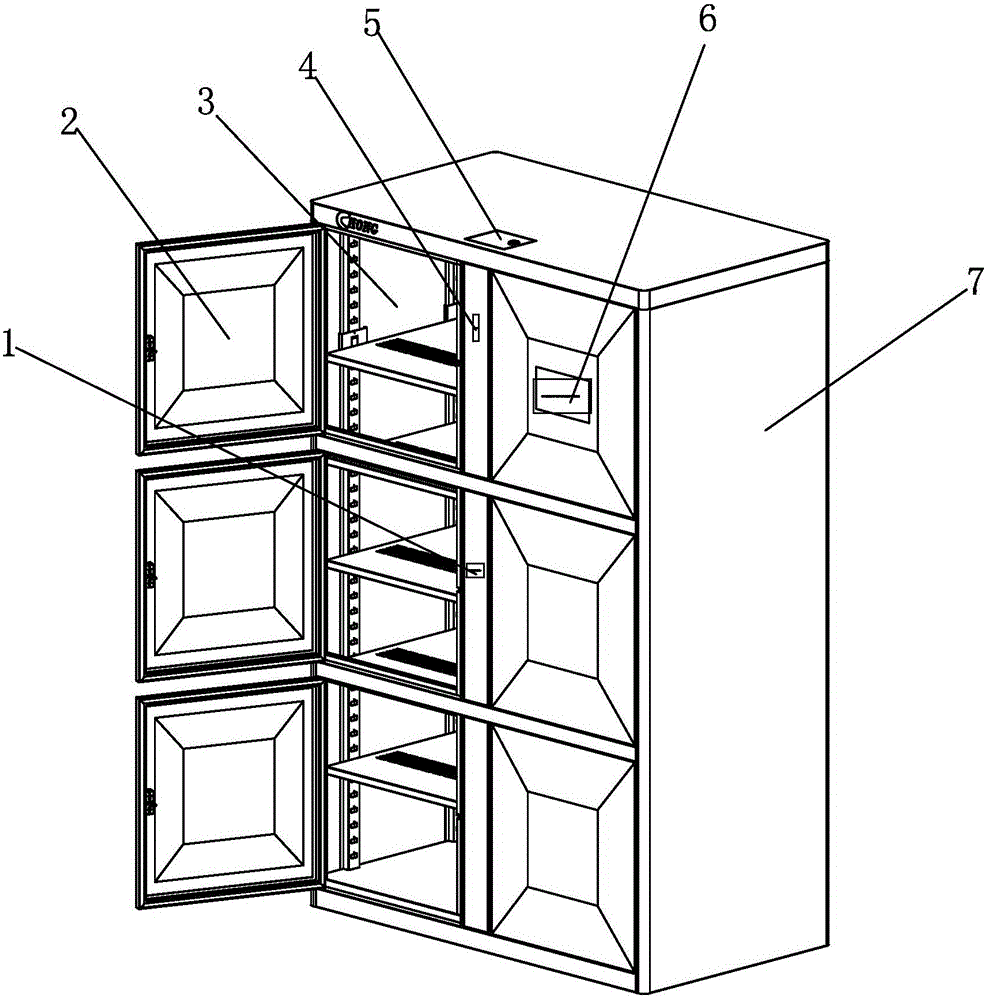

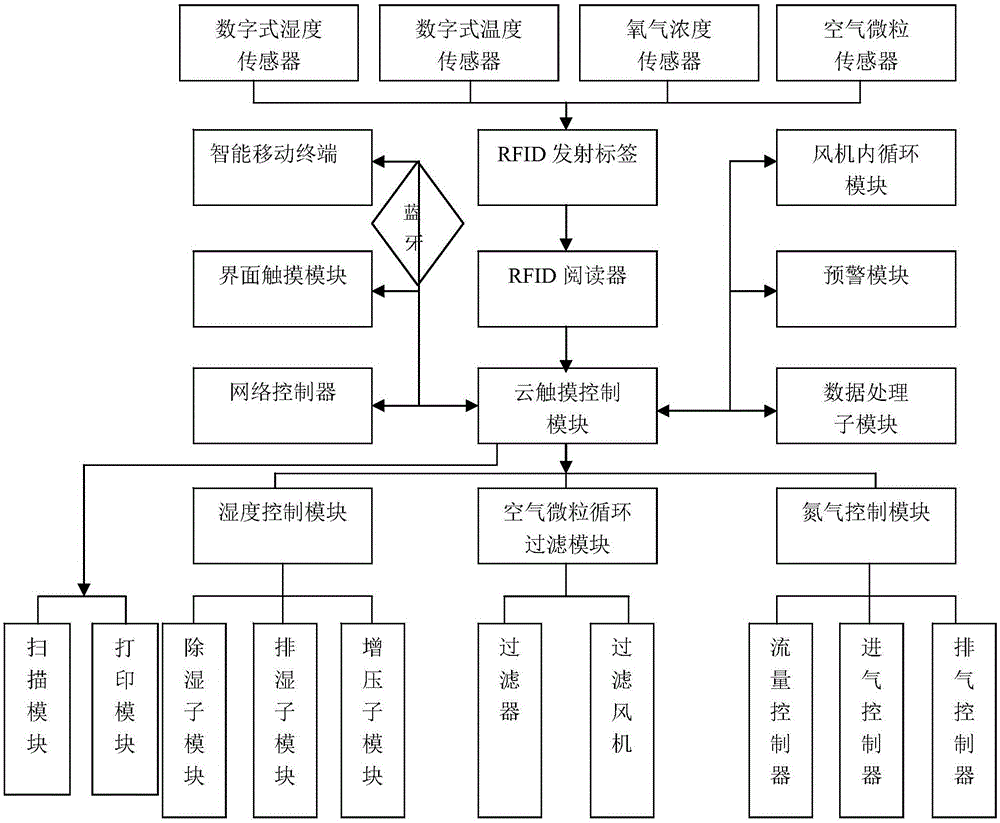

Touching-type cloud environment storage system based on Internet of Things

InactiveCN105045319AEasy to storeImprove delivery efficiencyPin hingesSimultaneous control of multiple variablesThe InternetData acquisition

The invention discloses a touching-type cloud environment storage system based on Internet of Things which realizes the precise control of the environment humidity, cleanliness and nitrogen concentration in a sealing cabinet by utilizing the software remote control of a mobile terminal (intelligent handset, computer, flat computer) and the related technology like the Bluetooth, RFID, intelligent touch, data acquisition and transmission, industrial Ethernet, intelligent