Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98 results about "Glass epoxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

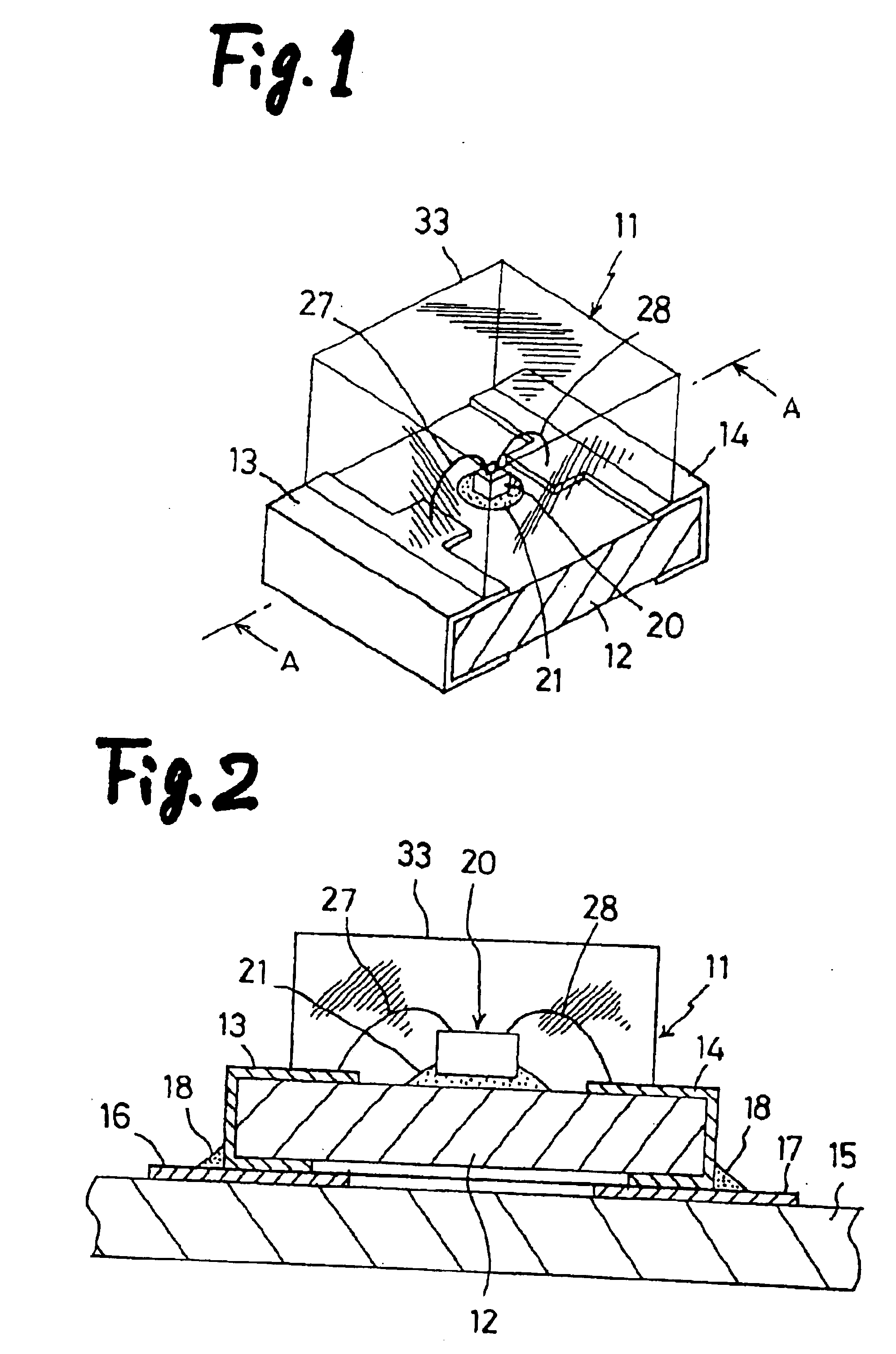

Wireless IC tag, and method and apparatus for manufacturing the same

InactiveUS20050140512A1Reduced durabilityImprove communication distanceSimultaneous aerial operationsAntenna supports/mountingsDielectricWireless

In a wireless IC tag, metallic antennas are deposited as thin films on the front and back surfaces of a spacer, made of a heat-resistant glass epoxy material having a desired dielectric constant, to form a first antenna and a second antenna. An IC chip is mounted in the center of the first antenna. The second antenna functions as an auxiliary antenna for resonating to a desired frequency of a transmission radio wave of the first antenna to strengthen the intensity of the radio wave. Accordingly, even when the IC tag is mounted to a cable or the like, the tag can be mounted in the interior of the enclosure of the cable and thus the radio wave intensity of the first antenna can be prevented from being weakened by a metallic member in the cable.

Owner:HITACHI LTD

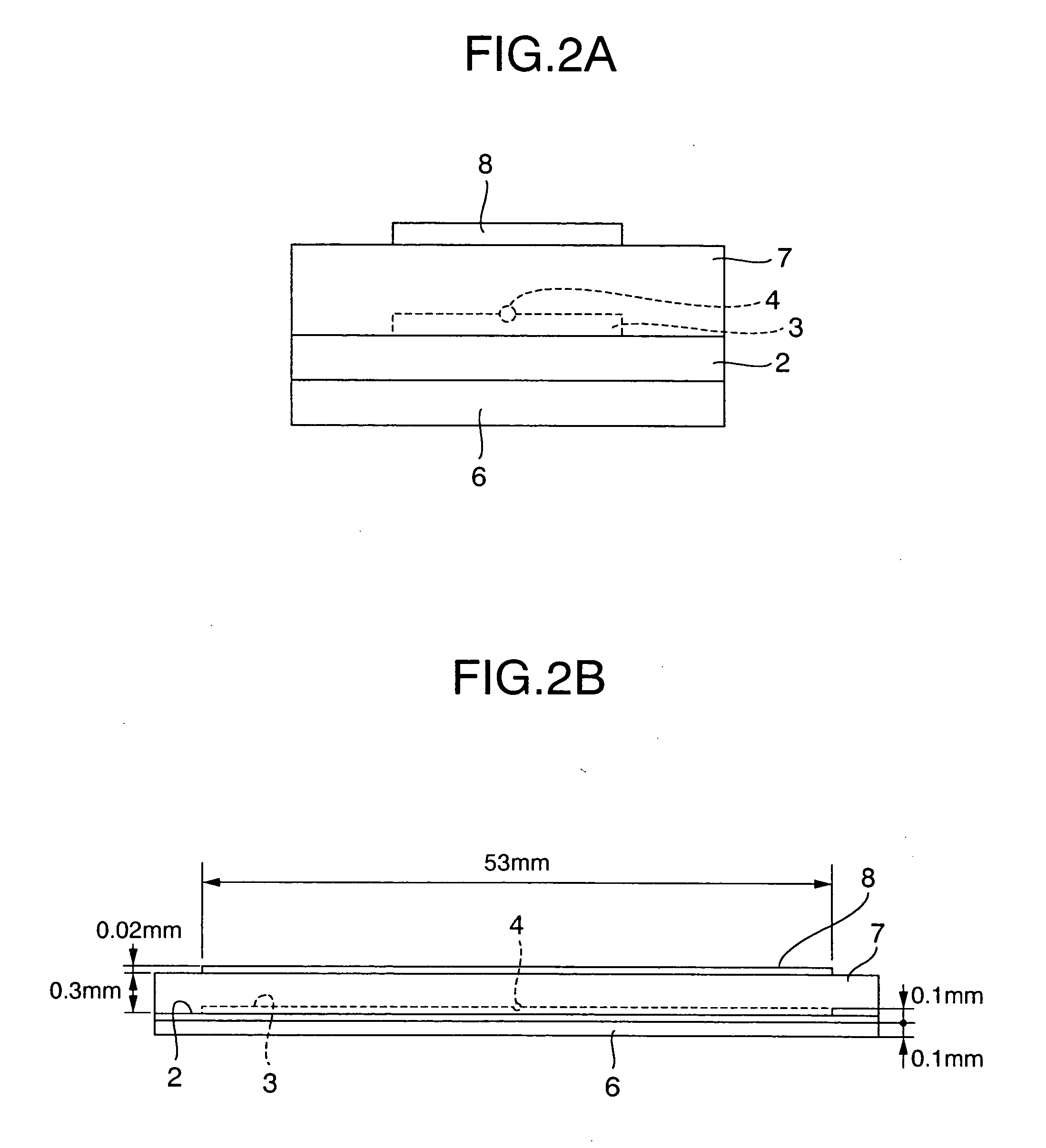

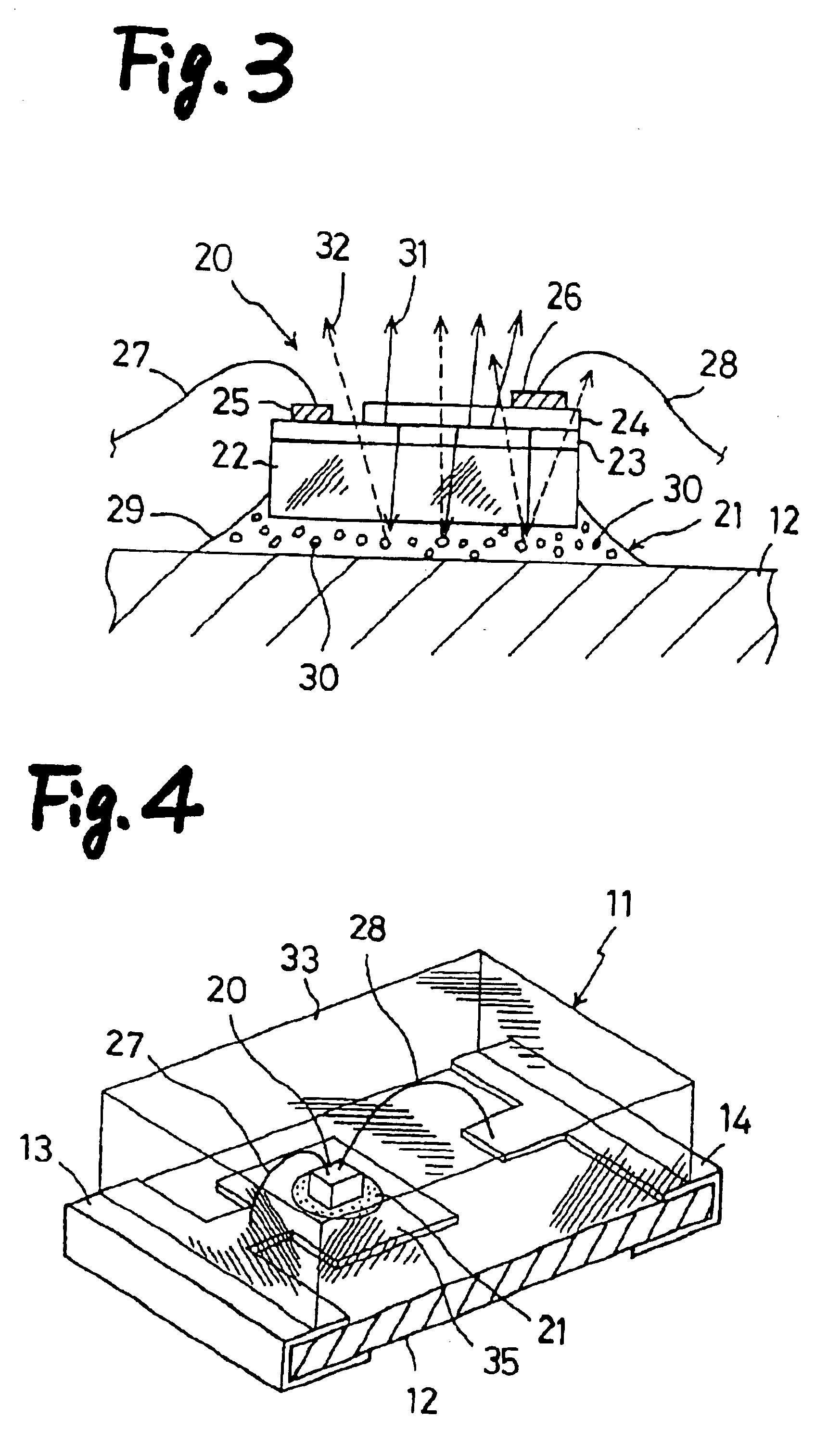

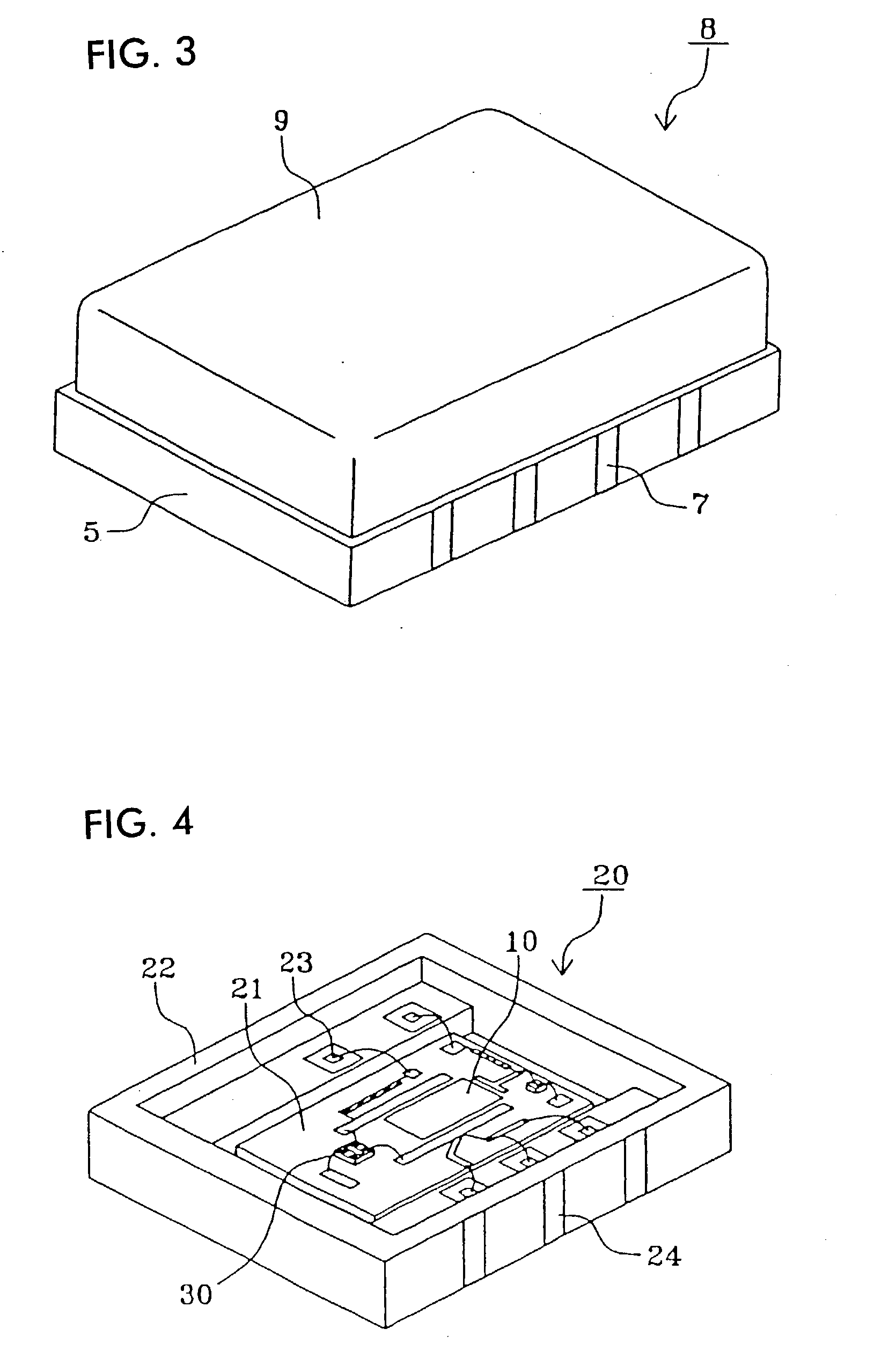

Light emitting diode

InactiveUS6914267B2Increase production capacityGood suitSolid-state devicesSemiconductor devicesElectrical conductorAdhesive

