Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267results about How to "Reduce cutting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

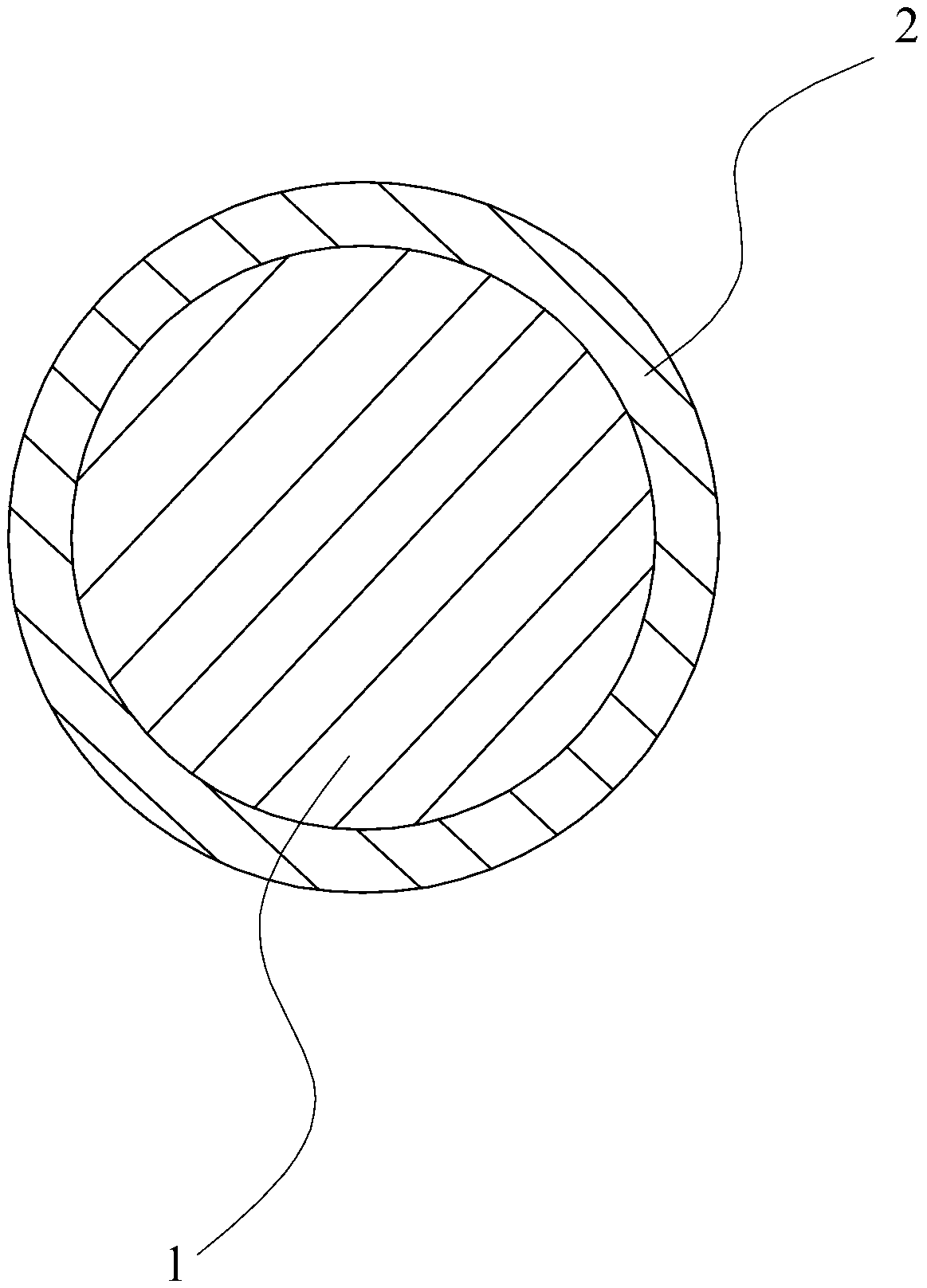

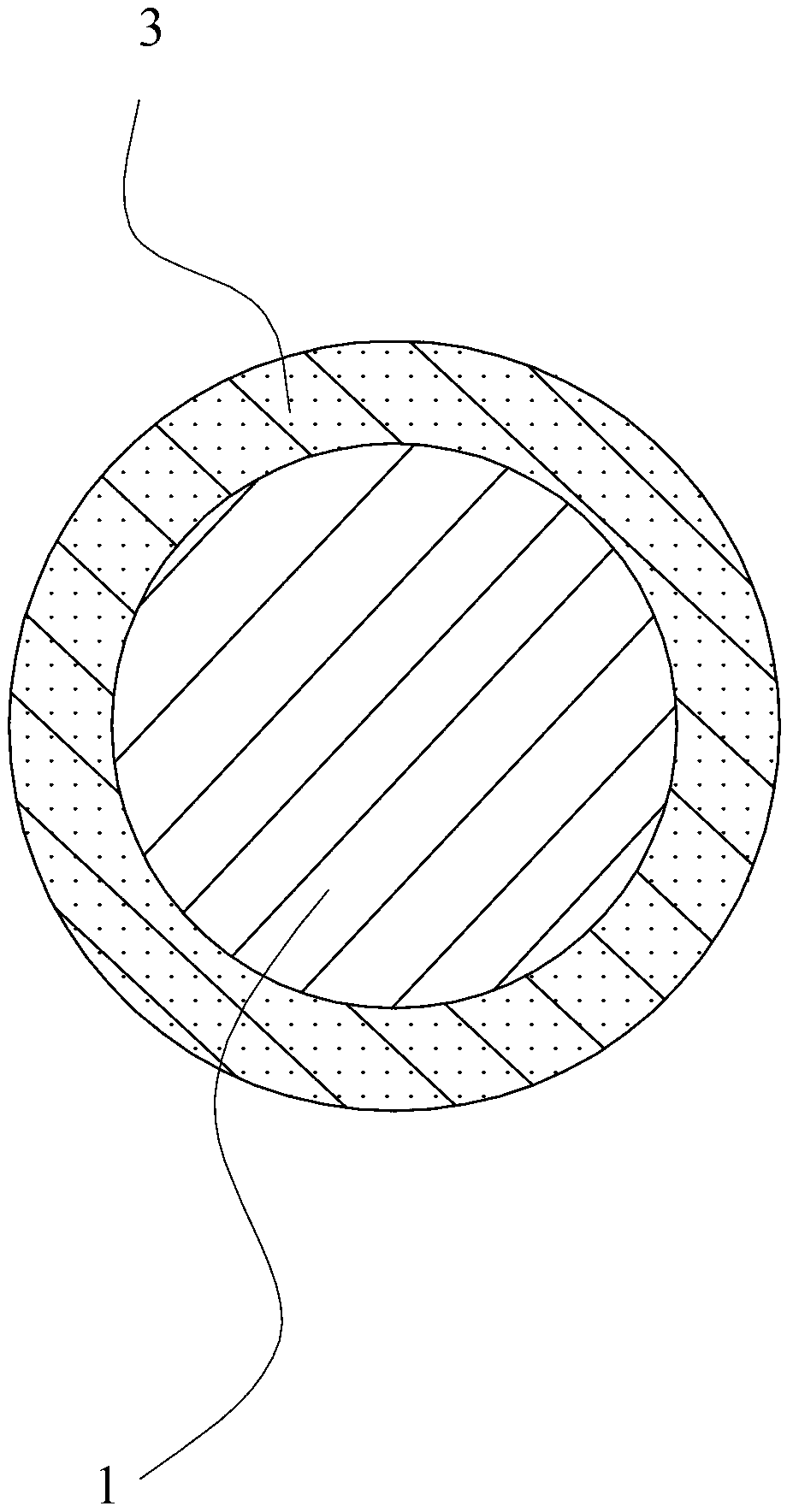

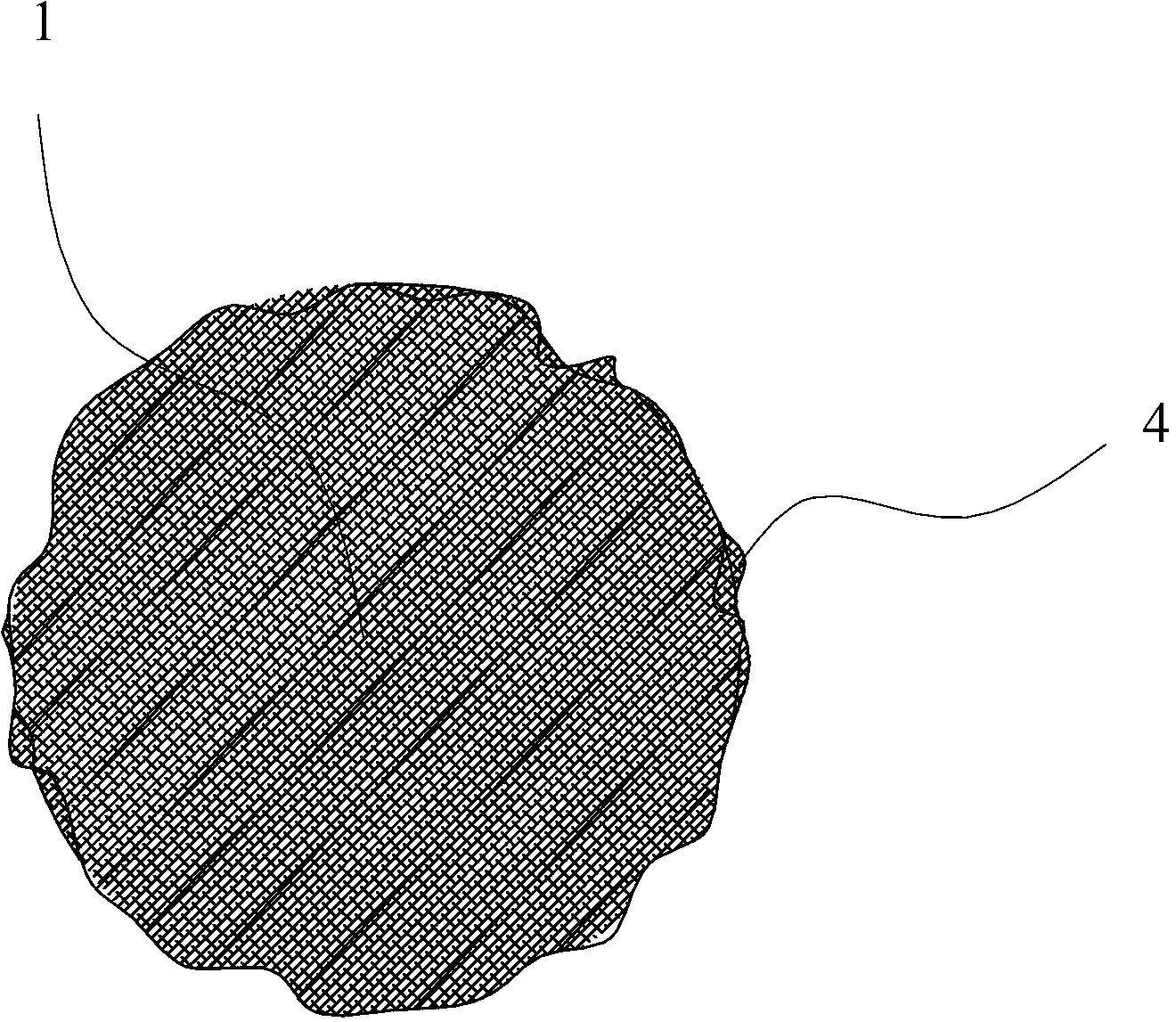

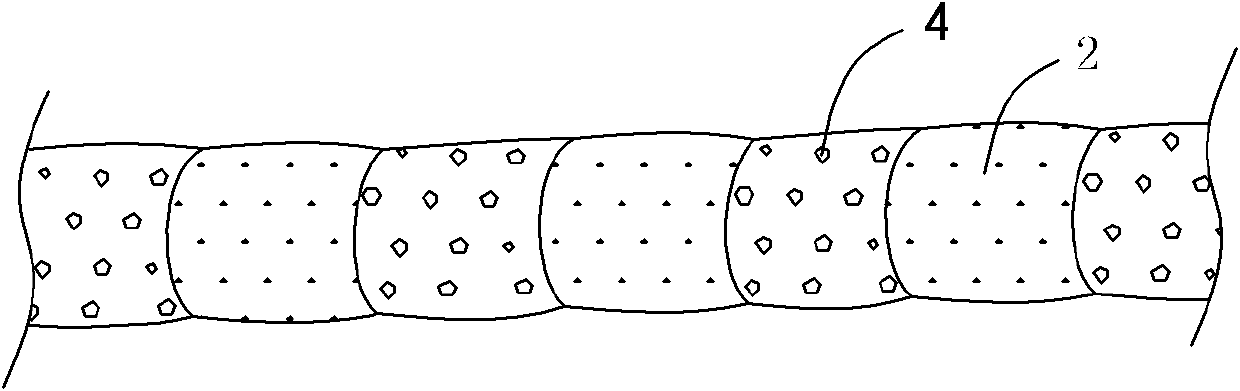

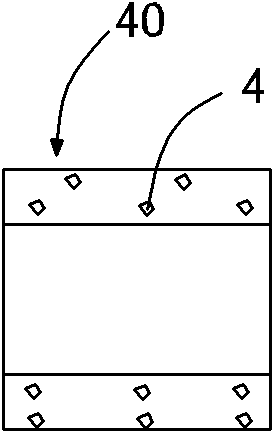

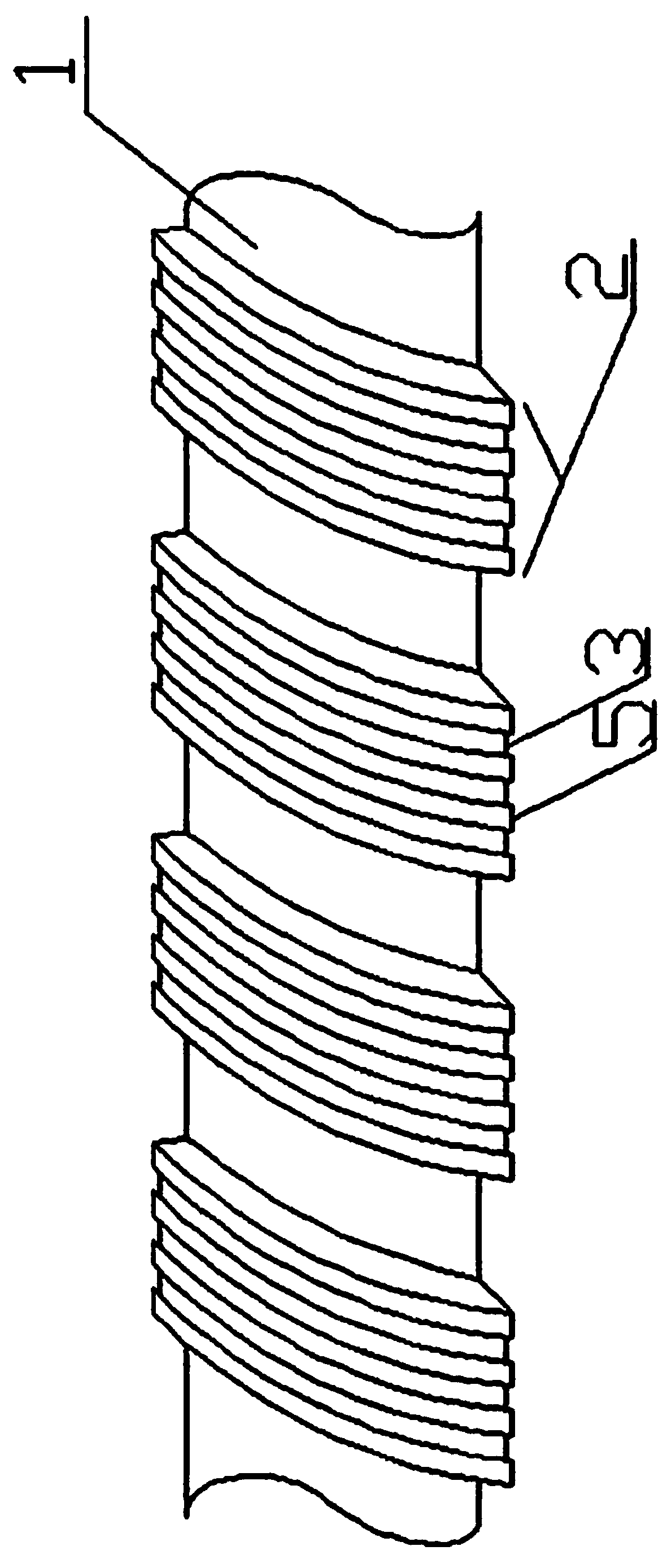

Diamond bead string and manufacturing method thereof as well as rope saw without base body supporting layer

ActiveCN102825254AReasonable ratioSmall kerfMetal sawing toolsStone-like material working toolsHot pressWire rope

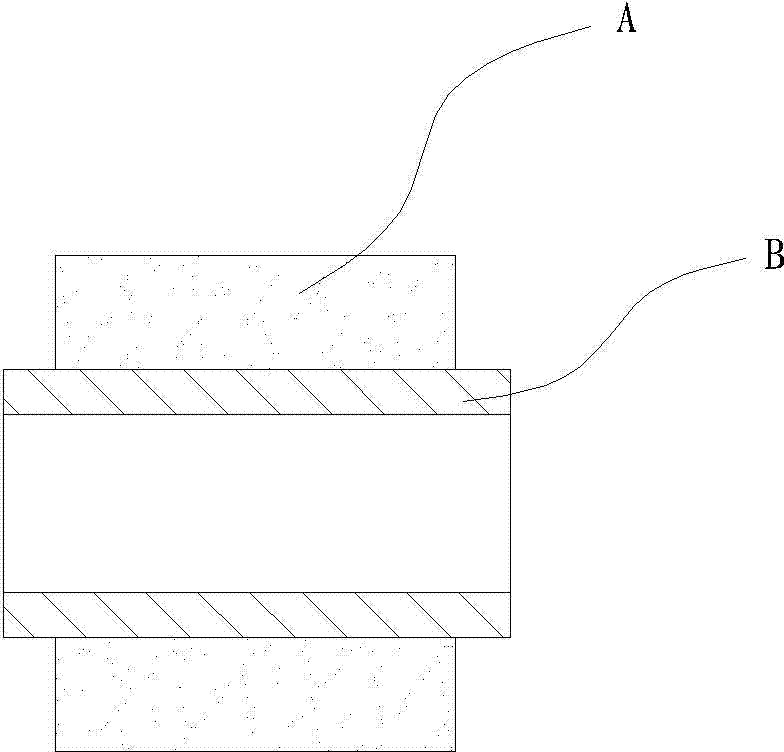

The invention discloses a diamond bead string and a manufacturing method thereof as well as a diamond bead string rope saw without a base body supporting layer. The manufacturing method of the diamond bead string comprises the following steps of: uniformly mixing metal powder, diamond and an organic binding agent; manufacturing a rough blank of the diamond bead string through a pre-hot-pressing modeling or metal injection molding (MIM) process; and obtaining a finished product of the diamond bead string by placing the rough blank in a high-temperature furnace for one-step sintering modeling process after degreasing. The manufacturing method of the diamond bead string provided by the invention can be used for sintering the rough blank in one step to form an entire cylindrical bead string without a bead string base body layer; the external diameter of the bead string becomes smaller, so that the bead string can be directly stringed into a steel wire rope to obtain a diamond rope saw with a smaller external diameter; the bead string is molded through one step without a last-stage permeation process, so that the production cost of the diamond bead string is greatly reduced. Furthermore, the diameter of the diamond rope saw is smaller, and a cutting seam of a stone material to be cut is smaller, so that the yield of rough stone block is improved. The manufacturing method of the diamond bead string is beneficial to large-range popularization and utilization of the diamond rope saw.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

