Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Reduce side erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetically controlled sputtering process of making printed circuit board

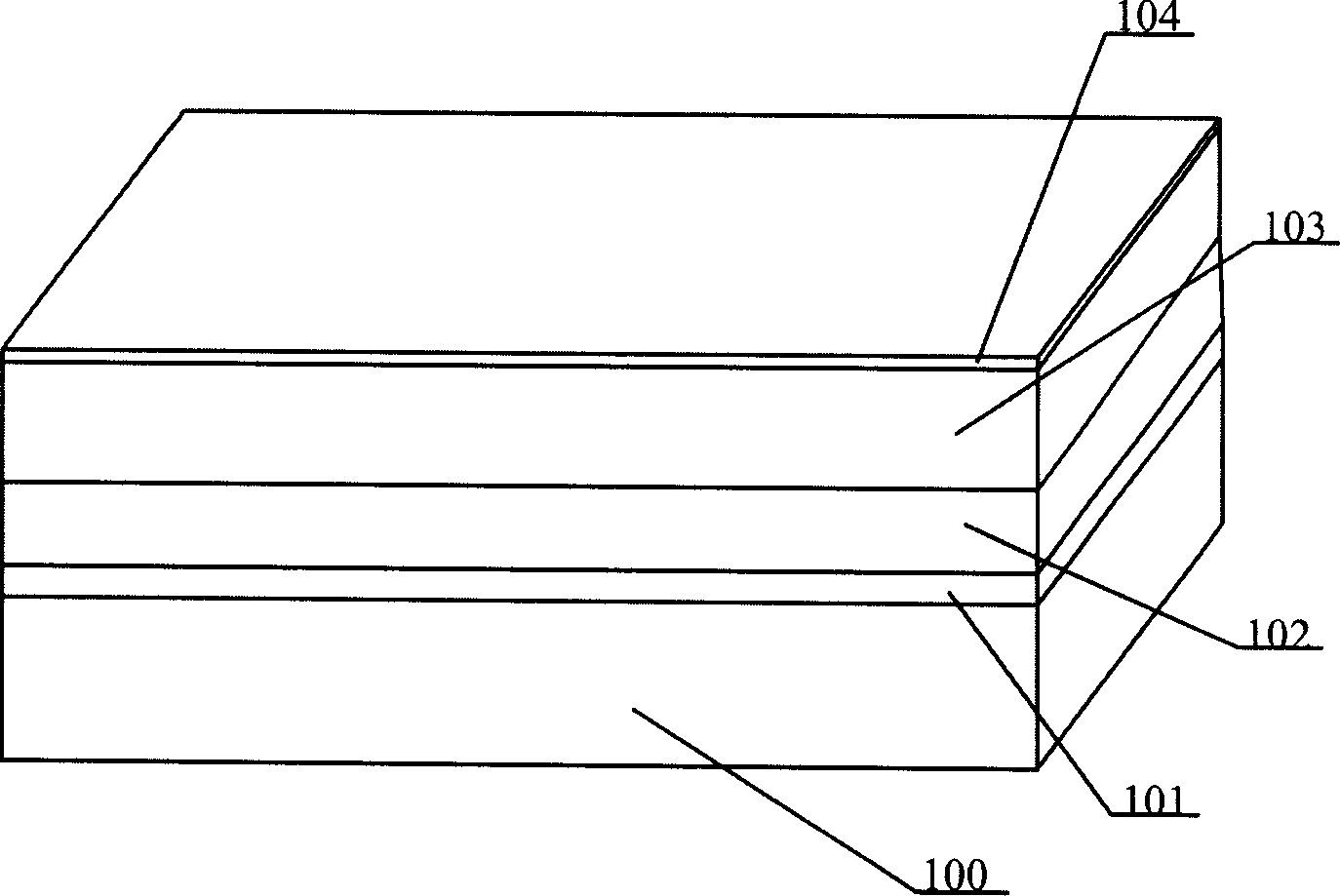

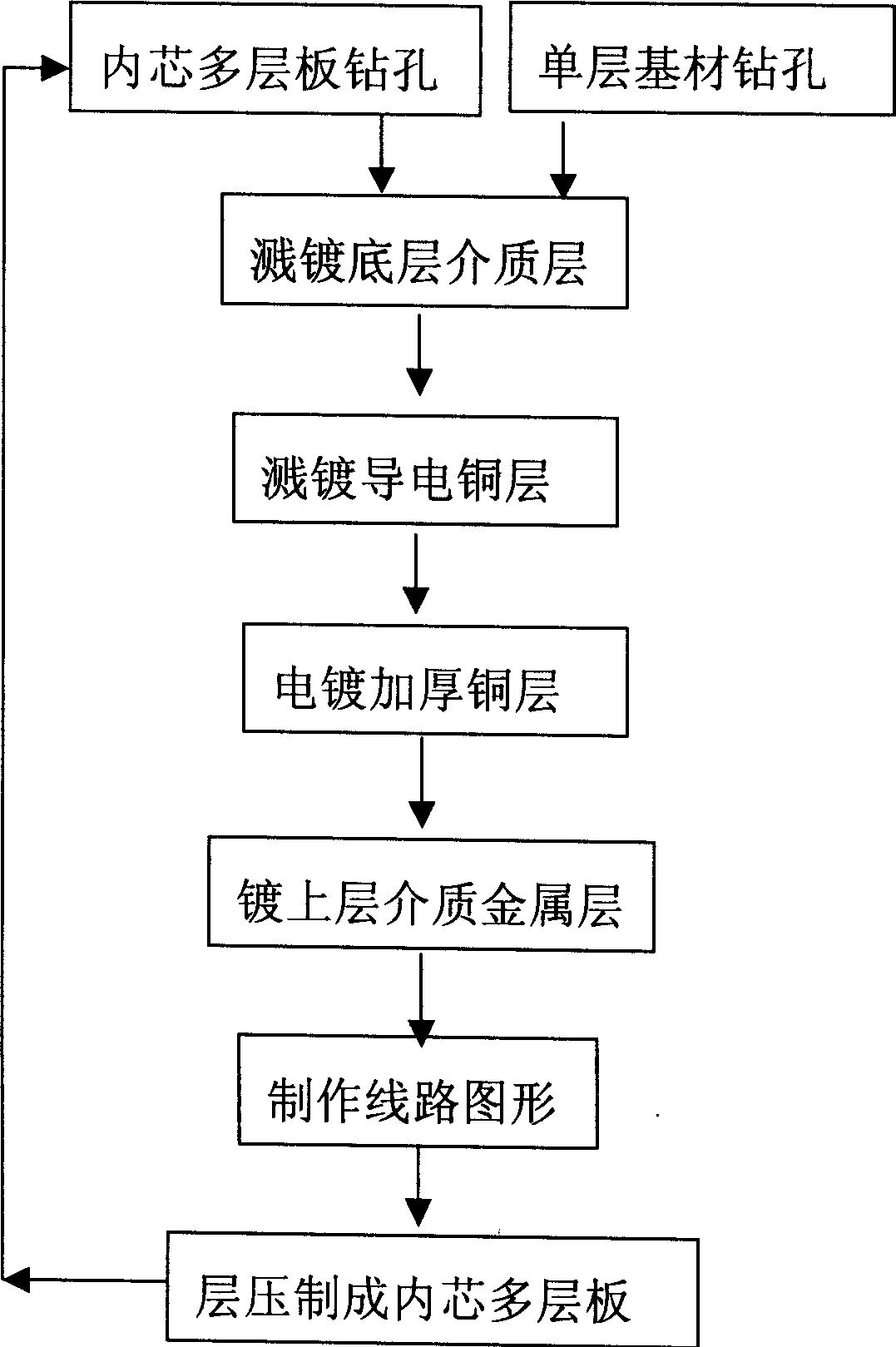

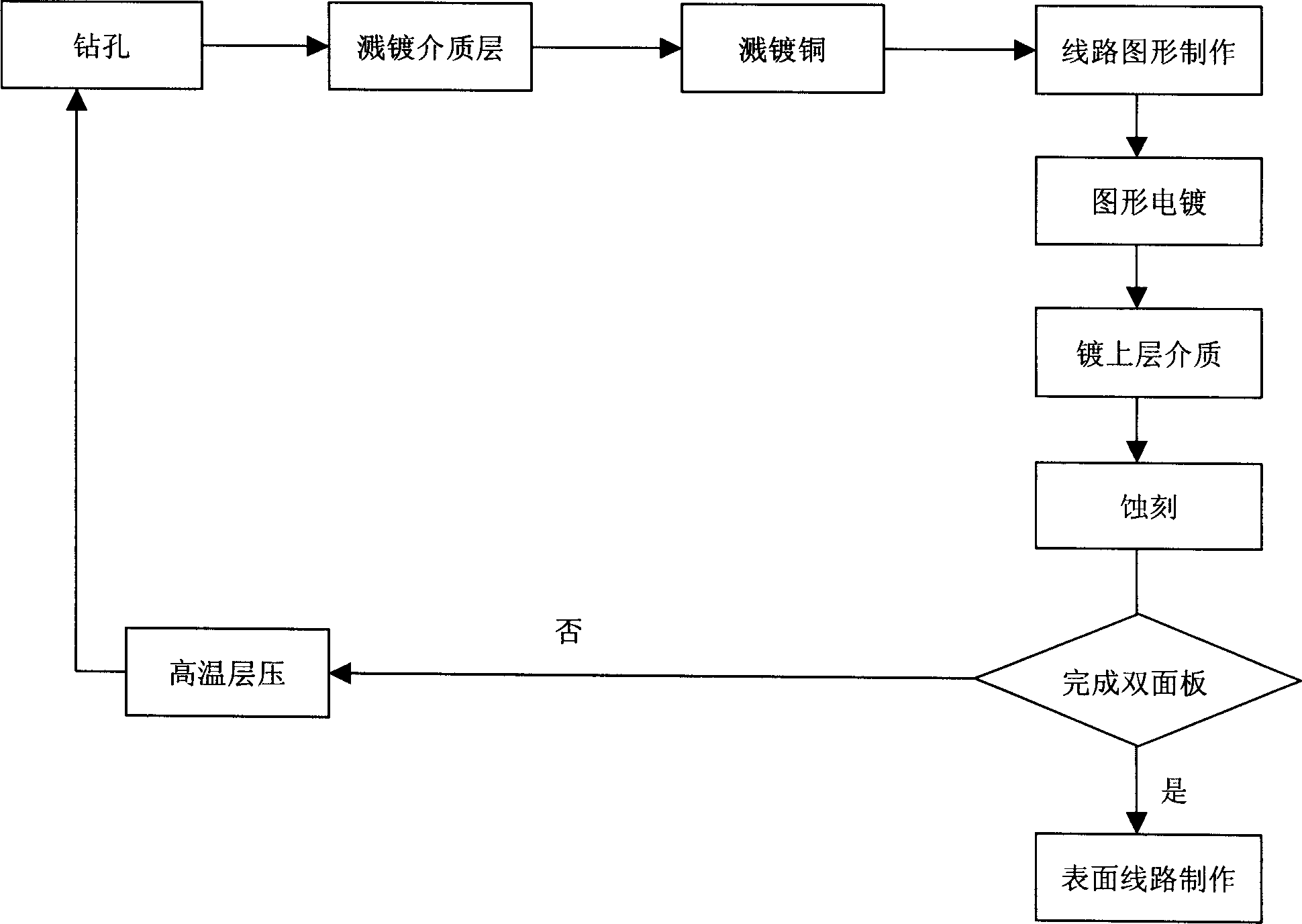

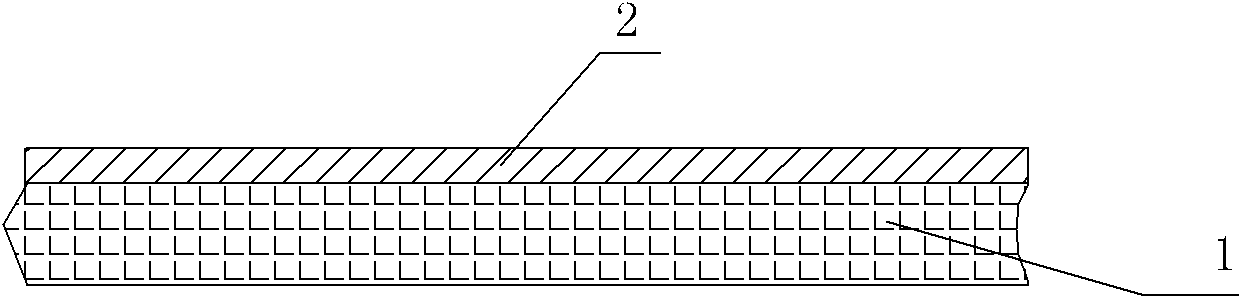

InactiveCN1527656AFlexible thickness controlAvoid inhomogeneityMultilayer circuit manufacturePrinted element electric connection formationCopper platingOptoelectronics

The present invention provides one kind of magnetically controlled sputtering process of making printed circuit board. The process includes the following steps: drilling holes on the single layer base material; magnetically controlled sputtering the bottom dielectric and metal layer on the drilled single layer base material; magnetically controlled sputtering conducting copper layer on the single layer base material; drilling holes on multilayer board; magnetically controlled sputtering bottom dielectric and metal layer on the drilled multilayer board; magnetically controlled sputtering conducting copper layer on the drilled multilayer board; and repeating the foregoing steps until reaching the required layer number of the printed circuit board. The present invention combines unique hole forming method and sputtering method and has raised copper-plating and hole-metallizing efficiency, raised reliability and high fine circuit making capacity.

Owner:曹波 +2

Electrochemical etching liquid and etching method

An electrochemical etching solution is an aqueous solution containing sulfuric acid and phosphoric acid, wherein the etching solution also contains a surfactant. The electrochemical etching solution and the etching method provided by the invention can greatly increase the etching speed and reduce the occurrence of side etching phenomenon.

Owner:BYD CO LTD

Method of manufacturing thick copper foil PCB (Printed Circuit Board)

InactiveCN102404942AEasy to produceIncreasing the thicknessConductive material chemical/electrolytical removalCircuit precursor manufactureManufacturing technologyCopper foil

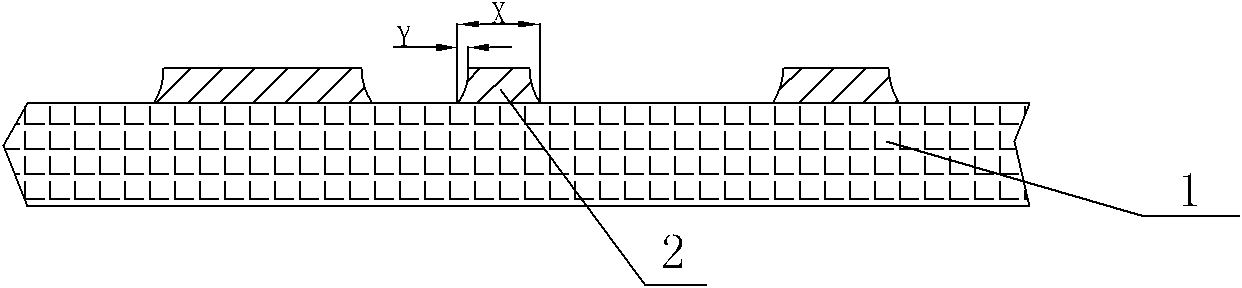

The invention discloses a method of manufacturing a thick copper foil PCB (Printed Circuit Board) and relates to a manufacturing technology of a PCB. The technical problem that thicker copper foil degree leads to bigger influence caused by obviously thinning surface of a copper foil circuit due to large lateral erosion amount in the etching process is solved. The method comprises the following steps of: 1) producing an anti-corrosion layer on a front surface of a copper foil according to a designed circuit diagram and applying the anti-corrosion layer on the back surface of the copper foil for protection; 2) etching the copper foil and stopping the etching when the depth of an etching area of the front surface is larger than 1 / 3 and is smaller than 2 / 3 the thickness of the copper foil; 3) removing the anti-corrosion layers on the front surface and the back surface of the copper foil and adhering the front surface to an insulating medium in a pressing manner; 4) forming an another anti-corrosion layer on the back surface of the copper foil again, wherein the anti-corrosion layer on the back surface of the copper foil is a mirror image of the circuit diagram on the front surface of the copper foil; and 5) etching the copper foil again and stopping the etching when the etching area of the back surface and the etching area of the front surface are etched to penetrate each other. The etching thickness of the copper foil can be increased by one time under the condition that the etching amount is reduced by 50% or the same lateral etching amount is required.

Owner:田先平

Fine-line PCB manufacturing method

InactiveCN104185377AAvoid side erosionReduce the binding forceConductive material chemical/electrolytical removalEtchingMetallurgy

The invention relates to the technical field of PCB manufacturing, in particular to a fine-line PCB manufacturing method. The fine-line PCB manufacturing method sequentially comprises a press-fit step, a drilling step, a copper foil removal step, a copper deposition step, a step of transferring an outer layer image, a pattern plating step, a micro-etching step and a common back-end work procedure. Outer layer copper foil arranged on a multi-layer board in a press-fit mode is removed, copper deposition is carried out on a prepreg layer, pattern manufacturing and pattern plating are directly carried out on a copper deposition layer, and press-fit of a copper foil layer is omitted, so that a base copper layer is thin, a micro-etching mode is adopted in the outer layer etching process, and therefore the phenomenon of serious lateral erosion of the two sides of a line is avoided. The lateral erosion quantity of the two sides of the line is less than 1 micrometer and is reduced by ten times or more compared with that of the existing manufacturing process, and the manufacturing quality of a fine-line PCB is guaranteed. The smooth surface of the copper foil and the prepreg are bonded together in a press-fit mode, the binding force between the copper foil and the prepreg is reduced, the copper foil and the prepreg are poorly bonded, as a result, the hole collapse problem can be avoided in the drilling process, and the copper foil can be torn off after the drilling step.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Etching liquid and method for etching fine lines of flexible circuit board by using same

InactiveCN103952702AIncrease etch rateIncrease etch factorConductive material chemical/electrolytical removalAcid etchingFine line

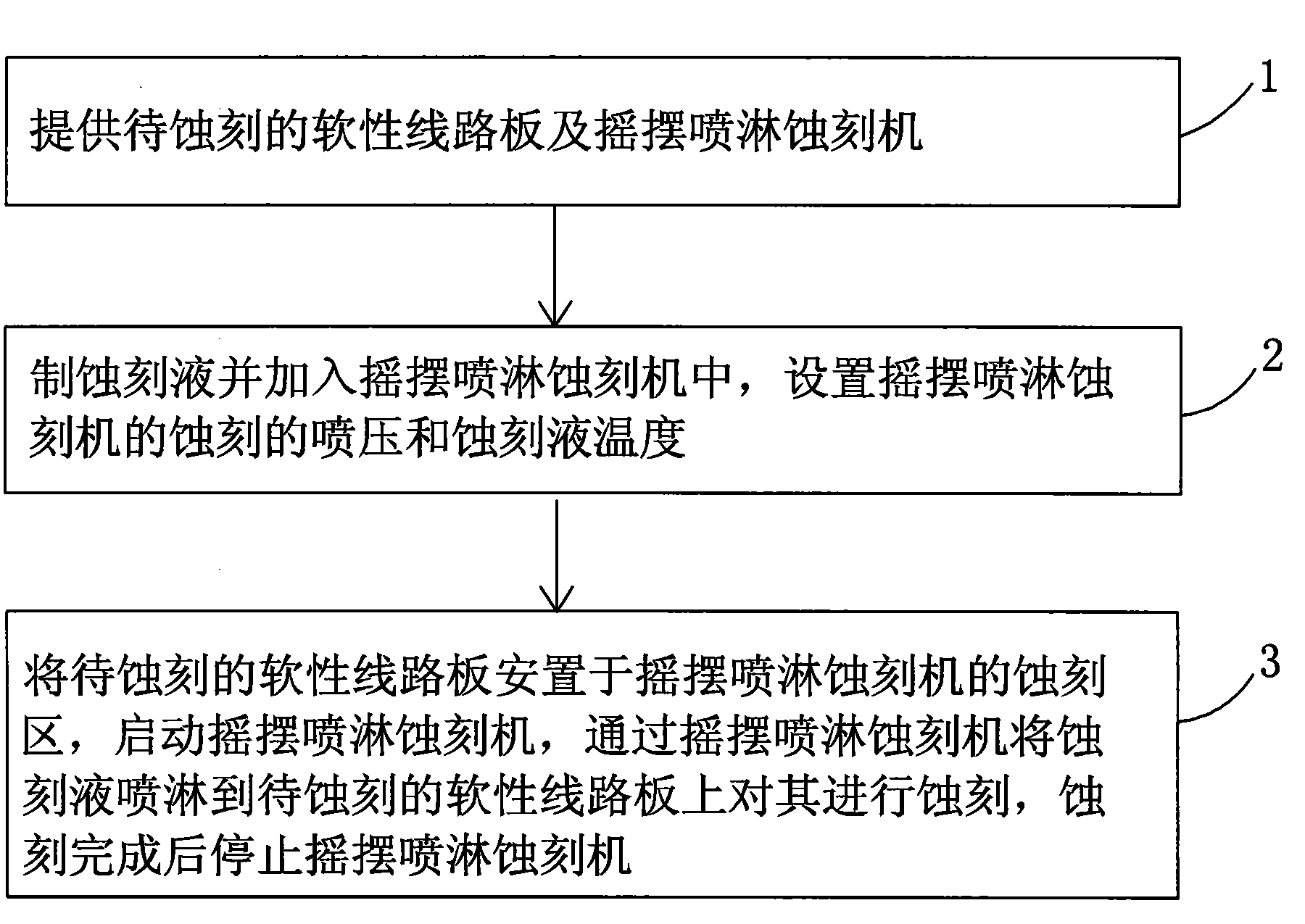

The invention provides etching liquid and a method for etching fine lines of a flexible circuit board by using the same. The etching liquid takes water as a solvent, and comprises the following solutes by concentration: 130g / L-250g / L of copper chloride dehydrate, 100 mL / L-150 mL / L of 30% hydrochloric acid, 26.7g / L-128.4g / L of ammonium chloride, 0.5g / L-16g / L of banking agent and 2g / L-6g / L of secondary solvent, wherein the banking agent is a corrosion inhibitor; the secondary solvent is polyhydric alcohol. The etching liquid is an acid etching liquid which is high in dissolved copper and quick in etching velocity, does not contain hydrogen peroxide or sodium hypochlorite, is low in acid content, and is mixed with the secondary solvent and the banking agent to achieve a purpose of relieving lateral erosion while improving the etching velocity. The method for etching the fine lines of the flexible circuit board by utilizing the etching liquid disclosed by the invention is capable of completing etching more rapidly within short time, straight and flat in etched lines and high in etching factor, and therefore, the method can be used for processing the fine lines of the flexible circuit board.