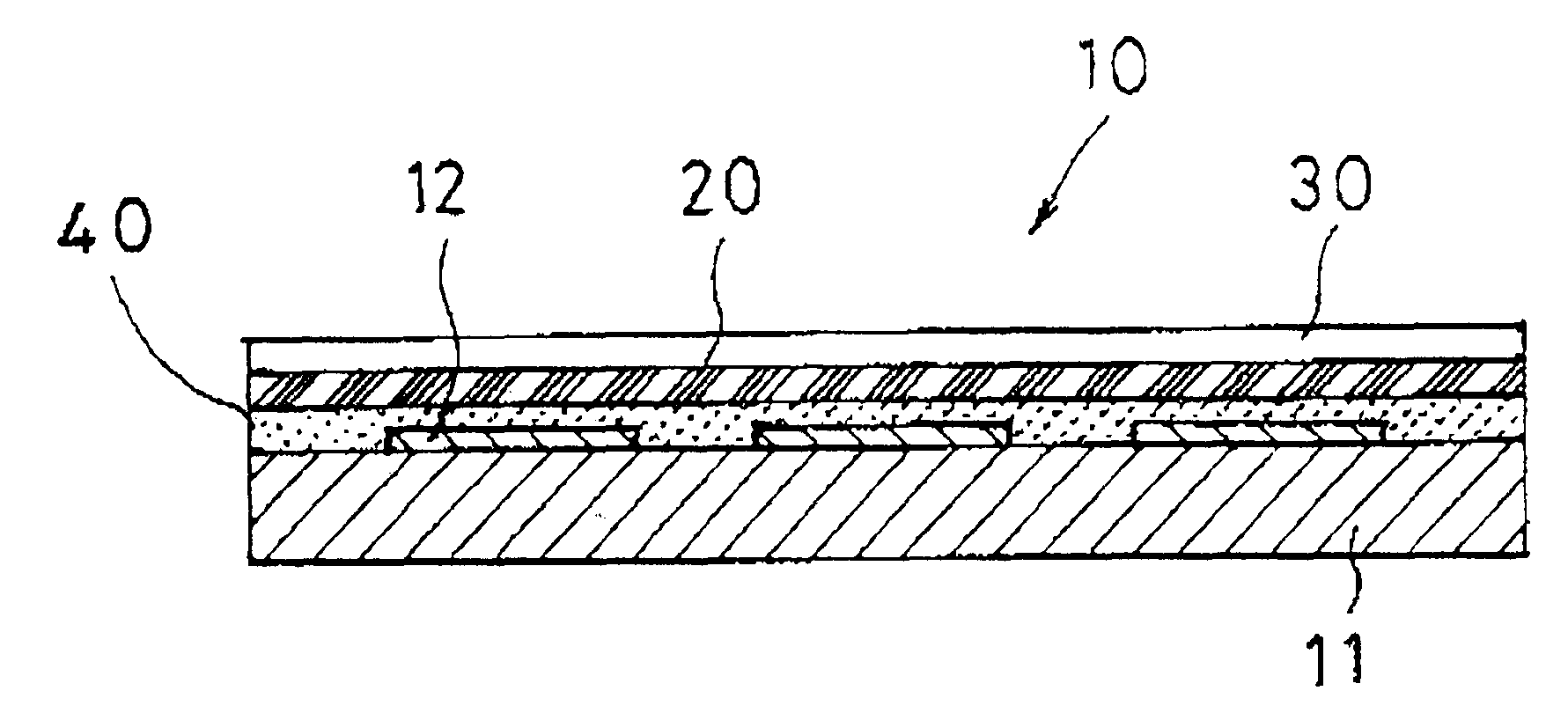

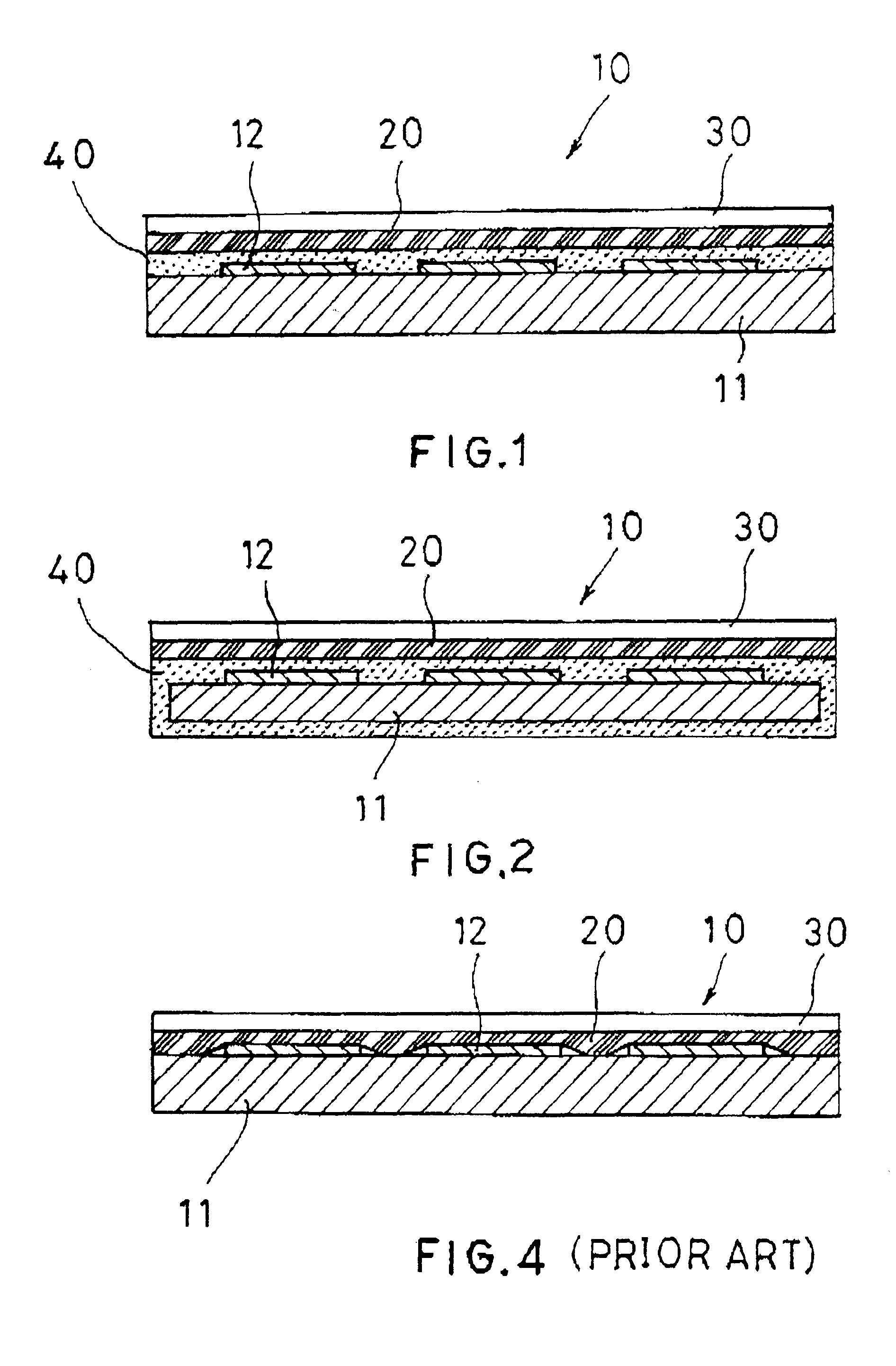

A light emitting diode comprising a light emitting diode element 20 mounted on a glass epoxy substrate 12, this light emitting diode element 20 being protected at its surface side by a resin seal member 33, in which: a light emitting diode element for blue luminescence, formed of gallium nitride type compound semiconductor is used as the above-mentioned light emitting diode element 20; and a fluorescent material containing layer 21 composed of a fluorescent material containing layer 21 composed of a fluorescent material dispersed into an adhesive is arranged on the back side of this light emitting diode element. On the back side of the light emitting diode element 20, blue luminescence is converted in wavelength to produce white luminescence of high intensity.

Owner:CITIZEN ELECTRONICS CO LTD

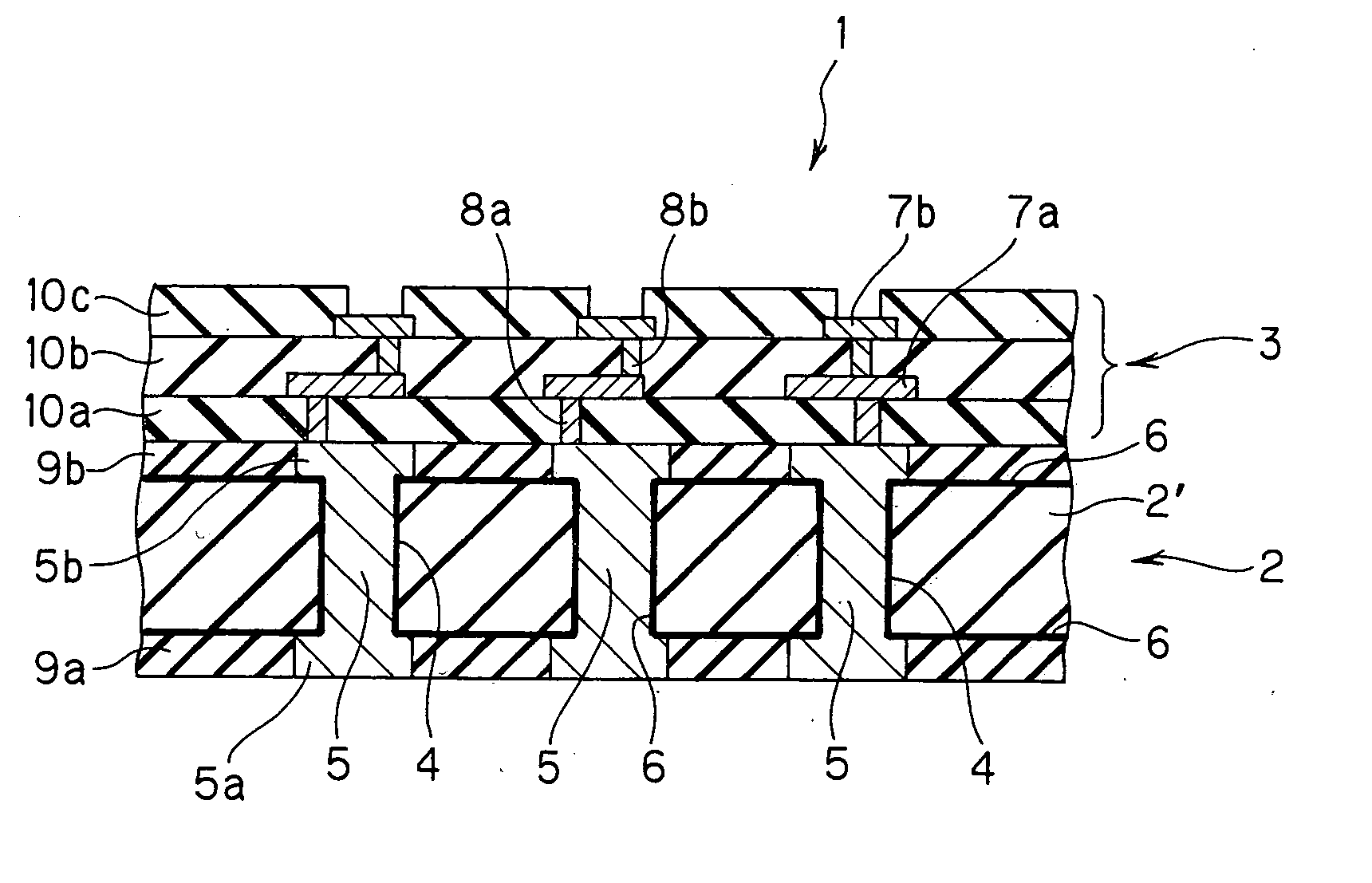

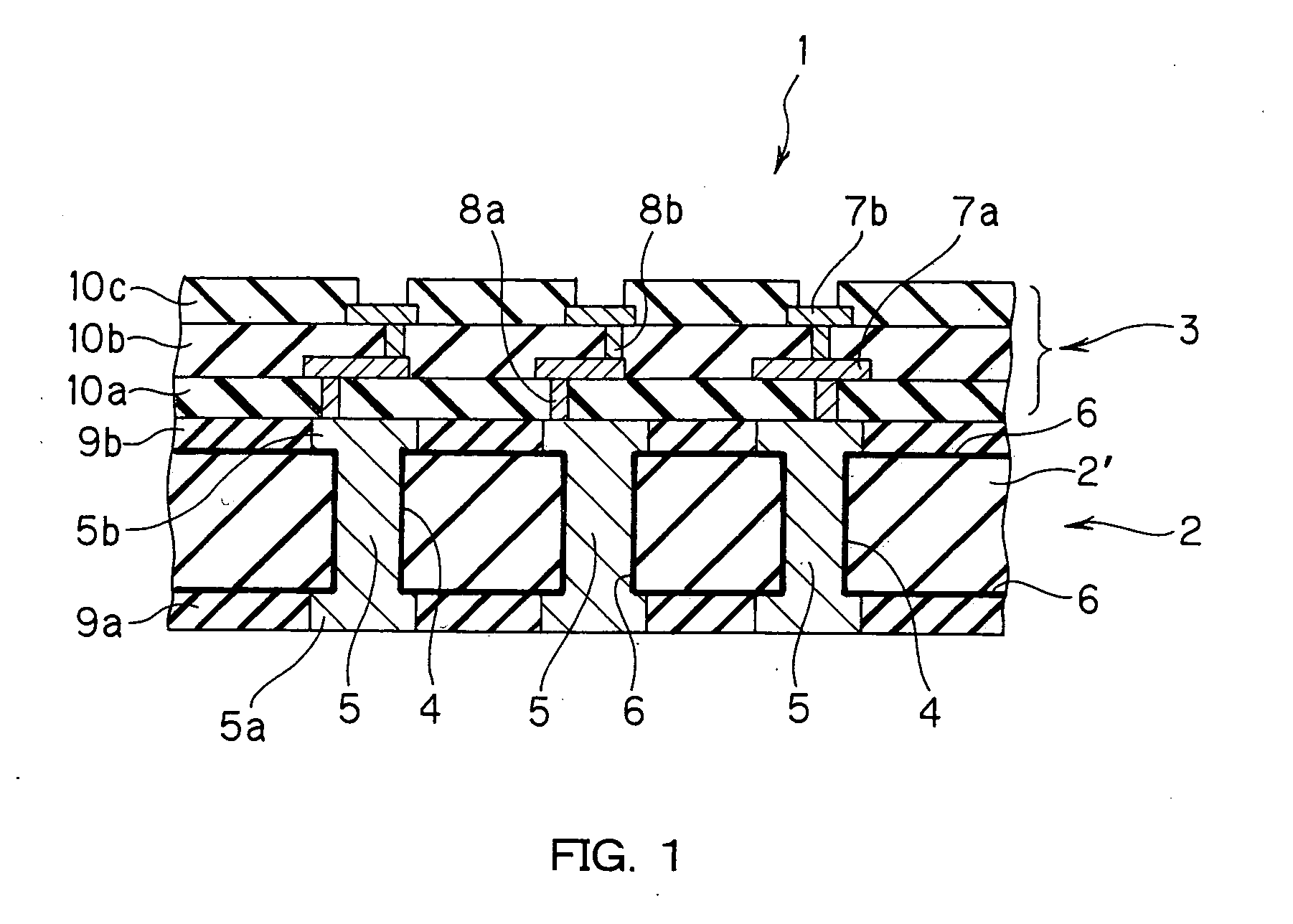

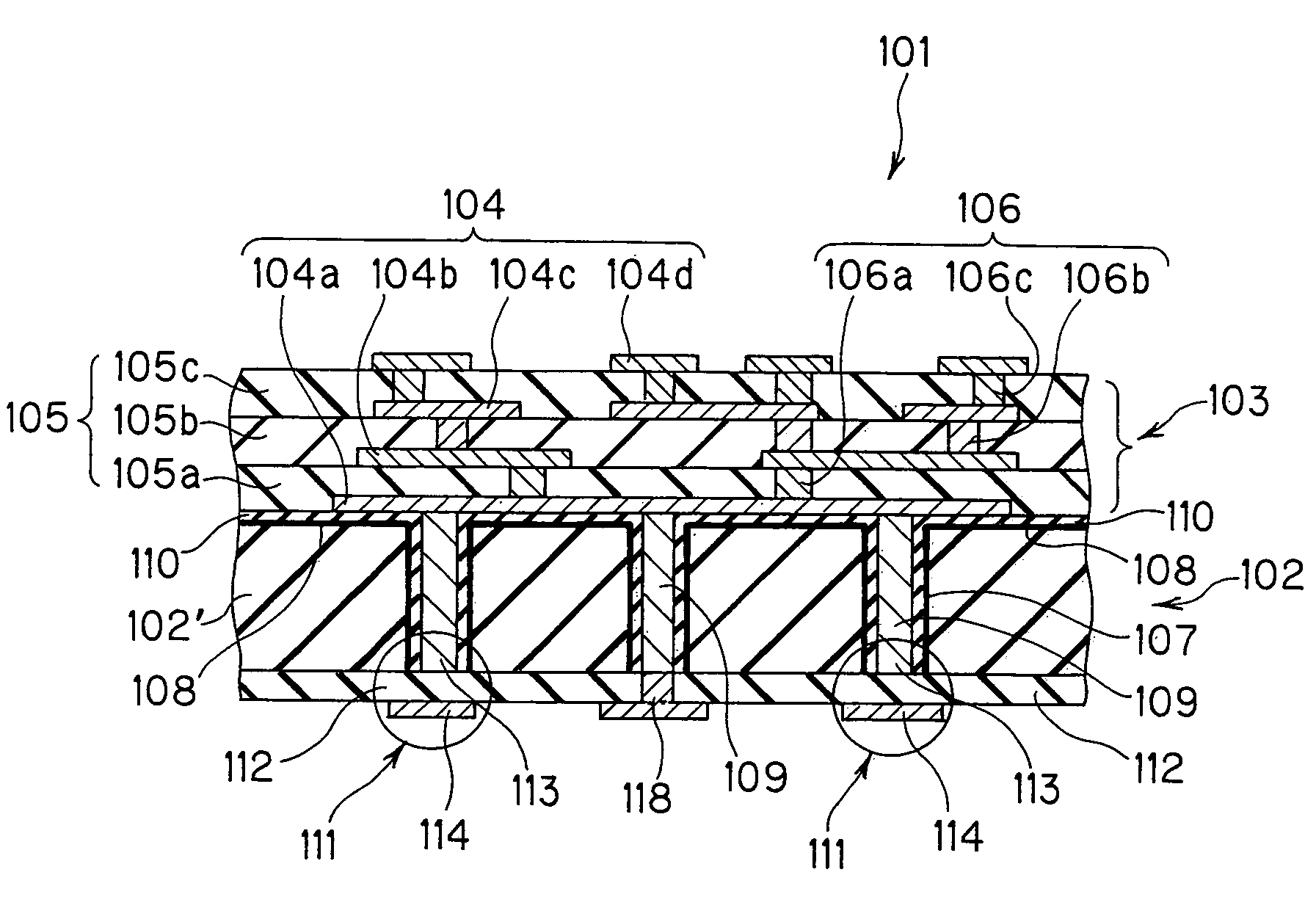

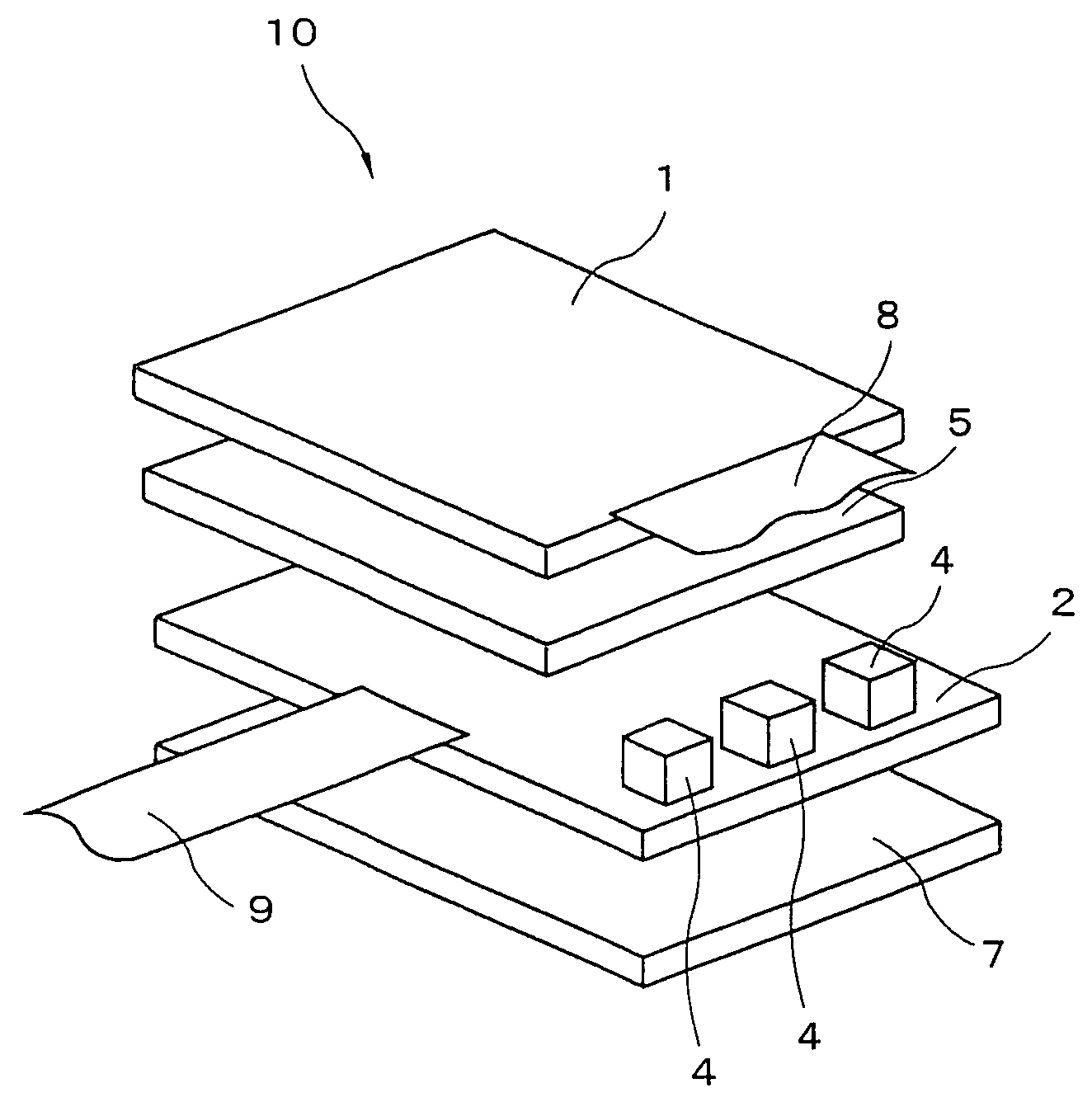

Multilayer wiring board and manufacture method thereof

ActiveUS20050012217A1Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringThermal expansion