control, fuzzy algorithm, and stock two-dimension code binding. Furthermore, the touching-type cloud environment storage system based on the Internet of Things provides a cloud storage system function which satisfies the storage requirement for various warehouse environments, and particularly satisfies the super-low-humidity environment of 10RH required by the war industry high technology field, and greatly improves efficiency of stock warehousing and stock removal.

Owner:HANGZHOU BONHONG OPTOELECTRONICS TECH

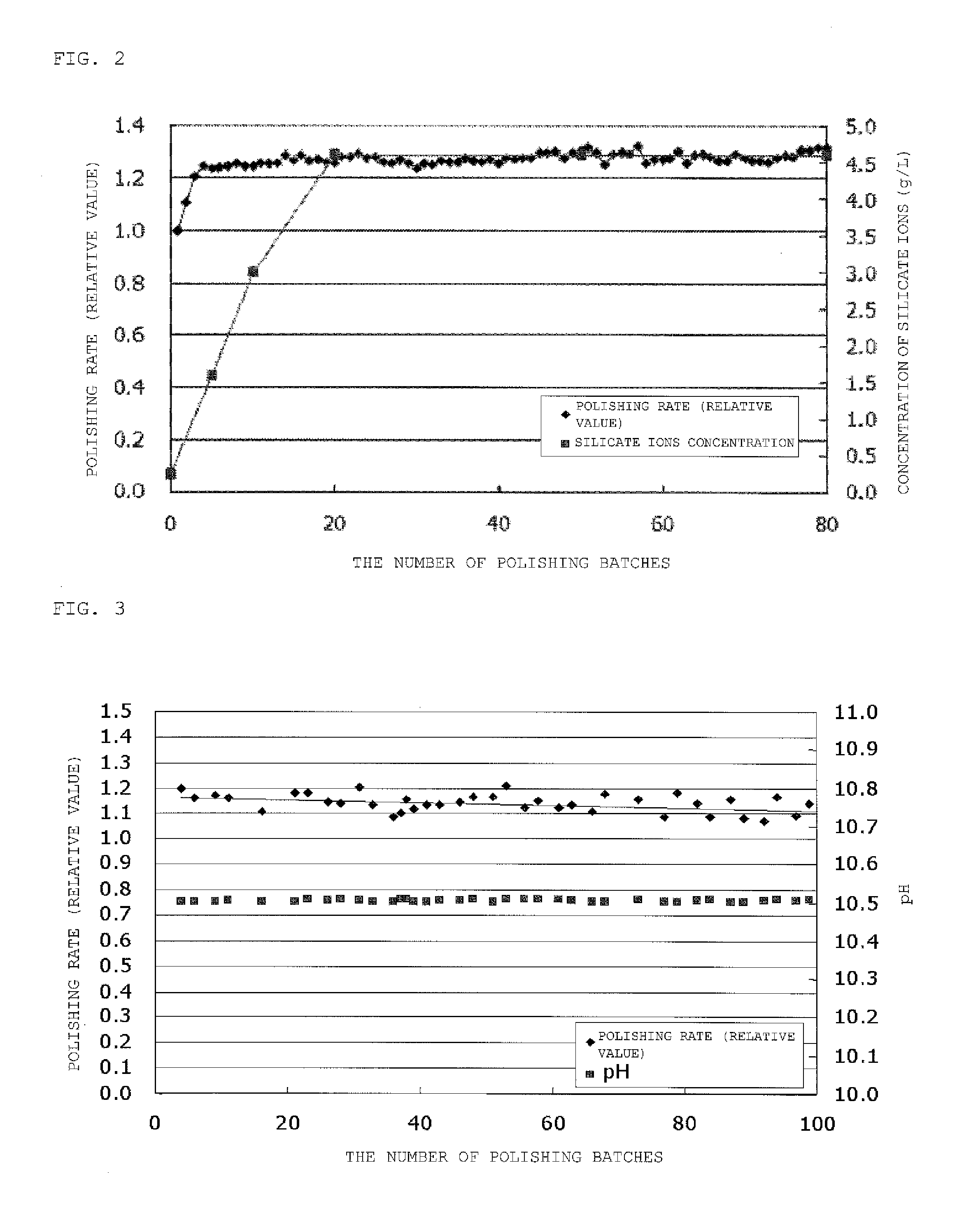

Method for polishing silicon wafer and polishing agent

InactiveUS20140162456A1Accurate polishing timeLong target lifeSemiconductor/solid-state device manufacturingLapping machinesEngineeringSliding contact