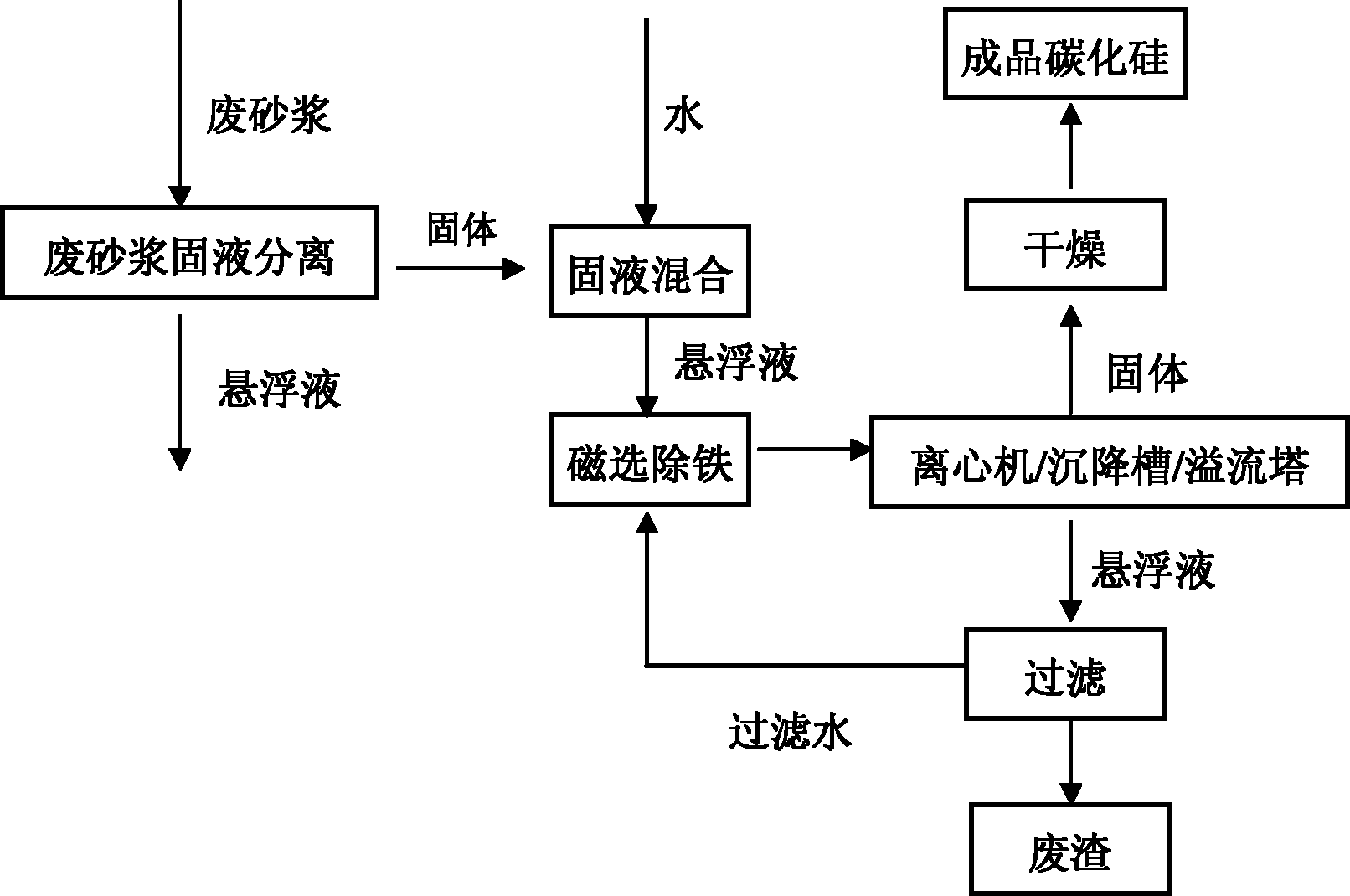

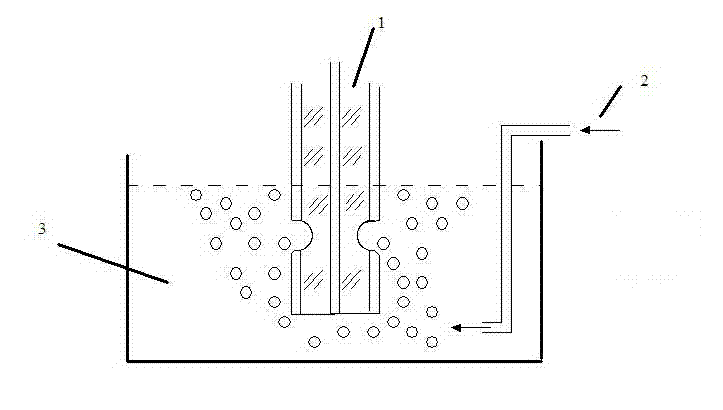

Method for recycling silicon carbide micropowder from waste mortar produced by cutting silicon wafer

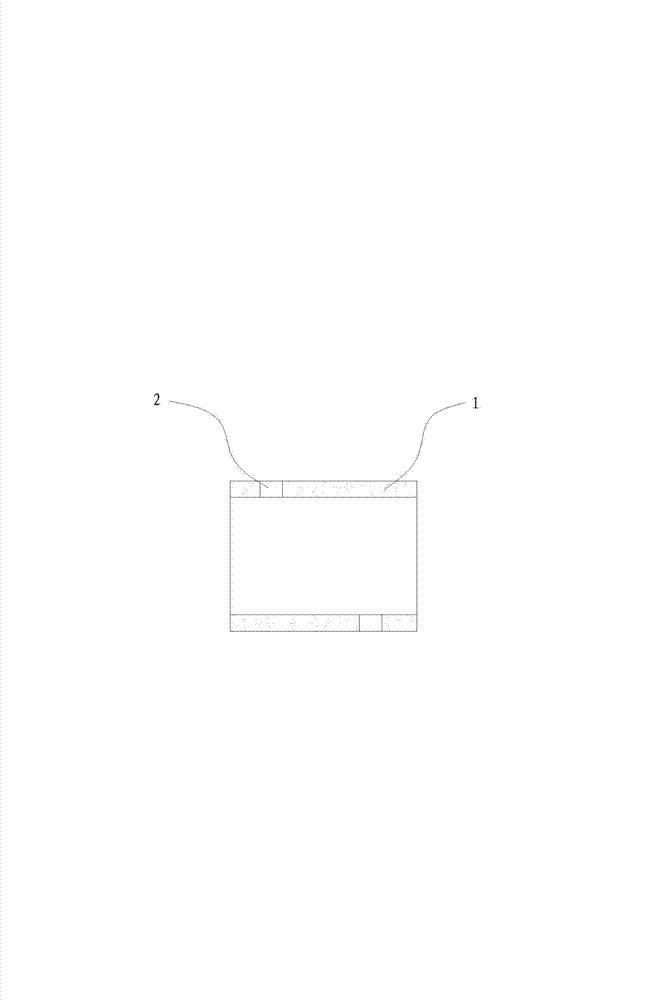

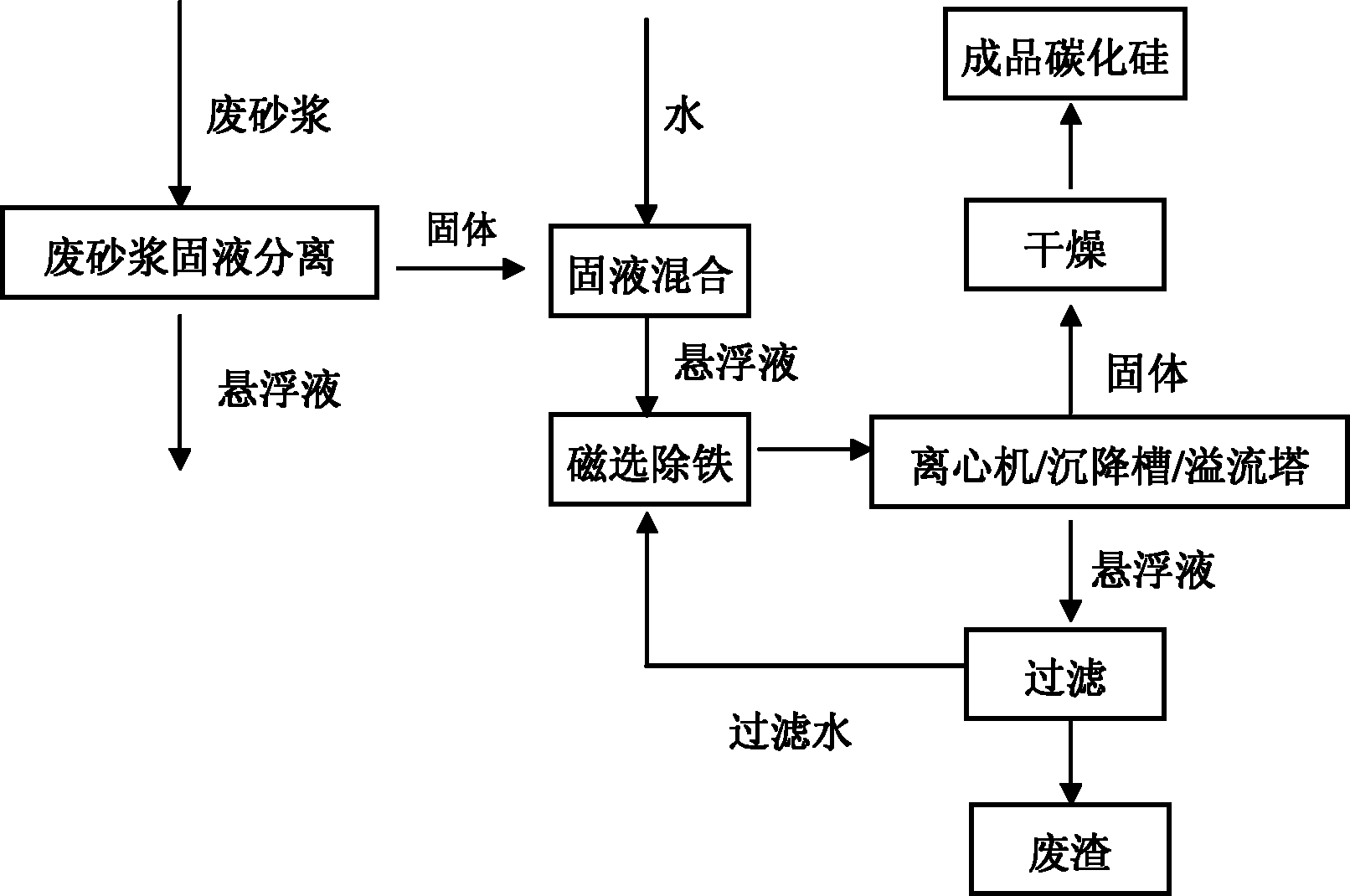

The invention relates to a method for recycling silicon carbide micropowder from waste mortar produced by cutting a silicon wafer. The method comprises the following steps of: firstly, performing solid-liquid separation on the waste mortar by use of a centrifuge, and mixing and stirring the separated solid sand and water; removing iron by magnetic separation, then adding a certain amount of dispersant, and performing ultrasonic treatment; realizing separation of silicon and silicon carbide particles as well as classification of the silicon carbide particles through precipitation or hydraulic overflow washing; and finally, drying the classified solids, and further separating the silicon powder and silicon carbide particles which are not completely separated by use of a cyclosizer so as to obtain high-purity silicon carbide powder. Through the invention, the silicon carbide micropowder in the waste mortar produced by cutting a silicon wafer rod can be effectively recycled, the recycling efficiency is high, the environmental pollution is little, the requirement for linear cutting of a silicon rod can be met, the recycling is realized, and the enterprise production cost is greatly lowered.

