Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205 results about "Deckle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A deckle is a removable wooden frame or "fence" used in manual papermaking. In a related sense, it can also mean deckle edge paper—a type of industrially produced paper with rough cut edges used in the book trade.

Manufacturing process for step circuit of PCB (Printed Circuit Board)

InactiveCN102651946AReduce copper thickness dropEliminate poor quality defectsConductive material chemical/electrolytical removalProduction scheduleEngineering

The invention discloses a manufacturing process for a step circuit of a PCB (Printed Circuit Board). According to the manufacturing process, different film patterns are adopted twice for manufacturing the circuit, during the primary film pattern circuit manufacture, a positive film circuit pattern is adopted, compensation is carried out a film substrate circuit at different positions according to copper thickness so as to manufacture a special circuit, and sunk copper plate electrification is carried out on the special circuit, so that the copper thickness meets the requirement; then board grinding is carried out by a twice board grinding mode so as to reduce the copper thickness difference of step positions; a dry film is enabled to be fully combined with the step positions by virtue of a film attaching and air compressing mode; and finally, normal circuit pattern manufacturing is carried out by utilizing a high-precision LDI (Laser Direct Imaging) exposure machine. Compared with the prior art, the manufacturing process for the step circuit can be used for eliminating the defects of open circuit at the position of the step circuit, notches, large deckle edges, serious lateral erosion, halfway etching and poor quality of thin lines and the like existing in the step circuit manufacturing process, improving the production efficiency and the production quality, quickening the production schedule and lowering the production cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for solidifying frame glue and meethod for making liquid crystal display panel by using sad method

InactiveCN1536404AThere is no need to consider the problem of absorption bandAvoid UV absorptionNon-linear opticsIdentification meansLiquid-crystal displayLiquid crystal

The invention provides a method of solidifying deckle glue and a method of making LCD panel by the solidifying method, where the former is adaptive to the deckle glue with the solidification site between the first and second basal plates, its character: using total reflection law, it makes a UV light incident into the two basal plates at a give angle, and makes the UV light enter into the deckle glue when the UV light meets with the deckle glue instead of the liquid crystal.

Owner:AU OPTRONICS CORP

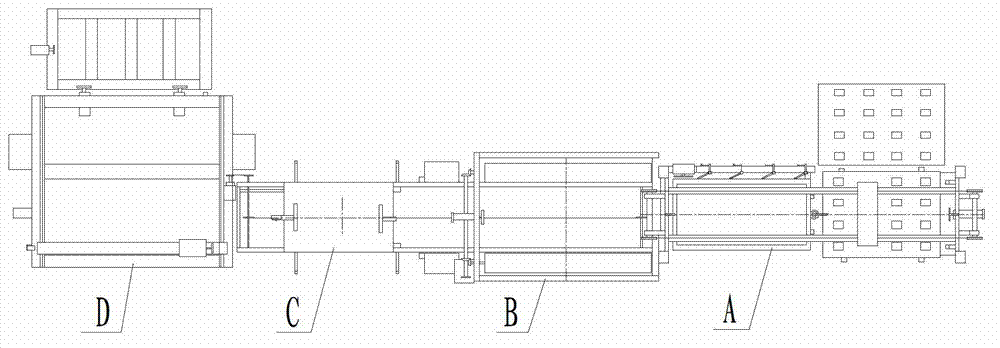

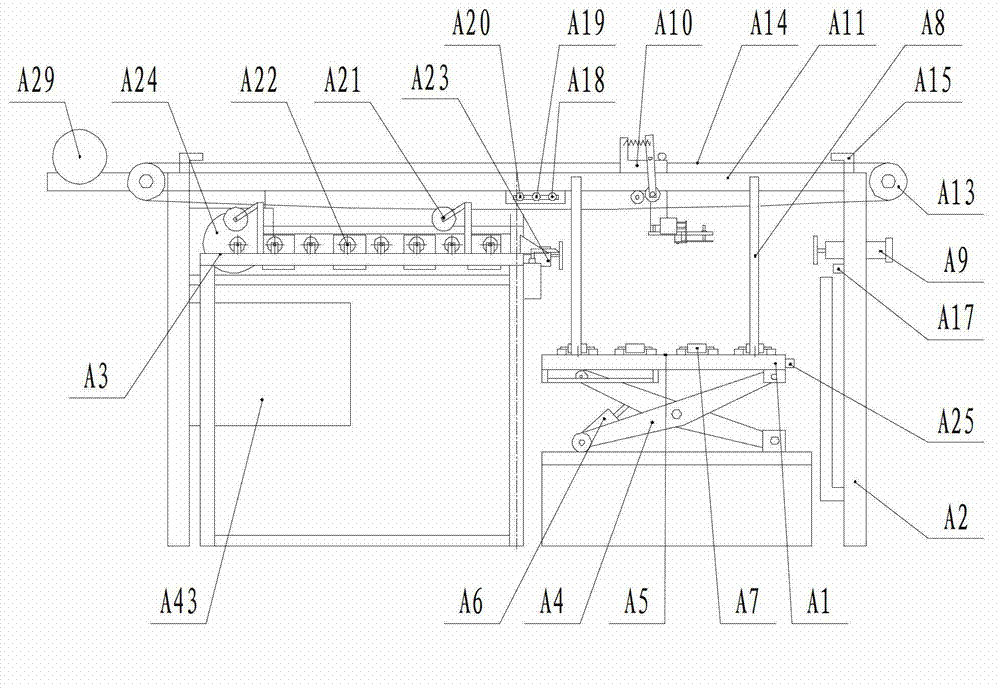

Board edge cutting machine

InactiveCN102814839AAvoid the trouble of manual frequent board deliveryPrecise positioningCircular sawsControl systemEngineering

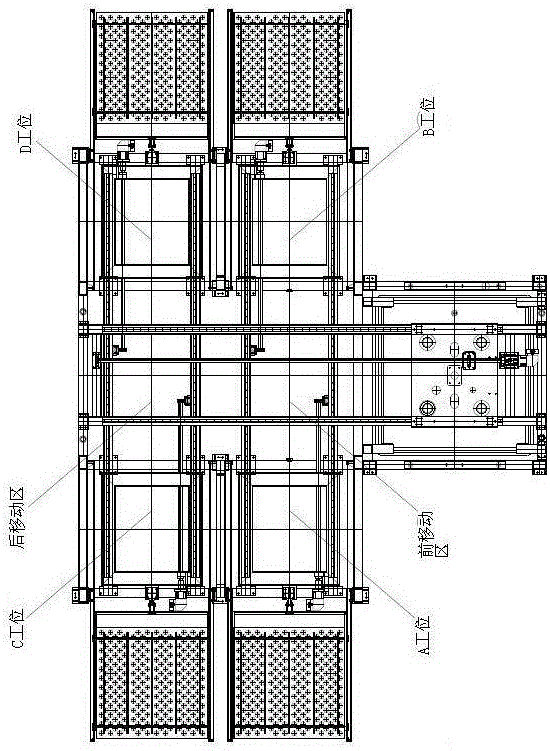

The invention discloses a board edge cutting machine, belonging to the field of board processing machinery and overcoming the defect that in the prior art, machinery which can replace manpower to cut edges of boards is lacked. The board edge cutting machine is characterized by comprising a board feeding machine, a board dropping machine, a longitudinal edge cutting machine, a transverse edge cutting machine and a control system, wherein the board feeding machine comprises a board feeding rack, a positioning platform and an elevator I; the tail of the board feeding machine is connected with the head of the board dropping machine; a part of the longitudinal edge cutting machine stretches into the inside of the board dropping machine; the longitudinal edge cutting machine is vertically connected with the transverse edge cutting machine; and the control system comprises an electrical cabinet and a control circuit. The board edge cutting machine can realize the full-automatic cutting of the deckle edges of the boards, saves the manpower cost and improves the production efficiency.

Owner:LINYI SHENGHUA MACHINERY MFG

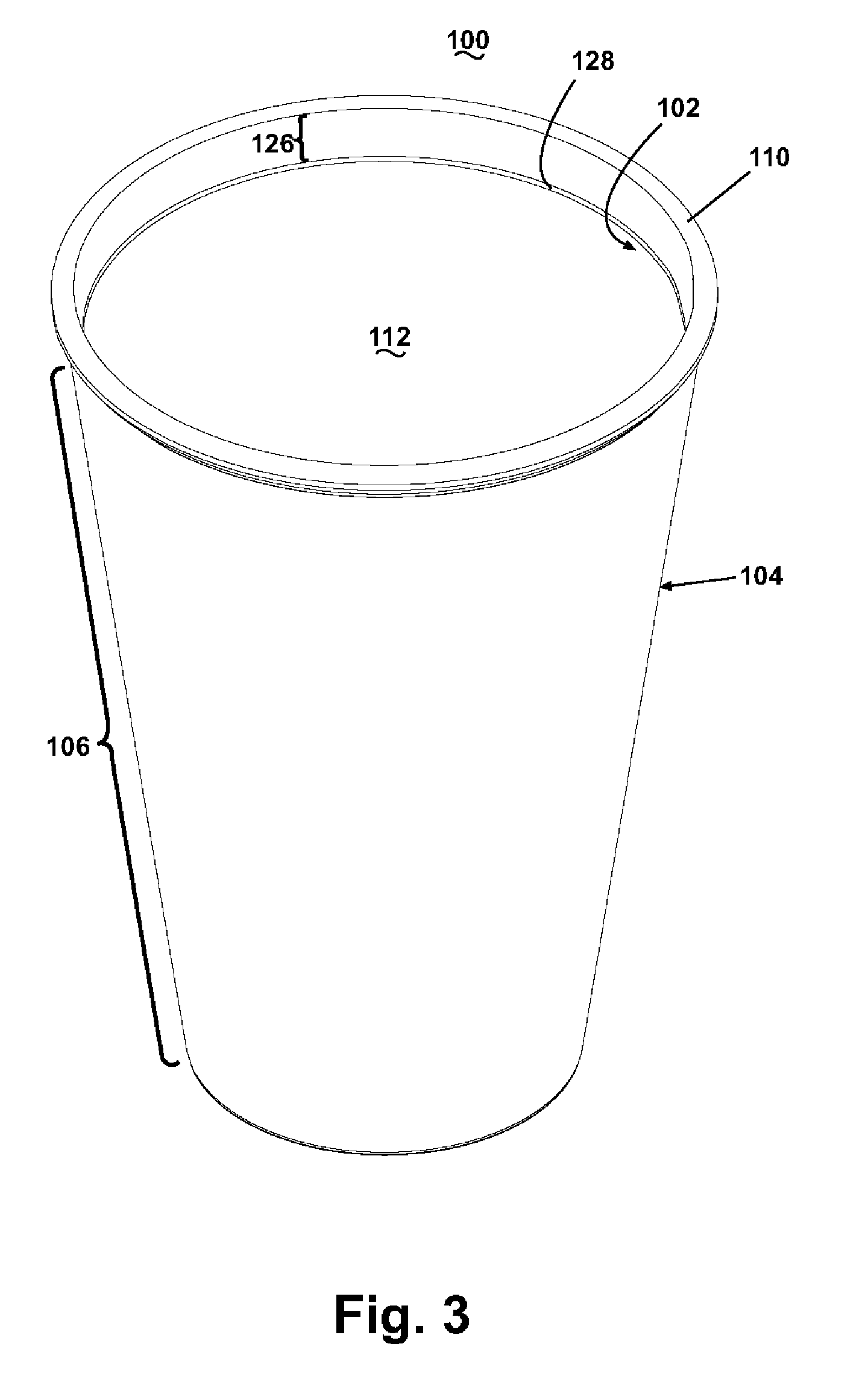

Paper wrapped foam cup and method of assembly

ActiveUS20050227029A1Efficient rollingDomestic cooling apparatusLighting and heating apparatusPulp and paper industryVisual appearance

A commercially viable paper wrapped foam cup comprising a taper portion that prevents the shrinkage-induced curling from interfering with the un-nesting of nested paper wrapped foam cups. The paper wrapped cup further comprises a fillet for strengthening the cup foot to retard shrinkage-induced curling of the foot. The paper wrapper has abutting to overlapping opposing ends to completely hide the foam cup to enhance the visual appearance of the cup. The overlapping portions of the paper wrapper are not bonded to each other to prevent wrinkling of the paper wrapper as the cup shrinks. A machine and corresponding method provide for automatically supplying foam cups and paper wrappers, wrapping the paper wrapped cup, and stacking the wrapped cups.

