Shoe manufacturing process

A kind of craft and upper technology, which is applied in the direction of shoemaking machinery, footwear, clothing, etc., can solve the problem of burrs and glue at the joint between the sole and the upper, and achieve the effect of avoiding burrs and glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as figure 1 Shown, a kind of shoemaking process comprises the following steps:

[0037] 1) Sole forming: prepare the sole in the mold;

[0038] 2) Preparation of shoe upper material: the shoe upper and the lining are compounded and formed by gluing;

[0039] 3) Cutting of the upper material: cutting the upper material prepared in step 2) into an upper matching the sole;

[0040] 4) Glue or sew the upper prepared in step 3) to the sole;

[0041] 5) Spray paint and wax the vamp and let it dry naturally;

[0042] 6), shoe edge correction: the shoes prepared in step 5) are deburred and glued with a correction tool. The correction tool includes a handle 1, and the handle 1 is connected with a knife part 2 through a connecting rod 3. The non-fixed end is provided with a cutting portion 21, the cutting portion 21 is an arc structure, the connecting rod 3 is connected with a protective sleeve 4 through a rotating shaft, and the protective sleeve 4 is arranged on the ou...

Embodiment 2

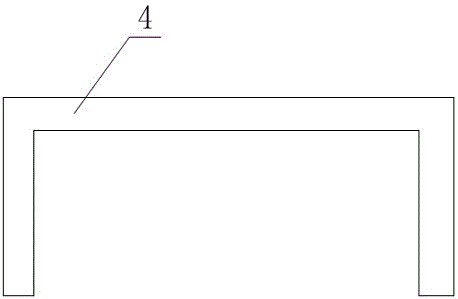

[0044] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the protective cover 4 is a U-shaped structure, the protective cover 4 includes a plurality of U-shaped sleeves, and the adjacent U-shaped sleeves are connected by elastic members 5; the elastic members 5 It is made of silica gel material; the outer wall of the handle 1 is provided with an annular groove 11; the shoe upper is subjected to thermal processing before composite molding of the shoe upper and the lining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com