Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Avoid burrs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

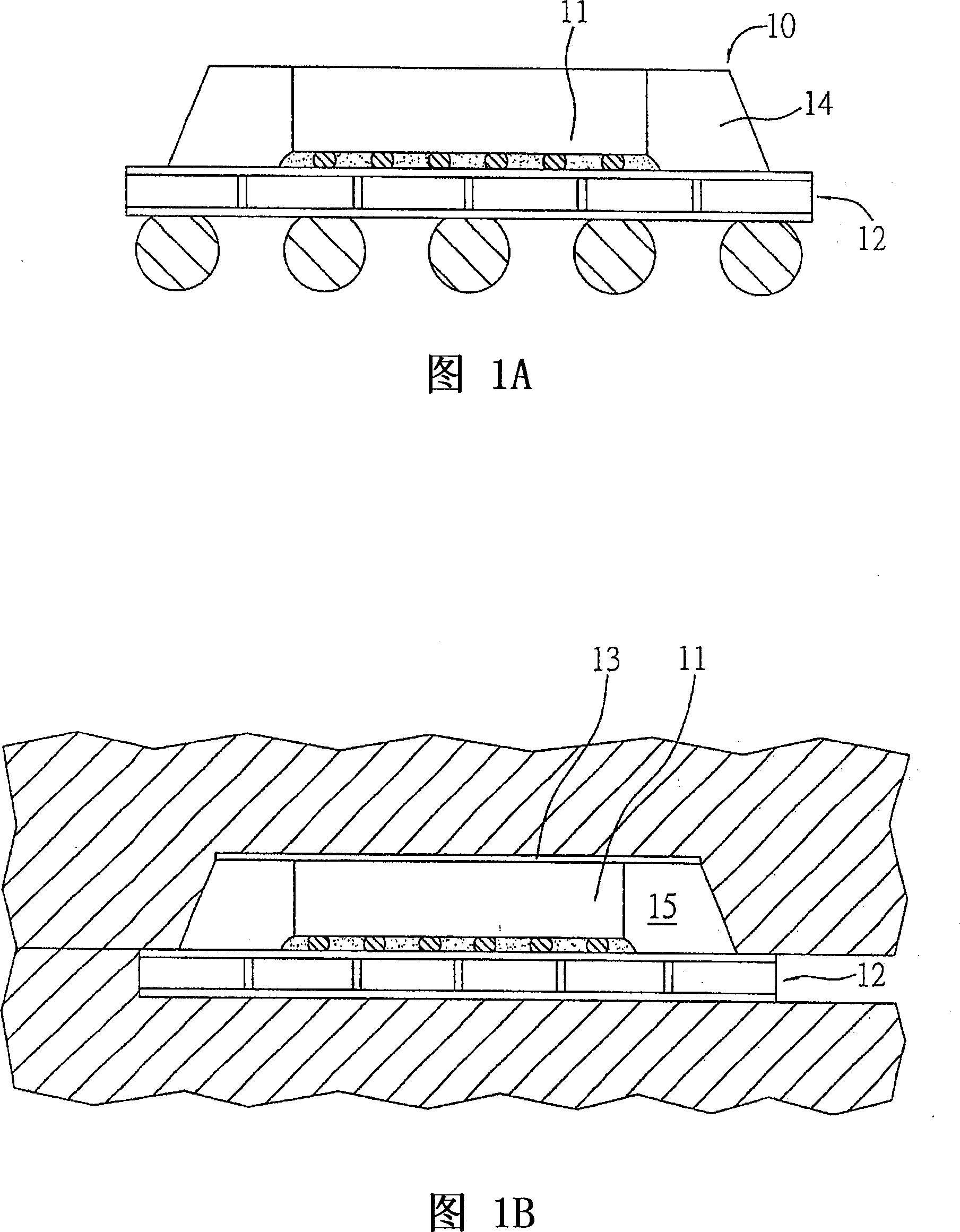

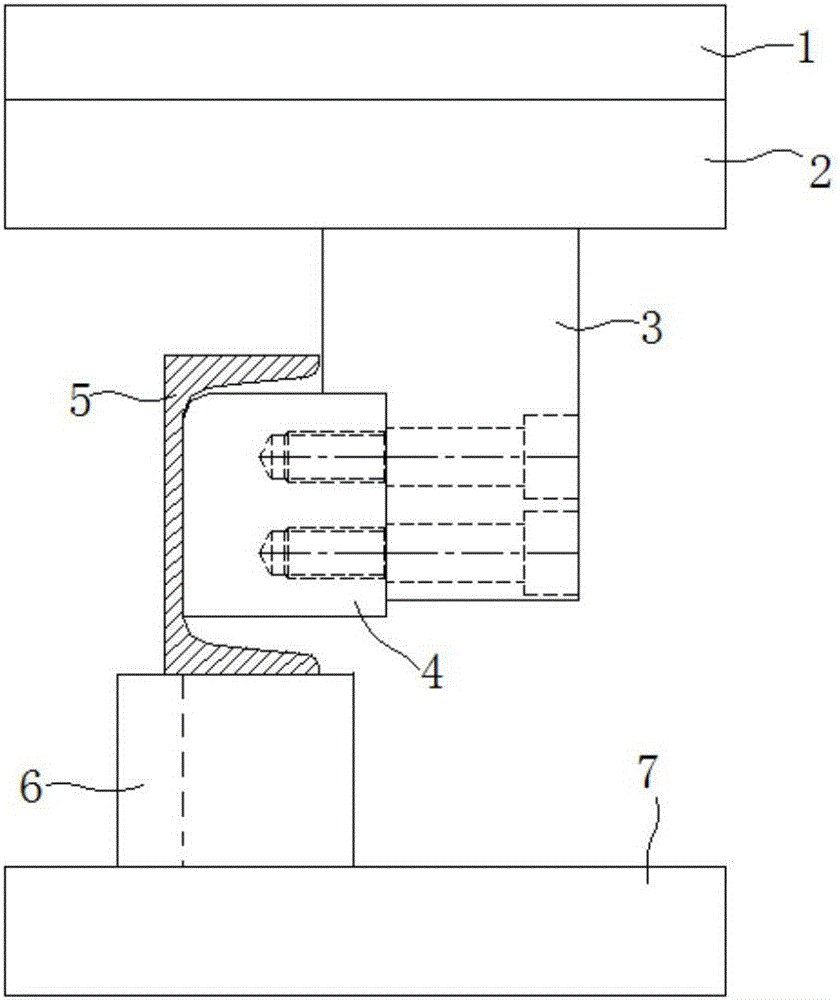

Heat-radiation type package structure and its method for making

InactiveCN101101880AAvoid pressure lossAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention is concerned with the thermolysis packaging structure and the making method, it is: attaches the semiconductor chip with the chip carrying piece by electricity to form the surface or the second heat sink with surface, and attaches the first heat sink with thermolysis part that is opposites the open whole of the semiconductor chip and the support part, with the chip carrying piece, next, is forms the surface or the second heat sink with surface that covers the semiconductor chip and the packaging colloid of the first heat sink, and there is must certain space leaves for the packaging colloid covering the surface, which is the way of preventing the problems of pressure damage and glue overflow of the current making method, and to the next step is incises the packaging colloid follows the surface edge and removes the unwanted, losses heat for the semiconductor chip, in order to prevent the problems of raw edge and tools wastage, which reduces the cost efficiently.

Owner:SILICONWARE PRECISION IND CO LTD

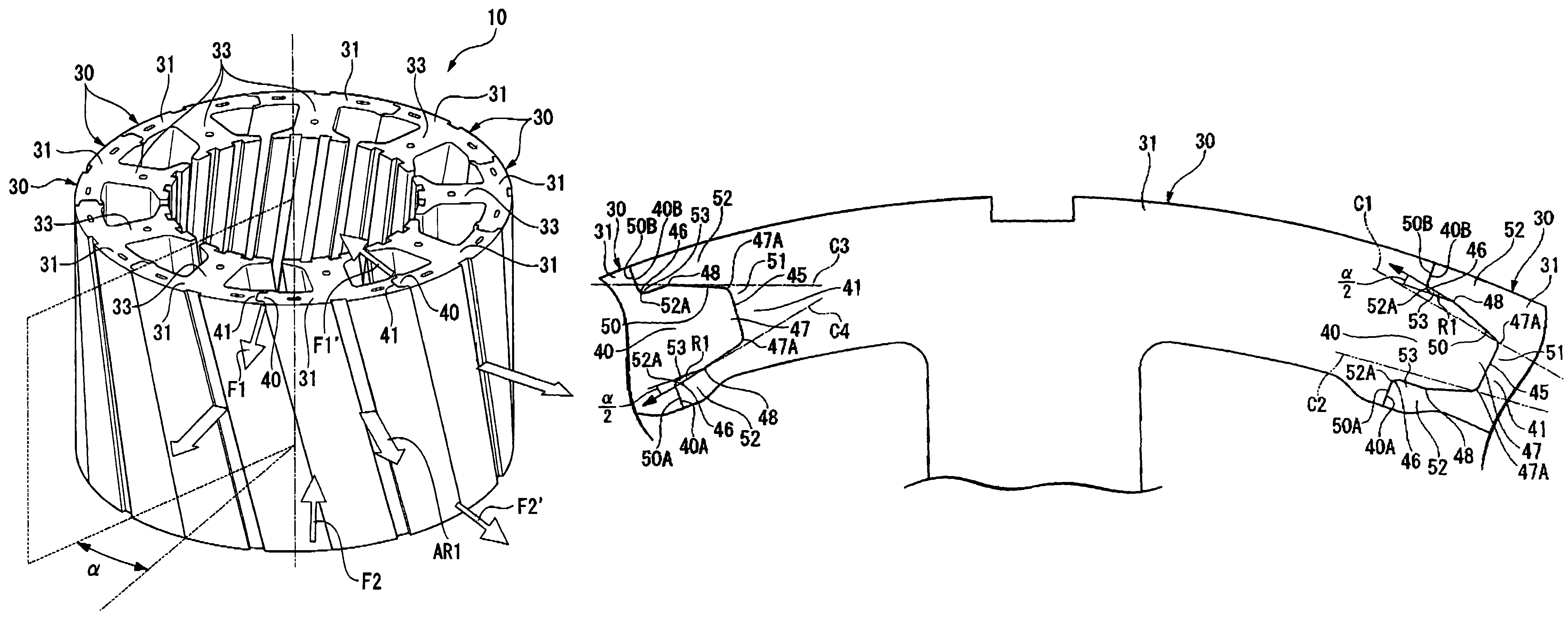

Motor, rotary electric machine and its stator, and method for manufacturing the stator

ActiveUS7595578B2Easy to assembleOptimize connection structureElectrical transducersMagnetic circuit stationary partsElectric machineEngineering

Owner:MITSUBA CORP

Method for mending excessive polishing of die cavity edge of shot-off forming master die cavity

The invention relates to a manufacturing method of the master die cavity which is used to shoot up forming die. It can prevent the edge of the die cavity from over buffing. An auxiliary gripper is utilized to protect the master die cavity while buffing. The auxiliary gripper has a center hole, and its shape is corresponded to the edge of the die cavity. The manufacturing method includes the following steps that the corresponding fixed structure and location structure are forming at a die cavity rough blank and auxiliary gripper. The auxiliary gripper is located at the die cavity rough blank by the location structure. And the relative relation of the auxiliary gripper and the die cavity rough blank is kept in constant by the fixed structure. The composite unit formed by the auxiliary gripper and the die cavity rough blank is practiced electro discharge machining programming by an electrode. The required master die cavity is made in the concave center of the die cavity. The composite unit is practiced buffing programming. Then the fixed structure is loosened. The auxiliary gripper is moved away from the master die cavity, so that the intact and satisfactory master die cavity is gained to practice the subsequent programming to shoot up the forming die.

Owner:BENQ CORP

Take-up structure with anti-winding effect for textile operation

The invention discloses a take-up structure with an anti-winding effect for textile operation, and belongs to the technical field of textile assistive devices. The take-up structure comprises a rack,one side of the rack is movably connected with a winding mechanism, one side of the winding mechanism is provided with a clamping mechanism, and the top of the winding mechanism is movably connected with the rack through a lifting mechanism; and the top of one side of the rack is fixedly connected with a wire arranging mechanism, the winding mechanism comprises a first motor, and an output shaft of the first motor is fixedly connected with a first rotating shaft. According to the take-up structure, by the arrangement of the winding mechanism and the wire arranging mechanism, wire harnesses canbe effectively prevented from being wound with one another during winding, the multiple wire harnesses can be taken up at the same time, the separation effect during simultaneous winding of the multiple wire harnesses can be guaranteed through a baffle connected to the outer wall of a winding drum, and burrs of the wire harnesses during pulling can be avoided through a smooth guide sleeve; and the winding efficiency is remarkably improved while winding of thread bodies is avoided, and the requirement for adapting to the textile operation is met.

