Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Good bath stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cationic electrodeposition coating composition

InactiveUS6333367B1Satisfactory corrosion resistanceReduce resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyAcrylic resin

A cationic electrodeposition coating composition containing (A) an acrylic resin obtained by subjecting a mixture of 10 to 60% by weight of a hydroxyl group-containing acrylic monomer (a), 5 to 35% by weight of an amino group-containing acrylic monomer (b), 5 to 55% by weight of an aromatic vinyl monomer (c) and optionally another acrylic monomer (d) to a radical copolymerization reaction; (B) a hydroxyl group-containing acrylic resin-modified epoxy resin obtained by reacting 65 to 95% by weight of a resin composition consisting of 10 to 90% by weight of an epoxy resin (e) and 90 to 10% by weight of a hydroxyl group-containing acrylic resin (f) with 5 to 35% by weight of an amine compound (g); (C) a aliphatic and / or alicyclic blocked polyisocyanate compound, and (D) a bismuth compound component, a mixing ratio of the components (A), (B) and (C) being such that the component (A) is in the range of 40 to 90% by weight, the component (B) is in the range of 5 to 55% by weight and the component (C) is in the range of 5 to 40% by weight based on a total weight of solid contents in the components (A), (B) and (C), the component (D) being contained in such an amount as to be in the range of 0.01 to 10 parts by weight as a bismuth content per 100 parts by weight of a resin solid content in the electrodeposition coating composition.

Owner:KANSAI PAINT CO LTD

Acid bright copper-plating electroplating process

The invention relates to an acid bright copper-plating electroplating process. The process comprises the steps of preparation of a copper plating solution, workpiece pretreatment, acid bright copper plating and the like. The process can continuously plate multiple copper coatings which are some millimeters thick on the surface of a metal substrate without electroplating for several times; the process guarantees good binding force between electroplated cast copper and the substrate, and can bear external force from turning, milling, drawing, externally throwing and other machining; and a plating solution is good in stability and uniform in surface.

Owner:河南江河机械有限责任公司

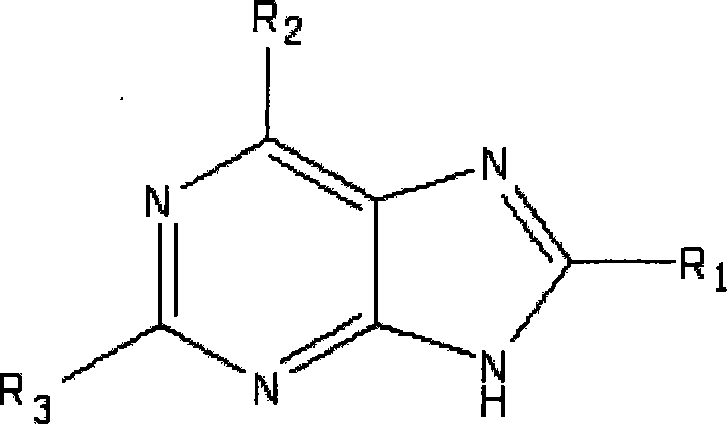

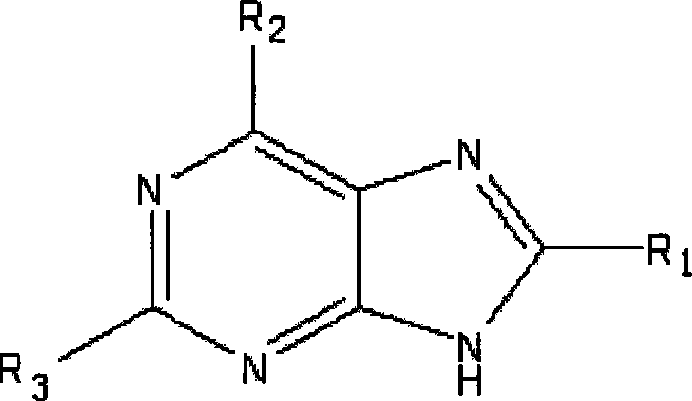

Electroplating solution without cyanogen for plating silver

This invention provides a cyanide-free silver-electroplating solution, which comprises: silver-containing organic or inorganic salt 1-200 g / L, purin coordination agent 1-800 g / L, supporting electrolyte 1-200 g / L, pH regulator 0-550 g / L, and additive system. The preparation method comprises: uniformly mixing the above components to prepare the cyanide-free silver-electroplating solution, and adjusting the temperature to 10-60 deg.C. Compared with the traditional formula, the cyanide-free silver-electroplating solution in this invention has such advantages as low or no toxicity, and high stability. Silver ions have a very low displacement rate with copper, nickel, iron, aluminum, chrome, titanium and alloy matrices. The work piece to be plated does not need preliminary silver plating or silver dipping. The silver-electroplating layer has such advantages as high adhesiveness and high shinness, and can be used in decorative and functional electroplating fields.

Owner:FUZHOU UNIV

Chemical gold plating solution

InactiveCN105543816AGolden appearanceBright colorLiquid/solution decomposition chemical coatingThioureaElectron

The invention relates to a chemical gold plating solution for quickly depositing a gold layer. The chemical gold plating solution comprises the following components: 0.5-3g / L of sodium gold sulfite (based on Au), 22-28g / L of sodium sulfite, 13-20g / L of sodium thiosulfate, 1-5g / L of triammonium citrate, 8-12g / L of borax, 0.1-5g / L of thiourea, and 0.01-0.09g / L of benzotriazole. The appropriate pH value of the plating solution is 6.5-7.2, and the appropriate temperature is 75-85 DEG C. The gold plating solution provided by the invention does not contain cyanide, is good in stability and high in plating speed, and can obtain a plated layer with thickness more than or equal to 0.4mu m in 20 minutes, the appearance of the plated layer is golden and bright in color, and the requirement of plating thick gold on most products can be met. The chemical gold plating solution not only can meet requirements of functional electron electroplating, but also can be used as a decorative gold plating solution.

Owner:HARBIN INST OF TECH AT WEIHAI

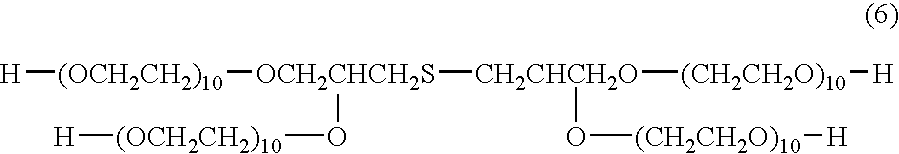

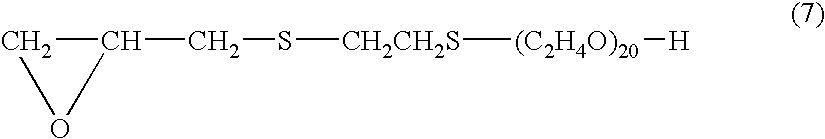

Silver and silver alloy plating bath

InactiveUS20090321269A1Good bath stabilityComposition is stableAnti-corrosive paintsLiquid/solution decomposition chemical coatingIridiumIndium

To develop stable, non-cyanide silver and silver alloy plating baths. The present invention is a silver and silver alloy plating bath, comprises: (A) a soluble salt, comprising a silver salt or a mixture of a silver salt and a salt of a metal selected from the group consisting of tin, bismuth, cobalt, antimony, iridium, indium, lead, copper, iron, zinc, nickel, palladium, platinum, and gold; and (B) at least one aliphatic sulfide compound comprising a functionality selected from the group consisting of an ether oxygen atom, a 3-hydroxypropyl group, and a hydroxypropylene group, with the proviso that the aliphatic sulfide compound does not comprise a basic nitrogen atom.

