A cutting machine used for necktie fabric processing

A cutting machine and fabric technology, applied in the field of cutting machines, can solve the problems of affecting processing, slow speed, and high cost, and achieve the effects of improving stability, stable and safe transmission, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

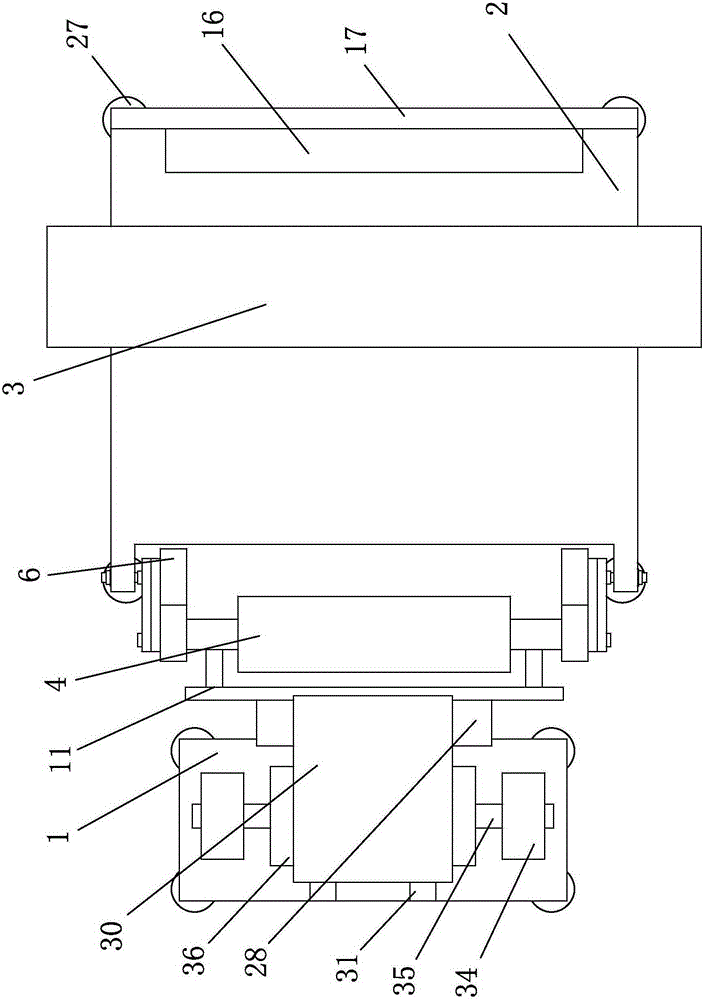

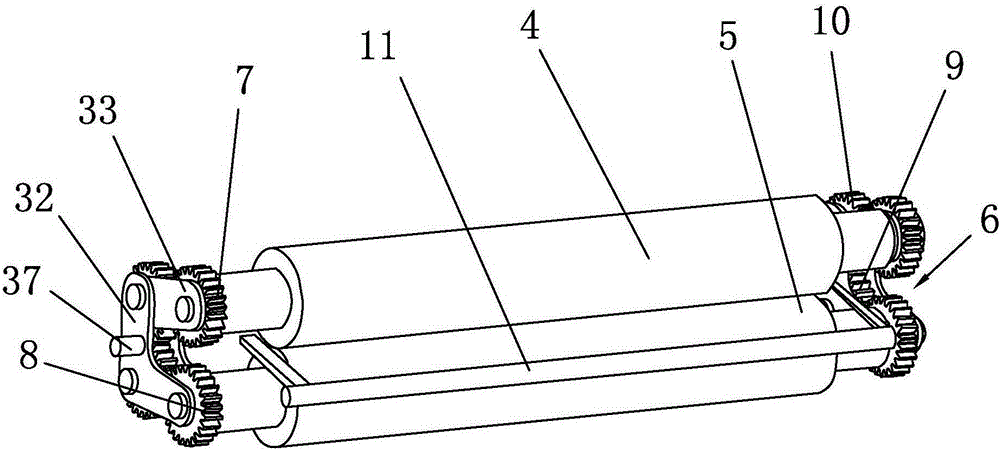

[0033] Such as Figure 1 to Figure 7 As shown, it is a cutting machine for necktie fabric processing according to the present invention, which includes a feeding table 1, a feeding device, a cutting platform 2 and a cutter device 3, and the design of the feeding table 1 can facilitate the placement of the cloth 36. The material table 1 is provided with a discharge rack 34 and a support shaft 35, the support shaft 35 runs through the discharge rack 34, the support shaft 35 is wound with cloth 36, the design of the discharge rack 34 and the support shaft 35 can facilitate the placement of the cloth 36 Compared with the design of placing the cloth 36 directly on the discharge table 1, it not only facilitates the transmission of the cloth 36, but also prevents the dust and impurities on the discharge table 1 from polluting the cloth 36. The distance between the discharge table 1 and the cutting platform 2 The bottom surface is provided with at least four support columns 27, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com