Owner:DART CONTAINER

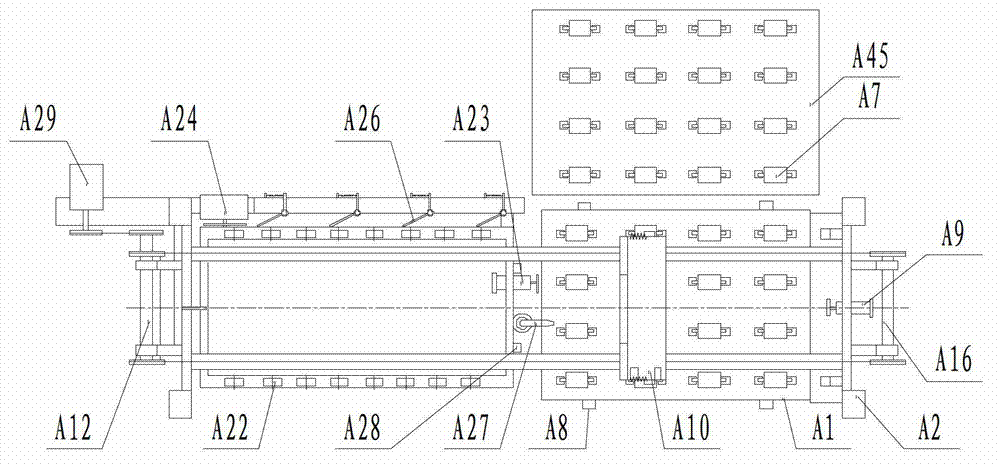

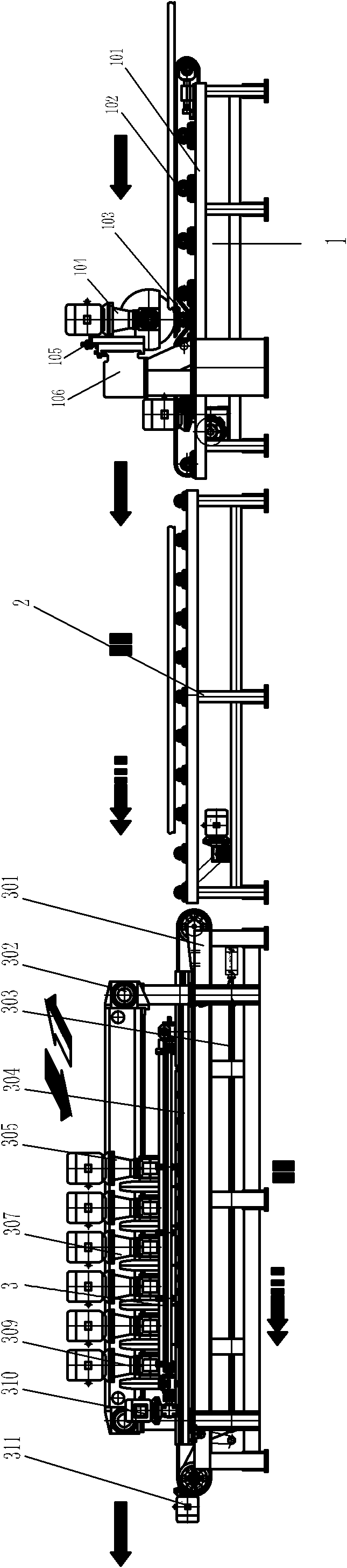

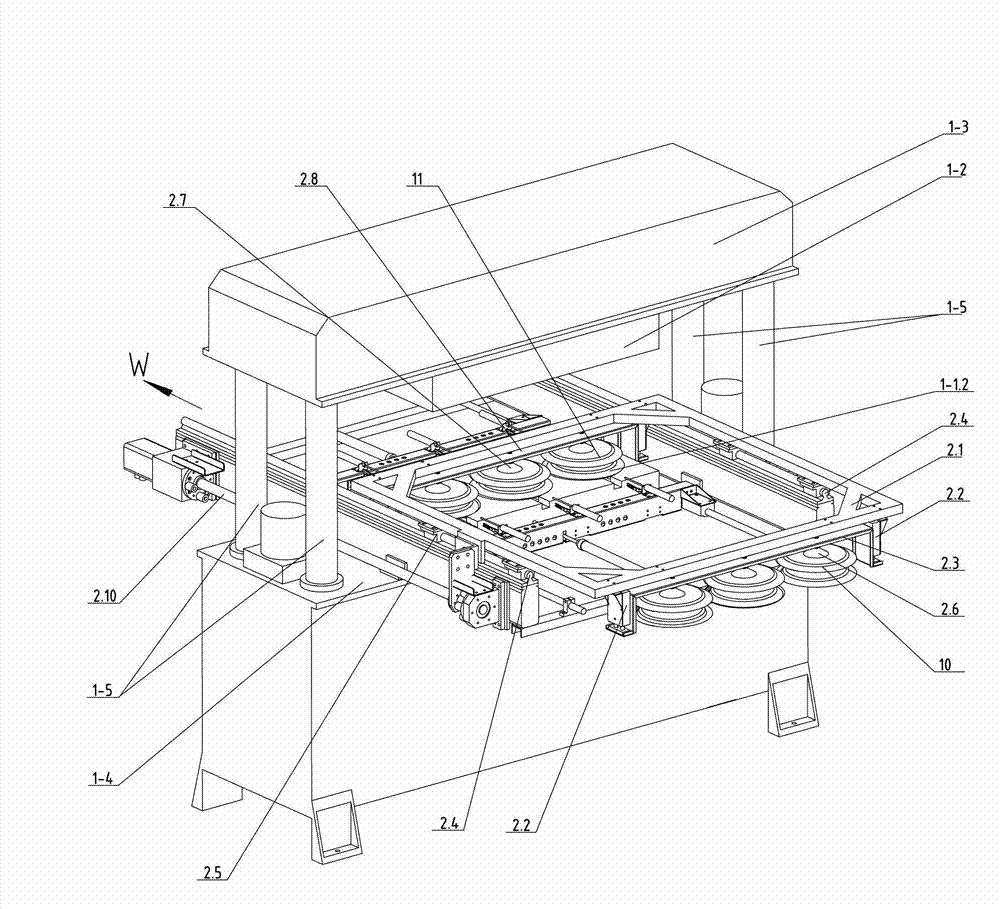

Full-automatic vertical-horizontal multi-cutter combined edge cutting machine

ActiveCN102528939AReduce labor intensityImprove working environmentWorking accessoriesStone-like material working toolsProduction lineEngineering

A full-automatic vertical-horizontal multi-cutter combined edge cutting machine comprises a longitudinal deckle machine, a transverse board cutting machine and an automatic controller, and is characterized in that the longitudinal deckle machine forms an automatic production line with the transverse board cutting machine through a two-speed intermediate conveyor of an embedded overrunning clutch. At least two independent longitudinal deckle machine power heads are transversely arranged abreast on a main frame crossbeam above a board conveying belt of the longitudinal deckle machine. A lifting conveying belt and a board transverse-cutting upright device are disposed on a frame of the transverse board cutting machine, at least two independent transverse board cutting machine power heads are longitudinally arranged abreast on a fixed operating table, and the independent longitudinal deckle machine power heads and the independent transverse board cutting machine power heads are structurally identical and all provided with structurally identical independent cutter power head transverse adjustment devices and identical independent cutter power head height adjusting devices. The multi-cutter longitudinal cutting and transverse cutting automatic production line is accurate, continuous and efficient, the full-automatic vertical-horizontal multi-cutter combined edge cutting machine is high in efficiency, low in cost, high in quality and yield, and labor intensity is relieved for operators.

Owner:南安市锋源机械有限责任公司

Lug processing method

InactiveCN101615664AReliable electrical connectionImprove core qualityElectrode manufacturing processesCell component detailsDeckleCurrent collector

The invention provides a lug processing method, which comprises the following steps: a. a processing belt with certain width is determined on the edge of a current collector of a pole piece; b. according to the needed position, size and shape, the processing belt of the current collector is cut by laser so as to obtain the lug integrative with the current collector. The lug is processed on the current collector by using the lug processing method and is integrative with the current collector; the lug and the current collector form a very reliable electrical property connection; the processed lug has non deckle edge and is beneficial to increase the quality of a roll core; the processing process is simplified; working procedures such as mechanical cutting of the lug, the lug being welded on the current collector, protective adhesive plaster being pasted on the lug after the lug being welded on the current collector and the like and possibly occurring technology shortcomings are omitted; the processing method is beneficial to increase producing efficiency and save cost; the processing method can be implemented by adding a laser cutting device on the corresponding position of the existing coiling production line; therefore, the lug processing and the electrical core coiling can be carried out on the same production line.

