Copper seed etching solution used for wafer level package

A technology of wafer-level packaging and etching solution, which is applied in the field of materials, can solve problems such as volatile, unstable hydrogen peroxide system, and rapid failure of copper etching solution, and achieve the effect of reducing the impact of side erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The formula consists of the following:

[0045] Hydrogen peroxide: 40g / L;

[0046] Ethylene glycol monobutyl ether: 2g / L;

[0047] Concentrated sulfuric acid: 20g / L;

[0048] Oxalic acid: 20g / L;

[0051] Taking 1L capacity as an example, weigh 40g hydrogen peroxide, 2g ethylene glycol monobutyl ether, 20g concentrated sulfuric acid, 20g oxalic acid, 30g copper sulfate, 1g chloride ion, add deionized water to a volume of 1L, mix and stir evenly, put Into the constant temperature water bath for etching test.

[0052] Etching result:

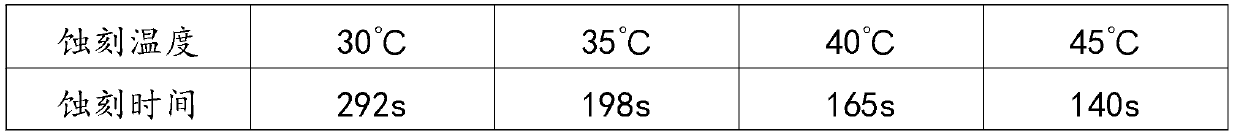

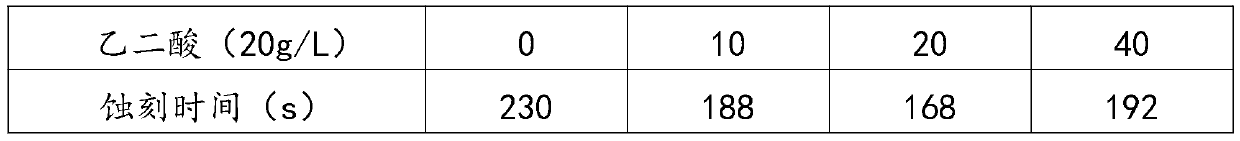

[0053]

[0054]

[0055] It can be seen from the etching results that the etching rate is fast when the etching temperature is 45°C, and the amount of side etching on one side reaches 1.4 μm.

Embodiment 2

[0057] The formula consists of the following:

[0058] Etching temperature: 35°C;

[0059] Ethylene glycol monobutyl ether: 2g / L;

[0060] Concentrated sulfuric acid: 20g / L;

[0061] Oxalic acid: 20g / L;

[0062] Copper ion: 30g / L;

[0063] Chloride ion: 1g / L

[0064] Taking 1L capacity as an example, weigh 2g ethylene glycol monobutyl ether, 20g concentrated sulfuric acid, 20g oxalic acid, 30g copper sulfate, 1g chloride ion, add deionized water to a volume of 1L, mix and stir evenly, and put it in a constant temperature water bath Etch test in pot.

[0065] Etching result:

[0066] Hydrogen peroxide concentration (g / L) 20 40 60 Etching time (s) 250 164 128 Unilateral undercut (μm) 1.3 1.2 2.4

[0067] It can be seen from the etching results that the higher the concentration of hydrogen peroxide, the shorter the etching time, but the amount of unilateral side etching will also increase accordingly. The concentration of hydrogen peroxide ...

Embodiment 3

[0069] The formula consists of the following:

[0070] Etching temperature: 35°C;

[0071] Hydrogen peroxide: 40g / L;

[0072] Ethylene glycol monobutyl ether: 2g / L;

[0073] Concentrated sulfuric acid: 20g / L;

[0074] Oxalic acid: 20g / L;

[0075] Chloride ion: 1g / L

[0076] Taking 1L capacity as an example, weigh 40g hydrogen peroxide, 2g ethylene glycol monobutyl ether, 20g concentrated sulfuric acid, 20g oxalic acid, 1g chloride ion, add deionized water to a volume of 1L, mix and stir evenly, and put it into a constant temperature water bath etch test.

[0077] Etching result:

[0078] Copper ion(g / L) 0 10 20 30 Etching time (s) 149 152 160 162 Unilateral undercut (μm) 1.2 1.3 1.2 1.4

[0079] Appropriately increasing the concentration of copper ions to the range of 1-30g / L can effectively increase the etching rate, but when the concentration of copper ions is too high, the copper ions in the solution are easily hydrolyzed, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com