Owner:SHENZHEN SHIRUITAI TECH

Copper seed etching solution used for wafer level package

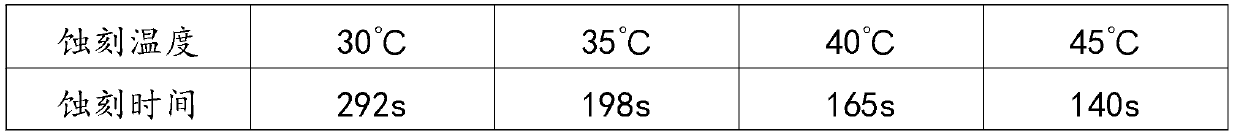

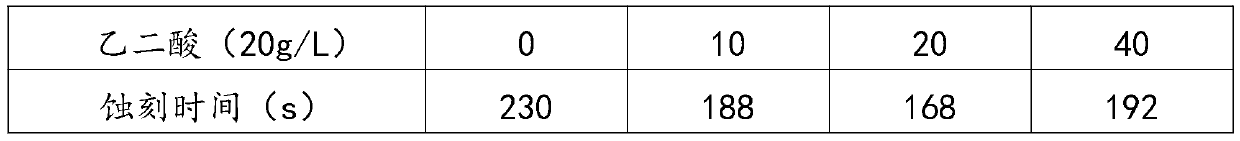

InactiveCN110499509AFacilitated reaction mechanismReduce the impact of side erosionReaction temperatureSurface-active agents

The invention discloses a copper seed etching solution used for wafer level package. The etching solution comprises the following components, 40-60g / L of hydrogen peroxide, 5-35g / L of inorganic acid,5-35g / L of organic acid, 1-30g / L of copper ions, 1-2g / L of chloride ions and 1-2g / L of surface active agents according to the concentration proportion. The components are mixed in proportion, the mixing reaction temperature is between 30 DEG C and 50 DEG C, the reaction time is 1s-400s, and the copper seed etching solution is formed after mixing. Chelating agents formed by mixing the hydrogen peroxide and the inorganic acid and the copper ions can be subjected to chelation to form water-soluble complexes, so that equilibrium is reached; and the chloride ions play a role in maintaining the PH value of a system in the solution, maintains charge balance of the system in the etching process and prolongs the service life of the etching solution. The copper seed etching solution has the characteristics of being stable in performance, suitable for superfine circuits, small in lateral erosion and hardly corrosive to copper and aluminum.

Owner:成功环保科技(南通)有限公司

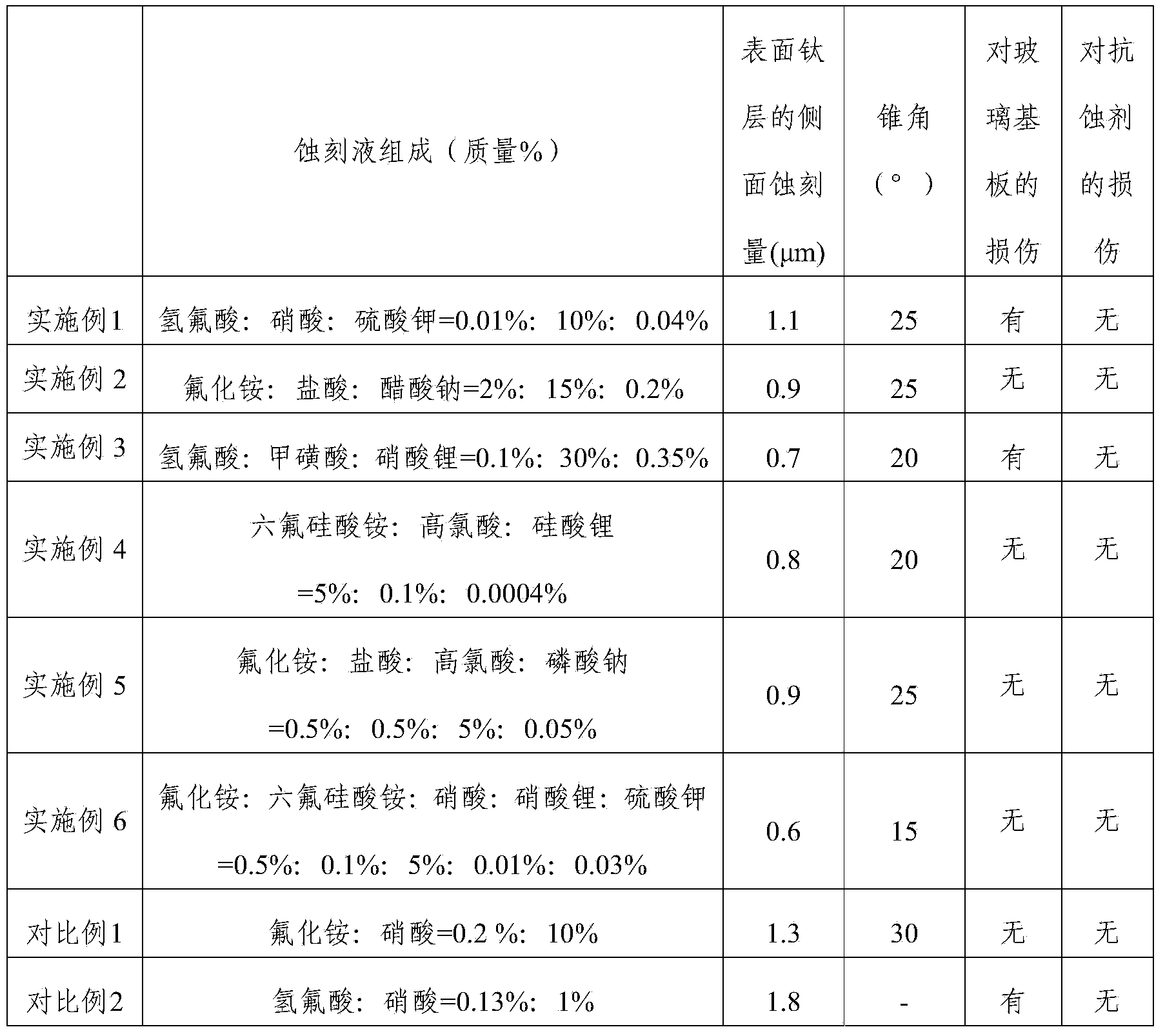

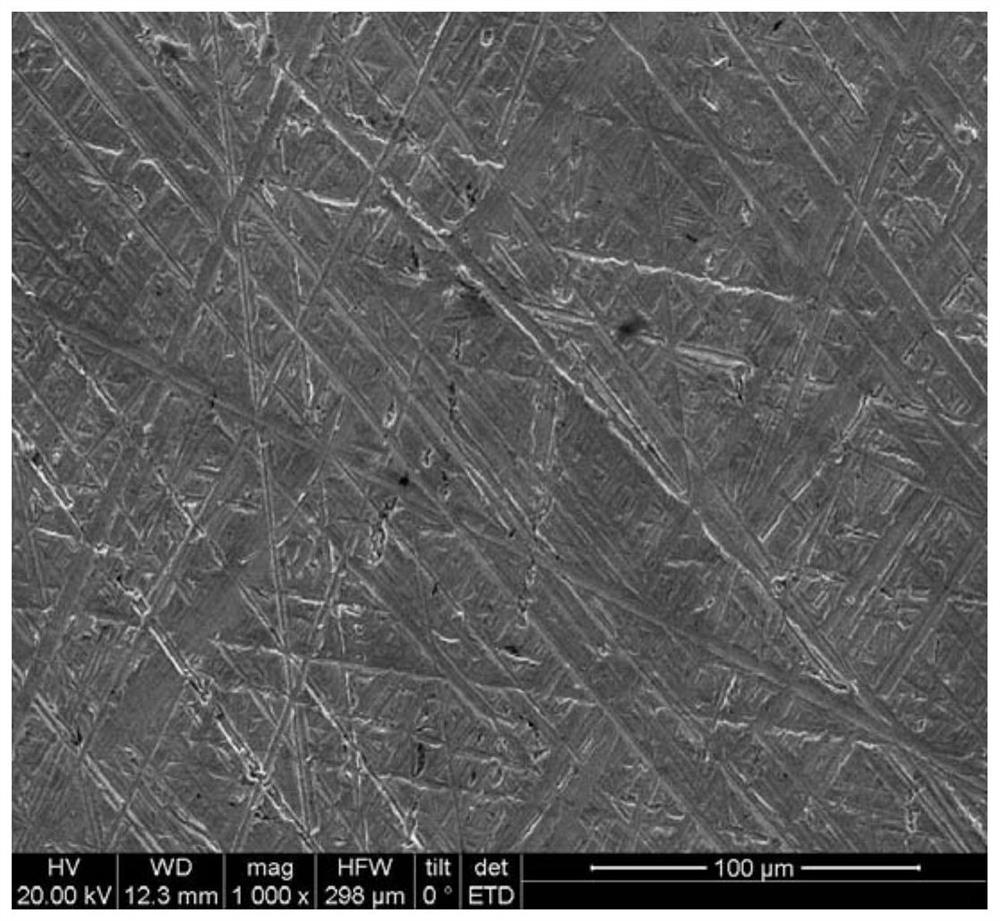

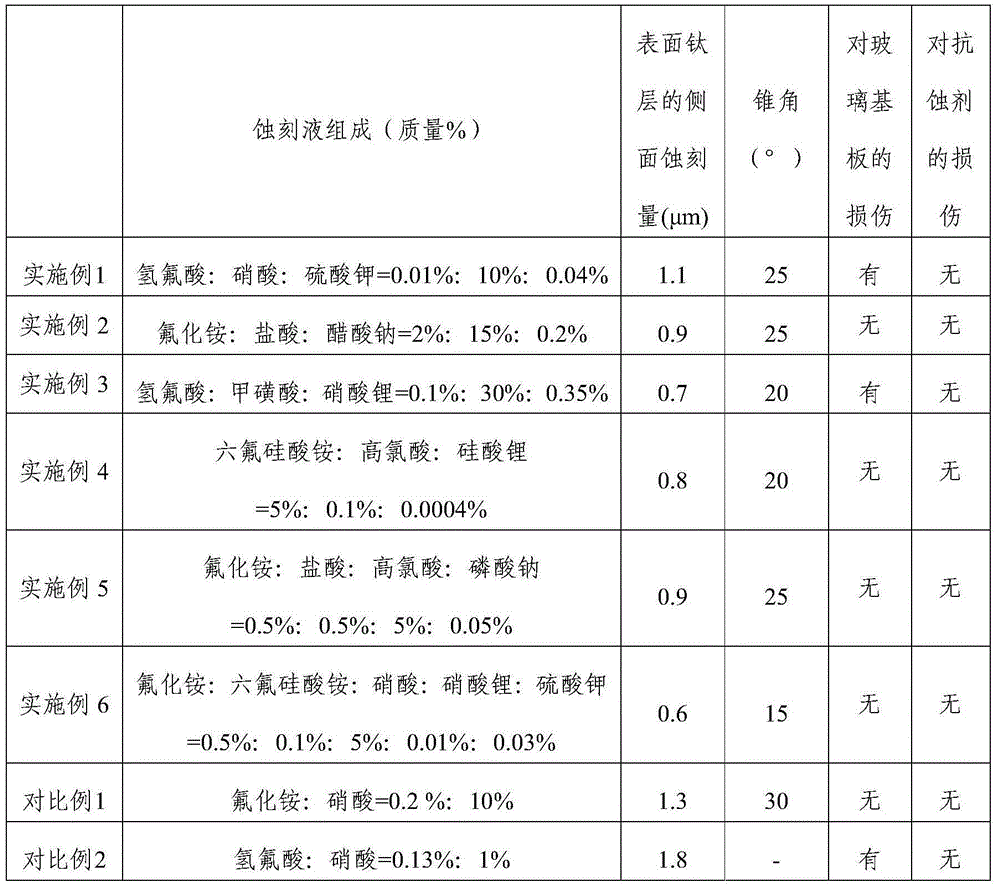

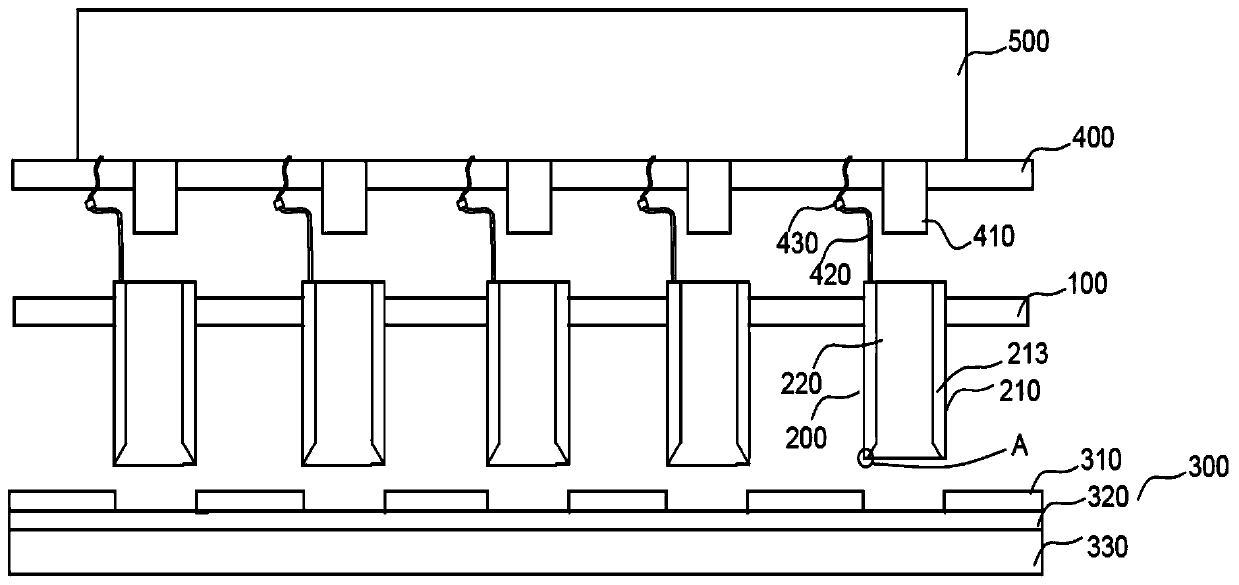

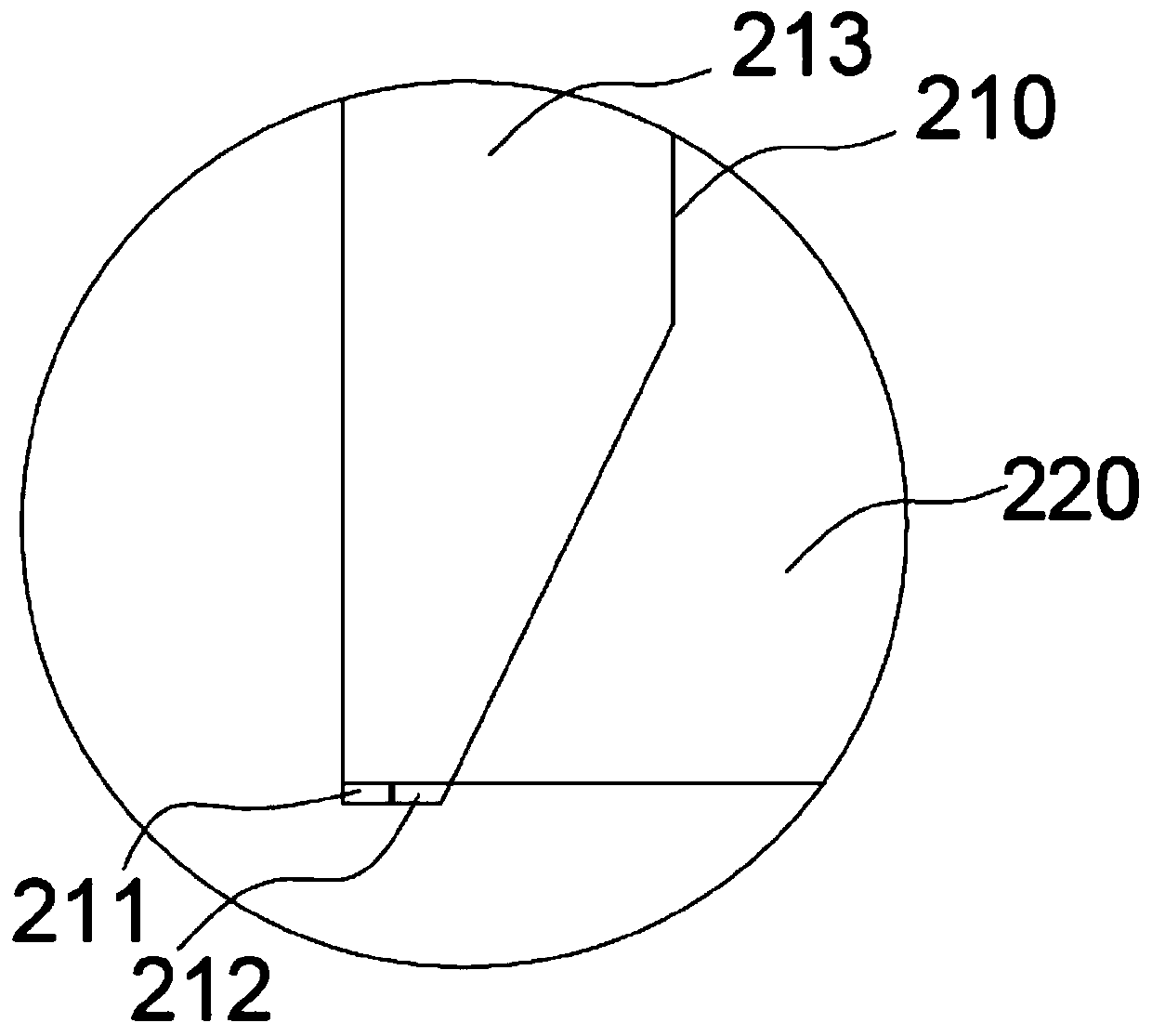

Etching solution composition for titanium-aluminum-titanium metal laminated membrane