Owner:西安通鑫半导体辅料有限公司

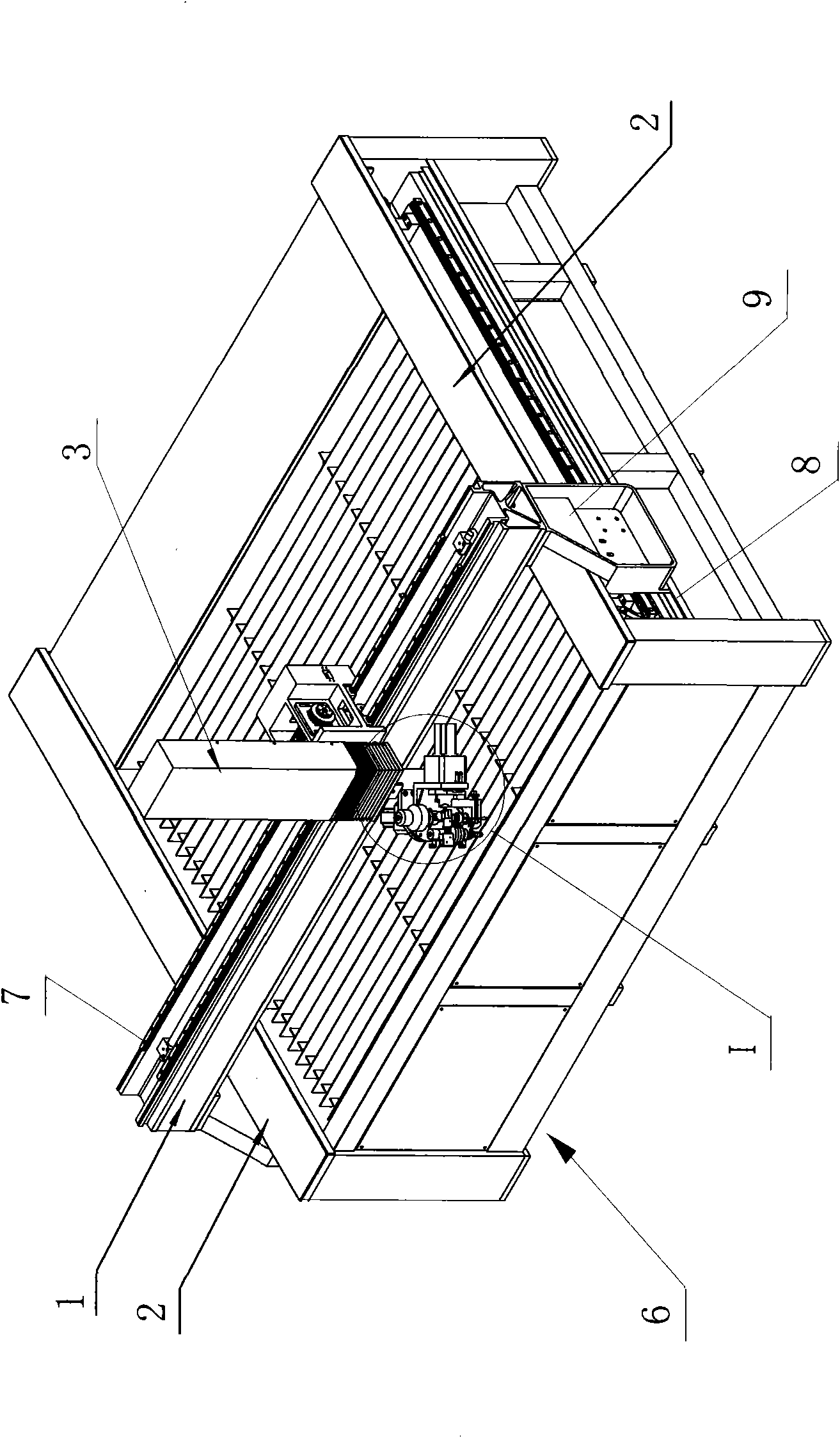

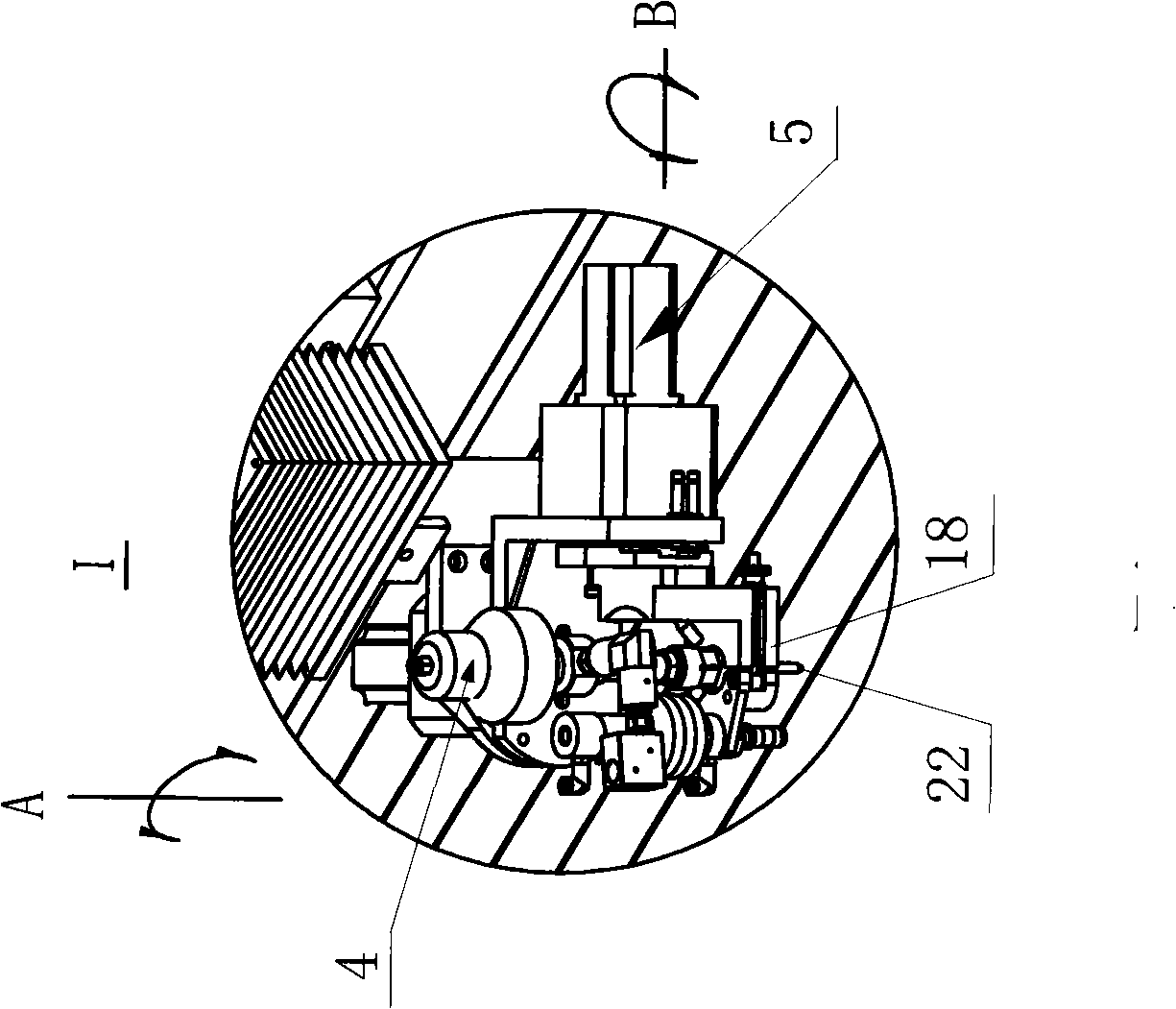

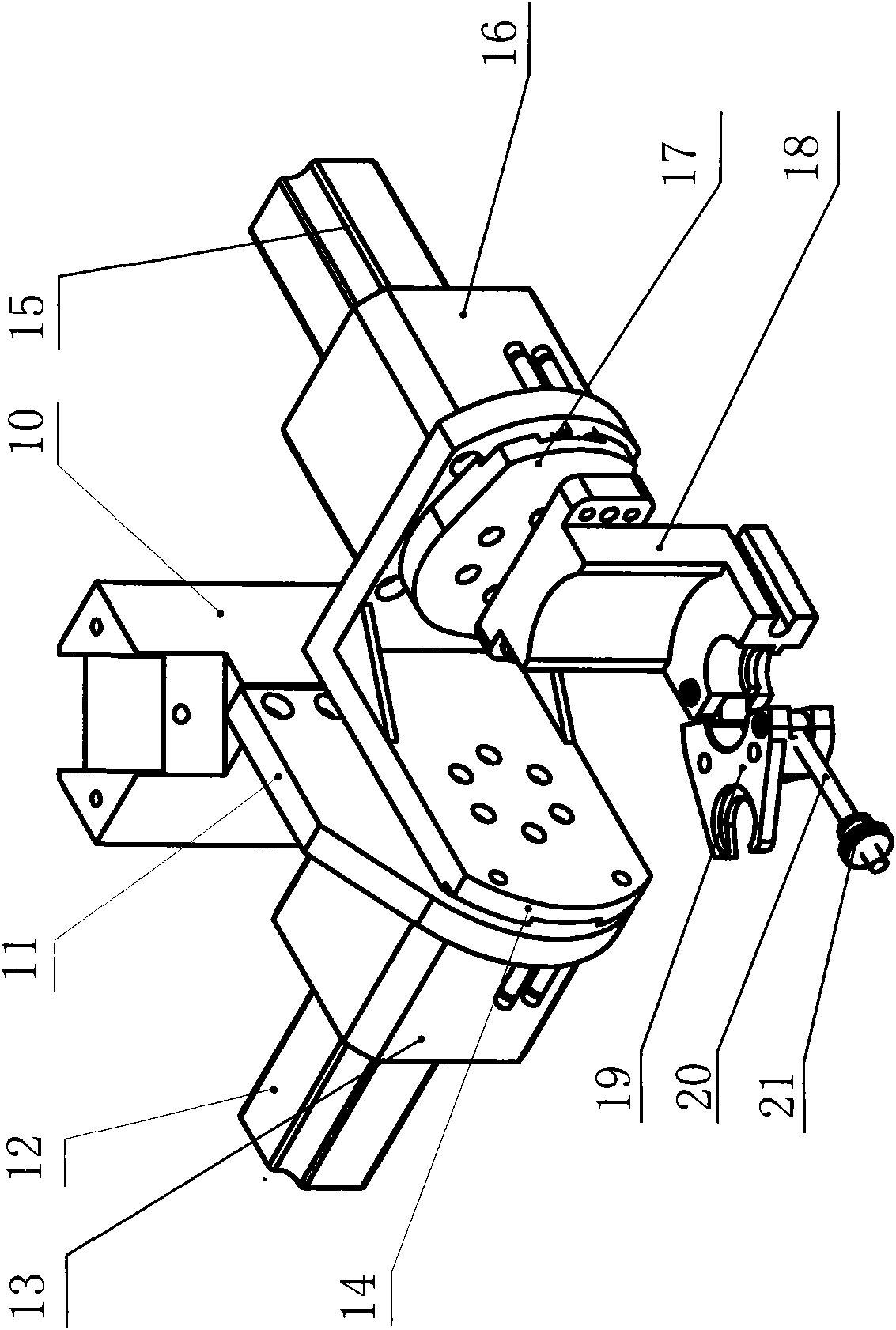

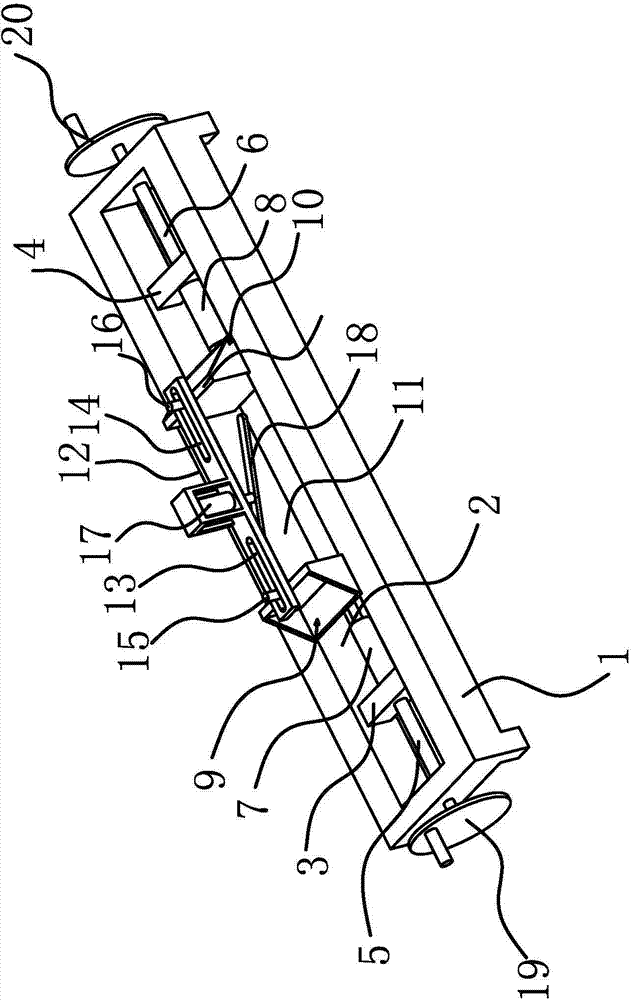

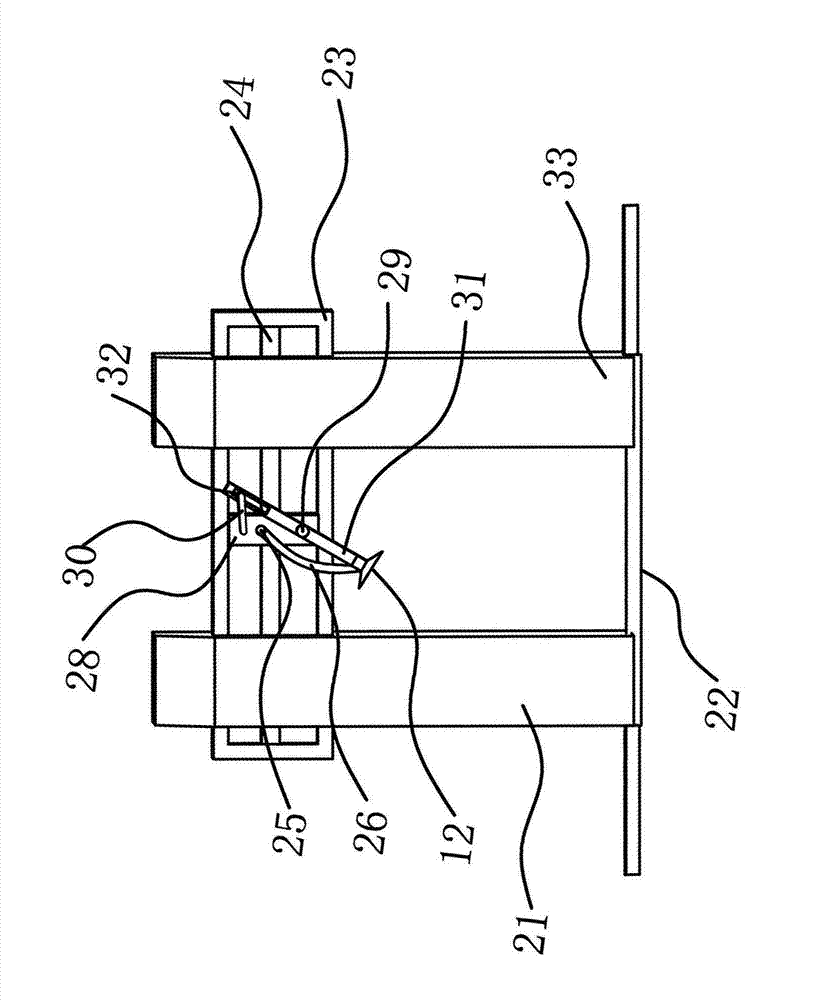

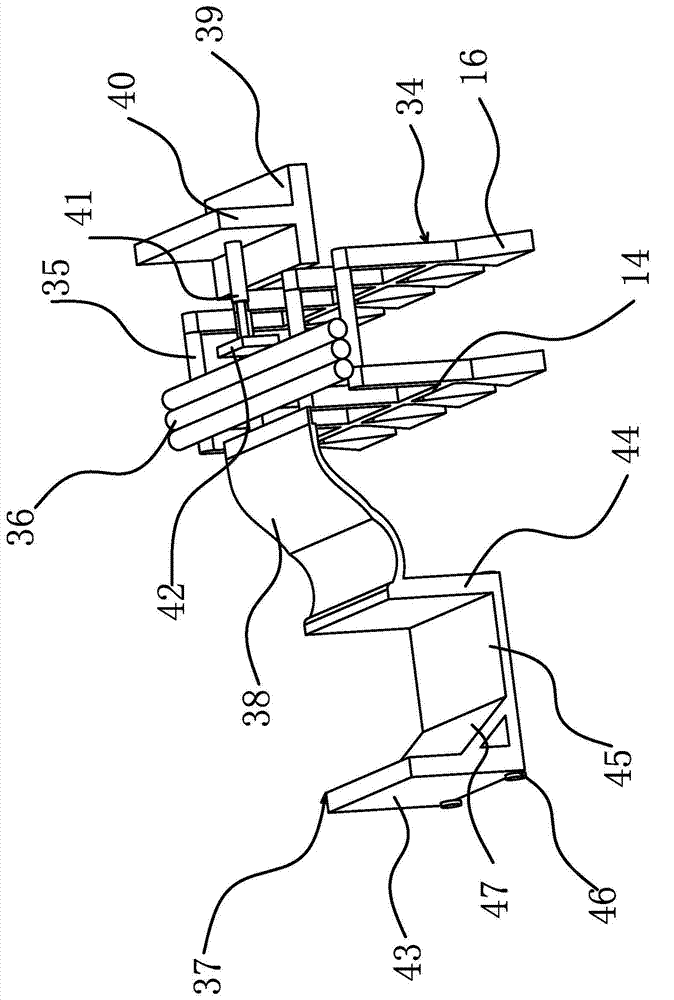

Numerical control five-axle linkage super-high pressure water jet cutting machine

ActiveCN101554738AHigh dimensional accuracyImprove cut qualityShearing machinesMetal working apparatusNumerical controlReducer

The invention relates to a numerical control five-axle linkage super-high pressure water jet cutting machine which comprises a super-high pressure water jet generator, a water jet cutting platform, an X-axle transmission mechanism, a Y-axle transmission mechanism, a Z-axle transmission mechanism and a cutting head connected with the Z-axle transmission mechanism. The numerical control five-axle linkage super-high pressure water jet cutting machine is characterized in that the cutting head has a composite rotating head of axles A and B. The composite rotating head of axles A and B comprises an A axle motor, a B axle motor, a connecting plate of axles A and B and a movable seat, wherein the A axle motor is fixedly connected to a transition plate of the Z-axle transmission mechanism through an A axle speed reducer of the A axle motor, and the output shaft of the A axle speed reducer is connected with the connecting plate of axles A and B; and the B axle motor is fixed on the connecting plate of axles A and B through a B axle speed reducer of the B axle motor, the output shaft of the B axle speed reducer is connected with the movable seat, the cutting head is clipped on the movable seat, the X-axle, the Y-axle, the Z-axle, the A axle and the B axle are interlocked under a main programmable digital controller to control the cutting head to incline in any direction, and the cut bevel edge generated after water jet cutting is filled up. The water jet cutting machine has high automation and cutting efficiency, effectively overcomes the problems of water jet lag and cut bevel edge of the traditional water jet cutting machine and has high cutting precision.

Owner:沈阳奥拓福科技股份有限公司

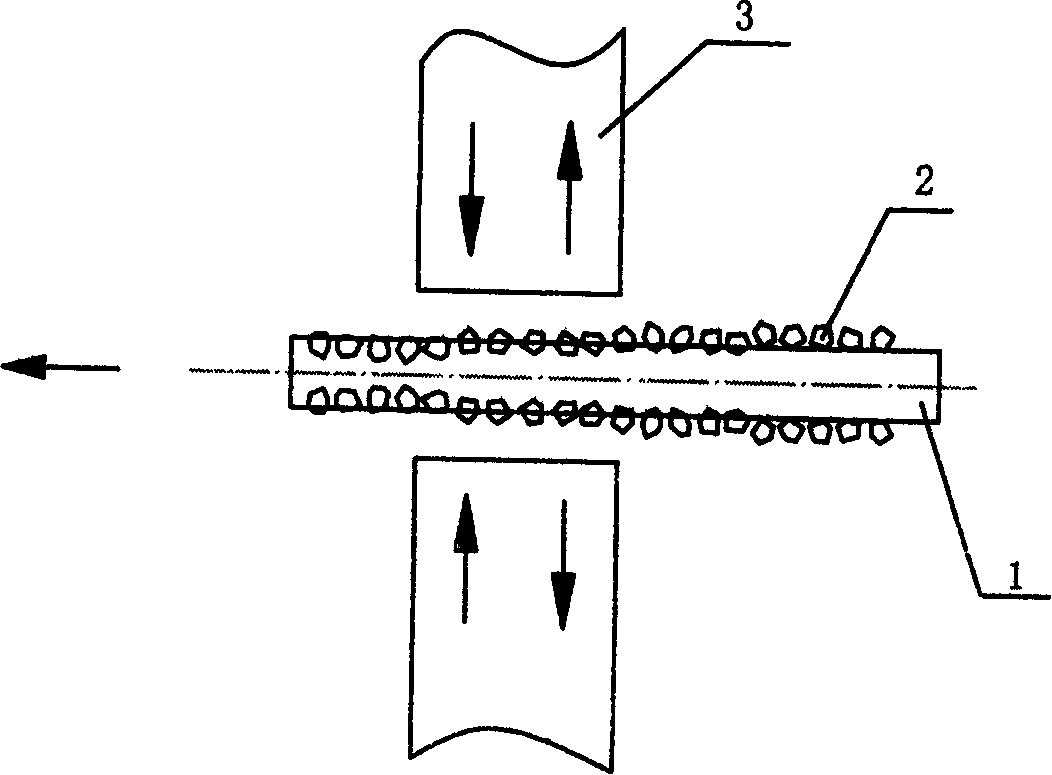

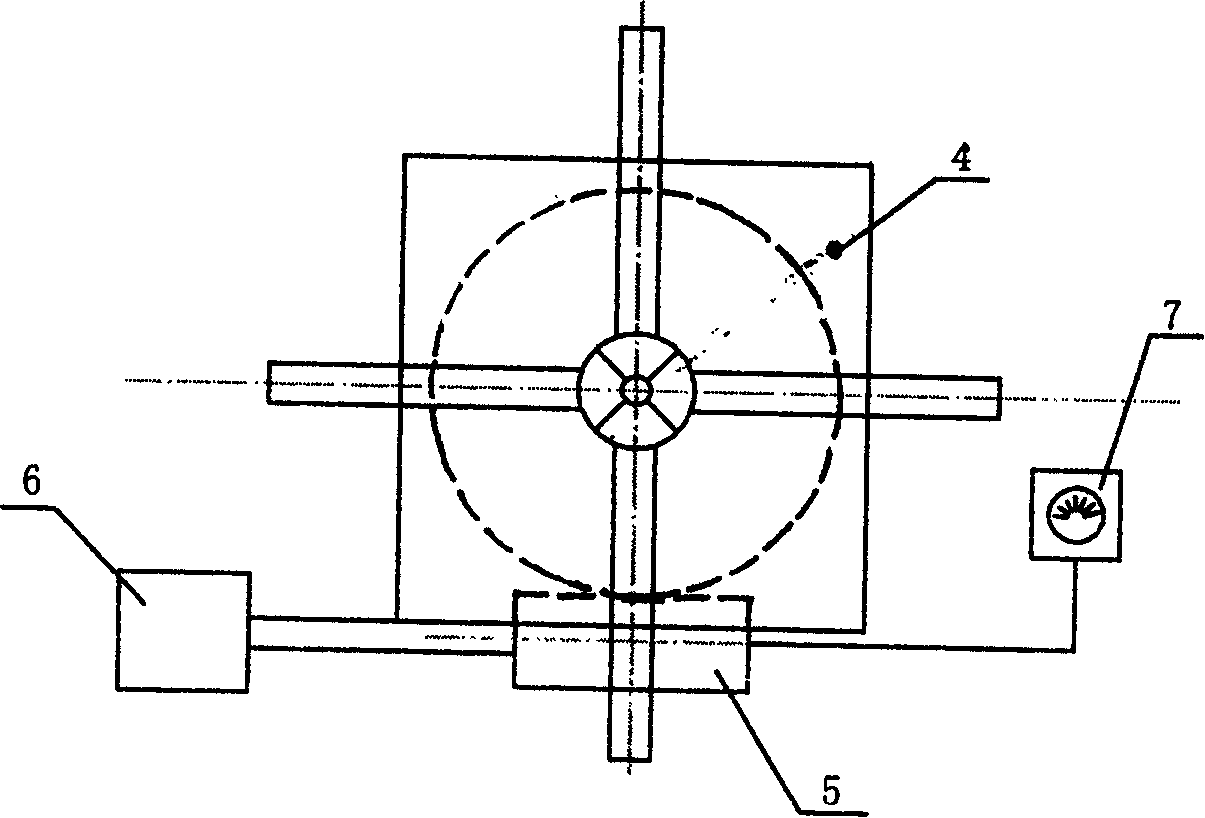

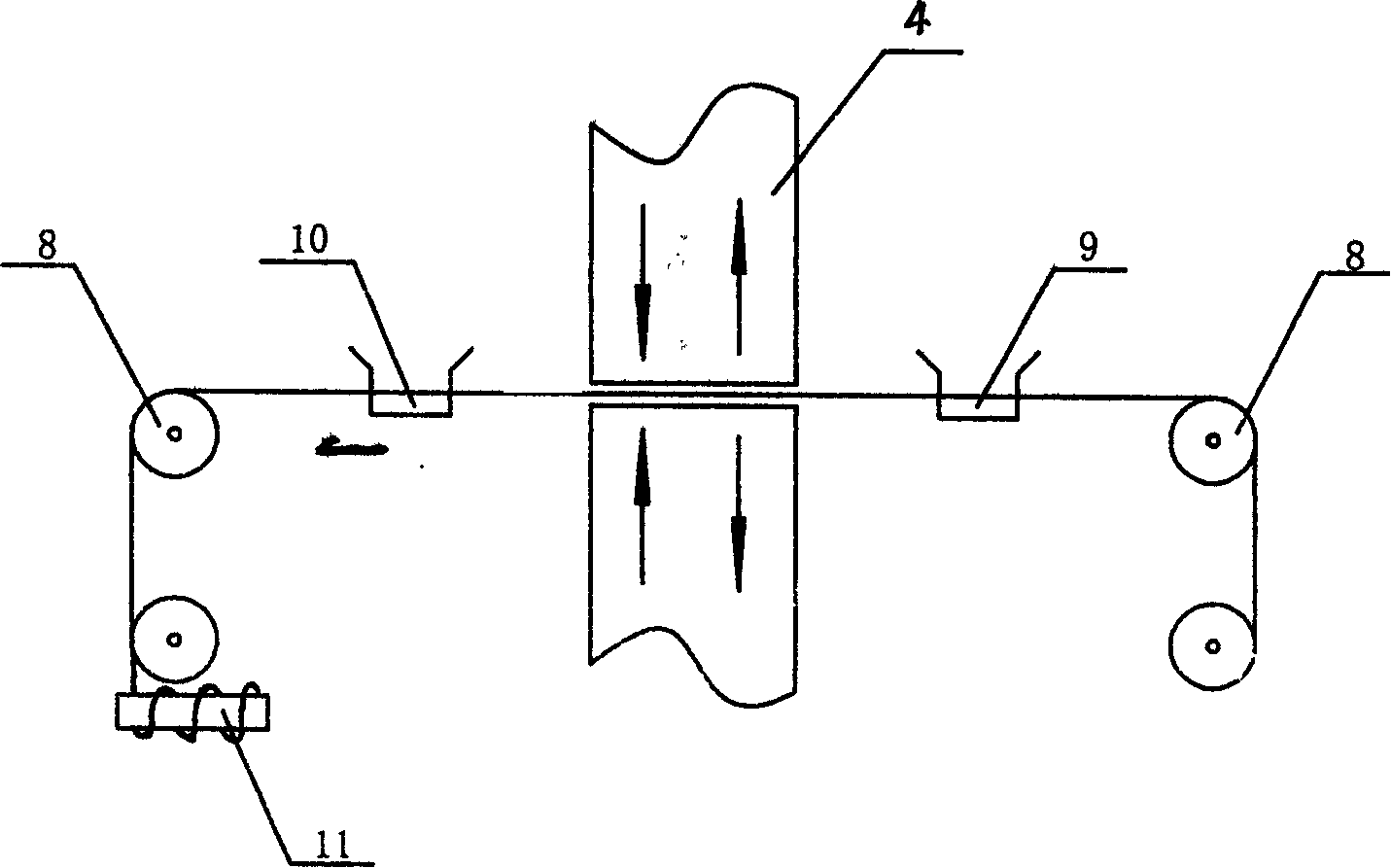

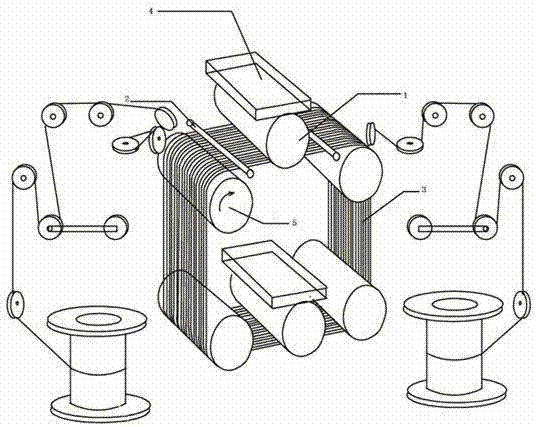

Process and apparatus for producing highly wear resistant diamond cutting wires

InactiveCN1456410AUniform diameterImprove wear resistanceHot-dipping/immersion processesMetal sawing toolsDiamond cuttingPunching

A technology and apparatus for manufacturing the antiwear combined cutting diamond wire features that the diamond microparticles are inlaid in the subsurface of steel wire by squeezing or punching. Its advantages are long length up to 60 km, uniform diameter, and high antiwear performance and tension strength.