Owner:GEESUN AUTOMATION TECH

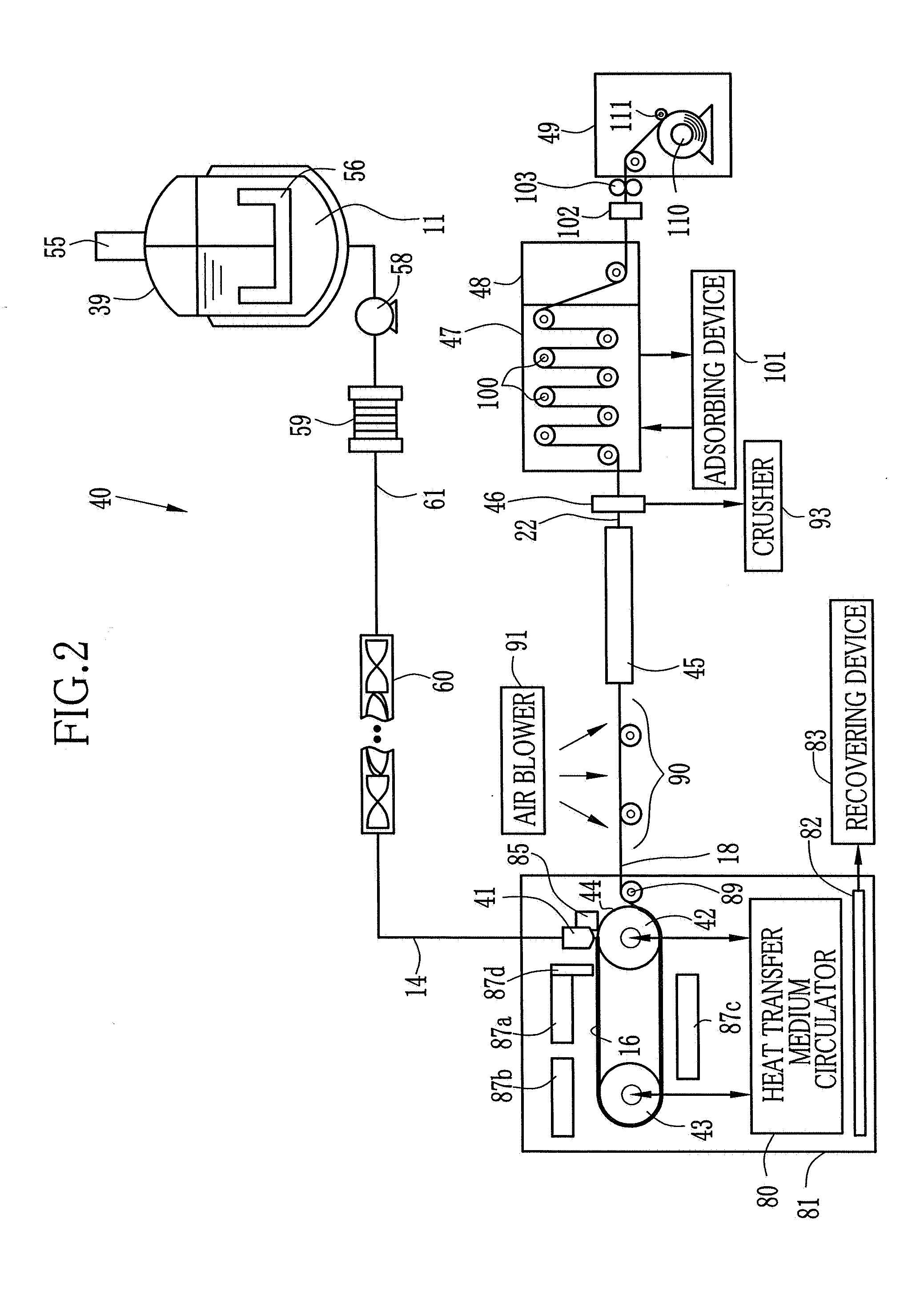

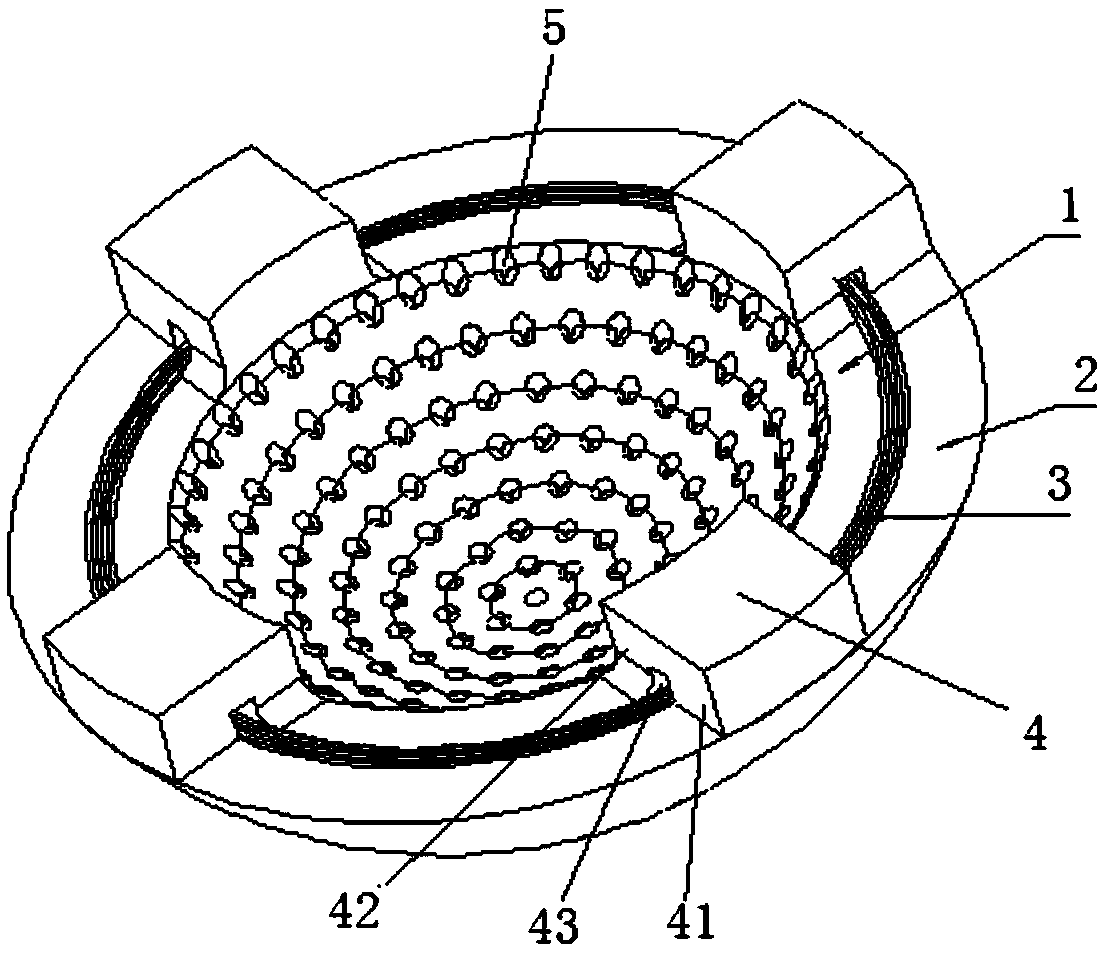

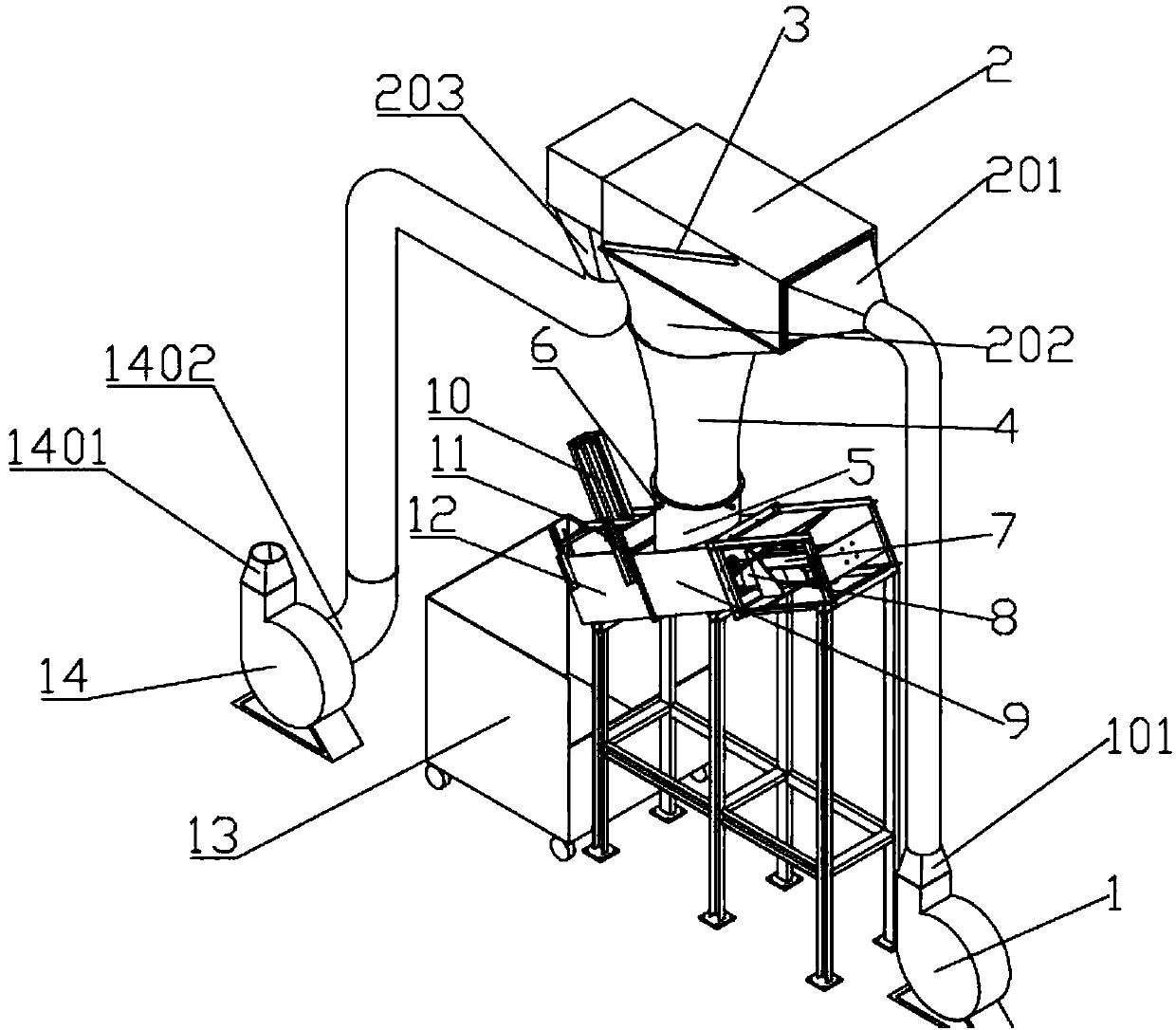

Full-automatic multi-station integrated pulp molding equipment and production technology

ActiveCN106638164AQuality improvementUniform slurryTextiles and paperShell moldingPulp and paper industry

The invention belongs to the field of pulp molding product production equipment in a papermaking technique. Full-automatic multi-station integrated pulp molding equipment comprises an electric-heat conduction oil universal heating device, a steam heating device, a pulp chest homogenizing device, an adsorptive molding device, hot-press sizing devices, a first kind product collection device not needing stacking and a second kind product collection device capable of automatically conducting stacking; a groove is formed in a molding template of the molding device, an airflow dispersion cover plate is installed over the groove, an airflow main pipeline is vertically installed, a deckle edge spraying and template cleaning device is independently installed, heating plates of the molding devices are fixed to an upper molding template and a lower molding template through heat insulation plates, the upper molding template achieves multi-point pressurizing through a pressure stabilizing frame, the lower molding template is fixed to a transverse tackle, and heat deformation of the heating plates is effectively controlled by the molding templates. The equipment is suitable for large-scale production of pulp molding products, few molds are used, and the molds are unified and easy to replace.

