Cyanide-free sulfite Au-Cu alloy electroplating solution and application

A cyanide-free sulfite and alloy electroplating solution technology, which is applied in the field of special processing, can solve problems such as different process ranges and no coating test results, and achieve good stability, good flatness, and no cracks in the plating solution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

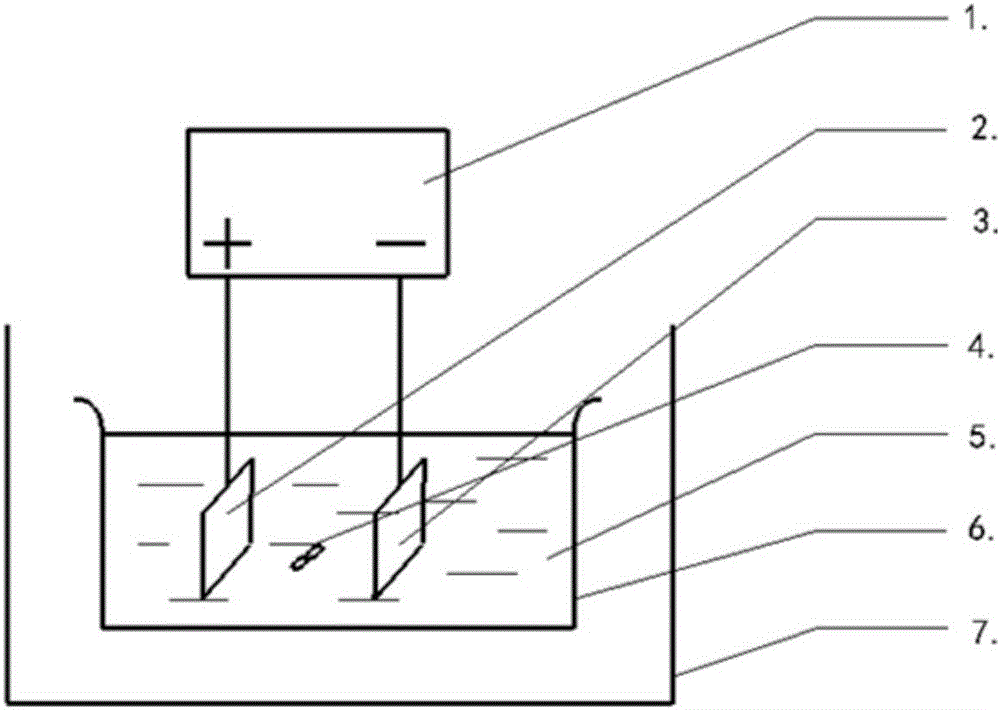

[0018] The technical scheme of the present invention is: a cyanide-free pulse electroplating gold-copper alloy plating solution and its process using sodium sulfite-HEDP as a complexing agent, selecting sodium sulfite and HEDP as a complexing agent, and adopting the method of pulse electroplating, specific production steps as follows:

[0019] 1) The composition ratio of the plating solution: gold (added in the form of sodium gold sulfite, sodium gold sulfite 21.6g / L) 10g / L, copper sulfate 1g / L, sodium sulfite 170g / L, hydroxyethylidene diphosphonic acid HEDP60g / L, potassium sulfate 80g / L.

[0020] 2) According to the formula, weigh the required amount of sodium sulfite powder and potassium sulfate powder and place them in a beaker, add an appropriate amount of distilled water into the beaker, and stir the mixture into a paste; weigh the required amount of HEDP into the beaker, and stir evenly ; Pipette the calculated amount of sodium gold sulfite solution, add it to the beak...

Embodiment 2

[0025] 1) The composition ratio of the plating solution: gold (added in the form of sodium gold sulfite, sodium gold sulfite 25.9g / L) 12g / L, copper sulfate 0.5g / L, sodium sulfite 140g / L, HEDP60g / L, potassium sulfate 60g / L.

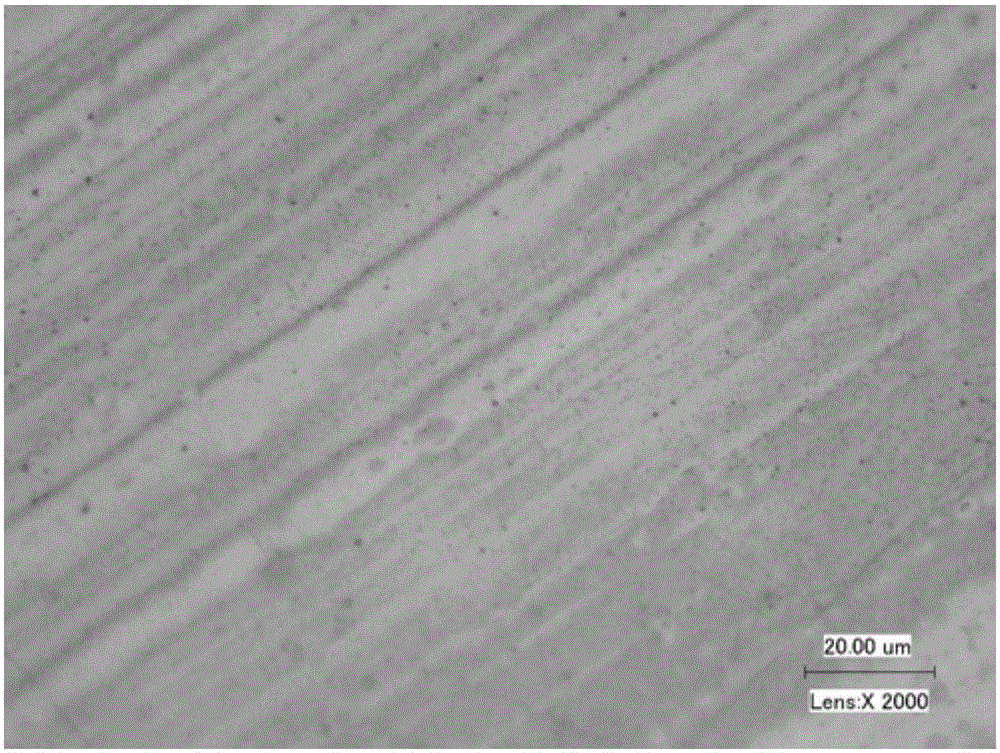

[0026] 2) The electroplating process parameters are: current density 0.3A / dm 2 , Duty ratio 10%, pulse frequency 1000Hz, plating solution pH value 9, electroplating temperature 60°C. The hardness of the obtained coating is 192.88Hv, the surface is fine and uniform, the porosity is low, and the flatness is good.

Embodiment 3

[0028] 1) The composition ratio of the plating solution: gold (added in the form of sodium gold sulfite, sodium gold sulfite 17.3g / L) 8g / L, copper sulfate 1.5g / L, sodium sulfite 170g / L, HEDP80g / L, potassium sulfate 80g / L.

[0029] 2) The electroplating process parameters are: current density 0.4A / dm 2 , Duty ratio 10%, pulse frequency 1000Hz, plating solution pH value 9.5, electroplating temperature 40°C. The hardness of the obtained coating is 203.89Hv, the surface is fine and uniform, the porosity is low, and the flatness is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com