Owner:江晓平 +2

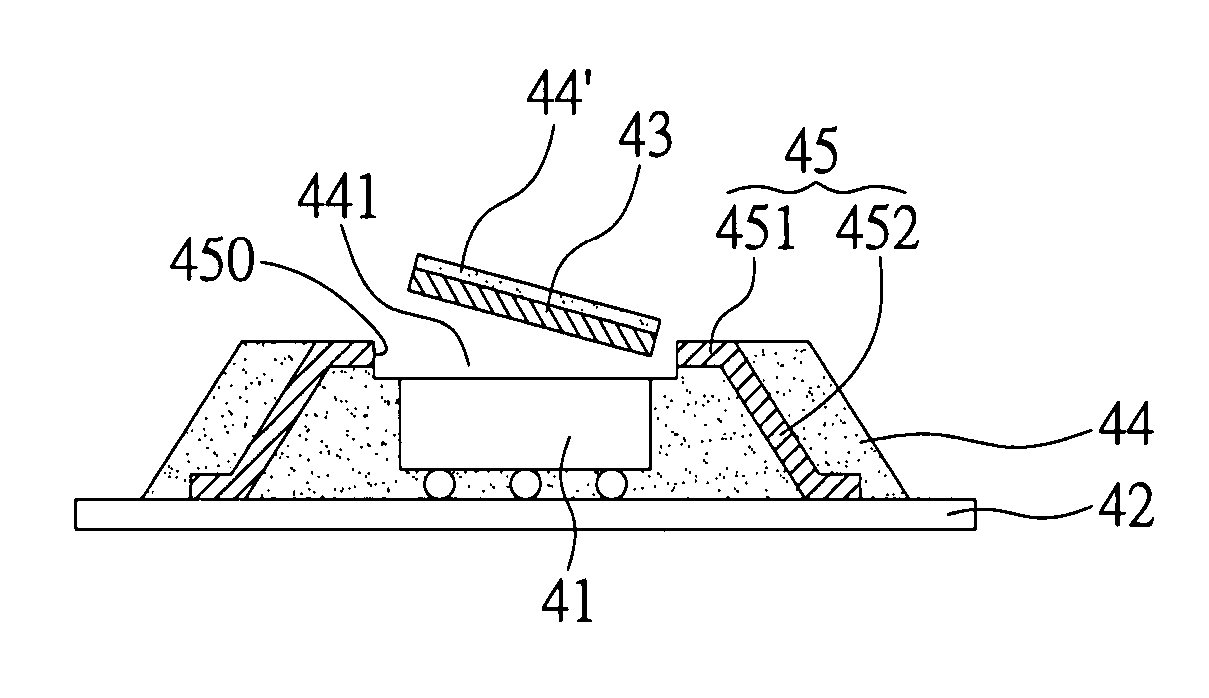

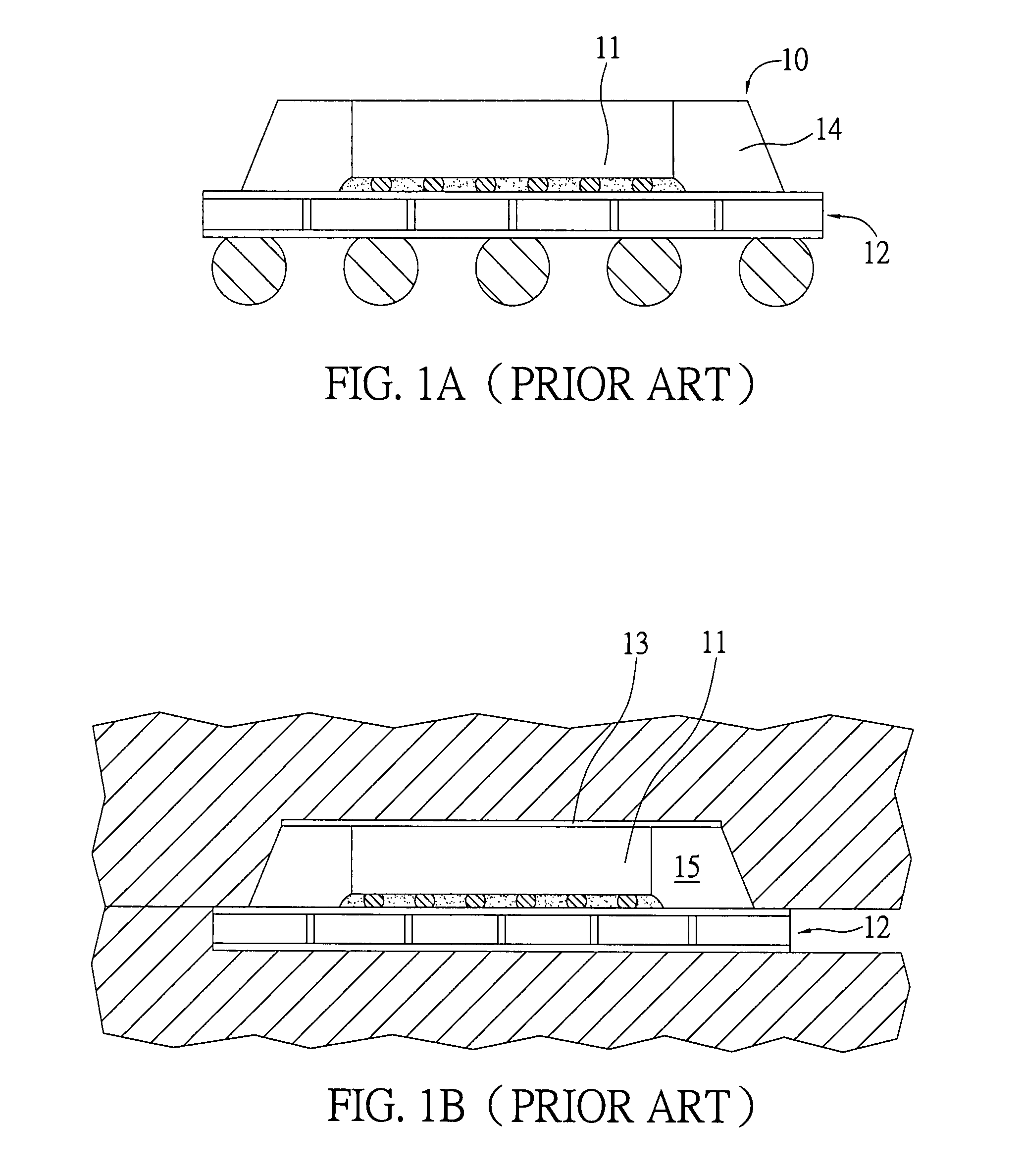

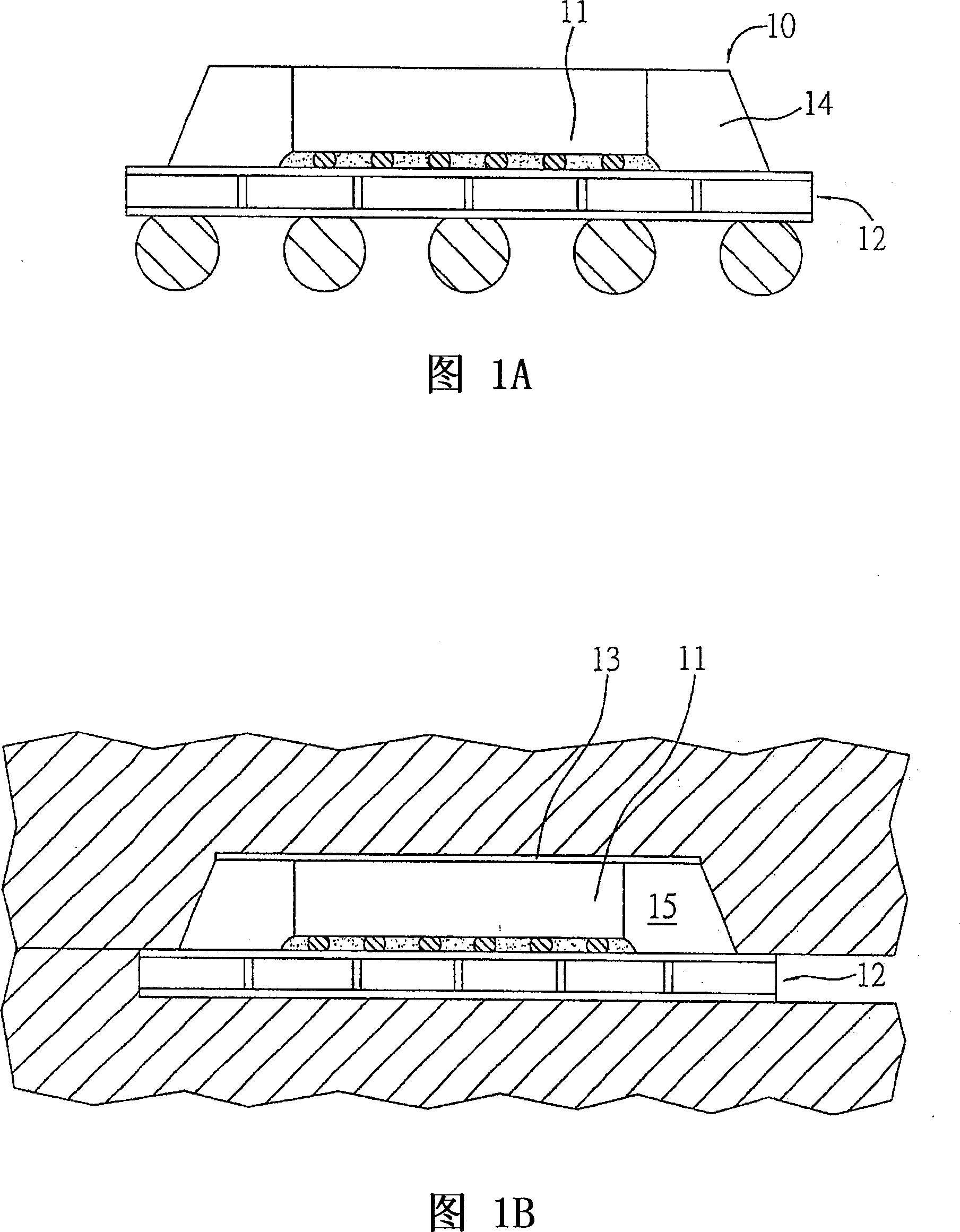

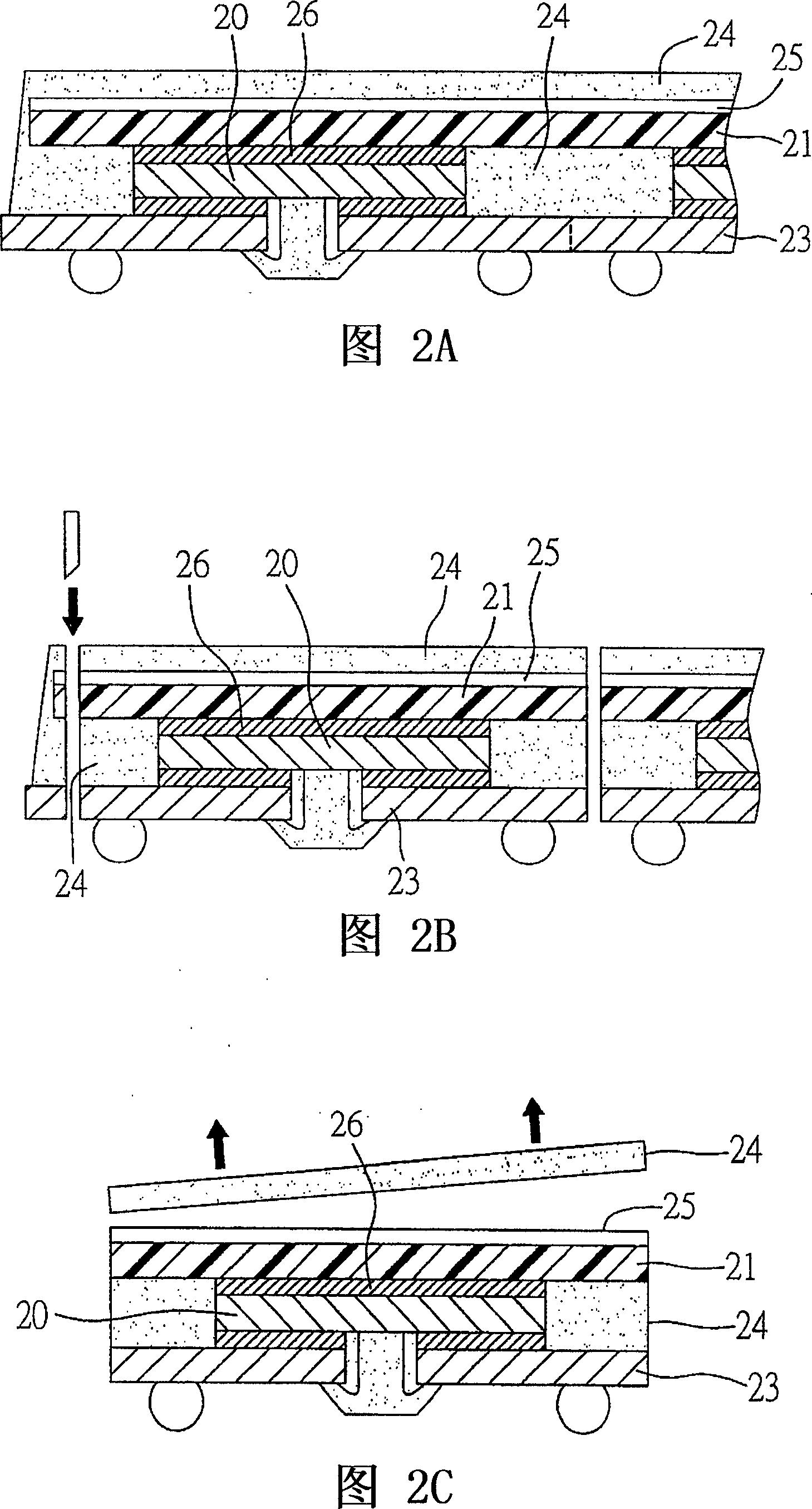

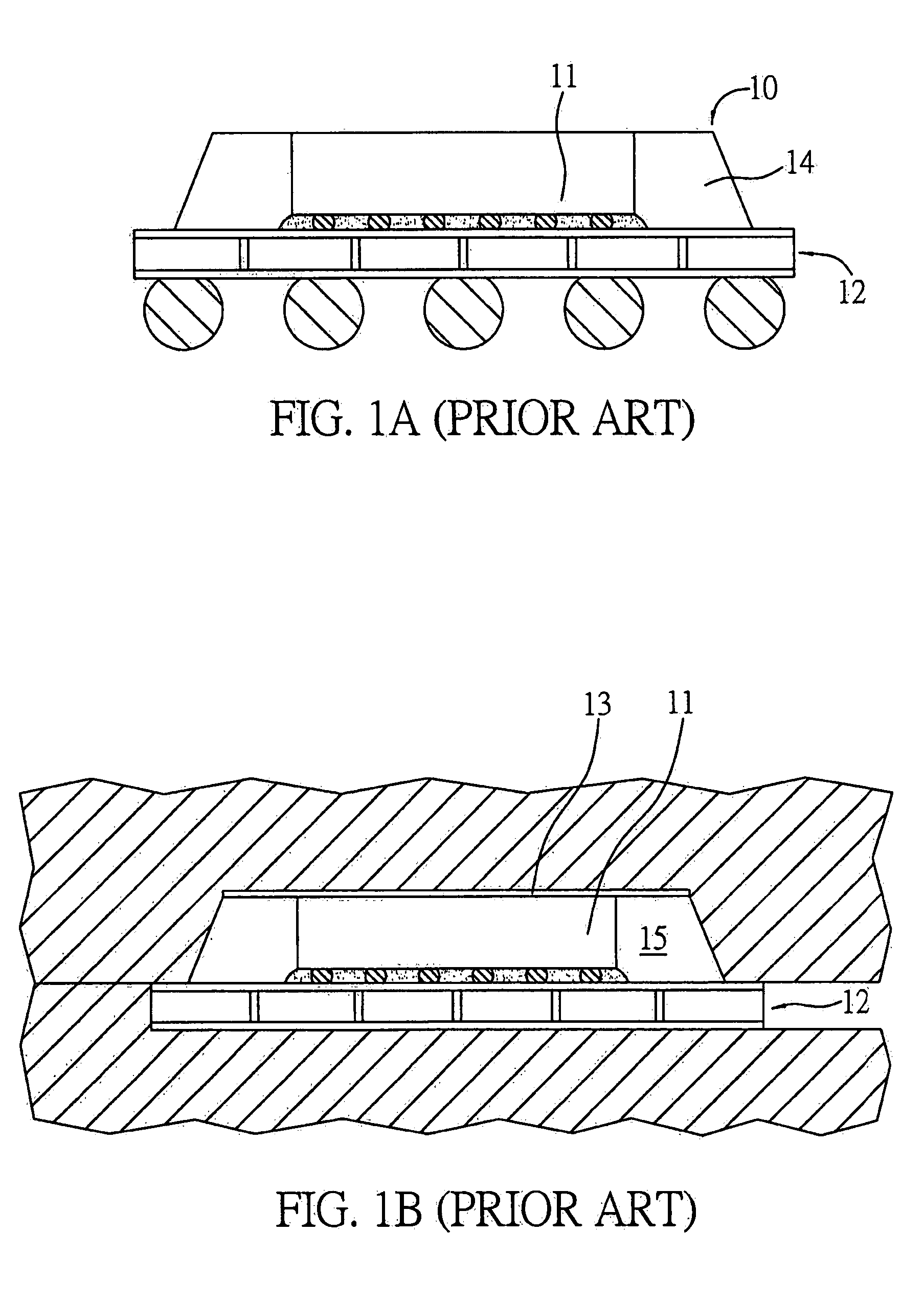

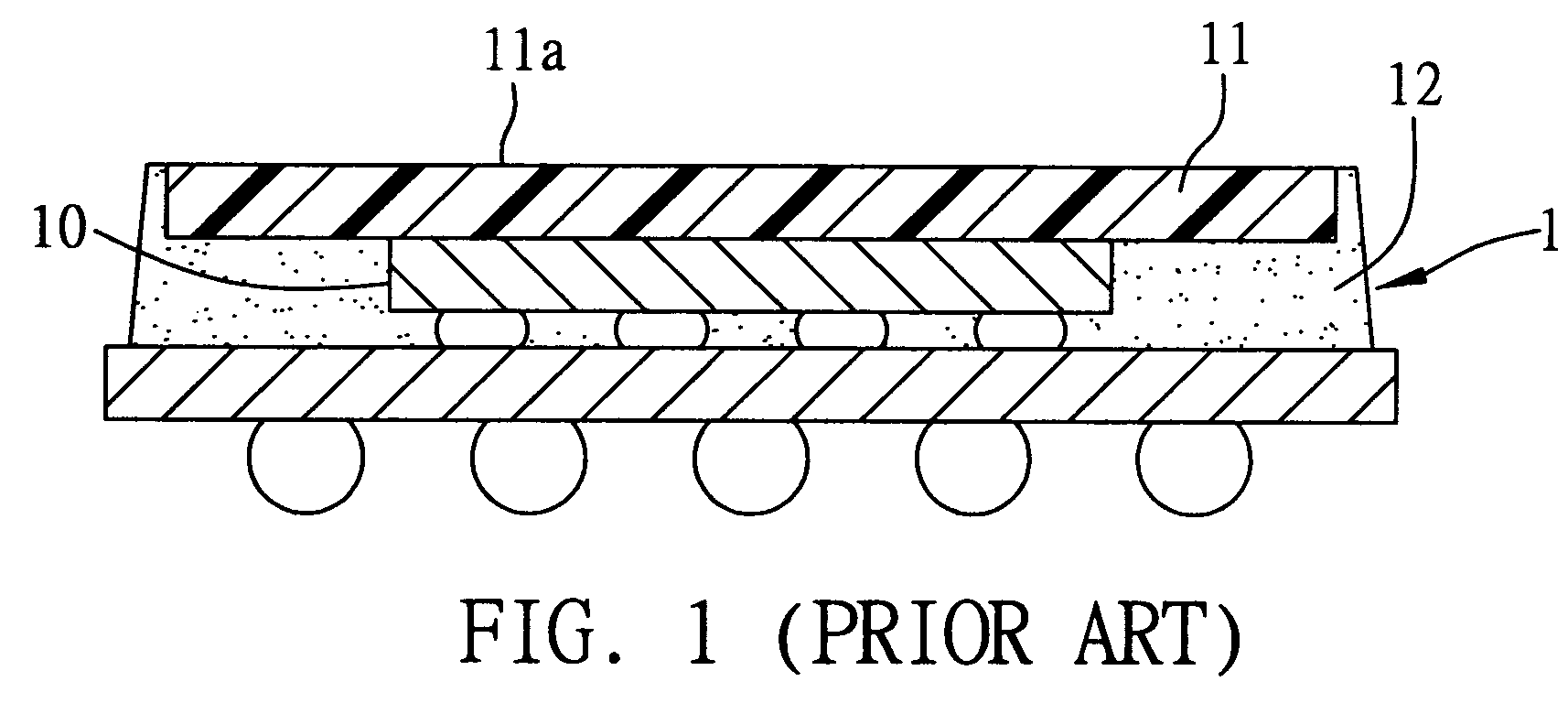

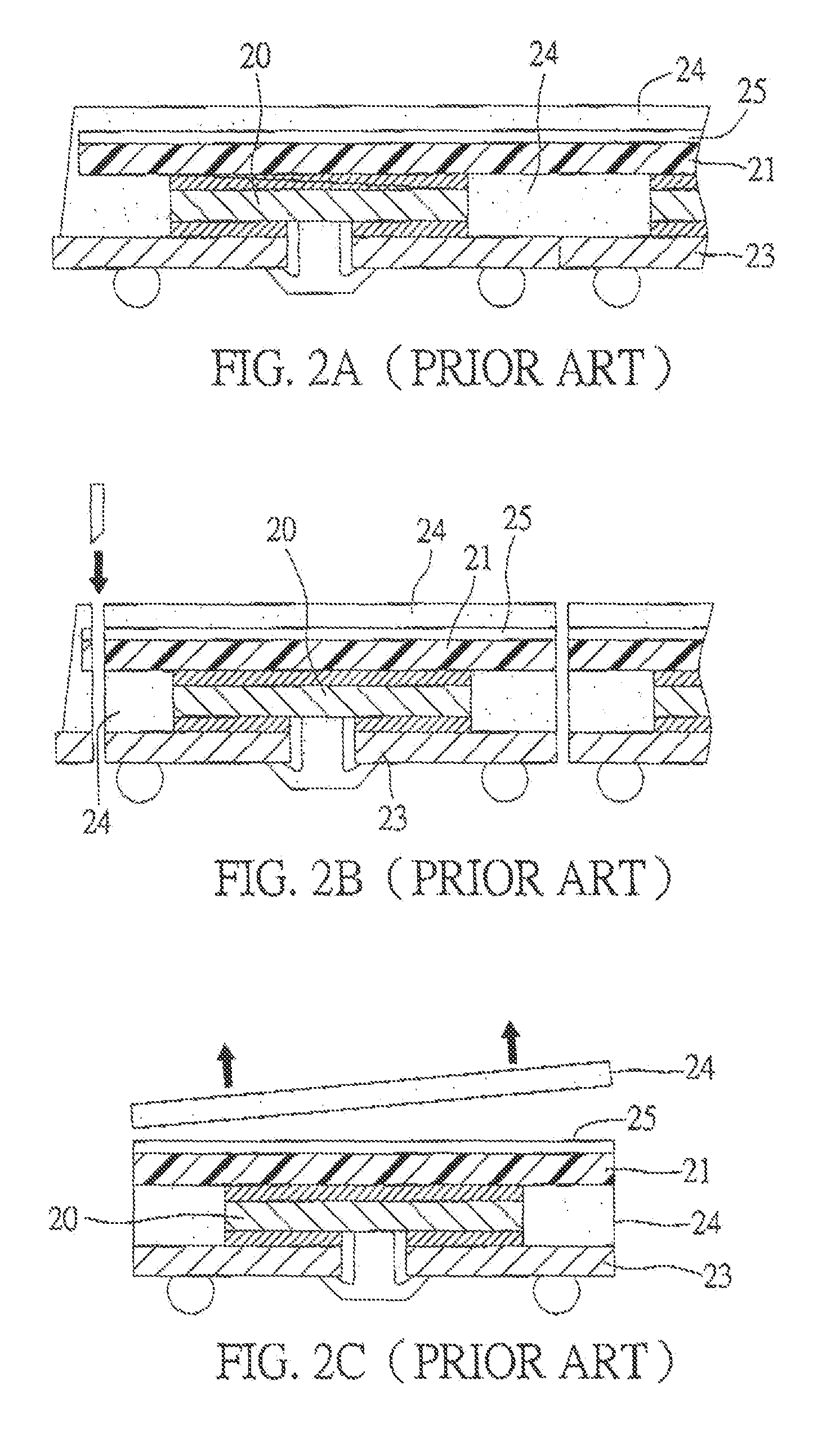

Heat dissipating structure and method for fabricating the same

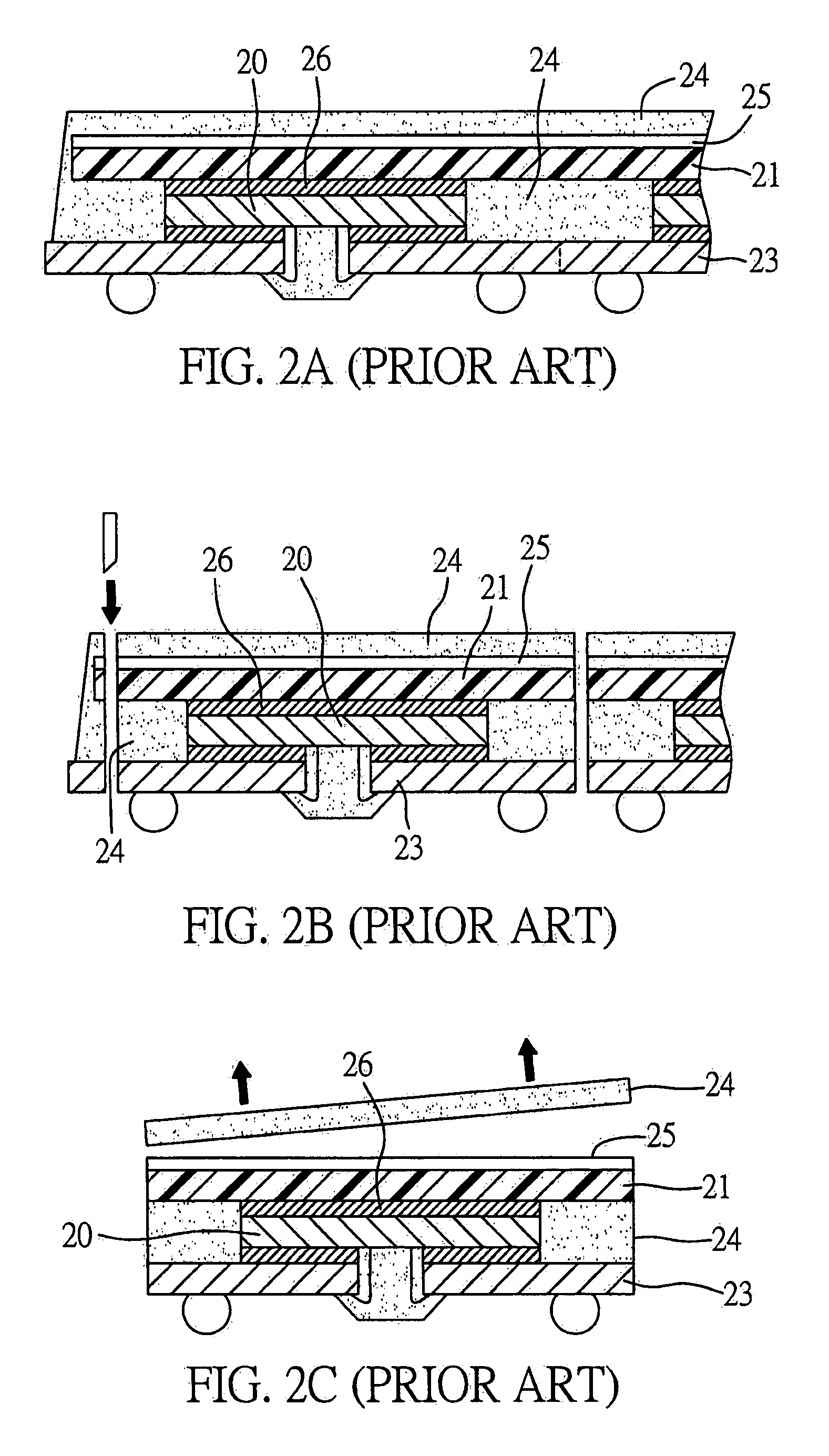

InactiveUS20070296079A1Avoid crackingReduce cutting costsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipInterface layer

A heat sink package structure and a method for fabricating the same are disclosed. The method includes mounting and electrically connecting a semiconductor chip to a chip carrier, forming an interface layer or a second heat dissipating element having the interface layer on the semiconductor chip and installing a first heat dissipating element having a heat dissipating portion and a supporting portion onto the chip carrier. The method further includes forming openings corresponding to the semiconductor chip in the heat dissipating portion, and forming an encapsulant for covering the semiconductor chip, the interface layer or the second heat dissipating element, and the first heat dissipating element. A height is reserved on top of the interface layer for the formation of the encapsulant for covering the interface layer. The method further includes cutting the encapsulant along edges of the interface layer, and removing the redundant encapsulant on the interface layer. Therefore, the drawbacks of the prior art of the burrs caused by a cutting tool for cutting the heat dissipating element and wearing of the cutting tool are overcome.

Owner:SILICONWARE PRECISION IND CO LTD

Efficient electrode wire for precision mould cutting and preparing method of efficient electrode wire

ActiveCN103273150AImprove cutting efficiencyLarge discharge energyElectrical-based machining electrodesOperabilityZinc

The invention relates to an efficient electrode wire for precision mould cutting. The efficient electrode wire comprises a core material and a shell layer wrapping the surface of the core material, the core material is made of yellow copper from the processes of smelting, casting, stretching and annealing, the shell layer is a discontinuous shell layer formed by heating, continuously drawing and continuously annealing a zinc metal plating layer plated on the yellow copper core material, and the discontinuous shell layer comprises shell particles which radially cover 40-90% of the surface of the core material and are distributed at intervals along an axial direction of the surface of the core material. The invention further relates to a preparation method of the electrode wire. The preparation method is simple in production technology, strong in operability, less in preparation steps, simple in production equipment and easy to prepare satisfactory products and realize large-scale and automated production. The efficient electrode wire is strong in universality and is particularly suitable for precision mould cutting.

Owner:NINGBO BODE HIGHTECH CO LTD

Heat-radiation type package structure and its method for making

InactiveCN101101880AAvoid pressure lossAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention is concerned with the thermolysis packaging structure and the making method, it is: attaches the semiconductor chip with the chip carrying piece by electricity to form the surface or the second heat sink with surface, and attaches the first heat sink with thermolysis part that is opposites the open whole of the semiconductor chip and the support part, with the chip carrying piece, next, is forms the surface or the second heat sink with surface that covers the semiconductor chip and the packaging colloid of the first heat sink, and there is must certain space leaves for the packaging colloid covering the surface, which is the way of preventing the problems of pressure damage and glue overflow of the current making method, and to the next step is incises the packaging colloid follows the surface edge and removes the unwanted, losses heat for the semiconductor chip, in order to prevent the problems of raw edge and tools wastage, which reduces the cost efficiently.

Owner:SILICONWARE PRECISION IND CO LTD

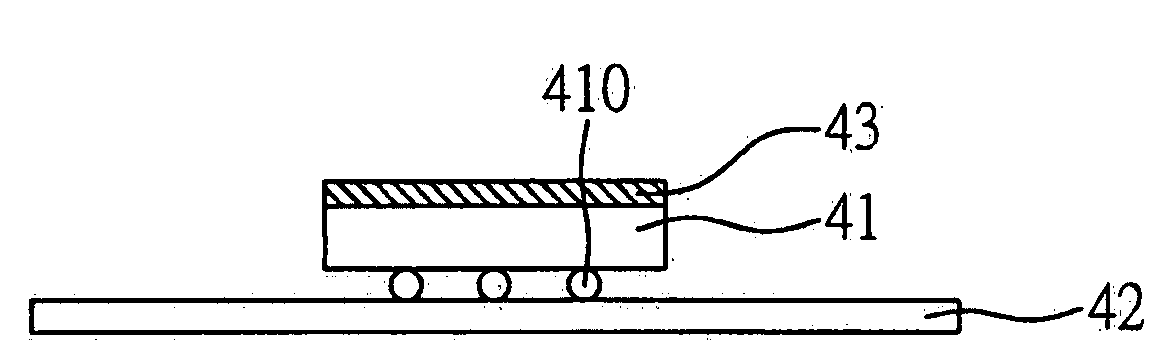

Semiconductor package and method for fabricating the same

InactiveUS20090096115A1Heat dissipationAvoid damageSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package and a method for fabricating the same are disclosed. The present invention discloses mounting and electrically connecting a semiconductor chip to a chip carrier, forming an interfacial layer or a heat-dissipating member having the interfacial layer on the semiconductor chip, and forming an encapsulant for covering the semiconductor chip, the interfacial layer or the heat dissipating member. The method further includes cutting the encapsulant along edges of the interfacial layer, and removing the redundant encapsulant on the interfacial layer so as to expose the semiconductor chip or the heat-dissipating member without forming burr or heavily wearing cutting tools.