Owner:青岛富思特纺织股份有限公司

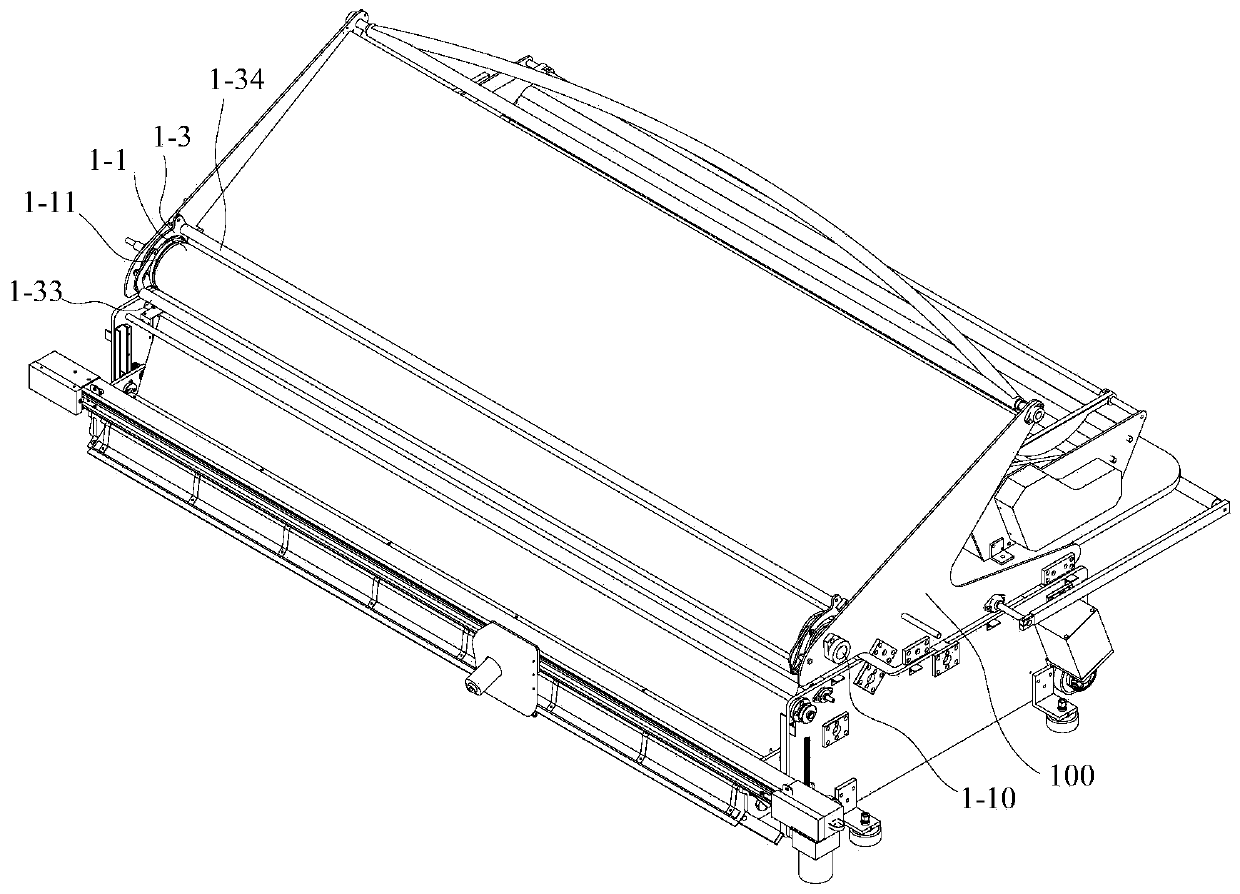

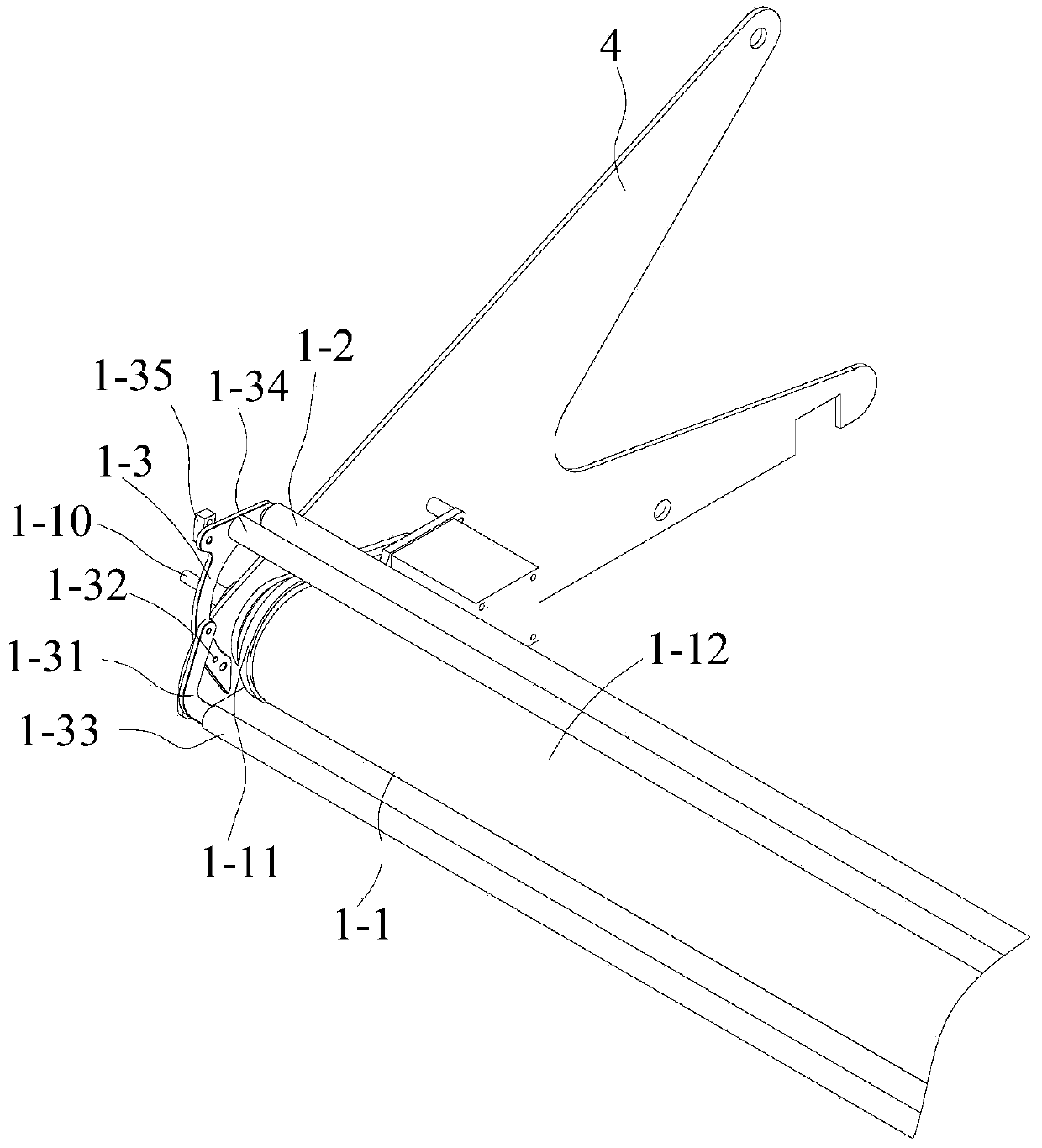

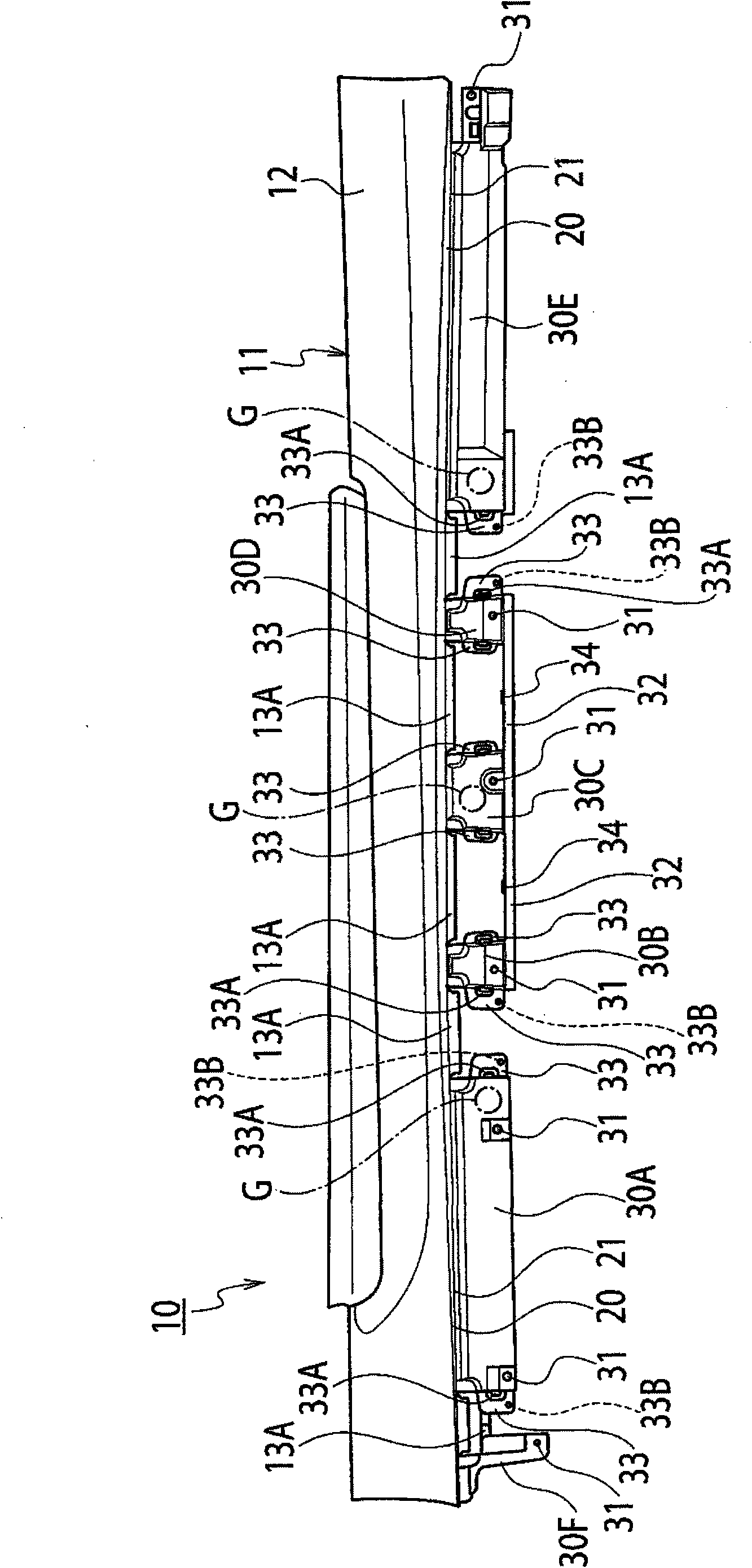

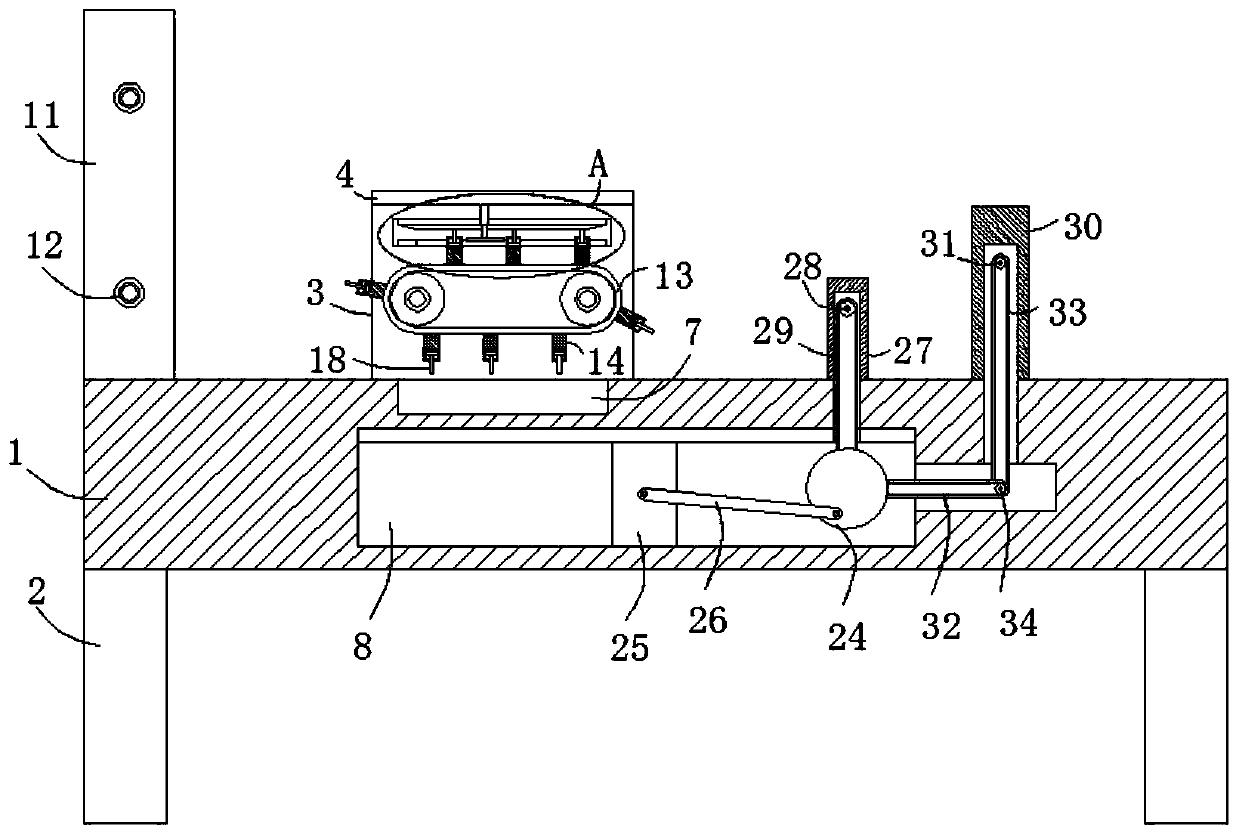

Cloth paving machine

ActiveCN104192632AFully compactedUniform tensionUnfolding thin materialsArticle deliveryAutomotive engineering