Owner:ISHIHARA CHEM +1

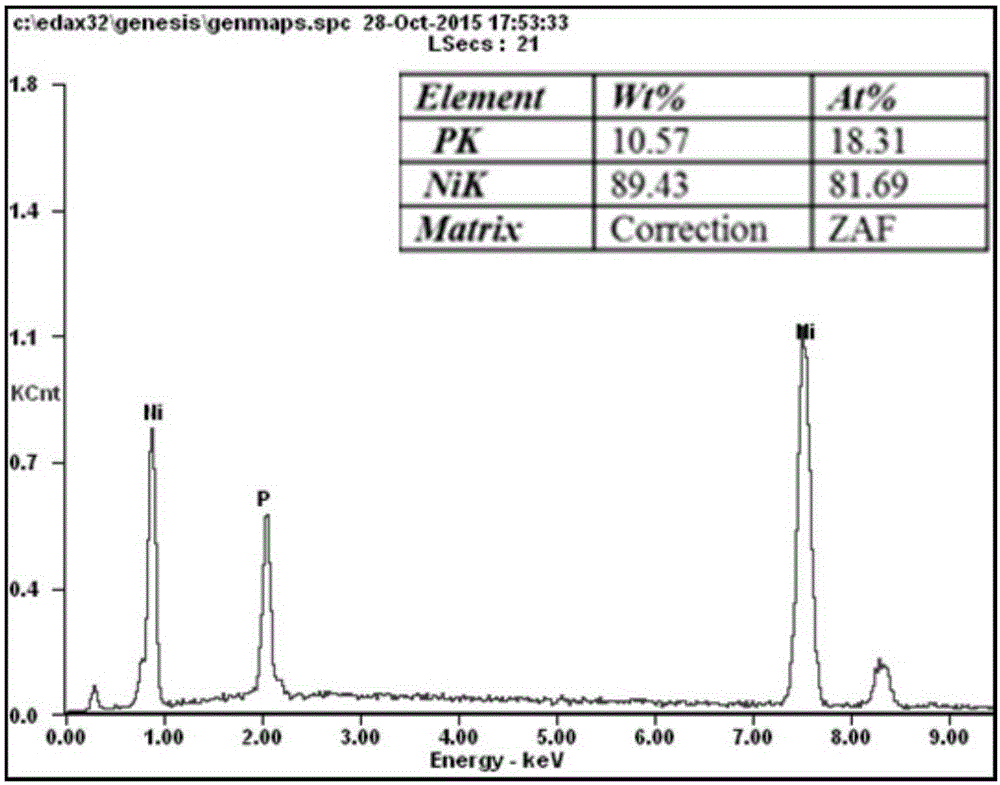

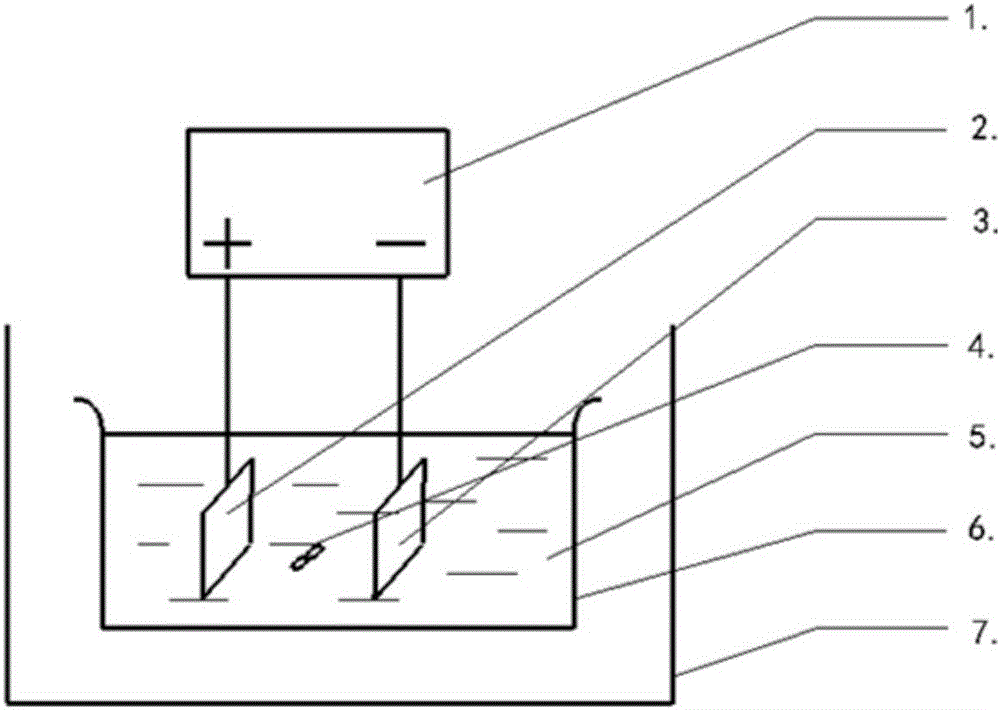

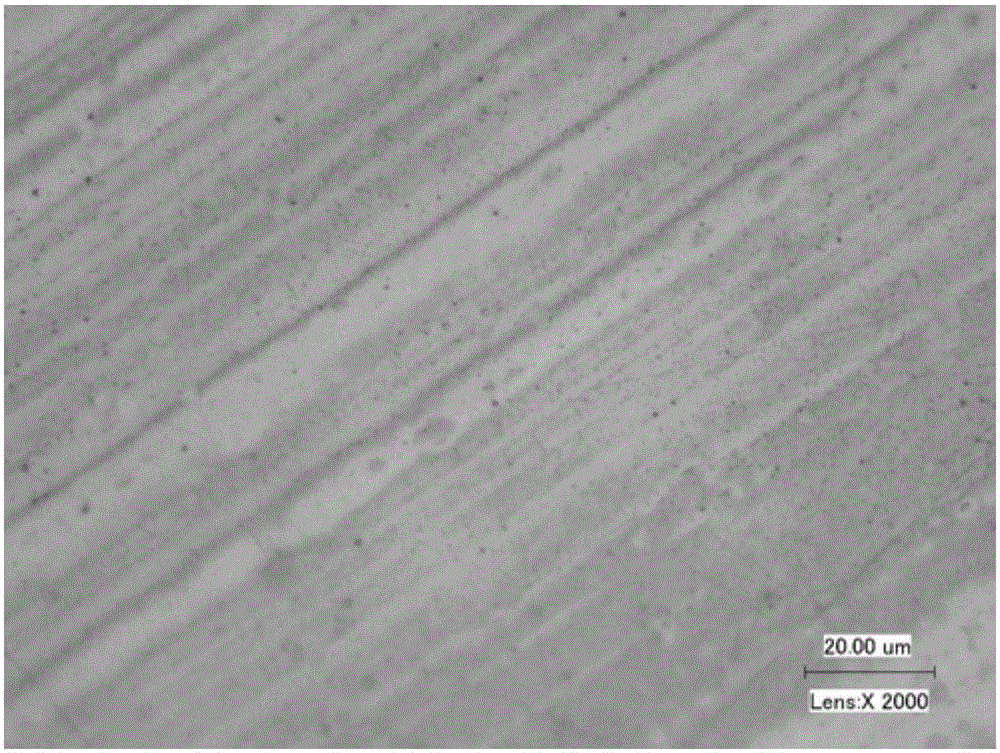

Phosphorus chemical nickel plating concentrated solution and plating process

ActiveCN104328395AFast deposition rateGood bath stabilityLiquid/solution decomposition chemical coatingSodium phosphatesPolyethylene glycol

The invention discloses a phosphorus chemical nickel plating concentrated solution and a plating process, the concentrated solution comprises three parts of an A solution, a B solution and a C solution, a main salt, a brightening agent, an accelerating agent and deionized water are mixed into the A solution at room temperature; a first buffer, a first complexing agent, sodium hypophosphite, a stabilizer, polyethylene glycol 6000, a brightening agent and deionized water are mixed into the B solution at room temperature; a second buffer, a second complexing agent, the stabilizer, the sodium hypophosphite, the polyethylene glycol 6000, the accelerating agent, the brightening agent, ammonia and the deionized wate are mixed r at room temperature into the C solution; the A solution and the B solution are used for grooving, and the A solution and the C solution are used for replenishment. According to the volume percentage, the A solution, the B solution, and dilution water are mixed into a chemical nickel plating solution for plating, the nickel content in the nickel plating solution is lower than 4.0g / L, and the A solution and the C solution are replenished. When the concentrated solution is used for nickel plating, deposition rate is quick, coating hardness and wear resistance are high, and the concentrated solution is suitable for chemical nickel plating of aluminum alloy, all kinds of iron alloy, copper alloy, nickel iron alloy, nickel copper alloy and some non conductive substrates.

Owner:JINCHUAN GROUP LIMITED

Potassium chloride-type galvanizing plating solution and its preparation method

Belonging to the field of plating solutions, the invention relates to a potassium chloride-type galvanizing plating solution and its preparation method. With water as the solvent, the plating solution of the invention is composed of the following components: zinc chloride at a concentration of 50-80g / L, potassium chloride at a concentration of 180-280g / L, boric acid at a concentration of 30-40g / L, a softening agent at a concentration of 6-10mL / L, a brightener at a concentration of 0.1-0.4mL / L, and a proper amount of a conditioning agent. The plating solution prepared by the method of the invention is characterized by fast lightening speed, good leveling, high temperature resistance, and fewer decomposition products.