Owner:SILICONWARE PRECISION IND CO LTD

Consolidation grinding material wire-electrode cutting method and cutting fluid

InactiveCN103121245AImprove line marksImprove micro damageOther chemical processesFine working devicesSurface roughnessEngineering

The invention relates to a consolidation grinding material wire-electrode cutting method and dedicated cutting fluid. The existing consolidation grinding material wire-electrode cutting is bad in cutting surface quality, possesses a plurality of deep check lines and tiny damage and is high in surface roughness, and meanwhile, swarf and dropped grinding material grains are easily adhered between the cutting line surface and grinding material grains to lower cutting force of cutting lines. The invention provides the novel consolidation grinding material cutting method and the dedicated cutting fluid used for the consolidation grinding material cutting method. Due to the development of the cutting fluid formula, the consolidation grinding material wire-electrode cutting method and the dedicated cutting fluid used for the consolidation grinding material cutting method overcome the technical limits, obviously improve check lines and tiny damage of the cutting surface, reduce roughness, reduce phenomenon of swarf attachment, improve cutting efficiency, reduce surface modification processing requirements such as grinding, polishing and the like of the cutting surface after cut and reduce cutting cost and follow-up process cost.

Owner:赵钧永

High-performance cutter coating material and smelting method thereof

The invention discloses high-performance cutter coating material and a smelting method of the high-performance cutter coating material. The coating material comprises Al, Co, Cr, Fe, Ni, Mo, Ti, Si, Al, Co, Cr, Fe, Ni, Mo, Ti and Si in mol ratio of 1: 1: 1: 1: 1: 1: 0.5: 0.5. Tests show that the hardness of the high-performance cutter coating material AlCoCrFeNiMoTi0.5Si0.5 is 1000.9HV0.200; the hardness is not changed basically after the coating material is annealed for 10h at 600 DEG C; and the hardness is reduced by 8% and 12% after the coating material is annealed at 800 DEG C and at 1100 DEG C for 10h; the high-entropy alloy is proven to have good high-temperature softening resistance and can be used for manufacturing cutter coating material; the cutting performance of a cutter is improved drastically in comparison with the prior cutter material. The alloy has no limit of application range when being used as the cutter coating, so that the cutter can be used for cutting various materials.

Owner:TAIYUAN INST OF TECH

Steel pipe cutting machine

ActiveCN103752935AAvoid jumping upFixed and accurateMetal-working feeding devicesOther manufacturing equipments/toolsGrinding wheelMechanical engineering

The invention belongs to the technical field of cutting and provides a steel pipe cutting machine which can improve the cutting efficiency of steel pipe cutting machines. The steel pipe cutting machine comprises a bench, and a clamping device, a cutting device, a trimming device, a cutting length adjusting device and a discharging device are disposed on the bench. The clamping device is used for clamping steel pipes, the cutting device is used for cutting the steel pipes, the trimming device is used for trimming a cutter, the cutting length adjusting device is used for adjusting the cutting length of the steel pipes, and the discharging device is used for moving the steel pipes into a containing box. When the steel pipe cutting machine is in use, the steel pipes are placed on the bench, the cutting length of the steel pipes can be adjusted through a measurement rod and a footstock, then the steel pipes are fixed by a first clamping block, a second clamping block and a pressure bar, the steel pipes cut by the cutter can be conveyed to the containing box through the discharging device, and when the cutter is abraded, a disc abrasive can be used for trimming the cutter. Cutting efficiency of the steel pipe cutting machine can be effectively improved.

Owner:QIDONG YONGXING RUBBER PROD

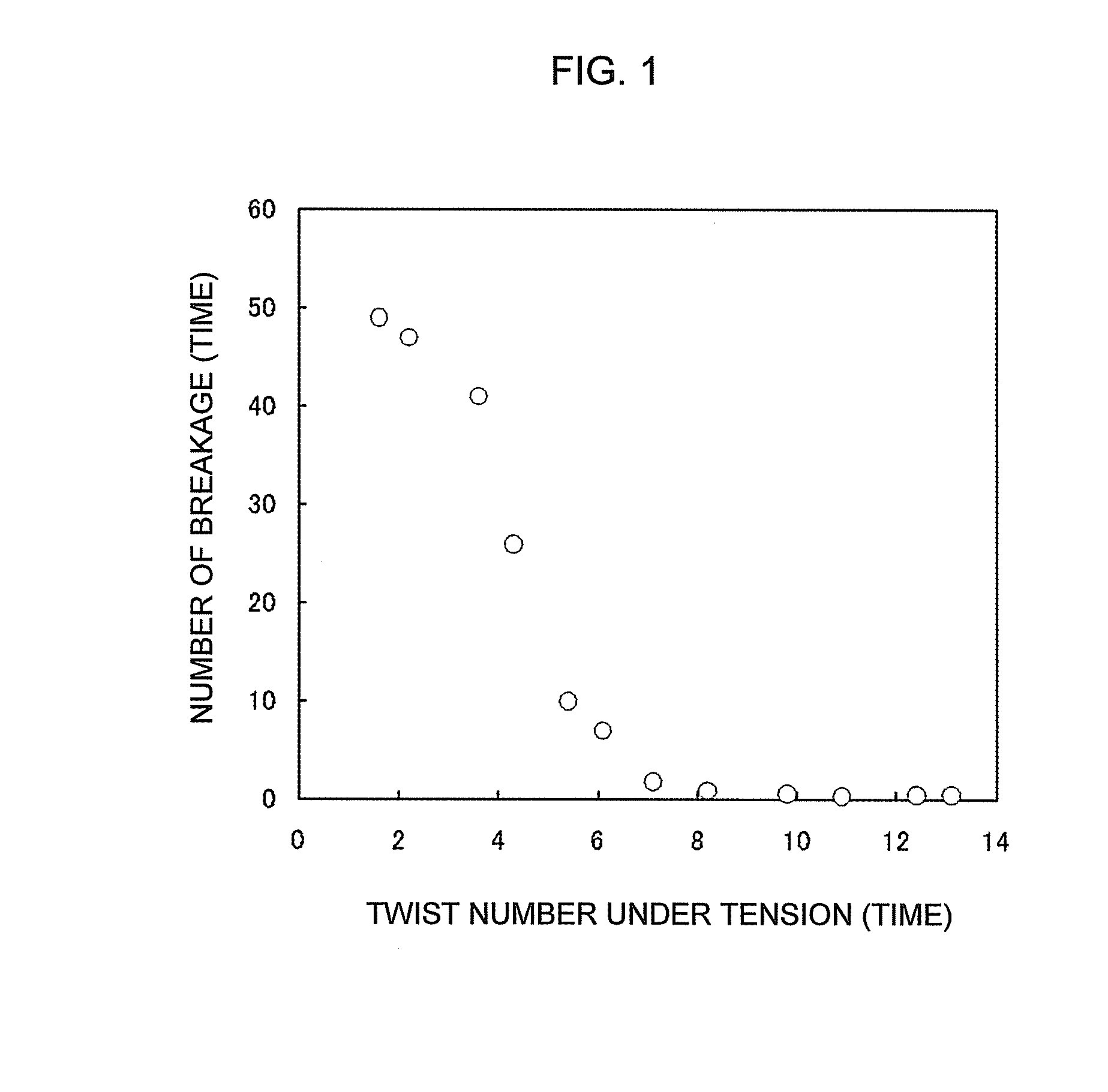

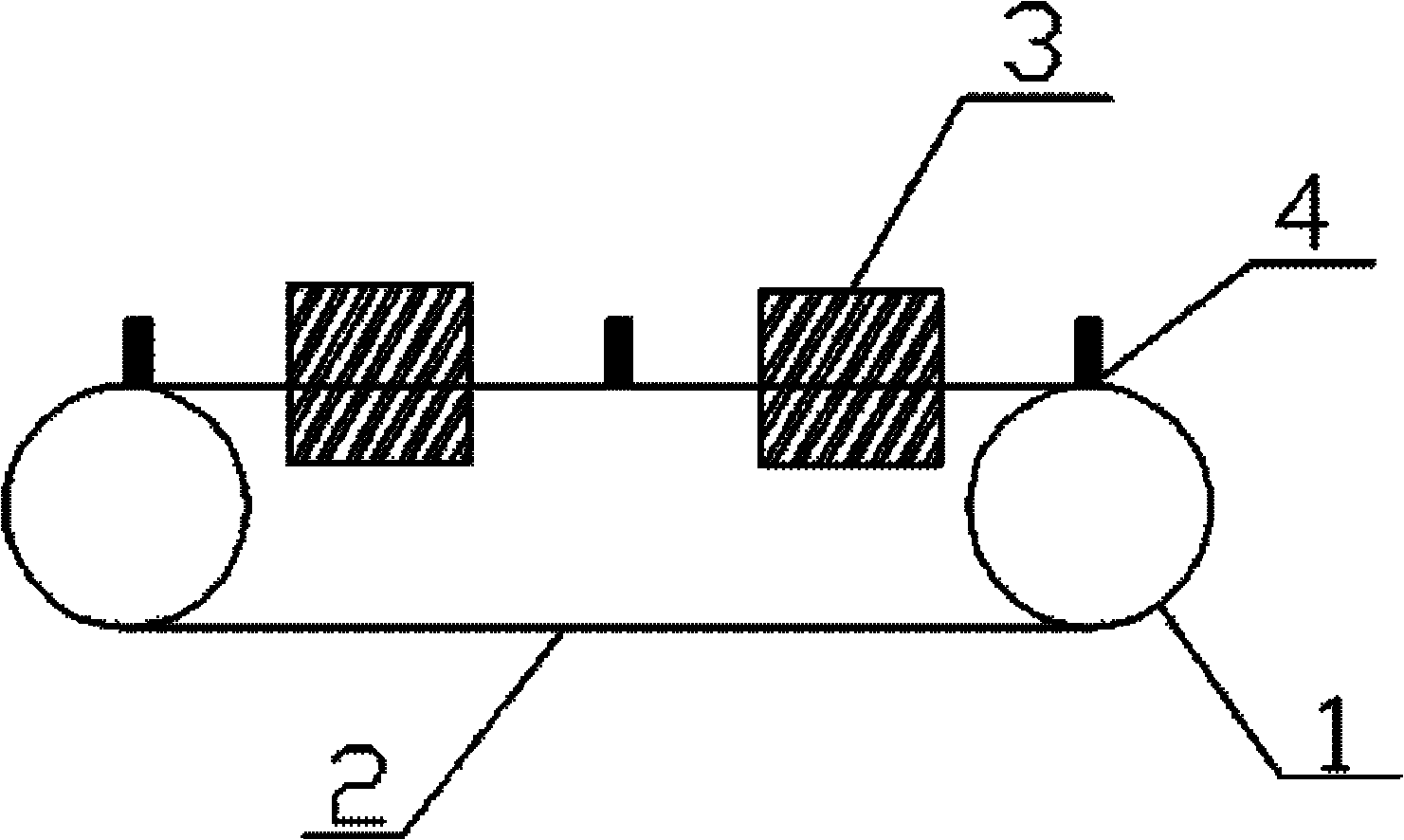

Strand for saw wire and manufacturing method thereof

InactiveUS20120318410A1High strengthImprove fracture resistanceMetal sawing toolsFurnace typesPearliteTensile testing

Regarding contents of C, Si, Mn and Cr, a value of parameter P represented by the following (equation 1) is 1000 or more. A metallic structure contains wire-drawn pearlite in an area ratio of 98% or more, a diameter is 0.05 mm to 0.18 mm, a tensile strength is 4000 MPa or more, and a twist number in a twist test in which a grip-to-grip distance is 100 mm, and a tension equal to a tensile strength×a cross-sectional area of wire×0.5 is applied, is 5 or more.P=1098×[C]+98×[Si]−20×[Mn]+167×[Cr] (equation 1)(in the (equation 1), [C], [Si], [Mn] and [Cr] indicate contents (mass %) of C, Si, Mn and Cr, respectively.)

