Cutting method combining deep hole cutting and small well cutting

A cutting method and technology for cutting wells, which are applied in earth drilling, surface mining, blasting, etc., can solve the problems of high cost of chamber blasting, difficulty in cutting chamber construction, and long construction time, and achieve enhanced blasting success rate, strong The effect of promoting application value and reducing cutting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

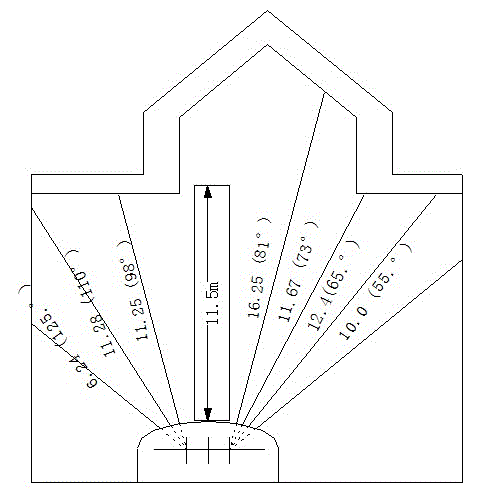

[0016] Below in the Huashugou mining area, the cutting method and test effect of the combination of cutting deep holes and cutting small wells of the present invention are described in detail.

[0017] The Huashugou mining area of Jingtieshan Mine is divided into seven ore belts, namely, I ore belt, II ore belt, III ore belt, IV ore belt, V ore belt, VI ore belt and VII ore belt. The segmental caving method without pillars is adopted, and the mining structure parameters are segmental height of 15m and approach spacing of 12m. In the Huashugou mining area I-II ore body and V ore body, the test work of cutting deep hole and cutting small shaft combined with trenching was carried out.

[0018] 1. Cutting method combining deep hole cutting and small well cutting

[0019] (1) Arrange the position of the cutting wells in the cutting roadway: generally one cutting well is arranged at both ends and in the middle of the cutting roadway, and the distance between the cutting wells is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com