The invention relates to an etching solution composition for a titanium-aluminum-titanium metal laminated membrane consisting of a titanium metal membrane, an aluminum metal membrane and a titanium metal membrane. The composition consists of fluorides, oxidizing acid, non-oxidizing alkali metal salt and water, wherein the non-oxidizing alkali metal salt is preferentially at least one of water-soluble lithium, potassium and sodium salts; the mass percent concentration of the fluorides, the oxidizing acid and the non-oxidizing alkali metal salt are 0.01-5 percent, 0.1-30 percent and 0.0004-0.35 percent, respectively. Compared with the prior art, the etching solution composition has the advantages that the three laminated metal membranes can be etched together, the lateral erosion amount can be effectively reduced, the etching uniformity is improved, and the obtained taper angle is 25 degrees below. In addition, the etching solution composition adopts low-price non-oxidizing salts or mixtures thereof instead of high-price salt-type auxiliary oxidants, so that the production cost is reduced, and the balance between the cost and performance is achieved.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

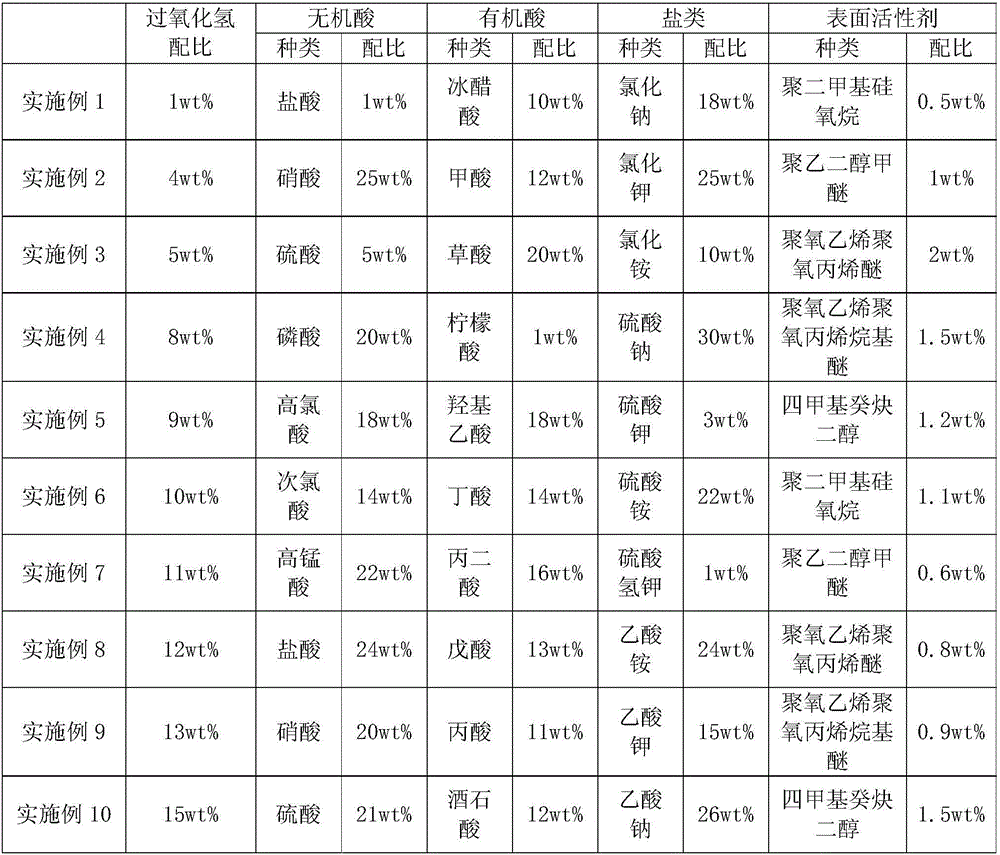

Copper etching liquid with little lateral etching

The invention belongs to the technical field of semiconductor machining and relates to copper etching liquid with little lateral etching. According to a formula, the copper etching liquid comprises 1-15 wt% of hydrogen peroxide, 1-25 wt% of inorganic acid, 1-20 wt% of organic acid, 1-30 wt% of salts, 0.5-2 wt% of a surface active agent and the balance deionized water. The surface active agent is one of polydimethylsiloxane, methoxypolyethylene glycol, polyoxyethylene polyoxypropylene, polyoxyethylene poly(propylene oxide alkyl ether) and tetramethyl decynediol. The copper etching liquid is even in etching, the lateral etching phenomenon is reduced, foam is avoided, and the stability is good.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Manufacturing method of circuit board taking boss as bonding pad

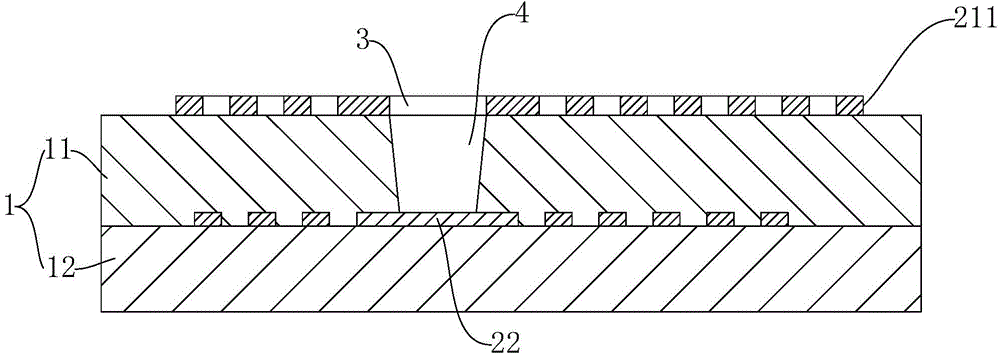

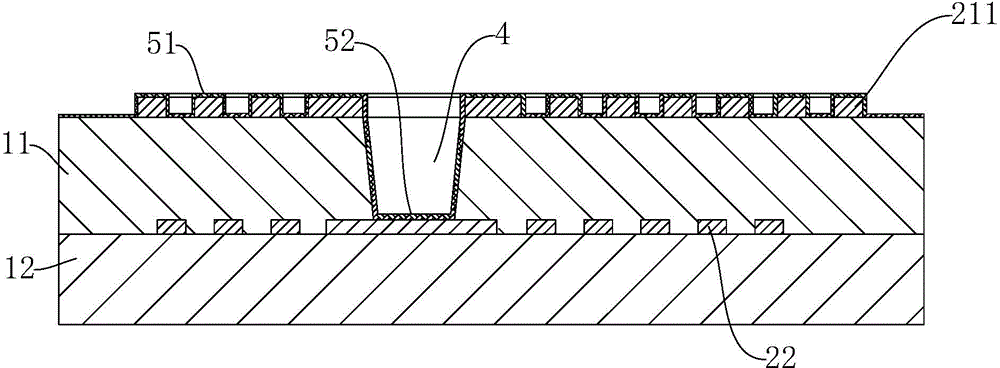

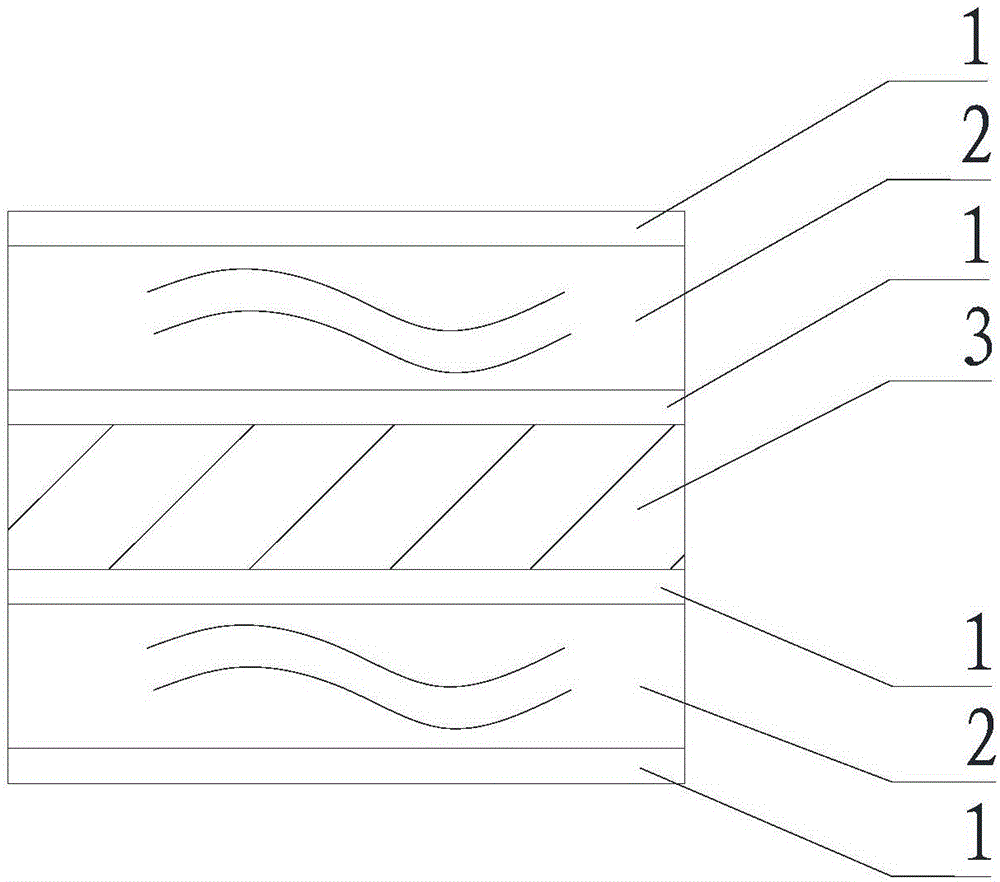

ActiveCN110536564AHigh modulusHigh glass transition pointPrinted circuit aspectsElectrical connection printed elementsEngineeringElectroplating

The invention discloses a manufacturing method of a circuit board taking a boss as a bonding pad. The manufacturing method comprises the following steps of cutting and reducing copper; drilling a hole; carrying out copper deposition; pressing a film; exposing and developing; carrying out circuit electroplating; pressing the film; exposing and developing; electroplating the bonding pad; demouldingand removing copper; laminating an insulating layer; and grinding: grinding a surface of the insulating layer till that the bonding pad is exposed, and forming a top layer / bottom layer bonding pad through windowing. A thermosetting insulating material is adopted, cost is low, silk-screen is not needed, green and environmental protection performance is achieved, and simultaneously, a manufacturingprocess is simple, operation is easy, the bonding pad is directly manufactured through grinding, the bonding pad with a small area and a large density can be conveniently manufactured, a manufacturedcircuit board is smooth in surface, precise packaging is facilitated, circuit attachment is firm, and quality is good.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