Owner:许洪涛 +1

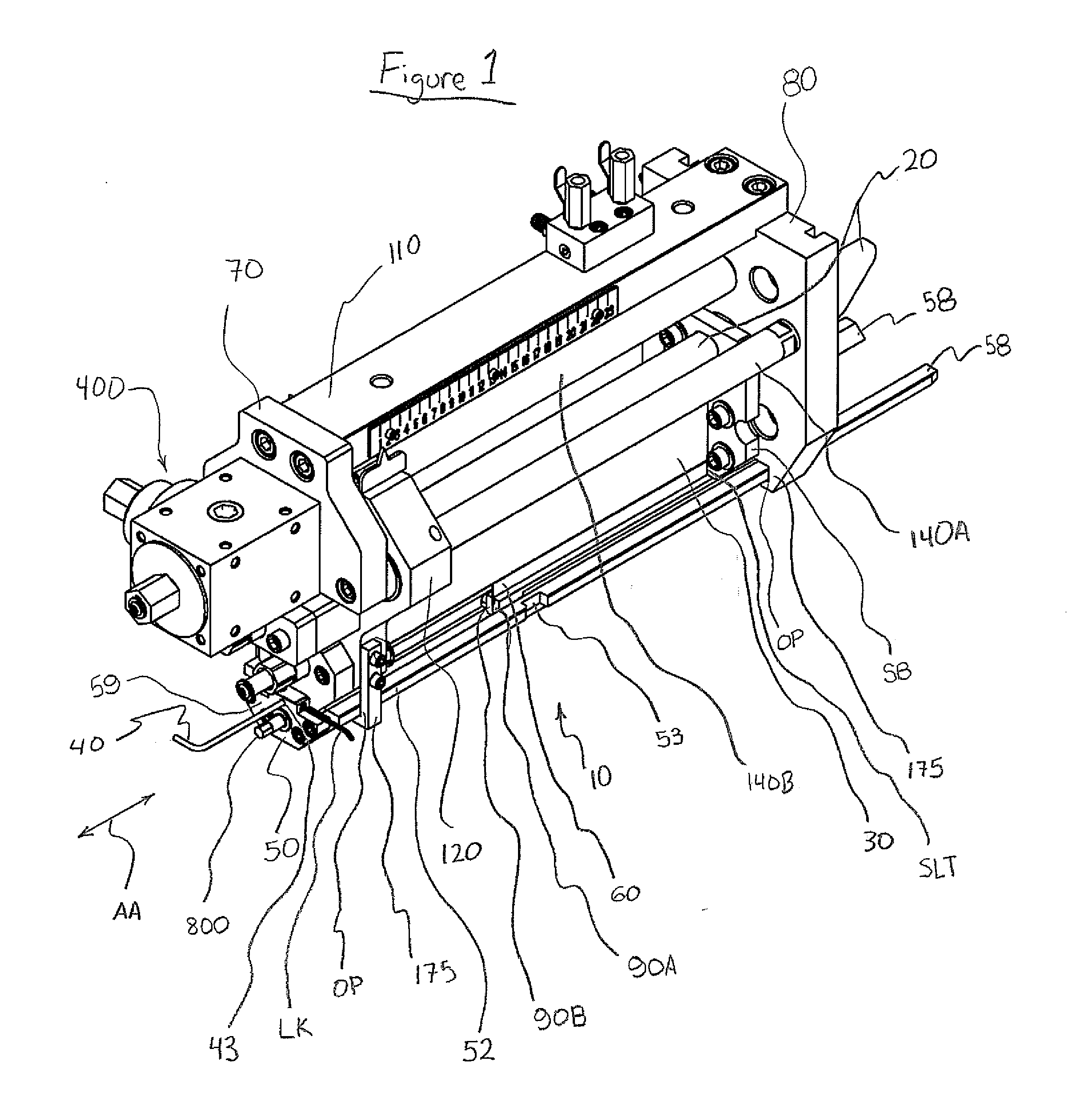

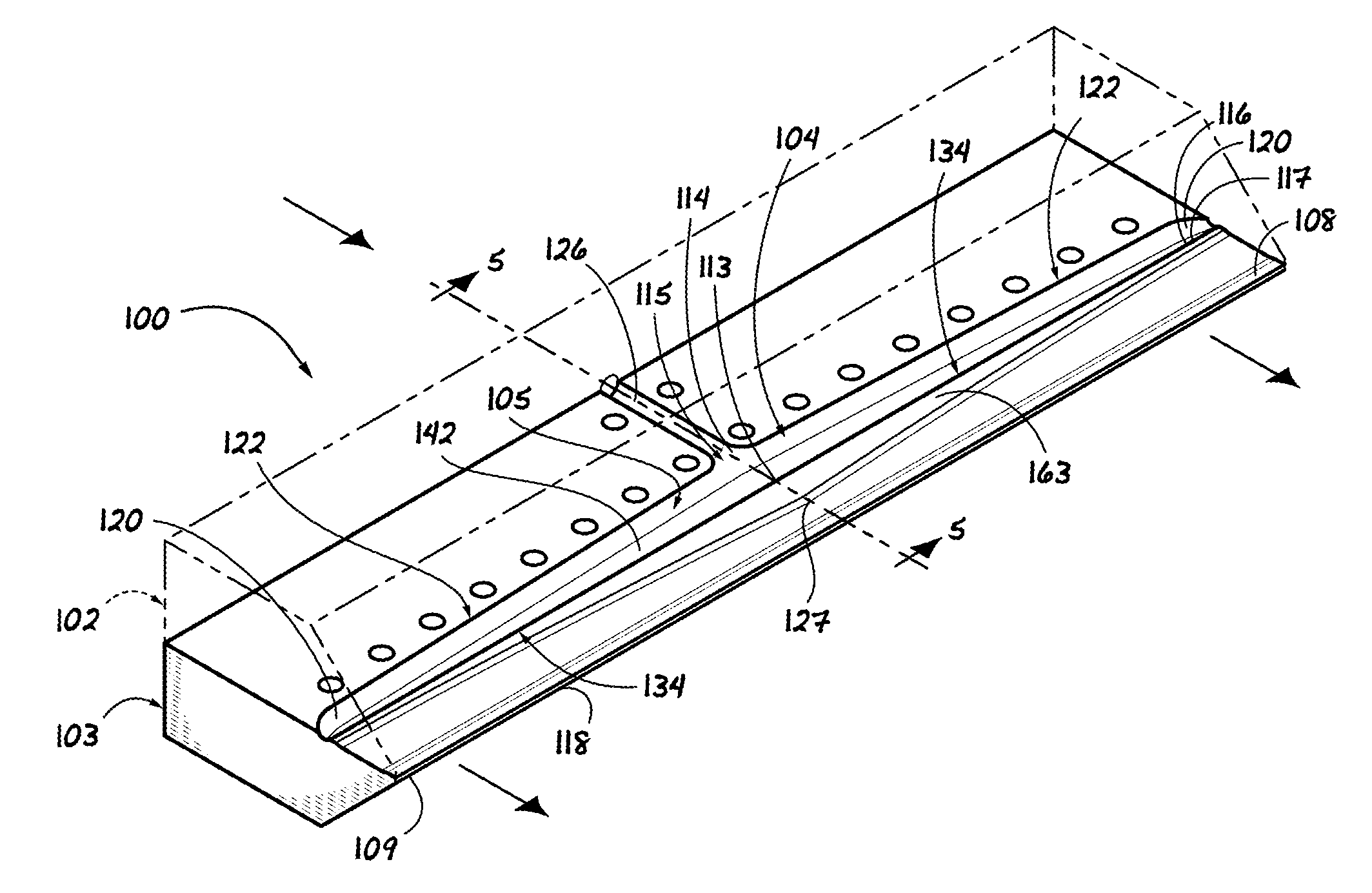

Deckle Technology

The invention provides a deckle system for extrusion dies. In certain embodiments, the invention provides methods of cleaning an extrusion die equipped with a retractable external deckle system. Also provided in some embodiments is a deckle system having a novel deckle adjustment mechanism. In other embodiments, the invention provides an advantageous internal deckle member equipped with a removable, replaceable internally threaded insert.

Owner:NORDSON CORP

Varying transition zone manifold

ActiveUS20130259965A1Reduced transition stagnationDelay transitionConfectionerySweetmeatsChannel widthResidence time

The present invention provides an extrusion die that includes a manifold transition zone that comprises a varying included angle. The varying included angle provides unparalleled freedom of design to achieve diverse fluid dynamic objectives, such as reduced residence time across the manifold width, reduced transition stagnation, improved streamlining of the mass flowing through the manifold, and reduced differential clamshell deflection across the flow channel width. The manifold may be transformed from one cross-sectional shape to another cross-sectional shape beneficially related to the varying included angle, including change from a generally extended cross-sectional shape to a generally teardrop-shaped cross-section. The manifold may include a first transition zone portion that includes the varying included angle, and a second transition zone portion that includes a constant included angle, and that is particularly beneficial for receiving an internal deckle.

Owner:THE CLOEREN

Flat pressing and flat die cutting process without paper powder and paper deckle edges

The invention discloses a flat pressing and flat die cutting process without paper powder and paper deckle edges, and belongs to post processing technique of printing of packaging products. The flat pressing and flat die cutting process without the paper powder and the paper deckle edges comprises a step one of manufacturing a die cutting tool plate, a step two of carrying out machine debugging on a flat pressing and flat die cutting machine, and a step three of carrying out quality inspection. The flat pressing and flat die cutting process without the paper powder and the paper deckle edges is characterized in that the step one comprises (1) drawing a die cutting pattern, (2) cutting out the die cutting tool plate by using laser, (3) carrying out tool bending on a die cutting tool, (4) mounting the die cutting tool in the manufactured die cutting tool plate, and (5) pasting sponges on the die cutting tool plate with the die cutting tool mounted. The step two comprises (1) fixing the die cutting plate, (2) adjusting the pressure of the die cutting plate, (3) carrying out mending operations, and (4) carrying out operations of indentation on the bottom die. The flat pressing and flat die cutting process without the paper powder and the paper deckle edges has the advantages that the effect of flat pressing and flat die cutting without the paper powder and the paper deckle edges is achieved by improving die cutting auxiliary materials and the die cutting pressure, and the rate of equipment utilization is improved by carrying out improvement on original equipment.

Owner:ZIBO TAIBAO FP PROD CO LTD

Copper strip surface defect identifying device for simulating human visual perception mechanism and method thereof

InactiveCN103091330AEasy to detectImprove classification performanceOptically investigating flaws/contaminationCopperComputer science

The invention discloses a copper strip surface defect identifying device for simulating a human visual perception mechanism and a method thereof. The device and the method have the advantages that various defects such as hollow, scratches, greasy dirt, deckle edges, gaps and the like possibly generated in processes of reproduction, storage and transportation of a copper strip can be identified, capacities of defect detection and classification on the surface of the copper strip are improved, moreover, the identifying accuracy and speed are increased, and the efficiency is high; and not only can requirements on surface information detection of the copper strip of the current enterprises be met, but also the device and the method are further suitable for surface detection of other materials such as steel plates and the like, the requirements of the enterprises on surface defect information detection and storage of the copper belt are met, and furthermore, the device and the method are also suitable for the defect detection of other materials and have wide application prospect and market value.

Owner:HOHAI UNIV CHANGZHOU

Casting device, solution casting apparatus and solution casting method

InactiveUS20080042315A1Prevent skinImprove productivityConfectioneryCeramic shaping apparatusMaterials scienceDeckle

In a casting process of a film production, a casting dope is discharged through an outlet of a casting die. In the casting die, lip plates and inner deckle plates are arranged such that a lower end of each inner deckle plates may be form a protrusion at a side edge of the outlet of the casting die. Each protrusion length from a bottom of the lip plate is at most 9 μm. Thus the retaining of the casting dope near the outlet through a dope passage in the casting die is reduced, and therefore the skinning doesn't occur in the casting dope.