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

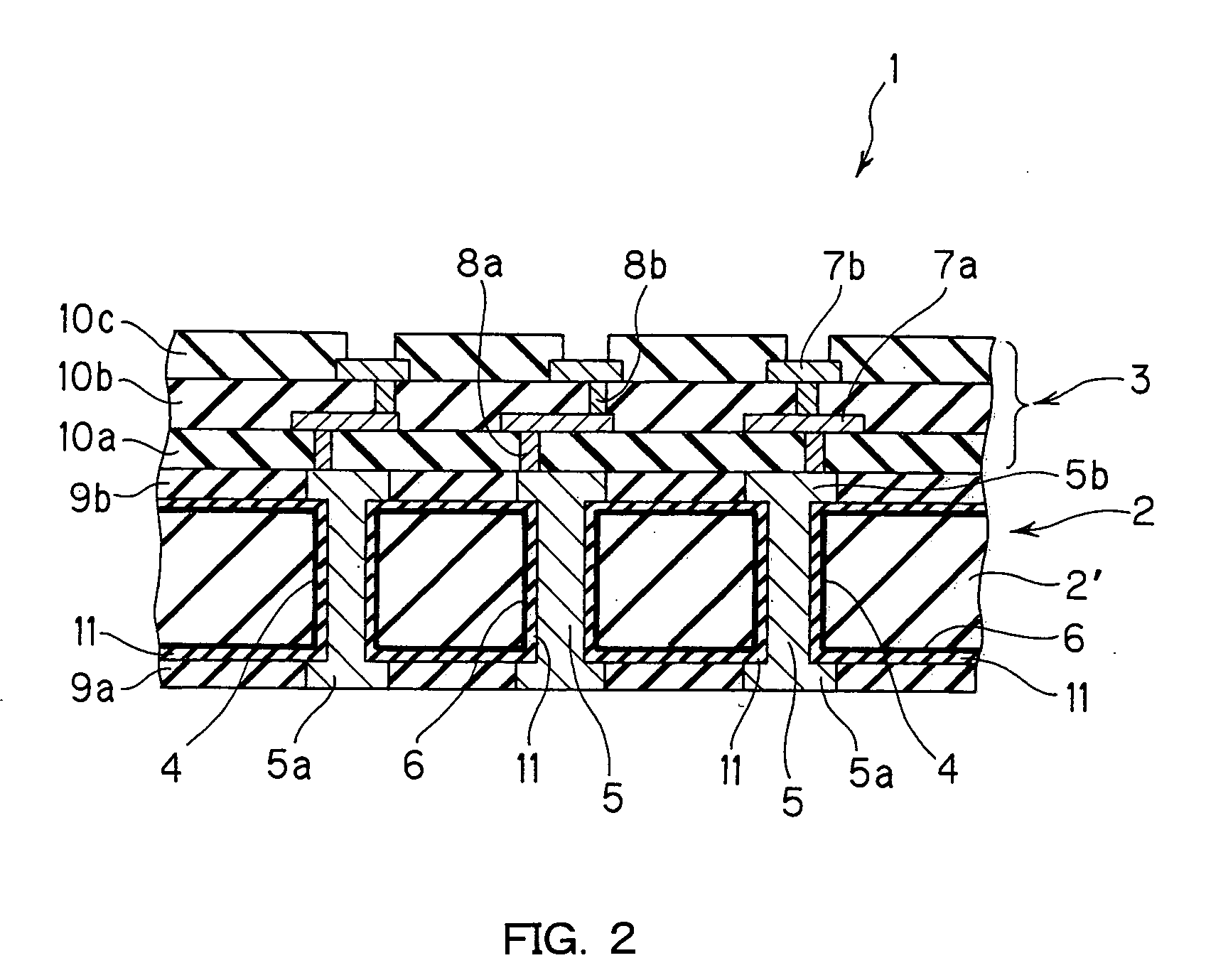

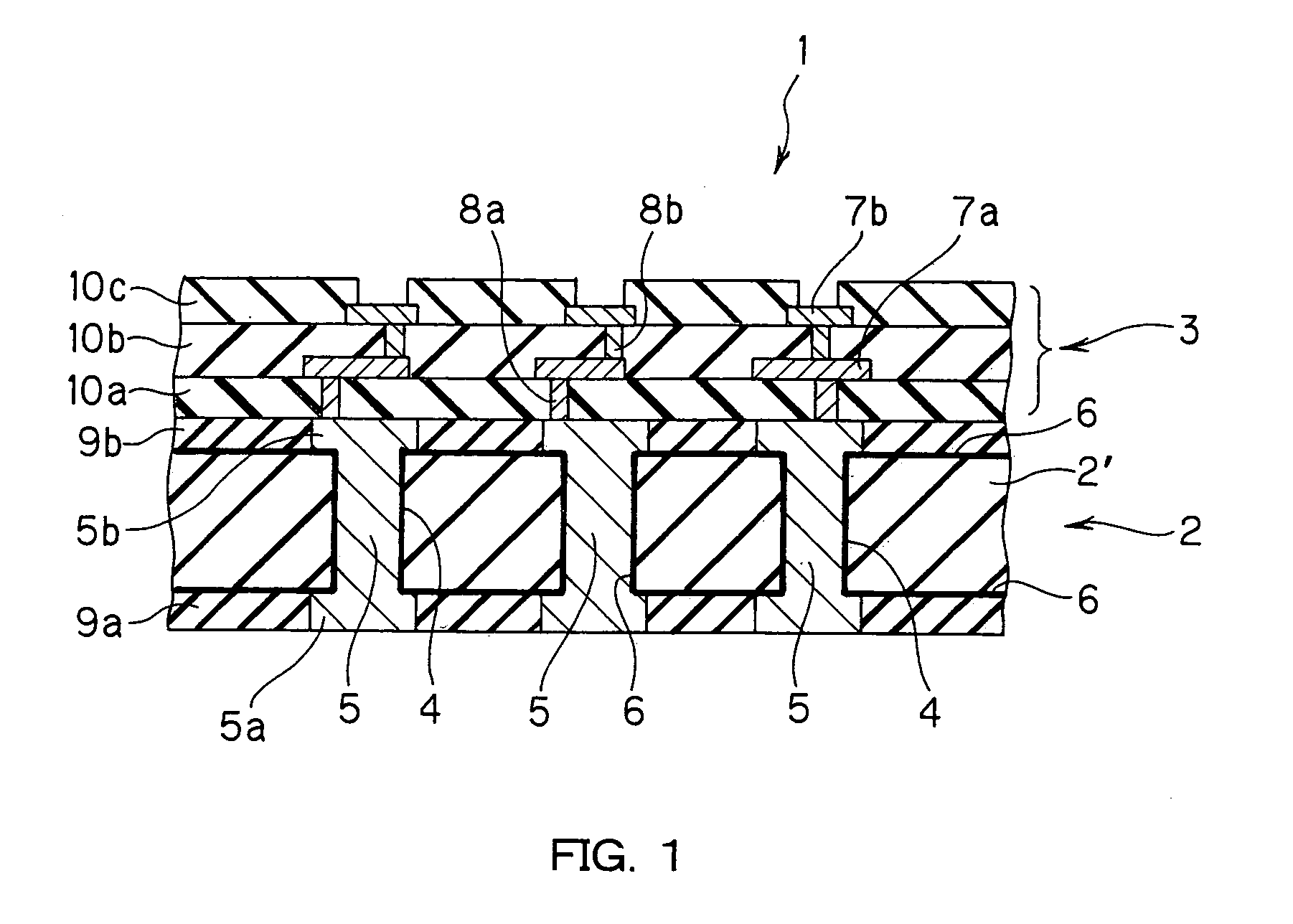

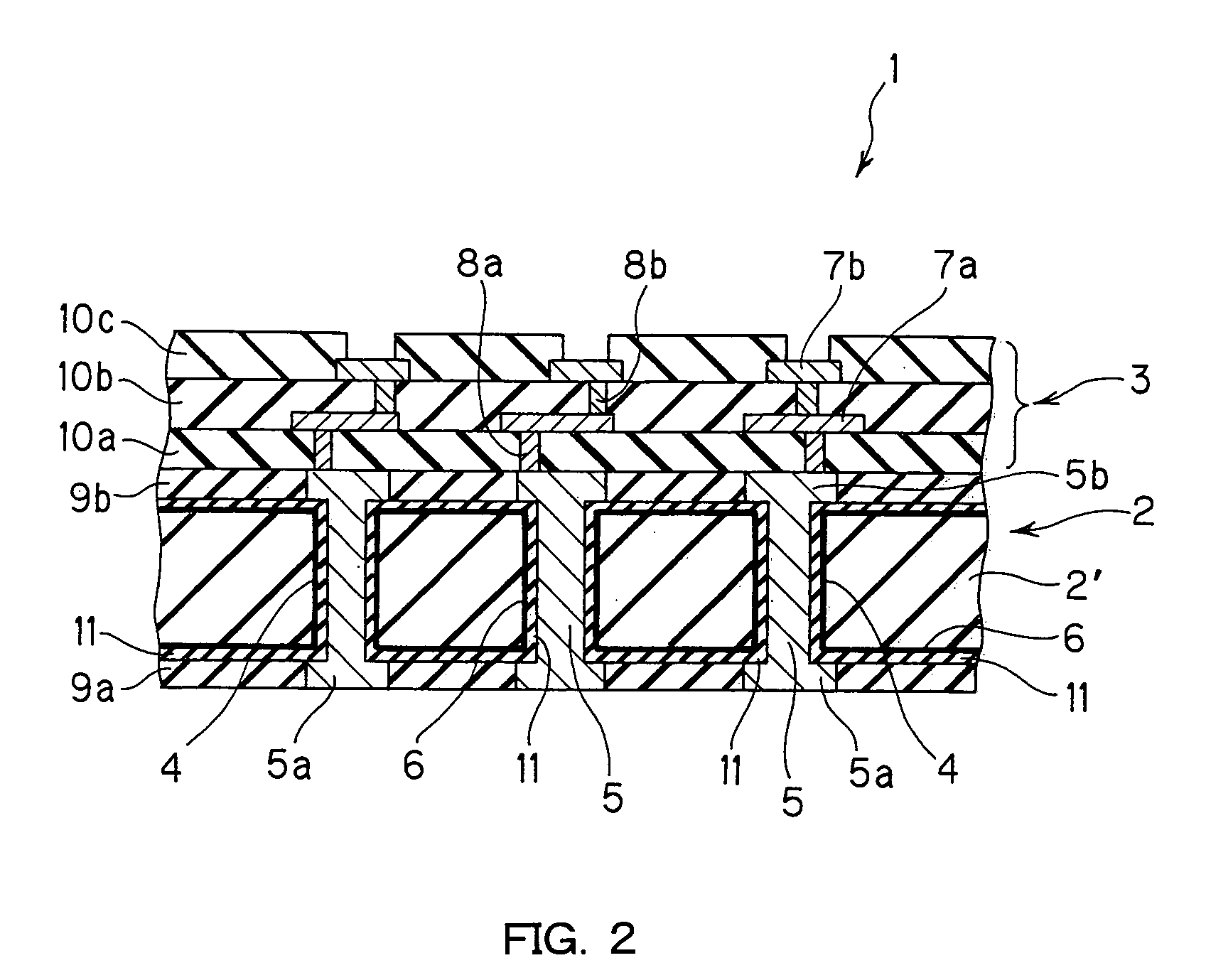

Multilayer wiring board and manufacture method thereof

InactiveUS7091589B2Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringConductive materials

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

Scale on an apparatus for measuring displacement

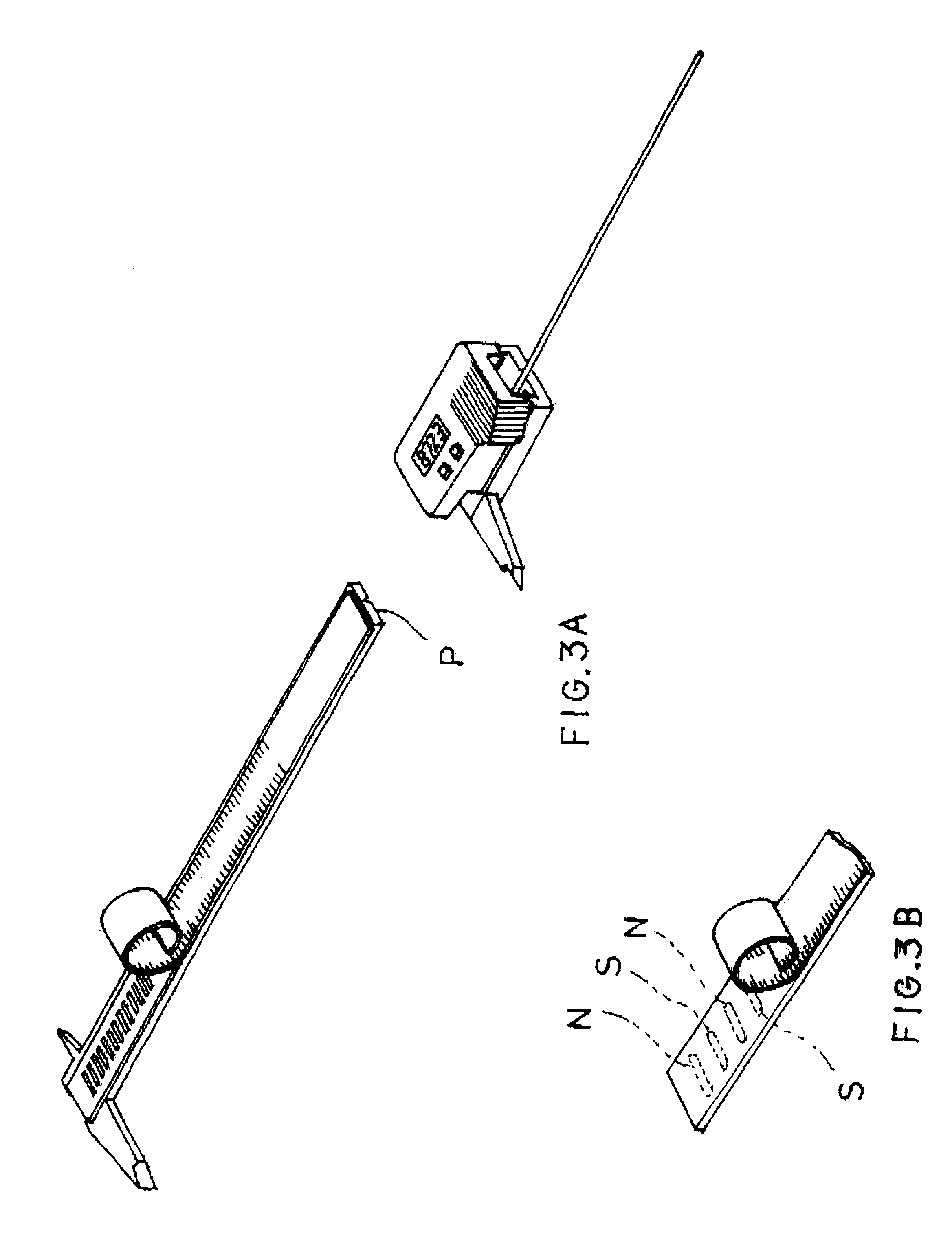

InactiveUS6675491B2Good solvent resistanceImprove adhesionWalking sticksSlide gaugesAdhesive beltGrating

A scale for an apparatus for measuring displacement is enclosed. It comprises a scale member having a plurality of rectangular gratings arranged in a periodic pattern on the glass epoxy substrate and the like, a coating layer covered on the side of the scale member on which a plural of the rectangular gratings are formed, a scale cover (film layer) which functions as a protective layer, and a scale forming material bonded to the outer portion of the coating layer by an adhesive layer so as to keep contaminants, oil or particles from intruding between the rectangular grating and the adhesive layer, for example an adhesive tape and the like.

