Aligned multi-diamond cutting tool assembly for creating microreplication tools

A technology of cutting tool components and diamond cutter heads, which is applied in the direction of manufacturing tools, tool workpiece connection, and cutting tools for lathes, and can solve the problems of high cost and time-consuming micro-replication tool technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

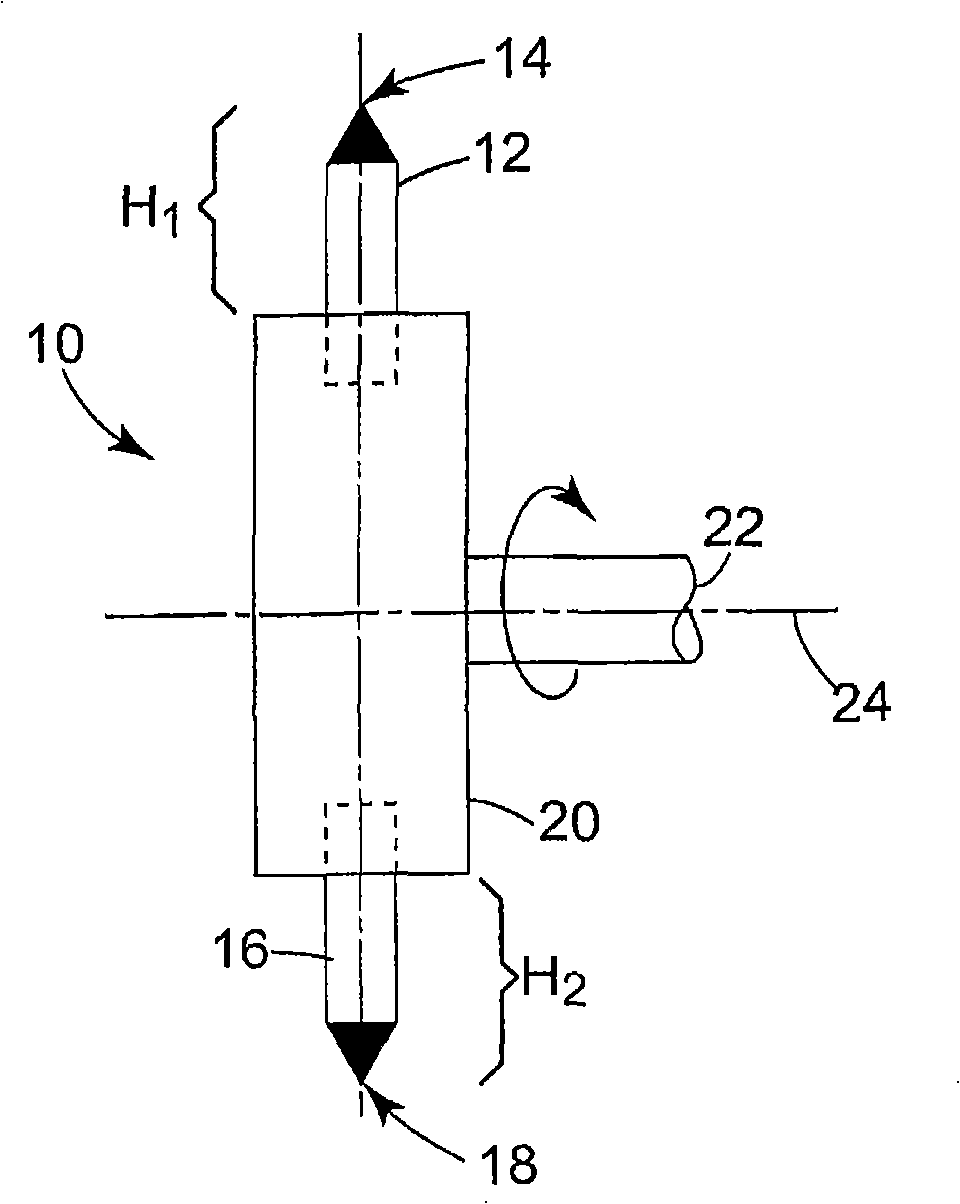

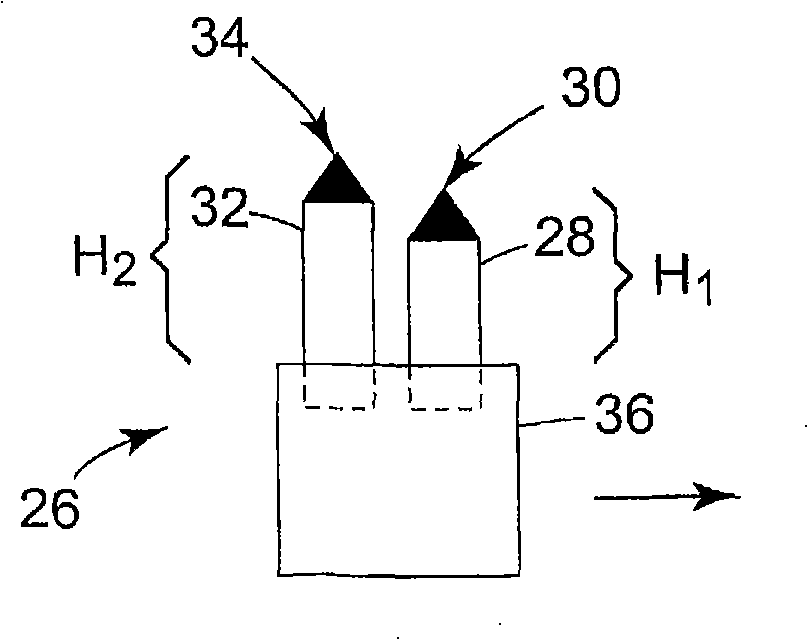

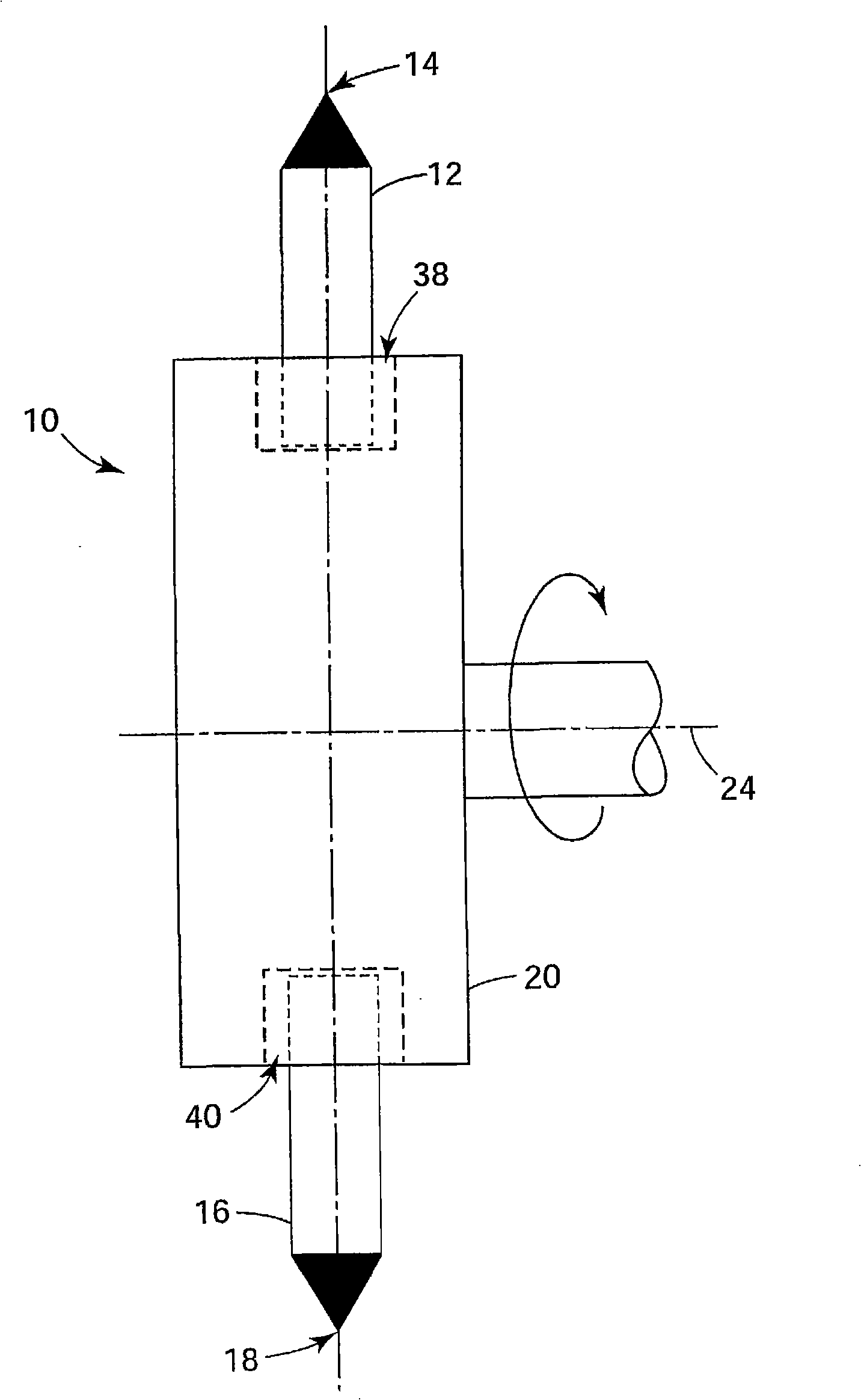

[0027] FIG. 1 is a top view of a cutting tool assembly 10 including two tool holders 12 and 16 mounted in a mounting structure 20 . The cutting tool assembly 10 is configured for fly cutting wherein the assembly 10 is rotated about an axis 24 . For example, assembly 10 may be mounted to drive shaft 22 which may be driven by a motor of a cutting machine (not shown) to rotate assembly 10 . Mounting structure 20 may include structure for securing tool holders 12 and 16, which include diamond tips 14 and 18, respectively. The handles 12 and 16 may be made of metal or a composite material, and the diamond may be secured to the handles 12 and 16 by a substantially permanent securing mechanism. In addition, the mounting structure 20 may have a structure capable of being connected to the transmission shaft 22 .

[0028] To secure the diamonds in the holders 12 and 16 to define the diamond tips 14 and 18, a substantially permanent securing mechanism (eg, brazing, soldering, adhesives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com