Owner:TIANJIN JUXING ELECTROPLATING

Neutral tin-plating addition agent

The invention discloses a neutral tin-plating addition agent. The neutral tin-plating addition agent is characterized by being prepared from the following raw materials in percentage by weight: 20%-30% of a complexing agent, 1%-3% of a wetting agent, 1%-5% of a surfactant, 10%-20% of a pH regulator and the balance of water. According to the neutral tin-plating addition agent, dangerousness and pollution caused by an acidic addition agent in the prior art are avoided, stable performance can be maintained at different temperatures, the storage life of products is prolonged, the stability of tin-plating liquid containing the neutral tin-plating addition agent is good while the uniform plating capability and the penetration capability are ensured, and a good tin-plating effect can be realizedwithin the large electroplating temperature range.

Owner:广东比格莱科技有限公司

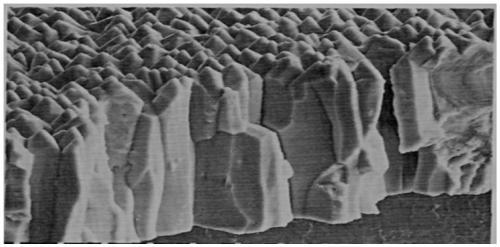

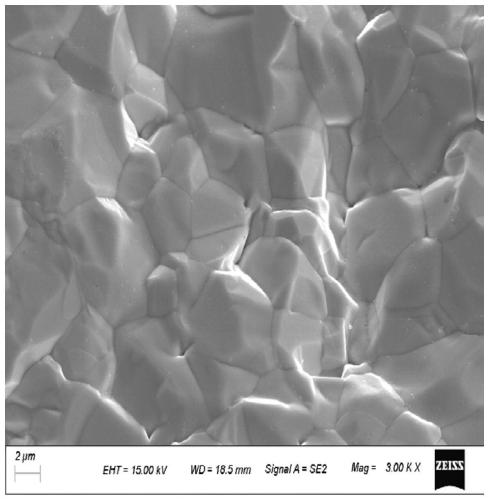

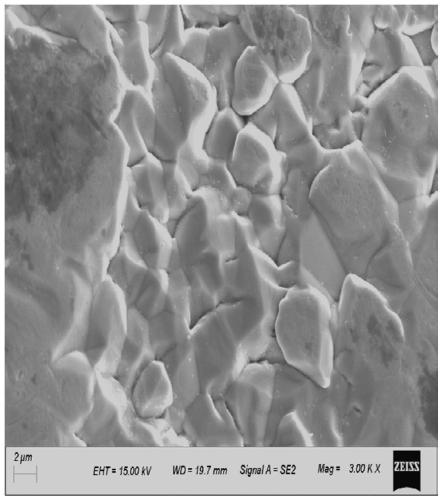

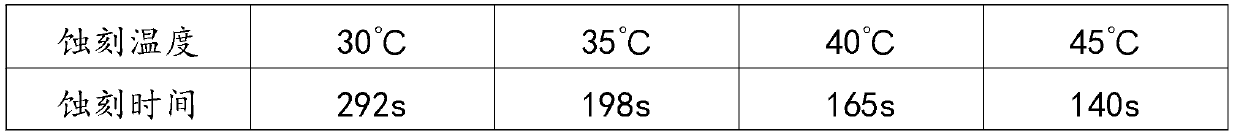

Copper seed etching solution used for wafer level package

InactiveCN110499509AFacilitated reaction mechanismReduce the impact of side erosionReaction temperatureSurface-active agents

The invention discloses a copper seed etching solution used for wafer level package. The etching solution comprises the following components, 40-60g / L of hydrogen peroxide, 5-35g / L of inorganic acid,5-35g / L of organic acid, 1-30g / L of copper ions, 1-2g / L of chloride ions and 1-2g / L of surface active agents according to the concentration proportion. The components are mixed in proportion, the mixing reaction temperature is between 30 DEG C and 50 DEG C, the reaction time is 1s-400s, and the copper seed etching solution is formed after mixing. Chelating agents formed by mixing the hydrogen peroxide and the inorganic acid and the copper ions can be subjected to chelation to form water-soluble complexes, so that equilibrium is reached; and the chloride ions play a role in maintaining the PH value of a system in the solution, maintains charge balance of the system in the etching process and prolongs the service life of the etching solution. The copper seed etching solution has the characteristics of being stable in performance, suitable for superfine circuits, small in lateral erosion and hardly corrosive to copper and aluminum.

