Pulsed electromagnetic shearing method and device

A pulsed electromagnetic and shearing device technology, used in shearing devices, shearing machine equipment, metal processing equipment, etc., can solve the problem of reducing the strength of mechanical support structures, and achieve the requirements for reducing strength, reducing demand, preventing curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

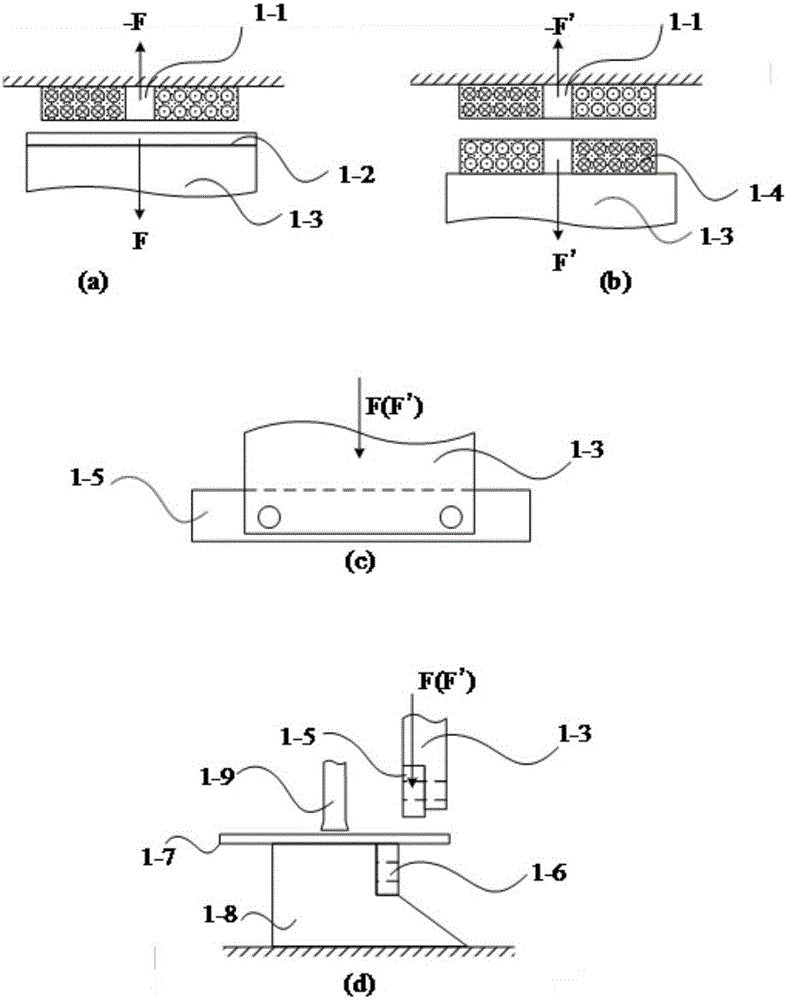

[0029] The generation of electromagnetic driving force, the mechanical transmission of electromagnetic force and the shearing process in the pulse electromagnetic shearing method of the present invention are as follows: figure 1 shown, where figure 1 (a) and figure 1 (b) illustrates two ways of generating pulsed electromagnetic force.

[0030] figure 1 The pulse magnetic force generating mechanism shown in (a) includes a pulse power supply, a pulse coil 1-1 and a driving board 1-2. Fix the pulse coil 1-1, discharge the pulse coil 1-1 through the pulse power supply, the pulse coil 1-1 generates a pulse magnetic field, and generates an induced eddy current on the drive plate 1-2, and the pulse magnetic field and the induced eddy current interact to generate a pulse electromagnetic force F, pushing the drive plate 1-2 to drive the mechanical transmission structure 1-3 to move.

[0031] figure 1 The pulsed magnetic force generating mechanism shown in (b) comprises a pulsed po...

no. 2 example

[0035] figure 2 It is a structural schematic diagram of a gantry type electromagnetic shearing machine, and its main components include: pulse coil 2-1, drive plate 2-2, mechanical transmission structure 2-3, upper blade 2-4, lower blade 2-5, base, The initial position fixing structure 2-7, the blade drop buffering structure 2-8, and the external support frame 2-9. The mechanical transmission structure includes a drive plate-upper blade connecting device 2-3 and a sliding guide rail 2-6. The driving board 2-2 is connected to the upper blade 2-4 through the connecting device 2-3, and the upper blade 2-4 is parallel to the lower blade 2-5. Wherein, the base is used to support the lower blade and the longitudinal sliding guide rail; the longitudinal sliding guide rail 2-6 is installed on the base, and the effect is to make the upper blade 2-4 slide smoothly in the direction of the guide rail. In order to make the most use of the pulsed electromagnetic force, before the shearin...

no. 3 example

[0037] image 3 It is a structural schematic diagram of a crocodile-type electromagnetic shearing machine, and its main components include: a pulse coil 3-1, a drive plate 3-2, an upper blade 3-3, a lower blade 3-4, a base 3-5, and an upper knife arm ( Mechanical transmission structure) 3-6, initial position fixed structure 3-7, blade falling buffer structure 3-8. The drive plate 3-2 is connected to the upper blade 3-3 through the upper knife arm 3-6, and the upper blade and the lower blade form a V shape. Because the space density of the pulsed electromagnetic force is large, but the range of action space is small, so in this structure, the pulsed electromagnetic force acts on the drive plate 3-2 to make the force arm of the upper knife arm rotate counterclockwise, which makes the upper arm rotate counterclockwise than the shear resistance. The force arm of the clockwise rotation of the knife arm is small. The initial position fixing structure 3-7 is a kind of spring buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com