Owner:MITUTOYO CORP

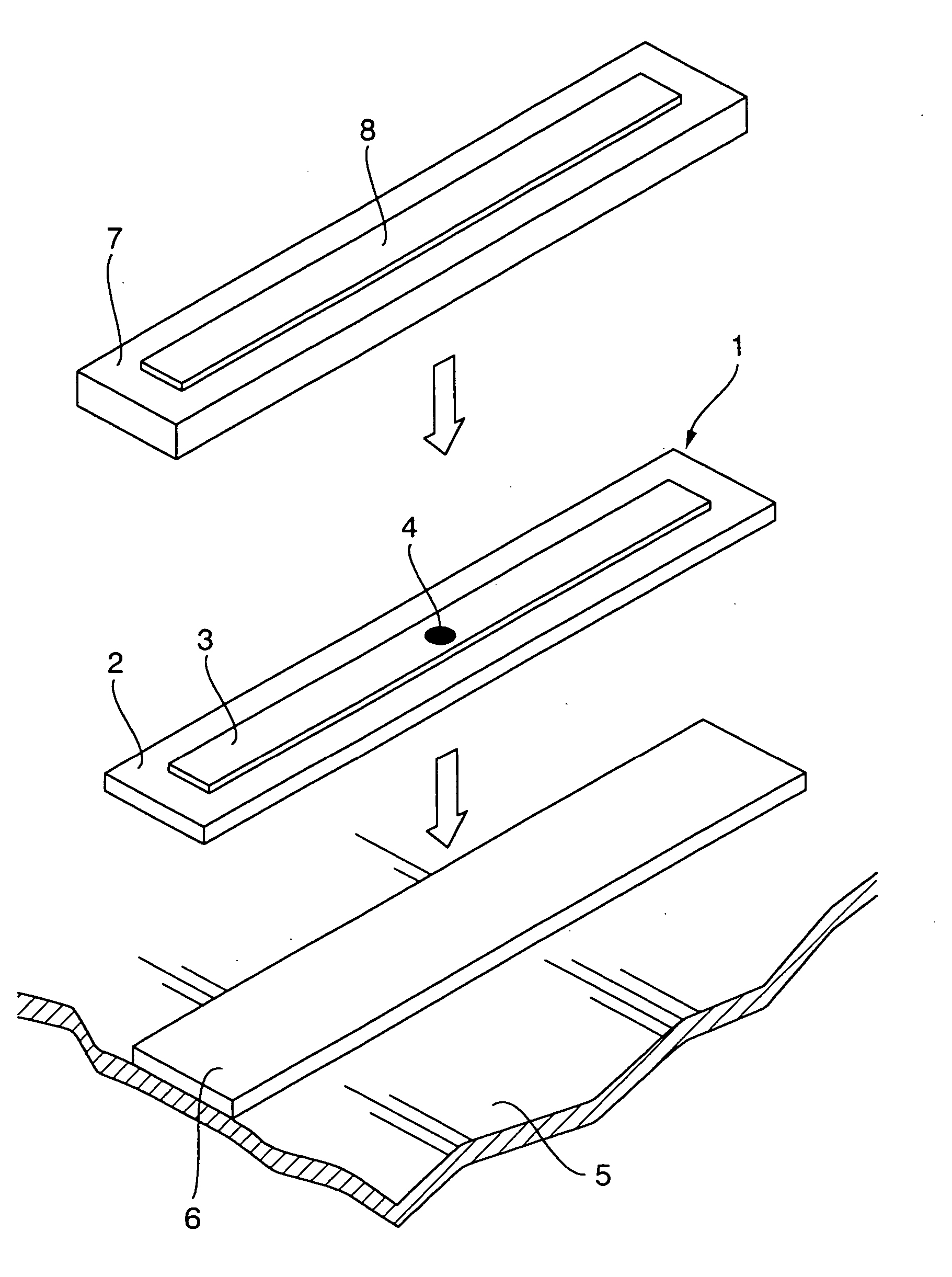

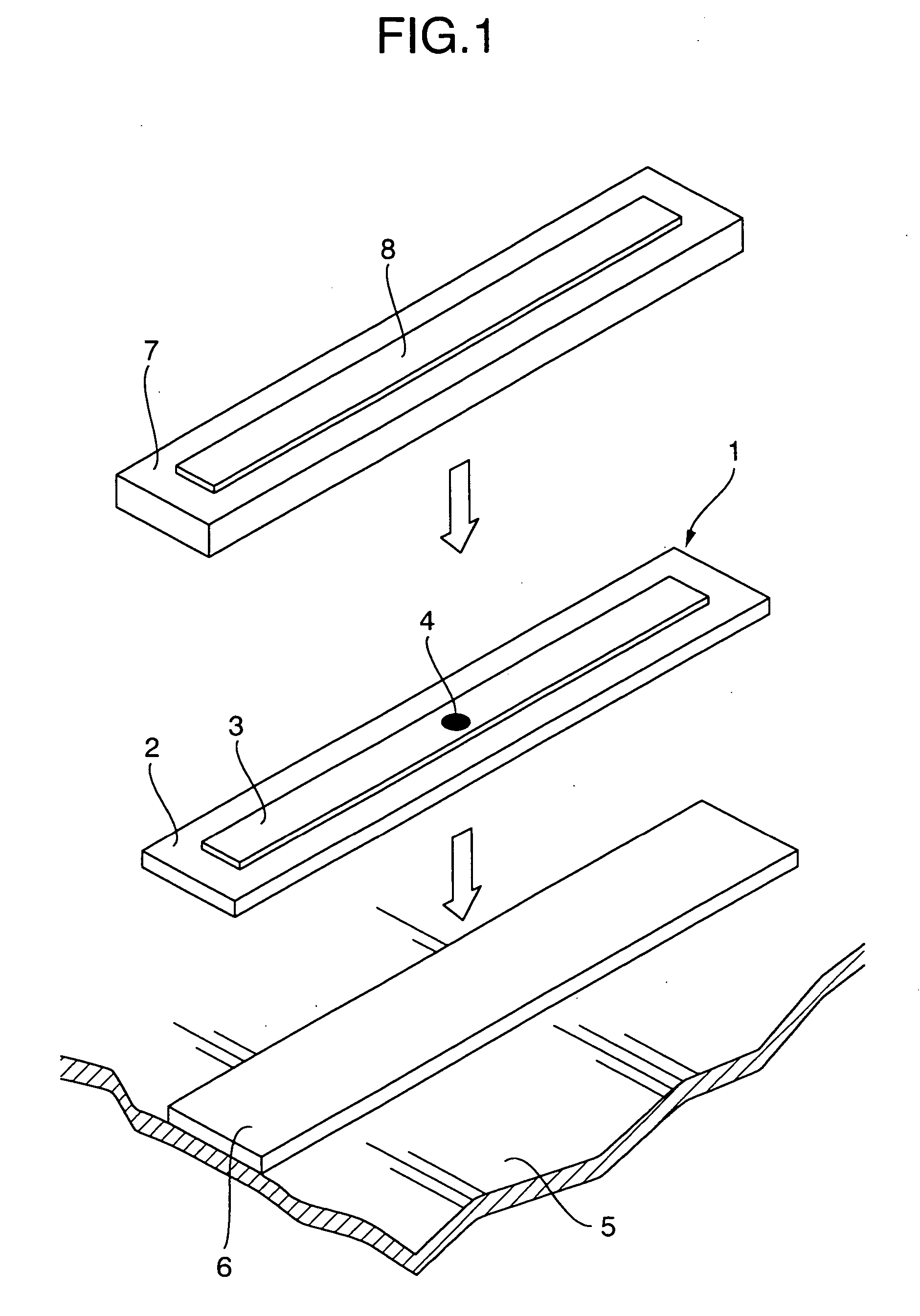

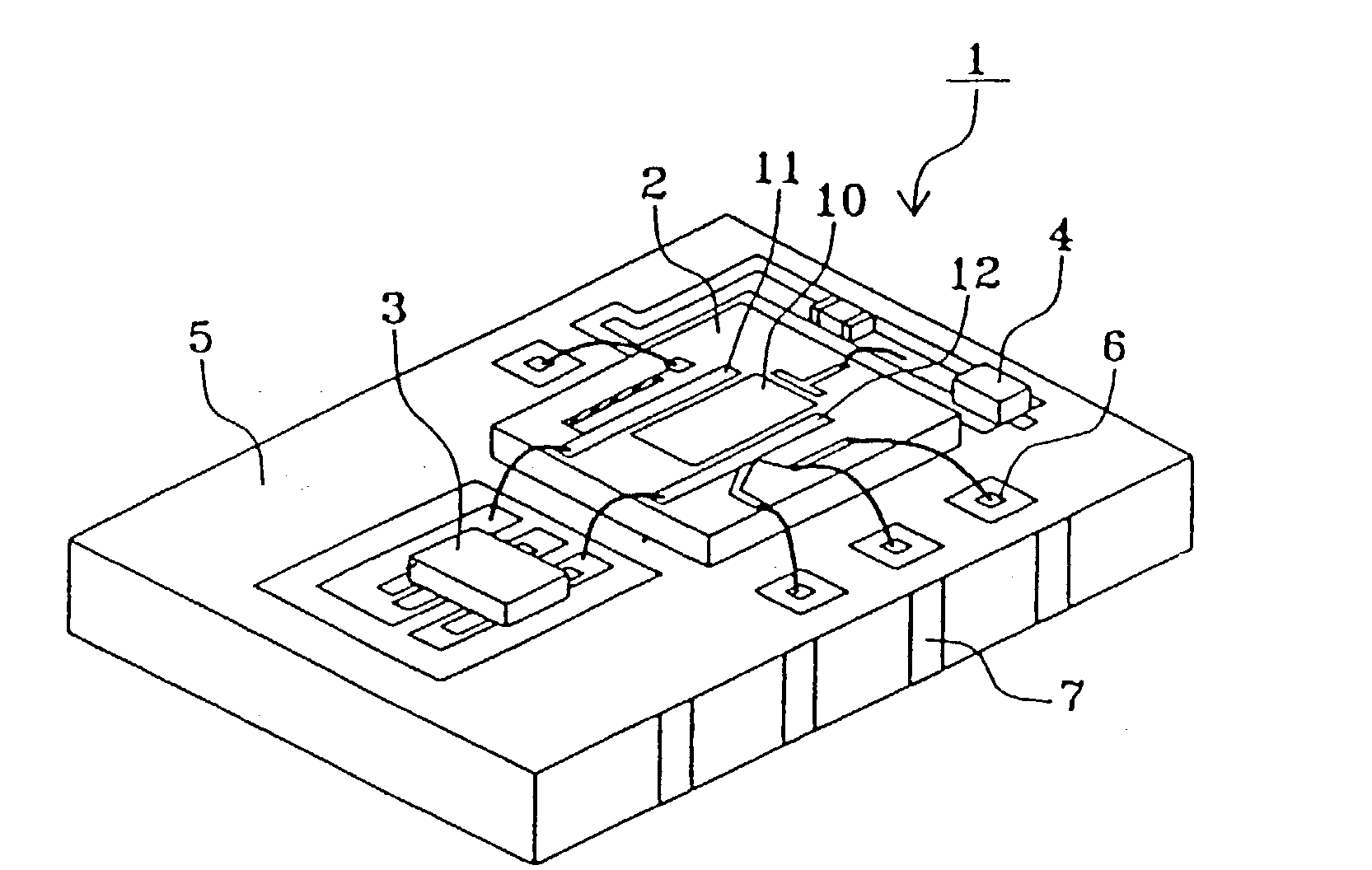

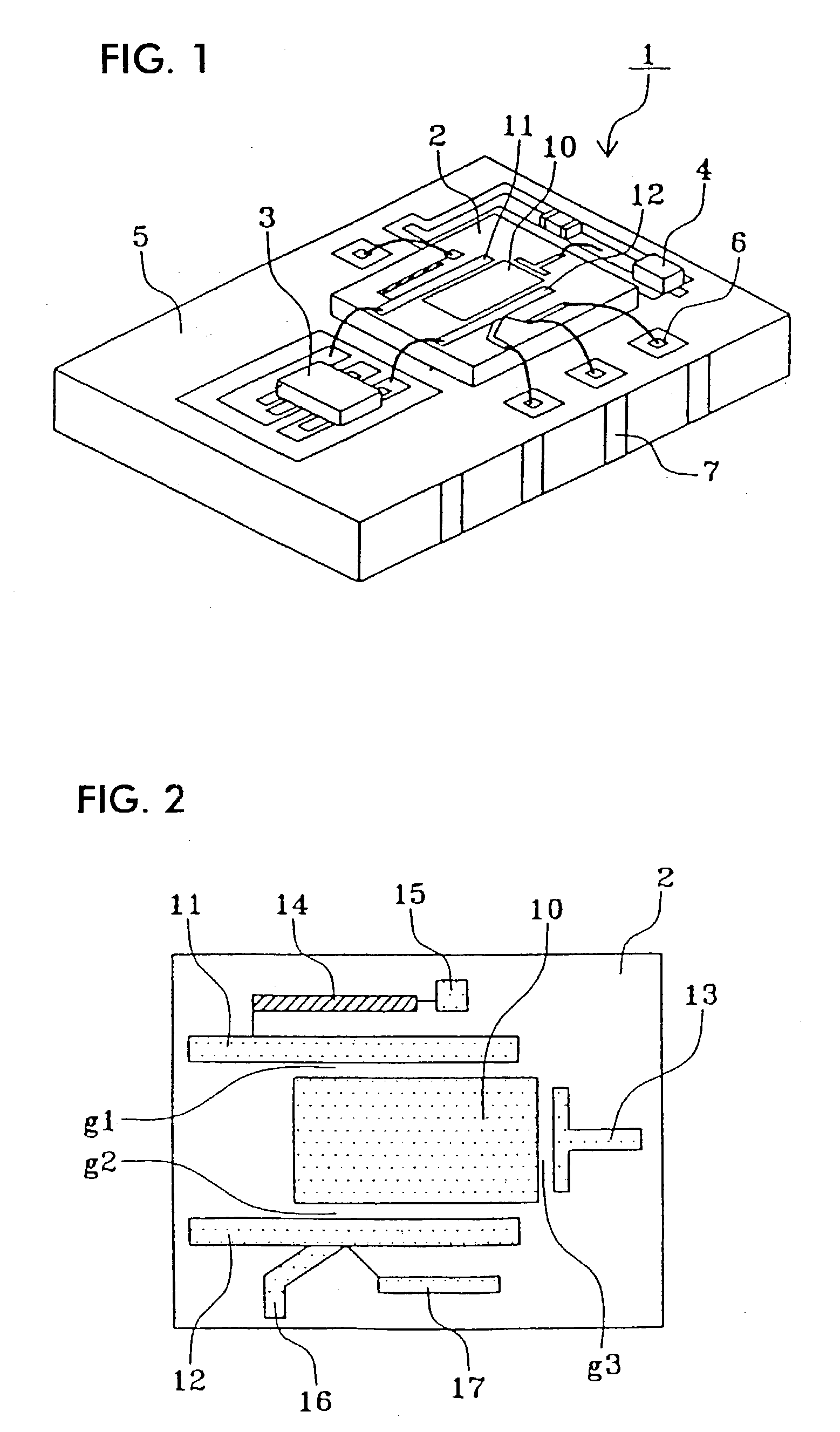

Memory card and manufacturing method of the same

InactiveUS20080173995A1Simple manufacturing processSemiconductor/solid-state device detailsPrinted circuit aspectsMass storageSemiconductor chip

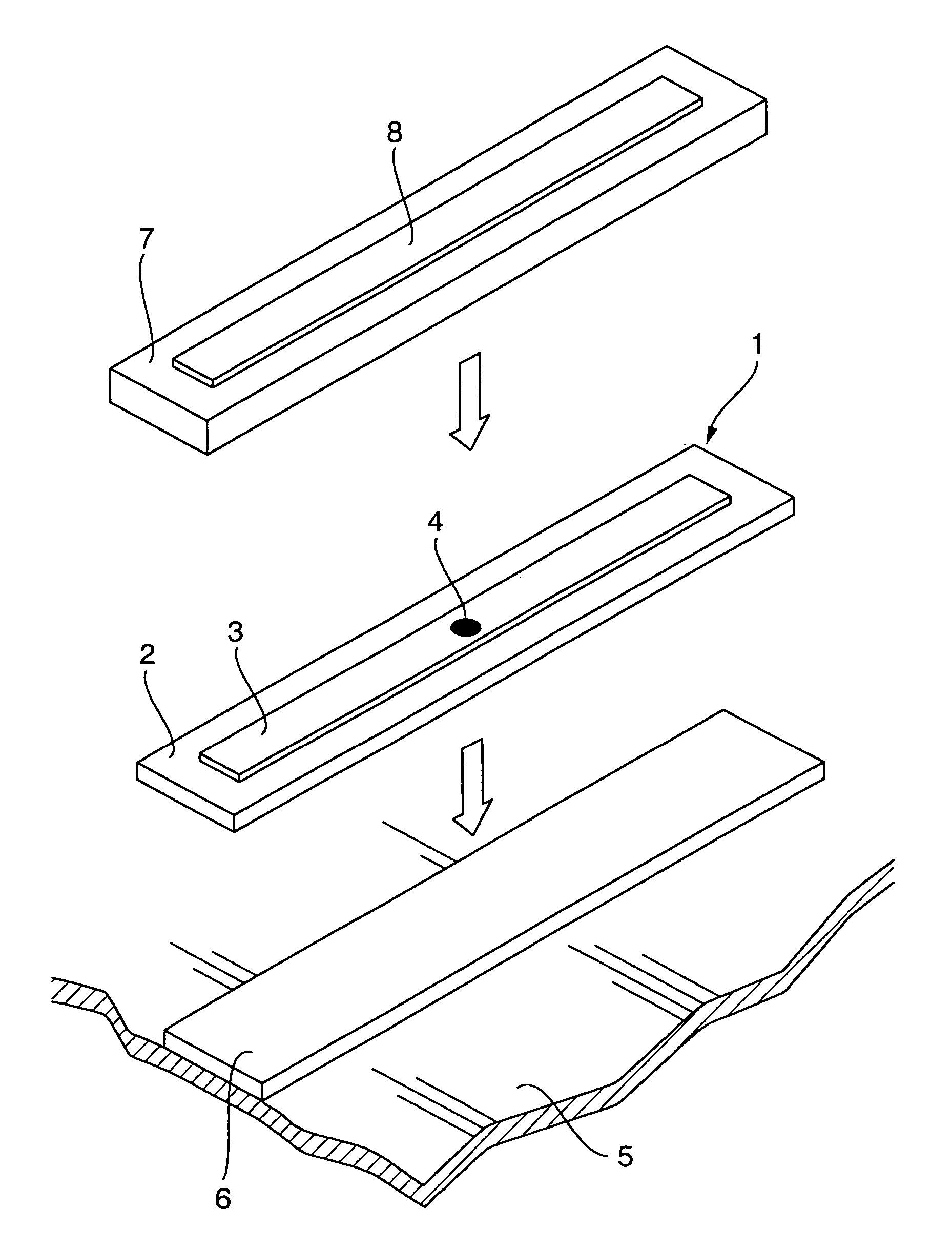

There is a need to provide a large capacity memory card for a portable communication device. A memory card 1 includes: a wiring board 2 mainly composed of a glass epoxy resin; multiple semiconductor chips (3C and 3F) mounted on a main surface of the memory card 1; and a mold resin 4 for encapsulating the wiring board 2 and the semiconductor chips (3C and 3F). The mold resin 4 is made of a thermosetting epoxy resin containing quartz filler. A back surface of the wiring board 2 is not covered with the mold resin 4 and is exposed to a back surface of the memory card 1. The back surface of the wiring board 2 is used to form multiple external connection terminals 7 electrically connected to the semiconductor chips (3C and 3F) . When the memory card 1 is attached to a card slot of a mobile phone, the external connection terminals 7 contact with a connector terminal contained in the card slot. This makes it possible to exchange signals between the memory card 1 and the mobile phone or to supply the power.

Owner:RENESAS ELECTRONICS CORP

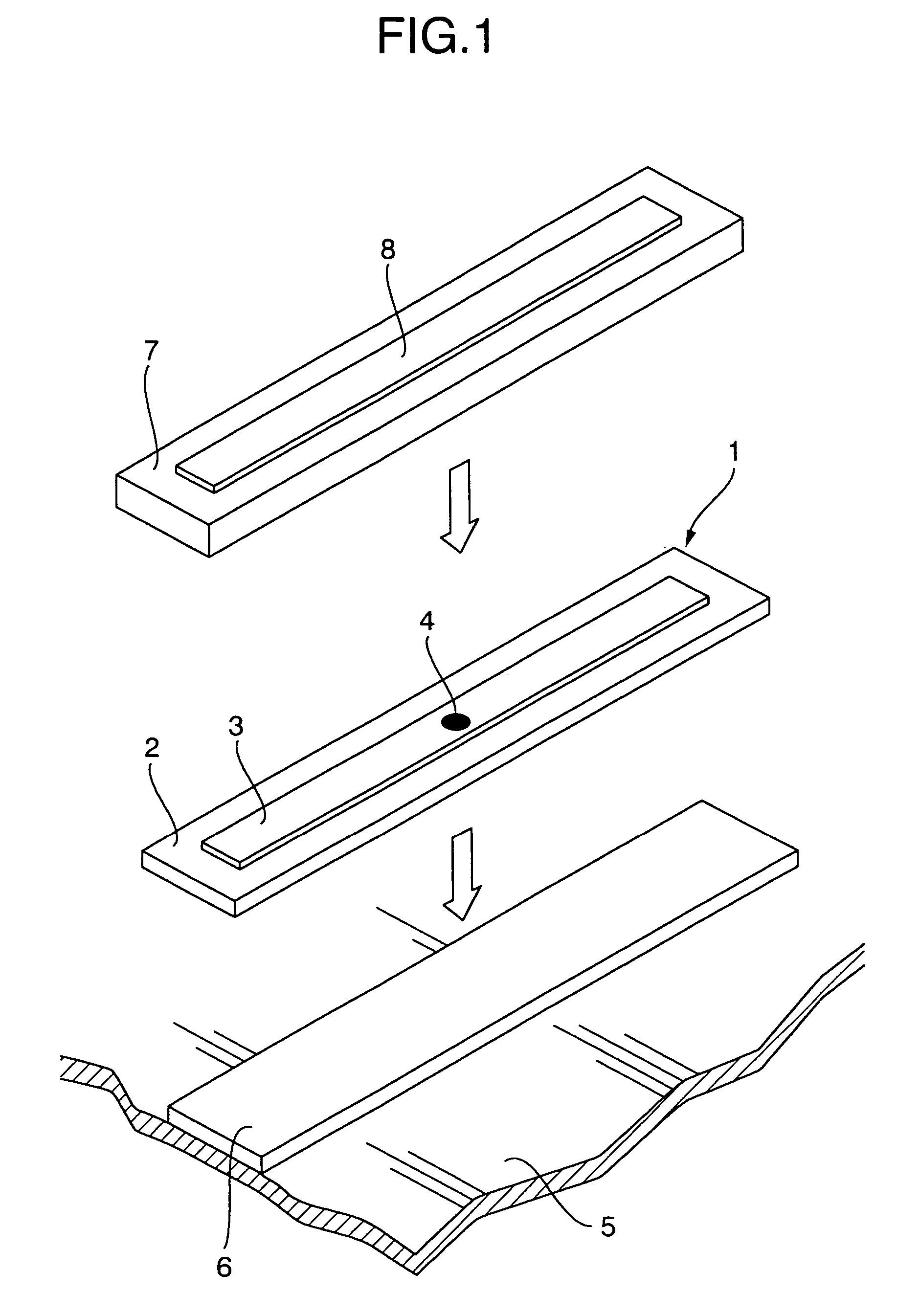

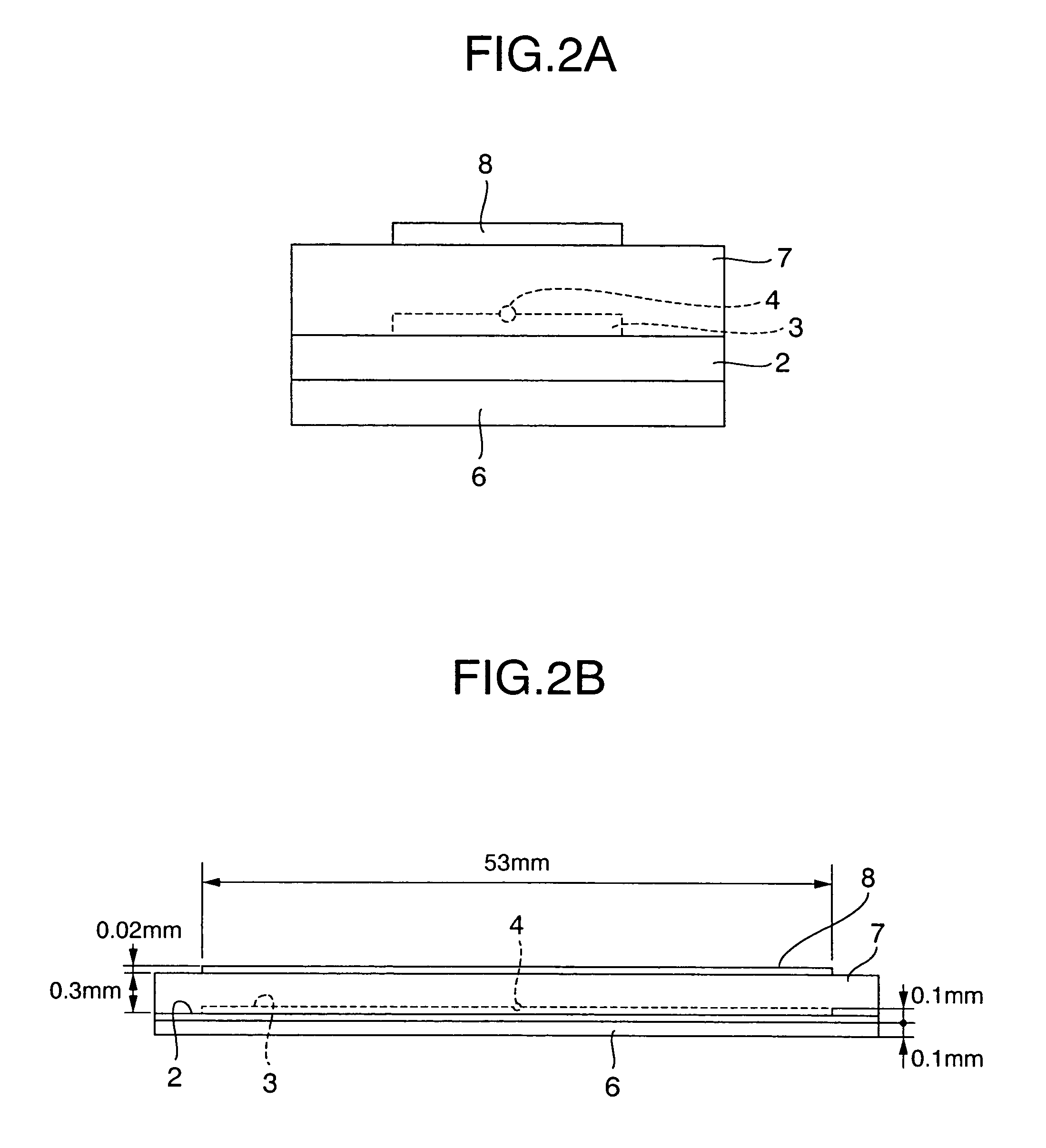

Wireless IC tag, and method and apparatus for manufacturing the same

InactiveUS7250867B2Improve communication distanceLong communication distanceSimultaneous aerial operationsAntenna supports/mountingsDielectricEngineering

In a wireless IC tag, metallic antennas are deposited as thin films on the front and back surfaces of a spacer, made of a heat-resistant glass epoxy material having a desired dielectric constant, to form a first antenna and a second antenna. An IC chip is mounted in the center of the first antenna. The second antenna functions as an auxiliary antenna for resonating to a desired frequency of a transmission radio wave of the first antenna to strengthen the intensity of the radio wave. Accordingly, even when the IC tag is mounted to a cable or the like, the tag can be mounted in the interior of the enclosure of the cable and thus the radio wave intensity of the first antenna can be prevented from being weakened by a metallic member in the cable.