Owner:成功环保科技(南通)有限公司

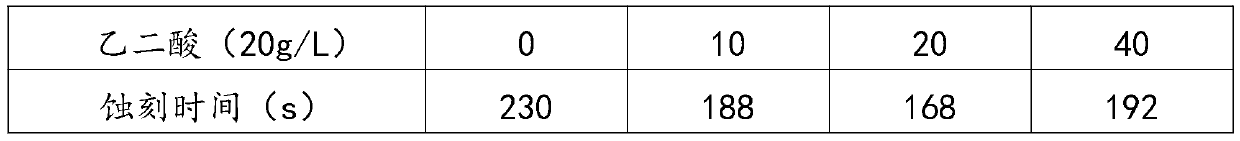

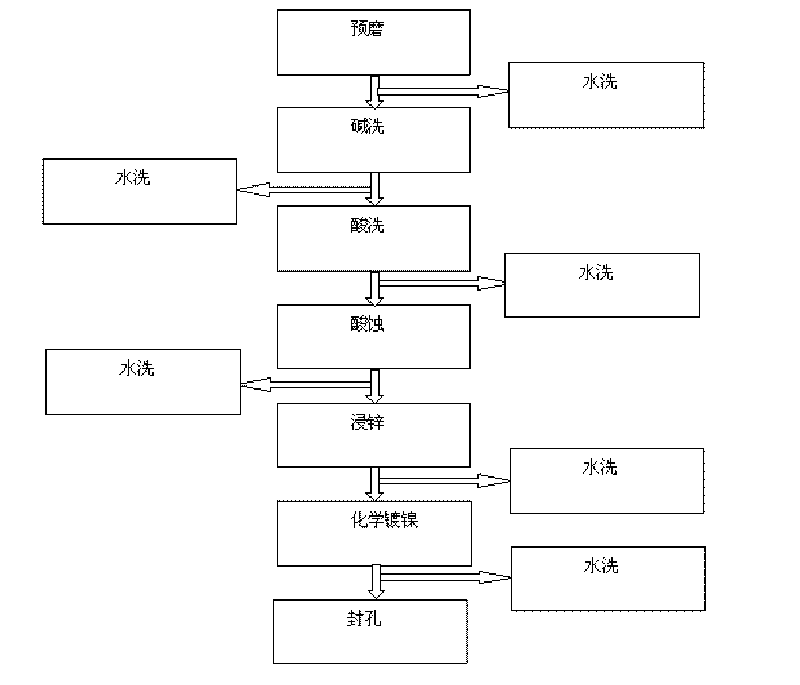

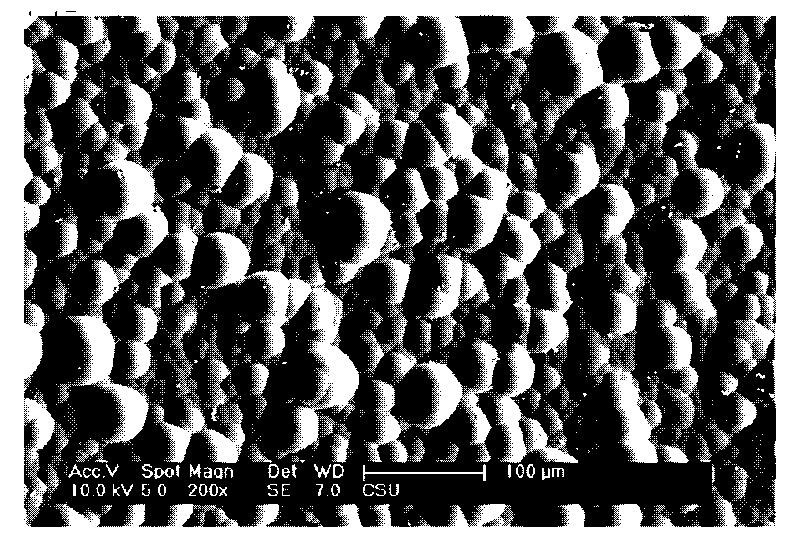

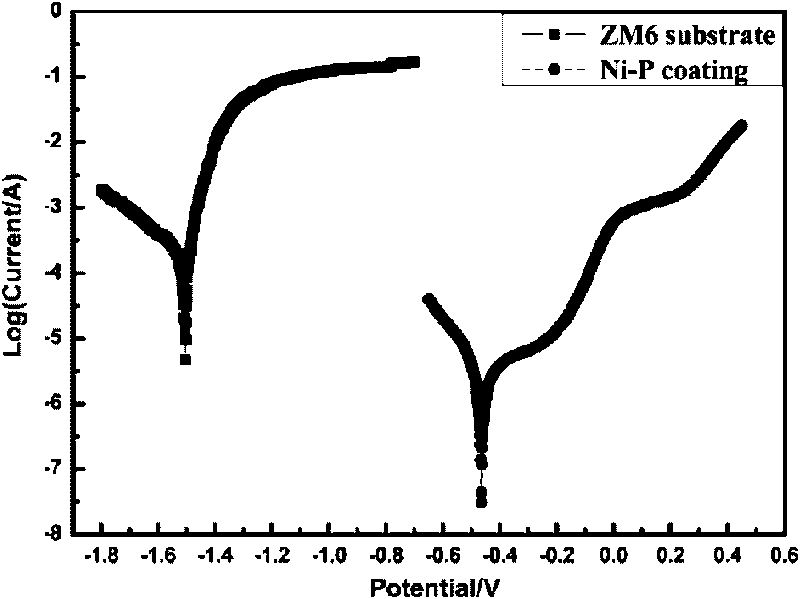

Chemical nickel-plating method for ZM6 magnesium alloy

InactiveCN101717926AImprove corrosion resistanceLess corrosiveLiquid/solution decomposition chemical coatingAcid etchingAcid washing

The invention relates to a method for chemically plating nickel to a ZM6 magnesium alloy. The method comprises the steps of performing pretreatment on a magnesium alloy matrix before plating and then performing chemical nickel plating to deposit a chemical nickel-plating layer, wherein the pretreatment before plating comprises four steps, namely alkali washing, acid washing, acid etching and zinc dipping; and the chemical nickel-plating layer is obtained by adopting basic nickel carbonate serving as a main salt, sodium hypophosphite serving as a reducing agent, hydrofluoric acid serving as a corrosion inhibitor, lactic acid serving as a complexing agent and mixed solution of cadmium sulfate and potassium iodate serving as a brightening agent and a stabilizing agent. The bright and flat nickel-plating layer can be obtained by plating at the temperature of about 85 DEG C after the zinc dipping of a plated piece. The method is suitable for chemically plating the nickel to the ZM6 magnesium alloy material to achieve the aim of protecting the ZM6 magnesium alloy. The method has the advantages of high plating speed and good protection.

Owner:CENT SOUTH UNIV

Electroless palladium plating solution

ActiveUS20120118196A1Good bath stabilityShorten induction timeSemiconductor/solid-state device detailsSolid-state devicesPhosphinic AcidsPhosphoric acid

Disclosed is an electroless palladium plating solution which can form a plating layer having excellent soldering properties onto electronic components and the like and excellent wire bonding properties. The electroless palladium plating solution comprises a palladium compound, an amine compound, an inorganic sulfur compound and a reducing agent, wherein a combination of hypophosphorous acid or a hypophosphorous acid compound and formic acid or a formic acid compound is used as the reducing agent, and wherein the palladium compound, the amine compound, the inorganic sulfur compound, the hypophosphorous acid compound, and formic acid or the formic acid compound are contained in amounts of 0.001 to 0.1 mole / l, 0.05 to 5 mole / l, 0.01 to 0.1 mole / l, 0.05 to 1.0 mole / l and 0.001 to 0.1 mole / l, respectively. The electroless palladium plating solution is characterized by having excellent soldering properties and excellent wire bonding properties.

Owner:KOJIMA CHEM CO LTD

Trichrome passivates for treating galvanized steel

ActiveUS20090266450A1Good bath stabilityImprove performanceWelding/cutting media/materialsSuperimposed coating processOrganic acidAmmonium compounds

In one embodiment, the invention provides a composition useful for passivating a metal surface, in particular a zinciferous surface, comprising, preferably consisting essentially of, most preferably consisting of water and:(A) dissolved phosphate ions;(B) dissolved trivalent chromium ions;(C) dissolved anions of at least one complex fluoride of an element selected from the group consisting of Ti, Zr, Hf, Si, Sn, Al, Ge and B; preferably Ti, Si and / or Zr;(D) an optional component of dissolved free fluoride ions;(E) organic acid inhibitor, preferably comprising quaternary ammonium compounds; and, optionally(F) a pH adjusting component; andoptionally organic hydroxyl acids.

Owner:HENKEL KGAA

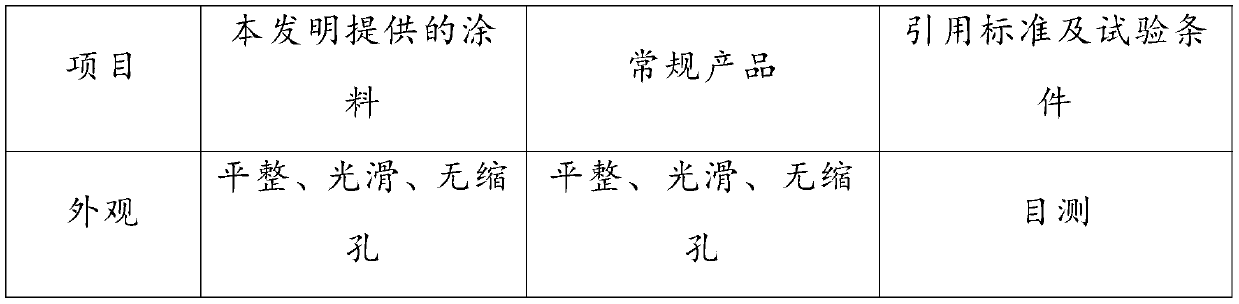

Multipurpose high weather resistant acrylic acid electrophoretic paint and preparation method thereof

ActiveCN103289498AGood alkali resistanceGood weather resistancePaints for electrolytic applicationsTO-18Weather resistance