The present invention is directed to a method for polishing a silicon wafer, the method comprising: polishing the silicon wafer by bringing the silicon wafer into sliding contact with a polishing pad attached to a turn table while supplying a polishing agent stored in a tank to the polishing pad; and circulating the polishing agent to recover the supplied polishing agent in the tank, wherein the silicon wafer is polished while adjusting a concentration of silicate ions contained in the polishing agent in the tank to be within a predetermined range. The present invention provides a polishing agent having a high polishing rate that enables the polishing rate to be kept constant among polishing batches, and a method for polishing a silicon wafer accurately with a target polishing stock removal or a target finishing thickness by using the polishing agent.

Owner:SHIN-ETSU HANDOTAI CO LTD

Machining method for stainless steel deep-hole thin-wall part

InactiveCN107953068AGuaranteed accuracy requirementsReduce labor intensityRoughcastMachining process

The invention relates to the field of machining, in particular to a machining method for a stainless steel deep-hole thin-wall part. The machining method includes the following steps that proper blankmaterials are selected and subjected to annealing treatment, and the cutting machining performance of the materials is improved; rough turning is carried out to remove the machining allowance of a blank, and an inner hole of a workpiece is machined through a corresponding deep hole internal spraying and sucking drill bit on special equipment; heat treatment and quenching are carried out; the outline of the workpiece is clamped, and an end surface of the workpiece is turned; a guide hole and a chamfer are turned; boring and reaming are carried out, the number of boring and reaming times is determined according to the machining allowance and is usually two to four, according to the characteristics of the part, after two times of boring and one time of reaming on a special deep hole drillingand boring machine, the inner hole is machined to have certain machining allowance, the inner hole is machined to have the required size finally, and cooling lubricating oil is adopted in the machining process. The machining method can guarantee the precision requirement of the workpiece, quality is stable and reliable, machining difficulty is lowered, production efficiency is improved, and laborintensity of workers is relieved.

Owner:SHAANXI QIYUAN TECH DEV

Technology for extruding specially-shaped aluminum barrel with square head

InactiveCN103691751AReduce processShort processExtrusion diesAbrasive blastingMechanical engineering

The invention discloses a technology for extruding a specially-shaped aluminum barrel with a square head. The technology comprises the following steps: a blanking step: selecting a square aluminum bar, and cutting the square aluminum bar into a blank according to set length and weight; a blank deburring step; a blank abrasive blasting step; a blank surface lubricating step; an extrusion molding step: putting the blank in an extrusion die, molding the blank into an extrusion for the specially-shaped barrel with the square head through a one-step extrusion technology, forming a barrel body blank, a square head blank and an ellipsoidal projection blank by the extrusion, and deflecting the central lines of the square head blank for 3.5-4.5 degrees relative to the symmetric axis of two projecting ribs on the barrel body blank; respectively overlapping a long axis and a short axis of the ellipsoidal projection blank with the two central lines of the square head blank; a finish processing step. The extruding technology has the characteristics of few procedures, short process, low cost, convenience in operation, stable product quality and great product consistency and is suitable for massive production.