The invention discloses a cloth paving machine which comprises a cloth paving machine cloth pressing and conveying device, a cloth paving machine wind shielding device and a cloth paving machine cutting device. The cloth paving machine cloth pressing and conveying device comprises a conveying roller and a pressing roller. The cloth paving machine wind shielding device comprises a wind shielding film, a wind shielding film first roller and a wind shielding film second roller. The cloth paving machine cutting device comprises an output roller, a cloth falling plate, a horizontal moving mechanism and a cutter assembly. The cloth paving machine has the advantages of being capable of comprehensively improving all the performance of the cloth paving machine.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

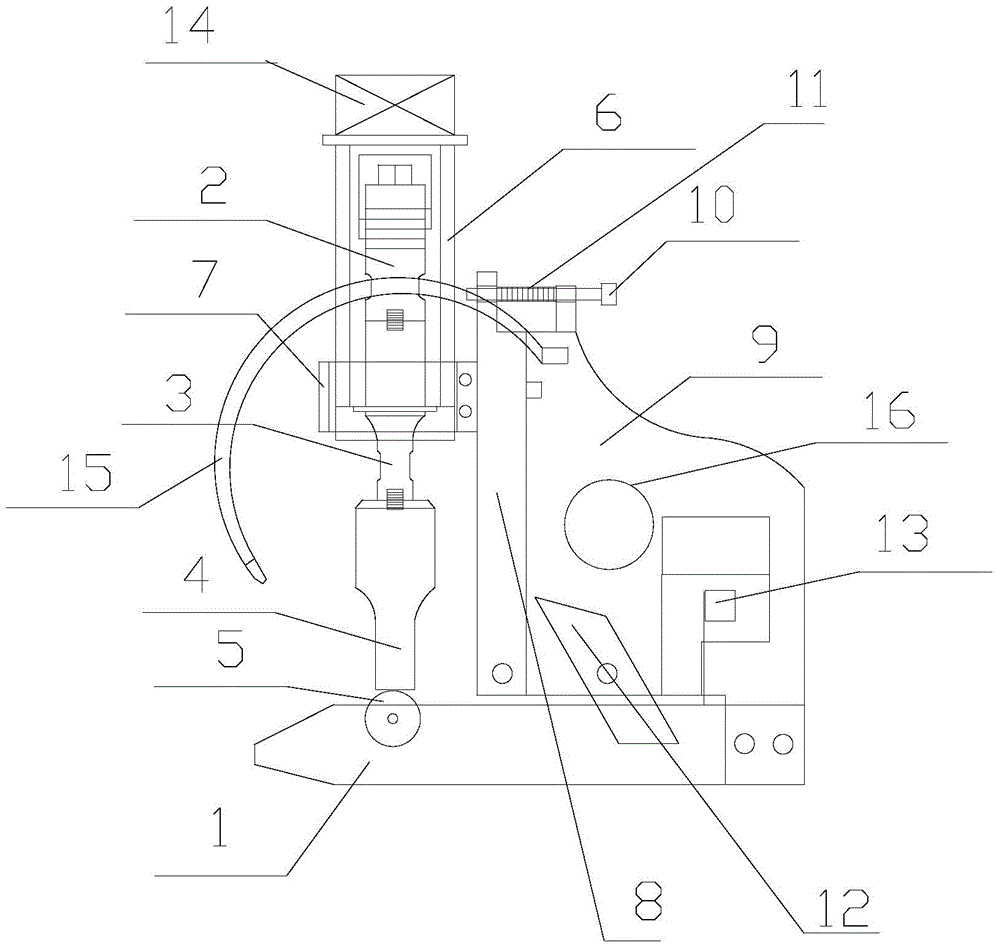

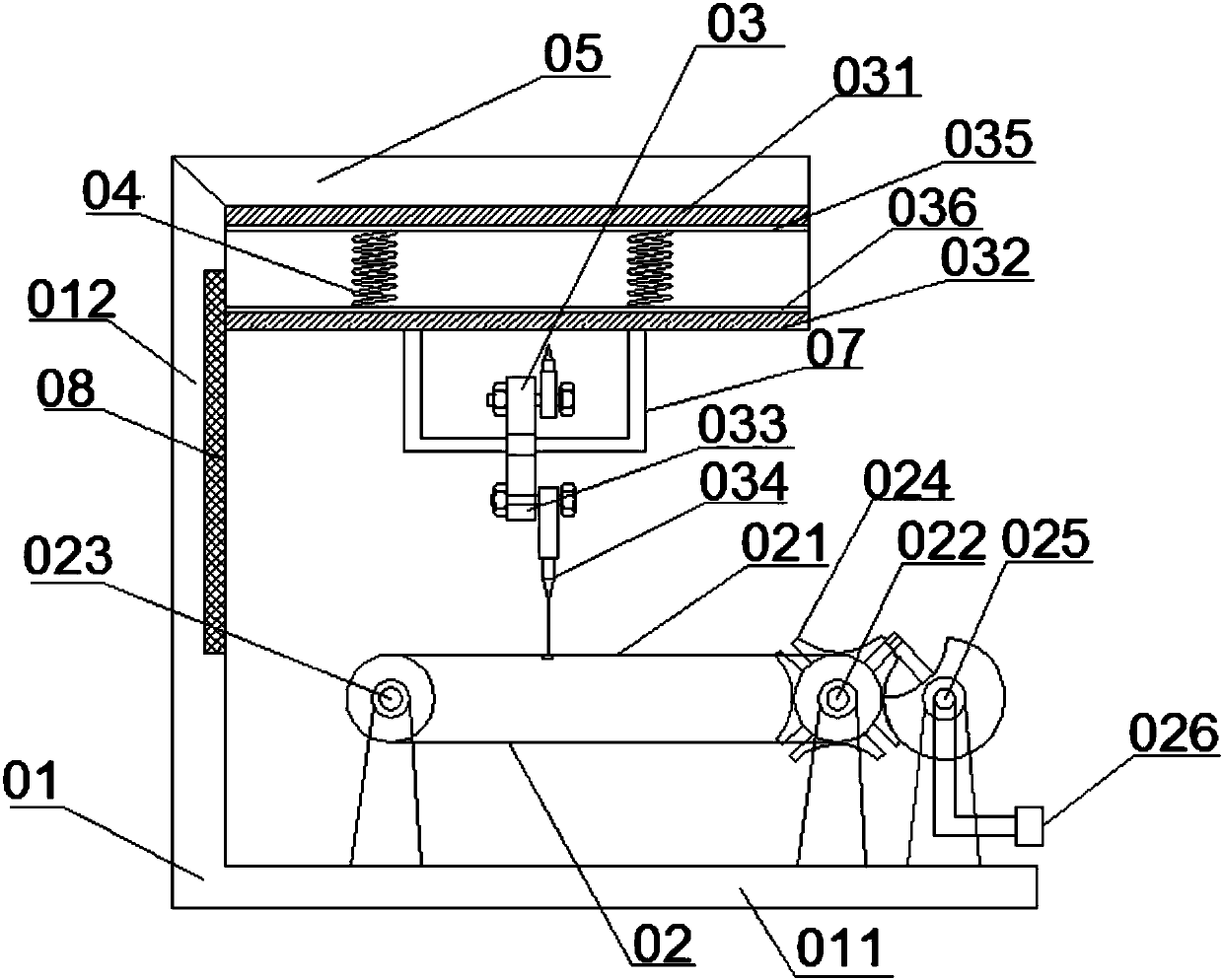

Ultrasonic welding machine for braided fabric

The invention provides an ultrasonic welding machine for a braided fabric. The ultrasonic welding machine comprises a base, a lifting fine tuning mechanism and a welding mechanism, wherein the lifting fine tuning mechanism is fixed on the base and is connected with the welding mechanism; the welding mechanism comprises an ultrasonic transducer, an amplitude-change pole and a tool head; the top end of the amplitude-change pole is connected to the ultrasonic transducer, the bottom end of the amplitude-change pole is connected with the tool head, and a gap is reserved between the tool head and the base. According to the ultrasonic welding machine, under the action of huge ultrasonic energy, a fused plastifying phenomenon is generated in a welding point part of the braided fabric, the braided fabric is not damaged, the welding part of the braided fabric is cut by virtue of a blade, so that the edge wear or the deckle edge of the braided fabric can be avoided.