Owner:FUJIFILM CORP

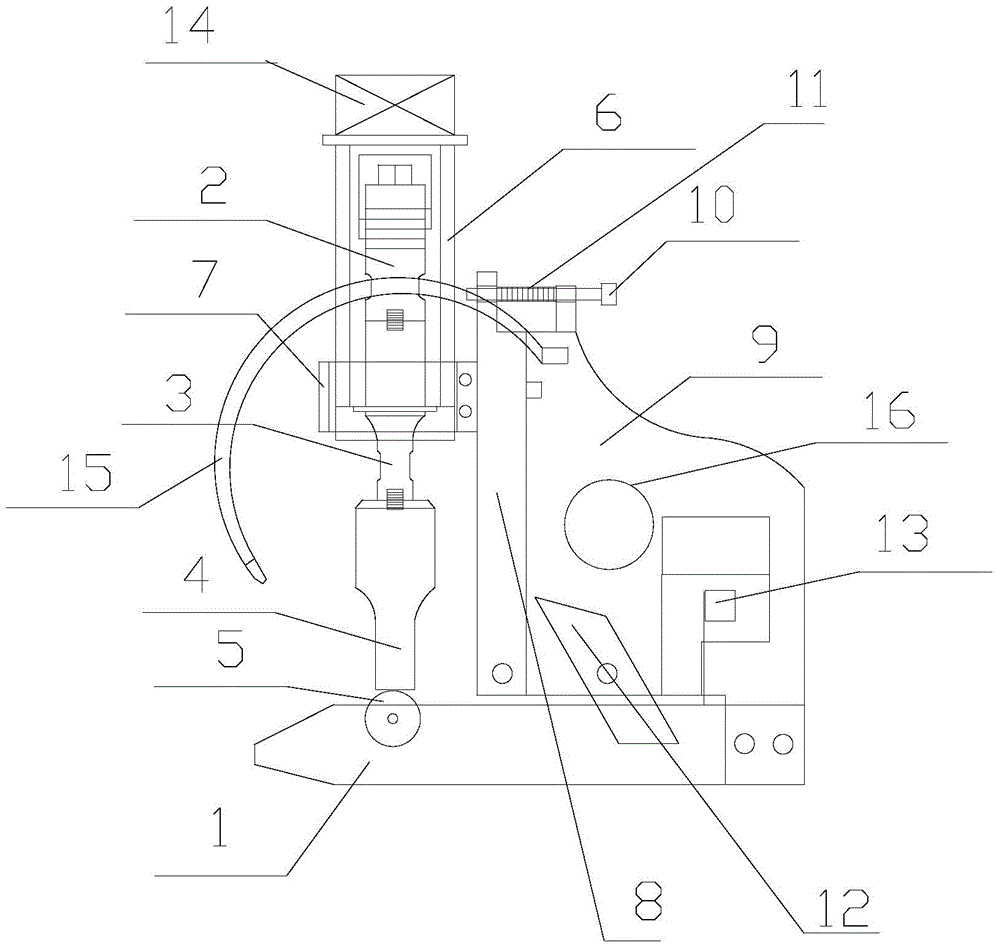

Trimming fixture

The invention discloses a trimming fixture for shaving deckle edges generated by forming a product, comprising a base plate, an electric motor, a fixed seat, an air cylinder and a deckle edge cutter, wherein a through hole is arranged on the base plate; a rotary shaft of the electric motor extends out of the through hole of the base plate; the fixed seat is fixed on the rotary shaft to be used for sheathing the product to be processed; the air cylinder is fixed on the base plate; the deckle edge cutter is fixed on the tail end of a piston rod of the air cylinder, and when the piston rod extends, the deckle edge cutter can collide with the deckle edges of the product to be processed. When used for trimming the deckle edges of the product, the trimming fixture not only saves labor power, but also greatly enhances the trimming speed of the deckles of the product.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Ultrasonic welding machine for braided fabric

The invention provides an ultrasonic welding machine for a braided fabric. The ultrasonic welding machine comprises a base, a lifting fine tuning mechanism and a welding mechanism, wherein the lifting fine tuning mechanism is fixed on the base and is connected with the welding mechanism; the welding mechanism comprises an ultrasonic transducer, an amplitude-change pole and a tool head; the top end of the amplitude-change pole is connected to the ultrasonic transducer, the bottom end of the amplitude-change pole is connected with the tool head, and a gap is reserved between the tool head and the base. According to the ultrasonic welding machine, under the action of huge ultrasonic energy, a fused plastifying phenomenon is generated in a welding point part of the braided fabric, the braided fabric is not damaged, the welding part of the braided fabric is cut by virtue of a blade, so that the edge wear or the deckle edge of the braided fabric can be avoided.

Owner:杭州班凌超声波设备有限公司

Stripping and fixing device of stretching machine

ActiveCN104003231BBlock replyPrevent swimmingUnfolding thin materialsWebs handlingScrew threadContact effects

An edge peeling and positioning device of a spreading machine belongs to the field of clothing machines. The spreading machine comprises a spreading table, a machine frame is arranged on the spreading table and provided with an upper cloth guiding roller, a lower cloth guiding roller, a cloth pressing roller, a large cloth spreading roller and a lower cloth spreading roller. The edge peeling and positioning device comprises a beam and a pair of toothed belt type edge peeling mechanisms and is characterized by further comprising a front cloth expanding roller, a rear cloth expanding roller and a peeled and expanded cloth edge maintaining roller, wherein the front cloth expanding roller is supported on the machine frame and provided with front cloth expanding threads, the rear cloth expanding roller is provided with rear cloth expanding threads, and the peeled and expanded cloth edge maintaining roller is provided with flanges; the beam is fixedly provided with a pair of belt supporting unit seats, which extend into an edge peeling toothed belt cavity and are fixedly provided with belt supporting units, and the belt supporting units are arranged inside the edge peeling toothed belt cavity and are in contact with the inner side of the edge peeling toothed belt. The edge peeling and positioning device of the spreading machine enables the cloth edges of both sides in the length direction of cloth spread on the spreading table to maintain a trim state, prevents both sides the cloth from moving towards the middle, eliminates the deflection of the edge peeling toothed belt and improves the integral contact effects of the edge peeling toothed belt with the cloth edges.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Sheet stock slitting machine

ActiveCN104275714ACrop stabilizationHigh precisionShearing machinesMetal working apparatusMetal stripsEngineering

The invention discloses a sheet stock slitting machine. The sheet stock slitting machine comprises a rack as well as a strip feeding mechanism, a slitting device and a strip rolling mechanism which are arranged on the rack, wherein the strip feeding mechanism and the strip rolling mechanism are respectively arranged in the front of and behind the slitting device. The sheet stock slitting machine is characterized in that the slitting device comprises a cutter shaft bracket, an upper cutter shaft, a lower cutter shaft and a cutter shaft power device for driving the upper cutter shaft and the lower cutter shaft to rotate; a plurality of groups of shearing modules are arranged at certain intervals between the upper cutter shaft and the lower cutter shaft; each group of shearing module is composed of an upper cutter on the upper cutter shaft and a lower cutter on the lower cutter shaft, and the upper cutters and the lower cutters are staggered at a horizontal interval of 0-2mm, and the distance between the upper cutter shaft and the lower cutter shaft is less than the radius sum of the upper cutters and the lower cutters. The sheet stock slitting machine is capable of slitting materials such as sheet metal strips and plastic films and is simple in structure, stable in operation and high in precision, the cutters are durable, and products are good in quality and free of deckle edges.

Owner:韶关市高信塑胶制品有限公司

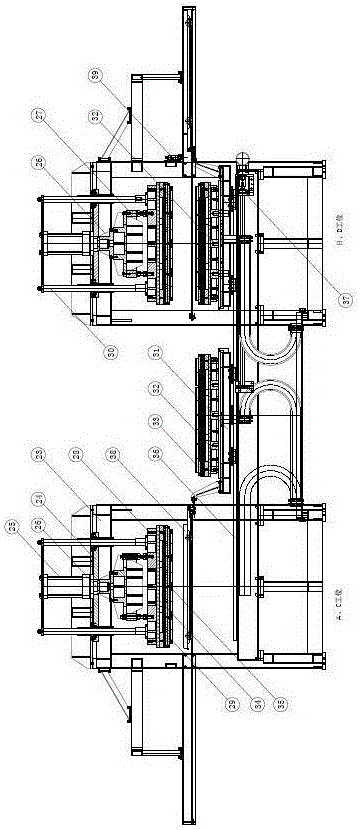

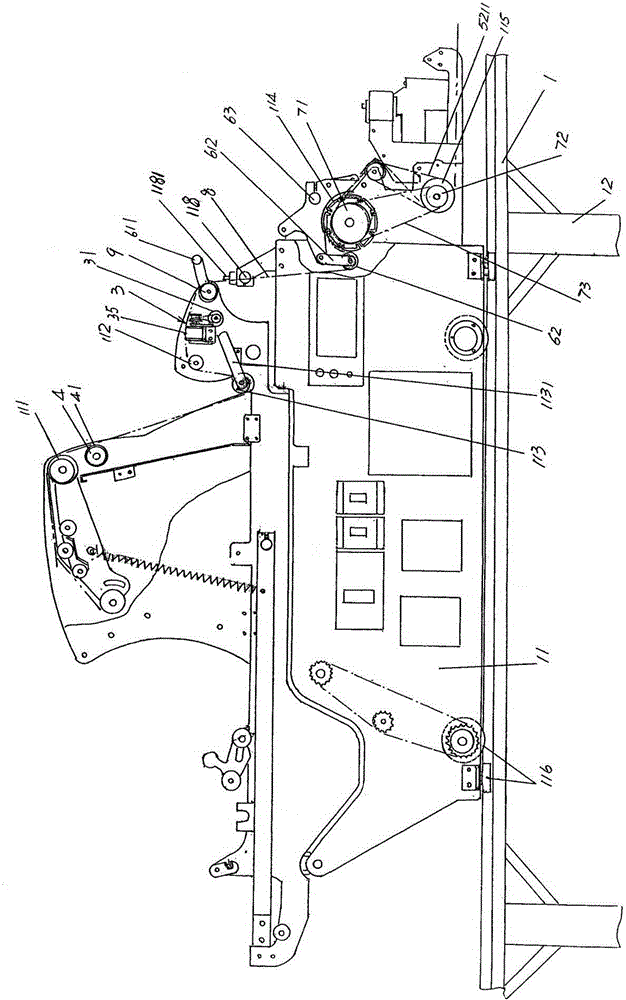

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639AAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

Forming mold and forming method for fiber cloth curved surface prefabricated member

The invention relates to a forming mold and a forming method for a fiber cloth curved surface prefabricated member. The forming mold comprises an inner mold and an outer mold, wherein a plurality of one-to-one correspondence ventilation holes are formed in the inner mold and the outer mold; the outer wall surface of the inner mold is identical with the inner wall surface of a component to be formed, and the inner wall surface of the outer mold is identical with the outer wall surface of the component to be formed. During forming, fiber cloth trimming is carried out according to the outer wallsurface of the forming part of the inner mold, then fiber cloth is soaked with a glue solution, each layer of fiber cloth is paved on the surface of the mold layer by layer to guarantee that the fibercloth is tightly laminated with a mold, trimming lines of every two adjacent layers of fiber cloth are staggered as much as possible, the fiber cloth is vertically sewn through the ventilation holesof the mold by using a fiber rope after pavement is completed, another mold is closed after sewing is completed, the alignment of the molds is guaranteed, unnecessary fiber cloth at the positions of deckle edge is trimmed, and then aftertreatment densification is carried out to obtain the fiber cloth curved surface prefabricated member. The prefabricated member formed by using the method is not restricted by complicated outer shape, fiber cloth is saved, and the method is simple and convenient in operation.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

