Cutting tool assembly including diamond cutting tips at half-pitch position for forming connection structure

A technology of cutting tool components and diamond cutter heads, which is applied to the lathe tools, workpieces, forming knives, etc., can solve the problems of high cost and time-consuming micro-replication tool technology, and achieve the effect of reducing processing costs and simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

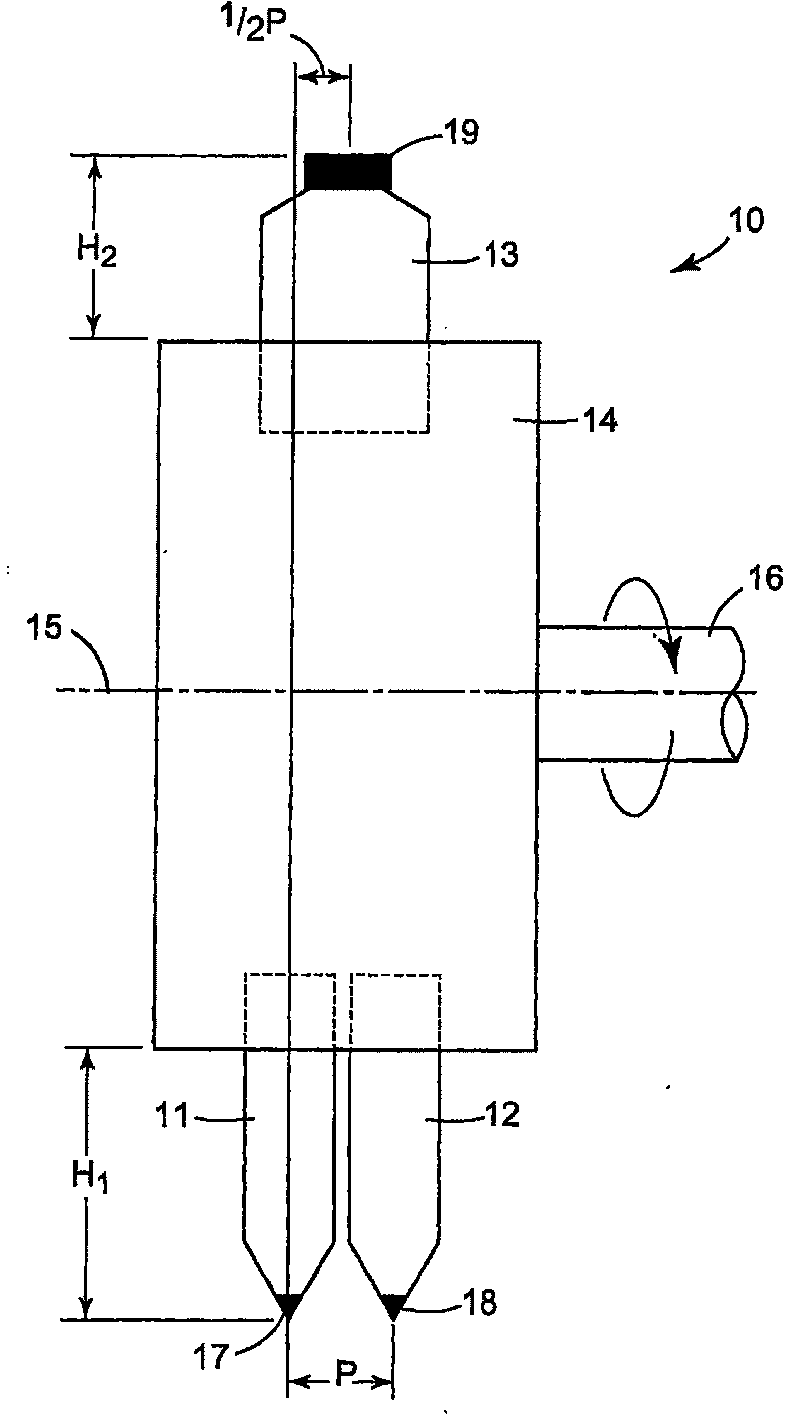

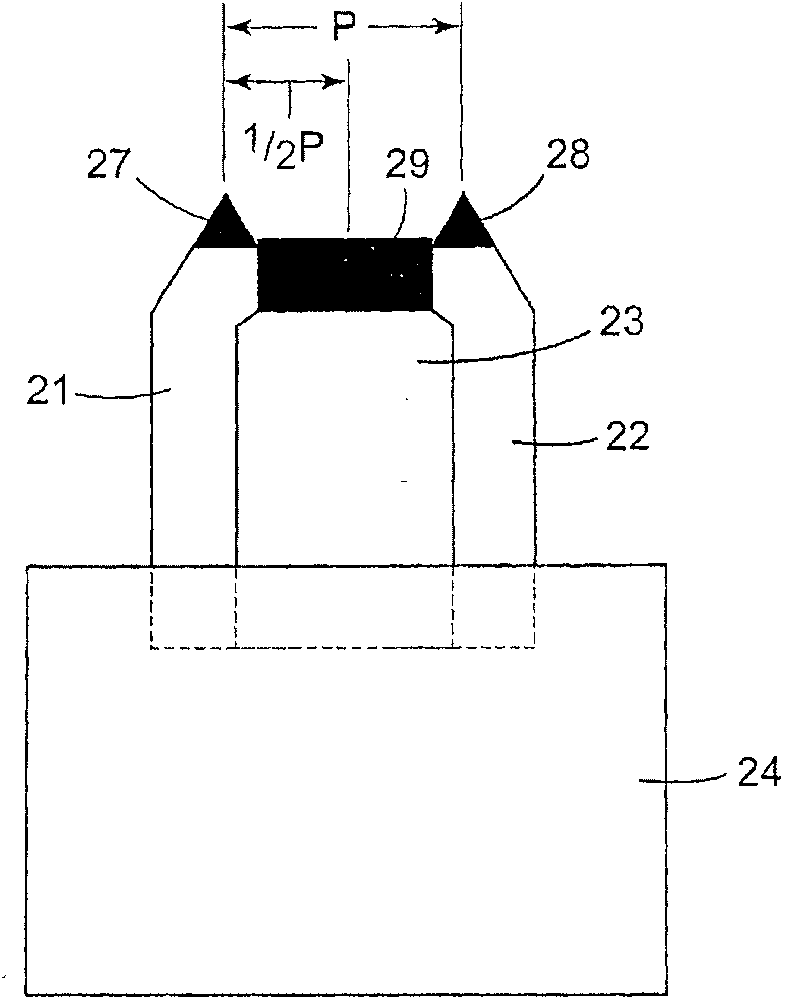

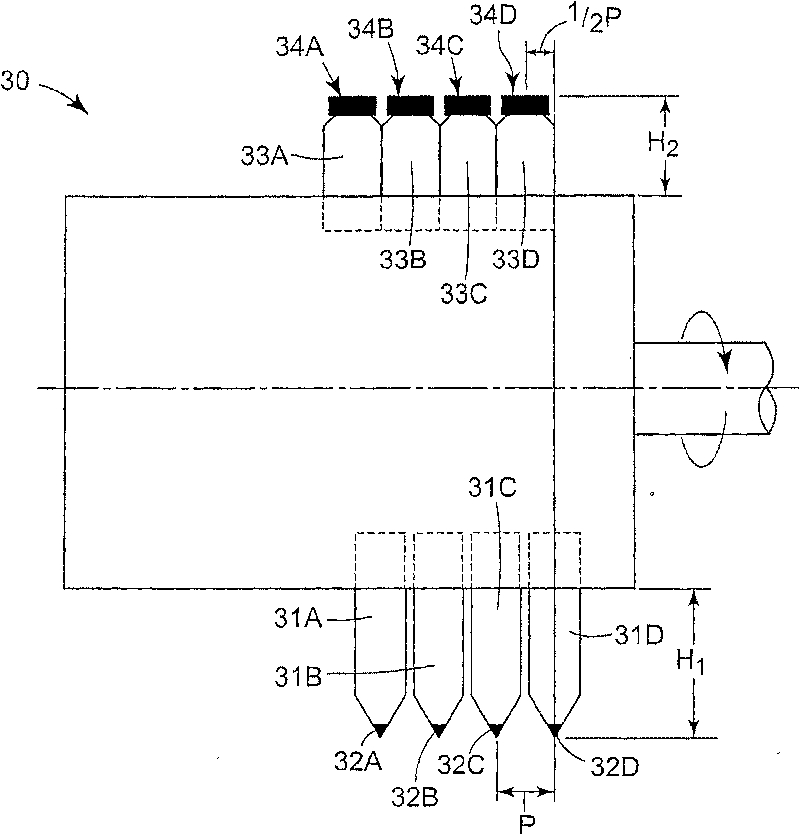

[0032] The present invention relates to a cutting tool assembly comprising a plurality of diamonds. Cutting tool assemblies with multiple diamonds can be used to fabricate microreplicated tools or other workpieces. The microreplication tool, in turn, can be used to form microreplicated structures, such as optical films, abrasive films, adhesive films, mechanical fasteners with self-mating profiles, or microscopic Copy any molded or extruded part of the structure.

[0033] In the following description, various aspects of the invention will be described in the context of manufacturing optical films. In this case, the cutting tool assembly described herein would be used to fabricate a microreplication tool, which in turn would be used to fabricate an optical film. However, the cutting tool assembly may be used to manufacture a variety of other workpieces. Thus, the cutting tool assembly is not limited to use in the manufacture of microreplication tools or optical films, but ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com