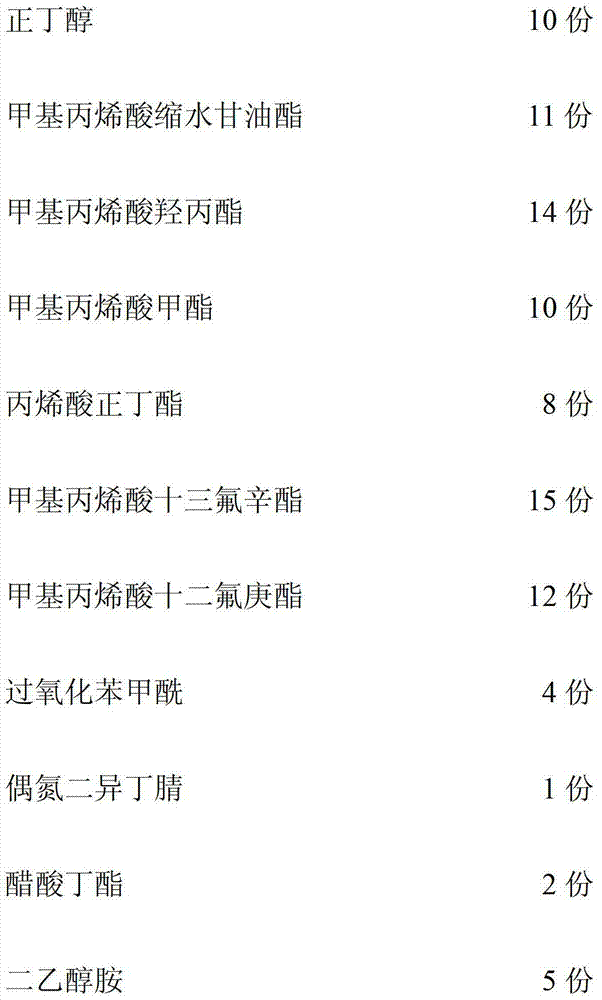

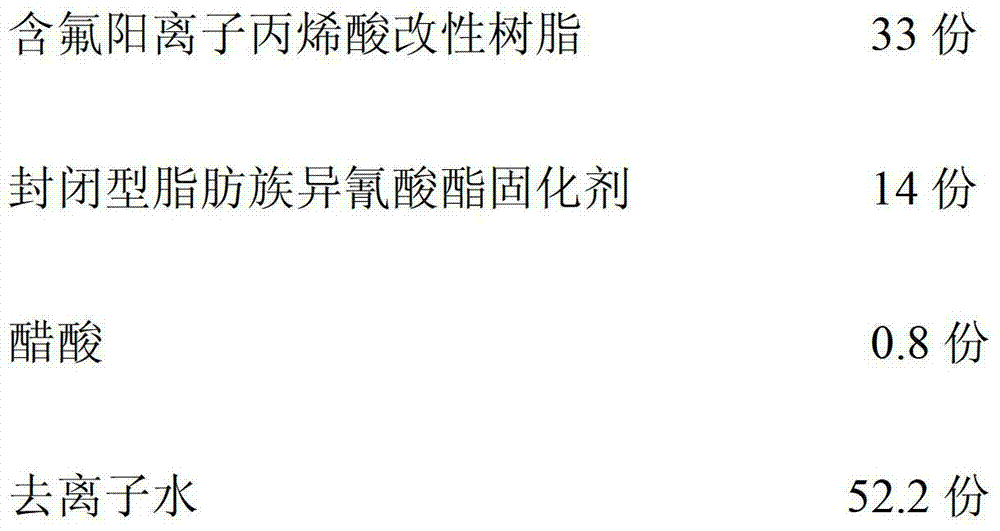

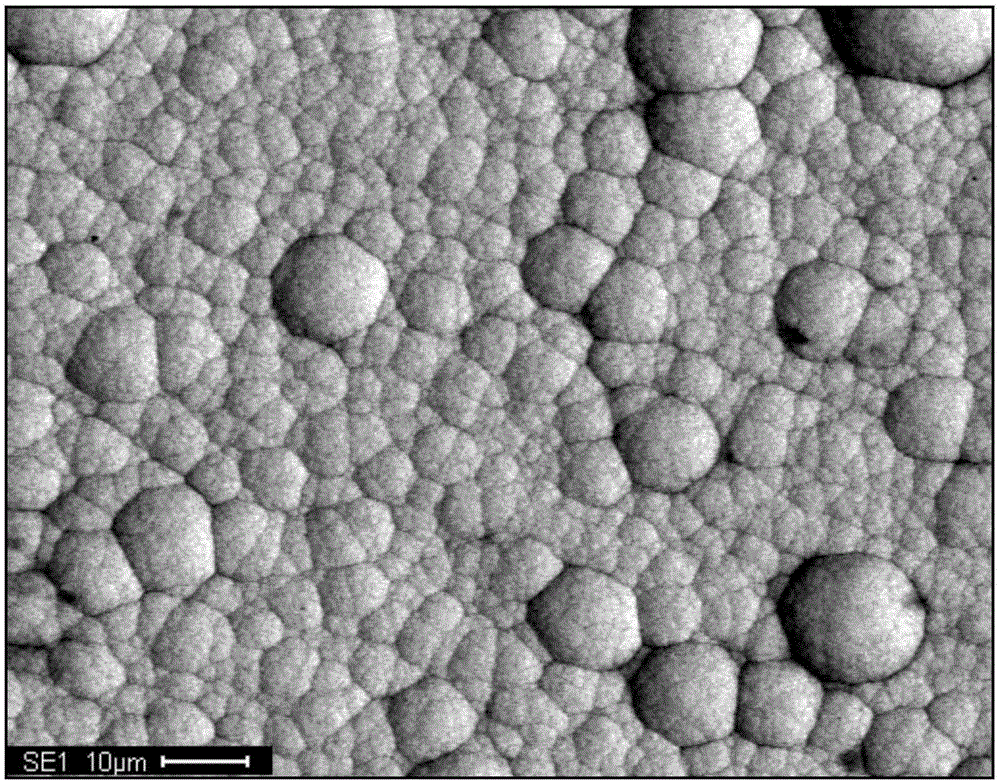

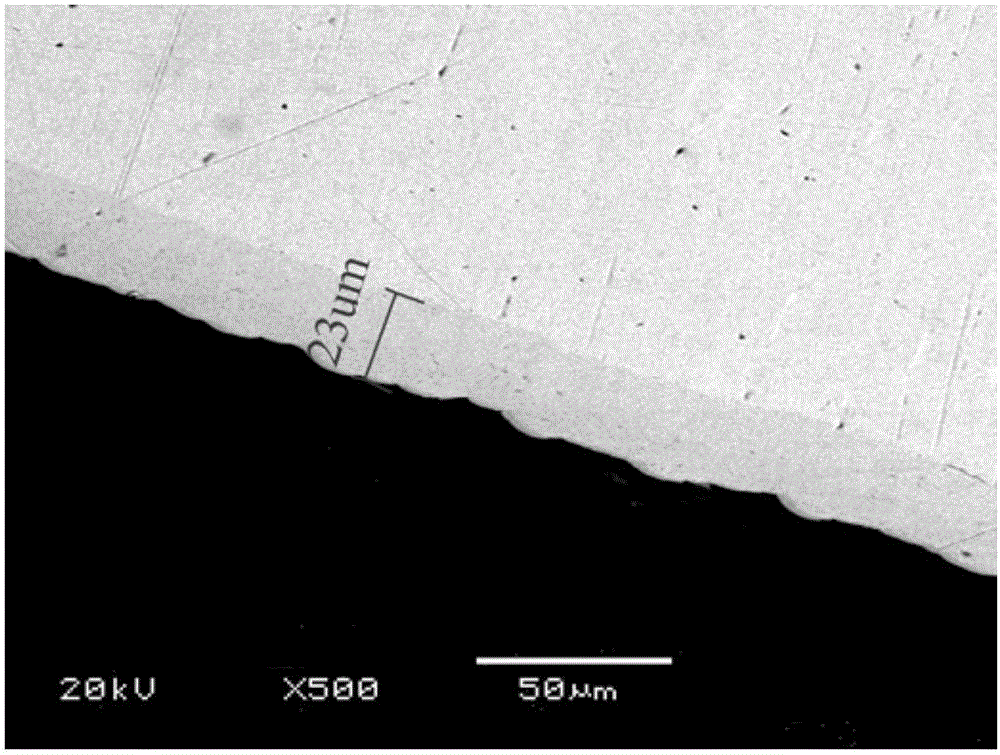

The invention relates to a multipurpose high weather resistant acrylic acid electrophoretic paint and a preparation method thereof. The paint comprises two components, and is produced from high weather resistant acrylic acid modified emulsion and weather resistant color paste at a ratio of 8:1. The high weather resistant acrylic acid modified emulsion comprises following ingredients, by weight: 33 to 39 portions of fluorine-containing cationic acrylic acid modified resin, 14 to 16 portions of blocked aliphatic isocyanate curing agent, 0.8 to 1 portion of a neutralizer and 44 to 52.2 portions of deionized water. The weather resistant color paste comprises following ingredients, by weight: 15 to 18 portions of acrylic acid grinding resin, 1 to 2 portions of a surfactant, 42 to 50 portions of deionized water and 34 to 38 portions of a pigment filler. Fineness of the weather resistant color paste is 15um or less. The paint of the invention is suitable for colorized, white and grey systems. Appearance of coatings is flat, smooth and bright after one time of electrophoretic painting. Yellowing resistance, mechanical properties, coating liquid stability, acid resistance, alkali resistance and weather resistance of the coatings are excellent.

Owner:HAOLISEN COATING SHANGHAI +1

Method for activating carbon fiber by colloid copper and preparing chemical plating copper-nickel duplex metal layer by one-step

InactiveCN109295442AReduce quality lossReduce pollutionLiquid/solution decomposition chemical coatingFiberHigh activation

The invention discloses a method for activating a carbon fiber by colloid copper and preparing a chemical plating copper-nickel duplex metal layer by one-step. According to the method for activating the carbon fiber by the colloid copper and preparing the chemical plating copper-nickel duplex metal layer by one-step, a colloid copper activating method is adopted to replace traditional palladium, cheap material copper sulfate is adopted, an optimized activating solution has good stability and high activation properties, and a composite plate formed during subsequent chemical plating is even andcontinuous; in addition, compared with a two-step method of nickel plating after copper plating, a one-step method of chemically plating the copper-nickel duplex metal layer reduces the using amountof copper sulfate and nickel sulfate, and the one-step method is faster and more efficient; and sodium monophosphate is used for replacing formaldehyde as a reducing agent, and environmental pollutionand harm to human bodies are reduced.