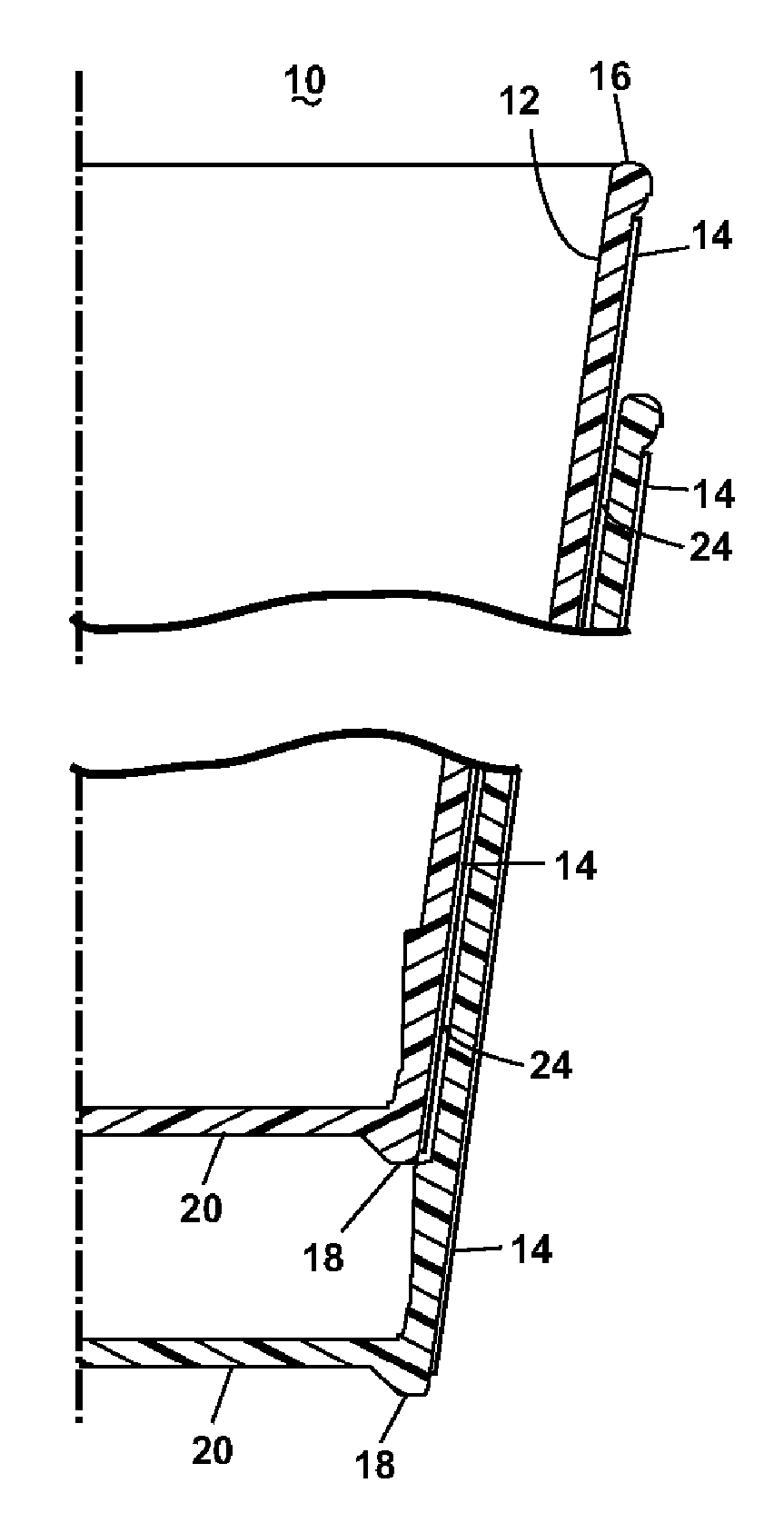

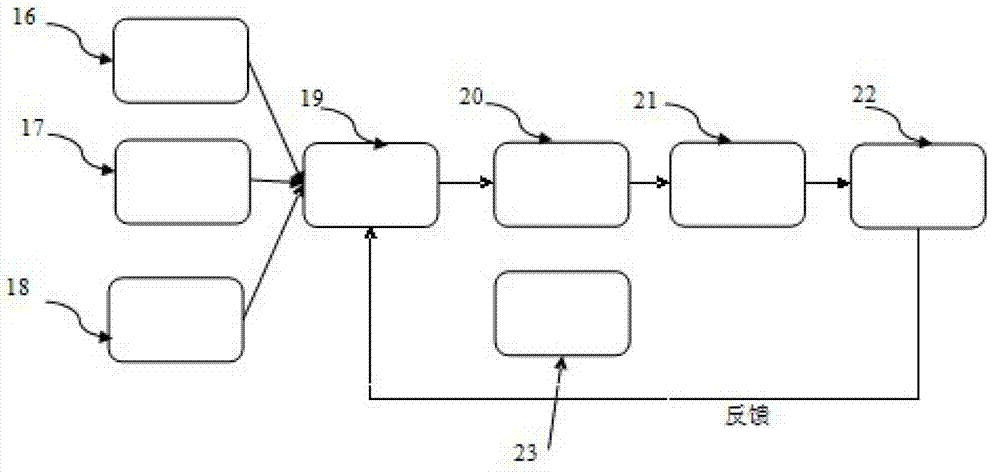

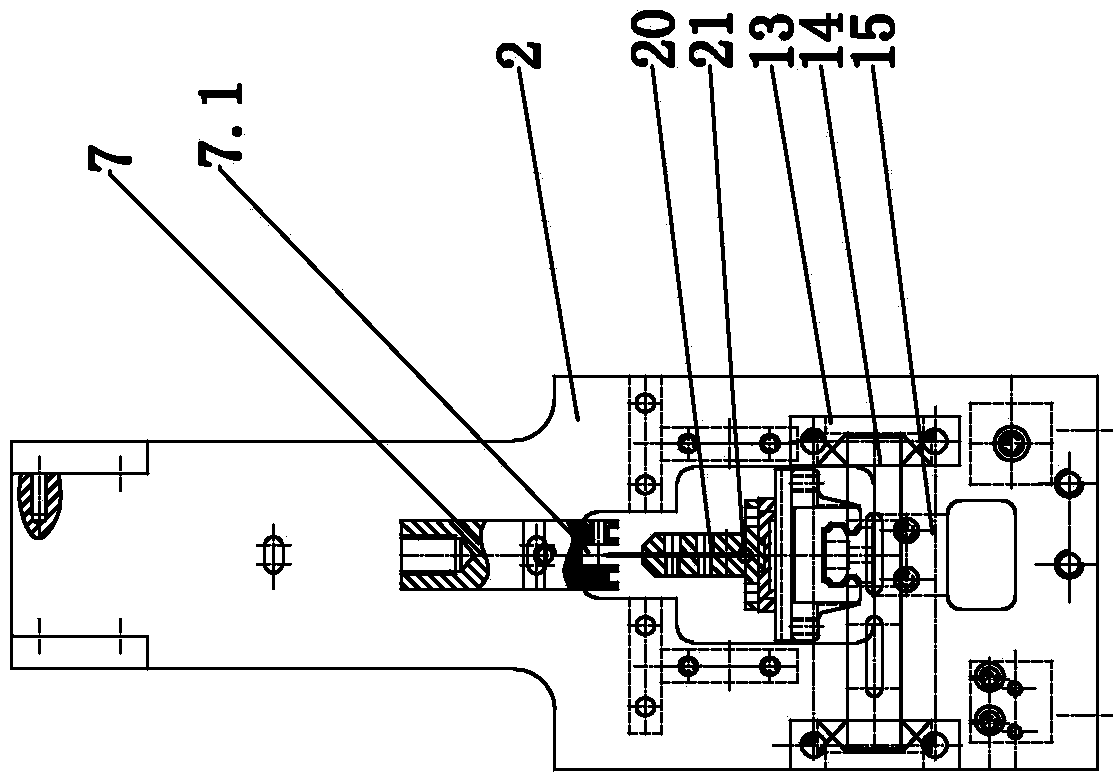

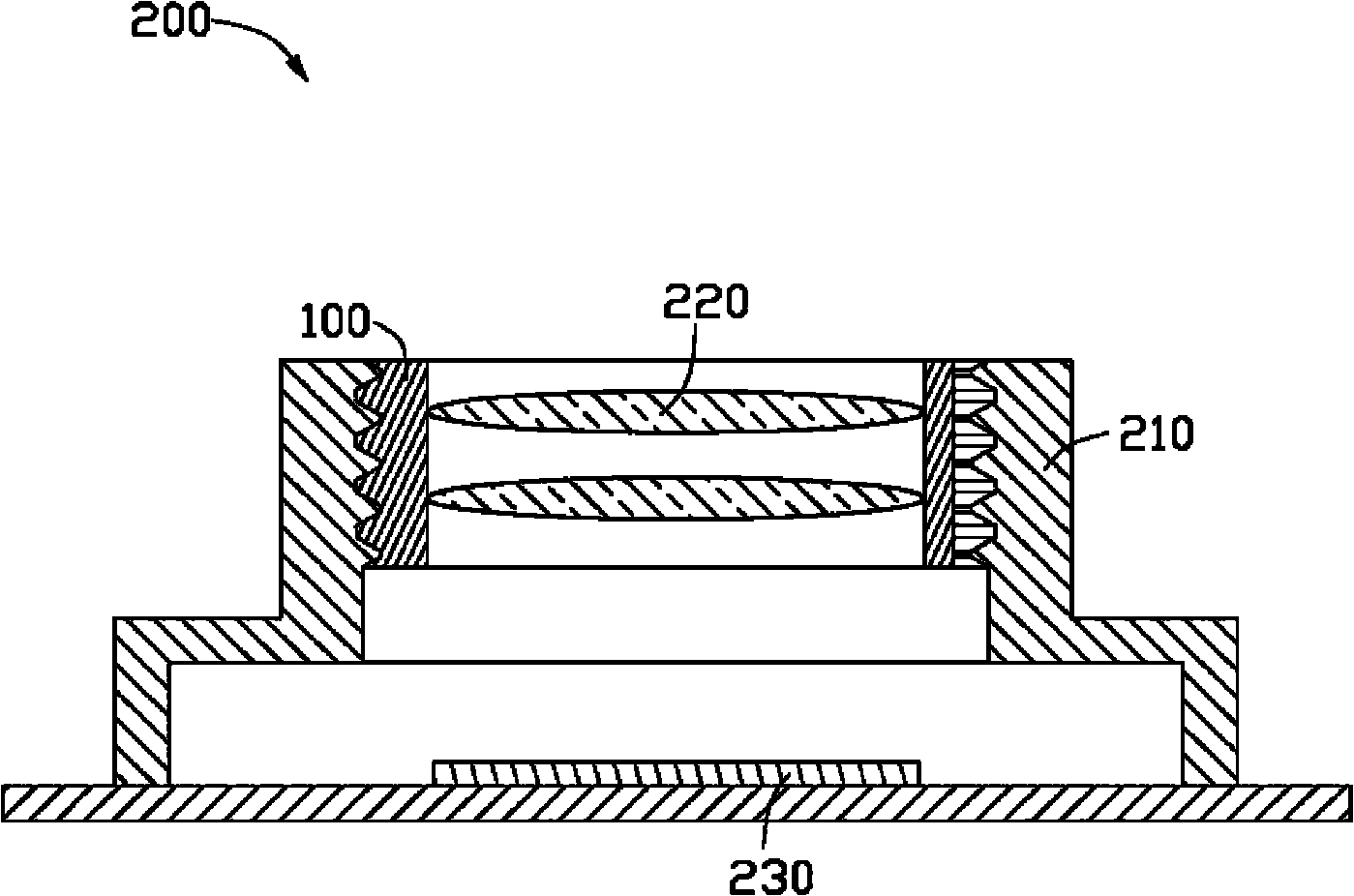

Manufacture method for resin seal molding product and manufacture apparatus for resin seal molding product

ActiveCN102386110ASemiconductor/solid-state device manufacturingCoatingsManufactured apparatusResin coating

The present invention provides a resin seal molding method and an apparatus thereof for a substrate, which can perform resin seal molding on the outer surface portion of a glass epoxy substrate (11) and enable a portion of the substrate to be exposed out of a resin molding body. The method comprises the steps of performing resin seal molding on the outer surface portion of the glass epoxy substrate (11) by using a thermal curing epoxy resin (R) and the resin seal molding apparatus, enabling a portion of the substrate to be exposed to a portion of a mold structure (21, 22) outside a resin molding seal body, and enabling a resin deckle edge formation preventing component (23) to closely contact with the exposed surface (13) of the substrate. The resin seal molding apparatus is provided with the mold structure (21, 22) used for seal molding. Additionally, the top end of the resin deckle edge formation preventing component (23) is provided with a resin coating layer (23a).