Owner:上海久丰汽车零件有限公司

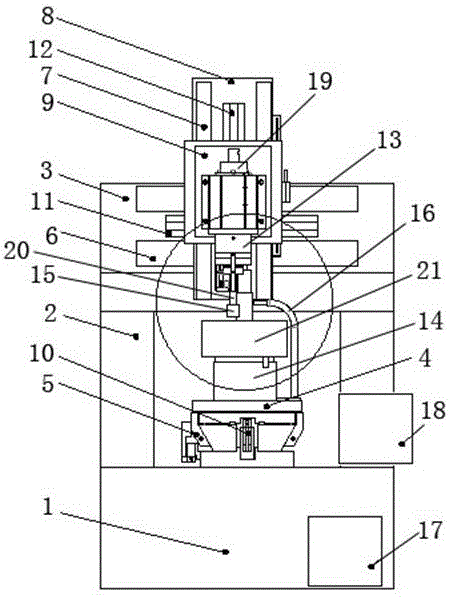

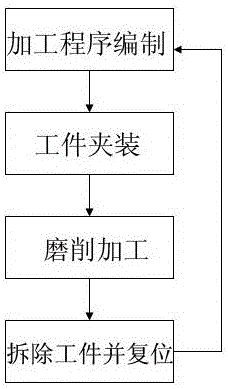

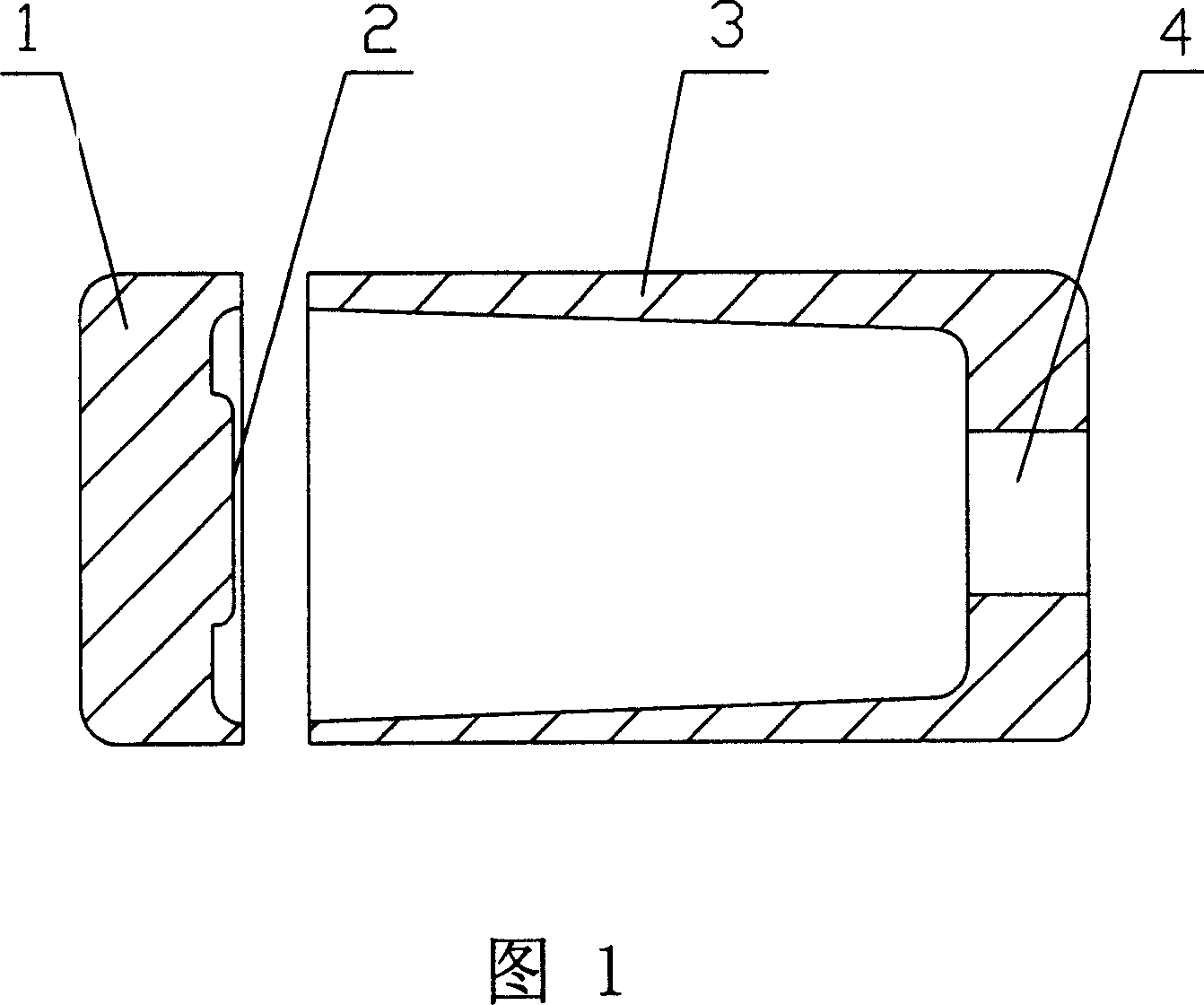

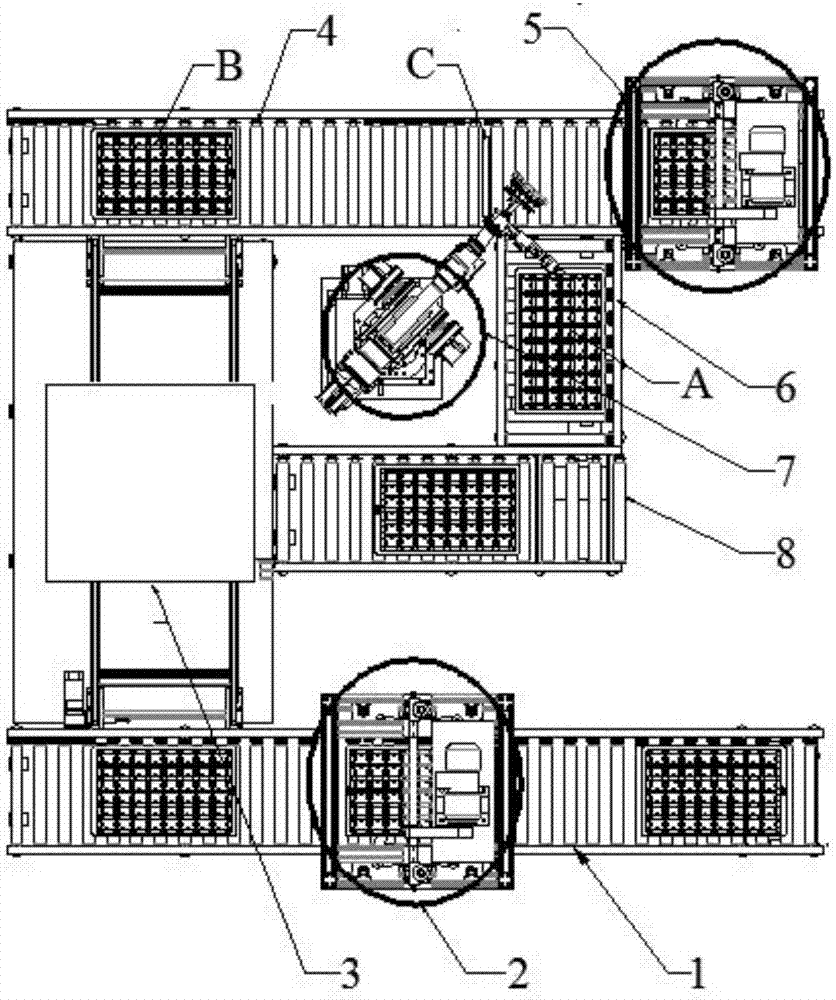

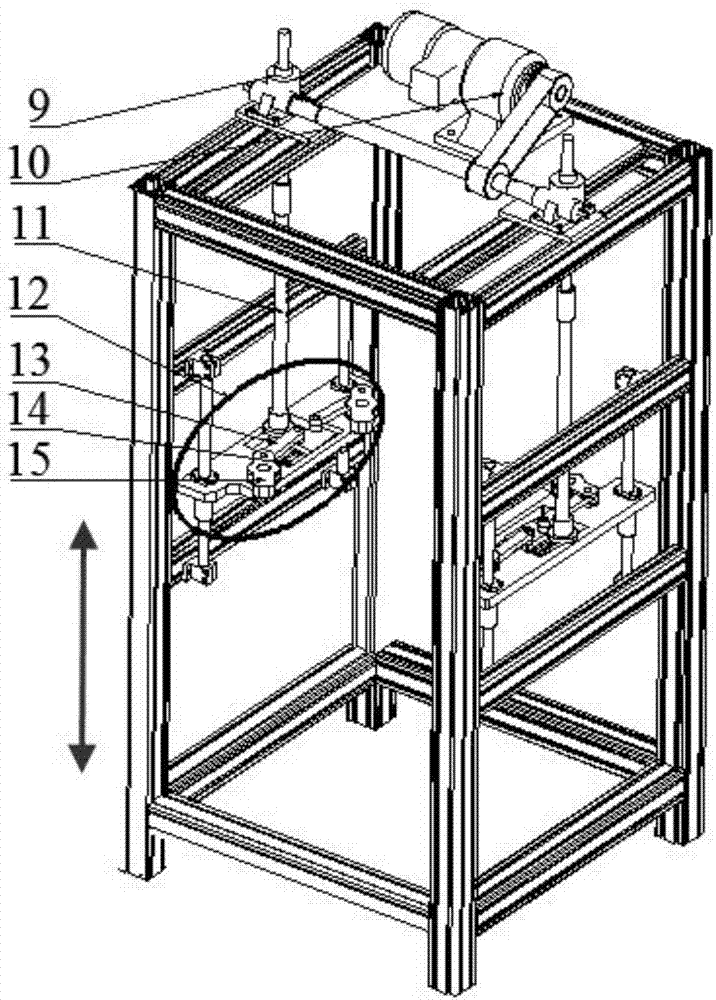

Ultra-precision shaft part electric grinding processing device and processing technology

InactiveCN105033375AHigh precisionHigh movement precisionLarge fixed membersControl systemEngineering

Owner:BEIJING AOTEPUSEN PRECISION MACHINERY

Forming process of large conic roller blank

InactiveCN101020199AGood tissue densityImprove processing efficiencyExtrusion diesExtrusion control devicesEngineeringForming processes

The present invention discloses forming process of large conic roller blank, and belongs to the field of cold extrusion forming technology. The forming process includes the steps of: cutting the metal rod into the material sections in required size, external grinding to required size, extruding in an extruder at pressure of 200-800 tons, and pushing out the extruded large conic roller blank. The forming process is superior to turning process, and has high steel material utilization rate, high production efficiency, improved material structure and other advantages.