Owner:HEBEI UNIV OF TECH

Electroless palladium plating solution

ActiveUS8562727B2Good bath stabilityShorten induction timeSemiconductor/solid-state device detailsSolid-state devicesPhosphoric acidInorganic compound

Disclosed is an electroless palladium plating solution which can form a plating layer having excellent soldering properties onto electronic components and the like and excellent wire bonding properties. The electroless palladium plating solution comprises a palladium compound, an amine compound, an inorganic sulfur compound and a reducing agent, wherein a combination of hypophosphorous acid or a hypophosphorous acid compound and formic acid or a formic acid compound is used as the reducing agent, and wherein the palladium compound, the amine compound, the inorganic sulfur compound, the hypophosphorous acid compound, and formic acid or the formic acid compound are contained in amounts of 0.001 to 0.1 mole / l, 0.05 to 5 mole / l, 0.01 to 0.1 mole / l, 0.05 to 1.0 mole / l and 0.001 to 0.1 mole / l, respectively. The electroless palladium plating solution is characterized by having excellent soldering properties and excellent wire bonding properties.

Owner:KOJIMA CHEM CO LTD

Method for preparing nichrome composite coating in environment-friendly trivalent chromium plating solution

The invention discloses a method for preparing a nichrome composite coating in environment-friendly trivalent chromium plating solution. A specific-content composite coordination agent is added into basic plating solution containing chromic chloride, nickel sulfate and nickel chloride, so that nickel and chromium are co-precipitated on the surface of a metal, and the nichrome composite coating with flat surface and firm combination with a base material is prepared. The method has the advantages that: the prepared nichrome composite coating has the thickness of 30-210 micrometers; compared with a chromium coating, the nichrome composite coating has higher rigidity, high corrosion resistance and excellent decoration performance; and the plating solution can be recycled to contribute to protecting environment.

Owner:QILU UNIV OF TECH

Composite complexing agent and chemical nickel-plating solution containing same

InactiveCN102021543AExtend the life cycleHigh hardnessLiquid/solution decomposition chemical coatingPropanoic acidWorking temperature

The invention discloses a composite complexing agent and a chemical nickel-plating solution containing the same. In the invention, the composite complexing agent comprises the following components: 5-100g of adipic acid, 3-15g of tartaric acid, 4-15g of one or two of malic acid and citric acid and 5-6g of succinic acid or propionic acid. The invention solves the problem of short circulation cycleof a plating solution in the prior art, and meanwhile, the chemical nickel-plating solution does not contain 18 pollutants, such as lead, cadmium and the like to which high global attention is paid, therefore, the invention has the advantages that the work temperature is lower, the hardness is high and the corrosion-resistance performance is high, and the requirement on cleaning production is met.

Owner:GUANGZHOU JINHUI CHEM SCI TECH

Solution for chemically plating nickel on surface of non-catalytic active material and plating process for solution

ActiveCN105695962AQuality improvementThe composition of the plating solution is simpleLiquid/solution decomposition chemical coatingNickel saltWater soluble

The invention relates to a solution for chemically plating nickel on the surface of a non-catalytic active material and a plating process for the solution, and belongs to the technical field of chemical nickel-plating. The solution comprises liquor A, liquor B, liquor C and / or liquor D, wherein the liquor A comprises a water-soluble nickel salt and a buffer agent; the liquor B comprises a reducing agent, a complexing agent, a buffer agent, a stabilizer and a surface wetting agent; the liquor C comprises the water-soluble nickel salt and the complexing agent; and the liquor D comprises the reducing agent and the stabilizer. The plating process for the solution comprises the following steps: preparing the liquor A, the liquor B and a diluent; uniformly mixing the liquor A, the liquor B and the diluent to obtain a mixture, regulating the pH value of the mixture to 7.0-8.0, heating the mixture to a temperature of 82-88 DEG C, and carrying out primary plating by using an iron material as an initiator; filtering plating liquor after carrying out primary plating; recycling filtrate for next-time plating, feeding plating liquor obtained by the next-time plating into the liquor C and the liquor D, and recycling the plating liquor. According to the solution and the plating process thereof, the combination and the process design are reasonable, generation and emission of waste liquor can be greatly reduced, and the utilization rate of the plating liquor can be increased.

Owner:CENT SOUTH UNIV

Chemical copper plating solution

InactiveCN103173750AReasonable formulaGood bath stabilityLiquid/solution decomposition chemical coatingCopper platingPotassium sodium tartrate

The invention discloses a chemical copper plating solution which comprises 10-20 g / L copper sulfate, 5-10 g / L potassium nitrate, 5-30 g / L potassium sodium tartrate, 5-30 g / L sodium ethylene diamine tetracetate, 5-50 g / L sodium hydroxide, 5-20 g / L sodium carbonate, 0.5-2 g / L ferrous sulfate, 5-50 g / L formaldehyde, 5-50 g / L methanol and the balance of deionized water. The invention has the advantages of reasonable formula, high stability, fewer impurities, high speed and high efficiency; and the coating thickness can reach higher than 20 mu m.

Owner:黄小飞

Cyanide-free sulfite Au-Cu alloy electroplating solution and application

The invention provide cyanide-free sulfite Au-Cu alloy electroplating solution. The Au-Cu alloy electroplating solution comprises sulfite gold salt, copper sulfate, sulfite, HEDP and potassium sulfate; sulfite is a main coordination agent of Au; HEDP is an auxiliary coordination agent of Au and a main coordination agent of Cu; and the adding of HEDP can improve the electrochemical polarization so as to improve the plating layer quality and to improve the stability of sulfite gold salt. The Au-Cu alloy electroplating solution is applied to plate an Au-Cu alloy on a metal surface by using a pulse electroplating method. The plating solution is excellent in stability; an obtained plating layer only contains gold and copper elements; the surface of the plating layer is fine and uniform, low in porosity, excellent in levelness and free of cracks; and the plating layer is high in hardness and excellent in bonding force and corrosion resistance.

Owner:DALIAN UNIV OF TECH

Chrome electroplating solution formula and method

The invention discloses a chrome electroplating solution formula and method. The chrome electroplating solution comprises 5-20 g / L sodium sulfate, 15-50 g / L boric acid, 5-30 g / L aluminum sulfate, 0.5-2 g / L sodium lauryl sulfate, 5-40 g / L succinic acid, 1-10 g / L oxalic acid, 3-15 g / L nitrilotriacetic acid and the balance of water. The method comprises the following steps: 1. before plating, cleaning, derusting and removing impurities; 2. activating; 3. electroplating, wherein the temperature is 25-30 DEG C, the current density is 10-30 A / dm<2>, the pH value is 1-2, and the electroplating time is 1-3 hours; and 4. washing with water, and drying. The chrome electroplating solution has the advantages of reasonable formula, high crystallization rate, high efficiency, high bonding strength of the coating, high surface smoothness and high stability; and the method is reasonable, low in cost and simple to operate.

Owner:李平

Preparation of fluorine-containing organosilicone modified anti-graffiti paint

ActiveCN109054571AEasy to paintEnvironmental protectionAntifouling/underwater paintsPaints with biocidesPolyesterWater based

The invention relates to preparation of fluorine-containing organosilicone modified anti-graffiti paint, in particular to preparation of organosilicone polyester modified cyclopropyl resin. The resin,namely cationic resin, can be used in both aqueous paint and electrophoretic paint, plays an anti-graffiti self-cleaning role in the electrophoretic paint, and is prepared from a fluorine-silicon modified emulsion and high-performance color paste in a ratio of 6:1. The preparation has the advantages that paint products have high storage stability; the paint has high salt spray resistance, high weather resistance and high functionality after electrophoretic coating, and is applicable to painting of kitchens and places with high self-cleaning requirements; the paint is water-based two-componentanti-graffiti electrophoretic paint, and is convenient to apply, environmentally friendly and safe to use; the surfaces of boards are smooth and bright, the functionality is high, and the stability of tank liquor is also high; coatings have high mechanical property, acid-alkali resistance, weather resistance and salt-pray resistance.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Nonaqueous cyanogen-free silver-plating solution

InactiveCN101311321ASmall particle sizeSilver particle clusters with smaller particle sizeSilver plateSolvent

The invention discloses non-aqueous cyanide-free silver plating electroplating solution. The electroplating solution adopts an organic solvent instead of the water as a solvent. The concentration of every component in the electroplating solution is that a silver iron source is 1 to 200 grams per liter, a complxant is 1 to 800 grams per liter and an electroplating additive is 10 to 10000 milligrams per liter. Compared with the traditional technical formula of cyanide silver plating, the non-aqueous cyanide-free silver plating electroplating solution of the invention is very low in toxicity; compared with the cyanide-free silver plating water system plating solution, the solution of the invention has good stability and the silver particle cluster in the plating is smaller. Under the control conditions, the average particle radius is within 100 nanometers. The plating is fine and bright and has good binding force, which can be applied in the fields of decorative electroplating and functional electroplating and especially has better application in electronic chip micro channel electroplating and nano material preparation.