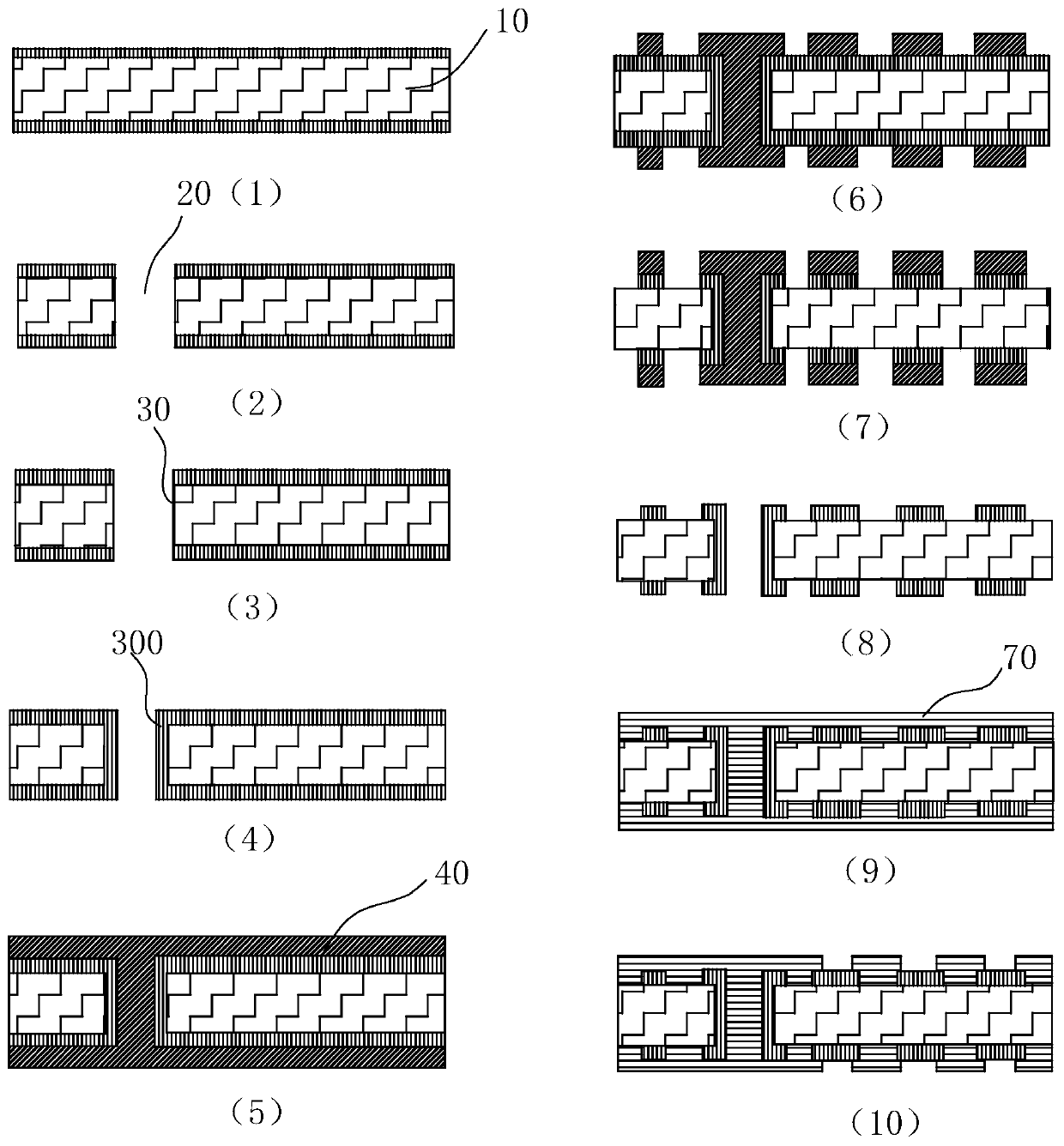

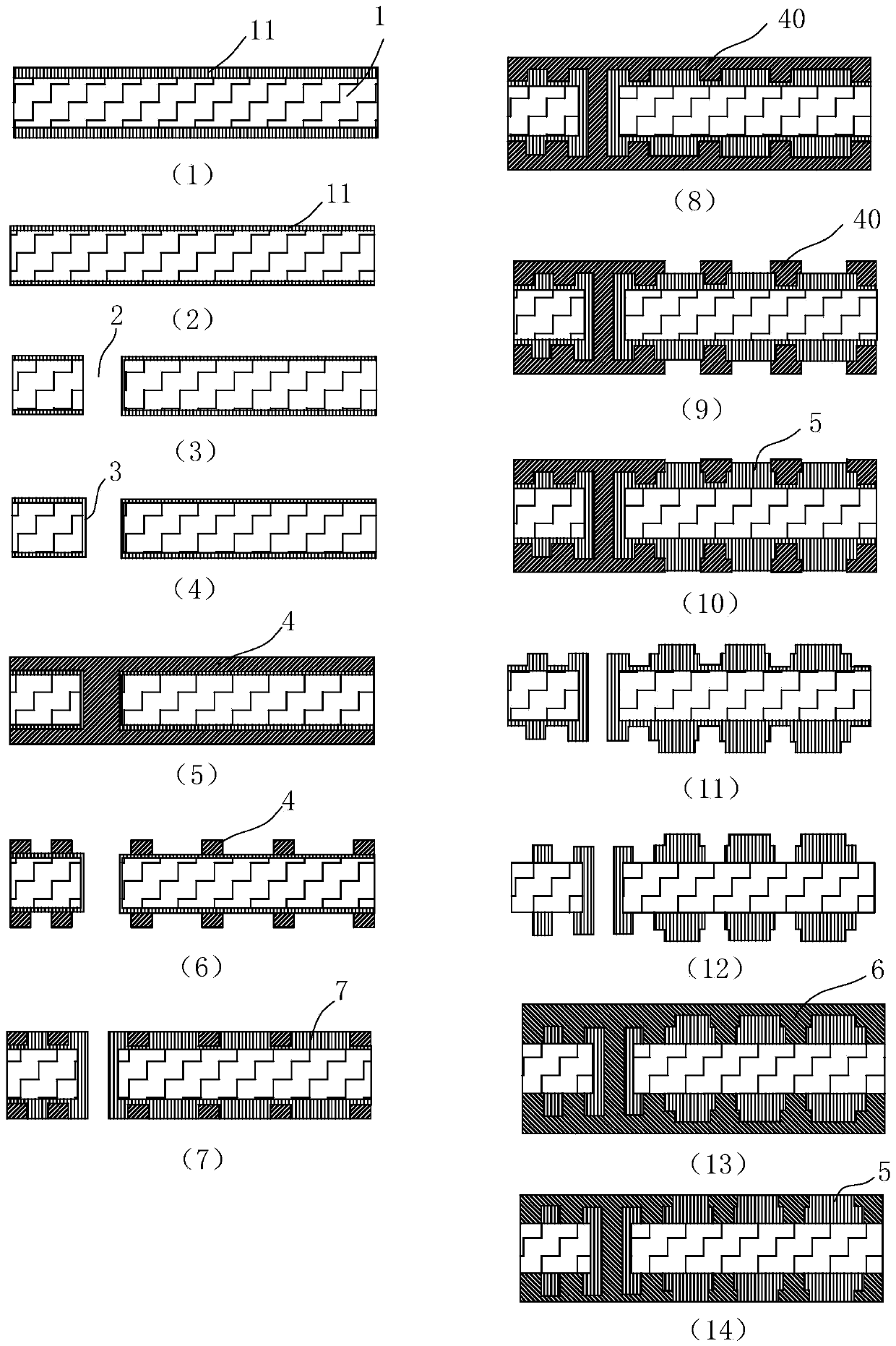

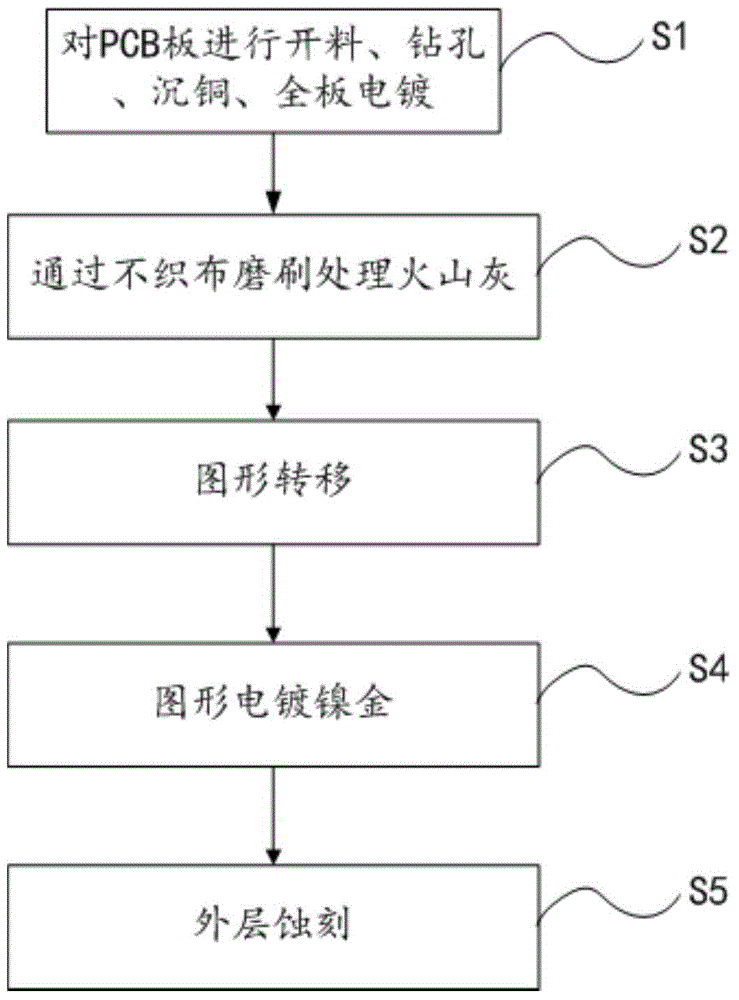

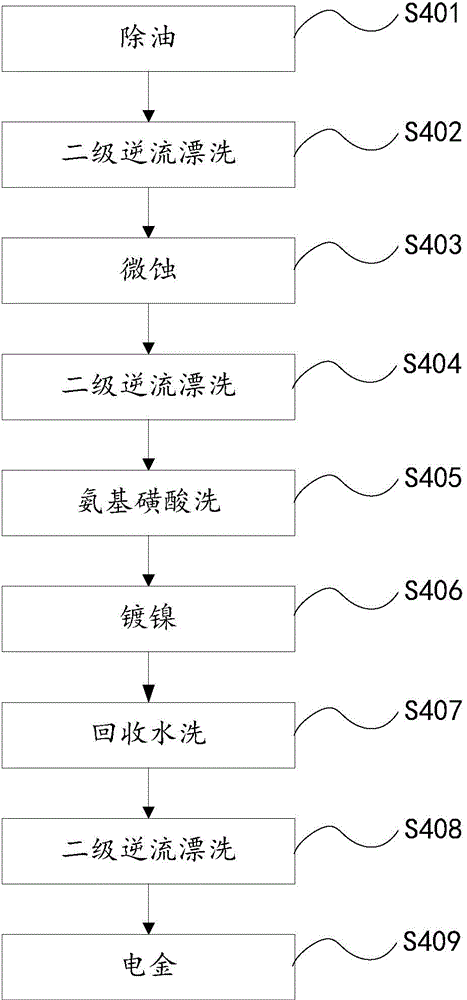

Printed circuit board (PCB) manufacturing method

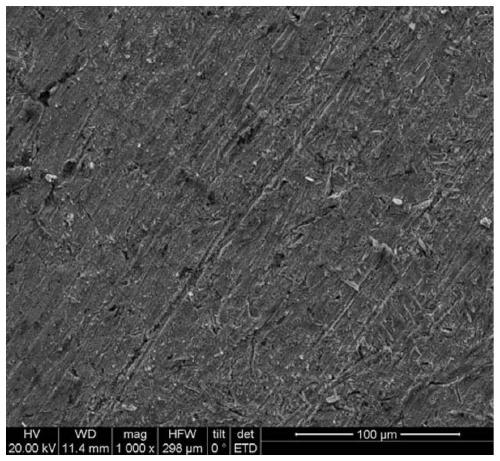

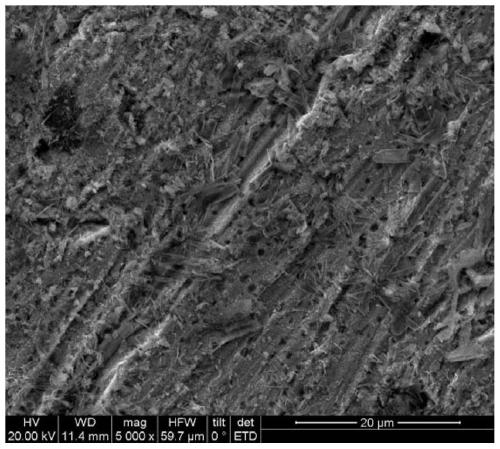

ActiveCN104619123AReduce burrsReduce side erosionInsulating substrate metal adhesion improvementConductive material chemical/electrolytical removalCopper platingEtching

The invention relates to a PCB manufacturing method. The method comprises the steps of S1, performing cutting, drilling, electroless copper plating and full-board electroplating; S2, brushing and processing cinerite through non-woven fabrics; S3, pattern transfer; S4, pattern nickel gold electroplating; S5, outer layer etching. By the aid of the method, the PCB bonding tension value can reach 9N, compared with the prior art, the bonding tension value is improved greatly, the problems of bonding de-soldering, bonding deviation, poor bonding recognition and the like are solved effectively, and accordingly, the PCB quality is improved greatly.

Owner:HUIZHOU XINGZHIGUANG TECH

Copper etching solution and method for manufacturing printed circuit board

The invention discloses a copper etching solution and a method for manufacturing a printed circuit board. The copper etching solution is used for carrying out copper etching on a flexible printed circuit board to form a circuit pattern and comprises the following components: 70-110g / L of copper ions, 2.0-5.0mol / L of chlorine ions, 2.5-5.5mol / L of a complexing agent and 0.1-2.0g / L of N-methyl-2-mercaptoimidazole, wherein the PH value of the copper etching solution is 7.5-9.5. The copper etching solution disclosed by the invention has the advantages that the phenomenon of lateral erosion can be effectively prevented in a circuit etching process, a regular rectangular circuit pattern is generated after etching, the open circuit condition among circuits is reduced and the etching velocity can be improved.

Owner:GUANGDONG DANBOND TECH

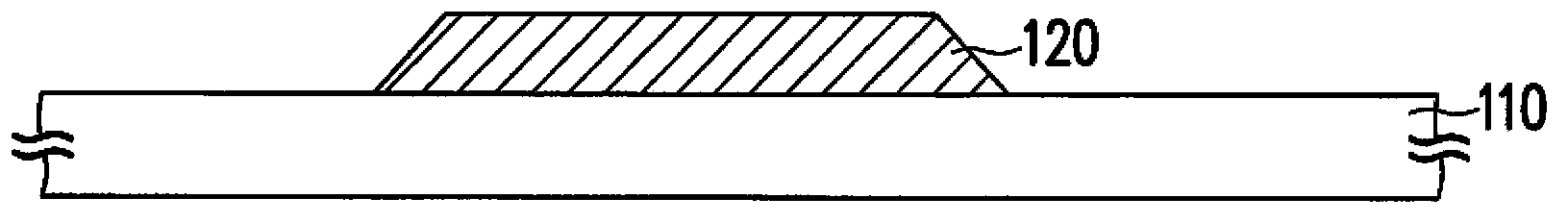

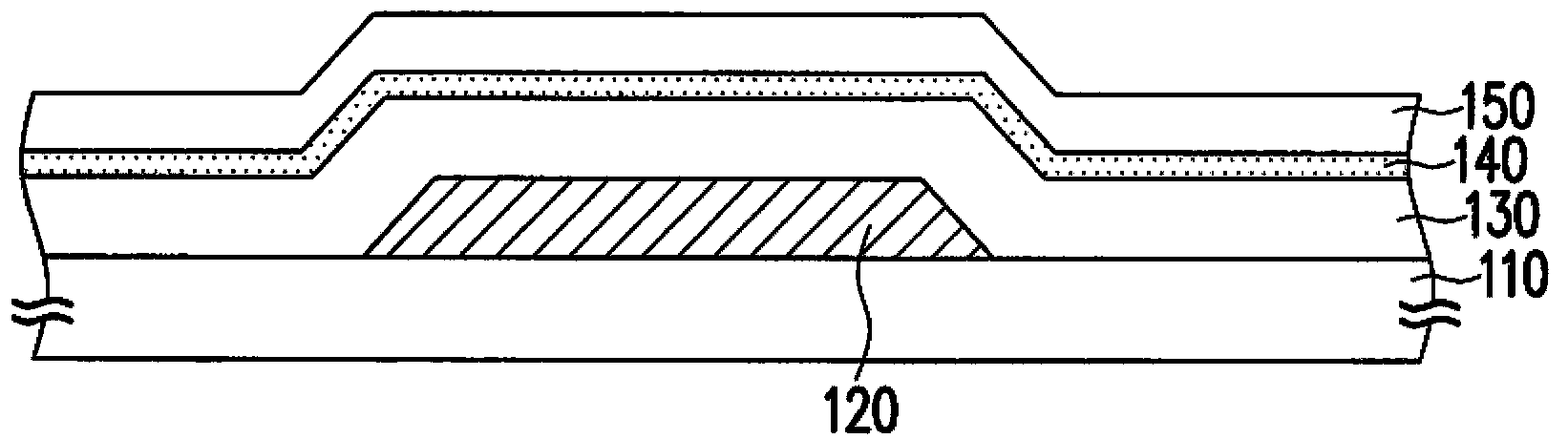

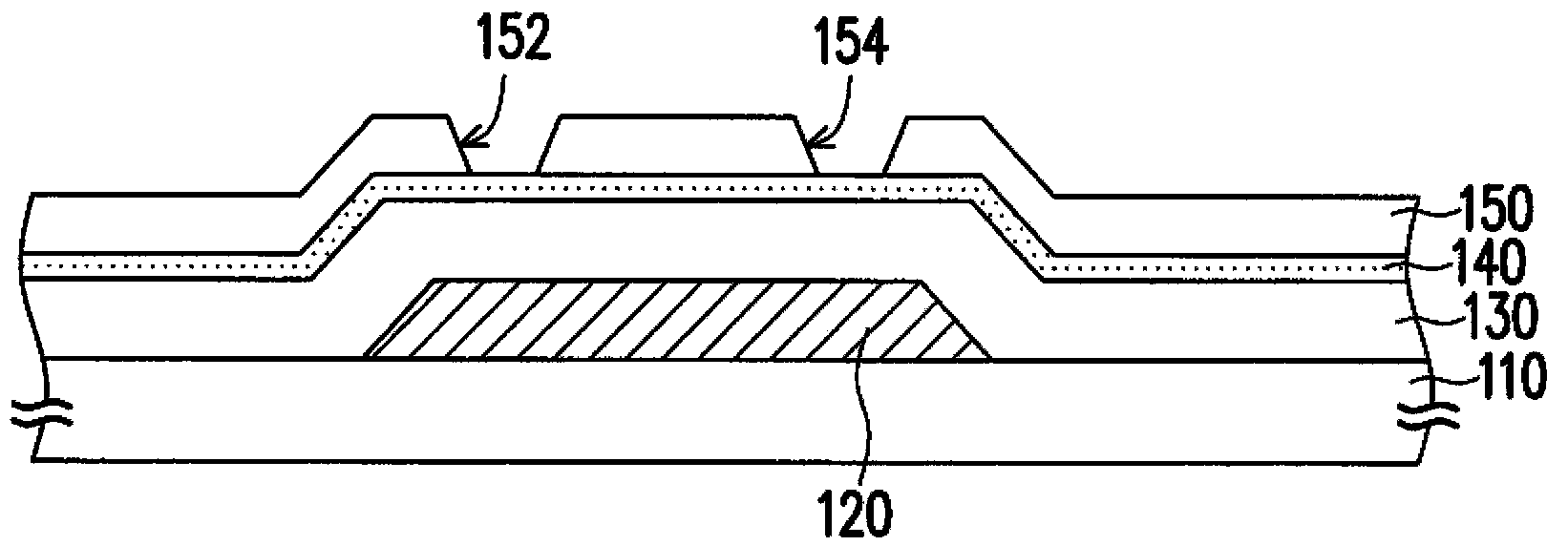

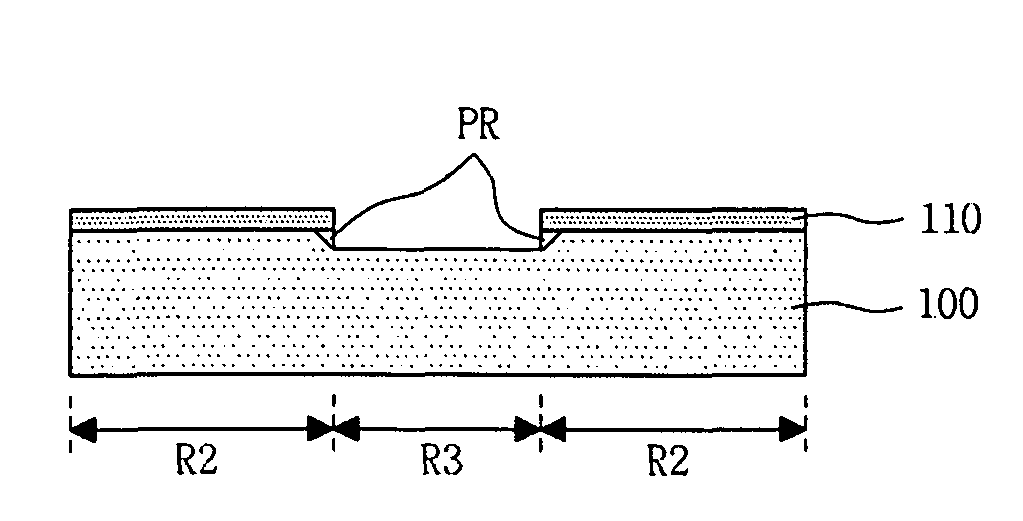

Semiconductor element and manufacturing method thereof

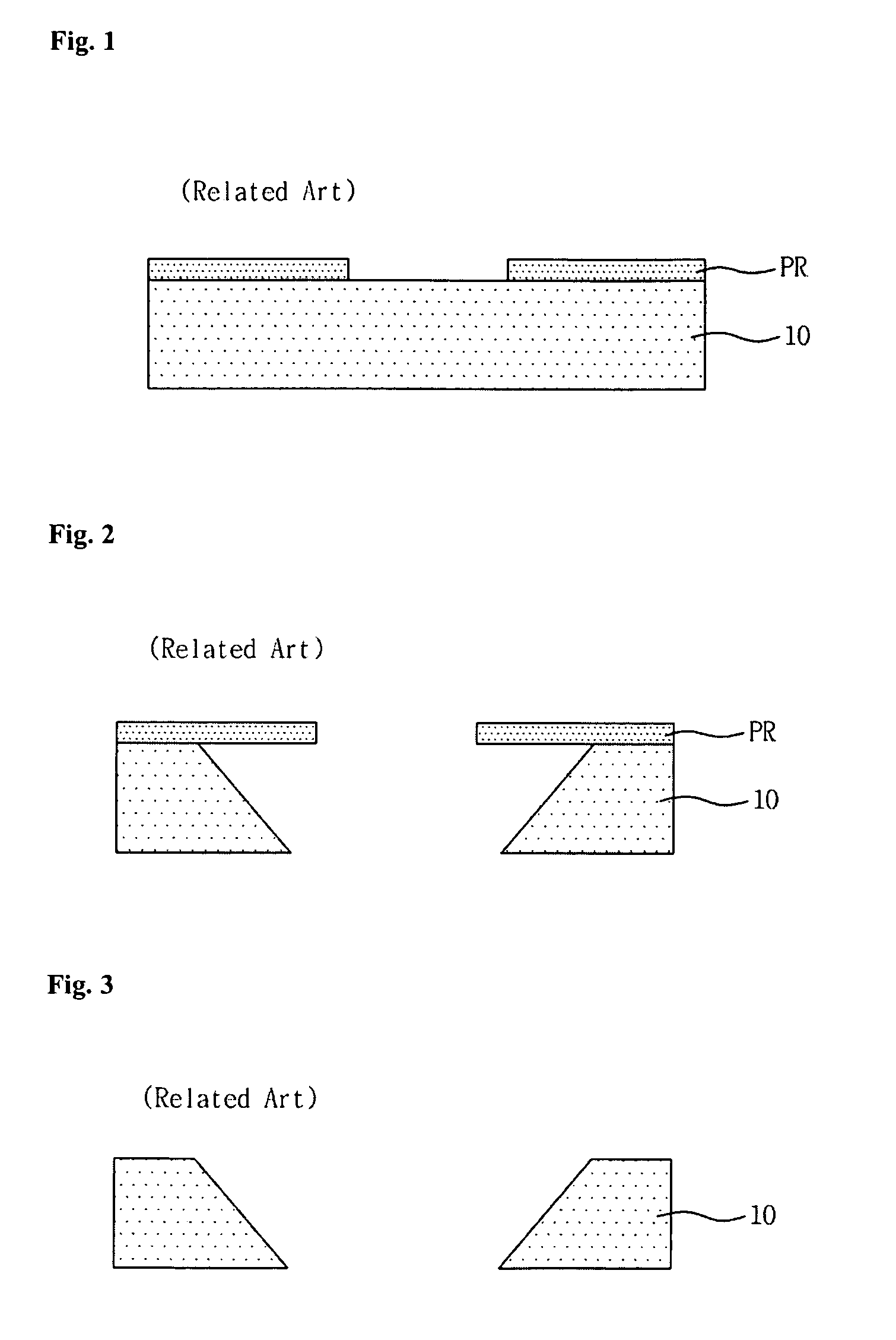

ActiveCN103578984AReduce side erosionReduce production processSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistMetal

Provided are a semiconductor element and a manufacturing method thereof. The manufacturing method of the semiconductor element comprises the steps of sequentially forming a gate electrode, a gate insulating layer, an oxide semiconductor layer and an etching stop layer on a substrate, wherein the etching stop layer is provided with two contact openings enabling a part of the oxide semiconductor layer to expose; forming a metal layer on the etching stop layer, wherein the metal layer is connected with the oxide semiconductor layer through the contact openings; forming a partly-adjustable type patterning photoresist layer on the metal layer; using the partly-adjustable type patterning photoresist layer as a mask to remove the metal layer being exposed out of the partly-adjustable type patterning photoresist layer and the etching stop layer under the metal layer; decreasing the thickness of the partly-adjustable type patterning photoresist layer till a second portion is completely removed and forming a patterning photoresist layer; using the patterning photoresist layer as a mask to remove the metal layer being exposed out of the patterning photoresist layer and the oxide semiconductor layer and defining a source electrode, a drain electrode and a channel region; removing the patterning photoresist layer.

Owner:HANNSTAR DISPLAY CORPORATION

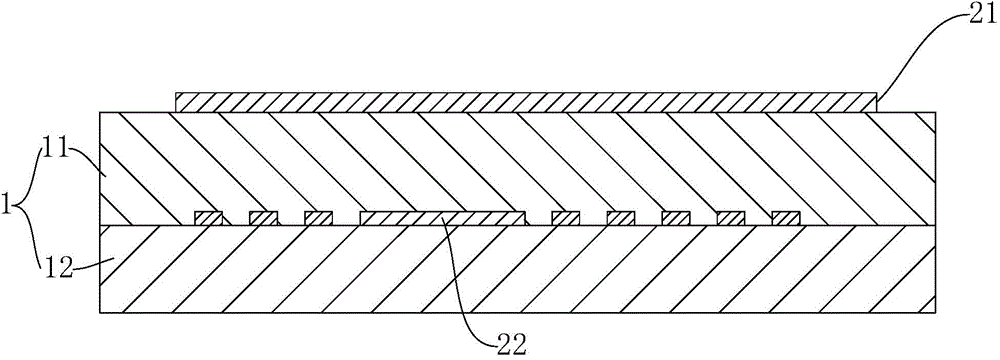

Preparation technology of high-density interconnecting printed circuit board

InactiveCN104135822AImprove qualityAvoid the effects of thickness uniformityMultilayer circuit manufactureNon-metallic protective coating applicationTectorial membraneHigh density

The invention discloses a preparation technology of a high-density interconnecting printed circuit board. The preparation technology is characterized by comprising the steps of providing a first substrate which comprises a first conducting layer, a second conducting circuit and first insulating layers, etching the first conducting layer to form a first conducting circuit and a first window, drilling one first insulating layer to form a through hole, performing chemical copper deposition treatment on the first substrate, arranging a protective film on the surface of metallic copper covering the upper surface of the first substrate, forming a second window corresponding to the first window in the protective film, performing electroplating treatment on the first substrate provided with the protective film to allow the through hole and the first window to be filled with metallic copper, removing the protective film, and removing the metallic copper covering the upper surface of one first insulating layer, wherein the first conducting layer is located on the surface of one first insulating layer. The preparation technology of the high-density interconnecting printed circuit board saves a procedure of etching to reduce the thickness of the conducting circuits, improves the accuracy and the thickness uniformity of the conducting circuits, and improves the quality of the high-density interconnecting circuit board.