Owner:杭州班凌超声波设备有限公司

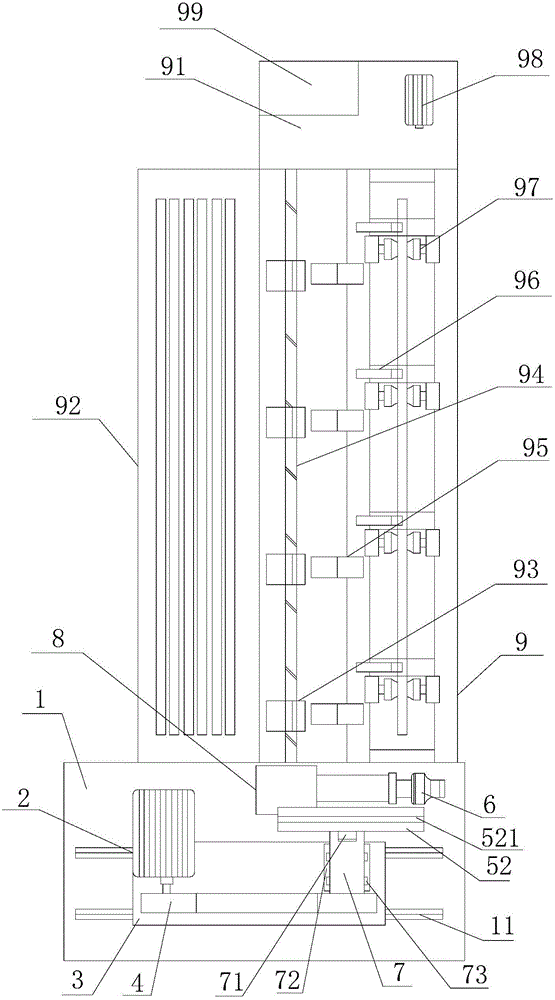

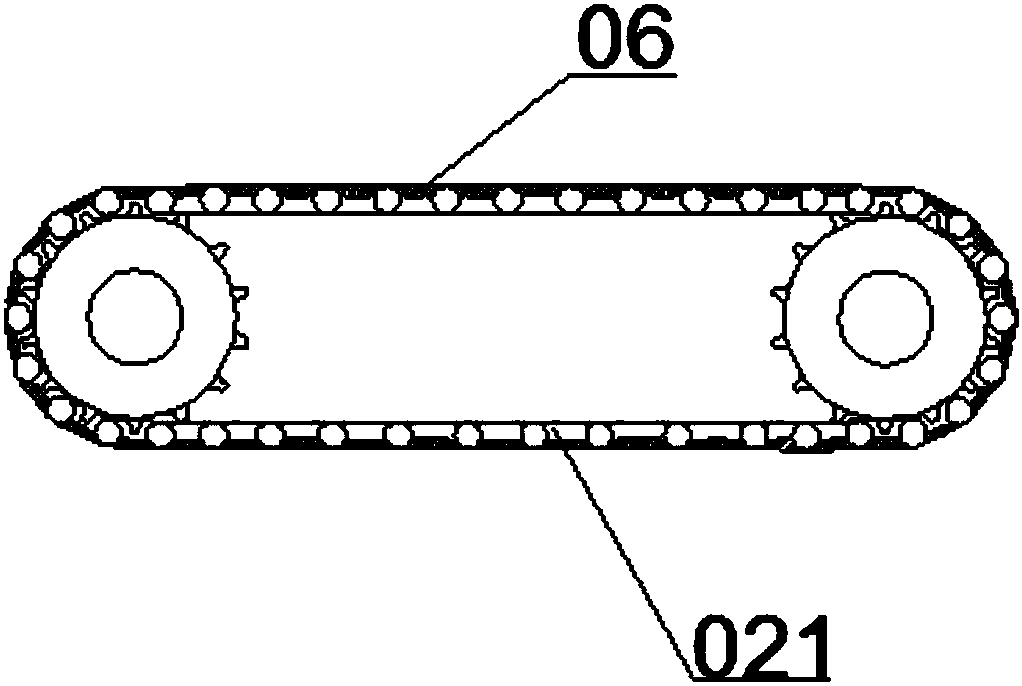

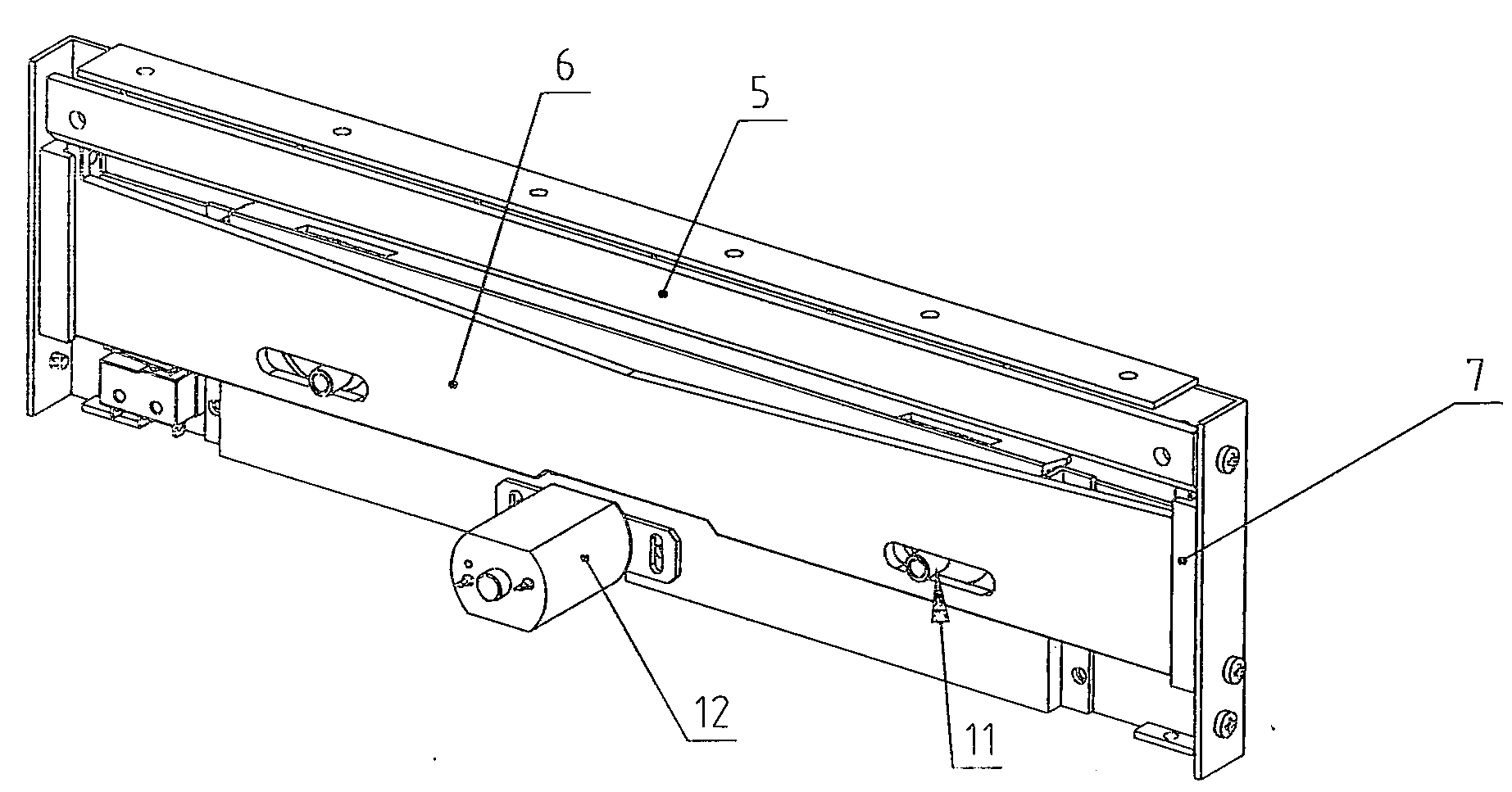

Automatically feeding type cutting machine for steel pipes

ActiveCN105881200AImprove cut qualityAvoid burrsGrinding machinesGrinding feedersHydraulic cylinderEngineering

The invention provides an automatically feeding type cutting machine for steel pipes. The automatically feeding type cutting machine for the steel pipes comprises a machine box, a motor, a sliding seat, a power box, a cutting device, a clamping device, a transmission device, a hydraulic cylinder and a feeding device, wherein a plurality of sliding rails are arranged on the machine box, the sliding seat is arranged on the sliding rails, a plurality of rollers are arranged on the sliding seat, the power box is arranged on the sliding seat, the motor is arranged on the machine box, the output shaft of the motor is connected with the input end of the power box, the transmission device is arranged at the rear of the power box, the output end of the power box is connected with the input end of the transmission device, the cutting device is mounted at the rear side of the transmission device, the output end of the transmission device is connected with the cutting device, the clamping device is arranged at the rear of the cutting device, and connected with the hydraulic cylinder, and the feeding device is arranged at the rear of the clamping device, therefore, the technical problems of difficult feeding, low efficiency and incision burrs caused by unstable steel pipe clamping and the like are solved.

Owner:ZHEJIANG ZHONGDA SPECIAL STEEL

Washable suit and processing method thereof

The invention discloses a washable suit, comprising top vent, sarcenet and lining. The suit is characterized in that the top vent material is made of water-washing fabric and the lower end part of the sarcenet is provided with multiple osculums, thus facilitating effluent in washing the suit and preventing the suit from deforming in water washing; each cut piece of the suit is bond off, thus preventing the ready-made suit from galling in water washing and ensuring the straight appearance of the ready-made suit; when in processing, the lining is washed at first, thus preventing ready-made suit from shrinking after water washing; and in addition, the lining of the suit is a single-layer large chest piece, thus enabling the whole suit to be light and permeable and being suitable for wearing in summer.

Owner:NINGBO YOUNGOR YINGCHENG UNIFORM +1

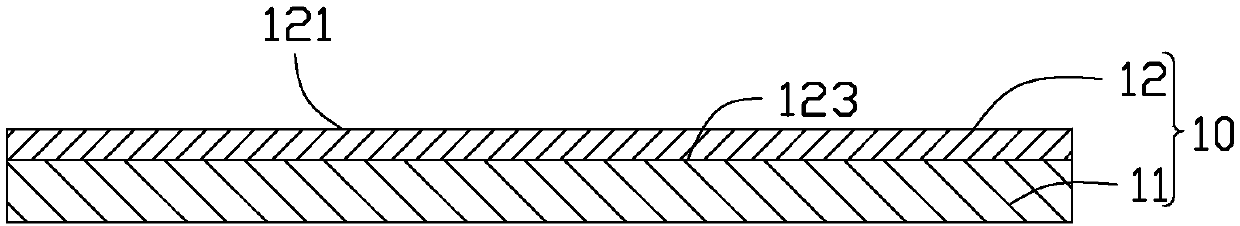

Die attach film

ActiveCN102656675APrevent disengagementAvoid diversionFilm/foil adhesivesSolid-state devicesProduction rateSemiconductor package

The present invention relates to a die attach film, a semiconductor wafer, and a semiconductor packaging method. The invention provides a die attach film, which can prevent chip scattering or generation of burrs or the like during a dicing process and shows excellent expandability and pickup effect when a die bonding process is performed. Further, according to the present invention, the die attach film is capable of preventing chips from being detached, pushed out or deflected during a wire bonding or molding process. Thus, the invention improves the embedding property, suppresses the warpage of a wafer or a wiring substrate, and enhances productivity during a semiconductor package process.

Owner:LG CHEM LTD

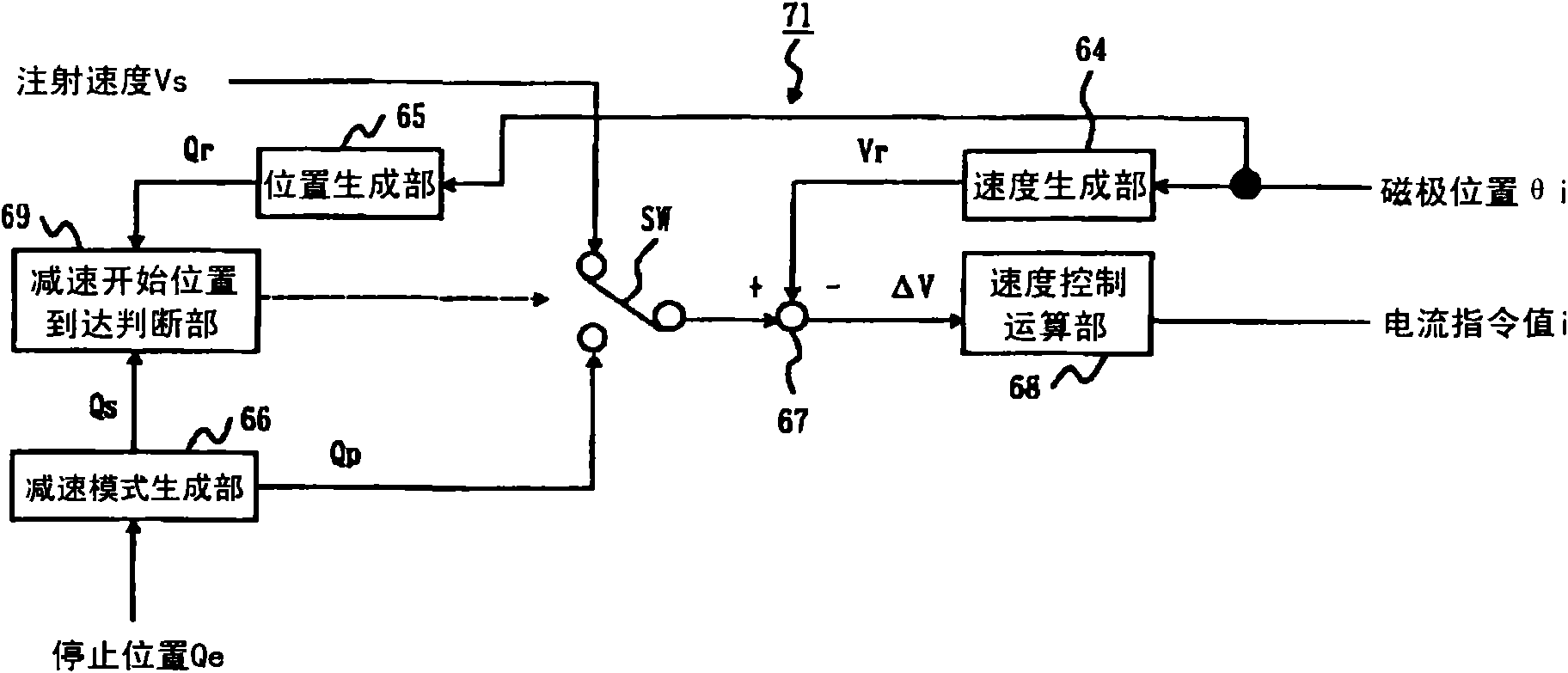

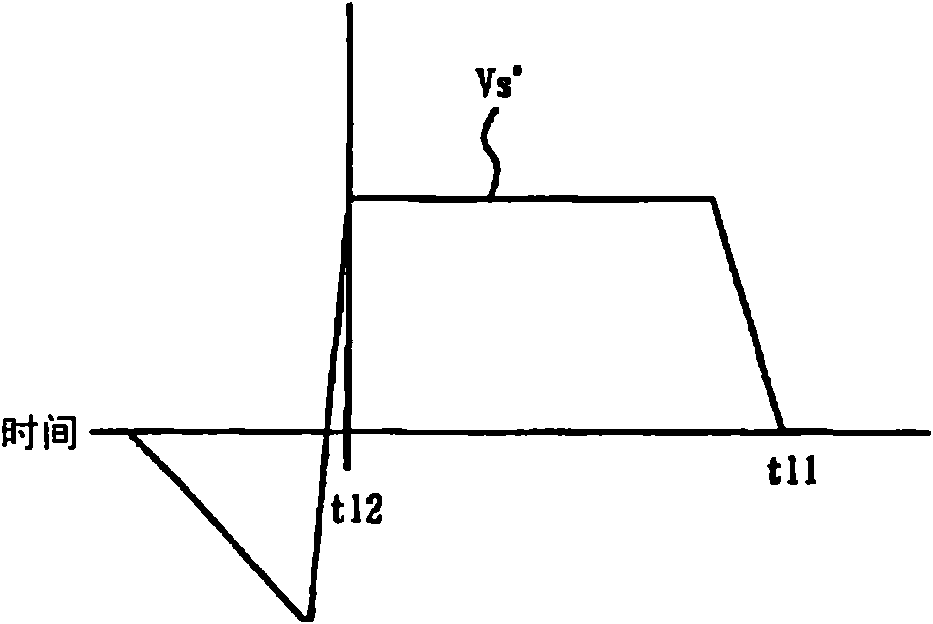

Injection controlling device and injection controlling method

ActiveCN101664988AControl advance and retreatFree to advance and retreatInternal pressureMechanical engineering