Owner:FUZHOU UNIV

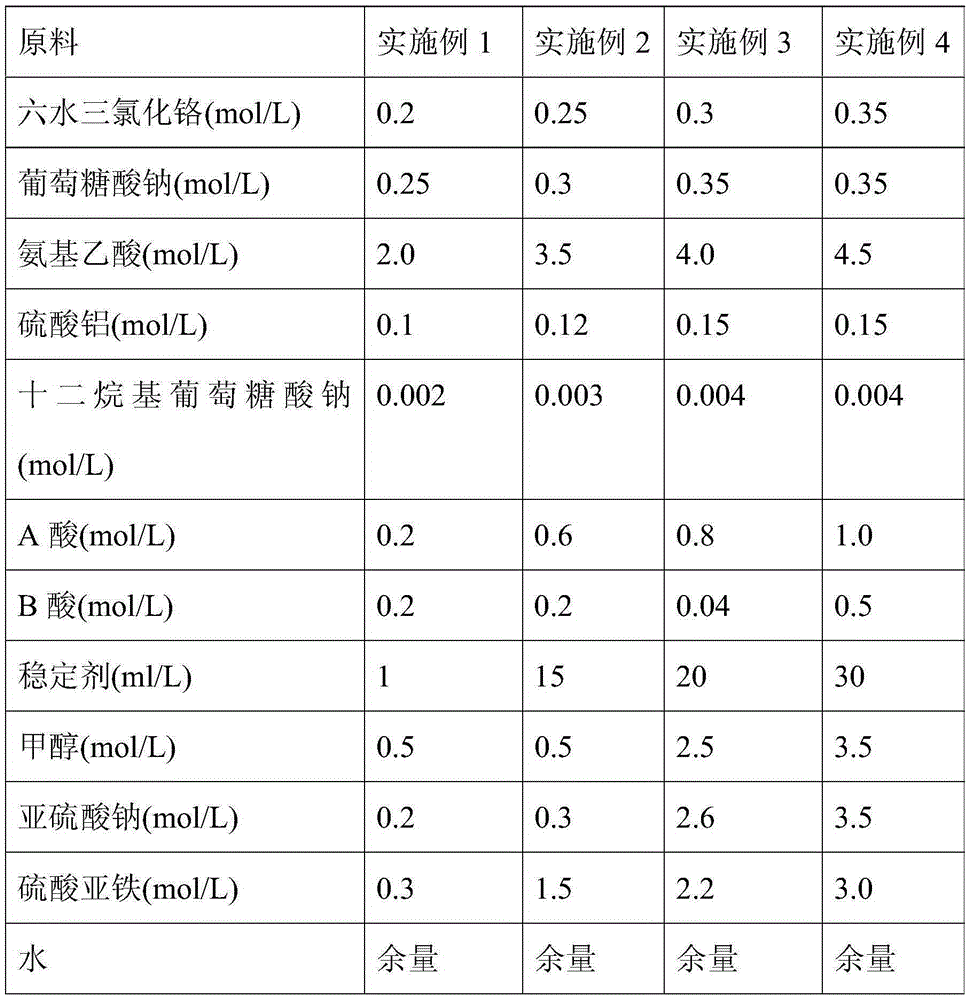

Trivalent chromium electroplate liquid and preparing method thereof

The invention discloses trivalent chromium electroplate liquid and a preparing method thereof. The trivalent chromium electroplate liquid comprises, by concentration, 0.2-0.35 mol / L of hexahydrate chromium trichloride, 0.25-0.35 mol / L of sodium gluconate, 2.0-4.5 mol / L of glycine, 0.1-0.15 mol / L of aluminum sulfate, 0.002-0.004 mol / L of dodecyl sodium gluconate, 0.4-0.8 mol / L of a complexing agent, 15-20 ml / L of stabilizer and the balance solvent water. The stabilizer is a water solution comprising 2-3 mol / L of methyl alcohol, 2-3 mol / L of sodium sulfite and 1-2 mol / L of ferrous sulfate. Compared with the prior art, the electroplate liquid is stable in performance and long in service life, and the quality of a coating is good. Meanwhile, the preparing method is simple, operation is easy, and very good application prospects and high using value are achieved.

Owner:WUXI QIAOYANG MACHINERY MFG

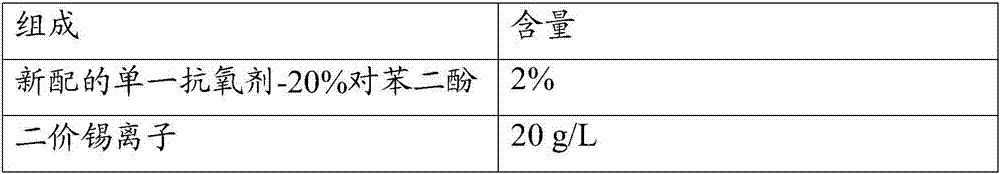

Methanesulfonic acid tin-plating solution

The invention relates to a methanesulfonic acid tin-plating solution. The methanesulfonic acid tin-plating solution comprises 10-40 g / L of Sn2+, 1-5% of methanesulfonic acid, 0.5-15% of a compound antioxidant and 0.5-4% of a grain refiner, wherein the compound antioxidant comprises a main antioxidant body and an auxiliary antioxidant body; the main antioxidant body is prepared from one or more of phenol, catechol, resorcinol, hydroquinone and carboxyl, amidogen, nitro and sulfonate group substitutes thereof; and the auxiliary antioxidant body is prepared from (2R, 3S)-2-(3,4- dihydroxy phenyl)-3,4-dihydro-2H-benzopyran-3,5,7-triol and (2S,3R)-2-(3,4-ihydroxy phenyl)-3,4-dihydro-1(2H)-benzo-3,5,7-triol3-(3,4,5-trihydroxybenzoic acid). The tin-plating solution contains the compound antioxidant, tin slurry in the plating solution can be effectively reduced, and meanwhile after the grain refiner is added, a tin-plated plate with a coating having excellent quality can be obtained.