Owner:王建昌

Automatic connection system used for detection of single-phase electric energy meter broadband power carrier module

InactiveCN107876435ARealize the automatic splitting of outboundReduce investmentLine-transmission monitoring/testingSortingStack machineCarrier signal

The invention relates to an automatic connection system used for detection of a single-phase electric energy meter broadband power carrier module. A circulation box containing the single-phase electric energy meter broadband power carrier module to be detected sequentially carries out conveying through a feeding assembly line, an unstacker, an electromagnetic shielded box, a conveying line and a stacking machine, a detection module is arranged in the electromagnetic shielded box and is used for carrying out multi-property detection on the single-phase electric energy meter broadband power carrier module, the detection frequency band of the detection module ranges from 2 MHz to 20 MHz, stock removal and automatic splitting of the whole single-phase electric energy meter broadband power carrier module can be achieved, qualified products are automatically stacked and connected with a storage system, manpower resource input in the module de-stacking and stacking process can be reduced, labor intensity is reduced, the system is suitable for batched module detection, and guarantee is provided for improving efficiency of the whole module detection system.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Casting method for thermal power ultra-supercritical valve cover

InactiveCN102825216ALower the altitudeEasy to cutFoundry mouldsFoundry coresUltimate tensile strengthPollution

The invention relates to a casting method for a thermal powder ultra-supercritical valve cover. The method is characterized by arranging the positions of the casting head and pouring water ports reasonably, so that shrinkage area at the center of a casting head is guaranteed to diverge from a circular truncated cone, and partial of the circular truncated cone is exposed to be used as a cutting datum; arranging two layer pouring water ports at the positions of a cylinder and a flange respectively, so that pouring rate at the flange is increased; employing a single-tank-double-hole pouring, with a pouring temperature of 1575-1585 DEG C; adopting a covering agent for heat-preservation after the casting head is poured full; and by using a hot-knockout process and loading the poured casting head on a furnace for full annealing heat treatment. Compared with a conventional method, the method provided by the invention has the beneficial effects that 1) the casting head employs eccentric arrangement, so that shrinkage defects at the position of the circular truncated cone on the flange is solved; 2) inclusion defects caused by splash generated by too fast bottom casting speed can be prevented by arranging the two layer pouring water ports; 3) crack defects are solved thoroughly, repair welding amount is decreased, and production cost is reduced; and 4) stock removal of the casting head is reduced, labor intensity and pollution of the cutting to environment is reduced, utilization rate of the furnace is increased, and the quality of a casting member is improved.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

