Cutting technique of oversized-diameter silicon rod

A cutting process and super-large diameter technology, applied in the field of super-large diameter silicon rod cutting process, can solve problems such as difficulty in cutting silicon rods, and achieve the effects of reducing cutting costs, improving wafer yield and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

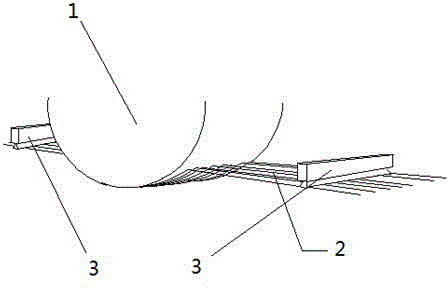

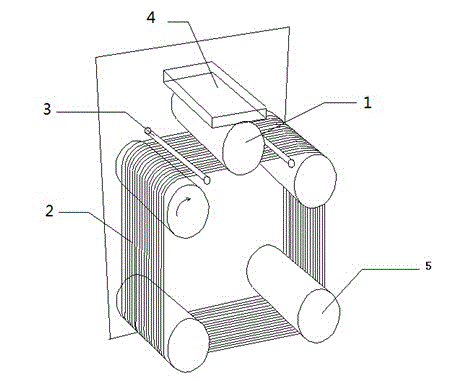

Image

Examples

Embodiment 1

[0028] The main equipment and raw materials in this embodiment are: multi-wire cutting machine model: MWM650SQ; raw materials: large-diameter silicon rods, with an outer diameter of 385 mm, an inner diameter of 0 mm, a length of 350 mm, and a groove pitch of 5 main rollers of 9240 μm.

[0029] The specifications of the silicon wafers to be cut are 385mm in diameter and 9mm in thickness. The following is the cutting of silicon wafers using a cutting wire with a diameter of 0.14mm.

[0030] The process of cutting ultra-large diameter silicon rods with the above equipment, the specific steps are as follows:

[0031] (1) Mortar configuration: Dry silicon carbide at a temperature of 60-100°C and a drying time of more than 360 minutes. This example uses 400 minutes. Calculate the amount of cutting fluid and silicon carbide according to the ratio. The mass ratio is 1:0.9 for configuration, and the mortar configuration is carried out in the mixing tank, and the mixing time is 6h;

[...

Embodiment 2

[0041] The main equipment and raw materials in this embodiment are: multi-wire cutting machine model: MWM650SQ; raw materials: large-diameter silicon rods, with an outer diameter of 335 mm, an inner diameter of 0 mm, a length of 350 mm, and a groove pitch of 5 main rollers of 4140 μm.

[0042] The specifications of the target cut silicon wafers are 335mm in diameter and 3.9mm in thickness. The following is the cutting of silicon wafers with a cutting wire with a diameter of 0.14mm.

[0043] The process of cutting ultra-large diameter silicon rods with the above equipment, the specific steps are as follows:

[0044] (1) Mortar configuration: Dry silicon carbide at a temperature of 60-100°C and a drying time of more than 360 minutes. This example uses 400 minutes. Calculate the amount of cutting fluid and silicon carbide according to the ratio. The mass ratio is 1:1.0 for configuration, and the mortar configuration is carried out in the mixing tank, and the mixing time is 6h;

...

Embodiment 3

[0054] The main equipment and raw materials in this embodiment are: multi-wire cutting machine model: MWM650SQ; raw materials: large-diameter silicon rods, with an outer diameter of 364 mm, an inner diameter of 280 mm, a length of 350 mm, and a groove pitch of 5 main rollers of 9240 μm.

[0055] The specifications of the silicon wafers to be cut are 364mm in diameter, 280mm in inner diameter, and 9mm in thickness. The following is the cutting of silicon wafers using a cutting wire with a diameter of 0.14mm.

[0056] The process of cutting ultra-large diameter silicon rods with the above equipment, the specific steps are as follows:

[0057] (1) Mortar configuration: Dry silicon carbide at a temperature of 60-100°C and a drying time of more than 360 minutes. This example uses 400 minutes. Calculate the amount of cutting fluid and silicon carbide according to the ratio. The mass ratio is 1:1.2 for configuration, and the mortar configuration is carried out in the mixing tank, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com