Owner:HITACHI LTD

Electronic device and semiconductor package

InactiveUS6097085ASemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageThermal expansion

The electronic device has a structure that a semiconductor package is mounted on a mother board. To relieve stress caused by cyclic thermal load and applied to solder bumps that are electrically and mechanically connect the semiconductor package and the mother board, a shape-holding plate (stiffener) adhered to a wiring film is composed of a metal with a thermal expansion coefficient of 13x10-6 to 17x10-6 almost close to that of a glass-epoxy wiring substrate as the mother board. Examples of the metal are 25Cr-20Ni stainless steel or copper alloy containing 0.01 to 0.03% by weight of Zr.

Owner:KK TOSHIBA

Printed Wiring Board And Method Of Manufacturing Same

InactiveUS20080164057A1Avoid it happening againPrinted circuit aspectsConductive pattern formationElectrical conductorEngineering

A printed wiring board has a via land, a glass epoxy resin layer, a via conductor, and a block layer. The via land is formed on a core layer. The glass epoxy resin layer is formed on the core layer and the via land. The via conductor is formed on the via land. The block layer is formed on the via land, between the via conductor and the glass epoxy resin layer.

Owner:IBM CORP

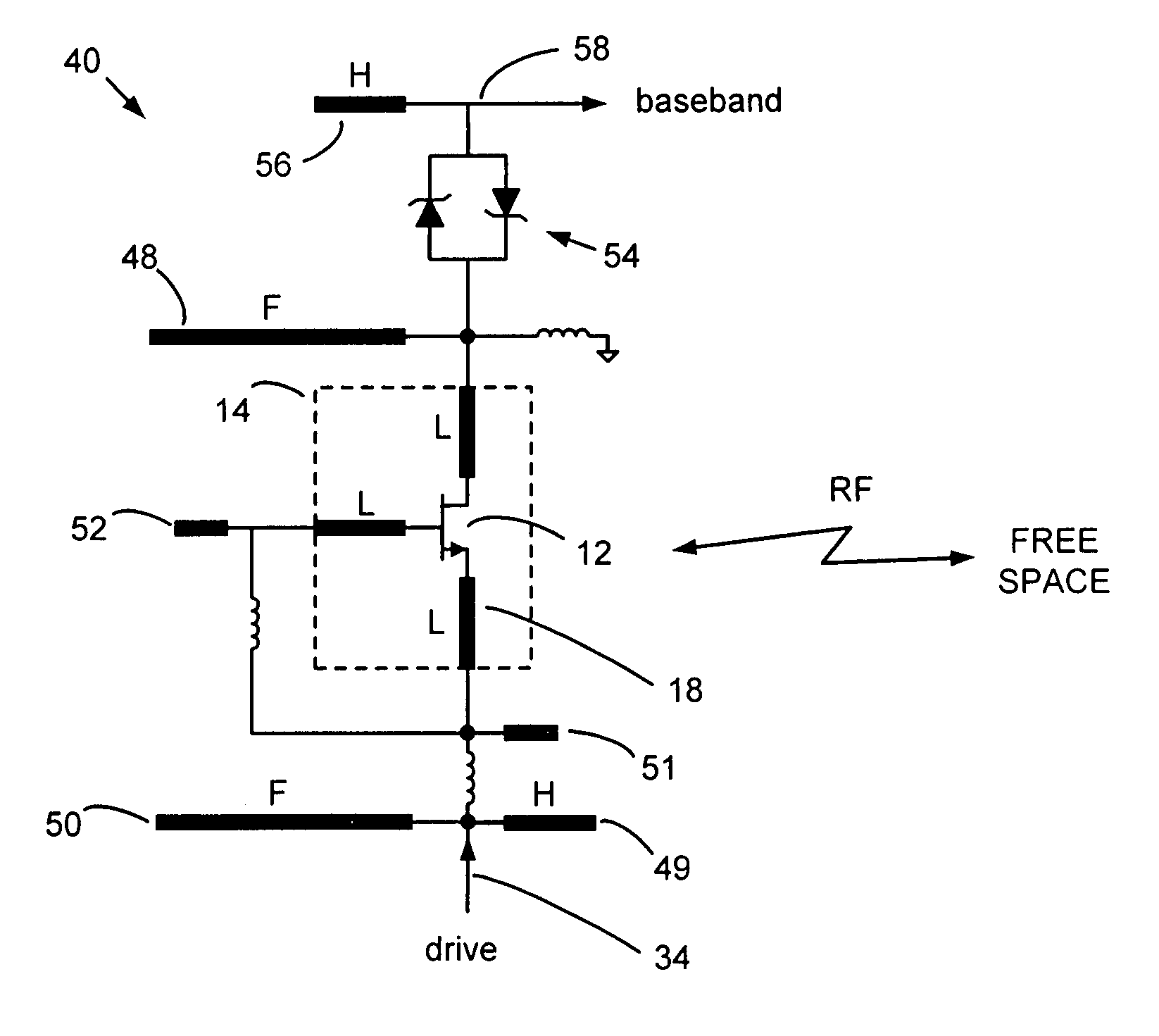

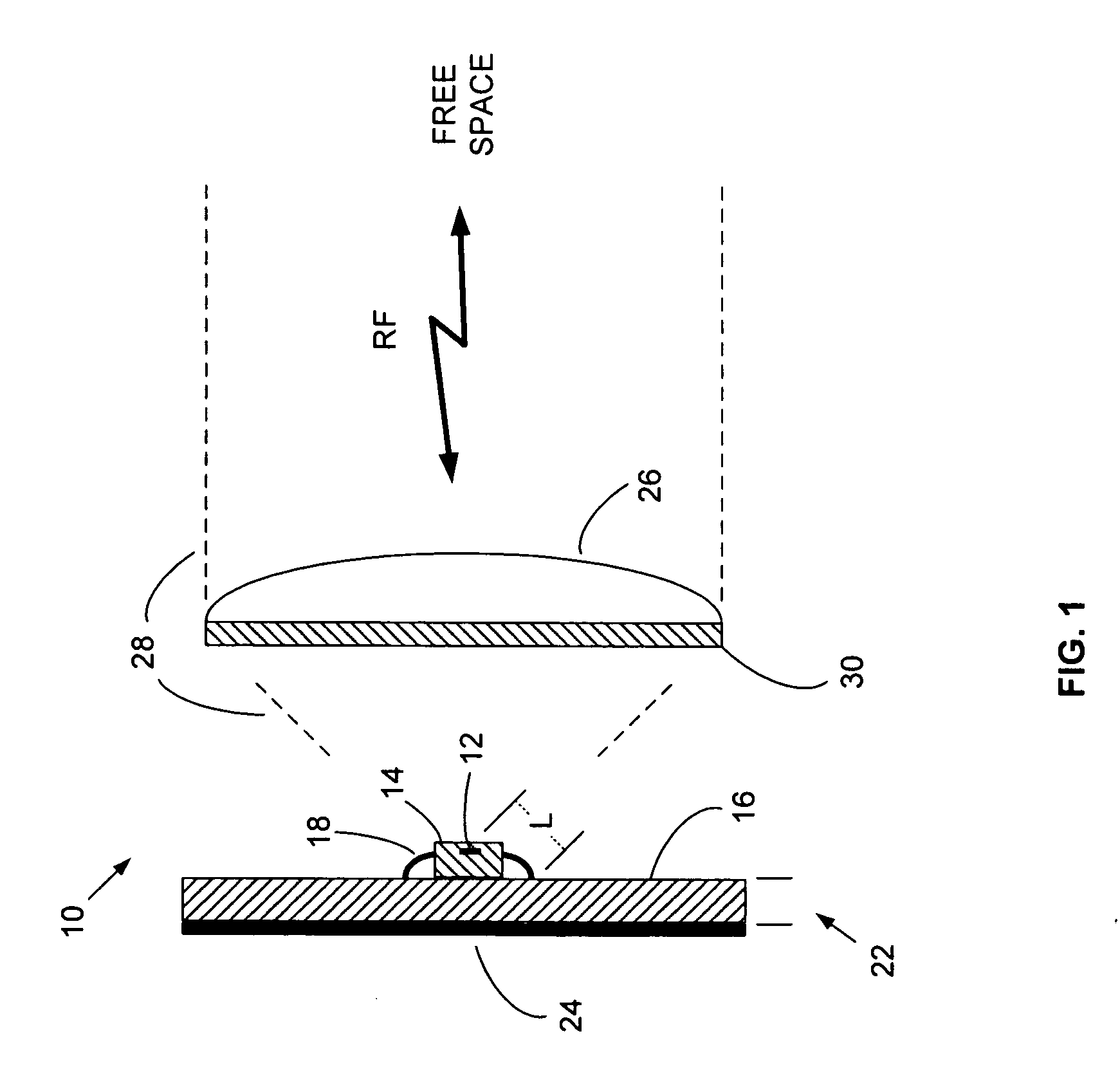

RF transceiver having a directly radiating transistor

InactiveUS7224944B2Antenna equipments with additional functionsRadio transmissionUltra-widebandTransceiver

Transistor package leads form quarter-wave antenna elements that directly radiate RF energy into free space without the need for a separate antenna. The transistor operates at a fundamental frequency and radiates a harmonic, thereby allowing radiation at frequencies normally considered “beyond cutoff” for a packaged transistor. This technique enables an additional 20 GHz of spectrum for use by surface mount technology. The transistor may be mounted on 1.6 mm thick glass-epoxy circuit board that also forms a quarter-wave reflector at 26 GHz. An optional dielectric lens produces a narrow beam and an optional planar filter rejects spurious fundamental emissions. A 26 GHz ultra-wideband (UWB) pulse-echo radar rangefinder implementation provides a low-cost upgrade to ultrasound.

Owner:MCEWAN TECH

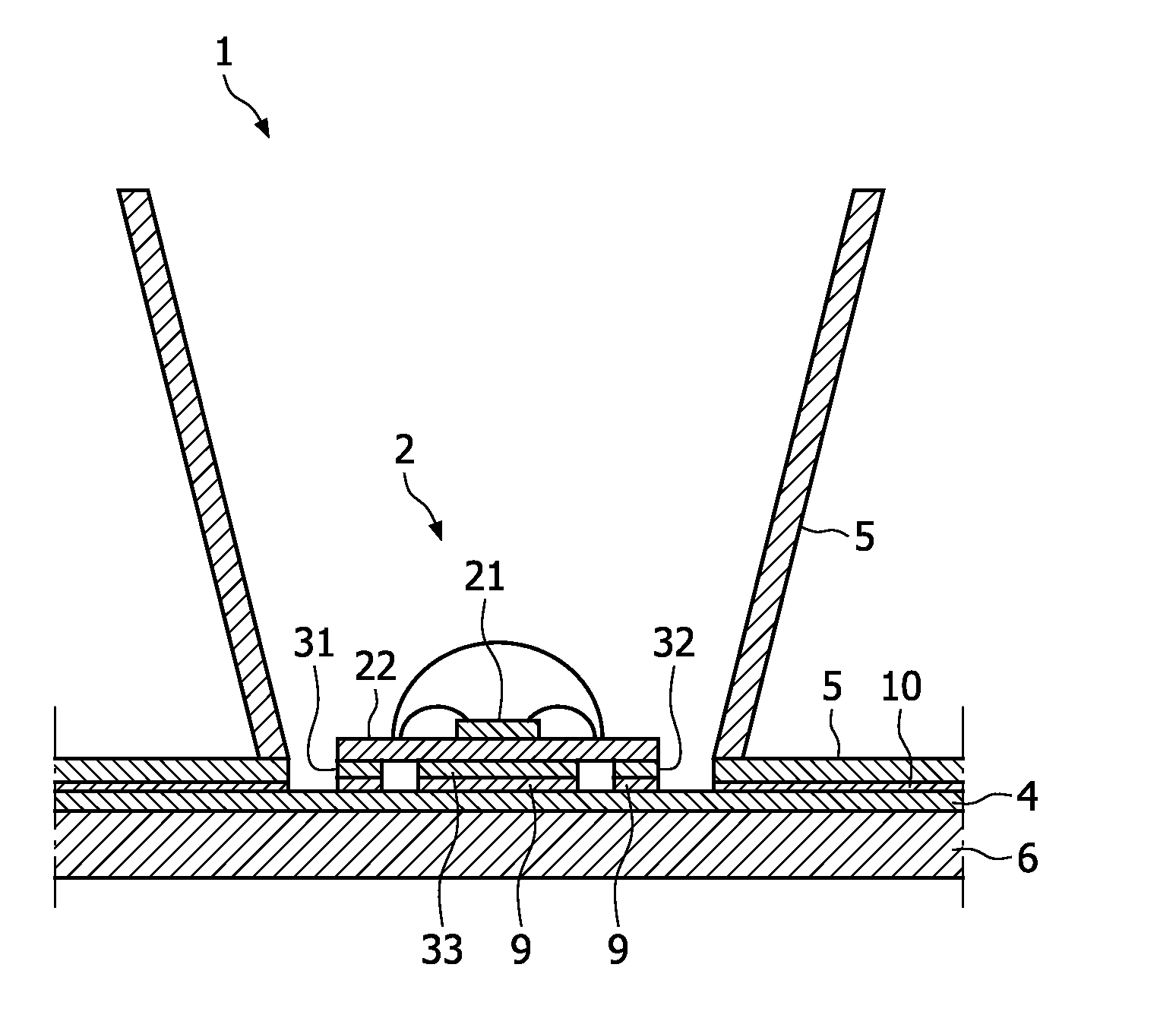

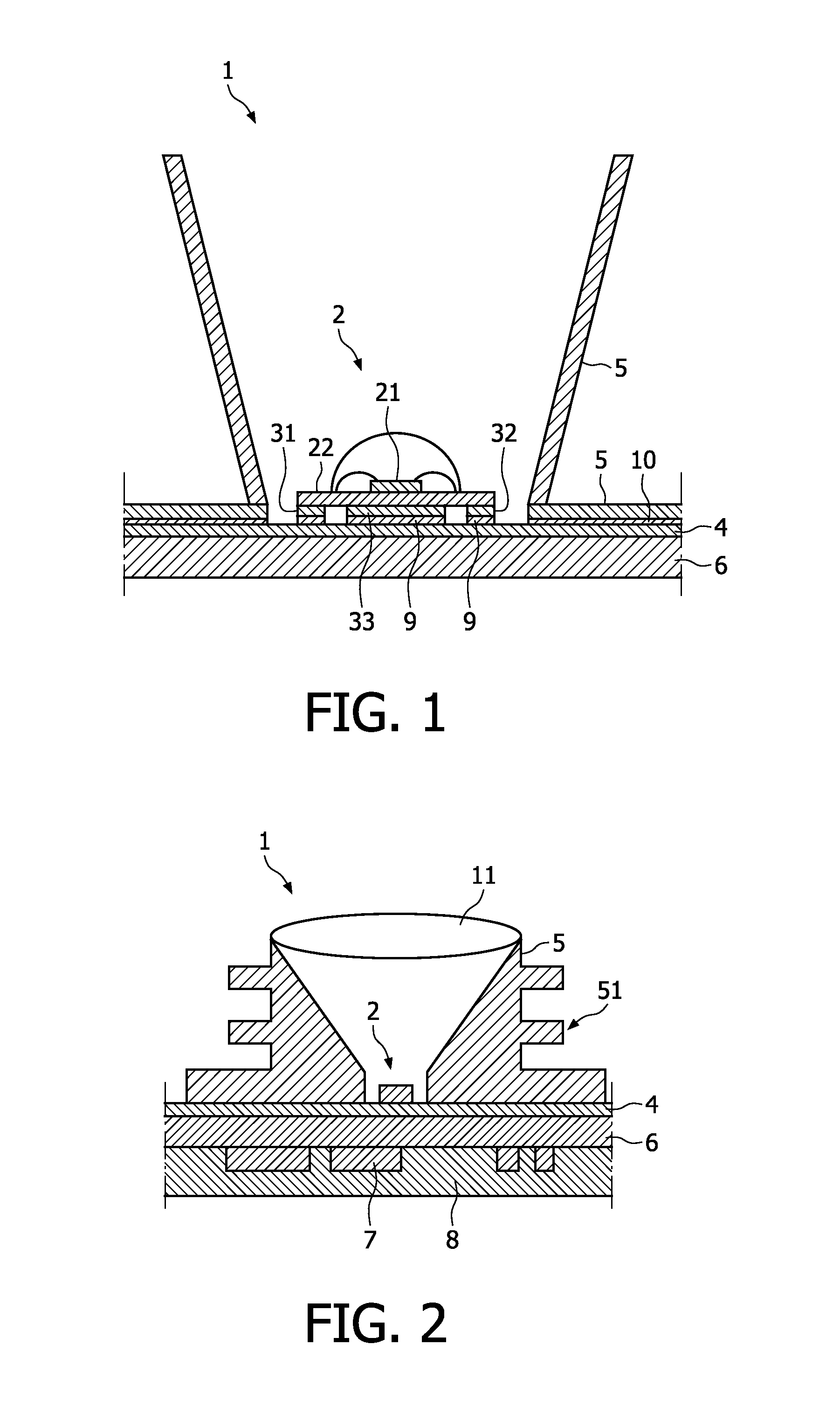

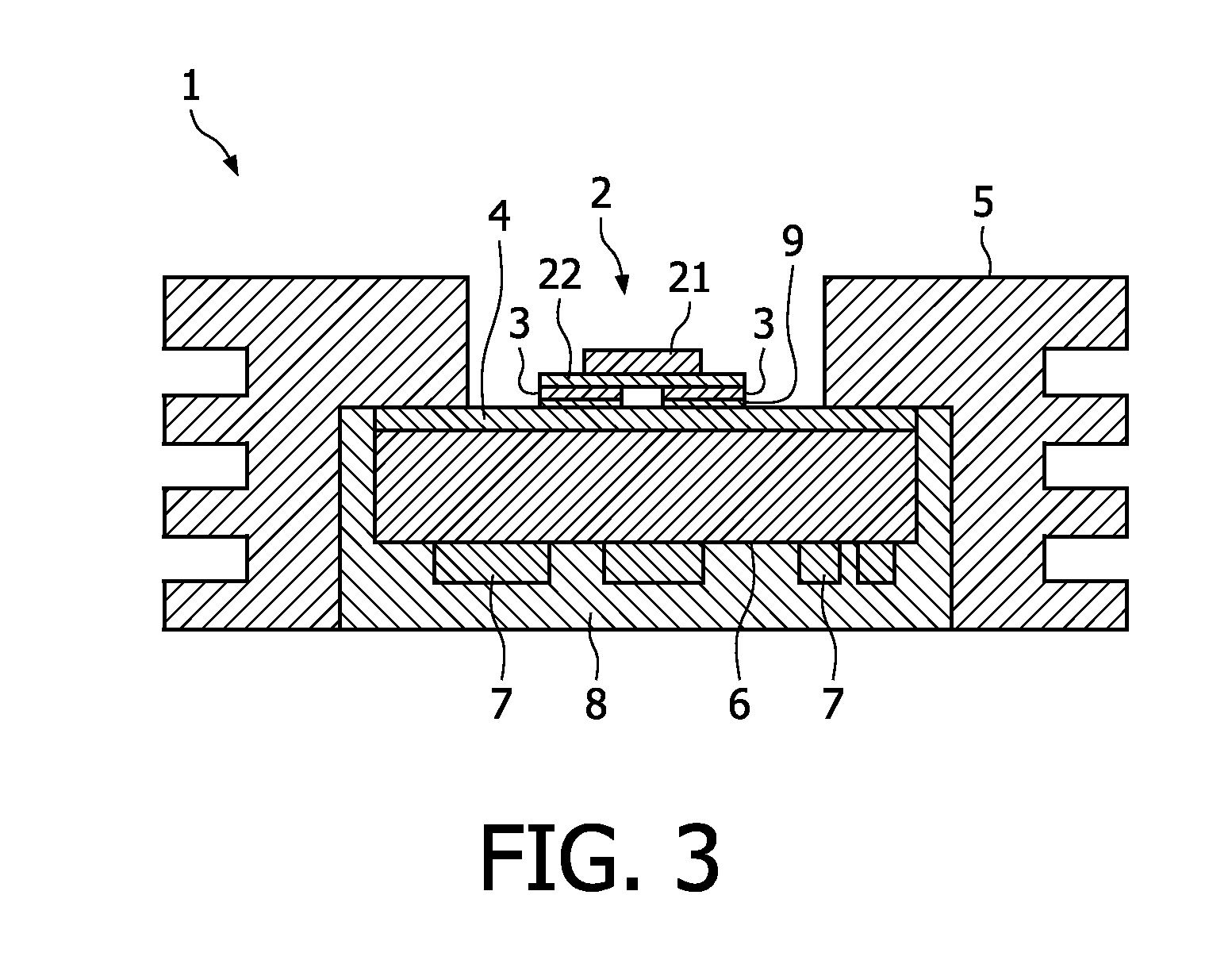

Light-emitting arrangement

InactiveUS20110180819A1Save spaceSimple manufacturing processLighting heating/cooling arrangementsPrinted circuit aspectsEngineeringLight emitting device