Owner:TOWA

Deckle technology

The invention provides a deckle system for extrusion dies. In certain embodiments, the invention provides methods of cleaning an extrusion die equipped with a retractable external deckle system. Also provided in some embodiments is a deckle system having a novel deckle adjustment mechanism. In other embodiments, the invention provides an advantageous internal deckle member equipped with a removable, replaceable internally threaded insert.

Owner:NORDSON CORP

Servo fly-cutter cutting-off device for bag making machine

ActiveCN103660368ASimple structureCompact structureBox making operationsPaper-makingEngineeringPiston rod

The invention relates to a cutting-off device, particularly relates to a servo fly-cutter cutting-off device for a bag making machine, and belongs to the technical field of bag making machines. The servo fly-cutter cutting-off device for the bag making machine comprises a left supporting wall plate and a right supporting wall plate, wherein two side plates are respectively arranged in middles of the inner sides of the left supporting wall plate and the right supporting wall plate; a fly-cutter pressing plate is connected between the two side plates through bolts; a cylinder is fixed in the middle of an upper fixing plate; the lower end of a piston rod of the cylinder is connected with the fly-cutter pressing plate; a driven synchronous wheel and a driving synchronous wheel are in transmission through a transmission synchronous belt; and a driving power wheel and a driven power wheel are in transmission through a driving synchronous belt. The servo fly-cutter cutting-off device for the bag making machine is simple, compact and reasonable in structure, rapid in action transmission and high in bag making speed; bags which are cut off are neat and do not have deckle edges; and the bag making quality is high.

Owner:WUXI KING MO MACHINERY

Sewing machine edge cutting presser foot

ActiveCN104088087ARealize the processing effectThe seaming process is neat and convenientPressersEngineeringDeckle

The invention discloses a sewing machine edge cutting presser foot which comprises a presser foot plate, a cutter plate and a swing handle. The presser foot plate comprises a cloth pressing foot, a guide plate and a supporting plate, wherein the supporting plate is perpendicular to the cloth pressing foot and the guide plate. One end of the cloth pressing foot is bent to form a stitch moving groove. One lateral side of the guide plate extends to form a lifting plate. The cutter plate comprises a vertical plate, a cutter and a slide rod, wherein the cutter is installed on the vertical plate, the vertical plate and the supporting plate are fixed through a cylindrical pin, and the cutter is placed above the guide plate. The swing handle comprises a pull handle and a fixed plate. A fork opening is formed in the pull handle. A slide groove corresponding to the slide rod is formed in the fixed plate. The fixed plate is installed on the other side face of the supporting plate through a cylindrical pin. By means of the sewing machine edge cutting presser foot, the deckle edge can be cut while lockstitch is conducted.

Owner:海门华夏时丽网络科技服务有限公司

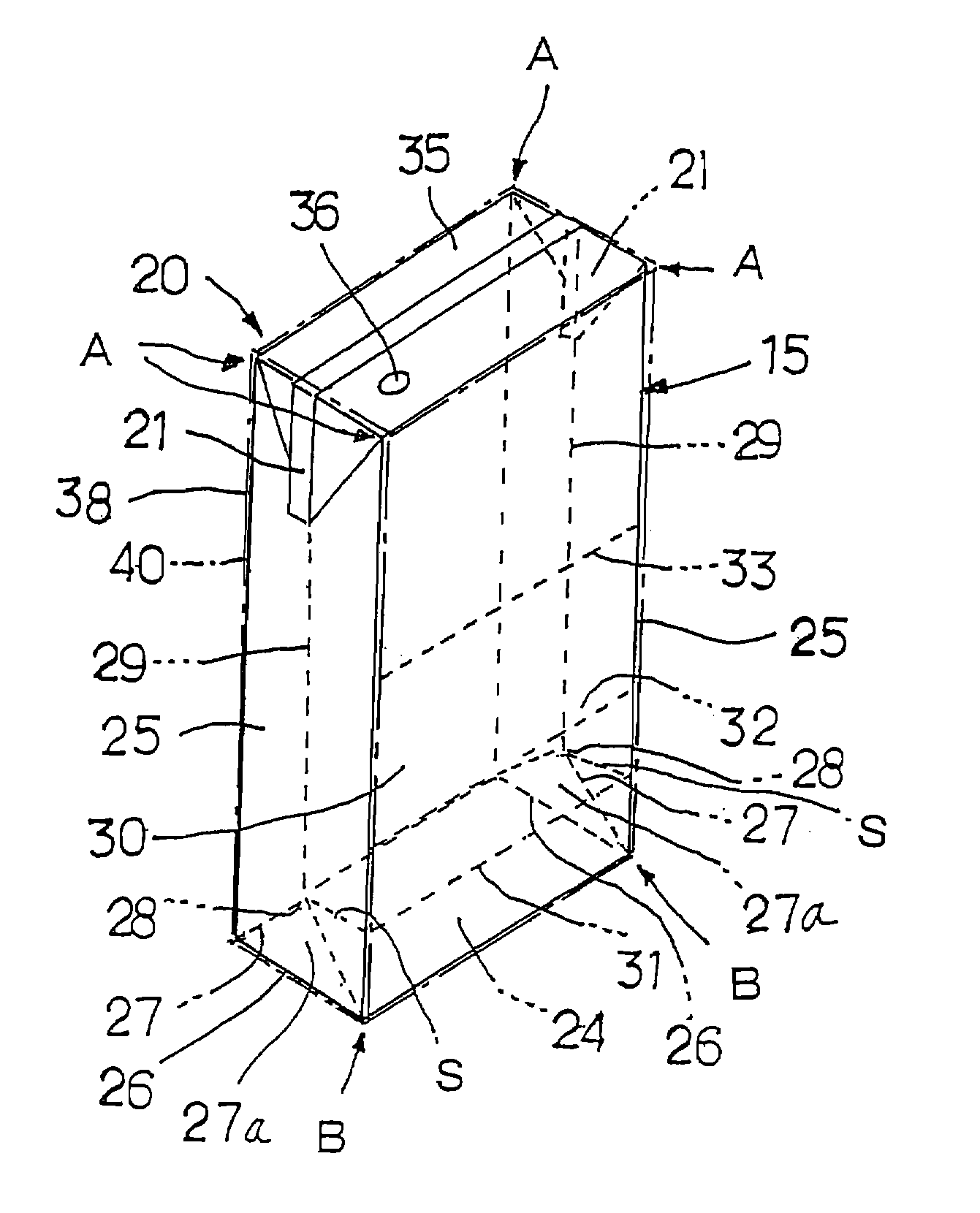

Paper package and straw

A person thrusts a straw into a press-foldable paper package (20) through an insertion section (36) formed in the top thereof, whereupon he or she can pressingly fold the package flat from outside so as to press out the contents for drinking. The top and bottom of the package are bent flat, and triangular projections (21) disposed in the top and projection left and right are bent downward and are weakly adhesively bonded to the lateral surfaces (25) of the package by thermal processing. Disposed below the opposite surfaces (25) of the package are an inverted V-shaped fold (27) in a triangle surface with their bottoms (24) on the bottom side, and vertical folds (29) extending vertically upward from the vertexes (28). The lateral surface (25) of the package can be folded flat by folding the vertical folds (29) and inverted V-shaped folds (27). A first horizontal fold (31) and a second horizontal fold (34) are disposed below and above the front surface (30), respectively, to allow the front half of the upper surface and the front half of the bottom surface to be folded flat onto the front surface (30).

Owner:KRACIE SEIYAKU +1

Waste paper collecting device of paper making splitting machine

PendingCN107932609AEasy to operateEliminate Flying AroundUsing liquid separation agentMetal working apparatusHygieneAir volume

The invention discloses a waste paper collecting device of a paper making splitting machine. The waste paper collecting device comprises a paper dust separator, a waste paper compressor and a rack. Areplaceable fine-mesh net plate is arranged in the paper dust separator, and the interior of the paper dust separator can be divided by the replaceable fine-mesh net plate into two cavities. The cavity in one side of the paper dust separator is provided with a waste paper feeding port and a deckle edge outlet, and the cavity in the other side of the paper dust separator is provided with a paper dust outlet. The paper dust outlet is connected with an inlet of a pressure releasing draught fan through a pipeline, and an abrasion-resisting oil sticking avoiding gauze is arranged below the deckle edge outlet. The paper dust separator is connected with the waste paper compressor through the abrasion-resisting oil sticking avoiding gauze. The whole device is ingenious in design and convenient andfast to operate, the problem that due to the excessive air volume of an air pump, paper dust and deckle edges fly all around is solved, tidiness and sanitation of the work site are guaranteed, and time and labor are saved.

Owner:VINDA PAPER ZHEJIANG

Local matting process adopting sequence of earlier hot stamping and later printing

InactiveCN104139621APrecise positioningAccurate print production overprintOther printing apparatusPrinting after-treatmentHot stampingEngineering

The invention discloses a local matting process adopting a sequence of earlier hot stamping and later printing. The local matting process comprises the following steps of adopting a deckle edge hot stamping and printing draw gauge positioning technology and using a corresponding hot stamping and printing forme and an alignment film, and overprinting cross lines the hot stamping and printing forme to ensure the accurate sleeved position and smooth and firm hot stamping and printing surface, wherein a hot stamping and printing material is UP100, and a flat hot stamping mode is adopted during hot stamping; adopting an aluminum laminated film coating as a water carrying prime coat, using a varnishing machine to achieve varnishing, controlling the speed of the varnishing machine and ensuring smooth, even and proper-thickness varnishing, wherein no abrasion mark is produced on the surface of the hot stamping and printing position; firstly using specific-color ink and wired UV gloss oil to perform printing, then performing pressing-printing ink fountain matte varnishing printing, wherein attention is paid on the pressing-printing ink fountain matte varnishing fastness in the step, an error at the position of the overprinted hot stamping and printing material is smaller than or equal to 0.2mm, and an varnishing overprinting error is smaller than or equal to 0.1mm. In the local matting process, a digital image and video positioning technology and the deckle edge hot stamping and printing draw gauge positioning technology are adopted to ensure accurate positioning of local hot stamping and printing positions and deinking-free matte varnishing printing.

