Acid etching solution for high-precision circuit board

An acid etching solution and circuit board technology, applied in printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of high-precision circuit board etching accuracy, etc. Accuracy, reduction of etching side reactions, reduction of corrosion and wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

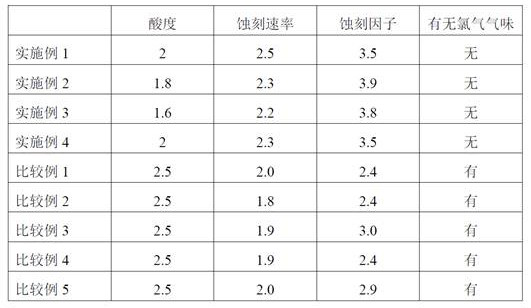

Examples

Embodiment 1

[0028] A high-precision circuit board acid etching solution, its components are: copper ion concentration 120g / L, hydrochloric acid 1.0mol / L, nitric acid 1.0mol / L, ammonium chloride 160g / L, complexing agent citric acid 0.5g / L L, accelerator potassium chloride 0.8g / L, surfactant sodium dodecylbenzene sulfonate 0.004g / L, bank protection agent benzotriazole 0.008g / L, and the rest is water.

[0029] The working temperature of the high-precision circuit board etching solution in this embodiment is 50°C.

[0030] The high-precision circuit board acid etching solution used in this embodiment can control the acid value at 2.0N, which is much lower than that of the prior art. At the same time, the bank revetment agent is introduced to make the etching factor reach 3.5, which effectively improves the precision of the etched circuit pattern; through Add complexing agent, accelerator to replace NaClO 3 Such strong oxidants control the generation of chlorine gas and increase the etching r...

Embodiment 2

[0032] A high-precision circuit board acid etching solution, its components are: copper ion concentration 120g / L, hydrochloric acid 0.9mol / L, nitric acid 0.9mol / L, ammonium chloride 150g / L, complexing agent triammonium citrate 0.8 g / L, accelerator potassium nitrate 1.0g / L, surfactant sodium α-olefin sulfonate 0.006g / L, bank protection agent benzimidazole 0.02g / L, and the rest is water.

[0033] The working temperature of the high-precision circuit board etching solution in this embodiment is 50°C.

[0034] The high-precision circuit board acid etchant used in this embodiment can control the acid value at 1.8N, which is much lower than that of the prior art, and the etching factor reaches 3.9, which effectively improves the precision of the etched circuit pattern; by adding a complexing agent , Accelerator to replace NaClO 3 Such strong oxidants control the generation of chlorine gas and increase the etching rate; introduce appropriate amount of HNO 3 Effectively guarantee th...

Embodiment 3

[0036] A kind of high precision circuit board acid etching solution, its each component is: copper ion concentration 120g / L, hydrochloric acid 0.8mol / L, nitric acid 0.8mol / L, ammonium chloride 160g / L, complexing agent sulfamic acid 1.2g / L, accelerator potassium nitrate 1.2g / L, surfactant OP-10 0.008g / L, bank revetment agent 2-mercaptobenzothiazole 0.04g / L, and the rest is water.

[0037] The working temperature of the environment-friendly precision circuit board etching solution in this embodiment is 50°C.

[0038] The environment-friendly precision circuit board acid etching solution used in this embodiment can control the acid value at 1.6N, which is much lower than that of the prior art, and the etching factor reaches 3.8, which effectively improves the precision of the etched circuit pattern; by adding a complexing agent , Accelerator to replace NaClO 3 Such strong oxidants control the generation of chlorine gas and increase the etching rate; introduce appropriate amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com