Owner:SHANGHAI MEADVILLE ELECTRONICS +1

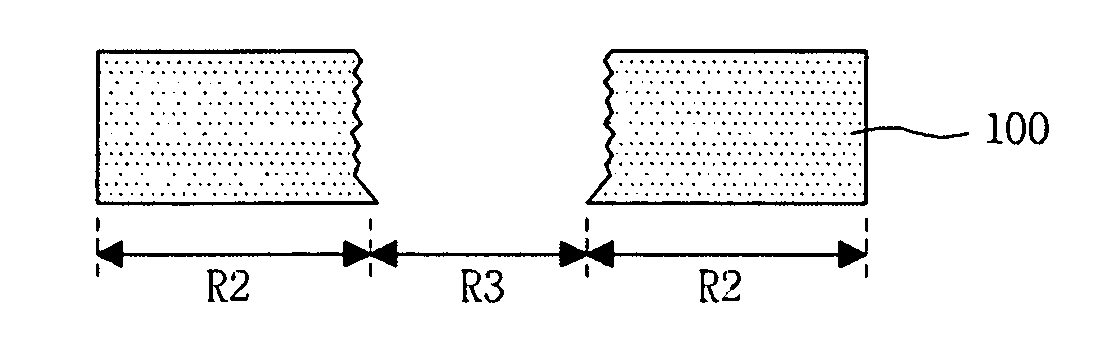

Lamination technology of precise circuit board

ActiveCN106255348AReduce etch timeReduce line side erosionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentSmooth surfaceLine width

The invention provides a lamination technology of a precise circuit board. Brown oxidation is carried out on the smooth surface of a copper foil, the copper foil is laminated with a core plate with the smooth surface facing a prepreg, and a rough surface copper foil at the external layer of the circuit board is polished to obtain a flat copper surface. The lamination technology has the advantages that the etching time of the circuit board is reduced, the etching amount of the circuit side is reduced, and the line width precision of the circuit board is ensured.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

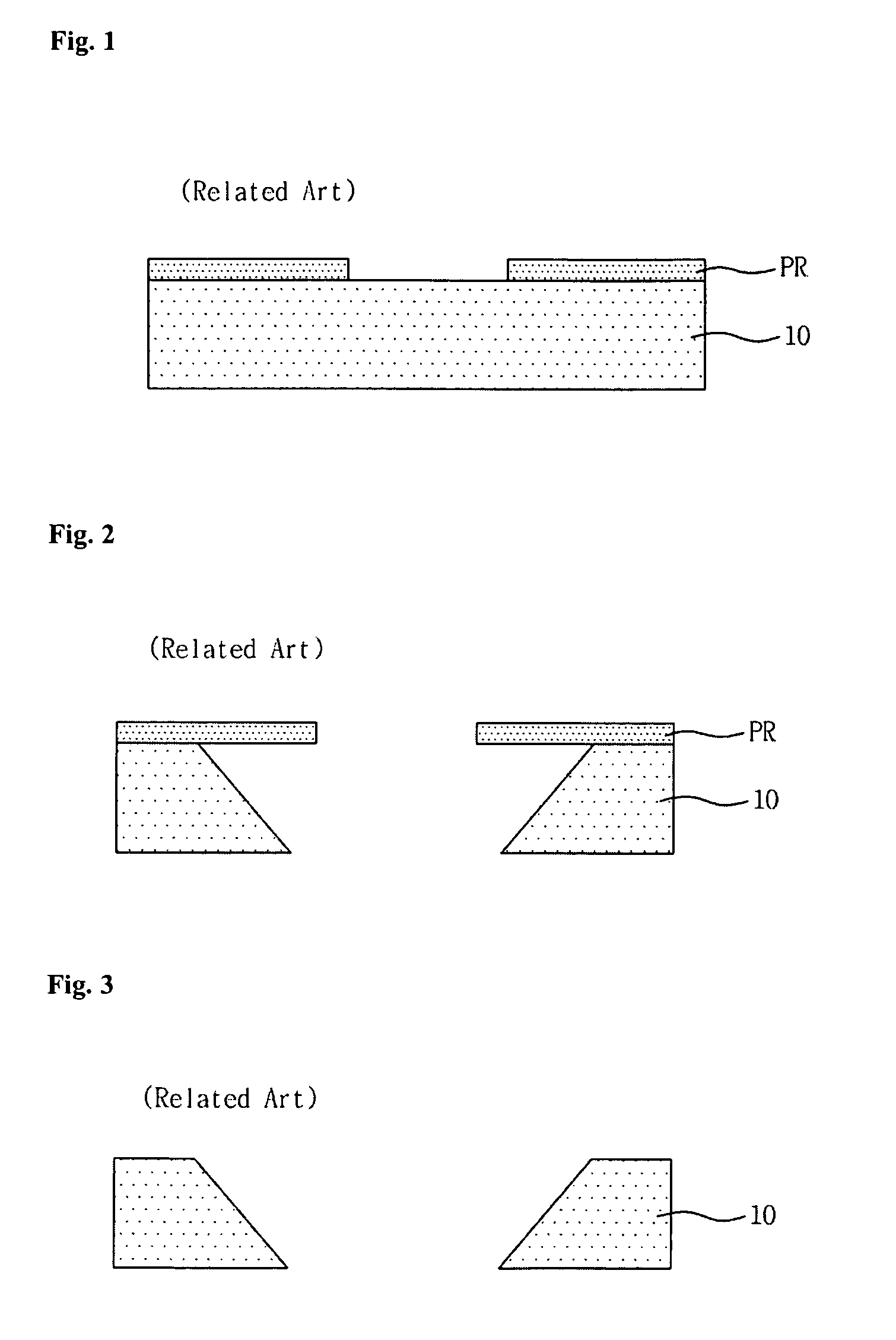

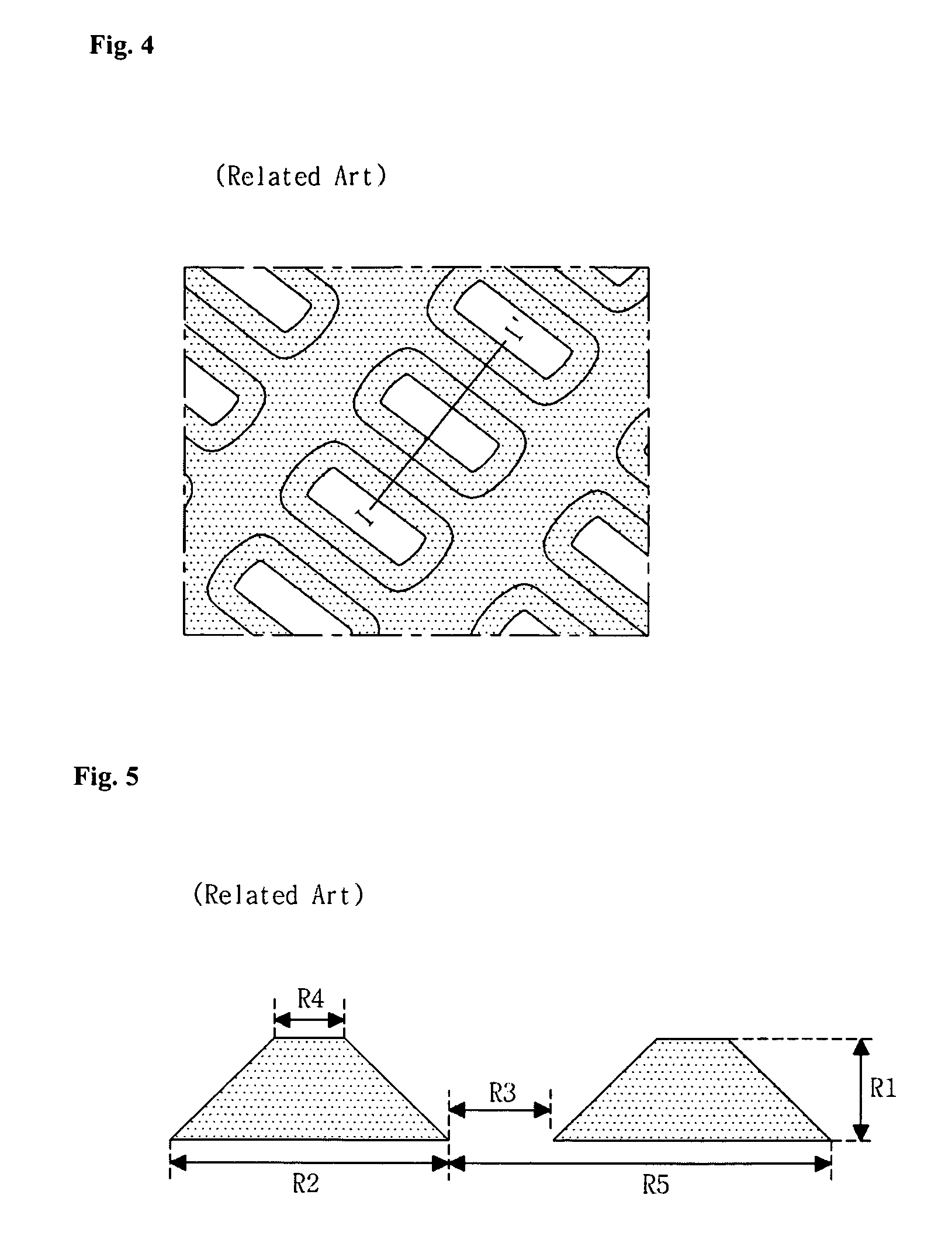

Shadow mask and manufacturing method thereof

ActiveUS20070001577A1Improve precisionImprove resolutionElectroluminescent light sourcesElectrode and associated part arrangementsImage resolutionMaterials science

Disclosed is a shadow mask having a fine slit that can improve precision and resolution of a pattern by reducing side etching during an etching process of a mask substrate, and a manufacturing method thereof. The shadow mask includes a mask substrate, a slit region formed by penetrating through the mask substrate, the slit region having a plurality of undercut portions at respective sides thereof, each undercut portion having a unit thickness, and a shadow region provided in the mask substrate, the shadow region corresponding to a region other than the slit region.

Owner:LG DISPLAY CO LTD

Double-component selective titanium corrosive liquid and titanium corrosion method

The invention discloses double-component selective titanium corrosive liquid formed by mixing a component A and a component B before using. The component A is mainly composed of an alkaline water solution, and alkali is at least one of soluble alkali and quaternary ammonium hydroxide. The component B comprises hydrogen peroxide, a hydrogen peroxide stabilizer and water. The component A further comprises strong alkali and weak acid salt, and the weak acid corresponding to the strong alkali and weak acid salt is non-reducing acid. According to the double-component selective titanium corrosive liquid, through adding of the strong alkali and weak acid salt, the concentration of hydroxyl in the corrosive liquid is stabilized, the performance of the corrosive liquid is stable, and the service life of the corrosive liquid can be better prolonged; and through further selection of the strong alkali and weak acid salt, the lateral corrosion amount of a copper layer and erosion of an aluminum layer are effectively reduced, and the etching uniformity is improved.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Preparation method of super-hydrophobic coating

ActiveCN110434034AIncreased complexityAdding complexity, increasing the hydrophobicity of the superhydrophobic coatingPretreated surfacesSpecial surfacesMicro nanoSilanes

The invention relates to a preparation method of a super-hydrophobic coating. According to the etching method, three different steeping liquors are correspondingly used for steeping for some time, inthis way, the etching rate is increased by using the different steeping liquors for steeping, the etching rate is increased by adopting the specific steeping liquor proportion, the side etching amountand bulges are reduced by increasing the etching rate, the micro-nano shape formed on the surface of a copper sheet is more complicated, and the hydrophobicity, the friction resistance and the fracture resistance of the super-hydrophobic coating are improved. Fluoroalkyl silane and silane with the boiling points being similar are selected to be better deposited on the surface of matrix copper etched well, so that the coating has the very low surface energy, the quality of the coating is relatively stable, the good hydrophobic effect is reached, the corrosion resistance and cleanness of the copper are better, and the service life is longer.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for manufacturing negative film circuit board with stepped circuit

InactiveCN110602890AOptimize film process parametersEnsure binding force and exposure accuracyConductive material chemical/electrolytical removalCircuit precursor manufactureLine widthPrinted circuit board

The invention relates to the technical field of printed circuit boards, in particular to a method for manufacturing a negative film circuit board with a stepped circuit. The method manufactures a circuit board with a stepped circuit by a negative film process by performing full-board electroplating twice, making a circuit pattern by using dry film exposure development, and removing the copper layer in the non-circuit area by acid etching, and solves the problem that the existing negative film process cannot produces the stepped circuit. In addition, the method uses a vacuum laminator and an LDI exposure machine to perform the corresponding lamination and exposure processes when making outer layer circuit pattern, optimizes the lamination process parameters to ensure the bonding force between the dry film and the board surface and the exposure accuracy, and by optimizing the process parameters during the acid etching, satisfies the protection performance requirements of the outer layerpattern on a production board during the etching process, avoids the quality problems such as open circuits and gaps caused by the infiltration of an etching solution into the outer layer pattern, reduces side etching, and avoids a large line width and line gap tolerance due to side etching.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