The invention provides an injection controlling device capable of maintaining the mold internal pressure as an appropriate value when the filling of the molding material is finished, and improving the quality of the molding product. The device comprises an injection member equipped in the cylinder member; a driving portion for injection for pushing the injection member forward; and a control portion (71) for controlling the driving portion in order to drive the injection member from an injection starting position to a speed control termination position. The control portion (71) performs control so that the volume of the forming material pushed into the injection member is a pushing amount of Ws during the period that the injection member is push from the injection starting position forward to the speed control termination position, Ws is larger than Wm1 when setting the volume of the forming material introduced into the die cavity space from the inlet of the mold device when the injection member reaches the speed control termination position. Before the complete filling of the forming material is performed, the injection member is stopped at the speed control termination position,so that the mold internal pressure is maintained as an appropriate value.

Owner:SUMITOMO HEAVY IND LTD

Fixing device for automobile die

InactiveCN107971410AAvoid burrsGuaranteed workmanship standardsShaping toolsFoundry moulding apparatusMechanical engineeringEngineering

Owner:柳州市钜嘉机械有限公司

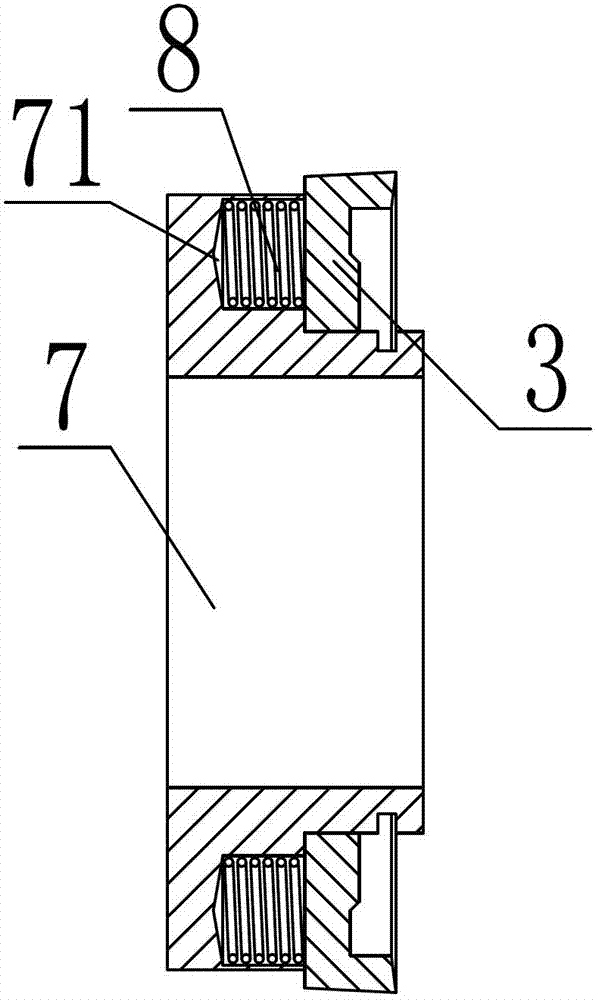

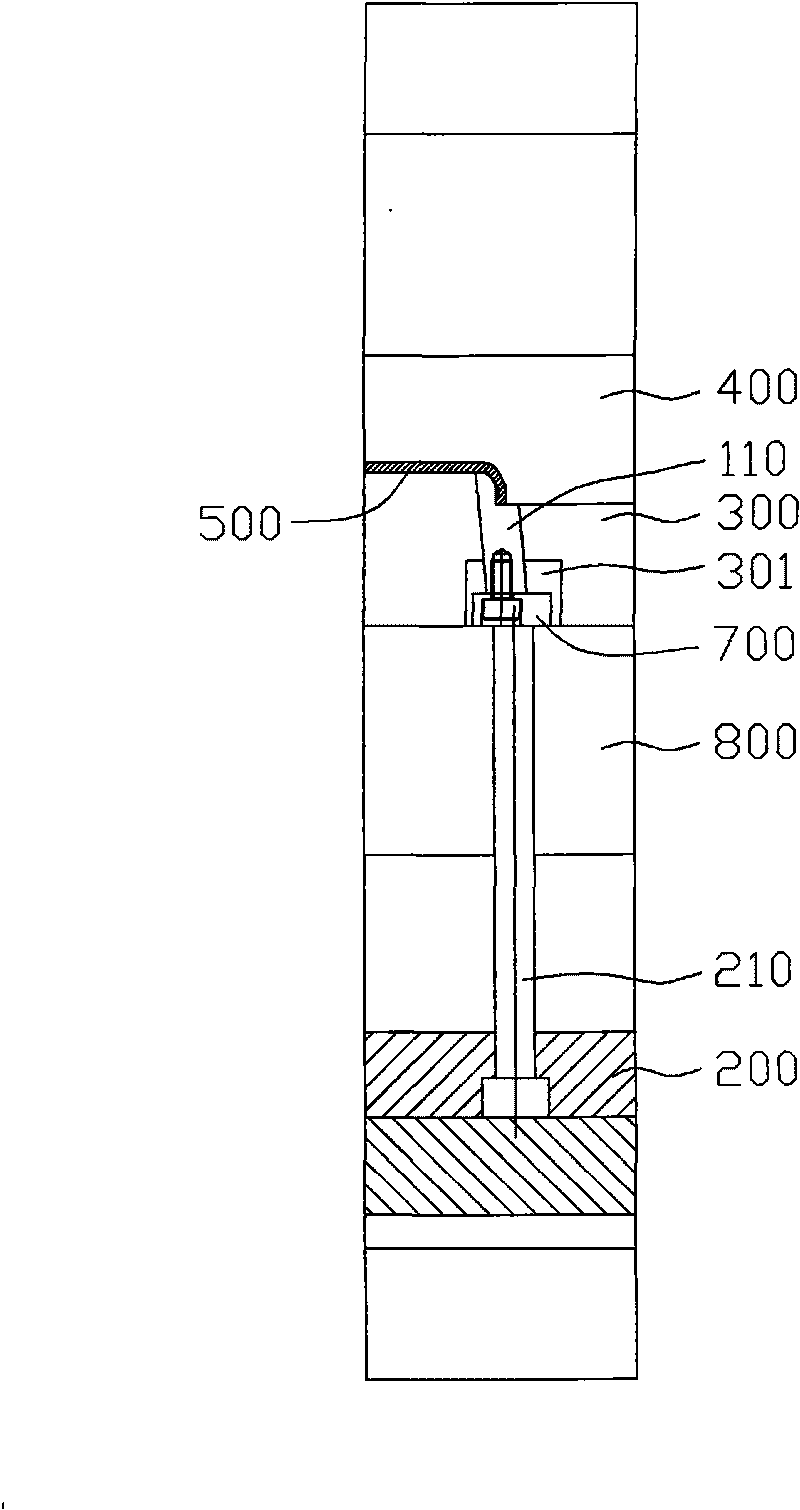

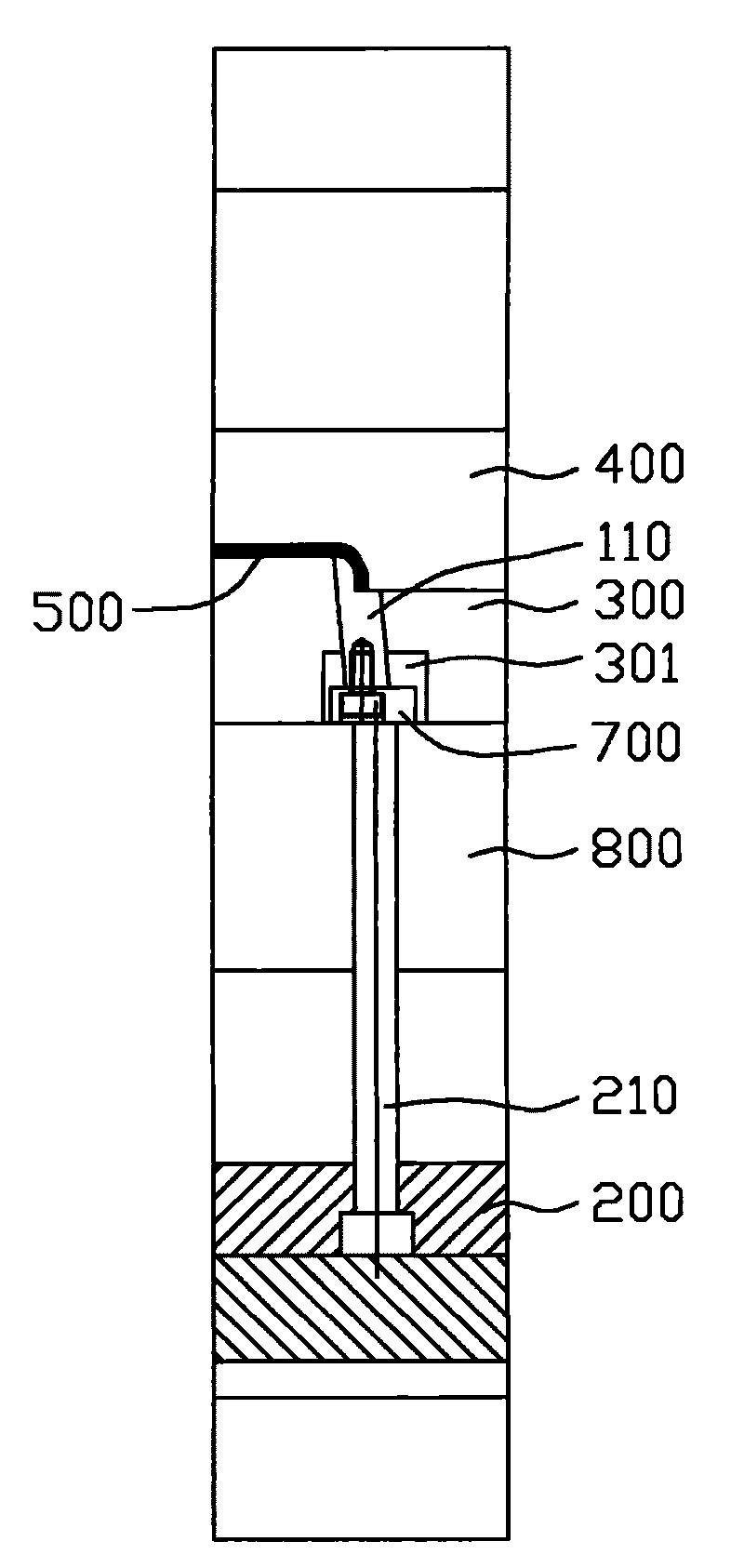

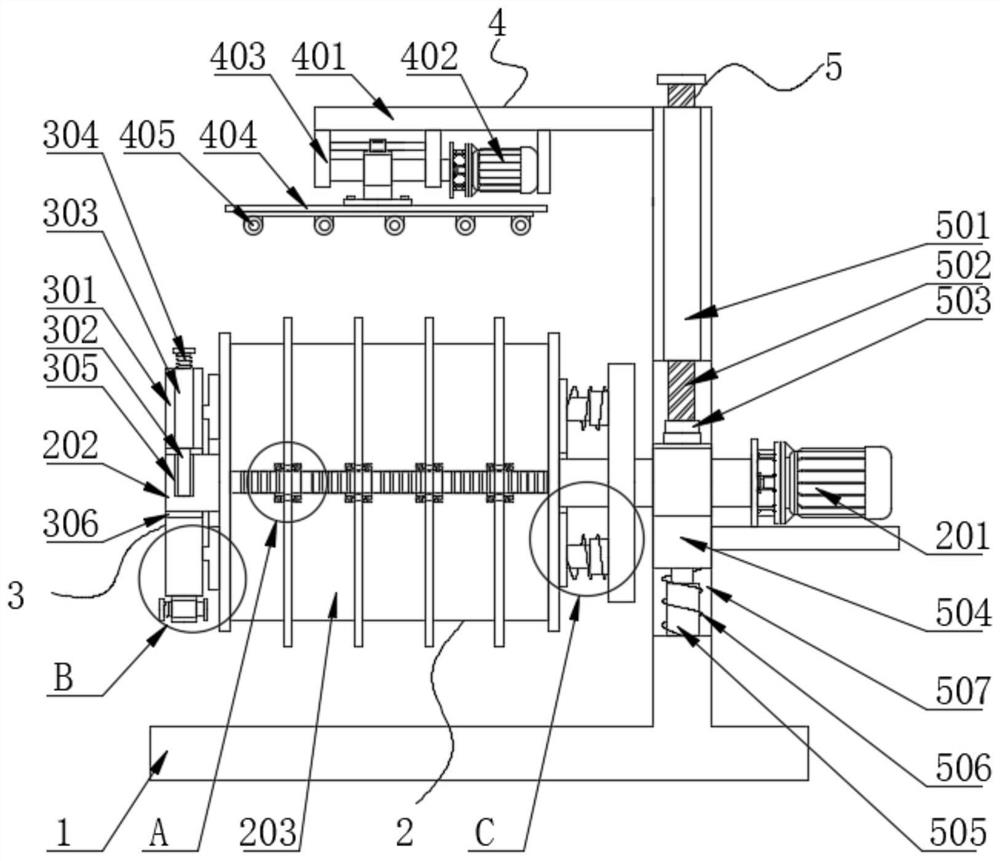

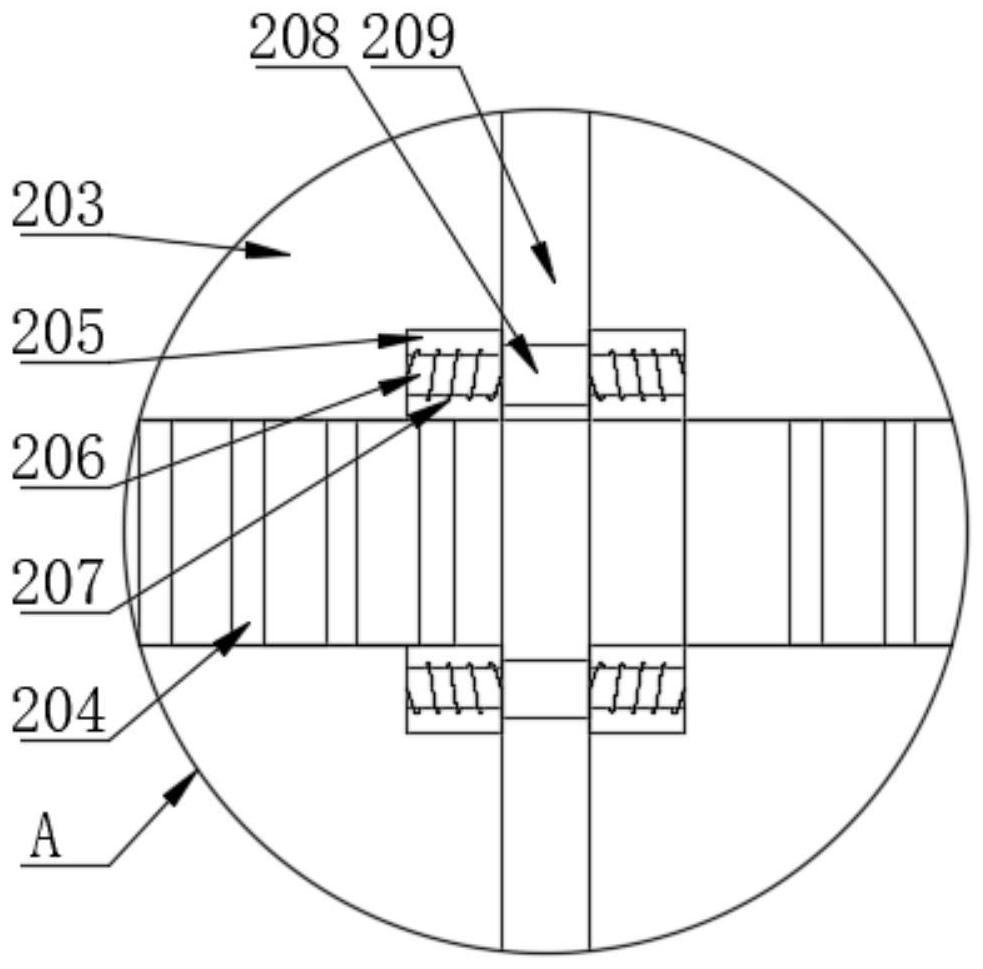

Automatic centering seal cover press-fitting machine for double row conical bearings

ActiveCN106112439AAchieve productionAvoid non-conforming situationsMetal working apparatusHydraulic cylinderEngineering

The present invention discloses an automatic centering seal cover press-fitting machine for double row conical bearings, and belongs to the technical field of bearing manufacturing. The automatic centering seal cover press-fitting machine comprises two hydraulic cylinders that are disposed on bedplates oppositely and fixedly, and two centering cover pressing devices disposed oppositely and connected to the two hydraulic cylinders, respectively. A bedplate height adjusting device is arranged below each centering cover pressing device. The automatic centering seal cover press-fitting machine for double row conical bearings has the following advantages: first centering and later press-fitting are achieved by means of the centering cover pressing devices to take the place of existing manual placement of seal covers onto bearings, and therefore, rejected products after press-fitting due to placement position errors can be avoided; according to the press-fitting machine, horizontal simultaneous two-side press-fitting is implemented without manual reversing of bearings, such that the workload is reduced, and the working efficiency and quality are improved; moreover, the bedplate height adjusting devices are provided for adjustment to enable the centers of different bearings to coincide with the centers of the hydraulic cylinders, and the production of bearings different in specification is thus realized.

Owner:DALIAN HUAKONG INDAL EQUIP

Wire connecting and slitting machine for large-sized pole piece of lithium-ion battery

InactiveCN106346067AImprove work efficiencyAvoid burrsShearing machinesShearing machine accessoriesElectrical batteryPush pull

The invention discloses a wire connecting and slitting machine for a large-sized pole piece of a lithium-ion battery. The wire connecting and slitting machine for the large-sized pole piece of the lithium-ion battery comprises a frame and a positioning panel, wherein two sides of the positioning panel are provided with positioning power air cylinders, pushing-pressing plates for positioning the pole piece and adsorption components, so as to form clamping plate type positioning on the pole piece; the front side of the positioning panel is provided with a material pushing motor; the rear of the positioning panel is provided with a roll-cutting machine head; the lower part of the roll-cutting machine head is provided with a material discharge roller; a roll-cutting motor, the material pushing motor and the material discharge roller form push-pull material feeding; the pole piece of a battery is subjected to roll-cutting forming. The wire connecting and slitting machine can be connected with one plate painting machine or synchronously connected with two plate painting machines. The wire connecting and slitting machine for the large-sized pole piece of the lithium-ion battery is high in complete-machine degree of automation, works reliably and is high in efficiency; the whole machine can be moderately adjusted and replaced according to the size of the pole piece of the battery, is convenient to adjust, is high in applicability, and is applicable to the forming production of different pole pieces of the lithium-ion battery; the problems that a burr and the powder fall exist in the forming of the pole piece by a single-chip die-cutting machine are solved; waste materials in the forming process of the pole piece are reduced; the production cost is decreased; the production efficiency is improved.

Owner:SHAOYANG DALI POWER SUPPLY IND CO LTD

Circuit board with thick copper circuit, and manufacturing method for circuit board

ActiveCN107920415AAvoid burrsAvoid the phenomenon of dirty etchingDielectric materialsElectrical connection printed elementsEngineeringCopper