Owner:NIPPON STEEL CORP

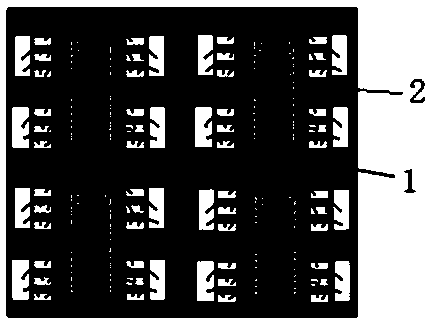

COB packaging structure of light-emitting diode

InactiveCN103594464AReduce design difficultyReduce wiring difficultySemiconductor/solid-state device detailsSolid-state devicesHigh densityChipset

The invention relates to a COB packaging structure of a light-emitting diode. The COB packaging structure comprises a substrate, n drive chips and n light-emitting diode chip sets, wherein each light-emitting diode chip set comprises N light-emitting diode chips, n and N are integers, n is larger than or equal to 1, N is larger than or equal to 1, the n drive chips and the n light-emitting diode chip sets are packaged on the front face of the substrate in a modular mode to form n sets of COB display modules, the n drive chips and the n light-emitting diode chip sets form lamp-driver co-plane devices in a one-to-one connection mode, a fixed number of bonding pads are arranged on the back face of the substrate, and all the drive chips and all the light-emitting diode chip sets are communicated with the bonding pads on the back face of the substrate in a routing and hole passing mode. The n lamp-driver co-plane devices are packaged to form a new COB device, the number of the bonding pads on the back face of the substrate is fixed and independent of the number of sets of the drive chips, and therefore a large number of pins are saved, external device cables are greatly reduced, and the higher density can be achieved compared with the density achieved through traditional packaging.

Owner:GUANGDONG VTRON TECH CO LTD

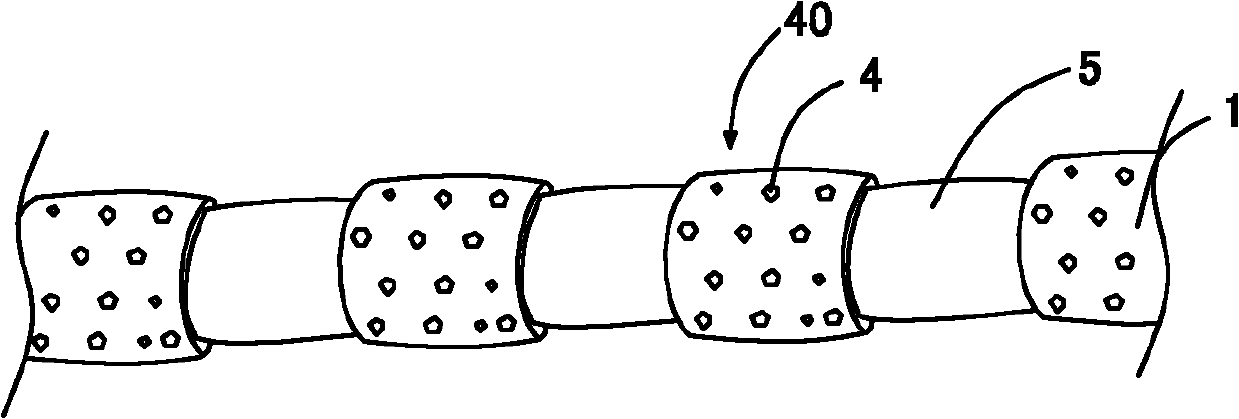

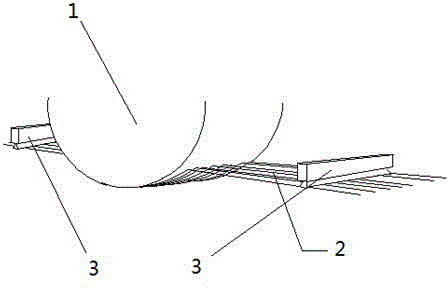

Diamond wire saw and manufacturing method thereof

ActiveCN101905491APrevent infiltrationGuaranteed softnessGrinding devicesFine working devicesDiamond wire sawPlastic materials

The invention discloses a diamond wire saw and a preparation method thereof. The diamond wire saw comprises a bending-resistant flexible multi-strand rope. The preparation method comprises the following steps: a, removing oil from the surface of the flexible multi-strand rope and coating high-temperature resistant inorganic glue onto the flexible multi-strand rope at intervals, so as to form an isolated coating layer after the glue is cured; b, adding metal soldering materials into the organic glue to prepare a pastry mixture; c, coating or impregnating the pastry metal soldering materials onto the spaced parts of the flexible multi-strand rope, and then spreading diamond abrasive particles onto the rope; spraying or cold-pressing a layer of metal soldering materials onto the surface of the rope after the organic glue is cured; d, putting the obtained flexible multi-strand rope into a vacuum brazing furnace for sintering, taking the rope out of the furnace and then removing the inorganic glue; after heat treatment, coating a layer of rubber-plastic material protection layer onto the spaced parts of the flexible multi-strand rope; after the glue is cured, obtaining the diamond wire saw. The diamond wire saw can effectively prevent a braze-welding material from entering into gaps of the flexible multi-strand rope so as to solve the problem that the conventional diamond wire saw manufactured by taking the flexible multi-strand rope as a centre line is too inflexible and is entirely unusable.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

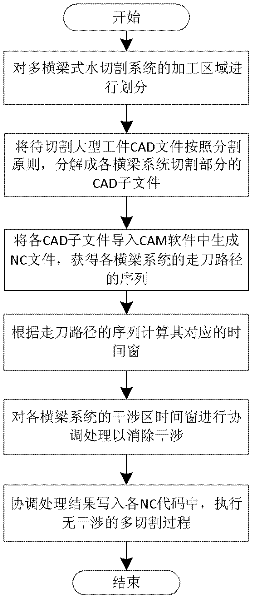

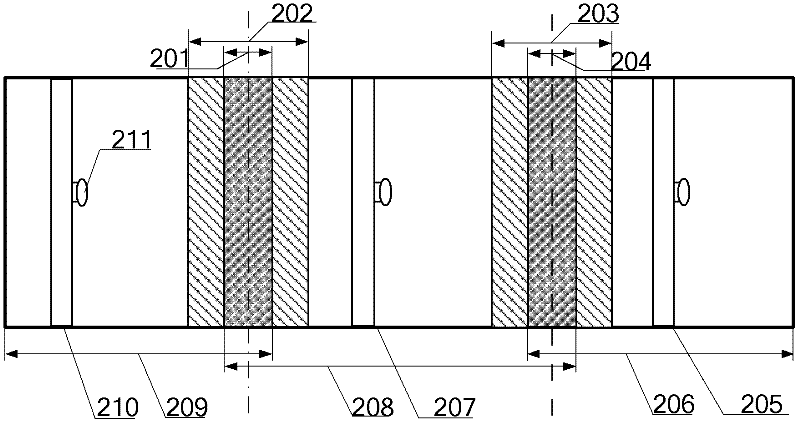

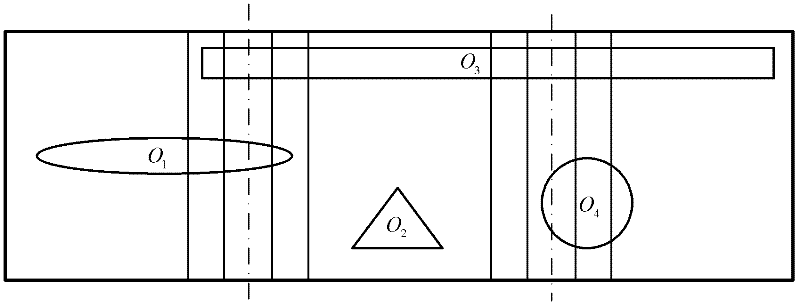

Cutting process offline coordination method of multi-beam type water jet cutting system

InactiveCN102346459ANo need to change KAEliminate interferenceProgramme controlComputer controlNumerical controlComputer-aided

The invention provides a cutting process offline coordination method of multi-beam type water jet cutting system. The method comprises the following steps: dividing a processing area of the multi-beam water cutting system; inputting a CAD (computer-aided design) file of a large workpiece to be cut, and decomposing and allocating the cutting contour accordingly to form the CAD sub-file of the cutting part of each beam system; importing each CAD sub-file into water cutting CAM (computer-aided manufacturing) software to generate an executable NC (numerical control) code file, and reading the NC code file to obtain a sequence of the cutting path of each beam system; calculating a time window executed by each path in each cutting sequence, and coordinating the time windows in an interference area so as to achieve the purpose of avoiding mutual interference between two adjacent beams; and writing the coordination result into the original NC code file, downloading the NC code file to a CNC (computer numerical controller) of each beam system, and executing the multi-beam water cutting process. According to the invention, smooth and non-interference execution of a parallel cutting processes of a water cutting system with more than three beams can be realized.

Owner:SOUTHEAST UNIV

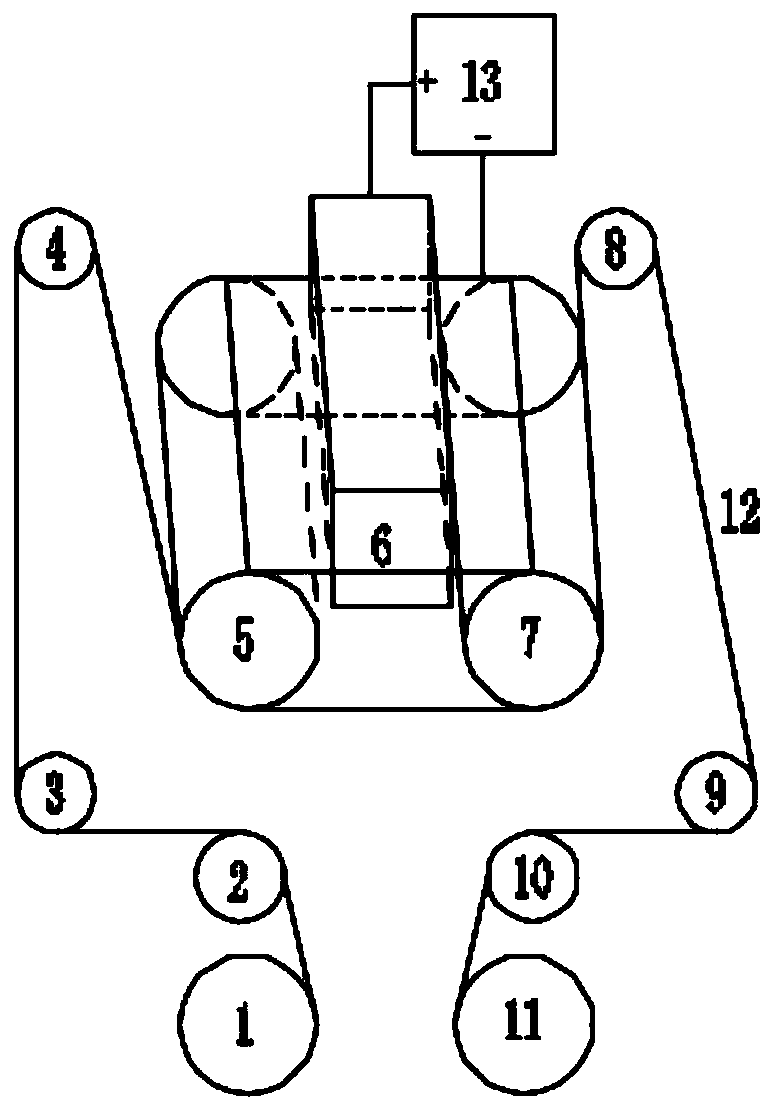

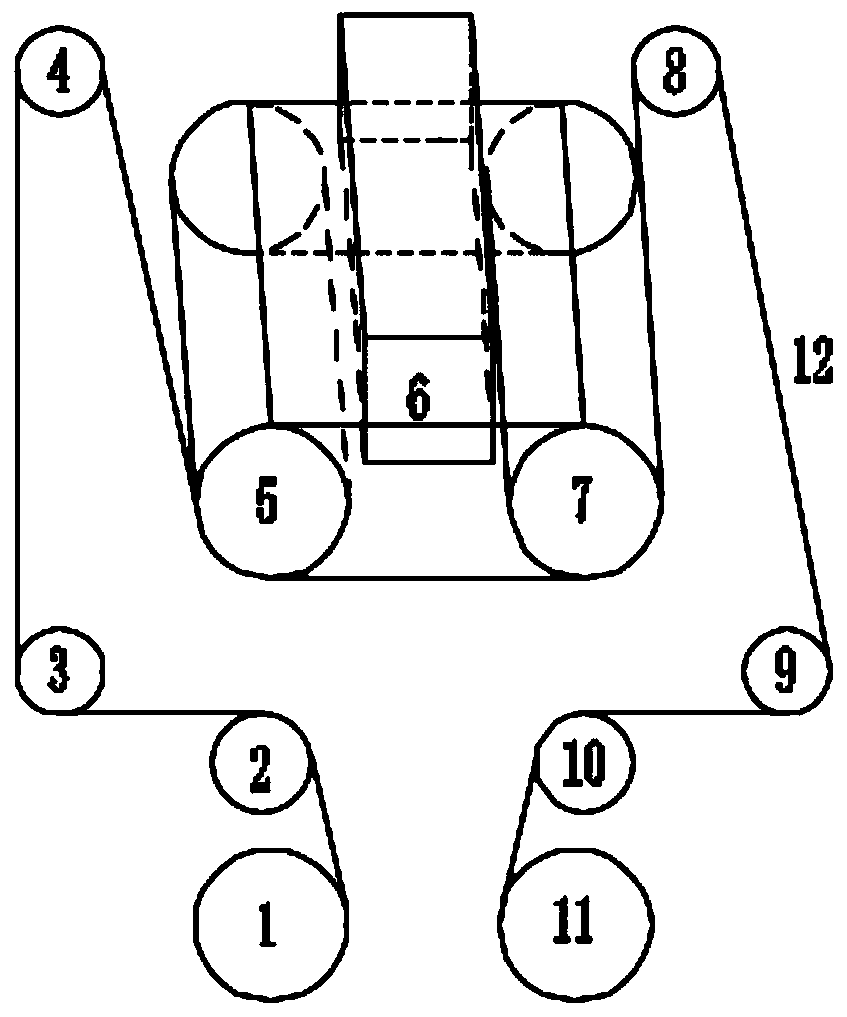

Silicon block cutting method

InactiveCN102350741AImprove cutting abilityImprove cutting efficiencyFine working devicesHardnessCooling fluid

The embodiment of the invention discloses a silicon block cutting method which comprises the following steps: driving a cooling fluid into a mortar jar; sequentially winding a diamond steel wire on a pulley and a guide pulley to knit a wire mesh; putting a silicon block on a machine tool, and setting a machine tool zero point and technological parameters in the silicon block cutting process; and cutting the silicon block by using the diamond steel wire. In the cutting method disclosed by the invention, the diamond steel wire is knitted into the wire mesh, and the wire mesh is used for cutting the silicon block, thereby replacing the method for cutting a silicon block by driving mortar with a steel wire in the prior art. Since the diamond grains have high hardness and strong cutting power, the cutting power of the diamond steel wire is stronger than that of the mortar-carrying steel wire, thereby greatly enhancing the cutting efficiency of the silicon block, increasing the cutting speed of the silicon block and lowering the cutting cost.

Owner:YINGLI ENERGY CHINA

Manufacture method for cutting liquid crystal display panel

ActiveCN102225841ALess prone to transverse cracksSmooth sectionEdge grinding machinesGlass severing apparatusEpoxyLiquid-crystal display

The invention discloses a manufacture method for cutting a liquid crystal display panel. A mode of chemical thinning liquid thinning glass is used for thinning a cutting frame of the liquid crystal display panel, a diamond grinding head is used for reconditioning a cutting plane, the reconditioned section is blocked by an epoxy resin, and edge sealing is performed by a metal film. The section cutby the method has the advantages of smooth flat, no stress and difficult cracking, and is capable of manufacturing the panels with any section shapes, wherein the thickness of the edge sealing glue-line is less than 0.2mm, thereby an ultra-narrow seam spliced screen with the width of seam-line of less than 1mm can be manufactured.

Owner:西藏贝珠亚电子科技有限公司

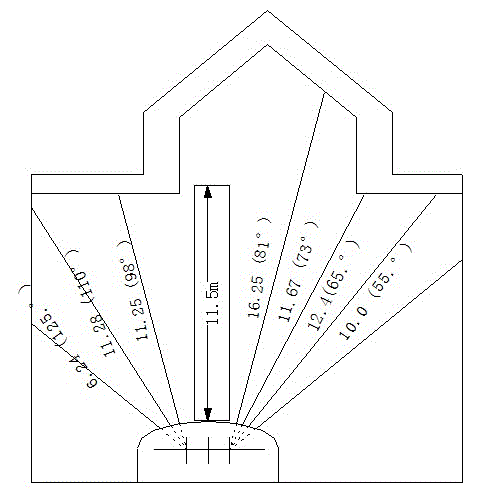

Cutting technique of oversized-diameter silicon rod

InactiveCN103331828AImprove production rateImprove cutting effectFine working devicesSilicon chipMechanical engineering

The invention discloses a cutting technique of an oversized-diameter silicon rod, which comprises the steps of mortar preparation, rod adhesion, charging, cutting, preheating, cutting and blanking, setting various parameters in a cutting process, and cutting the oversized-diameter silicon rod into silicon wafers in required sizes. The cutting technique can increase a wafer outlet rate of the cutting silicon wafers in a unit kilo effectively, can improve the cutting capacity, can reduce the cutting consumption and wearing capacity, and can lower the cutting cost.