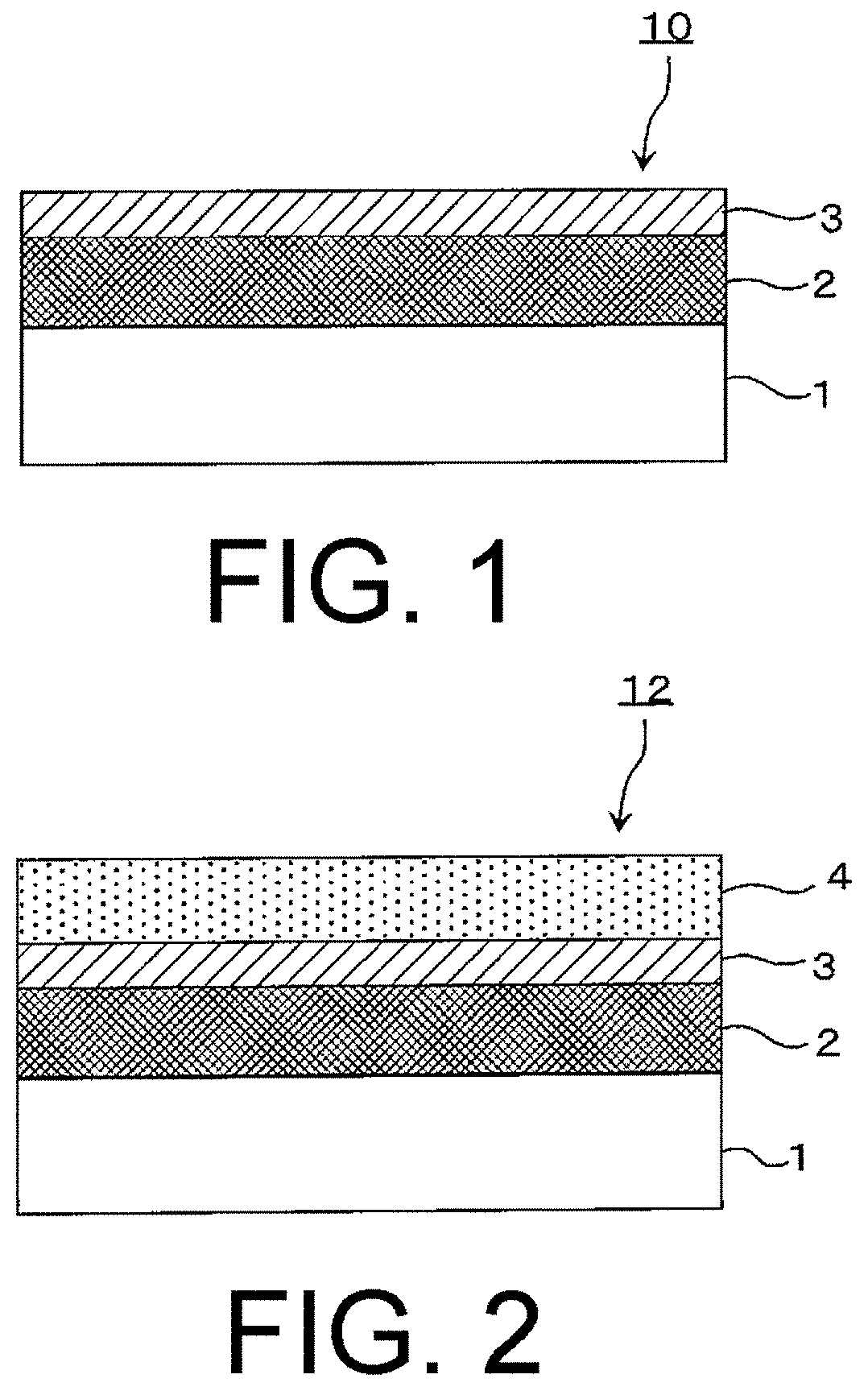

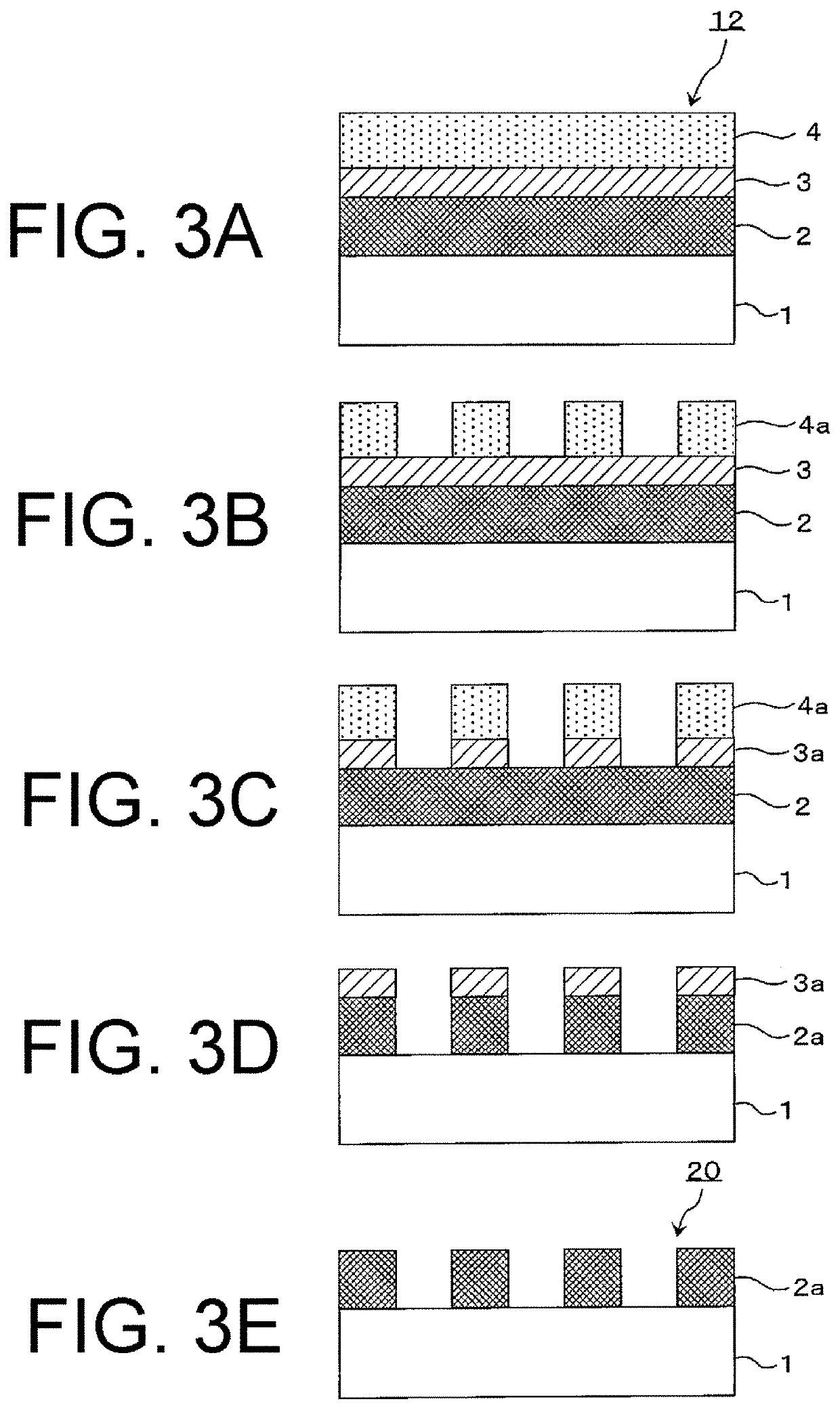

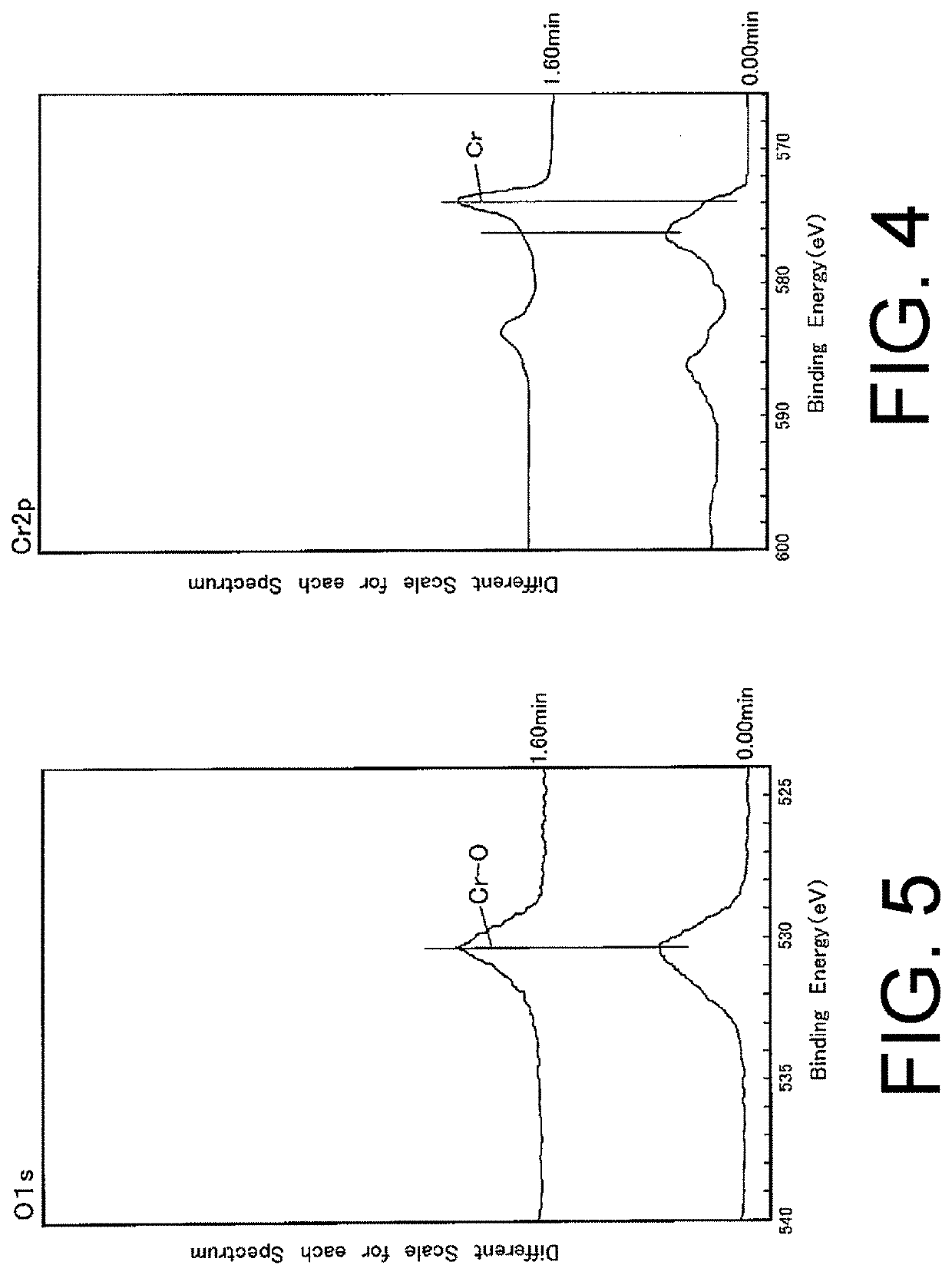

Mask blank, method for manufacturing transfer mask, and method for manufacturing semiconductor device

ActiveUS11281089B2Forming accuratelyAccurately form fine patternPhotomechanical apparatusSemiconductor/solid-state device manufacturingDevice materialPhysical chemistry

A light shielding film made up of a material containing one or more elements selected from silicon and tantalum and a hard mask film made up of a material containing chromium, oxygen, and carbon are laminated on a transparent substrate. The hard mask film is a single layer film having a composition gradient portion with increased oxygen content on the surface and on the neighboring region. The maximum peak for N1s in a narrow spectrum obtained via X-ray photoelectron spectroscopy analysis is the lower limit of detection or less. The portions excluding the composition gradient portion of the hard mask film have a 50 atom % or more chromium content, and the maximum peak for Cr2p in a narrow spectrum obtained via X-ray photoelectron spectroscopy analysis has a binding energy of 574 eV or less.

Owner:HOYA CORP

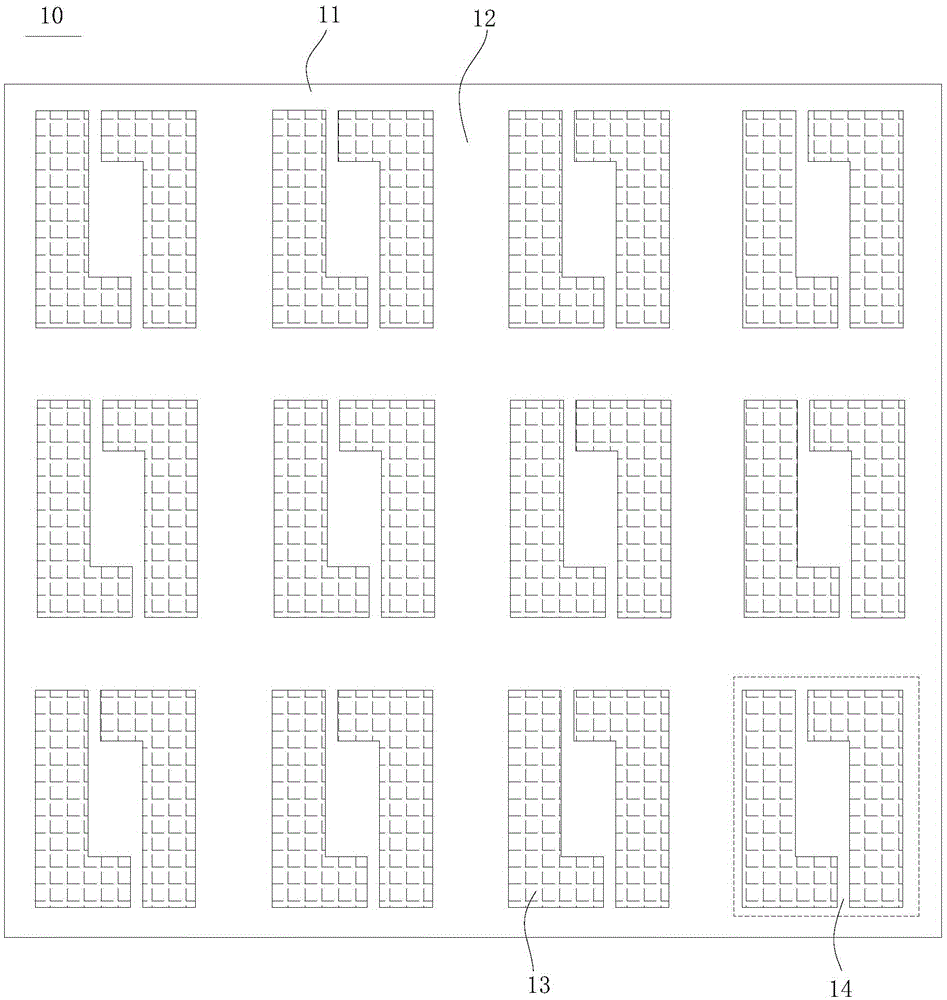

Manufacturing method for fine circuit

InactiveCN105611743AIncreased risk of plate breakagePromote exchangePrinted circuit manufactureEngineeringMachining process

The invention relates to the technical field of circuit board production, and specifically to a manufacturing method for a fine circuit. An overflow hole is drilled in a molding edge of a multi-layered board; residual etching liquid medicine in the middle of the board can flow out of the overflow hole in an etching process so as to accelerate etching liquid medicine exchange, weaken a pool effect and improve the etching capability in order to reduce the lateral-etching quantity and deckle edges, improve the etching uniformity and improve the manufacturing precision of the circuit. By controlling the size and the hole edge distance of the overflow hole, the etching liquid medicine exchanging speed is improved while the increasing risk of board-breaking in the machining process of the multi-layered board due to the existence of the overflow hole is avoided as well; and by controlling alkali etching parameters, the etching effect can be further improved, and the precision of the circuit can be further improved as well.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Method for laser-assisted manufacturing of precise circuit

PendingCN114158195AEasy to prepareReduce thicknessConductive material chemical/electrolytical removalMachiningMaterials science

The invention discloses a laser-assisted precise circuit manufacturing method, which comprises the following steps that a production board is provided, and circuits needing to be manufactured on the production board comprise a thick circuit with the circuit distance larger than 50 microns and a precise circuit with the circuit distance smaller than or equal to 50 microns; a film is pasted on the production board, exposure treatment is carried out, exposure of the coarse lines and the precise lines is completed, and all gap parts between the precise lines are exposed; developing and etching the production board, wherein the etching amount during etching is controlled to be greater than half of the copper thickness of the circuit, and the bottom layer base material is not exposed; ablating a gap part between the precision circuits by adopting laser to remove a film and a part of copper layer at the gap of the precision circuits; and carrying out etching treatment and film stripping on the production board again, and forming a thick circuit and a precise circuit on the production board. According to the method, the technological process is optimized, the laser ablation and chemical etching combined copper removal mode is adopted in sequence, manufacturing of the precise circuit with the distance smaller than or equal to 50 micrometers can be achieved, the material and machining cost is low, and the technological process is simple.

Owner:SIHUI FUJI ELECTRONICS TECH

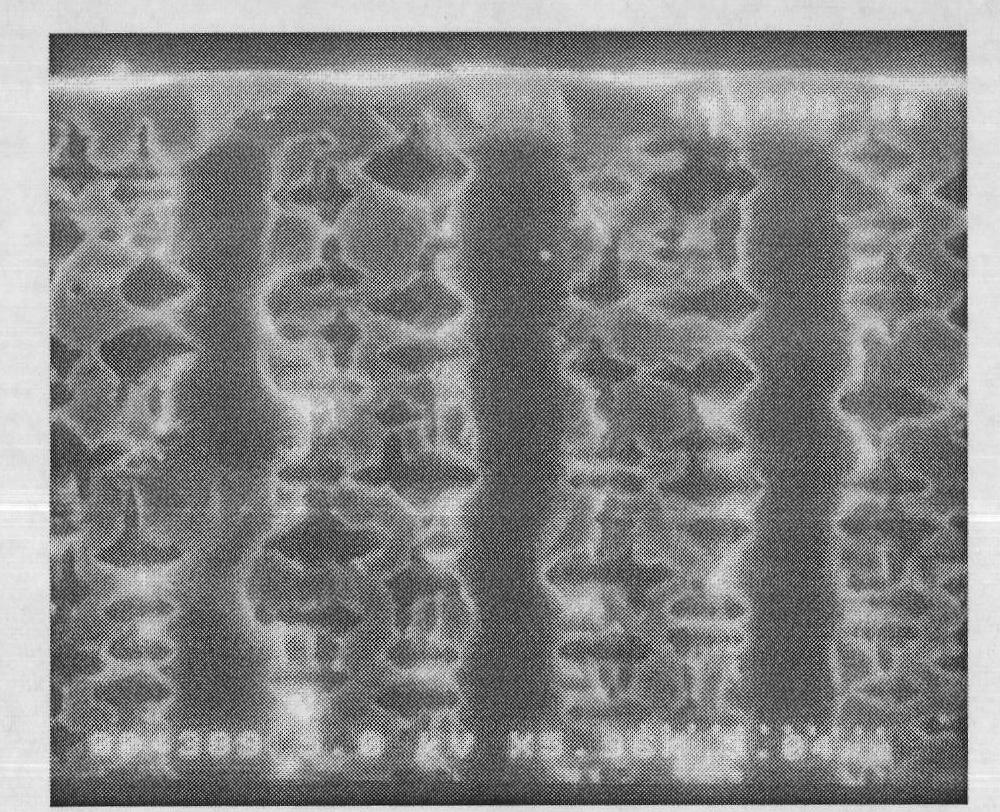

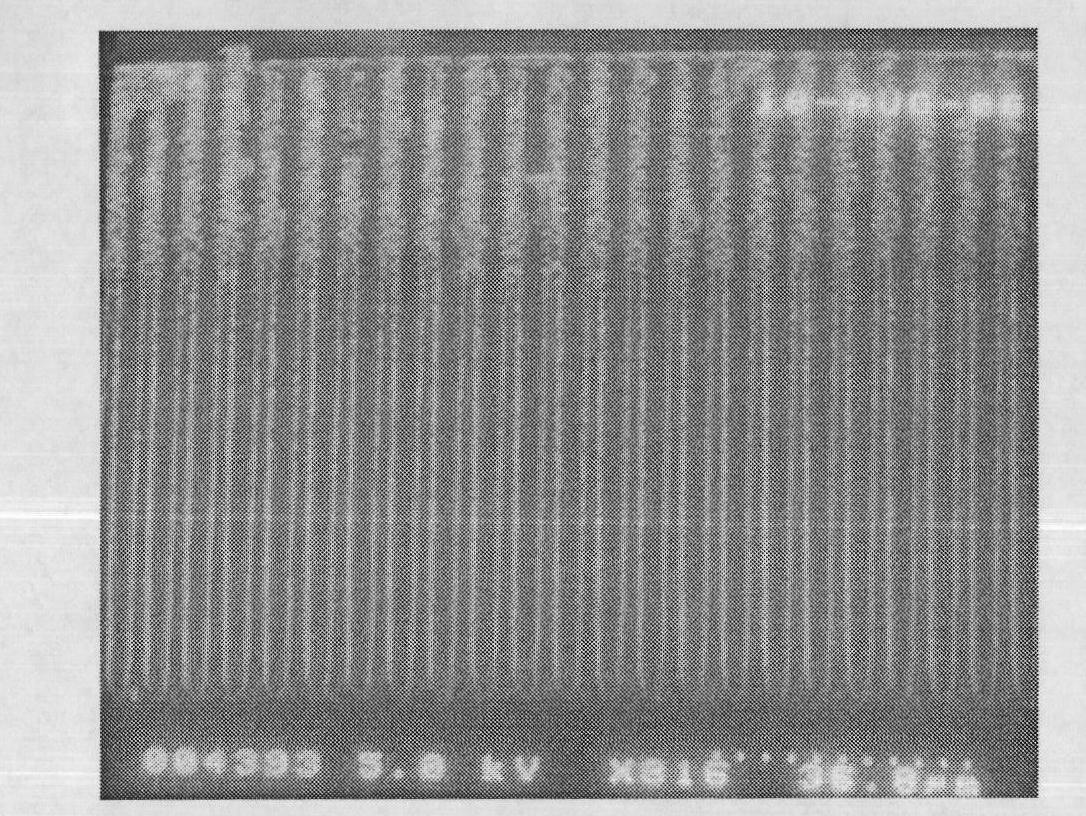

Etching solution for processing N-type silicon microchannel array by photon-assisted electrochemical etching method

InactiveCN101792106AEasy to controlReduce side erosionSemi-permeable membranesFixed microstructural devicesHydrofluoric acidPhenyl Ethers

The invention relates to an etching solution for processing an N-type silicon microchannel array by a photon-assisted electrochemical etching method, which belongs to the technical field of silicon micro-processing. In the prior art, the etching solution for processing an N-type silicon microchannel array by a photon-assisted electrochemical etching method is made by adding ethanol or p-octyl polyethylene glycol phenyl ether, which is used as a surfacetant, into hydrofluoric acid electrolyte, and the etching solution can result in severe lateral erosion in the etching process. The etching solution of the invention is prepared from hydrofluoric acid and ethanol water solution, wherein the concentration of the hydrofluoric acid is 1-10 wt%, and the concentration of the ethanol is5-10 wt%. In addition, an anionic surfactant is added, and the amount of the anionic surfactant is 0.1-1% of the hydrofluoric acid and ethanol water solution by volume. The invention is used for processing N-type macro-pore silicon microchannel arrays.

Owner:CHANGCHUN UNIV OF SCI & TECH

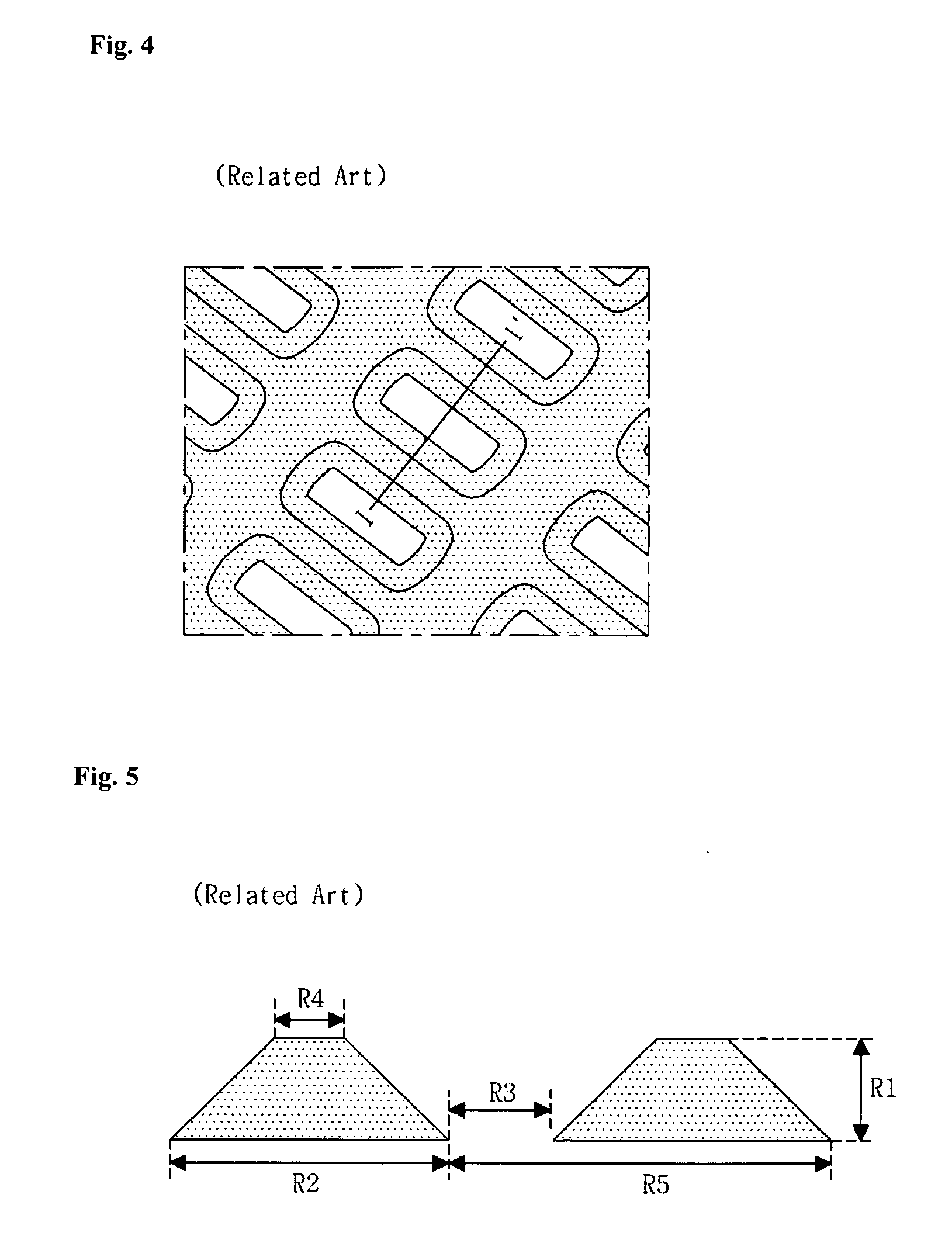

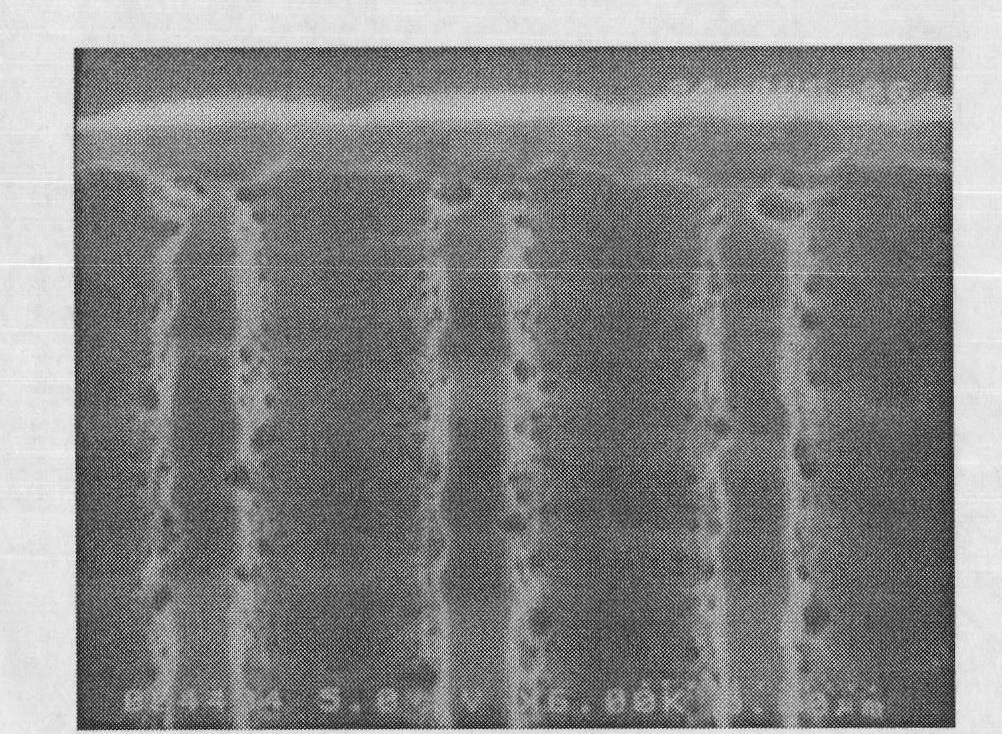

Shadow mask and manufacturing method thereof

ActiveUS8007967B2Improve resolution and precisionReduce side erosionElectroluminescent light sourcesElectrode and associated part arrangementsImage resolutionMaterials science

Disclosed is a shadow mask having a fine slit that can improve precision and resolution of a pattern by reducing side etching during an etching process of a mask substrate, and a manufacturing method thereof. The shadow mask includes a mask substrate, a slit region formed by penetrating through the mask substrate, the slit region having a plurality of undercut portions at respective sides thereof, each undercut portion having a unit thickness, and a shadow region provided in the mask substrate, the shadow region corresponding to a region other than the slit region.