The invention provides a manufacturing method for a circuit board, and the method comprises the steps: providing a copper-coated substrate which comprises a supporting layer and a base copper layer; carrying out the electroplating on one surface of the base copper layer to form a first conductive circuit diagram; forming a first protection layer on the surface of the first conductive circuit diagram, wherein the first protection layer is disposed in a gap between the first conductive circuit diagram and the base copper layer; peeling off the support layer; carrying out the electroplating on the other surface of the base copper layer to form a second conductive circuit diagram; removing the parts, which are exposed by the first and second conductive circuit diagram, of the base copper layerthrough etching, so as to enable the base copper layer to form a base copper conductive circuit diagram, wherein the base copper conductive circuit diagram and the first and second conductive circuitdiagrams jointly form a conductive circuit diagram; forming a second protection layer on the surface of the second conductive circuit diagram, wherein the second protection layer is disposed in a gapbetween the second conductive circuit diagram and the first protection layer.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Shoe manufacturing process

The invention discloses a shoe manufacturing process. The shoe manufacturing process comprises the following steps: (1) molding a sole: preparing the sole in a mold; (2) preparing an upper material: compounding and molding a vamp and a lining through gluing; (3) cutting the upper material: cutting the upper material prepared by the step (2) into an upper matched with the sole; (4) gluing or sewing the upper prepared by the step (3) onto the sole; (5) carrying out paint spraying and waxing treatment on the vamp, and naturally airing; and (6) correcting a shoe edge. By setting a shoe edge correction step, burrs and gluing at the shoe edge of a prepared shoe are treated by adopting a correction tool and the problems of the burrs and the gluing of the shoe edge of the finished-product shoe are avoided.

Owner:CHENGDU LIXIN SCI & TECH

Resin molded component for vehicle and manufacturing method thereof

ActiveCN101987637ASolve the shortageReduce loadSuperstructure subunitsDomestic articlesEngineeringMechanical engineering

Owner:FOSHAN FALTEC AUTOMOTIVE PARTS CO LTD

Trimming knife after film coating of plastic product film coating combination machine

InactiveCN102729274AAvoid burrsAvoid the problem of incomplete cut-offMetal working apparatusEngineeringFilm coating

The invention relates to a trimming knife after film coating of a plastic product film coating combination machine, comprising a rack, an upper blade, a lower blade, a blade adjusting mechanism and a driving mechanism, wherein the upper blade and the lower blade are disc-shaped and are respectively arranged on the rack by an upper knife rest and a lower knife rest; an elastic blade adjusting device for adjusting the blades is also arranged between the lower blade and the lower knife rest and comprises at least three springs; the lower knife rest is provided with hole grooves for installing the springs; and the springs are arranged in spaces formed by matching of the hole grooves and the lower blade and are in a compressed state. The trimming knife has the advantages that the distance between the upper blade and the lower blade is adjusted by the elastic blade adjusting device, so that the upper blade and the lower blade are attached together all the time, and further the problem of film-coating material burrs or incomplete cutting caused by separation of the upper blade and the lower blade is solved.

Owner:常州市永明机械制造有限公司

Spreading machine

ActiveCN104192632BFully compactedUniform tensionUnfolding thin materialsArticle deliveryEngineeringAutomotive engineering

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

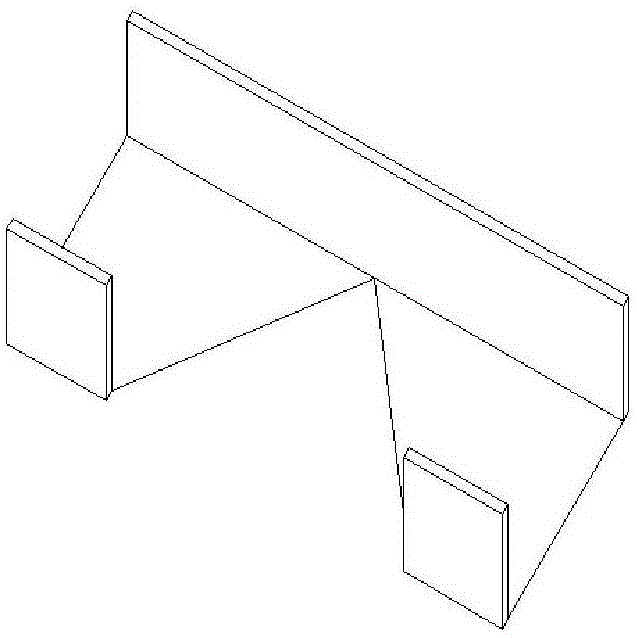

Machining device and method for steel channel grooving and bending combined assembly

ActiveCN106734518AAvoid bending deformationImprove processing efficiencyShaping toolsEngineeringMechanical engineering

The invention discloses a machining device and method for a steel channel grooving and bending combined assembly and belongs to the technical field of shearing and bending machining. The machining device comprises a rectangular groove cutting machining mold, a triangular groove cutting machining mold and a bending machining mold, wherein the rectangular groove cutting machining mold comprises a first movable cutter and a first fixed cutter; the first movable cutter is fixedly connected with a first movable cutter base, and the shearing edge face of the first movable cutter is a V-shaped face with the middle portion sunken downwards; the first fixed cutter is installed on a first fixed cutter base and forms a "rightward-right-angle-u-shaped" structure; the triangular groove cutting machining mold comprises a second fixed cutter and a second movable cutter; the second movable cutter is fixedly connected with a second movable cutter base; the shearing edge face of the second movable cutter is a plane inclined to the other side from the position of a sharp corner of the plane; and the second fixed cutter is installed on a second fixed cutter base and forms an "L-shaped" structure. By adopting the machining device to perform grooving and bending machining on steel channels, the machining efficiency and the machining quality can be remarkably improved, and the precision and the quality of the combined assembly are made to meet the using requirements.