Owner:阳光硅谷电子科技有限公司

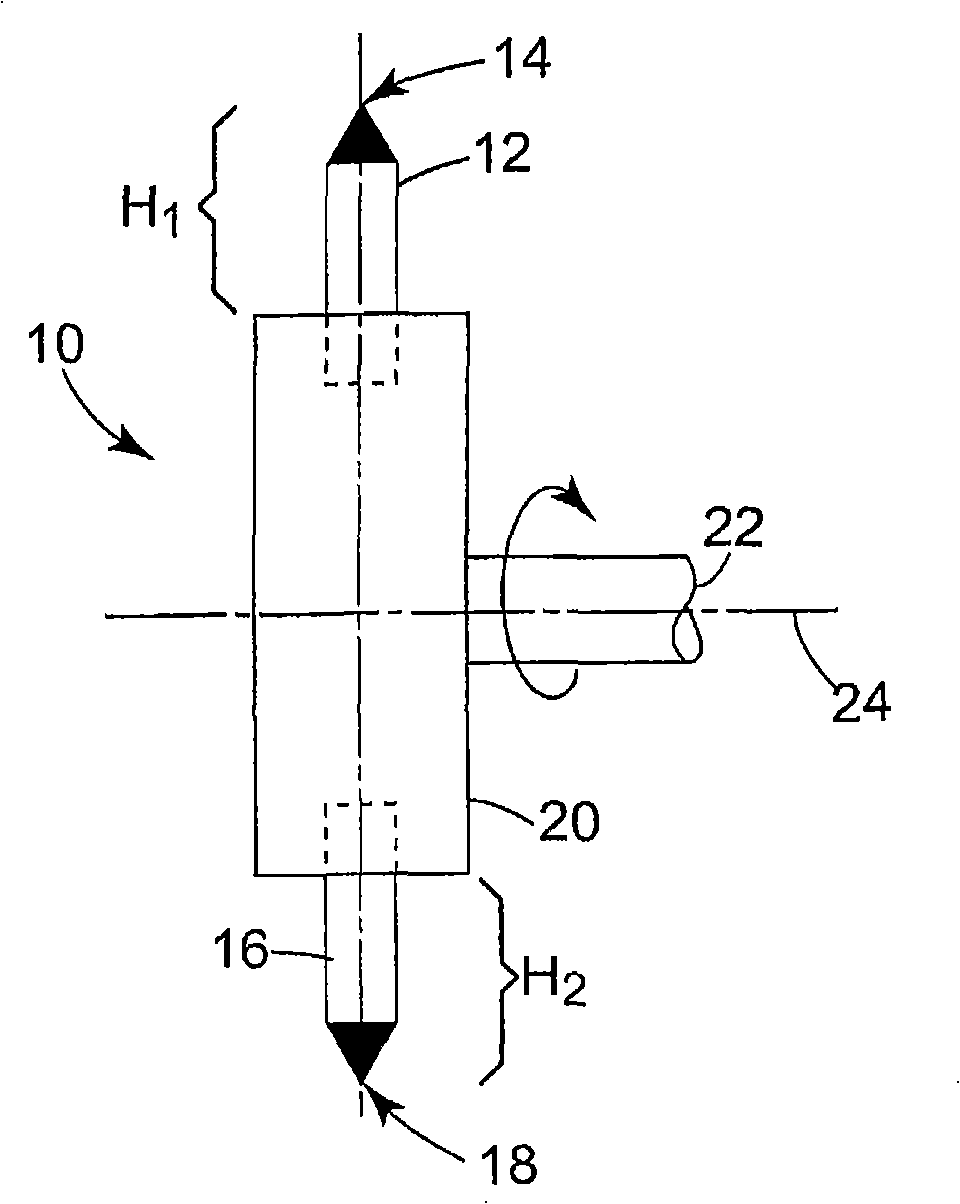

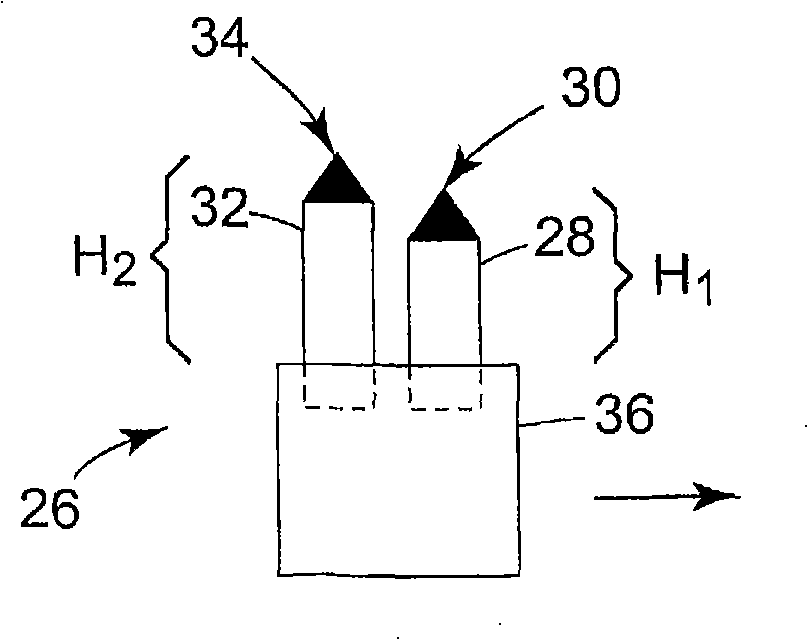

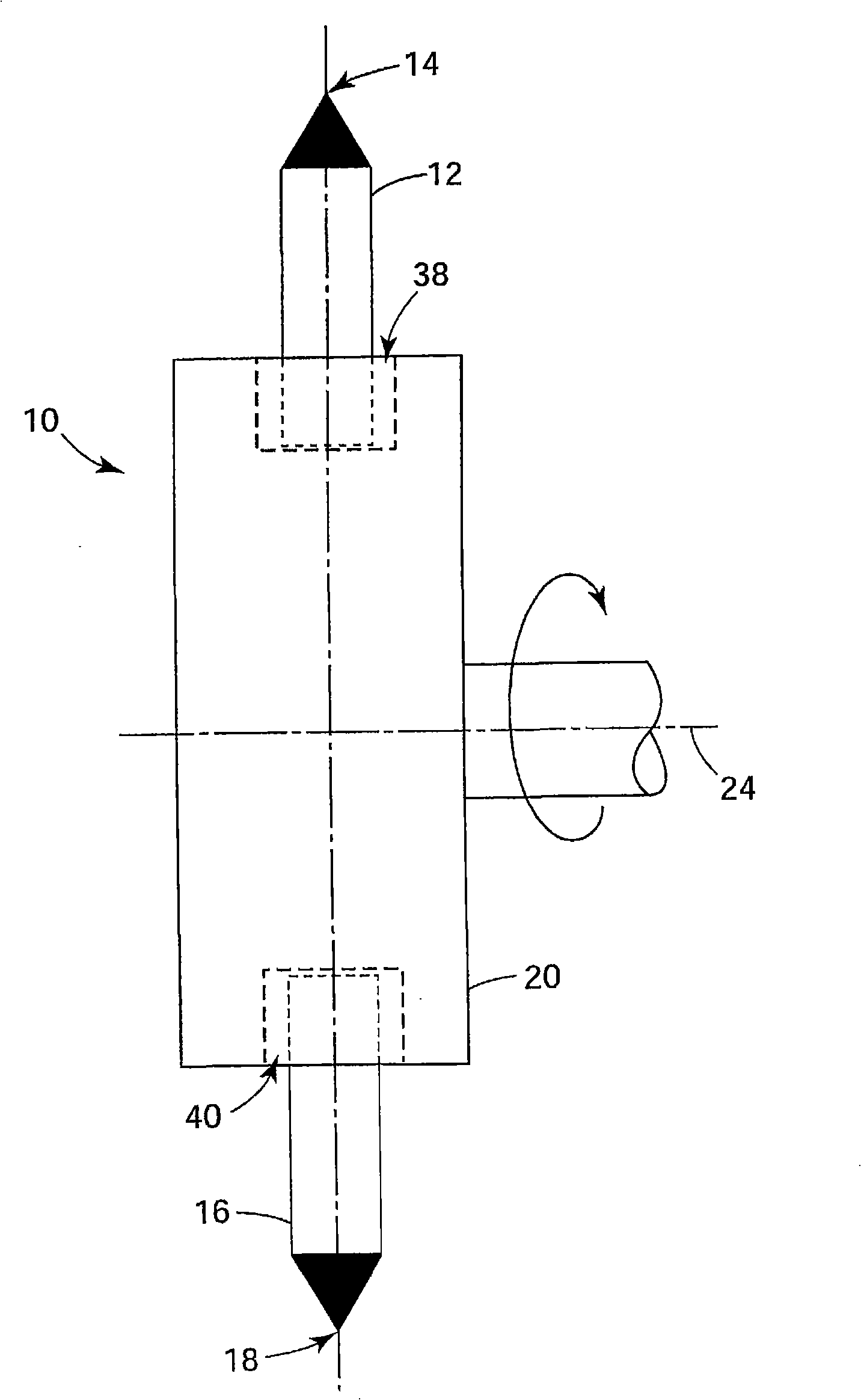

Aligned multi-diamond cutting tool assembly for creating microreplication tools

InactiveCN101291764AImprove or simplify manufacturingReduce the number of cutting passesTool workpiece connectionMilling cuttersDiamond cuttingEngineering

The disclosure is directed to a cutting tool assembly used for creating grooves in a microreplication tool. The cutting tool assembly includes a mounting structure and multiple diamonds aligned in the mounting structure to a tolerance of less than 10 microns. For example, first and second tool shanks having first and second diamond tips can be positioned in the mounting structure such that a cutting location of the first diamond tip is identical to a cutting location of the second diamond tip. However, the second diamond tip may be a defined distance further away from the mounting structure than the first diamond tip, or the second diamond tip may have a different shape than the first diamond tip. In this manner, the first diamond tip may cut a groove into a work piece and the second diamond tip may cut a sub-feature into the groove to create a multi-featured groove.

Owner:3M INNOVATIVE PROPERTIES CO

Heat dissipating semiconductor package and fabrication method thereof

InactiveUS7508066B2Avoid excessive wearLess heat sinkPrinted circuit assemblingSemiconductor/solid-state device detailsSemiconductor packageSemiconductor chip

A heat dissipating semiconductor package and a fabrication method thereof are provided. A semiconductor chip is mounted on a chip carrier. A heat sink is mounted on the chip, and includes an insulating core layer, a thin metallic layer formed on each of an upper surface and a lower surface of the insulating core layer and a thermal via hole formed in the insulating core layer. A molding process is performed to encapsulate the chip and the heat sink with an encapsulant to form a package unit. A singulation process is performed to peripherally cut the package unit. A part of the encapsulant above the thin metallic layer on the upper surface of the heat sink is removed, such that the thin metallic layer on the upper surface of the heat sink is exposed, and heat generated by the chip can be dissipated through the heat sink.

Owner:SILICONWARE PRECISION IND CO LTD

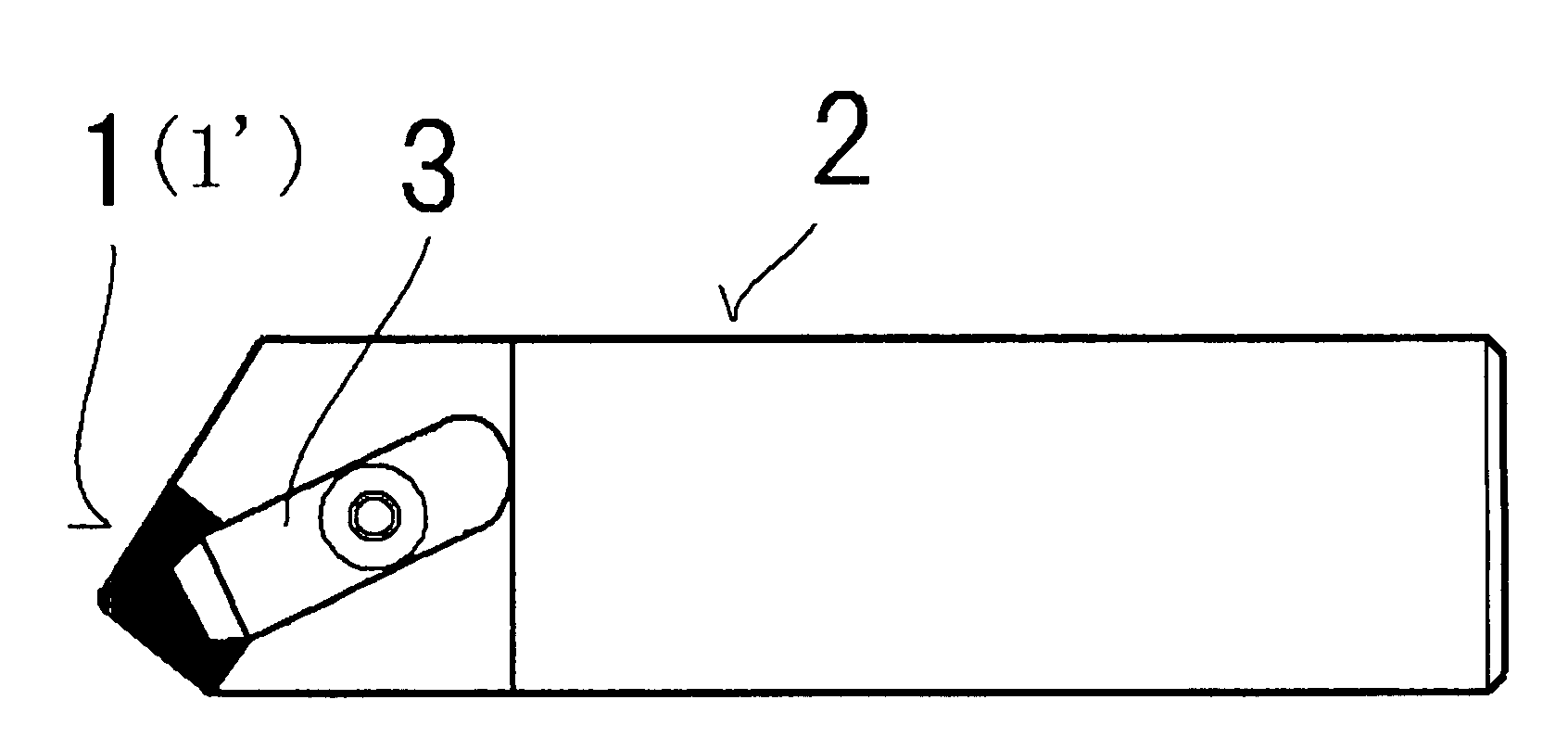

Sialon Insert and Cutting Tool Equipped Therewith

InactiveUS20080119349A1Control decompositionLimit wearCutting insertsTurning toolsEngineeringKnife blades

This invention provides a long-life Sialon insert, the cutting edge of which is resistant to wear and hard to fracture, and a cutting tool equipped with the Sialon insert.Provided are a Sialon insert made of a Sialon sintered body including a Sialon phase comprising an α-Sialon and a β-Sialon, and at least one element, originating from a sintering aid, selected from the group consisting of Sc, Y, Dy, Yb, and Lu in an amount of 0.5 to 5 mol % in terms of an oxide thereof, wherein an α-value, which shows the proportion of the α-Sialon in the Sialon phase, is from 10% to 40%; the β-Sialon has a value of Z from 0.2 to 0.7 wherein Z is a variable of the formula Si6-ZAlZOZN8-Z and within a range: 0<Z≦4.2; and the sintered body has an average thermal expansion coefficient of 3.5×10−6 / K or less at temperatures of room temperature to 1000° C., and a thermal conductivity of 10 W / m·K or more at temperatures of room temperature to 1000° C., and a cutting tool comprising a holder equipped with the Sialon insert.

Owner:NGK SPARK PLUG CO LTD

Diamond particle reinforced metal matrix composite material and preparation method and application thereof

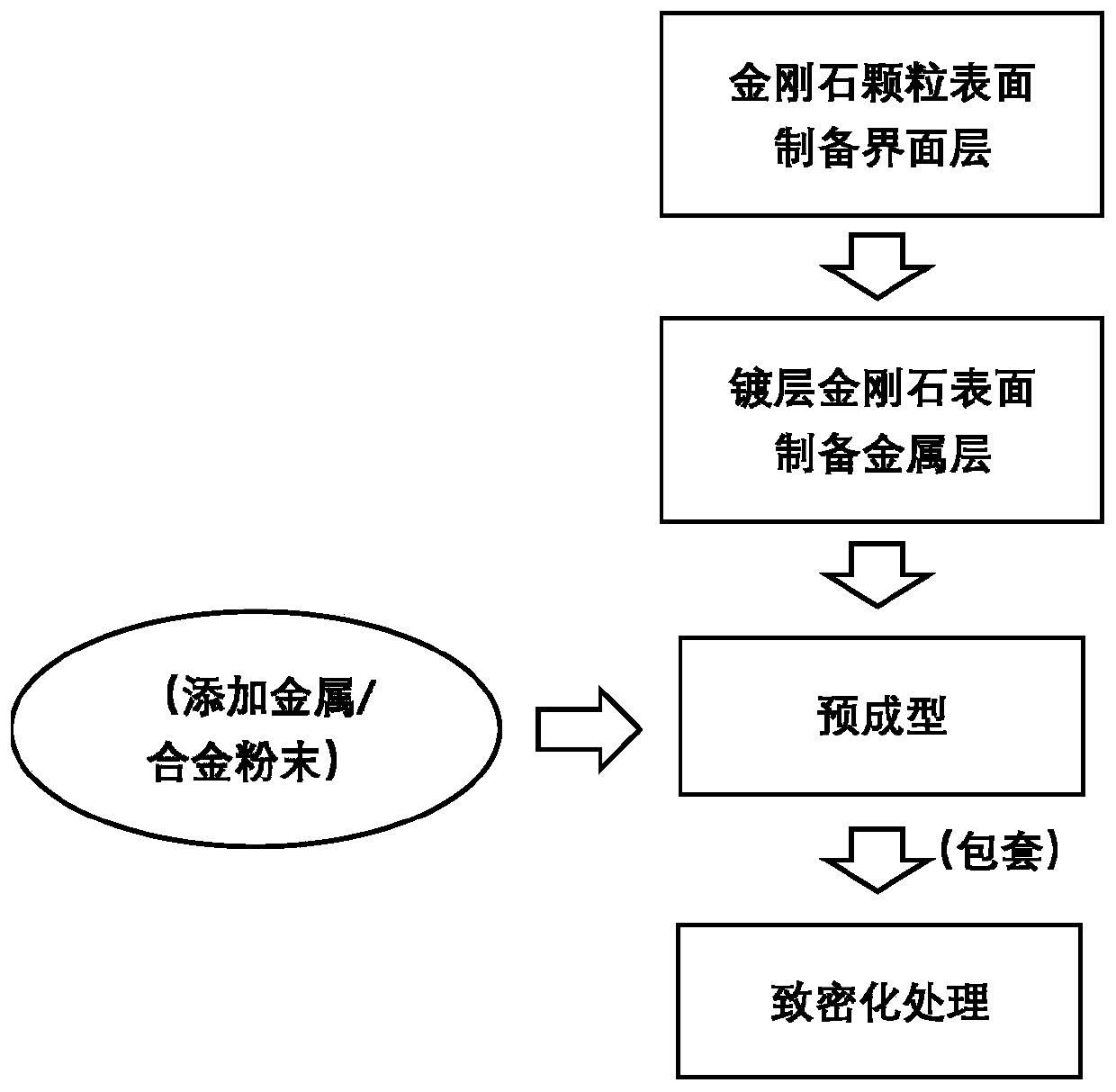

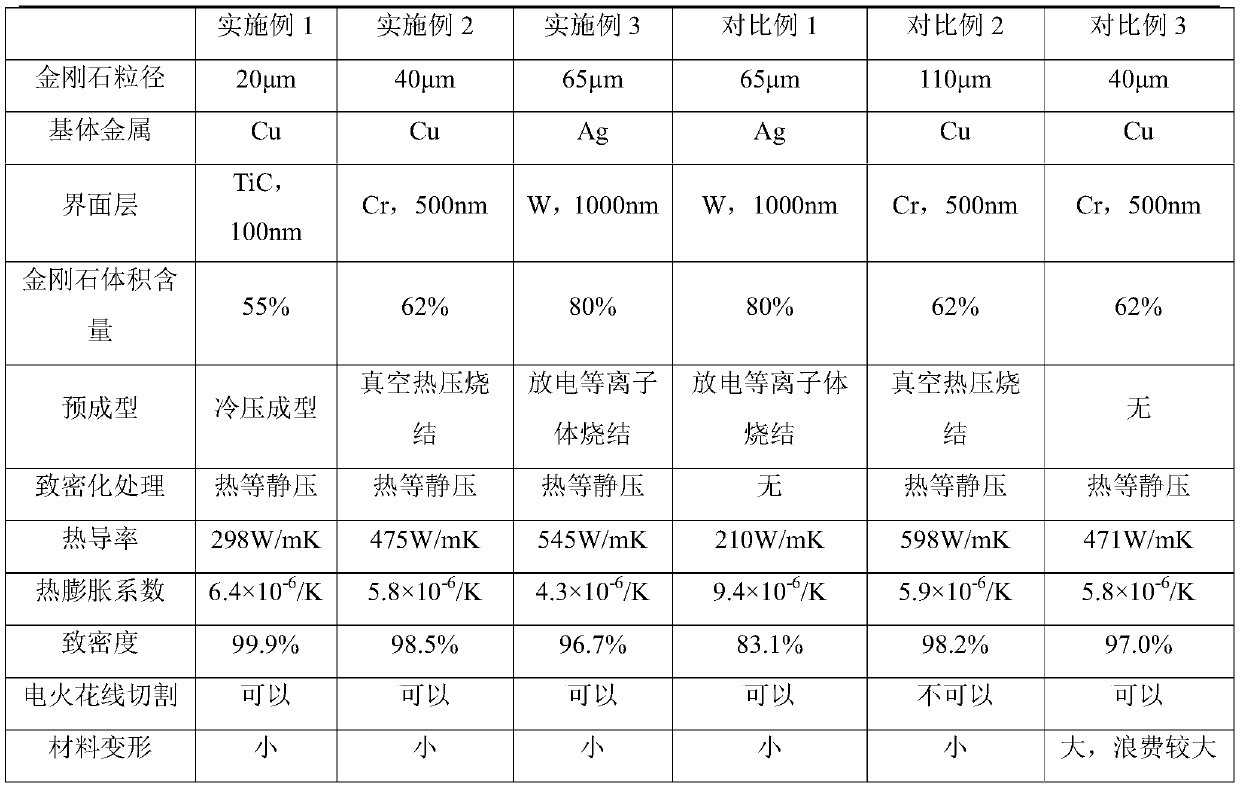

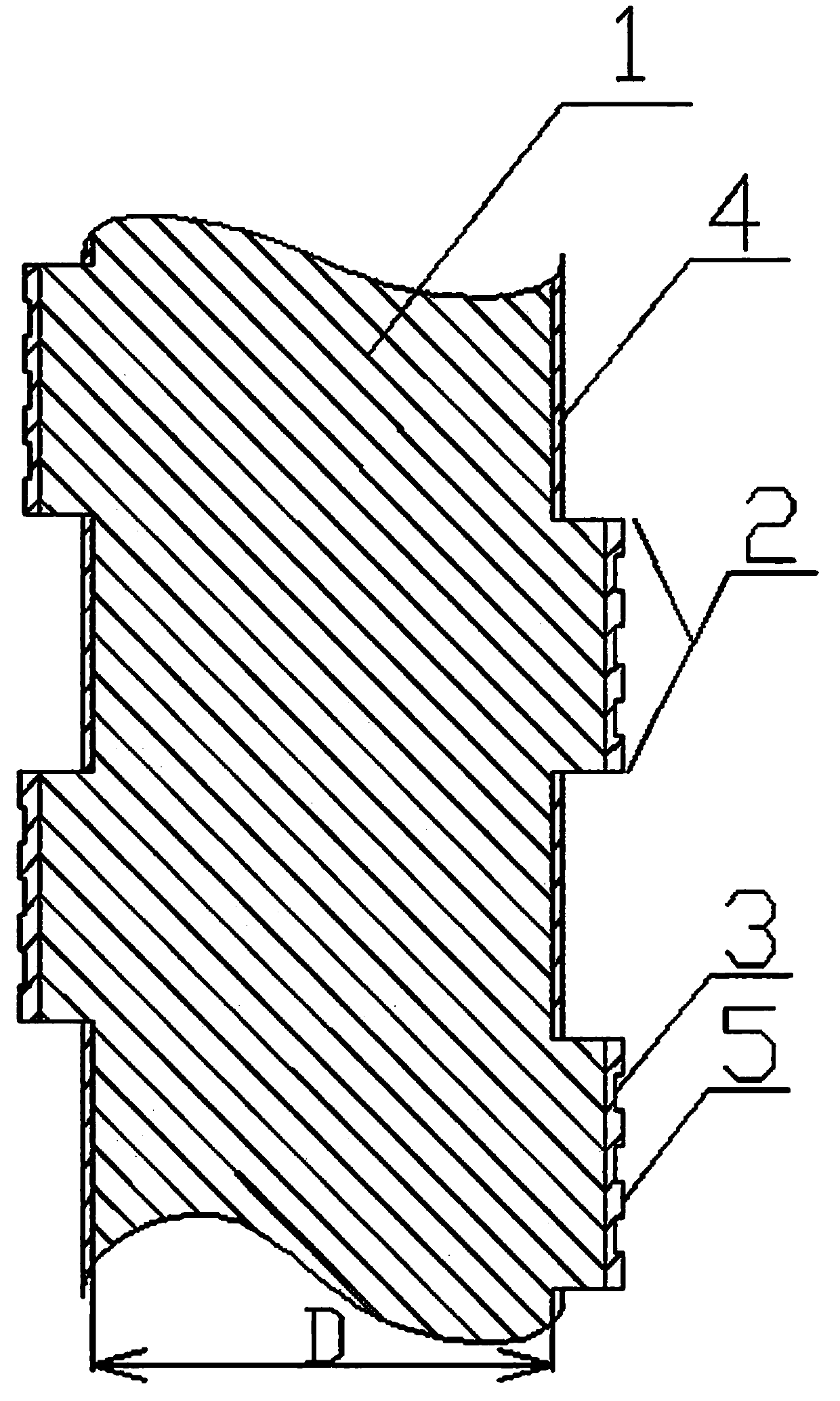

InactiveCN111519076AEliminate uneven powder mixingHigh thermal conductivityTransportation and packagingMetal-working apparatusInterface layerThermal expansion

The invention discloses a diamond particle reinforced metal matrix composite material and a preparation method and application thereof. The preparation method comprises the steps of 1, preparing an interface layer; 2, preparing a metal layer; 3, premolding; and 4, carrying out densification treatment. According to the diamond particle reinforced metal matrix composite material and the preparationmethod and application thereof, the adopted sintering of a two-step solid-phase method combined with the premolding and densification treatment is characterized by complementing for each other, fostering strengths and circumventing weaknesses, so that the the characteristic that the solid-phase sintering method capable of preparing a material with smaller particle size is retained, the size of thematerial prepared in a single batch is larger, the thickness reaches the centimeter level or a higher level, the production efficiency is higher, and the cost is greatly reduced; the prepared material has higher thermal conductivity, adjustable thermal expansion coefficient and better uniformity and reliability, and can be directly cut for processing by an electric spark wire; and meanwhile, thepremolding before the densification treatment can solve the problem that a bag sintered by directly adopting hot isostatic pressing is deformed too much so as to result in too much waste of the material, and the material utilization rate is higher.