The invention relates to a light-emitting arrangement comprising a printed circuit board, PCB, having at least one electrically and thermally conductive portion, a light-emitting diode, LED, being thermally connected to the at least one electrically and thermally conductive portion by at least one contact of the LED, and a heat release member for dissipating heat generated by the LED, the heat release member being thermally connected to the at least one electrically and thermally conductive portion, wherein the heat generated by the LED is transferred along a heat transfer path extending from the LED via the at least one contact and the at least one electrically and thermally conductive portion to the heat release member.The light-emitting arrangement according to the invention provides greatly improved heat removal from the LED while using a low-cost glass-epoxy material for the PCB.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

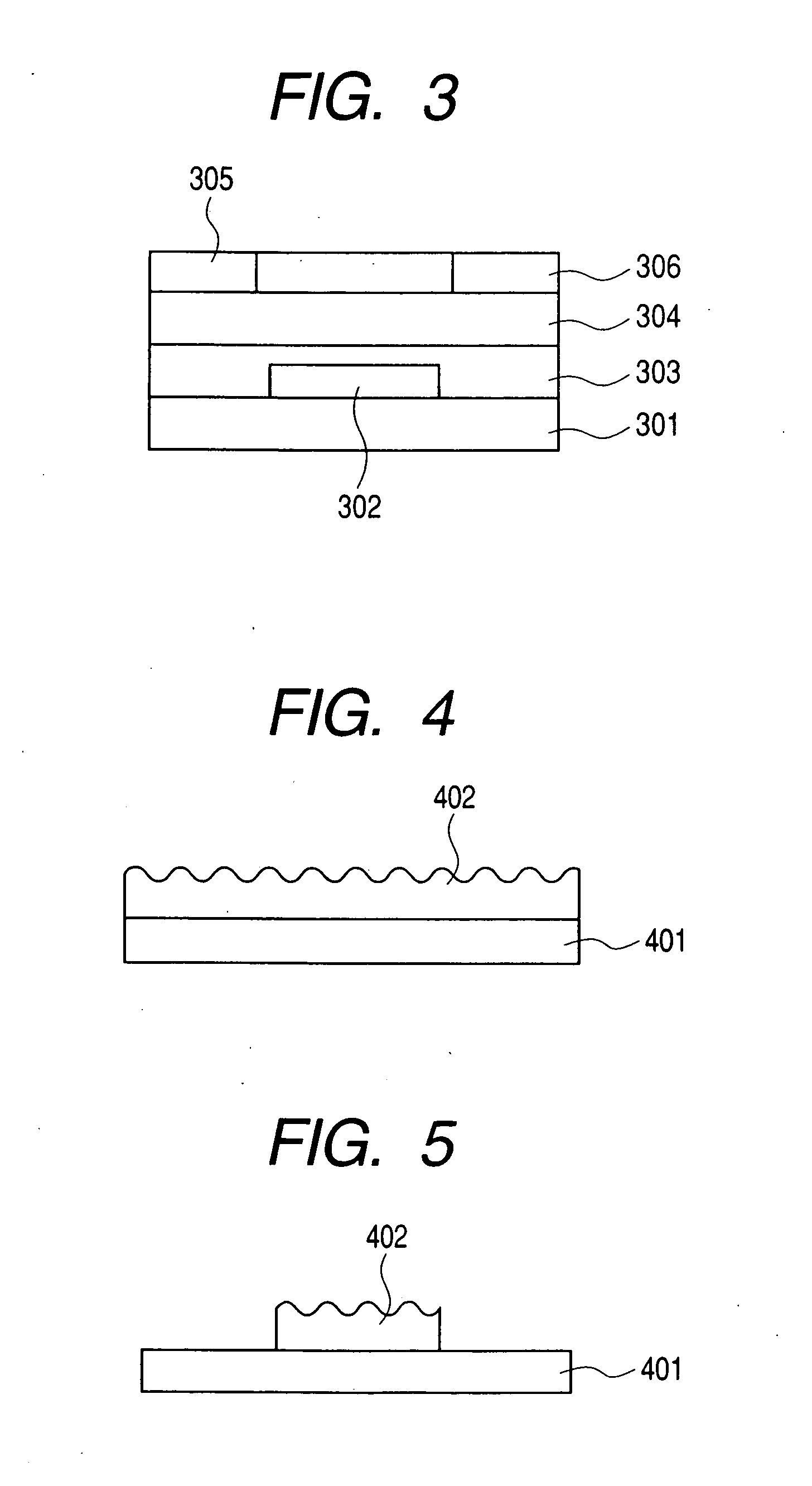

Organic thin film transistor and manufacturing method thereof

InactiveUS20060163559A1Low flatnessLow costSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmSurface roughness

There is provided an organic thin film transistor comprising: an organic substrate; a gate electrode; a gate insulating film; an organic semiconductor film; a source electrode; and a drain electrode, and in the organic thin film transistor, an average surface roughness Ra of the gate electrode which is in contact with the gate insulating film is 0.1 nm to 15 nm. The organic thin film transistor provides a stable performance characteristic even when a conductor film provided on a substrate whose shape is unstable and whose flatness is low as compared with a silicon wafer, such as a substrate made of a glass epoxy resin, is used as a gate electrode.

Owner:CANON KK

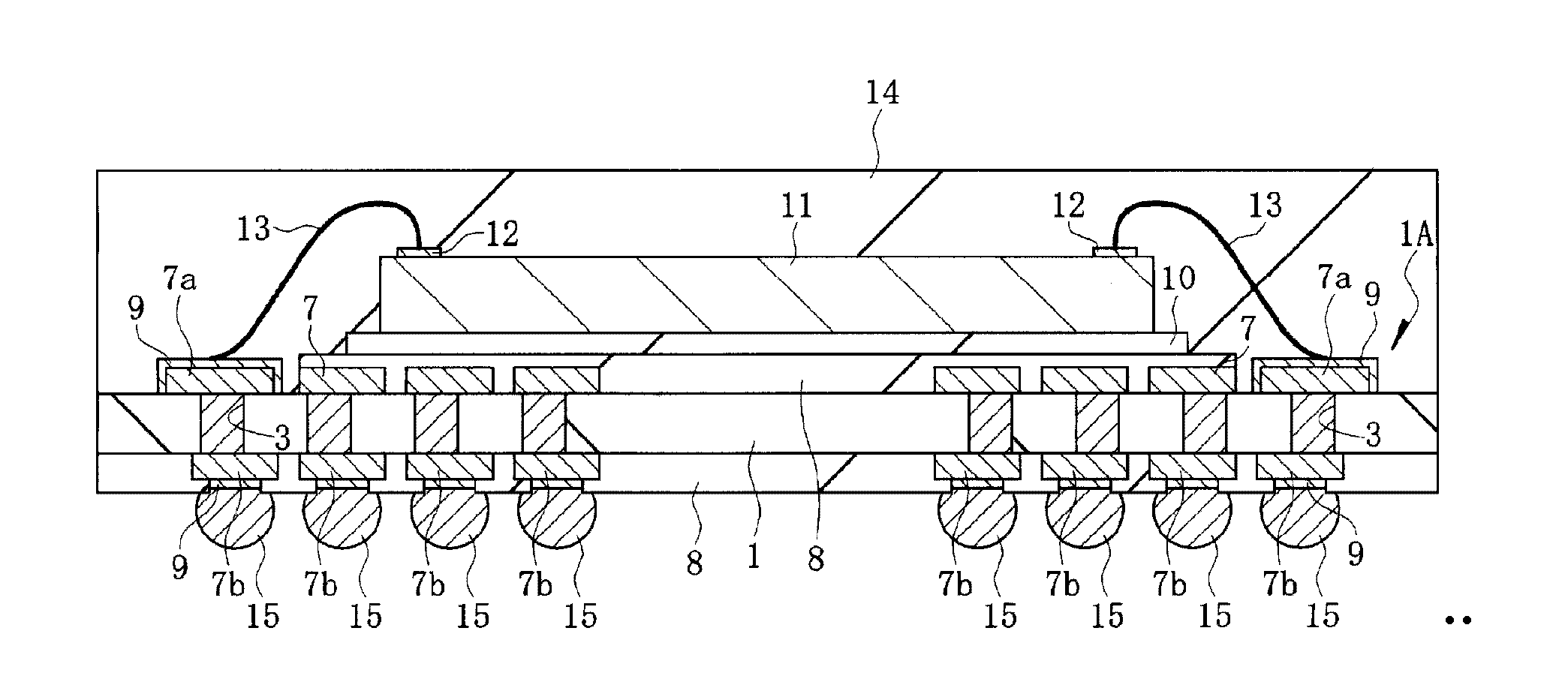

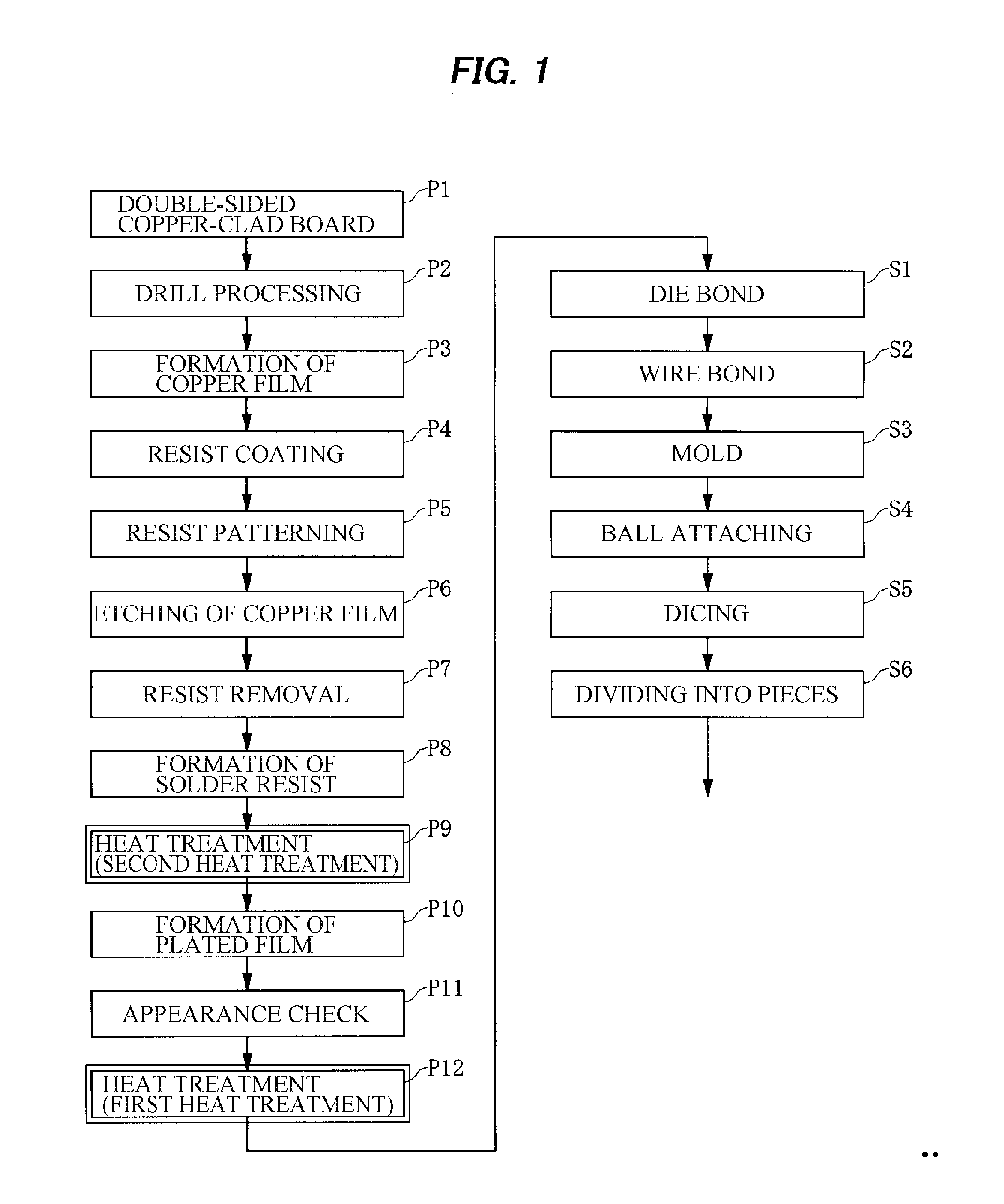

Manufacturing method of semiconductor device

InactiveUS20110201155A1Reliability is deterioratedInhibit deteriorationSemiconductor/solid-state device detailsSolid-state devicesResistOrganic solvent

To provide a technology capable of preventing the deterioration of the reliability of semiconductor devices caused by the gasification of a part of components of the material constituting a wiring substrate.A wiring layer constituting a circuit pattern is formed over each of the front and rear surfaces of a glass epoxy substrate, and after the formation of a solder resist covering the wiring layer while exposing a part of the wiring layer and prior to a heat treatment (first heat treatment) at 100° C. to 150° C. for dehumidification, a heat treatment (second heat treatment) at 160° C. to 230° C. for gasifying and discharging an organic solvent contained in the material constituting a wiring substrate is performed for the wiring substrate.

Owner:RENESAS ELECTRONICS CORP

Fabrication method of semiconductor integrated circuit device

InactiveUS20050095734A1Increase productionLow costSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsElectricityElastomer

Any damage inflicted on test pads, inter-layer insulating films, semiconductor elements or wiring at the time of electrical inspection of semiconductor integrated circuit devices is to be reduced. Reinforcements having a substantially equal linear expansion ratio (coefficient of thermal expansion) relative to a wafer to be inspected are formed over an upper face of a thin film probe, grooves are cut in the reinforcements above the probes, a first elastomer which is softer than a second elastomer is so arranged as to fill the grooves and overflow the grooves by a prescribed quantity, a glass epoxy substrate, which is a multi-layered wiring board, is fitted over the second elastomer, and pads provided over an upper face of the glass epoxy substrate and bonding pads which are part of wirings belonging to the thin film probe are electrically connected by wires.

Owner:RENESAS ELECTRONICS CORP

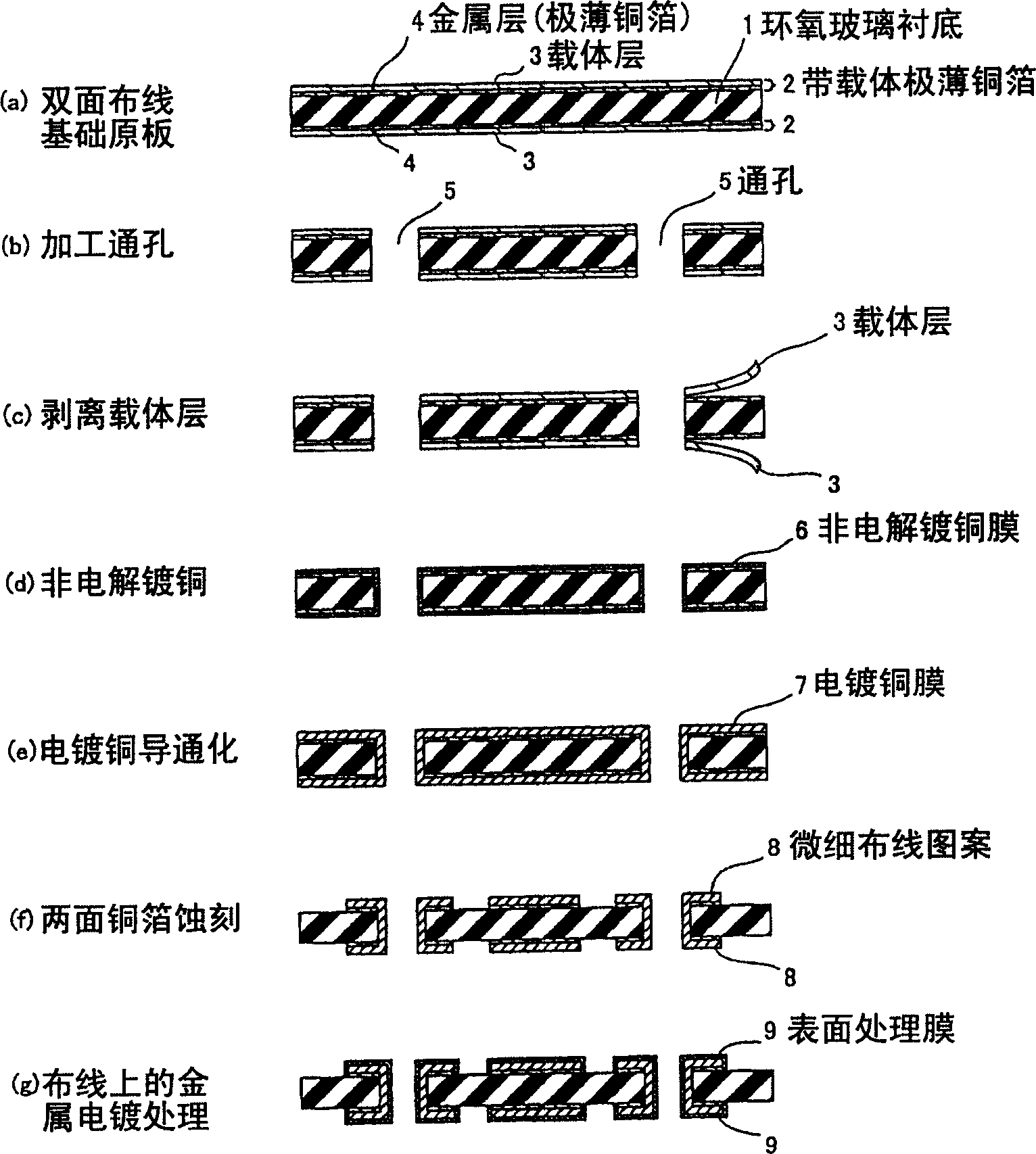

Double-sided wiring board fabrication method, double-sided wiring board, and base material therefor

InactiveCN1842254APrinted circuit aspectsSemiconductor/solid-state device manufacturingCopper platingCopper foil

Owner:HITACHI CABLE LTD

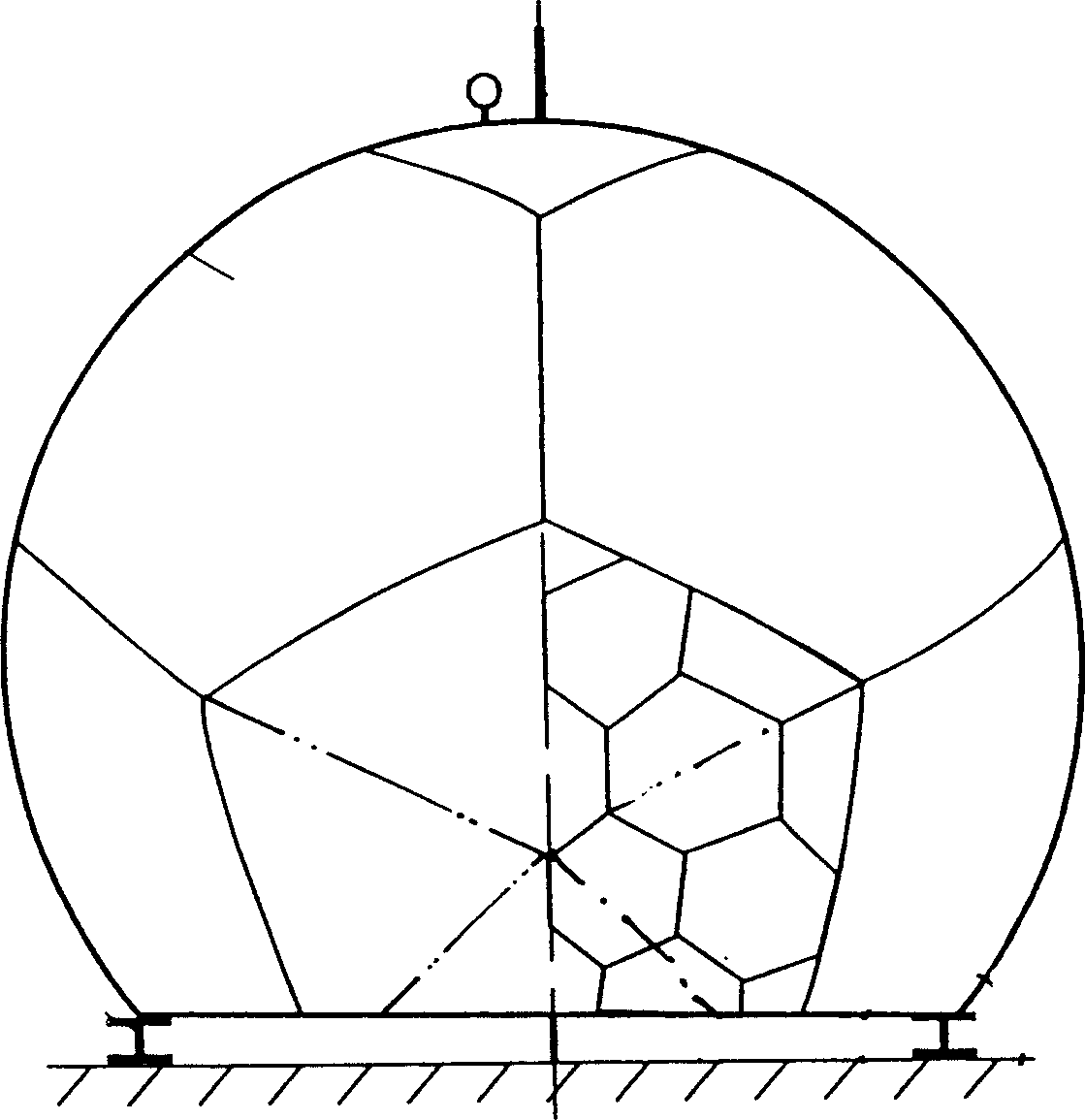

Radar dome unit piece and manufacturing process, connecting method and dividing method thereof

InactiveCN1464590AImprove electrical performanceHigh strengthRadiating element housingsRadarBlock method

The present invention provides a unicell for radar dome with waterproof resin glue covering and glass epoxy layer outer layer, glass epoxy layer as inner layer ,while froth core layer located between the inner layer and outer layer. Seam structure of peripheral of the unicell is plane overlapping edge with solid glass steel layer integrately formed with the unicell, in which stainless steel screw cap is preburied in the upper overlapping edge, and attachment hole is opened in the lower overlapping edge. The present invention further provides manufacturing technique, attaching method and partiting method for unicell. The present invention realizes blocking method without parallel for adjacent edge, improves electrical property of radom, and enhances overall strength of radom, also improves wind resistance ability and leak resistance ability.