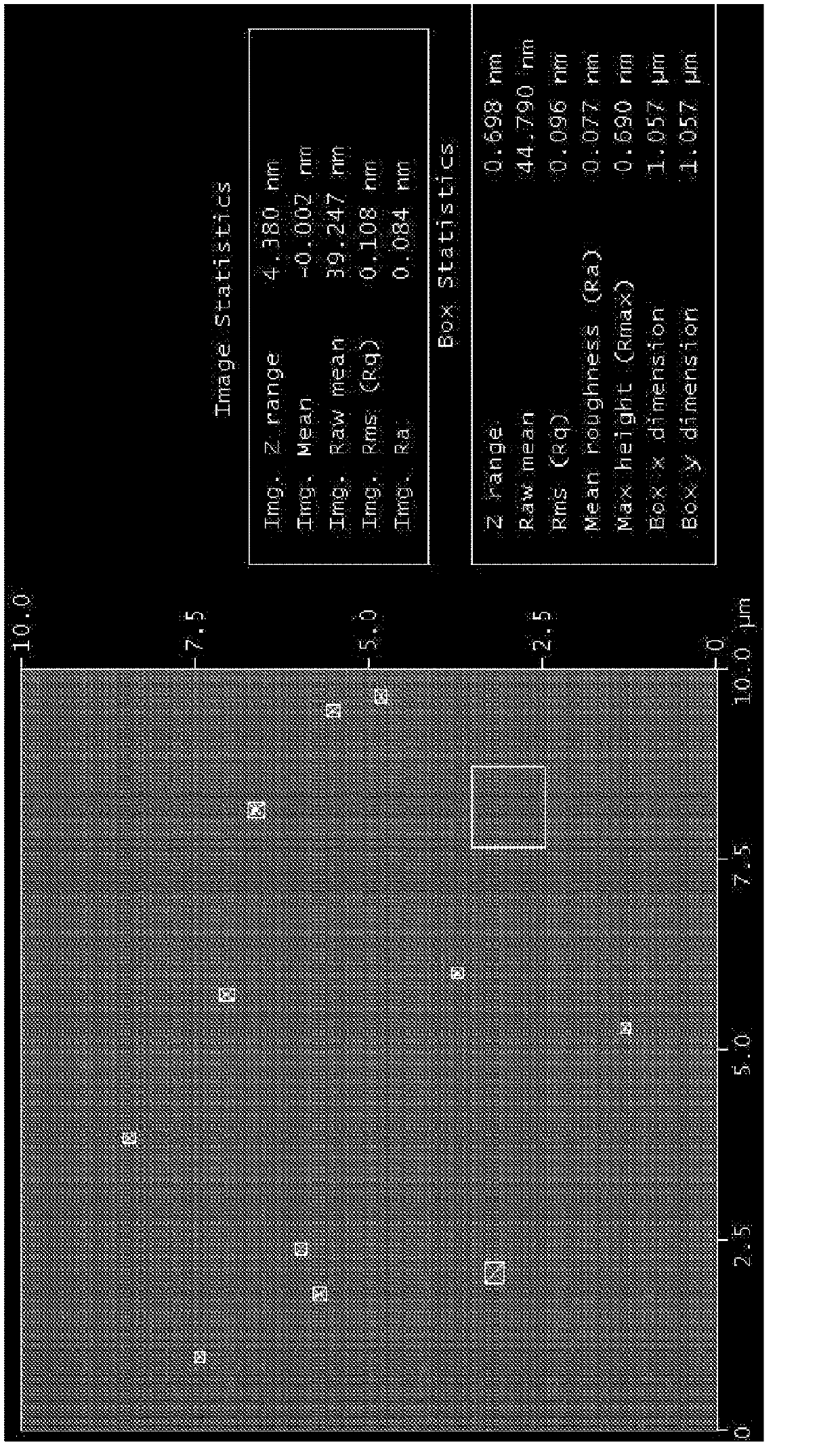

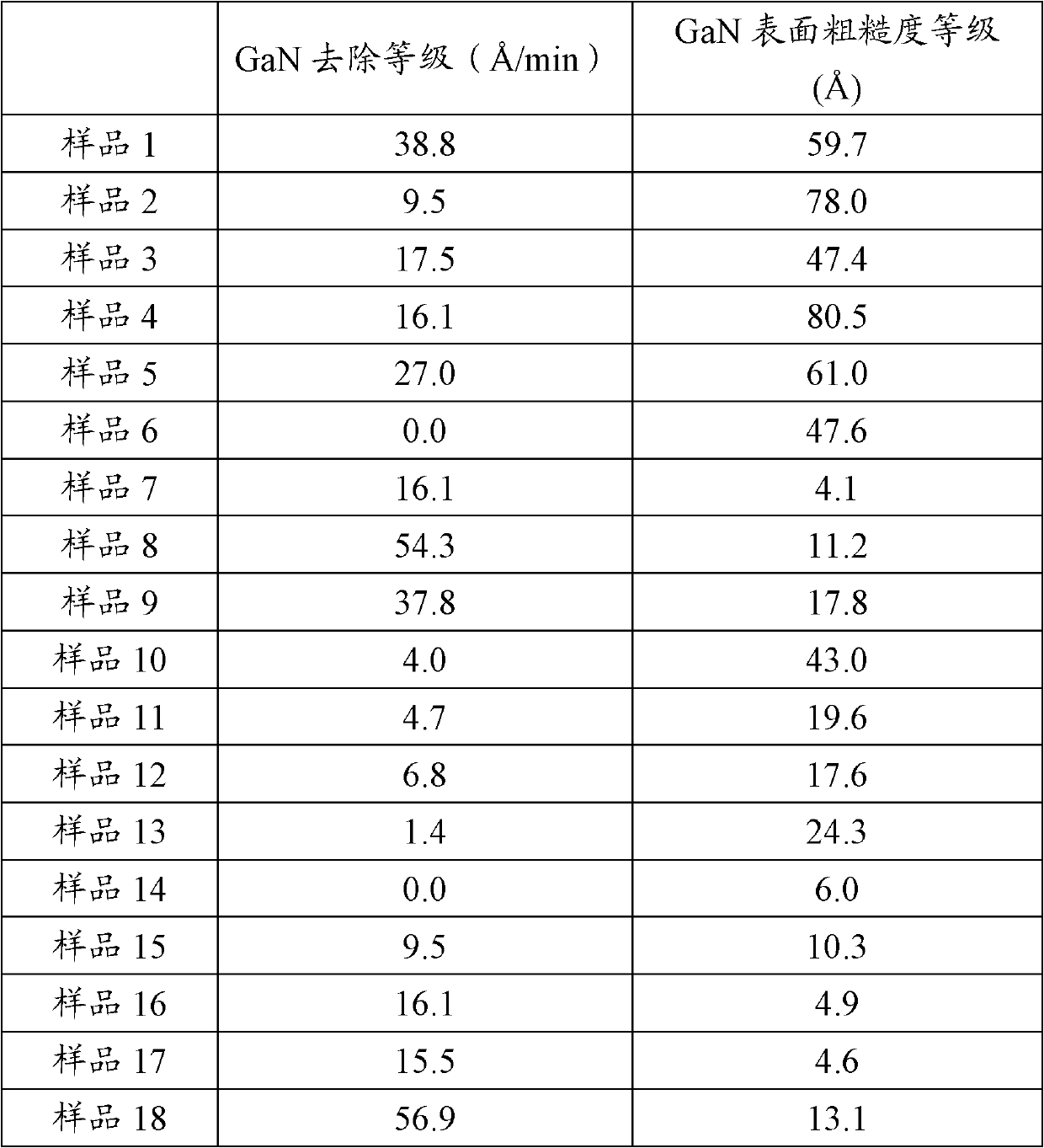

Chemical mechanical planarization using nanodiamond

A method for chemical mechanical polishing of a substrate includes polishing the substrate at a stock removal rate of greater than about 2.5 Angstrom / min to achieve a Ra of not greater than about 5.0 Angstrom. The substrate can be a III-V substrate or a SiC substrate. The polishing utilizes a chemical mechanical polishing slurry comprising ultra-dispersed diamonds and at least 80 wt% water.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

System and method for precision machining of high hardness gear teeth and splines

ActiveUS7527548B2Minimize impactBig advantageEdge grinding machinesRevolution surface grinding machinesReciprocating motionGear wheel

A gear shaper machine system drives and maneuvers a hone tool to generate teeth geometry in a manner the teeth were machined prior to a hardening process. After heat treatment, the hone tool is indexed to the teeth geometry spacing of the workpiece so as to divide the stock removal evenly between the drive and coast sides. The hone tool may be driven with rotational and reciprocating synchronous teeth generating motion in which the hone tool reciprocates along the length of the teeth parallel to the centerline of the workpiece while the workpiece and hone tool rotate with synchronous motion.