Owner:马鞍山市欧姆科技发展有限公司

Method for forming deep concave and convex cement decorative plate by adopting mold box overlapping and vertical vibration

InactiveCN104690826AAvoid burrsSolve the problem of compact moldingMoulding surfacesShaping press ramMaterials scienceVertical vibration

The invention belongs to a method for forming a cement decorative plate with deep concave and convex patterns by adopting mold box overlapping and vertical vibration. Forming mold boxes comprise a movable mold box and a forming machine mold box which are overlapped, the movable mold box comprises a mold frame and a plastic mold box loaded in the mold frame, and the plastic mold box comprises an outer hard plastic box and an inner elastic soft plastic box; a vibrator is arranged at the upper part of a press head of a forming machine, and a vibrating table at the lower part of the forming machine and the vibrator at the upper part of the press head are started simultaneously during vibrating. With the adoption of the method, the problem about demolding of the deep concave and convex decorative surface can be solved very well, and the problem about forming compaction when the inner elastic soft plastic box is used by a cement mixing material is solved.

Owner:上海欧墅节能科技股份有限公司 +1

Packing bag punching equipment

The invention provides a packaging bag punching device, which relates to the technical field of packaging bag punching, including a base, a transmission mechanism, a punching mechanism and a support seat fixedly connected to the top of the base. The transmission mechanism is set on the support seat, and the punching mechanism includes an upper fixed block, a lower moving block, a circular dial and a punching needle arranged on the annular dial, and several elastic parts are arranged between the upper fixed block and the lower moving block , the upper fixed block is fixed on the lower end of the support seat, and the annular needle disc is connected to the lower end of the lower moving block; when punching, the elastic member instantly drives the lower moving block to drive the punching hole on the annular needle disc to punch the packaging bag on the transmission mechanism hole. Through the implementation of this technical solution, it is possible to effectively avoid the phenomenon of rough edges or out-of-roundness in the punching in the prior art, and improve the punching quality of the packaging bag; and it can also produce packaging bags with different apertures at the same time, improving the efficiency of punching the packaging bag .

Owner:弘毅天承知识产权股份有限公司

Angle lifter base

The invention provides a novel angle lifter base applied in a mold, which comprises a sliding block, wherein the sliding block is movably embedded in an upper top plate of the mold, one end of an angle lifter is fixed on the sliding block, and the other end is matched with a core insert and a cavity insert of the mold for molding a product. Preferably, the invention provides the novel angle lifter base, wherein the sliding block is a cylinder. The angle lifter base can reduce the strength weakening effect of the angle lifter of the mold to the upper top plate, thereby avoiding the problem of burrs or more adhesive of the product due to inadequate strength of the upper top plate and having excellent practical value.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

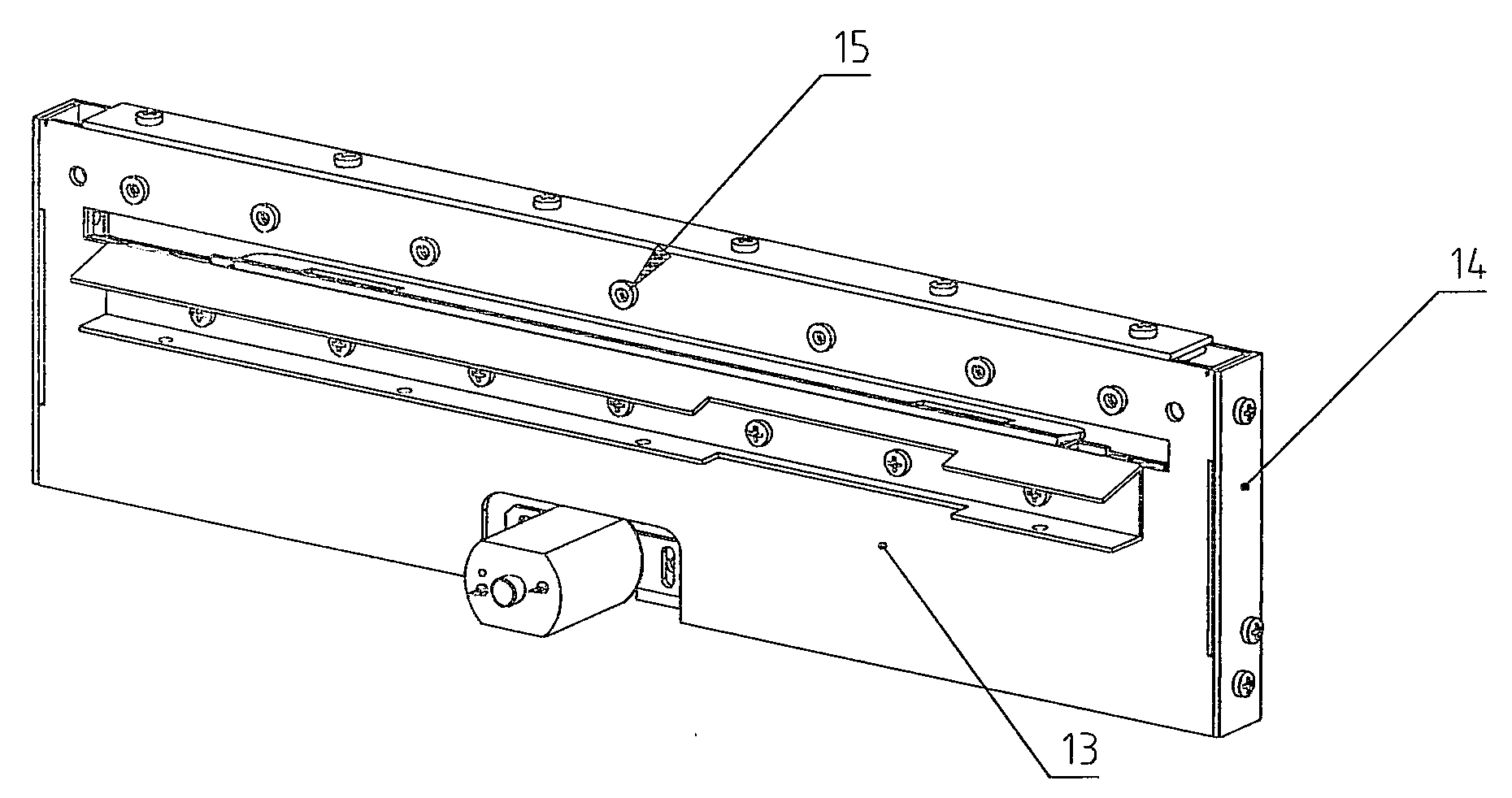

Automatic paper cutting device for multi-piece chain paper bill printer

InactiveCN103158374ASolution to short lifeAvoid burrsOther printing apparatusEdge surfacePulp and paper industry

The invention discloses an automatic paper cutting device for a multi-piece chain paper bill printer. The automatic paper cutting device comprises a fixed knife installation frame, a movable knife installation frame, a fixed knife, a movable knife matched with the fixed knife, a movable limit guide mechanism and a drive transmission mechanism which drives the movable knife to slide on the movable knife installation frame up and down and is matched with the fixed knife to cut paper; the fixed knife installation frame is arranged on the top of the movable knife installation frame; the fixed knife is arranged on the fixed knife installation frame; the movable knife is arranged on the movable knife installation frame; the fixed knife installation frame is provided with a jacking and bending structure which can ensure that the fixed knife has certain curvature and gradually bends toward one side of the movable knife from two sides of the fixed knife to the middle part of the fixed knife; and the movable knife is provided with a knife edge surface of which the middle part is lower than two sides. The automatic paper cutting device avoids phenomena that burrs are easily produced, and paper is wound and jammed during paper cutting, a cut of cut paper is smooth and clean, the paper is cut reliably, and multiple layers of paper can be cut.

Owner:颜炳辉

Thin film material cutting device

InactiveCN107953388AImprove cutting effectAvoid burrsMetal working apparatusEngineeringMechanical engineering

The invention relates to a thin film material cutting device. The thin film material cutting device comprises a machine frame with the supporting function, a first roller shaft, first gears, a secondroller shaft and second gears, wherein the first gears are coaxially arranged on the first roller shaft, and the second gears are coaxially arranged on the second roller shaft. According to the thin film material cutting device, before cutting, a thin film material is placed between the first roller shaft and the second roller shaft, the first roller shaft and the second roller shaft rotate so that cutting blades can be matched with annular grooves, and therefore the thin film material can be cut; moreover, the radius of each first gear is smaller than the radius of each second gear, so that the rotating speed of the first roller shaft is higher than the rotating speed of the second roller shaft, that is, the rotating speed of the cutting blades is higher, so that the speed difference between the cutting blades and the thin film material is larger; at the moment, the higher the cutting speed of the cutting blades is, the better the cutting effect of the thin film material is; and therefore the thin film material cutting device can effectively prevent the occurrence of burrs when the thin film material is cut.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Trimming device for cotton cloth processing

ActiveCN110371742APrevent burrsGuaranteed qualitySevering textilesWebs handlingHydraulic cylinderEngineering

The invention discloses a trimming device for cotton cloth processing. The trimming device for the cotton cloth processing comprises a bottom plate, wherein a plurality of support legs are fixedly connected with the bottom of the bottom plate, two support plates are fixedly connected with the top of the bottom plate, a clamping mechanism is arranged between the two support plates, the same horizontal plate is fixedly connected with the tops of the two support plates, two hydraulic cylinders are fixedly connected with the bottom of the horizontal plate, and a cutting tool is fixedly connected with the bottoms of the hydraulic cylinders. When the trimming device for the cotton cloth processing is used, cloth is in a tensioned state when the cutting tool cuts the cloth by changing the relative position of a moving plate and a fixed plate in the process of using a belt conveyor for driving a limiting plate to move under interaction among the belt conveyor, the limiting plate, the moving plate, a vertical rod, the fixed plate, a first pressing plate and a second pressing plate, and then the circumstance that rough edges appear on the cloth is avoided, quality of the cloth is guaranteed,and convenience is provided to following processing of the cloth.

Owner:徐州兰岳企业管理服务有限公司

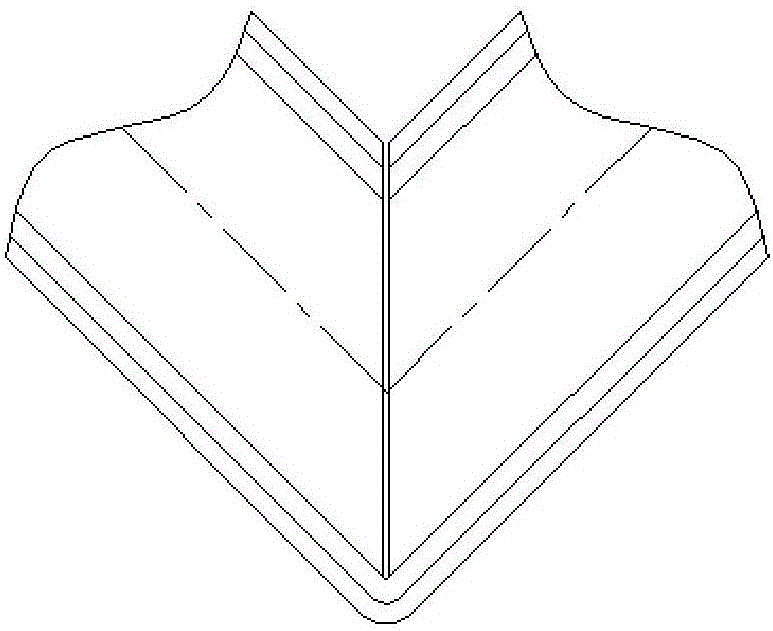

Sandwich fabric bra mould cup for female sports underwear and manufacturing technology

InactiveCN109892712AValid packagePlay a fixed roleBrassieresCorsetsManufacturing cost reductionManufacturing technology

The invention discloses a sandwich fabric bra mould cup for female sports underwear and a manufacturing technology. The sandwich fabric bra mould cup comprises a mould cup body and an edge covering layer, the mould cup body comprises at least one sandwich fabric layer, and the edge covering layer and the external circumferential side face of the mould cup body are hot-pressed into a whole in an adhesive spraying and bonding manner through adhesives. The manufacturing technology includes the steps: equipment installation; sandwich fabric preparation; mould cup sizing and transferring; edge covering layer adhesive spraying, bonding and hot-pressing; mould cooling and pressing; finished product detection. A mesh layer in a sandwich fabric layer can be effectively fixed, and raw edges are prevented from being formed at the edge of the bra mould cup, easily itching skins and causing wearing discomfort. The manufacturing technology with the simple steps is high in practicability. Compared with an existing bra mould cup with sewn covering edges, the bra mould cup manufactured by the technology can be rapidly restored to an original shape even if the bra mould cup deforms, raw edge piercing cannot be caused in long-time use and cleaning, wearing effects cannot be affected, assembly line processing production requirements can be met, and manufacturing cost is reduced.