Owner:上海之合玻璃钢有限公司

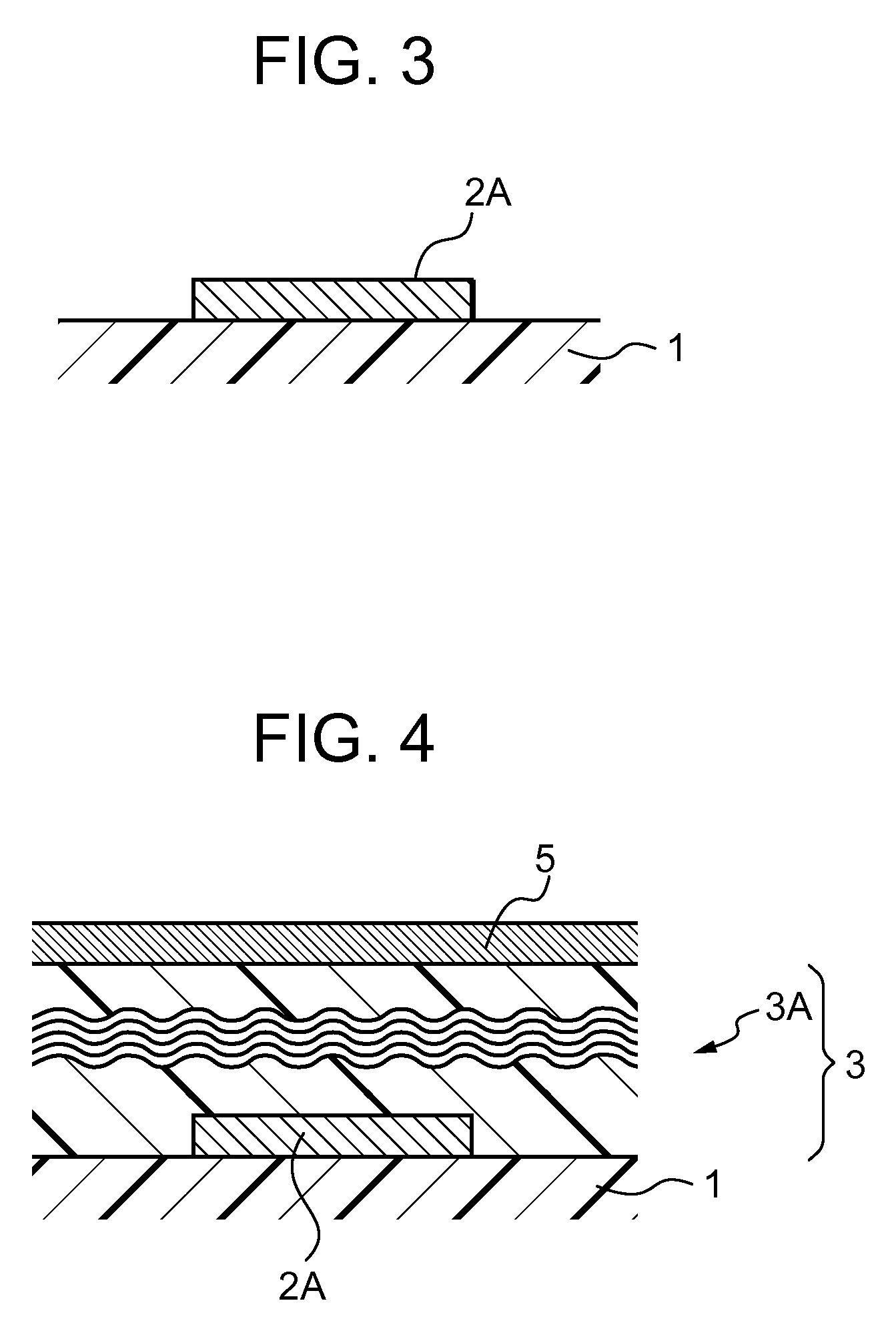

Method for fabricating electronic circuit device, semiconductor device and electronic circuit device

InactiveUS20010051396A1Printed circuit assemblingSemiconductor/solid-state device detailsSemiconductor chipEngineering

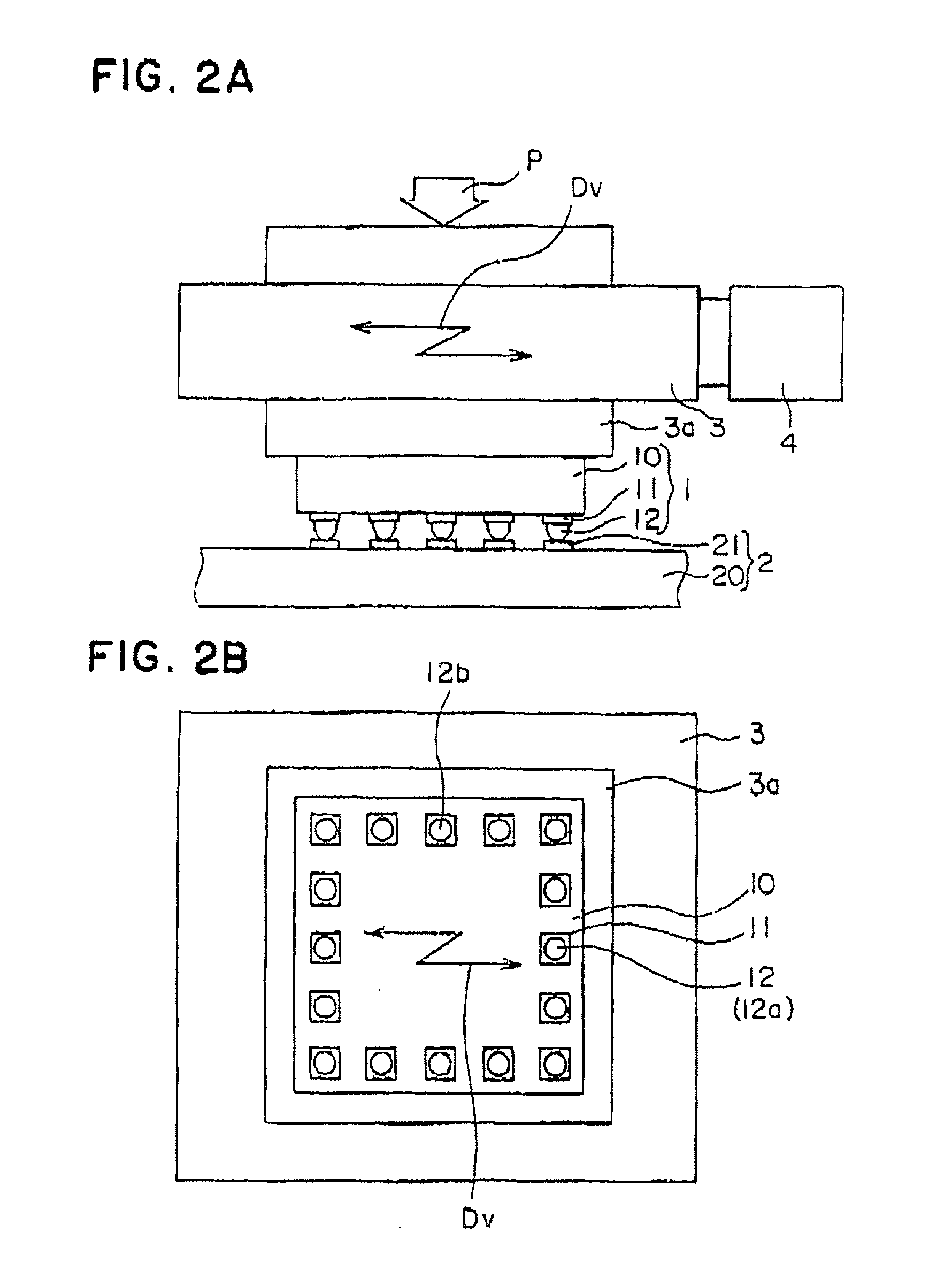

A method for fabricating an electric circuit device able to ensure bonding strength and bond bumps without occurrence of cratering or other mechanical damages The method for fabricating an electric circuit device wherein a semiconductor device having a plurality of bumps formed in an approximate polygonal shape or others on a semiconductor chip so as to be connected with the circuit pattern of a semiconductor chip is mounted on a mounting board including electrodes formed on a board made of glass-epoxy based or other materials, comprises steps of, first, aligning the bumps with the electrodes and placing the semiconductor device on the mounting board, then while pressing from the upside of the semiconductor device to make the bumps and electrodes contact closely, applying ultrasonic vibration to the semiconductor device with the application direction Dv to be the direction of a diagonal of the semiconductor chip or a direction not parallel with any side of the approximate polygon formed by the arranged bumps, and fusing the bumps and electrodes by the generated heat.

Owner:SONY CORP

RF transceiver having a directly radiating transistor

InactiveUS20050164643A1Low costAntenna equipments with additional functionsTransmission monitoringUltra-widebandTransceiver

Transistor package leads form quarter-wave antenna elements that directly radiate RF energy into free space without the need for a separate antenna. The transistor operates at a fundamental frequency and radiates a harmonic, thereby allowing radiation at frequencies normally considered “beyond cutoff” for a packaged transistor. This technique enables an additional 20 GHz of spectrum for use by surface mount technology. The transistor may be mounted on 1.6 mm thick glass-epoxy circuit board that also forms a quarter-wave reflector at 26 GHz. An optional dielectric lens produces a narrow beam and an optional planar filter rejects spurious fundamental emissions. A 26 GHz ultra-wideband (UWB) pulse-echo radar rangefinder implementation provides a low-cost upgrade to ultrasound.

Owner:MCEWAN TECH

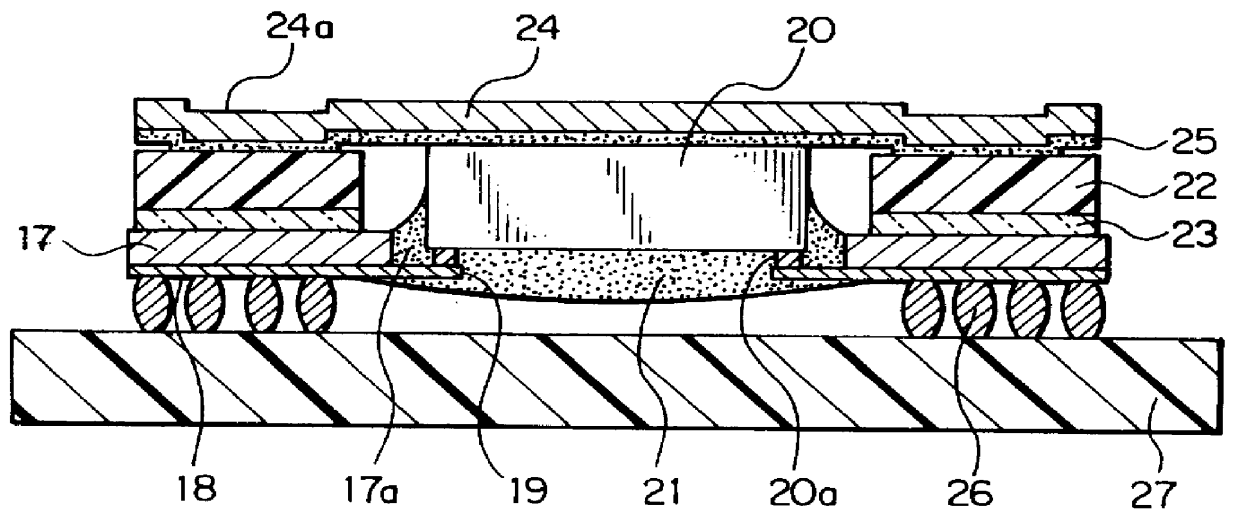

Semiconductor device and method of manufacturing the same

InactiveUS20020008311A1Low costImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesDevice materialAdhesive

A semiconductor device has a gap between a semiconductor chip mounted on a mounting plate and a glass epoxy substrate to be attached, and, at the time of resin sealing, molten resin is injected into the gap to form an adhesive layer. Thereby, the adhesive needed conventionally is not needed. In addition, by providing a metal mounting plate having excellent heat conductivity to the rear surface of the semiconductor chip, the high heat radiation effect can be obtained, thereby it can be applied to large-scale array.

Owner:NEC CORP

Liquid crystal display apparatus

ActiveUS8810521B2Reduce generationEffect on environmentCathode-ray tube indicatorsOptical light guidesLiquid-crystal displayLight guide

A plurality of LEDS used for a light source are mounted on the surface of an electromagnetic-induction touch panel in which coiled wiring is formed on a glass epoxy substrate. A dual-use touch-panel / backlight I / F FPC substrate is connected to the touch panel in order to feed power to the LEDs and to feed power and signals to the touch panel. A shield plate 7 is disposed on the reverse side of the touch panel, and a backlight light guide plate and a liquid crystal panel are disposed in the stated order on the side on which the LEDs are mounted. A liquid crystal panel I / F FPC substrate for feeding power to the liquid crystal panel is connected to the liquid crystal panel.

Owner:NEC LCD TECH CORP

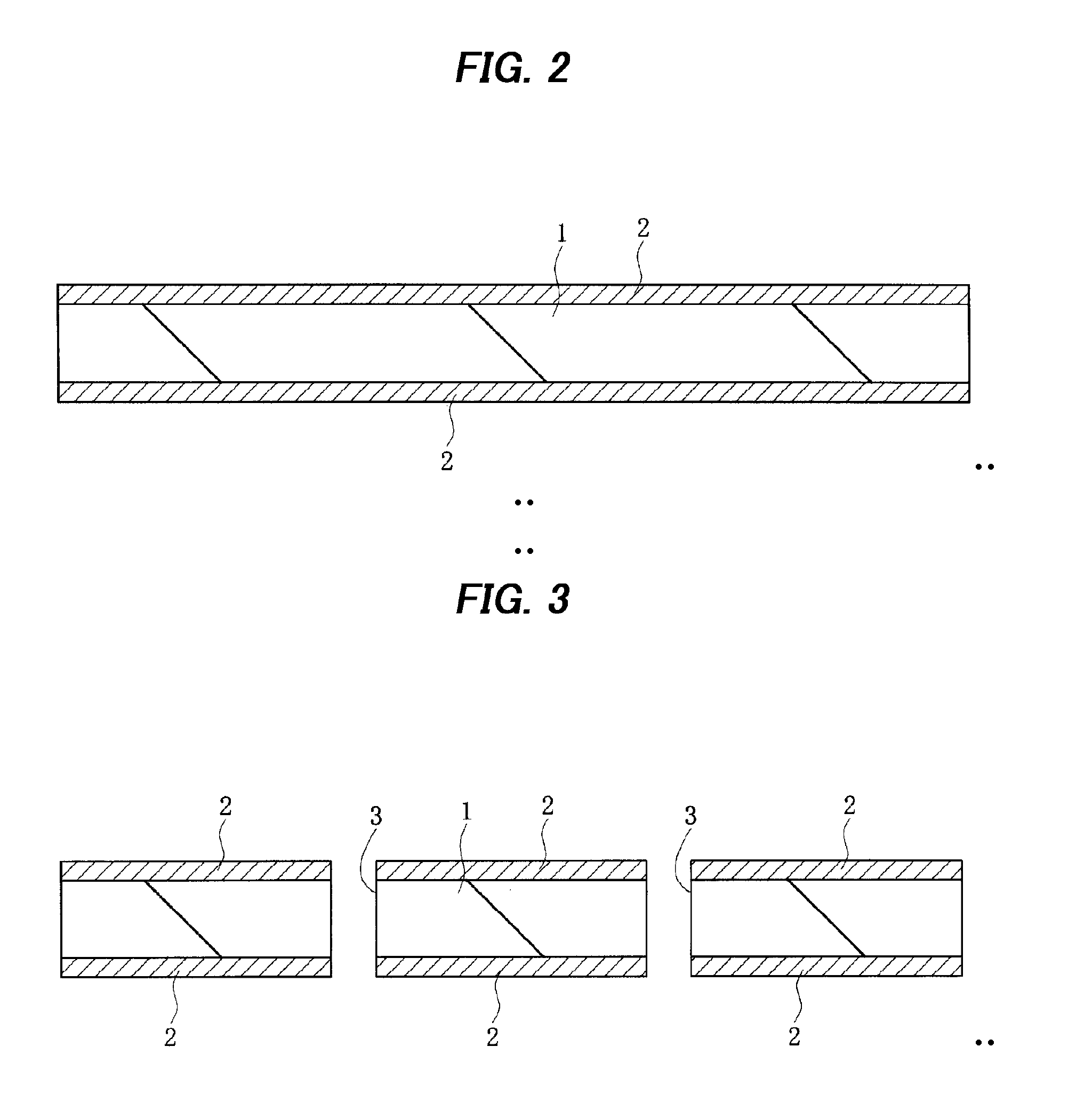

Semiconductor device and method for fabricating same

InactiveUS7109067B2Improve reliabilityAdhesive strengthPrinted circuit assemblingInsulating substrate metal adhesion improvementSolder maskFilling materials

Lands and Cu wirings are formed on surfaces of a glass epoxy substrate, and a solder mask is formed on the lands and the Cu wirings to form a chip-mounting substrate. A bottom surface of the chip-mounting substrate is made rough, and a semiconductor chip is mounted on a top surface of the chip-mounting substrate. Through holes communicating with the Cu wirings are formed on the solder mask to expose the Cu wirings. Solder balls are formed on the Cu wrings by thermal compression welding. Underfill material is injected into a clearance formed between the chip mounting substrate and a printed circuit board. Since the surface of the chip-mounting substrate is made rough, an area of a contact surface between the chip-mounting substrate and underfill material increases, hence an adhesive strength between the chip-mounting substrate and the printed circuit board is heightened.

Owner:NEC CORP

Method for manufacturing a circuit board

InactiveUS6996902B2Less variationPrinted circuit assemblingPrinted circuit aspectsIn planeHigh density

A circuit board includes an electrical insulator layer formed of a reinforcer sheet with density distribution in its in-plane direction, an electrical conductor filled in a plurality of inner via holes provided in the electrical insulator layer in its thickness direction, and a wiring layer connected to the electrical conductor. The inner via holes provided in a high-density portion of the reinforcer sheet are formed to have a smaller cross-section than the inner via holes provided in a low-density portion of the reinforcer sheet. In this manner, it is possible to provide a circuit board that can achieve a high-density wiring and an inner via connection resistance with less variation, when a base material including a reinforcer sheet with density distribution in its in-plane direction such as a glass-epoxy base material is used for an insulator layer.