Owner:成都本征新材料技术有限公司

Process adopting extra-fine steel wire to cut silicon rod

The invention discloses a process adopting an extra-fine steel wire to cut a silicon rod. The process comprises the working procedures of preparing mortar, bonding the rod, loading the rod, carrying out preheating for cutting, carrying out cutting, discharging and the like. Parameters in the cutting process are set. The silicon rod can be cut into silicon wafers with the required size. According to the cutting process, the rate of forming the silicon wafers of each kilogram in a cutting mode can be effectively increased, the cutting ability is improved, cutting consumption and abrasion loss are reduced, and the cutting cost is lowered.

Owner:阳光硅谷电子科技有限公司

Nickel-based amorphous alloy modified cutting steel wire

The invention relates to an amorphous modified cutting steel wire, which consists of a metal wire and an amorphous alloy layer, wherein the amorphous alloy layer is coated on the outer surface of the metal wire and is made of nickel-based amorphous alloy. The nickel-based amorphous alloy modified steel wire can further improve cutting efficiency and reduce cost.

Owner:蒙特集团(香港)有限公司

Silicon-block cutting method

InactiveCN103448154AImprove work efficiencyShorten the timeFine working devicesVolumetric Mass DensityOxidation resistant

The invention discloses a silicon-block cutting method, which relates to the technical field of crystalline-silicon manufacture. The method comprises the following steps of respectively preparing the usage amounts of recycled silicon carbide and a recycled suspending liquid used in mortar as 40 to 100 percent, modulating the density of the mortar as 1.625 to 1.635kg / L, and adding the mortar according to the effective cutting length of a silicon block in the cutting process, wherein the adding proportion of the added mortar is 0.235 to 0.3L / mm, and the adding amount of the mortar is equal to the effective cutting length of the silicon block multiplied by the adding proportion of the mortar; selecting a guiding wheel to enable the notch of the guiding wheel to be matched with a steel wire; setting the cutting speed of the steel wire as 12 to 14m / s, the moving speed of a worktable as 250 to 330mu m / min and the flow quantity of the mortar as 130 to 160kg / min, cutting the silicon block, and cooling; cutting a structural wire, the outer surface of which is provided with spiral bulges and is coated with an anti-oxidation layer by the steel wire. According to the invention, through the technical matching property of the cutting speed of the steel wire, the moving speed of the worktable and the flow quantity of the mortar, the updating of the mortar is reduced, the production cost can be lowered, the rate of fragments generated in silicon-block cutting is reduced, the rate of finished products is increased, and the quality of the products is improved.

Owner:HENGSHUI YINGLI NEW ENERGY

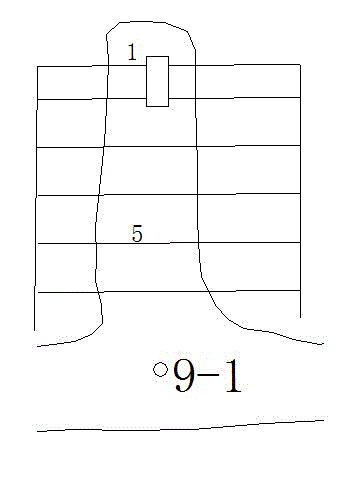

Cutting method combining deep hole cutting and small well cutting

InactiveCN102943673ASimple cutting processReduce cutting costsUnderground miningBlastingStructural engineeringEngineering physics

The present invention provides a cutting method combining deep hole cutting and small well cutting, and belongs to the technical field of ore belt mining. The invention adopts a cutting process combining deep hole cutting and small well cutting, not only cancels the roadway cutting, simplifies the cutting process, and reduces cutting cost significantly, but also provides an experimental basis to realize cutting of deep hole cutting blasting, and has strong promotion and application value. Medium-length holes on both sides of the small well are cut by dual radiation center construction. Taking the small well as a free surface, delay blasting is performed from small well center to the two sides to realize medium-length hole blasting pull trough without roadway cutting, and blasting initial free surfaces are created for follow-up blasting of medium-length hole breaking ground. The long axis direction of a cutting well is perpendicular to the row surface of the cutting deep hole, and the length direction is greater than the row spacing of the cutting deep hole, therefore the deep hole blasting gets the maximum free surface, greatly enhancing the blasting success rate which can reach 100%.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Sialon ceramic blade and cutting tool equipped therewith

ActiveCN101087670AHigh strengthExtended service lifeMilling cuttersCutting insertsCeramic sinteringBeta phase

This invention provides a long-life Sialon insert, the cutting edge of which is resistant to wear and hard to fracture, and a cutting tool equipped with the Sialon insert. Provided are a Sialon insert made of a Sialon sintered body including a Sialon phase comprising an alpha-phase Sialon and a beta-phase Sialon, and at least one element, originating from a sintering aid, selected from the group consisting of Sc, Y, Dy, Yb, and Lu in an amount of 0.5 to 5 mol% in terms of an oxide thereof, wherein an alpha value, which shows the proportion of the alpha-phase Sialon in the Sialon phase, is from 10% to 40%; the betal Sialon has a value of Z from 0.2 to 0.7 wherein Z is a variable of the formula Si 6-Z Al Z O Z N 8-Z and within a range: 0 / K or less at temperatures of room temperature to 1000 DEG C, and a thermal conductivity of 10 W / m*K or more at temperatures of room temperature to 1000 DEG C, and a cutting tool comprising a holder equipped with the Sialon insert.

Owner:NTK CUTTING TOOLS CO LTD

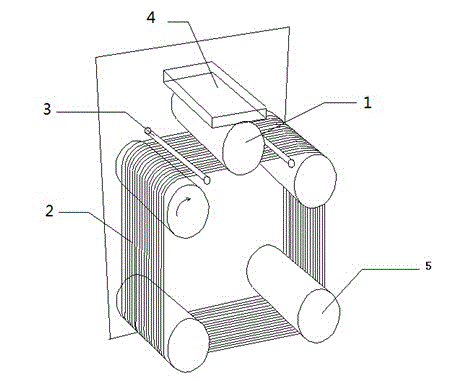

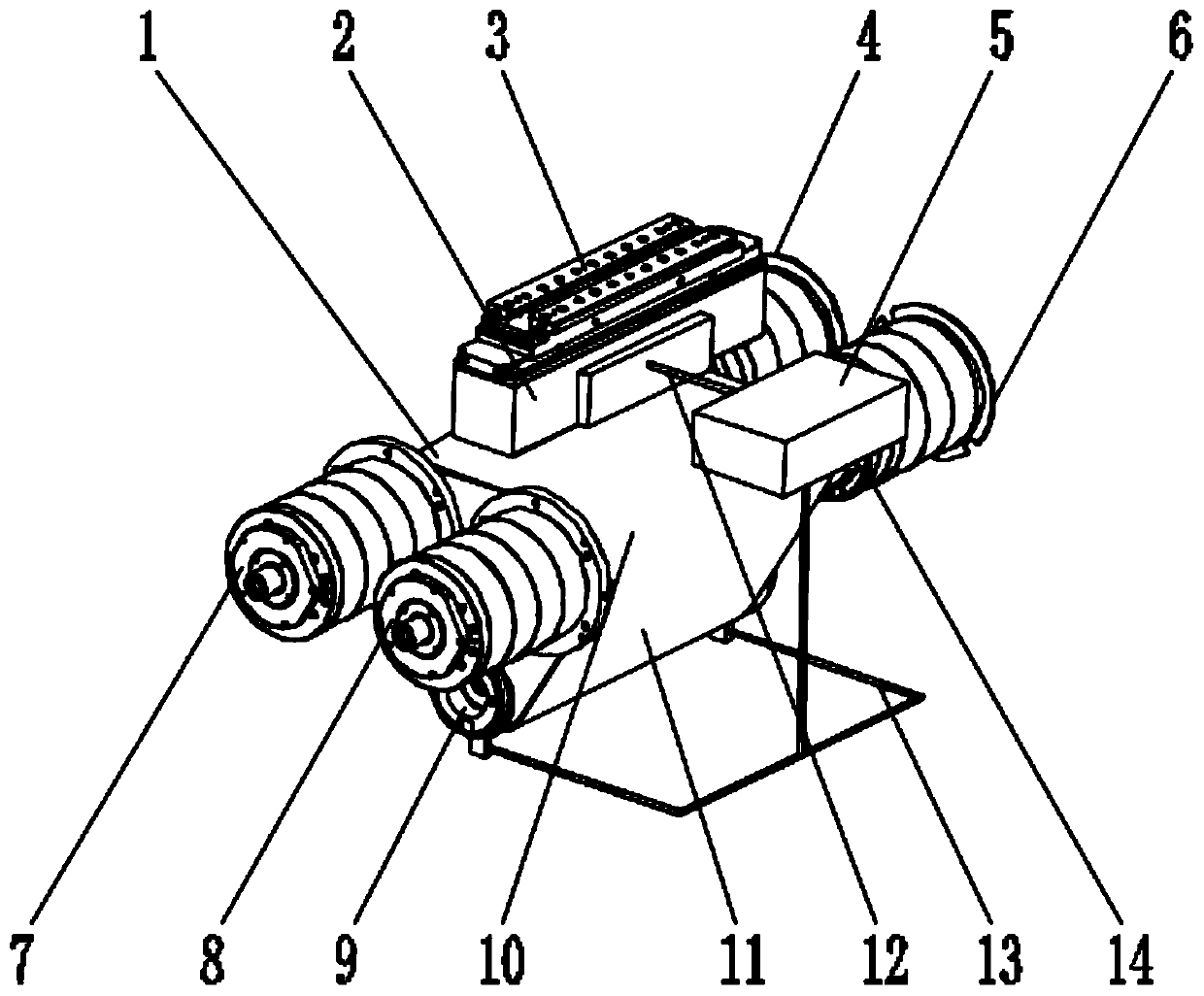

Diamond multi-wire electric spark discharge cutting method and diamond multi-wire electric spark discharge cutting wire cutting device

PendingCN110587840AAvoid surface microcracksReduce cutting forceFine working devicesDiamond wire sawWire cutting

The invention discloses a diamond multi-wire electric spark discharge cutting wire cutting device. The diamond multi-wire electric spark discharge cutting wire cutting device comprises a cutting device body. A first cutting roller is arranged on one side of the middle of the cutting device body, and a second cutting roller is arranged on one side of the first cutting roller. A first driving spindle is arranged at the front end of the first cutting roller, and a second driving spindle is arranged at the front end of the second cutting roller. A first driven spindle is arranged on the outer surface of the rear end of the first cutting roller. According to the diamond multi-wire electric spark discharge cutting wire cutting device, a fixing abrasive diamond wire saw and electric spark wire cutting are combined, then the diamond wire saw and electric spark combined machining is generated, the machining efficiency of diamond multi-wire cutting photovoltaic silicon wafers is further improved, and the machining cost is reduced. In order to solve the machining quality problems of micro cracks on the machined surfaces of diamond wire multi-wire cutting machining semiconductor silicon wafersand the like, the electric spark discharge machining is added on the basis of diamond wire multi-wire cutting so as to achieve the improvement of the quality of the machined surfaces.

Owner:QINGDAO GAOCE TECH CO LTD

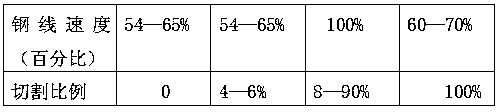

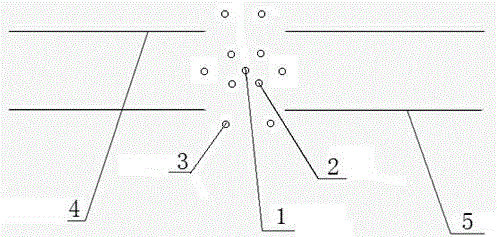

Method for forming cutting surface in deep hole blasting

ActiveCN104807381ARealize integrated productionImprove recovery rateBlastingEngineeringPsychological health

The invention discloses a method for forming a cutting surface in deep hole blasting, and relates to the technical field of underground mining blasting. The structure comprises a central charge hole (1), an empty hole (2), an auxiliary charge hole (3), cutting scallop holes (4) and emission centers (5). The structure achieves the purpose of deep hole blasting cutting, a recovery cutting process is simplified, cutting efficiency is improved, cutting cost is reduced, benefits are remarkable, ore recovery rate is increased, recovery cost is reduced, the cutting scallop holes are distributed in the double emission centers, cutting effects are improved, a cutting operation environment is effectively improved, the physical and psychological health of staff is guaranteed, cutting and recovery are integrated in production, three-grade reserve remaining period can be reduced, and the fund utilization efficiency of a mining engineering is improved.

Owner:JIUQUAN IRON & STEEL GRP

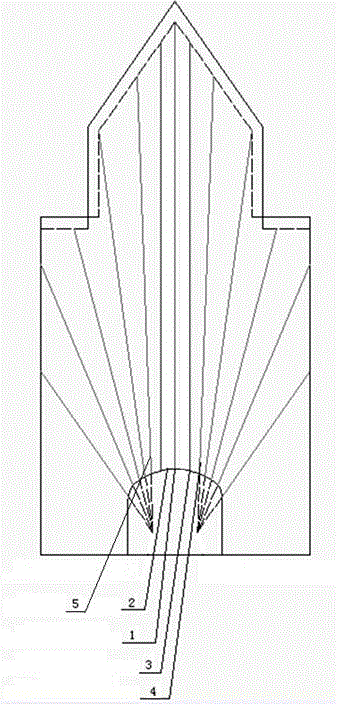

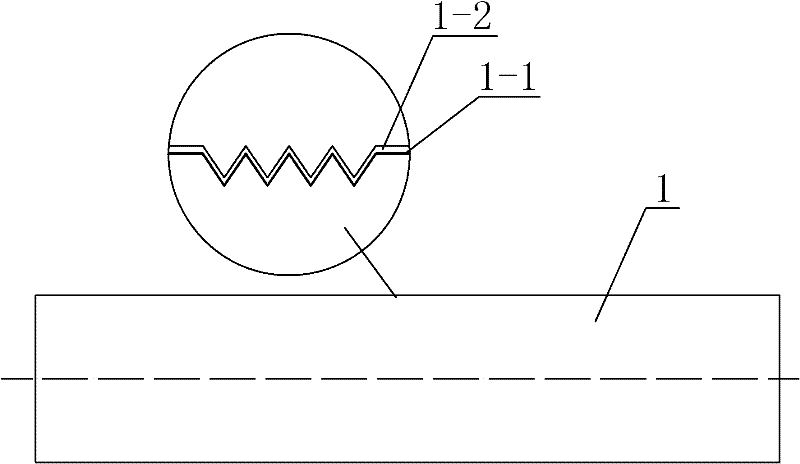

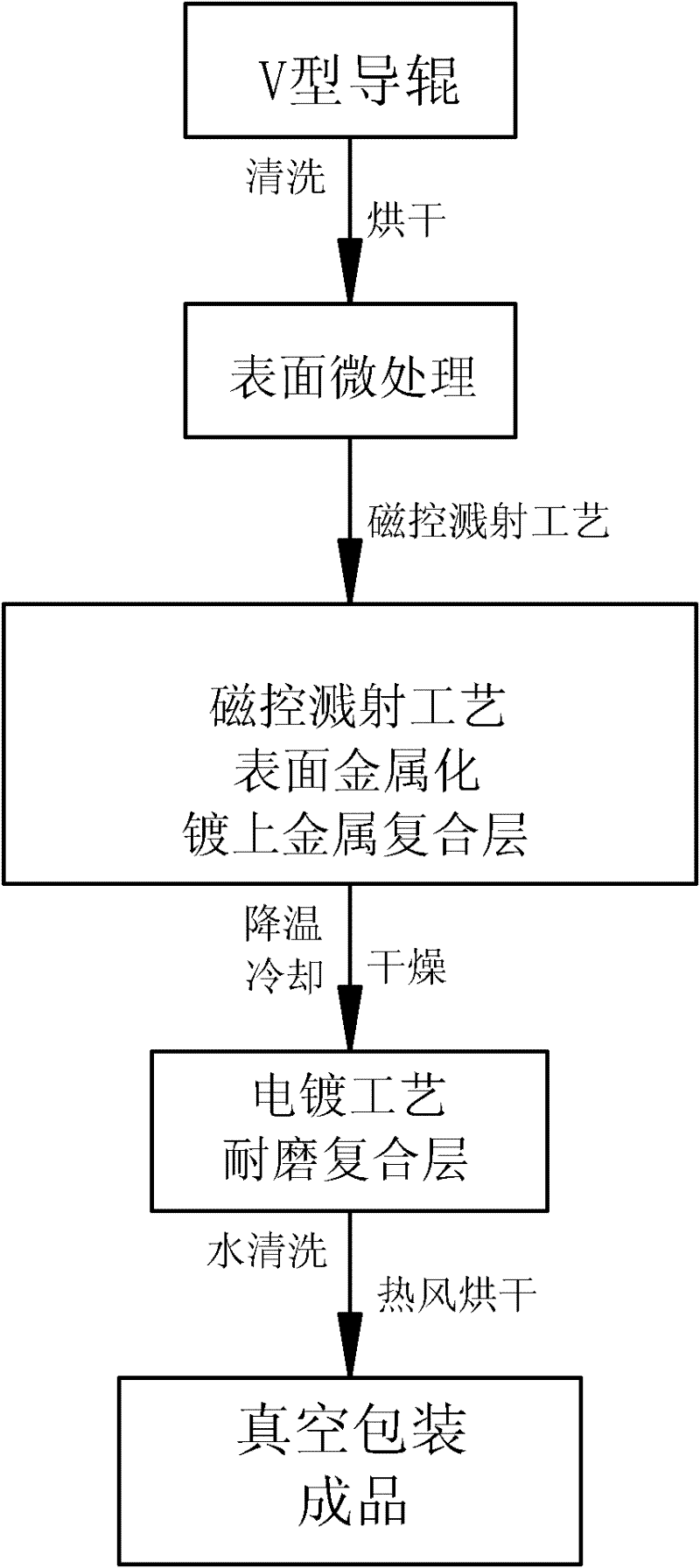

Solar silicon wafer wire cutting guide roller and manufacturing method and special film coating machine and electroplating machine

InactiveCN102225598AReduce wearExtended service lifeFinal product manufactureVacuum evaporation coatingWear resistantWire cutting

The invention relates to a solar silicon wafer wire cutting guide roller and a manufacturing method and a special film coating machine and an electroplating machine. the method comprises the following steps of: making a V-shaped guide roller base body made from composite polyurethane, plating a metal composite layer on the surface of the V-shaped guide roller base body, and plating a wear-resistant composite layer on the surface of the metal composite layer,wherein the metal composite layer is compounded by one or more then one of nickel, titanium, copper and chromium, the wear-resistant composite layer is a antiseize polymer in which wear-resistant particles are contained. According to the invention, under the condition of not changing the existing cutting technique, the service life of the V-shaped guide roller manufactured by the invention is prolonged, the replacement frequency can be reduced, the cutting yield is stabilized, the equipment utilization ratio is improved, and the overall cutting cost is lowered.

Owner:蒙特集团(香港)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com