Owner:LG DISPLAY CO LTD

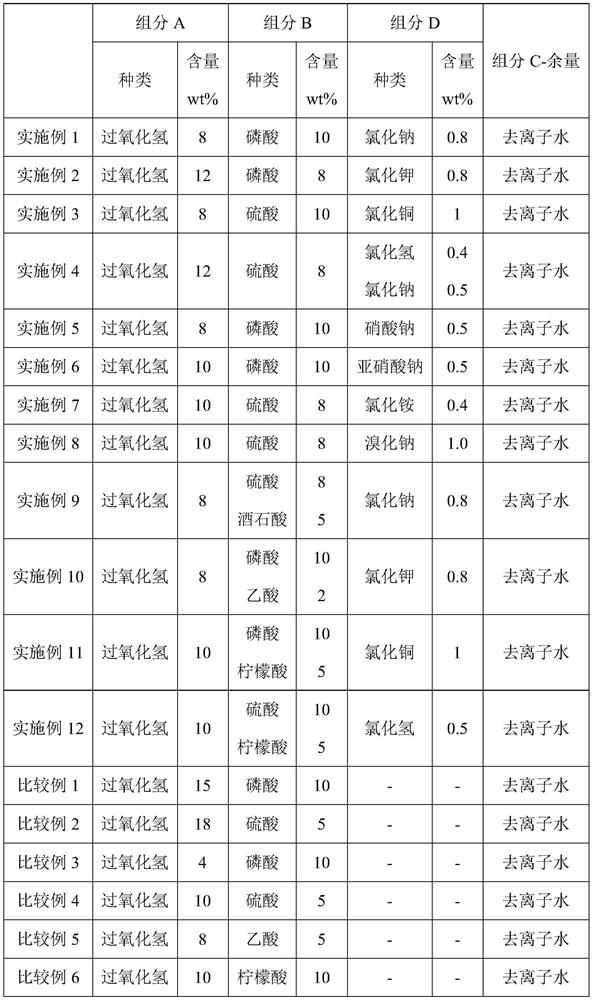

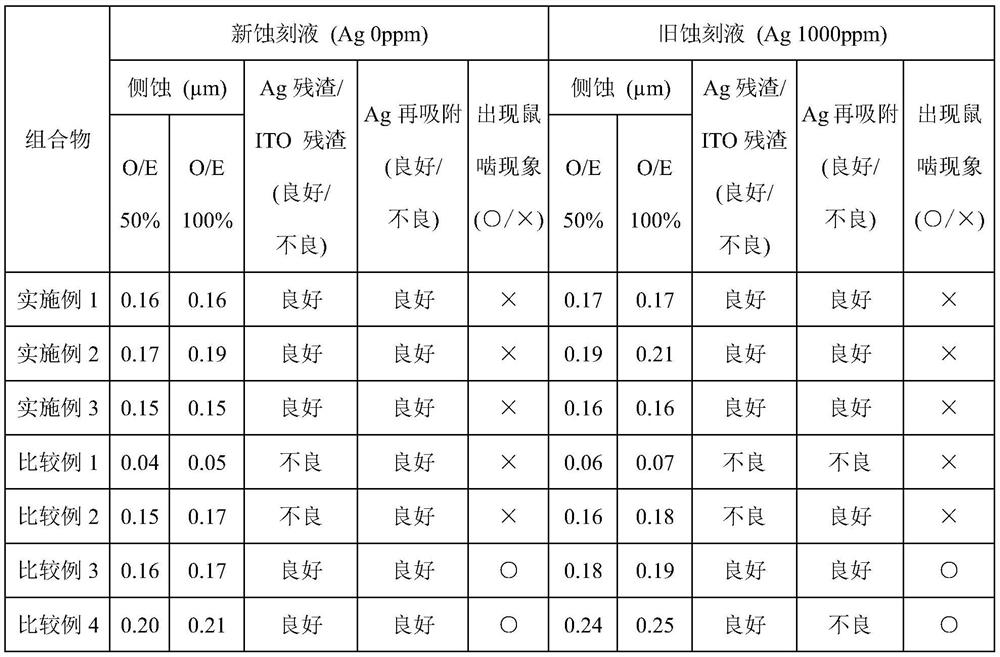

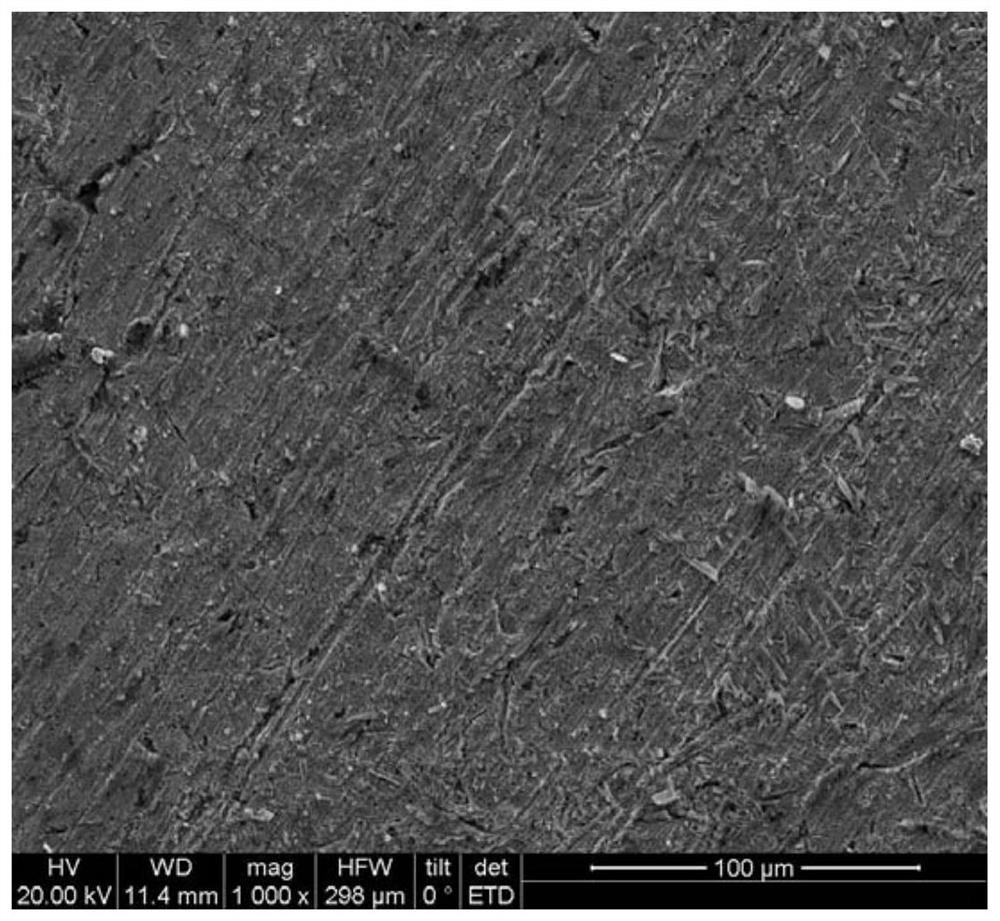

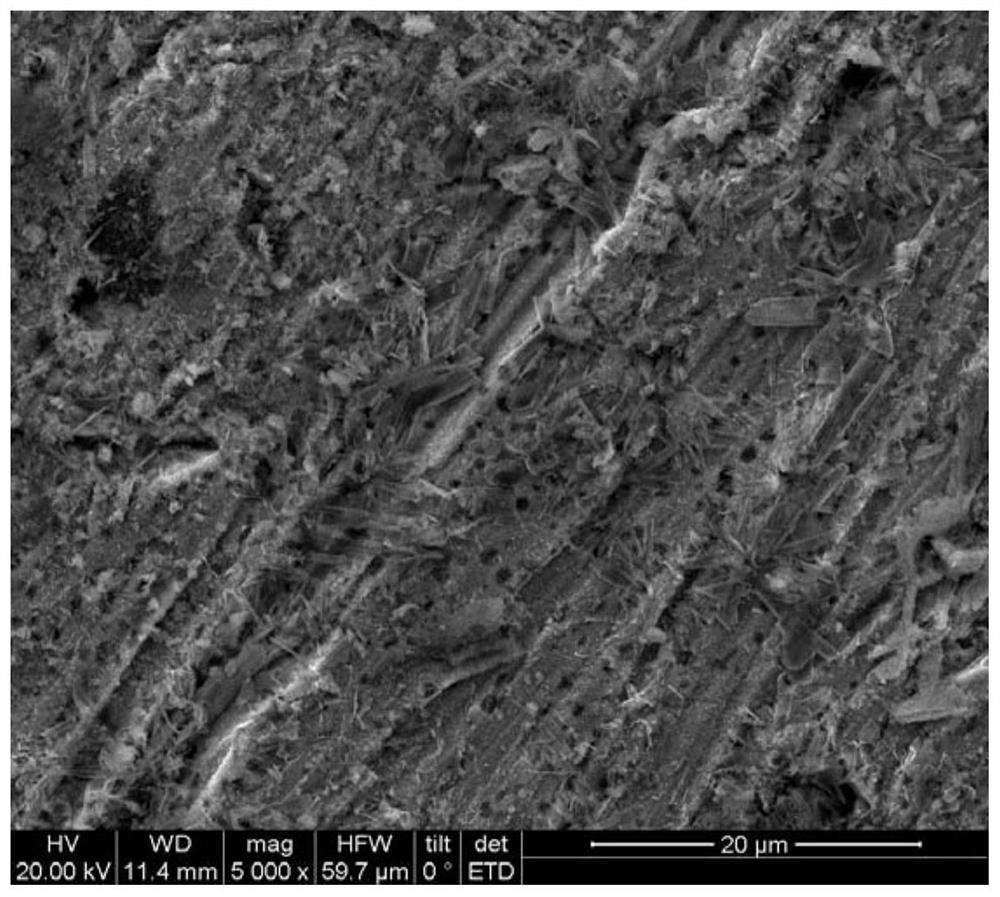

Thick copper etching composition and application thereof

The invention relates to the field of semiconductor wafer packaging, in particular to a hydrogen peroxide system copper etching composition used in a wet etching process, and particularly relates to a thick copper etching composition and application thereof. The thick copper etching composition at least comprises the following components in percentage by weight: 1-20wt% of a component A, 1-30wt% of a component B and a component C, the component A is an oxidizing agent; the component B is inorganic acid and / or organic acid; and the component C is deionized water. The etching composition provided by the invention has the advantages of high stability, long etching life and large sheet running amount, the utilization rate of the etching composition is effectively improved, and only copper can be selectively etched; in addition, the etching composition also has the advantages of extremely low lateral erosion amount, good etching selection ratio, excellent etching uniformity, relatively high etching stability, relatively high etching rate stability, relatively long service life and the like.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

Silver thin film etching liquid composition, etching method using same, and metal pattern forming method

PendingCN113652693AAvoid over etchingImprove re-adsorption and other issuesSemiconductor/solid-state device manufacturingOrganic acidPhysical chemistry

The present invention relates to a silver thin film etching liquid composition, an etching method using the same, and a meta pattern forming method. The silver thin film etching liquid composition comprises: (A) nitric acid; (B) an alkyl sulfonic acid having 1 to 3 carbon atoms; (C) an organic acid other than an alkyl sulfonic acid having 1 to 3 carbon atoms; (D) sulfate; (E) an iron-containing ternary metal salt; and (F) water.

Owner:DONGWOO FINE CHEM CO LTD

A kind of preparation method of superhydrophobic coating

ActiveCN110434034BIncreased complexityImprove hydrophobicityPretreated surfacesSpecial surfacesSuperhydrophobeMicro nano

The invention relates to a method for preparing a super-hydrophobic coating. The etching method in the invention uses three different immersion solutions to immerse for a period of time, so that the etching rate can be accelerated by using different immersion solutions. The proportion of the liquid can speed up the etching rate. By speeding up the etching rate, the amount of side etching and the edge can be reduced. The micro-nano morphology formed on the surface of the copper sheet is more complex, which increases the hydrophobicity, friction resistance and durability of the super-hydrophobic coating. Bending resistance: the present invention selects two kinds of fluorosilanes and silanes with similar boiling points, which can be better deposited on the surface of the etched substrate copper, so that the coating has a very low surface energy, the coating quality is relatively stable, and good hydrophobicity is achieved. The effect makes the corrosion resistance and cleaning performance of copper better, and the service life is longer.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Etching solution composition for titanium-aluminum-titanium metal laminated film

The invention relates to an etching solution composition for a titanium-aluminum-titanium metal laminated membrane consisting of a titanium metal membrane, an aluminum metal membrane and a titanium metal membrane. The composition consists of fluorides, oxidizing acid, non-oxidizing alkali metal salt and water, wherein the non-oxidizing alkali metal salt is preferentially at least one of water-soluble lithium, potassium and sodium salts; the mass percent concentration of the fluorides, the oxidizing acid and the non-oxidizing alkali metal salt are 0.01-5 percent, 0.1-30 percent and 0.0004-0.35 percent, respectively. Compared with the prior art, the etching solution composition has the advantages that the three laminated metal membranes can be etched together, the lateral erosion amount can be effectively reduced, the etching uniformity is improved, and the obtained taper angle is 25 degrees below. In addition, the etching solution composition adopts low-price non-oxidizing salts or mixtures thereof instead of high-price salt-type auxiliary oxidants, so that the production cost is reduced, and the balance between the cost and performance is achieved.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