Owner:PANASONIC CORP

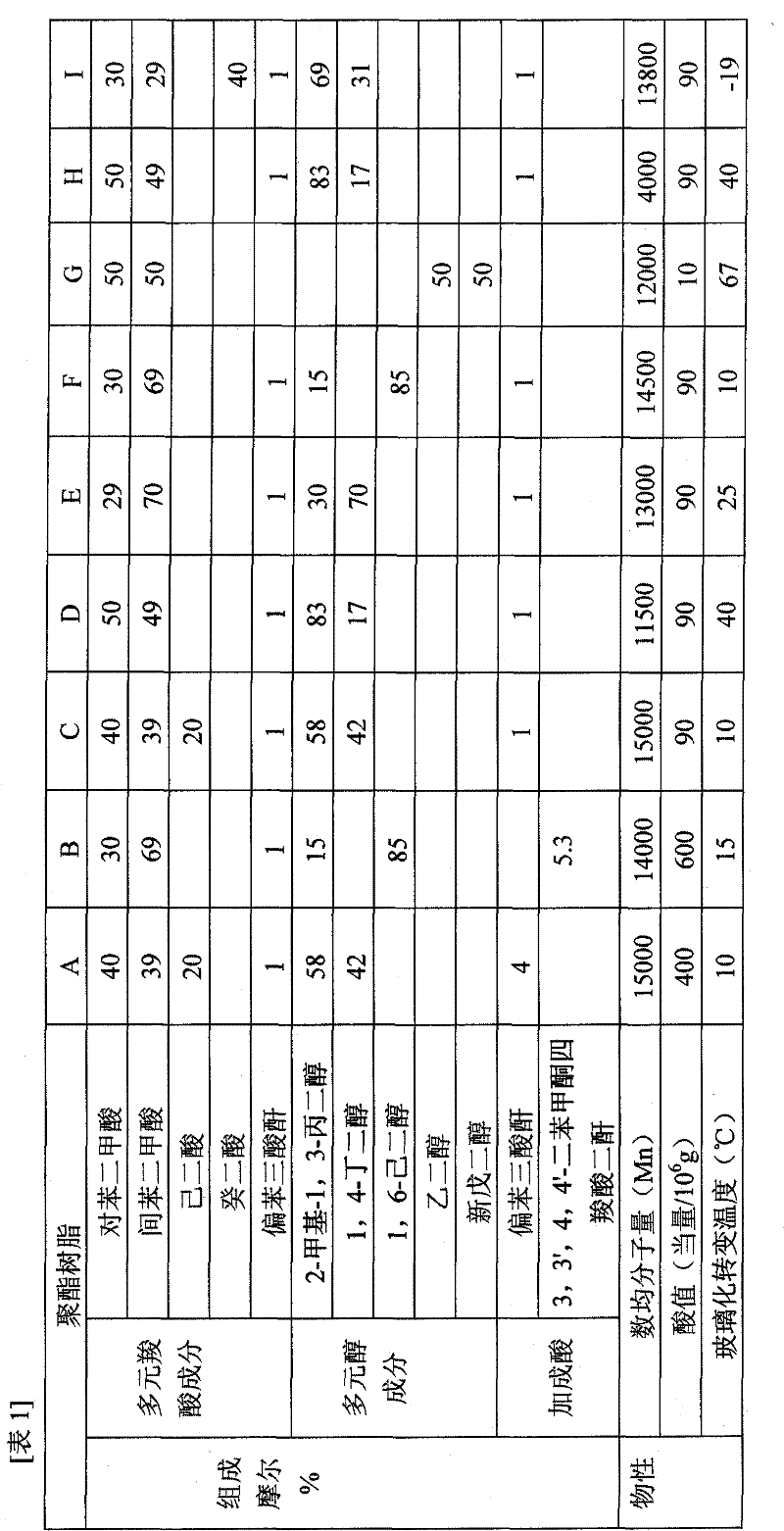

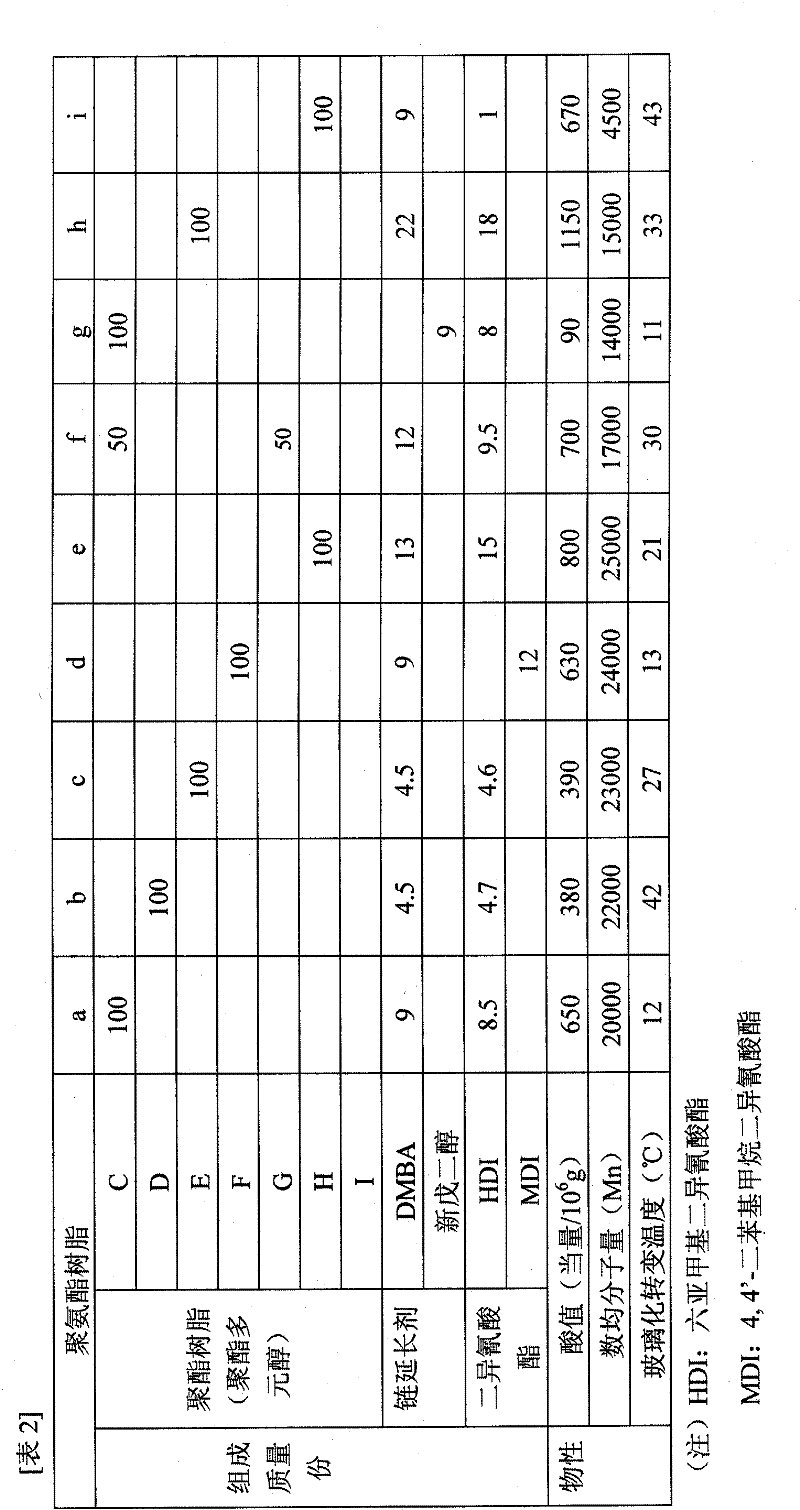

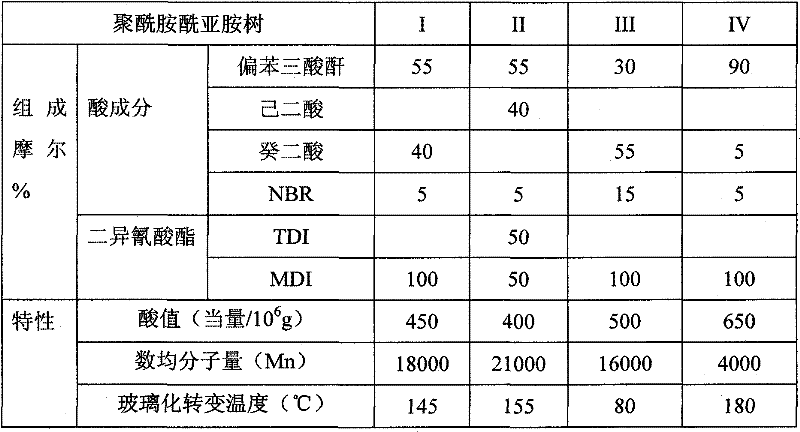

Resin composition for adhesive, adhesive containing same, adhesive sheet, and printed wiring board containing adhesive sheet as adhesive layer

ActiveCN102264855AImprove adhesionExcellent heat and humidity resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveSolvent

The present invention provides an adhesive which has a high degree of moist-heat resistance that enables the adhesive layer to withstand soldering with a lead-free solder under high-humidity conditions and which has excellent adhesiveness under high-temperature high-humidity conditions, while retaining adhesion to various plastic films, metals, and glass-epoxies. A B-stage adhesive sheet obtained from the adhesive is provided which has a satisfactory sheet life and can retain satisfactory adhesive properties even when used after having been transported under high-temperature high-humidity conditions. The resin composition for adhesives comprises a thermoplastic resin (A), an inorganic filler (B), a solvent (C), and an epoxy resin (D), wherein the thermoplastic resin (A) has an acid value and a number-average molecular weight which are in specific ranges, the epoxy resin (D) is an epoxy resin having a dicyclopentadiene skeleton, and a dispersion (a) having a specific makeup including the thermoplastic resin (A) and the inorganic filler (B) in a total amount of 25 parts by mass and in the same proportion as in the resin composition for adhesives has a thixotropic index (TI value) of 3-6 at 25 C.

Owner:TOYO TOYOBO CO LTD

Fabrication method of semiconductor integrated circuit device

InactiveUS7235413B2Increase productionLow costSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsElectricityElastomer

Any damage inflicted on test pads, inter-layer insulating films, semiconductor elements or wiring at the time of electrical inspection of semiconductor integrated circuit devices is to be reduced. Reinforcements having a substantially equal linear expansion ratio (coefficient of thermal expansion) relative to a wafer to be inspected are formed over an upper face of a thin film probe, grooves are cut in the reinforcements above the probes, a first elastomer which is softer than a second elastomer is so arranged as to fill the grooves and overflow the grooves by a prescribed quantity, a glass epoxy substrate, which is a multi-layered wiring board, is fitted over the second elastomer, and pads provided over an upper face of the glass epoxy substrate and bonding pads which are part of wirings belonging to the thin film probe are electrically connected by wires.

Owner:RENESAS ELECTRONICS CORP

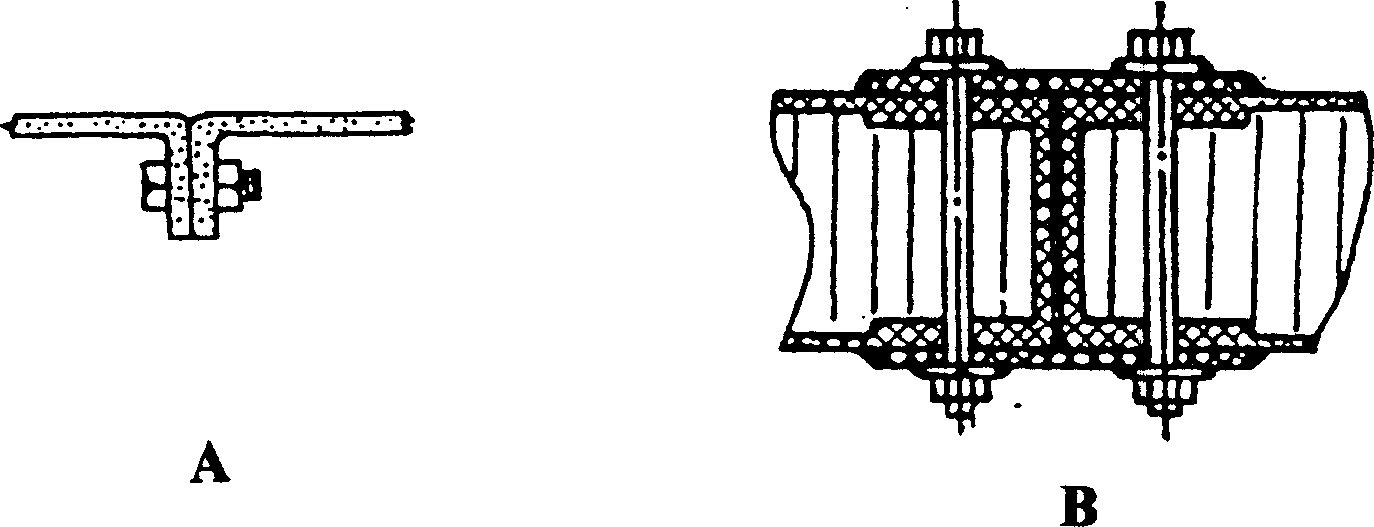

Spacer - connector stud for stacked surface laminated multichip modules and methods of manufacture

InactiveUS20030038373A1Semiconductor/solid-state device detailsSolid-state devicesHemt circuitsEngineering

A spacer-connector stud comprises a stacked array of glass epoxy laminates, each laminate having a copper layer laminated thereto. The top and bottom laminates of the stud include a spatial array of thermal contacts suitable as a footprint for C4 bump technology. A location is selected on a circuitized base card to accommodate the laminated stud. The stud has a thickness greater than twice the thickness of the components attached to the card. The thermal contacts on the stud, typically solderable, join to a wiring array on the card. A second multi-chip module card having attached and interconnected components on both sides of the second card is mechanically aligned with the based card and pressed against the contacts on the top layer of the stud to form an assembly. The assembly is heated causing the second card to become soldered to the contact footprint on the stud.

Owner:IBM CORP

Copper column and process for producing same

ActiveUS20130025917A1Avoid destructionSemiconductor/solid-state device detailsSolid-state devicesCopper wireHardness

To prevent the breakage of the joint between a ceramic substrate and a glass epoxy substrate.The copper column is formed by a wiredrawing step for drawing a copper wire formed linearly to a predetermined diameter; a cutting step for cutting the copper wire, which has been drawn in the wire drawing step, in a predetermined length; a pressing step for pressing one end of the copper wire, which has been cut in the cutting step, in a longitudinal direction to form a copper column member; and an annealing step for annealing the copper column member, which has been formed in the pressing step, by maintaining a heating period of 60 minutes or longer at 600° C. or higher. Thereby, the Vickers hardness of the copper column becomes is 55 HV or less and the copper column is softened. Therefore, when joining the ceramic substrate and the glass epoxy substrate through the copper column, heat stress caused by a difference between the thermal expansion of the ceramic substrate and the thermal expansion of the glass epoxy substrate can be absorbed by the copper member. As a result, the breakage of the joint between the ceramic substrate and the glass epoxy substrate can be prevented.

Owner:SENJU METAL IND CO LTD

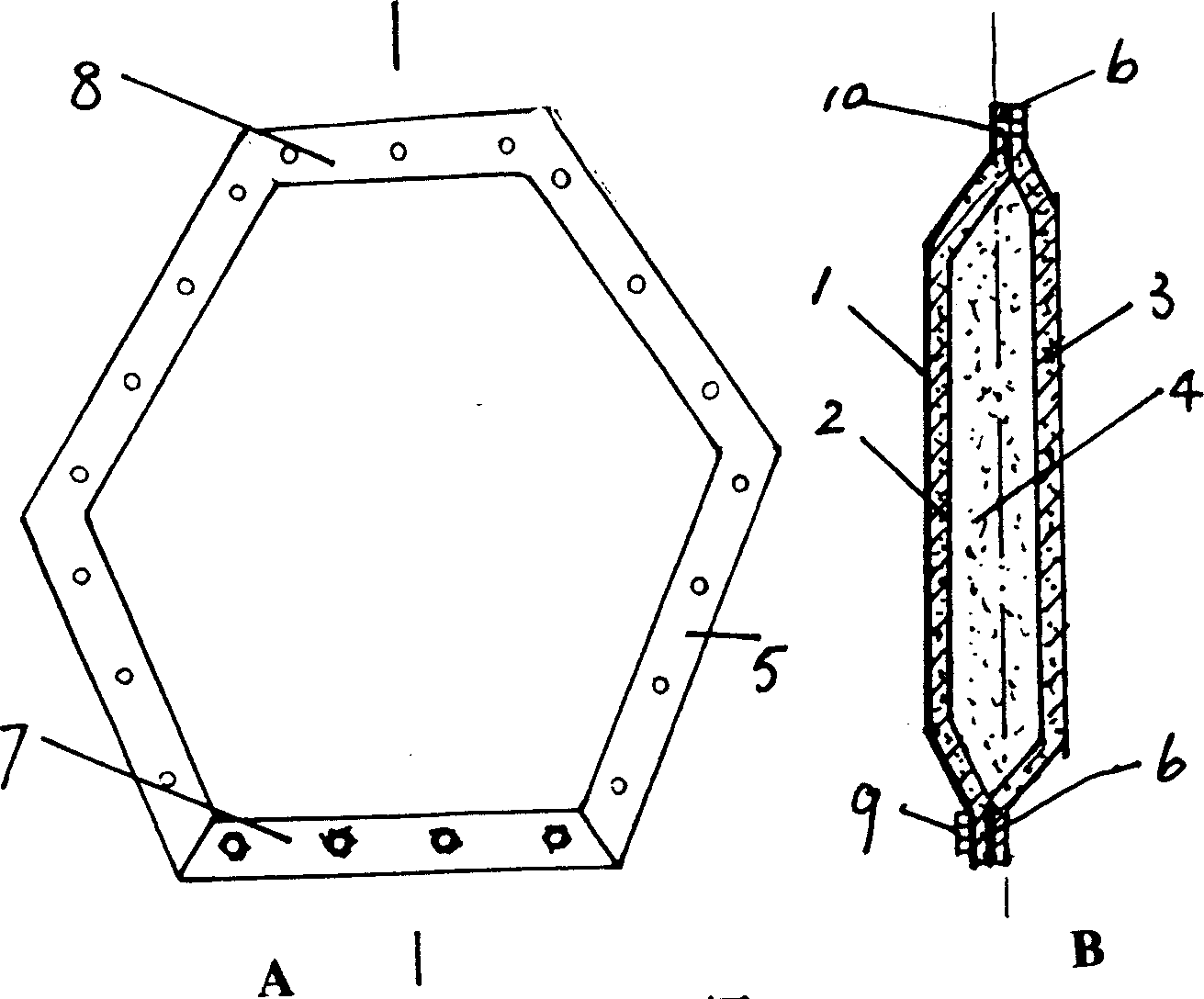

Window well

A rust-proof window well manufactured from a composite material. The window well may have integrally formed steps to assist in egress from inside the well. Walls forming the well typically are ¼ inch thick, or greater. While generally made with a spray-up process from a glass / epoxy composite, the well may be manufactured from a variety of composite materials with corresponding manufacturing techniques.

Owner:TILEY ALBIN J +2

Oscillator and electronic apparatus using the same

InactiveUS20030107444A1Printed circuit assemblingSemiconductor/solid-state device detailsDielectric lossStripline resonator

PROBLEM TO BE SOLVED: To provide a voltage controlled oscillator providing a strip line resonator in the inside layer of a multilayer substrate and less in the dispersion of oscillation frequency by humidity. SOLUTION: Polytetrafluoroethylene is used as the core material of the multilayer substrate. Since the polytetrafluoroethylene has smaller water absorptivity than glass epoxy, the change of dielectricity to the change of humidity. As a result, also the change of the resonant frequency of the strip line resonator formed in the inside layer of the multilayer substrate is small, as a result, also the change of oscillation frequency becomes small. Then, since the change of the oscillation frequency is small, control voltage sensitivity can be reduced, and thus, C / N characteristics is improved. Then, since also the property of the polytetrafluoroethylene material itself is small in dielectric loss comparing with the glass epoxy and also specific dielectricity is small, the Q of resonant system is improved, and thereby, the C / N characteristics is improved too.

Owner:MURATA MFG CO LTD

Spacer - connector stud for stacked surface laminated multichip modules and methods of manufacture

InactiveUS6537852B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringThermal contact

A spacer-connector stud comprises a stacked array of glass epoxy laminates, each laminate having a copper layer laminated thereto. The top and bottom laminates of the stud include a spatial array of thermal contacts suitable as a footprint for C4 bump technology. A location is selected on a circuitized base card to accommodate the laminated stud. The stud has a thickness greater than twice the thickness of the components attached to the card. The thermal contacts on the stud, typically solderable, join to a wiring array on the card. A second multi-chip module card having attached and interconnected components on both sides of the second card is mechanically aligned with the based card and pressed against the contacts on the top layer of the stud to form an assembly. The assembly is heated causing the second card to become soldered to the contact footprint on the stud.

Owner:INT BUSINESS MASCH CORP

Liquid crystal display apparatus

ActiveUS20070030242A1Increase the number ofLow costStatic indicating devicesOptical light guidesLiquid-crystal displayLight guide

A plurality of LEDS used for a light source are mounted on the surface of an electromagnetic-induction touch panel in which coiled wiring is formed on a glass epoxy substrate. A dual-use touch-panel / backlight I / F FPC substrate is connected to the touch panel in order to feed power to the LEDs and to feed power and signals to the touch panel. A shield plate 7 is disposed on the reverse side of the touch panel, and a backlight light guide plate and a liquid crystal panel are disposed in the stated order on the side on which the LEDs are mounted. A liquid crystal panel I / F FPC substrate for feeding power to the liquid crystal panel is connected to the liquid crystal panel.

Owner:NEC LCD TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com