Owner:义乌梓涵网络科技有限公司

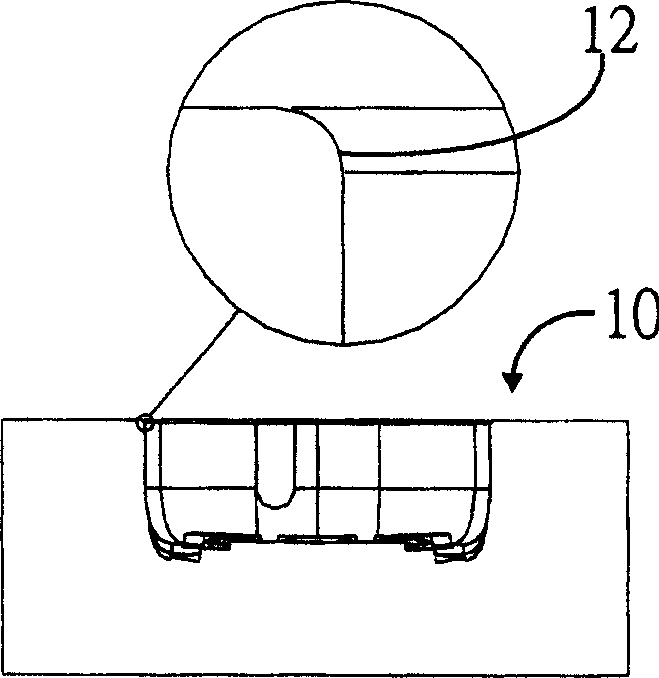

Lifter set system

InactiveCN101733878ALittle impact on strengthAvoid raw edges or excess glueEngineeringMechanical engineering

The invention provides a lifter set system which is applied to a die and comprises an angle pin, wherein the angle pin penetrates through a male die core of a die, one end of the angle pin is matched with a moulding product of the male die core and a female die core of the die, and the other end is connected with a top block; and the top block is movably arranged between the male die core and a male template. The lifter set system also comprises an ejector pin, wherein one end of the ejector pin is fixed on a top plate on the die, and the other end is abutted against the top block. The invention can reduce the strength influence of a lifter set on the upper top plate, avoid the problem of burr or excess glue caused by insufficient strength of the top plate and have more favorable practical value.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

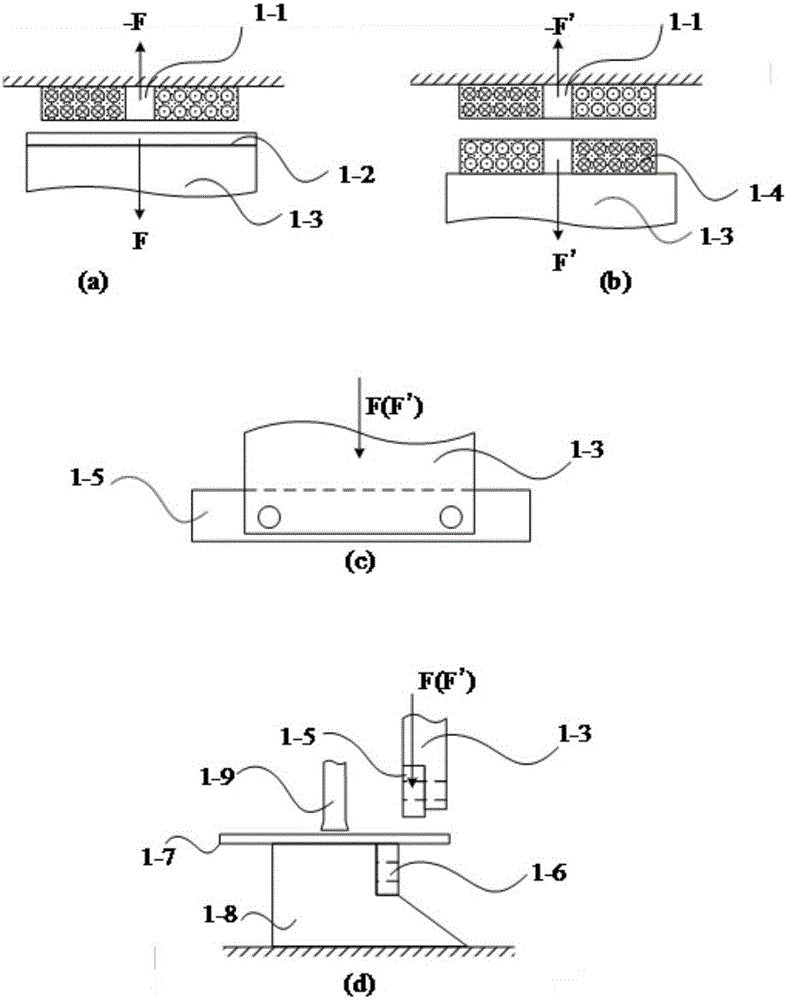

Pulsed electromagnetic shearing method and device

The invention discloses a pulsed electromagnetic shearing method and device.The method comprises the steps that a metal workpiece is placed between an upper blade and a lower blade, pulsed electromagnetic force is taken as driving force to drive the upper blade to move towards the lower blade, and the upper blade and the lower blade cooperate with each other to complete metal workpiece shearing.The device comprises the upper blade, the lower blade and a pulsed magnetic force generating mechanism, the lower blade is used for containing the metal workpiece, the pulsed magnetic force generating mechanism is used for generating the pulsed electromagnetic force, the pulsed electromagnetic force is taken as the driving force to drive the upper blade to move towards the lower blade, and the upper blade and the lower blade cooperate with each other to complete metal workpiece shearing.According to the pulsed electromagnetic shearing method and device, the electromagnetic cutting application field is expanded, the phenomenon that the defects such as turned edges, deckle edges and wrinkles are generated after workpiece shearing is completed is effectively prevented, and the requirement for the mechanical support structure strength can be effectively lowered.

Owner:HUAZHONG UNIV OF SCI & TECH

A take-up structure for textile operation with anti-winding effect

The invention discloses a take-up structure for textile operation with an anti-winding effect, which belongs to the technical field of textile auxiliary appliances, and comprises a frame, one side of the frame is movably connected with a winding mechanism, and one side of the winding mechanism is provided with There is a clamping mechanism, the top of the winding mechanism is movably connected with the frame through a lifting mechanism, and the top of one side of the frame is fixedly connected with a wire management mechanism, the winding mechanism includes a first motor, and the output shaft of the first motor The first rotating shaft is fixedly connected. In the present invention, by providing a winding mechanism and a wire management mechanism, it is possible to effectively prevent the wire bundles from being entangled with each other during winding, and it is possible to simultaneously take up multiple wire bundles, and the baffle connected to the outer wall of the reel can ensure that multiple wire bundles are wound at the same time The separation effect when pulling, and the smooth guide sleeve can avoid the burr of the wire harness when pulling, which can significantly improve the winding efficiency while avoiding the winding of the wire body, and meet the needs of adapting to the textile operation.

Owner:青岛富思特纺织股份有限公司

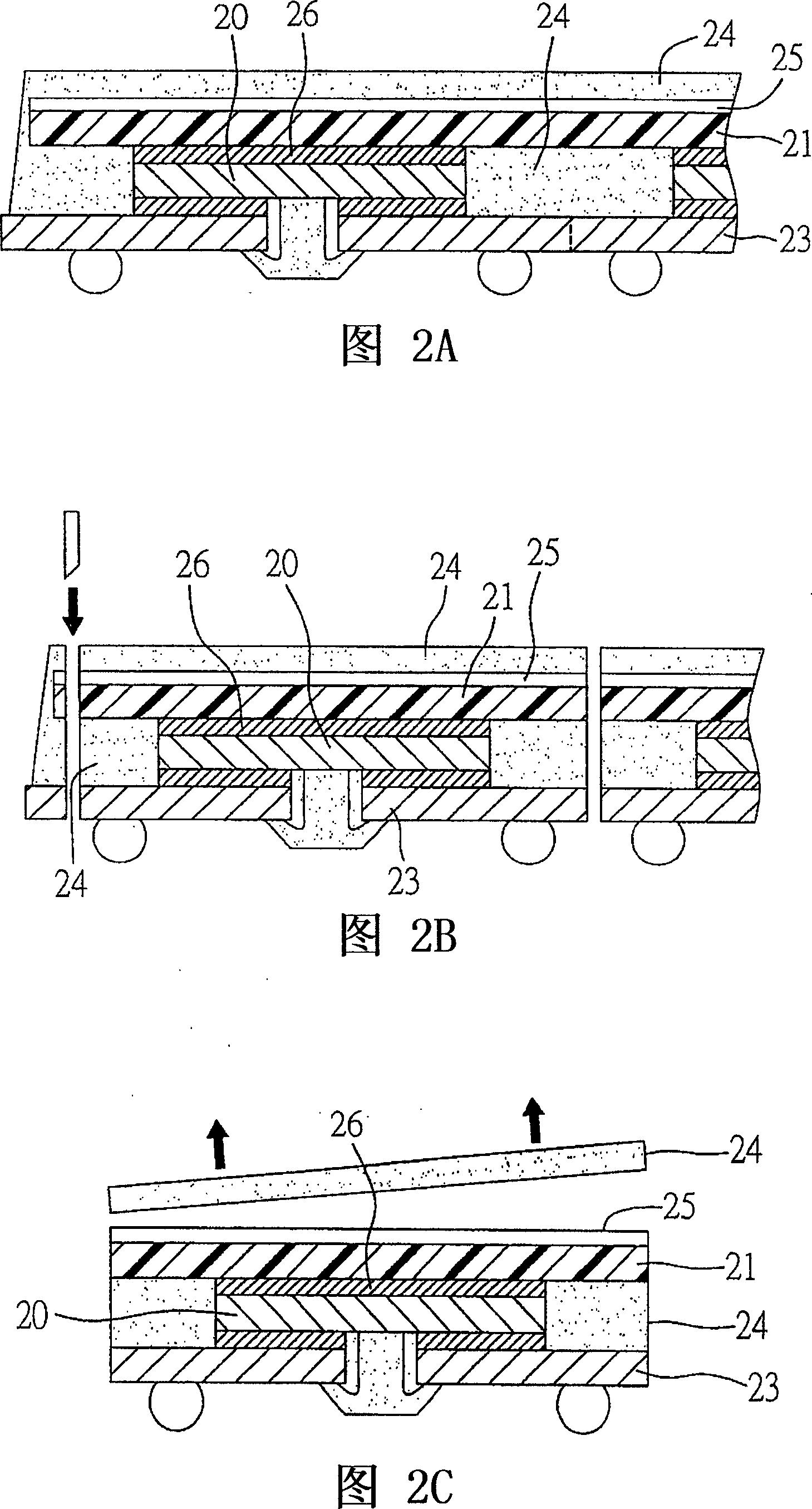

Radiating packaging structure and manufacturing method thereof

InactiveCN101110370AAvoid burr problems and tool wear problemsReduce cutting costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A heat dispersion encapsulation structure and its method are provided, which is characterized in that: place and connect a semiconductor wafer to a wafer bearing component; position a heat dispersion component with a interference face layer on its surface on the semiconductor wafer, so as to form a complete encapsulation glue body that wraps the semiconductor wafer and the heat dispersion component; then, cut the wafer bearing component and the encapsulation glue body according to the preset dimension of the encapsulation structure and form a bevel at the top brim of the encapsulation glue body, so as to partially expose the brim of the heat dispersion component; then, remove the encapsulation glue body on the interference face layer and form the encapsulation glue body that covers the interference face layer by keeping a spacing elevation between the encapsulation glue body and the top face of the interference face layer. Meanwhile, because the cutting path of the cutting operation does not pass the heat dispersion component, the invention is able to prevent the problem of flash and wearing of cutter due to the direct cutting of the heat dispersion component by the cutter, thus reducing the cutting cost.

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com