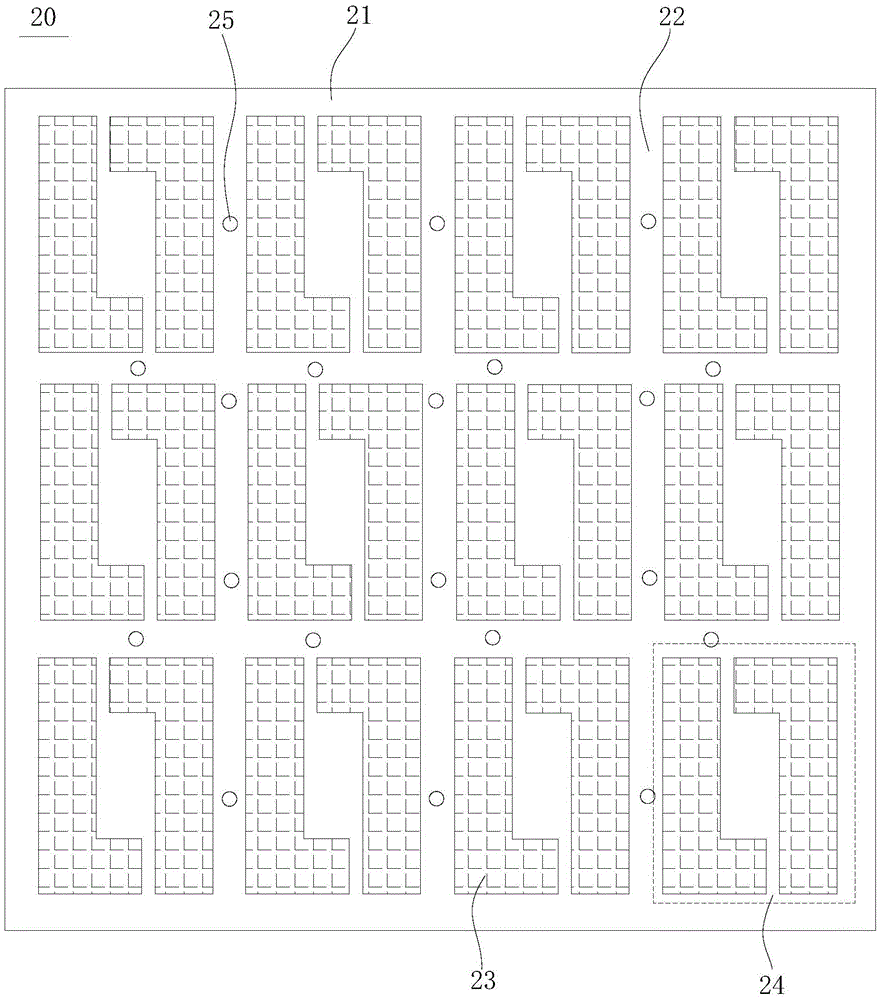

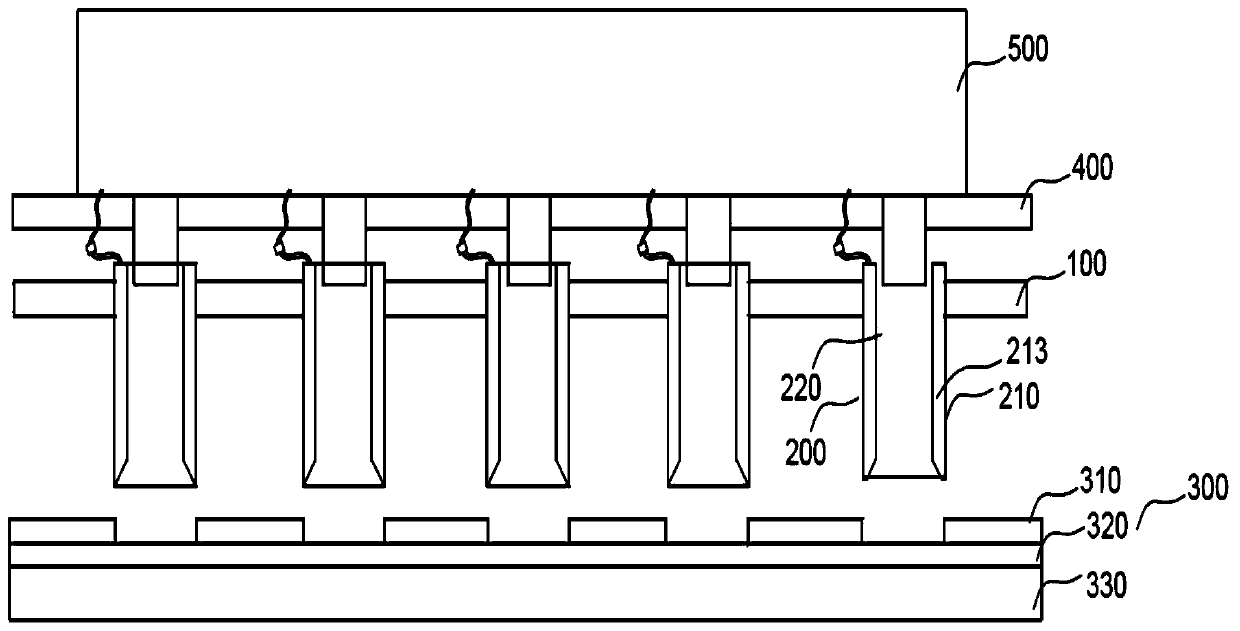

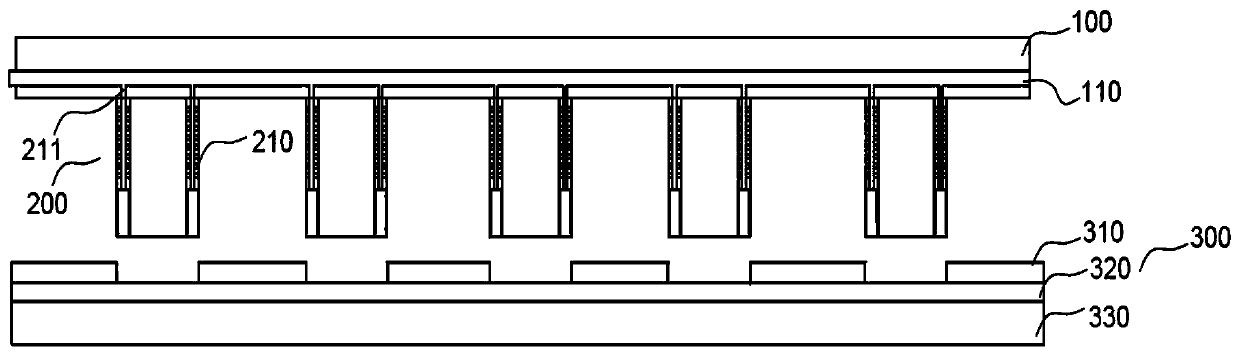

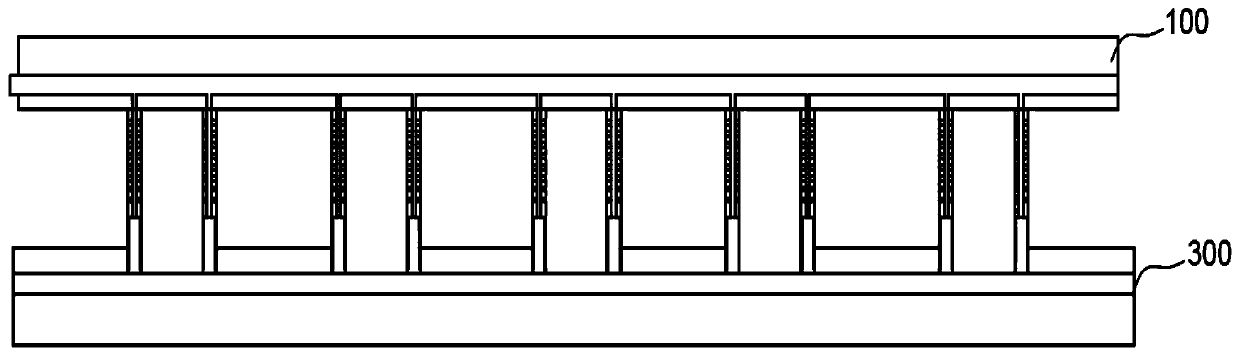

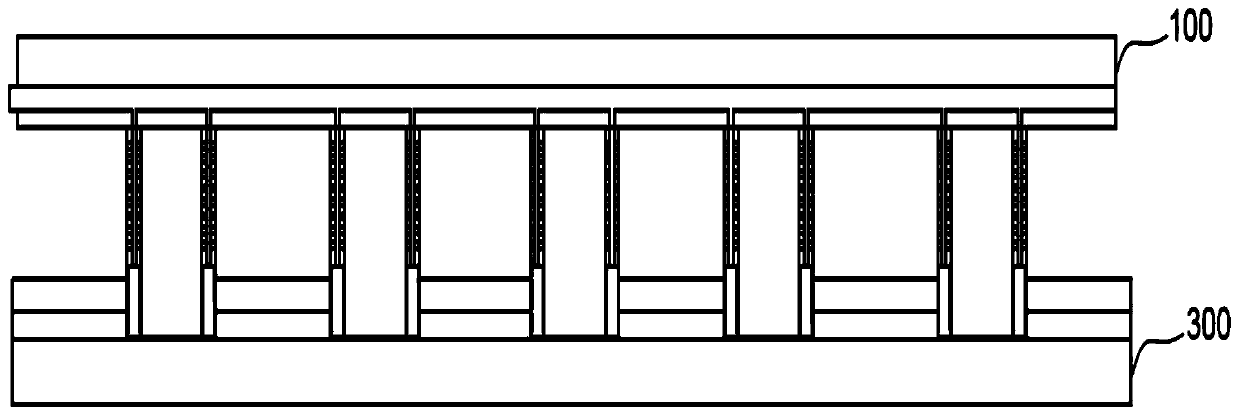

Device and method for increasing circuit board wiring density

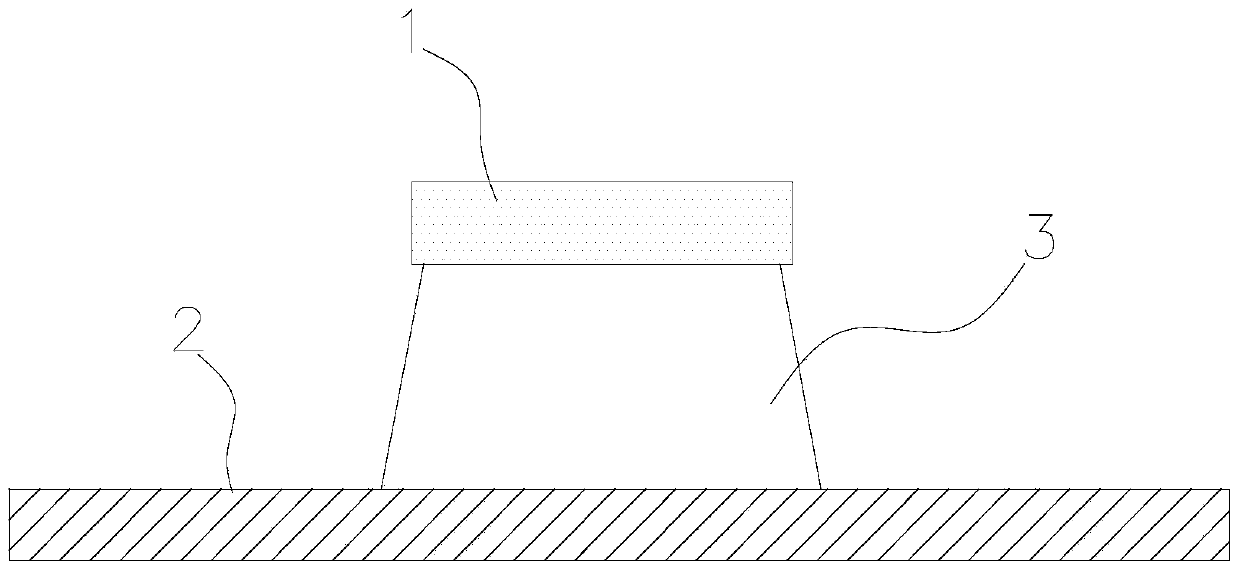

ActiveCN107529284BEffective protectionReduce side erosionConductive material chemical/electrolytical removalEngineeringMechanical engineering

The invention discloses a device and method for increasing the wiring density of a circuit board. The device comprises a mask plate, a pressure plate, a protection sleeve and a moving plate. The upper end of the protection sleeve penetrates through the bottom of the pressure plate. The protection sleeve is formed by splicing a plurality of side plates. The side plates are provided therein with a hollow chamber. A nozzle is embedded in the bottom of the hollow chamber, emits solutions obliquely downward, and communicates with the hollow chamber. The shapes and the positions of the protection sleeves correspond to those of through holes on the mask plate one to one. The upper end of moving plate is provided with a closed container containing an etching solution. A plurality of first pipes and second pipes penetrate through the moving plate. The upper end of each first pipe communicates with the closed container. The lower end of each first pipe is aligned with the upper port of the corresponding protection sleeve. The upper end of the hollow chamber communicates with the second pipe via a delivery pump. The device and method solve a decrease in the wiring density of the circuit board due to serious undercut.

Owner:CHANGSHU MUTUAL TEK CO LTD

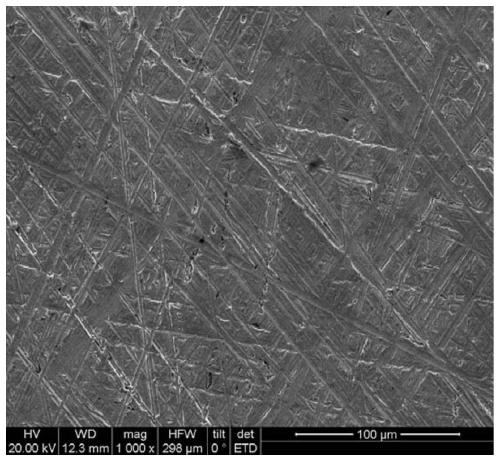

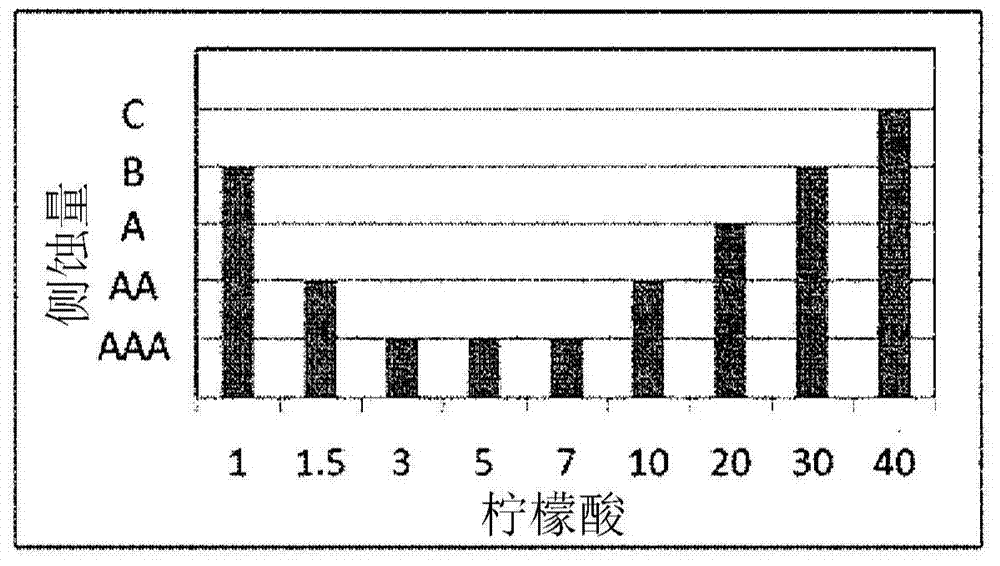

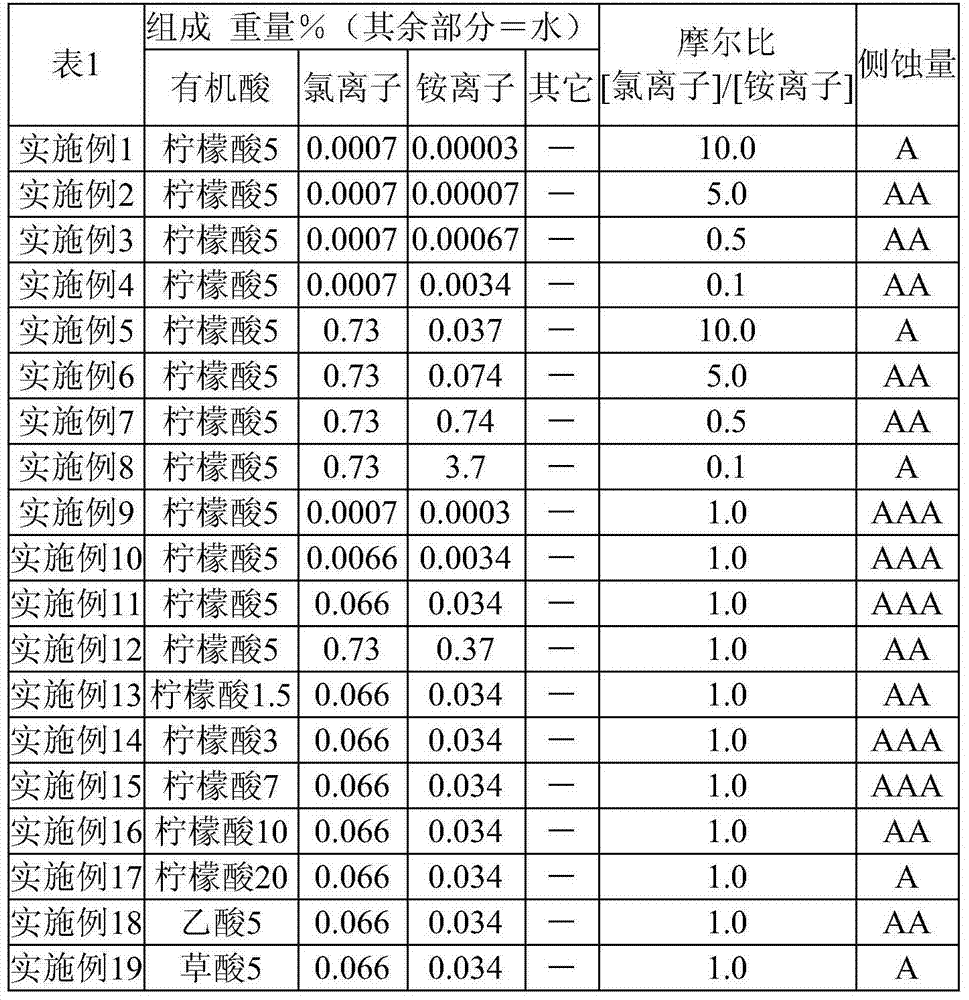

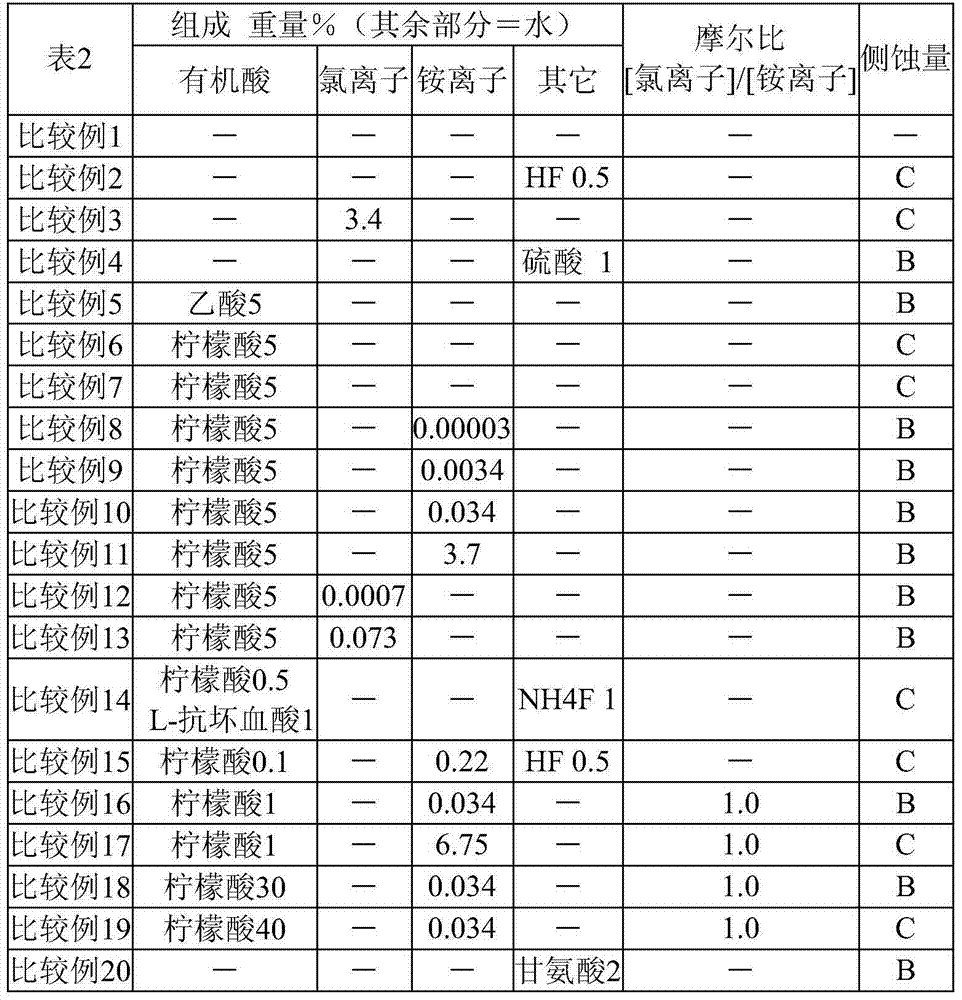

Resist adhesion improver and method for producing copper wiring line

InactiveCN104246017AExcellent adhesionReduce side erosionSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistOrganic acid

A resist adhesion improver which contains 1.5-20% by weight of an organic acid, 0.0007-0.73% by weight of chloride ions and 0.00003-3.7% by weight of ammonium ions, with the balance made up of water, and wherein the molar concentration ratio of the chloride ions to the ammonium ions is within the range of 0.1-10; and a method for producing a copper wiring line, wherein when a photosensitive resist film is formed on a copper film, the copper film surface is processed using the resist adhesion improver and then the photosensitive resist film is formed on the copper film. Consequently, adhesion of the photosensitive resist to the copper film surface is improved.

Owner:NAGASE CHEMTEX CORPORATION

Etching device and etching method for reducing side erosion angle of circuit board

ActiveCN107690229BEffective protectionReduce side erosionNon-printed masksConductive material chemical/electrolytical removalStructural engineeringMechanical engineering

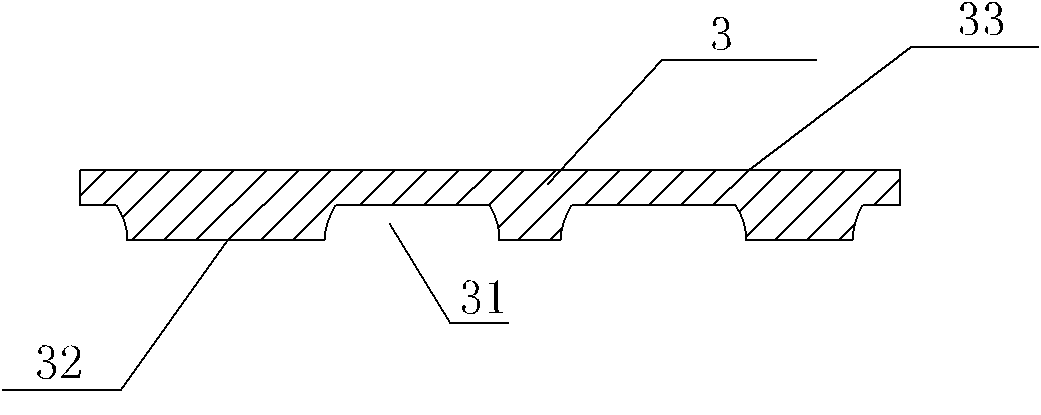

The invention discloses an etching device and method for reducing a side-etching tilt angle of a circuit board. The etching device comprises a mask plate which is movably arranged at the upper end ofthe circuit board, and is provided with a plurality of through holes, a pressure plate which is movably arranged at the upper end of the mask plate, and is internally and transversely provided with afirst channel of which an inlet is communicated with a container with an etching liquid, and a protective sleeve which is of a cylindrical structure having a cross section and is coincident with the cross section of the through hole, wherein the upper end of the protective sleeve is connected with the bottom of the pressure plate, and the protective sleeve is formed by splicing a plurality of sideplates; a hollow cavity is arranged in the bottom of the side plate, and a second channel is longitudinally arranged at the upper part of the side plate; and the second channel is communicated with the first channel and the hollow cavity, and a plurality of side holes are formed in the upper end of each side plate in a penetrating way. The etching device and method provided by the invention solvethe technical problem that the precise wiring of the circuit board is affected due to severe side-etching.

Owner:CHANGSHU MUTUAL TEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com