Owner:SIKORSKY AIRCRAFT CORP

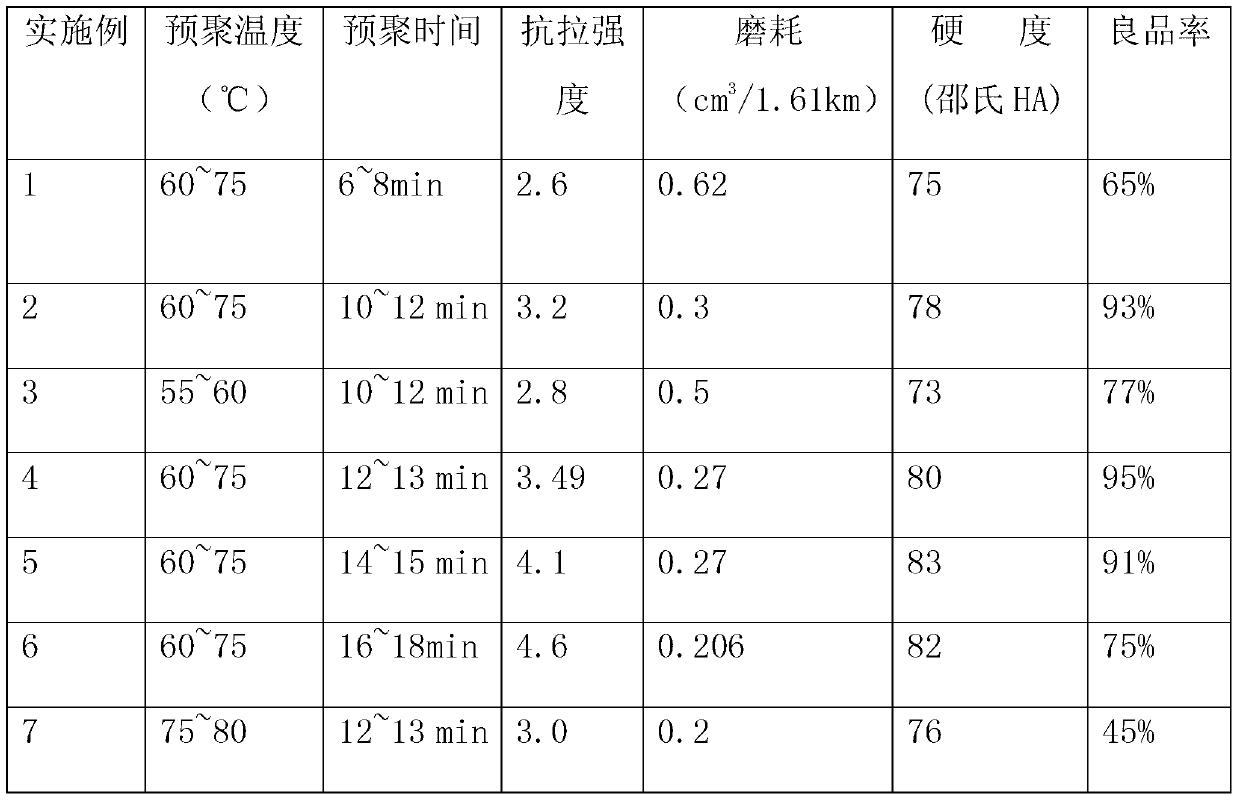

Preparation method for polyurethane polishing material by using network interpenetration

InactiveCN103342795AStable material systemLong storage time at room temperaturePolishing compositions with abrasivesEpoxyPolyol

The invention discloses a preparation method for a polyurethane polishing material by using network interpenetration. A secondary hydroxyl group and an epoxy group in polymer polyol and an epoxy resin are allowed to react with isocyanate by using an interpenetrating polymer network (IPN) method, then polishing powder is interpenetrated and filled into a polyurethane network, so pressure resistance, heat resistance and hydrolytic stability of the polyurethane polishing material can be improved, and wear resistance of a substrate material is appropriately reduced at the same time; meanwhile, since a part of organic dispersions are filled in the structure of the material, wear resistance of a polyurethane foam substrate is reduced, which enables the substrate and a polishing powder filling material to fall off synchronously, so the problems of great possibility of passivation and reduction of a stock removal rate of a polishing gasket with high wear resistance are solved.

Owner:HEFEI HONGGUANG ABRASIVE SCI & TECH

Screw for osteosynthesis and arthrodesis

The invention relates to a self-tapping and self-boring osteosynthesis screw for compressive orthopaedic surgery, characterised in that, in the bone engagement regions, at both the distal portion (A1a) and at the proximal portion (A2a), the sum of the angles defining the outer taper of the shank (f) and the taper of the crest line of the screw thread pitch (P) is higher than 45°, and in that the leading portion (i.e. the most distal one) of each thread includes a plurality of cutting edges (AR) obtained by stock removal.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com