Owner:星光印刷(苏州)有限公司

Surface wrinkle removal finishing method for rolled gray cloth

InactiveCN107237079AReduce generationImprove finishing effectMechanical cleaningPressure cleaningWrinkle skinEngineering

The invention discloses a surface wrinkle removal finishing method for rolled gray cloth. A feeding device is used for conveying the rolled gray cloth out, a wrinkle removal roll is used for removing wrinkles on the surface of the rolled gray cloth, and a detection device is used for detecting a deckle edge position on the edge of the deckle edge of wrinkle-removed gray cloth and is specifically used for detecting the edge position and the width of the deckle edge; deckle edges on the edge of the gray cloth are trimmed by virtue of a trimming device according to a detection signal, and the trimmed gray cloth is rolled up by virtue of a rolling device. According to the surface wrinkle removal finishing method for the rolled gray cloth utilizing the optimal design, the surface of the gray cloth is subjected to wrinkle removal by virtue of the wrinkle removal roll, the edge position is changed after wrinkle removal, and then the deckle edges are trimmed according to the detected edge position, so that the finishing effect is greatly improved, and the waste is effectively reduced.

Owner:ANHUI LIANGLIANG TEXTILE CO LTD

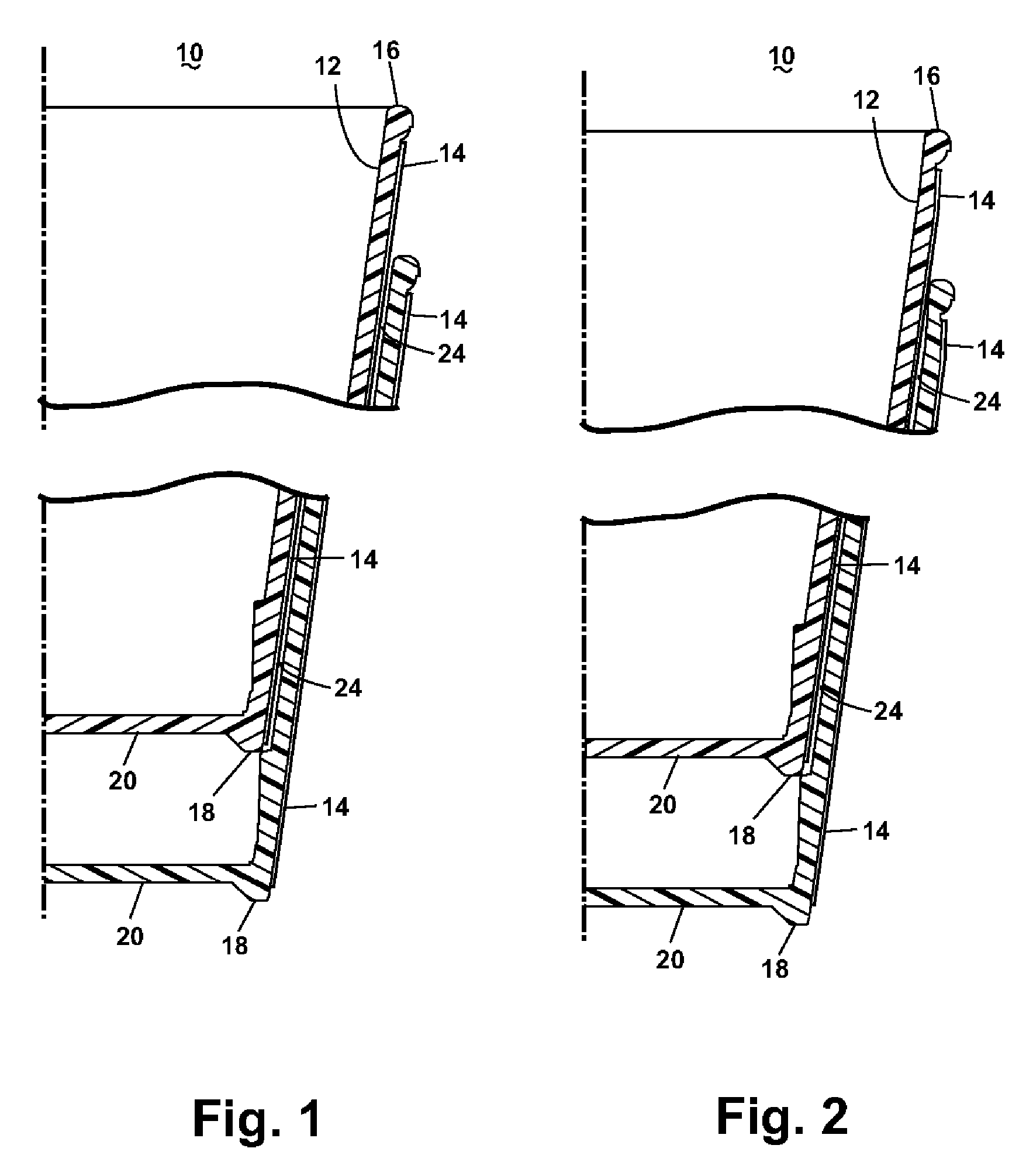

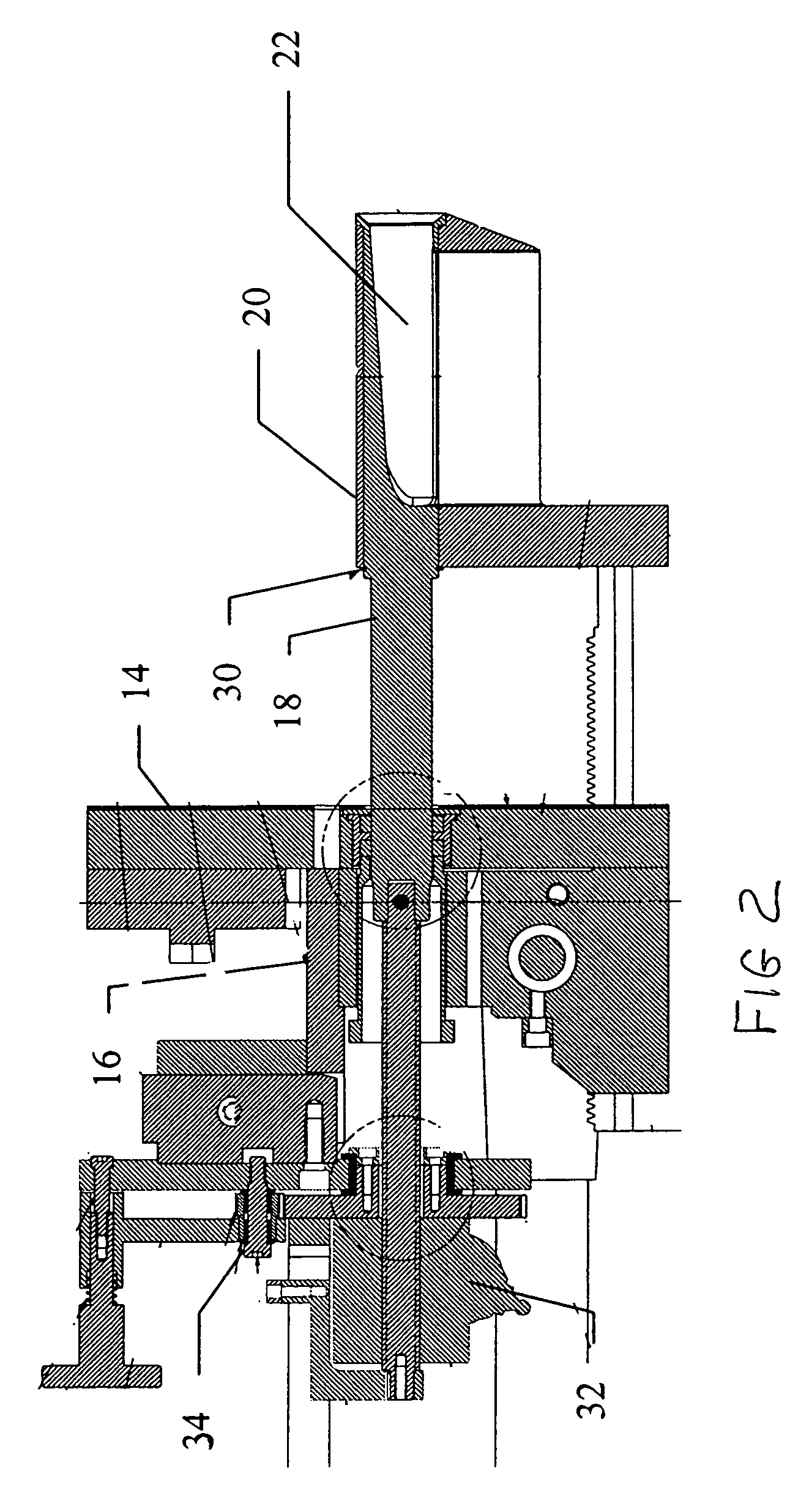

International die deckle with flow control

InactiveUS7104778B2Extension of timeVelocity increasesLiquid surface applicatorsConfectioneryEngineeringDeckle

An apparatus (10) for changing the width of an internal die cavity (12) to accommodate product width changes has a die end plate (14) with a front surface facing the internal die cavity (12), a rear surface and defines an opening that extends through the front and rear surfaces. An internal deckle mounting block (16) attaches to the rear surface of end plate (14). An internal deckle has inner (18) and outer (20) members and mounts on the mounting block (16). Inner member (18) extends through the opening of the die end plate (14) and defines a chamber (22) and a first longitudinal slot (24). The outer member (20) is positioned about the inner member (18) concentric therewith and defines a second longitudinal slot (26). The inner member (18) rotates about the outer member (20) to vary alignment of the slots and create a passageway narrower than either slot to control coating thickness.

Owner:EASTMAN KODAK CO

Lens cone and camera lens module thereof

InactiveCN101872051AReduce frictionImprove assembly accuracyMountingsRadiation controlled devicesCamera lensEngineering

A lens cone comprises a hollow columnar cone body which comprises an outer side wall and an inner side wall. External threads around the cone body are formed on the outer side wall of the cone body. Three tangential sections for separating the external threads are arranged on the outer side wall of the cone body at equal intervals. The lens cone and the camera lens module thereof of the invention utilize three tangential sections to separate the tangential sections on the outer side wall of the cone body so as to decrease the area of the threads, decrease the friction generated in the process of assembling the lens cone, as well as reduce the impurities like deckle edge formed on the threads and decrease the possibility of generating dropped crumbs, therefore promoting the assembling precision and the reliability in the assembling process of the lens cone. The invention also provides a camera lens module using the lens cone.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Filter paper die cutting device of transfusion device automatic assembling machine

InactiveCN101249290AEliminate the phenomenon that it cannot be completely stamped and droppedExtended service lifeFiltering accessoriesMetal working apparatusWrinkle skinPunching

The invention provides a filter paper punching device of an automatic assembly machine of an infusion device, belongs to the field of mechanical technology, and solves the concave wrinkles and deckle edges phenomena that occur on the filter papers punched by the present filter paper punching device of the automatic assembly machine of the infusion device. The filter paper punching device of the automatic assembly machine of the infusion device comprises a stent, and a paper punching mold is fixed at the stent, and at least a mold hole is opened in the paper punching mold, and a paper punching rod which is arranged in one to one correspondence to the mold hole along the vertical direction is arranged at the upper part of the paper punching mold, and the paper punching rod is fixed at a punching mechanism that is arranged at the stent; the front end of the paper punching rod is provided with a punching plane which is used for punching the filter papers. The filter paper punching device of the automatic assembly machine of the infusion device which uses the secondary punching is fast in speed, big in punching force and can punch and drop off the filter papers easily and completely. The filter paper punching device of the automatic assembly machine of the infusion device, which can be punched down completely and be punched to the installation position correctly, is not prone to be destroyed and is long in service life.

Owner:王兴章

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com