Owner:QUAKER CHEM CHINA

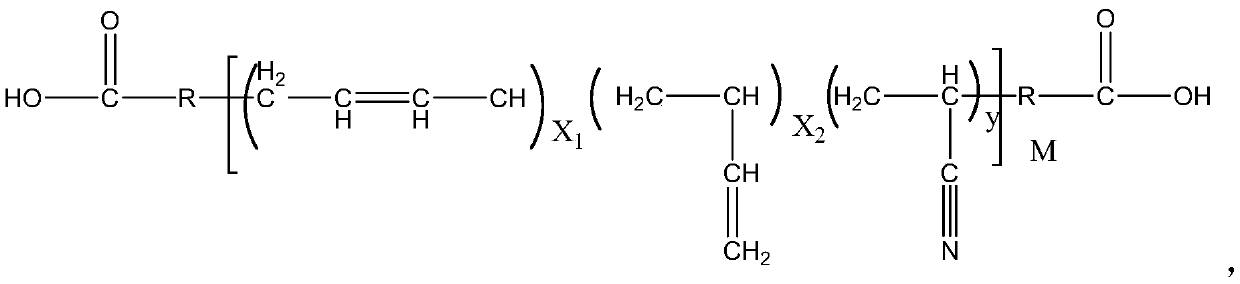

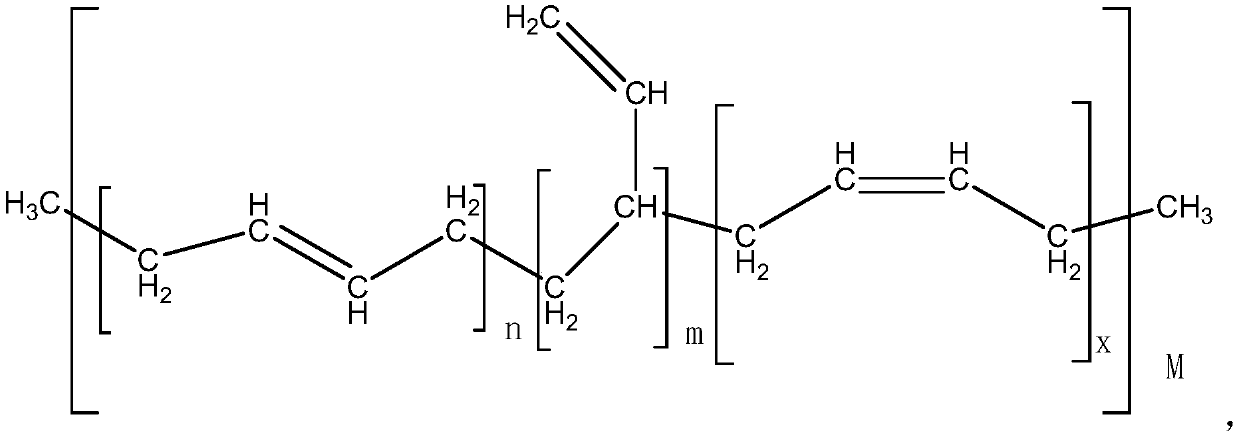

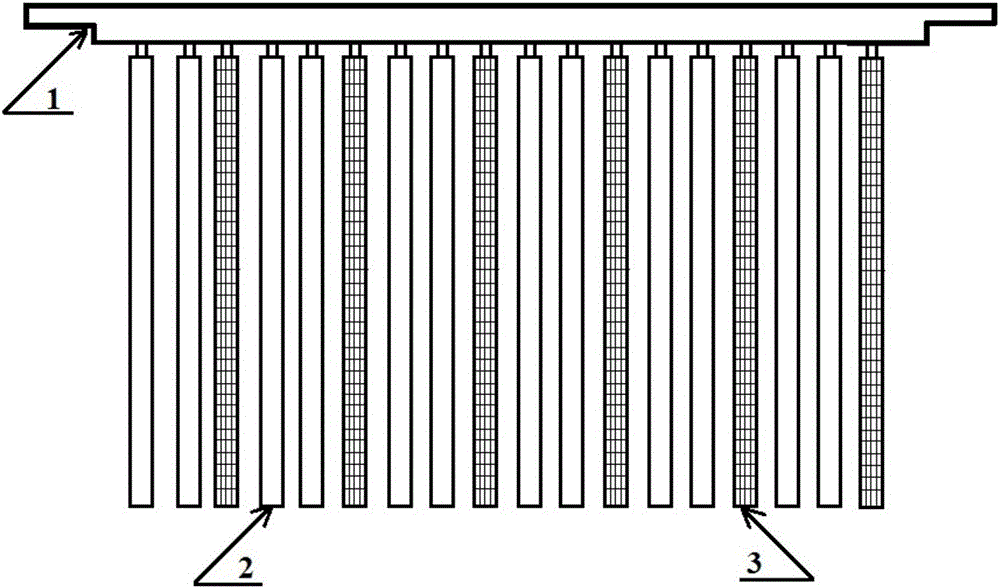

Cation-modified epoxy resin, modified epoxy resin polymer, emulsion and production method thereof, paint and application

ActiveCN109851760AImprove performanceImprove water resistancePolyurea/polyurethane coatingsPaints for electrolytic applicationsEpoxyEmulsion

The invention provides cation-modified epoxy resin, a modified epoxy resin polymer, emulsion and a production method thereof, paint and application. The cation-modified epoxy resin comprises an epoxyresin compound, an alkaline catalyst, an amine compound and a terminal amino butyronitrile copolymer. The modified epoxy resin polymer comprises the cation-modified epoxy resin, an isocyanate curing agent, an epoxy resin compound, an alkaline catalyst, acid and an amine compound. The emulsion comprises purified water, acid, cation-modified polybutadiene epoxy resin, the modified epoxy resin polymer and deionized water. According to the application of the paint, the paint is used for cathode electrophoretic painting. According to the cation-modified epoxy resin, the modified epoxy resin polymer, the emulsion and the production method thereof and the paint, the paint has the advantages that the water resistance is good, the VOC content is low, the leveling appearance is good, throwing poweris high, the sharp edge anti-corrosive property is high, adhesion between the paint and a base material is good, the anti-impact performance is good, and the like.

Owner:GUANGDONG KODEST EP SC CO LTD

Chemical nickel plating solution with high corrosion resistance and stability on surface of aluminum alloy and preparation method and application thereof

ActiveCN111074250AImprove stabilityQuality improvementLiquid/solution decomposition chemical coatingButanedioic acidSodium phosphates

The invention discloses a chemical nickel plating solution with high corrosion resistance and stability on the surface of an aluminum alloy and a preparation method and application of the chemical nickel plating solution. The chemical nickel plating solution is composed of deionized water, main salt, a reducing agent, a complexing agent, a buffering agent, a stabilizer and a brightener. The main salt is nickel sulfate, the reducing agent is sodium hypophosphite, the complexing agent is composed of glycine and lactic acid, the buffering agent is composed of sodium tetraborate and succinic acid,the stabilizer is composed of cobalt nitrate and potassium iodide, and the brightener is polyethylene glycol. An environmental-friendly chemical nickel plating system with high corrosion resistance and high stability and a simple and efficient pretreatment process are developed, so that the process flow is simplified, the production cost is reduced, and the corrosion resistance of the aluminum alloy is greatly improved.

Owner:XI AN JIAOTONG UNIV

Combined titanium anode for hexavalent chromium electroplating and preparation method thereof

The invention discloses a combined titanium anode for hexavalent chromium electroplating. The combined titanium anode comprises a titanium base noble metal oxide anode and a titanium base base metal oxide anode arranged on a conducting bar; a titanium base noble metal oxide anode coating layer consists of Ta2O5, IrO2-Ta2O5, IrO2-Ta2O5-SnO2 and IrO2-SnO2 from inside to outside; and a titanium base base metal oxide anode coating layer is PANI-doped PbO2. A preparation method of the combined titanium anode for hexavalent chromium electroplating comprises the following steps: the coating layers are firstly prepared for the titanium base noble metal oxide anode and the titanium base base metal oxide anode, and are combined to obtain the combined titanium anode. The combined titanium anode is high in electrocatalytic activity and corrosion resistance, can work under high current density in the hexavalent chromium electroplating production, generates no anode mud, and is long in service life.

Owner:西安博岳环保科技有限公司

Zero emission type chemical nickel plating liquid

ActiveCN104131272AFast deposition rateGood corrosion resistanceLiquid/solution decomposition chemical coatingPhosphinic AcidsOrganic acid

The invention discloses a zero emission type chemical nickel plating liquid. In the nickel plating liquid, a used main salt and reducing agent is nickel hypophosphite, an auxiliary reducing agent is hypophosphorous acid, and other complexing agent, stabilizer, buffering agent, accelerator, brightening agent and other ingredients are all organic acids or lithium salts thereof or metal organic salts containing cations for doping lithium iron phosphate. All the raw materials do not contain nitrogen or sulfur elements, and do not pollute the environment in a plating process; the deposition rate of an obtained plated layer is large, the corrosion resistance is excellent, the plating liquid is good in stability, and the service life is long; and a waste liquid can be directly used for preparing multielement doped lithium iron phosphate / carbon composite positive electrode materials, no waste is generated, and clean production requirements are met. The plating liquid provided by the invention has quite broad application prospects.

Owner:HUNAN INSTITUTE OF ENGINEERING

Method for preparing nichrome composite coating in environment-friendly trivalent chromium plating solution

The invention discloses a method for preparing a nichrome composite coating in environment-friendly trivalent chromium plating solution. A specific-content composite coordination agent is added into basic plating solution containing chromic chloride, nickel sulfate and nickel chloride, so that nickel and chromium are co-precipitated on the surface of a metal, and the nichrome composite coating with flat surface and firm combination with a base material is prepared. The method has the advantages that: the prepared nichrome composite coating has the thickness of 30-210 micrometers; compared with a chromium coating, the nichrome composite coating has higher rigidity, high corrosion resistance and excellent decoration performance; and the plating solution can be recycled to contribute to protecting environment.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com